Patents

Literature

191results about How to "Achieve coincidence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

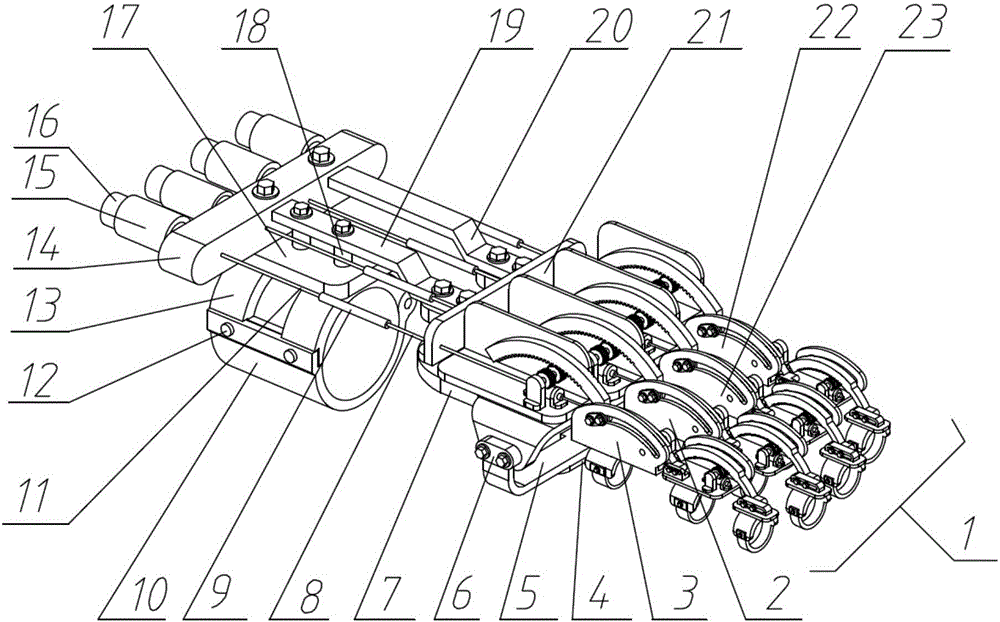

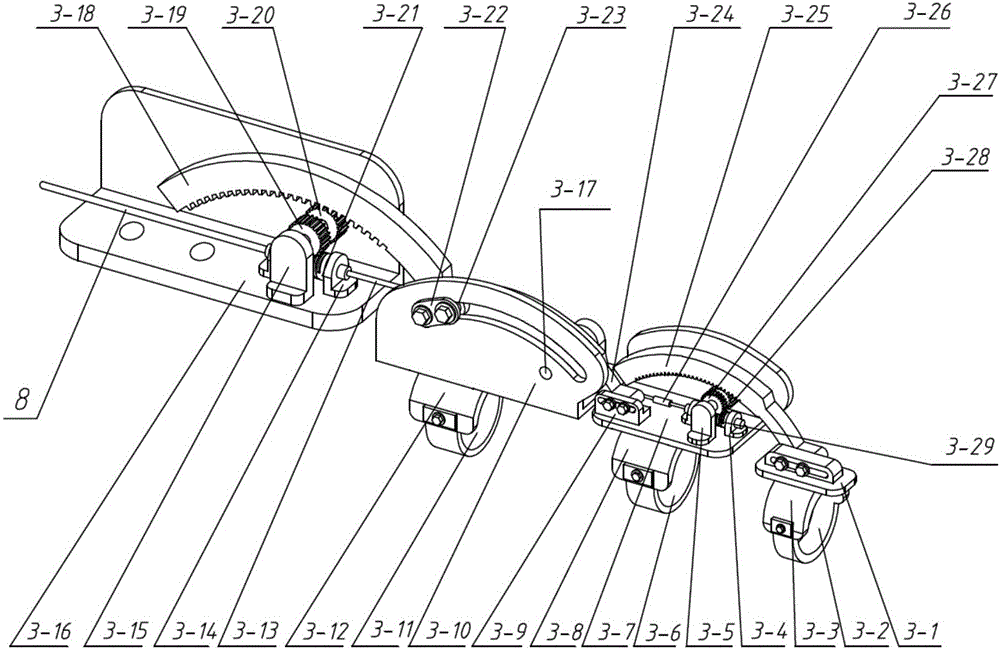

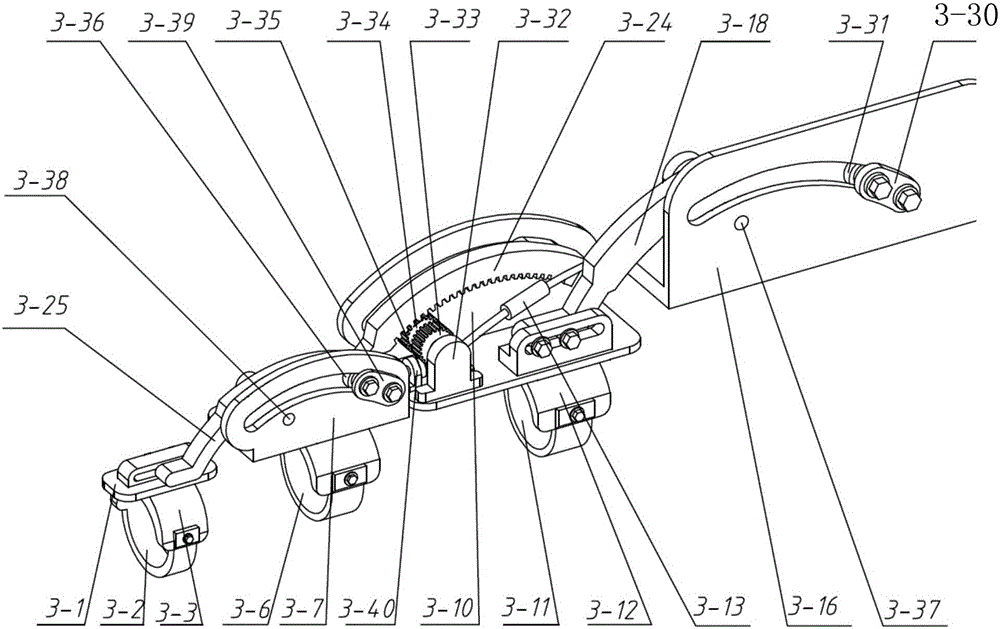

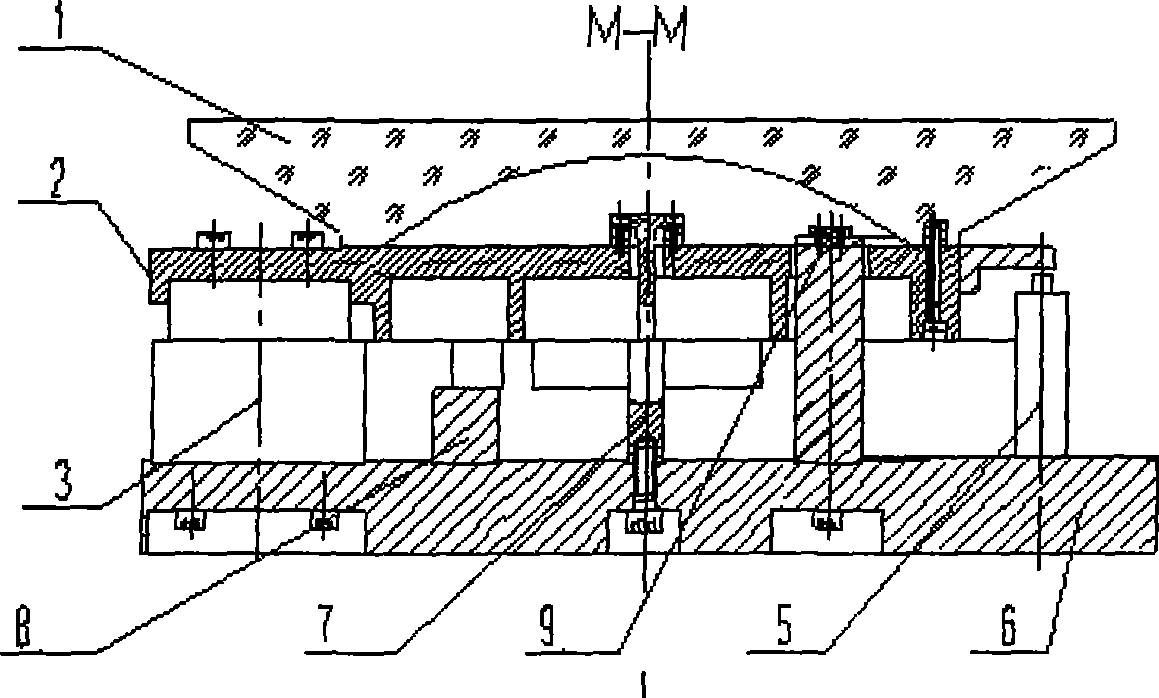

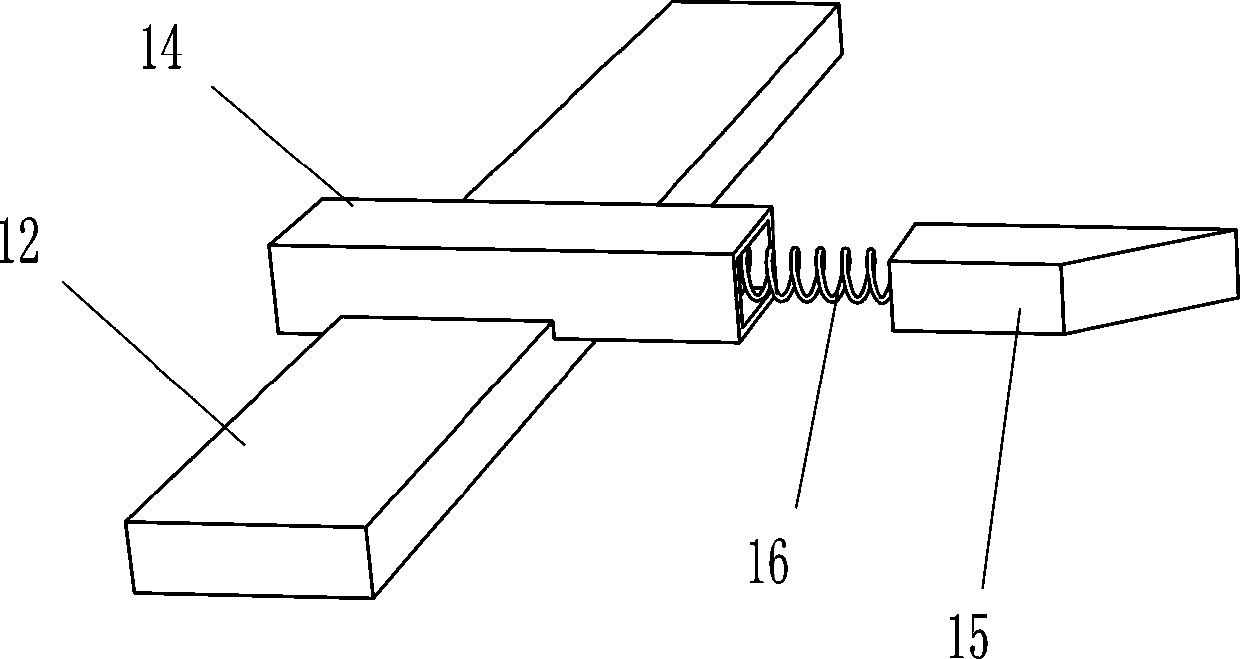

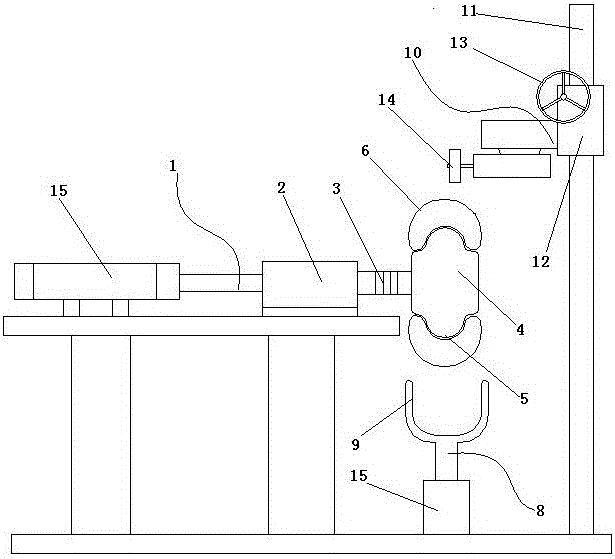

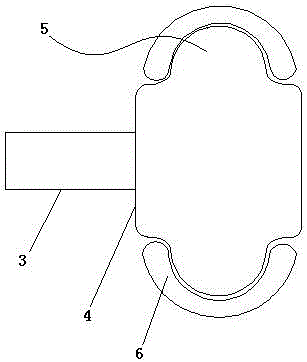

Exoskeleton hand rehabilitation training device

The invention provides an exoskeleton hand rehabilitation training device for hand rehabilitation training of a stroke patient. The exoskeleton hand rehabilitation training device mainly comprises a finger driving device, a hand supporting assembly, a wrist supporting assembly and a motor driving device. The finger driving device is installed on the hand supporting assembly. The hand supporting assembly and the motor driving device are installed on the wrist supporting assembly. Power of a motor is transmitted to the finger driving device through a steel wire flexible shaft assembly, finger joints can move through gear transmission, the four fingers can be driven independently, the structure is simple and easy to obtain, and due to the rear motor driving device and the steel wire flexible shaft driving mode, the weight of the finger exoskeleton structure is lowered. Due to the fact that an arc track structure is arranged on the finger driving device, the rotation center of the exoskeleton device and the rotation center of the finger joints are kept consistent, and the finger driving device can adjust the length of the exoskeleton finger and replace a finger fixing ring according to the lengths and radiuses of fingers of the patient.

Owner:HARBIN ENG UNIV

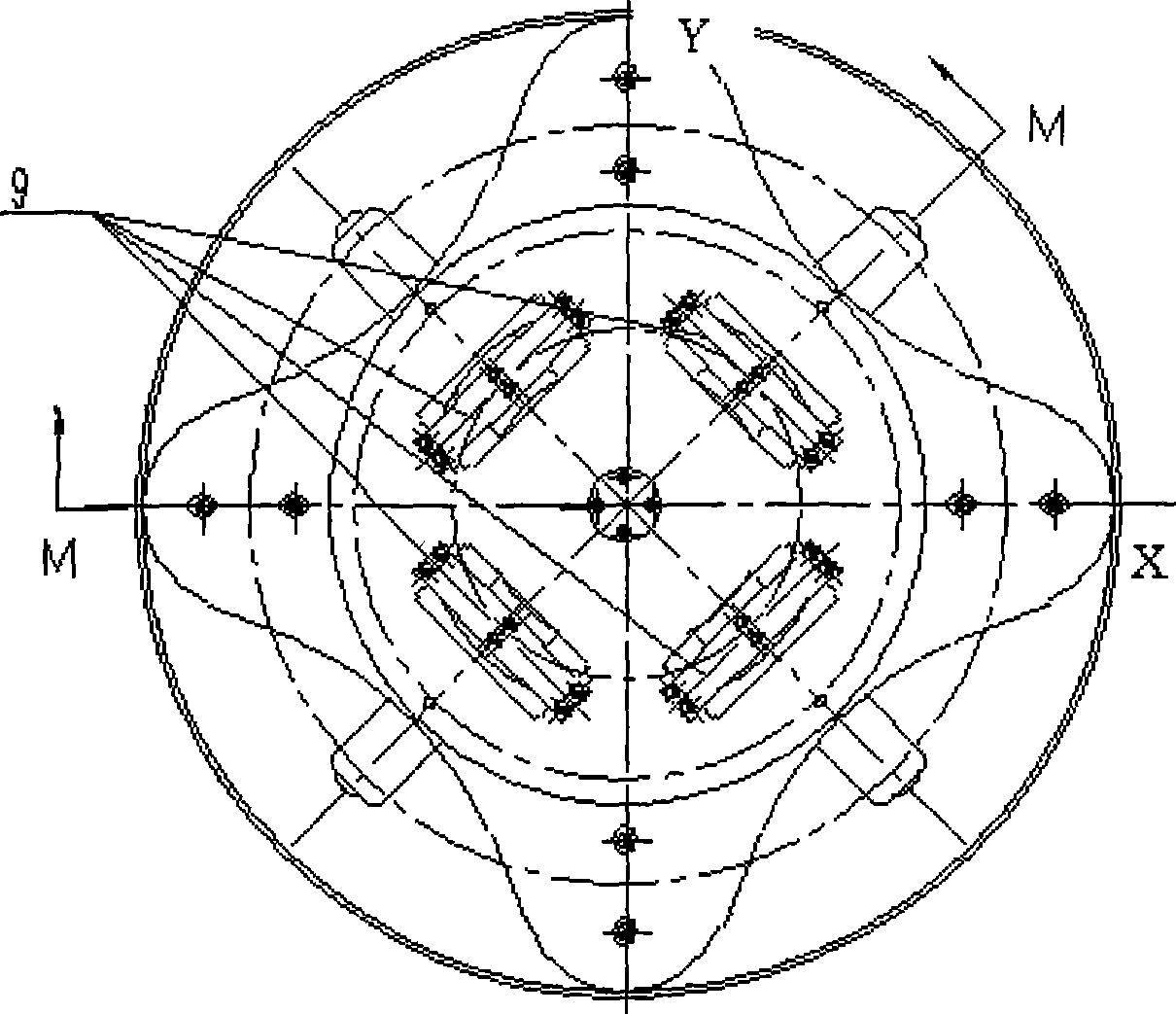

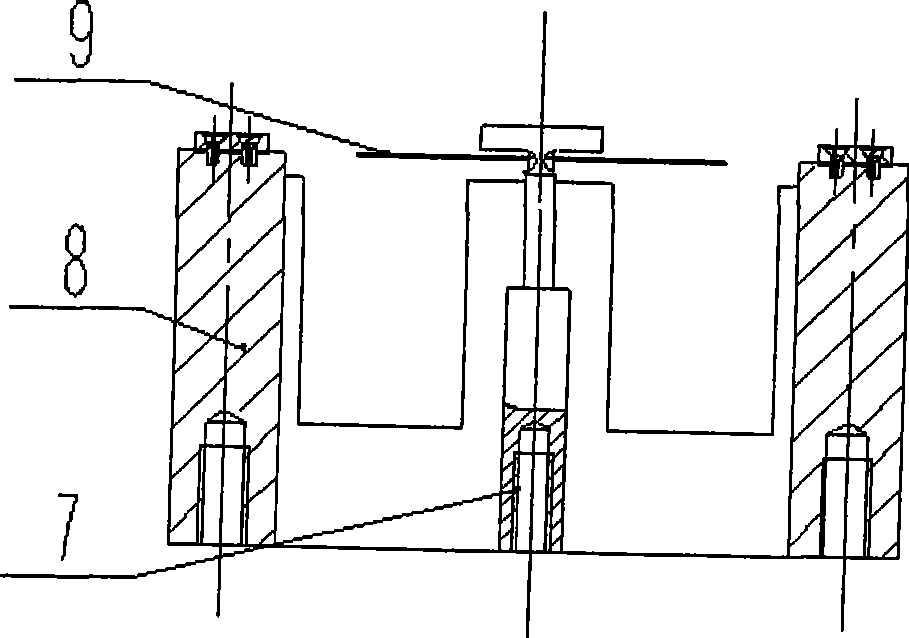

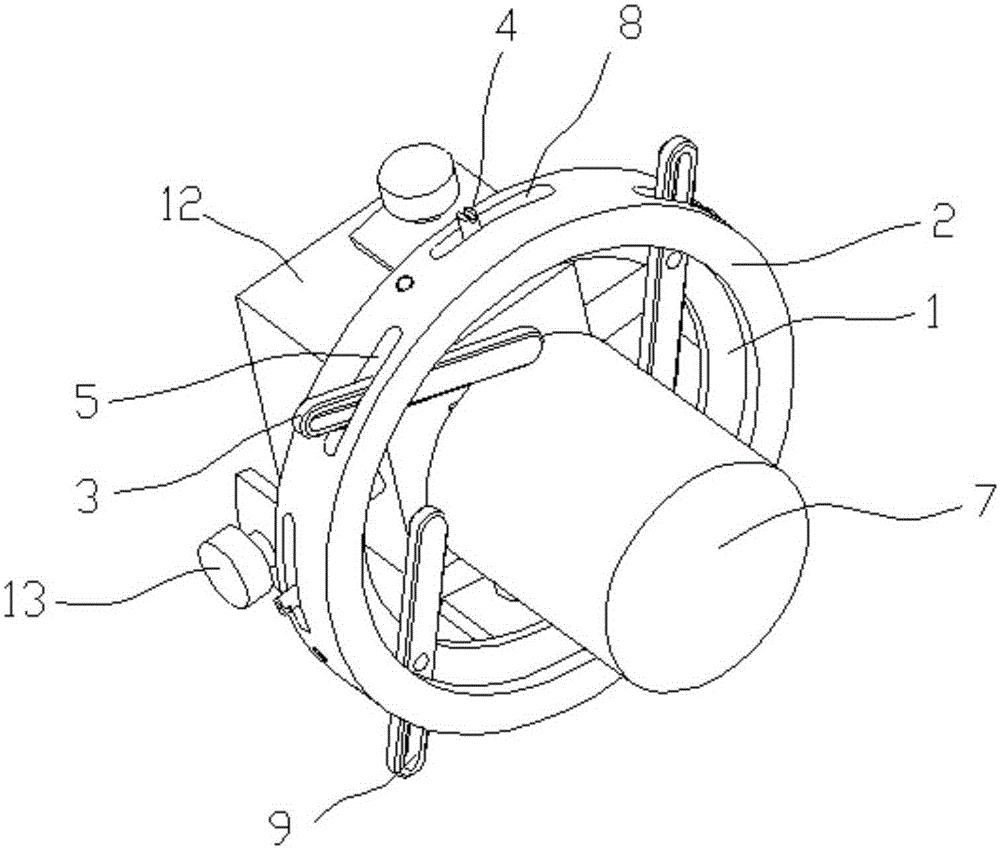

Bidimensional large-diameter fast control reflection mirror

A two-dimensional large caliber fast control reflection mirror is suitable for various optical systems to drive and stabilize the light beam. The problem to be solved is that, the requirement of the reflection mirror caliber larger than 250 mm is satisfied driven by a straight-line drive device, the inclination angle range and the resonance frequency of the fast control reflection mirror can be effectively improved and increased. The invention compares four blocks of distributed spring sheets to the central spherical hinge to implement the flexible rotation around the dual shafts of the reflection mirror and rigid fastening of the rest freedom degrees; the light weighting of the rotating body and the minimum of the rotational inertia around the shaft can be implemented by improving the reflection mirror fixing mode, uniting the rotating centers of the dual shafts and the gravity centers of the rotating body and light weighting design of the supporting frame and the reflection mirror; the compact whole structure and the small appearance size can be implemented by reasonable arrangements of the straight-line drive device and the micro-displacement position sensor.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

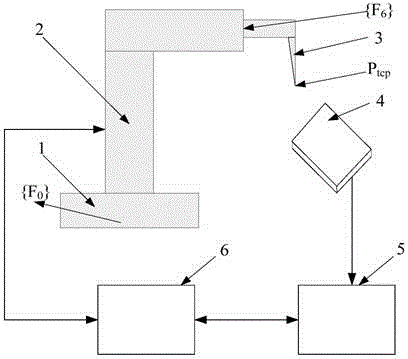

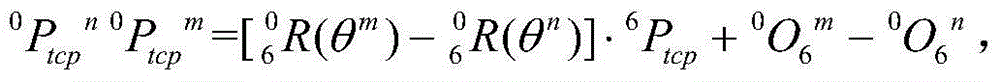

Robot tool central point calibration method using two-dimensional measurement functional tablet

ActiveCN104457645AAchieve coincidenceAvoid overlappingMeasurement devicesJoint coordinatesSimulation

The invention discloses a robot tool central point calibration method using a two-dimensional measurement functional tablet. A robot is controlled to enable a TCP to make contact with a measurement area of a calibration tool more than three times in different postures in the calibration process, joint coordinate information of the robot is recorded in the contact process, and the two-dimensional coordinates of the contact points in a measurement plane are output through the two-dimensional position measurement function of the calibration tool; the coordinates of the TCP in a robot tail end tool coordinate system are calculated according to measured joint rotation angle information of the robot and the coordinate data of the contact points on the tablet and in combination with the structural parameters of the robot, and the calibration accuracy is evaluated. According to the calibration method, the TCP of the robot does not need to coincide with the same fixed point multiple times, the point-point coincidence requirement is weakened to point-surface coincidence, and operation is easy. When the TCP of the robot has small deviation, autonomous calibration can be realized.

Owner:CENT SOUTH UNIV

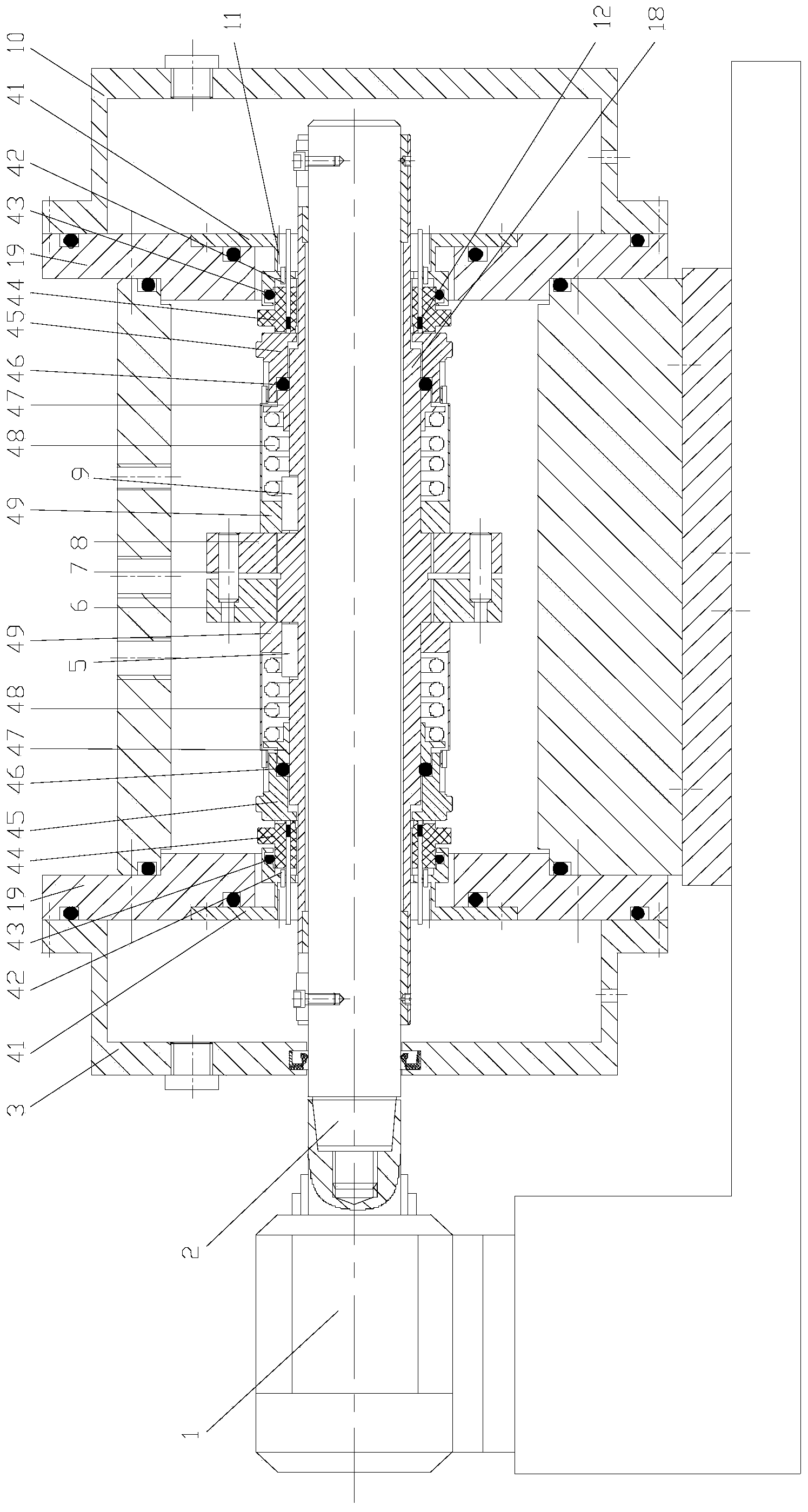

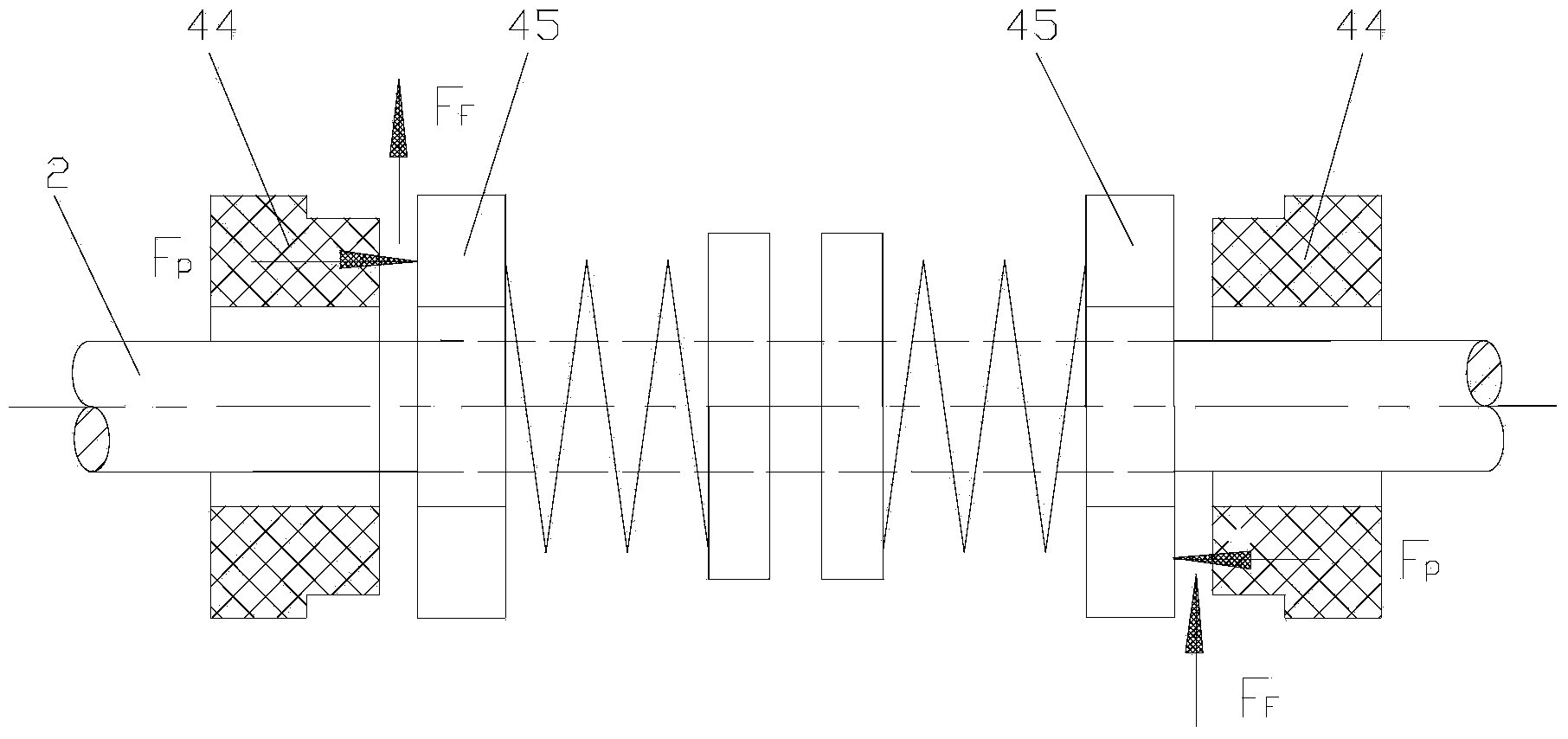

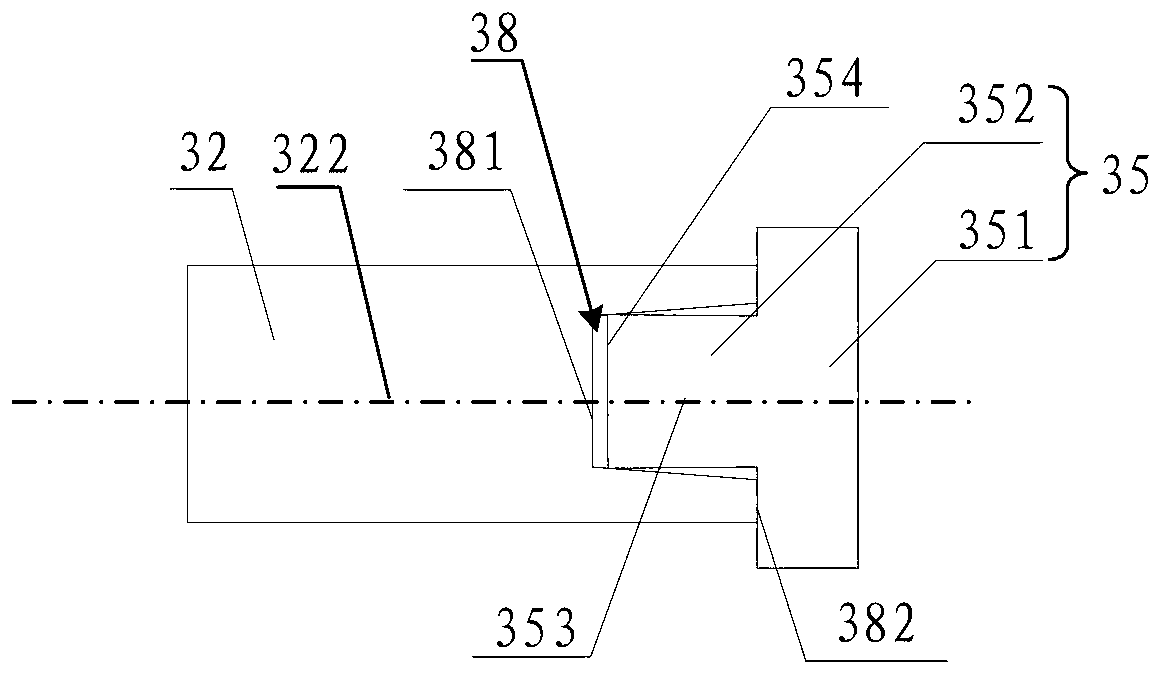

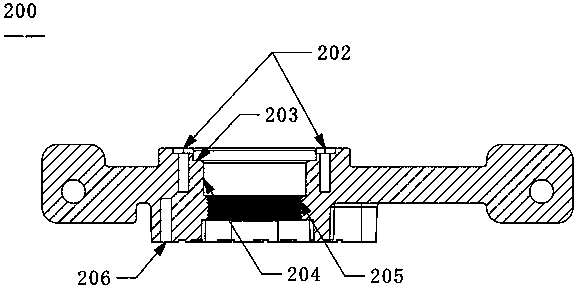

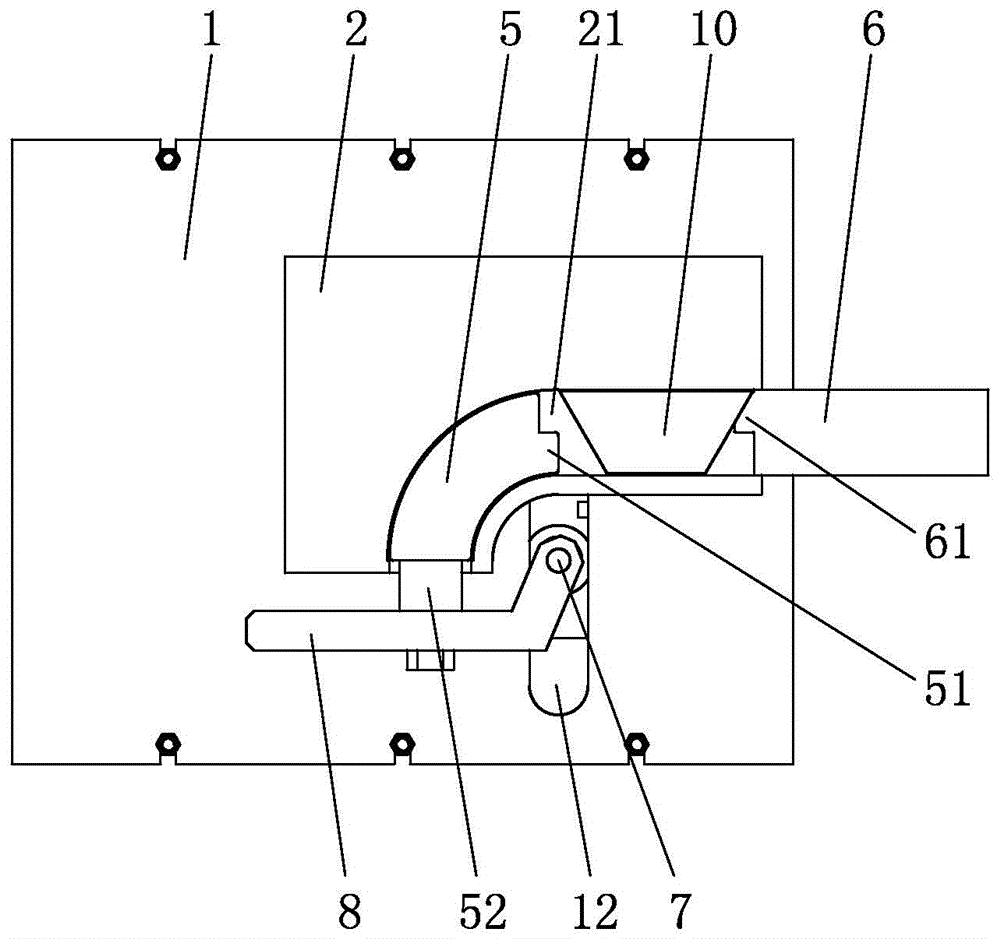

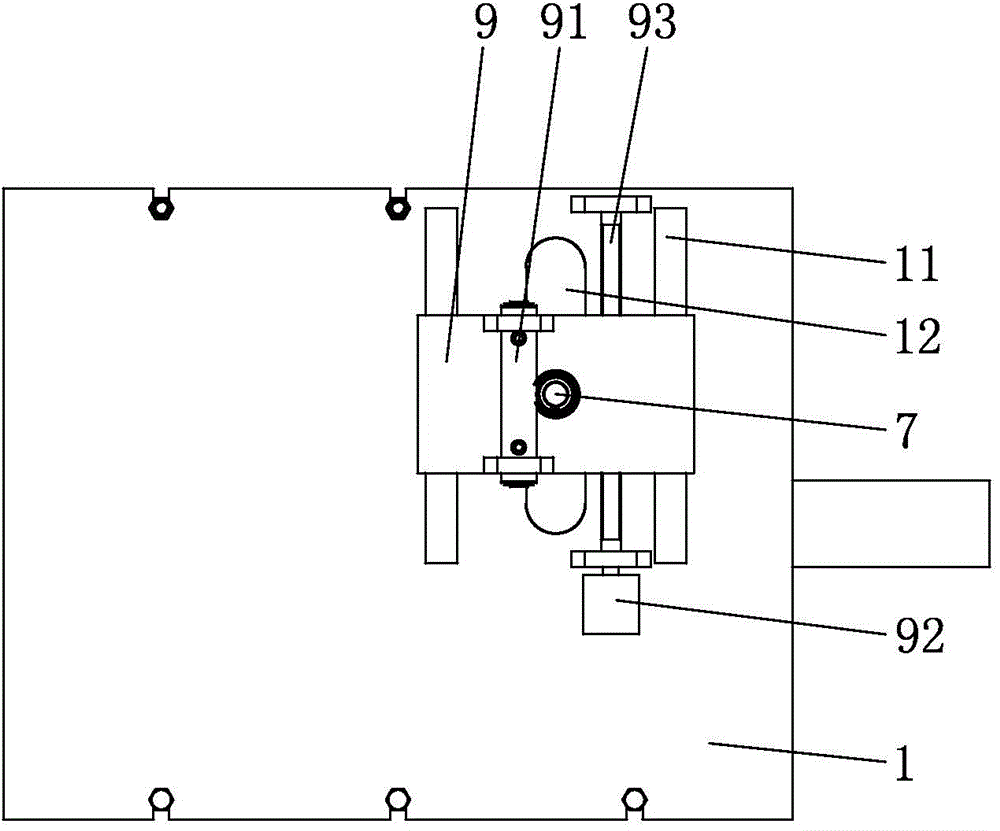

Mechanical sealing property testing device and method for measuring axial force and temperature of sealed end surfaces

ActiveCN104330223AAvoid destructionSimple structureApparatus for force/torque/work measurementPyrometry using electric radation detectorsEngineeringAxial force

The invention discloses a mechanical sealing property testing device. An electric main shaft is connected with a single cantilever working main shaft; floating support of the single cantilever working main shaft is achieved by virtue of the geometric pressure compressing function of a moving ring end surface and a static ring end surface; the edge end of a force measurement sleeve is of a flange structure; an axial force strain piece is arranged on the force measurement sleeve; a shaft sleeve sleeves the single cantilever working main shaft and penetrates through end covers at the left end and right end of a sealing cavity; the shaft sleeve is slidably connected with the single cantilever working main shaft in a sliding manner in the axial direction and in a positioning manner by using an embedding block in the circumferential direction; two sections of threads of which the screw pitches are equal and the spiral lines are in opposite directions are formed in the shaft sleeve; the threads are respectively screwed with a left screw nut and a right screw nut; the back sides of two push rings respectively contact two moving ring bases; the moving ring bases are connected with the shaft sleeve in an sliding manner in the axial direction and in a positioning manner in the circumferential direction; a through hole which is communicated with a sealed end surface is formed inside a static ring; an infrared probe is arranged inside the through hole. Due to the structural design, measurement on property parameters such as large diameter and high rotation speed of mechanical sealing, particularly the measurement on the axial force and the temperature between sealed end surfaces can be achieved.

Owner:NANJING FORESTRY UNIV

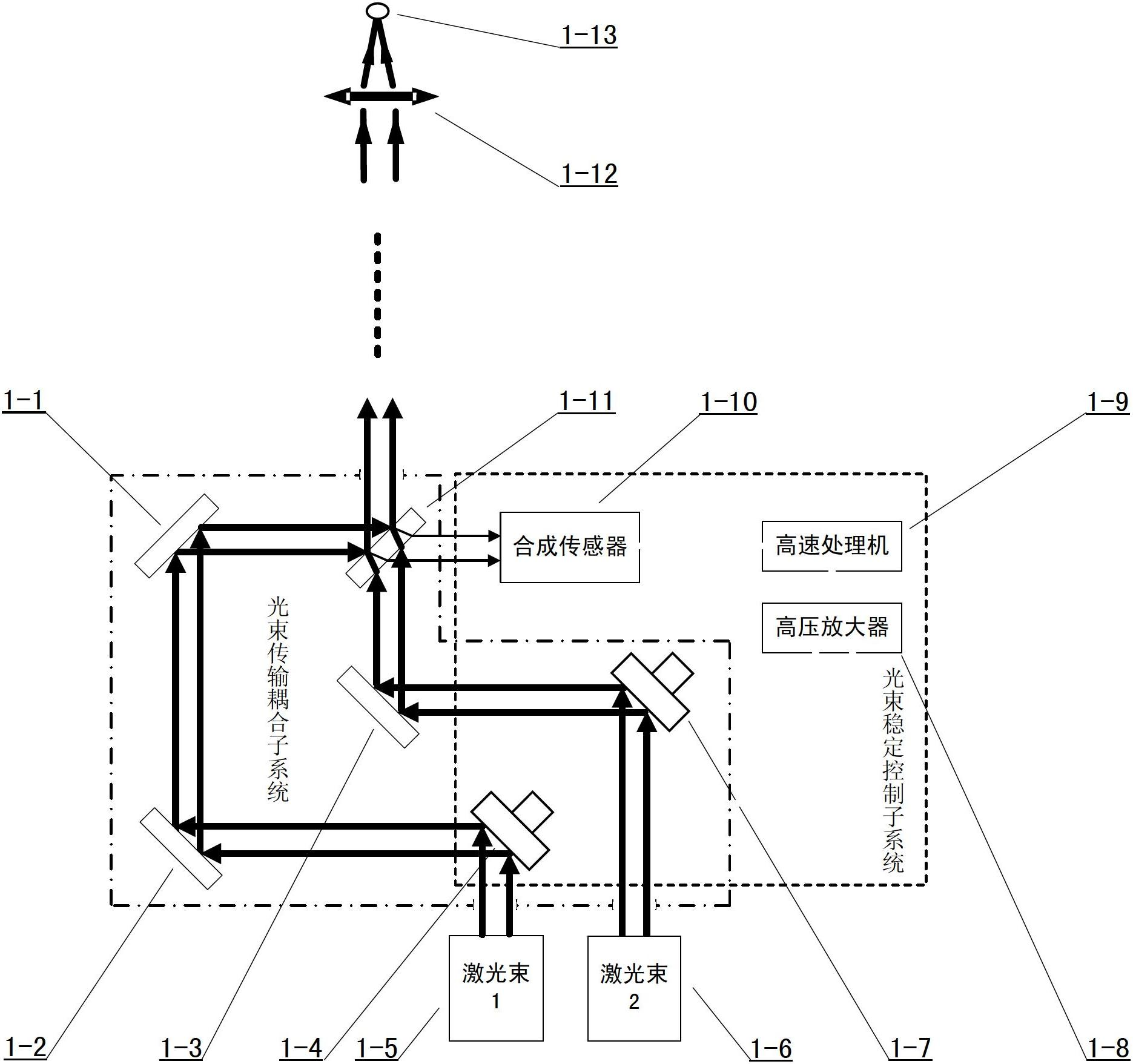

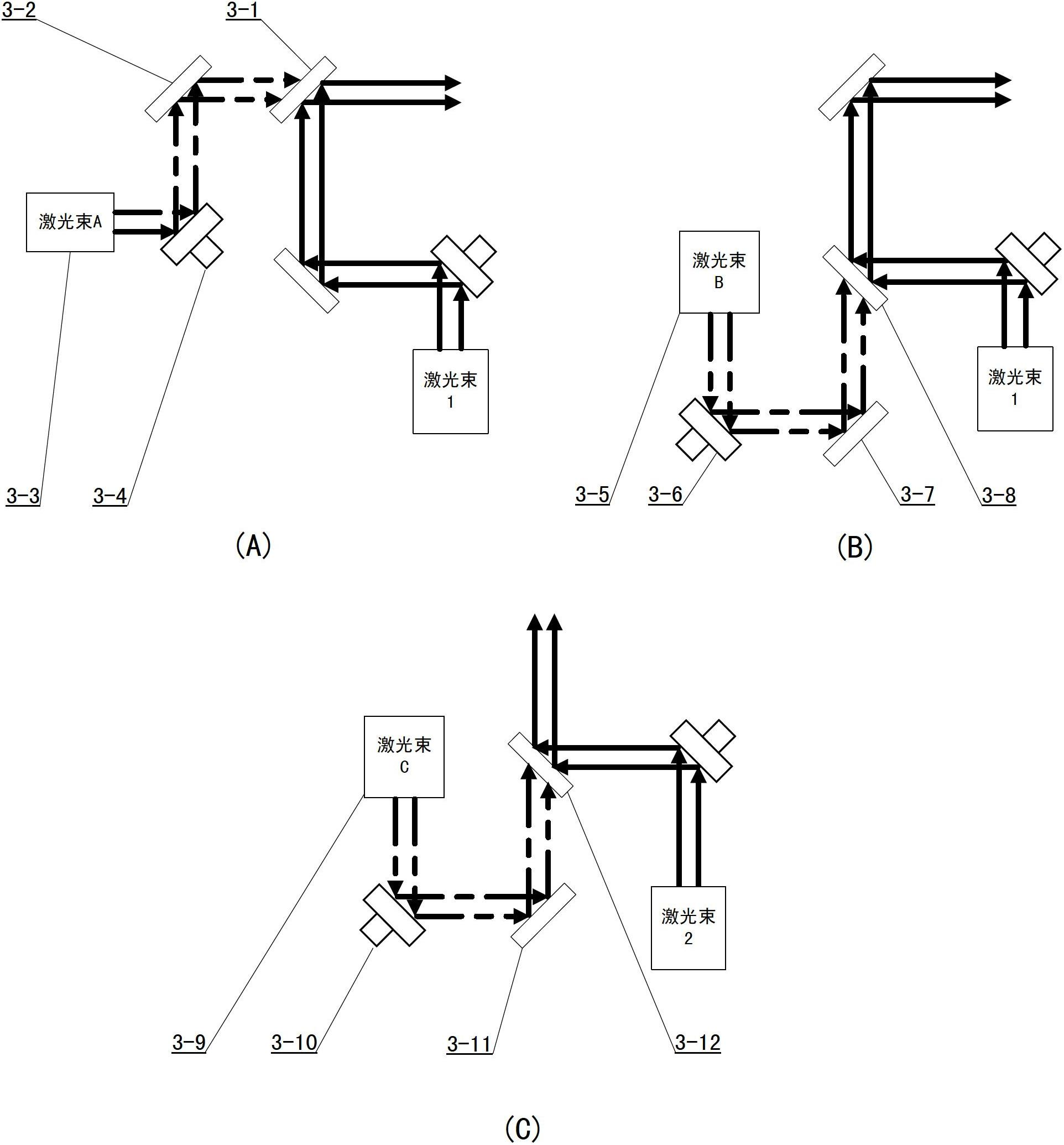

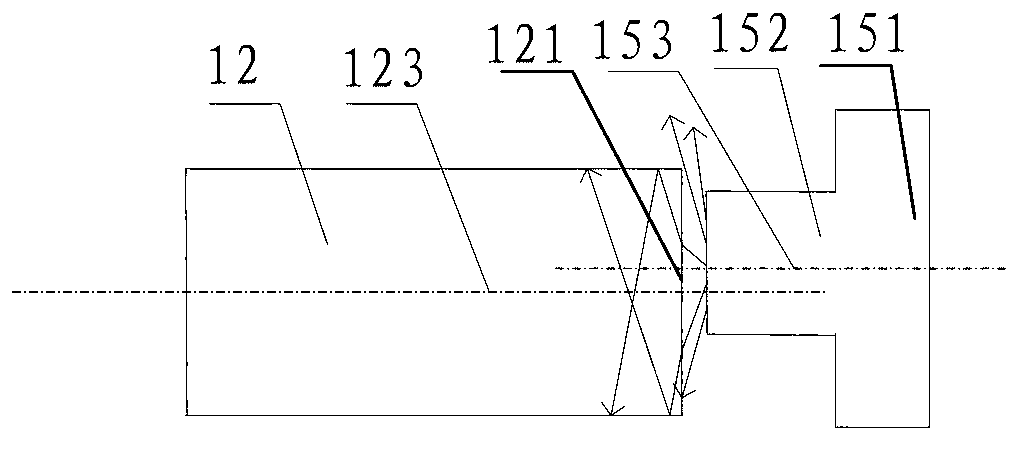

Laser beam common aperture power synthesizing system based on light beam stable closed-loop control

ActiveCN102662241AReal-time correction of pointing errorsAchieve coaxial launchOptical elementsLoop controlBeam splitting

The invention provides a laser beam common aperture power synthesizing system based on light beam stable closed-loop control. Aiming to solve the technical problems, light beam high-precision synthesis is carried out by a light beam stable closed-loop control method aiming to two paths of laser beams with different wavelengths. Two paths of laser respectively pass through respective tilting mirrors and transmission mirrors and the light beam coupling is realized on a synthesizing mirror; meanwhile, appointed error information of each path of the light beam is detected by a synthesizing sensor through a manner of beam splitting and imaging of a dispersion element; the appointed error information of the light beam is converted into driving voltage through calculation and treatment to drive the tilting mirror to carry out angle deflection to eliminate an appointed error of the light beam; finally, high-speed and high-precision synthesis of a plurality of paths of the light beams is realized and the power density of a target point is improved; and the path quantity of the synthesizing light beams can be expanded according to actual requirements. The laser beam common aperture power synthesizing system based on the light beam stable closed-loop control, can be used for fields of material science, nuclear industry, machining, scientific researches and the like, has the advantages of good continuity, high stability and strong anti-interference capability, and is suitable for high-precision incoherent synthesis of a plurality of paths of the light beams under long-time continuous working conditions.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

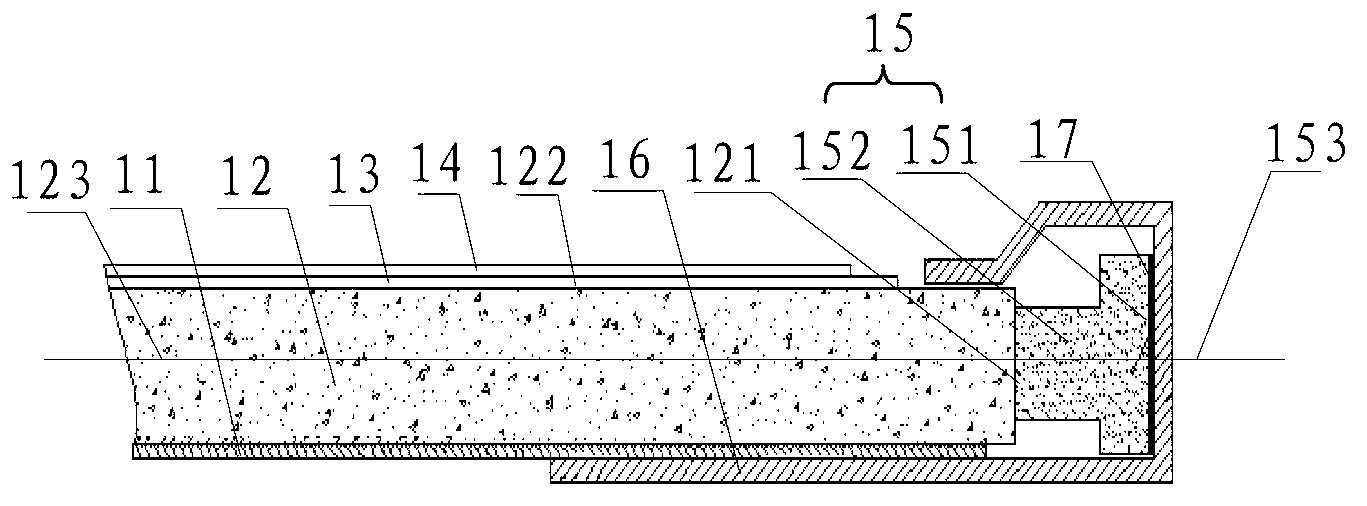

Light guide plate, backlight module and display device including same

InactiveCN103323904AReduce difficultyEliminate the hotspot phenomenonMechanical apparatusPoint-like light sourceLiquid-crystal displayEngineering

The invention provides a light guide plate, a backlight module and a display device including the same, and relates to the technical field of displaying. By means of the light guide plate, the backlight module and the display device including the same, the problem that the light-emitting center line of an LED light and the light-receiving center line of the guide plate are not coincident accurately in an existing backlight module is solved. According to the light guide plate, the backlight module and the display device including the same, the light guide plate is used for guiding the light emitted by the LED light on an LED light bar, a groove is formed in a light-entering face on the side portion of the light guide plate, and when the LED light is arranged in the groove in a clamping mode, the light-emitting center line of the LED light and the light-receiving center line of the guide plate are coincident. The light guide plate, the backlight module and the display device including the same are mainly applied to the field of liquid crystal display.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

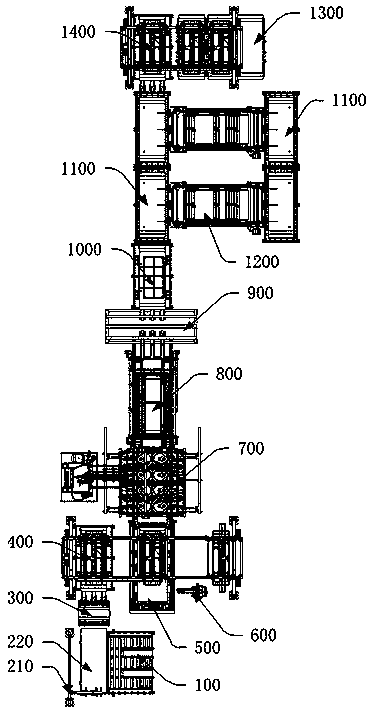

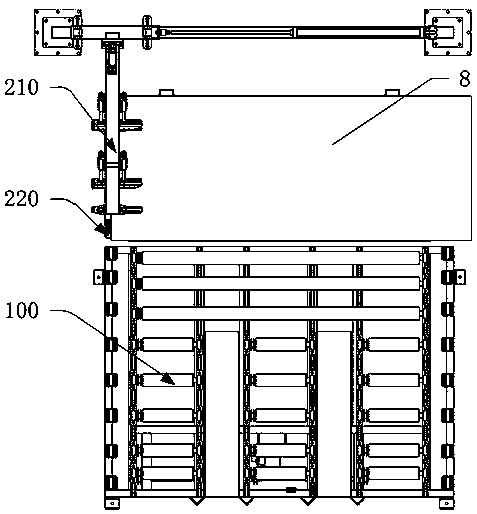

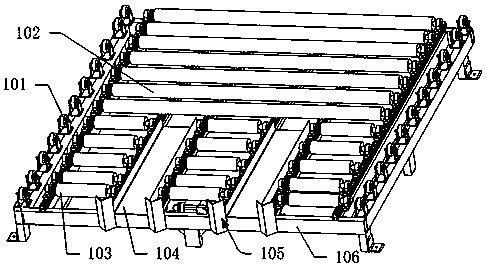

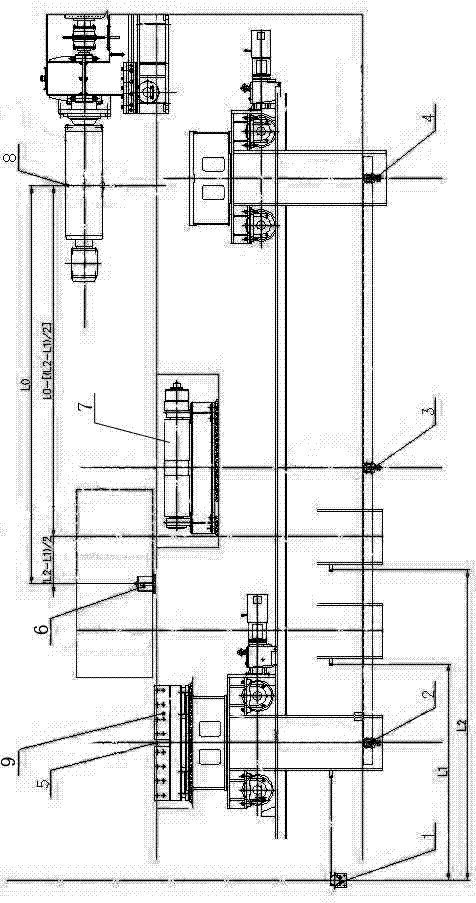

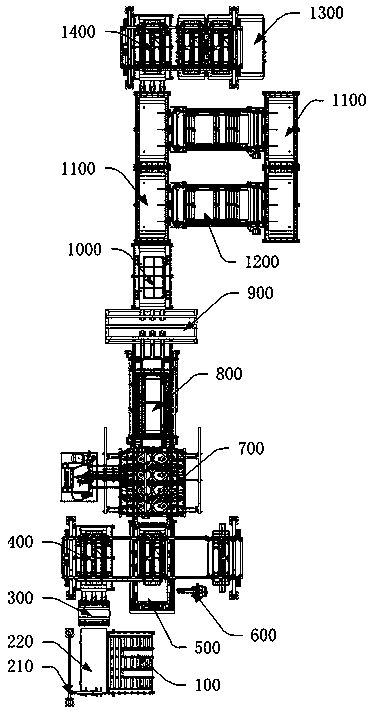

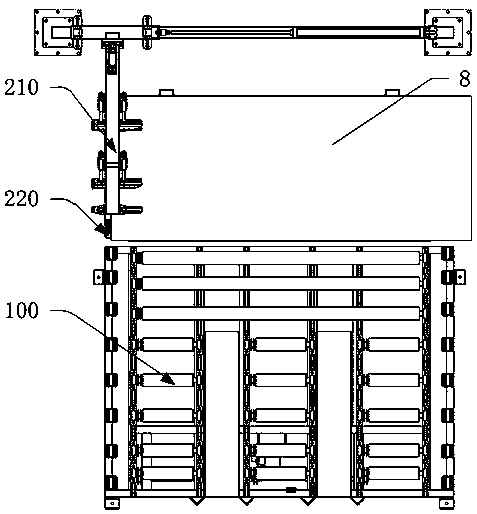

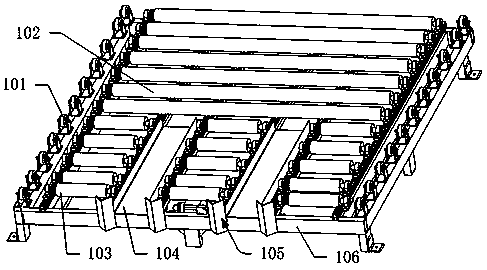

Double-sided synchronous knurling embossed wood veneer production line

PendingCN110315603APrecise positioningChange the manual laying methodPlywood pressesVeneer pressesWood veneerMaterials preparation

The invention discloses a double-sided synchronous knurling embossed wood veneer production line which is capable of automatically finishing knurling embossing of veneers. The production line comprises an industrial personal computer, a longitudinal hot press, a material preparation table, a material discharging table, an automatic plate edge trimmer, an automatic plate airing line, a base material lifting platform arranged at an outlet of the material preparation table, a push plate device arranged above the base material lifting platform, a feeding conveying mechanism arranged at an inlet ofthe longitudinal hot press, a first automatic centering and conveying device arranged at an outlet of the base material lifting platform and arranged one side of the feeding conveying mechanism, a second automatic centering and conveying device arranged at an outlet of the automatic plate airing line and arranged on one side of the discharging table, a paper lifting platform arranged on the otherside of the feeding conveying mechanism, a paper laying manipulator device arranged above the paper lifting platform, a visual system arranged above the paper lifting platform, and a discharging conveying mechanism arranged at an outlet of the longitudinal hot press, wherein an outlet of the discharging conveying mechanism is connected with an inlet of an automatic plate edge trimmer, the automatic plate airing line comprises a plate airing machine and a roller conveyer arranged at an inlet of the plate airing machine, and an outlet of the automatic plate edge trimmer is connected with an inlet of the automatic plate airing line.

Owner:广东英达斯列智能科技有限公司

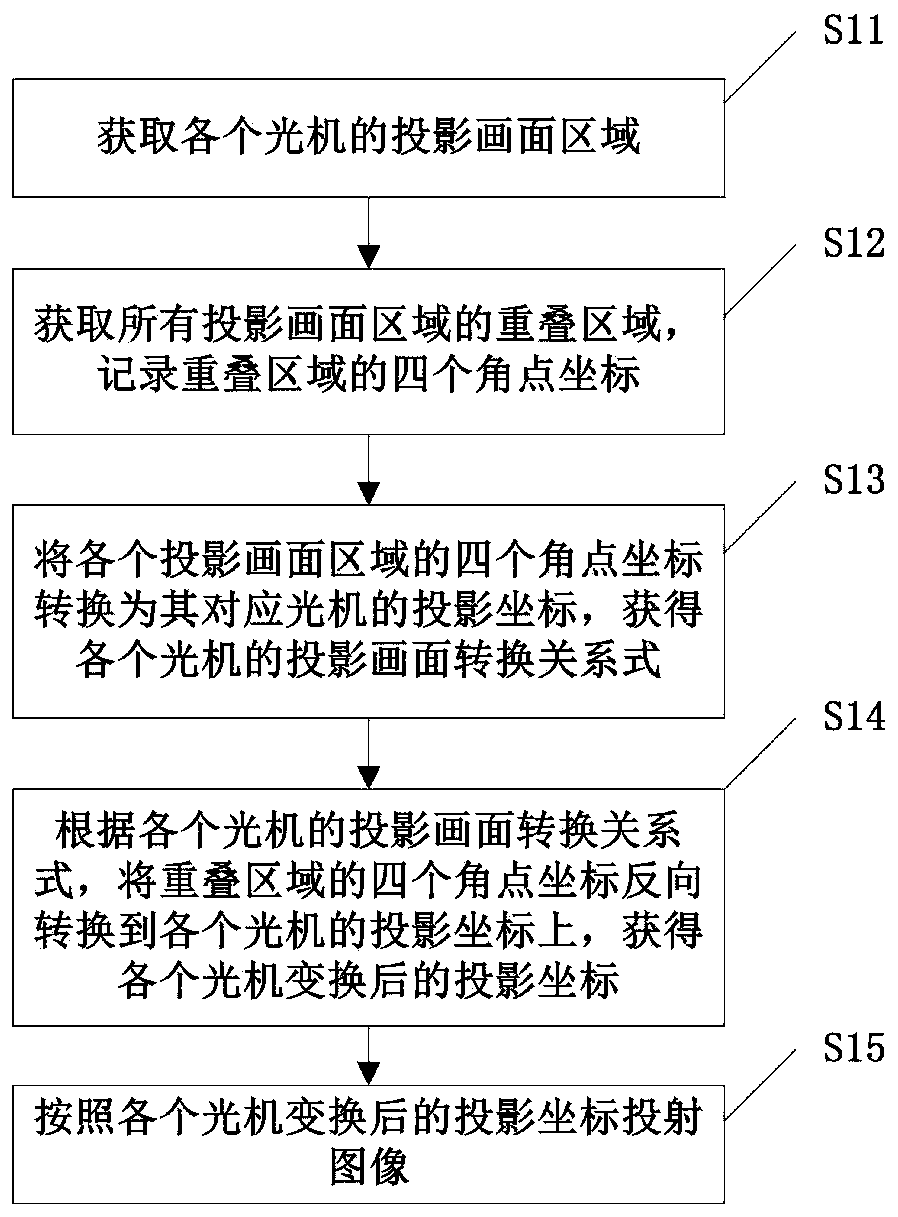

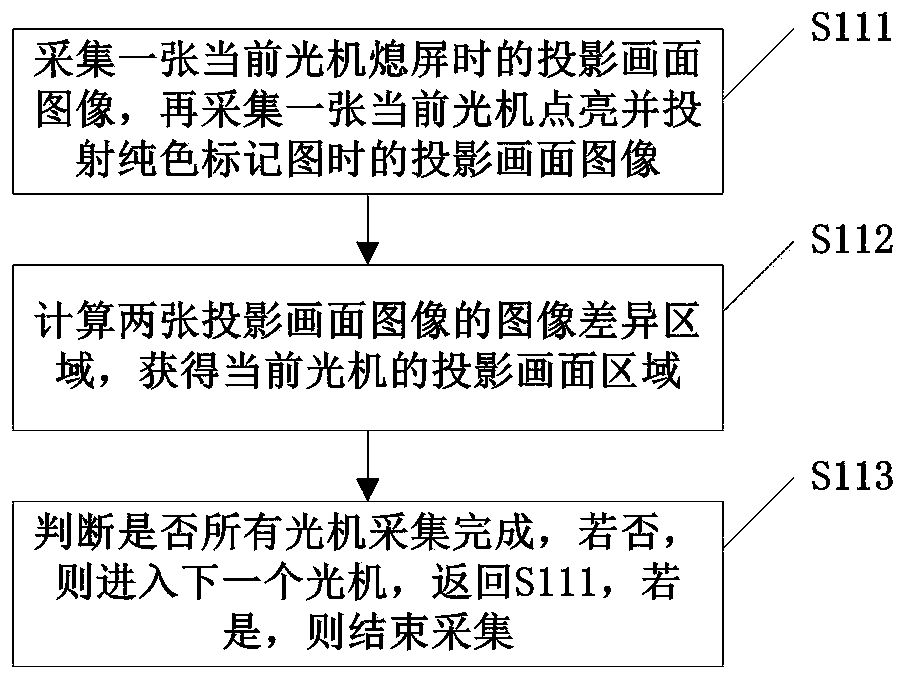

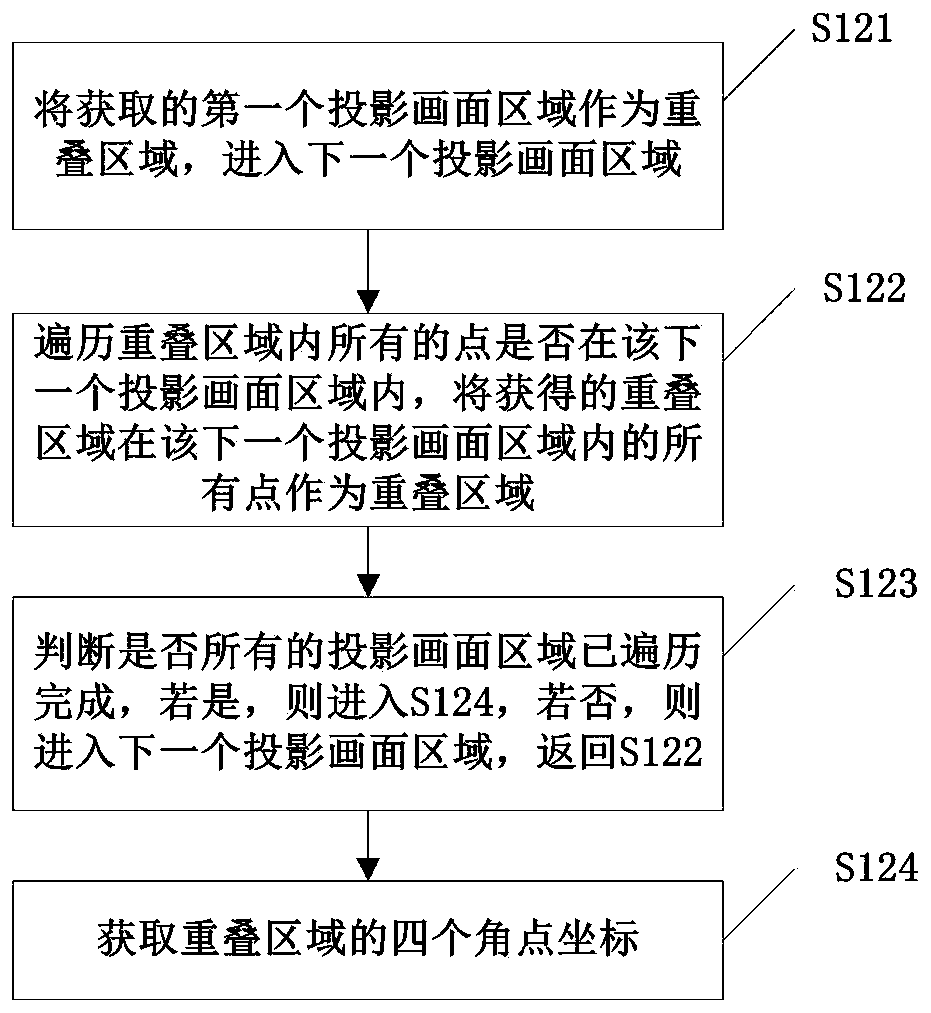

Correction method and device for multi-optical-machine projection image and multi-ray machine projector

ActiveCN111083457AIncrease projection brightnessAssembly accuracy is lowPicture reproducers using projection devicesProjection imageEngineering

The embodiment of the invention relates to the technical field of multi-optical-machine projection, and particularly discloses a correction method and device for a multi-optical-machine projection image, a multi-optical-machine projector and a readable storage medium. The method comprises the steps: acquiring a projection picture area of each optical machine; calculating coordinates of four angular points of an overlapping region of projection picture regions of all optical machines and a projection picture conversion relational expression of each optical machine; reversely converting the coordinates of the four angular points of the overlapping area to the projection coordinates of each optical machine to adjust the projection coordinates of each optical machine, so the projection imagesof the multiple optical machines can completely coincide with the projection images of the multiple optical machines, the projection brightness is improved, the assembly precision requirement of the projector with the multiple optical machines is not high, and the projector is suitable for wide popularization.

Owner:CHENGDU XGIMI TECH CO LTD

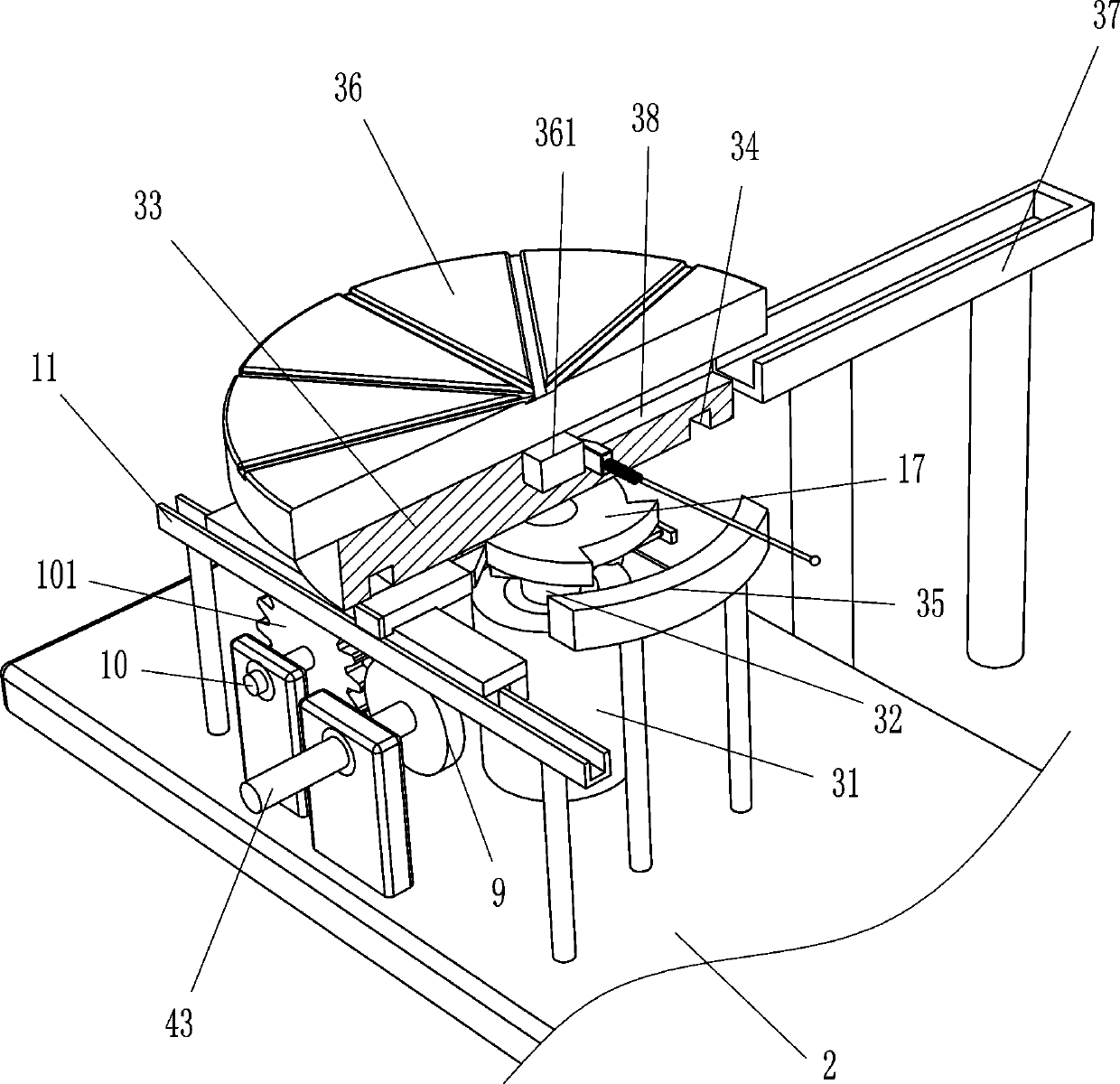

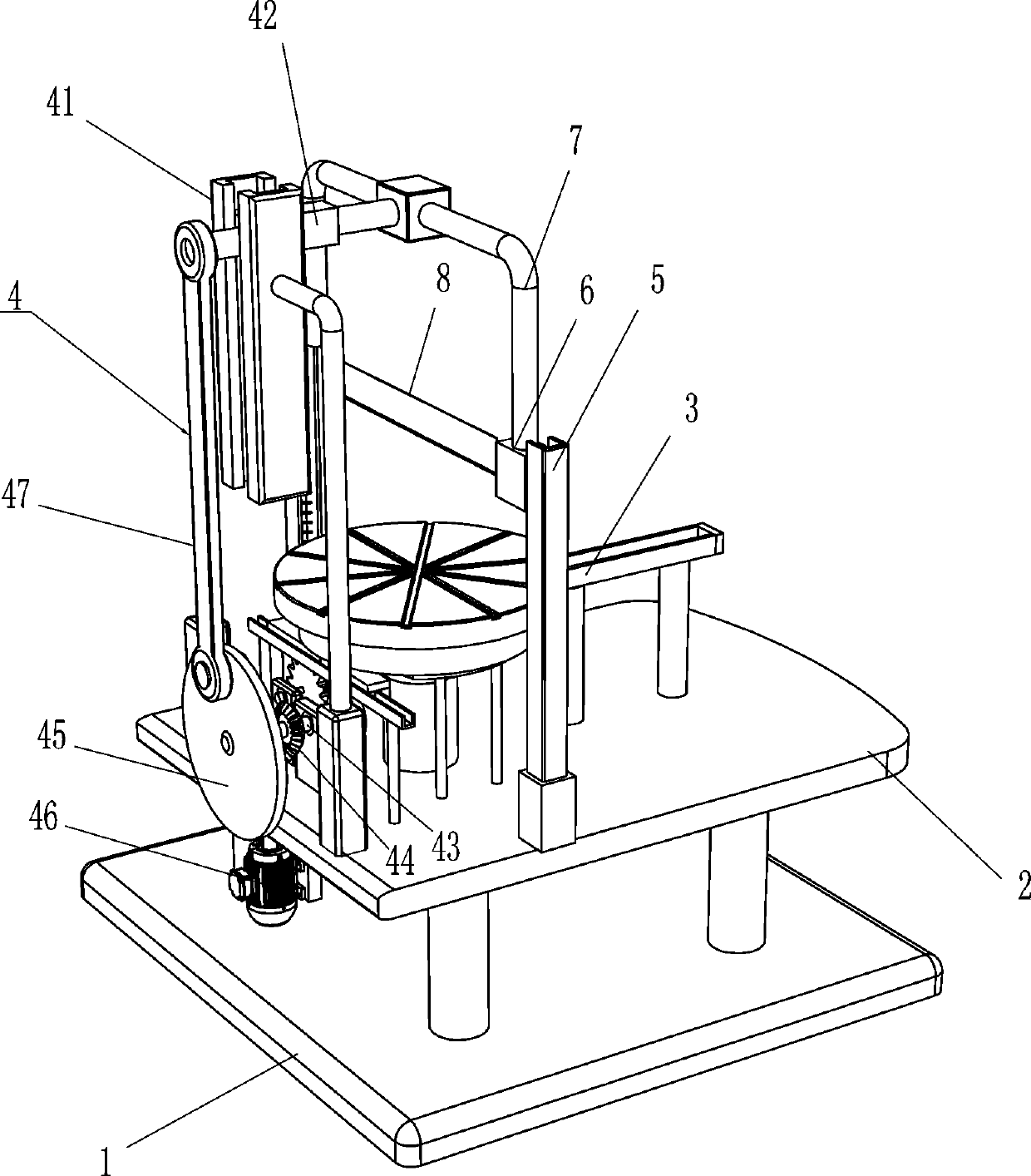

Equal dividing and cutting device for cake

InactiveCN111374163AEasy to operatePrecise cuttingBaked article cutting/slicingStructural engineeringKnife holder

The invention relates to a cutting device, in particular to an equal dividing and cutting device for a cake. The technical problem of the invention is to provide the equal dividing and cutting devicefor the cake that is convenient to operate and accurate to cut. According to the technical scheme, the equal dividing and cutting device for the cake comprises a bottom plate, a holding device, a lifting device, guide plates, a knife rest and a cutting knife, wherein the top part of the bottom plate is provided with a worktable; the holding device used for holding the cake is arranged on the worktable; the lifting device is arranged on the worktable; the guide plates are symmetrically arranged on the worktable with respect to the holding device, and the two guide plates are each glidingly provided with a second sliding block; the knife rest is arranged at upper parts of the two second sliding blocks, and the knife rest is connected with the lifting device; and the cutting knife is detachably provided on the two second sliding blocks. The equal dividing and cutting device achieves the effects of convenient operation and precise cutting.

Owner:丘三贱

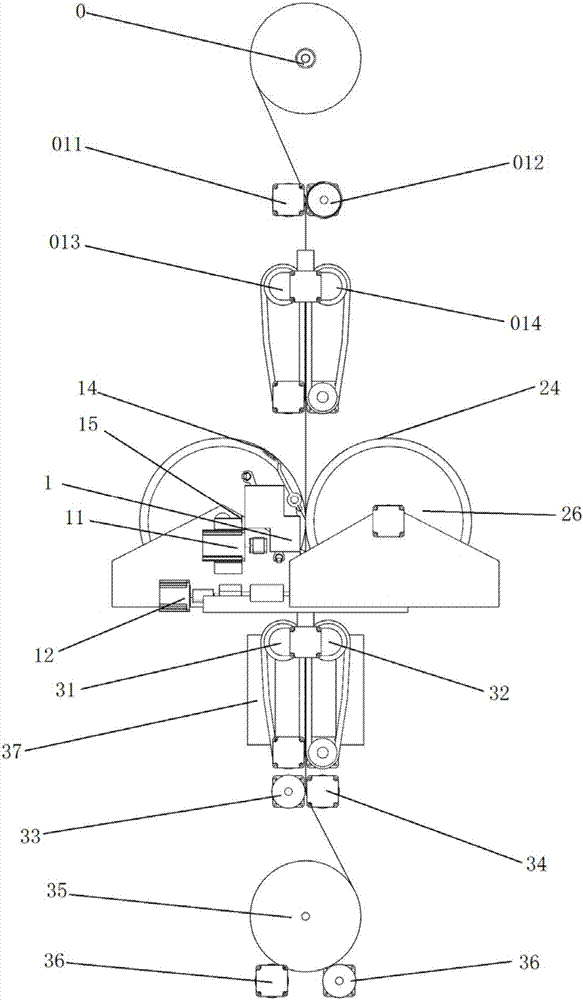

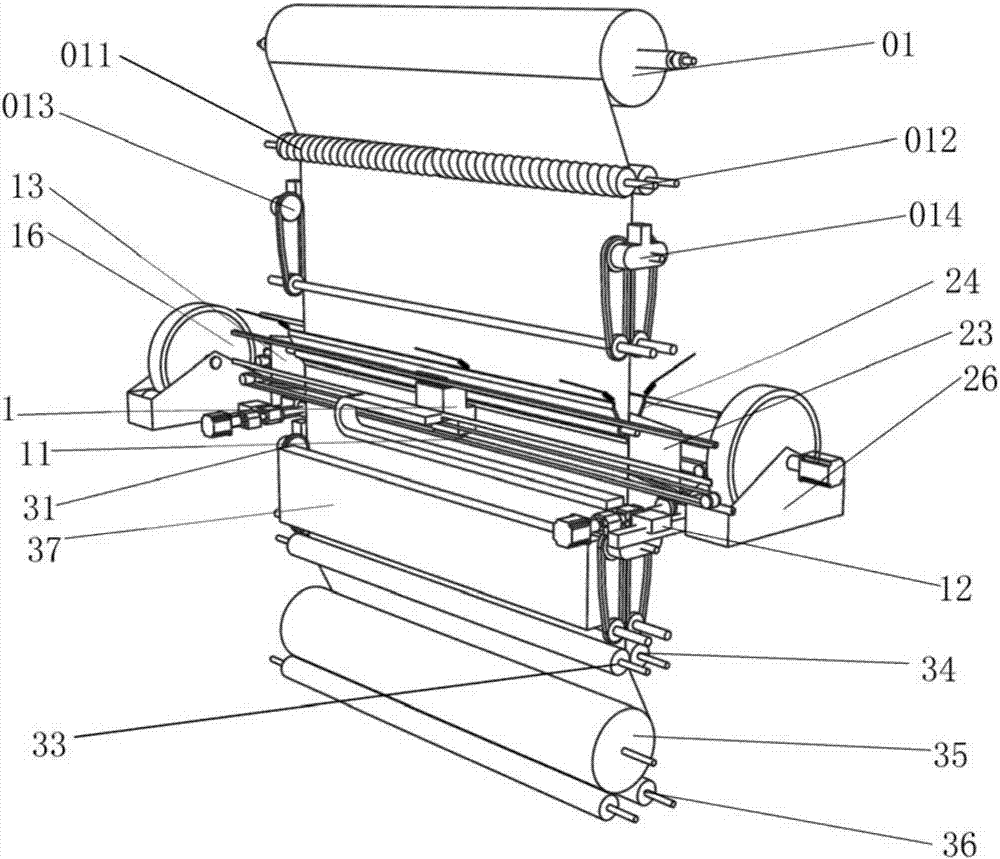

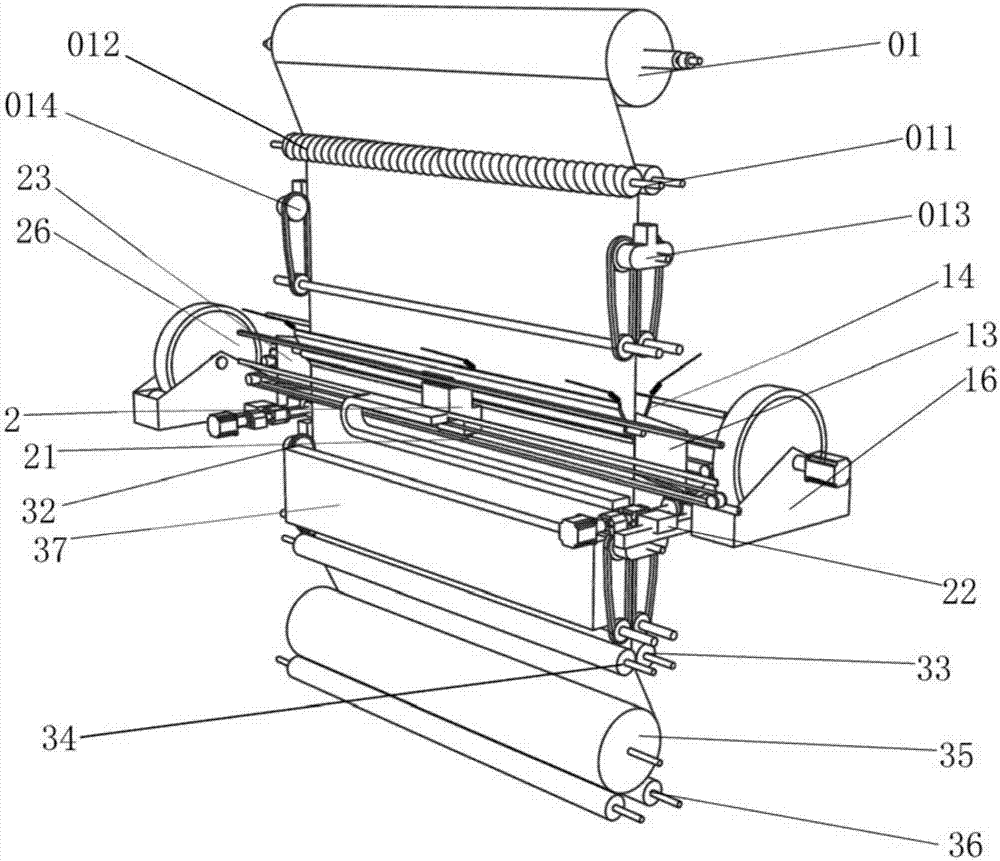

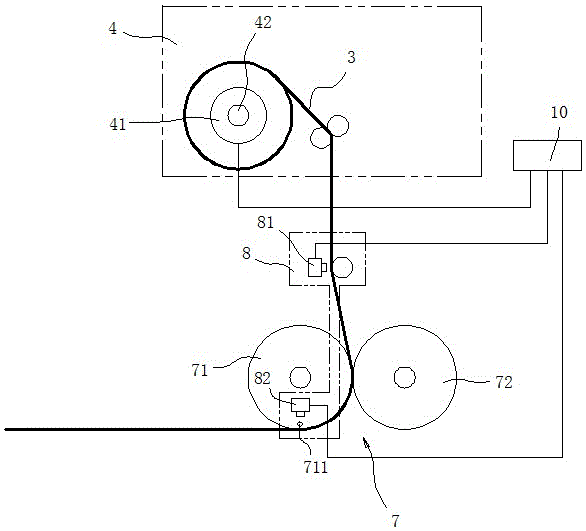

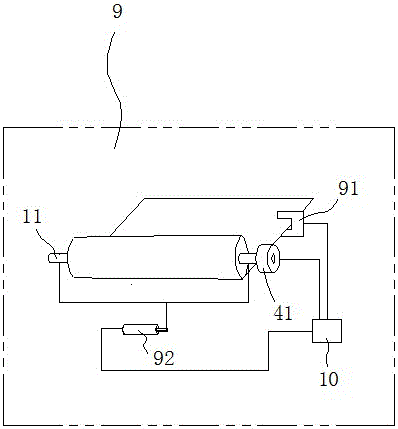

Two-sided printer adopting vertical printing manner

The invention discloses a two-sided printer adopting a vertical printing manner. The two-sided printer comprises a support. A cloth feeding mechanism, a printing mechanism and a cloth collecting mechanism are arranged on the support. The printing mechanism comprises a first printing assembly and a second printing assembly. The first printing assembly is used for conducting printing on the first face of fabric and comprises a first spray nozzle and a first spray nozzle movement servo system, wherein the first spray nozzle is used for discharging ink, and the first spray nozzle movement servo system controls the first spray nozzle to move. The second printing assembly is used for conducting printing on the second face of the fabric and comprises a second spray nozzle and a second spray nozzle movement servo system, the second spray nozzle is used for discharging ink, and the second spray nozzle movement servo system controls the second spray nozzle to move. By means of the two-sided printer with the ink outlet direction of the first spray nozzle and the ink outlet direction of the second spray nozzle located on the same horizontal plane, the existing printing manner is changed, two-sided synchronous same-position printing or two-sided synchronous different-position printing can be achieved, overlapping of patterns on two sides can be achieved particularly when textiles or silk products are printed, and printing requirements can also be met when the two-sided printer is applied to printing of various other types of fabric.

Owner:朱辛伟

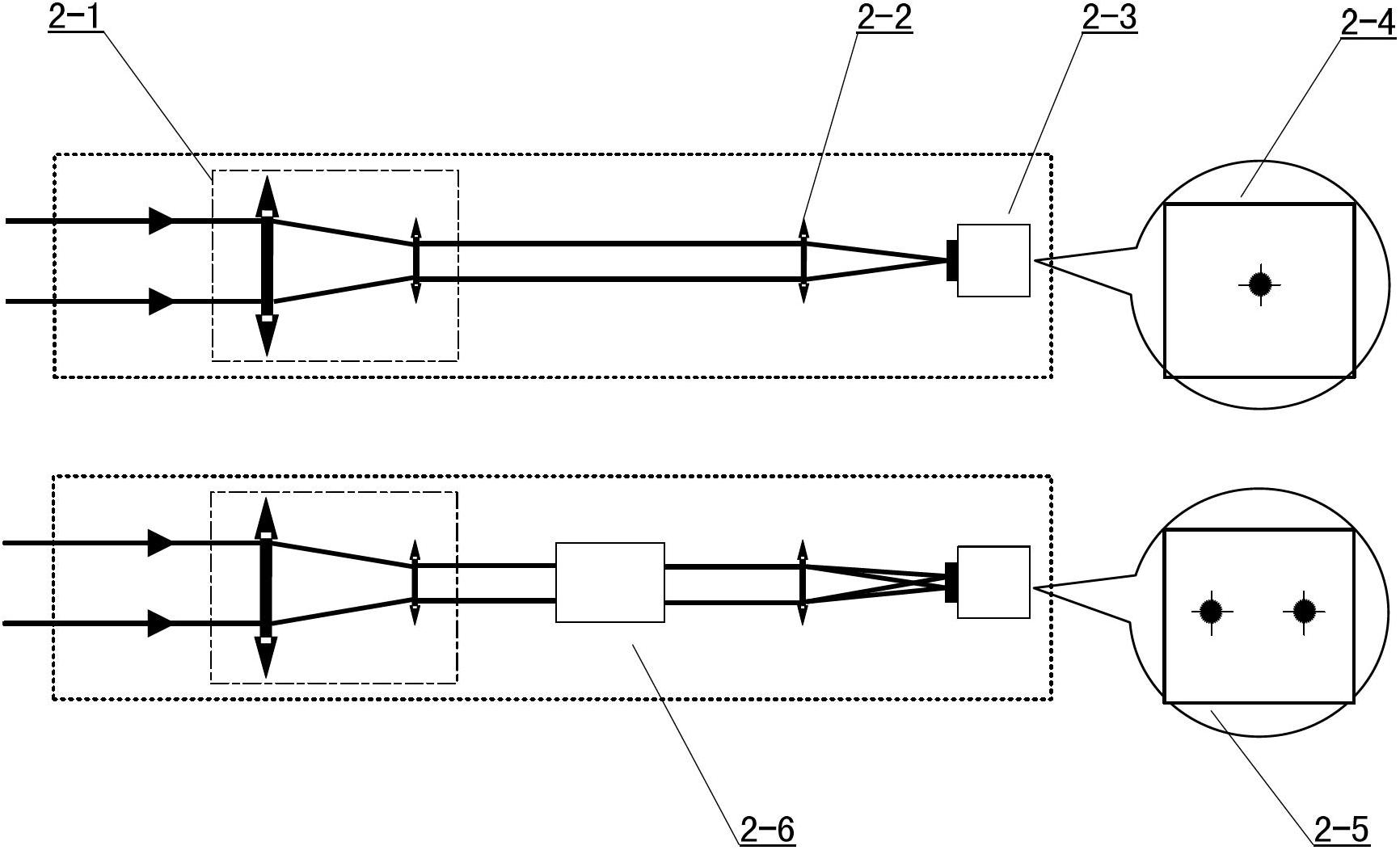

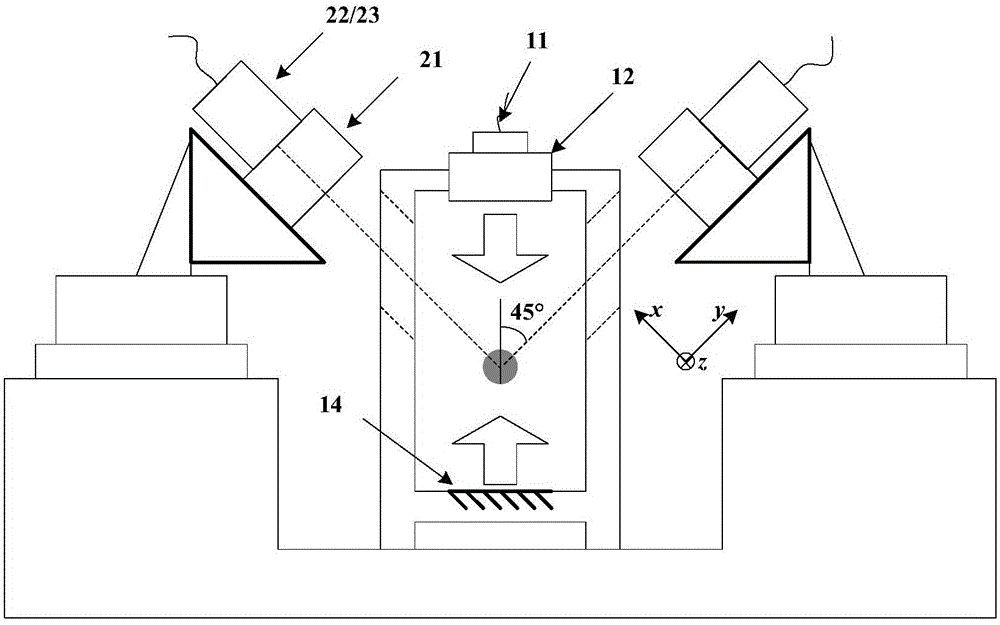

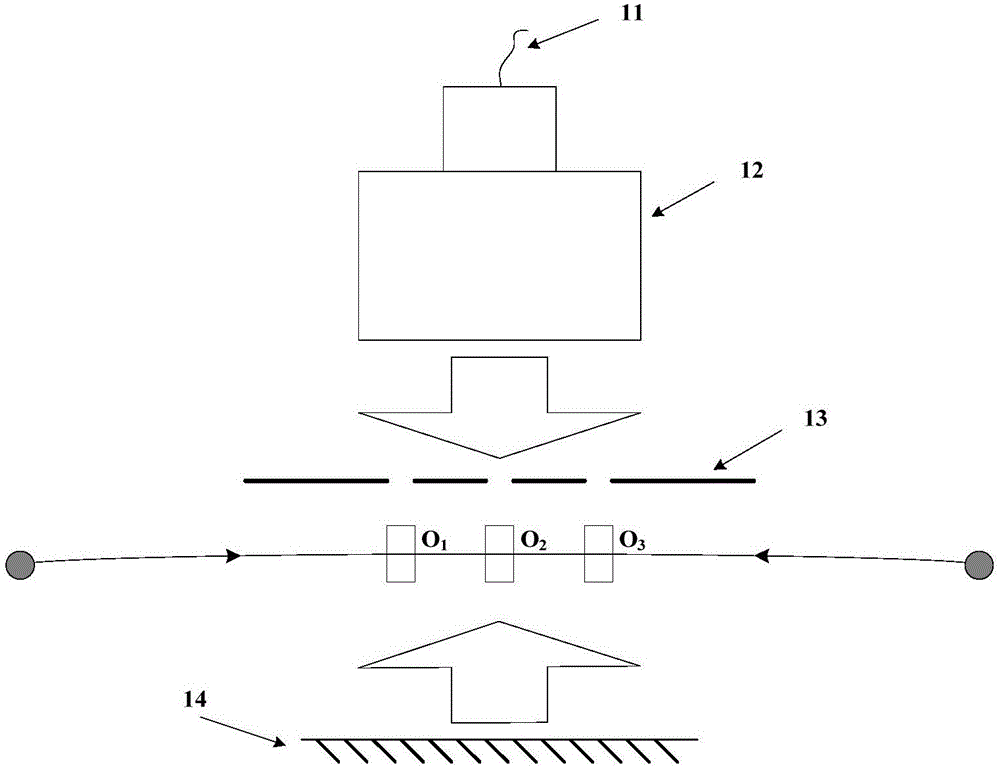

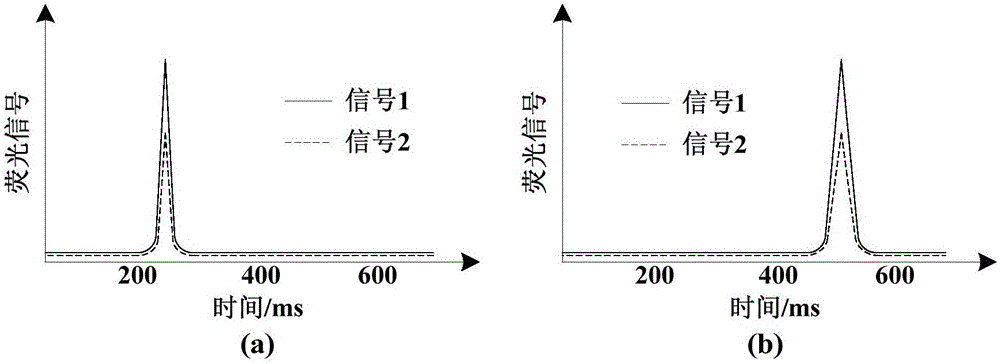

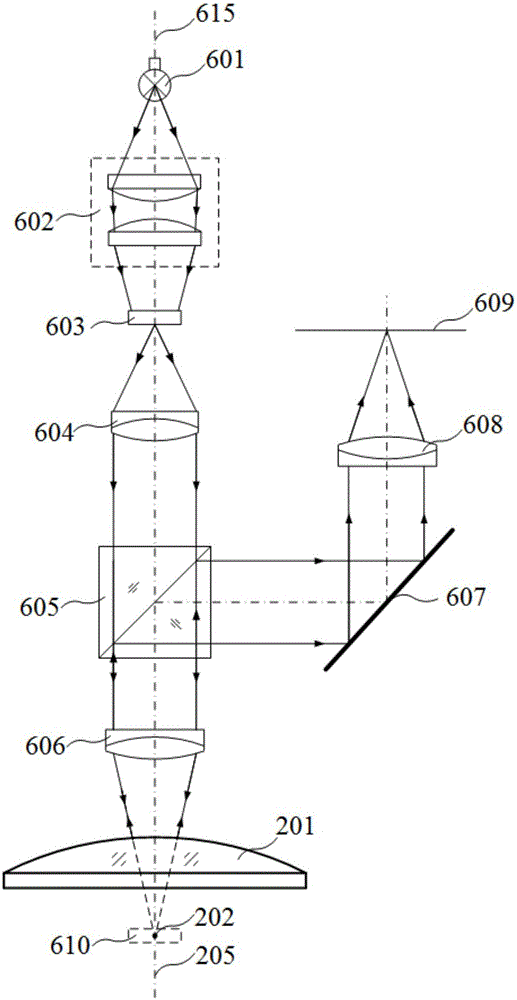

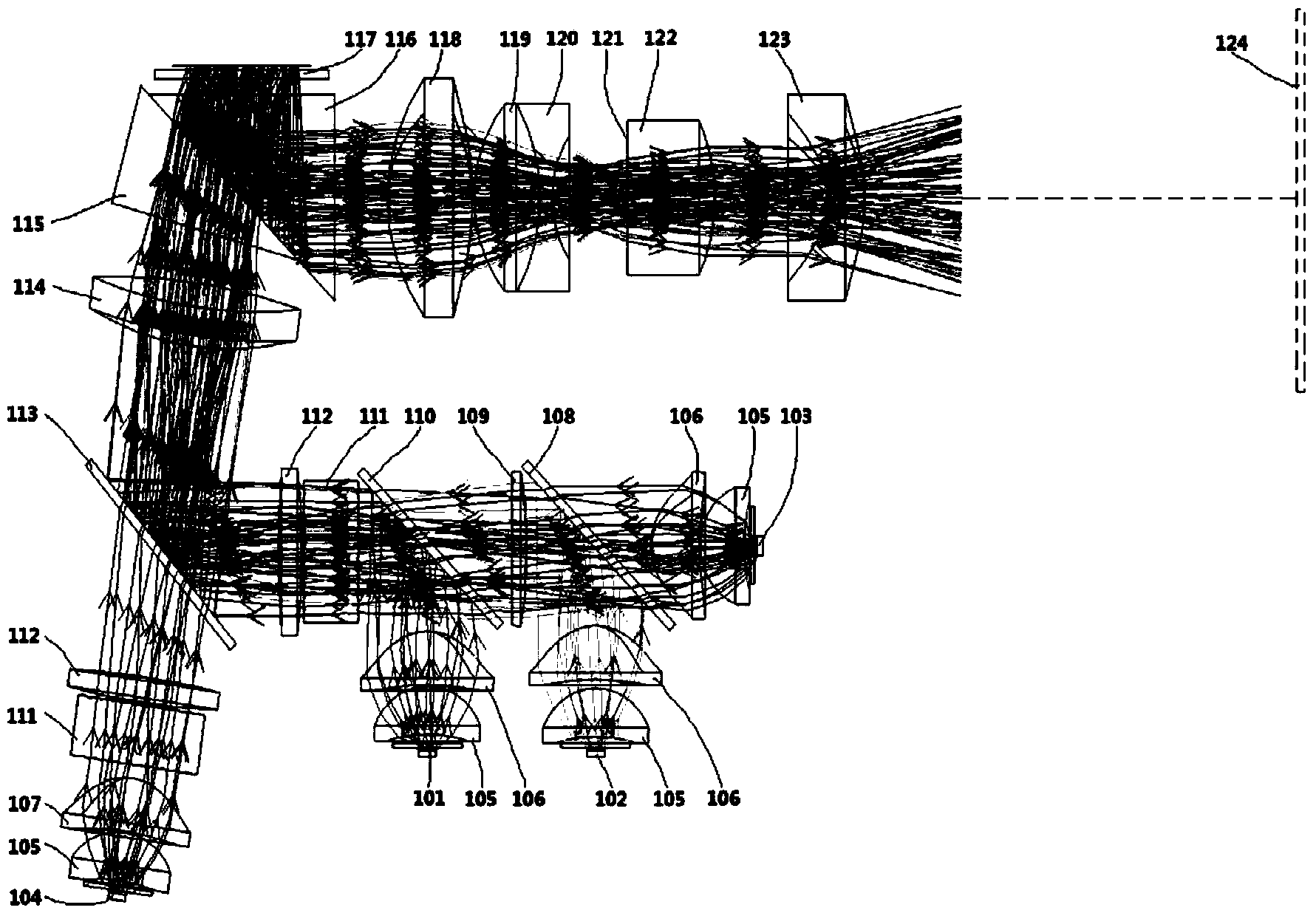

Detection method and device of radical cooling temperature, flying speed, and movement track

ActiveCN105066983ARealize two-dimensional detectionAchieve coincidenceTurn-sensitive devicesGyroscopeLight beam

The invention discloses a detection device of radical cooling temperature, flying speed, and movement track. The detection device comprises a detection light path system and a single acquisition system; the detection light path system comprises an incident optical fiber (11), a beam expanding and collimation system (12), a diaphragm (13), and a reflector (14); the single acquisition system comprises a focusing lens (21), a photodiode PD (22), and a CCD (23); three intersection areas of three flake-like parallel light beams, which are formed via illuminating of the diaphragm (13) by the beam expanding and collimation system (12), with the radical movement track are taken as detection areas. The detection method and device are skillful is design, and simple in structure, can be used for detection of radical cooling temperature, flying speed, and movement track with a single detection device, and improving atom laser gyroscope performance further.

Owner:NO 717 INST CHINA MARINE HEAVY IND GRP

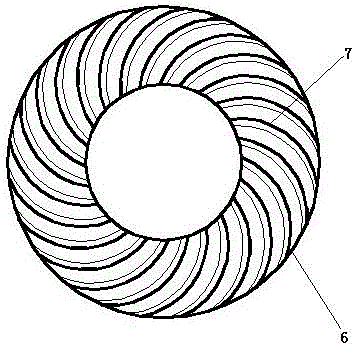

Tire grinding device

InactiveCN105690196ASimple structureRealize full area fixationRevolution surface grinding machinesGrinding work supportsEngineeringGrinding wheel

The invention relates to a tire grinding device. The tire grinding device comprises a positioning mechanism with a positioning head, and a grinding mechanism close to the positioning head. The positioning head is provided with a rotating shaft. A runner is arranged at the end of the rotating shaft. Protruding parts are arranged on the runner in the outer circumferential direction. The outer circumference of the runner is sleeved with an annular air bag. Grooves coinciding with the structures of the protruding parts are formed in the inner circumference of the annular air bag. The air bag is provided with an air nozzle. Protruding patterns are arranged on the outer surface of the air bag, incline by a certain angle in the radial direction of the annular new air bag and extend. The grinding mechanism is arranged on a vertical guide rod, a grinding wheel is further arranged on the grinding mechanism, and the positioning head can be close to the grinding wheel under driving of the drive mechanism. By means of the air bag, a positioning mechanism made of metal or other hard materials is replaced in the prior art, the positioning mechanism conducts full-area fixing on a tire in an inner cavity of the tire, and after the air bag is fully inflated with air, the inner cavity of the tire can be inflated fully through the air bag, and the inner portion of the tire is supported; and during grinding wheel grinding, the grinding position is not prone to being sunk.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

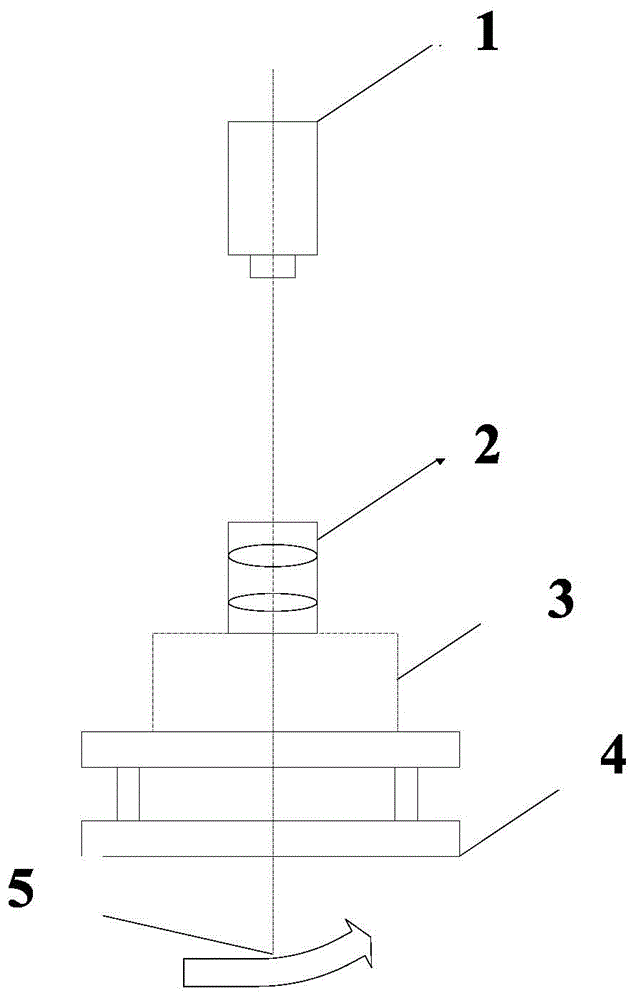

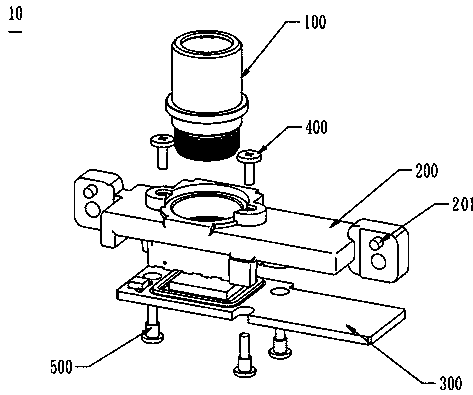

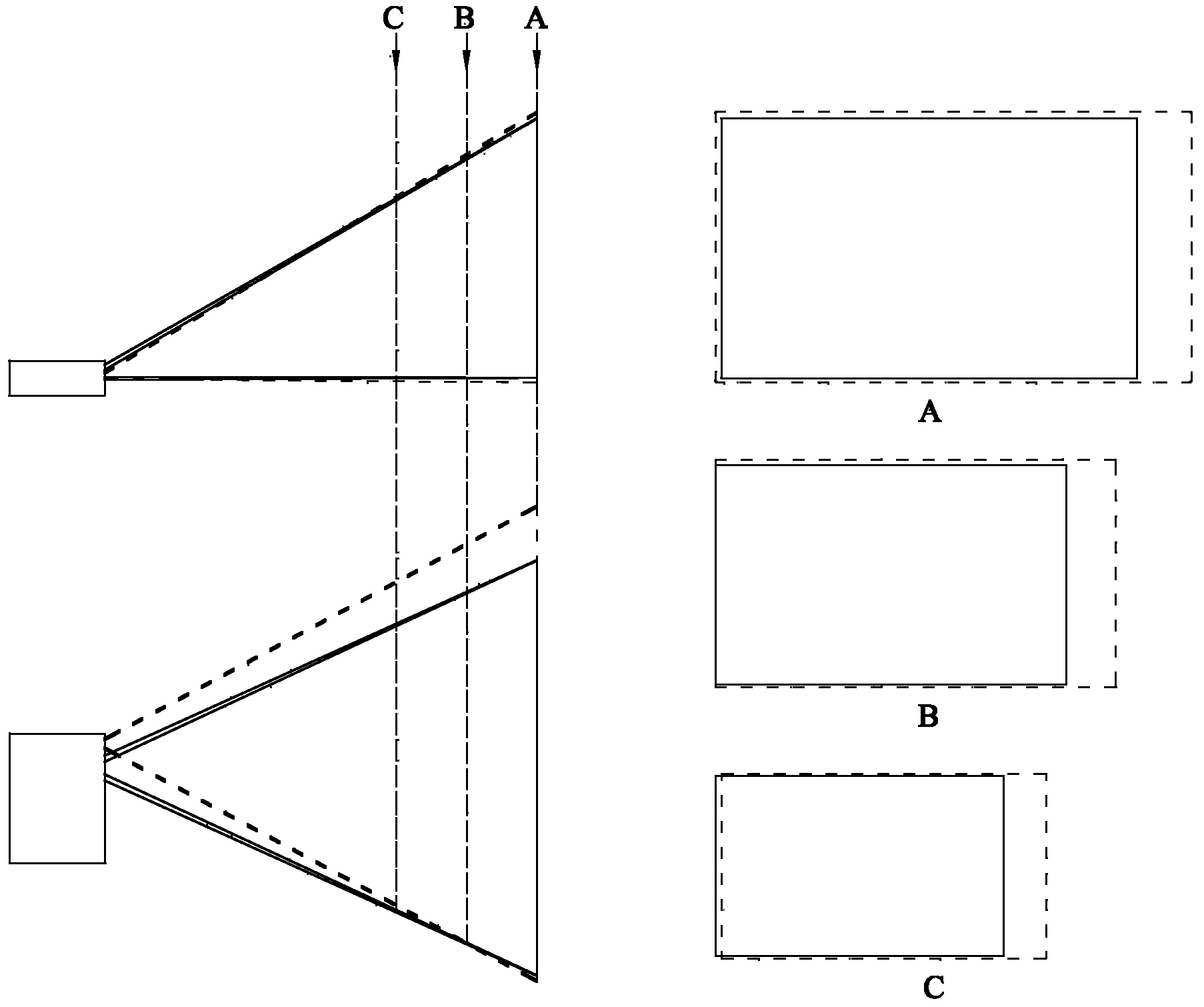

System capable of realizing optical lens and focal plane assembly high-precision centering, and method capable of realizing optical lens and focal plane assembly high-precision centering

The present invention relates to a system capable of realizing optical lens and focal plane assembly high-precision centering, and a method capable of realizing the optical lens and focal plane assembly high-precision centering. The system comprises an auto-collimation centering instrument, a two dimensional adjusting bench and a rotating shaft, a to-be-debugged focal plane assembly is arranged on a two-dimensional turntable adjusting bench, and a to-be-debugged optical lens is arranged on the to-be-debugged focal plane assembly. The two dimensional adjusting bench can realize the translation and pitching adjustment, a translation precision is 0.01mm, and a pitching adjustment precision is 5''. The rotating shaft is connected with the two dimensional adjusting bench and drives the to-be-debugged focal plane assembly and the to-be-debugged optical lens to rotate axially around the rotating shaft via the two dimensional adjusting bench, and the to-be-debugged focal plane assembly and the to-be-debugged optical lens are arranged in an emergent light path of the auto-collimation centering instrument orderly. The present invention provides the system and the method which are simple in structure and high in centering precision, are easy to operate, and can realize the optical lens and focal plane assembly high-precision centering.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

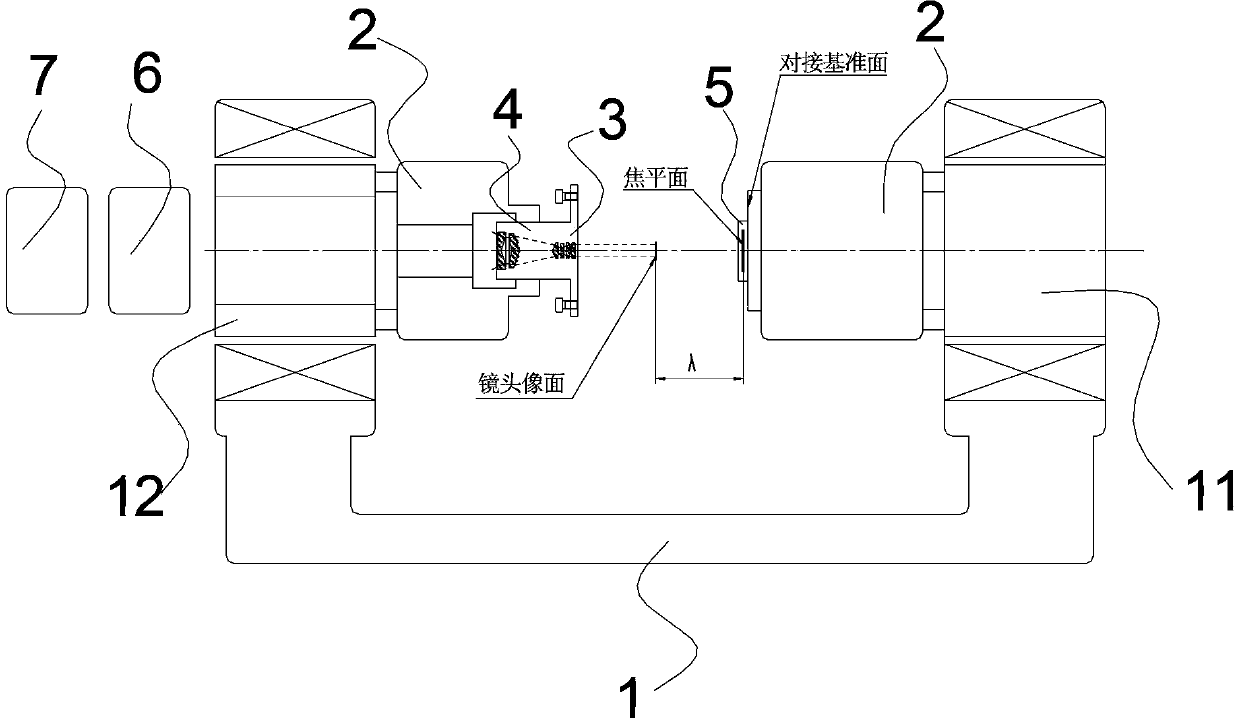

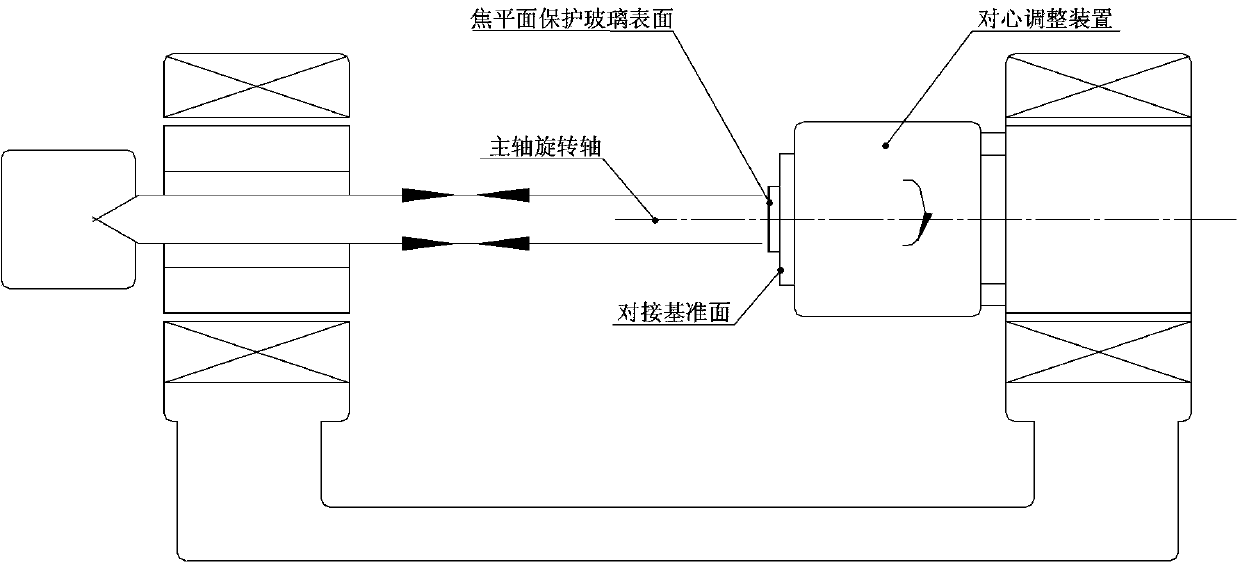

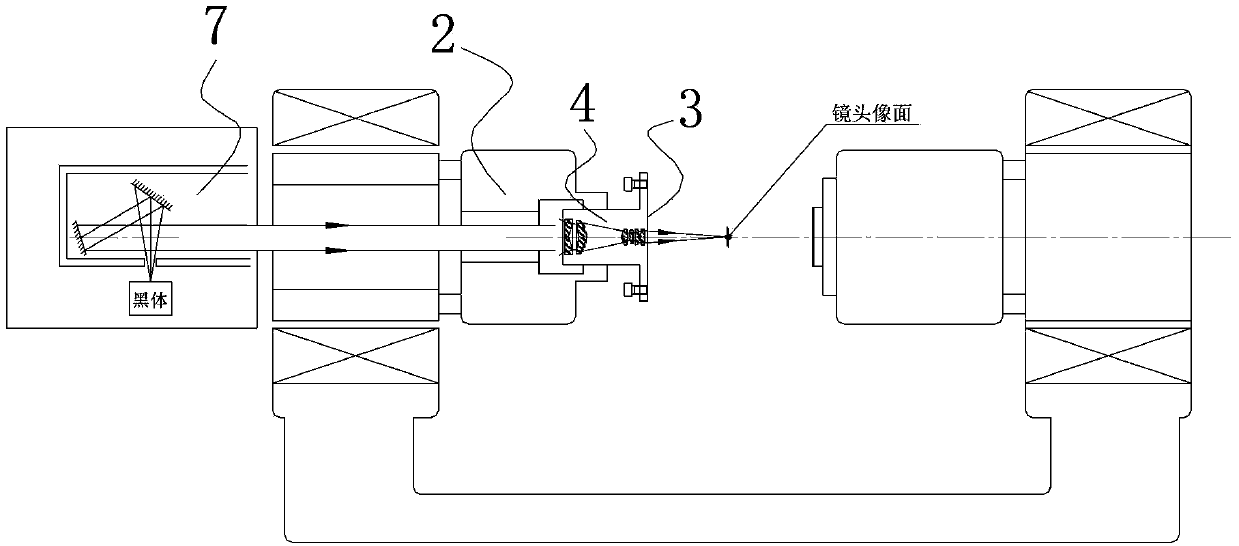

High-precision combined calibration and butt-joint method and mechanism for infrared imaging system

ActiveCN103399416AEliminate assembly errorsGuaranteed parallelismOptical elementsReference surfaceTarget surface

The invention provides a high-precision combined calibration and butt-joint method and a high-precision combined calibration and butt-joint mechanism for an infrared imaging system, which are mainly used for solving the problem that the verticality precision of the optical axis of an optical imaging system and an imaging focus plane, the verticality accuracy of the optical axis of the optical imaging system and the central normal of the target surface of an imaging focal plane and the verticality accuracy of the image plane of the optical imaging system and an imaging focal plane cannot be ensured in the conventional image plane but-joint process. According to the method and the mechanism, a high-precision dual-shaft lathe is used for clamping at one time, and meanwhile turning machining of the butt-joint reference surface of a focusing plane assembly and the flange mounting end face of an optical lens is realized after a given adjusting target is achieved and the adjusting precision is reached, so that the parallelism of two planes is ensured, and assembling errors caused by earlier assembling loops of the focal plane assembly and optical lens are fully eliminated.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

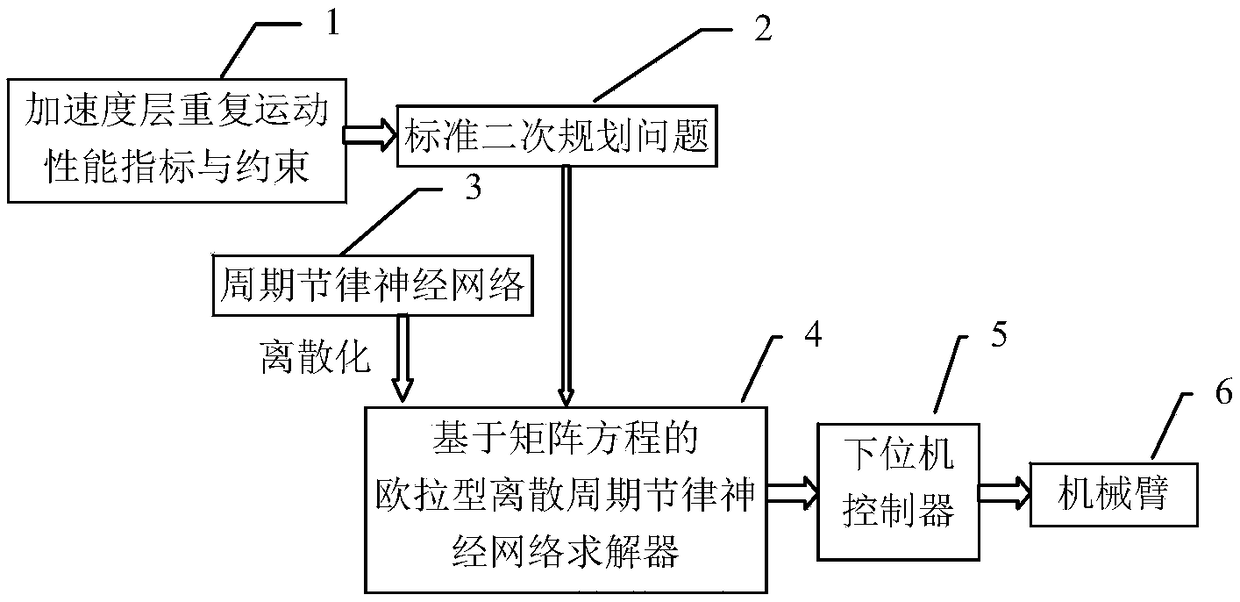

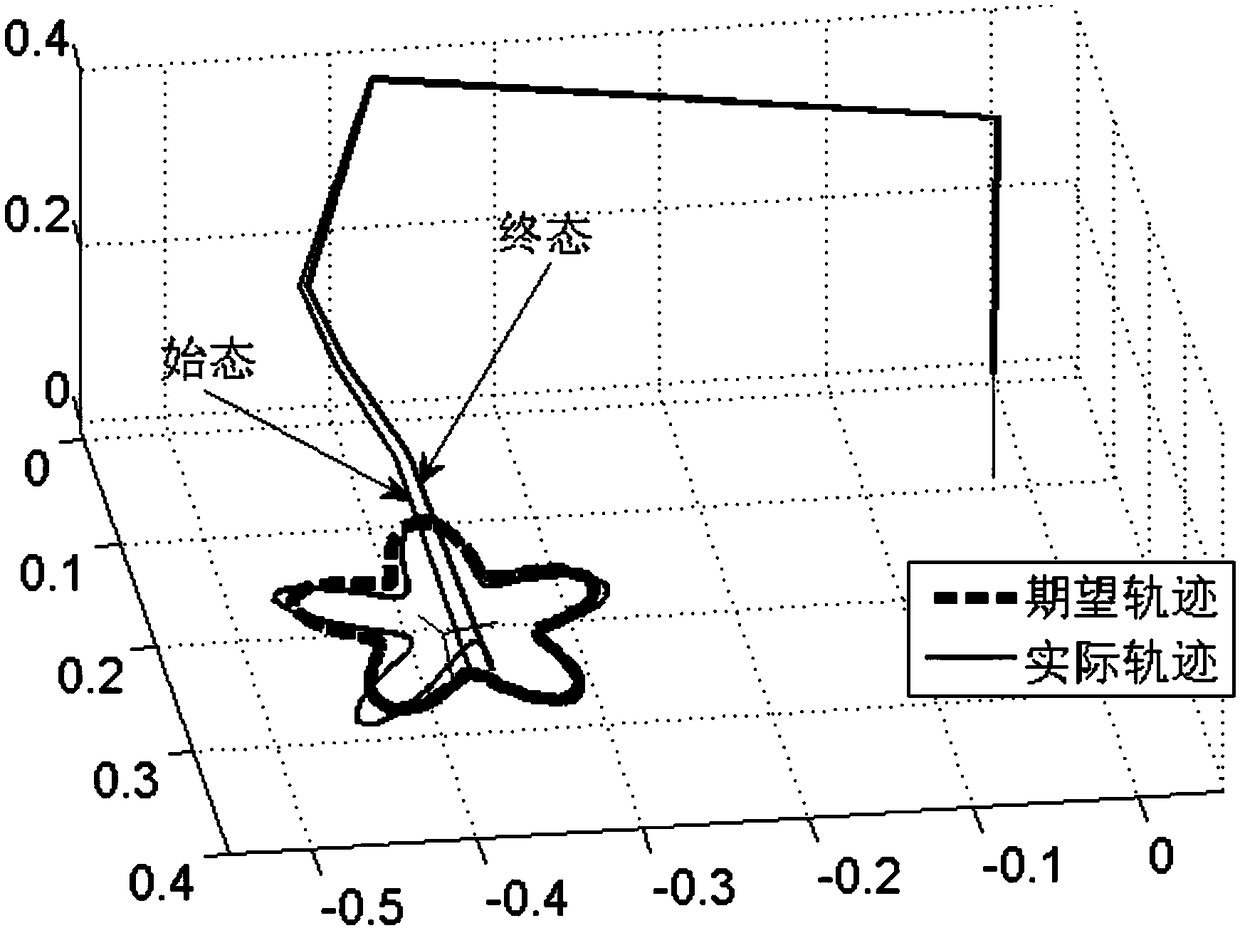

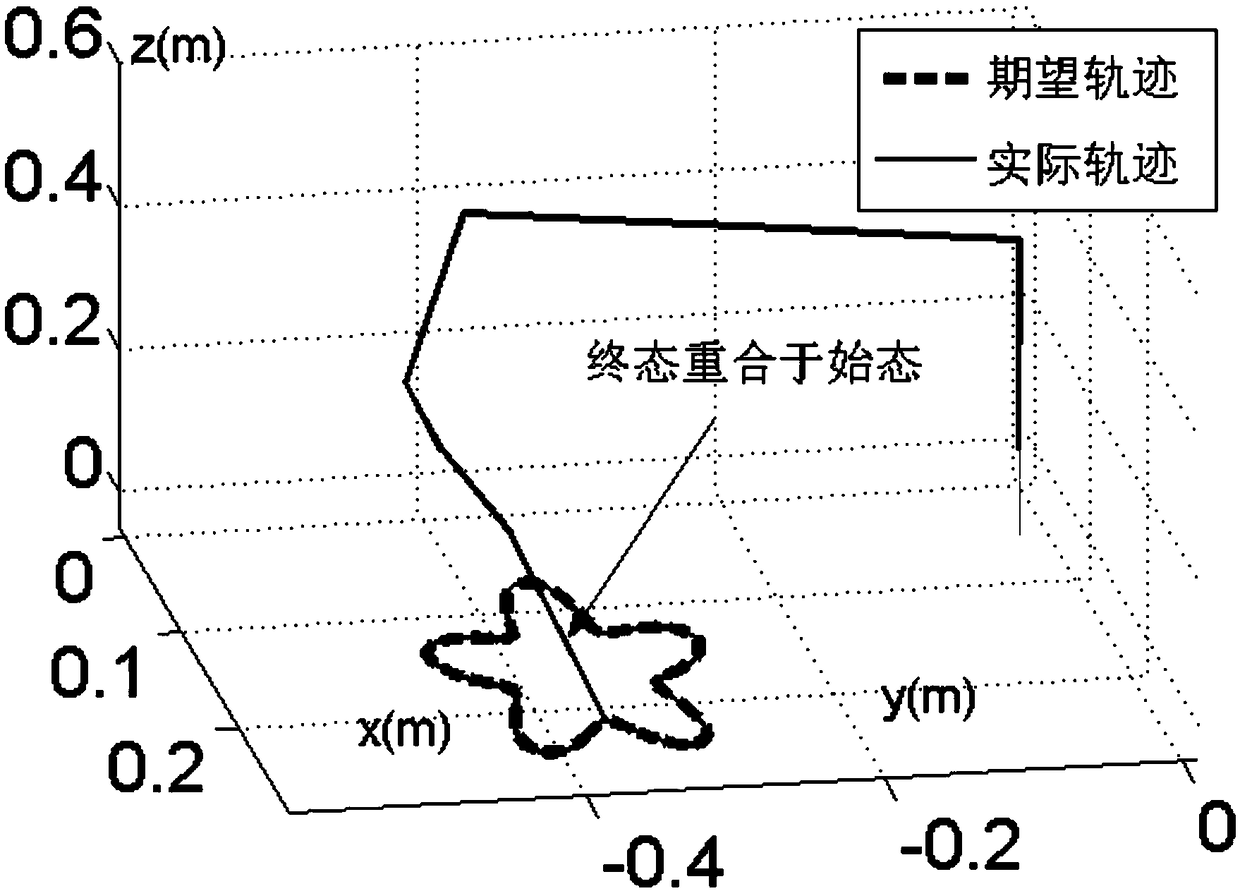

A redundant manipulator repetitive motion planning method based on Euler discrete periodic rhythm neural network

ActiveCN109086557AAchieve coincidencePeriodic Noise SuppressionGeometric CADNeural architecturesEngineeringManipulator

The invention relates to a redundant manipulator repetitive motion planning method based on an Euler-type discrete periodic rhythm neural network, comprising the following steps: 1) adopting a quadratic optimization to analyze the inverse kinematics of the manipulator on an angular acceleration layer, and designing an angular acceleration Jacobian equation; 2) the angular velocity norm being equivalent to the angular acceleration norm, and a standard quadratic program scheme being established; 3) discretizing the periodic rhythm neural network by the Euler forward differential method to obtainan Euler-type discrete periodic rhythm neural network solver and use the solver to solve a standard quadratic programming scheme; 4) driving each joint motor through the controller to make the manipulator carry out repetitive motion planning from the initial position. The invention realizes the repetitive motion planning of the control redundant manipulator by using the Euler-type discrete periodic rhythm neural network, and the Euler-type discrete periodic rhythm neural network is easier to realize the suppression of periodic noise in hardware.

Owner:SOUTH CHINA UNIV OF TECH +1

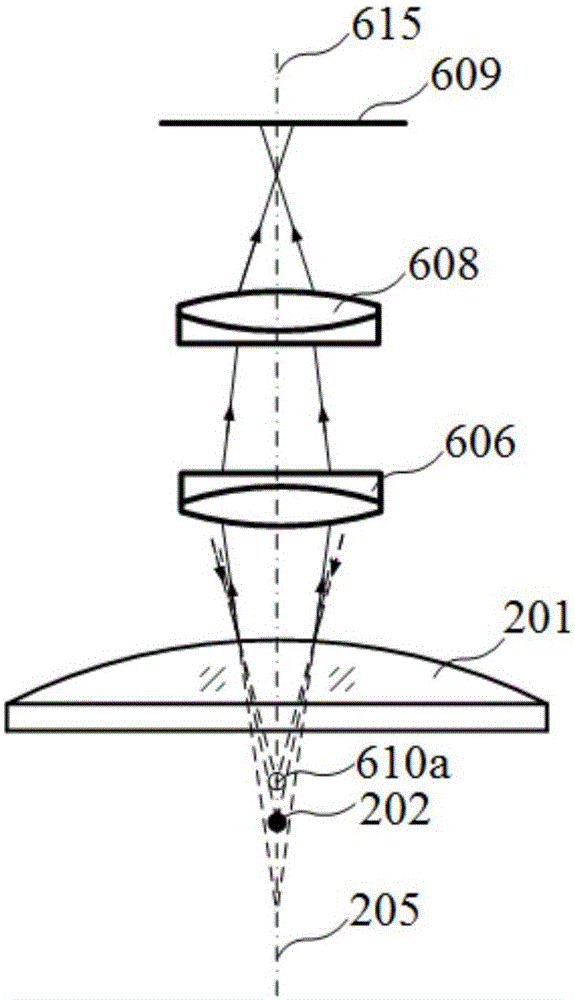

Spherical surface automatic centering method applied to spherical surface optical element surface defect detection

ActiveCN105157617AAchieve coincidenceRealize automatic and accurate measurementUsing optical meansOptical axisComputer vision

The invention discloses a spherical surface automatic centering method applied to spherical surface optical element surface defect detection. The method comprises the following steps that a spherical surface centering unit is initialized, and then a spherical surface optical element is moved to an initial position; Z-direction scanning is performed, and the clearest crosshair image is found by utilizing an image entropy definition evaluation function in the scanning process; then whether the crosshair is a surface image or a spherical center image is judged; if the crosshair is the surface image, the spherical center image is found through scanning along Z-direction, and radius of curvature of the spherical surface optical element is measured; if the crosshair is the spherical center image, the optical axis of the spherical surface optical element is enabled to be overlapped with the optical axis of the spherical surface centering unit through movement; and finally fitting is performed on the center of the crosshair image by a least square method optimal circle fitting method to obtain movement tracks, calculation of the maximum deviation of the crosshair image is completed, and the maximum deviation is judged so that shafting consistency adjustment is completed. Automatic centering of the spherical surface optical element is realized so that centering efficiency and centering precision are greatly enhanced.

Owner:ZHEJIANG UNIV

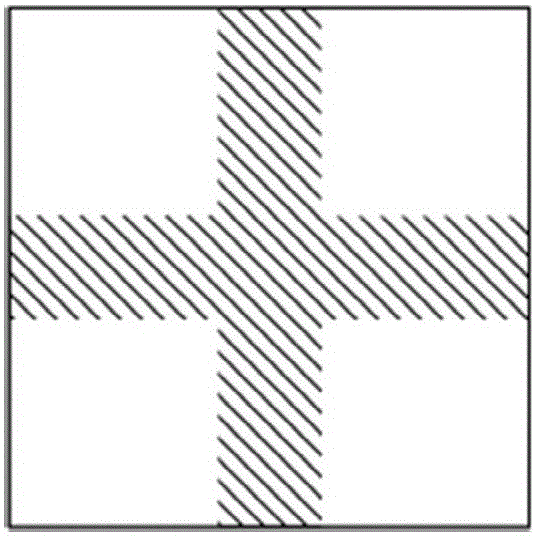

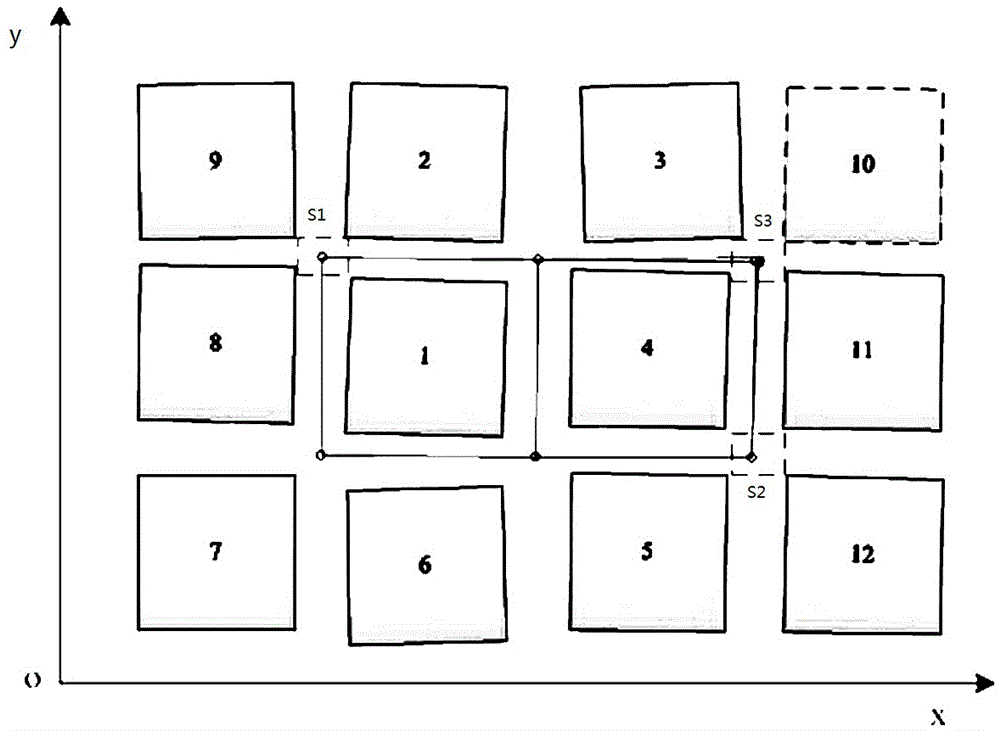

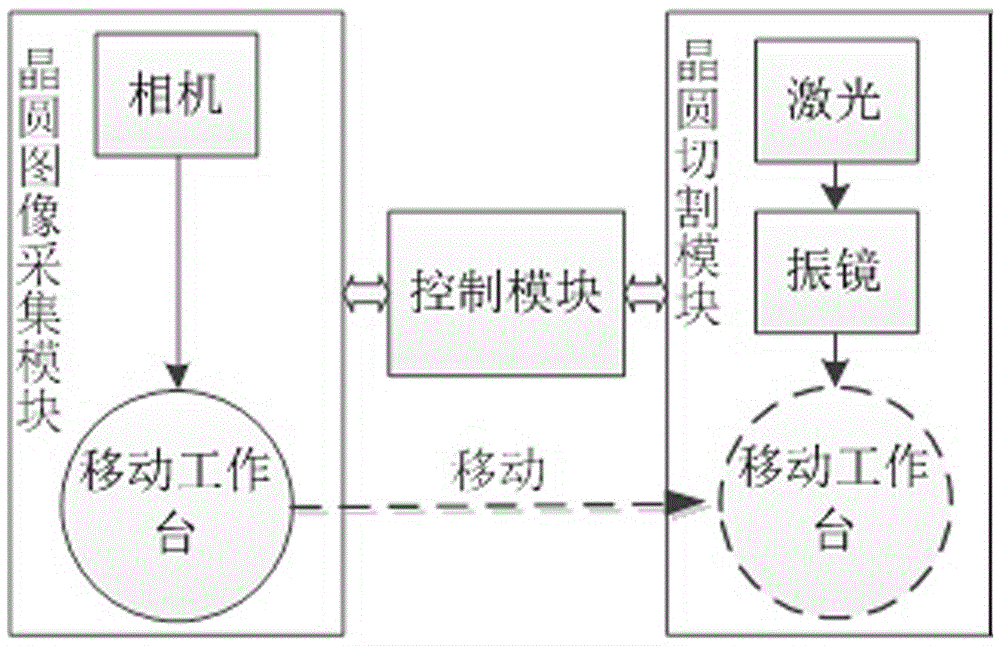

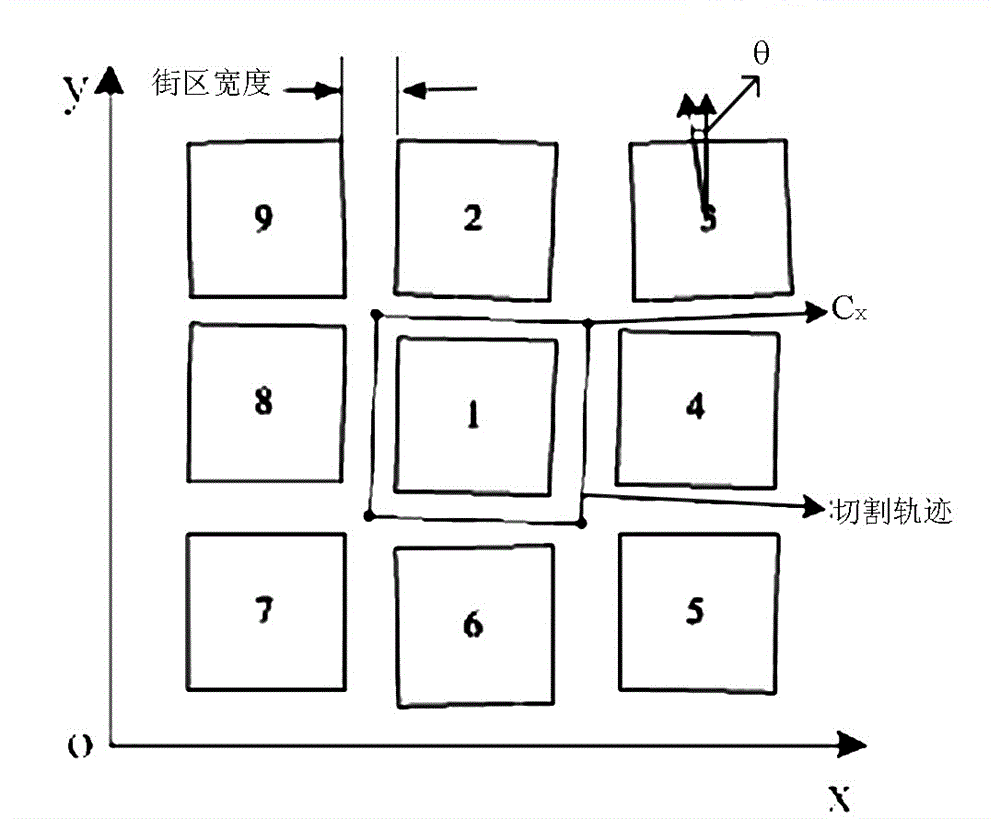

Cutting method for wafer with irregularly-distributed chips

ActiveCN106783738ARemove the effects of block width variationsEliminate the effects ofSemiconductor/solid-state device manufacturingGalvanometerEngineering

A cutting method for a wafer with irregularly-distributed chips comprises the following steps of 1, controlling to move a workbench and a camera by a control module, and scanning the wafer on the workbench so as to achieve full image acquisition one by one; 2, processing each image obtained by scanning; 3, determining whether scanning on the wafer is completed or not; 4, integrating wafer data after the wafer scanning is completed; 5, judging whether cutting tracks of all chips to be processed in the whole wafer are determined or not; 6, inputting cutting position information of each chip to be processed into a galvanometer when that the cutting tracks of all chips to be processed are determined; and 7, moving the workbench to a part below the galvanometer, and controlling laser to cut the wafer by the galvanometer. By the cutting method, the cutting of the wafer with the irregularly-distributed chips formed by non-standard processing is achieved, and the cutting method has the characteristics of no cutting residue and high efficiency.

Owner:BEIJING SEMICON EQUIP INST THE 45TH RES INST OF CETC

Control method and control system for width centering of steel coil carried by steel coil car

The invention provides a control method and a control system for the width centering of a steel coil carried by a steel coil car. The control system comprises a saddle seat position, a ground roll position, a drum, the steel coil car and a track for the traveling of the steel coil car, wherein a V-shaped saddle seat capable of lifting up and down is arranged on the steel coil car; an absolute value rope encoder is arranged below the track; a steel coil car retreat limit position travel switch, a steel coil car advance limit position travel switch and a steel coil car speed-reducing position travel switch are respectively mounted below the track; a coil-contacting approach switch, steel coil width detection correlation switches and a control module are further arranged above the track. The control system is simple, and accurate in width centering effect; and through the application of the control system, the degree of automation can be greatly improved, and the operating efficiency of a machine set can be improved.

Owner:WISDRI ENG & RES INC LTD

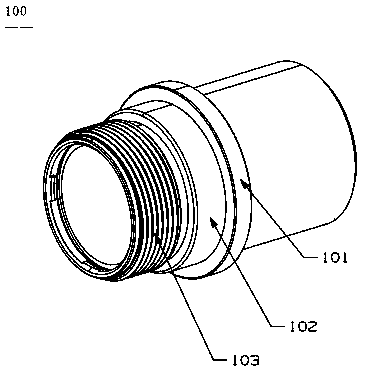

Camera module and assembling process thereof

ActiveCN110351469AEasy to installLow flatnessTelevision system detailsColor television detailsCamera lensOptical axis

The invention provides a camera module and an assembling process thereof. The camera module comprises a lens, a lens seat, an image sensor assembly and an anti-loosening screw, the bottom of the lensis provided with external threads; a limiting ring is arranged in the middle of the lens, and a positioning guide step is arranged between an external thread at the bottom of the lens and the limitingring; the lens seat comprises a lens assembling hole, the lens assembling hole is arranged in the lens seat in a penetrating manner, and the upper end part of the lens assembling hole sinks to form abearing table; an annular boss is formed at the bottom of the lens assembling hole and is provided with an internal thread; a positioning guide cylinder is arranged between the bearing table and theannular boss; the anti-loosening screws are used for fixing the lens and the lens seat and fixing the lens seat and the image sensor assembly, so that the stability of connection between the lens andthe lens seat and between the lens seat and the image sensor assembly is ensured, and the optical axis of the lens coincides with the normal of the image sensor; the camera module provided by the invention is assembled by taking the lens seat as a reference, so that the yield of the camera module is effectively improved.

Owner:JIANGXI LIANYI OPTICS CO LTD

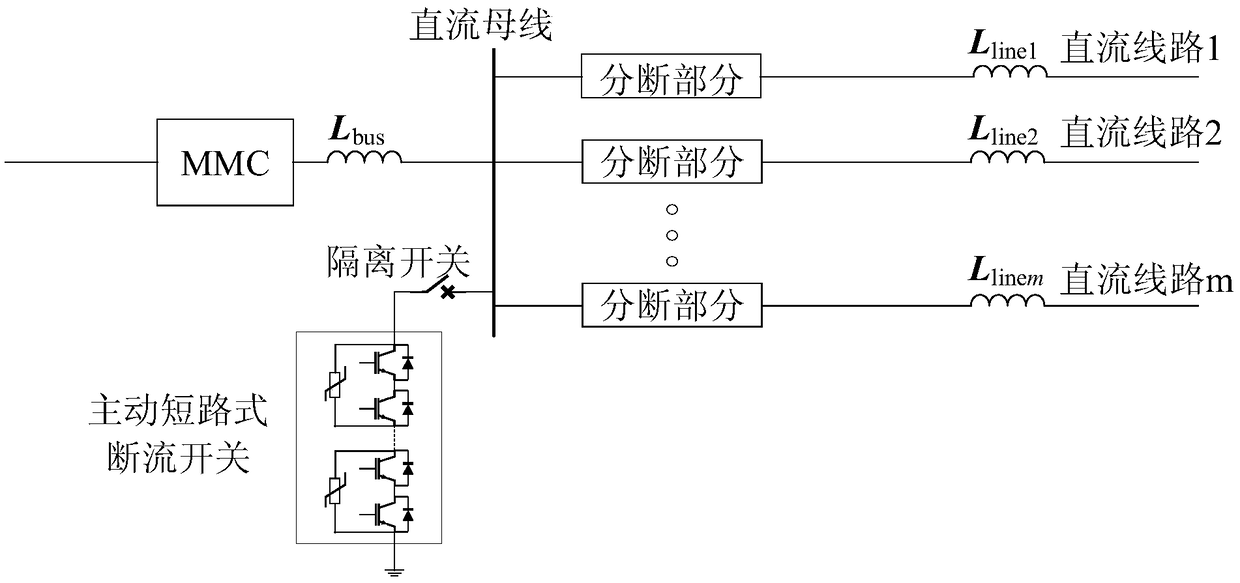

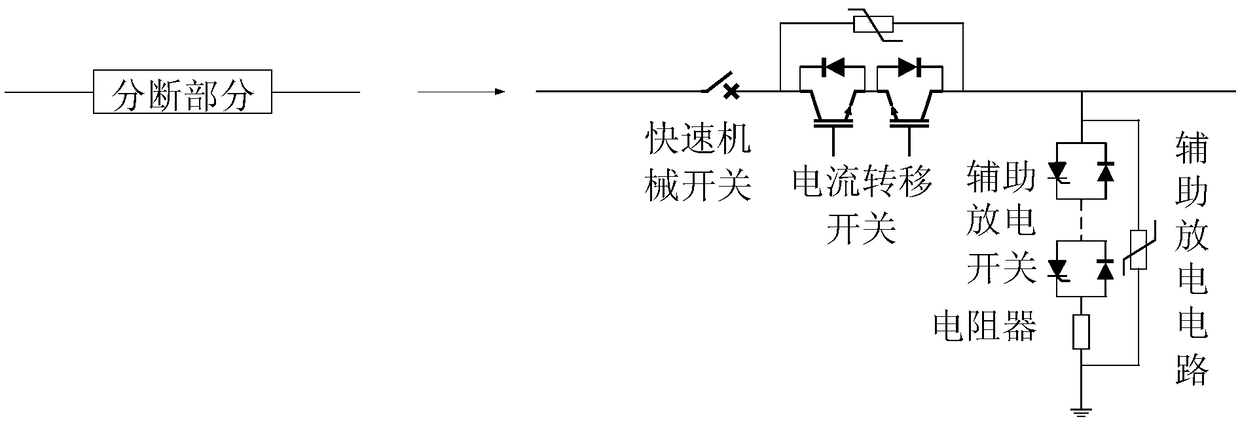

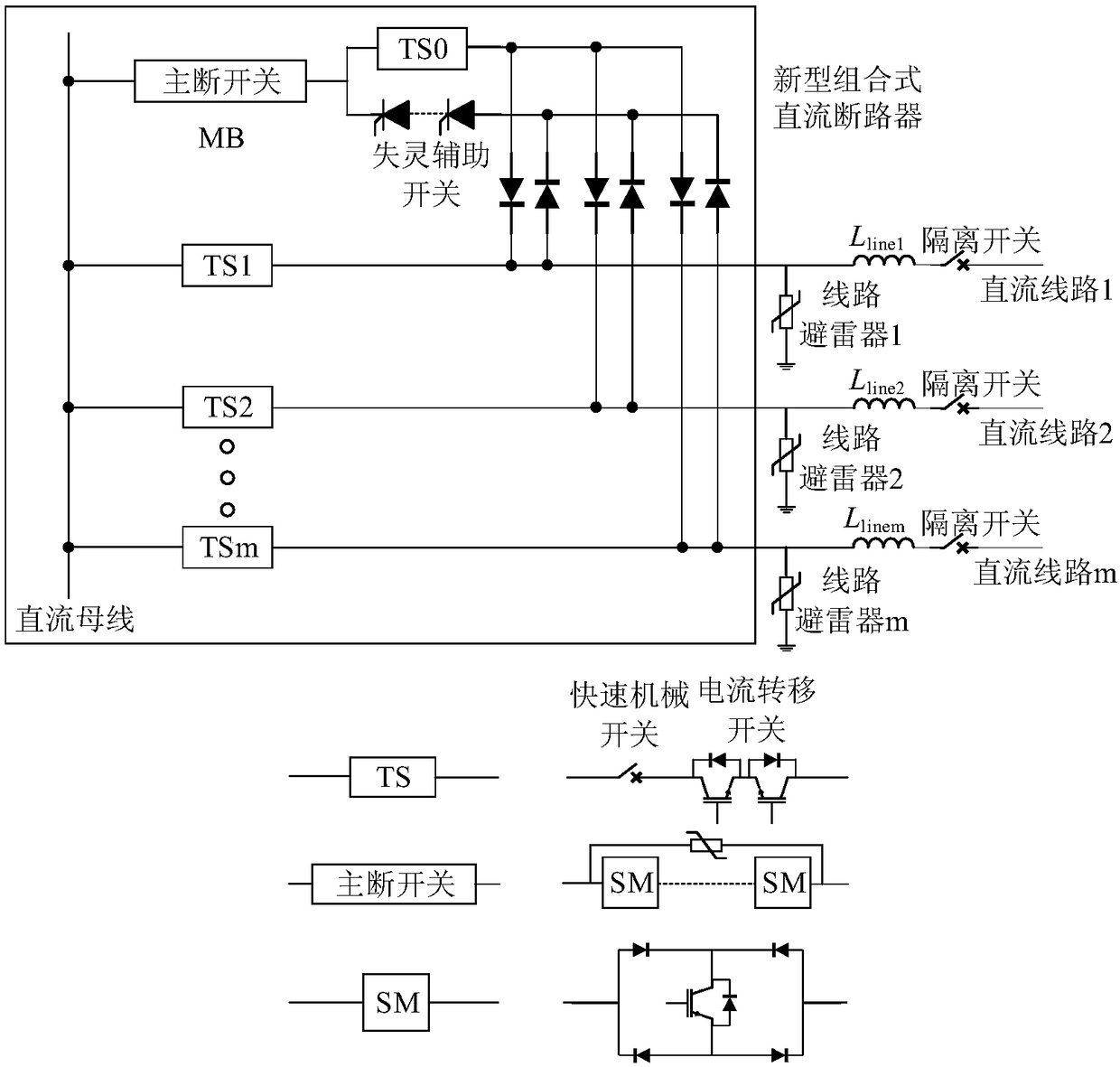

A novel combined DC circuit breaker topology

ActiveCN109193625AImprove economyReduce breakdown rateEmergency protective arrangements for automatic disconnectionEmergency protective arrangements for limiting excess voltage/currentDc circuit breakerTransfer switch

The invention discloses a novel combined DC circuit breaker topology, which adopts only one main breaker switch, one malfunctioning auxiliary switch, one transfer switch TS0 connected in series with the main breaker switch, two groups of diodes in different directions, and a transfer switch TS1 corresponding to m lines on each DC bus bar, wherein, the main breaker switch TS0 is connected with themain breaker switch TS0, and the main breaker switch TS1 is connected with the main breaker switch TS0-TSm. The transfer switch TS0 is connected in parallel with the failed auxiliary switch in serieswith the main disconnect switch, one end of the main disconnect switch is connected with the DC bus bar, the other end is connected with the diode group in the direction of the inflow line through thetransfer switch TS0, and is also connected with the diode group in the direction of the outflow line through the failed auxiliary switch. The transfer switch TS1-TSm is respectively connected to thebus bar and the corresponding line 1-Line m. When the system is in normal operation, the voltage on both ends of the switches of each part of the novel combined DC circuit breaker is zero, which can effectively reduce the breakdown probability of the device, improve the operation reliability of the system as a whole, adopt fewer main devices, and have better economy.

Owner:SOUTH CHINA UNIV OF TECH

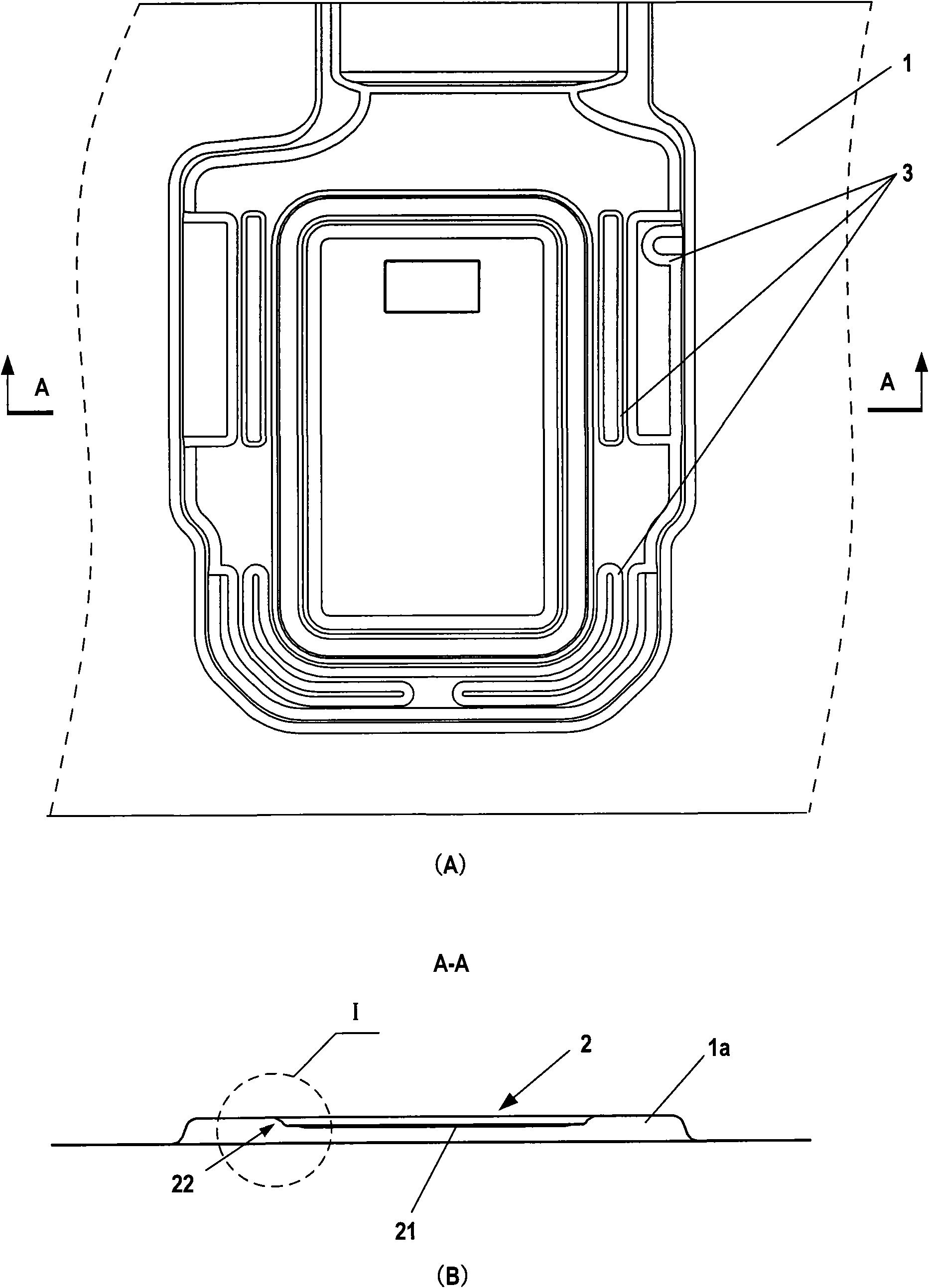

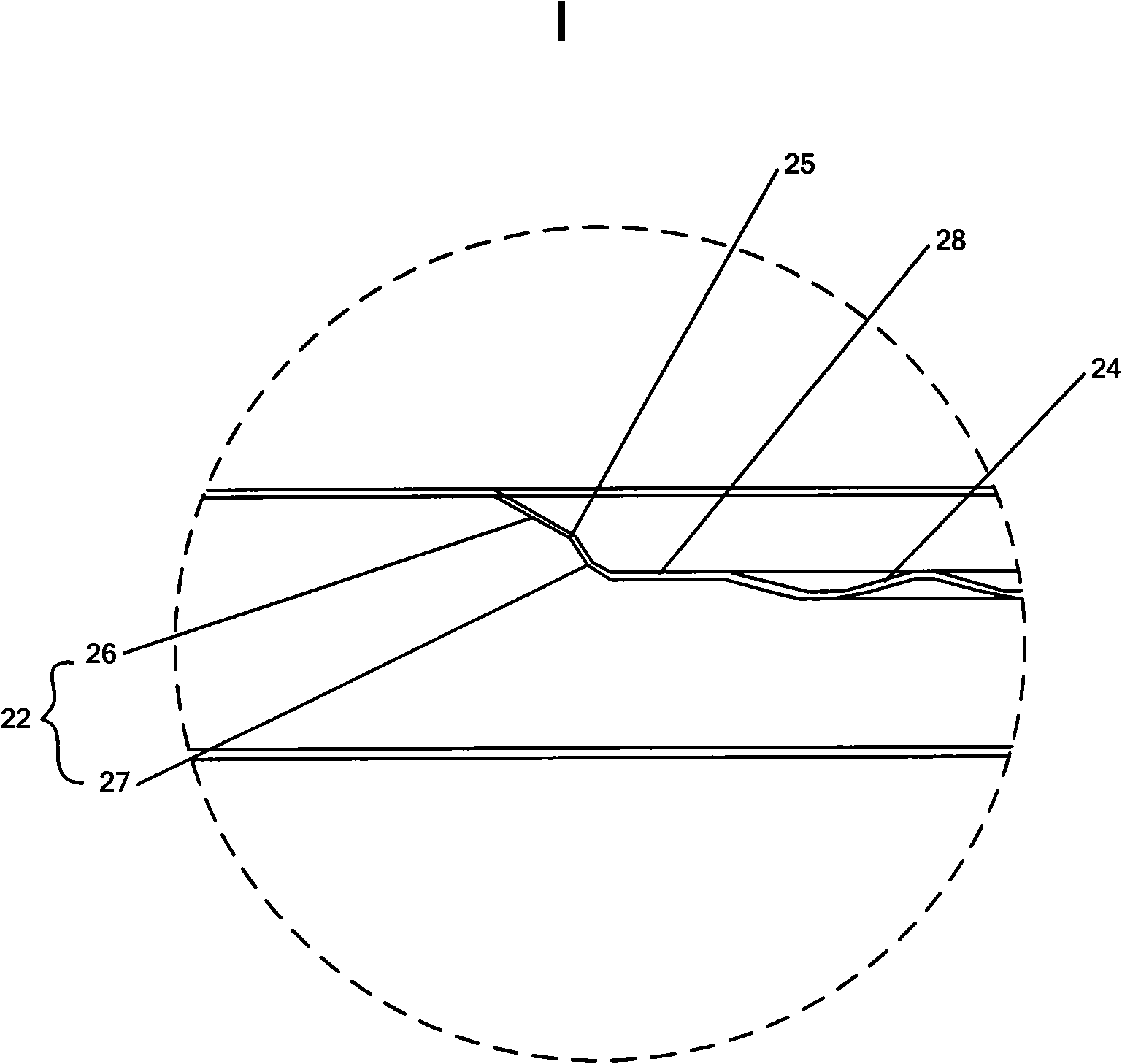

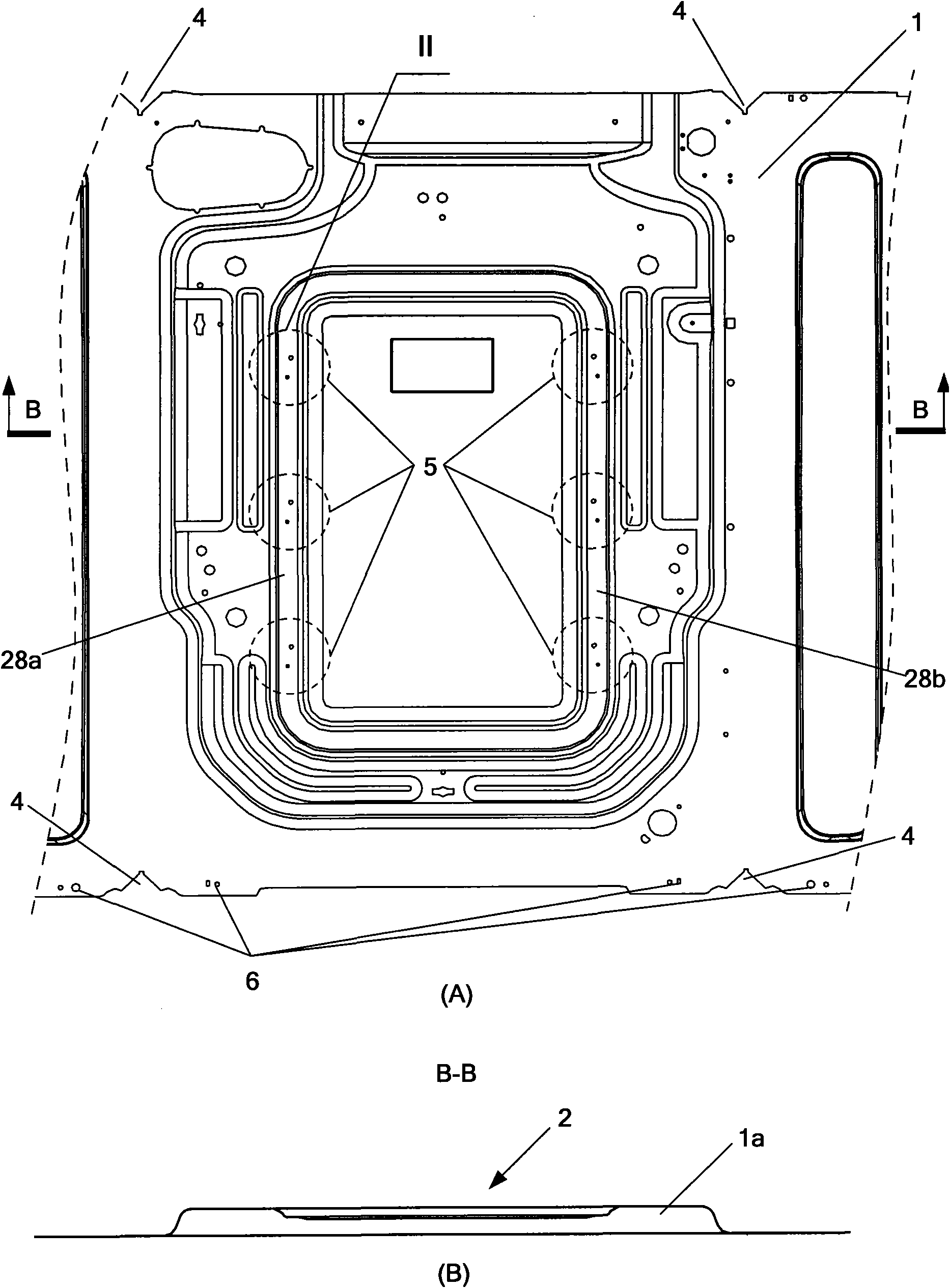

Box body and cover plate and manufacturing process thereof

ActiveCN101898215AAchieve coincidenceIncrease the areaOther washing machinesTextiles and paperEngineeringWaste material

The invention provides a process for manufacturing a box body and a cover plate as well as the box body and cover plate manufactured by the manufacturing process. The box body is provided with an opening (12'), the cover plate (11) is arranged at the opening (12') of the box body. The manufacturing process includes: a stretching working procedure, namely stretching processing is carried out on a plate (1) used for forming the box body, so as to form a sunk part (2) larger than the opening (12'); a blanking working procedure, namely blanking processing is carried out on the sunk part (2) of the plate (1), so as to separate the cover plate (11); and a levelling working procedure, namely the rest part (21b) of the sunk part (2) on the plates (1) is levelled, so as to form an opening (12') which is coincident with the periphery of the cover plate (11). Thus the box body and cover plate can be simultaneously processed on one plate, not only waste material produced when processing the opening is reasonably utilized, but also two processing working procedures are combined, so that working procedure is saved.

Owner:QINGDAO HAIER MOLDS

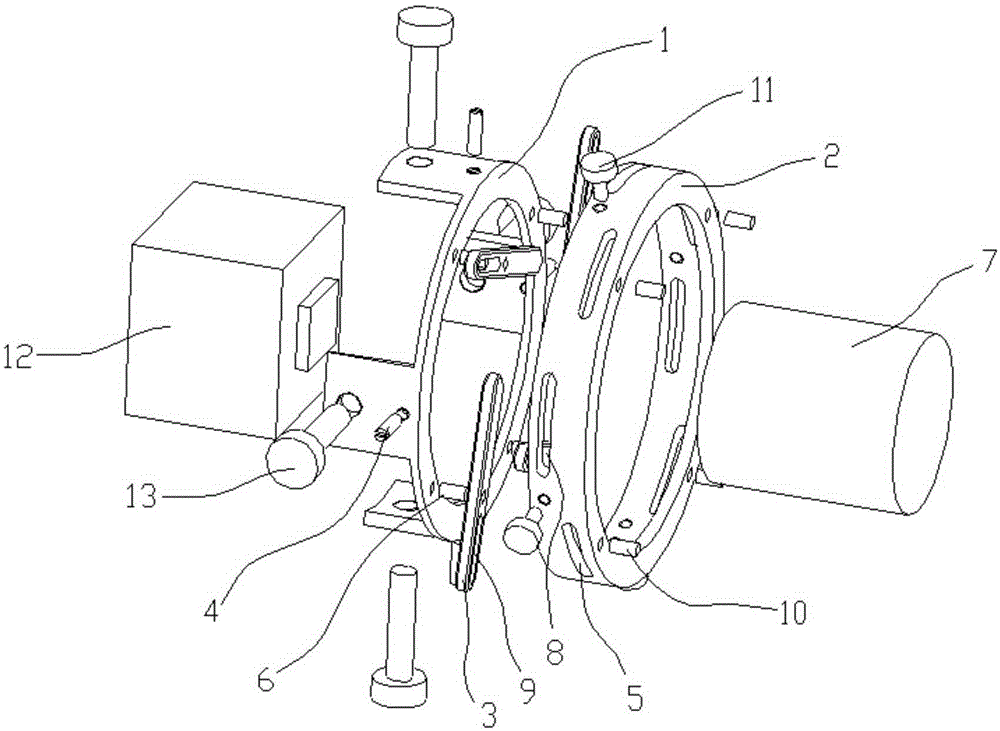

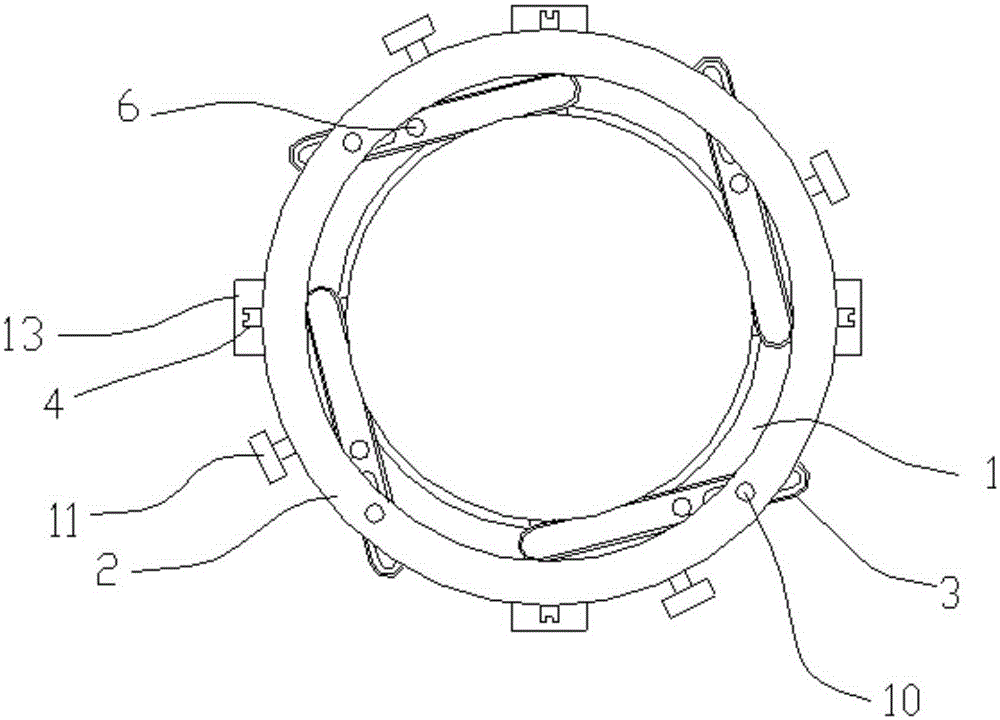

Flange structure applicable to infrared thermal imaging module

The invention relates to a flange structure applicable to an infrared thermal imaging module, comprising a movement frame, a flange ring and clamping jaws. The movement frame is disposed at one side of the flange ring. The movement frame and the flange ring are connected by limiting guide pins, and the limiting guide pins can limit the angle of rotation of the flange ring relative to the movement frame. The flange ring is provided with strip-shaped hollow first slots, and the clamping jaws are arranged in the first slots. The middle of each clamping jaw is rotationally connected with the movement frame through a rotating shaft. One end of each clamping jaw can abut on a lens inside the flange ring, and the other end of each clamping jaw can abut on the edge of the corresponding first slot. Compared with the prior art, the flange structure of the invention is applicable to multiple different movement and lens combinations, has a wide range of application, is low in cost and high in speed of combination, and enhances the imaging effect of the movement and the lens.

Owner:IRAY TECH CO LTD

Interactive projection optical system and working method thereof

The invention discloses an interactive projection optical system and a working method of the interactive projection optical system. The interactive projection optical system is integrated with an infrared lighting device sharing a projection optical engine optical path with the system, an infrared lighting area and a protection display area coincide completely, and area dislocation between infrared lighting and projection pictures under different projection distances can be avoided; meanwhile, optical power of a three-primary-color light source and optical power of an infrared light source are effectively utilized under the situation of low cost; in addition, an interactive projection product can be applied only by selecting a proper infrared shooting device without additionally considering matching and adjustment of the infrared lighting device.

Owner:SHENZHEN ANHUA OPTOELECTRONICS TECH

Double-sided synchronous patterned and embossed wood veneer production system and management method

ActiveCN110406298AIngenious designStable structureEmbossing decorationsWood veneerMaterials preparation

The invention discloses a double-sided synchronous patterned and embossed wood veneer production system and management method. Through the production system and management method, double-sided synchronous patterning and embossing of a wood veneer can be automatically completed, and maintenance and early warning can be carried out. The production system comprises a management system, a material preparation table, a discharging table, an automatic plate drying line, a base material lifting platform arranged at an outlet of the material preparation table, a pushing plate device arranged above thebase material lifting platform, a feeding and conveying mechanism, a longitudinal hot press, a discharging and conveying mechanism, an automatic plate trimming machine which are connected in sequence, a first automatic centering and plate conveying device arranged at the outlet of the base material lifting platform and on one side of the feeding and conveying mechanism, a second automatic centering and plate conveying device arranged at the outlet of the automatic plate drying line and on one side of the discharging table, a paper lifting platform arranged on the other side of the feeding andconveying mechanism, a paper paving manipulator device arranged above the paper lifting platform and a visual system; the automatic plate drying line comprises a plate drying machine and a roller conveyer arranged at an inlet and outlet end of the plate drying machine; and an outlet of the automatic plate trimming machine is connected with an inlet of the automatic plate drying line.

Owner:广东英达斯列智能科技有限公司

Embossing and pattern coincident long plastic layer and rolling method and equipment

InactiveCN105904823AReduce lossReduce longitudinal deviationLamination ancillary operationsControlling laminationEmbossingEnergy consumption

The invention discloses an embossing and pattern coincident long plastic layer and a rolling method and equipment. The method comprises the steps of feeding, wherein a plastic layer to be rolled is made to enter a rolling double roller; rolling, wherein hot rolling embossing is performed on the plastic layer. According to the step of rolling, the feeding tension of the plastic layer is adjusted according to the embossing and pattern longitudinal deviation value; the equipment comprises a first feeding device, a rolling double roller control device, a detection device and a tension controller arranged on the first feeding device; according to the embossing and pattern coincident long plastic layer manufactured through the method, embossing on the transparent plastic layer through hot rolling and patterns on the plastic layer coincide with each other. According to the method, the equipment, and the embossing and pattern coincident long plastic layer processed through the method, coincidence of the embossing on the plastic layer and the patterns on the plastic layer is achieved, the production efficiency is high, the cost is low, and energy consumption is low.

Owner:ZHEJIANG TIANZHEN BAMBOO & WOOD DEV

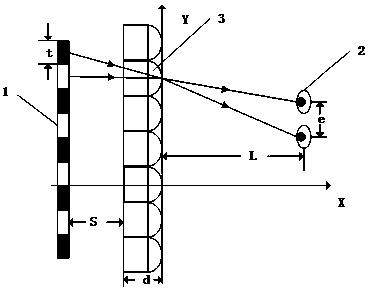

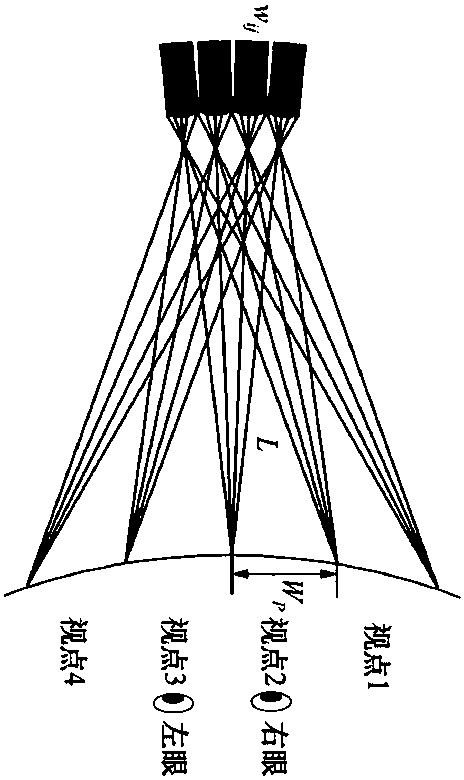

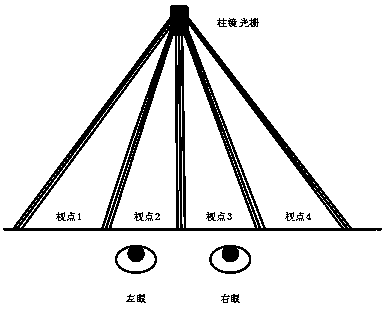

Lenticular grating based LED stereoscopic display screen device with great many of viewpoints

The invention provides a lenticular grating based LED stereoscopic display screen device with a great many of viewpoints. The display screen device comprises an LED planar display screen and human-eye watching viewpoints, an arc lenticular grating is arranged between the LED planar display screen and human-eye watching viewpoints, the LED planar display screen is arranged along the axis x and symmetric by taking the axis x as the center, the vertex of a cylindrical lens of the intermediate arc lenticular grating is positioned in the coordinate origin, an image side of the LED planar display screen is positioned in the focal plane of the cylindrical lens of the arc lenticular grating, the width of sub-pixel is t, the lenticular thickens of the arc lenticular grating is d, distance between the cylindrical lens of the arc lenticular grating and the LED planar display screen is s, the human-eye watching viewpoints are positioned in positions whose distance to the cylindrical lens of the arc lenticular grating is L, and the distance between the eyes is set as e. A 3D structure with a static effect as well as a 3D image with a dynamic effect can be realized.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

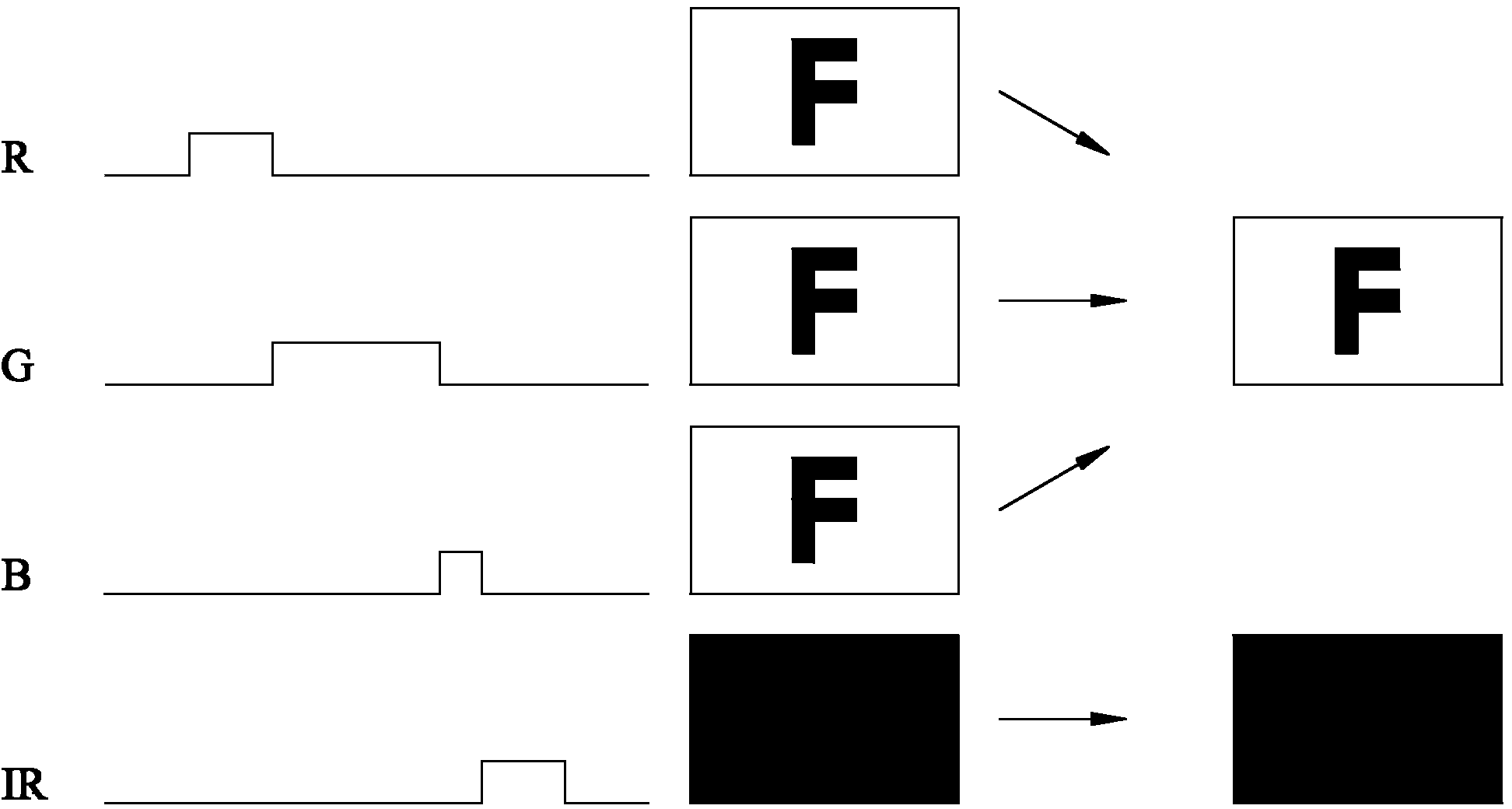

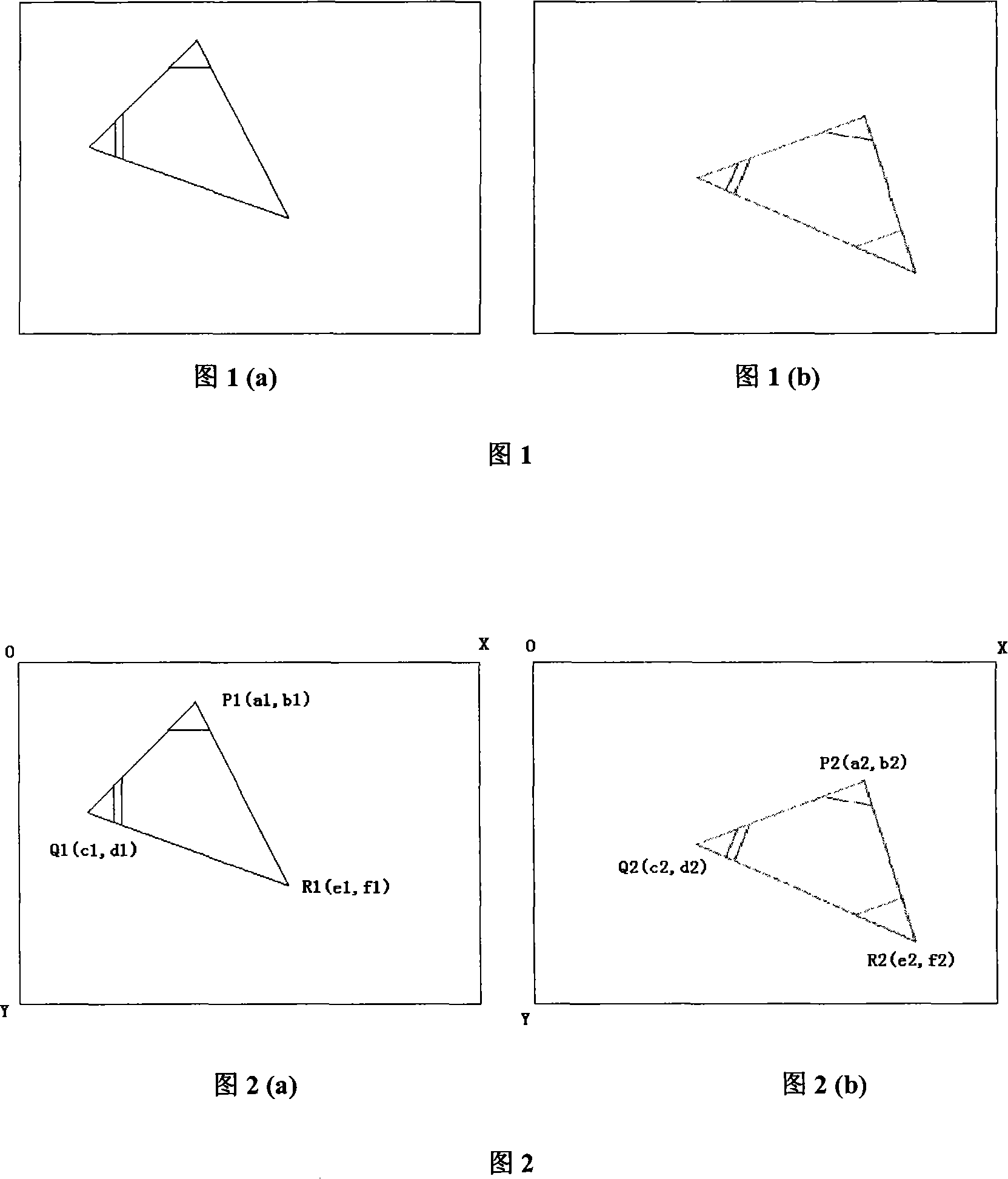

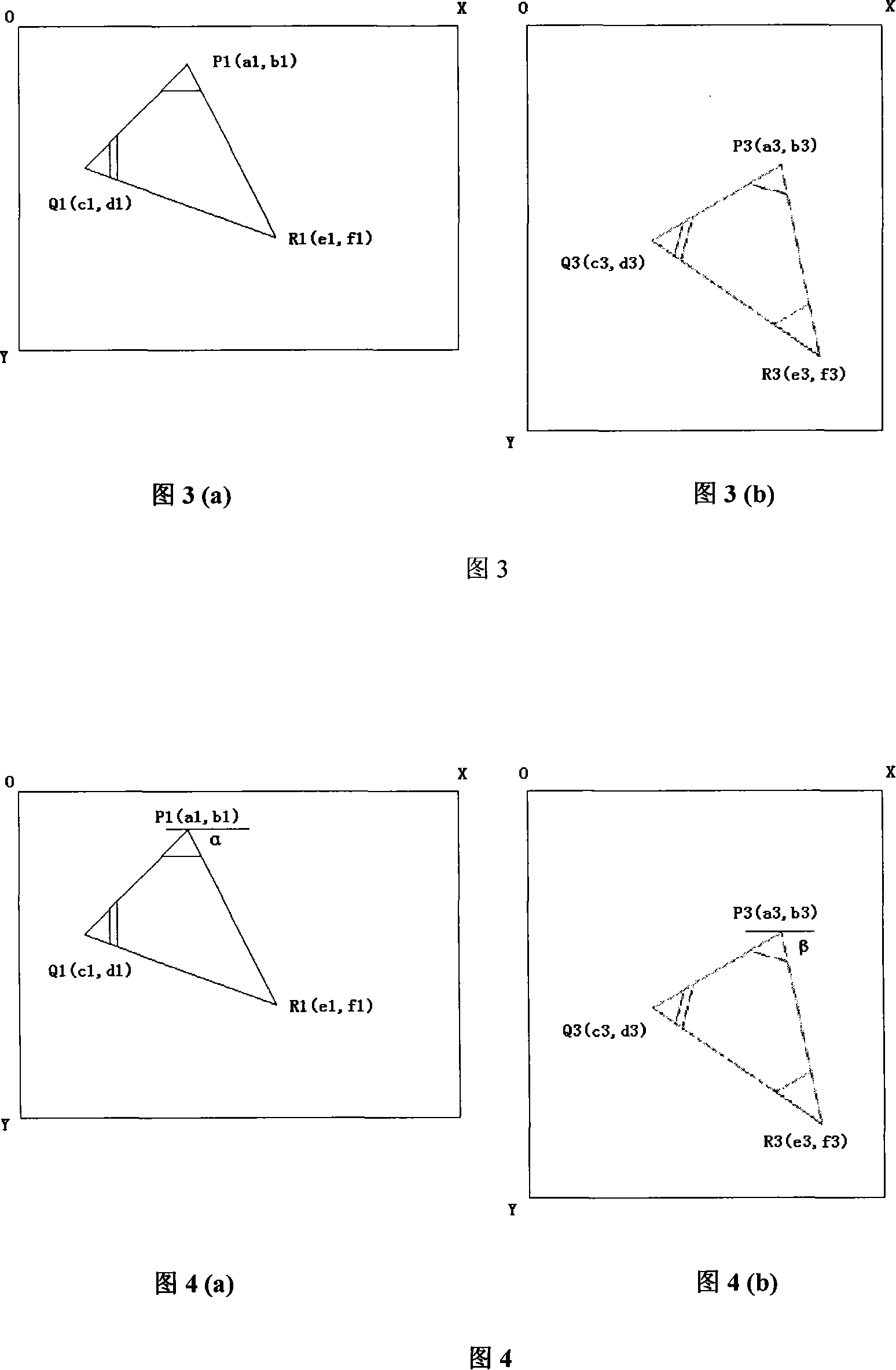

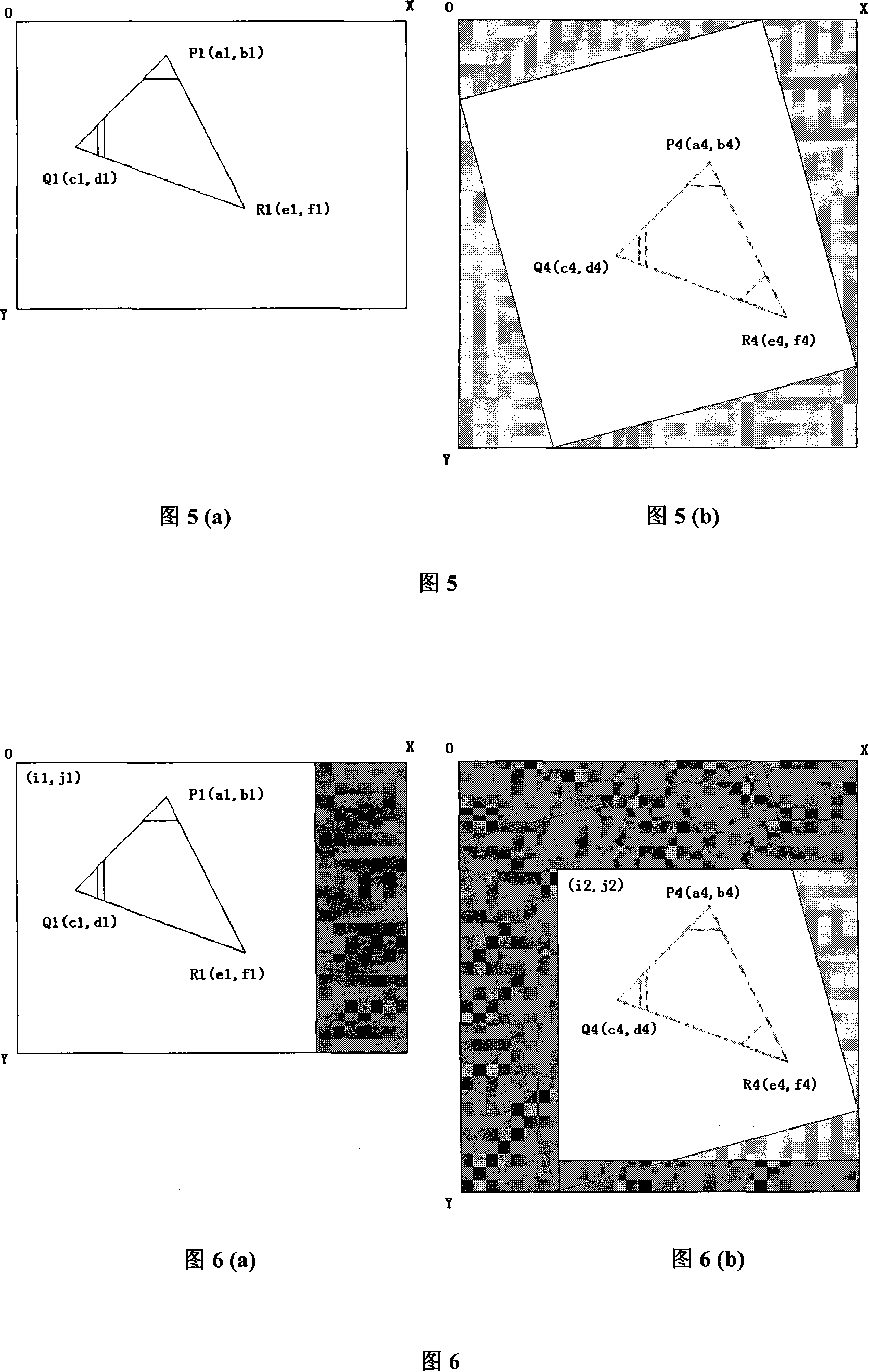

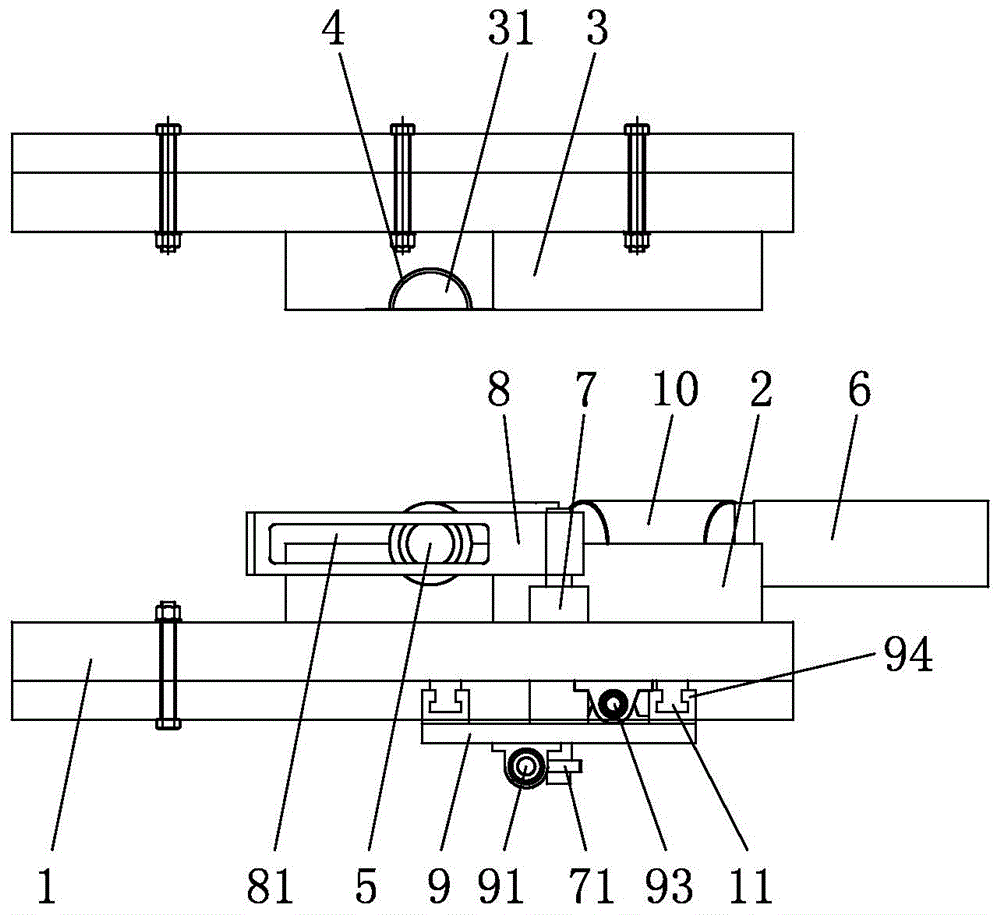

A pre-processing method for obtaining differential image

InactiveCN101150651AConvenient differential processingImplement recovery processingImage data processing detailsPictoral communicationComputer visionPretreatment method

The invention provides a preprocessing technology for acquiring difference images, in particular a method for recovery processing of a horizontal and longitudinal pulling and pressing deformation, a rotational deformation and a translation deformation of two input digital images which have specific deformation step by step, realizing image regitration, finally acquiring two difference images. The specific deformation images have one or more deformations of horizontal and longitudinal pulling and pressing deformation, rotational deformation and translation deformation, and the horizontal and longitudinal pulling and pressing deformation is generated at last. The invention is characterized in that for two input images, regardless whether or not having relative deformation, the second image is carried out recovery processing for deformations of horizontal and longitudinal pulling and pressing deformation, rotational deformation and translation deformation in order, common parts of two images are overlapped completely, then image difference is executed, a image which shows different portions of common parts of two images is input. The method can compare, recover and difference input images automatically to acquire clear difference images.

Owner:BEIHANG UNIV +1

Bent pipe device

ActiveCN104368686AReduced precision requirementsAchieve coincidenceShaping toolsEngineeringMachining

The invention relates to a bent pipe device, and belongs to the field of bent pipe machining devices. The bend pipe device solves the problem that a bent pipe is less in bending specifications. The bent pipe device comprises a bottom plate, a punch and a bent head core rod. The bottom plate is provided with a core rod traction assembly and a detachable bent pipe forming die. The bent pipe forming die is provided with a bent pipe forming cavity. The bent pipe forming cavity comprises a feed opening and a discharge opening. The core rod traction assembly comprises a rotating shaft, a transmission rod and a drive unit. One end of the transmission rod is fixed to the rotating shaft. The other end of the transmission rod is provided with a transverse track. The bent head core rod is fixed to the transverse track and moves along the transverse track relative to the bottom plate. The bottom plate is provided with a vertical track. The rotating shaft is arranged at the vertical track. The drive unit drives the rotating shaft to move along the vertical track relative to the bottom plate. The bent head core rod conducts circumference motion along with the core rod traction assembly.

Owner:HUZHOU MACHINE TOOL WORKS

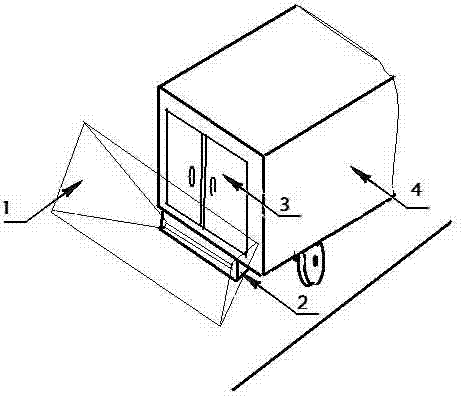

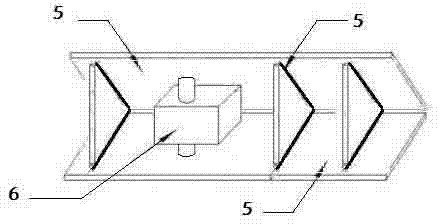

Method for quickly detecting and identifying fault repair bicycles of shared bicycles, and carriage transfer vehicle

InactiveCN107994910AImprove efficiencyLower success rateParticular environment based servicesCycle equipmentsIdentification deviceSingle vehicle

The invention provides a method for quickly detecting and identifying fault repair bicycles of shared bicycles, and a special carriage transfer vehicle for solving the problem of discovering breakageand repair bicycles from a stack of shared bicycles without adding additional manpower cost. The efficiency of discovering the breakage bicycles is higher than that of a manual direct two-dimensionalcode scanning mode or the like. The method is to add an identification device on the special carriage transfer vehicle of daily used deployed shared bicycles of a shared bicycle company; the identification device is installed in the special carriage transfer vehicle for transporting the shared bicycles and is limited by a wireless communication pile; when the shared bicycles are loaded and unloaded from the carriage vehicle and are deployed to other areas, only one shared bicycle achieves wireless communication in an air travelling orbit interval of the manually transferred shared bicycles through the direction limiting board technology. A large number of repair bicycles are screened. The objective of the invention is achieved.

Owner:西安立东行智能技术有限公司

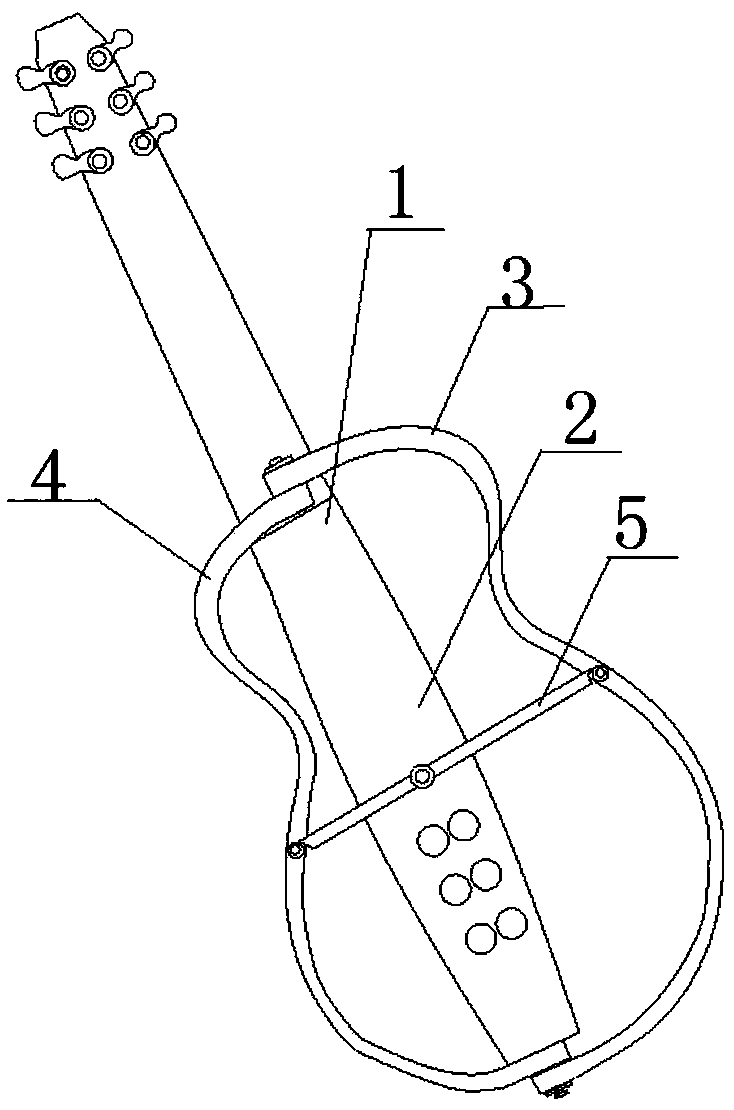

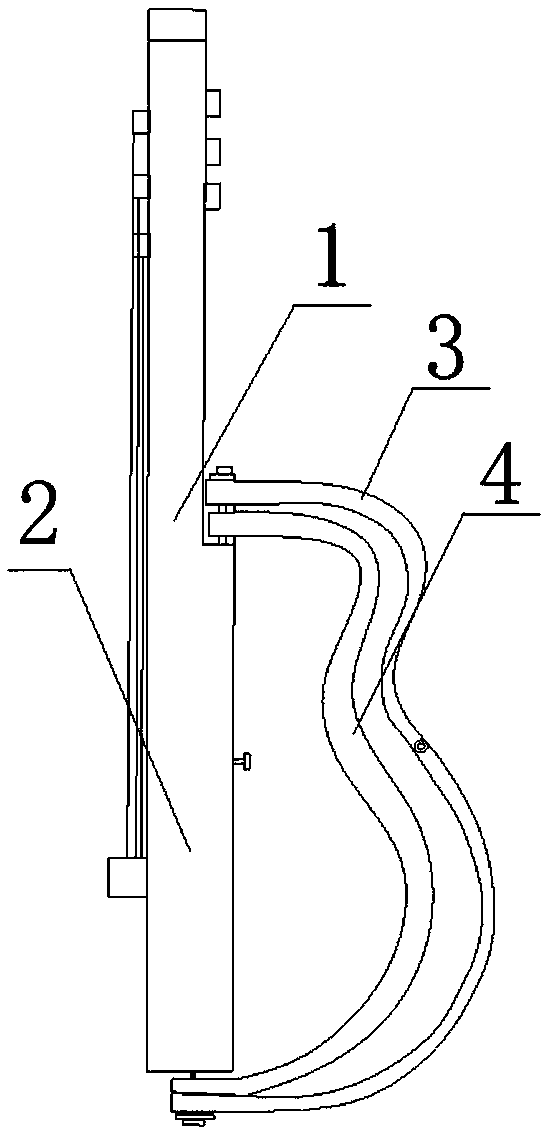

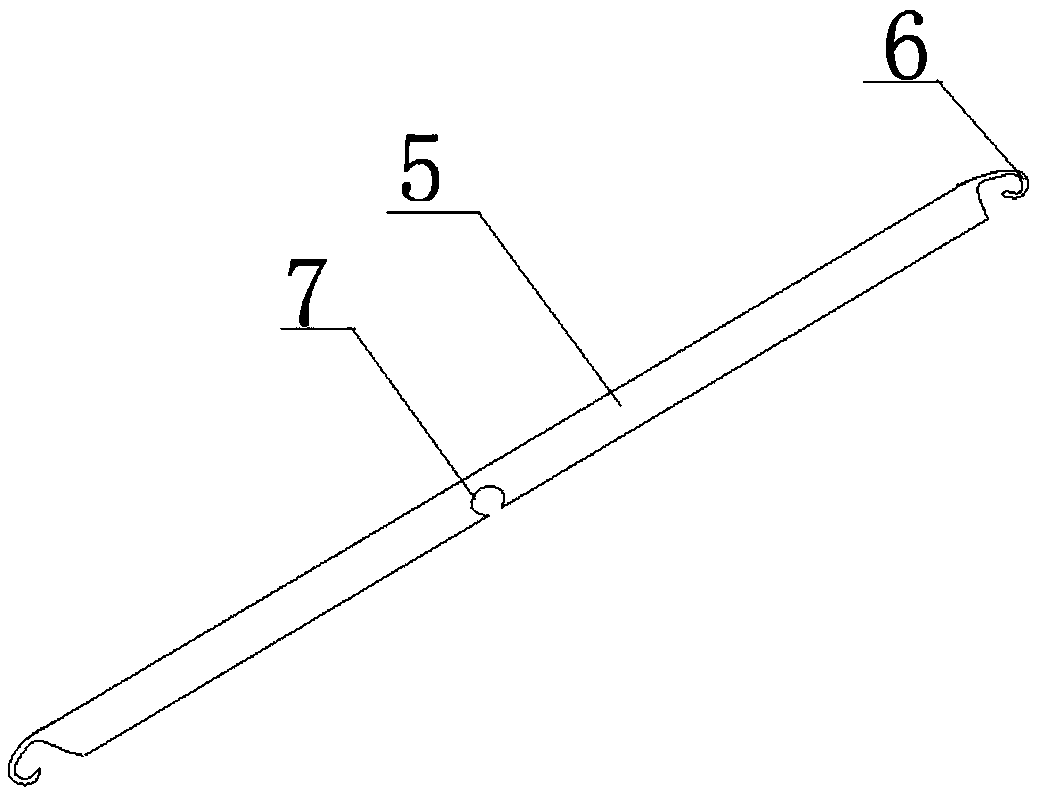

Portable rotatable overlapping silent guitar

InactiveCN108962196AAchieve coincidenceSimple structureGuitarsMusic aidsEngineeringMechanical engineering

The invention discloses a portable rotatable overlapping silent guitar and helps solve a problem that a foldable guitar is thick and heavy after being folded. The silent guitar comprises support racks, a guitar neck and a guitar body, wherein an upper end of a back part of the guitar neck is provided with a circular shaft A, a fixed end above a large support rack and a fixed end above a small support rack are arranged on a shaft rod of the circular shaft in a rotatable and sleeving manner, the position of the fixed end above the large support rack is higher than the position of the fixed end above the small support rack, a bottom part of the guitar body is provided with a circular shaft B, and a fixed end below the large support rack and a fixed end below the small support rack can be arranged on a shaft rod of the circular shaft B in a rotatable and sleeving manner. The position of the fixed end of the large support rack is lower than the position of the fixed end below the small support rack, and a circular shaft C and a circular shaft D are fixedly arranged on the large support rack and the small support rack. A back part of the guitar body is provided with a circular shaft E. Aconnecting rod is arranged among the circular shaft C, the circular shaft E and the circular shaft D; the connecting rod is arranged on shaft rods of the circular shaft C, the circular shaft E and the circular shaft D in a sleeving manner.

Owner:德阳好哲创意文化科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com