Patents

Literature

57results about How to "Excessively uniform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

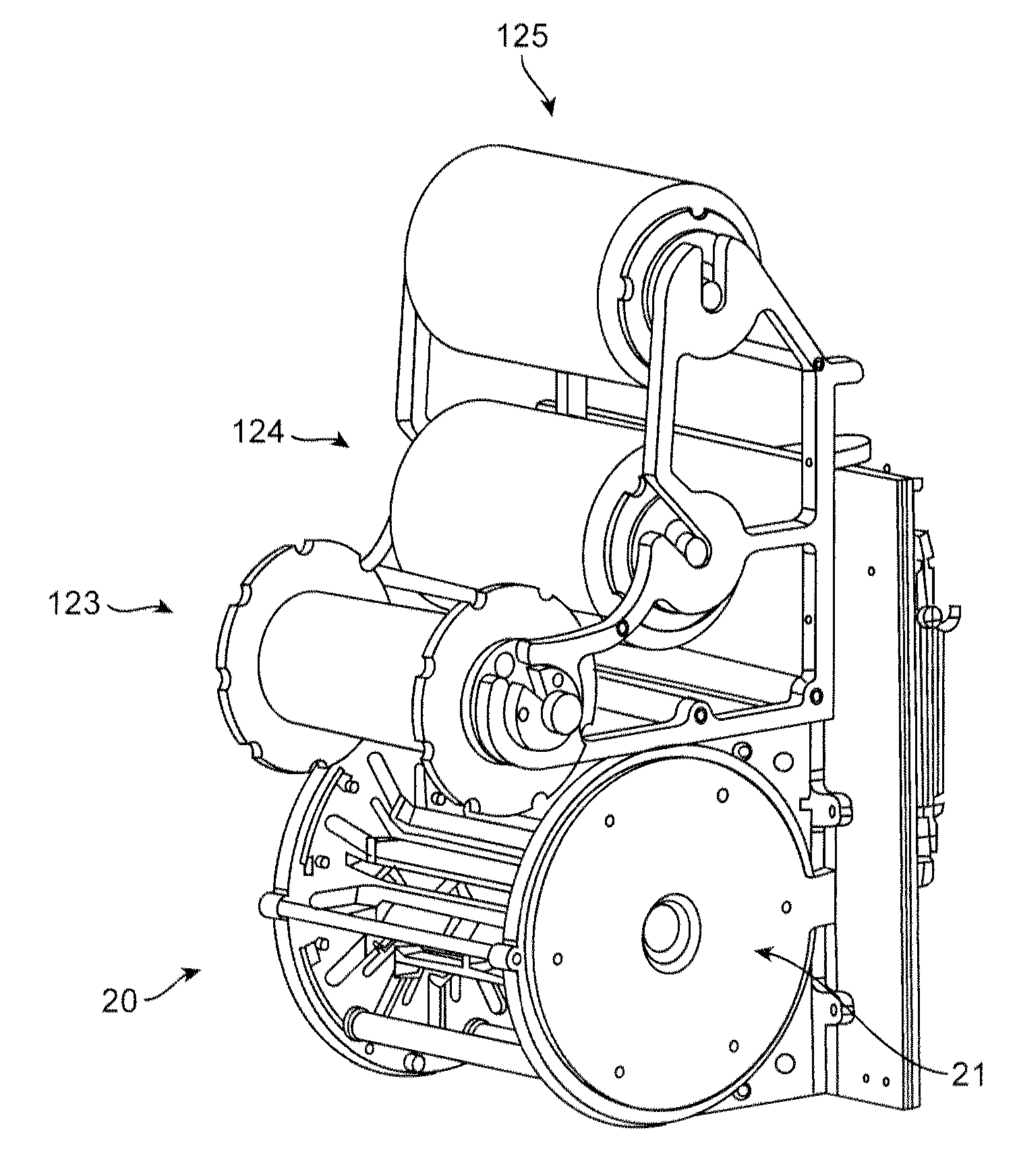

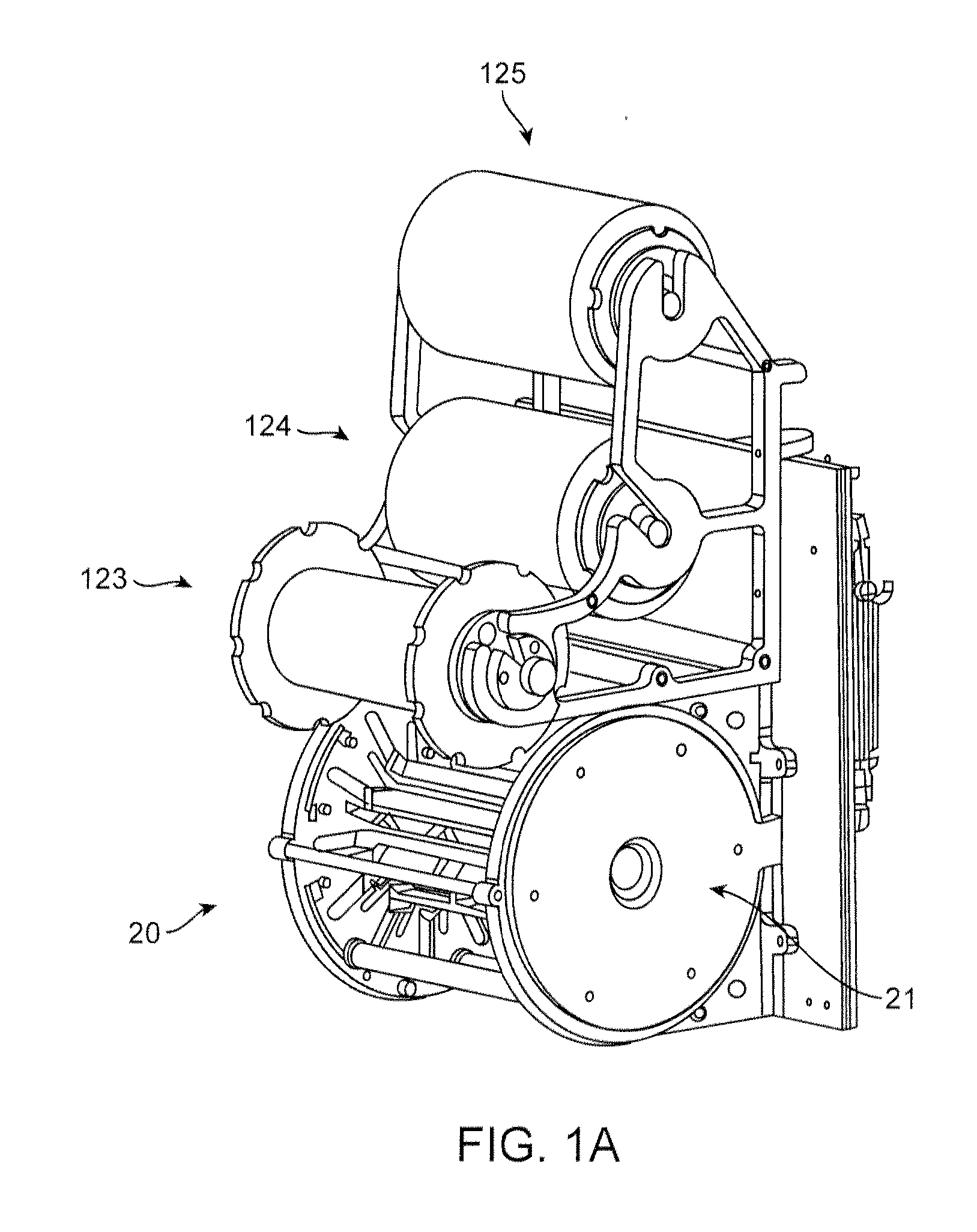

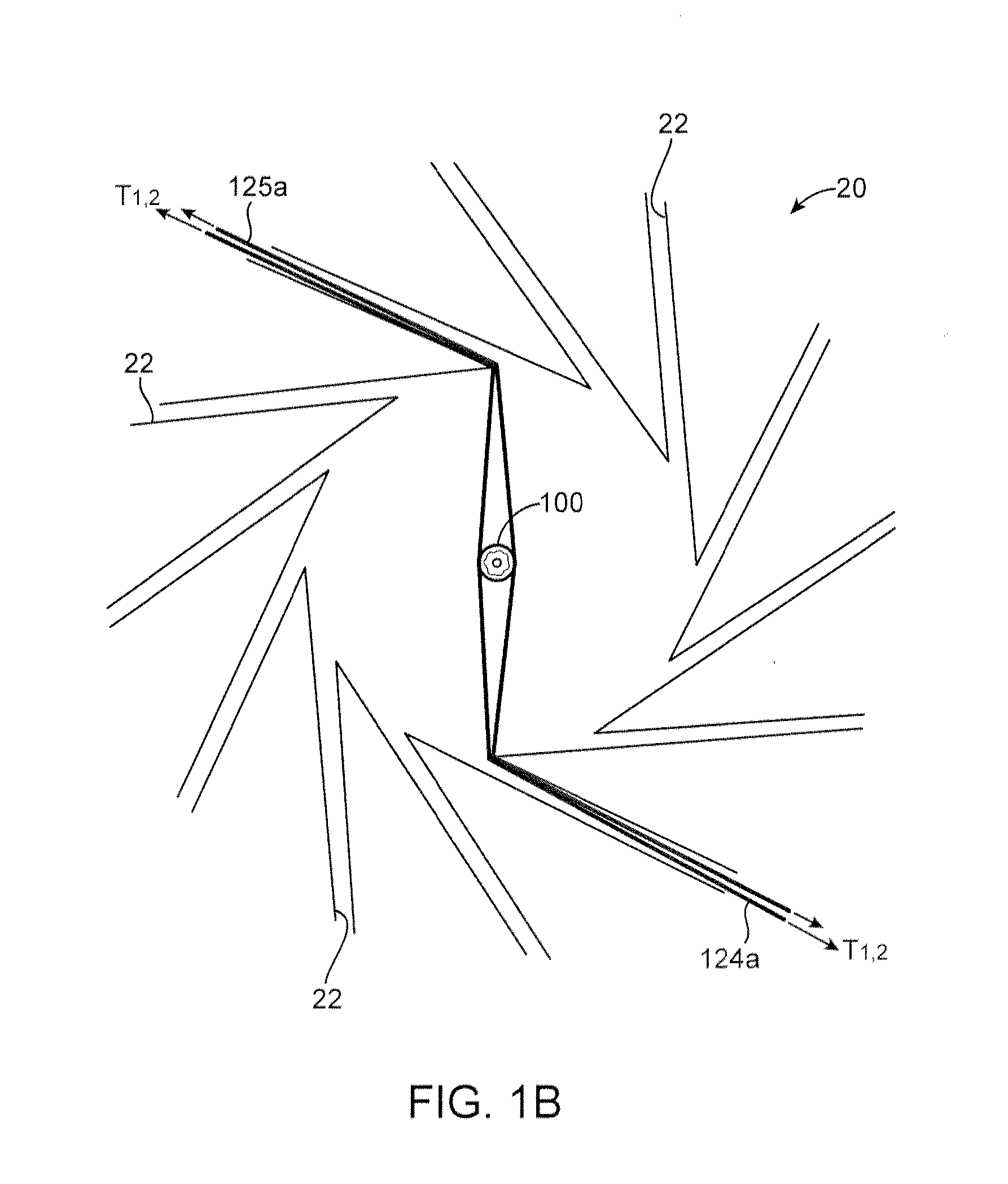

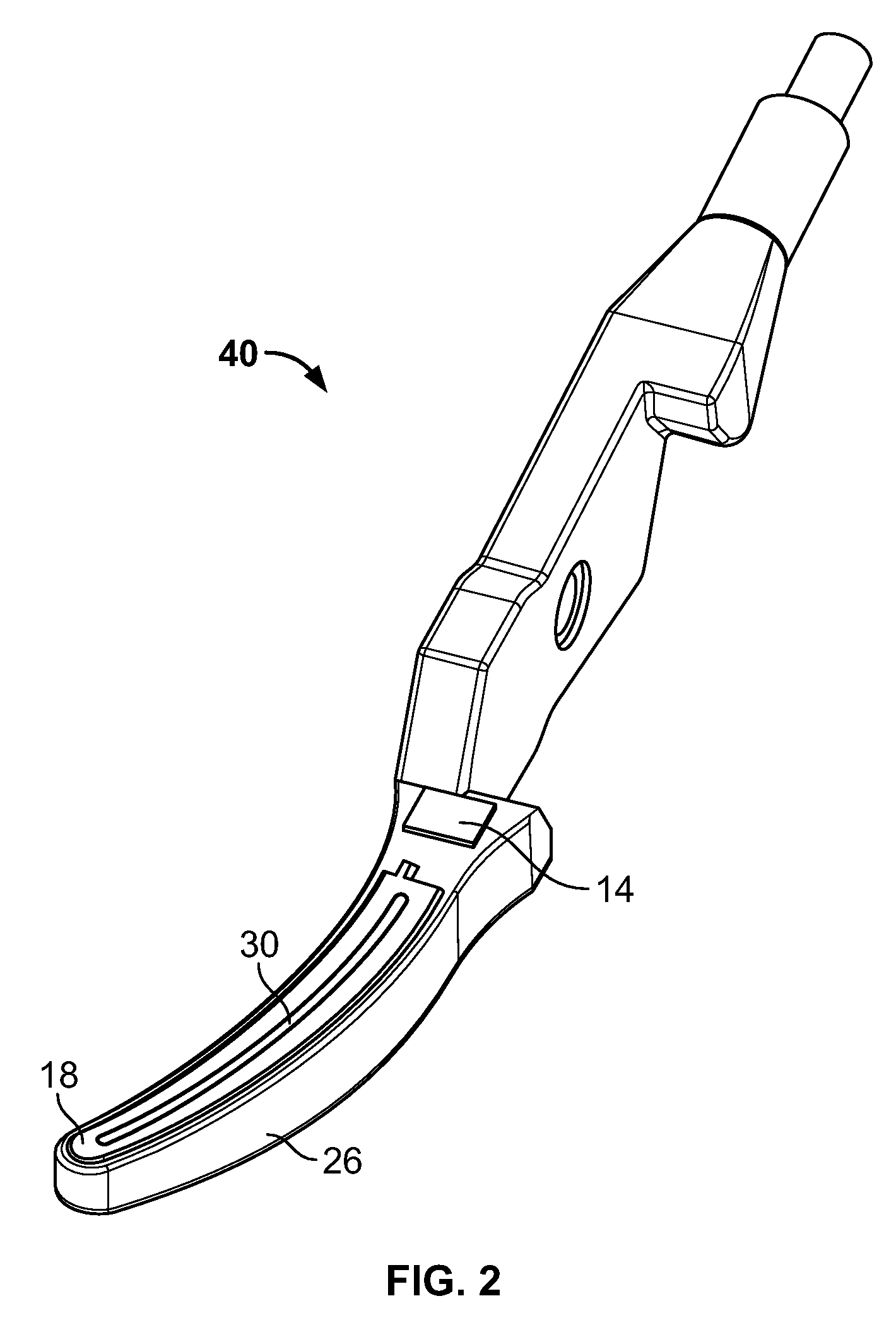

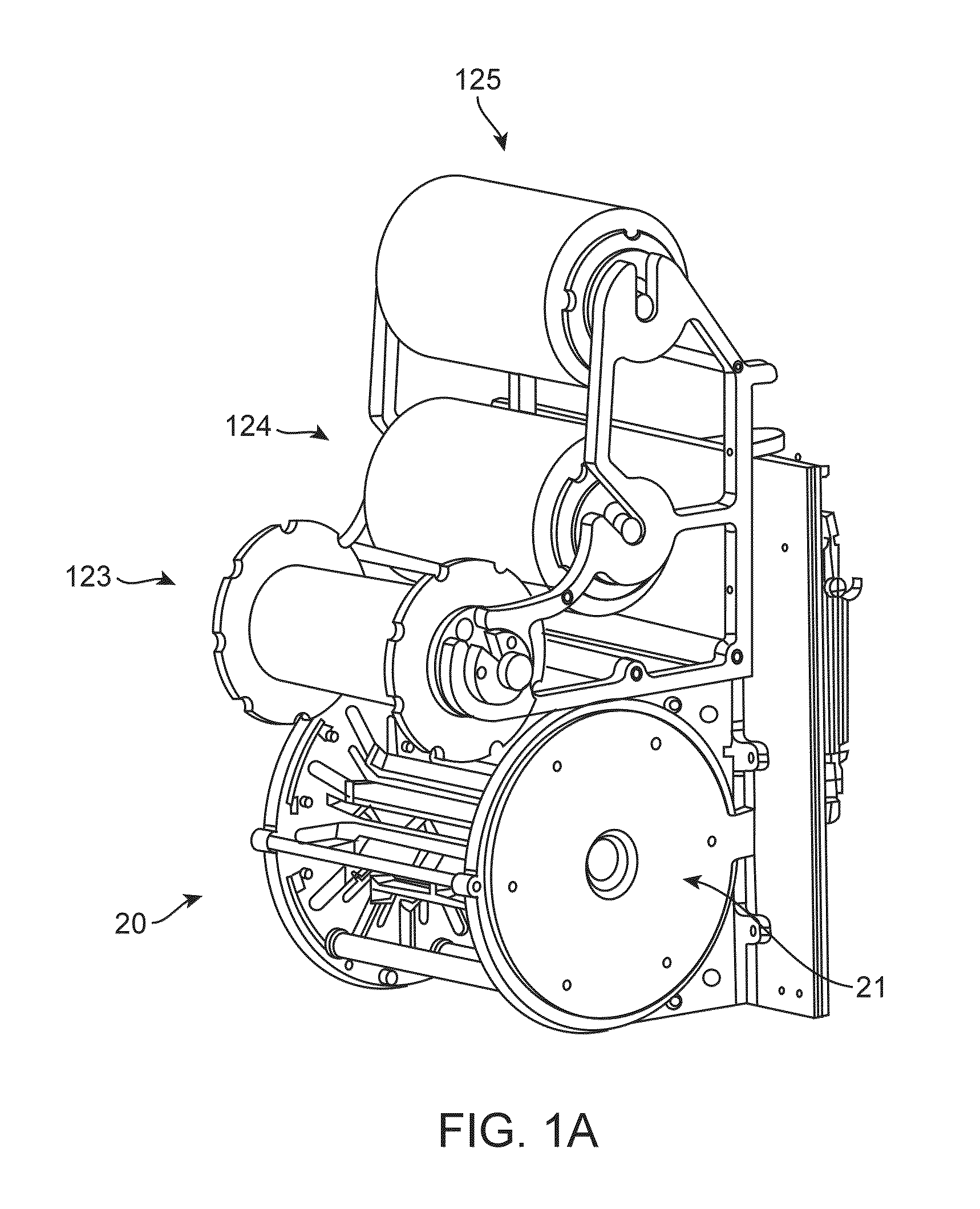

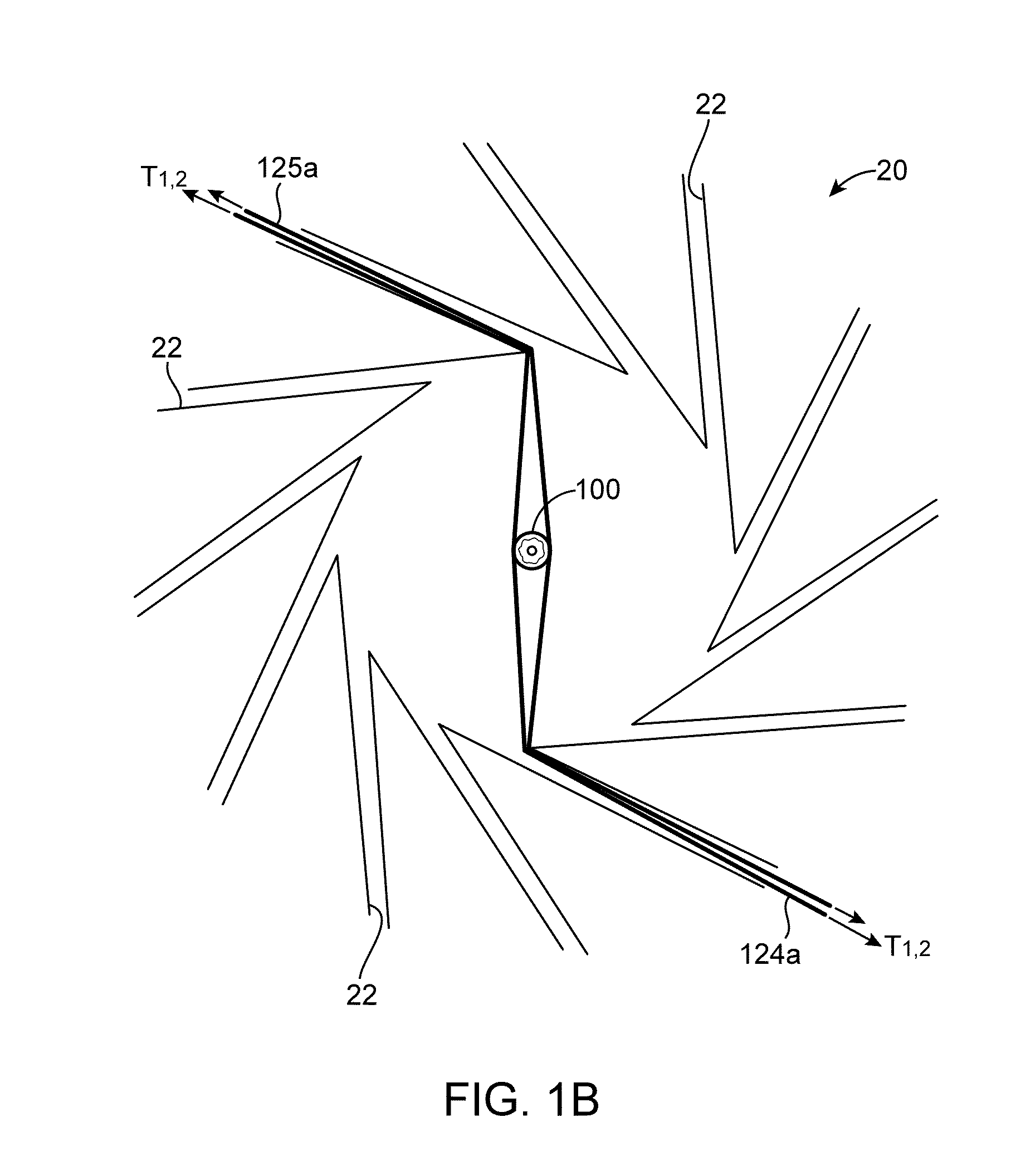

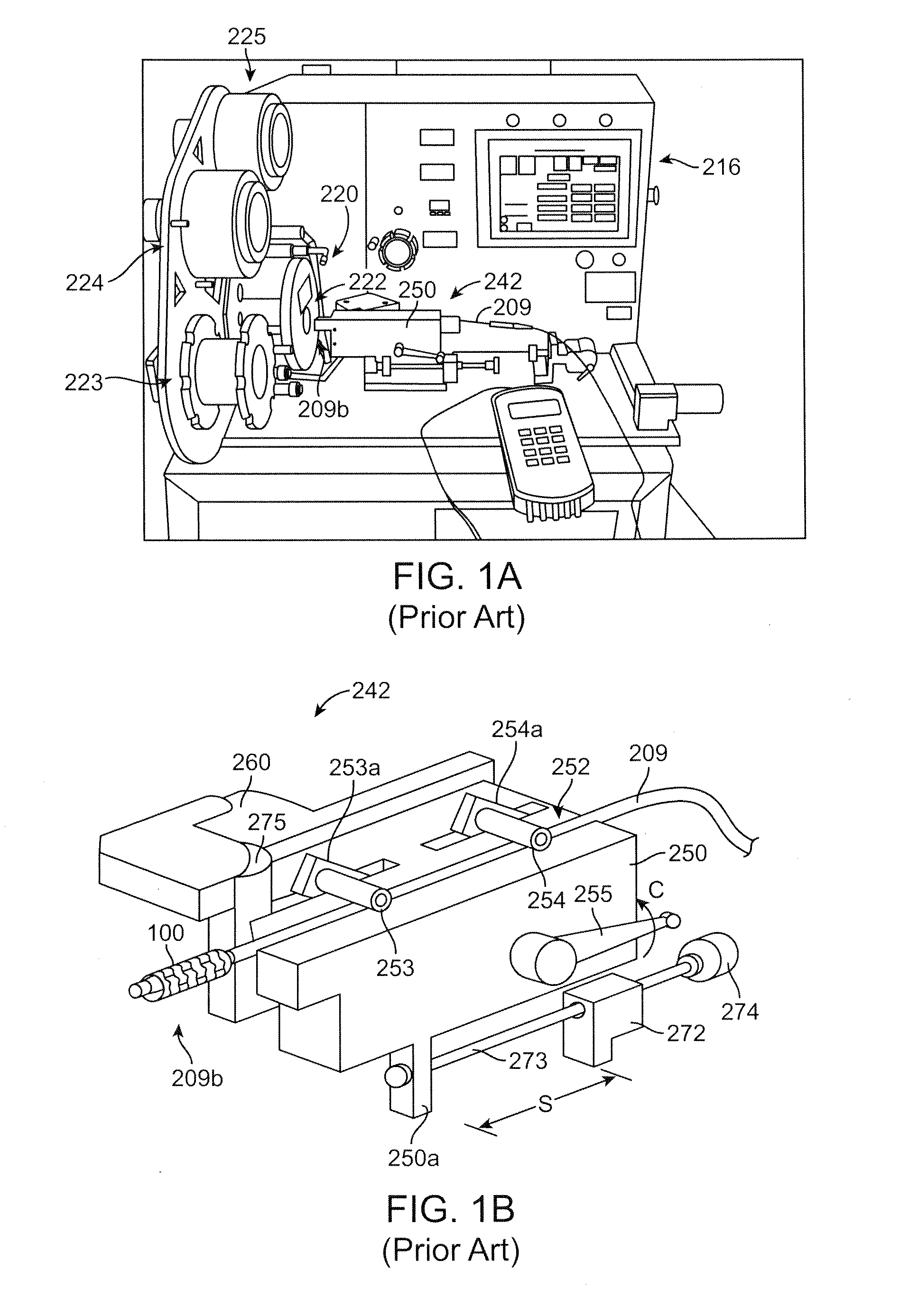

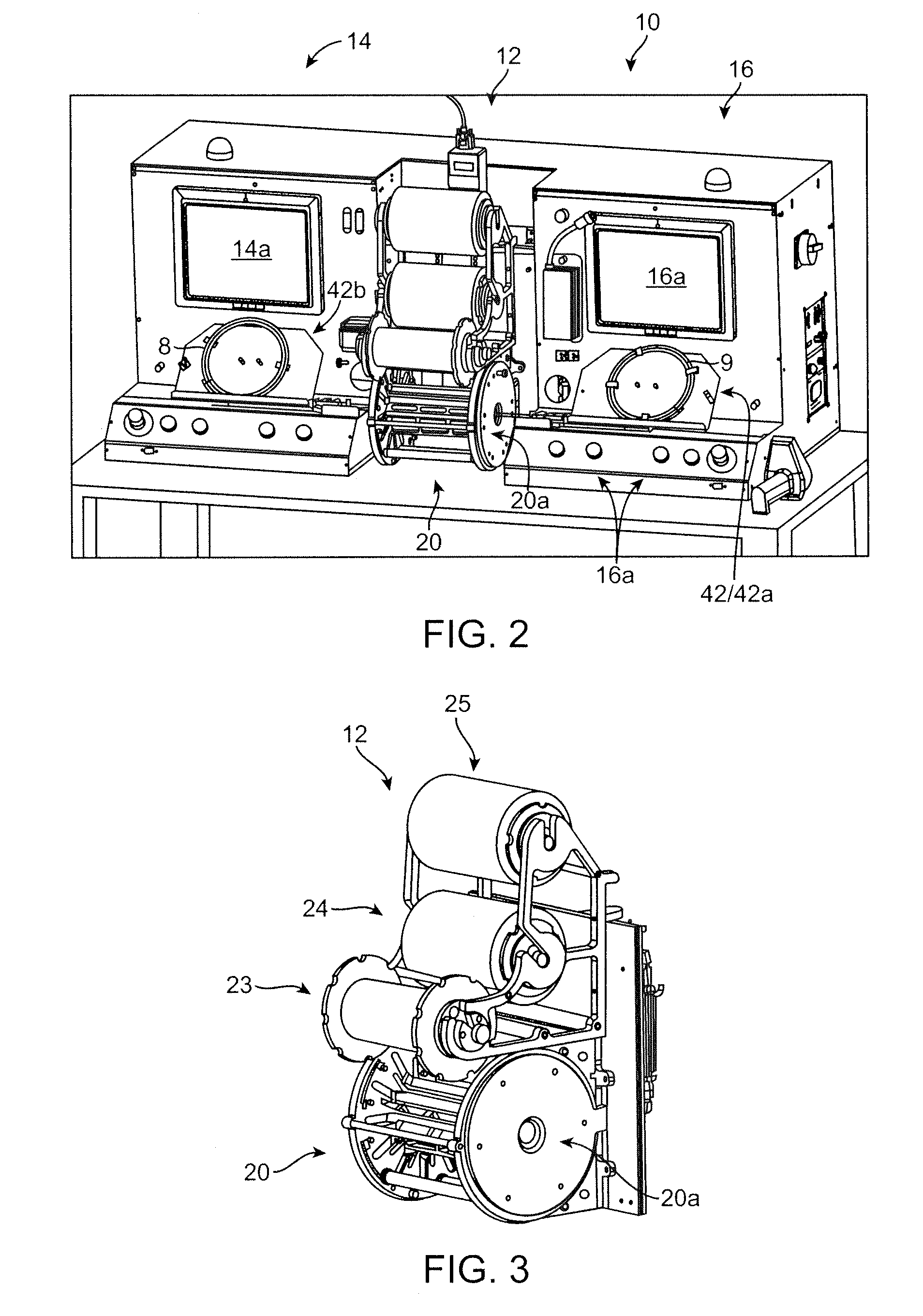

Reducing Crimping Damage to Polymer Scaffold

ActiveUS20120042501A1Reduce harmImprove batch yieldStentsLarge fixed membersCatheterPolymer scaffold

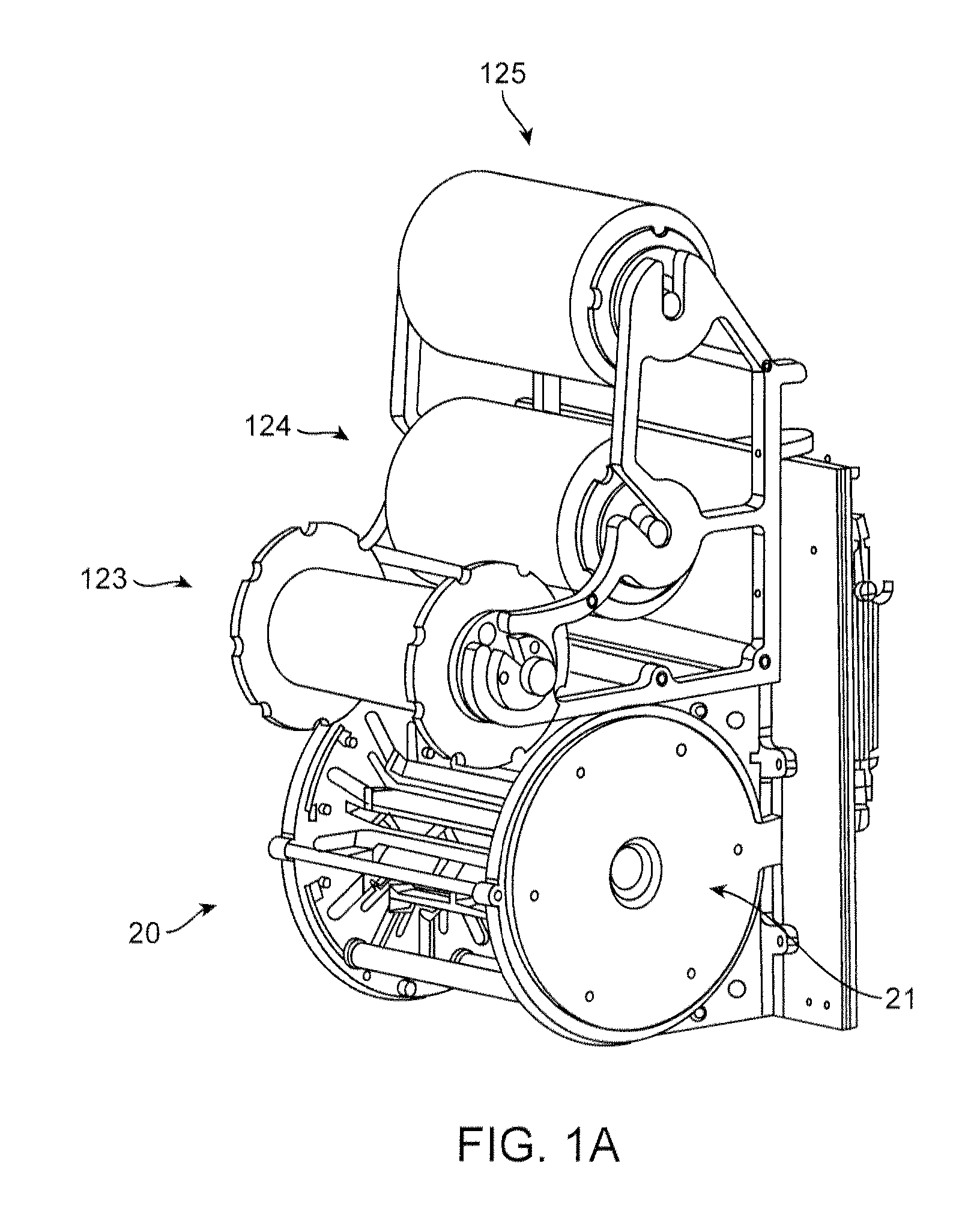

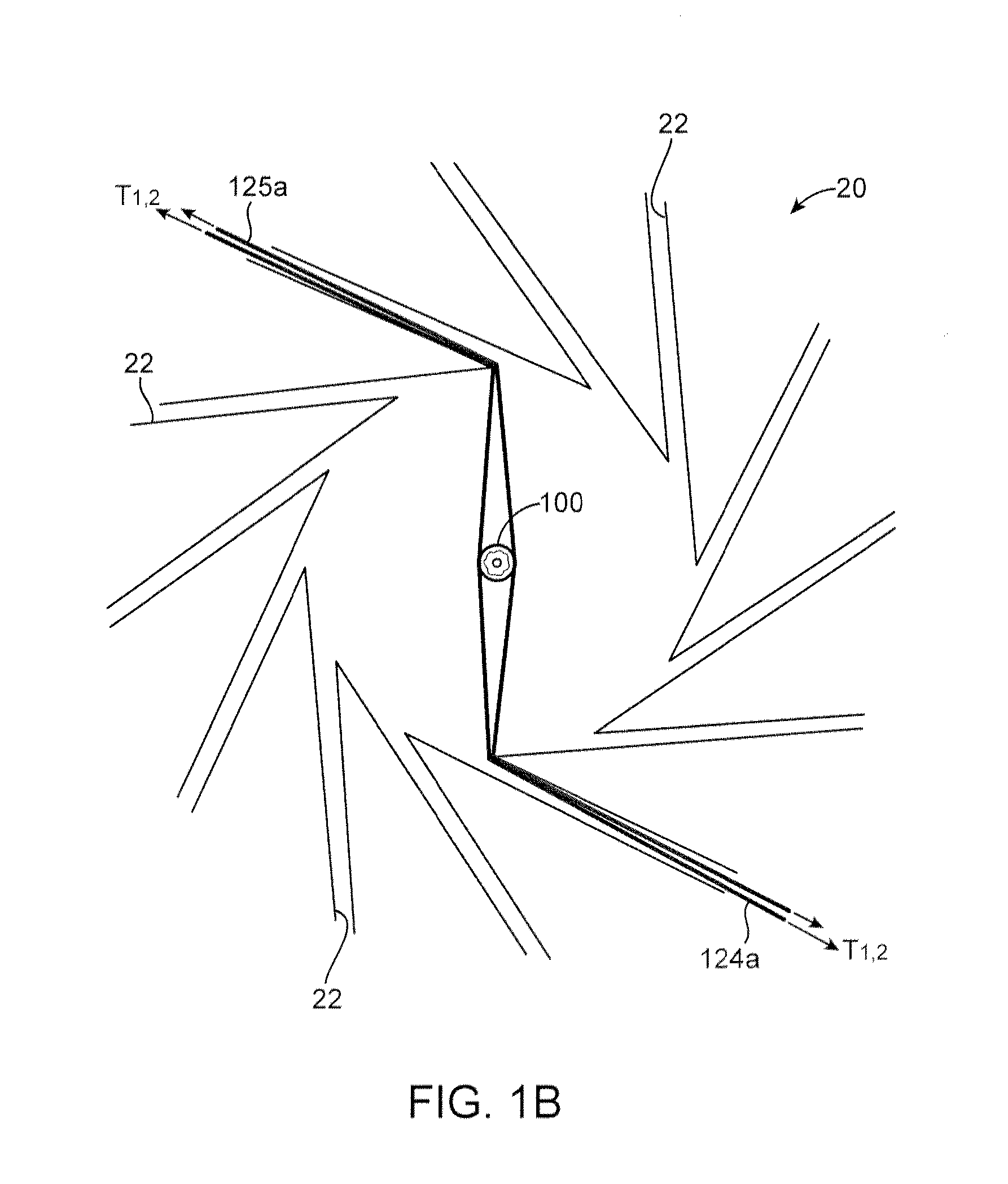

A medical device includes a polymer scaffold crimped to a catheter having an expansion balloon. The scaffold is crimped to the catheter by a multi-step process for increasing scaffold-catheter yield following a crimping sequence. Damage reduction during a crimping sequence includes modifying blades of a crimper, adopting a multi-step crimping sequence, and inflating a supporting balloon to support the scaffold during crimping.

Owner:ABBOTT CARDIOVASCULAR

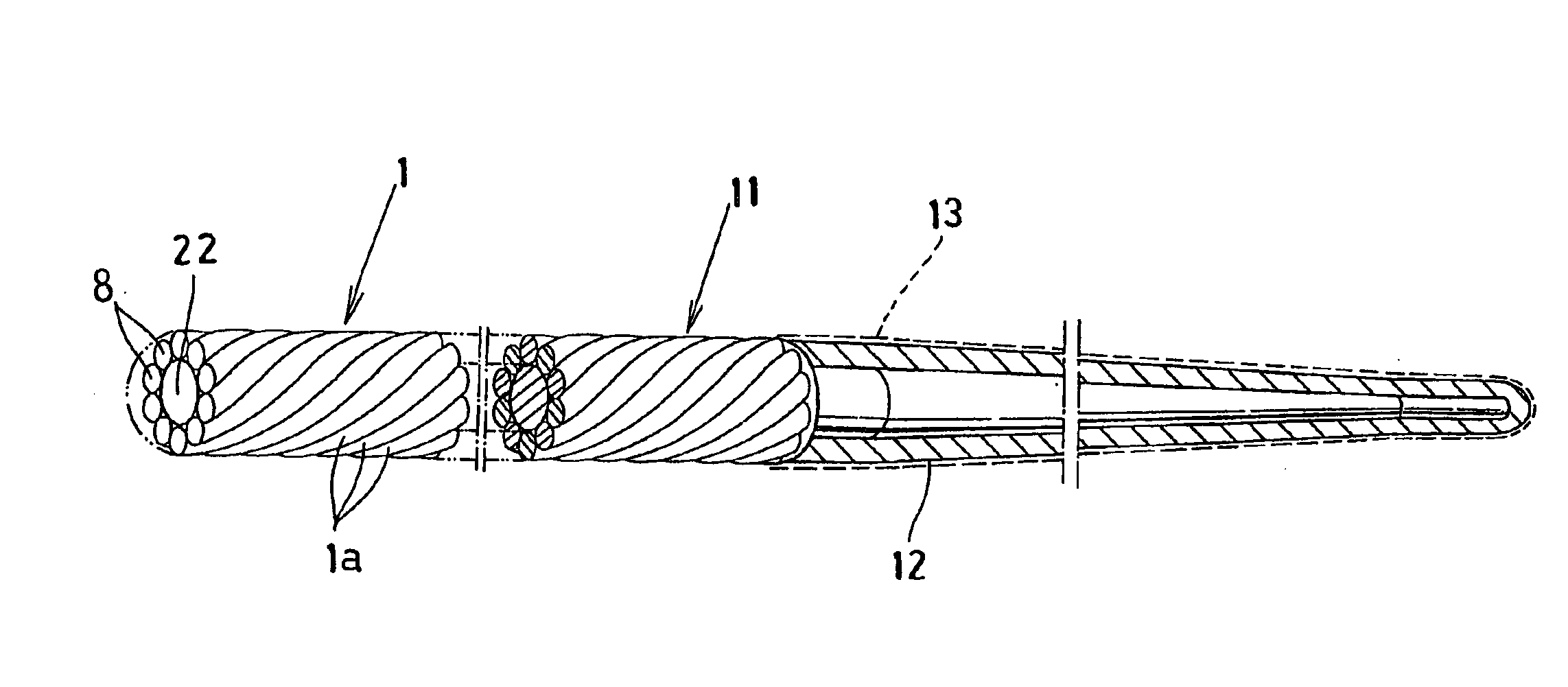

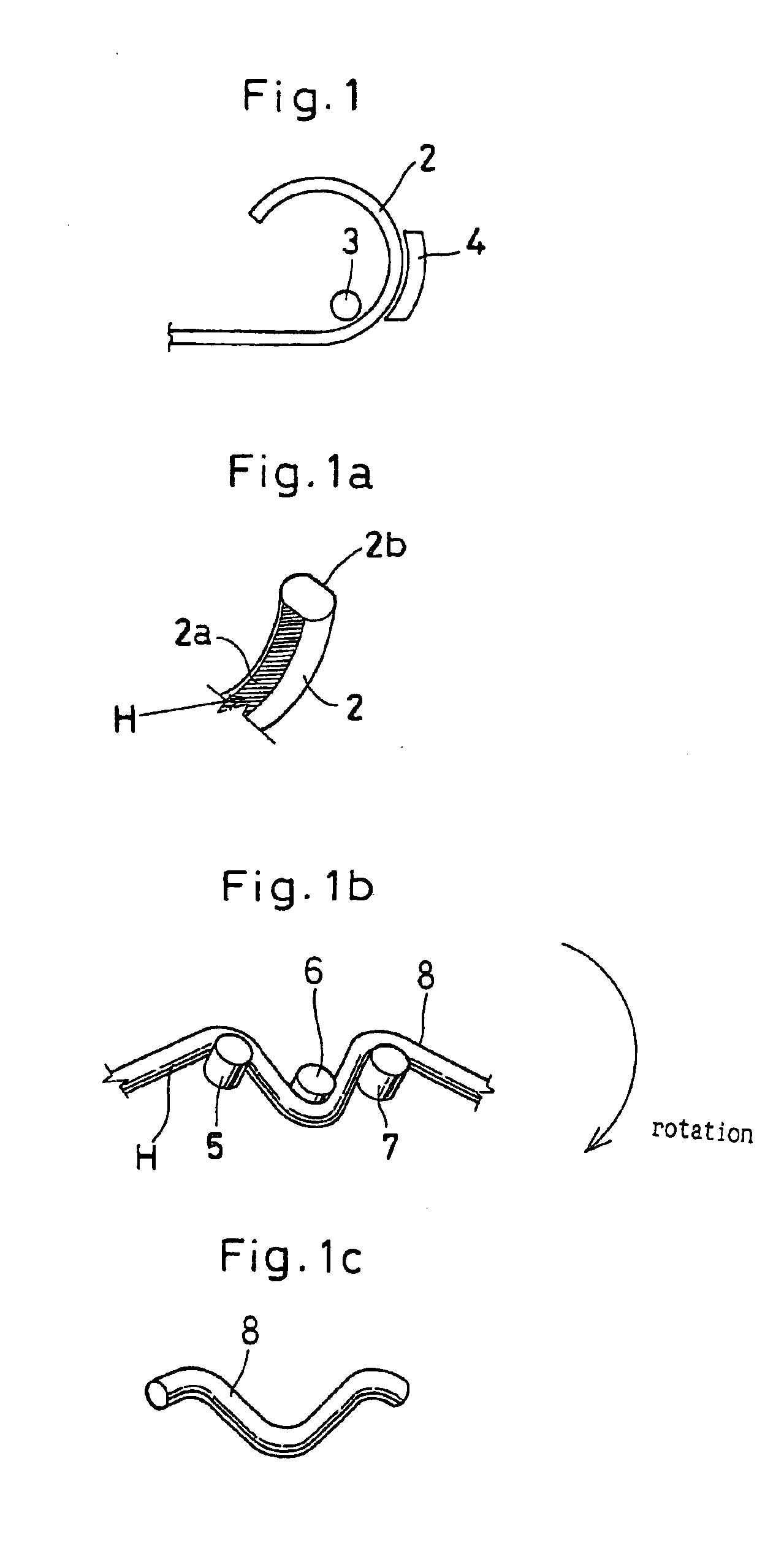

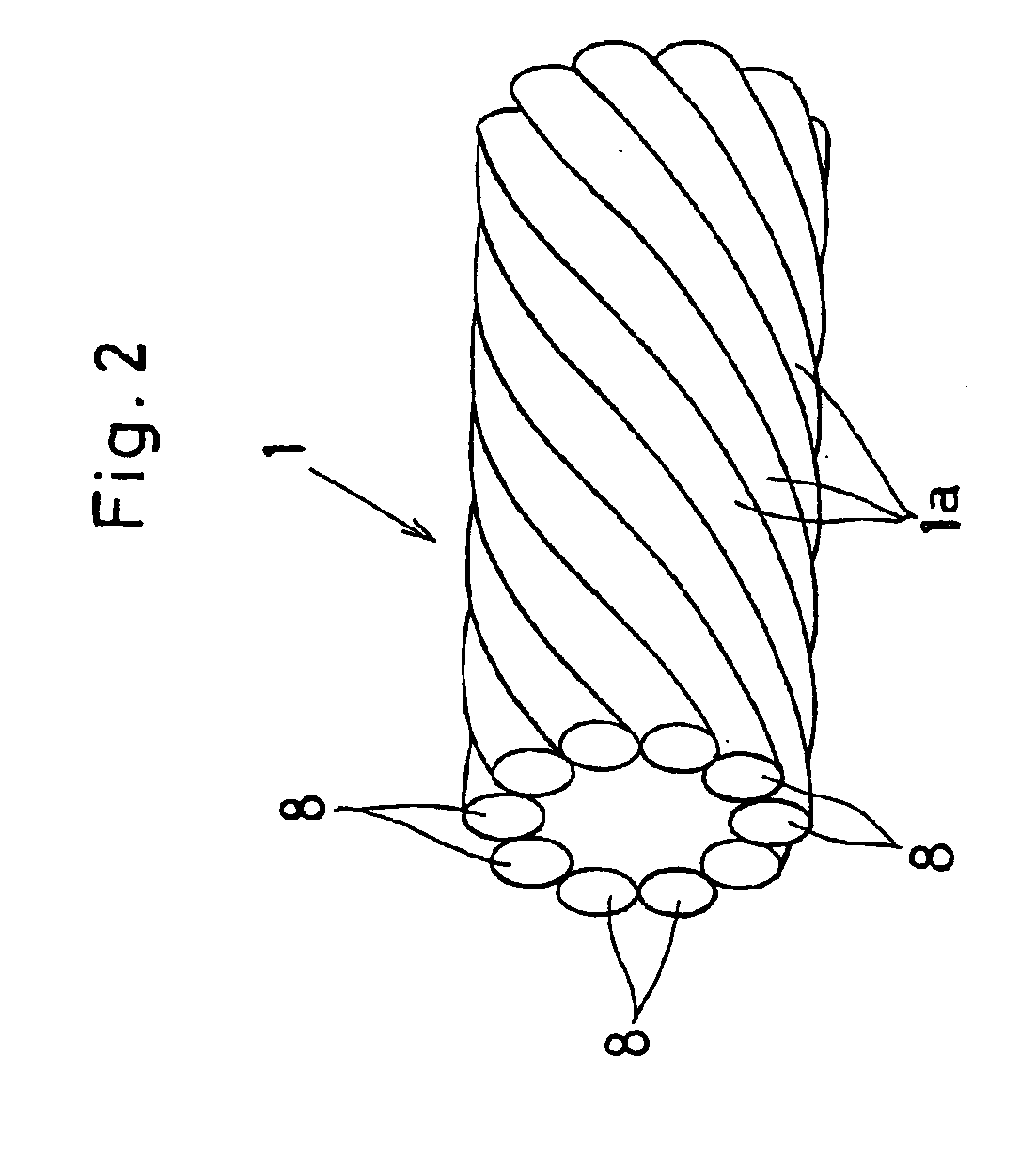

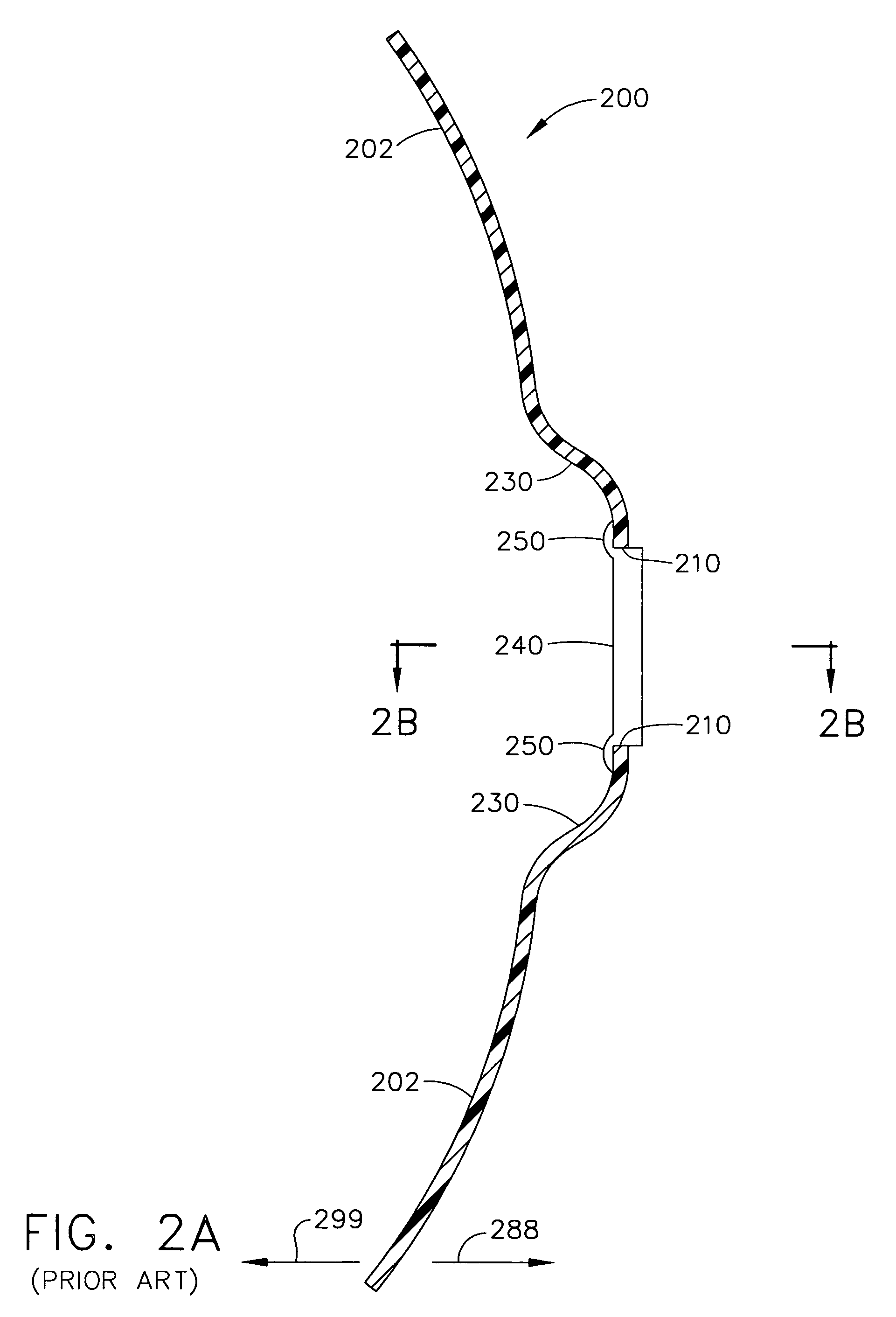

Wire-stranded medical hollow tube, and a medical guide wire

InactiveUS6881194B2Good flexibilitySmoothly introducedGuide wiresMedical devicesContact pressureEngineering

In a wire-stranded hollow tube (1), a plurality of metallic wires (8) preformed with a predetermined forming rate are twisted along a circular line into a careless hollow configuration. When twisting the metallic wires (8), the neighboring metallic elements (1a, 1a) are subjected to compression with no gap between the neighboring metallic elements (1a, 1a). This increases a contact pressure between the neighboring metallic elements (1a, 1a) to attain a good tightness with a good circularity and diametrical uniformity secured therebetween, thus preventing the wire-stranded hollow tube (1) from inadvertently collapsing. A tightness is strengthened between the neighboring metallic elements (1a, 1a) when the metallic elements (1a, 1a) of different helical pitch are used. By applying the wire-stranded hollow tube (1) to a medical guide wire, a quick torque response and a good torque transmissibility are ensured which lead to a good manipulatability with a favorable follow-on capability.

Owner:ASAHI INTECC CO LTD

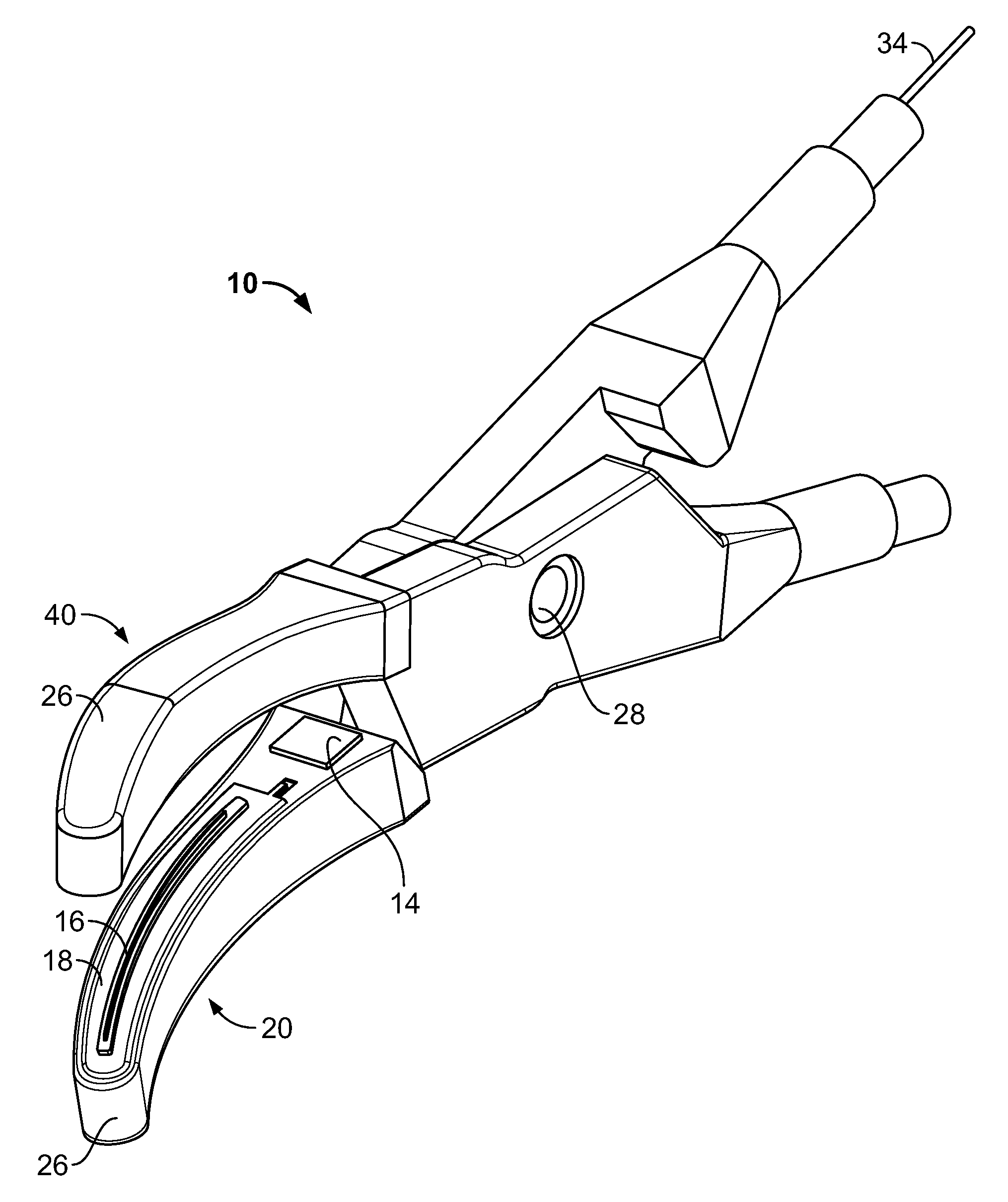

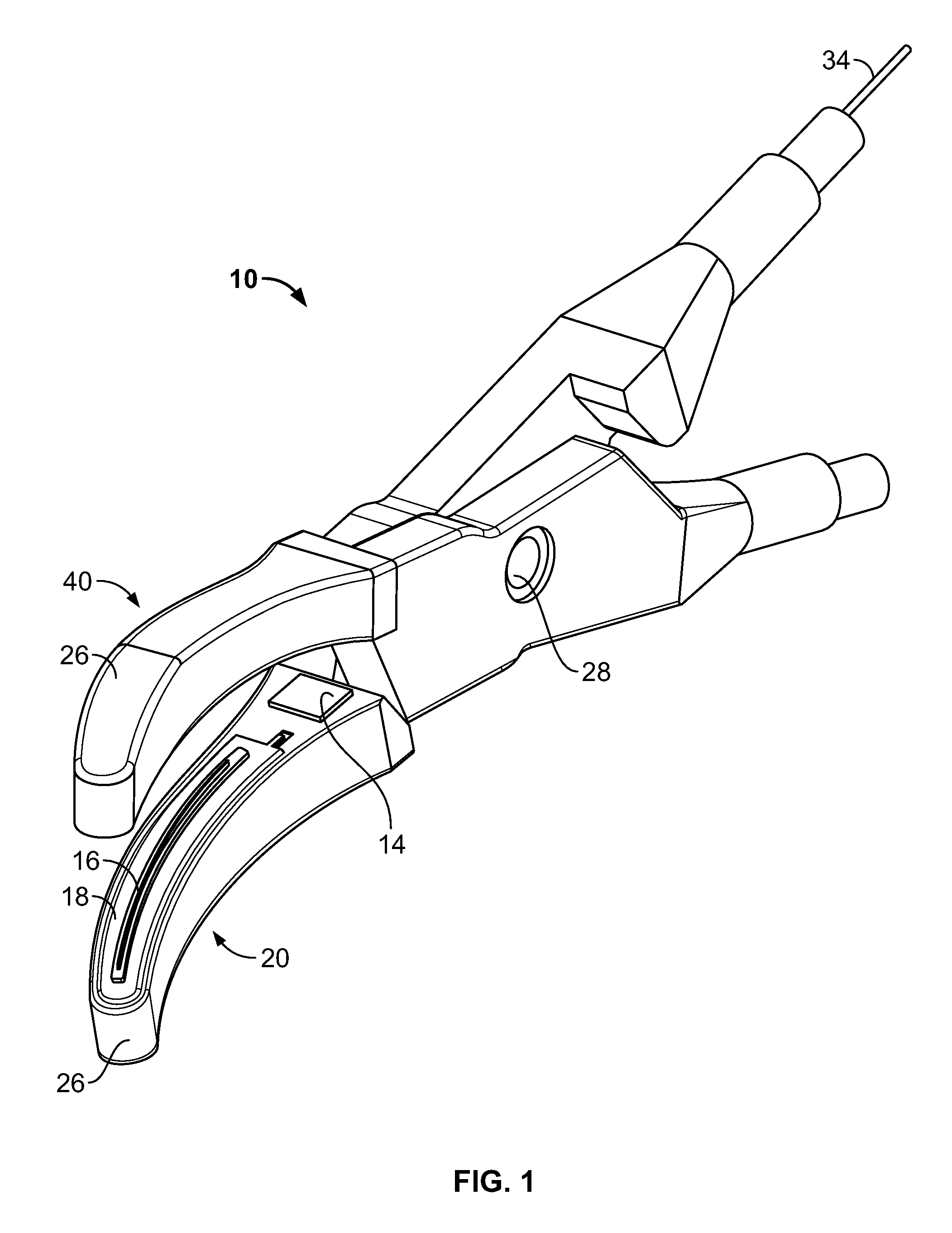

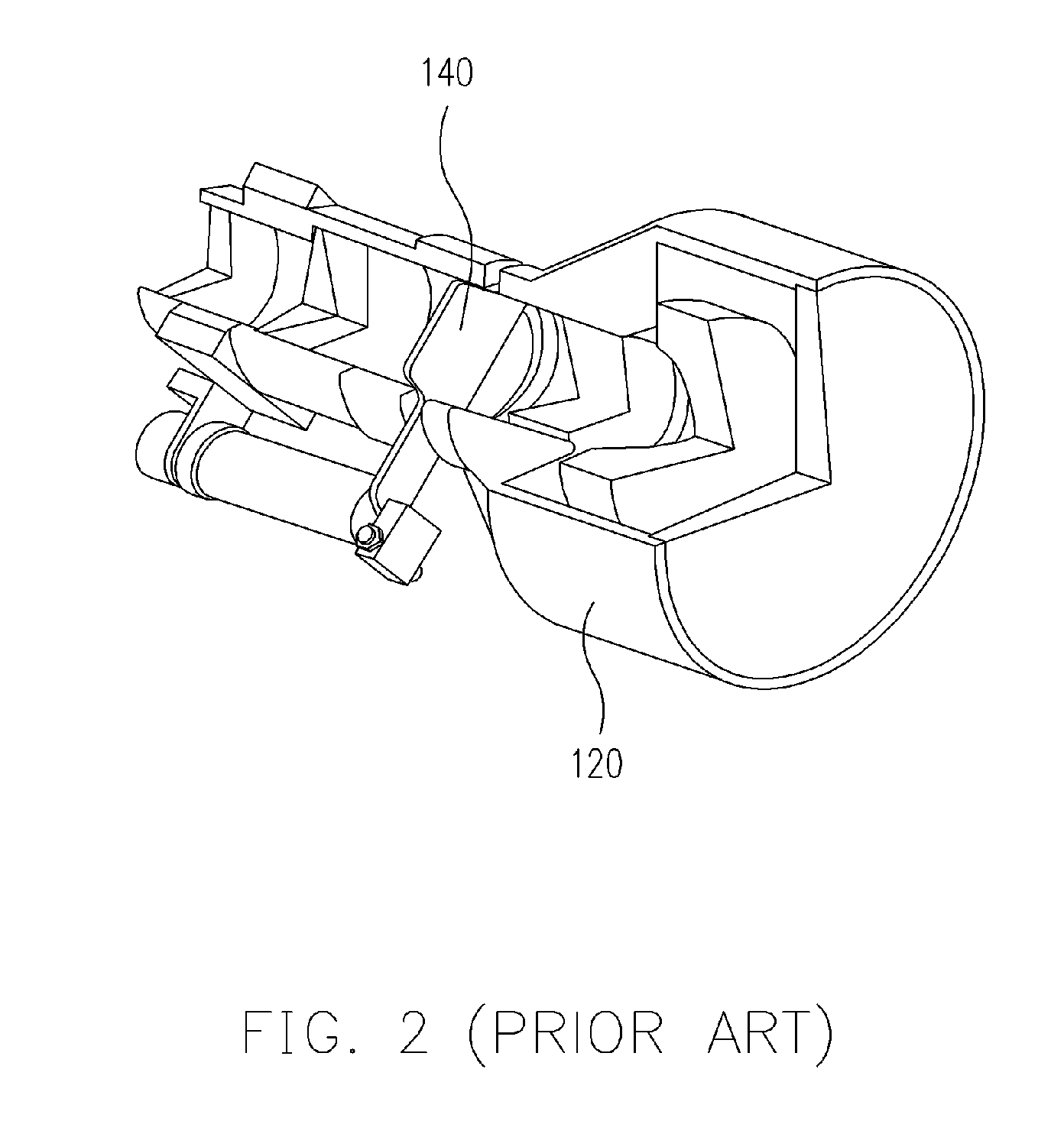

System and method for surgical jaw assembly

InactiveUS20090254081A1Assembly precisionExcessively uniformDiagnosticsAssembly machinesMechanical engineeringEngineering

A surgical jaw assembly having a top portion and a bottom portion hingedly attached. The top and bottom portion having a base, a seal plate and a cover, the seal plate and base being in direct contact and being electrically common. The bottom portion having a blade that is stationary relative to the base and the top portion having an insert configured to receive the blade when the top portion and bottom portion are in a predetermined position. The cover is overmolded onto the base, securing the seal plate to the base on both the top portion and bottom portion.

Owner:CREGANNA UNLTD

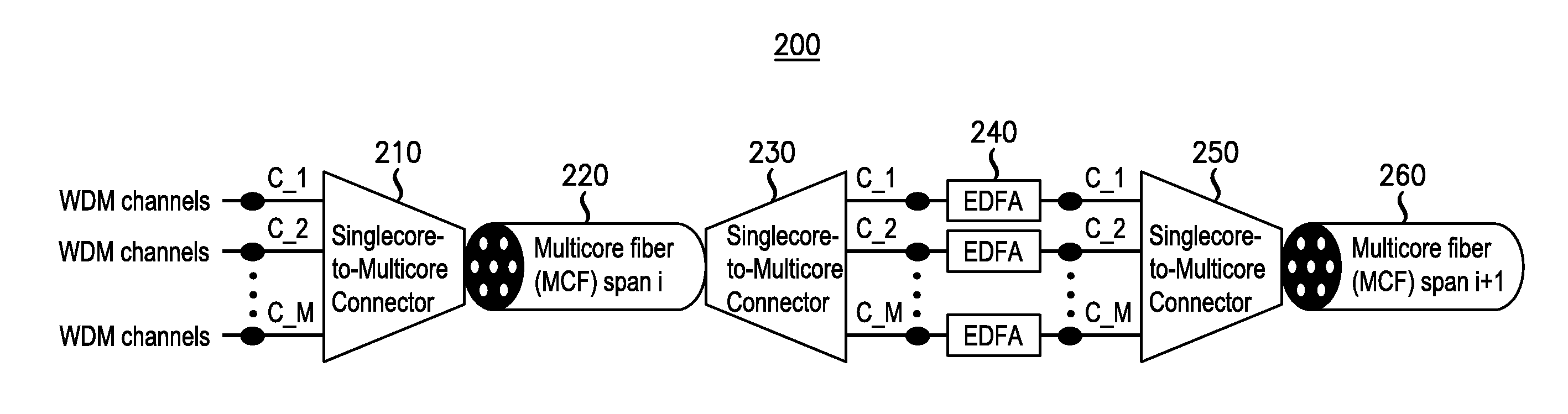

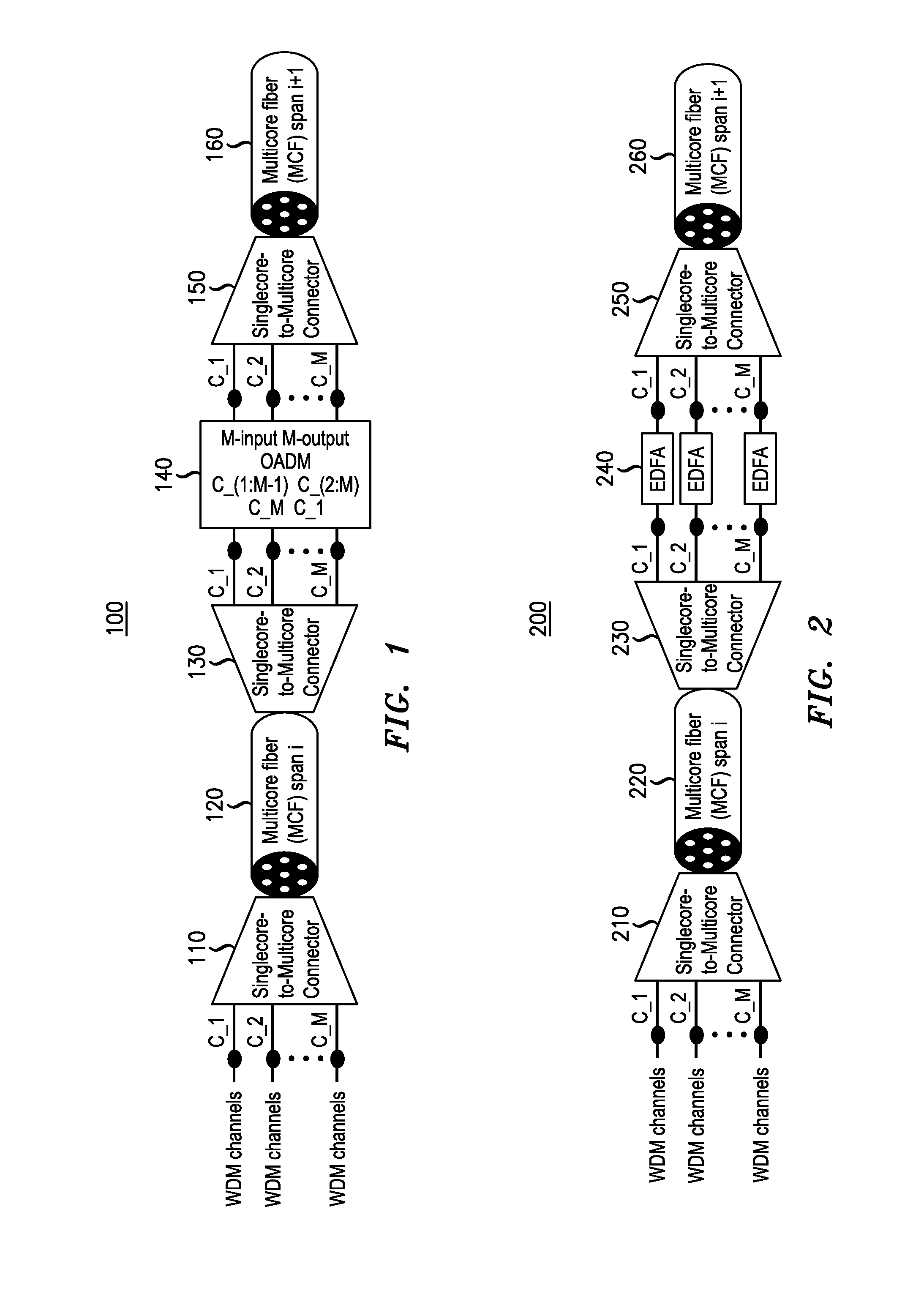

Method And Apparatus For Space-Division Multiplexing Systems

ActiveUS20130236175A1Reducing performance variationImprove system performanceMultiplex system selection arrangementsWavelength-division multiplex systemsFew mode fiberSignal on

A space division multiplexed (SDM) transmission system that includes at least two segments of transmission media in which a spatial assignment of the two segments is different is provided. For example, the SDM transmission may include a first segment of transmission media having a first spatial assignment and a second segment of transmission media having a second spatial assignment, wherein the first spatial assignment differs from the second spatial assignment. An example method obtains an optical signal on a first segment of transmission media having a first spatial assignment and forwards the optical signal on a second segment of transmission media with a different spatial assignment. The transmission media may be a multi-core fiber (MCF), a multi-mode fiber (MMF), a few-mode fiber (FMF), or a ribbon cable comprising nominally uncoupled single-mode fiber (SMF).

Owner:ALCATEL LUCENT SAS

Reducing crimping damage to polymer scaffold

A medical device includes a polymer scaffold crimped to a catheter having an expansion balloon. The scaffold is crimped to the catheter by a multi-step process for increasing scaffold-catheter yield following a crimping sequence. Damage reduction during a crimping sequence includes modifying blades of a crimper, adopting a multi-step crimping sequence, and inflating a supporting balloon to support the scaffold during crimping.

Owner:ABBOTT CARDIOVASCULAR

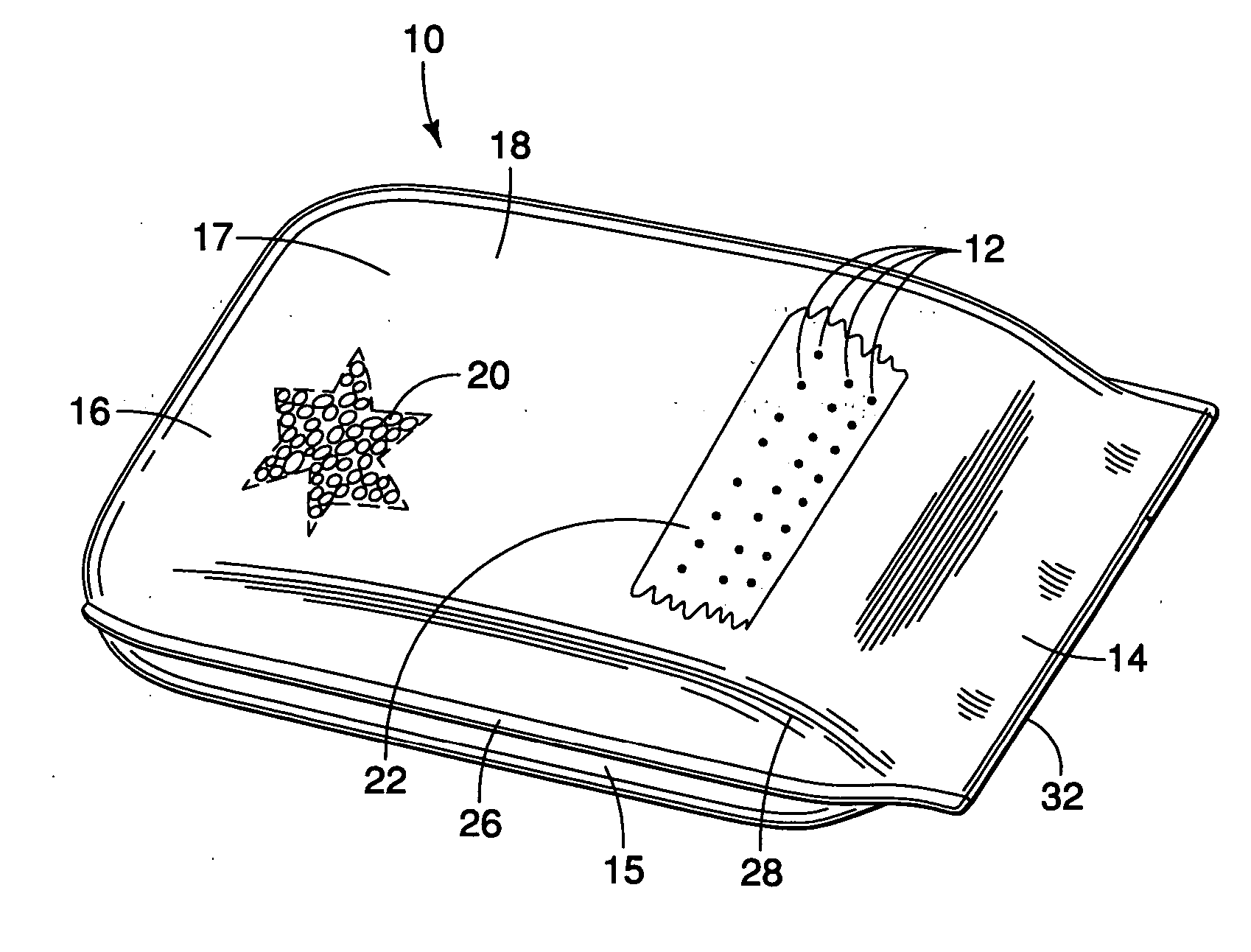

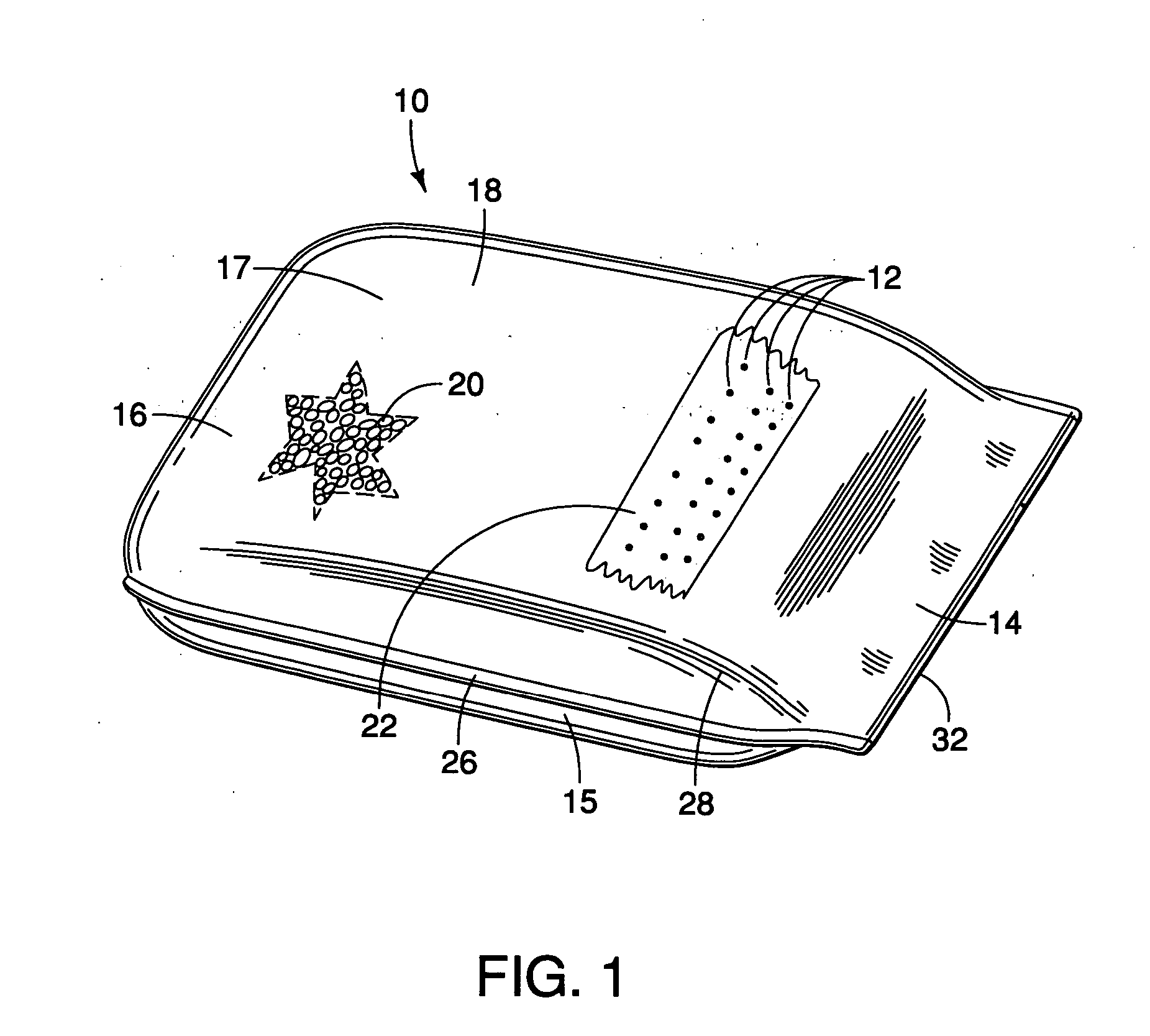

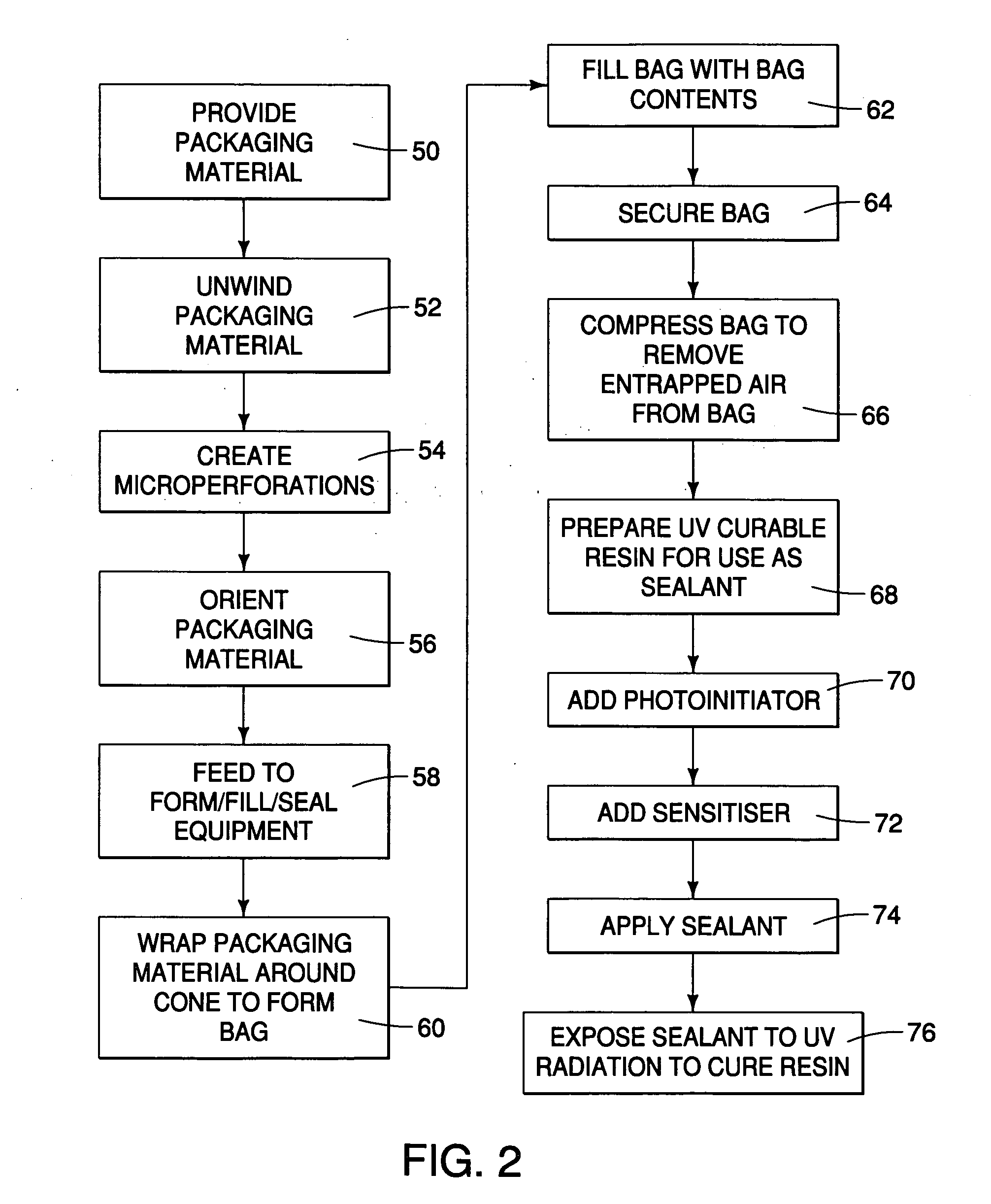

Plastic bag for fine powders

A method of making and filling a plastic bag includes the steps of providing a bag having a plurality of microperforations; filling the bag with a powdered product; securing the bag; removing at least a portion of entrapped air in the bag through the microperforations; and sealing the microperforations. A product includes a bag configured for being formed from a plastic film into which a plurality of microperforations have been created. The bag contents include less air than that present in the bag when the top and the bottom were secured, at least a portion of the air sealed inside the bag having been expelled through the microperforations. A sealant is used for sealing the microperforations.

Owner:UNITED STATES GYPSUM CO

Compositions to permit print-patterned coagulation of polyurethane on fabric substrates

InactiveUS6040393AImprove thermal stabilityReduce chanceFibre treatmentSpecial tyresPolyesterCompound (substance)

A process for the production of a fabric / elastomer composite is provided. The inventive process involves the impregnation through a printing procedure of an inventive elastomer composition comprising (i) a water-borne polyurethane latex, (ii) an acid-generating chemical, (iii) a cloud point surfactant, (iv) a thickener, and (v) optionally, a cross-linking agent, within a textile fabric. Subsequently, the impregnated fabric is then heated, preferably with steam, in order to generate an acid, which, in turn, permits the surfactant to gel and uniformly coagulate the latex over the fabric surface. The fabric is preferably a circular knit comprised of polyester and / or lycra fibers. The composite may be utilized within any fabric application requiring a support function, particularly as joint braces, sports brassieres, support apparel, and the like. The inventive elastomer composition is also provided.

Owner:MILLIKEN & CO

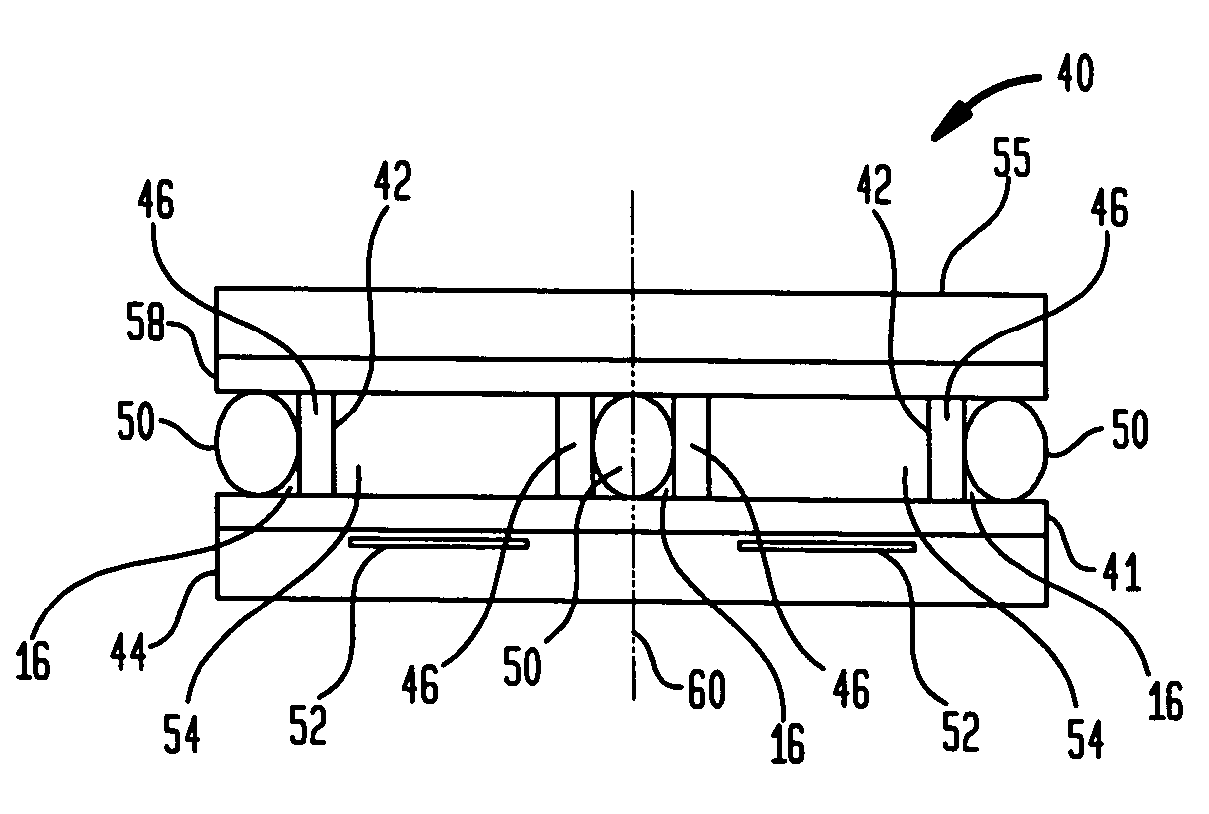

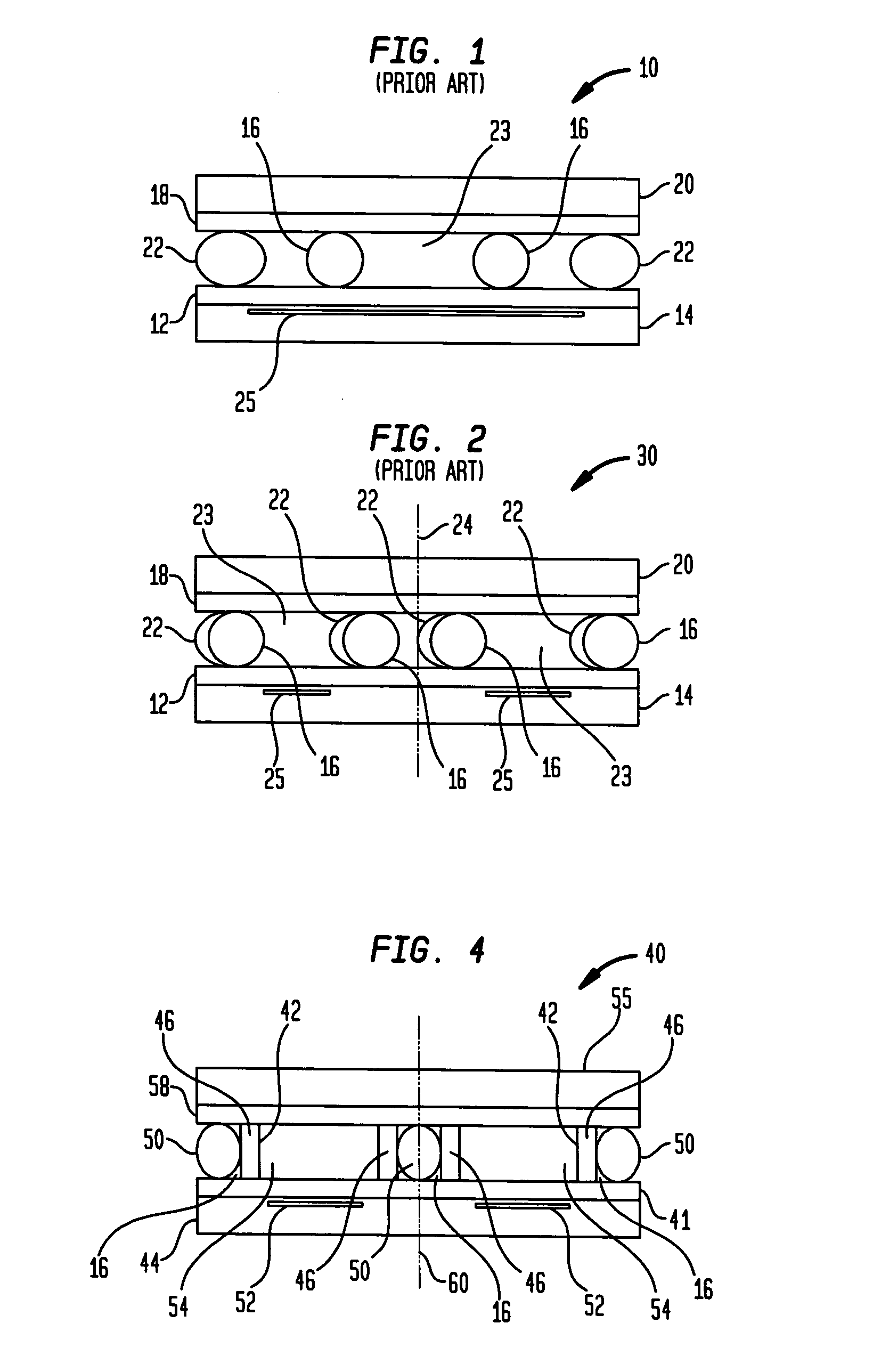

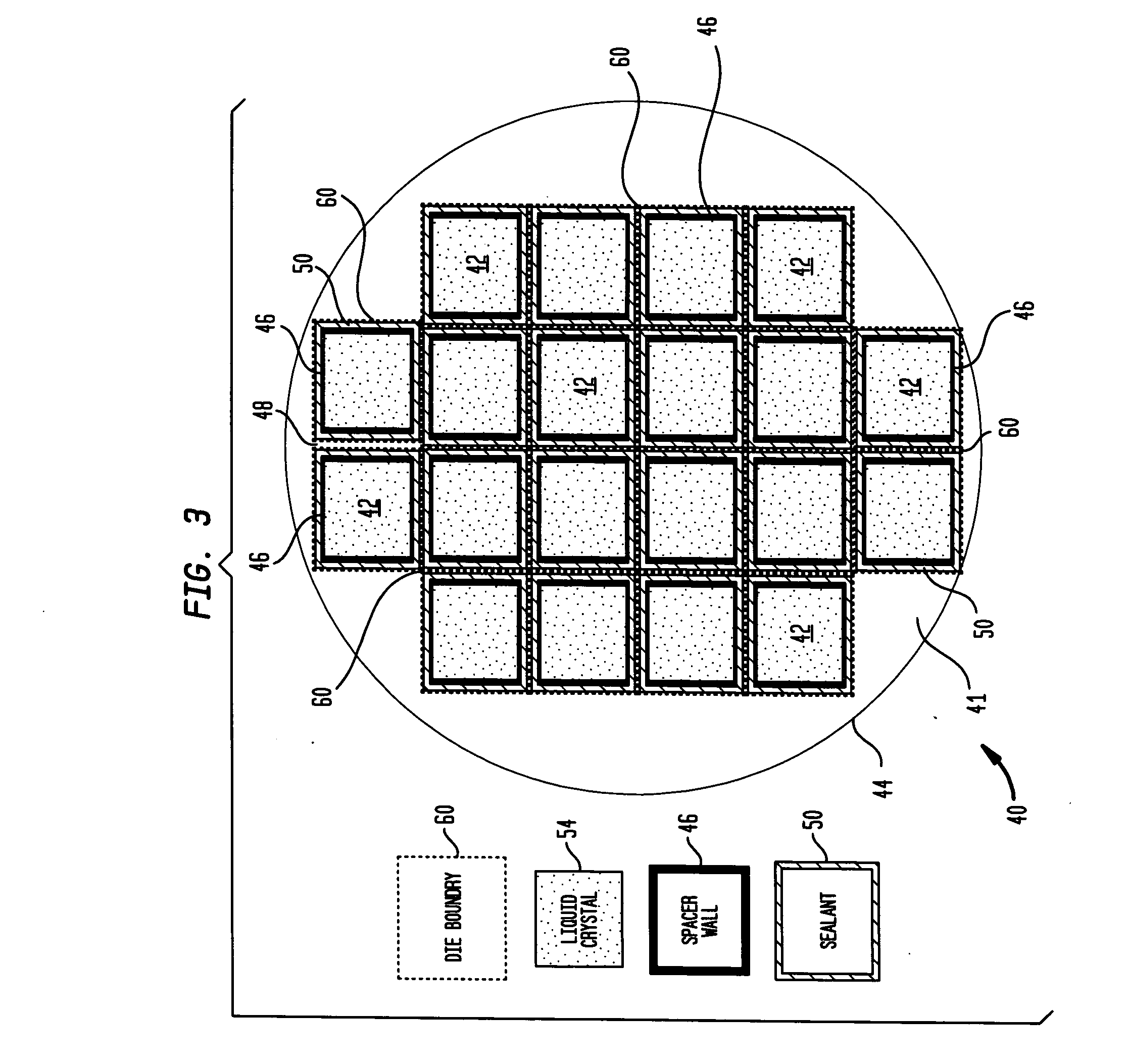

One-drop fill spacerless process for liquid crystal cell on a silicon backplane or microdisplays

A method and an arrangement for the spacerless dispensing of precise amounts of liquid crystals into cells to form active liquid crystal display areas on silicon backplane or microdisplays. There is implemented a unique spacerless manufacture of miniature liquid crystal displays (LCD's), particularly at the wafer level in that, subsequent to imparting the active elements and mirrors on a silicon wafer, there is formed a completely enclosed spacer wall, preferably by photolithographic applications, along a peripheral wall region extending externally of the active display area and leaving a narrow space for a sealant externally of the spacer wall. Thereafter, an alignment layer is applied to the wafer, and a covering glass, which is of similar size and configuration, is provided in order to cover the entire active area of the wafer. Thereafter, the sealant is dispensed in the sealant region outside of the spacer wall extending about the liquid crystal areas, which may contain discrete spacer balls or posts, and thereafter lamination implemented under a vacuum, and the sealant is cured.

Owner:IBM CORP

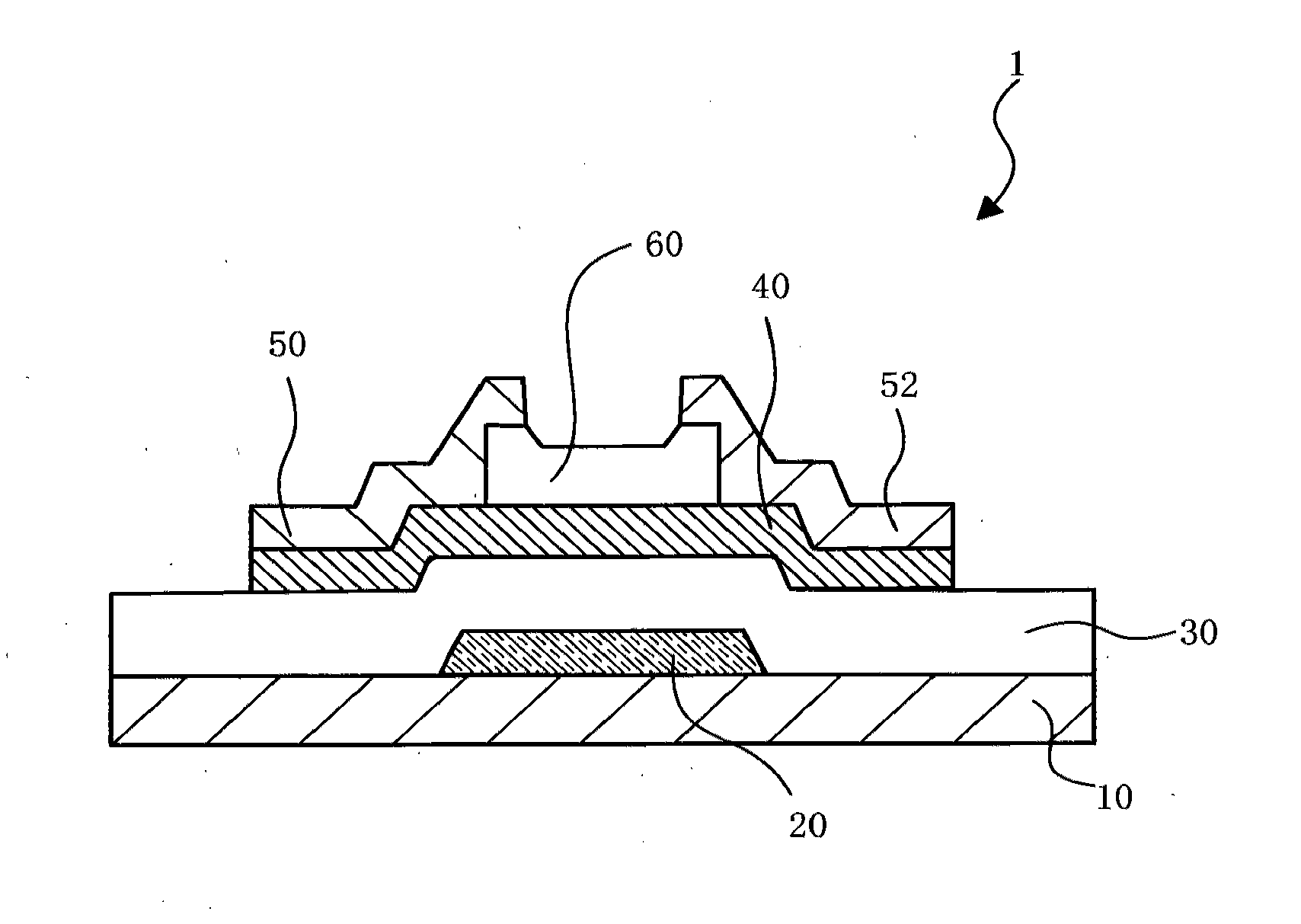

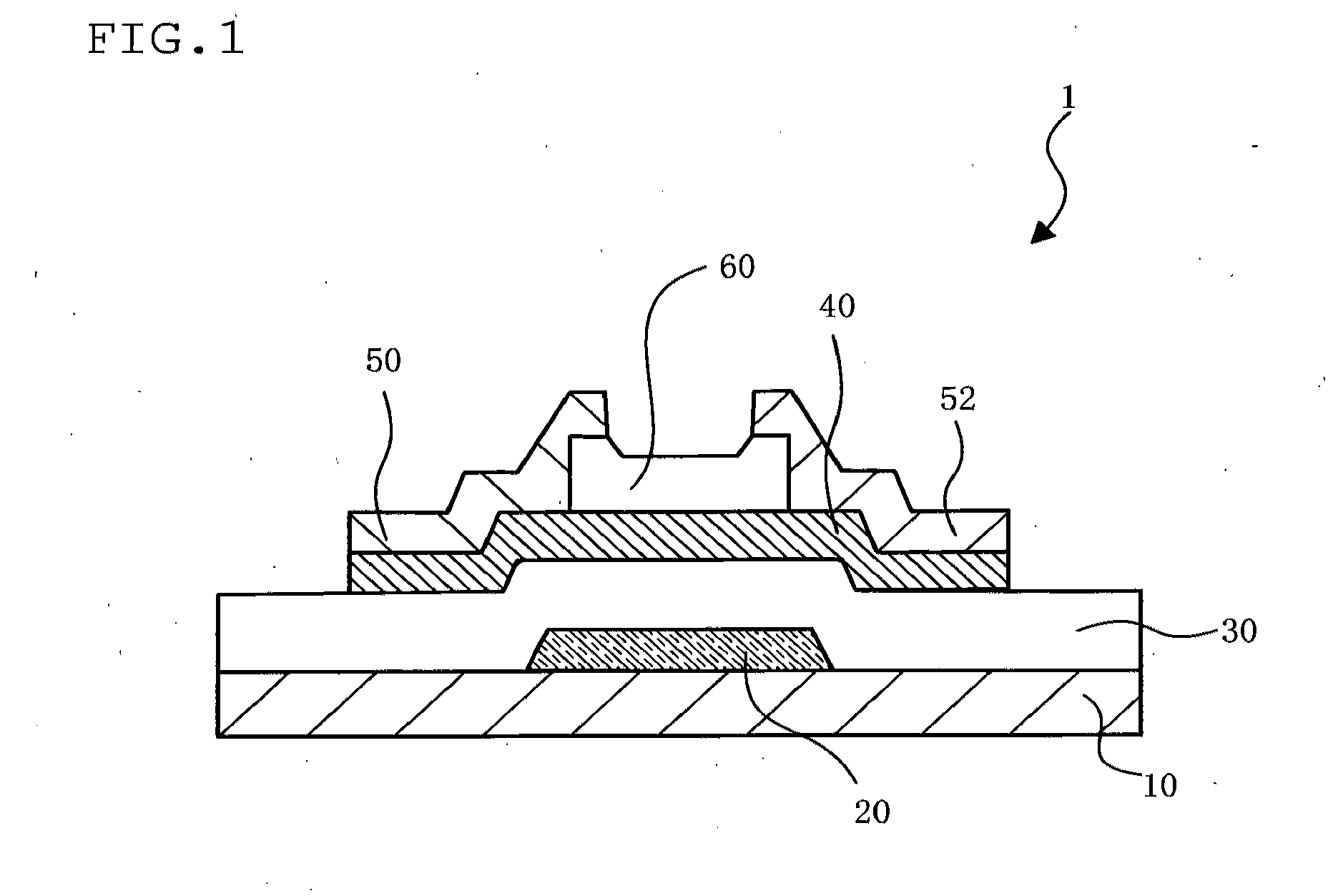

SINTERED In-Ga-Zn-O-TYPE OXIDE

InactiveUS20120184066A1Improve developmentLow resistivityCellsVacuum evaporation coatingIndiumOxygen

An oxide sintered body including In (indium element), Ga (gallium element) and Zn (zinc element), having a total content of In, Ga and Zn relative to total elements except for an oxygen element of 95 at % or more, and including a compound having a bixbyite structure represented by In2O3 and a compound having a spinel structure represented by ZnGa2O4.

Owner:IDEMITSU KOSAN CO LTD

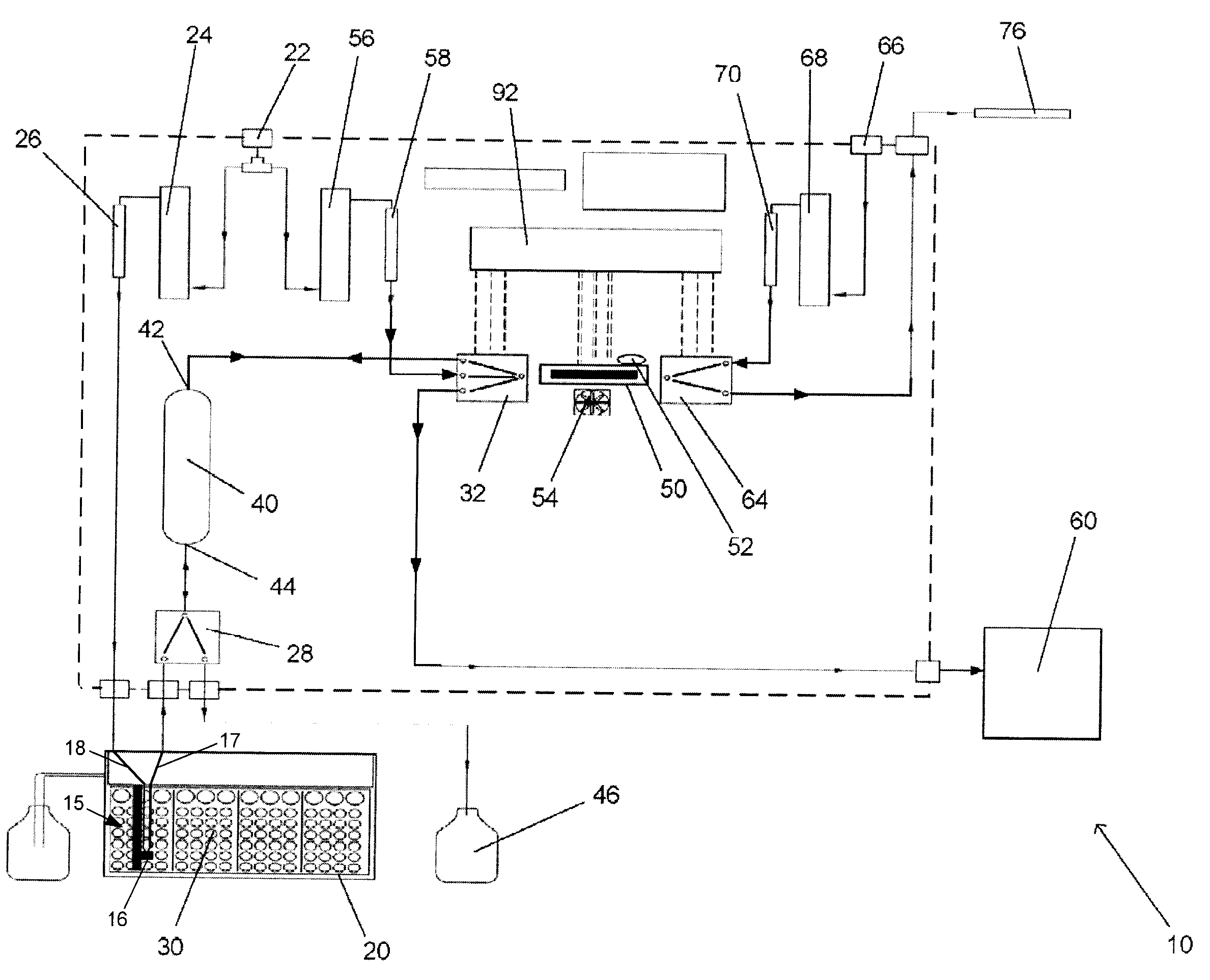

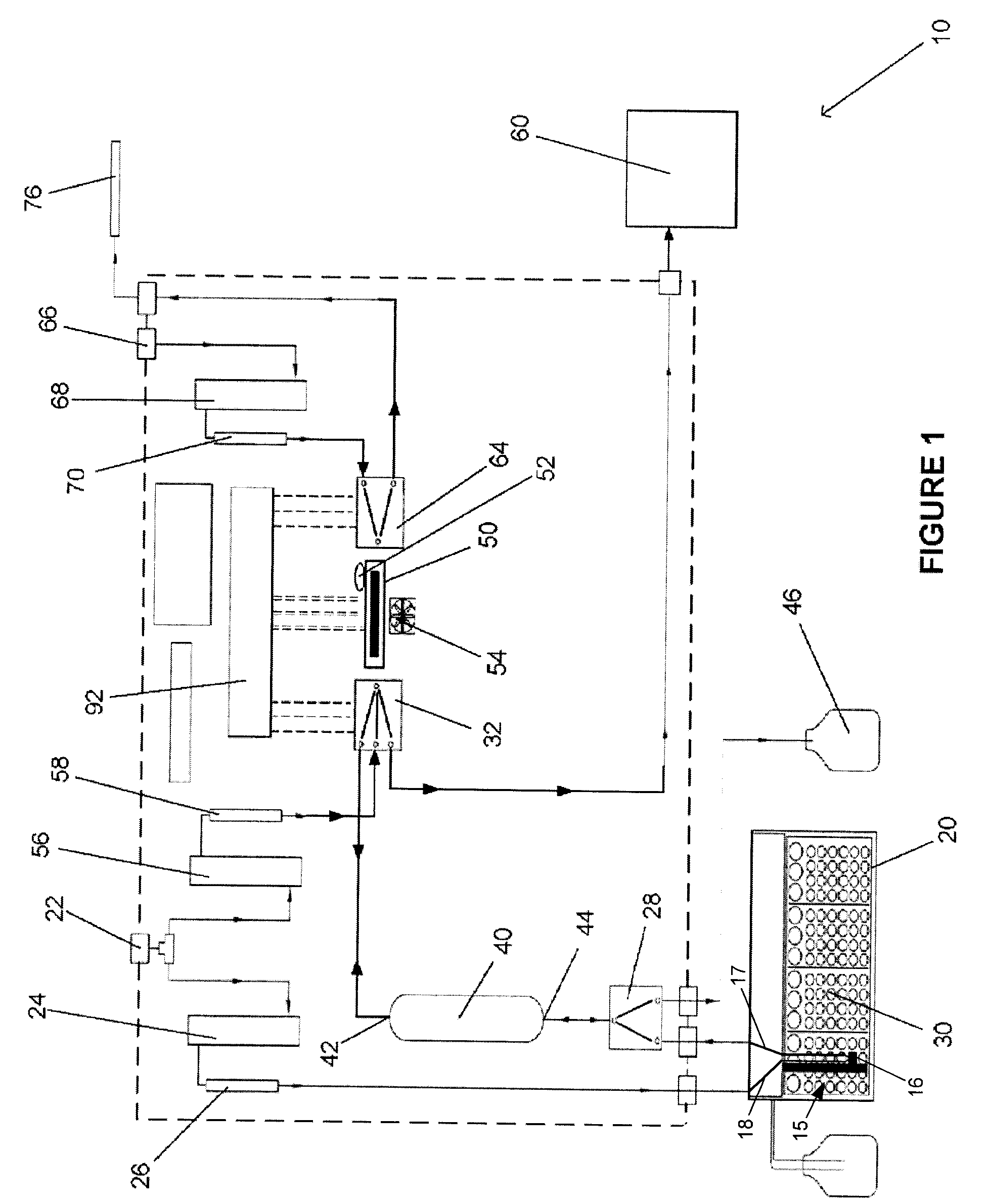

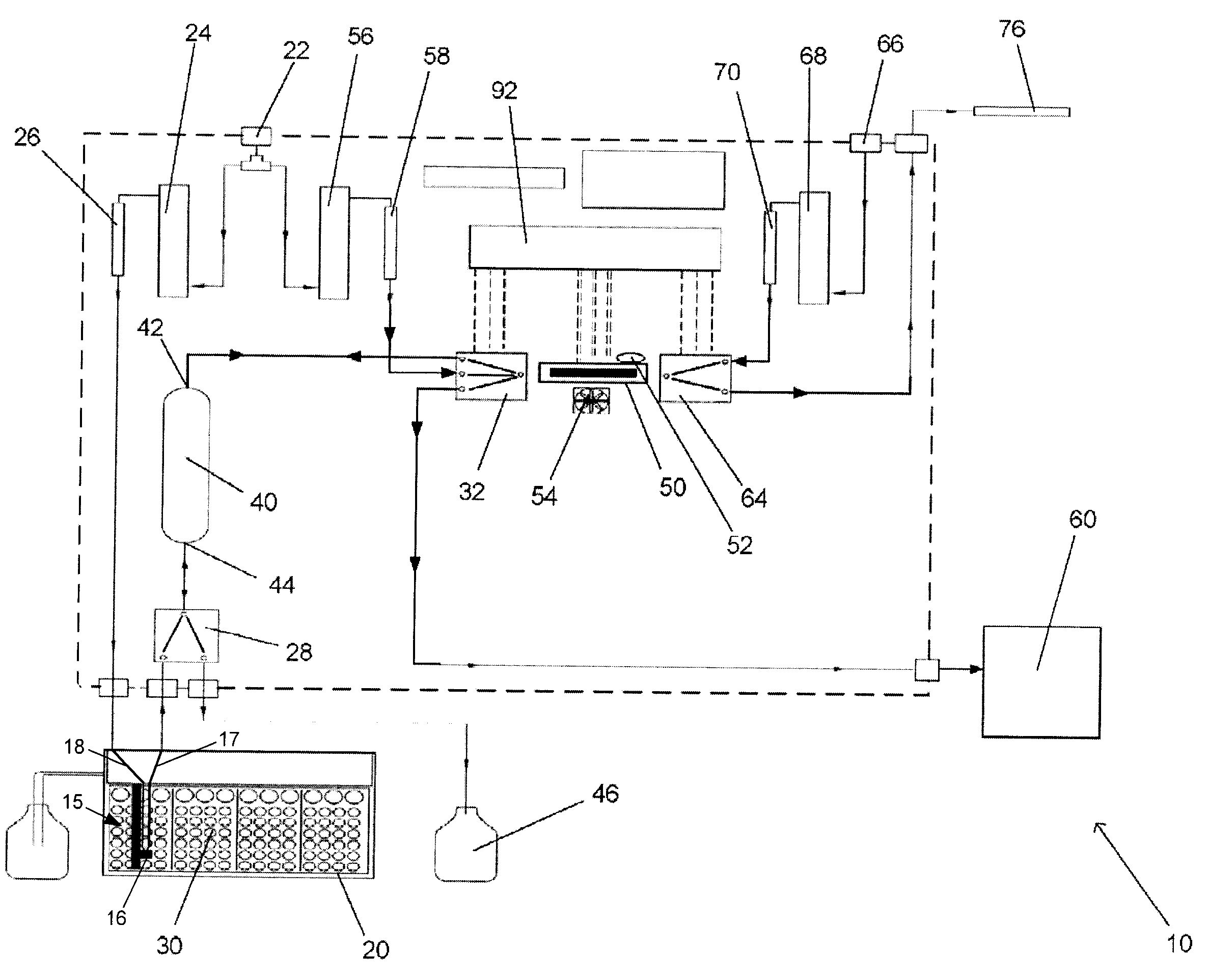

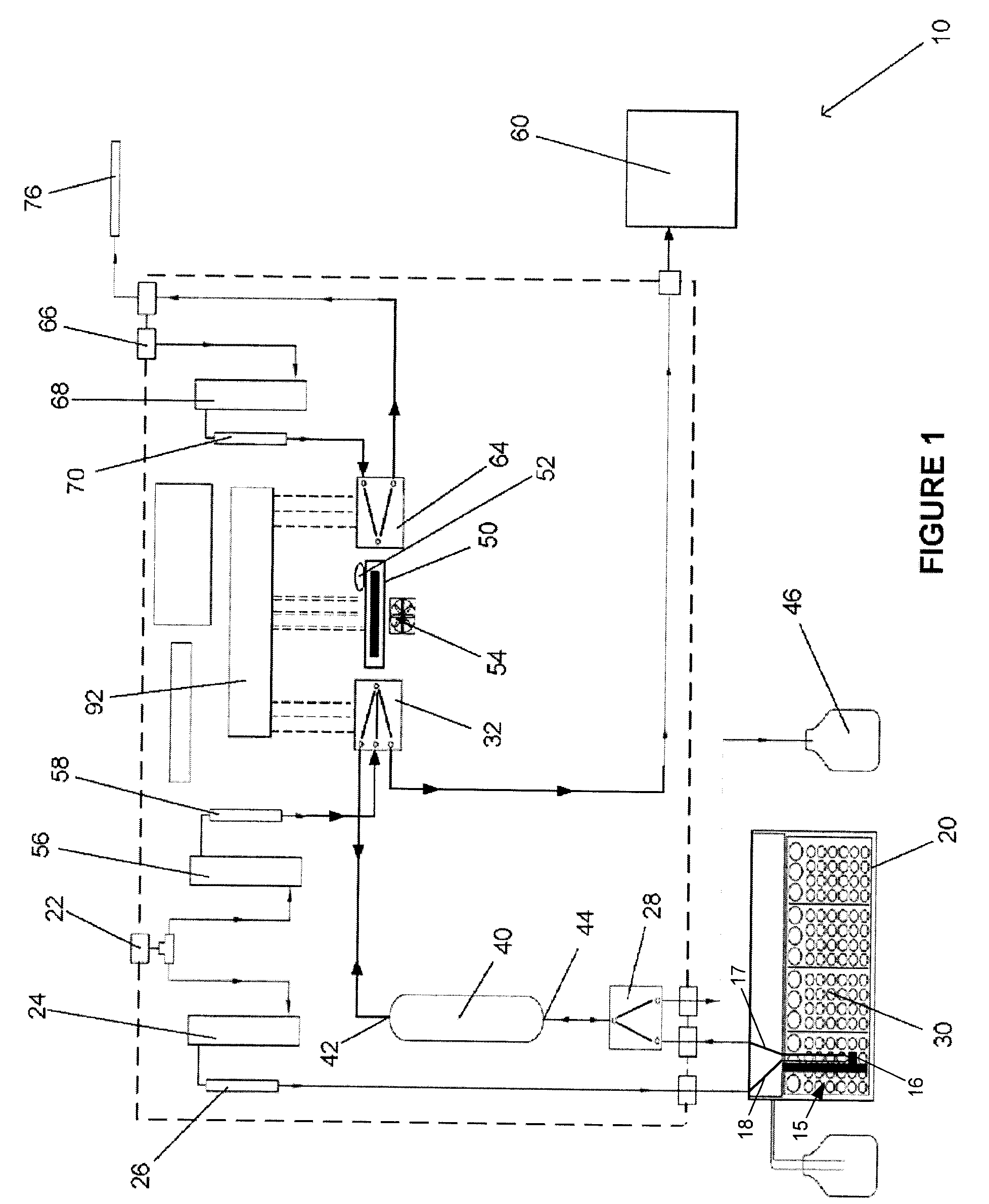

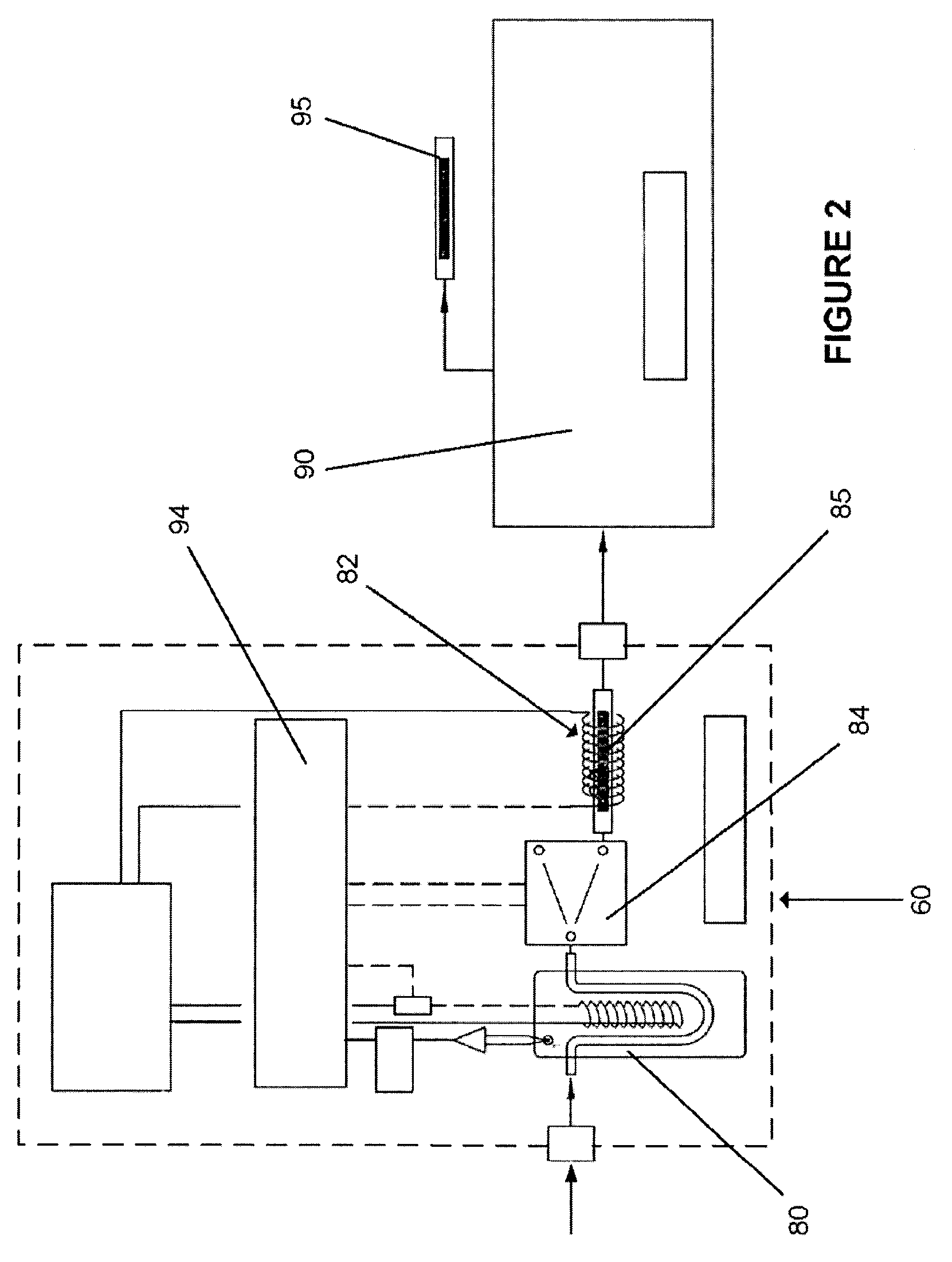

Automated system for detection of chemical compounds

ActiveUS7552617B2Efficient and cost-effective processing and detectionReduce amountLiquid degasificationComponent separationVapor–liquid separatorChemical compound

An automated system for processing a liquid test sample is provided. The disclosed automated system comprises a gas and liquid separator; an attachment for a first gas source that provides a flow of gas for transferring the test sample from a sealable sample container to the gas and liquid separator and for removing at least one volatile component from the test sample in the gas and liquid separator, wherein a chemical compound of interest present in the test sample is converted to at least one volatile species prior to transfer of the test sample into the gas and liquid separator, a trapping vessel in fluid communication with the gas and liquid separator, wherein the trapping vessel contains at least one material capable of separating the at least one volatile species of the chemical compound from the at least one volatile component and retaining the at least one volatile species, and a heat source for rapidly heating the at least one material in the trapping vessel to a temperature sufficient to release the at least one volatile species from the at least one material.

Owner:BROOKS RAND LABS

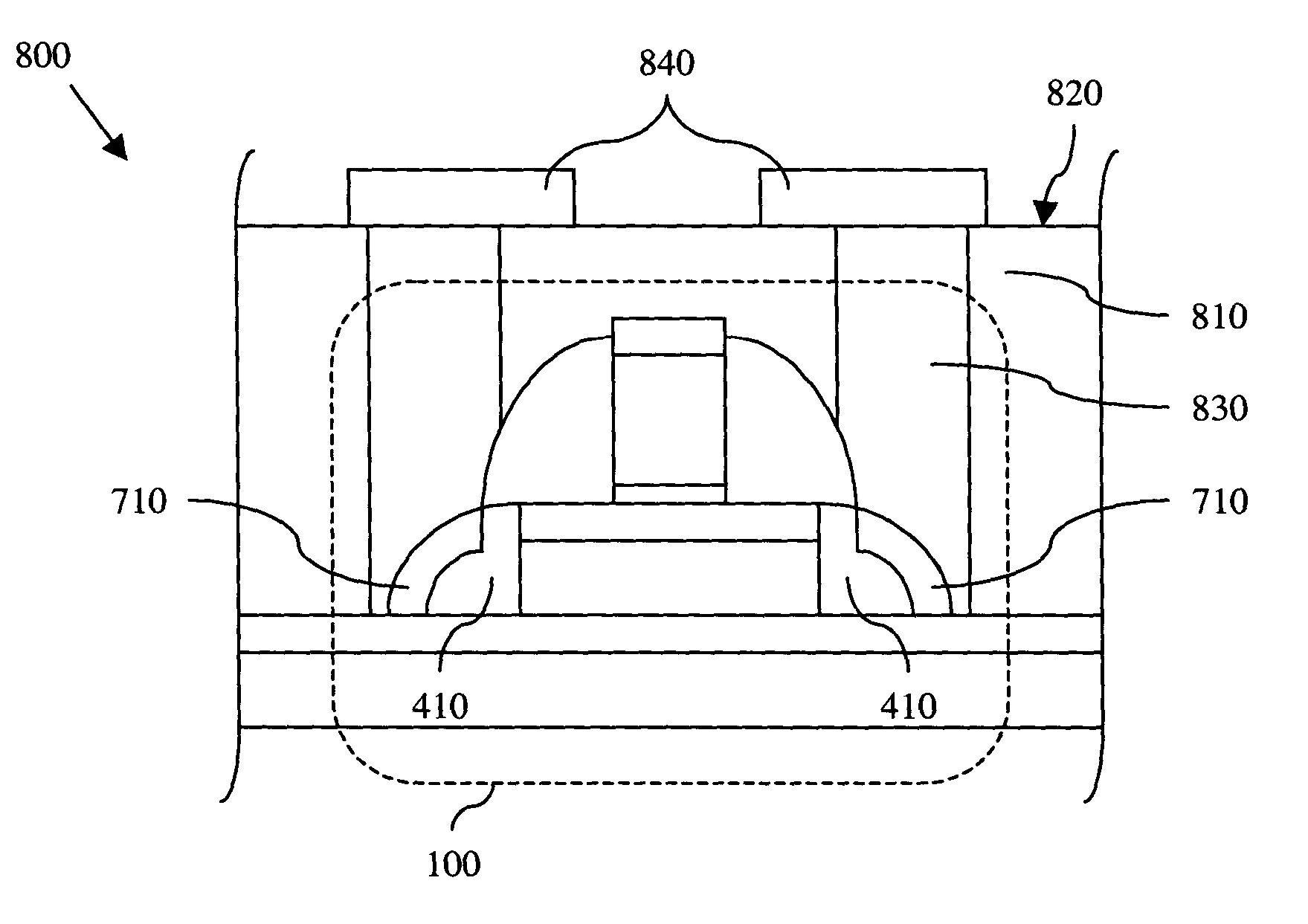

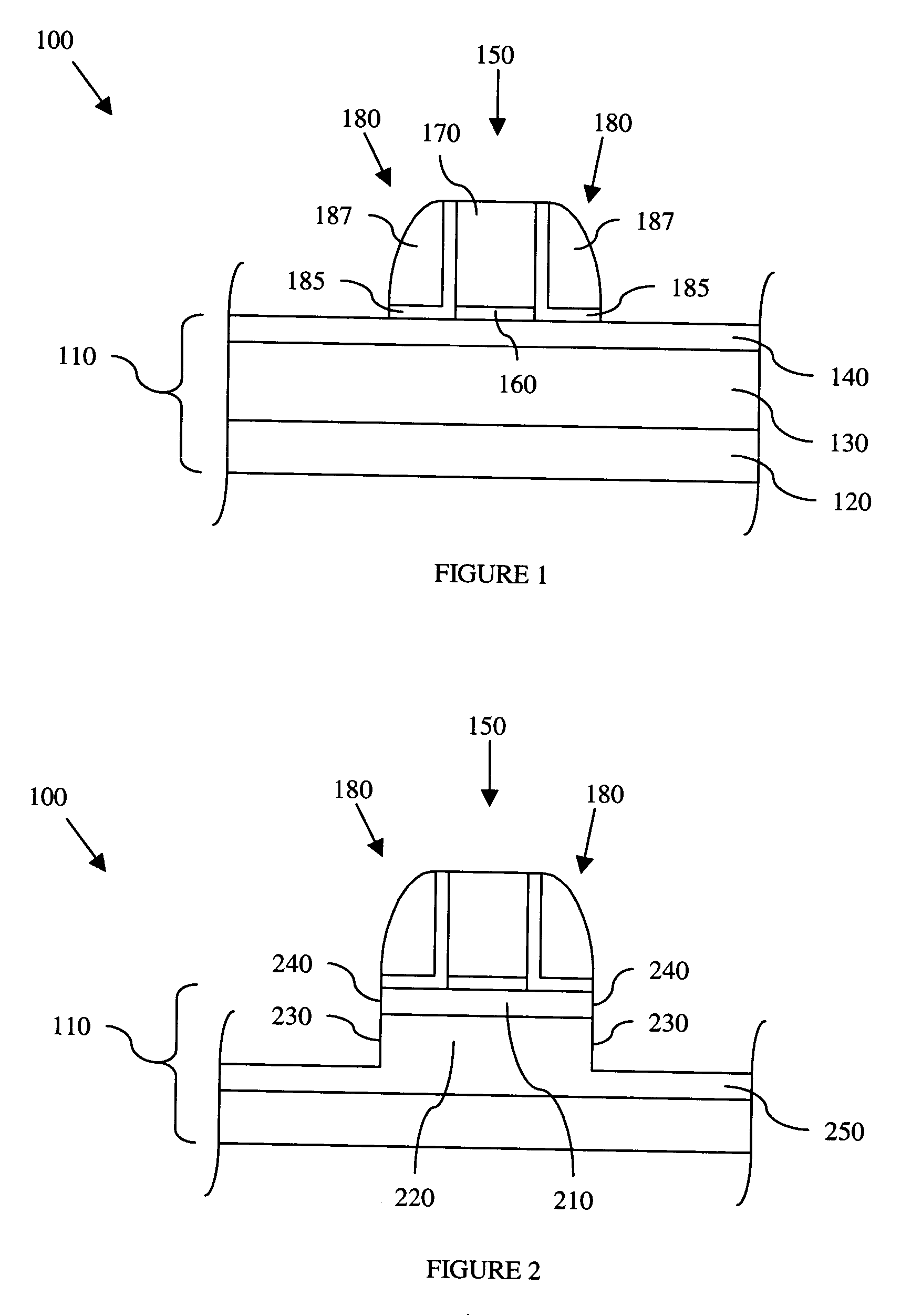

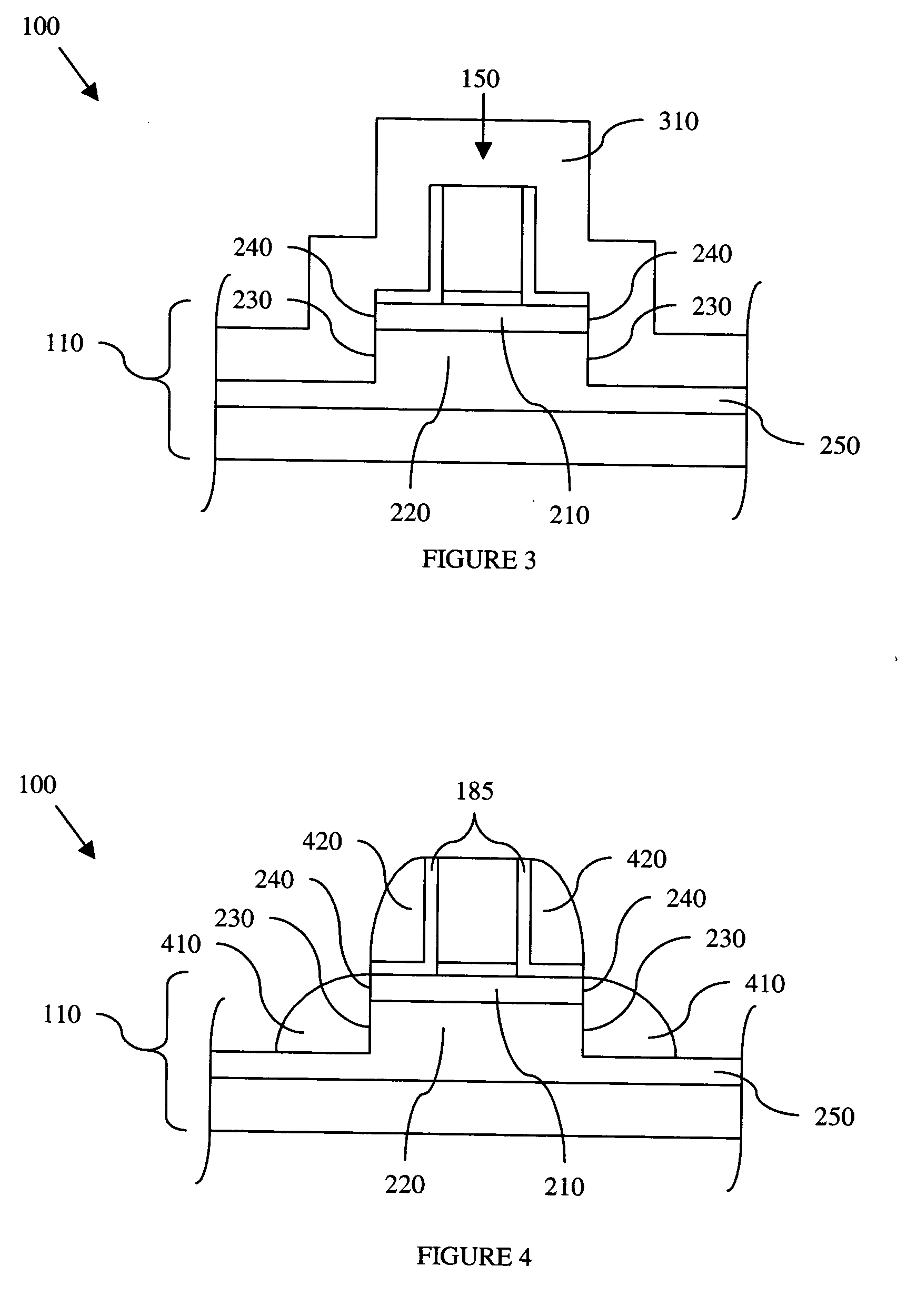

Ultra-thin body transistor with recessed silicide contacts

InactiveUS20050045949A1Avoid insufficient thicknessIncreasing the thicknessTransistorSolid-state devicesDielectricDevice material

A semiconductor device (100), including a dielectric pedestal (220) located above and integral to a substrate (110) and having first sidewalls (230), a channel region (210) located above the dielectric pedestal (220) and having second sidewalls (240), and source and drain regions (410) opposing the channel region (210) and each substantially spanning one of the second sidewalls (240). An integrated circuit (800) incorporating the semiconductor device (100) is also disclosed, as well as a method of manufacturing the semiconductor device (100).

Owner:TAIWAN SEMICON MFG CO LTD

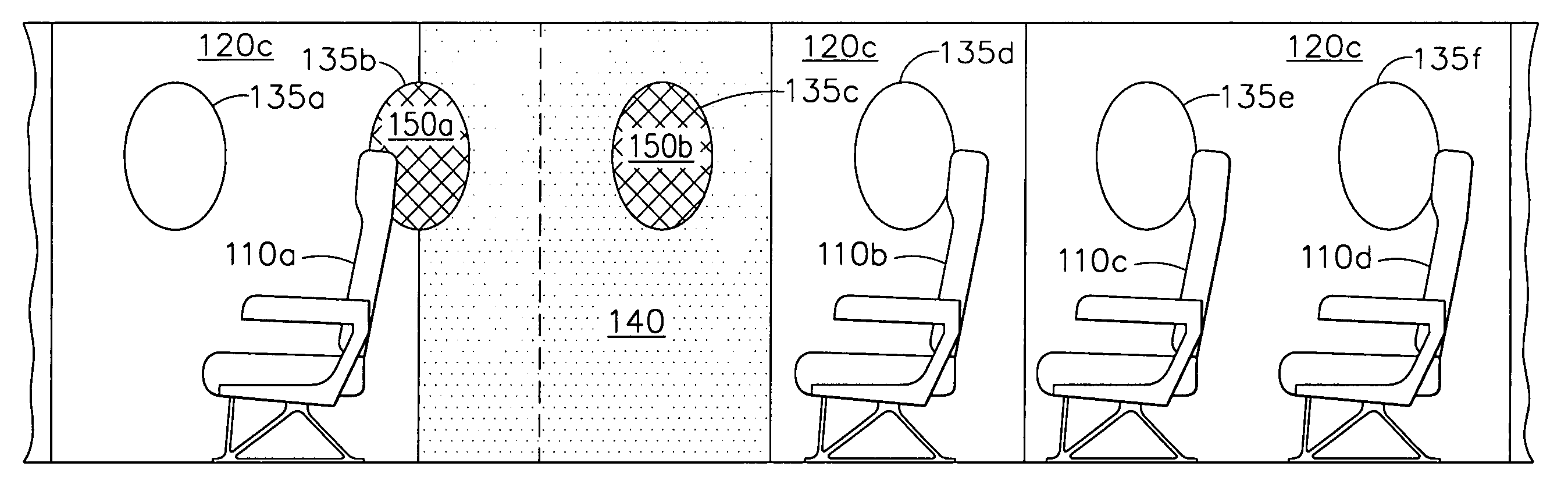

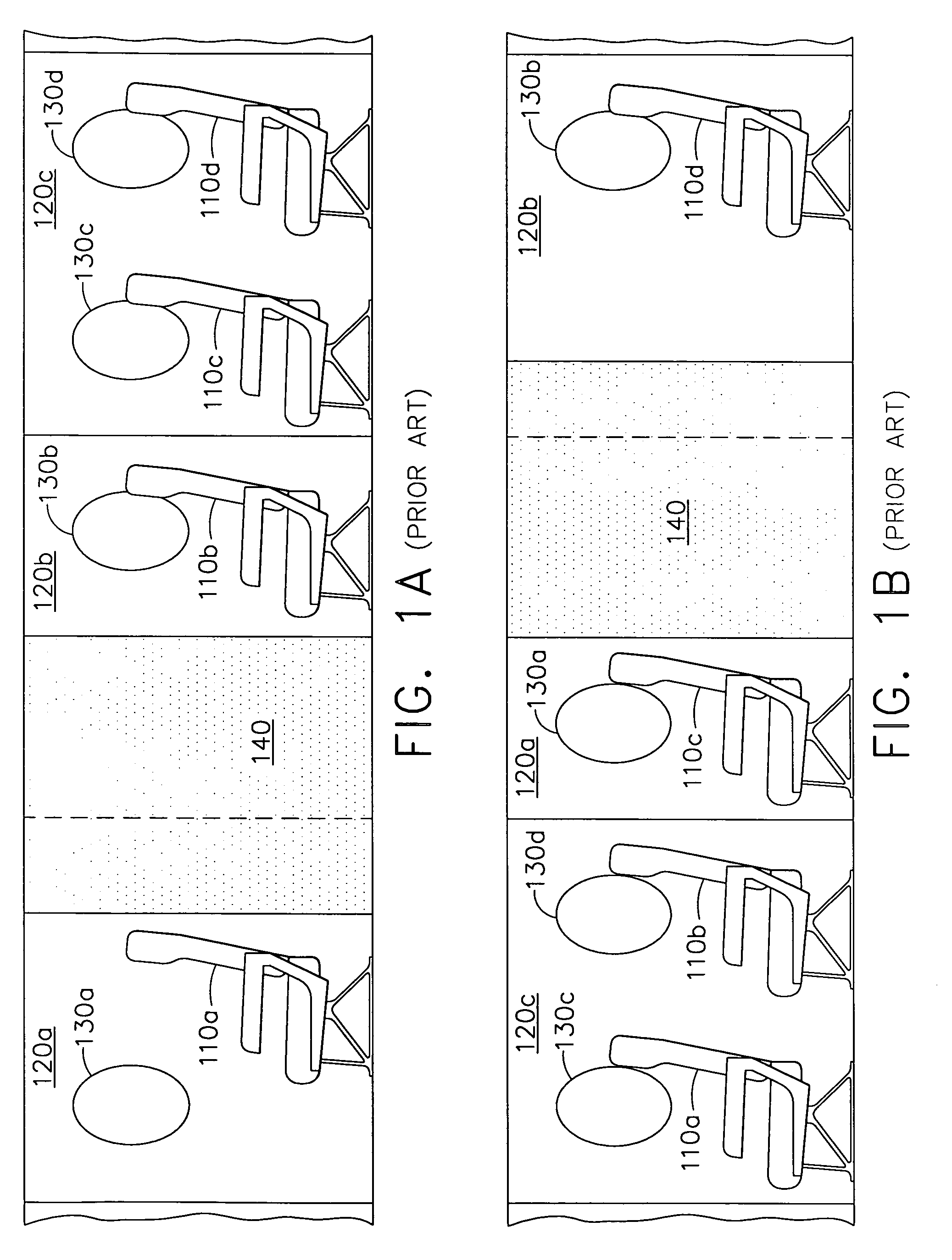

Reconfigurable interior sidewall

InactiveUS7210655B2Excessively uniformFaster and less expensive interior reconfigurationsFuselagesAircraft floorsEngineeringFuselage

A reconfigurable interior sidewall system includes one or more simply curved sidewall panels, each curved around the fuselage but longitudinally linear and providing a consistent mating surface for monuments. Panel openings are provided in each panel so that inner window assemblies may be installed for opposing structural windows, each inner window assembly having outward sculpturing for additional cabin room. A cover plate is also provided for flush insertion into the opening to fill the opening when it is not needed and to provide a constant profile for cabin monuments whenever the layout of the cabin changes. This results in the production of fewer parts as well as facilitating faster and less expensive interior reconfigurations.

Owner:THE BOEING CO

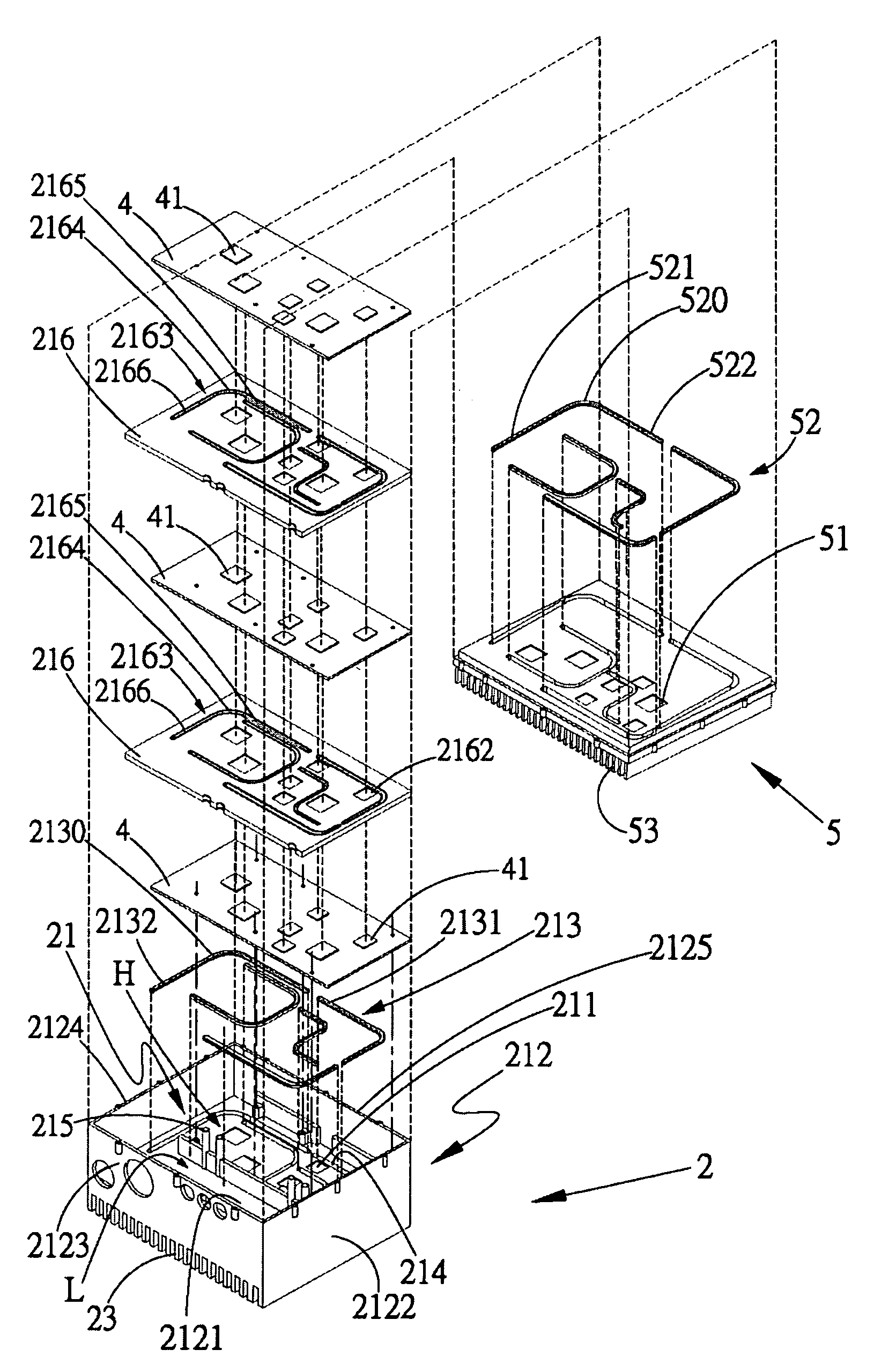

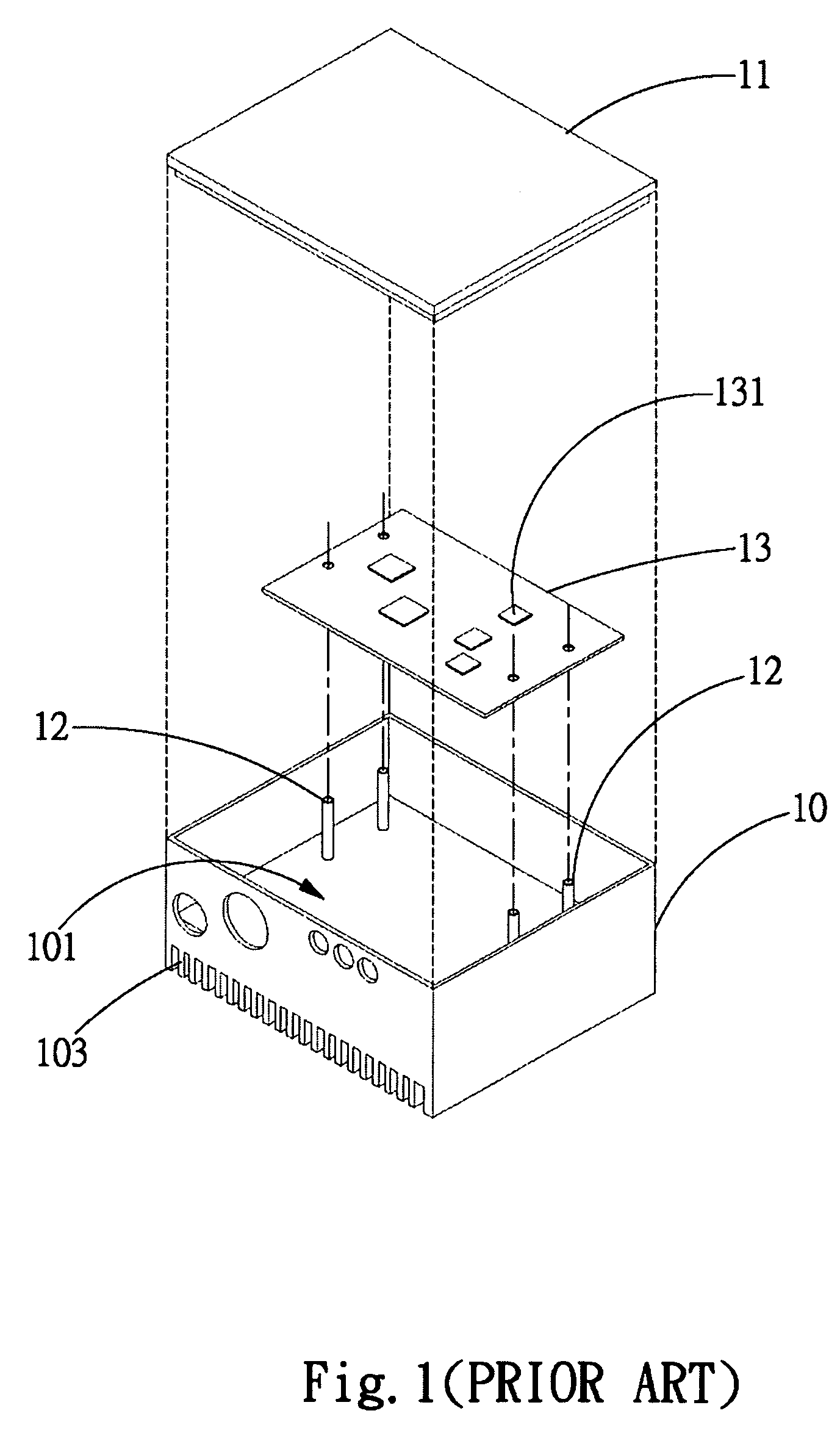

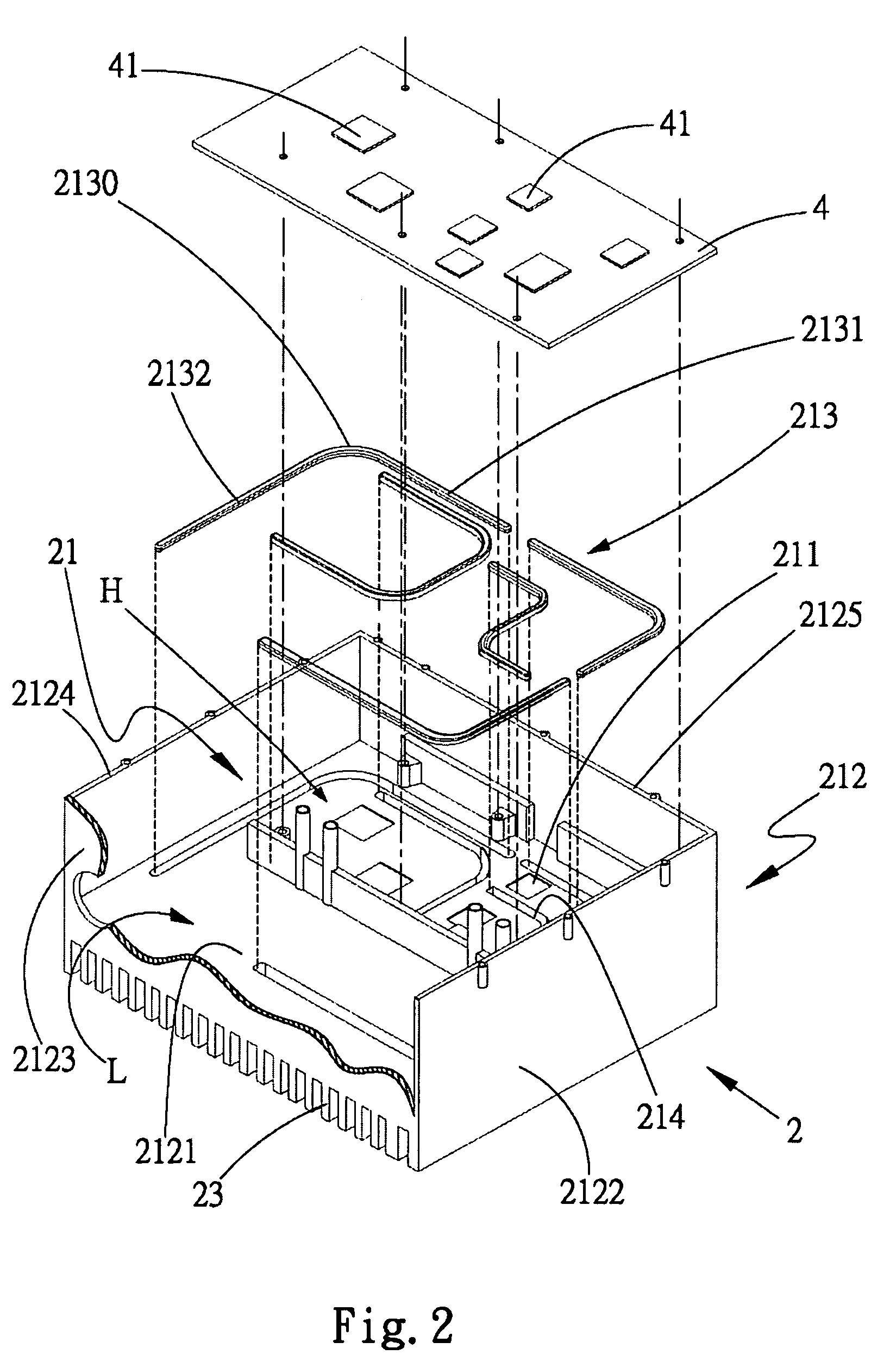

Heat dissipation structure for communication chassis

InactiveUS7924565B2Increase heat dissipation structureHeat dissipation fastDigital data processing detailsInsulated cablesEngineeringCopper

A heat dissipation structure for communication chassis. The heat dissipation structure includes an enclosure. At least one first copper heat absorption component and at least one first heat pipe assembly are disposed in the enclosure. The first heat pipe assembly is connected with the first copper heat absorption component and a section not in contact with the first copper heat absorption component. The first heat pipe assembly serves to quickly transfer heat absorbed by the first copper heat absorption component to the section not in contact with the first copper heat absorption component to dissipate the heat.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

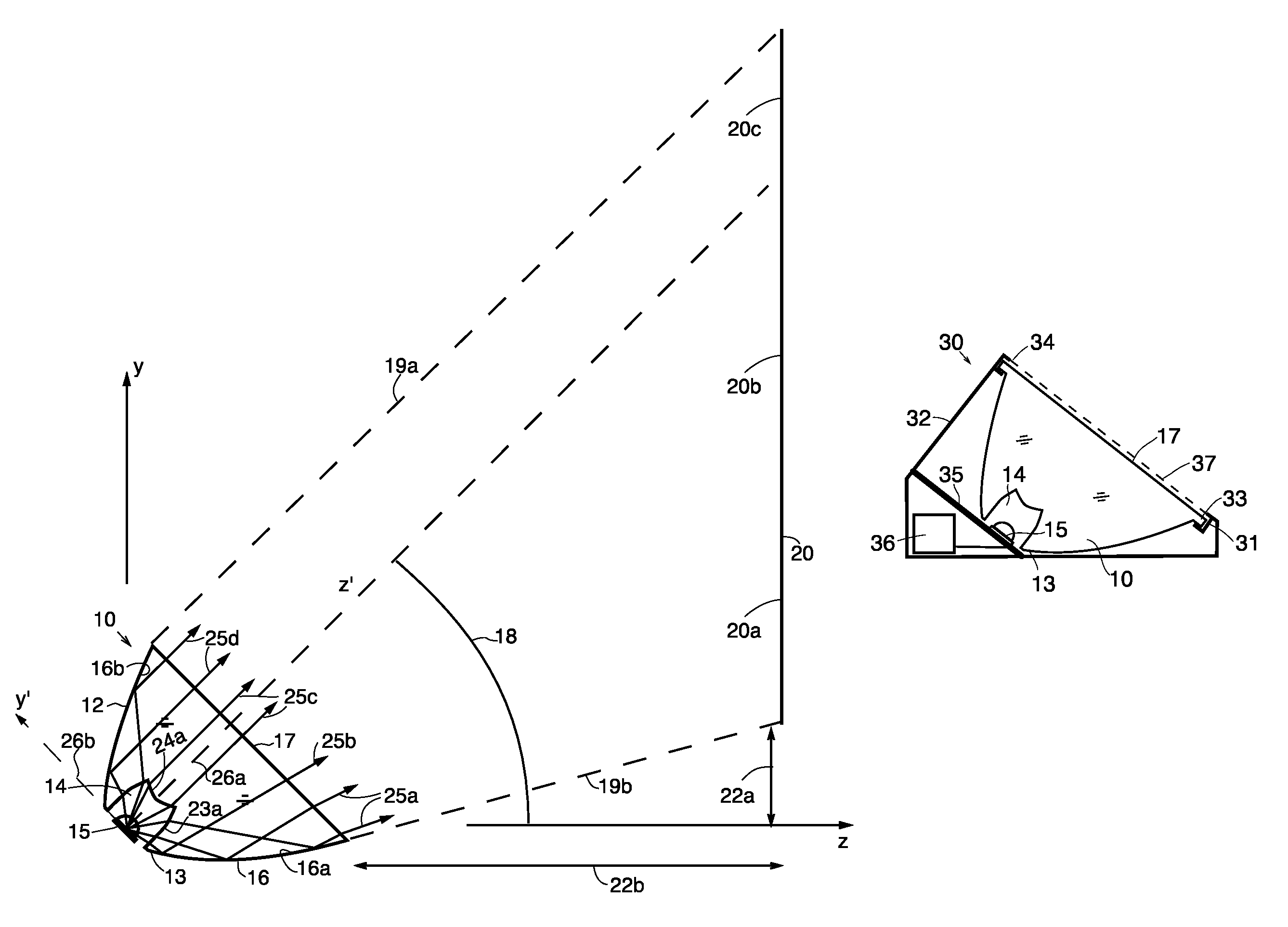

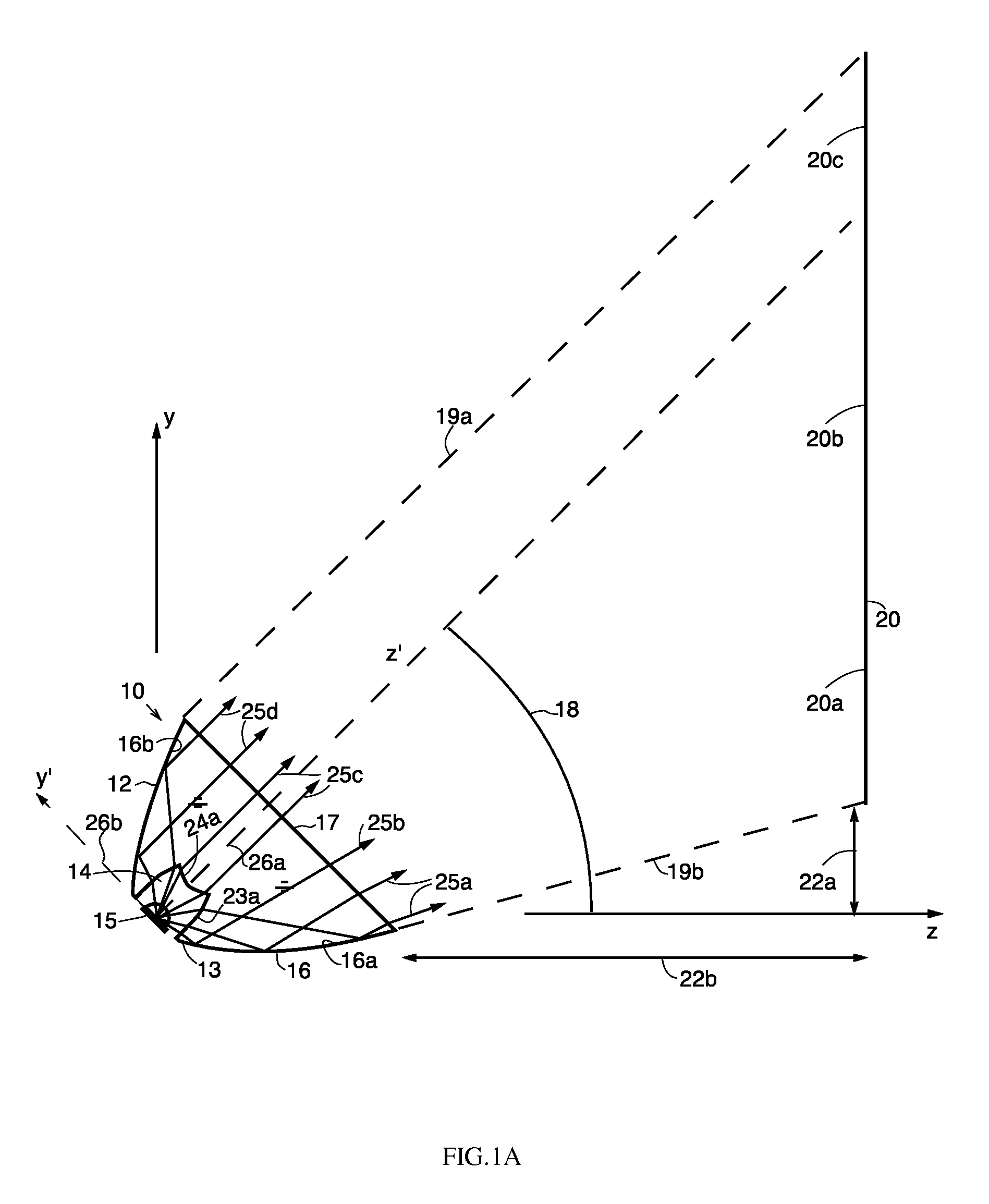

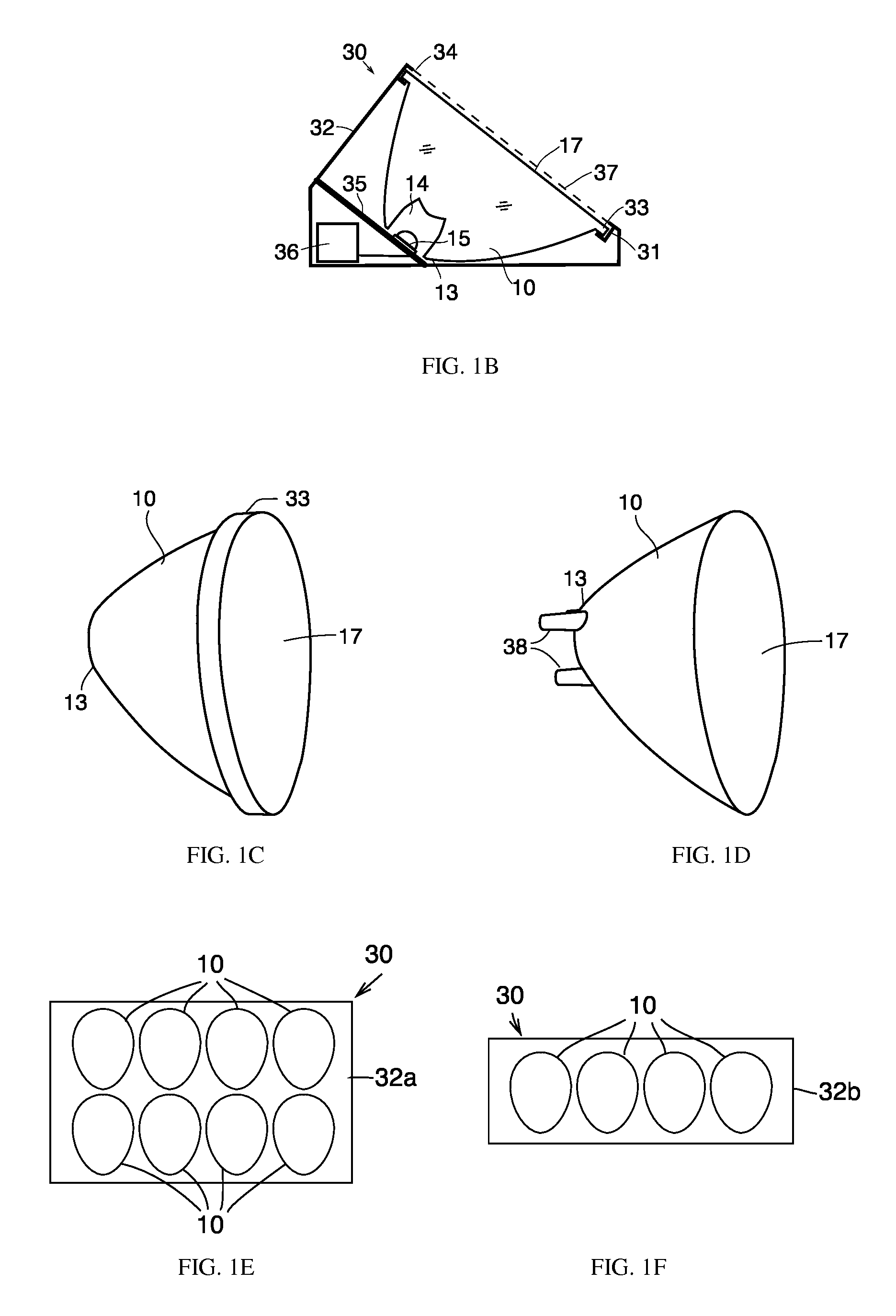

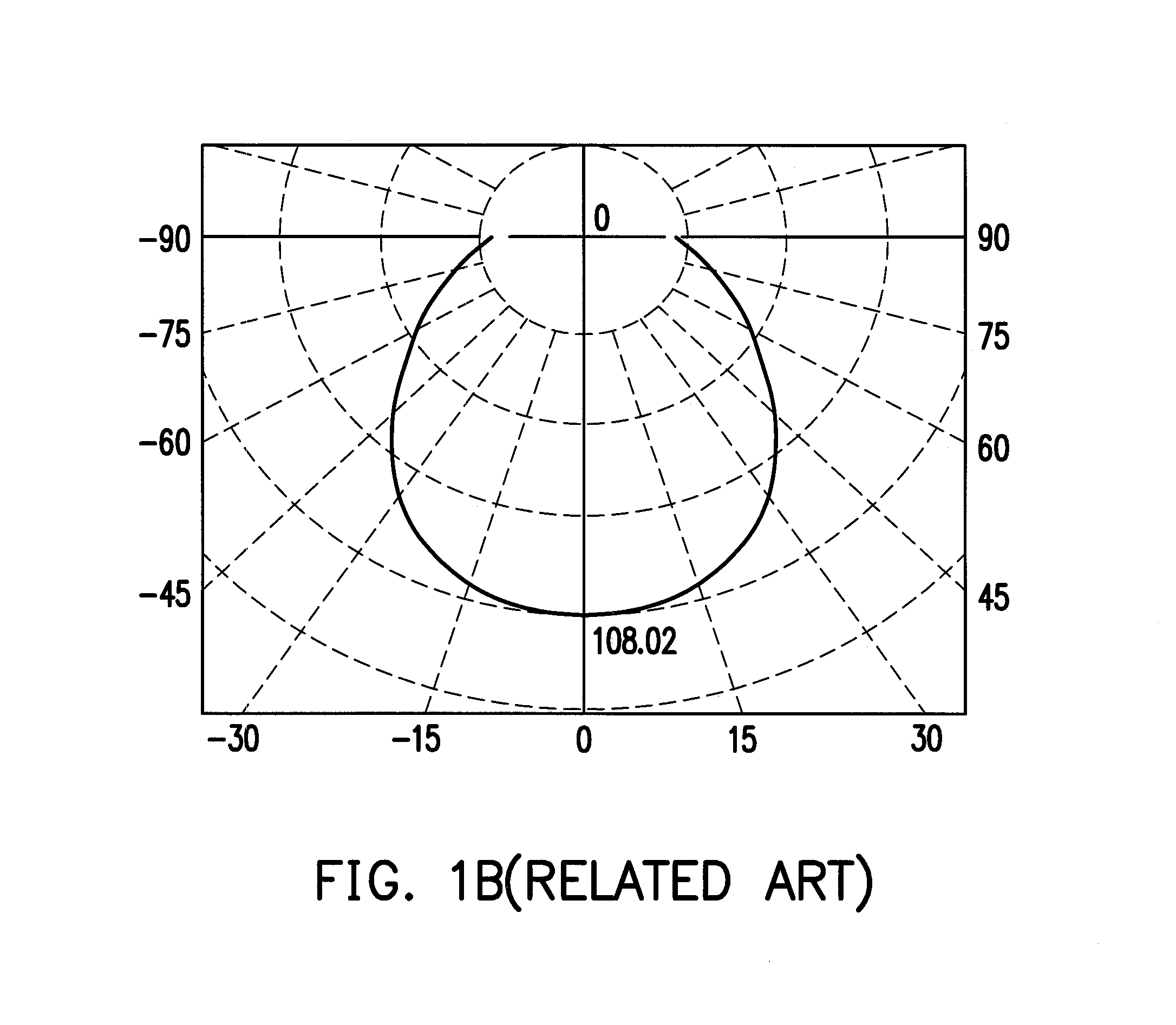

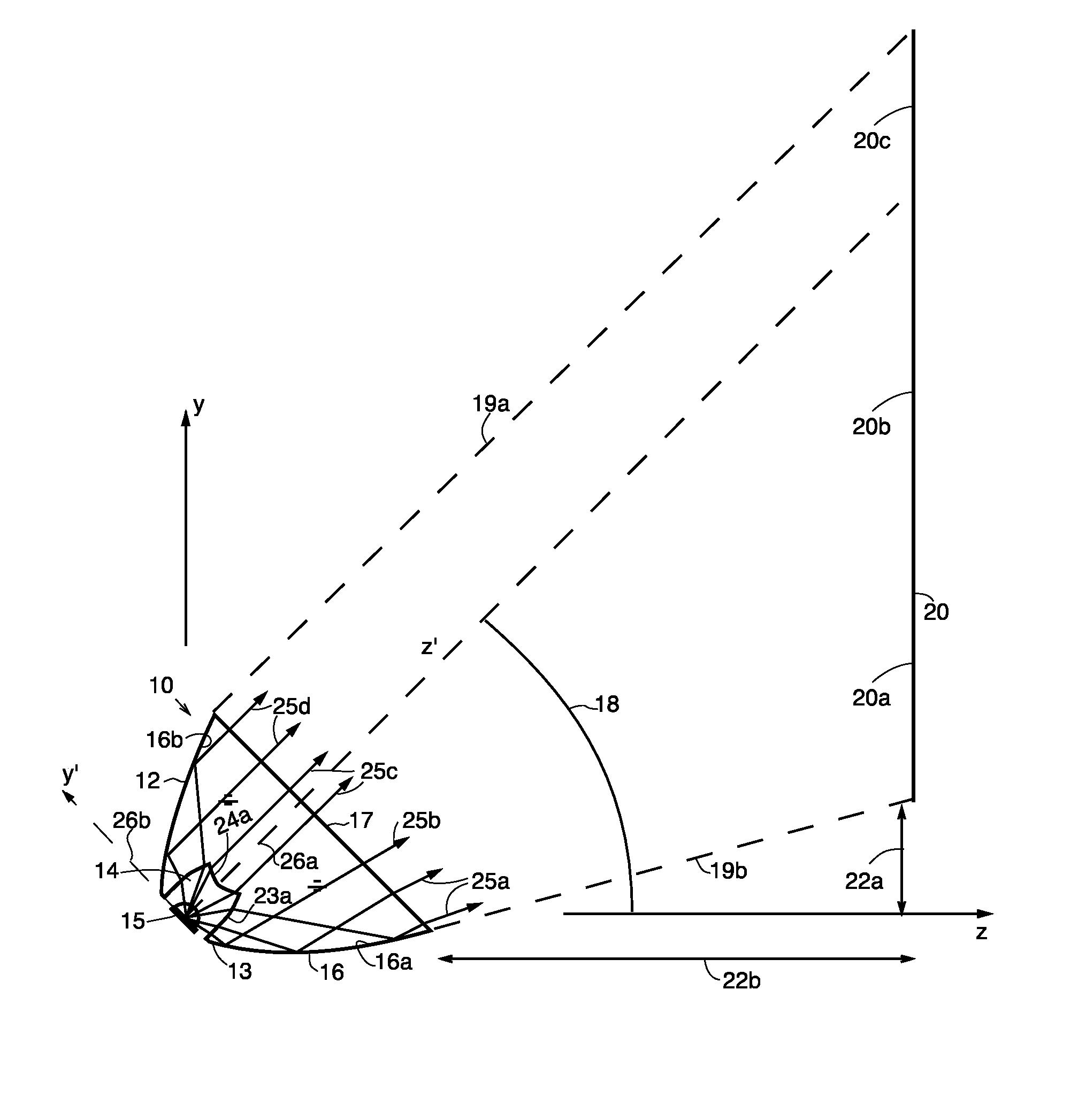

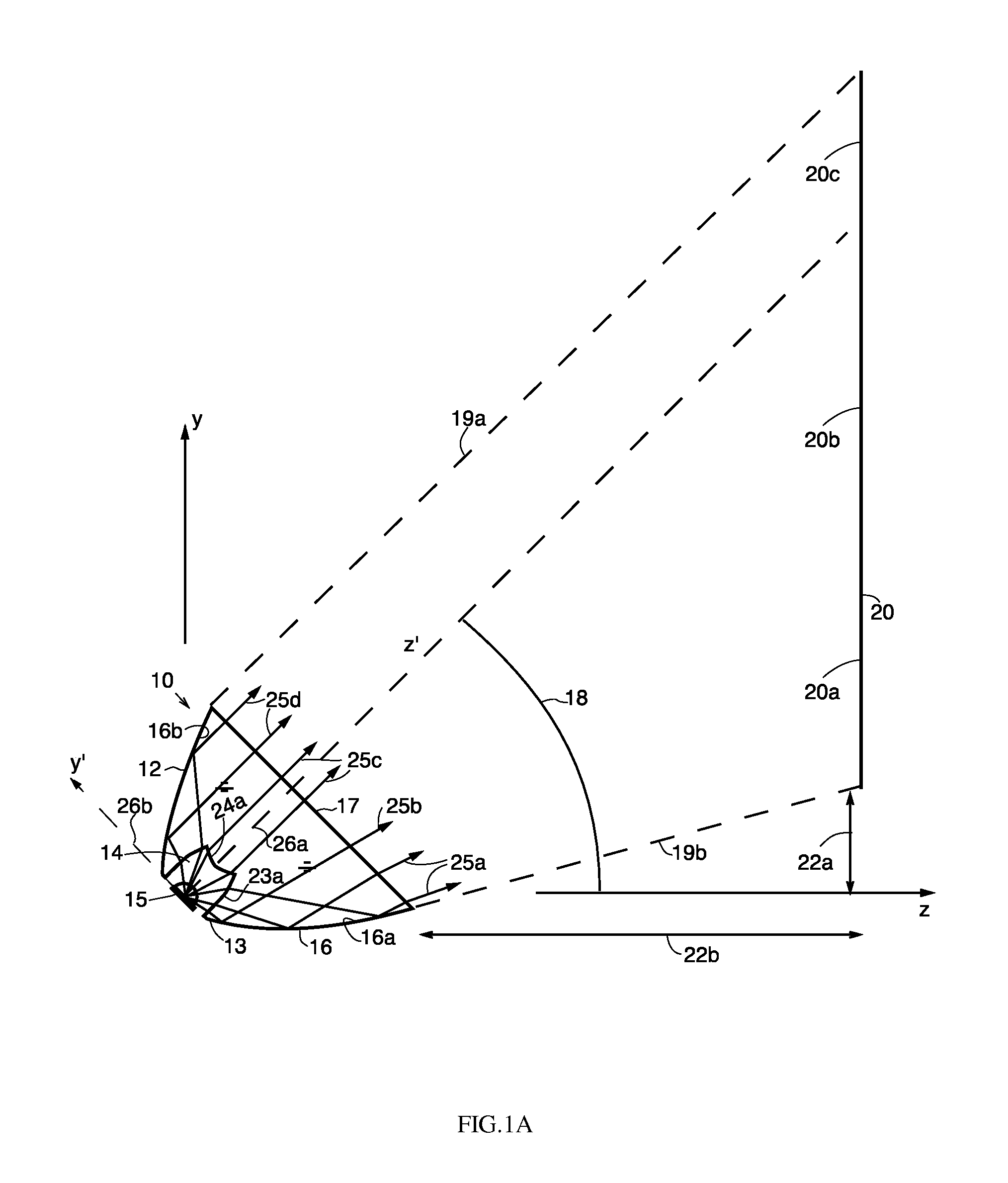

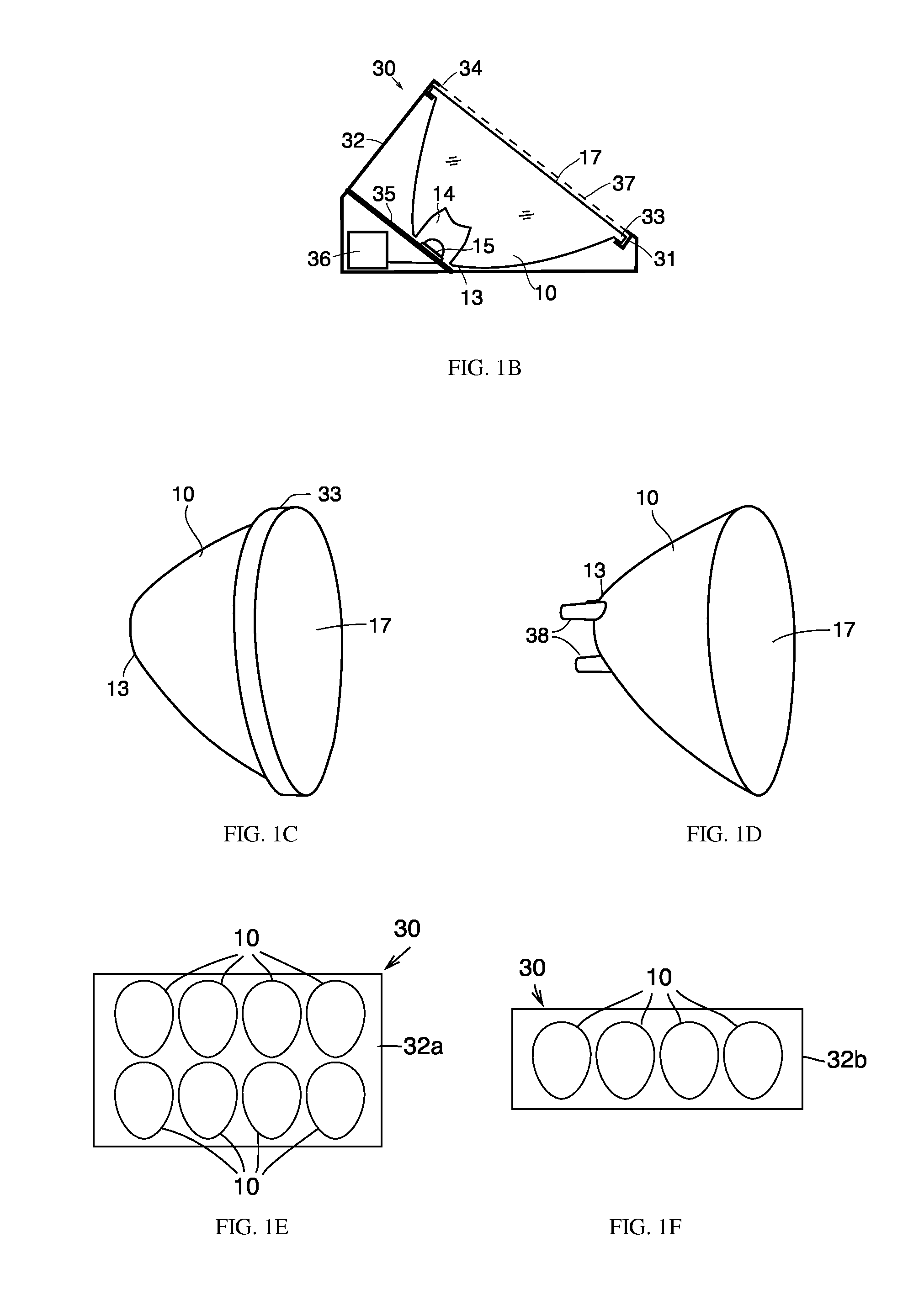

Optical element providing oblique illumination and apparatuses using same

ActiveUS9239141B1Increase illuminationExcessively uniformPlanar light sourcesMechanical apparatusTarget surfaceOptical axis

An optical element is provided having an asymmetric body, a light source, and a front face tilted at an oblique angle with respect to a target surface to provide illumination that is at least substantially uniform along the target surface's height. One or more optical elements may be in an apparatus, and multiple apparatuses may be disposed in front of one edge of a target surface to provide thereto at least substantially uniform oblique illumination. When the light source is an LED that is spectrally non-uniform at increasing angles away from its optical axis, the optical elements having such LEDs provide illumination that is spectrally non-uniform along a portion of the target surface, and additional optical elements with LED light sources are provided having a spectrum in one or more spectral ranges that compensates for such spectral non-uniformity to correct spectral non-uniformity along such portion of the target surface.

Owner:VIAVI SOLUTIONS INC

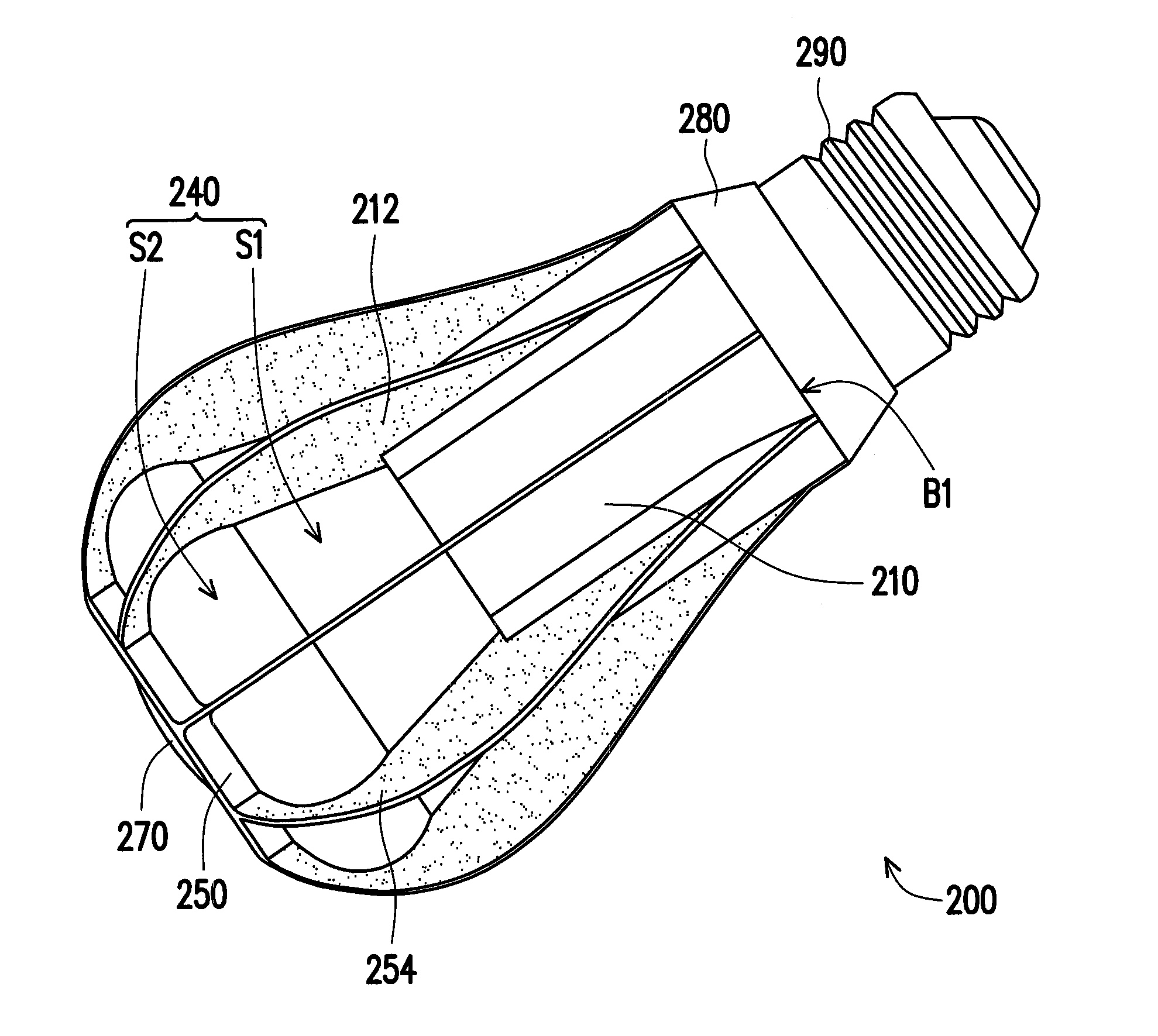

Light emitting diode bulb

ActiveUS20120326589A1Better heat dissipation structureWide angleSolid cathodesDischarge tube main electrodesOptical surfaceLight emitting device

A light emitting diode bulb including a heat sink, a light source plate, a reflective frame and a secondary optical component is provided. The light source plate includes a circuit board disposed on the heat sink and a plurality of light emitting devices disposed on the circuit board. The reflective frame disposed on the light source plate includes a plate portion and a reflective pillar. The plate portion has a plurality of openings exposing the light emitting devices. The secondary optical component has a first optical surface and a second optical surface. An absolute value of the slope of a tangent line of any point on the first optical surface with respect to the heat sink is constant. An absolute value of the slope of a tangent line of any point on the second optical surface is gradually smaller along the direction away from the heat sink.

Owner:AMTRAN TECH

Automated System for Detection of Chemical Compounds

ActiveUS20080028930A1Efficient and cost-effective processing and detectionReduce amountLiquid degasificationComponent separationVapor–liquid separatorTest sample

An automated system for processing a liquid test sample is provided. The disclosed automated system comprises a gas and liquid separator; an attachment for a first gas source that provides a flow of gas for transferring the test sample from a sealable sample container to the gas and liquid separator and for removing at least one volatile component from the test sample in the gas and liquid separator, wherein a chemical compound of interest present in the test sample is converted to at least one volatile species prior to transfer of the test sample into the gas and liquid separator, a trapping vessel in fluid communication with the gas and liquid separator, wherein the trapping vessel contains at least one material capable of separating the at least one volatile species of the chemical compound from the at least one volatile component and retaining the at least one volatile species, and a heat source for rapidly heating the at least one material in the trapping vessel to a temperature sufficient to release the at least one volatile species from the at least one material.

Owner:BROOKS RAND LABS

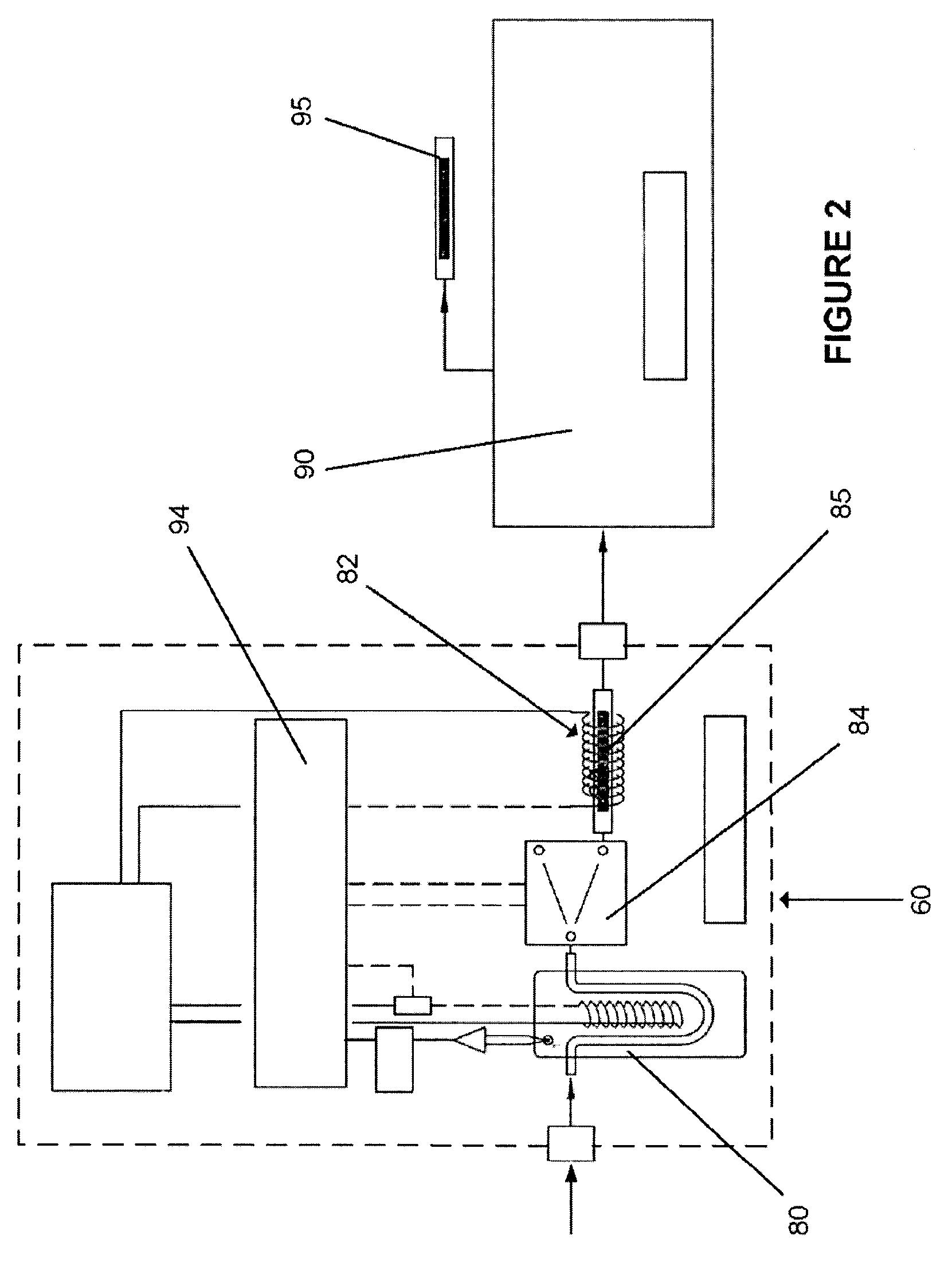

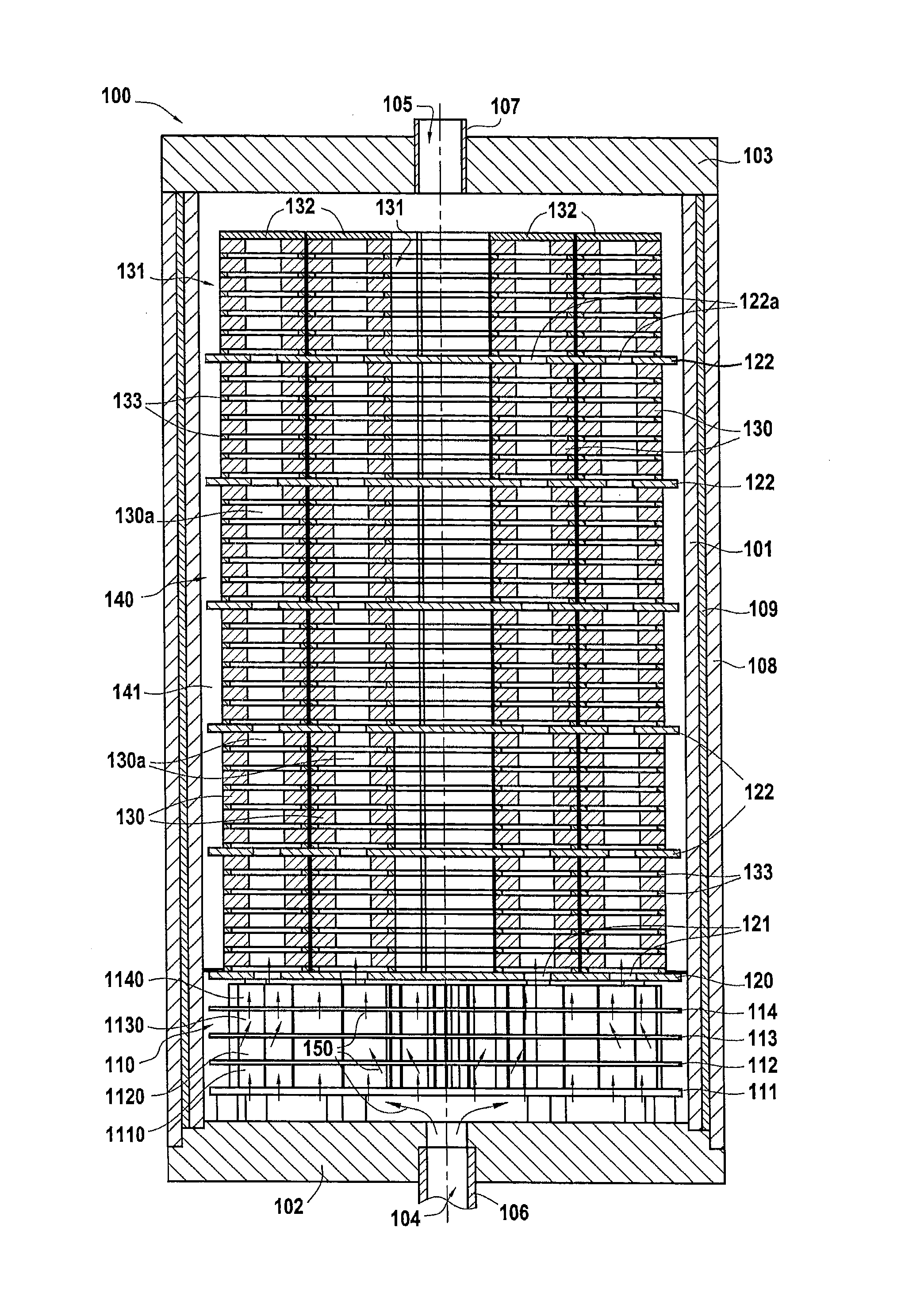

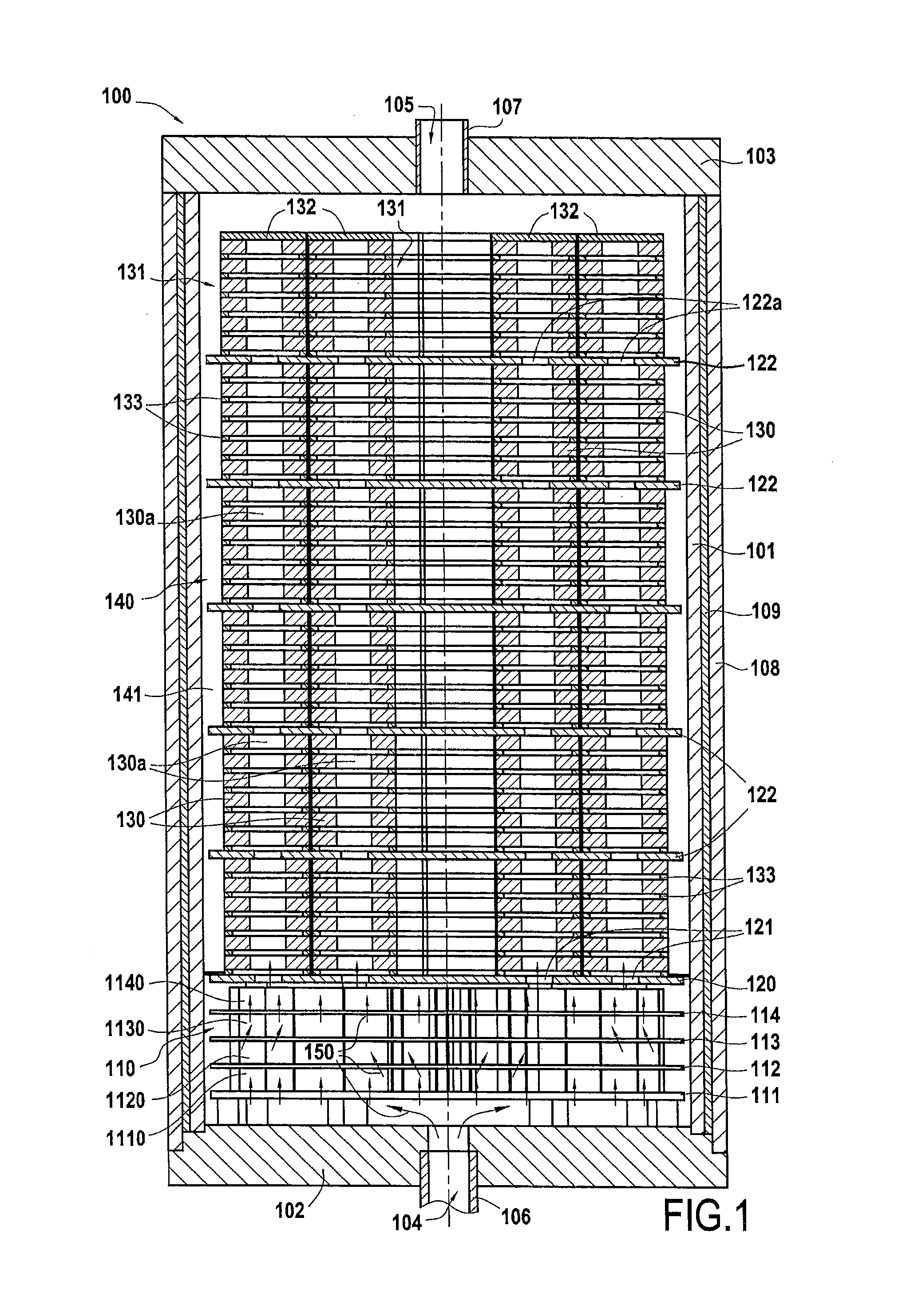

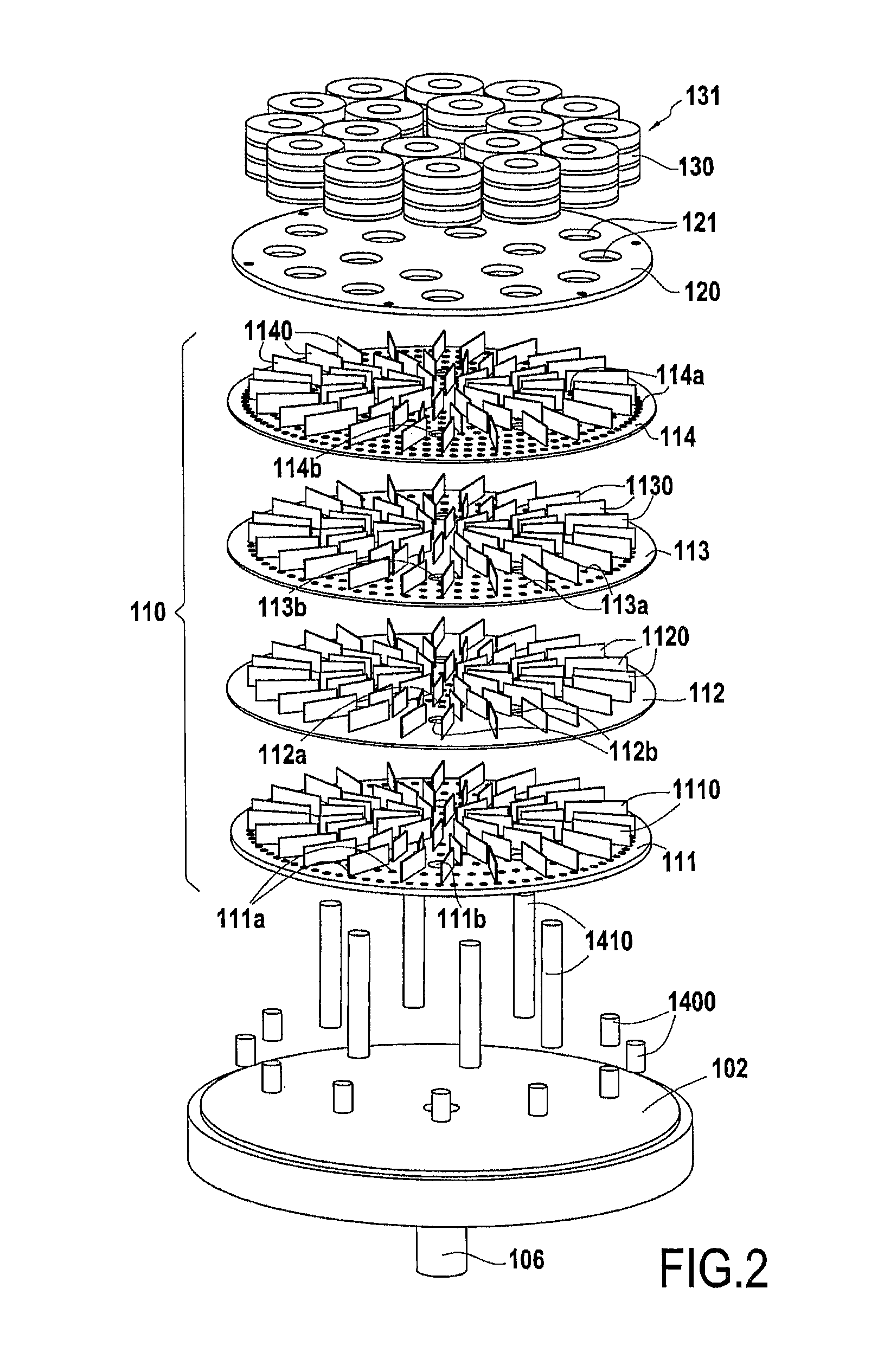

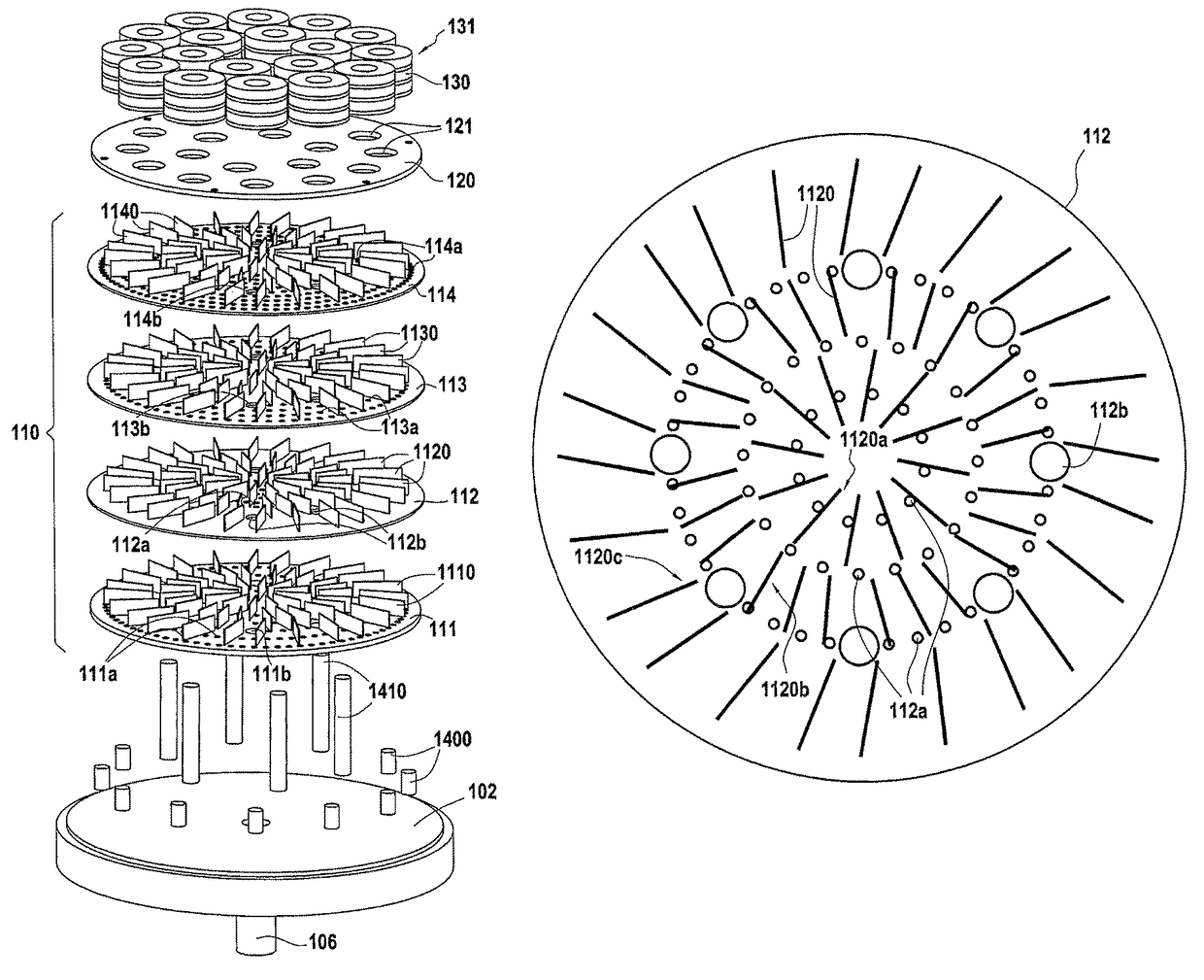

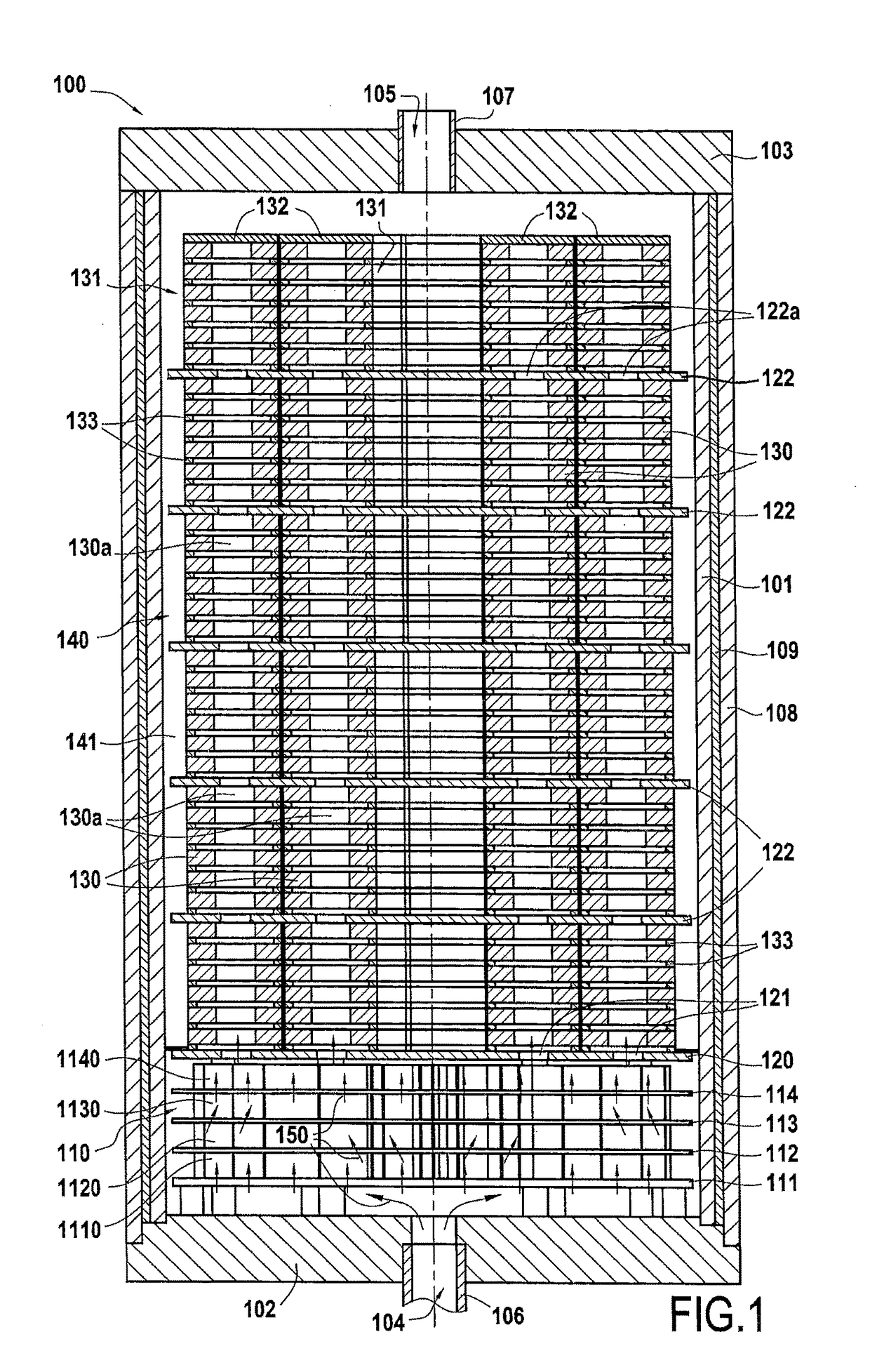

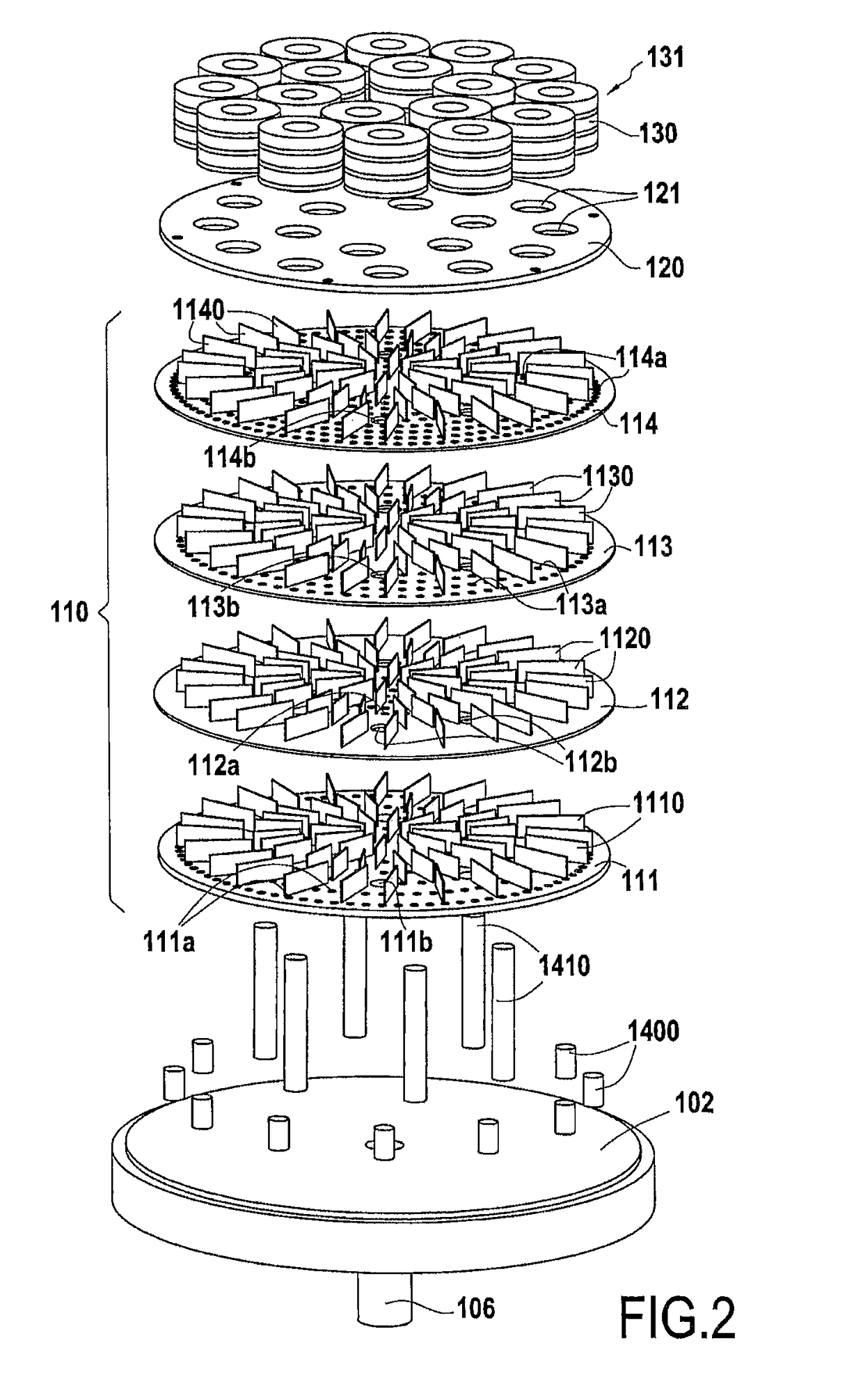

A cvi densification installation including a high capacity preheating zone

ActiveUS20170002466A1Improve productivityIncrease volumeHeat treatmentsMuffle furnacesProcess engineeringReaction chamber

A thermochemical treatment installation includes a reaction chamber, at least one gas inlet, and a gas preheater chamber situated between the gas inlet and the reaction chamber. The preheater chamber has a plurality of perforated distribution trays held spaced apart one above another. The preheater chamber also includes, between at least the facing distribution trays, a plurality of walls defining flow paths for a gas stream between said trays.

Owner:SAFRAN CERAMICS SA

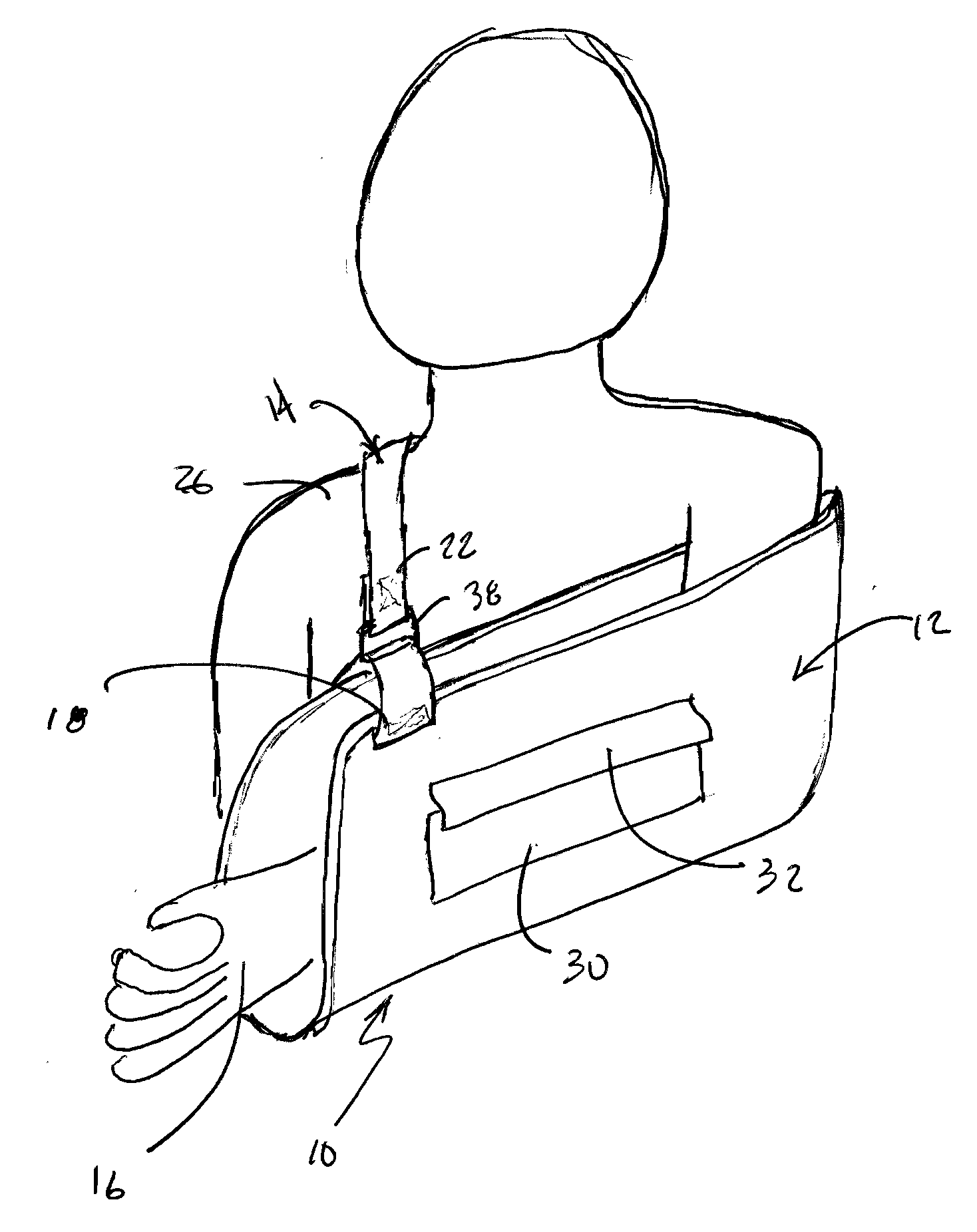

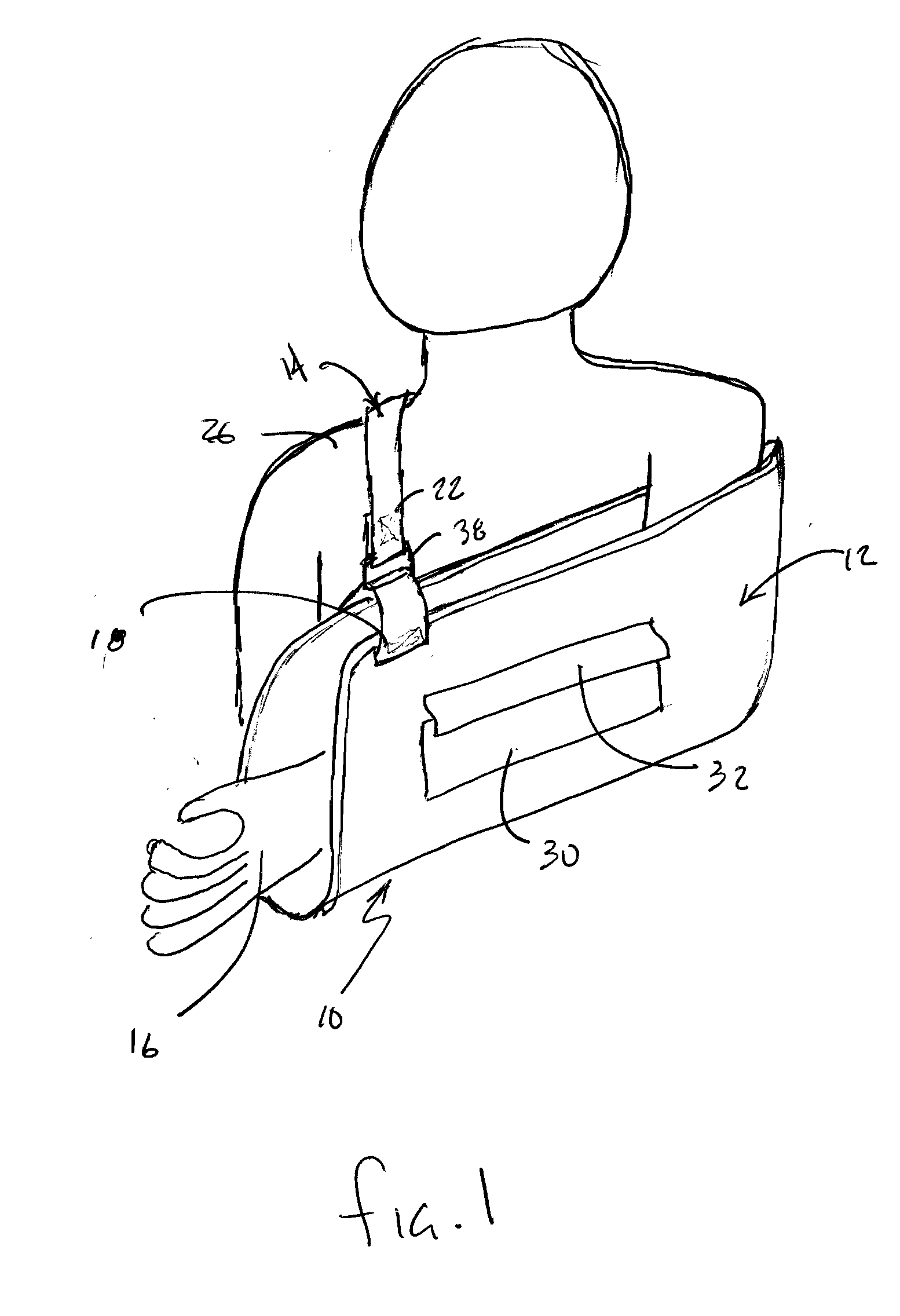

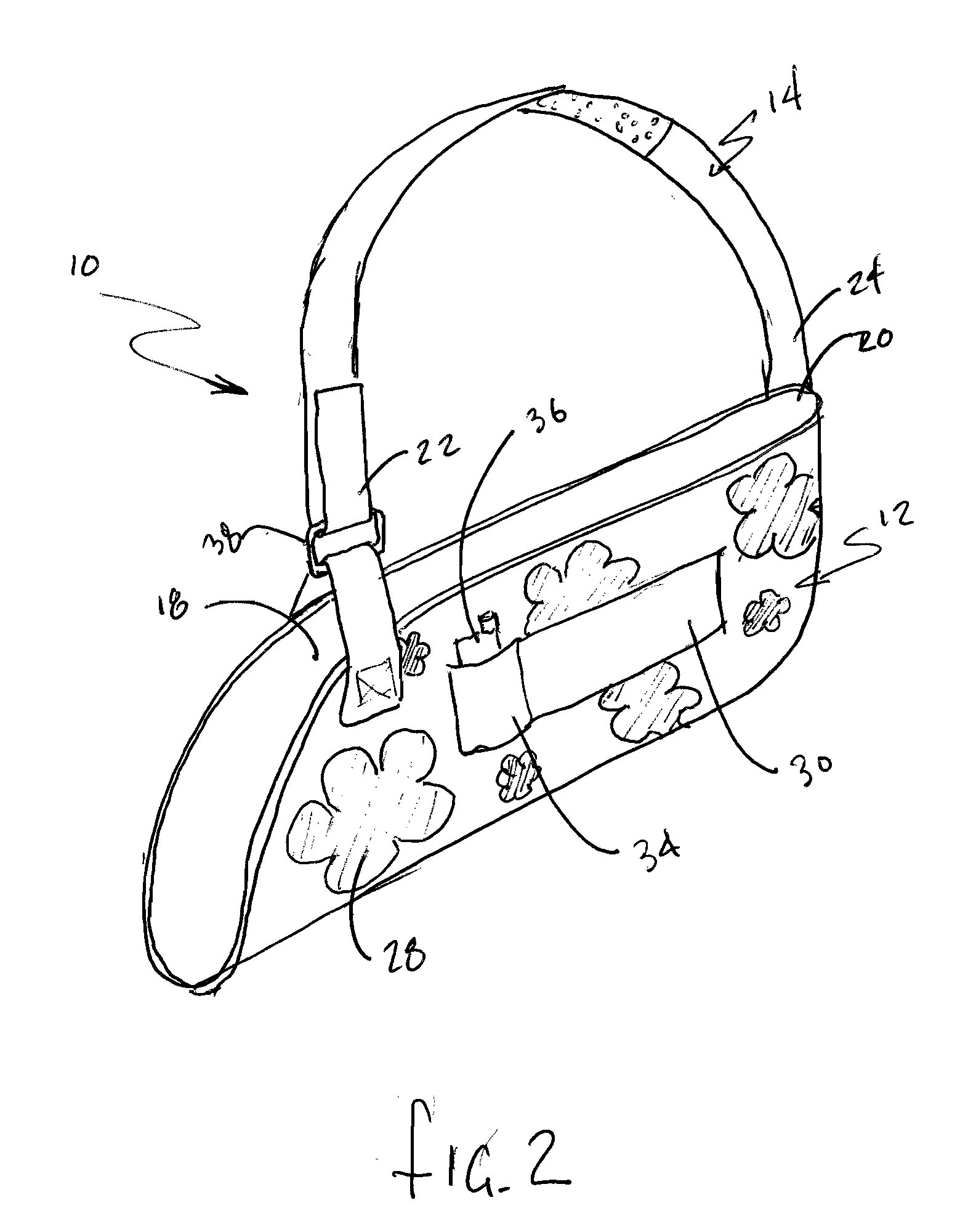

Sling design

InactiveUS20080015479A1Preventing strap bunchingPrevent creepRestraining devicesSuspensory bandagesModularityArchitectural engineering

A sling construction is provided that includes an improved support strap for more uniformly distributing the weight of the supported arm of the wearer's shoulder while preventing strap bunching and creep. The strap is preferably formed from an elastomer or a rubber that is relatively compliant yet has a low coefficient of elongation. This allows the strap to be highly supportive of the sling while also conforming to the contour of the wearer's neck and shoulders in a manner that makes the strap and sling comfortable to wear. The inner contact surface of the strap includes nubs or raised features that prevent the strap from sliding. Further, the improved strap support construction may be used in a modular fashion in conjunction with standard sling pouches or with an enhanced sling pouch in order to greatly improve the performance and appearance of the sling.

Owner:SOSCIA SUSAN

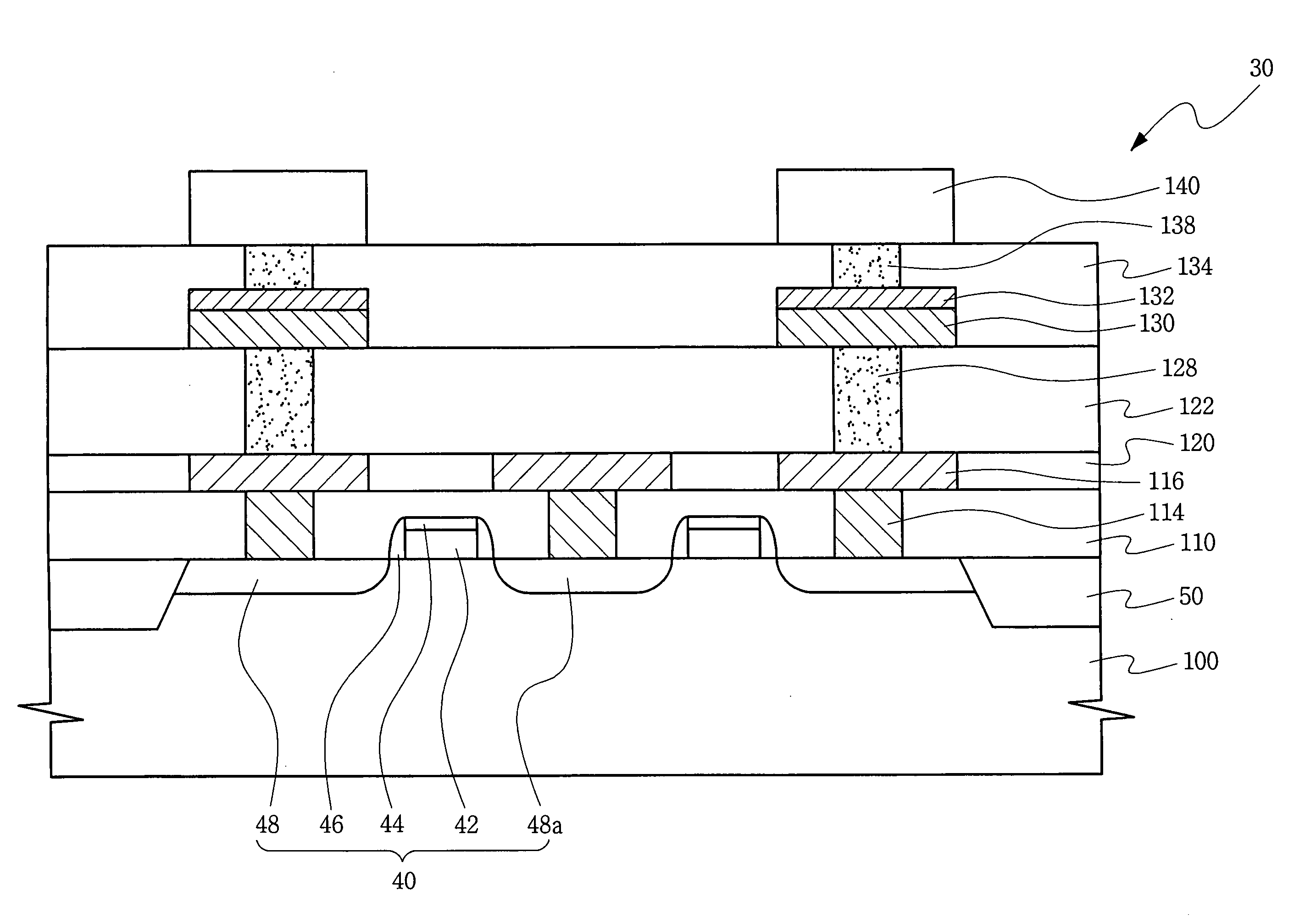

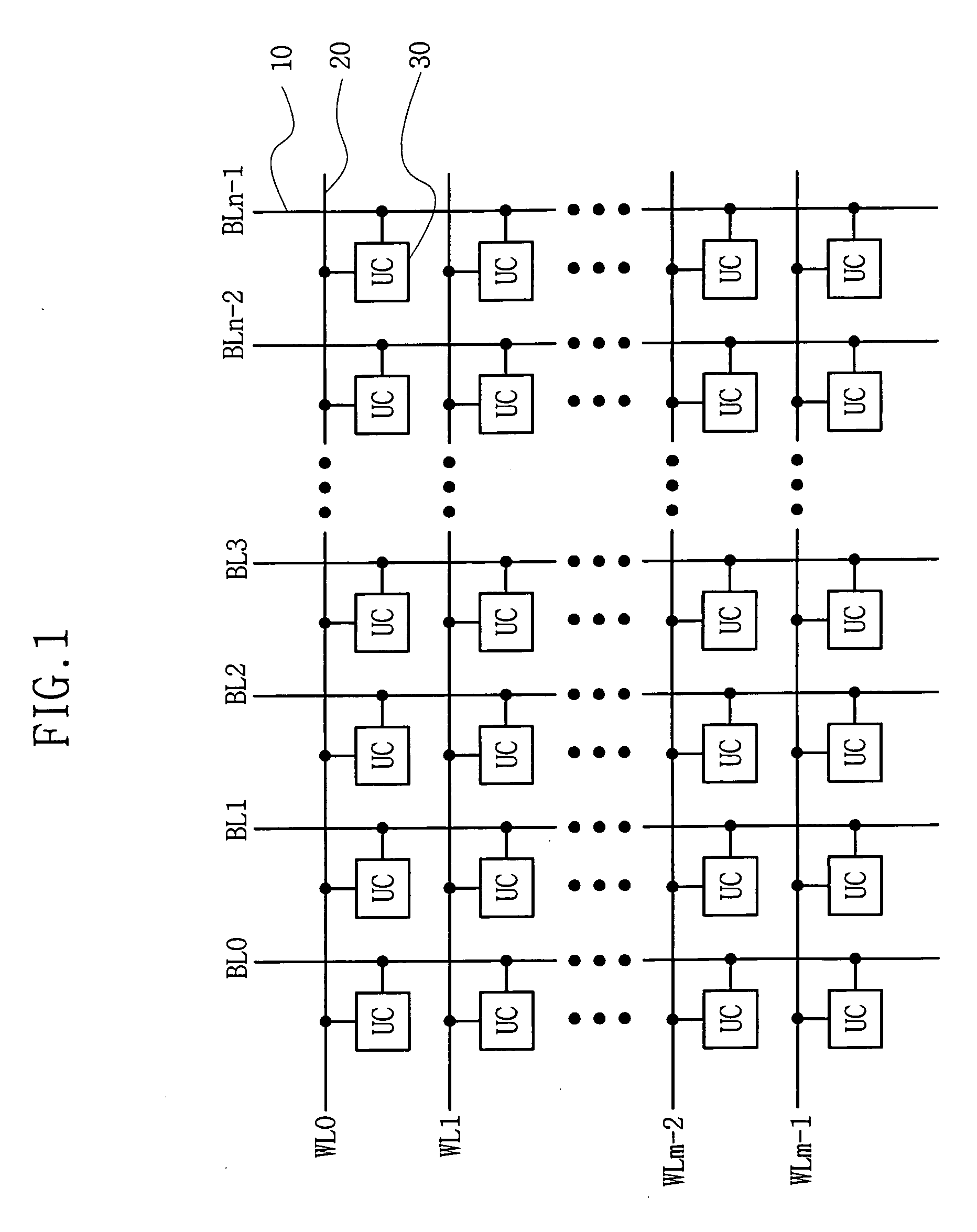

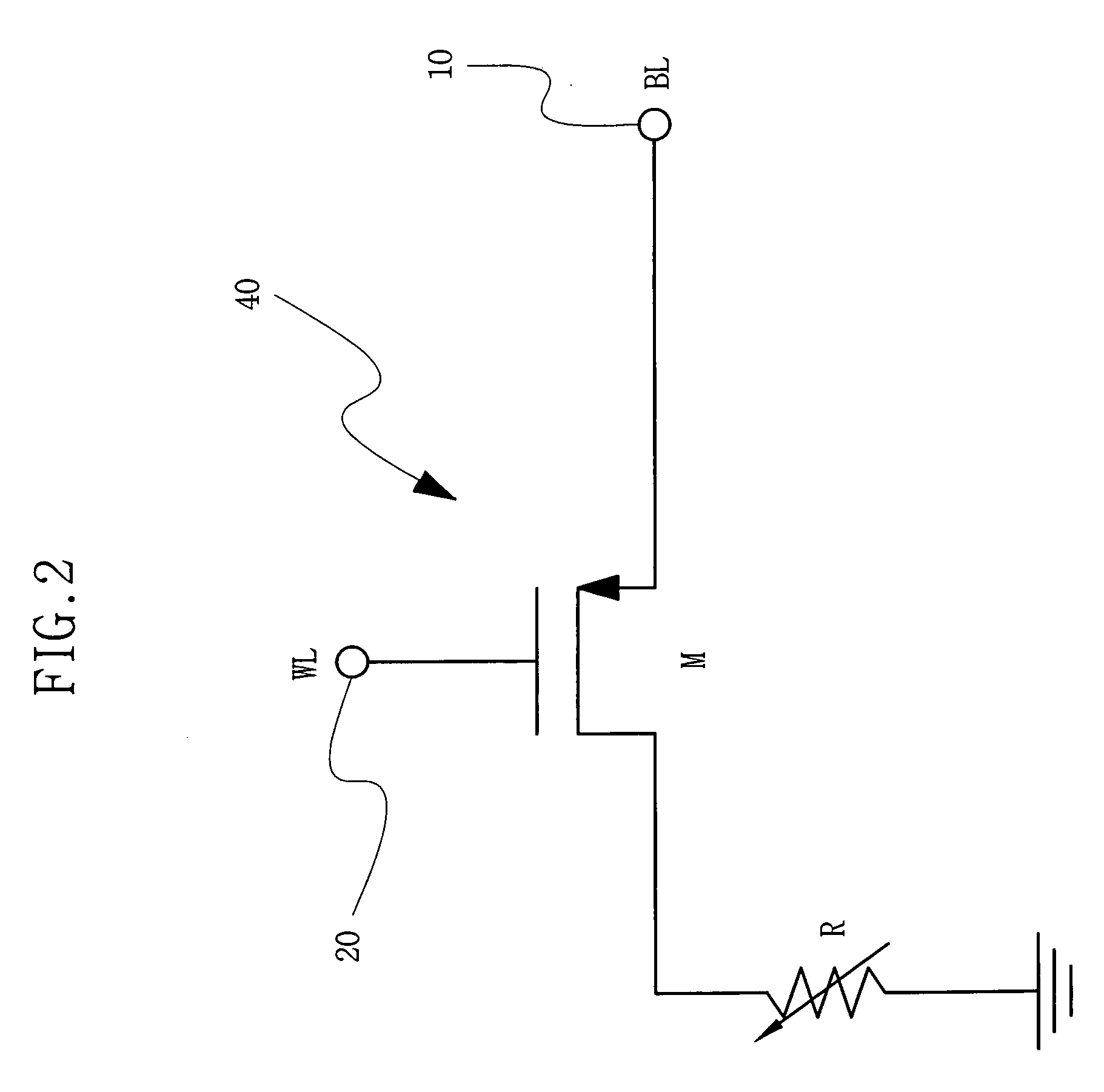

Phase change memory device and method of fabricating the same

InactiveUS20070210334A1Improving and maximizing yieldUniform resistanceTravelling carriersHoldersElectrical resistance and conductanceContact pad

Example embodiments relate to a semiconductor memory device and a method of fabricating the same. Other example embodiments relate to a phase change memory device and a method of fabricating the same. There are provided a phase change memory device and a method of fabricating the same for improving or maximizing a production yield. The method comprises: after first removing a first hard mask layer used to form a contact pad electrically connected to a semiconductor substrate, forming a lower electrode to be electrically connected to the contact pad through a first contact hole in a first interlayer insulating layer formed on the contact pad and to have a thickness equal or similar to a thickness of the first interlayer insulating layer; and forming a phase change layer and an upper electrode on the lower electrode. Because change of the resistance value of the lower electrode is reduced or prevented, which has been caused due to a non-uniform thickness of a conventional first hard mask layer, a production yield may be improved.

Owner:SAMSUNG ELECTRONICS CO LTD

Method and apparatus for space-division multiplexing systems

ActiveUS9344779B2Reduce variationMore dispersedMultiplex system selection arrangementsOptical fibre with multilayer core/claddingFew mode fiberSignal on

A space division multiplexed (SDM) transmission system that includes at least two segments of transmission media in which a spatial assignment of the two segments is different is provided. For example, the SDM transmission may include a first segment of transmission media having a first spatial assignment and a second segment of transmission media having a second spatial assignment, wherein the first spatial assignment differs from the second spatial assignment. An example method obtains an optical signal on a first segment of transmission media having a first spatial assignment and forwards the optical signal on a second segment of transmission media with a different spatial assignment. The transmission media may be a multi-core fiber (MCF), a multi-mode fiber (MMF), a few-mode fiber (FMF), or a ribbon cable comprising nominally uncoupled single-mode fiber (SMF).

Owner:ALCATEL LUCENT SAS

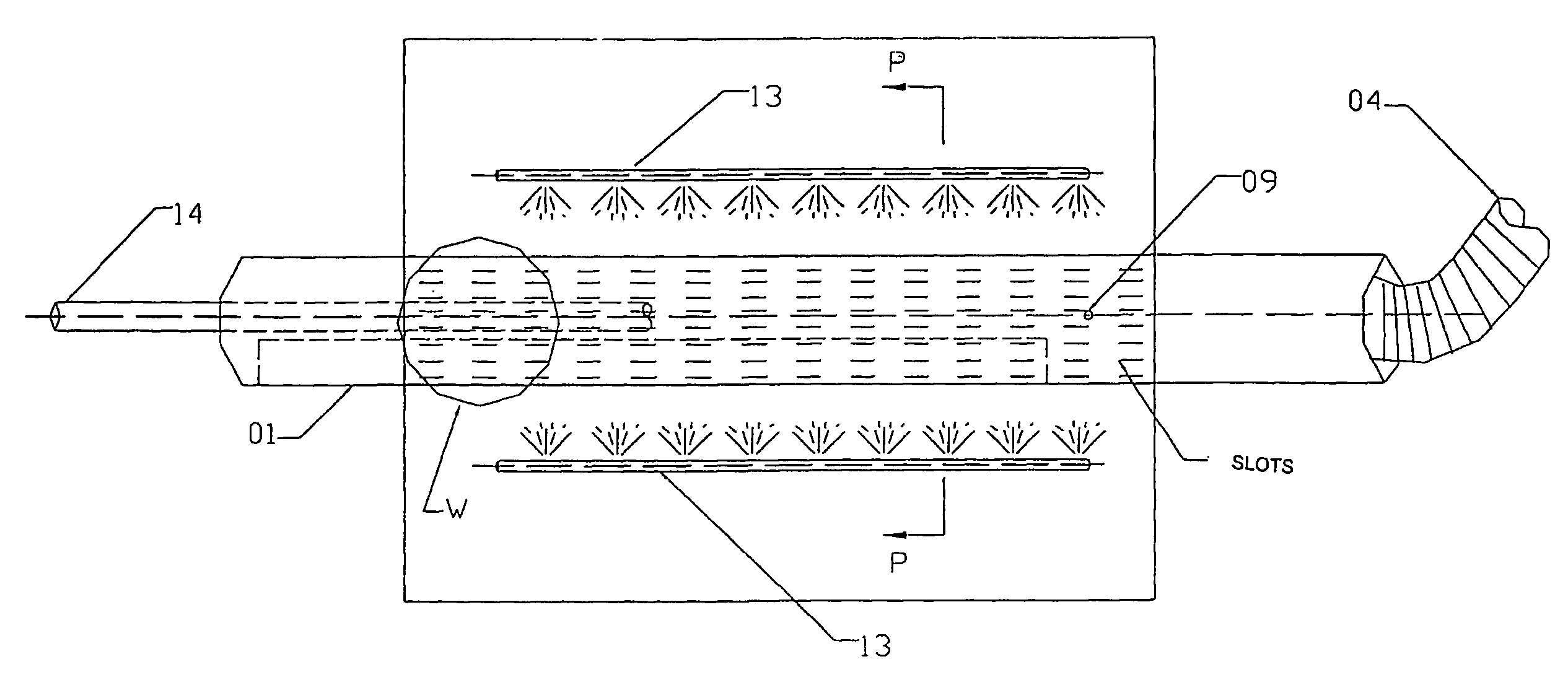

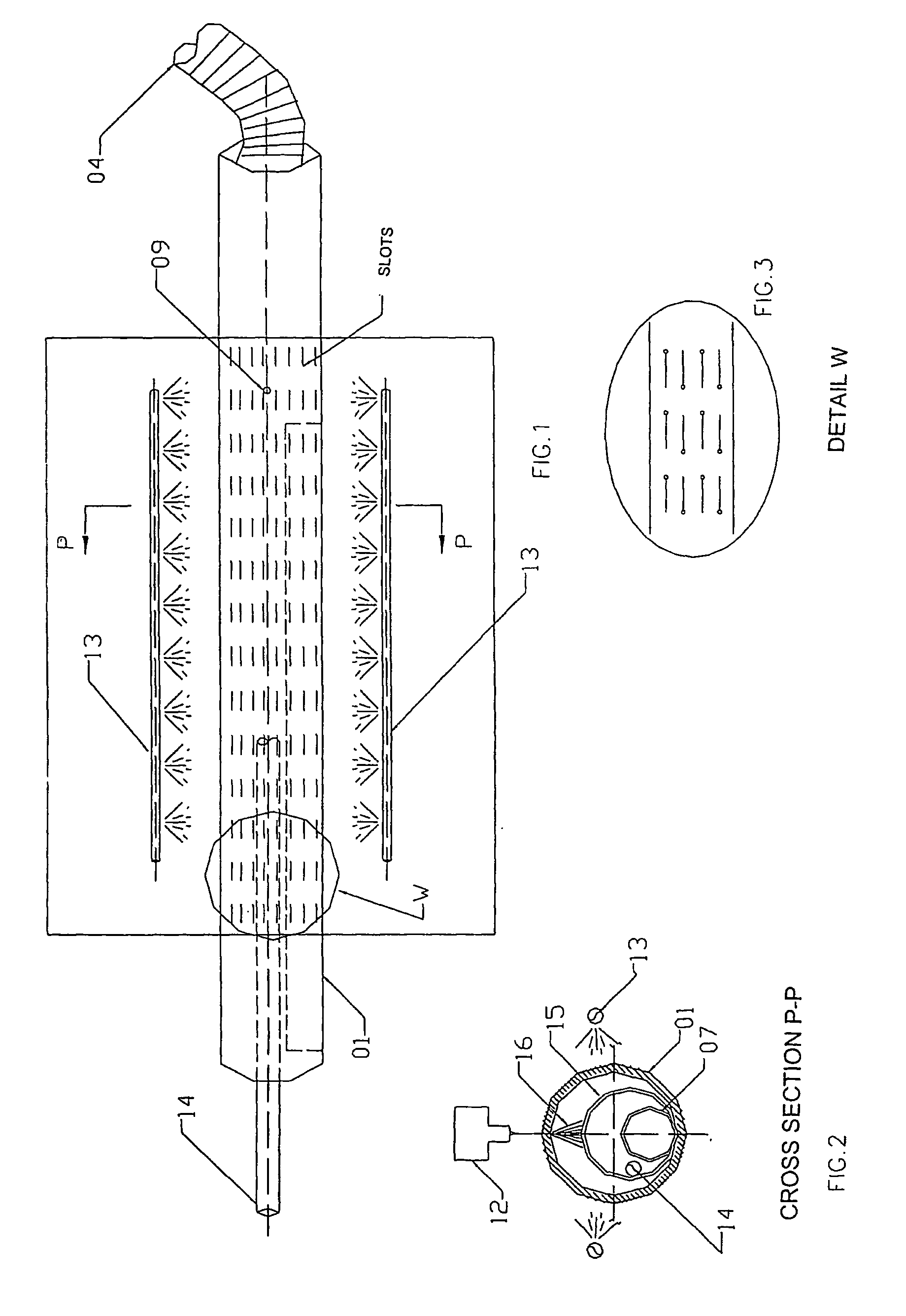

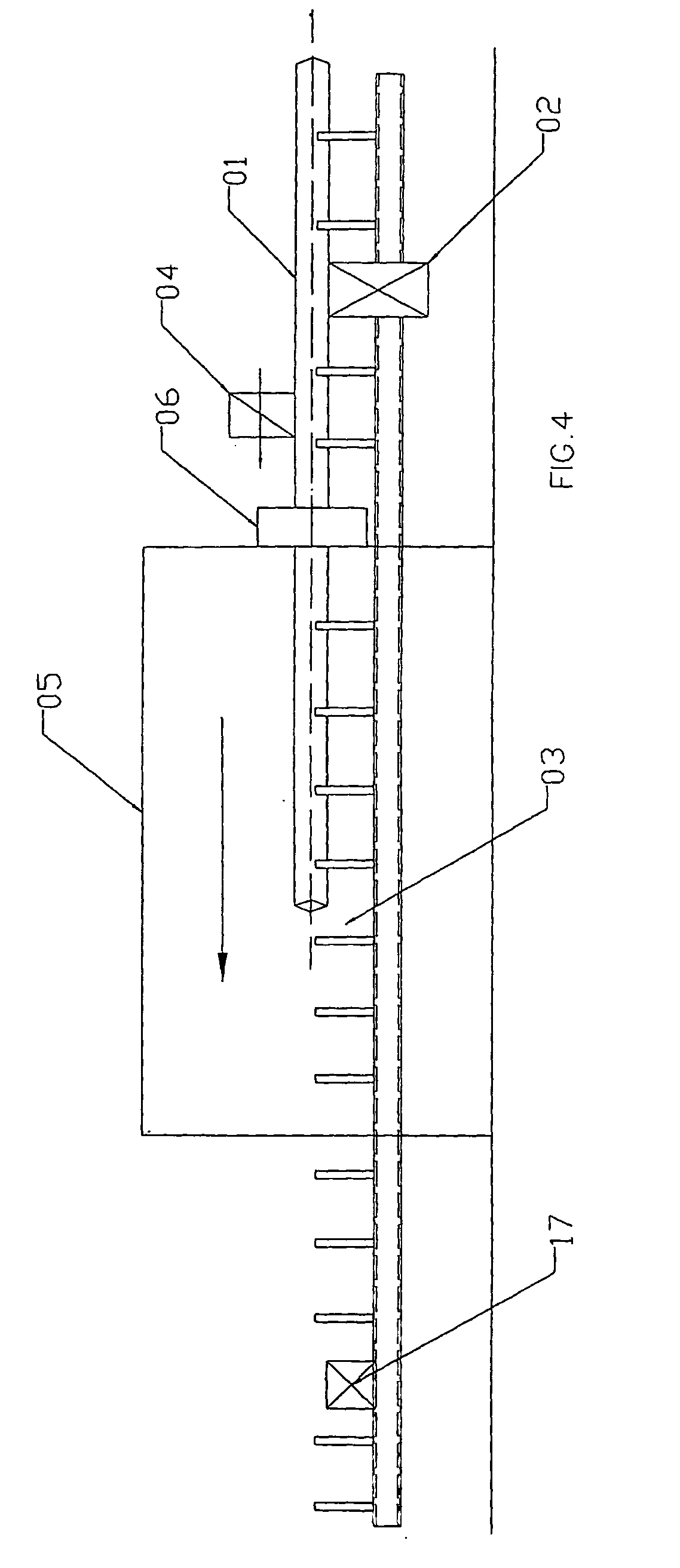

Method to Provide Slots in Pipes

The present invention refers to a method to provide slots in pipes and, more specifically, to a method to provide slots in metal pipes used to extract oil or to form slotted lines, wherein said slots are specially designed to avoid the intake of impurities while pumping oil. More specifically, the method consists of the following steps: a) external cleaning of the pipe (1) with slag jetting to remove the protecting layer that comes from its manufacture or to remove the impurities due to its oxidation; b) placing the pipe (1) on the receiving table by the set of motors (2) to be subsequently transferred to the cutting table (3), by means of motors (4); c) positioning and fixation of the pipe in the cutting cabin (5) by screwing the pneumatic rotating plate (6); d) execution of the first sequence of slots in the pipe by means of laser or plasma, in a refrigerated environment, by making a first slot with pre-defined power and subsequently the opening of the slot with determined length and thickness, according to the characteristics of the pipe, with said slot having an initial section with parallel shape and subsequently with divergent section; e) angle rotation of the pipe by means of turning the rotating plate (6) to make the second sequence of slots, in the opposite direction of the first sequence and then successively on the whole perimeter of the pipe to meet the desired specification; f) removal of the sludge and impurities generated by the cut by the sleeves (7); g) internal cleaning of the slotted pipe with slag jetting; h) visual inspection of the slotted pipe to correct failures and possible imperfections with MIG soldering; and i) painting to provide a uniform visual aspect to the slotted pipe.

Owner:PEGORETTI MARCOS ROGERIO

CVI densification installation including a high capacity preheating zone

ActiveUS9845534B2Improve productivityIncrease volumeHeat treatmentsMuffle furnacesProcess engineeringReaction chamber

A thermochemical treatment installation includes a reaction chamber, at least one gas inlet, and a gas preheater chamber situated between the gas inlet and the reaction chamber. The preheater chamber has a plurality of perforated distribution trays held spaced apart one above another. The preheater chamber also includes, between at least the facing distribution trays, a plurality of walls defining flow paths for a gas stream between said trays.

Owner:SAFRAN CERAMICS SA

Optical element providing oblique illumination and apparatuses using same

ActiveUS9217554B1Improved illumination of surfaceConvenient lightingMechanical apparatusLight source combinationsAsymmetry bodyTarget surface

An optical element is provided having an asymmetric body with a base cavity for receiving a light source, and outer sides providing total internal reflection, and a front face tilted so that the optical element's optical axis is at an oblique angle with respect to a target surface. Curvatures along cavity surfaces and outer sides are selected to output illumination from the body's front face having a distribution extending along the target surface's height and at least a portion of the width thereof having increased intensity with increasing height to provide at least substantially uniform illumination along the target surface's height. One or more optical elements may be in an apparatus, and multiple apparatuses may be disposed in front of one edge of a target surface and spaced from each other to provide the target surface with at least substantially uniform oblique illumination.

Owner:VIAVI SOLUTIONS INC

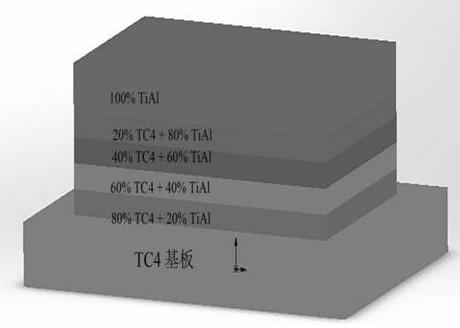

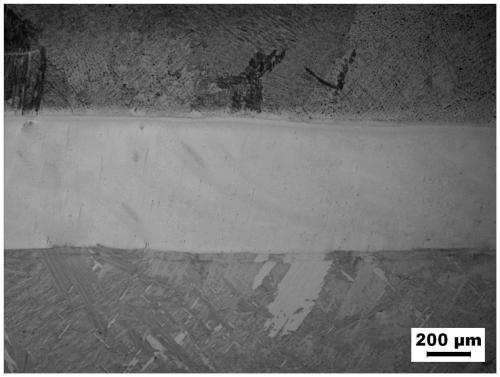

Method for preparing TC4/TiAl gradient material through laser synchronous powder feeding

InactiveCN111230113AIncrease energy densitySmall tissueAdditive manufacturing apparatusTransportation and packagingSi substrateTitanium alloy

The invention provides a method for preparing a TC4 / TiAl gradient material through laser synchronous powder feeding. The method comprises the following steps that firstly, TC4 alloy powder and TiAl alloy powder are mixed in four ratios of mass fractions; secondly, an oxidation film of a TC4 titanium alloy substrate is removed, and the surface of the substrate is deoiled; thirdly, the four kinds ofmixed alloy powder obtained in the first step are put into a vacuum drying oven for drying to obtain dried powder; fourthly, four gradient layers are prepared on the TC4 titanium alloy substrate deoiled in the second step by using the four kinds of mixed alloy powder obtained in the first step from bottom to top in sequence, finally, a total TiAl layer is prepared on the gradient layers, and theTC4 / TiAl gradient material is obtained; and fifthly, whole destressing annealing is conducted. By means of the method, uniform transition of the elements Ti and Al is achieved, residual stress is reduced, the interface structure is improved, cracks are prevented from being produced, connection between the titanium alloy and the TiAl alloy is achieved, the using temperature of a part is increased to 700 DEG C or above from about 400 DEG C, and the high-temperature using performance of a hot-end part is improved.

Owner:SHENYANG POLYTECHNIC UNIV

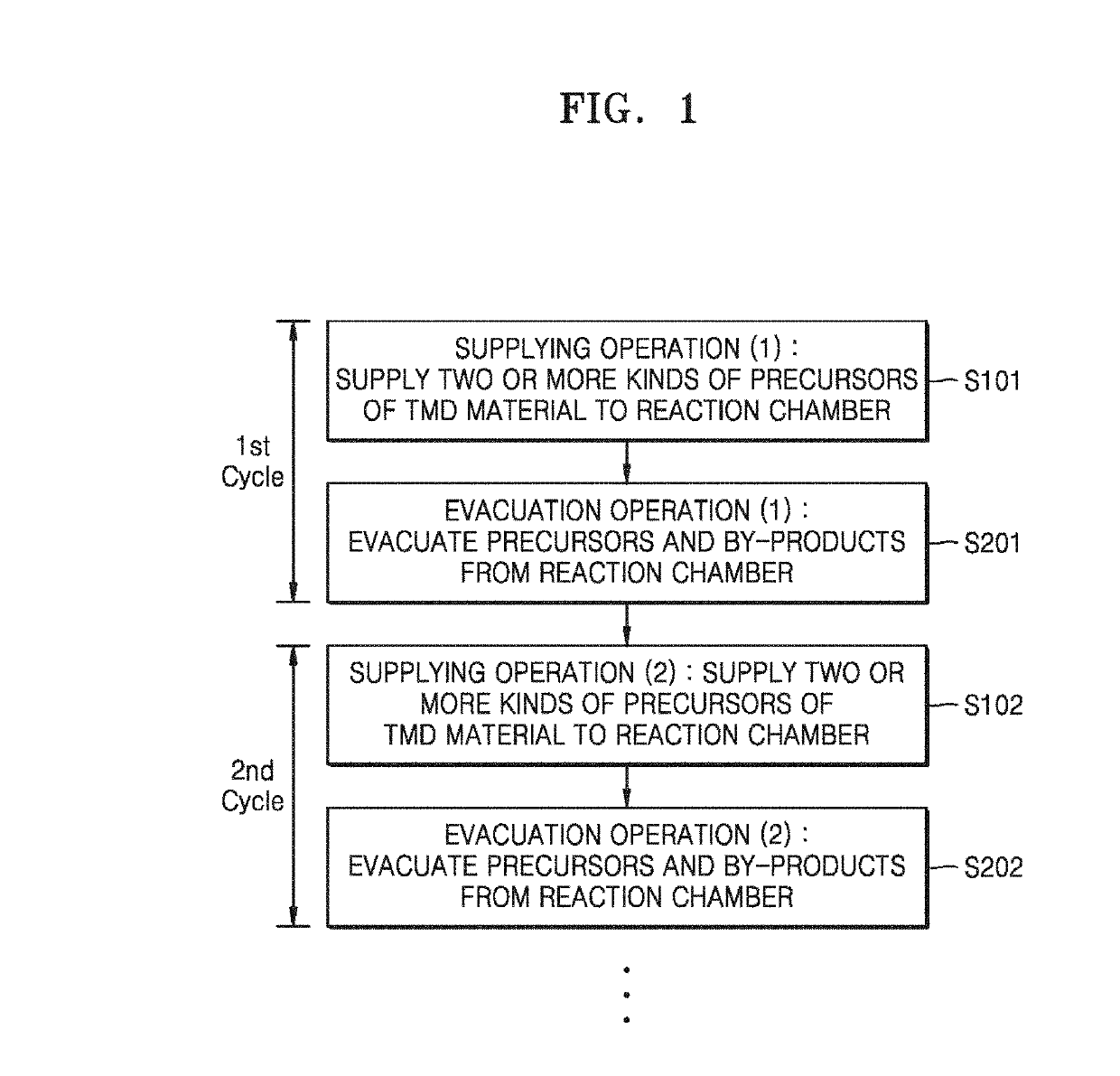

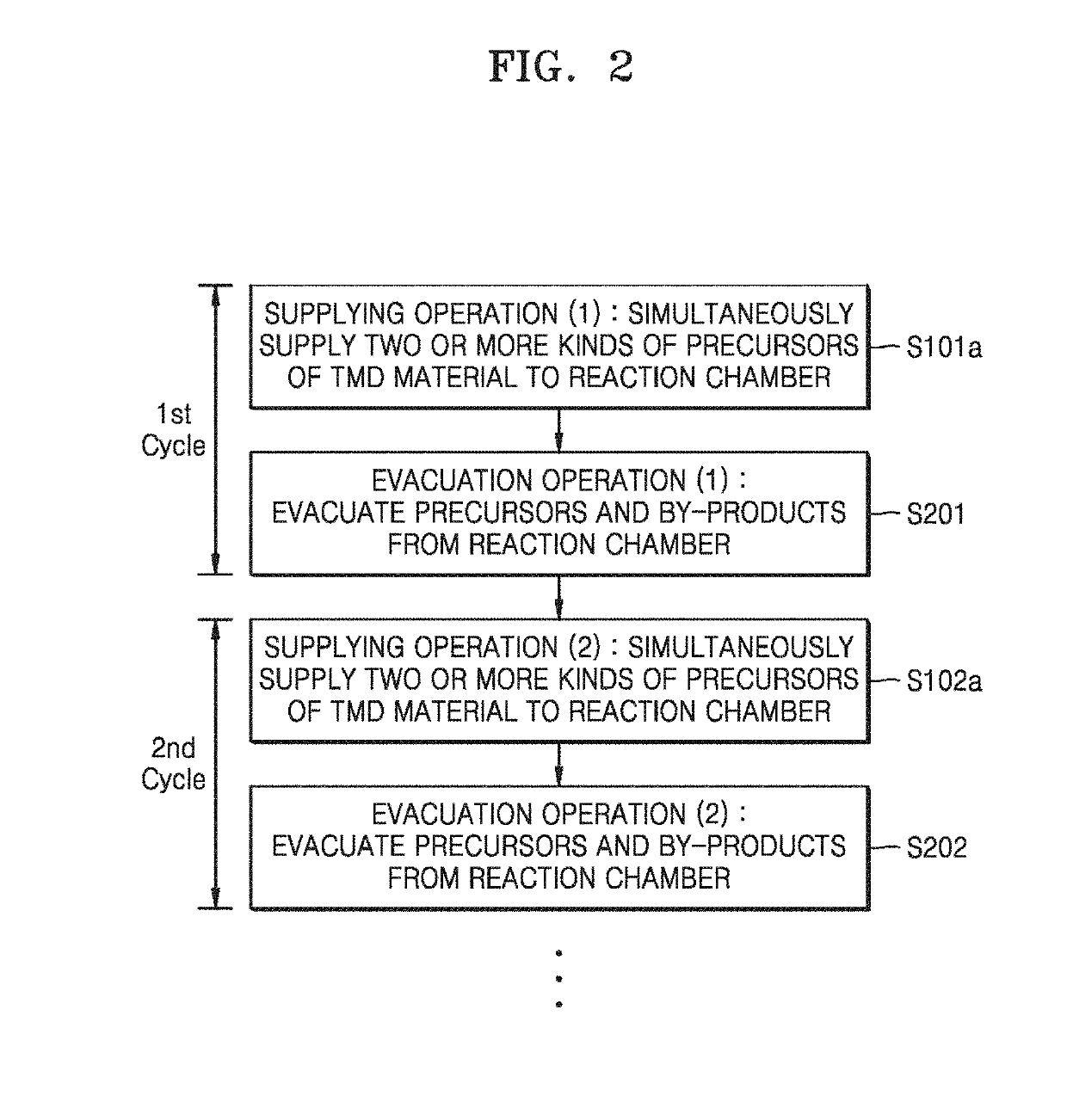

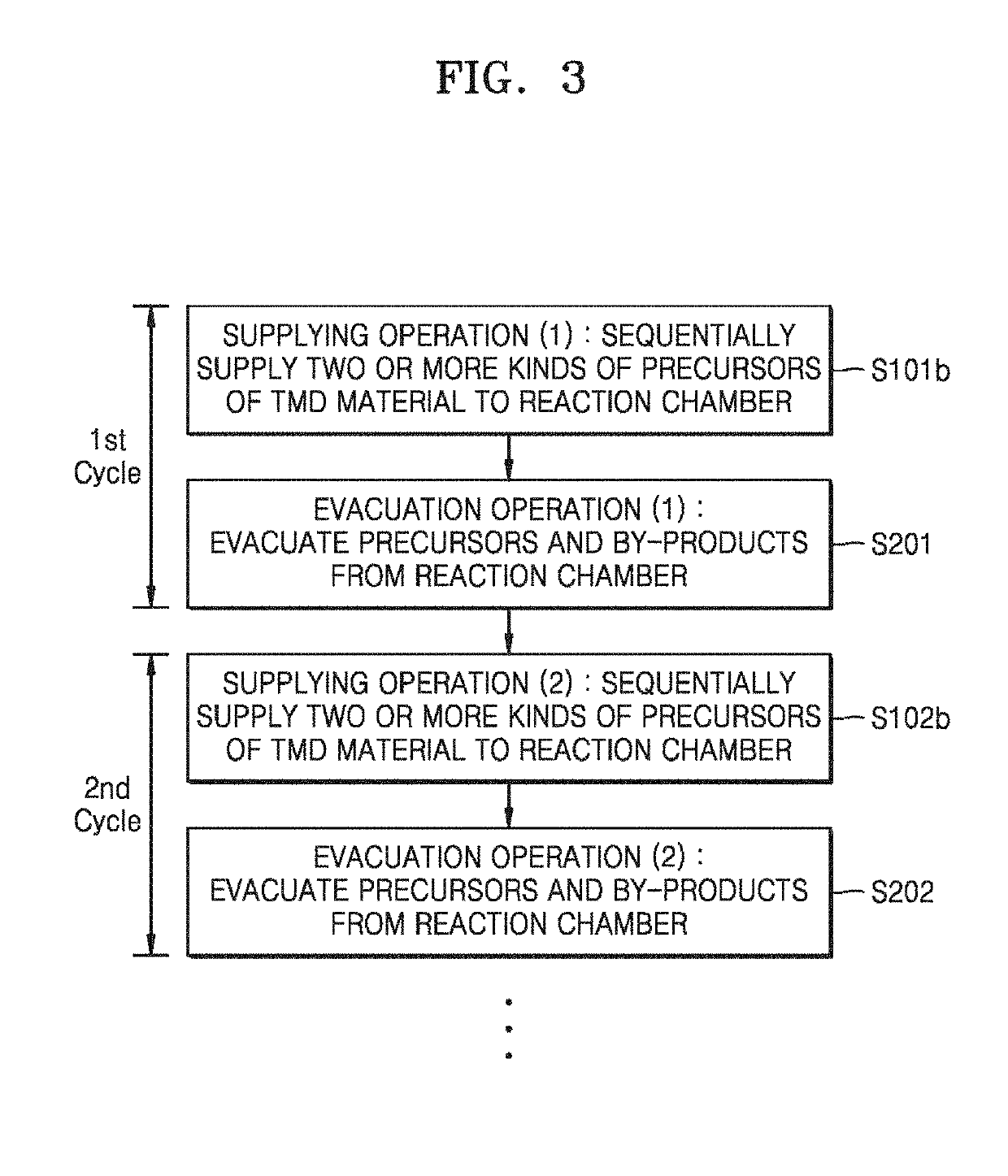

Method of growing two-dimensional transition metal dichalcogenide thin film and method of manufacturing device including the same

ActiveUS20190164754A1Increase the areaQuality improvementTransistorSemiconductor/solid-state device manufacturingMetalReaction chamber

A method of growing a two-dimensional transition metal dichalcogenide (TMD) thin film and a method of manufacturing a device including the two-dimensional TMD thin film are provided. The method of growing the two-dimensional TMD thin film may include a precursor supply operation and an evacuation operation, which are periodically and repeatedly performed in a reaction chamber provided with a substrate for thin film growth. The precursor supply operation may include supplying two or more kinds of precursors of a TMD material to the reaction chamber. The evacuation operation may include evacuating the two or more kinds of precursors and by-products generated therefrom from the reaction chamber.

Owner:SAMSUNG ELECTRONICS CO LTD

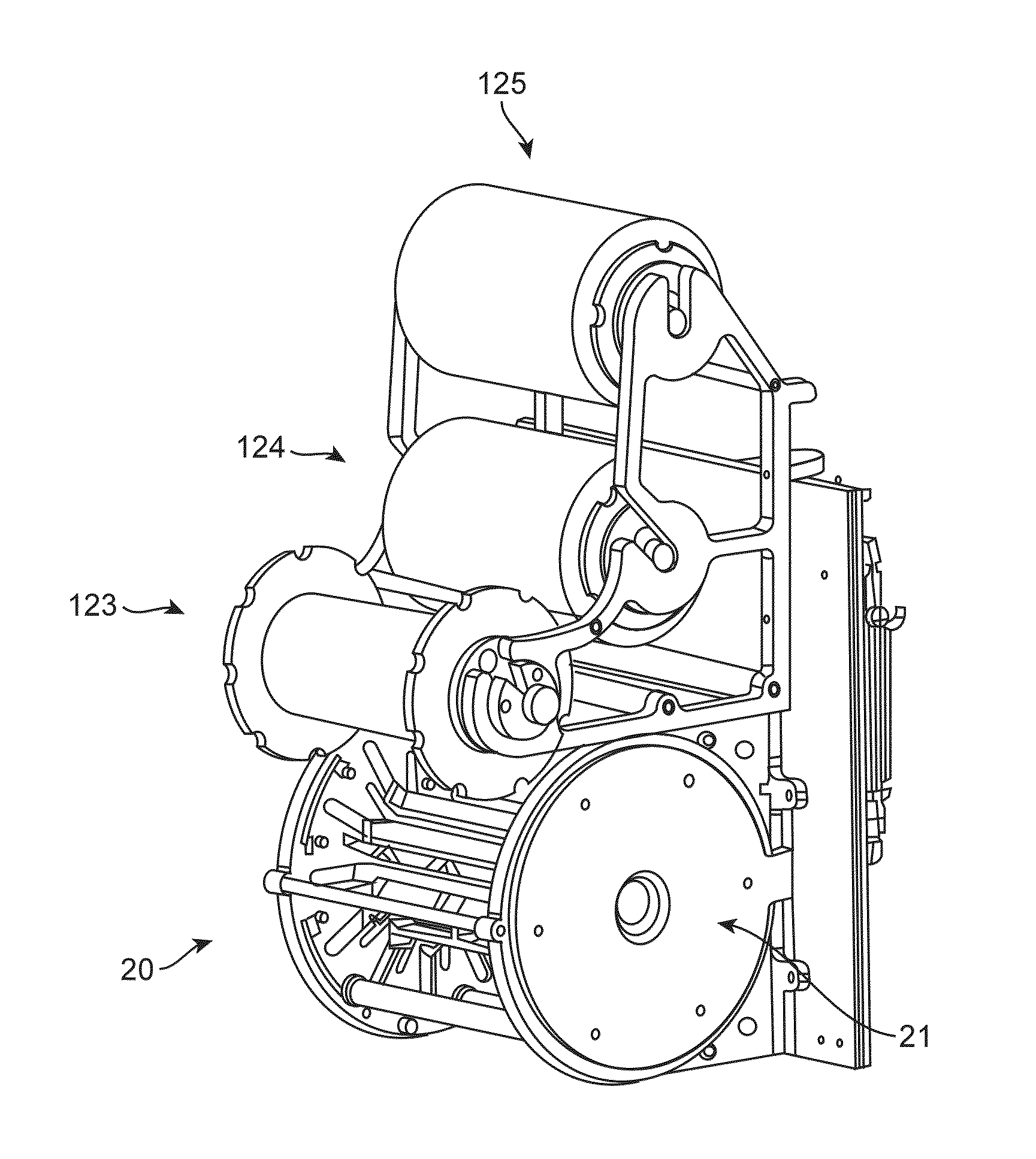

Reducing crimping damage to a polymer scaffold

ActiveUS20140008007A1Reduce harmImprove batch yieldStentsLabelling non-rigid containersCatheterPolymer scaffold

A medical device includes a polymer scaffold crimped to a catheter having an expansion balloon. The scaffold is crimped to the catheter by a multi-step process for increasing scaffold-catheter yield following a crimping sequence. Damage reduction during a crimping sequence includes modifying blades of a crimper, adopting a multi-step crimping sequence, and inflating a supporting balloon to support the scaffold during crimping.

Owner:ABBOTT CARDIOVASCULAR

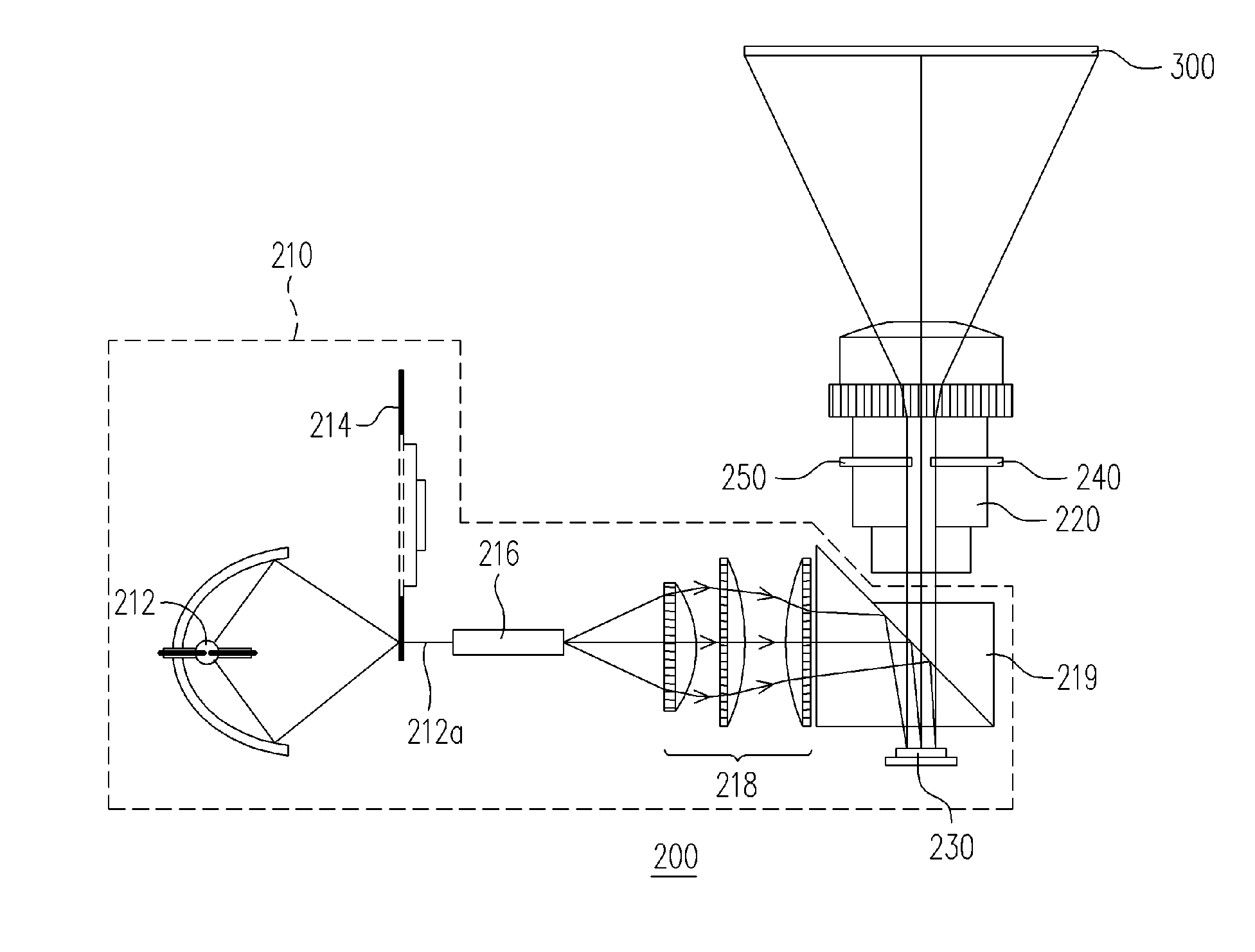

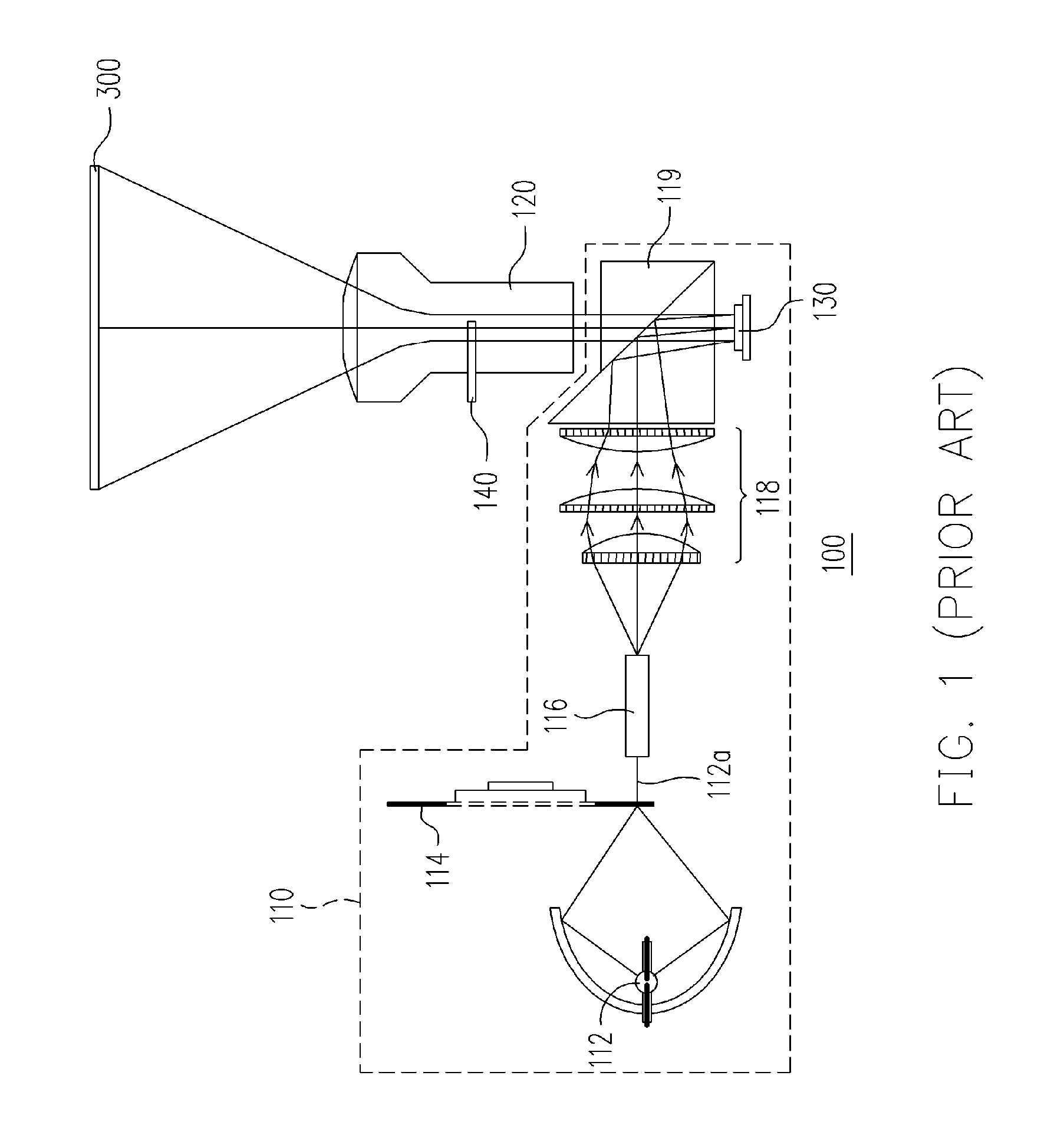

Optical projection apparatus

An optical projection apparatus includes an illumination system, a projection lens unit, a reflective light valve, a first beam breaker and a second beam breaker. A light beam is provided by the illumination system. The projection lens unit and the reflective light valve are disposed on the transmission path of the light beam, and the reflective light valve is disposed between the illumination system and the projection lens unit. The first beam breaker and the second beam breaker are used to cut into the transmission path of the light beam from different directions to block a part of the light beam, and part of the light beam passes through the first beam breaker and the second beam breaker. The darker image projected by the optical projection apparatus has higher contrast and better uniformity.

Owner:YOUNG OPTICS

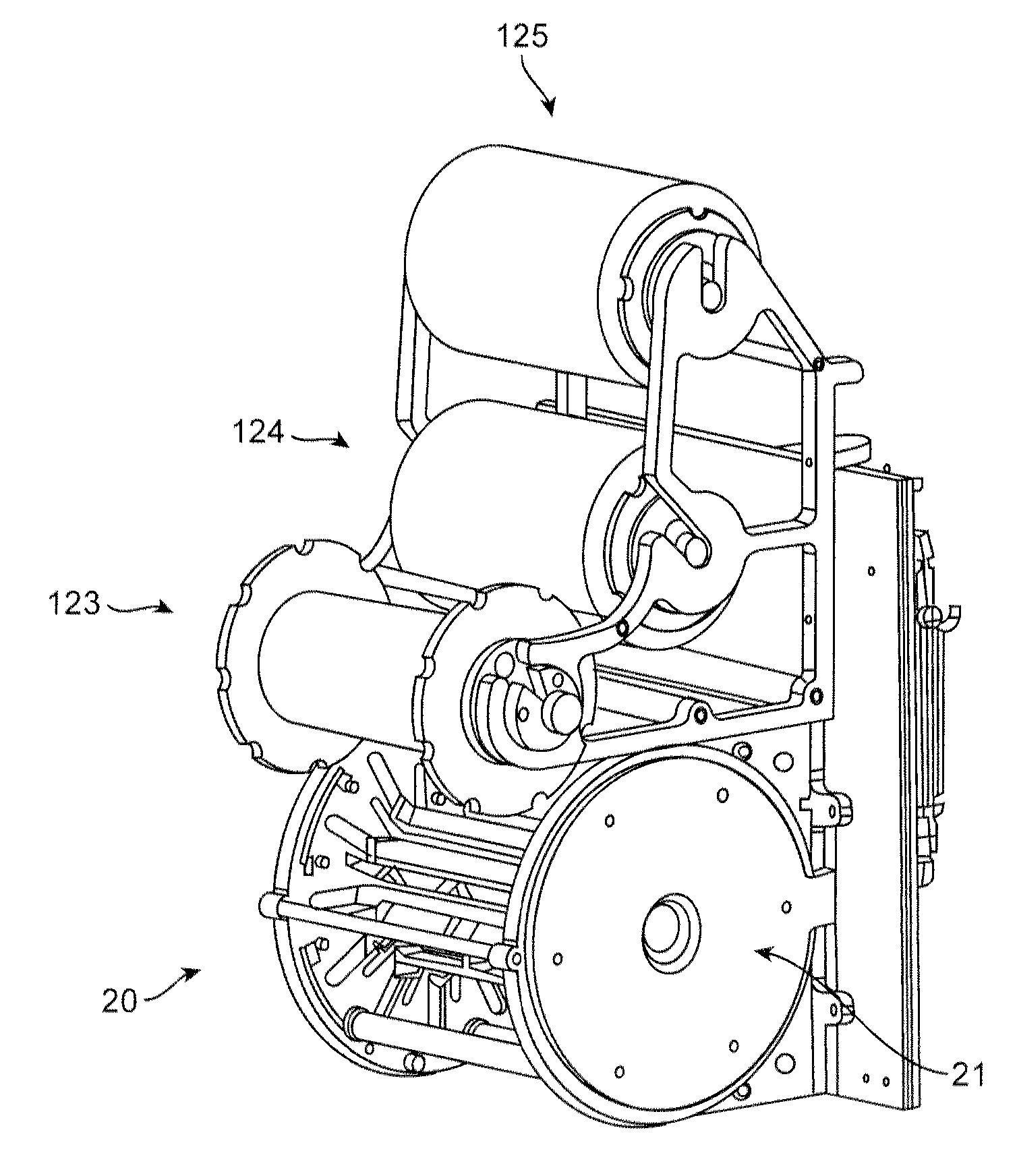

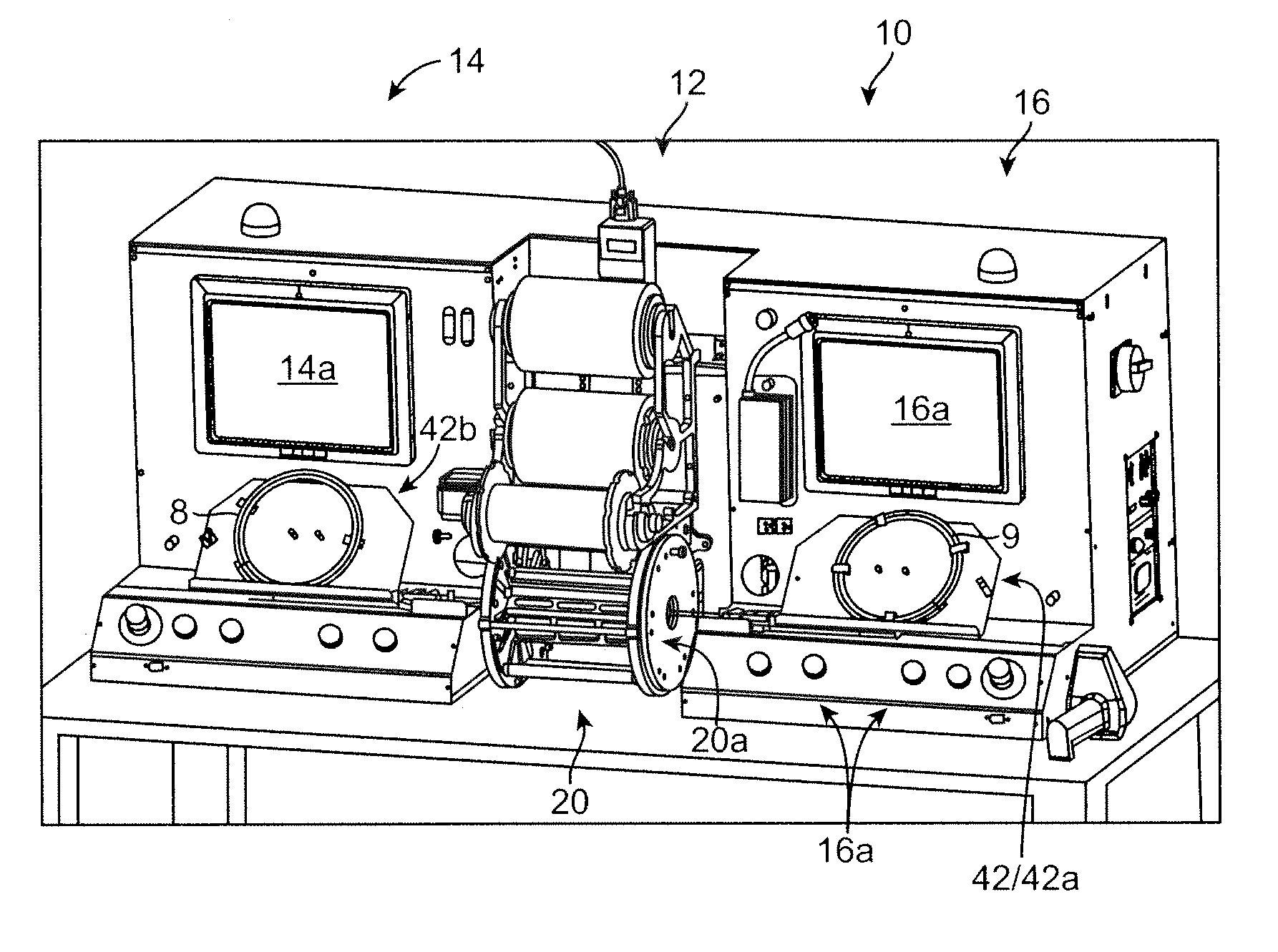

Post-Crimping Inspection of Scaffolds Mounted on Scaffold Delivery Systems

ActiveUS20140189994A1Maximize yieldIncreased yieldStentsAutomatic control devicesBiomedical engineeringMedicine

A system for mounting a scaffold on a balloon catheter includes two positioning and alignment stations, which are used to prepare a scaffold and catheter for crimping using the same crimping head. The system is configured for automated assembly of the scaffold and catheter prior to crimping and performing post-crimping inspection for the crimped scaffold and prior to placing a restraining sheath over the crimped scaffold.

Owner:ABBOTT CARDIOVASCULAR

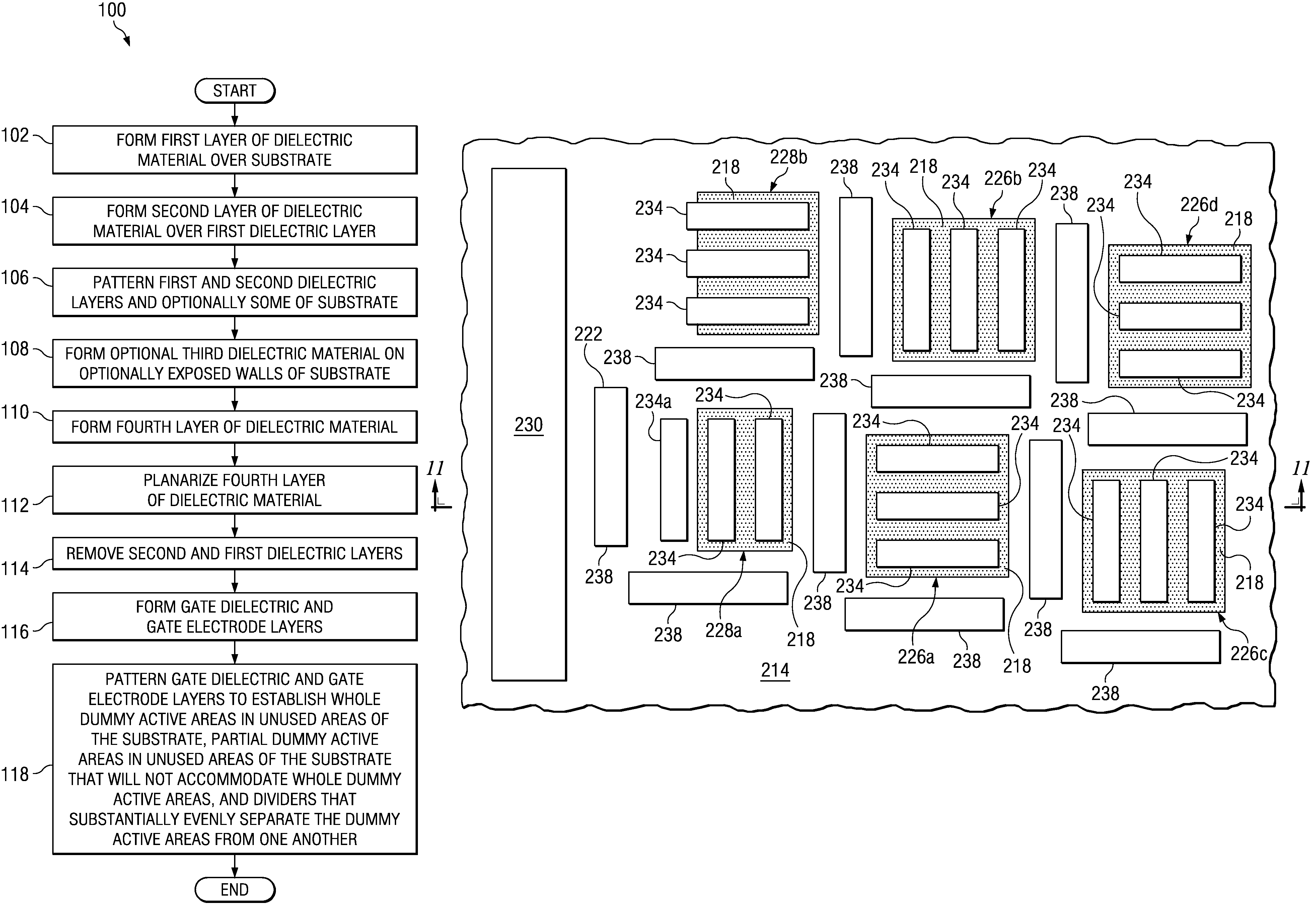

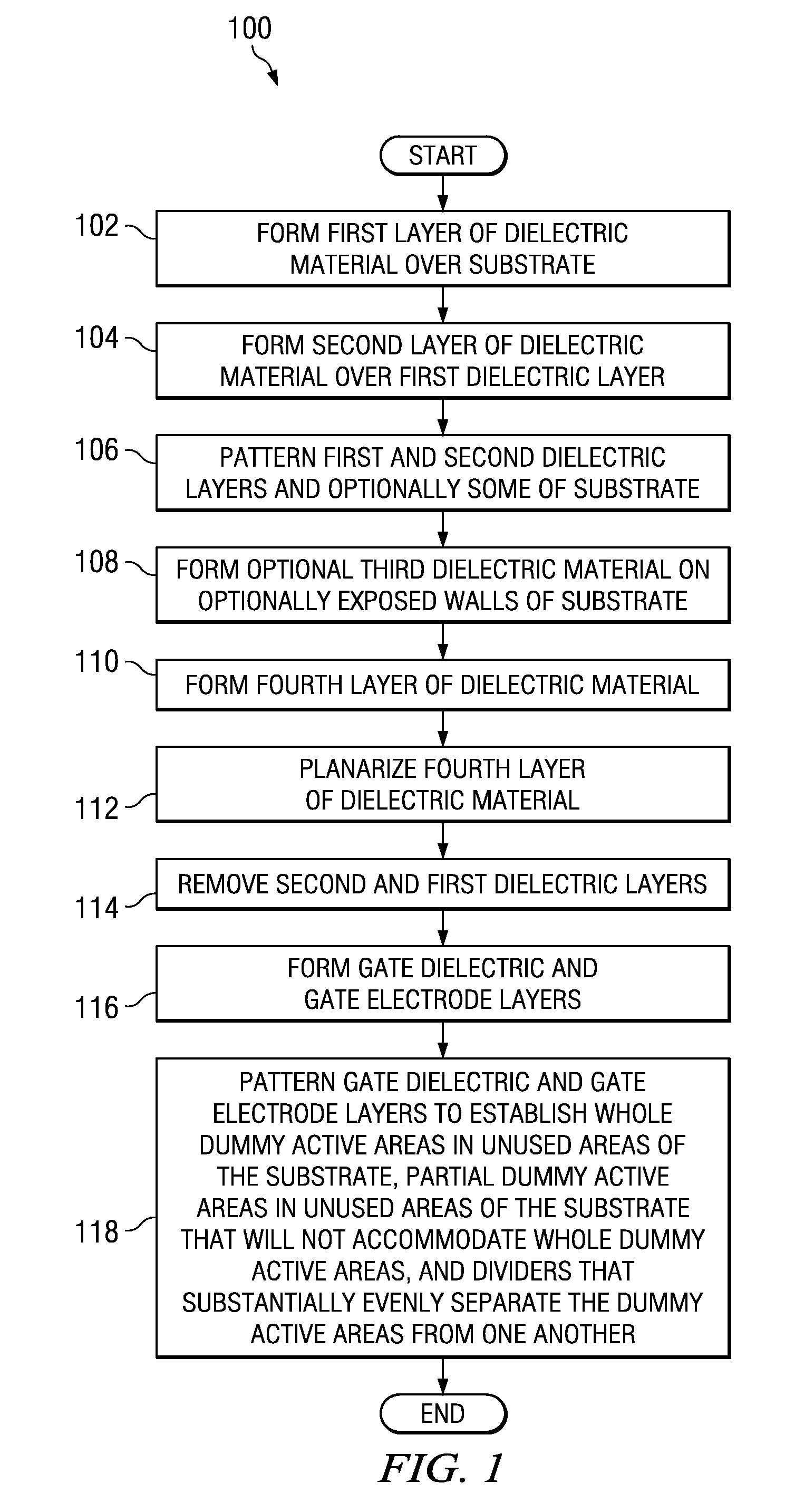

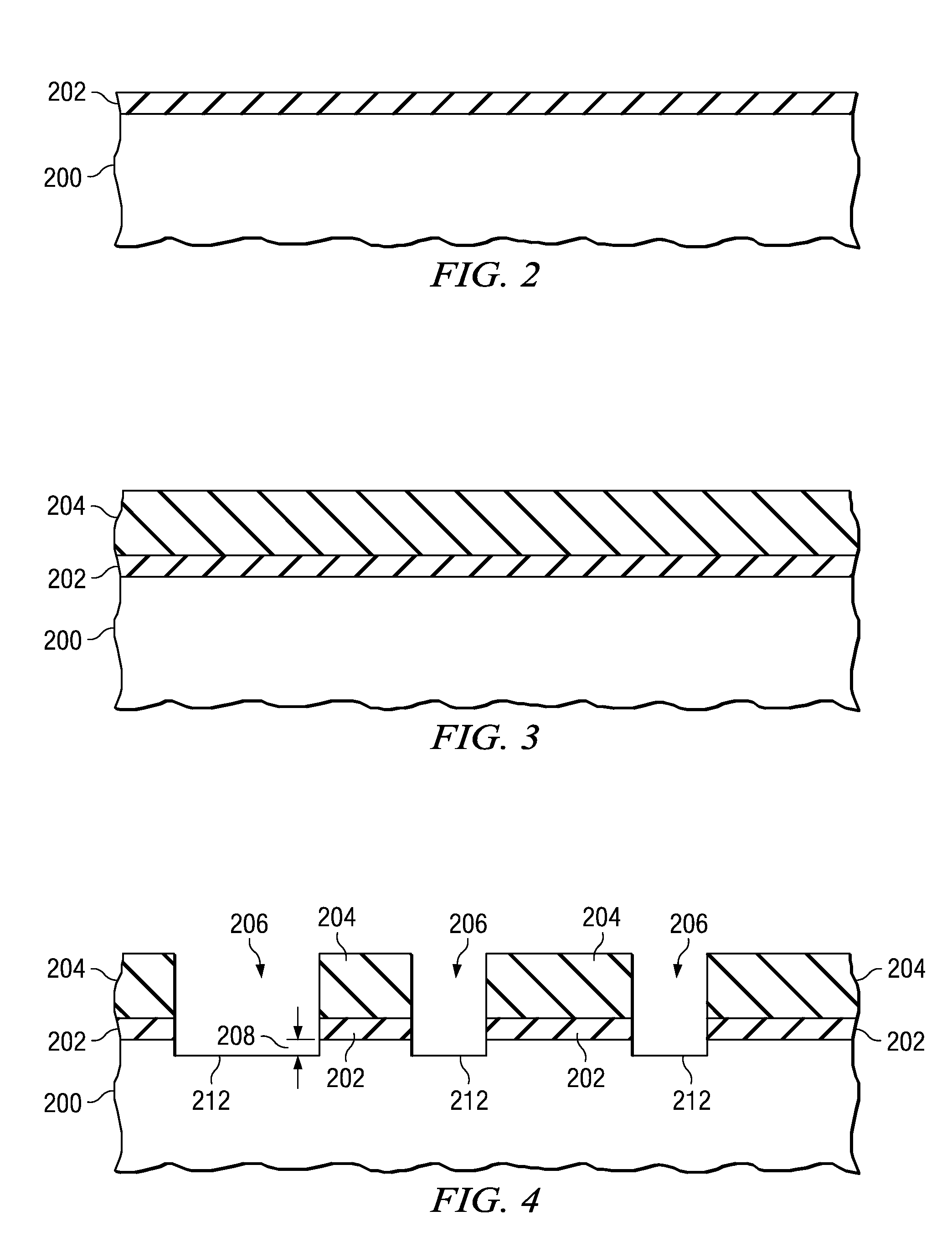

Dummy active area implementation

ActiveUS7759182B2Reduce yield lossExcessively uniformSolid-state devicesSemiconductor/solid-state device manufacturingCapacitive couplingParasitic capacitance

Areas of a semiconductor substrate where semiconductor devices are not to be formed are filled in with dummy active areas. Whole dummy active areas are formed in areas of the semiconductor substrate where semiconductor devices are not to be formed, and partial dummy active areas are formed in areas of the semiconductor substrate where semiconductor devices are not to be formed, but where whole dummy active areas can not be accommodated. The dummy active areas are staggered so as to provide uniform parasitic capacitive coupling to overlying leads regardless of the placement of the leads. The dummy active areas are substantially evenly separated from one another by dividers. The dummy active areas and dividers are formed concurrently with formation of semiconductor devices in non-dummy active areas. The dummy active areas mitigate yield loss by, among other things, providing more uniformity across the substrate, at least with regard to parasitic capacitances and stress and subsequent processing.

Owner:TEXAS INSTR INC

Steel gas protection welding wire for railway vehicle welding

InactiveCN107350657AImprove corrosion resistanceSolve the strength problemWelding/cutting media/materialsSoldering mediaImpact energyGas protection

The invention discloses a steel gas protection welding wire for railway vehicle welding. The steel gas protection welding wire comprises chemical components, by mass, of 0.04-0.10% of C, 0.35-0.65% of Si, 1.30-1.60% of Mn, 0.020% or less of P, 0.010% or less of S, 0.20-0.50% of Cr, 0.30-0.80% of Ni, 0.19-0.40% of Cu and the balance Fe and inevitable impurities. According to the steel gas protection welding wire, the comprehensive property is good, the tensile strength is 620 MPa or over, impact energy of minus 40 DEG C is 124 J or over, and the anti-corrosion property is outstanding.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com