Die for punching irregular edge-turned holes in batch on steel plate

An irregular and edge-turning technology, applied in the direction of perforation tools, manufacturing tools, metal processing equipment, etc., can solve the problems of low production efficiency, long cycle and unsuitable for mass production, etc., to improve production efficiency, reduce labor, reduce Workflow Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

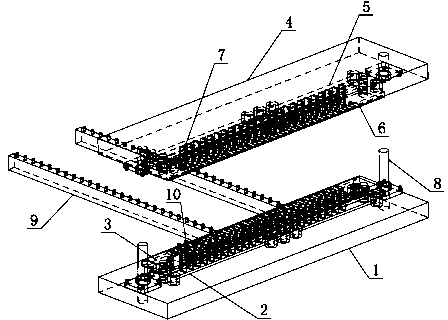

[0014] The present invention will be further described below in conjunction with the accompanying drawings: the mold for punching irregular turning holes in batches on the steel plate includes a bottom plate (1), an upper plate (4), a lower fixing plate (2), a lower supporting plate (3), an upper fixing plate Plate (5), upper support plate (6), irregular turning punch (7), guide post (8), positioning clamp (9) and positioning pin (10).

[0015] Install the lower supporting plate (3) on the lower fixing plate (2), then install it on the bottom plate (1), and install the punch (7) along the irregular hole on the upper supporting plate (6), and then connect it with the upper The fixed plates (5) are installed together, and then they are installed together on the upper plate (4), and the lower die is matched with the cutting edge of the upper die by debugging. The guide post (8) connects the bottom plate (1) and the upper plate (4), so that the upper plate (4) can move linearly in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com