Patents

Literature

254results about How to "Improve crosstalk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

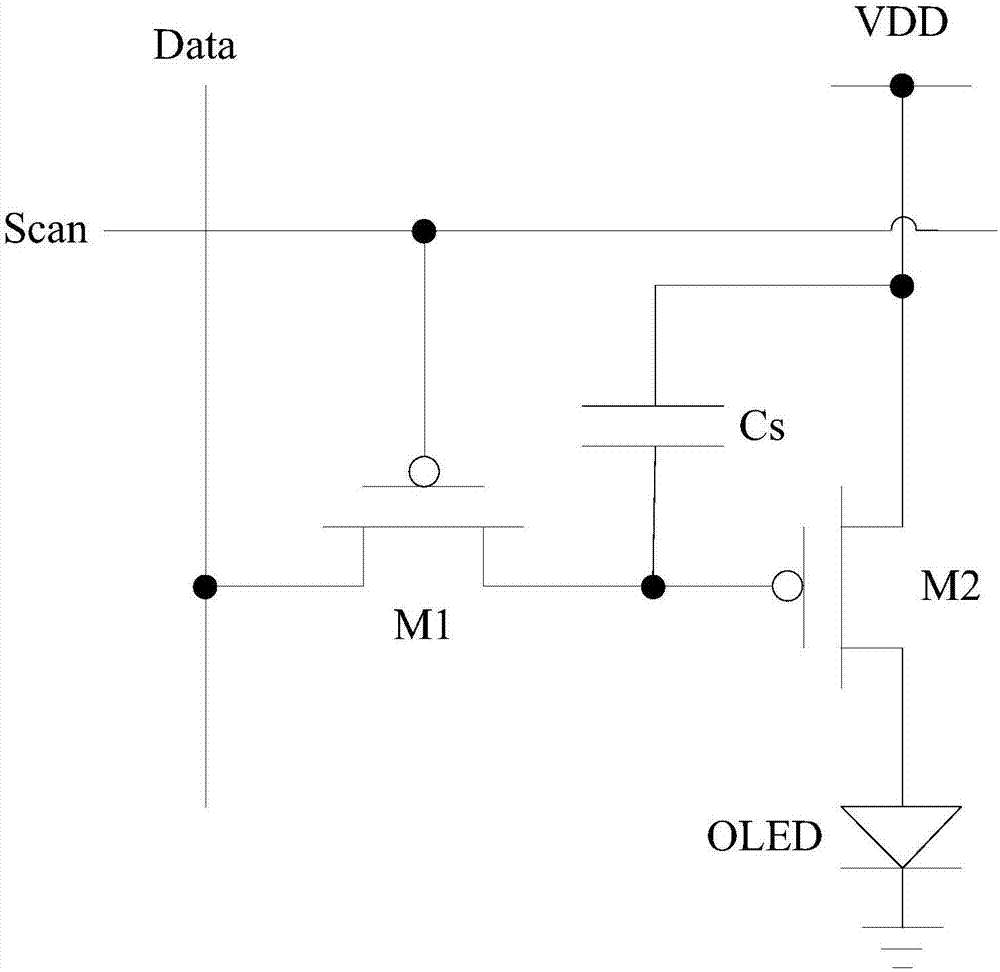

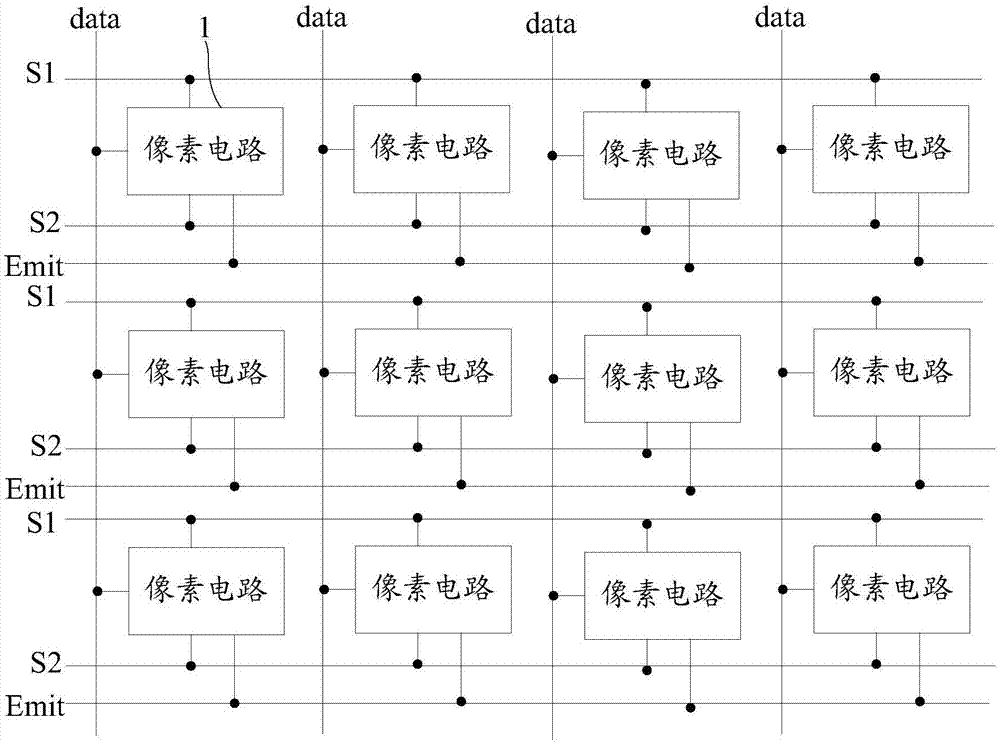

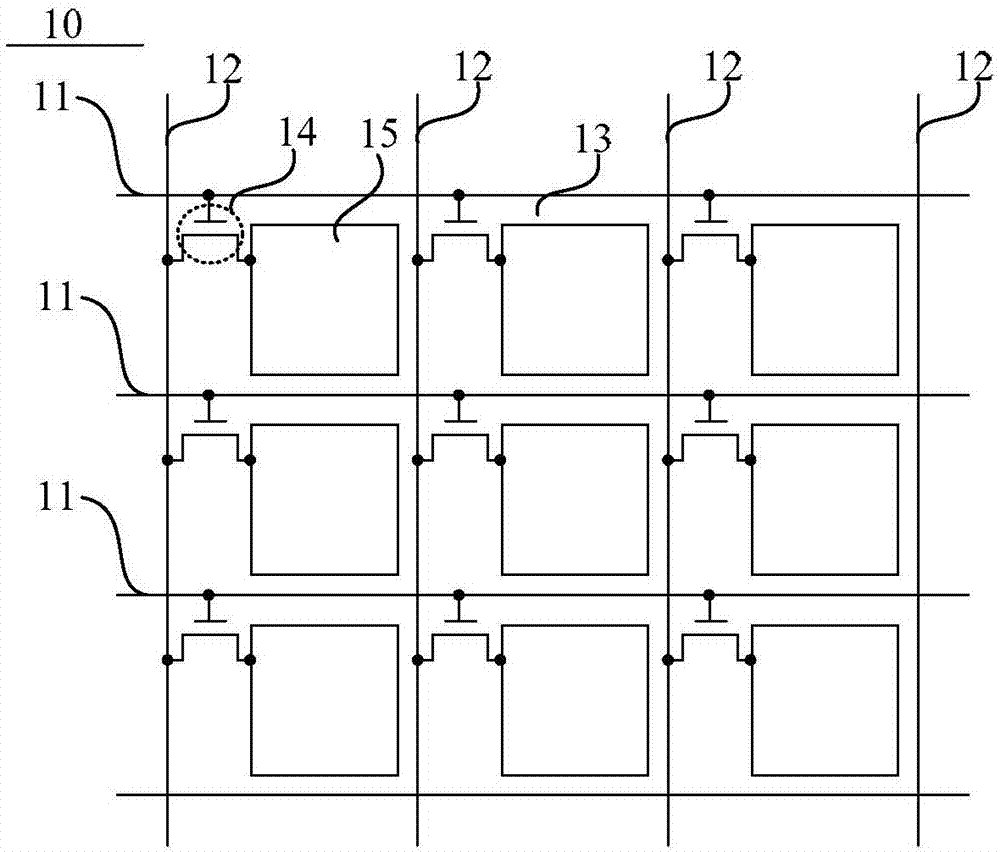

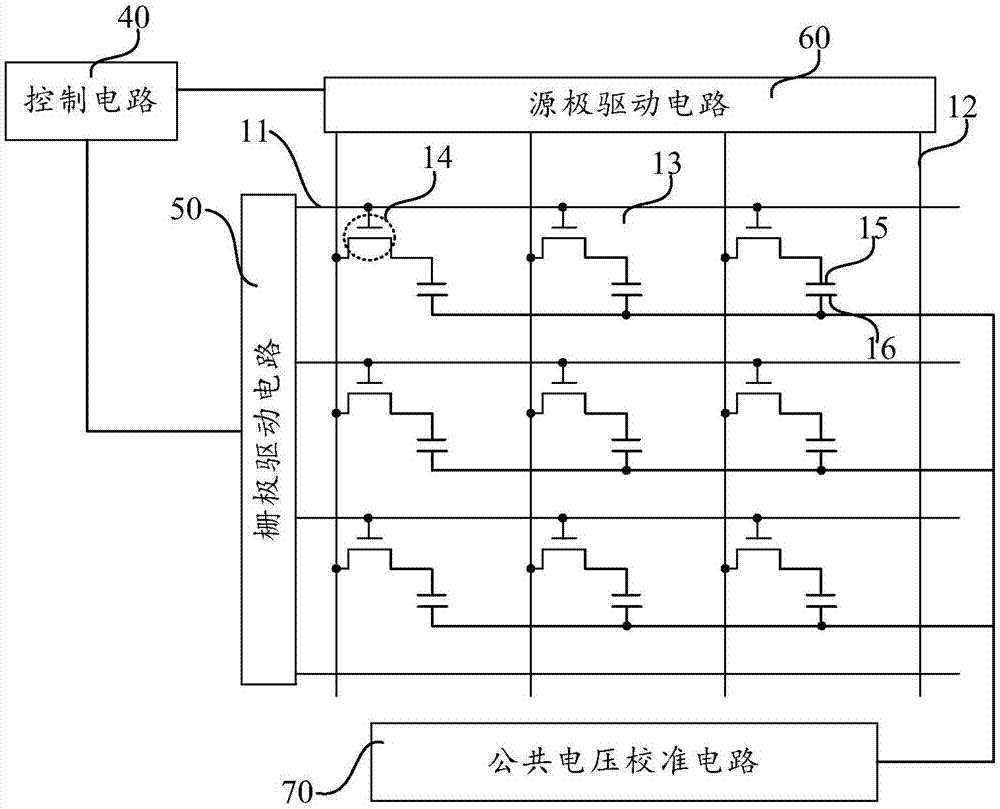

Display panel, display device and driving method of pixel circuit

ActiveCN106910468AImprove crosstalkImprove uniformityStatic indicating devicesDisplay deviceData signal

The invention discloses a display panel, a display device and a driving method of a pixel circuit. The pixel circuit comprises a data writing module, a light-emitting control module, a driving control module, a threshold compensation module, an anode reset module, a node initialization module and an organic light-emitting diode. The threshold compensation module can compensate the drift of threshold voltages of a driving transistor so that light-emitting working currents of a light-emitting device which is driven by the driving transistor are only related to signals of data cables and voltages of a reference signal end and not related to the threshold voltages and a first power supply voltage end, and the influence of the threshold voltages and IR Drop on currents which flow through the organic light-emitting diode can be avoided. Furthermore, the anode reset module can reset an anode potential of the organic light-emitting diode so that the organic light-emitting diode does not emit light completely in a dark state. In addition, an initial signal end and the reference signal end are set separately, not only can the problems of crosstalk and uneven display of the circuit be improved, but also the range of data signals can be increased.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

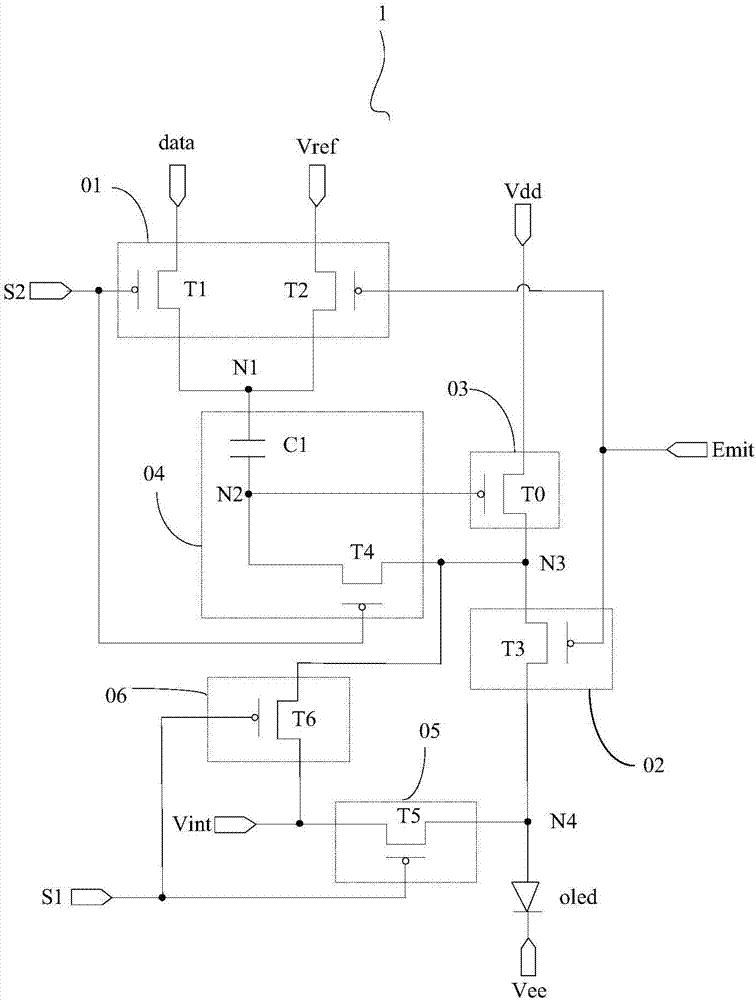

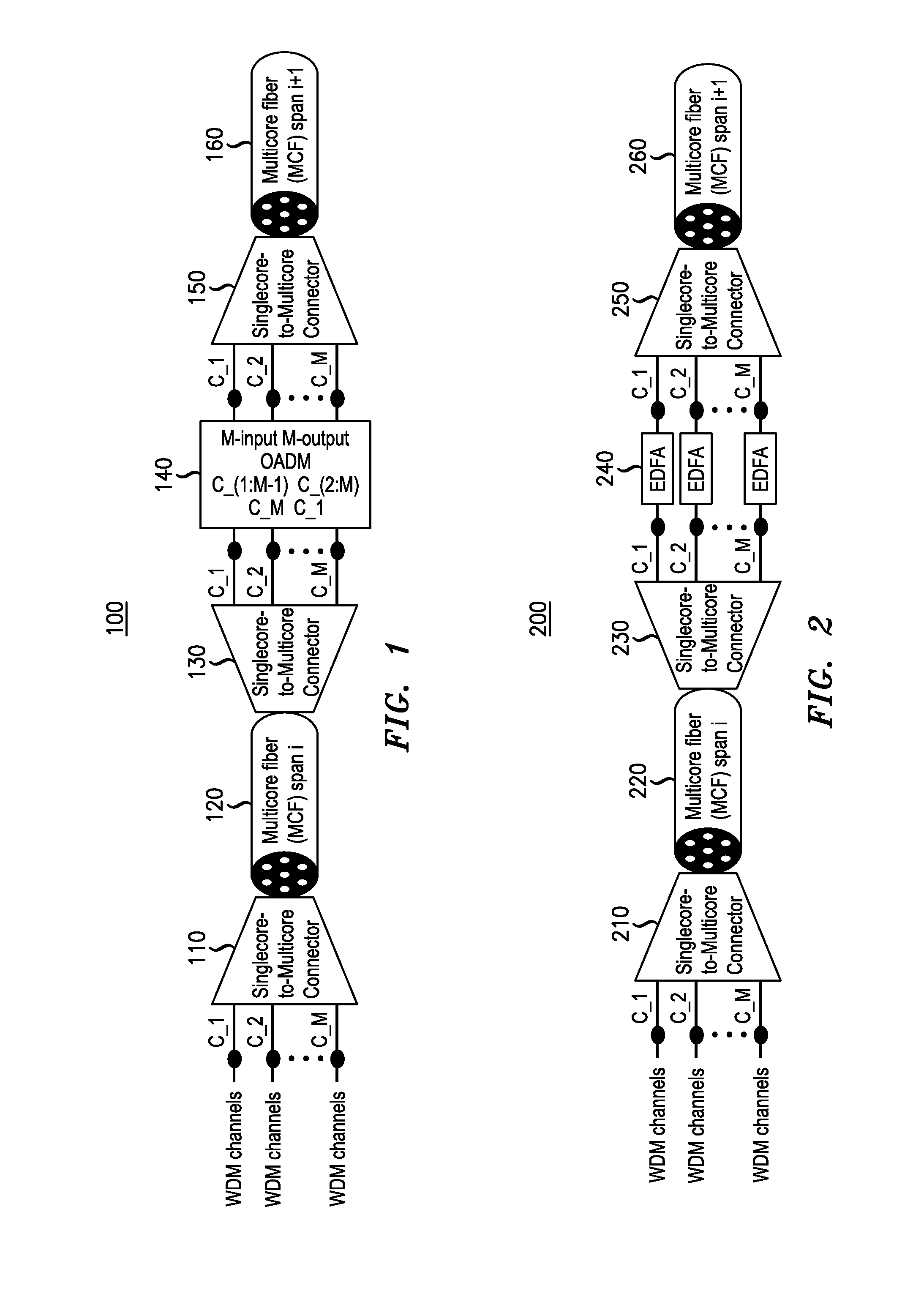

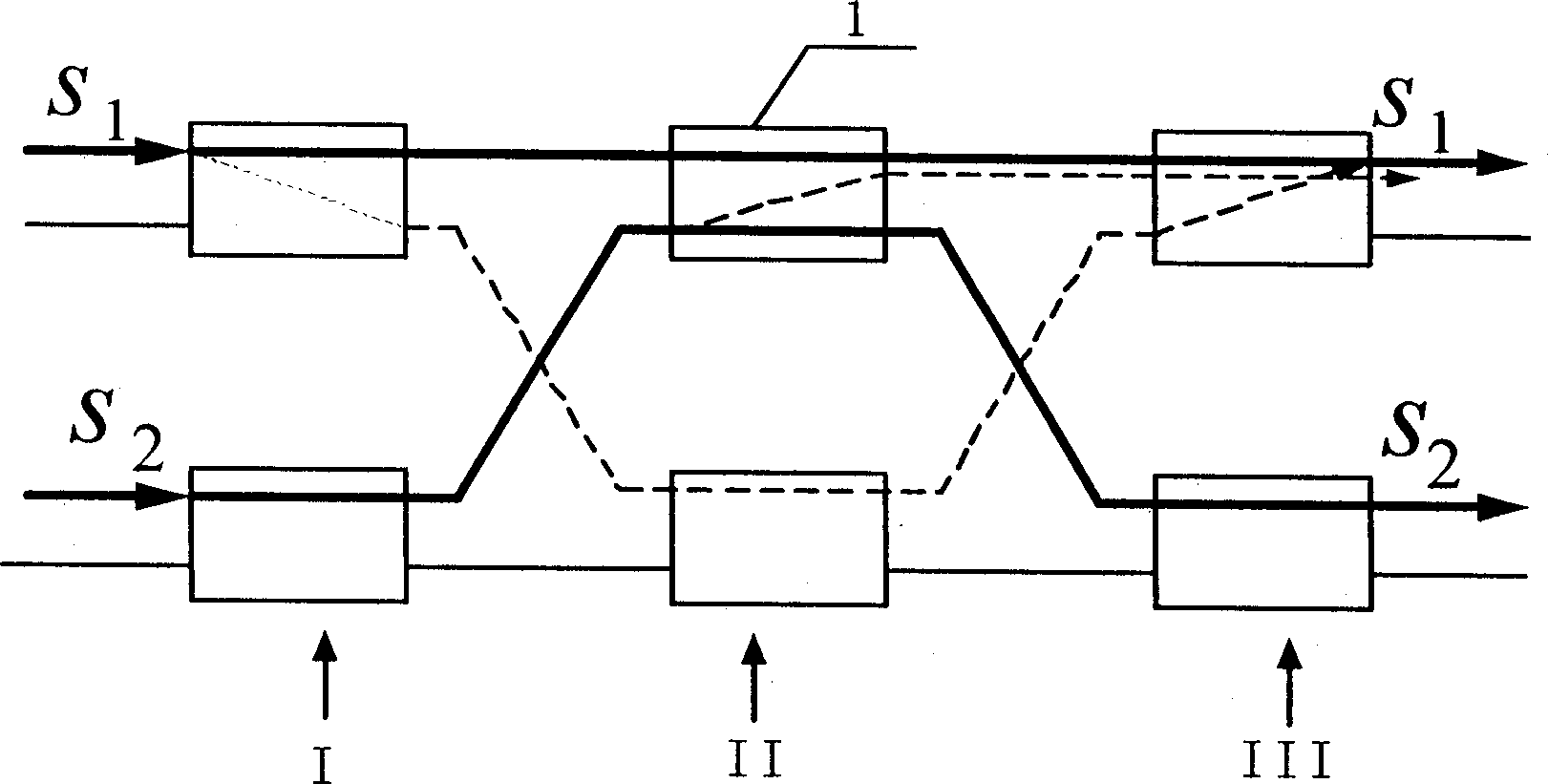

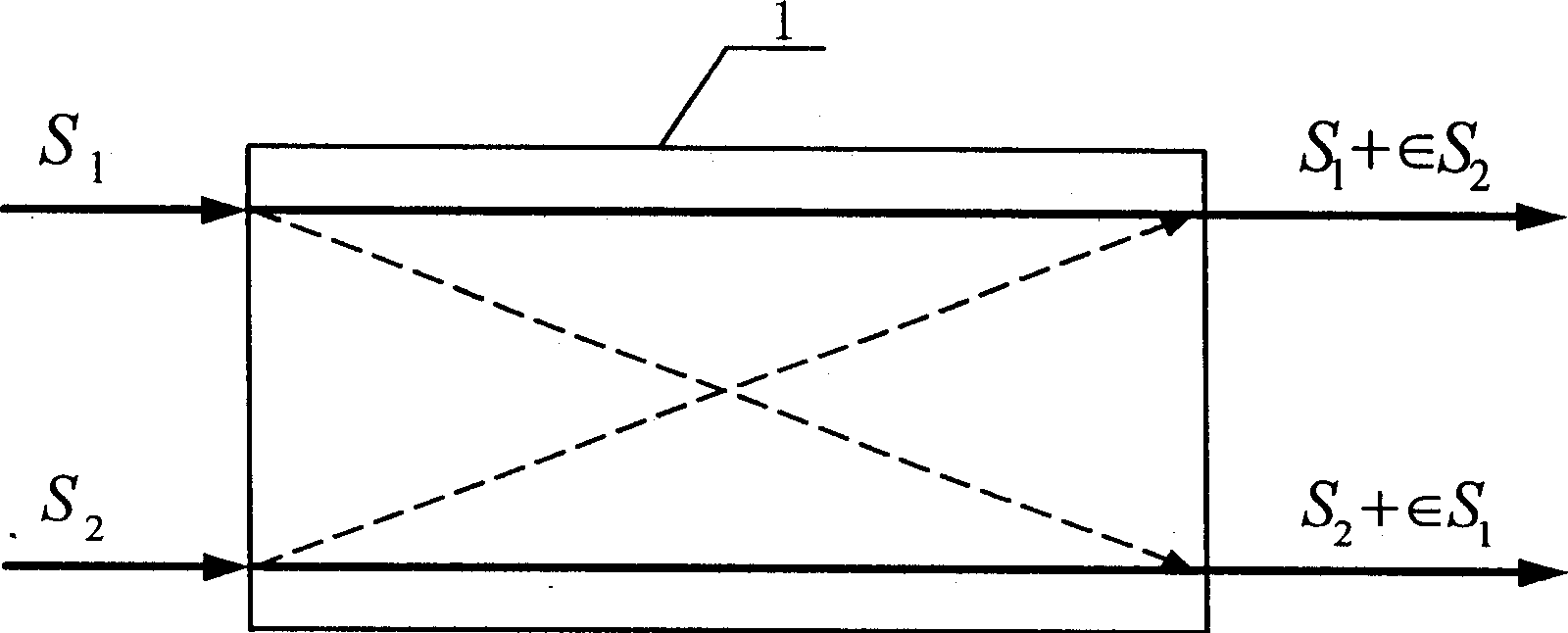

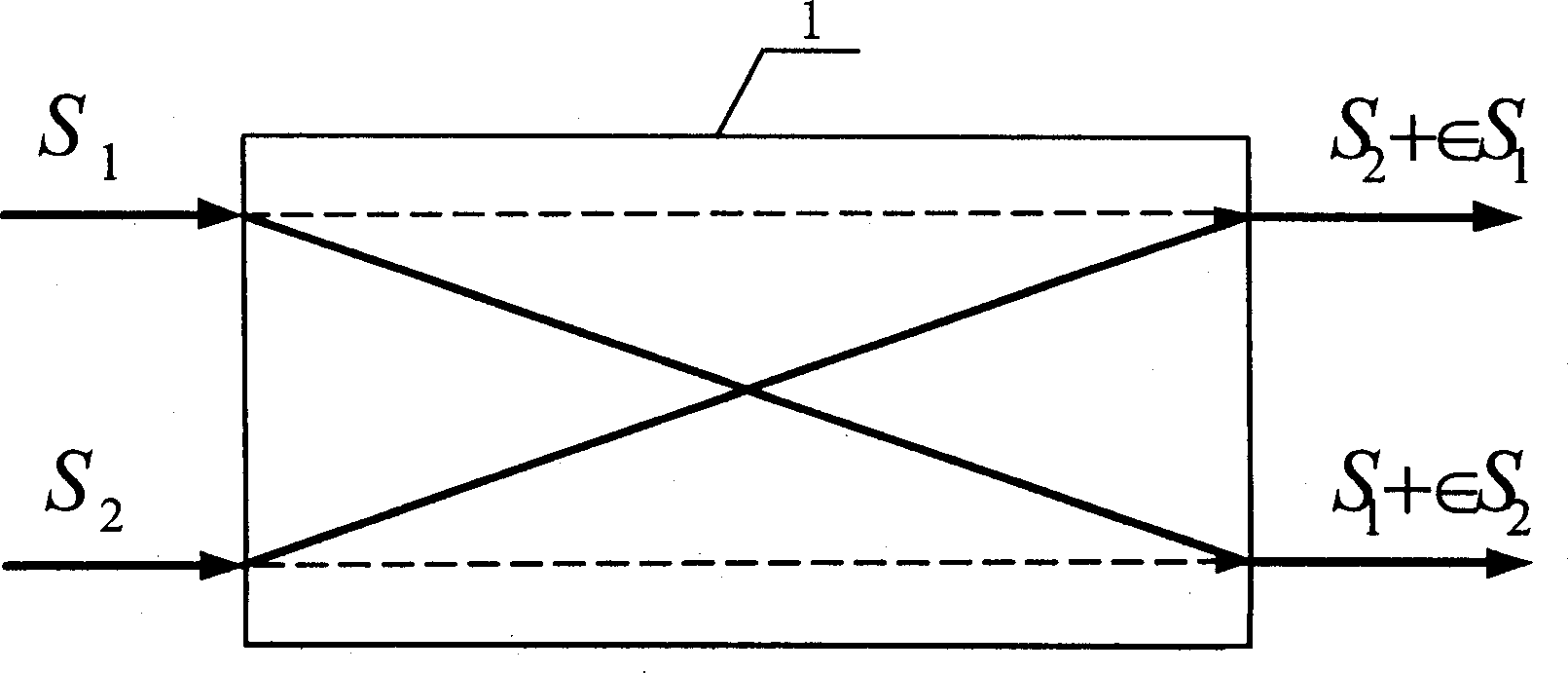

Method And Apparatus For Space-Division Multiplexing Systems

ActiveUS20130236175A1Reducing performance variationImprove system performanceMultiplex system selection arrangementsWavelength-division multiplex systemsFew mode fiberSignal on

A space division multiplexed (SDM) transmission system that includes at least two segments of transmission media in which a spatial assignment of the two segments is different is provided. For example, the SDM transmission may include a first segment of transmission media having a first spatial assignment and a second segment of transmission media having a second spatial assignment, wherein the first spatial assignment differs from the second spatial assignment. An example method obtains an optical signal on a first segment of transmission media having a first spatial assignment and forwards the optical signal on a second segment of transmission media with a different spatial assignment. The transmission media may be a multi-core fiber (MCF), a multi-mode fiber (MMF), a few-mode fiber (FMF), or a ribbon cable comprising nominally uncoupled single-mode fiber (SMF).

Owner:ALCATEL LUCENT SAS

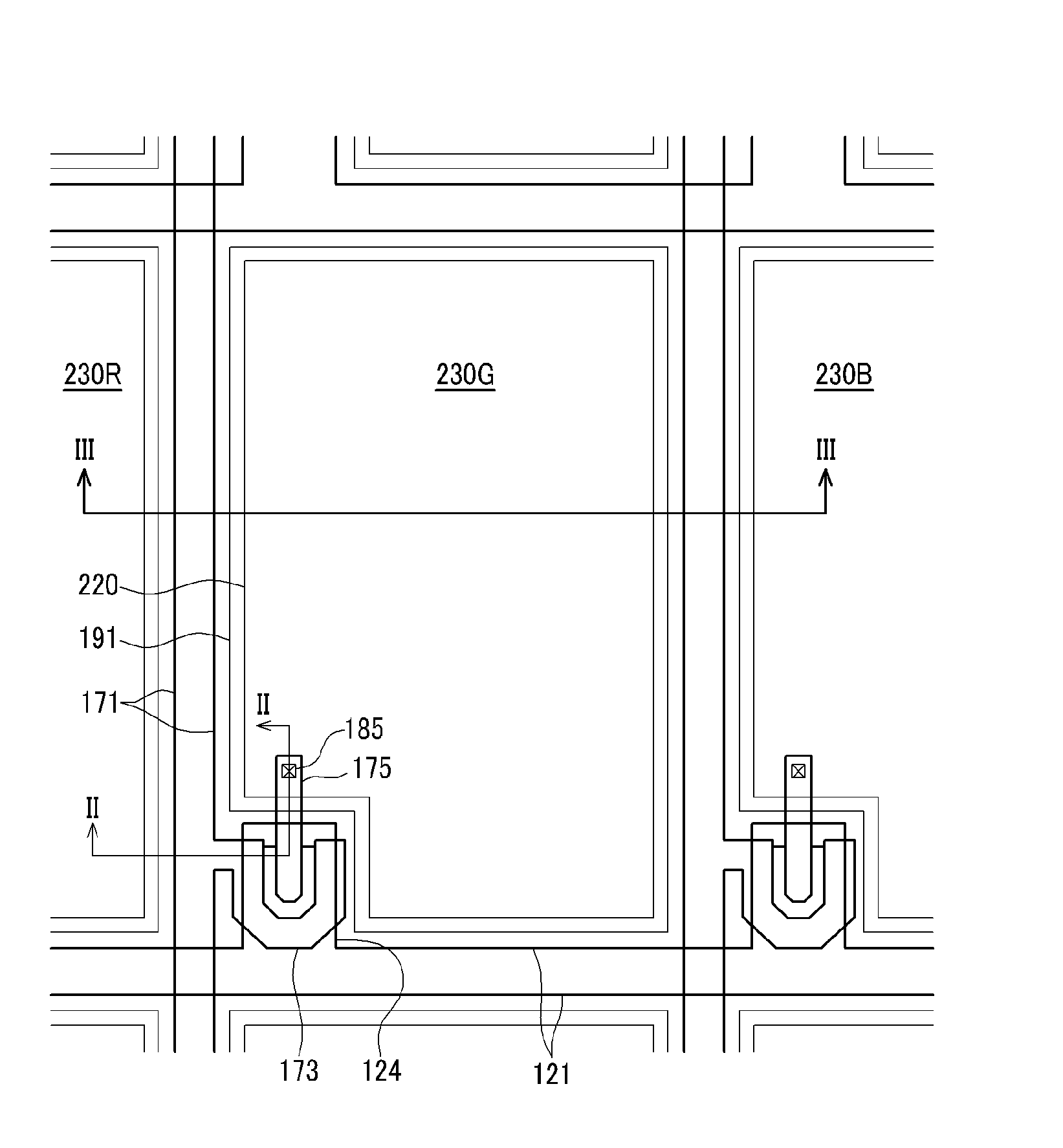

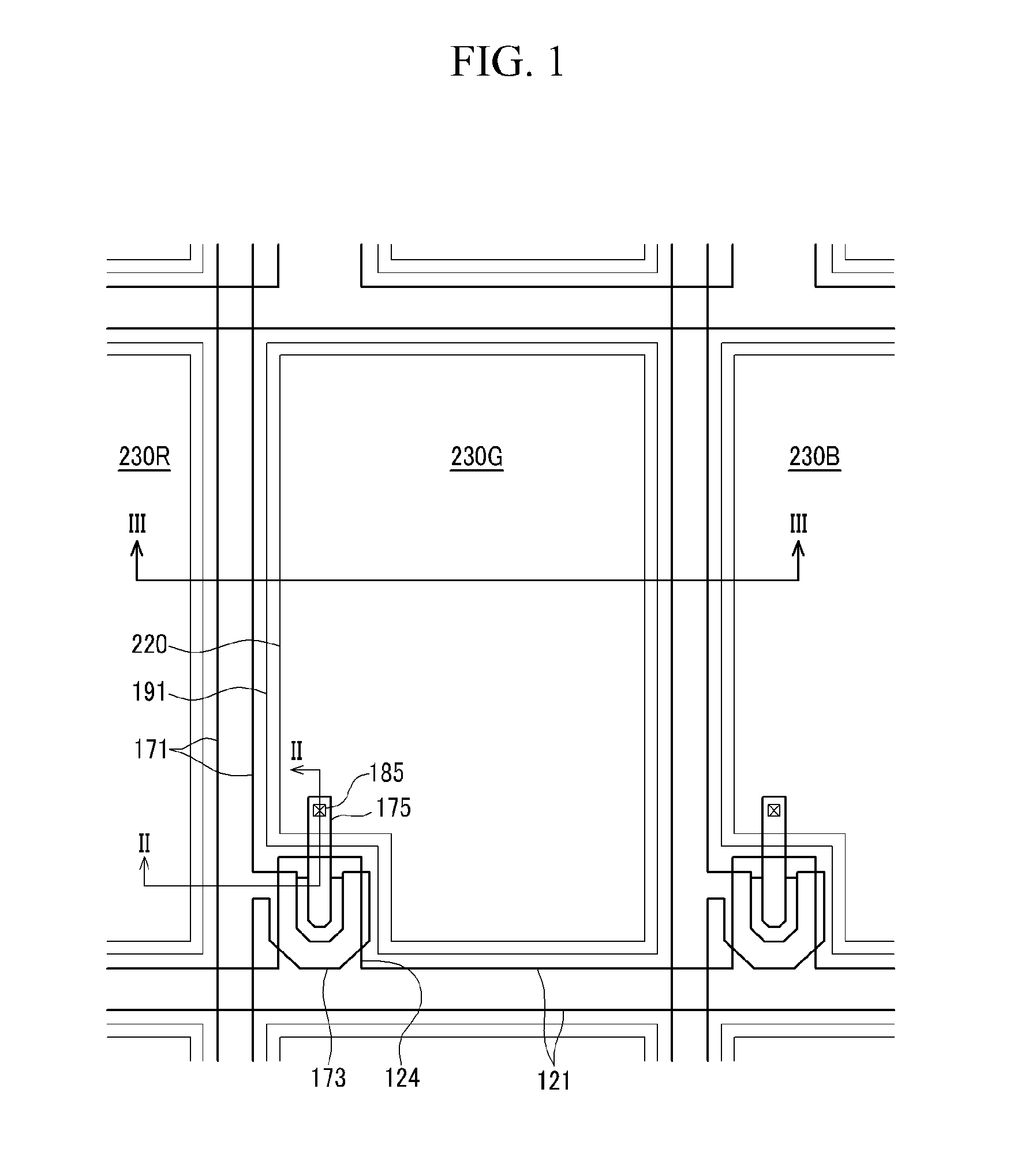

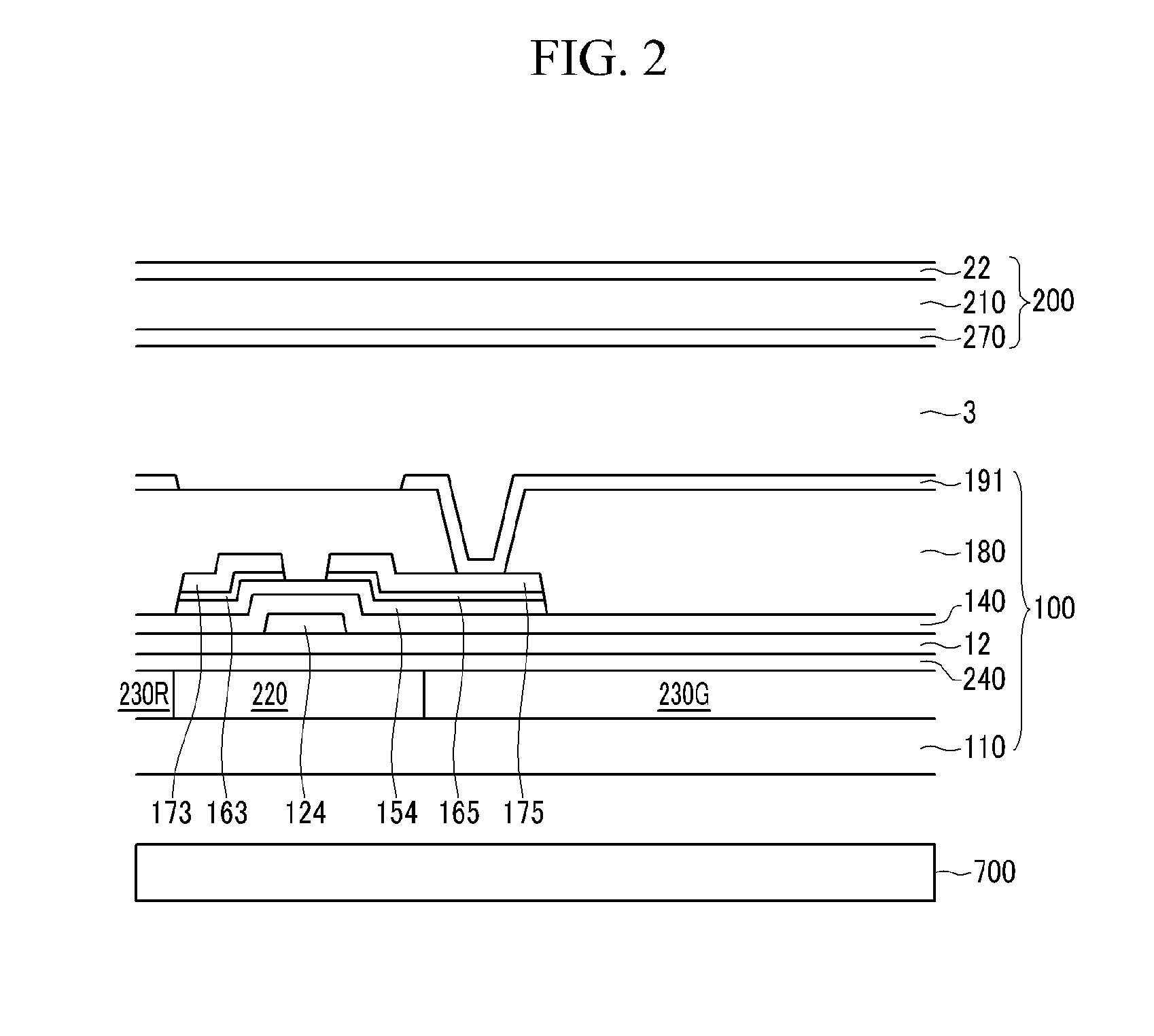

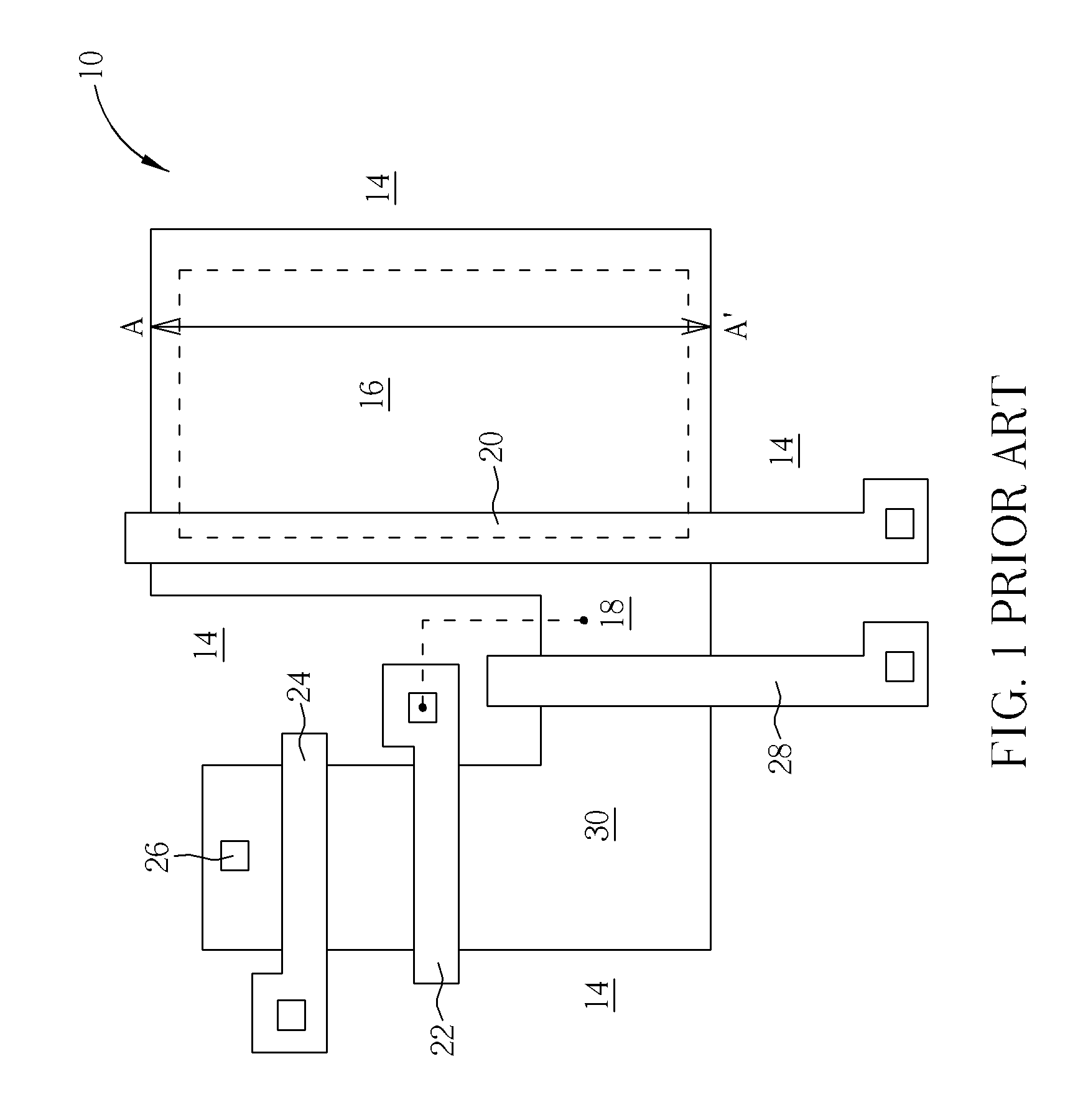

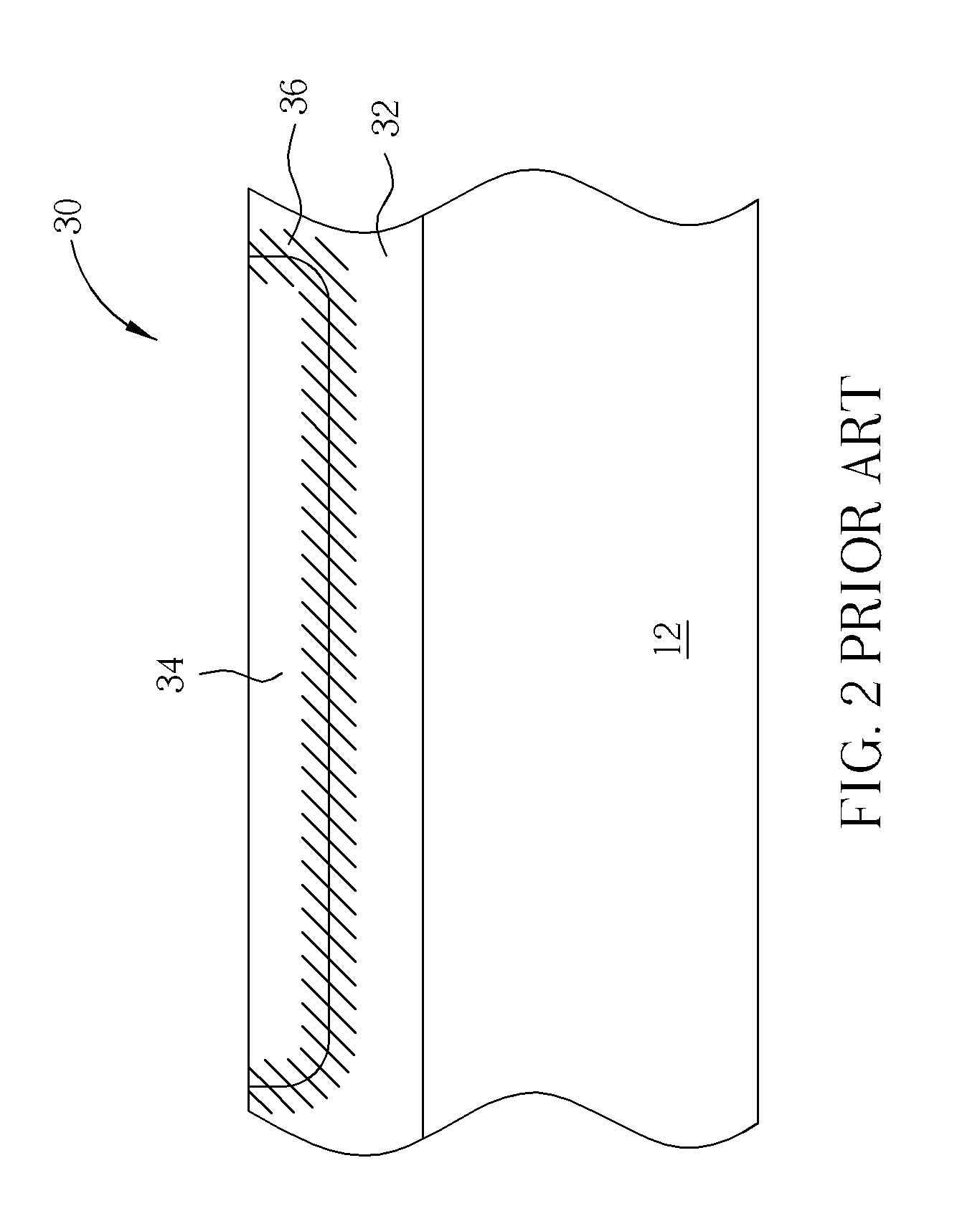

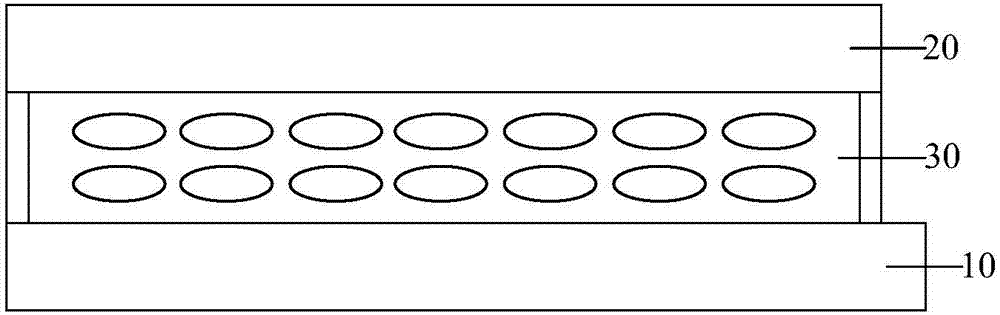

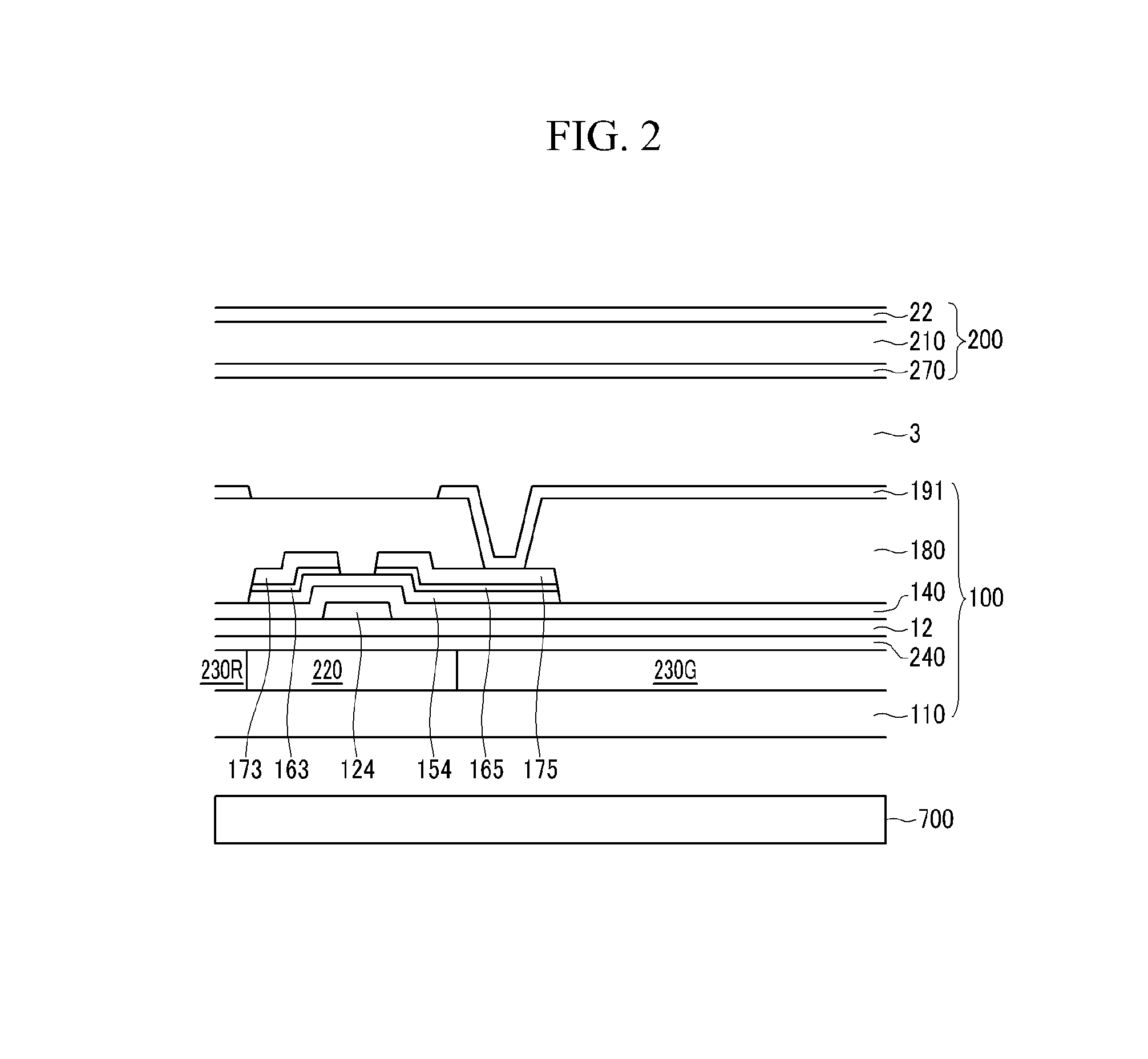

Liquid crystal display

ActiveUS20100091219A1Improve efficiencyReduces and substantially prevents cross talkNon-linear opticsPolarizerUv blocking

A liquid crystal display including a first substrate; a light-blocking member disposed on the first substrate; an emission layer disposed on the first substrate; an ultraviolet-light blocking filter disposed on the emission layer; a lower polarizer disposed on the ultraviolet-light blocking filter; a gate line and a data line disposed on the lower polarizer and substantially perpendicular to each other; a thin film transistor electrically connected to the gate line and the data line; a pixel electrode electrically connected to the thin film transistor; a second substrate disposed facing the first substrate; a common electrode disposed on the second substrate; and a liquid crystal layer interposed between the first substrate and the second substrate.

Owner:SAMSUNG DISPLAY CO LTD

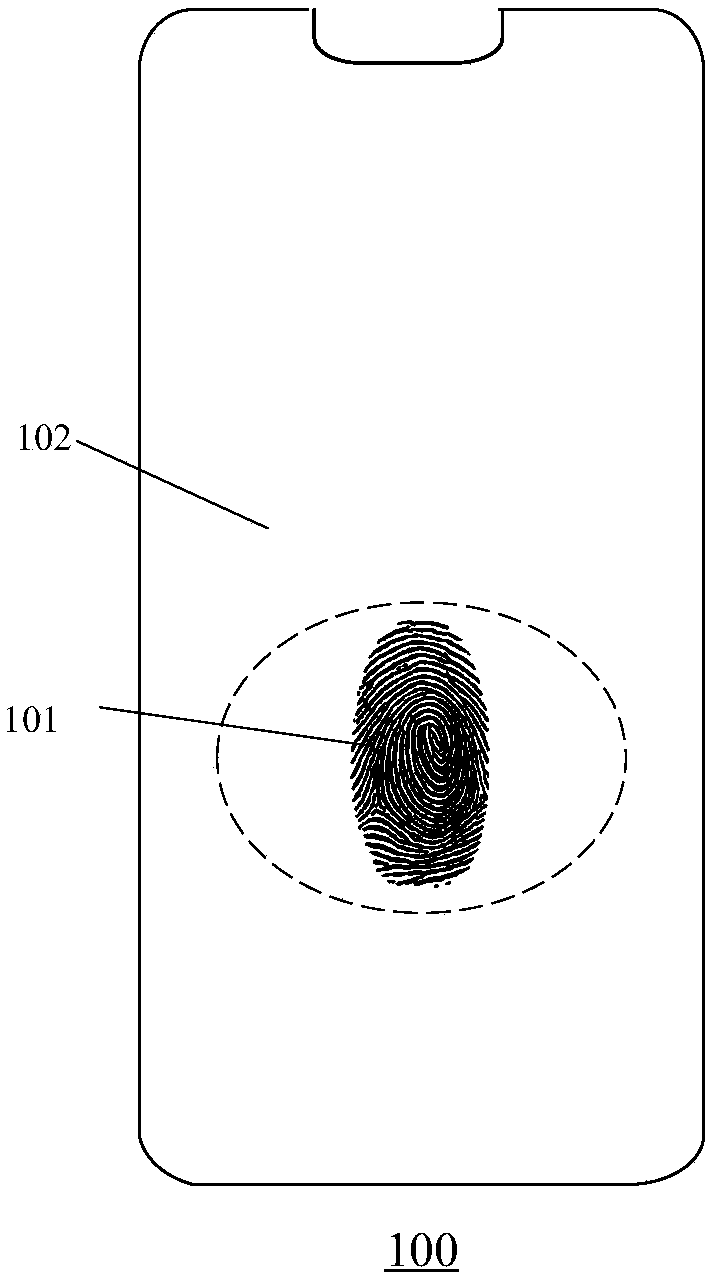

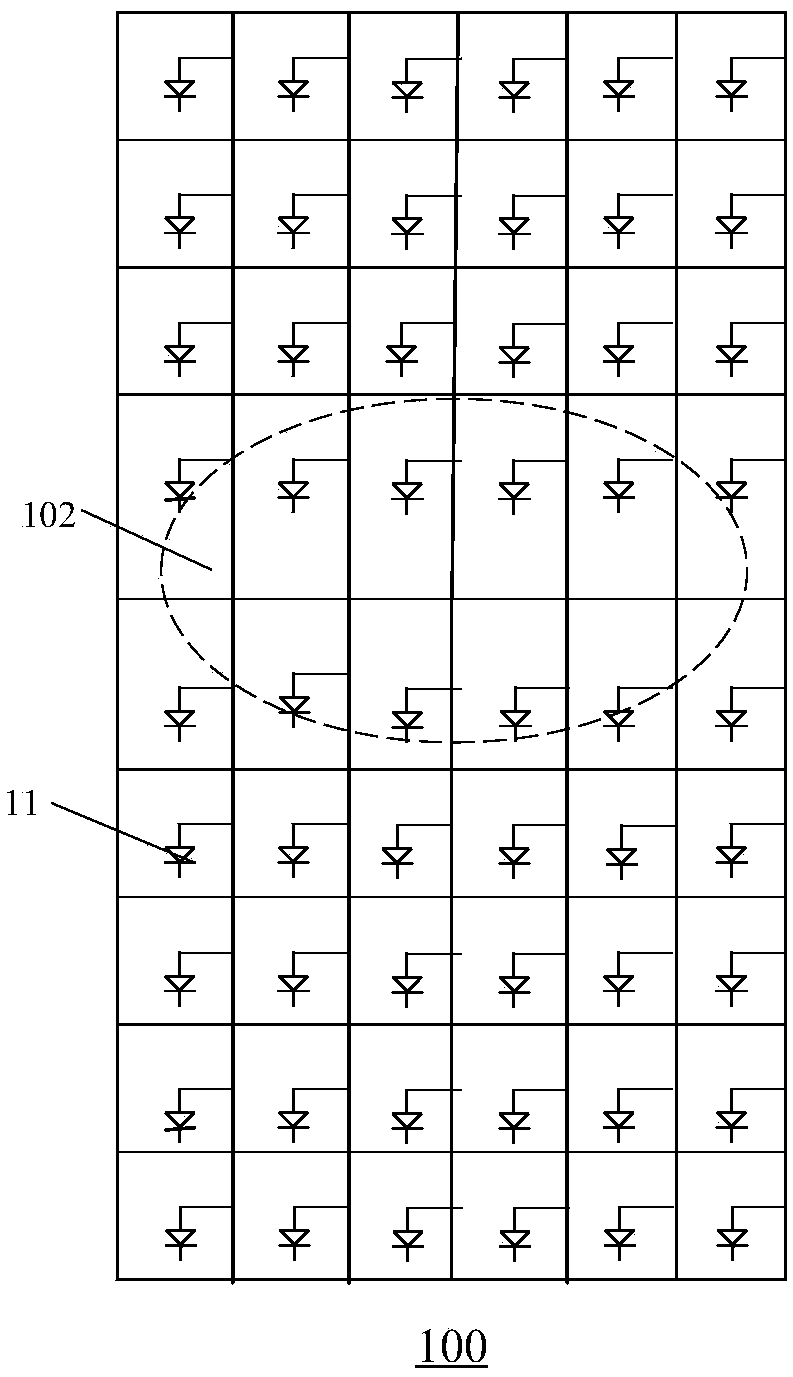

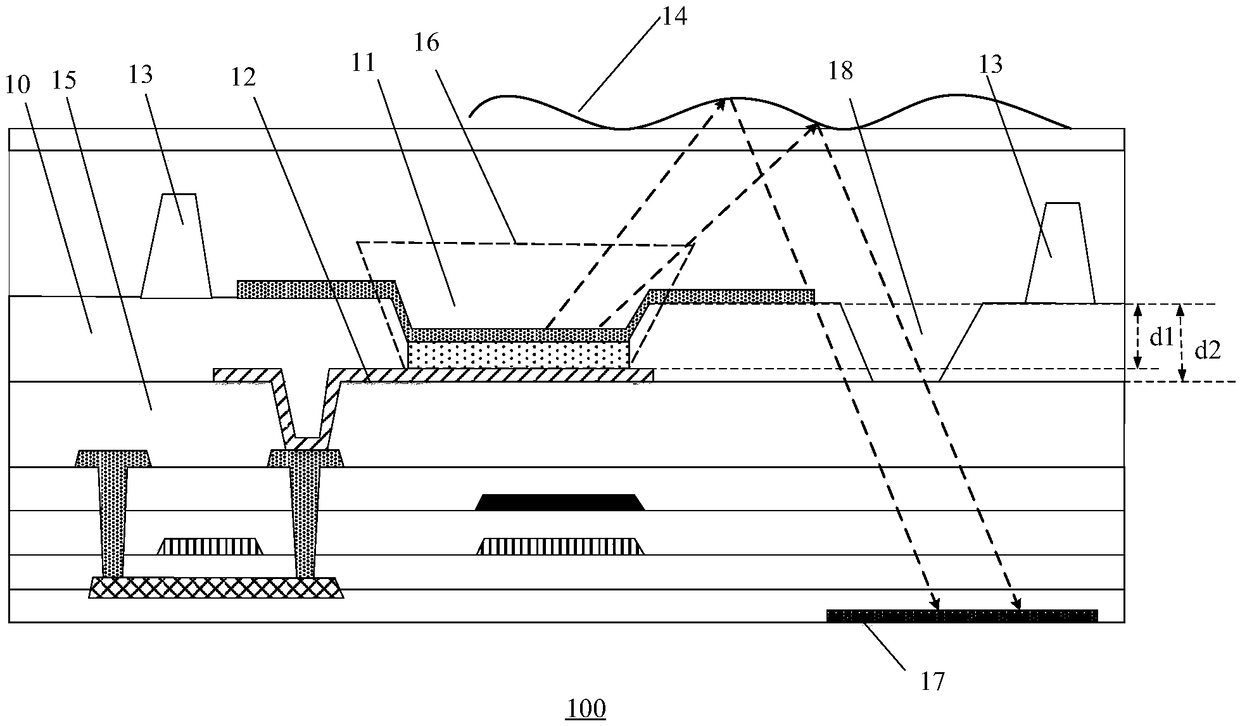

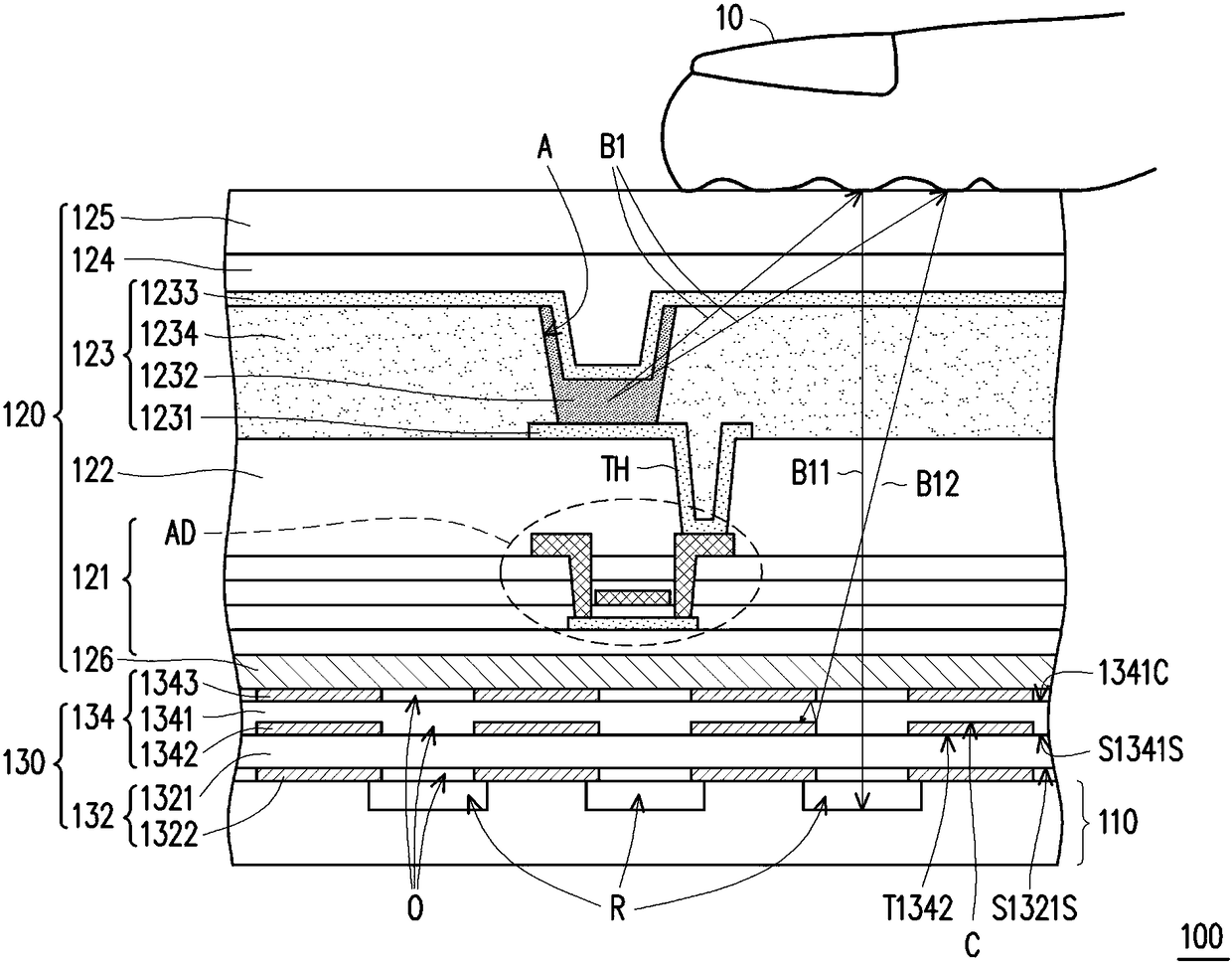

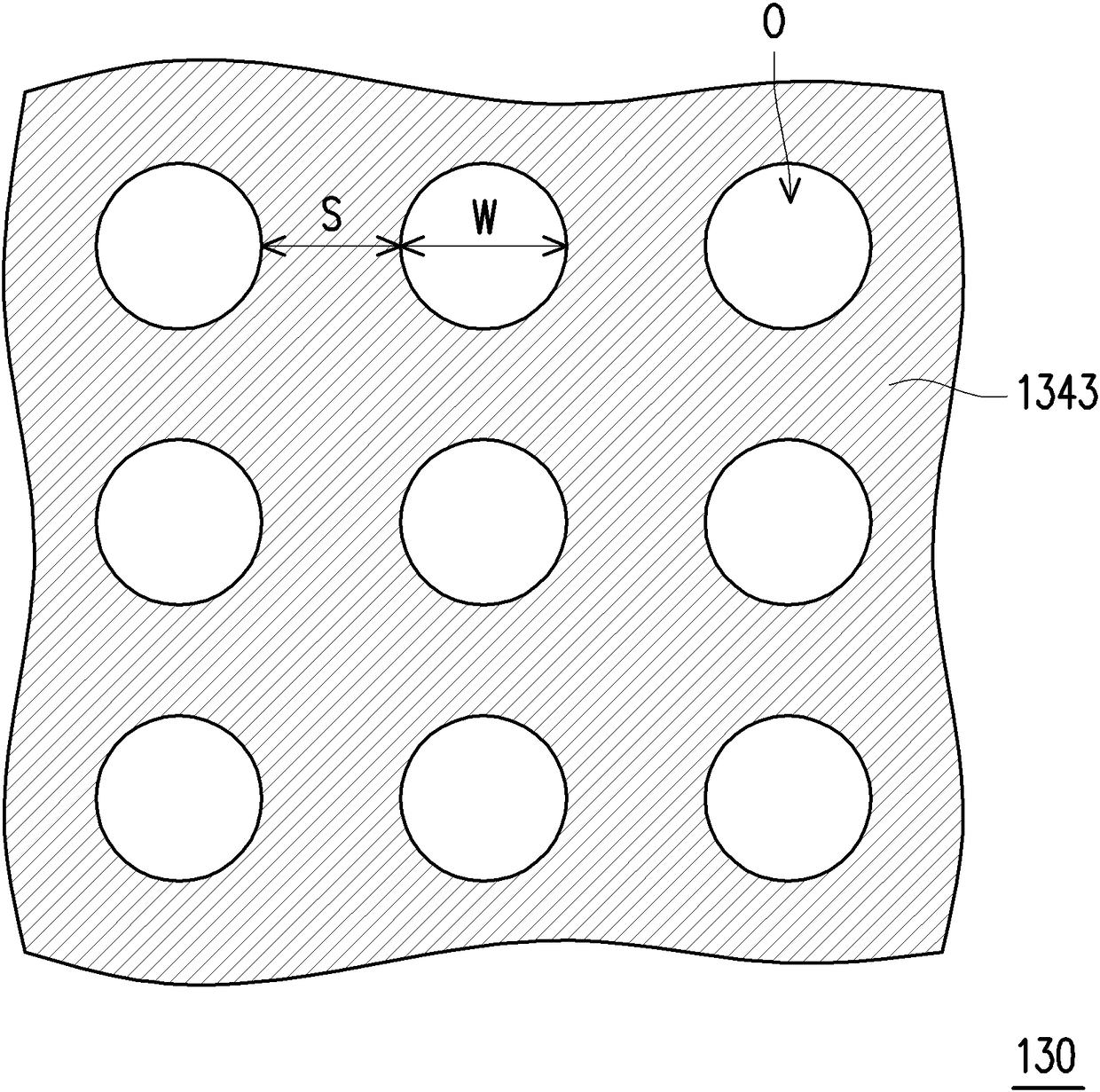

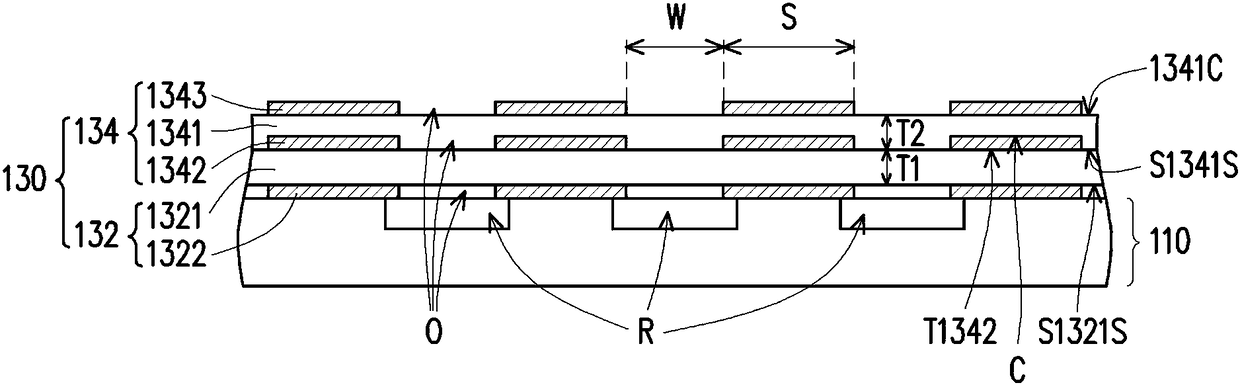

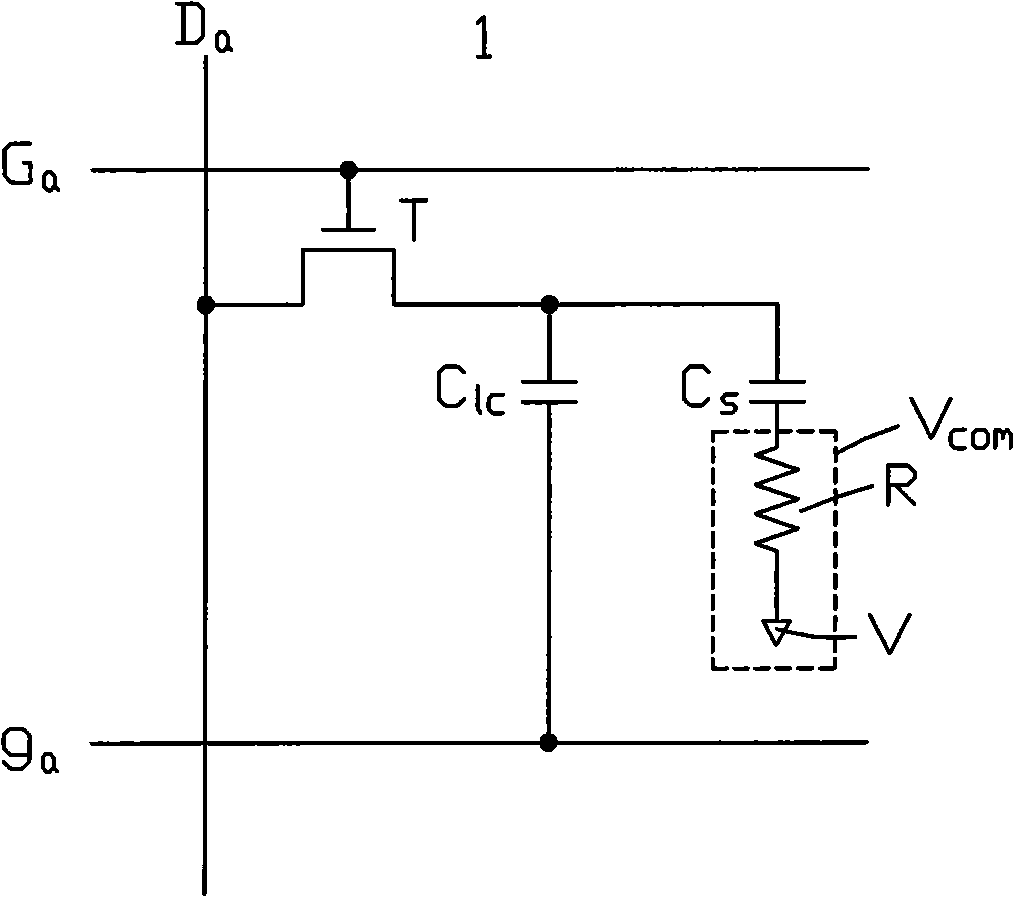

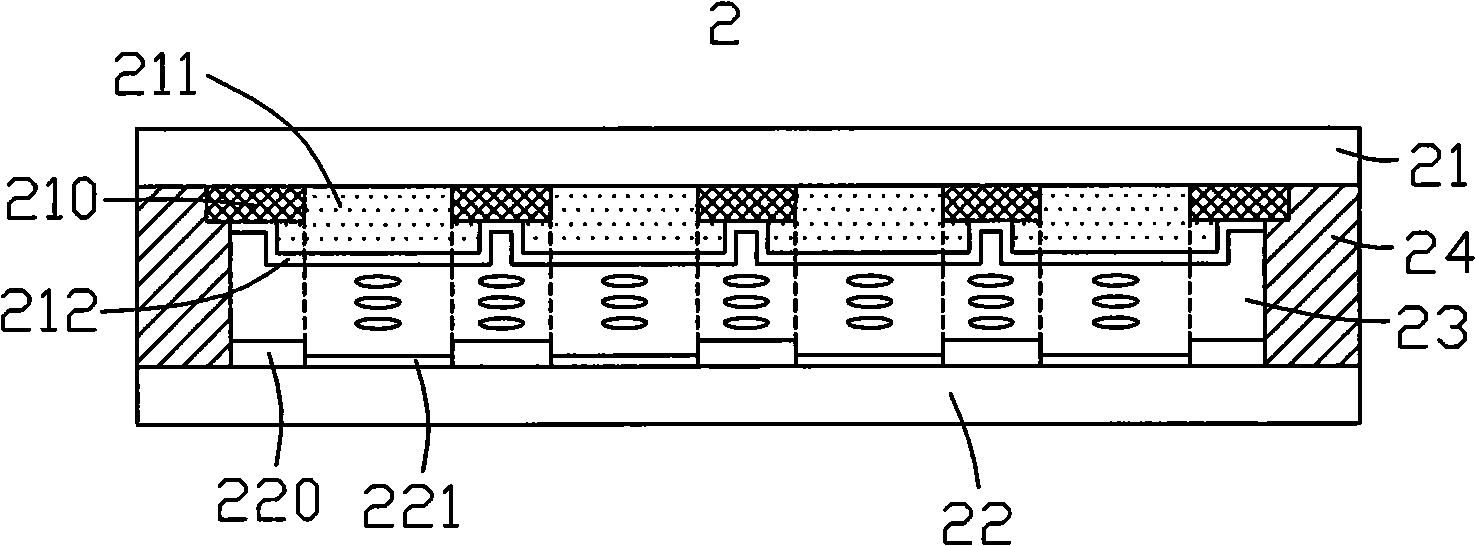

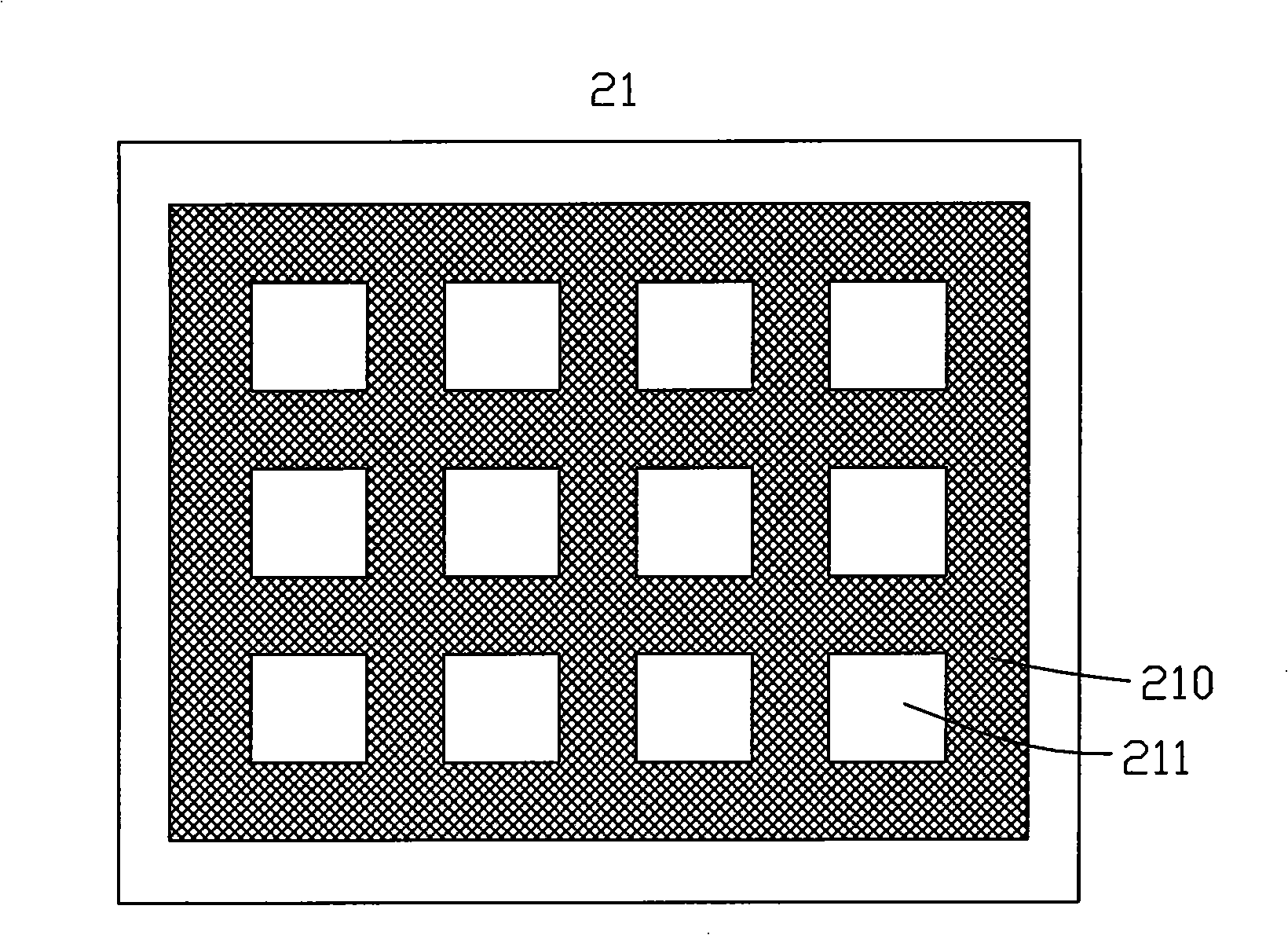

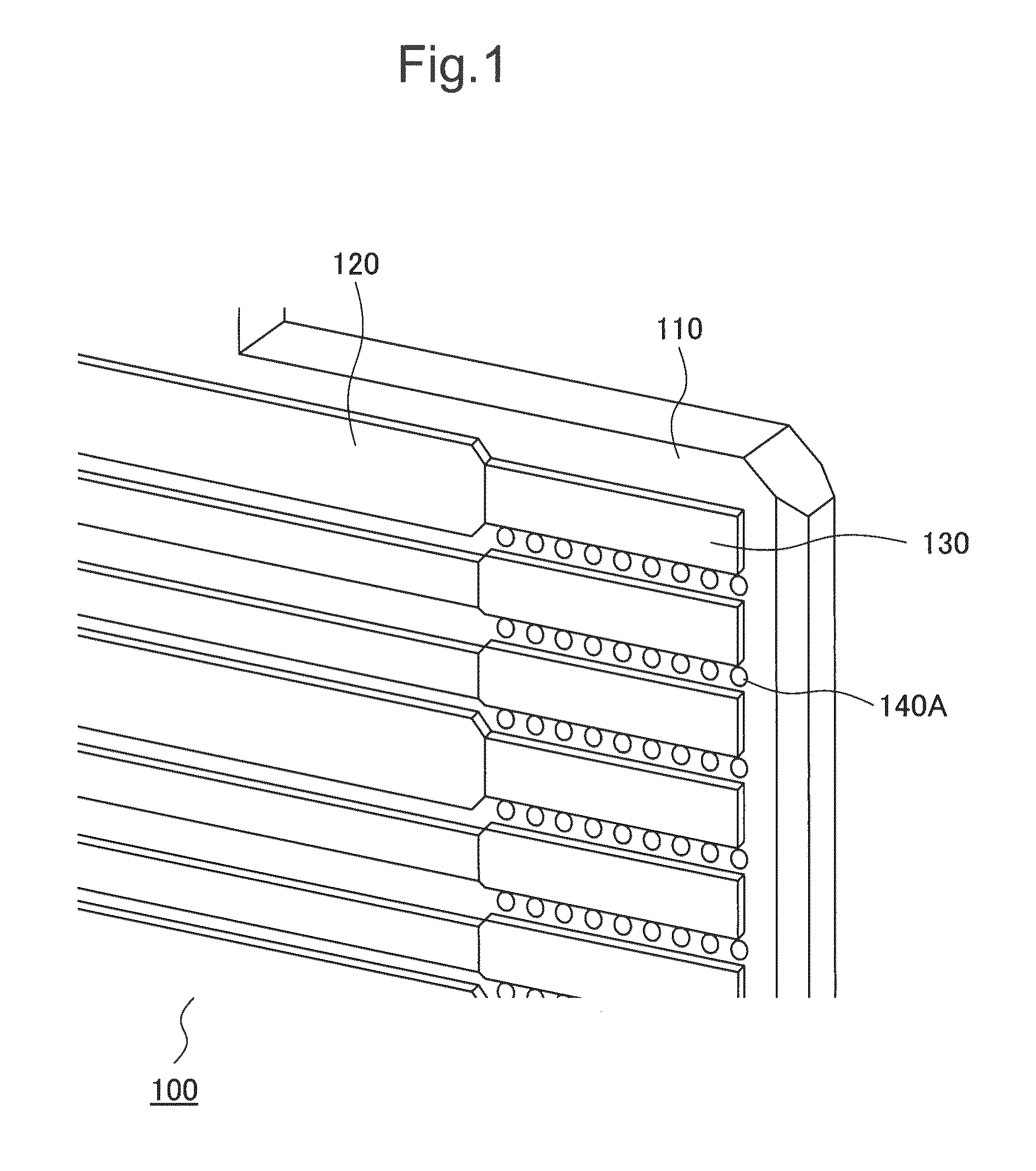

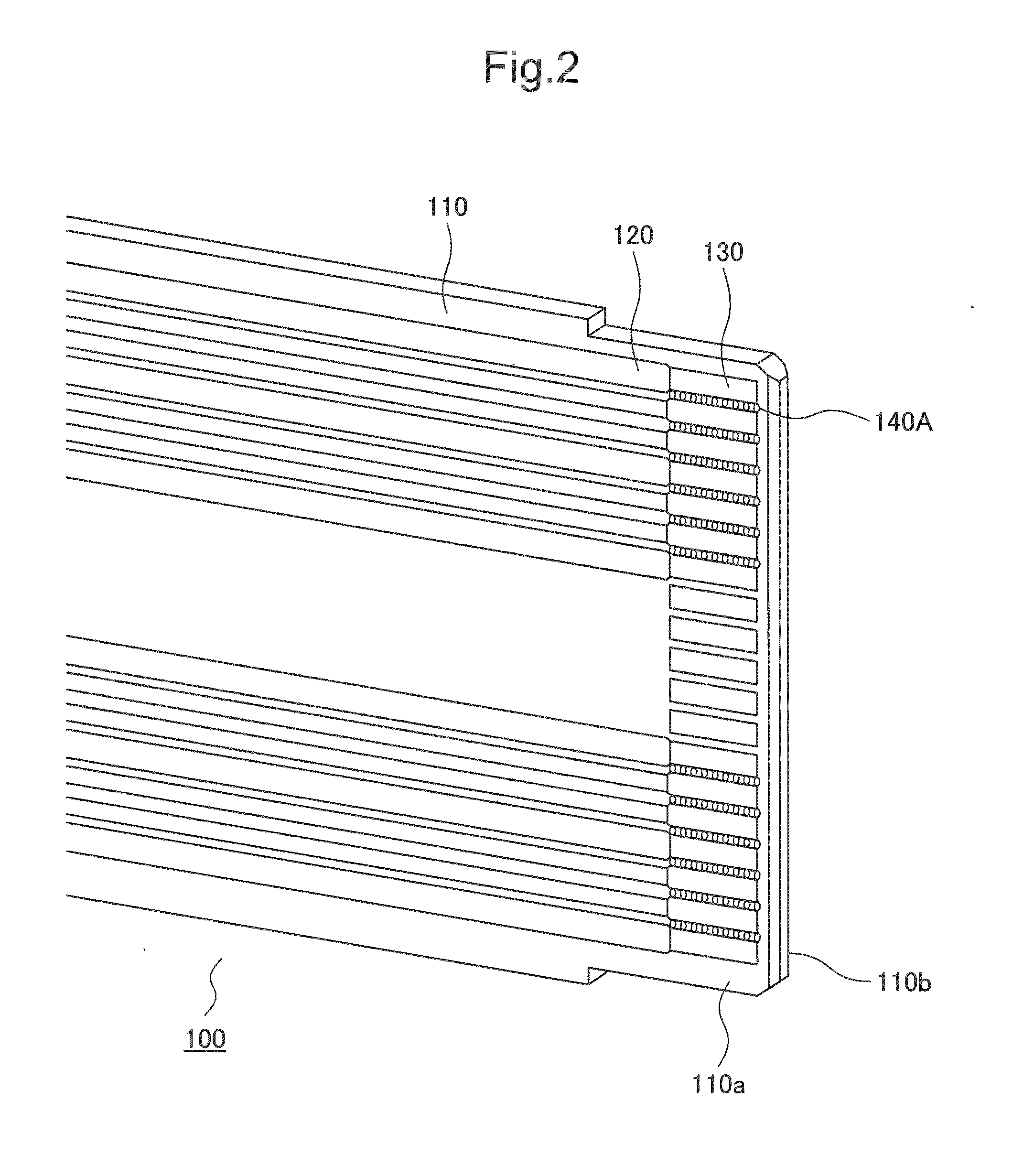

Display panel and display device

ActiveCN108807487AHigh light transmittanceHigh precisionSolid-state devicesSemiconductor devicesOrganic filmScattering function

An embodiment of the invention provides a display panel and a display device. The absorption and scattering functions of an organic film layer in the light ray propagation process are reduced throughthinning treatment of a partial area of the thicker organic film layer of the display panel, the effective transmission rate on the display panel is increased, and loss and crosstalk of light ray signals after light rays pass by an organic film in the fingerprint recognition process are reduced, so that the sensitivity and the recognition accuracy of light-sensing fingerprint recognition are improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

NXN light exchanging structure in full photo exchanging nodal point

InactiveCN1392696ACrosstalk limitImprove crosstalkWavelength-division multiplex systemsSelection arrangementsNODALAudio power amplifier

This invention relates to a NxN optical exchange structure for all-optical exchange nodal points composed of 2n stages, in which n=log2N characterized by a "on / off" gate of a semiconductor amplifier between nth stage and n+1th stage forming 2n+1th stage; or different numbers of semiconcutor optical mplifier "on / off" gates can be designed in any second stage optical switches according to specific need. This invention uses restructured enlarge Bense optical exchange structure to limit the rrosstalk. A semiconductor optical amplifier "on / off" gate (SOA gate) is added to a NxN enlarge Bense optical exchange structure with equivalent variance to the route. The invention reserves good performances of the enlarged Bense optical exchange structure; generalized unblockness, optimality of the hardware, and reduced crosstalk.

Owner:HUAZHONG UNIV OF SCI & TECH

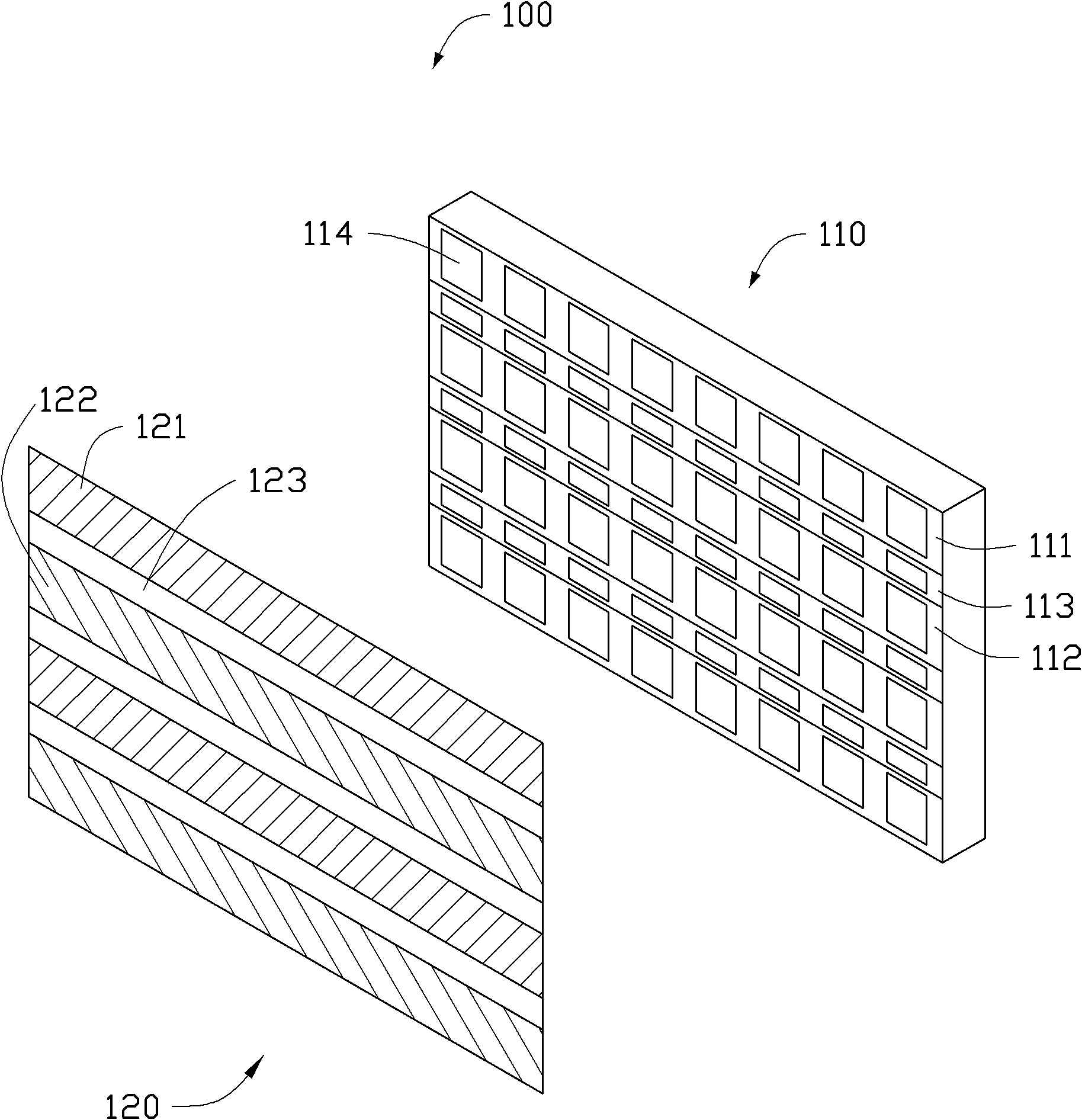

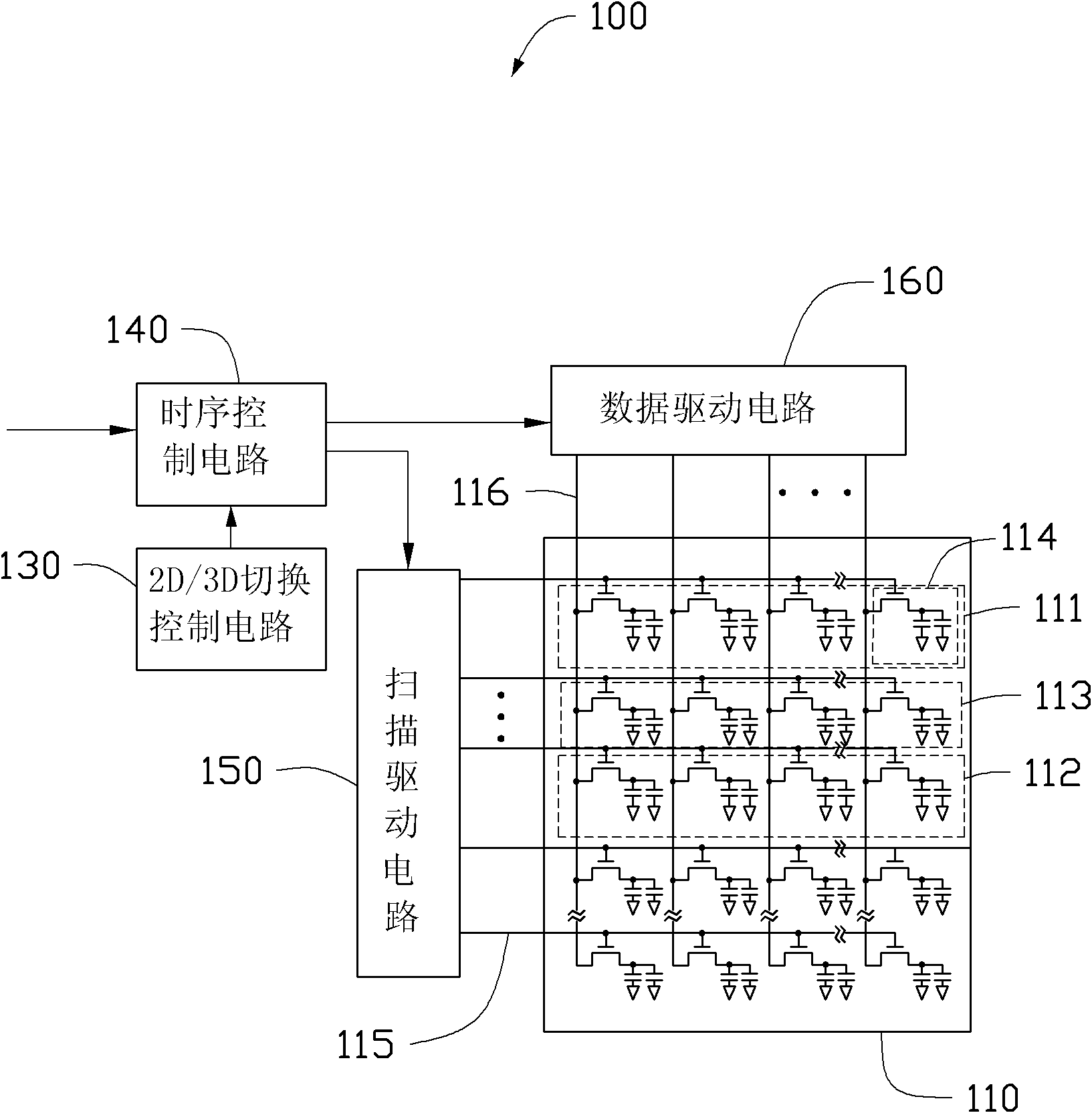

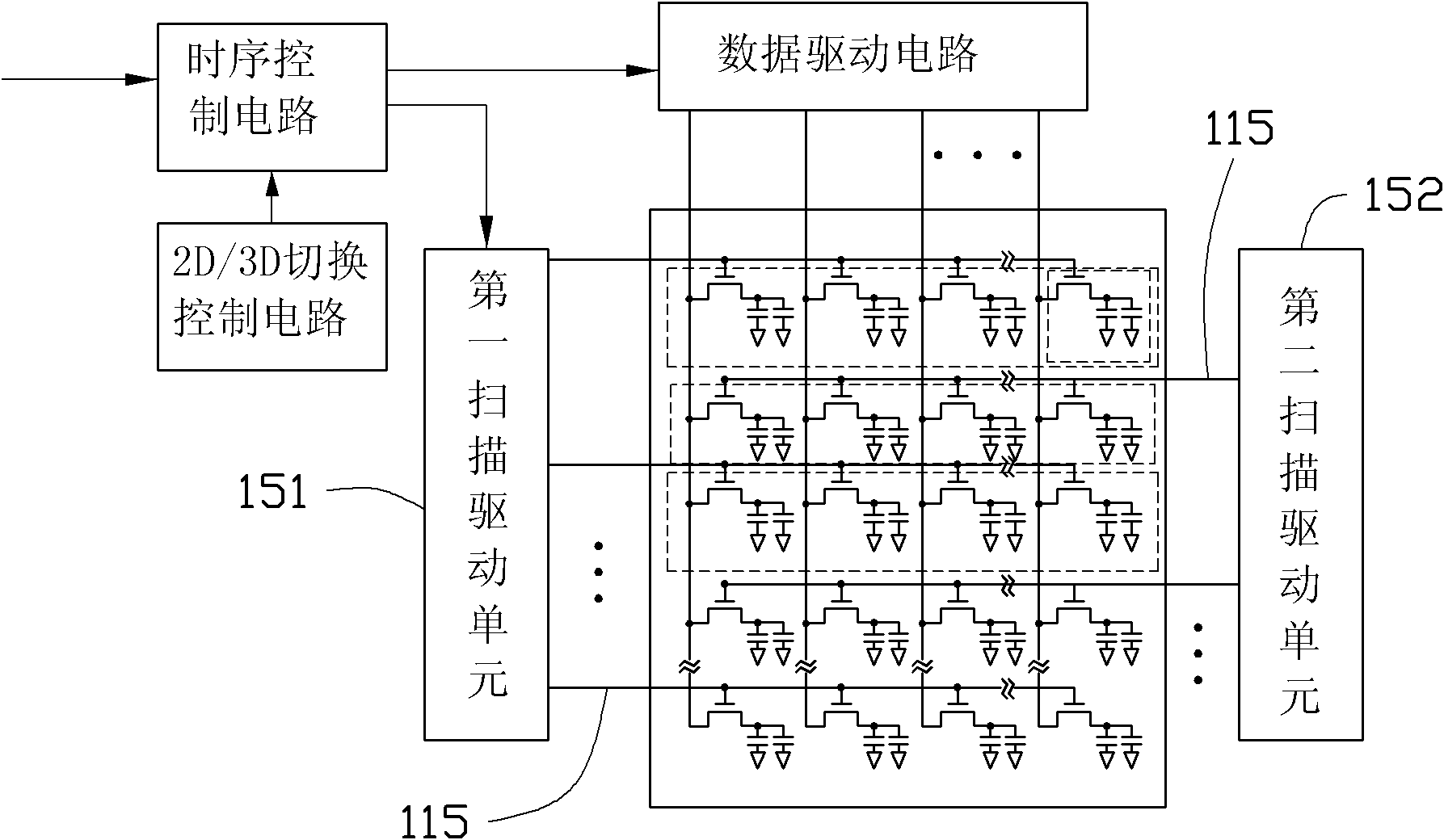

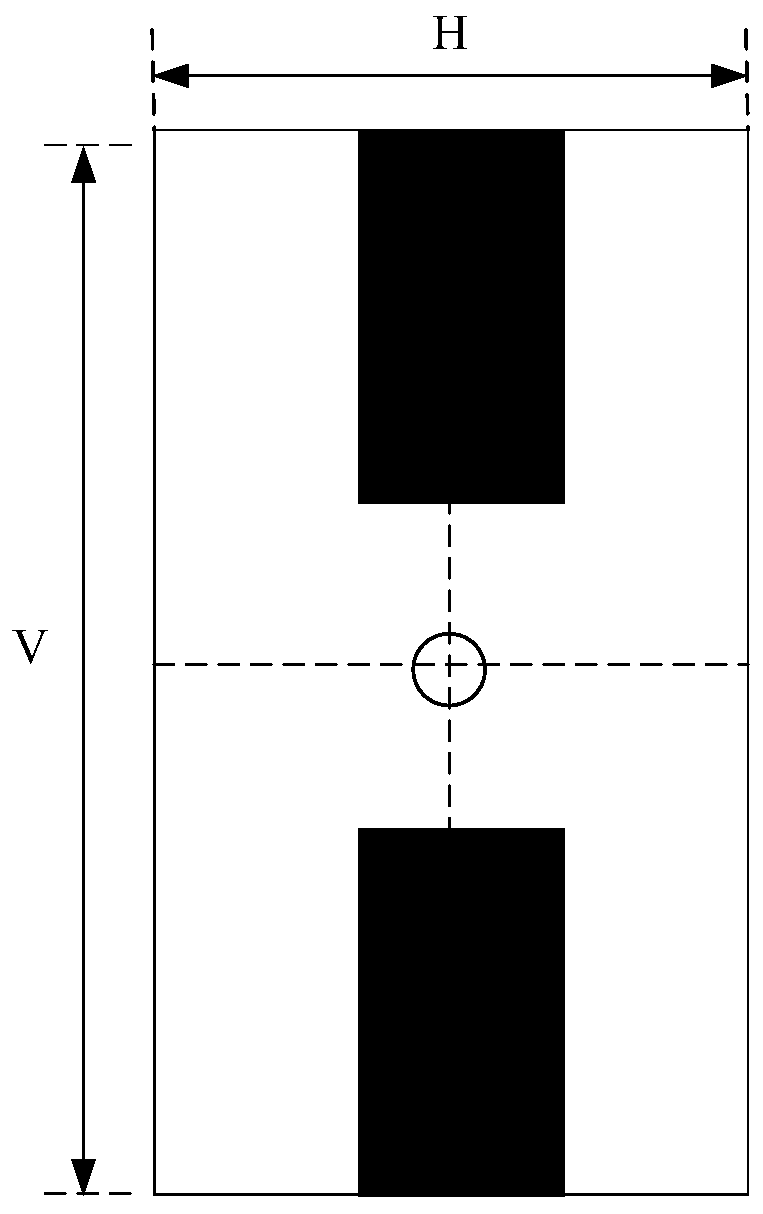

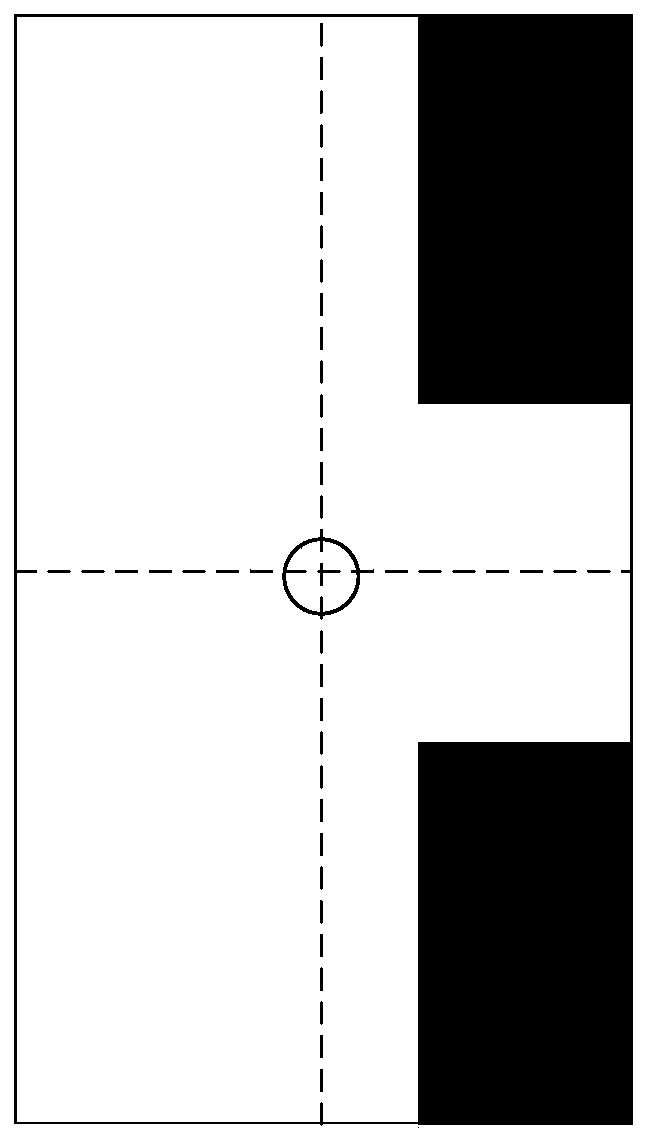

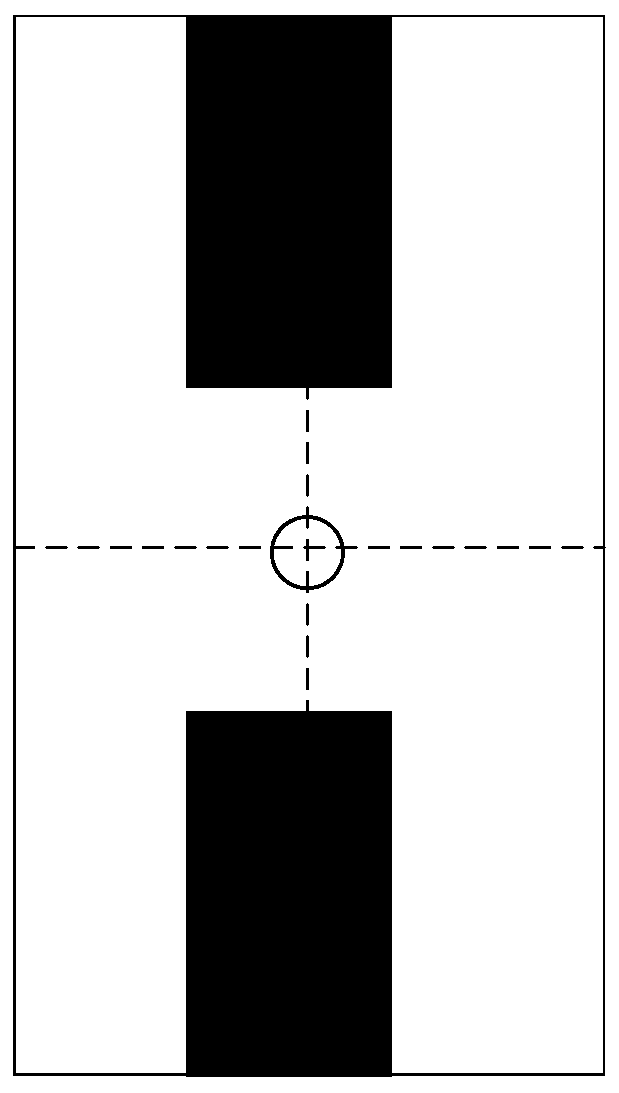

Two-dimensional/three-dimensional (2D/3D) switchable display device and driving method thereof

ActiveCN102387375ADoes not reduce brightnessImprove crosstalkStatic indicating devicesSteroscopic systemsPhase differenceComputer science

The invention relates to a two-dimensional / three-dimensional (2D / 3D) switchable display device and a driving method thereof. The 2D / 3D switchable display device comprises a display panel and a phase difference control element. The display panel comprises at least one left eye image area for displaying left eye images and at least one right eye image area for displaying right eye images, and the phase difference control element is used for adjusting the polarization state of the left eye images displayed by the display panel and the polarization state of the right eye images displayed by the display panel so as to enable the adjusted left eye images and the adjusted right eye images to have different polarization states. The display panel further comprises at least one switching area located between the left eye image area and the right eye image area, and light of the switching area can pass through the phase difference control element. When the 2D / 3D switchable display device performs three-dimensional display, the switching area displays a black image; and when the 2D / 3D switchable display device performs two-dimensional display, the switching are displays a gray scale image.

Owner:INNOLUX CORP

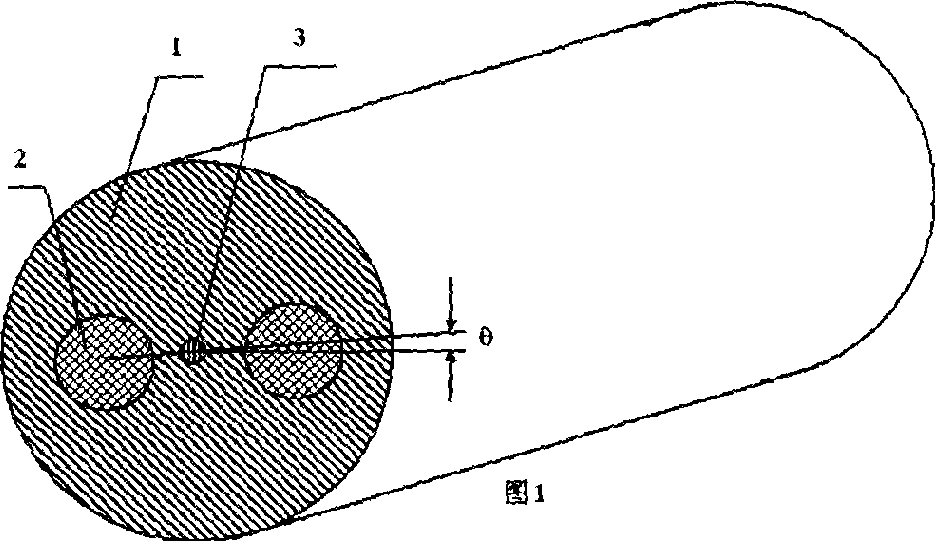

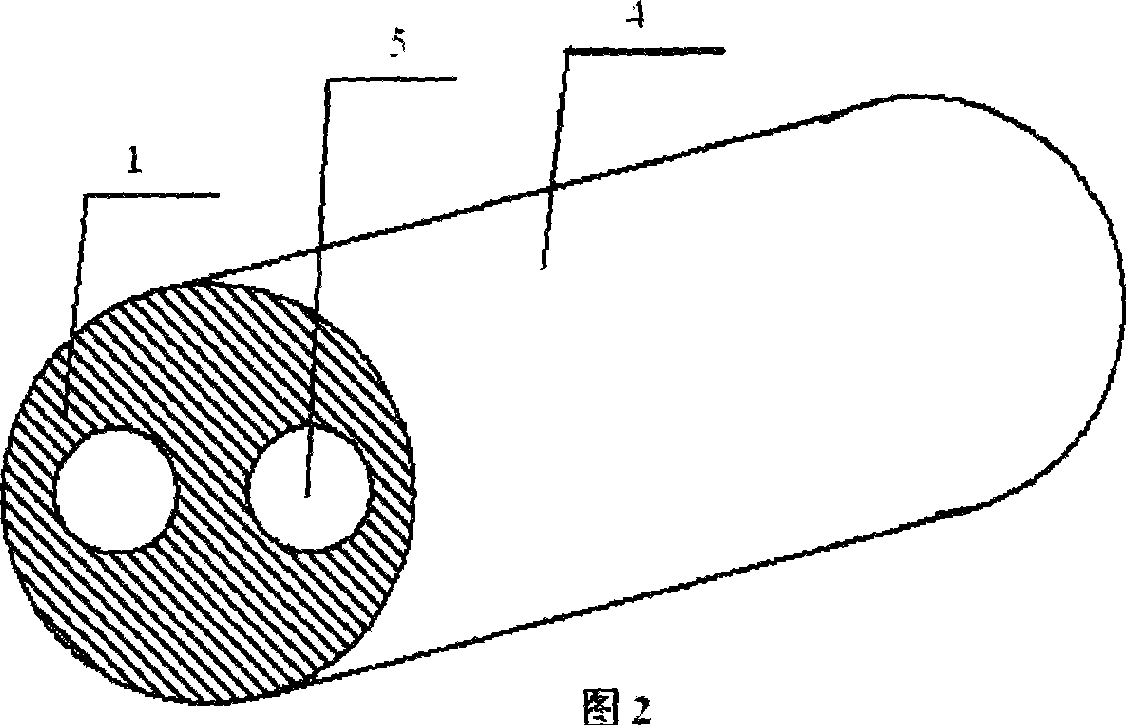

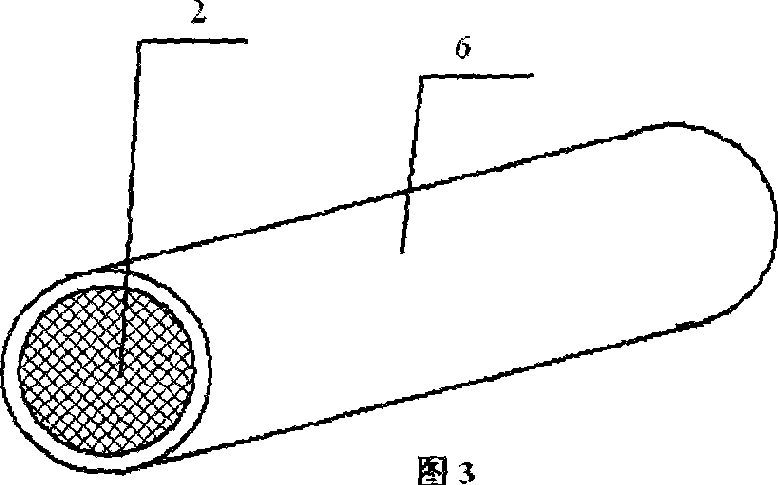

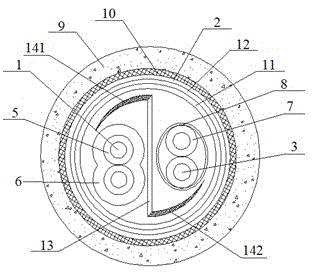

Large size combined optical fibre perform of polarization maintaining fiber and production method thereof

ActiveCN101391861AEasy to moveEvenly heatedGlass making apparatusGlass fibre productsStructural symmetryPolarization-maintaining optical fiber

The invention relates to a polarization maintaining optical fibre large-size composite optical fibre preform and a preparation technological method, and comprises the optical fibre preform with a fibre core and cladding layers; the areas of the cladding layers of the two sides of the fibre core of the optical fibre perform are provided with two holes which run through lengthways and are parallel to the fibre core; the two holes are provided with stress rods so as to form the composite optical fibre preform; the invention is characterized in that the optical fibre preform has the diameter of 30 to 80mm and the length of 200 to 800mm, the diameter range of the two side holes is 12 to 27mm and the diameter range of the stress area of the stress rod is 10 to 25mm. The polarization maintaining optical fibre large-size composite optical fibre preform and the preparation technological method lead the wire-drawing condition to be stable and controllable, and the drawn polarization maintaining optical fibre has excellent mechanical property and can pass the tension screening of 1 percent, even 2 percent; the preform with large diameter and large length is used for producing the polarization maintaining optical fibre; the wire-drawing length of a single preform reaches to be more than 200km, even more than 100km; and the production efficiency of the optical fibre is high. The drawn optical fibre structure has good symmetry and lengthwise uniformity and is easy to control.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

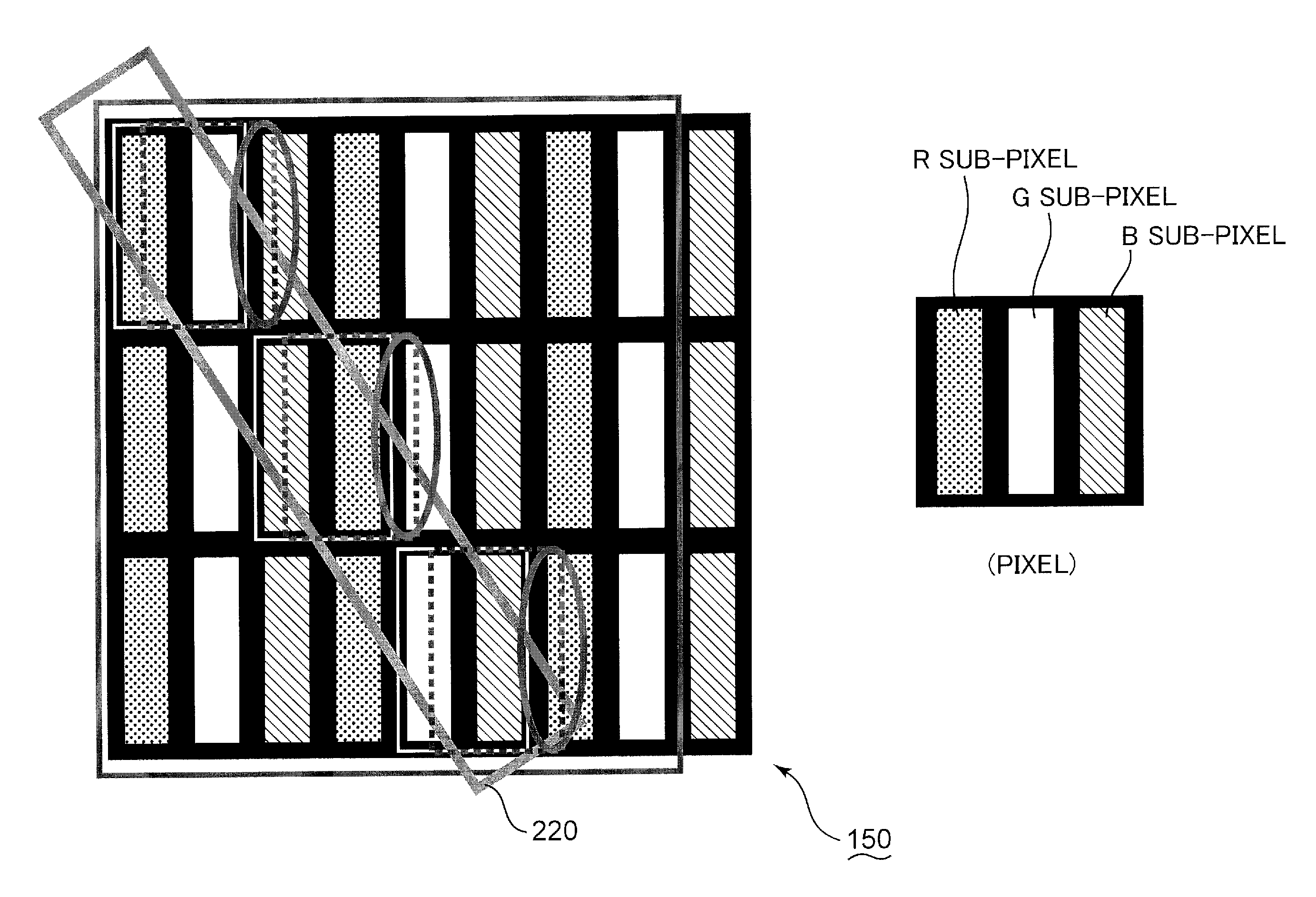

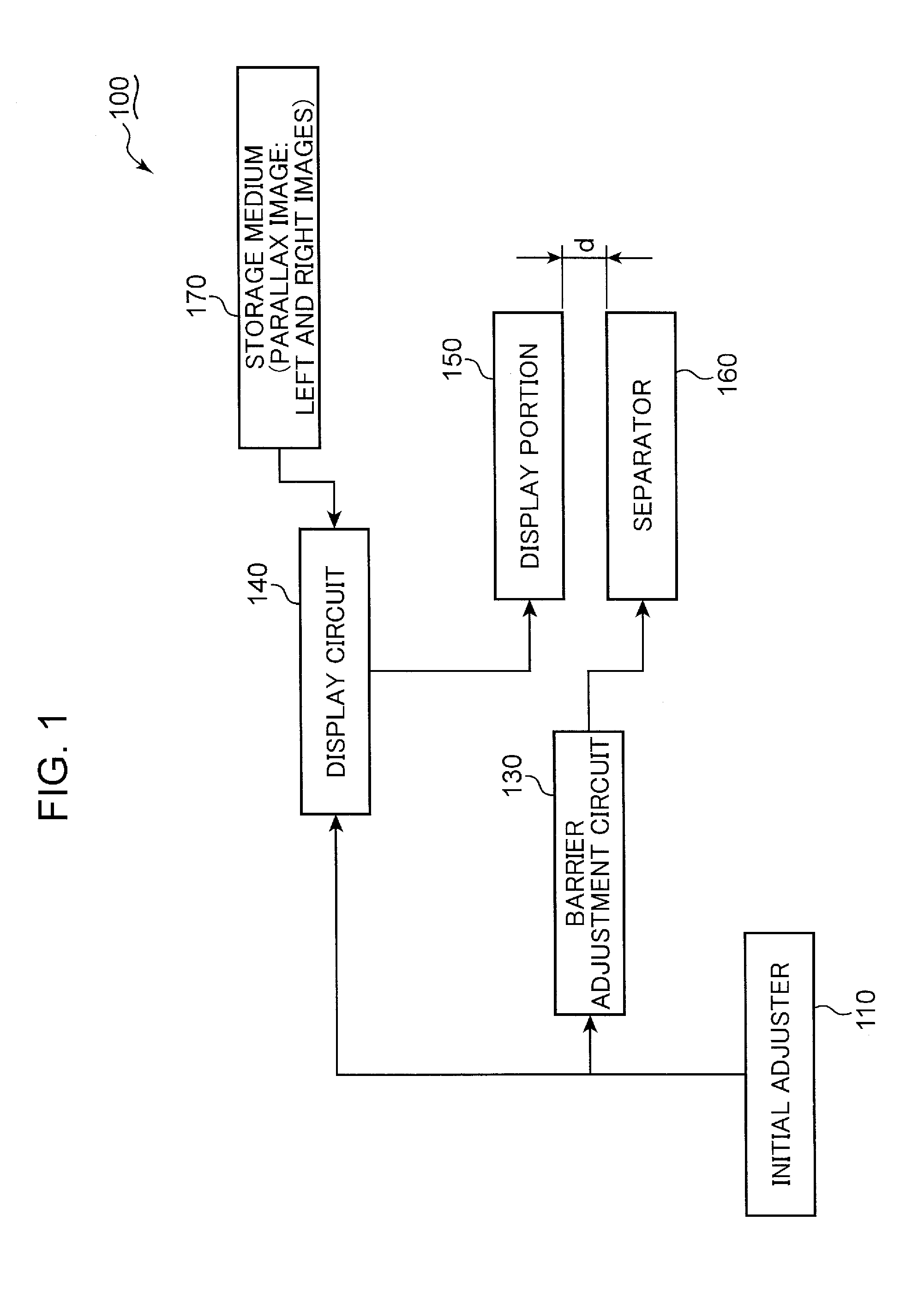

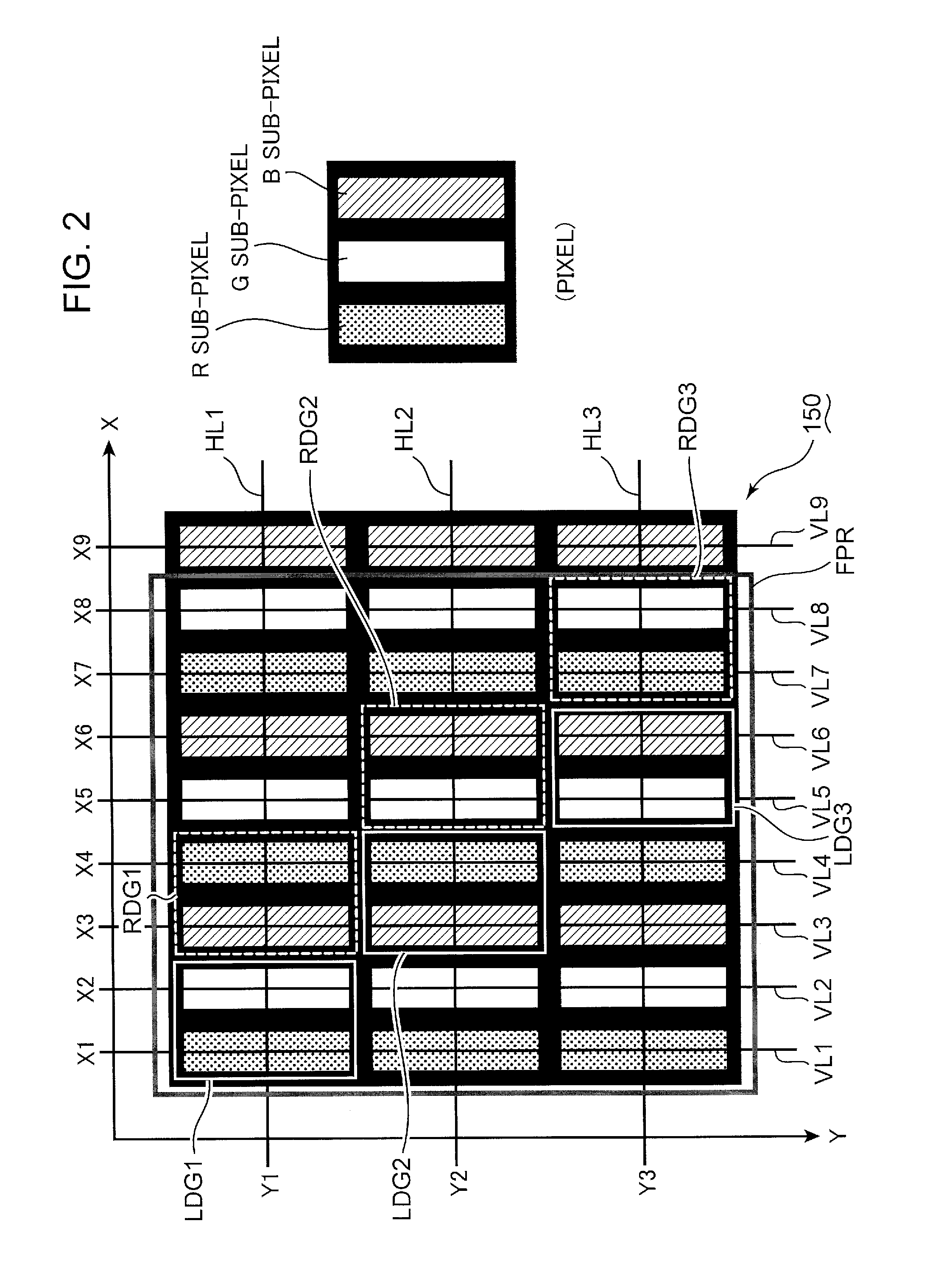

Display device

InactiveUS20140340746A1Reducing moire intensityImprove crosstalkStatic indicating devicesSteroscopic systemsDisplay deviceComputer science

The present application discloses a display device including a display portion for displaying a composite image of left and right images to be viewed by left and right eyes by using display elements arranged in a matrix. The display portion defines first and second element groups for displaying the left and right images, respectively. The first element groups include first and second height group situated at first and second vertical positions, which is different from each other. The second element groups include first and second adjacent groups horizontally adjacent to the first and second height group, respectively. The first and second adjacent groups include first and second adjacent elements adjacent to the first and second height groups, respectively. The first adjacent element emits different light in a luminescent color from the second adjacent element.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

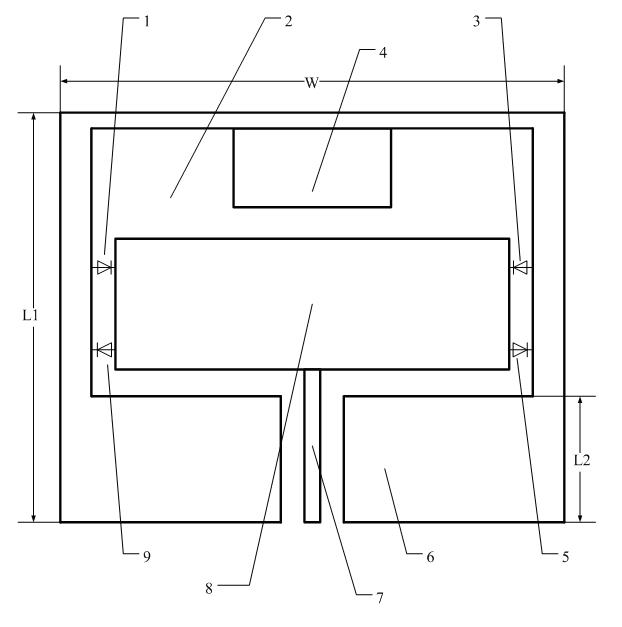

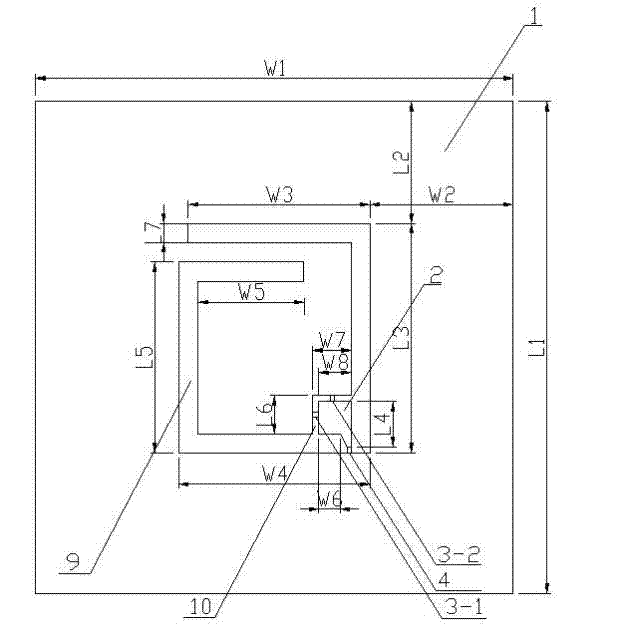

Three-frequency frequency reconfigurable antenna for coplanar waveguide feed

InactiveCN102437420AImproving Impedance MatchingReduce designSimultaneous aerial operationsRadiating elements structural formsReconfigurable antennaMetal coating

The invention relates to a three-frequency frequency reconfigurable antenna for coplanar waveguide feed, which comprises a metal microstrip on the upper layer, a dielectric substrate on the middle layer and a back floor board on the lower layer. The metal microstrip comprises a radiating patch, a coplanar waveguide floor board, a coplanar waveguide feeder, a matching branch and four PIN (P-Intrinsic-N) diodes, and the radiating patch is surrounded by the coplanar waveguide floor board. The coplanar waveguide floor board is connected with the radiating patch through the four PIN diodes, the coplanar waveguide feeder is arranged at a central opening on the lower edge of the coplanar waveguide floor board and is connected with the radiating patch into a whole, and the matching branch is connected with the upper part of the coplanar waveguide floor board into a whole. The back floor board is arranged on the back of the dielectric substrate and corresponds to metal coatings on the lower part of the coplanar waveguide floor board and under the coplanar waveguide feeder, and a microstrip antenna is formed by the back floor board and the metal microstrip. The three-frequency frequency reconfigurable antenna can work on three wireless communication frequency bands of 0.9GHz, 1.8GHz and 2.4GHz. Moreover, directional diagrams on the three frequency bands basically remain unchanged and have larger bandwidth. Meanwhile, the design of a switch bias circuit can be eliminated, and the impact of a switch on the radiation performance of the antenna can be reduced.

Owner:SHANGHAI UNIV

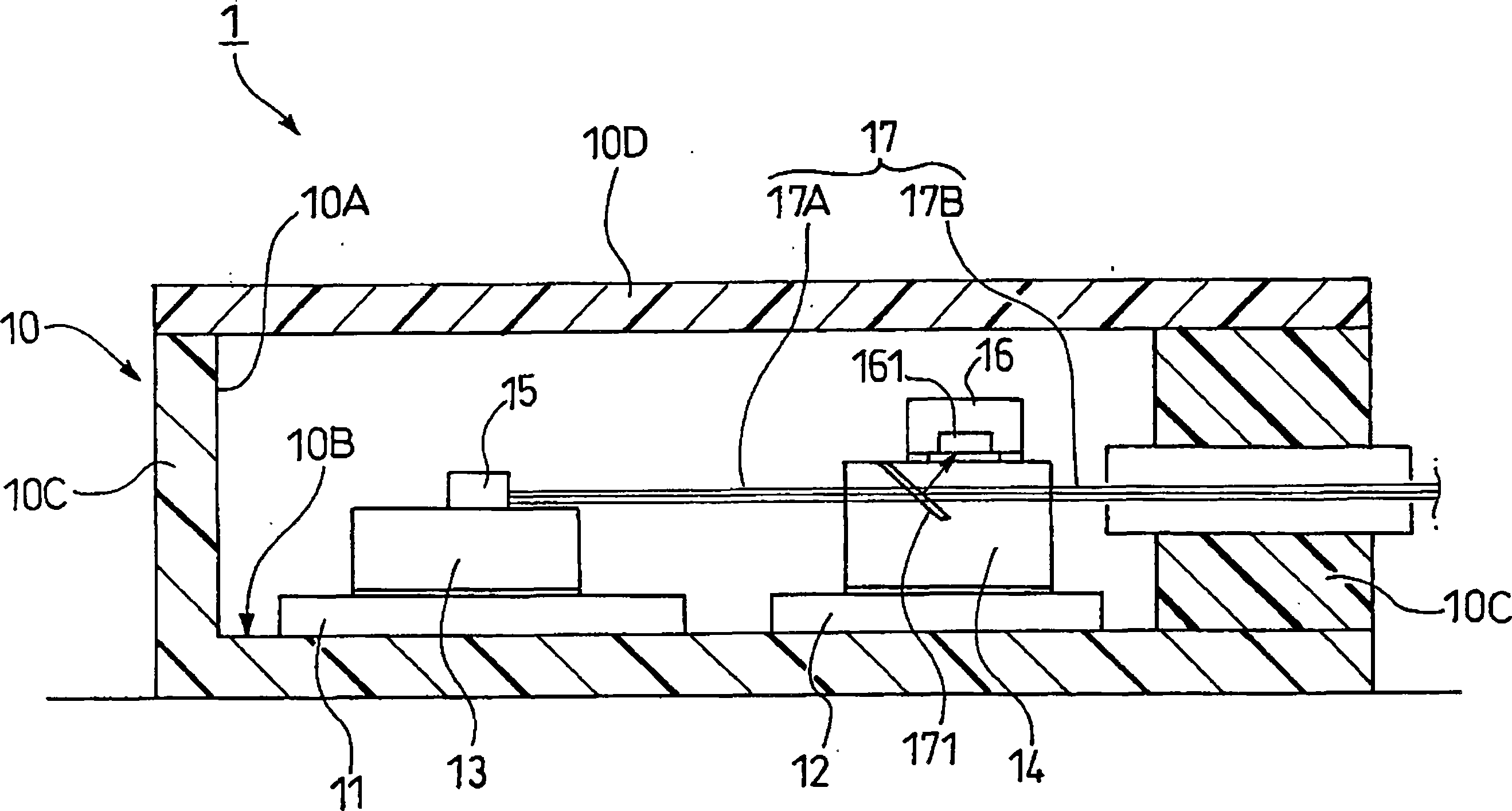

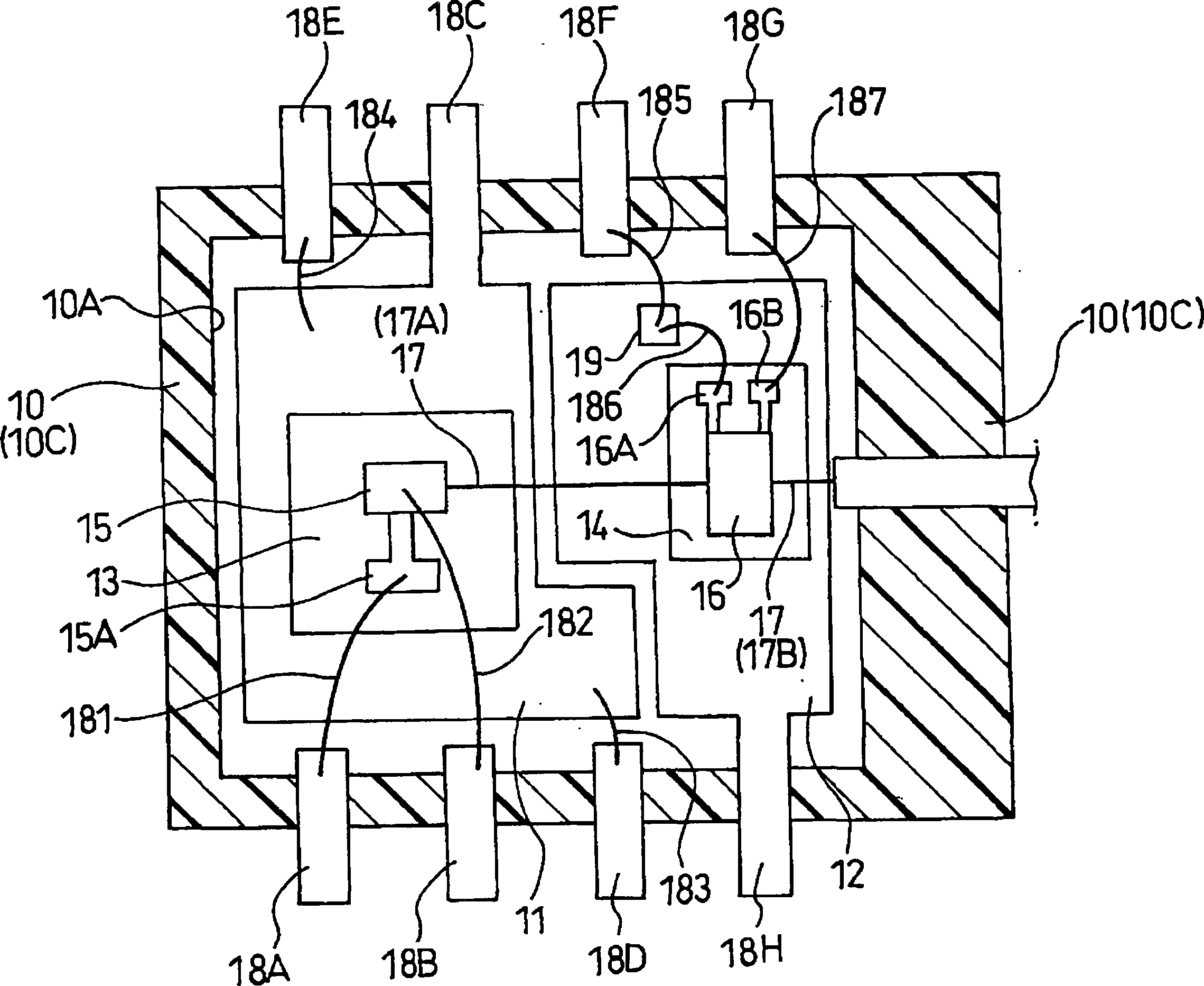

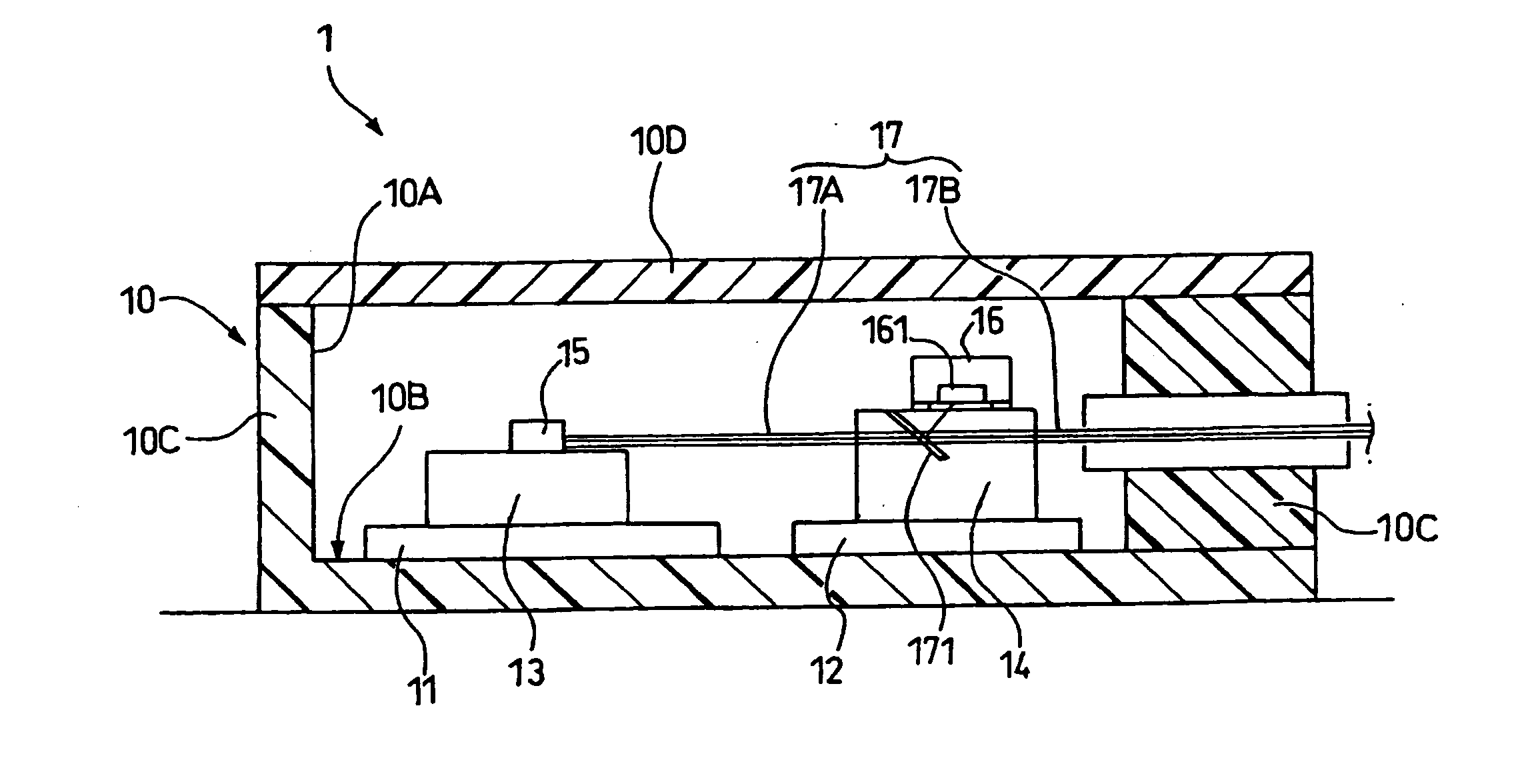

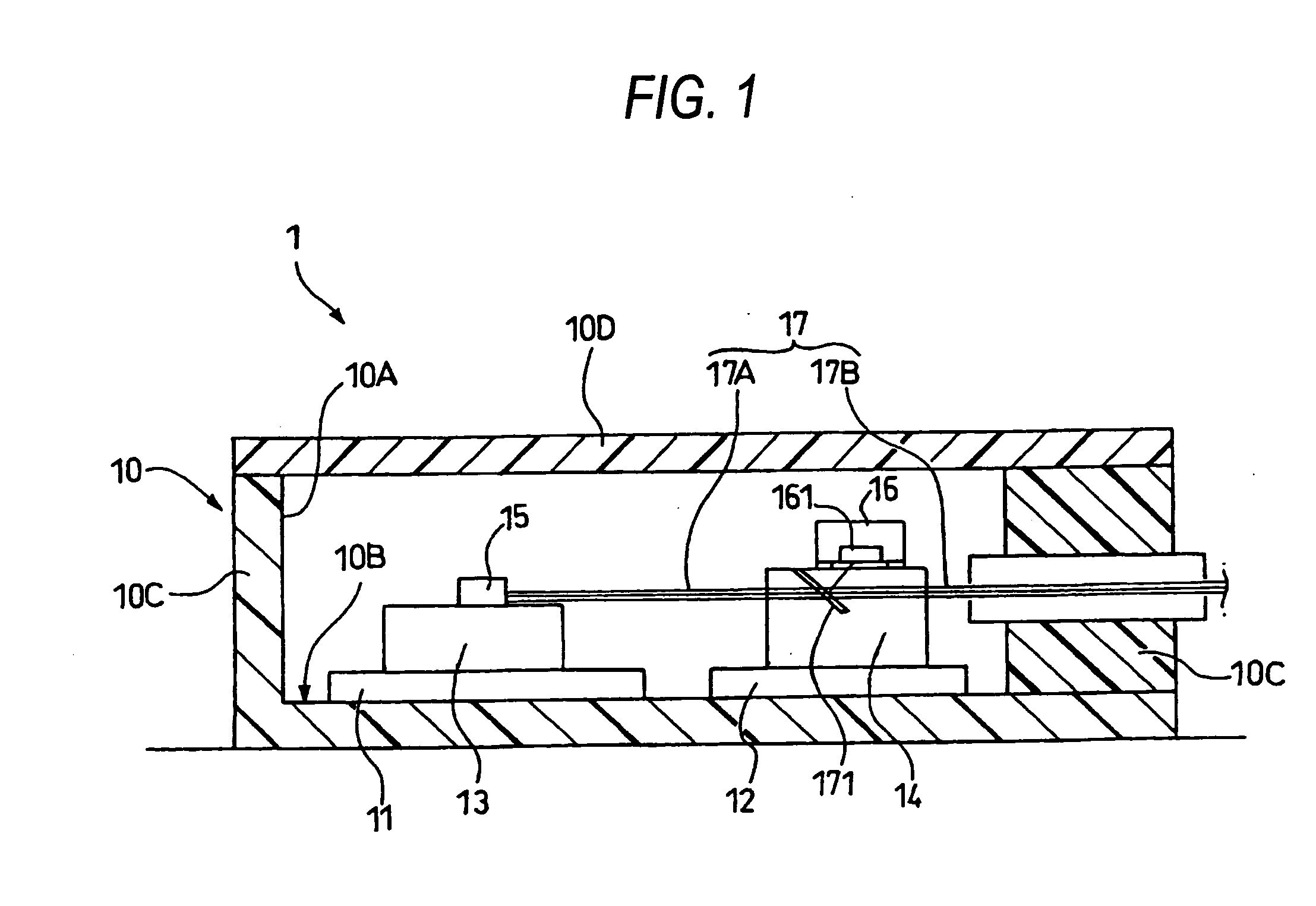

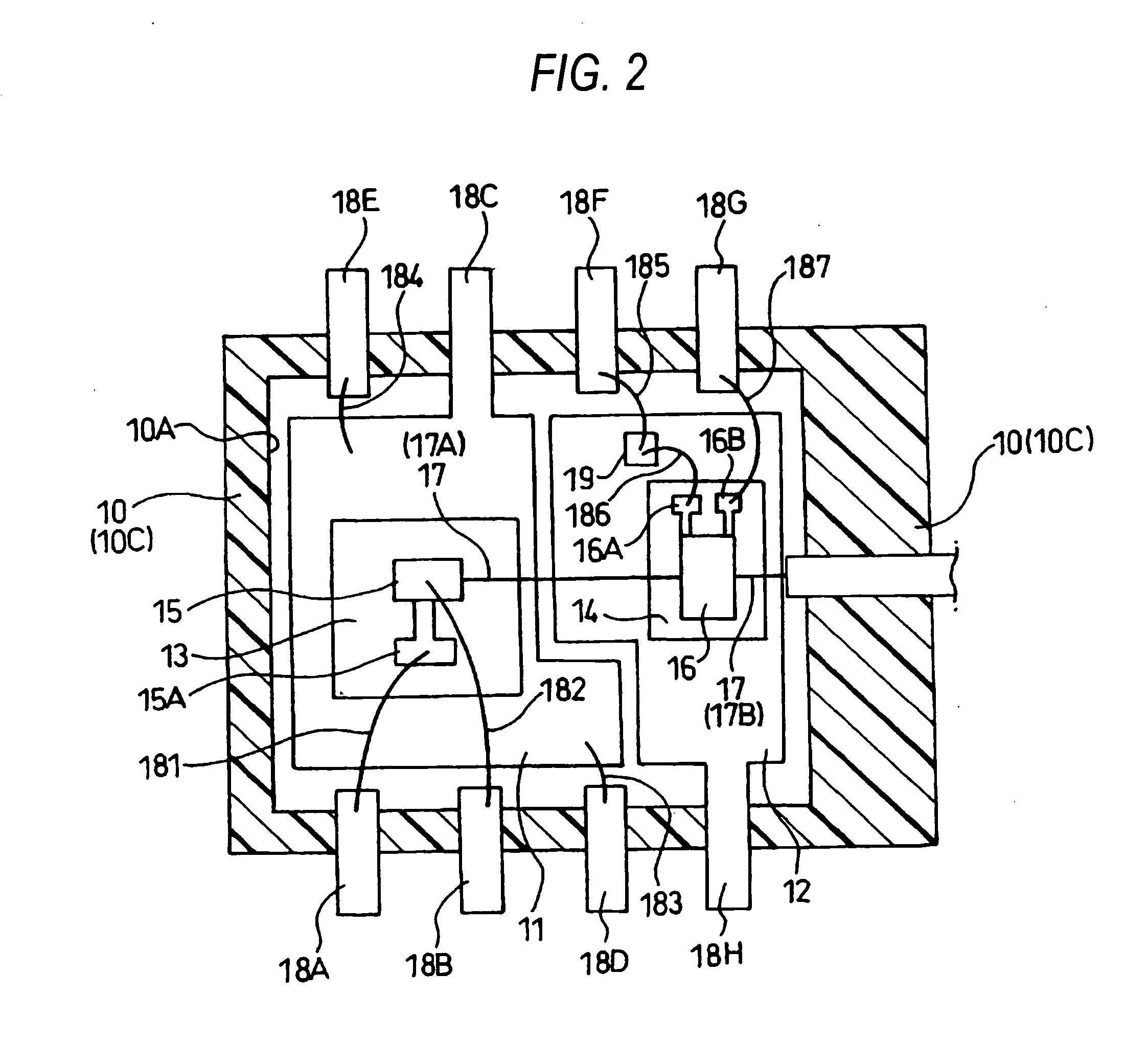

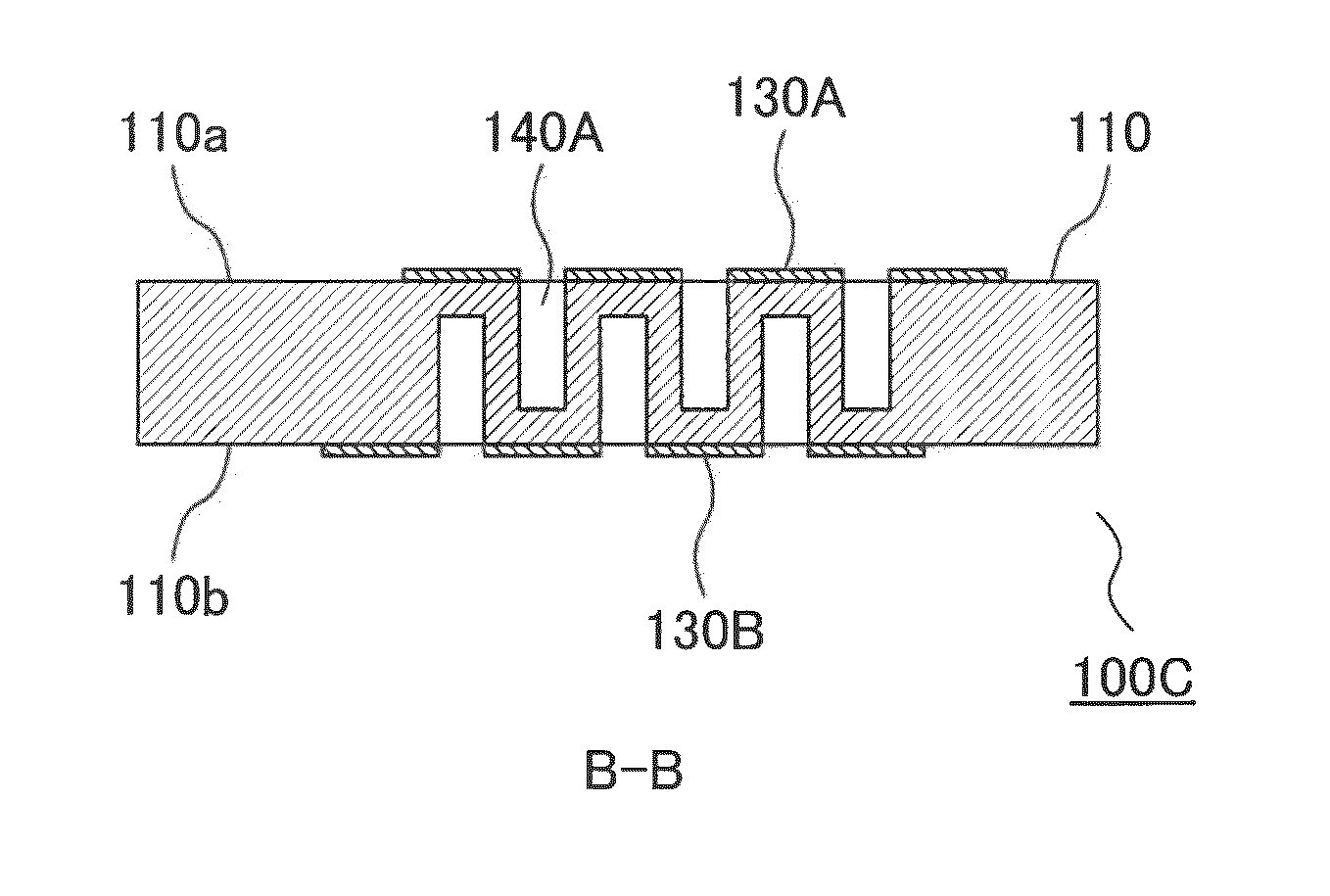

Light transmission/reception module and light transmission/reception device

InactiveCN1902763AAvoid Capacitive CasesIncrease capacitanceLaser detailsSemiconductor laser structural detailsTransceiverPhotodetector

Providing an optical transceiver module that reduces electric crosstalk between a light emitting device and a photodetector while providing an excellent high-frequency characteristic, and an optical transceiver including the same. According to the invention, a first metal plate having a first substrate for mounting a light emitting device and a at second metal plate having a second substrate for mounting a photodetector are provided separately and independently of each other in a resin package, thus reducing the parasitic capacitance. This provides an optical transceiver module capable of suppressing electric crosstalk where part of a high-frequency signal causes a variation in the potential at a terminal of a photodetector while improving the high frequency characteristic in driving the light emitting device with a high-frequency signal, and an optical transceiver including the same.

Owner:PANASONIC CORP

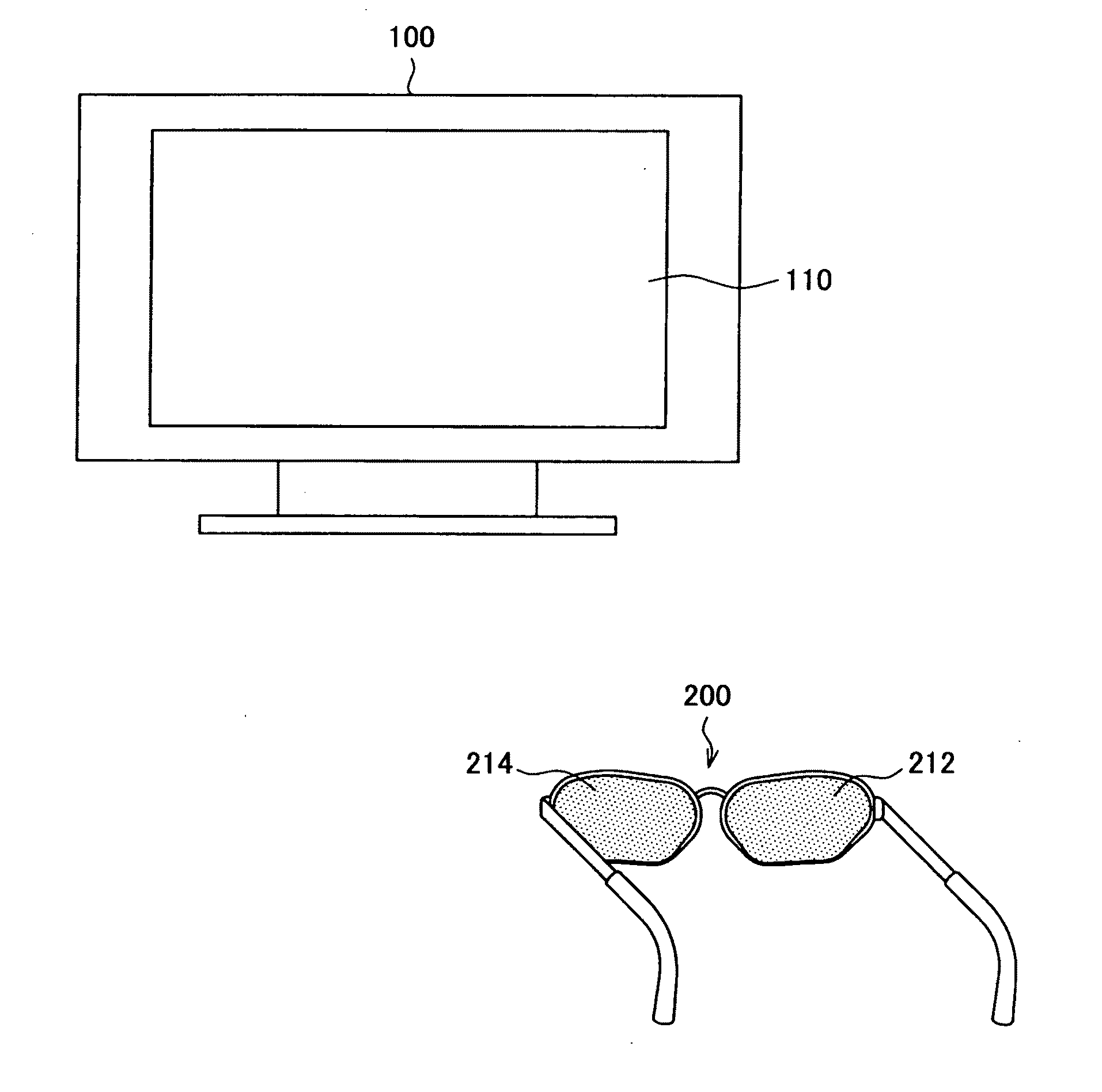

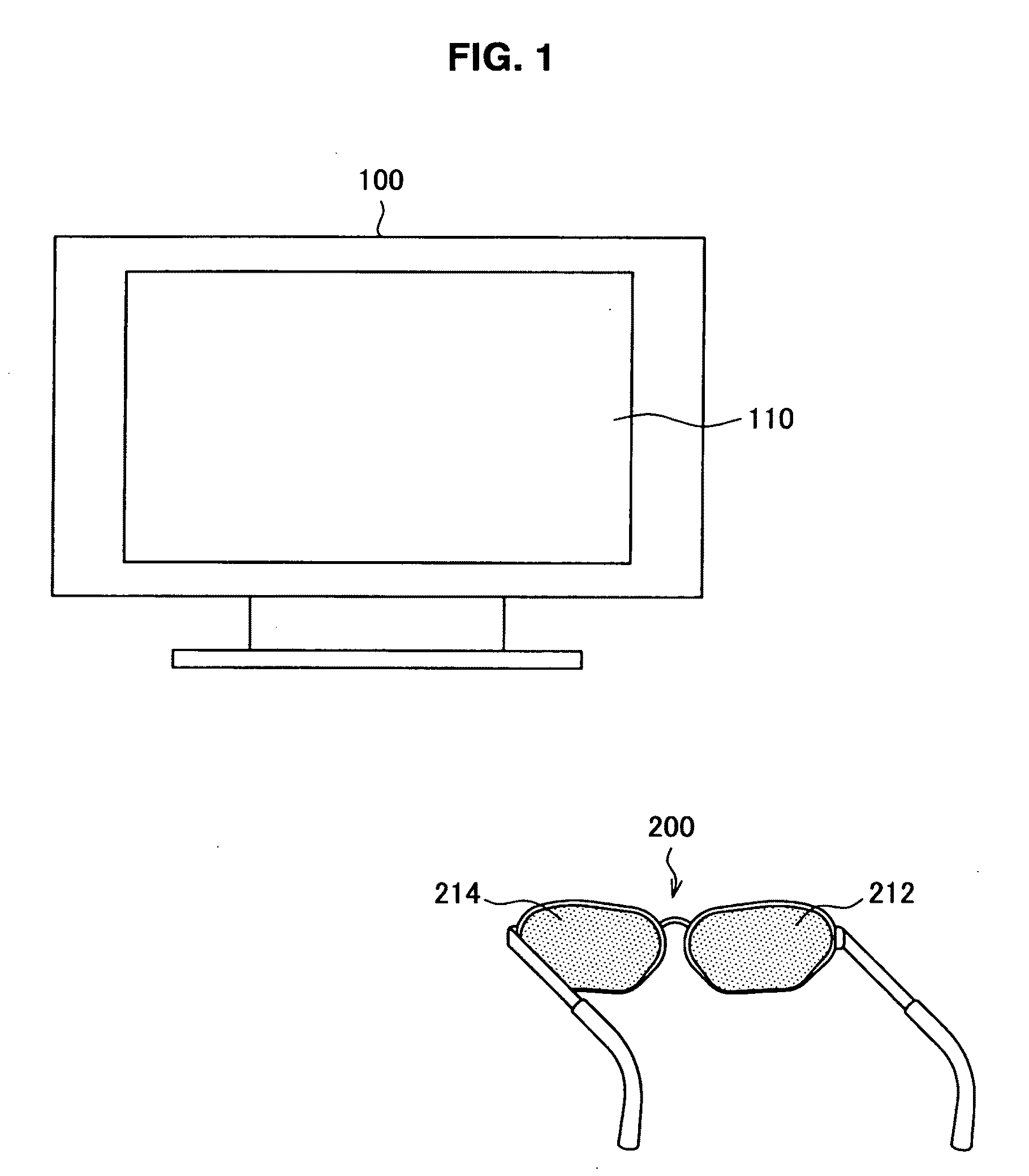

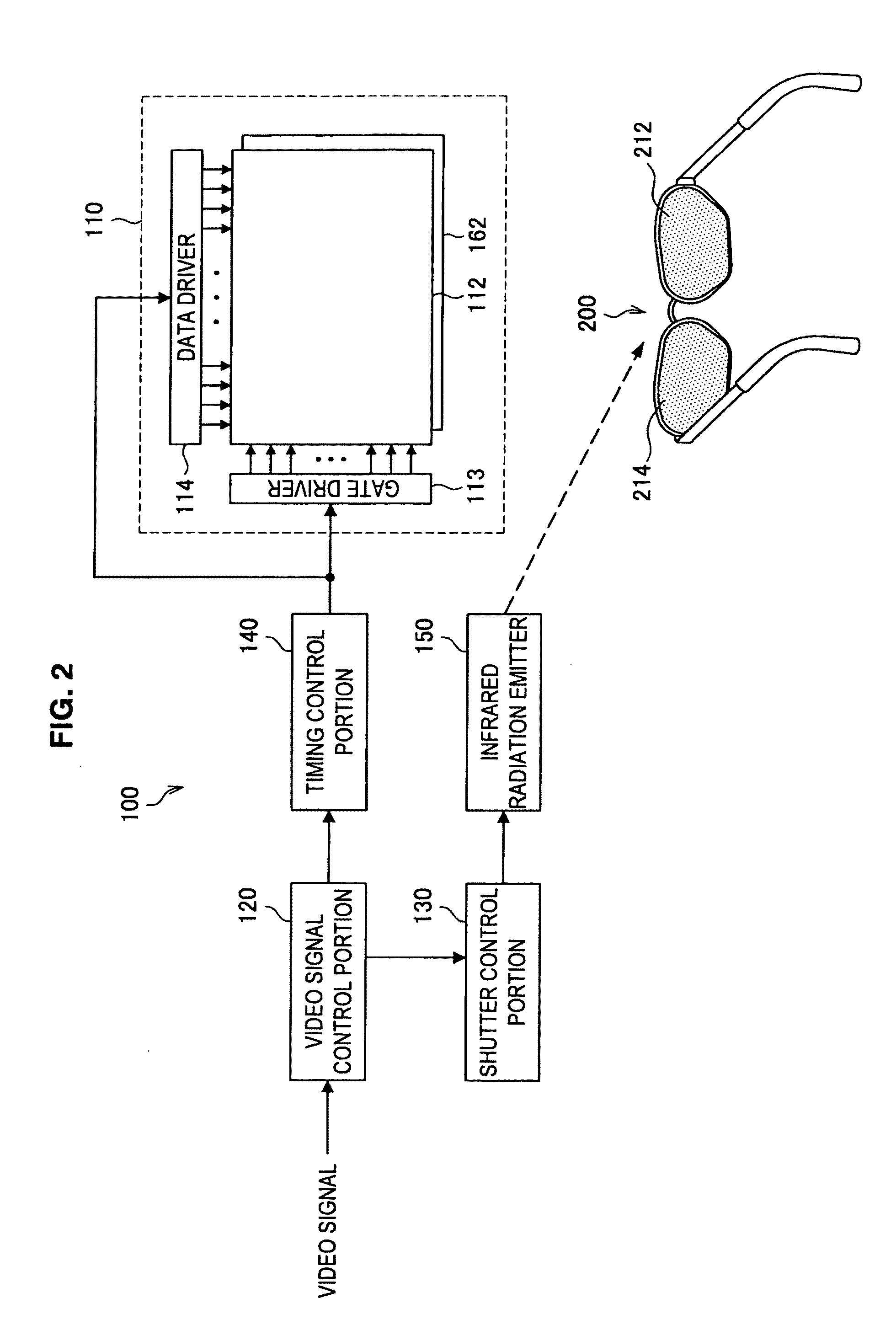

Display device and display method

ActiveUS20100245400A1Improve crosstalkCrosstalk can be improvedCathode-ray tube indicatorsSteroscopic systemsImage basedImaging Signal

Owner:SATURN LICENSING LLC

Image capturing apparatus

ActiveCN109271829AStrong recognition abilityImprove crosstalkSolid-state devicesPrint image acquisitionLight-emitting diodeOLED

An image capturing apparatus includes a sensor, an organic light emitting diode display panel, and a collimator. The organic light emitting diode display panel is disposed on the image pickup side ofthe sensor. The collimator is disposed between the organic light emitting diode display panel and the sensor. The collimator includes a plurality of collimator elements overlapping each other. Each ofthe plurality of collimating elements includes a light-transmitting substrate and a light-absorbing layer disposed on the light-transmitting substrate. The light absorbing layer includes a pluralityof light transmissive openings, and the plurality of light transmissive openings exposes a plurality of sensing regions of the sensor.

LCD device

ActiveCN101295090AImprove crosstalkConductiveNon-linear opticsLiquid-crystal displayConductive materials

Owner:INNOCOM TECH (SHENZHEN) CO LTD +1

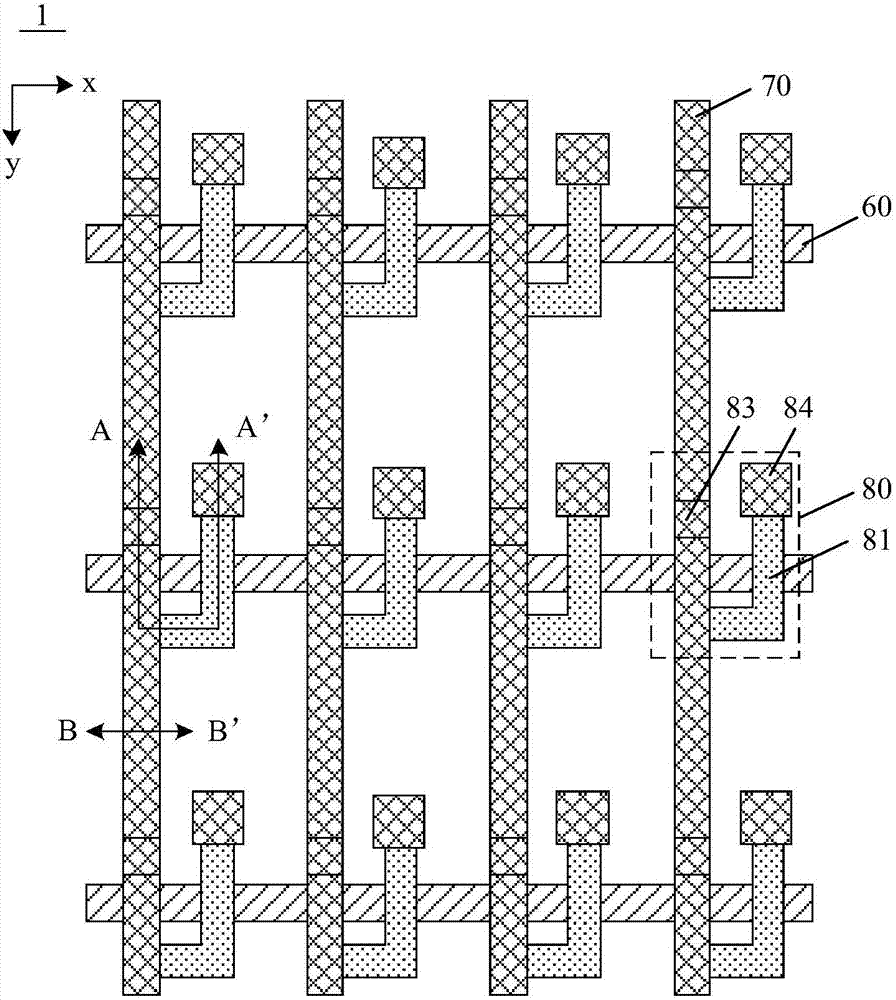

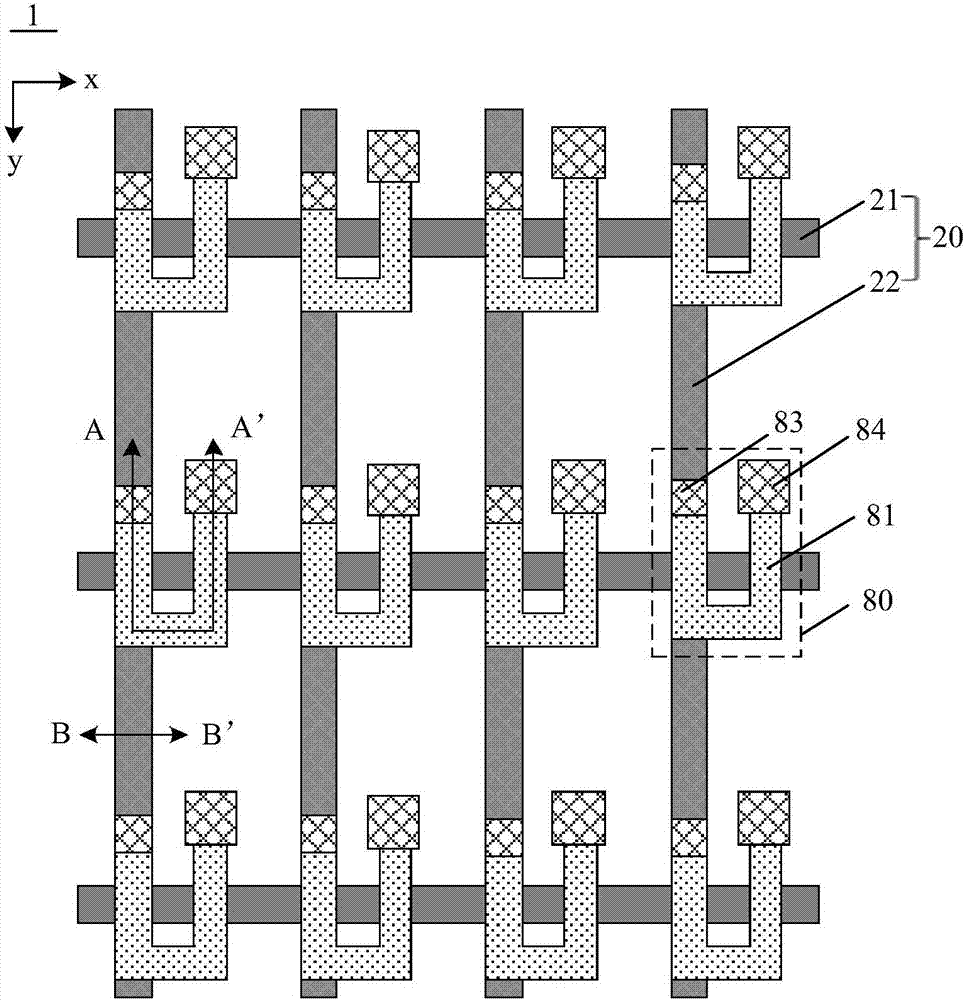

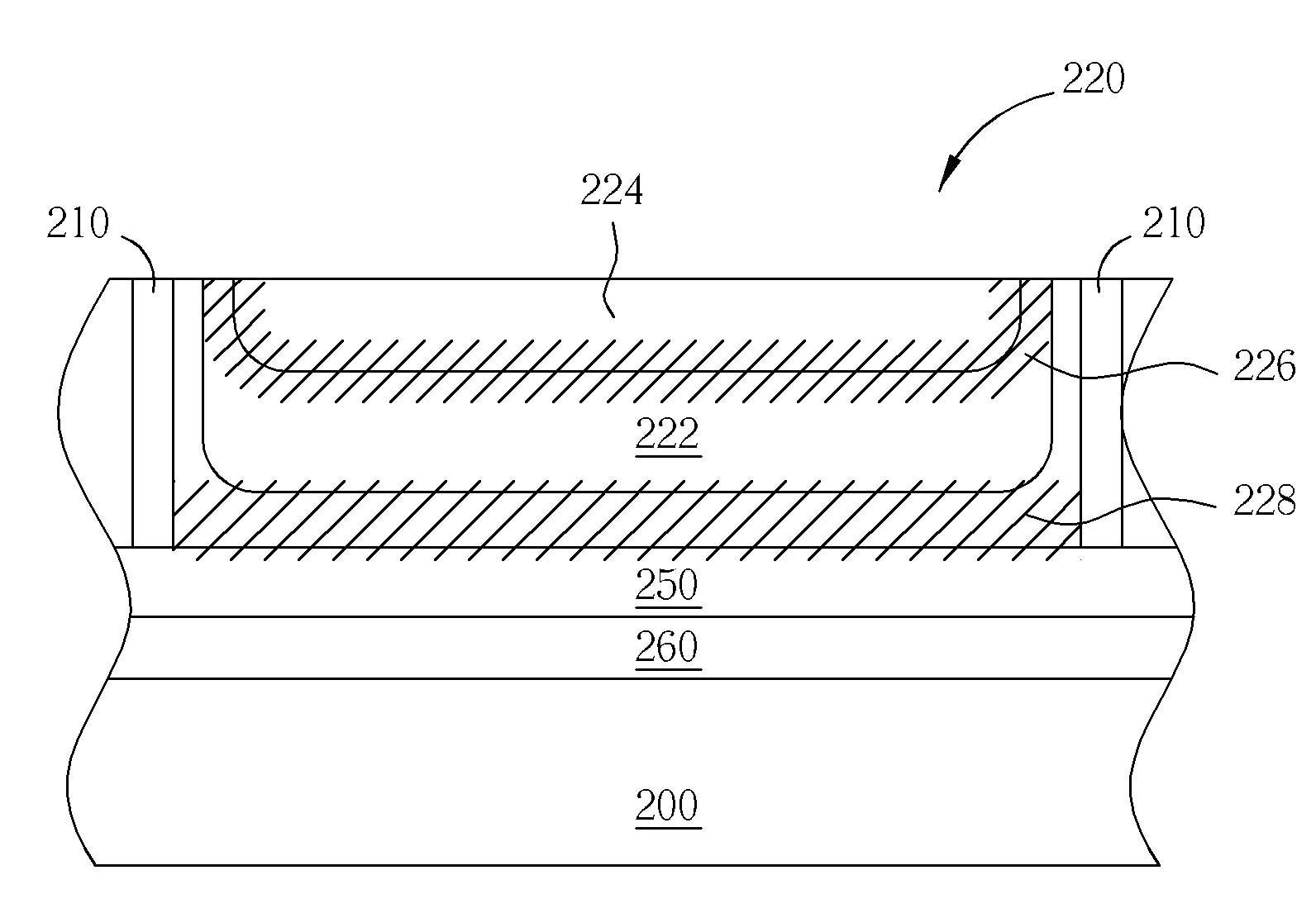

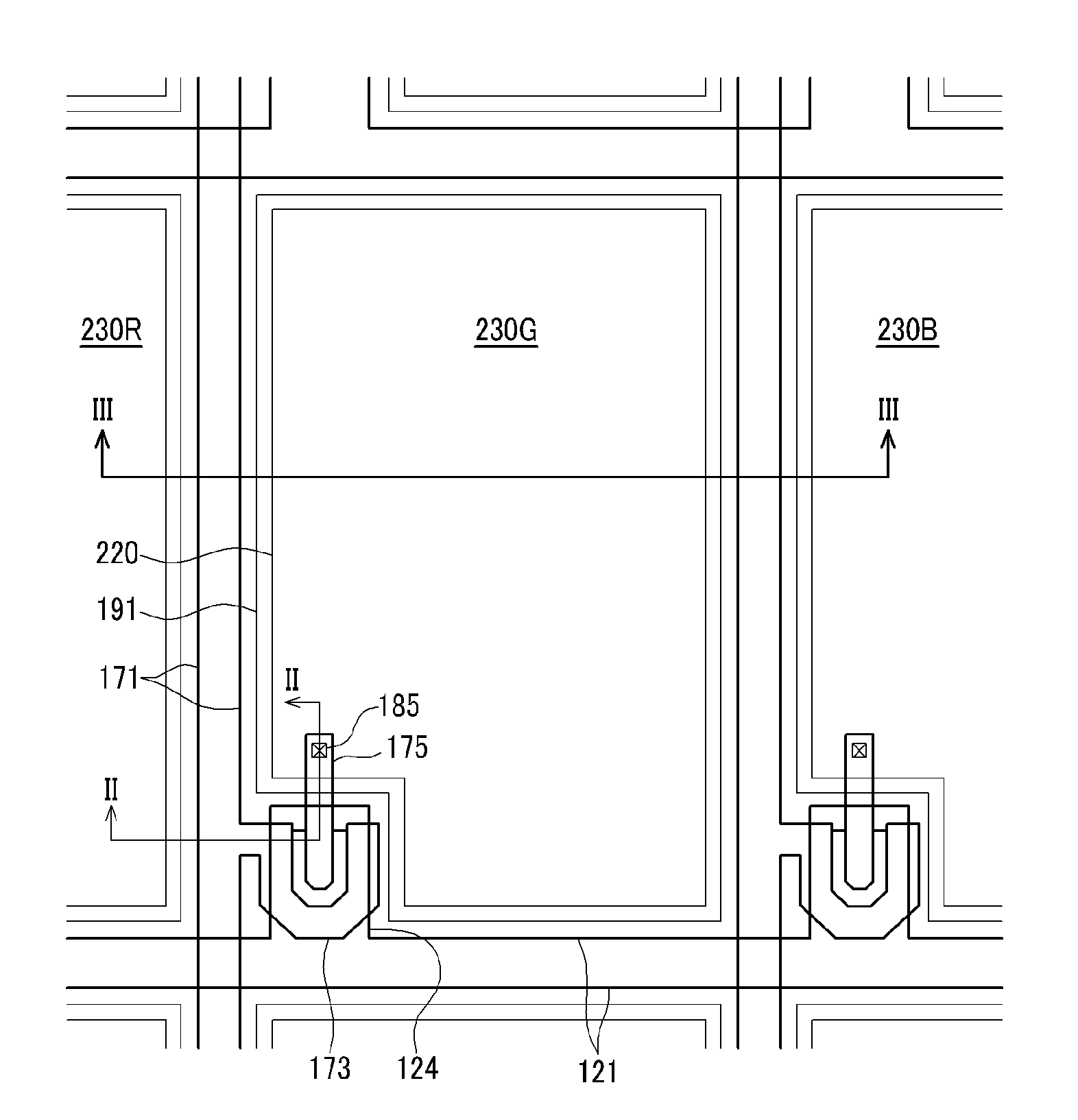

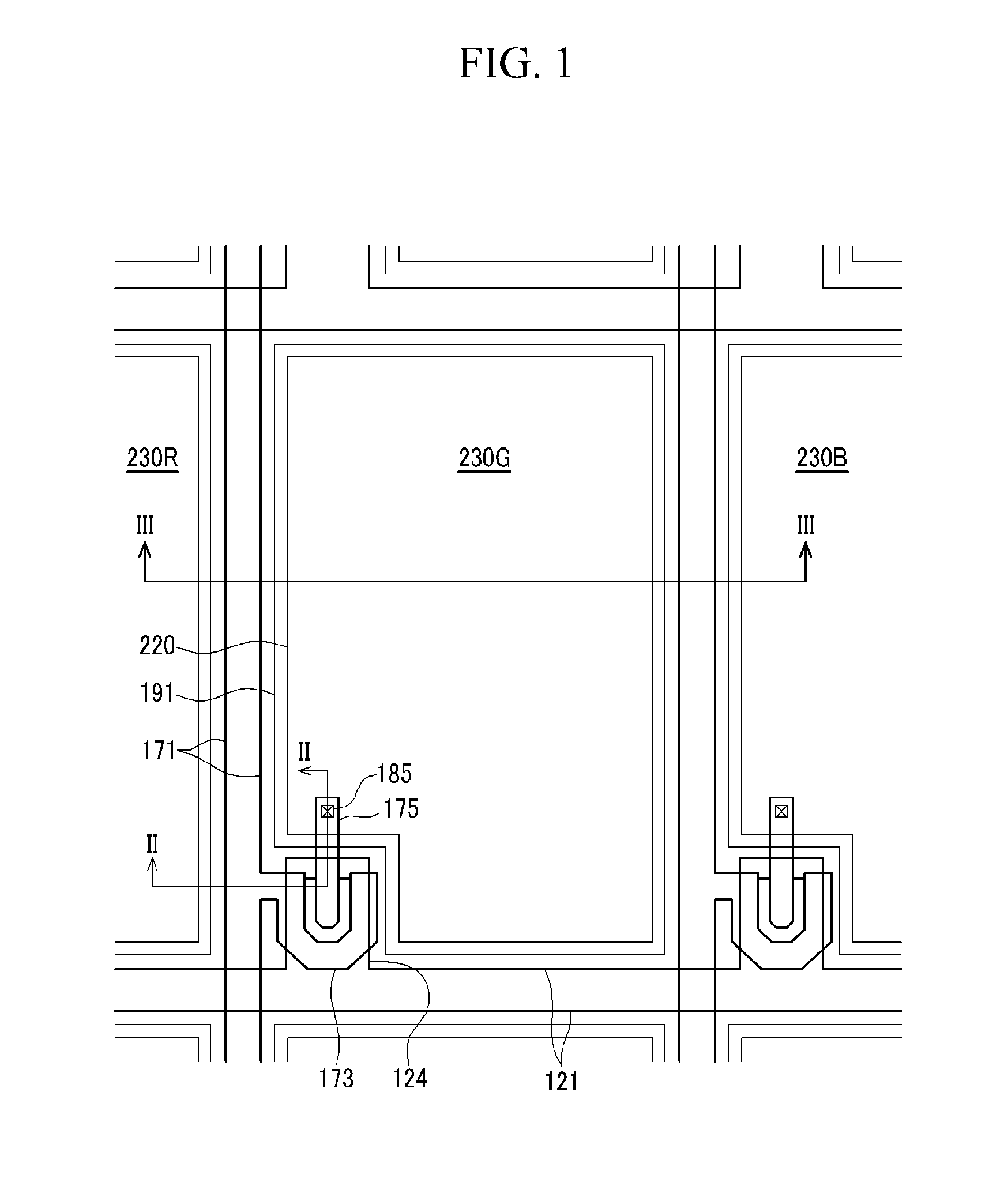

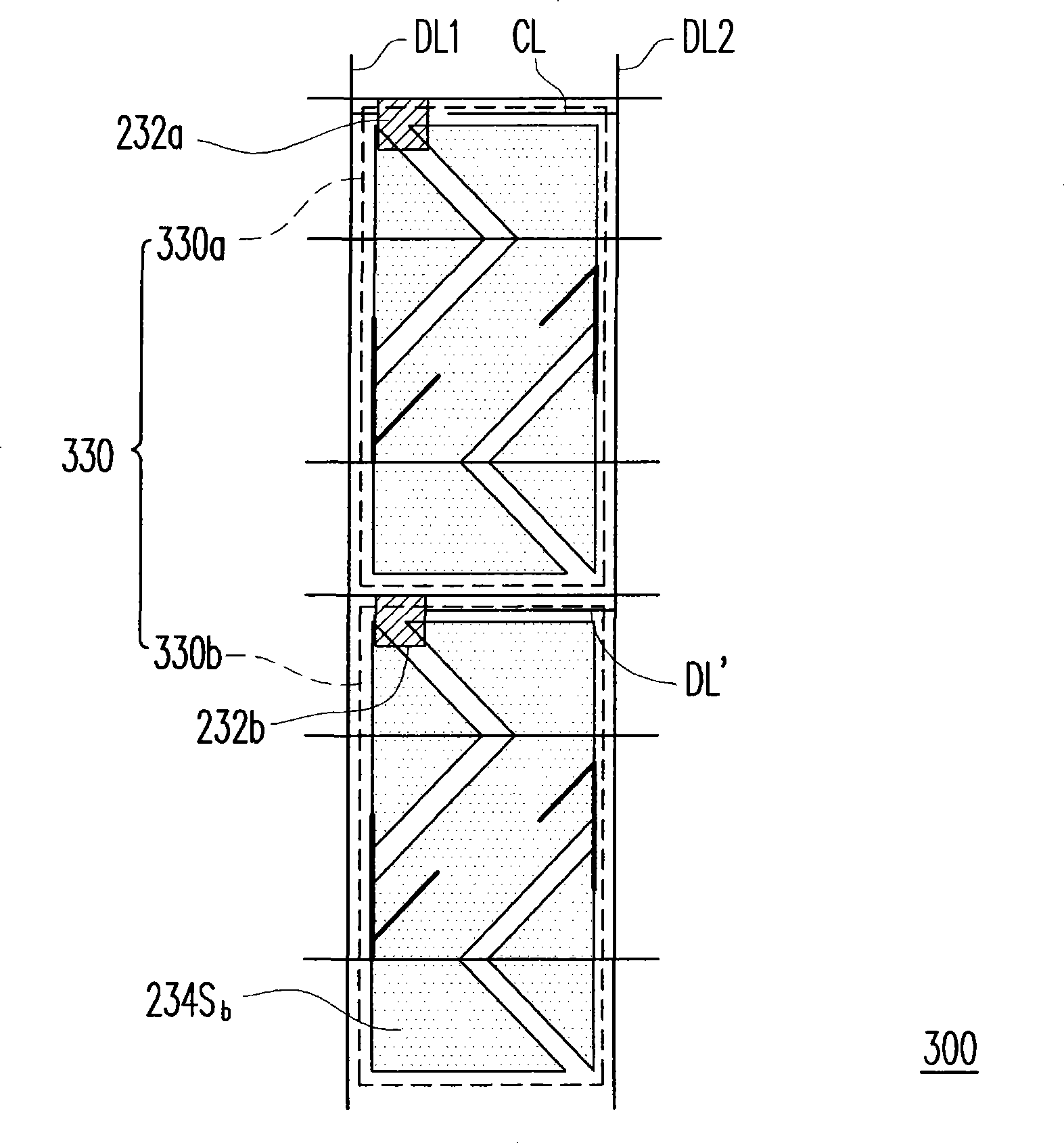

Array substrate, production method thereof, display panel, and display device

ActiveCN107256872AImprove crosstalkImprove afterimageSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringData lines

The invention provides an array substrate, a production method thereof, a display panel, and a display device, and relates to the display technology field. The array substrate comprises a substrate; an auxiliary shade layer, an insulation layer, a main shade layer, and a buffer layer, which are sequentially arranged in a direction away from the substrate. A plurality of grid lines and a plurality of data lines are used to form a plurality of pixel areas in a limited way, and thin film transistors are disposed in the pixel areas. The auxiliary shade layer comprises a plurality of first auxiliary shade parts, and the main shade layer comprises a plurality of main shade parts. The orthogonal projection of the channel areas of the active layers of the thin film transistors on the array substrate is disposed in the orthogonal projection of the main shade parts on the array substrate, and the orthogonal projection of the channel areas of the active layers of the thin film transistors on the array substrate is disposed in the orthogonal projection of the first auxiliary shade parts on the array substrate. By adopting the technical scheme provided by the invention, intensities of light irradiated on the channel areas of the active layers of the thin film transistors are reduced, and the light leakage flows of the thin film transistors are reduced.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

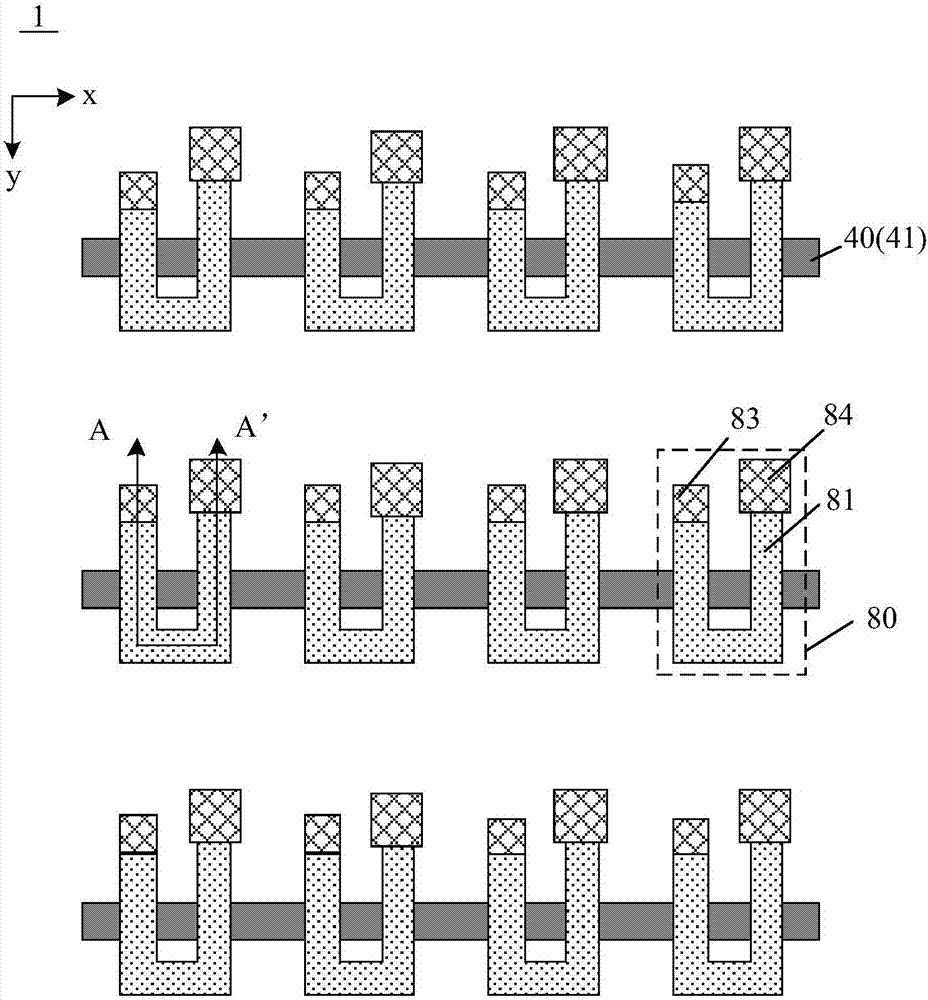

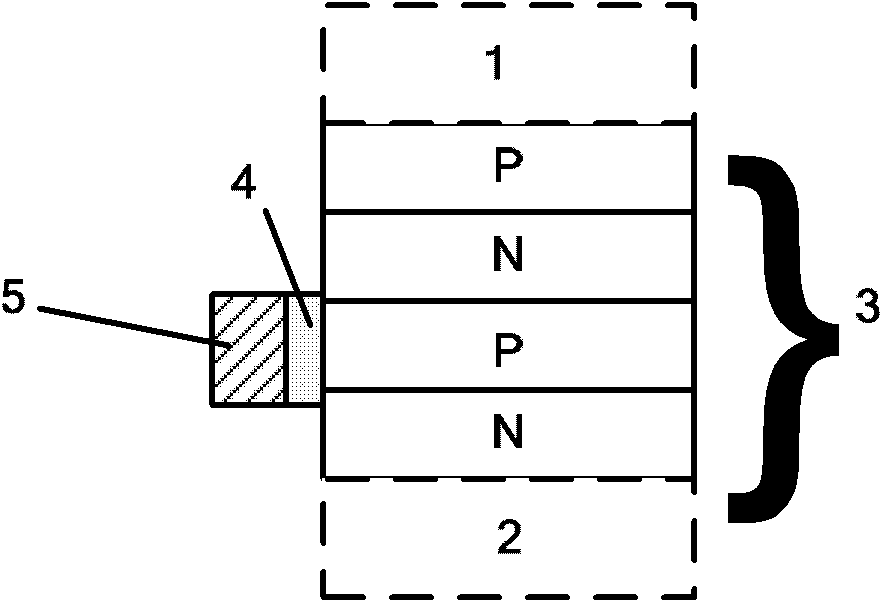

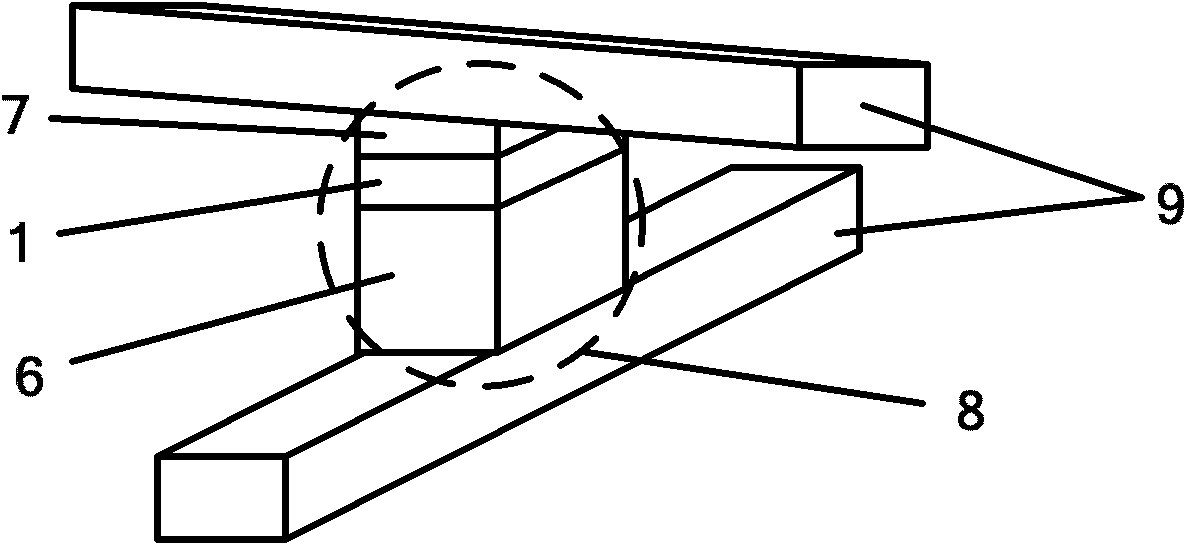

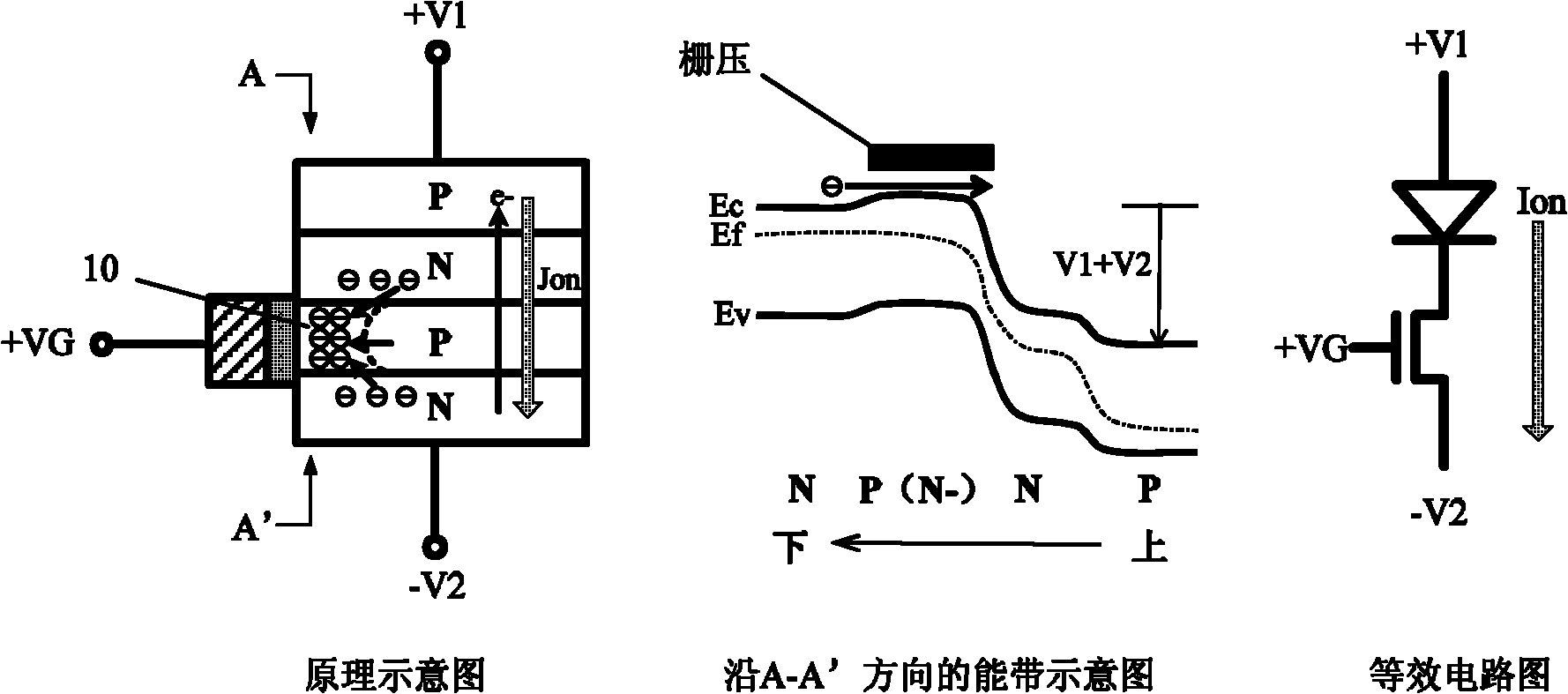

Three-dimensional storage device array structure and manufacturing method thereof

ActiveCN102306655ASimple structureGet rid of dependenceSolid-state devicesSemiconductor devicesElectricitySwitched current

The invention provides a three-dimensional storage device array structure and a manufacturing method thereof. The three-dimensional storage array is formed by the derivation of grid control PNPN vertical selection tubes connected in series mutually and a storage cell of a resistant transformation or phase transformation cell in a three-dimensional space. The cross interference and leakage of electricity problems between adjacent units of the storage array in operation are improved effectively through the storage cell with high switching current ratio, also the structure of the storage cell issimplified, the multi-layer stacking is realized, and the storage density is improved.

Owner:XIAMEN IND TECH RES INST CO LTD

Photodiode of an image sensor and fabricating method thereof

InactiveUS20090127643A1Increased sensitivityExcessive chargingSolid-state devicesSemiconductor/solid-state device manufacturingReflective layerPhotodiode

A method for fabricating a photodiode of an image sensor includes providing a substrate having a first conductive type and photo sensing regions, respectively forming photodiodes in the photo sensing region, and performing an ion implantation to form an implanted reflective layer having a second conductive type under the plurality of photodiodes for reflecting light and creating depletion regions in the substrate.

Owner:UNITED MICROELECTRONICS CORP

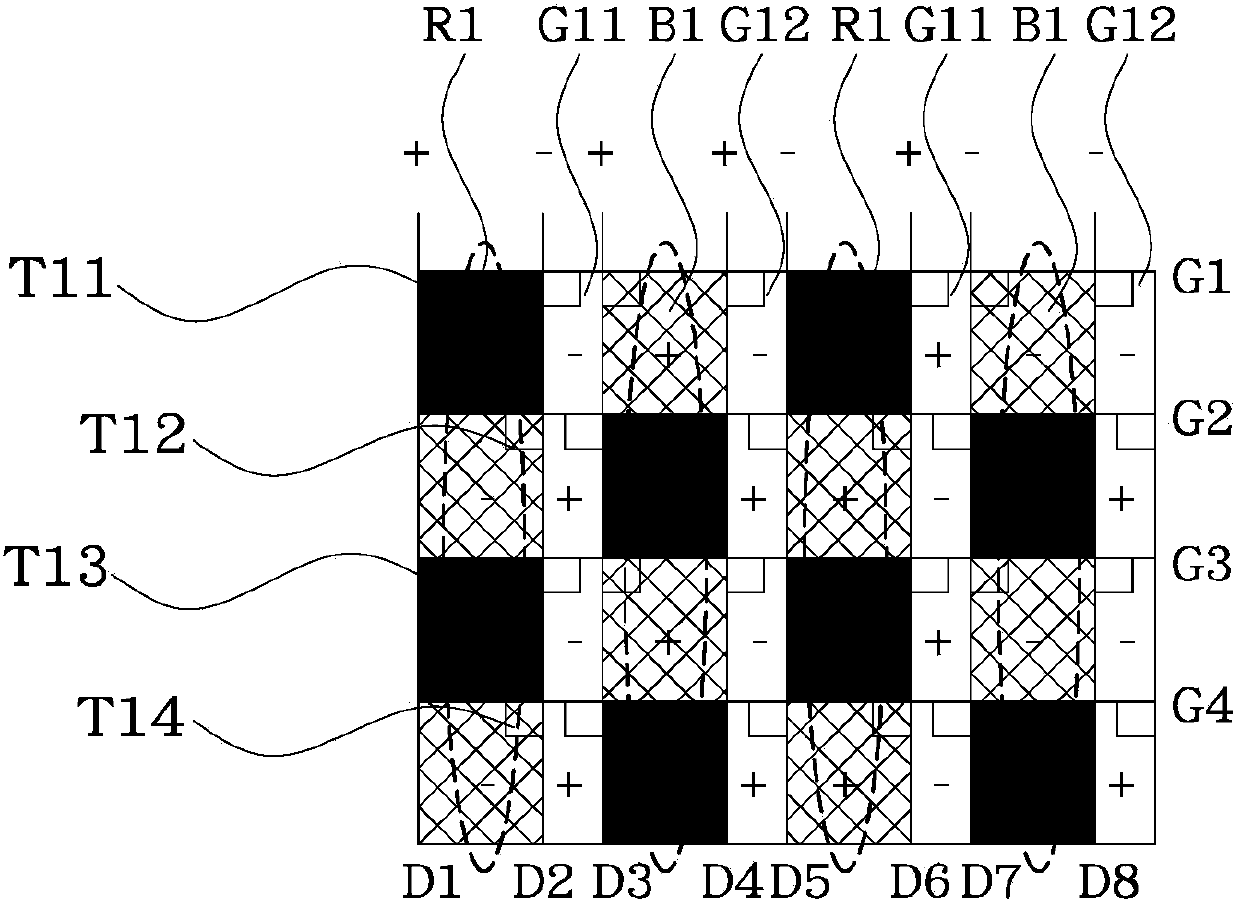

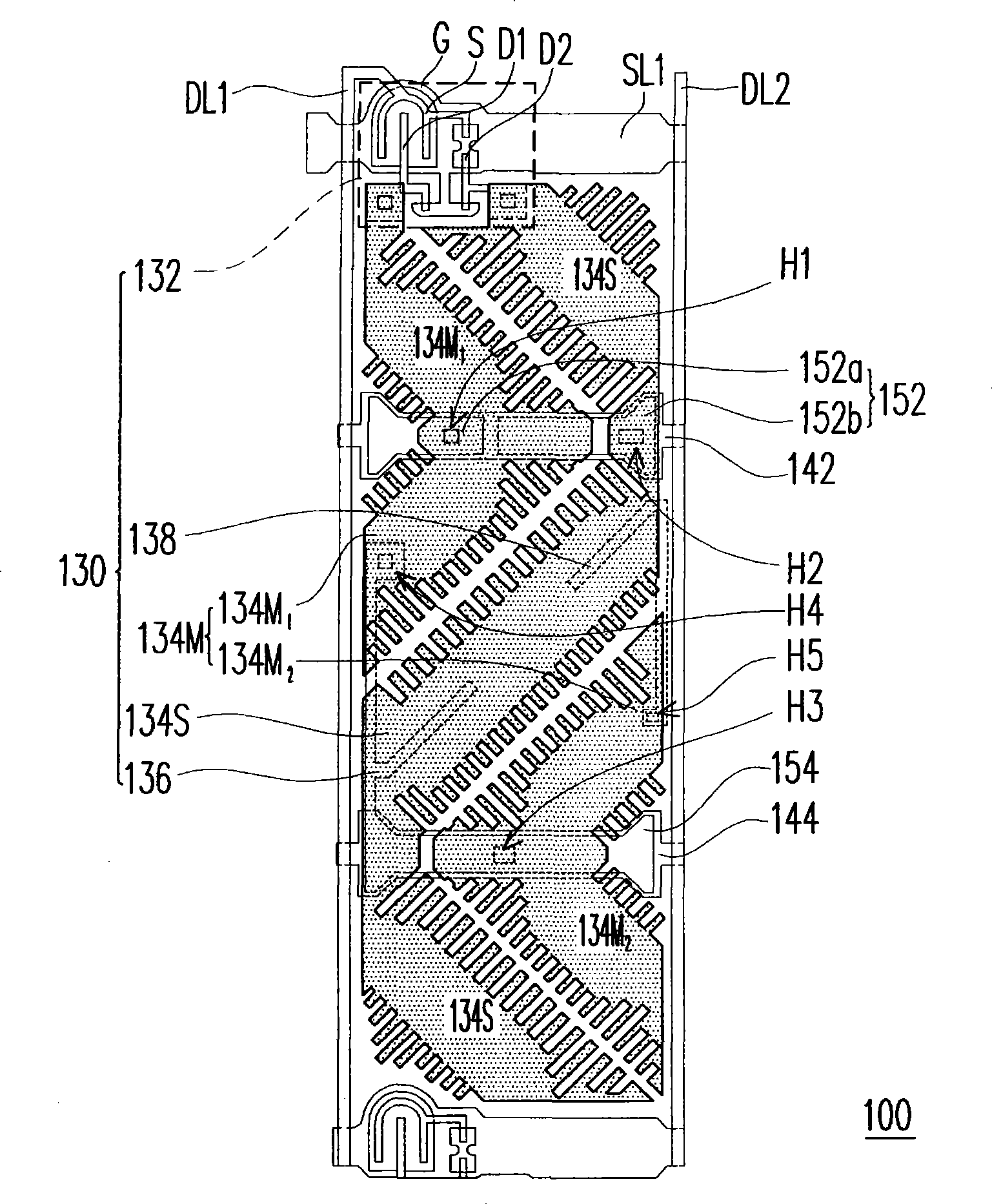

Pixel structure of liquid crystal display

InactiveCN104049396AReduce power consumptionImprove flickering and crosstalkStatic indicating devicesNon-linear opticsLiquid-crystal displayPixel array

The invention provides a pixel structure of a liquid crystal display. The pixel structure of the liquid crystal display is a pixel array with the dimension of 4M * 8N, odd number lines are provided with multiple repeated first pixel sets, and even number lines are provided with multiple repeated second pixel sets. Each pixel set comprises sub pixels of at least three colors. At least one line of pixels comprises sub pixels of two or more colors. The thin film transistors corresponding to all the sub pixels of the jth line of the front 2M lines are all connected to the jth data line in an electric coupling mode, the thin film transistors corresponding to all the sub pixels of the jth line of the rear 2M lines are all connected to the (j+1)th data line in an electric coupling mode, and all the sub pixels in the same line form a Zig-Zag arrangement. Compared with the prior art, the positions of the thin film transistors are adjusted to enable the thin film transistors corresponding to the sub pixels of each line to be connected to different data lines in the electric coupling mode, a low power consumption polarity overturn mode is matched, the flicker and crosstalk of a panel are improved effectively, and the display quality of the panel is improved.

Owner:AU OPTRONICS CORP

Light transmission/reception module and light transmission/reception device

InactiveUS20070086708A1Increase capacitanceImprove crosstalkLaser detailsSemiconductor laser structural detailsElectricityTransceiver

Providing an optical transceiver module that reduces electric crosstalk between a light emitting device and a photodetector while providing an excellent high-frequency characteristic, and an optical transceiver including the same. According to the invention, a first metal plate having a first substrate for mounting a light emitting device and a at second metal plate having a second substrate for mounting a photodetector are provided separately and independently of each other in a resin package, thus reducing the parasitic capacitance. This provides an optical transceiver module capable of suppressing electric crosstalk where part of a high-frequency signal causes a variation in the potential at a terminal of a photodetector while improving the high frequency characteristic in driving the light emitting device with a high-frequency signal, and an optical transceiver including the same.

Owner:PANASONIC CORP

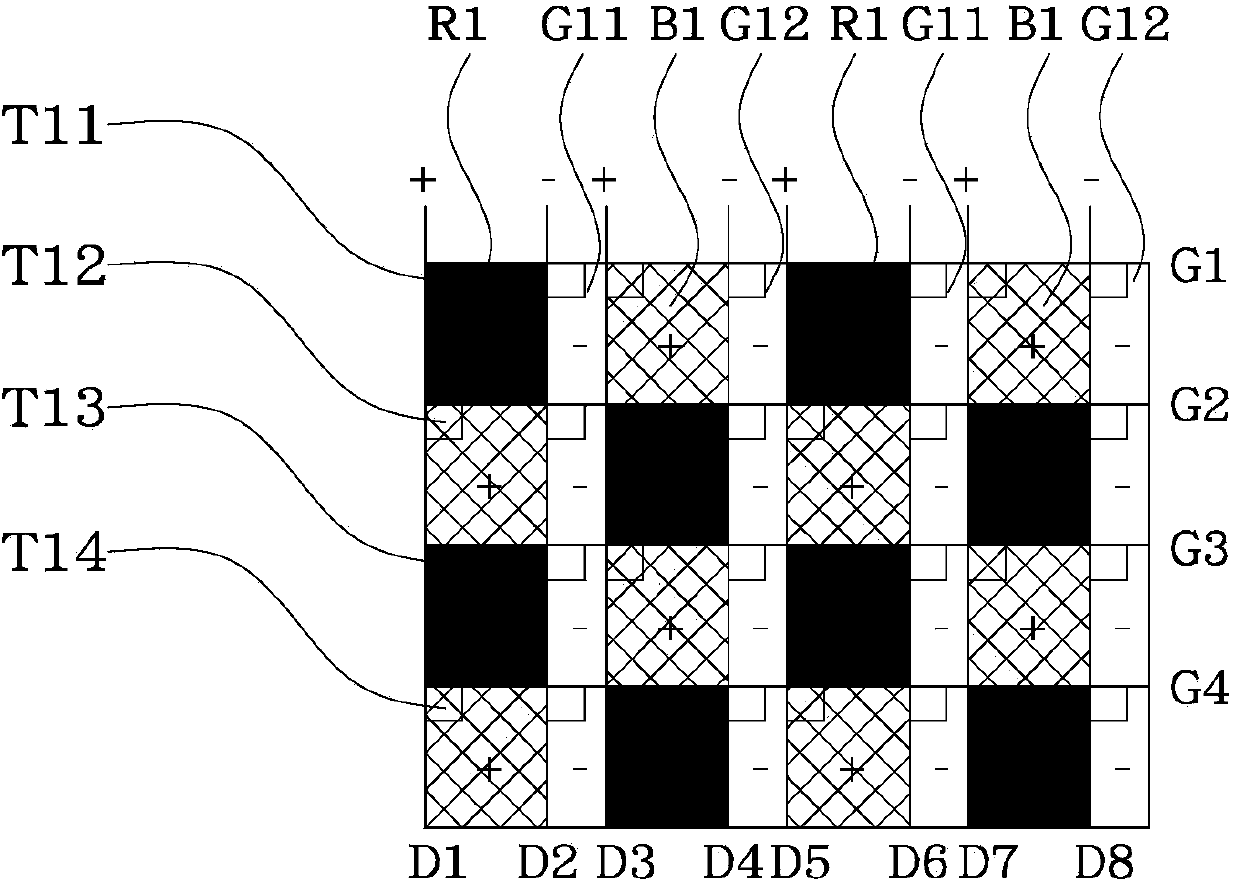

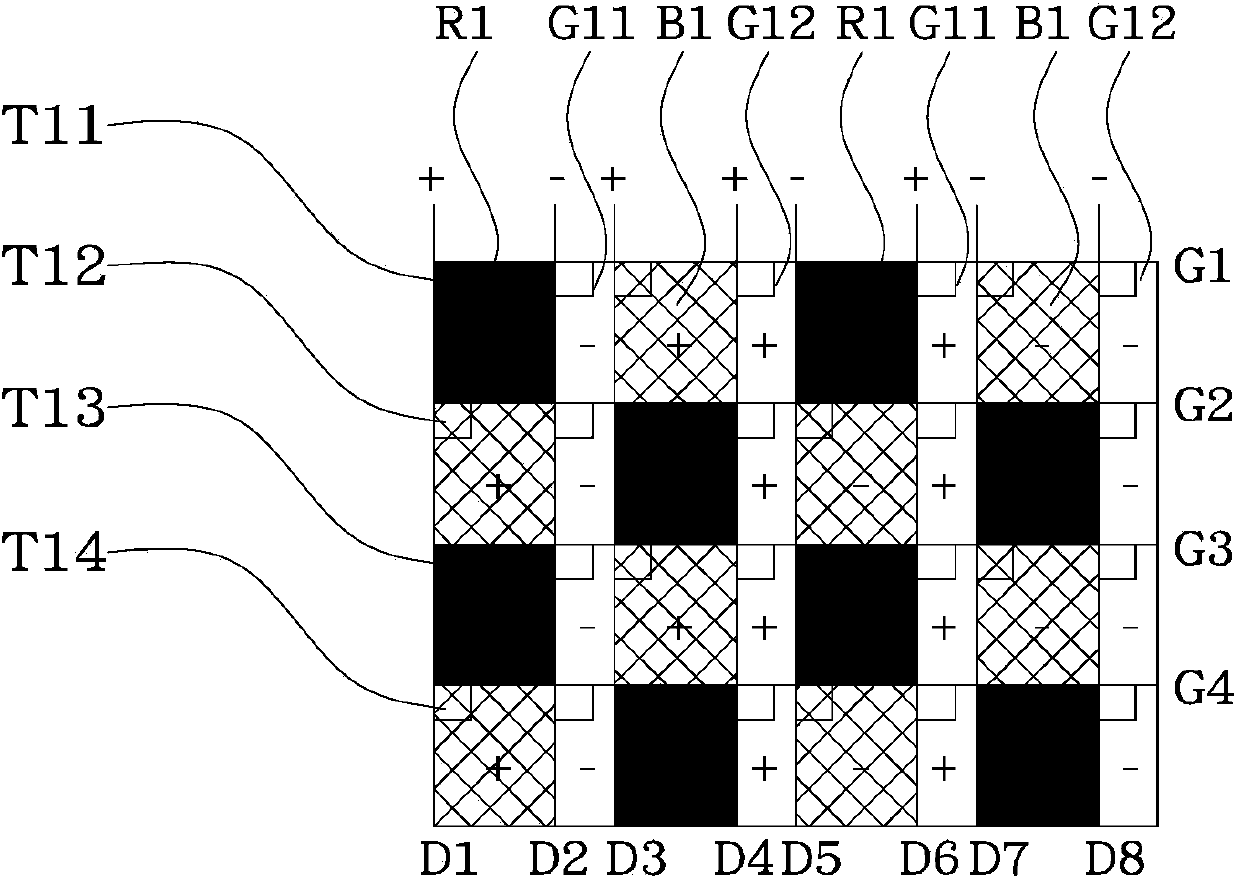

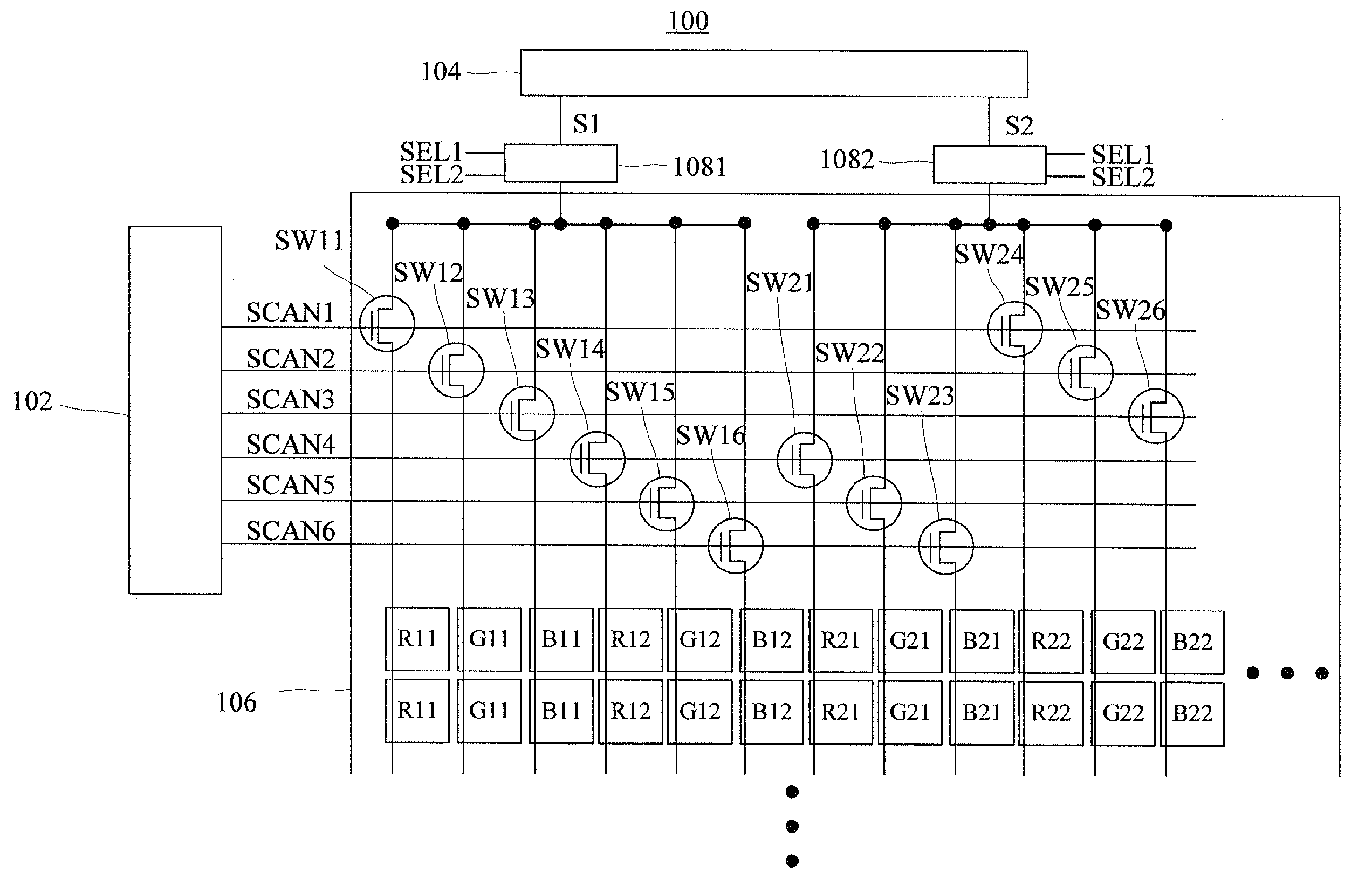

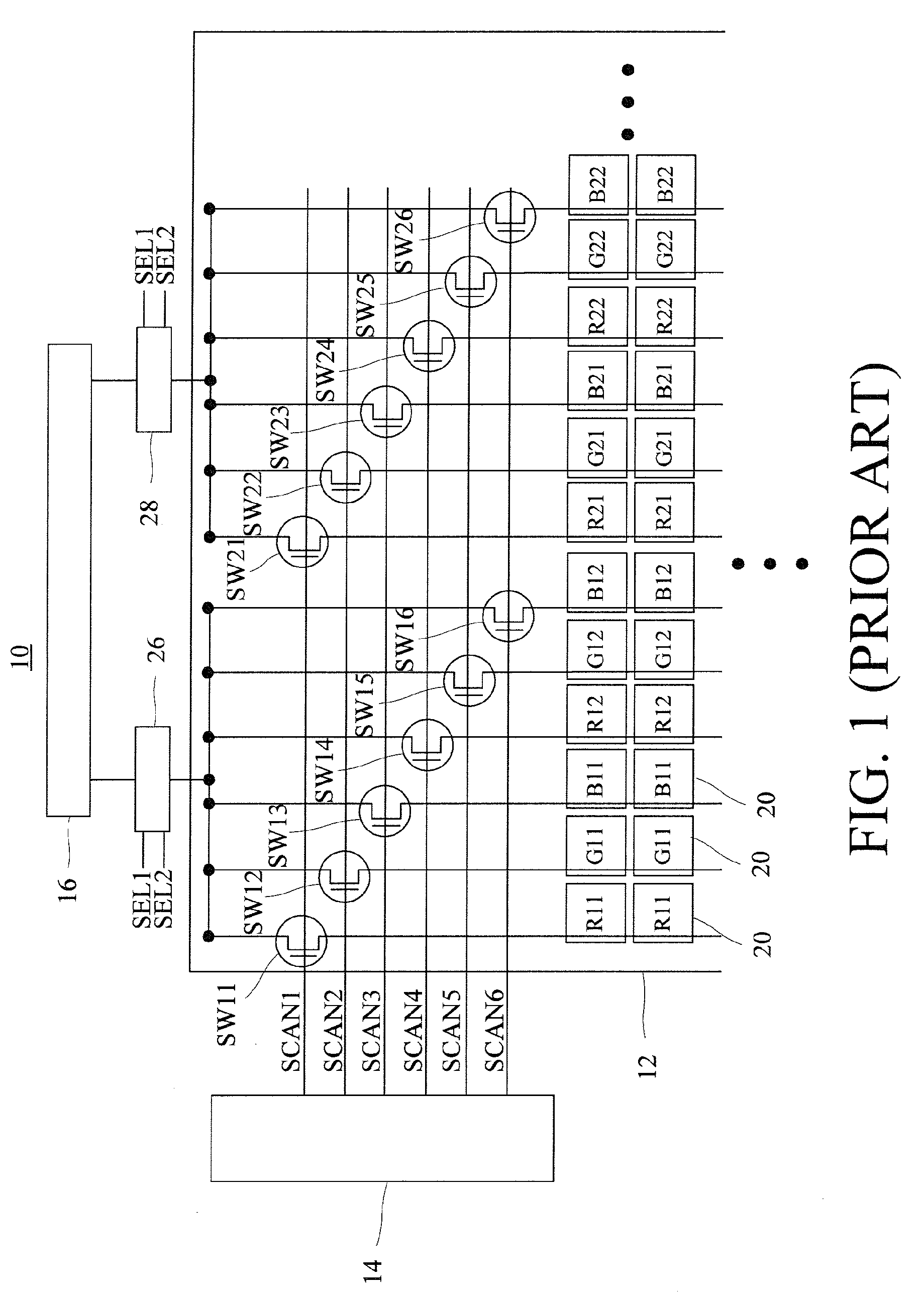

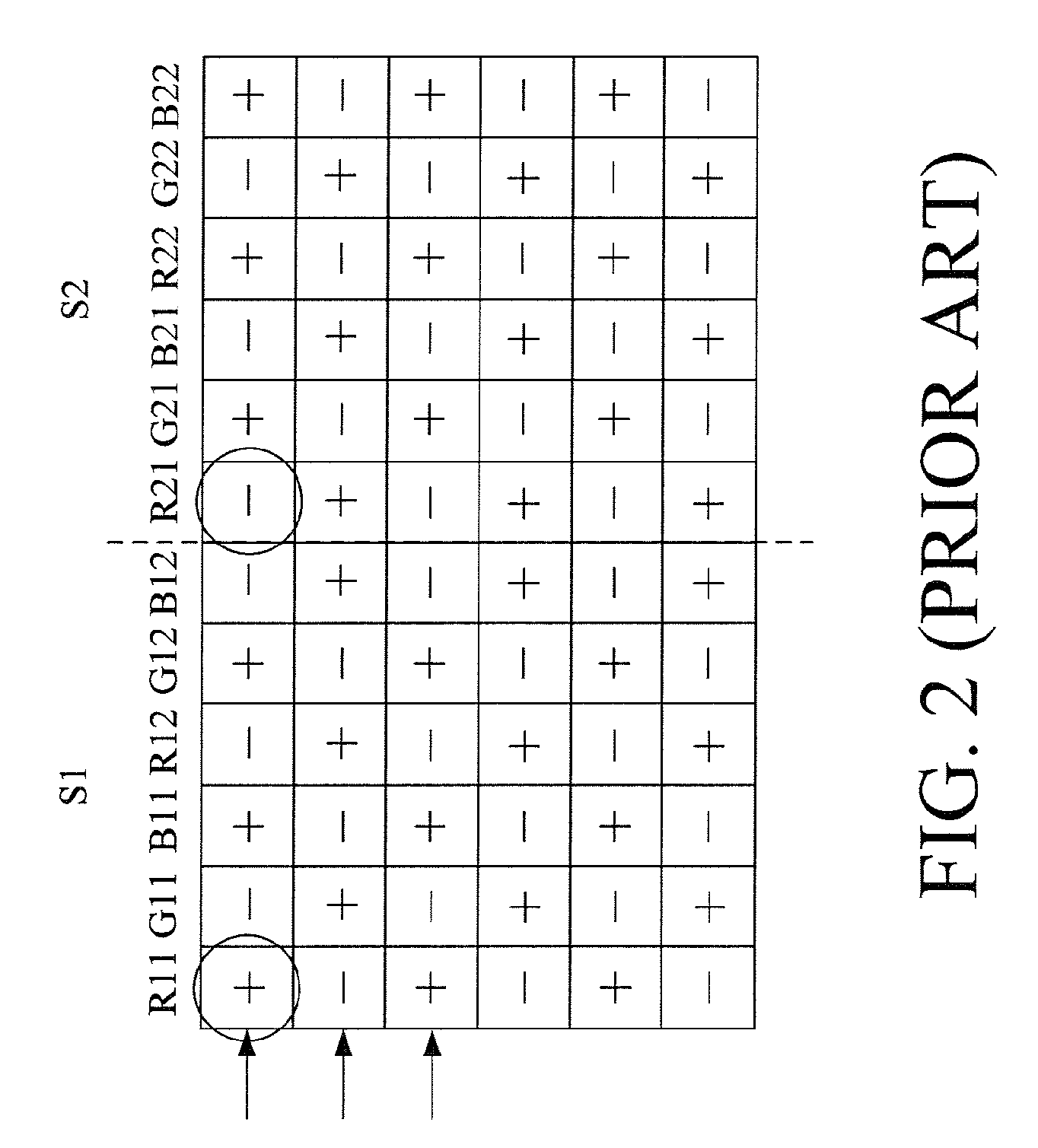

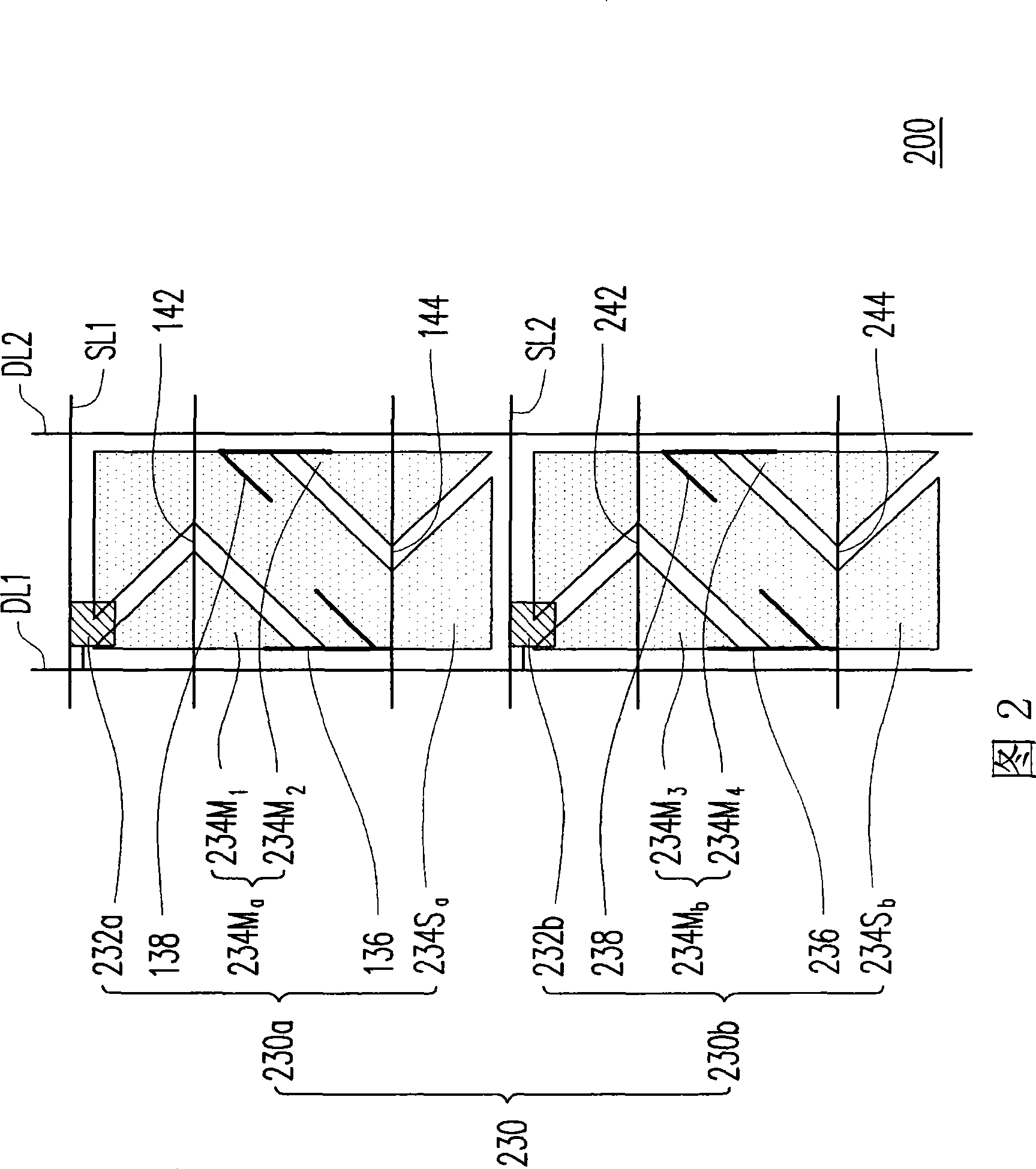

Data multiplexer architecture for realizing dot inversion mode for use in a liquid crystal display device and associated driving method

ActiveUS20090231363A1Improve crosstalkCathode-ray tube indicatorsInput/output processes for data processingLiquid-crystal displayGray level

A liquid crystal display device includes a gate driver for generating a first scan signal voltage and a second scan signal voltage, a source driver for generating a first polarity data voltage and a second polarity data voltage, and a liquid crystal display panel having a first pixel set and a second pixel set. Each first and second pixel set includes a first pixel and a second pixel. Both the first pixel of the first pixel set and the second pixel of the second pixel set display grey level based on the first polarity data voltage in response to the first scan signal voltage. Both the second pixel of the first pixel set and the first pixel of the second pixel set display grey level based on the second polarity data voltage in response to the second scan signal voltage.

Owner:AU OPTRONICS CORP

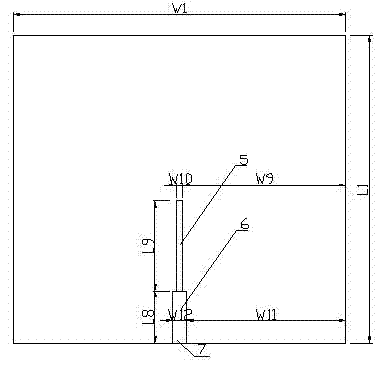

Novel dual-frequency and polarization reconfigurable antenna

InactiveCN102832450AReduce designSimple designSimultaneous aerial operationsRadiating elements structural formsCapacitanceDual frequency

The invention relates to a novel dual-frequency and polarization reconfigurable antenna which comprises a three-layer structure: a big metal layer, a small metal layer, a radio-frequency PIN diode and capacitors are arranged on the front, a medium plate layer and an input port are arranged at the middle, and a metal feeder line is arranged on the back of the medium plate layer, wherein in the metal layer, a square spiral big gap and a right-angle small gap are etched on the whole metal surface to form a big metal layer and a small metal layer. Meanwhile, the radio-frequency PIN diode and two blocking capacitors are bridged on the big and small gaps, thus the reconfigurable function is realized by controlling the working state of the diode. The reconfigurable antenna provided by the invention can work on two mainstream wireless communication frequency bands of 1.6GHz and 3.0GHz, and is in a right-handed circular polarization state on 1.6GHz and a linear polarization state on 3GHz. The antenna has relatively great bandwidth on the two working frequency bands. With the characteristics, the antenna provided by the invention has great prospects in engineering application.

Owner:SHANGHAI UNIV

Display panel, manufacturing method thereof and display device

PendingCN111508977AImprove crosstalkGuaranteed stabilityStatic indicating devicesSolid-state devicesDisplay deviceHemt circuits

The invention provides a display panel, a manufacturing method of the display panel and a display device, relates to the technical field of the display. The invention aims to solve the problem that the voltage jump of a data signal in the display panel drives the grid voltage of a driving transistor to change through a parasitic capacitor, so that the brightness of a part of area of the display panel is abnormal. In a sub-pixel driving circuit of the display panel, a grid electrode of a driving transistor is coupled with a second electrode of a second transistor through a fourth conductive connecting part, and a second polar plate of a storage capacitor is coupled with a second electrode of a first transistor through a third conductive connecting part; a grid electrode of the first transistor and a grid electrode of the second transistor are respectively coupled with the grid line patterns in the corresponding sub-pixel regions; the orthographic projections of the grid line patterns onthe substrate are not overlapped with the orthographic projection of the third conductive connecting part on the substrate, and / or the orthographic projections of the grid line patterns on the substrate is not overlapped with the orthographic projection of the fourth conductive connecting part on the substrate. The display panel provided by the invention is used for displaying pictures.

Owner:BOE TECH GRP CO LTD

Common voltage calibration circuit, circuit board and display device

ActiveCN107578752AAchieve precision controlImprove stabilityStatic indicating devicesDisplay deviceEngineering

The embodiment of the invention discloses a common voltage calibration circuit, a circuit board and a display device and relates to the technical field of display. The precision and stability degree of common voltage which is actually input to a common electrode can be improved. The common voltage calibration circuit comprises a differencing module, an integral module, a compensation module and asummation module; the input end of the differencing module is connected with the input end of the common voltage and the feedback end of the common voltage, the differencing module is used for acquiring a voltage difference value of the input end of the common voltage and the feedback end of the common voltage, and the voltage difference value is output through the output end; the input end of theintegral module is connected with the output end of the differencing module, the output end of the integral module is connected with the input end of the summation module, and the integral module isused for controlling the precision of the common voltage; the input end of the compensation module is connected with the output end of the differencing module, the output end of the compensation module is connected with the input end of the summation module, and the compensation module is used for compensating the common voltage; the output end of the summation module is connected with the outputend of the common voltage, and the summation module is used for overlapping and outputting results output by the integral module and the compensation module.

Owner:BOE TECH GRP CO LTD +1

Integrated data cable for power and data transmission

ActiveCN104008797AExtended service lifeImprove balancePower cables with screens/conductive layersInsulated cablesPolyesterCopper conductor

The invention discloses an integrated data cable for power and data transmission. A first insulating layer covers power copper conductors. An inner sheath layer covers the first insulating layer. A second insulating layer covers data copper conductors. A single-face aluminum foil layer covers the second insulating layer. The inner sheath layer and the single-face aluminum foil layer are located on the two sides of a partition plate respectively. A first side tail wing part, the partition plate and a second side tail wing part are sequentially connected. The first side tail wing part and the second side tail wing part are located on the two sides of the partition plate. A polyester belt layer covers the inner sheath layer, the single-face aluminum foil layer, the partition plate, the first side tail wing part and the second side tail wing part. A double-face aluminum foil layer covers the polyester belt layer. A flame retarding layer covers the double-face aluminum foil layer. By the adoption of the mode, the integrated data cable has long service life, higher balance and reliability, reflection and absorption of high-frequency electromagnetic waves are improved, crosstalk and signal attenuation are improved; meanwhile, crosslinking strength of a base material is enhanced, and the integrated data cable has good physical mechanical performance such as tensile strength and tearing strength.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

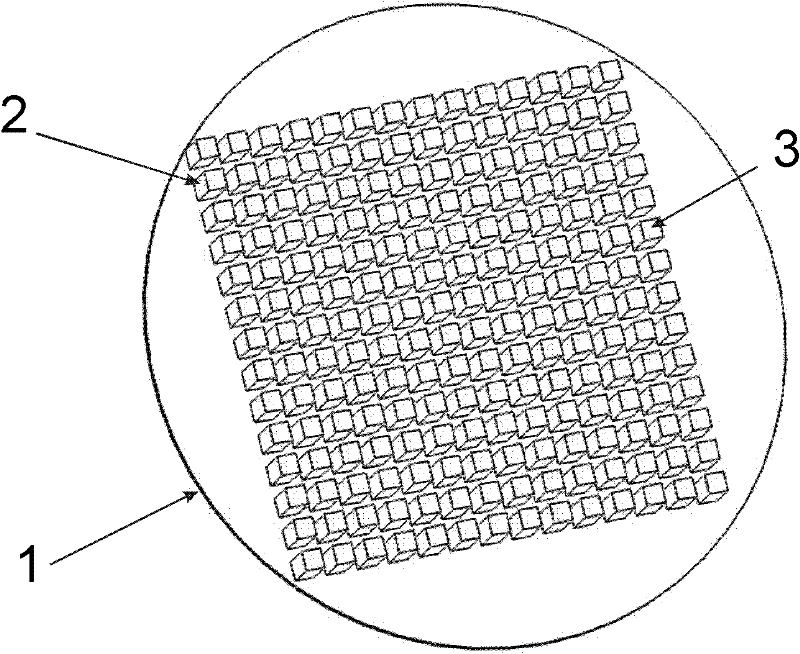

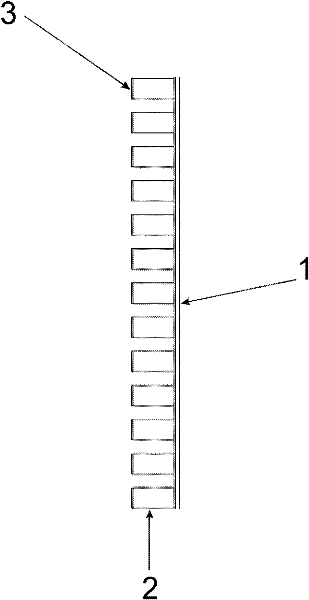

Fiber array dynamic infrared scene generation apparatus based on MEMS technology

InactiveCN102520334ASimple processImprove controllabilitySolid-state devicesFluid speed measurementOptical pathFiber array

The invention relates to a fiber array dynamic infrared scene generation apparatus based on a MEMS technology and belongs to a dynamic infrared scene generation technology field. By using the apparatus of the invention, conversion from a visible light image to an infrared image can be realized. Purposes of greatly increasing a performance index of the dynamic infrared image generation apparatus and reducing cost can be reached. The apparatus comprises: a substrate, a fiber array formed by pixel columns and a visible light absorption infrared radiation layer of a pixel column top. A substrate material can use transparent glasses or silicon according to different optical path designs. The fiber array is made on the substrate by using a MEMS technology. The pixel columns forming the fiber array are mutually independent and can be taken as an imaging unit. A visible light absorption infrared radiation film is made on the each pixel column top. The visible light absorption infrared radiation film absorbs energy of the incident visible light image, radiates outwards the infrared light after the temperature is increased and generates the infrared image corresponding to the visible light image.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Liquid crystal display with UV or blue light blocking filter

ActiveUS8817207B2Improve efficiencyReduces and substantially prevents cross talkNon-linear opticsLiquid-crystal displayUltraviolet lights

A liquid crystal display including a first substrate; a light-blocking member disposed on the first substrate; an emission layer disposed on the first substrate; an ultraviolet-light blocking filter disposed on the emission layer; a lower polarizer disposed on the ultraviolet-light blocking filter; a gate line and a data line disposed on the lower polarizer and substantially perpendicular to each other; a thin film transistor electrically connected to the gate line and the data line; a pixel electrode electrically connected to the thin film transistor; a second substrate disposed facing the first substrate; a common electrode disposed on the second substrate; and a liquid crystal layer interposed between the first substrate and the second substrate.

Owner:SAMSUNG DISPLAY CO LTD

Pixel array of LCD

ActiveCN101387803AImprove crosstalkReduce stray capacitanceNon-linear opticsCapacitanceLiquid-crystal display

The invention discloses a pixel array of liquid crystal display devices, comprising M data lines, N scan lines and a plurality of pixel structures electrically connected with the data lines and the scan lines and arranged in an array, wherein each pixel structure comprises a switch component, at least one main pixel electrode, at least one pixel electrode, a first capacity coupling electrode pattern and a second coupling electrode pattern, the switch component is electrically connected with the first scan line and the first data line, at least one main pixel electrode and at least one pixel electrode are electrically connected with the switch component, the first and the second capacitor coupling electrode patterns are electrically connected with at least one main pixel electrode and are coupled with at least one pixel electrode in a capacitor type, the first capacitor coupling electrode pattern is adjacent to the first data line and the second capacitor coupling electrode pattern is adjacent to the second data line.

Owner:AU OPTRONICS CORP

Electronic substrate and structure for connector connection thereof

InactiveUS9433094B2Reduce parasitic capacitanceImprove crosstalkHigh frequency circuit adaptationsCoupling device detailsEngineeringElectrical and Electronics engineering

Owner:NEC CORP

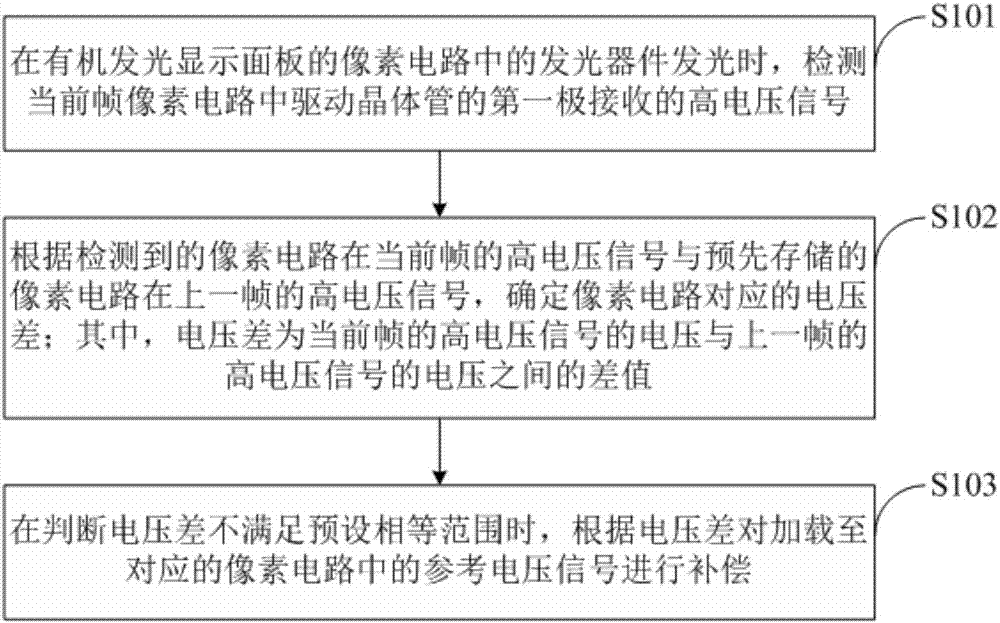

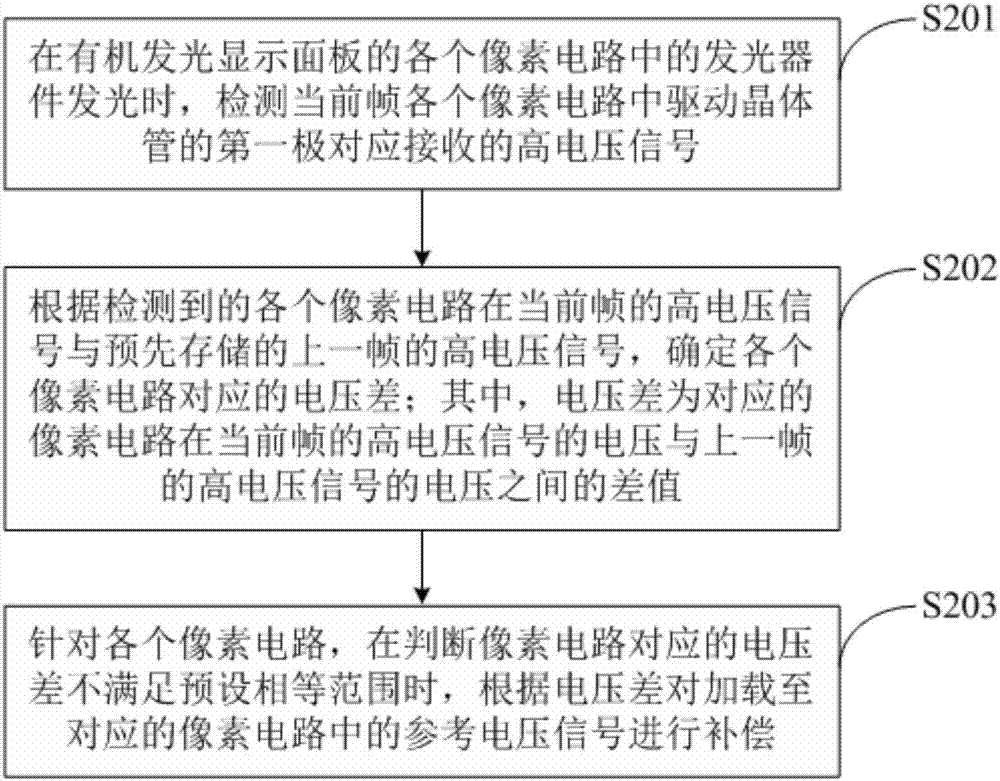

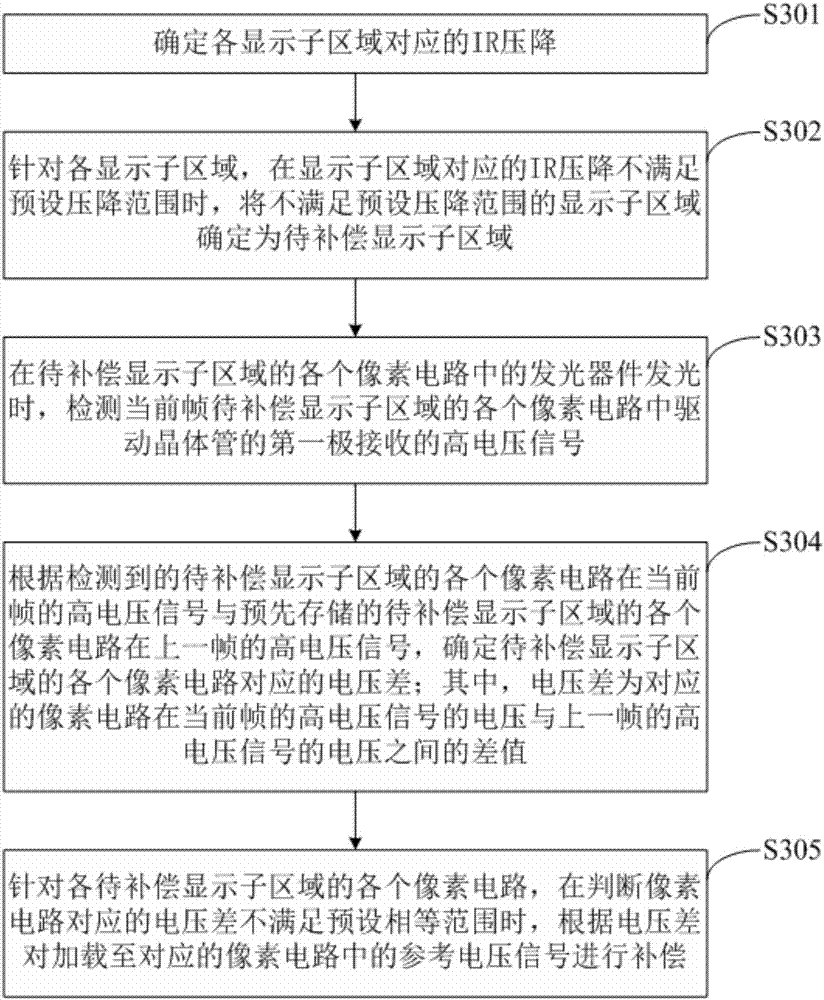

Compensation method and device for organic light emitting display panel

ActiveCN107103879AImprove crosstalkImprove the display effectStatic indicating devicesVoltage referenceLight emitting device

The invention discloses a compensation method and device for an organic light emitting display panel, and an organic light emitting display panel. When a light emitting device in a pixel circuit in the current frame emits light, the high voltage signal received by a first pole of a driving transistor in the pixel circuit in the current frame is detected, wherein the high voltage signal is a signal which the driving transistor in the current frame is used for generating current to drive the connected light emitting device. Then the voltage difference between the high voltage signals received in the current frame and the previous frame by the driving transistor is determined based on the detected high voltage signal of the current frame in the pixel circuit and the pre-stored high voltage signal of the previous frame in the pixel circuit. A reference voltage signal applied to the pixel circuit is compensated based on the voltage difference when it is judged that the voltage difference does not satisfy the preset equal range, thereby solving the problem that the user is touching the moving picture to cause crosstalk of the screen, and further improving the screen display effect.

Owner:BOE TECH GRP CO LTD

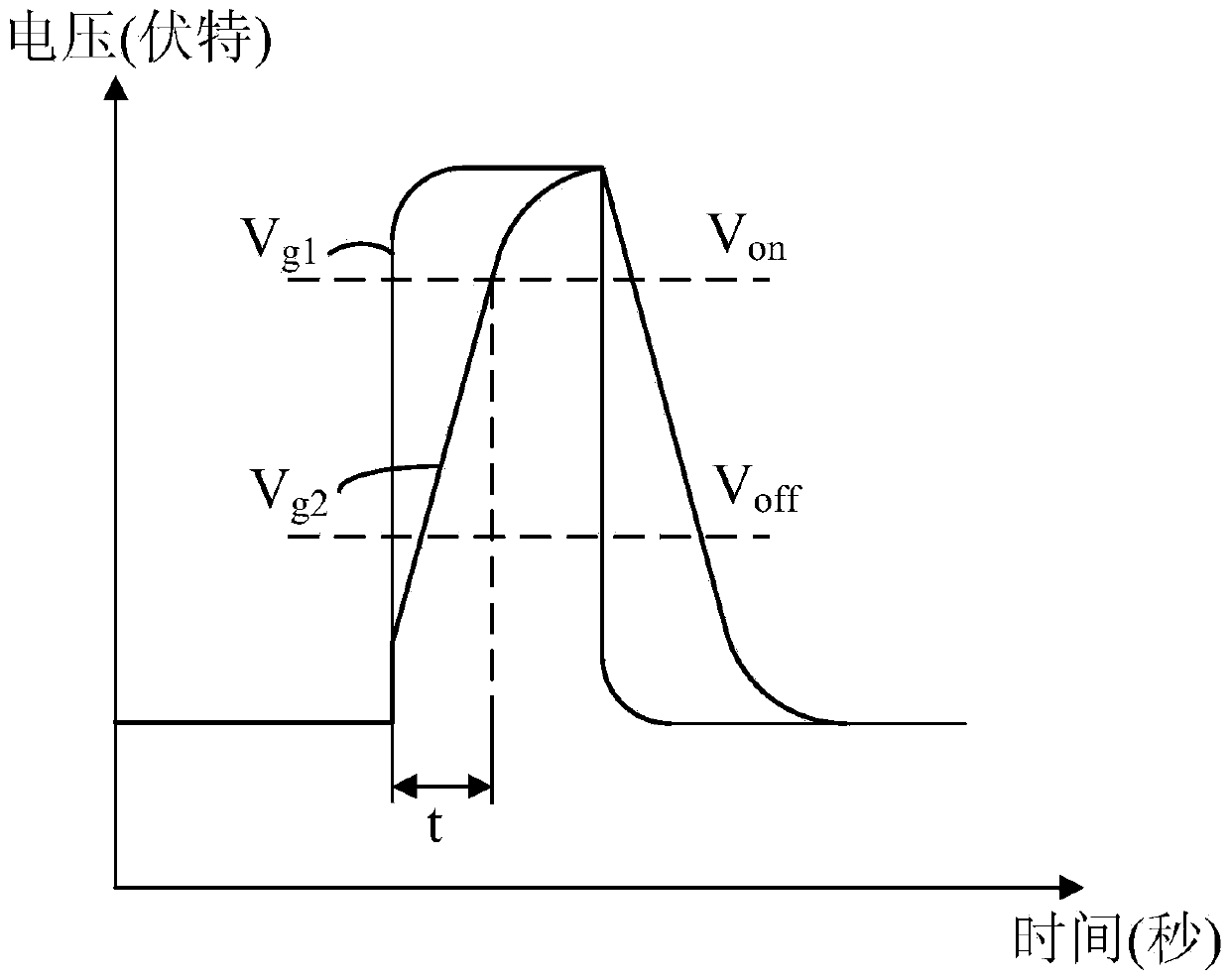

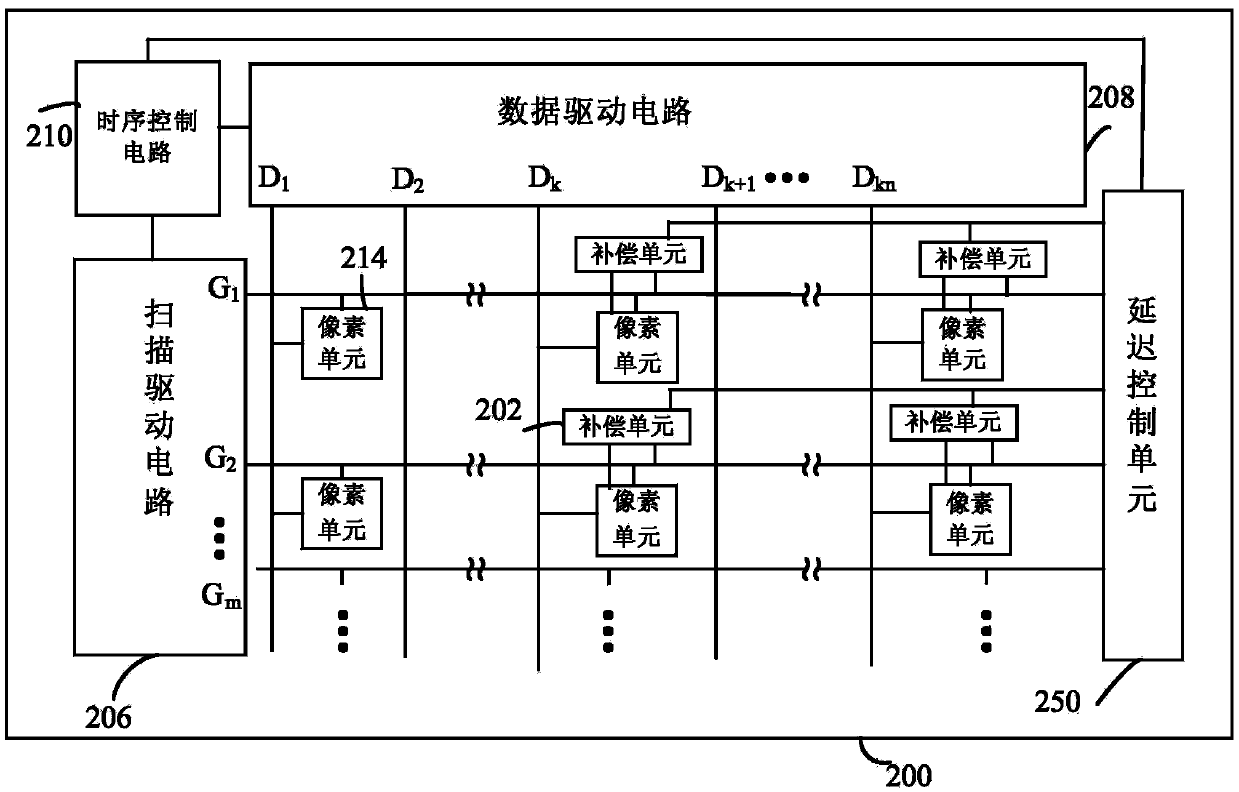

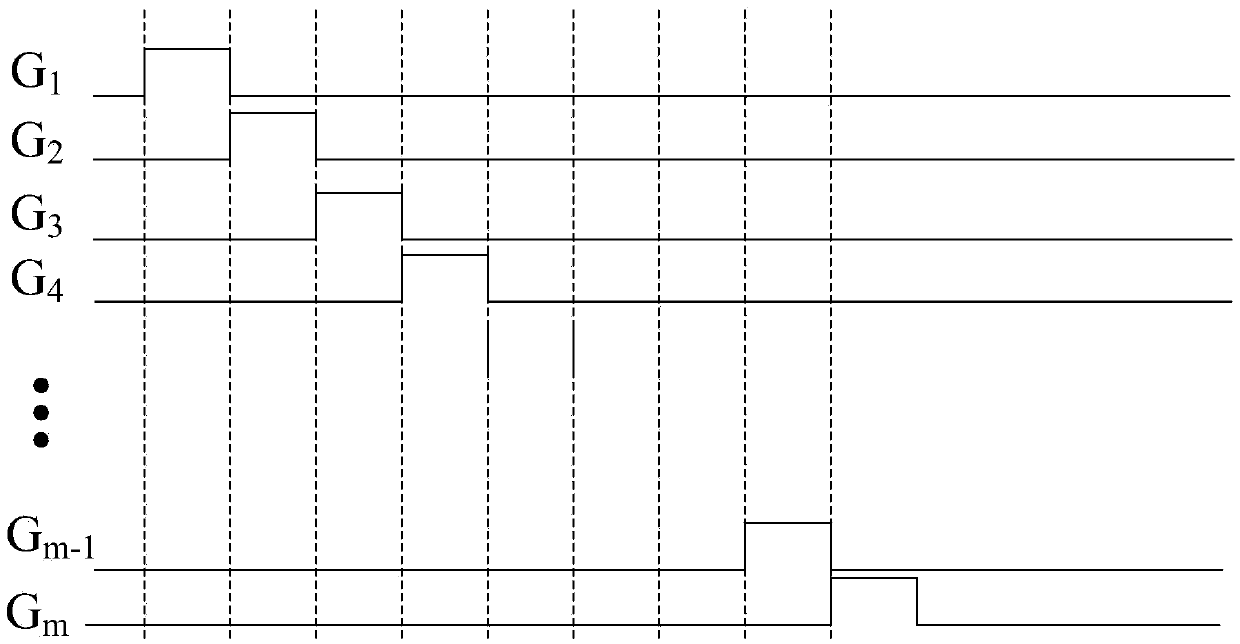

Display device and driving method thereof

ActiveCN105374330AReduce the impact of latency effectsImprove the problem of signal crosstalkStatic indicating devicesElectrical resistance and conductanceResistance capacitance

The present invention discloses a driving method of a display device. A plurality of pixel units on each scanning line are divided into a plurality of blocks for scanning and driving, a plurality of interval times are inserted into the scanning period of each scanning line to separate rising edges and falling edges of scanning signals of adjacent blocks, and the thin film transistor of the final pixel unit in each block is able to have fully time to complete charge and switch off with no need for regulation and changing of the duty cycle of the scanning signals. According to the invention, the influence of a delayed effect caused by a parasitic resistance and a parasitic capacitance on a scanning line is effectively reduced, and therefore the problem of signal crosstalk may be improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

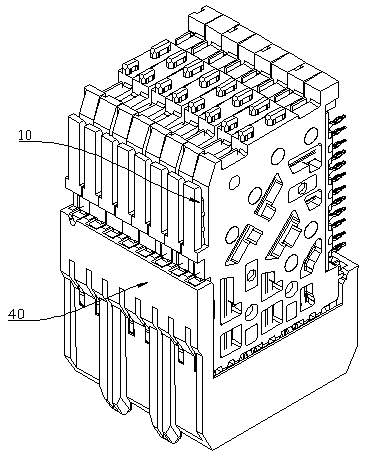

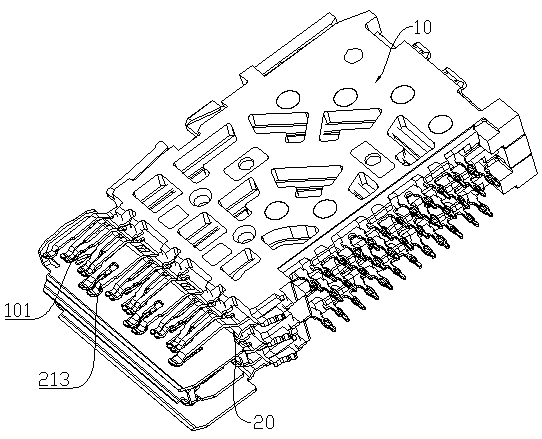

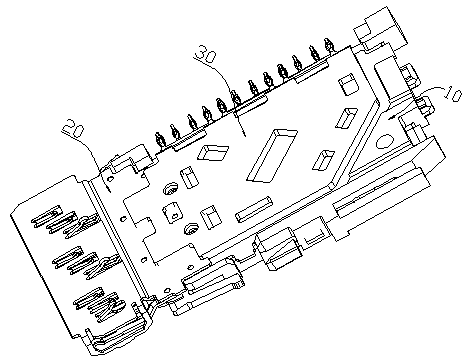

Module structure for high-speed connector and high-speed connector

PendingCN109830849AEnsure consistencyImprove performanceCoupling contact membersCoupling protective earth/shielding arrangementsDifferential signalingComputer module

The invention discloses a module structure for a high-speed connector and a high-speed connector. The module structure comprises a signal transmission module and a shielding component disposed on thesignal transmission module, wherein the signal transmission module is provided therein with differential signal terminals at intervals; the differential signal terminals have differential pair pins; and the vertical distance A between the shielding component and the differential signal terminals in the signal transmission module and the center distance B of the differential pair pins satisfy: A<B / 8. By limiting the distance between the shielding component and a signal wire, the module structure ensures a low impedance change of the differential pairs as much as possible, thereby improving theperformance of the connector.

Owner:SICHUAN HUAFENG ENTERPRISE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com