Embossing and pattern coincident long plastic layer and rolling method and equipment

A technology of plastic layer and embossed pattern, applied in the direction of chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve the problems of low production efficiency, coincidence deviation, heavy workload, etc., and achieve high production efficiency, The effect of reducing energy loss and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

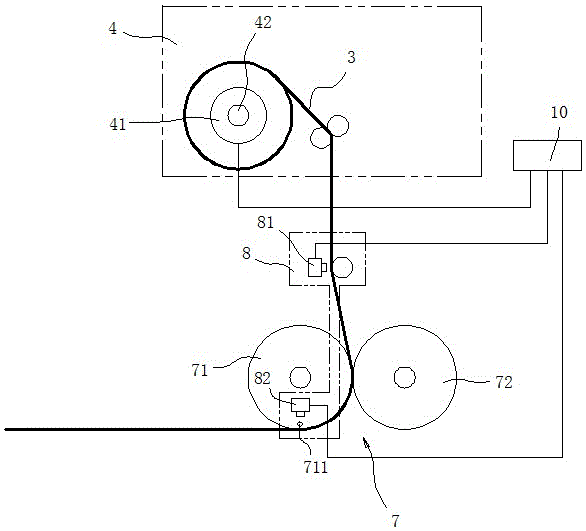

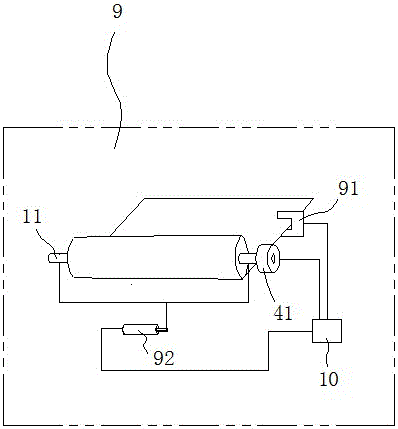

[0038] In order to make the technical solution of the present invention clearer, the following in conjunction with the attached Figures 1 to 6 , the present invention will be described in detail. It should be understood that the specific implementations described in this specification are only for explaining the present invention, and are not intended to limit the protection scope of the present invention.

[0039] The invention is a rolling method of a long plastic layer with overlapping embossing and pattern, comprising

[0040] The plastic layer 3 to be rolled enters the feeding step of the rolling pair of rollers 7, and the plastic layer 3 is printed with a continuous unit pattern;

[0041] Carrying out the rolling step of hot rolling embossing to the plastic layer 3;

[0042] In the feeding step, the front side of the plastic layer 3 is adjacent to the hot embossing roller 71 in the rolling pair of rollers 7, and the embossing pattern 712 arranged on the outer circumfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com