Purification method of electrolyte in indium electrolysis process

An electrolyte and process technology, which is applied in the improvement of process efficiency, photography process, photography auxiliary process, etc., can solve the problems of polluted electrolyte, limited effect, and poor purification effect of indium.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Static purification:

[0039] Take InSO with a purity of 99.99% indium 4 Electrolyte solution 1L, wherein indium concentration 100g / L, impurity content sees the data before processing in Table 1. Add 5.5mL of 50wt% sulfuric acid solution, and add 0.5mol / L BaCl dropwise while stirring at a water bath temperature of 50°C 2 solution, adding BaCl 2 The amount is 0.05mol, after adding BaCl 2 Continue to stir the solution for half an hour, filter to obtain purified InSO 4 Solution, then evaporated to 1L, test.

[0040] 2. Dynamic purification

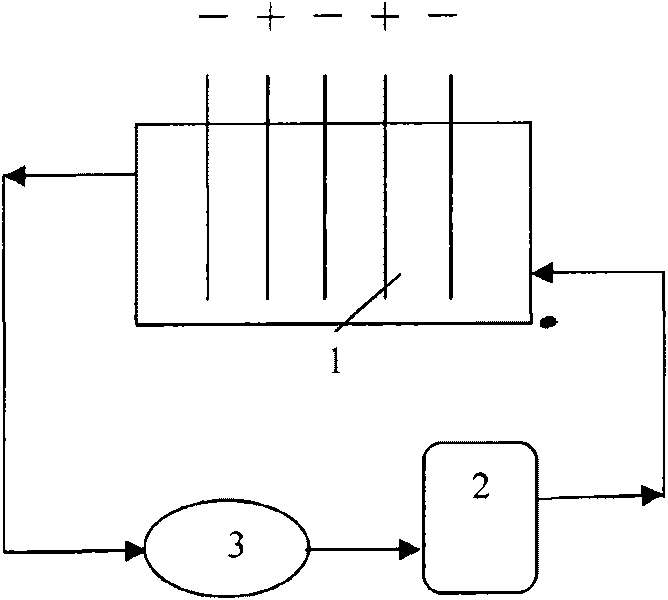

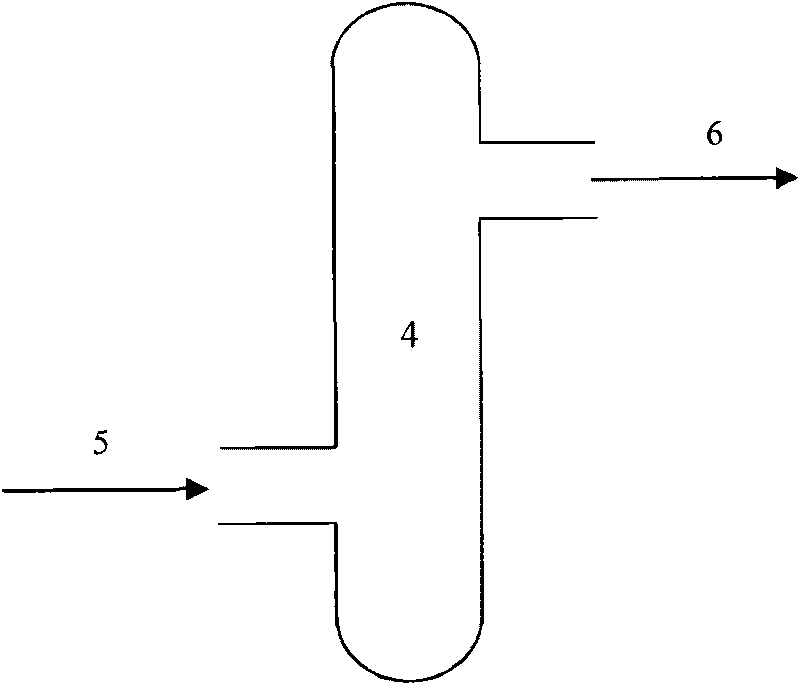

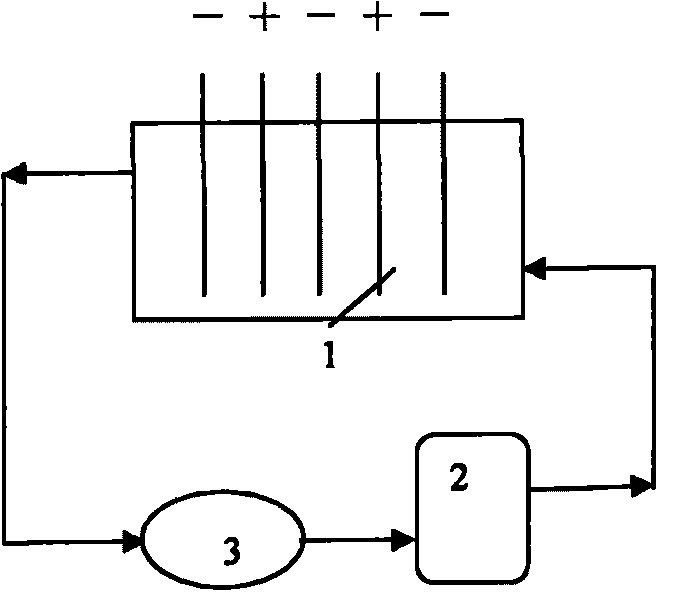

[0041] Put 150g of sponge indium with a purity of 99.999% into a 60ml column height×column diameter=240×18 quartz column, and then connect the electrolytic cell, sponge indium column, circulation pump and power supply according to the schematic diagram of the electrolysis process to start the indium Electrolytic purification process. The electrolytic cell is filled with 3L of electrolyte that has been treated by the above-men...

Embodiment 2

[0045] 1. Static purification

[0046] Take InSO prepared from crude indium (purity4 Electrolyte solution 1L, wherein indium concentration 50g / L, impurity content sees the data before processing in Table 2. Add 17mL of 50wt% sulfuric acid solution, and add 1.5mol / L BaCl dropwise while stirring at a water bath temperature of 30°C 2 solution, adding BaCl 2 The amount is 0.15mol, after adding BaCl 2 Continue to stir the solution for half an hour, and then filter to obtain purified InSO 4 Solution, then evaporated to 1L, test.

[0047] 2. Dynamic purification

[0048] Put 300g of sponge indium with a purity of 99.99% into a 135ml column height×column diameter=300×24 quartz column, and then connect the electrolytic cell, sponge indium column, circulation pump and power supply according to the schematic diagram of the electrolysis process to start the indium Electrolytic purification process. The electrolytic cell is filled with 3L of electrolytic solution treated by the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com