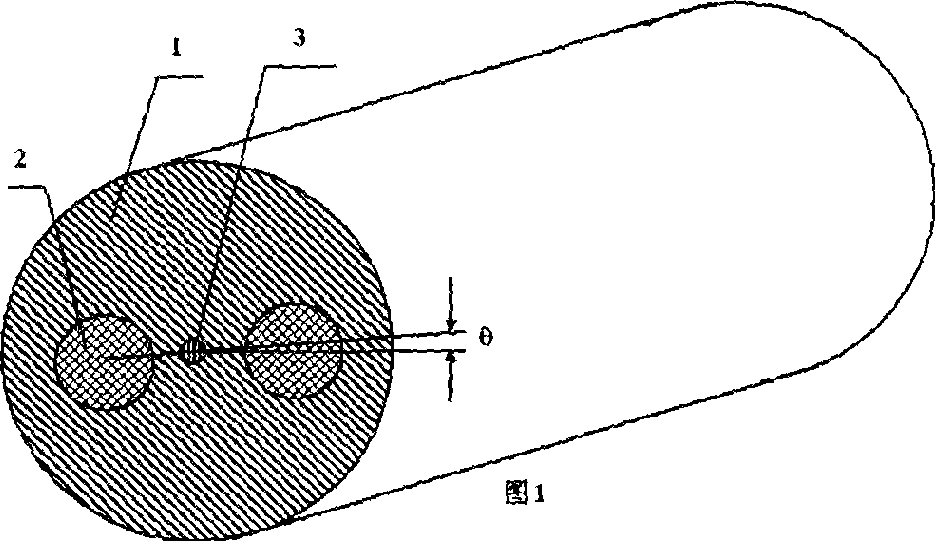

Large size combined optical fibre perform of polarization maintaining fiber and production method thereof

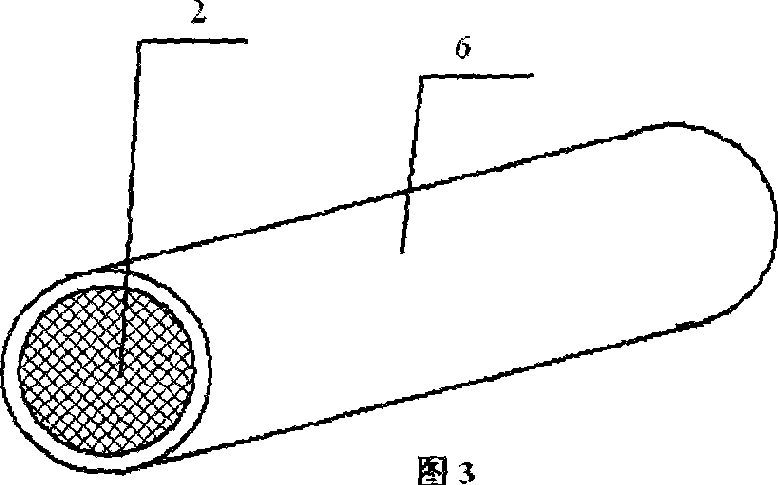

An optical fiber preform and polarization-maintaining optical fiber technology, which is applied to manufacturing tools, glass manufacturing equipment, glass fiber products, etc., can solve the problems of high stability requirements of fixtures, unsatisfactory symmetry of punched preforms, etc. Improved symmetry and longitudinal consistency, stable and controllable drawing conditions, slow and stable movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The geometric parameters of the combined preform and the length and performance index of the polarization-maintaining optical fiber drawn by using the combined preform are shown in Table 1.

[0057] Table 1: Geometric dimensions of combined preforms and related indicators of drawn optical fibers

[0058]

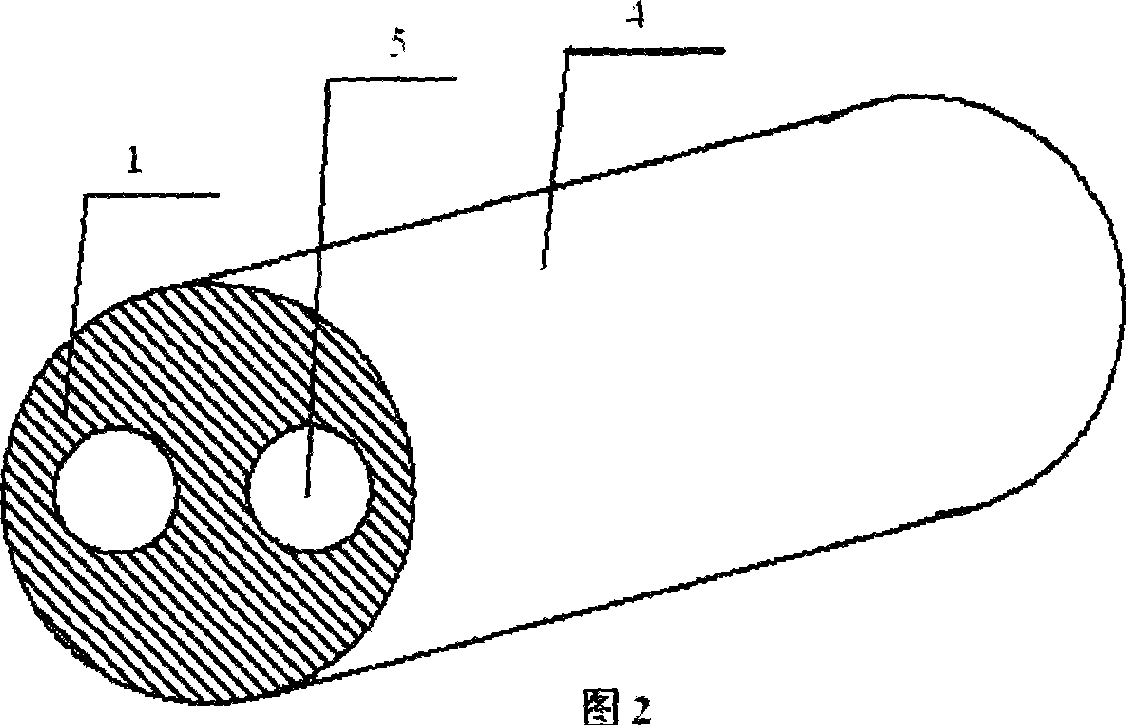

[0059] Use a perforated preform with a diameter of 30mm, the diameter of the hole is 12mm, and insert a stress rod with a diameter of 10mm in the stress zone into the hole of the preform. After cleaning and drying, the upper tower of the combined optical fiber preform is drawn into a cladding diameter of 80 μm. Polarization-maintaining optical fiber, a total of 35km of qualified polarization-maintaining optical fiber products have been produced. The crosstalk of the panda-type polarization-maintaining optical fiber per kilometer can reach -25dB, and the birefringence of the optical fiber can reach 6×10 -4 ; Draw a polarization maintaining fiber with a cladding diam...

Embodiment 2

[0061] The geometric parameters of the combined preform and the length and performance index of the polarization-maintaining optical fiber drawn by using the combined preform are shown in Table 2.

[0062] Table 2: Geometric dimensions of combined preforms and related indicators of drawn optical fibers

[0063]

[0064]

[0065] Use a perforated preform with a diameter of 40mm, and the diameter of the hole is 13.5mm. Use a stress rod with a diameter of 13mm in the stress zone to insert into the hole of the preform. After cleaning and drying, pull the combined optical fiber preform into a tower with a cladding diameter of 80μm. A total of 65km of qualified polarization-maintaining fiber products have been produced. The crosstalk of the panda-type polarization-maintaining fiber per kilometer reaches -25dB, and the birefringence of the fiber reaches 6×10 -4 ; Pulling a polarization maintaining fiber with a cladding diameter of 125μm can produce a qualified polarization main...

Embodiment 3

[0067] The geometric parameters of the combined preform and the length and performance index of the polarization-maintaining optical fiber drawn using the combined preform are shown in Table 3.

[0068] Table 3: Geometric dimensions of combined preforms and related indicators of drawn optical fibers

[0069]

[0070] Use a perforated preform rod with a diameter of 50 mm, wherein the diameter of the hole is 16 mm, and insert a stress rod with a diameter of 14 mm in the stress zone into the hole of the preform rod. Polarizing optical fiber, a total of 100km of qualified polarization-maintaining optical fiber products have been produced. The crosstalk of the panda-type polarization-maintaining optical fiber per kilometer can reach -25dB, and the birefringence of the optical fiber can reach 6×10 -4 ; Pulling a polarization maintaining fiber with a cladding diameter of 125μm can produce qualified polarization maintaining fiber products with a length of 60km. -4 , all performanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com