Method for preparing TC4/TiAl gradient material through laser synchronous powder feeding

A laser synchronous powder feeding and gradient material technology, applied in metal material coating process, additive manufacturing, additive processing, etc., can solve the problems of high temperature gradient, difficult TC4 substrate, large residual stress, etc., and achieve high energy density, High performance, fine tissue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The steps of this method are:

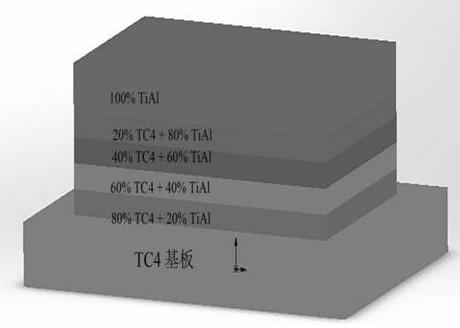

[0048] Step 1: Weigh the TC4 alloy powder and Ti-48Al-2Cr-2Nb alloy powder according to the mass fraction ratio of 4:1, 3:2, 2:3 and 1:4 respectively, and mix them mechanically for 2 hours to obtain the mixed powder. The particle size of the powder is 50-150 μm;

[0049] Step 2: Use an electric grinder to polish the surface of the TC4 titanium alloy substrate to remove the oxide film, wipe the surface of the substrate with alcohol to remove oil, and then put it into the laser 3D printing equipment (LDM8060 laser synchronization produced by Nanjing Zhongke Yuchen Laser Technology Co., Ltd. powder feeding additive manufacturing equipment), the size of TC4 substrate is 100mm×100mm×10mm;

[0050] Step 3: Put the alloy powder in step 1 into a vacuum drying oven for drying treatment at 150°C / 2h, and then use a pneumatic powder feeder to send the alloy powder into the laser cladding head;

[0051] Step 4: Form 5 layers of 80% TC4 + 20% TiAl gr...

Embodiment 2

[0054] The steps of this method are:

[0055] Step 1: Weigh the TC4 alloy powder and Ti-48Al-2Cr-2Nb alloy powder according to the mass fraction ratio of 4:1, 3:2, 2:3 and 1:4 respectively, and mix them mechanically for 3 hours to obtain the mixed powder. The particle size of the powder is 50-150 μm;

[0056] Step 2: Use an electric grinder to polish the surface of the TC4 titanium alloy substrate to remove the oxide film, wipe the surface of the substrate with alcohol to remove oil, and then put it into the laser 3D printing equipment (LDM8060 laser synchronization produced by Nanjing Zhongke Yuchen Laser Technology Co., Ltd. powder feeding additive manufacturing equipment), the size of TC4 substrate is 100mm×100mm×10mm;

[0057] Step 3: Put the alloy powder in step 1 into a vacuum drying oven for drying treatment at 150°C / 1h, and then use a pneumatic powder feeder to send the alloy powder into the laser cladding head;

[0058] Step 4: Form 5 layers of 80% TC4 + 20% TiAl gr...

Embodiment 3

[0061] The steps of this method are:

[0062] Step 1: Weigh the TC4 alloy powder and Ti-48Al-2Cr-2Nb alloy powder according to the mass fraction ratio of 4:1, 3:2, 2:3 and 1:4 respectively, and mix them mechanically for 2 hours to obtain the mixed powder. The particle size of the powder is 50-150 μm;

[0063] Step 2: Use an electric grinder to polish the surface of the TC4 titanium alloy substrate to remove the oxide film, wipe the surface of the substrate with alcohol to remove oil, and then put it into the laser 3D printing equipment (LDM8060 laser synchronization produced by Nanjing Zhongke Yuchen Laser Technology Co., Ltd. powder feeding additive manufacturing equipment), the size of TC4 substrate is 100mm×100mm×10mm;

[0064] Step 3: Put the alloy powder in step 1 into a vacuum drying oven for drying treatment at 150°C / 1.5h, and then use a pneumatic powder feeder to send the alloy powder into the laser cladding head;

[0065] Step 4: Form 2 layers of 80% TC4+20% TiAl gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com