Patents

Literature

86results about How to "Achieve precision control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

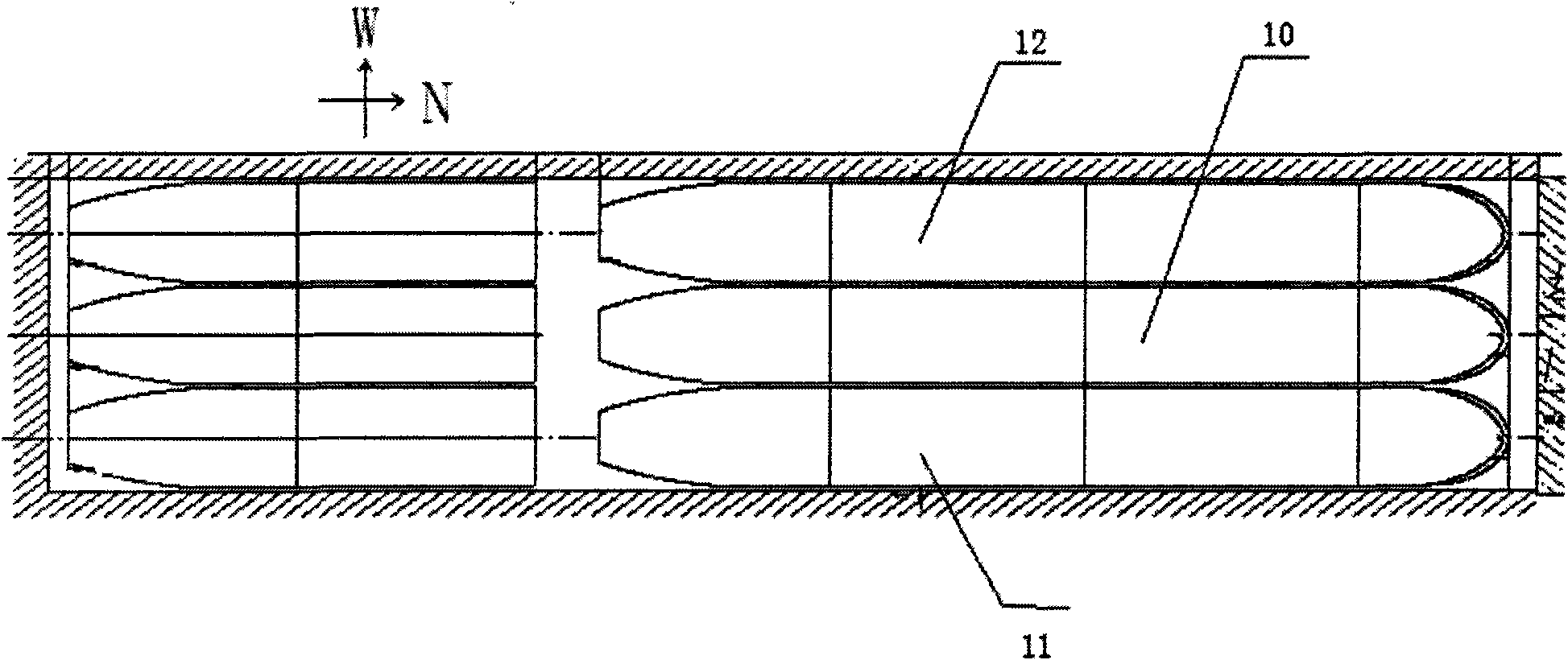

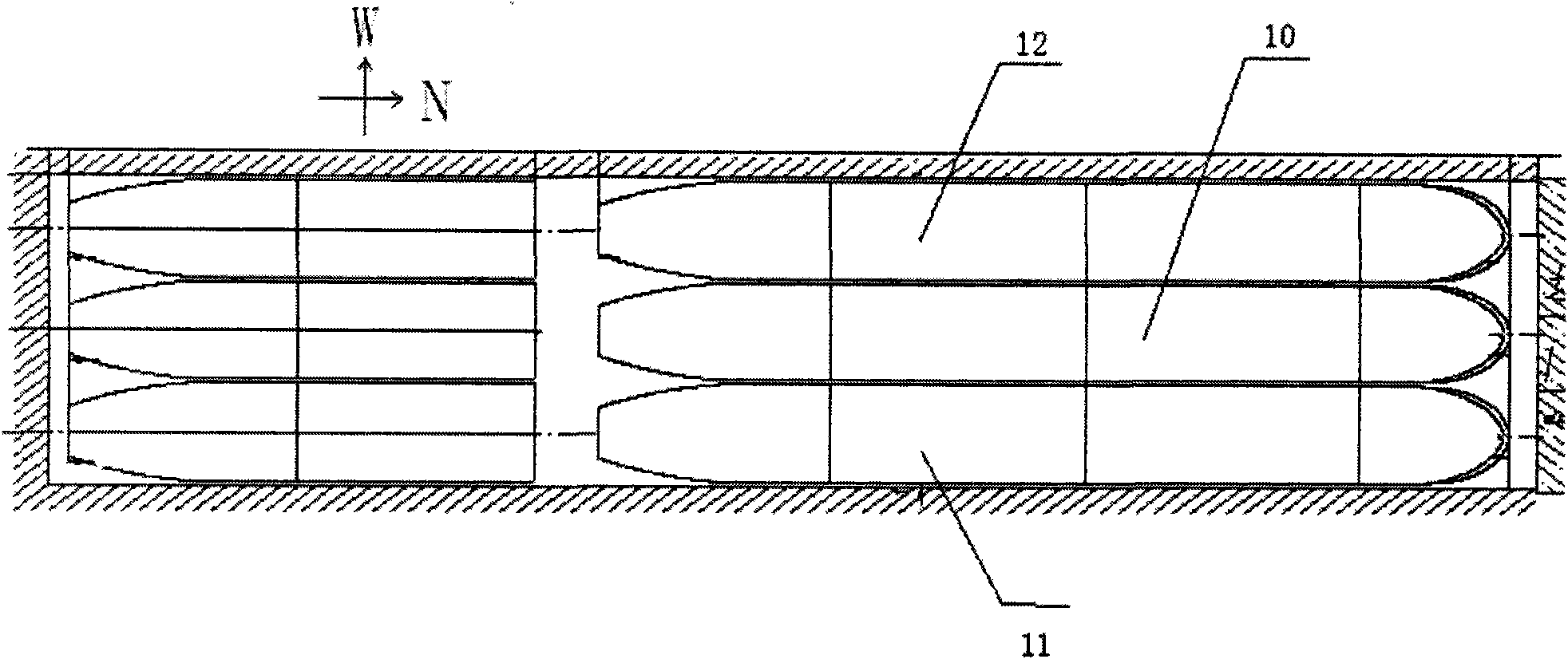

Shipbuilding method

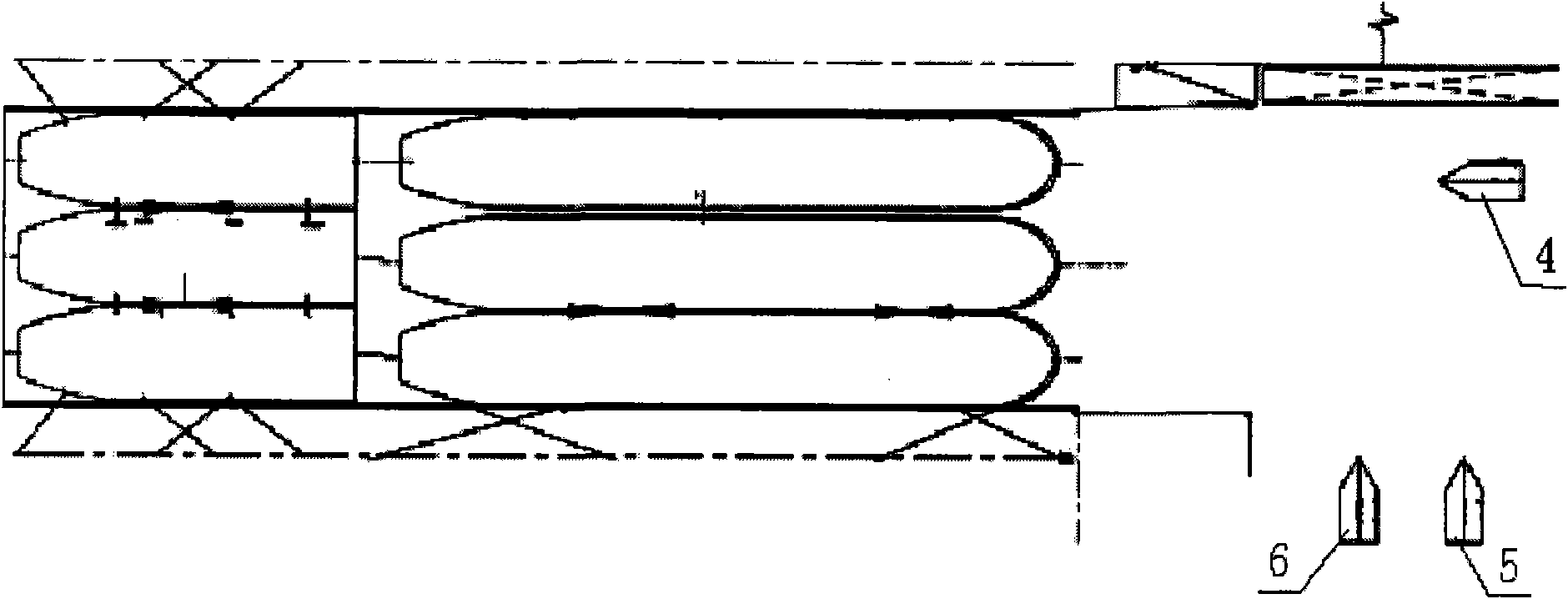

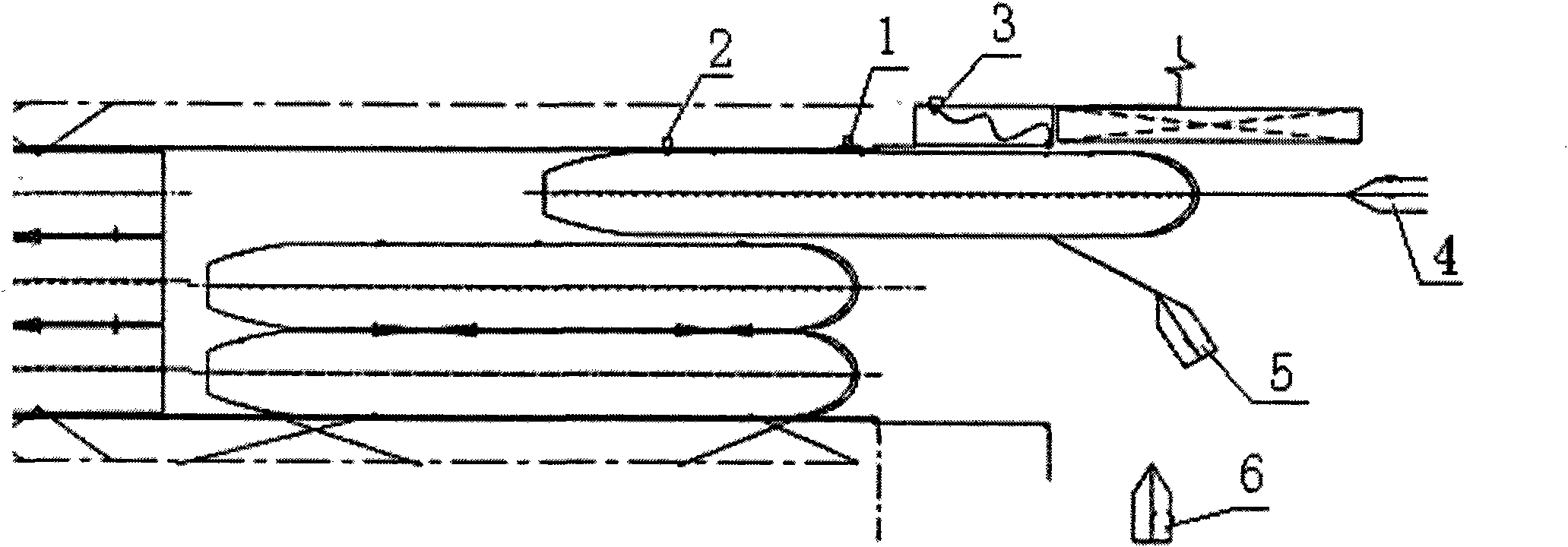

The invention relates to a shipbuilding method, in particular being applied to building a Panama bulk freighter in a dock, and belonging to the technical field of shipbuilding methods. The shipbuilding method comprises the following steps: simultaneously building three whole ships at the front of the dock, wherein the mutual interval among the three ships is 1.2m; simultaneously building three after semi-ships at the back of the dock, wherein the mutual interval among the three semi-ships is 1.2m; folding the three whole ships, driving out of the dock for entering the water, and carrying out underwater operation; after the three whole ships are in the water, moving the three after semi-ships to the front of the dock and keep 1.2m at intervals; and at that time, turning to a building stageof the three whole ships for the three after semi-ships, and carrying out new building of three after semi-ships at the back of the dock. The invention belongs to a 3+3 building method, which furthest utilizes dock resources, improves use ratio of the dock and shortens shipbuilding period in the dock.

Owner:蓬莱中柏京鲁船业有限公司

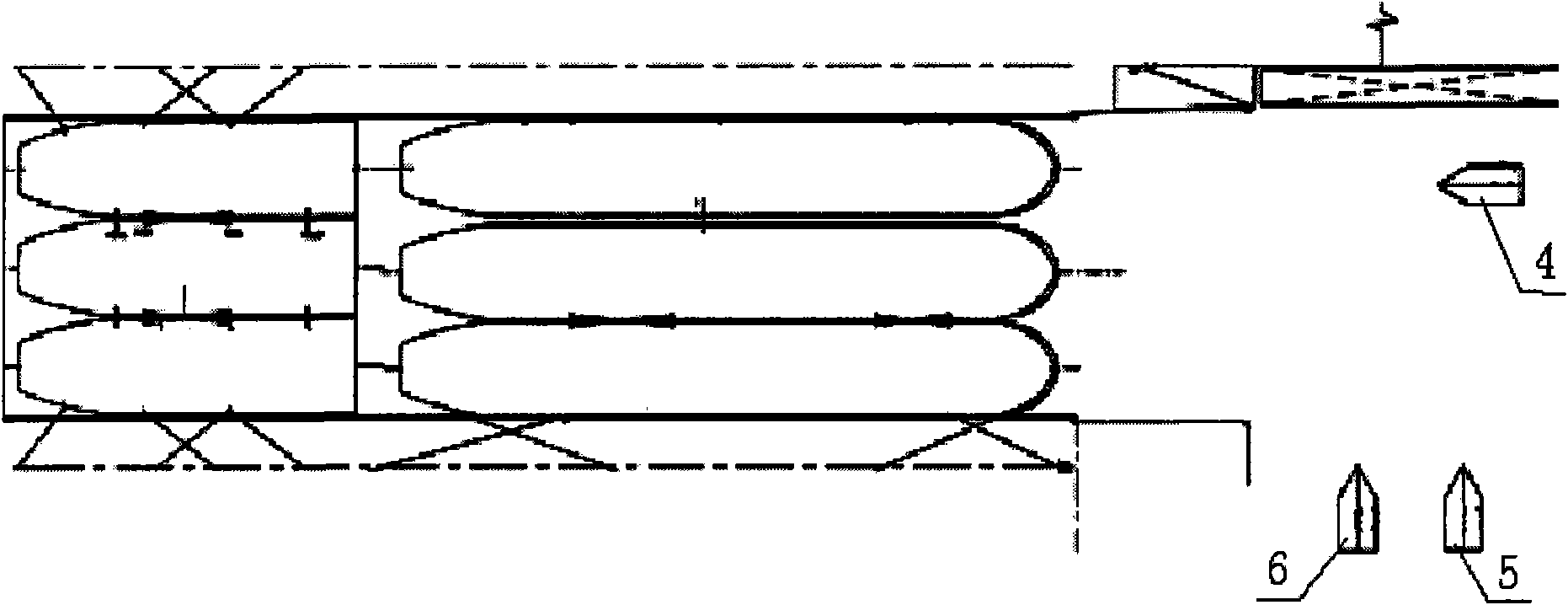

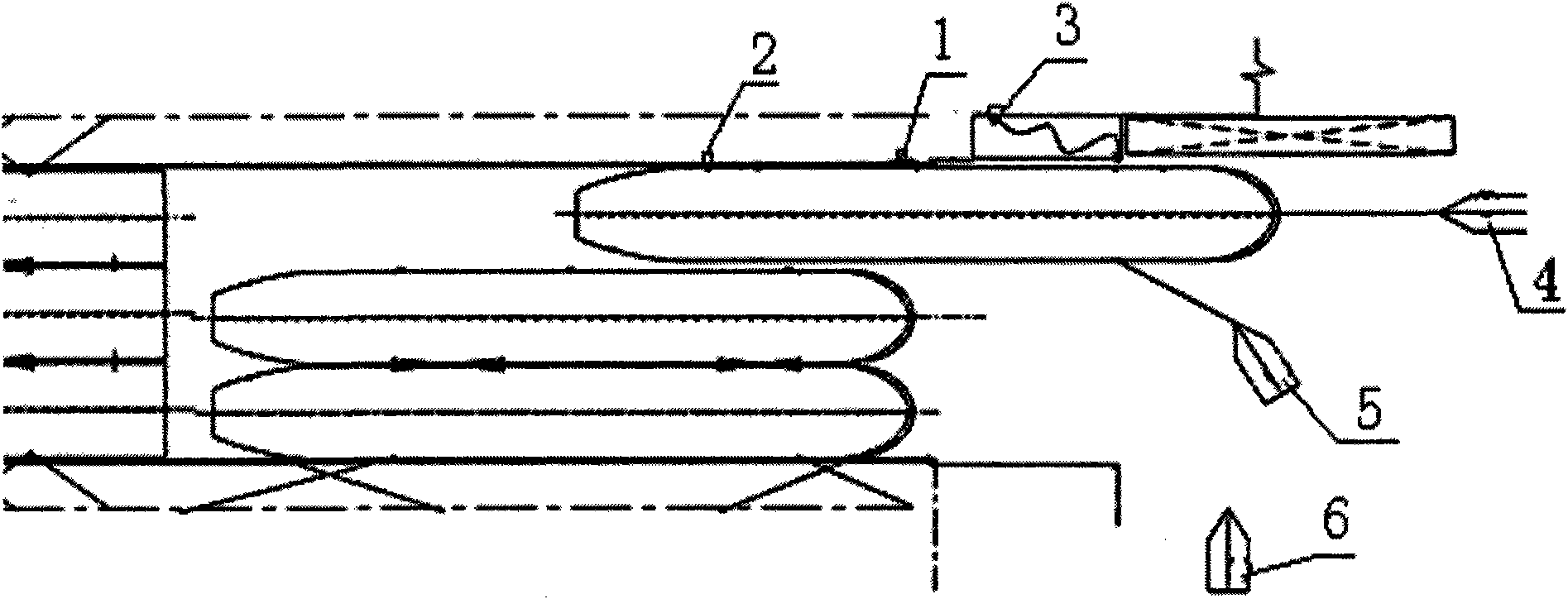

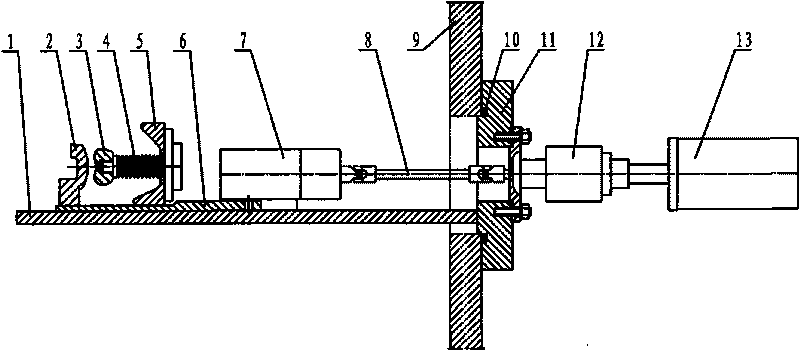

Method for undock ballasting in ship building

ActiveCN101920771AEffectively expandAchieve precision controlSlipwaysSecondary stageMarine engineering

The invention relates to a method for undock ballasting in ship building, which is particularly applicable to the building of Panamax bulk carrier in a dock and belongs to the technical field of dock building methods. The method is characterized in that: before large dock water injection, first-stage ballasting which comprises tail half ship ballasting and entire ship ballasting by three identical ships is performed; after the large dock water injection, second-stage ballasting which consists of primary large dock water injection, secondary large dock water injection, tertiary large dock water injection and quaternary large dock water injection is performed; and after ship ballasting is finished completely, water is injected into a large dock again till the water is 4.6 to 4.8 meters deep. The undock ballasting method is used in a '3+3 building method', realizes maximum utilization of dock resources, improves the utilization rate of docks and reduces an in-dock ship building period.

Owner:蓬莱中柏京鲁船业有限公司

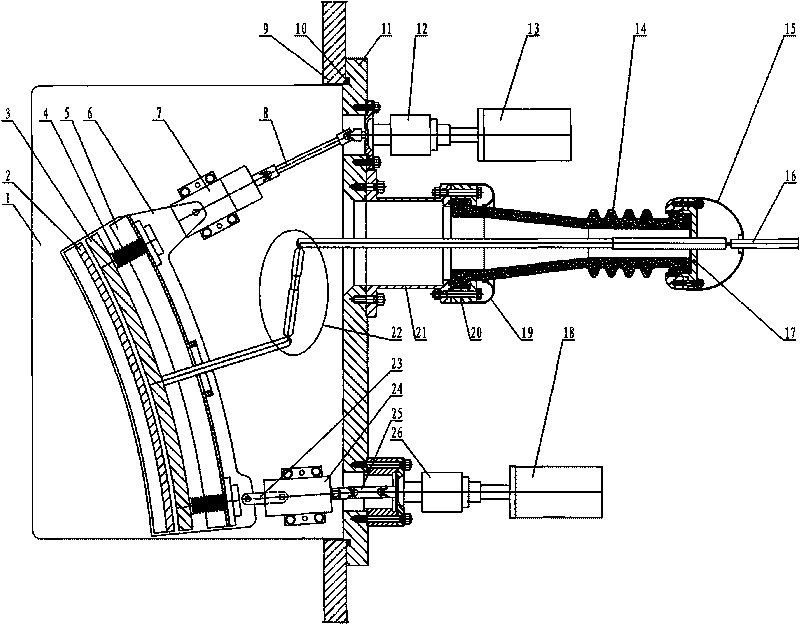

Precision plunger metering pump

InactiveCN101709693AHigh surface hardnessImprove cylindricityPumpsPositive-displacement liquid enginesRubber ringEngineering

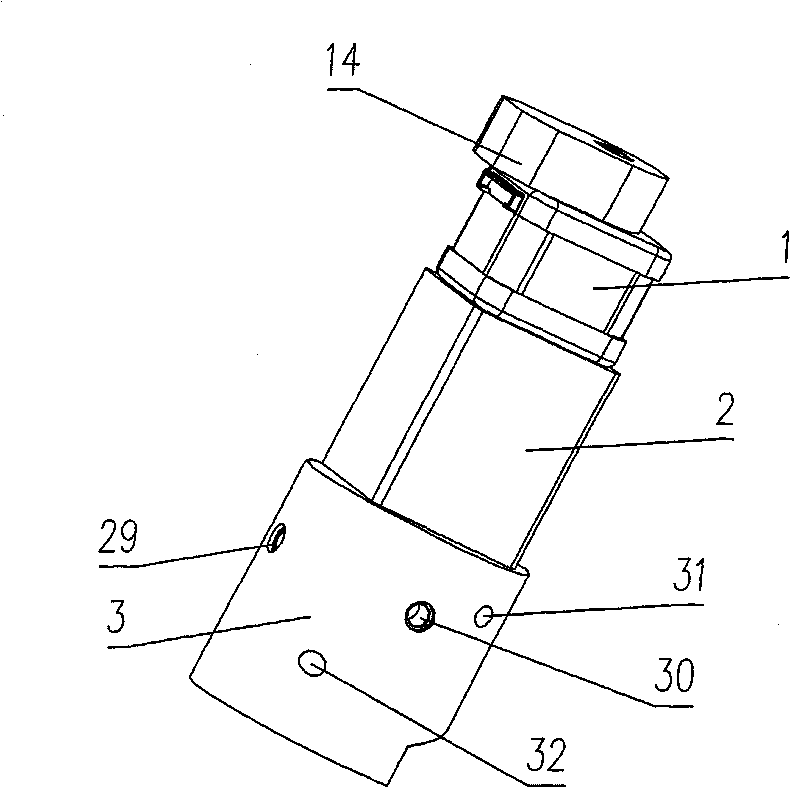

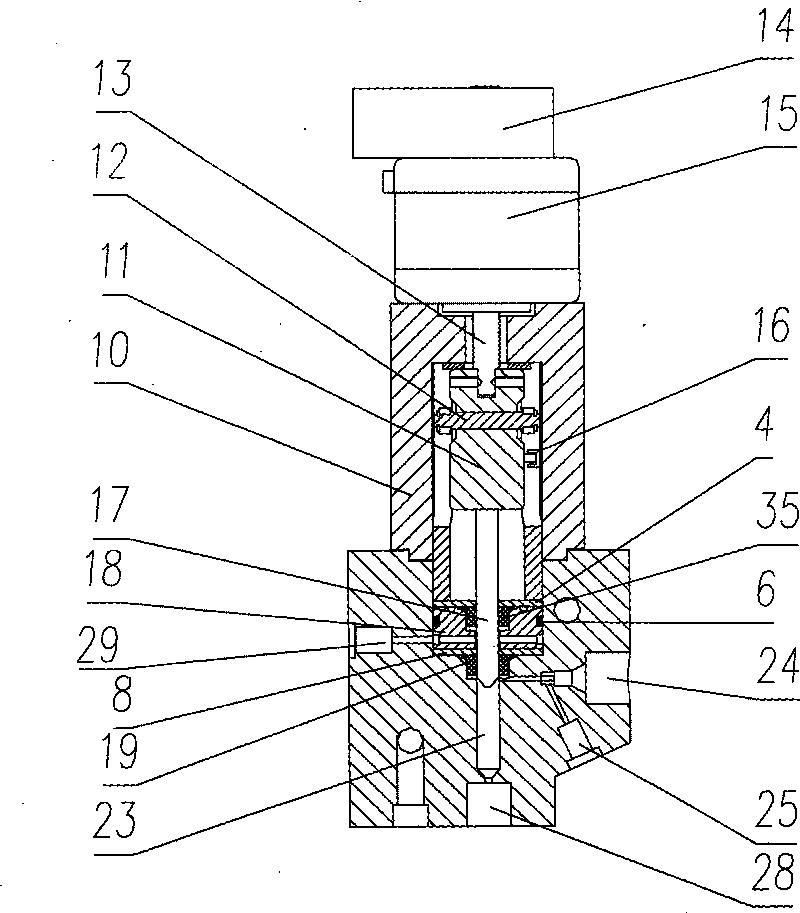

The invention relates to a precision plunger metering pump, comprising three parts, including a driving mechanism, a sealing mechanism and a pump head, wherein by utilizing a photoelectric encoder, the driving mechanism accurately controls the movement of a stepper motor, thereby effectively preventing the error of pump output caused by the falling out of step or the idling of the motor from being generated; a sealing ring in the sealing mechanism is matched with a plunger piston to realize precision fit, and the sealing ring based on a stainless steel spring enclasping mechanism solves the problems of low enclasping force and easy aging of a traditional rubber ring and prolongs the service life; the pump head has the design of water washable airtight cabin, realizes the washing and sealing functions of the plunger piston and the sealing ring and prolongs the sealing life; the technic level of processing the plunger piston and slab rubber achieves the purpose that a miniature precision plunger metering pump can provide 20MPa pressure intensity; and the slab rubber has good polishing performance, extremely high transparency, compact structure, small volume and delicate appearance. The precision plunger metering pump can be applied to the precise metering of fluid in the fields of medication, sanitation, biology and chemistry.

Owner:THE FIRST RES INST OF MIN OF PUBLIC SECURITY +1

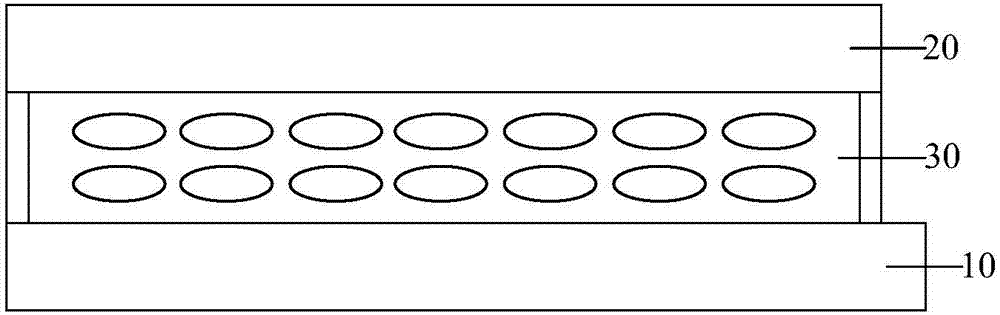

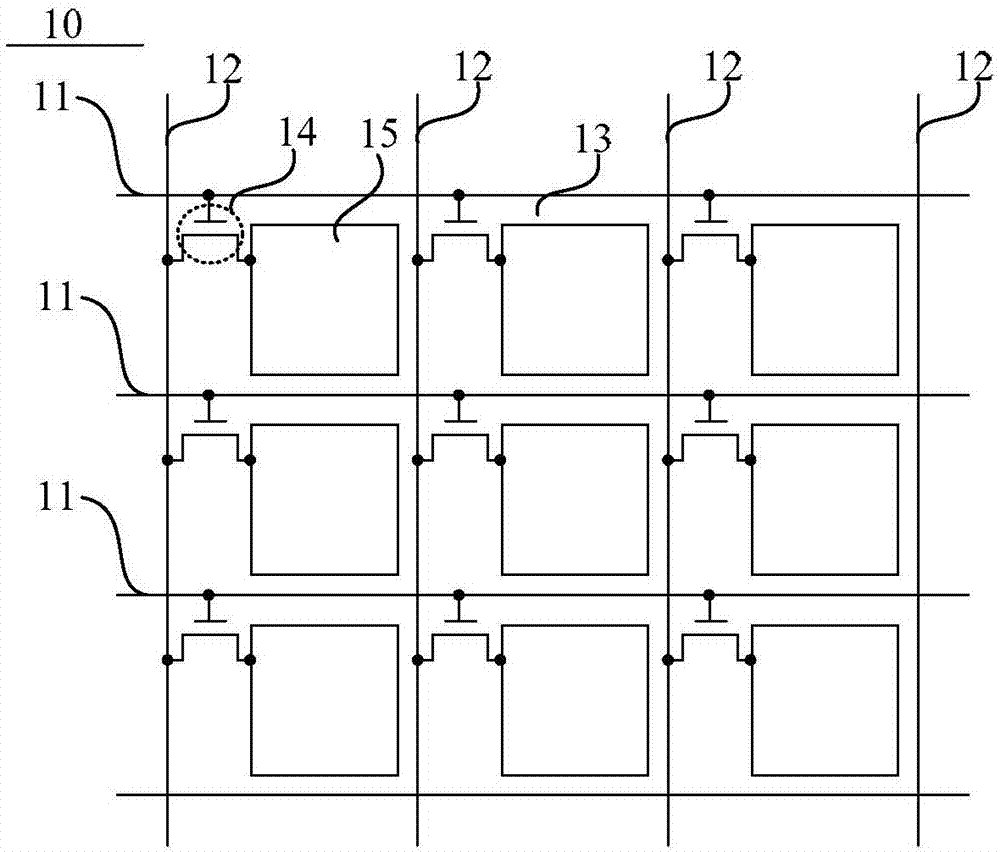

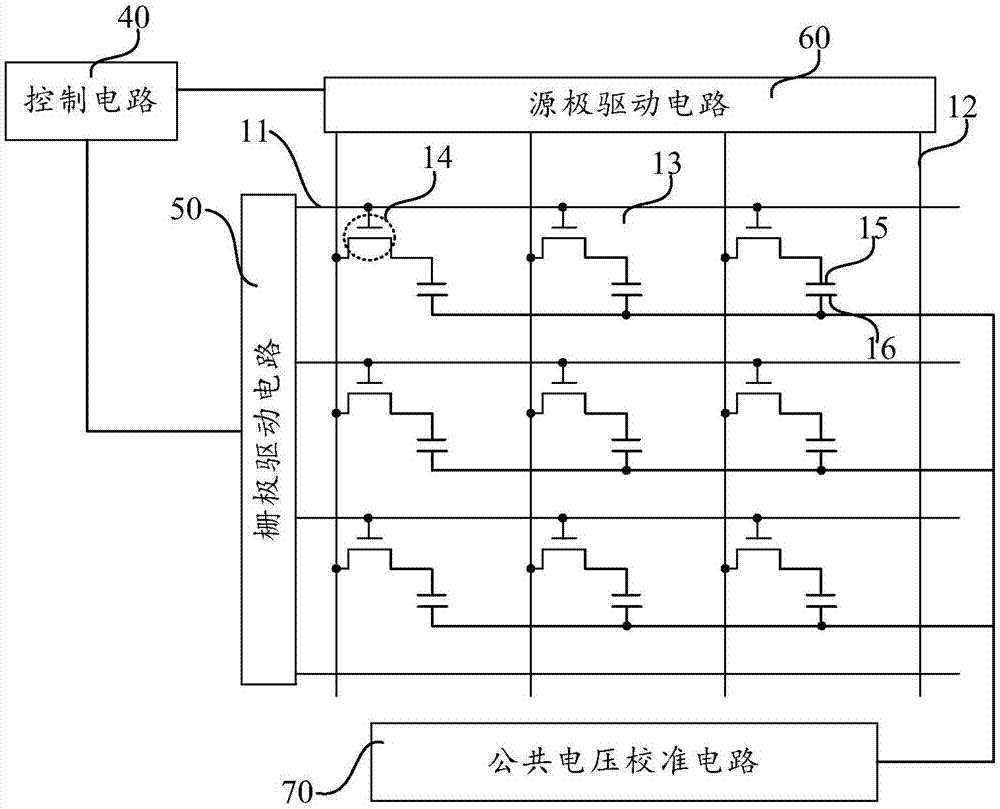

Common voltage calibration circuit, circuit board and display device

ActiveCN107578752AAchieve precision controlImprove stabilityStatic indicating devicesDisplay deviceEngineering

The embodiment of the invention discloses a common voltage calibration circuit, a circuit board and a display device and relates to the technical field of display. The precision and stability degree of common voltage which is actually input to a common electrode can be improved. The common voltage calibration circuit comprises a differencing module, an integral module, a compensation module and asummation module; the input end of the differencing module is connected with the input end of the common voltage and the feedback end of the common voltage, the differencing module is used for acquiring a voltage difference value of the input end of the common voltage and the feedback end of the common voltage, and the voltage difference value is output through the output end; the input end of theintegral module is connected with the output end of the differencing module, the output end of the integral module is connected with the input end of the summation module, and the integral module isused for controlling the precision of the common voltage; the input end of the compensation module is connected with the output end of the differencing module, the output end of the compensation module is connected with the input end of the summation module, and the compensation module is used for compensating the common voltage; the output end of the summation module is connected with the outputend of the common voltage, and the summation module is used for overlapping and outputting results output by the integral module and the compensation module.

Owner:BOE TECH GRP CO LTD +1

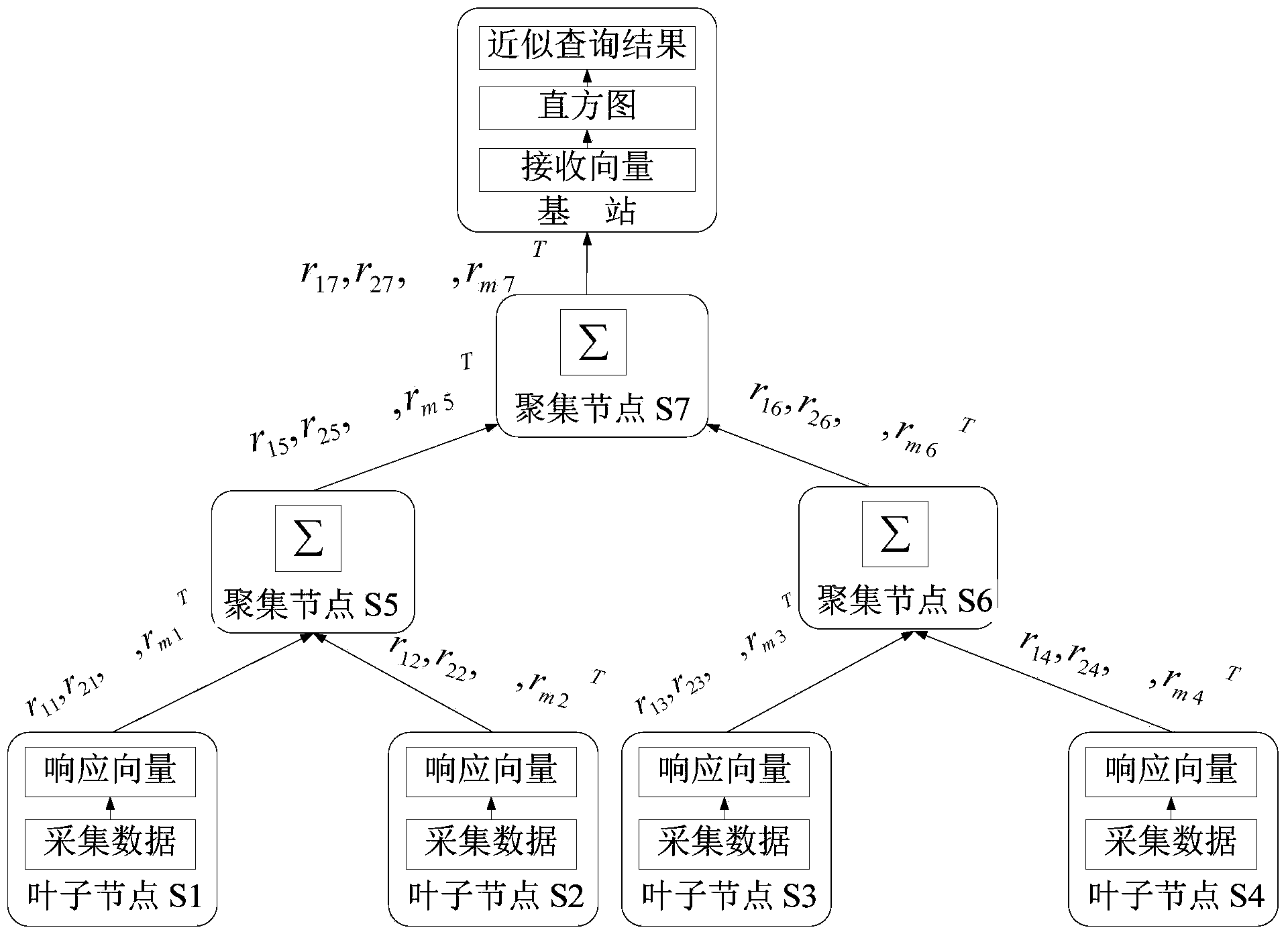

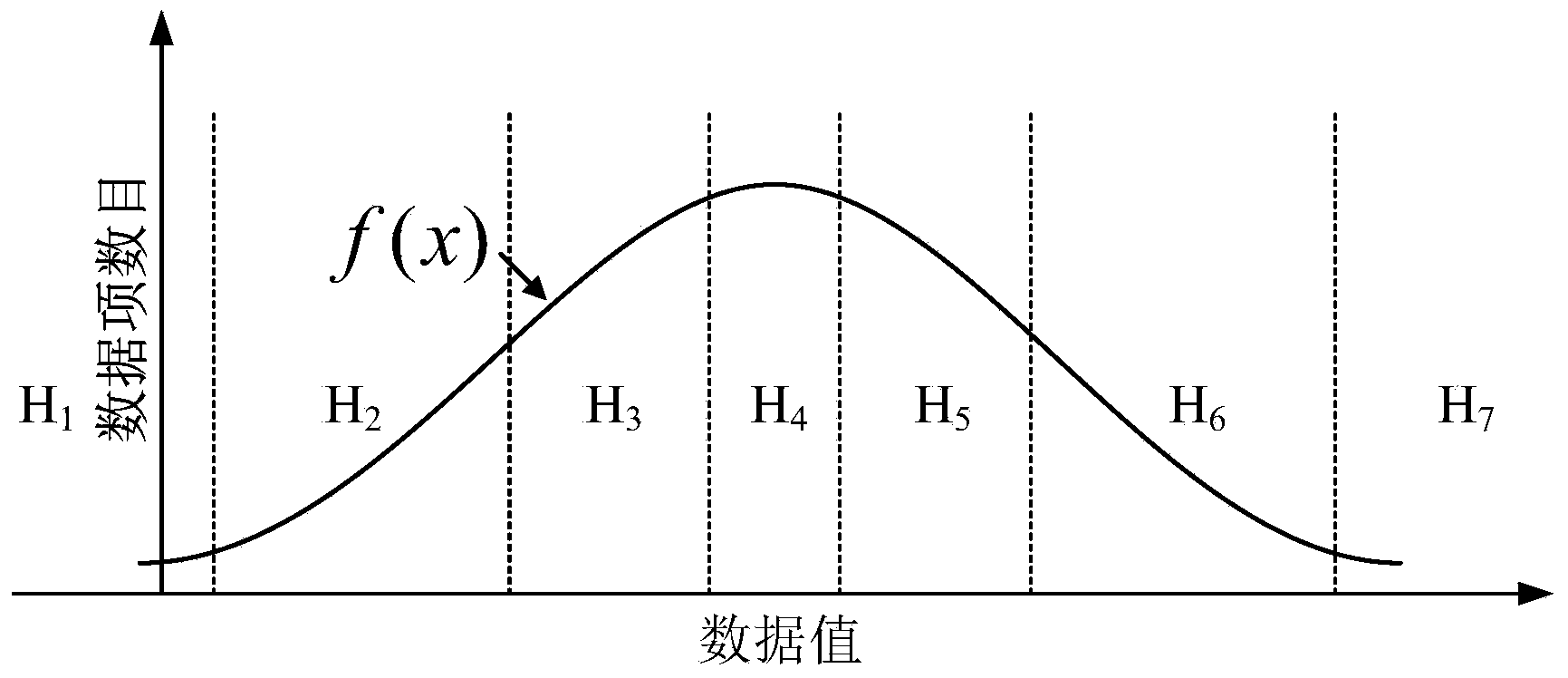

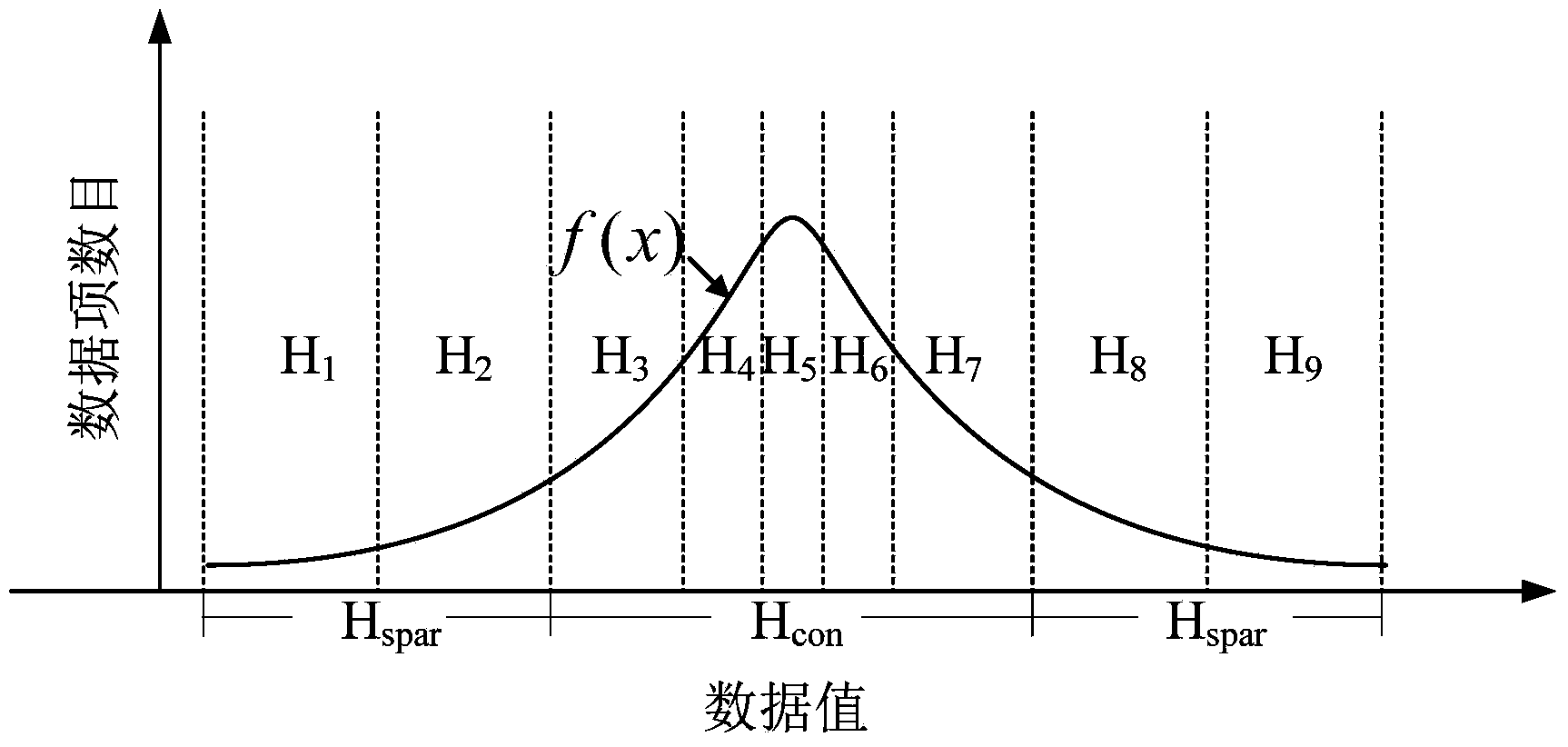

Sensor network-oriented approximate query method commonly used for privacy protection

ActiveCN103491535AReduce consumptionAchieve precision controlEnergy efficient ICTNetwork topologiesPrivacy protectionSensor node

The invention provides a sensor network-oriented approximate query method commonly used for privacy protection. The method includes the following steps that the shared data structure of a base station and sensor nodes is used for enabling the numbers and collection data of the sensor nodes to be hidden in a vector; gathering nodes transmit the vector to the base station through a tree route; a linear system of equations is constructed in the base station, and a column diagram with global statistical information and a corresponding sensor node number are solved; the needed approximate query is completed according to the statistical information of the column diagram. According to the sensor network-oriented approximate query method, under the condition that privacy information is not leaked, approximate query energy consumption is reduced by the adoption of the strategies like network internal data gathering and a filter, and under the condition that the model does not need to be modified, accuracy control over the privacy protection approximate query can be achieved by the way of parameter adjustment.

Owner:RENMIN UNIVERSITY OF CHINA

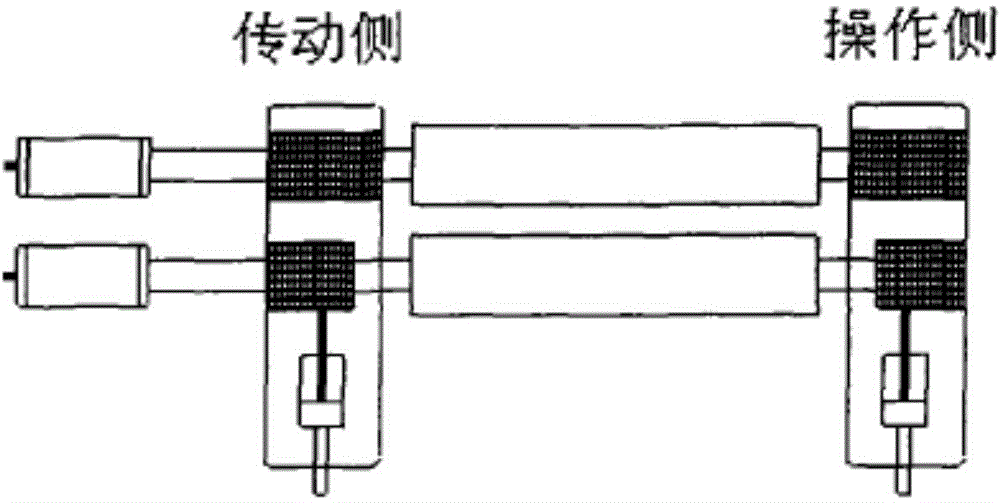

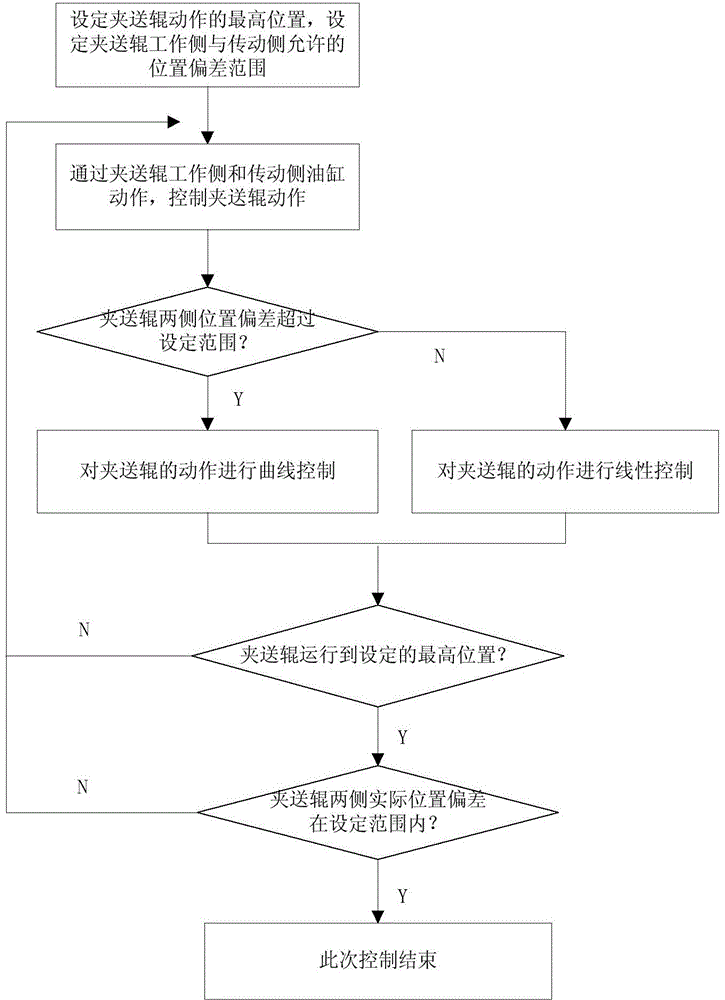

Method for controlling position of pinch roll at finish rolling inlet of hot continuous rolling device

ActiveCN104874611AAchieve precision controlRealize automatic controlRoll force/gap control deviceMetal rolling arrangementsLinear controlControl manner

The invention relates to a method for controlling position of a pinch roll at a finish rolling inlet of a hot continuous rolling device. The method comprises deciding to adopt a linear control method and a non-linear control method according to different position deviations at two sides of a pinch roll during pinch roll gap control, determining an entry switching point between linear control and non-linear control according to the curvature of a curve in the non-linear control process and the straight slop in the linear control process through combination of linear control and non-linear control, to precisely control position deviations, and implementing uninterrupted high precision position control according to combination of characteristics of the two control methods during control to meet demands of the whole automatic positioning control. By adopting the method for controlling the position of the pinch roll at the finish rolling inlet of the hot continuous rolling device, the problem that the efficiency of a manual control method and the control precision are low can be solved.

Owner:BAOSHAN IRON & STEEL CO LTD

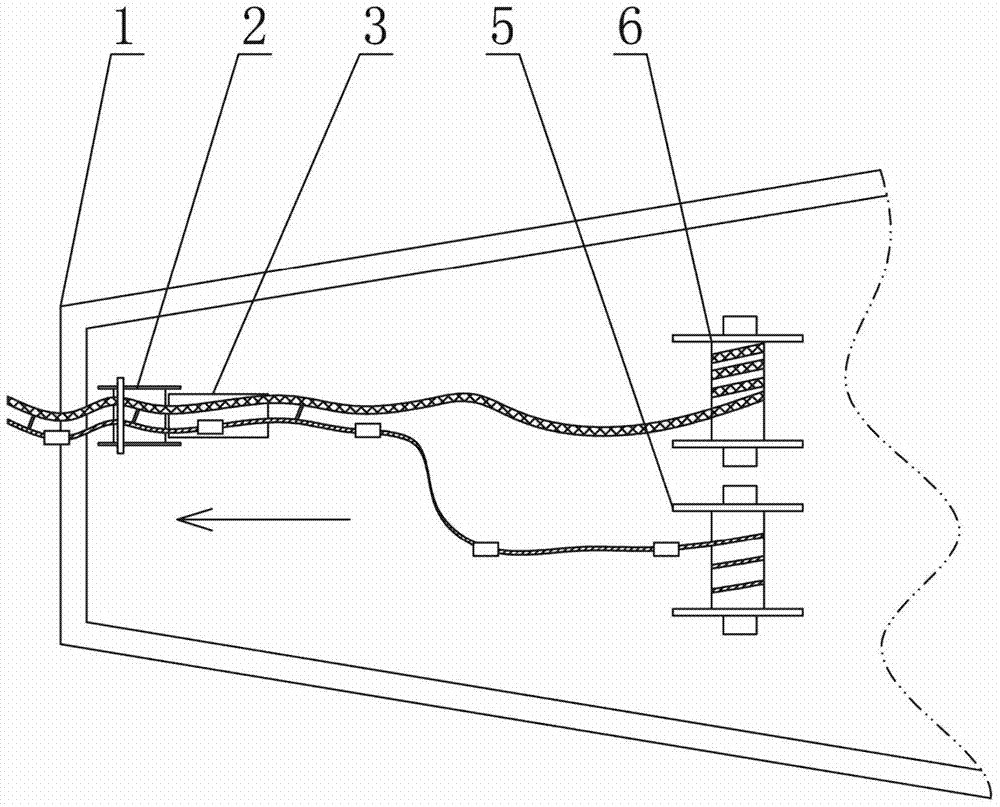

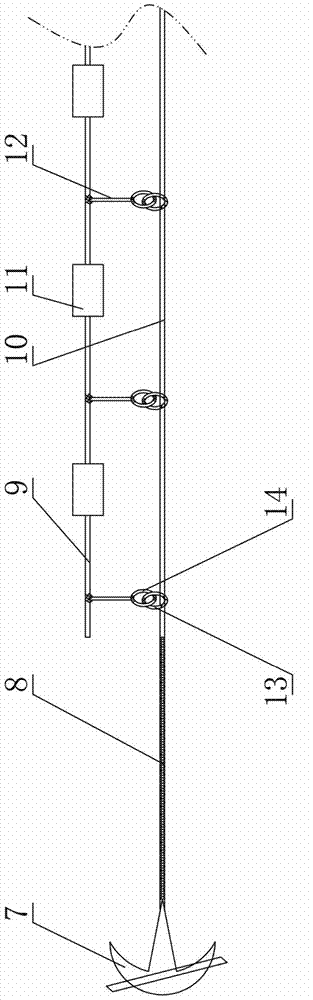

Cable laying precision control method and device

ActiveCN104269782AAchieve precision controlAchieve orientationApparatus for laying cablesMooring systemStern

The invention discloses a cable laying precision control method and device. The method includes the steps that a, when the stern is located over the target coordinate points, at the sea bottom, of a positioning anchor, a gravity anchor connected to the front end of a traction rope inside a positioning rope is thrown into the sea bottom, wherein the length of the traction rope is determined according to the suspension length, in the sea water, of a submarine cable with wave detectors. The device comprises a mooring rope system and a winch system, wherein the winch system is used for throwing the mooring system into the sea together. The cable laying precision control method and device can be applied to the technical field of submarine cable seismic exploration operation, by the utilization of the cable laying precision control method and device, the defects in the prior art can be effectively overcome, influences of multi-lamination currents, undercurrents, ocean currents and irregular currents inside a deep ocean region can be effectively avoided, and the technical effect of precision control over deep ocean operation is achieved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

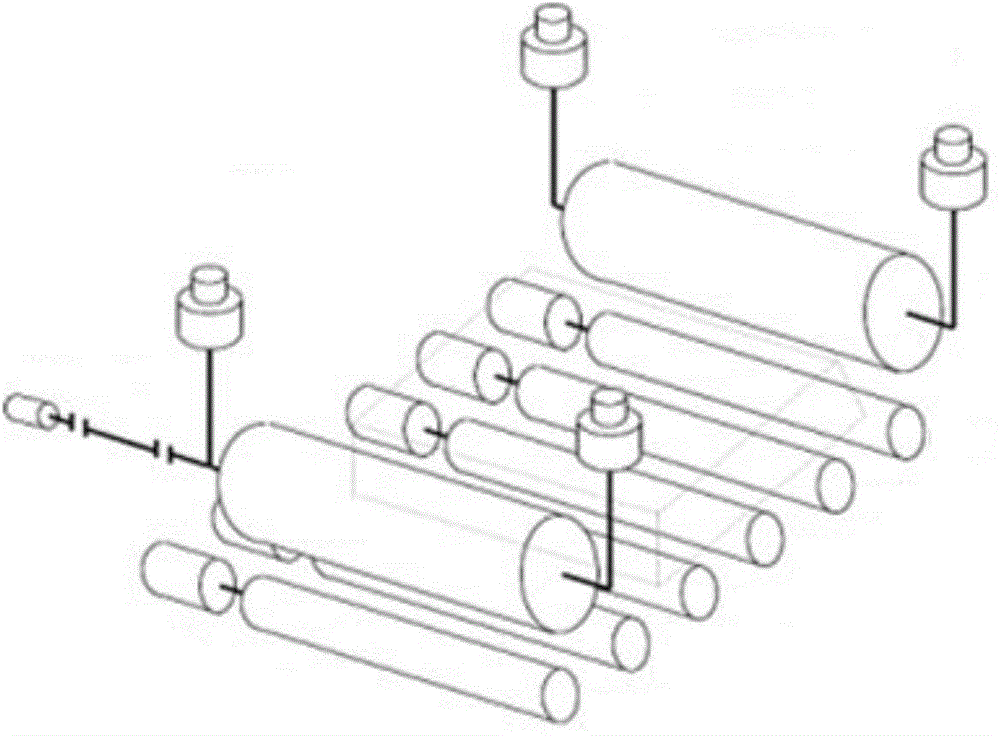

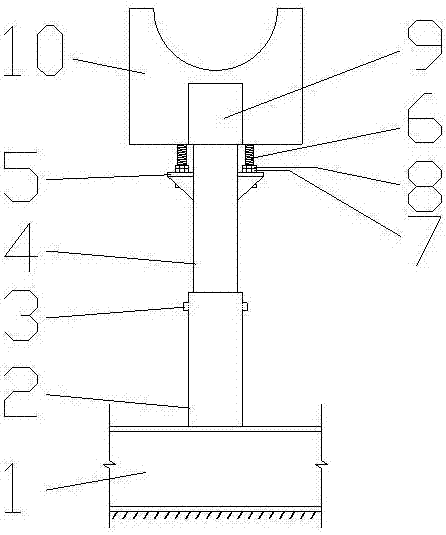

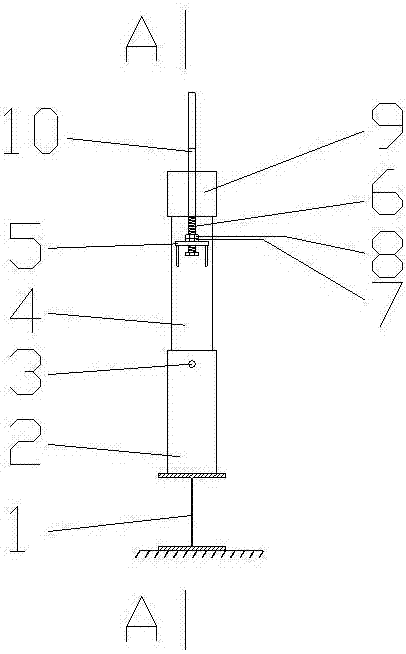

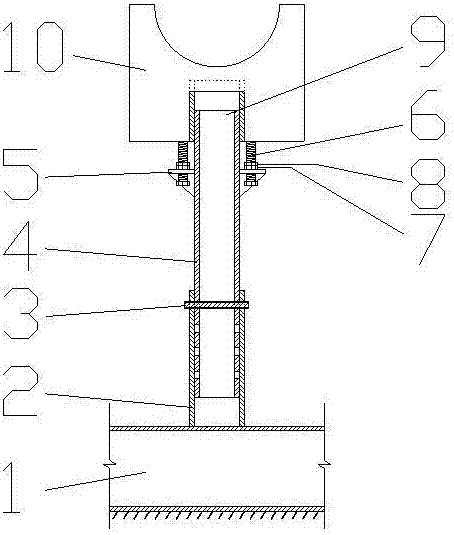

Fabricated simple jig frame used for assembly of steel structure and using method thereof

InactiveCN107327146AAchieve precision controlLarge adjustment rangeBuilding material handlingEngineeringScrew cap

The invention particularly relates to a jig frame used for assembly of a steel structure. The jig frame comprises a base part, a support part and a bracket part and is characterized in that the base part comprises a horizontal bottom plate and a bottom circular pipe, wherein the bottom circular pipe is vertically welded to the horizontal bottom plate; the supporting part comprises a supporting circular pipe, screw caps and screws, the screw caps and the screws are located on the two sides of the supporting circular pipe and fixed to the supporting circular pipe by being welded to brackets on the side faces of the supporting circular pipe on the same horizontal plane; the screws are connected with the supporting circular pipe through screwing-in nuts and fastened through second nuts on the nuts; the bracket part comprises a supporting plate and a top circular pipe, and the supporting plate is vertically welded to the middle-upper part of the top circular pipe; the heights of the base part and the supporting part are adjusted through a plug pin positioning method, and fine adjustment of the heights of the supporting part and the bracket part is achieved through bolt adjustment; and the shape of the supporting plate can be changed according to the shape of an assembly member. The jig frame is used for assembly of the steel structure, assembly precision can be improved, assembly efficiency is improved, and the assembly jig frame can be used repeatedly.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

Ink drop point precision control method and system for ink-jet printing

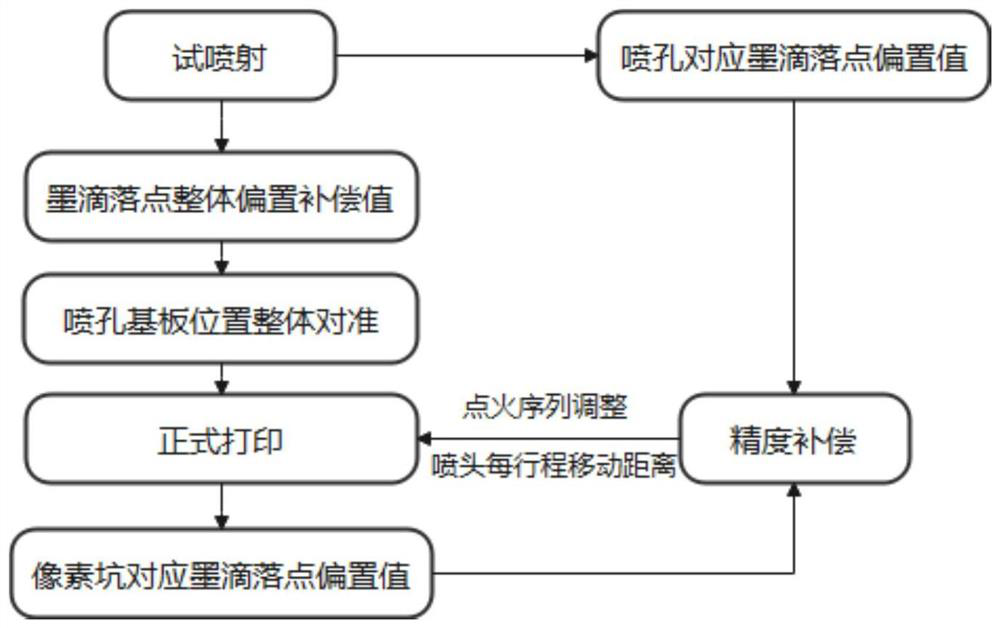

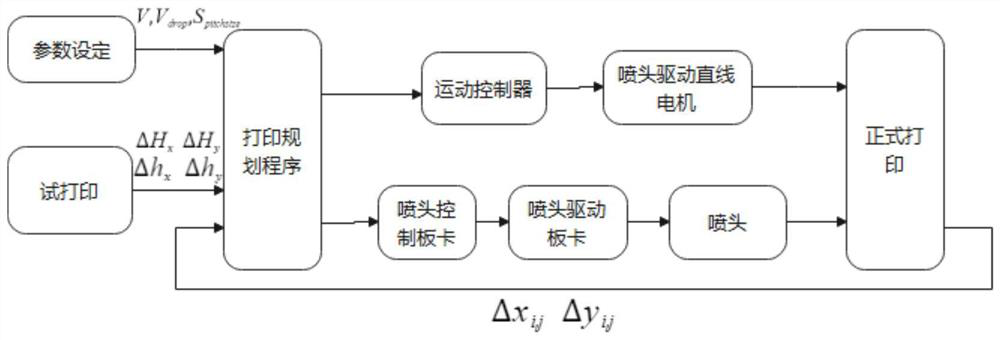

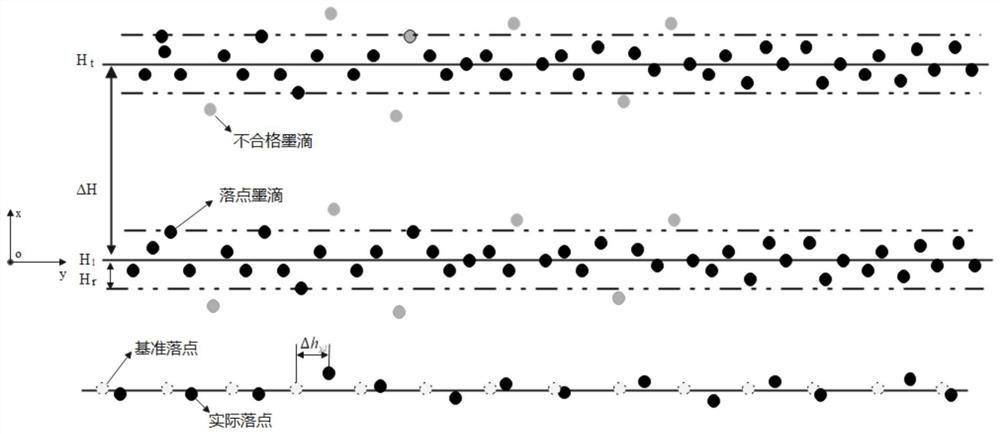

ActiveCN113752698AAchieve precision controlCompensate for multiple errorsPrintingDisplay deviceElectronic component

The invention belongs to the technical field of ink-jet printing, and particularly discloses an ink drop point precision control method and system for ink-jet printing. The method comprises the steps that (1) spray holes are moved to a trial printing area for trial spraying, the offset value of an ink drop point corresponding to each spray hole is detected, and then the overall offset compensation value of the ink drop points is obtained; (2) the position precision of the spray holes relative to pixel pits of a substrate is integrally compensated by using the overall offset compensation value of the ink drop points; (3) the spray holes are started to implement formal printing, and the offset value of each ink drop point corresponding to each pixel pit is detected in the printing process; and 4) according to the offset value, on one hand, the compensation position precision of the ignition sequence is adjusted in the moving direction of the substrate, and on the other hand, the moving distance of each nozzle in each stroke is adjusted so as to compensate the position precision in the moving direction of the corresponding nozzle. Multiple errors in the ink-jet printing process can be compensated, and the ink-jet printing method is particularly suitable for being used in the application occasions of manufacturing high-resolution displayers, electronic components and the like in an ink-jet printing mode.

Owner:HUAZHONG UNIV OF SCI & TECH

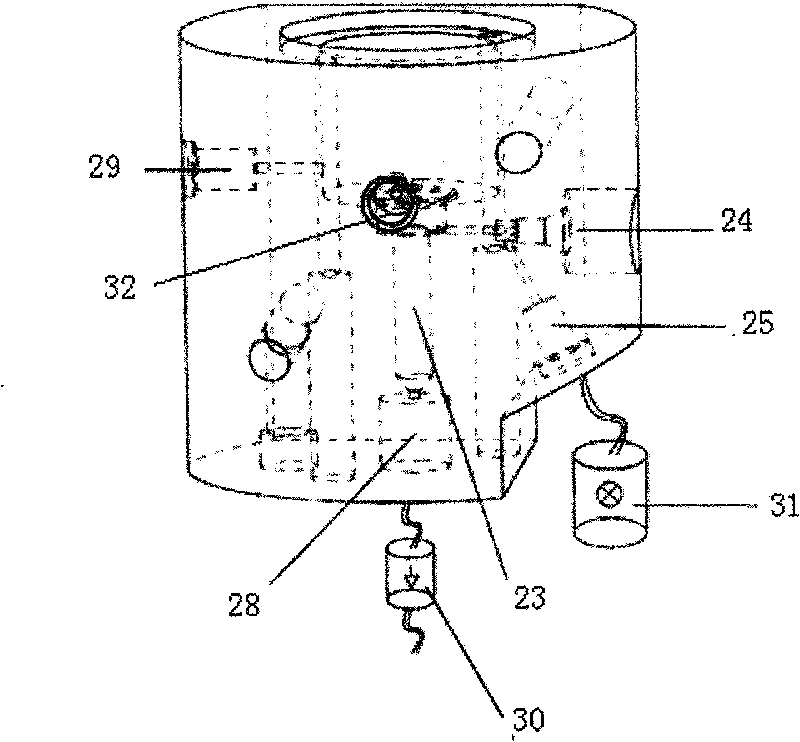

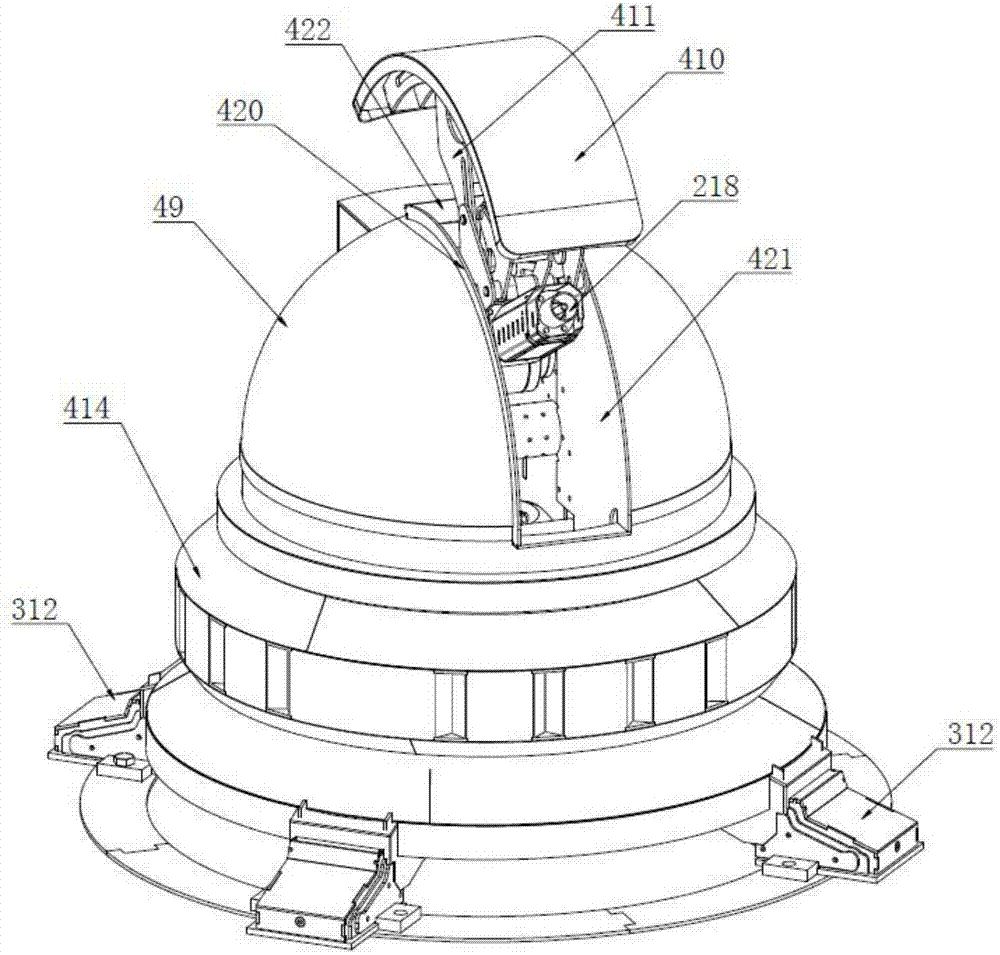

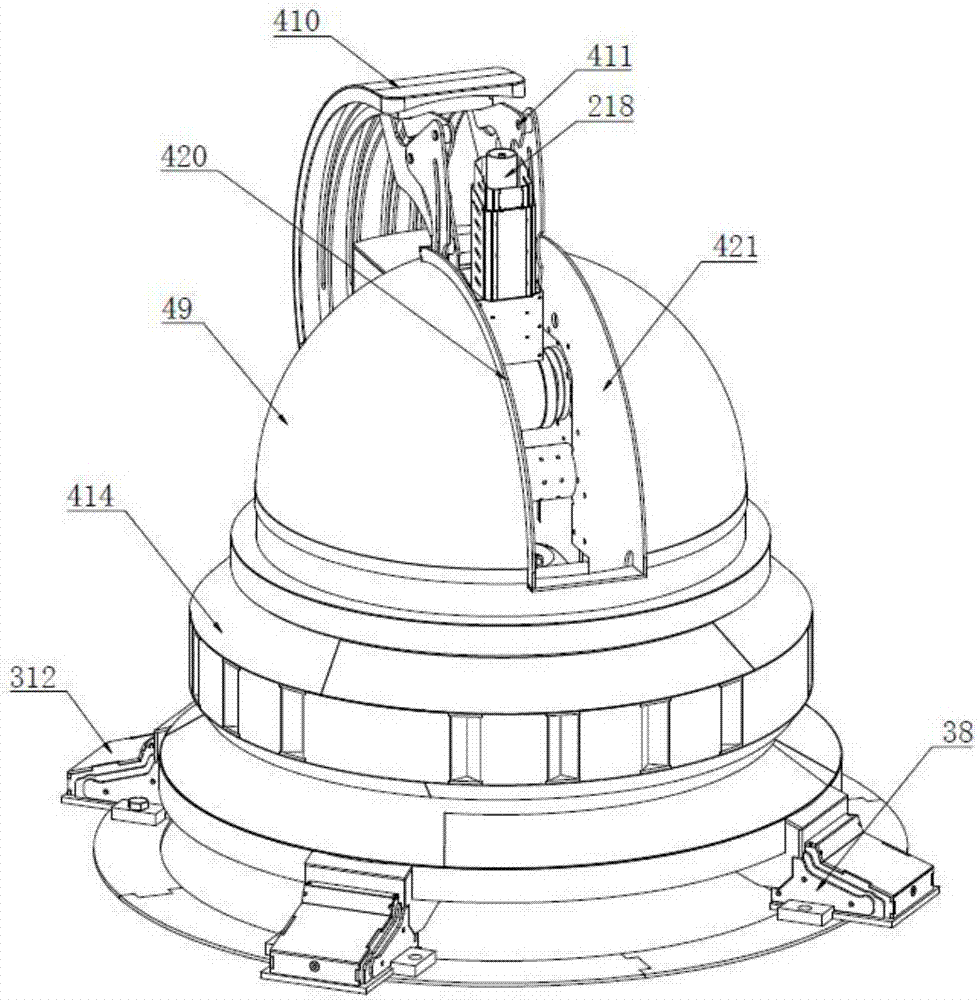

Rotation type fluid injection device

InactiveCN107998565ADust-proofAnti-corrosionMechanical apparatusLighting and heating apparatusGear driveGun barrel

The invention discloses a rotation type fluid injection device, and belongs to the technical field of environment protection. The device comprises a rotation supporting mechanism, a fluid injection mechanism and a fluid supply pipeline. The rotation supporting mechanism comprises a base, a main shaft, a main gear, a drive gear, an oil cylinder shell, a rotation platform and a gear drive mechanism.The main shaft is vertically arranged on the upper surface of the base, and the main shaft is provided with an up-down penetrating main shaft through hole. The main gear sleeves and is fixed to the outer side of the main shaft, and the drive gear is engaged with the main gear. The gear drive mechanism and the drive gear are in transmission connection. The fluid injection mechanism comprises an injection gun barrel, a gun barrel supporting frame and a gun barrel drive mechanism, the gun barrel supporting frame is arranged on the rotation platform, the gun barrel drive mechanism is connected with the injection gun barrel, and the tail end of a fluid supply pipeline is connected with the injection gun barrel. By means of the rotation supporting mechanism, the injection gun barrel rotates inthe horizontal direction, the injection gun barrel rotates in the up-down direction through the gun barrel drive mechanism, the gun barrel injection range is enlarged, and the service life of the device is prolonged.

Owner:宙斯流体系统(上海)有限公司

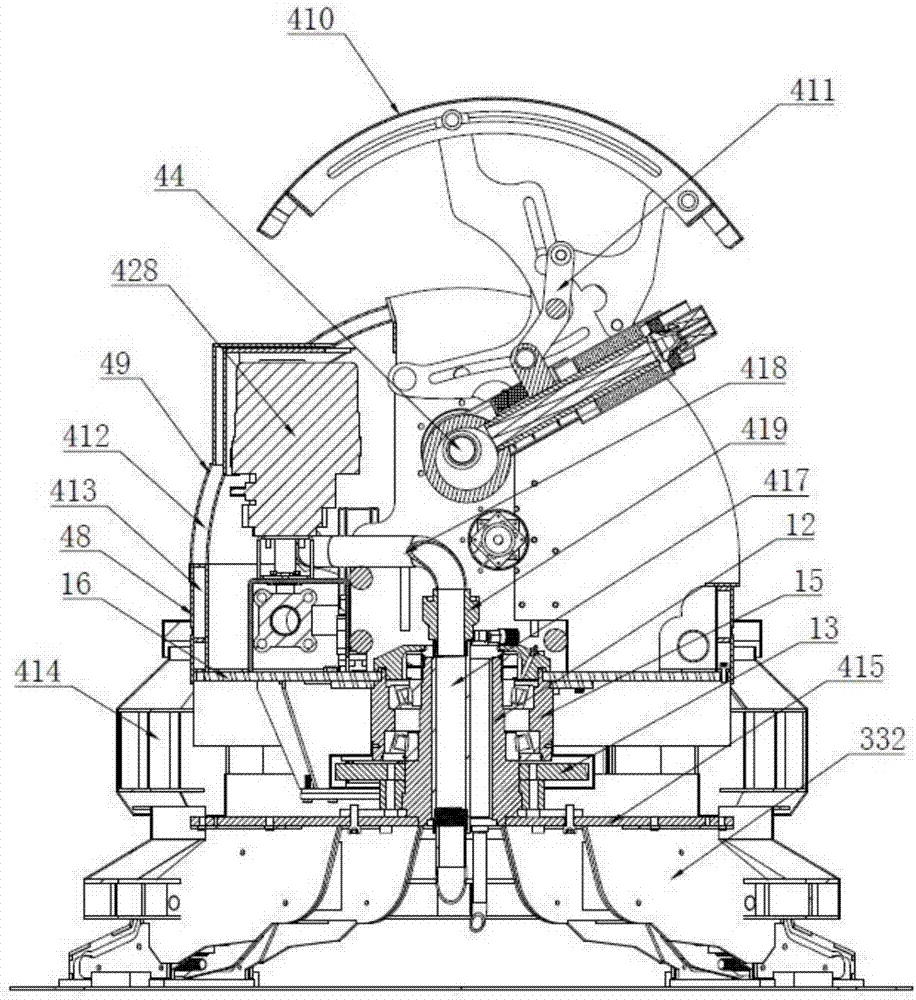

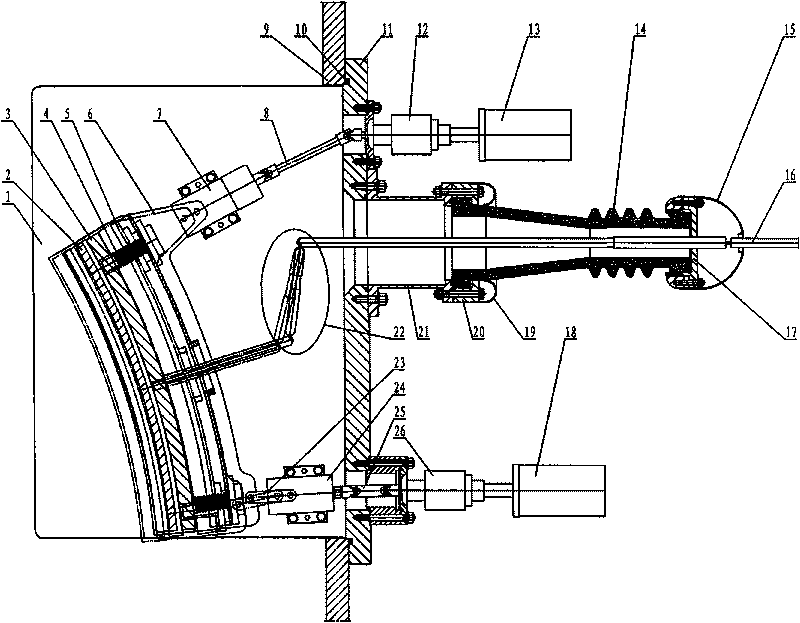

High-voltage feed-in vacuum state device with motion compensation

ActiveCN101699929AEliminate movement resistanceHigh delivery voltageAcceleratorsEngineeringHigh pressure

The invention mainly relates to a high-voltage feed-in vacuum state device with motion compensation, which comprises a high-voltage feed-in conductive pole (22). The conductive pole (22) is positioned in a vacuum cavity (9), one end of the conductive pole (22) is connected with a high-voltage electrode (3), a grounding electrode (2) is arranged corresponding to the high-voltage electrode (3), the other end of the conductive pole (22) passes through a transition sleeve (21) and an outer insulating ceramic (14) and is connected with a high-voltage output element (16), the transition sleeve (21) is arranged on the vacuum cavity (9) through a flange (11), one end of the outer insulating ceramic (14) is connected with the transition sleeve (21) through a pressing ring (20) and a bolt, the other end of the outer insulating ceramic (14) is provided with a gland (17), and two ends of the outer insulating ceramic (14) are provided with a shielding ring (19) and a shielding ball (15) respectively. The high-voltage feed-in vacuum state device eliminates the motion resistance of the additional high-voltage electrode and a driving device thereof, implements precise control for the motion in a high-voltage electric field, and has the characteristics of flexibility, reliability, high vacuum, small volume and high transmitted voltage.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

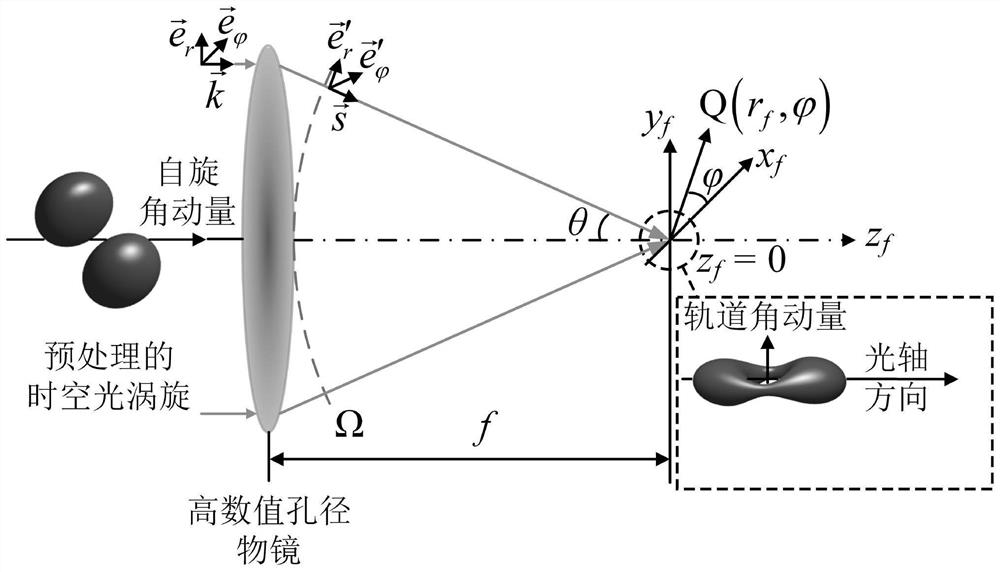

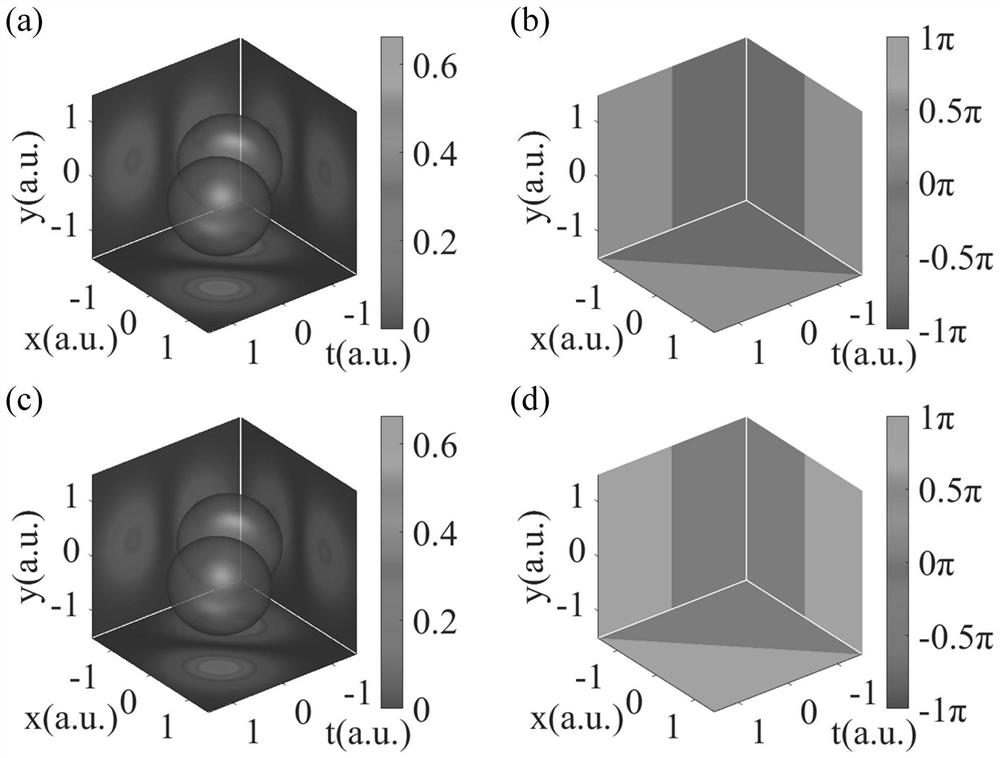

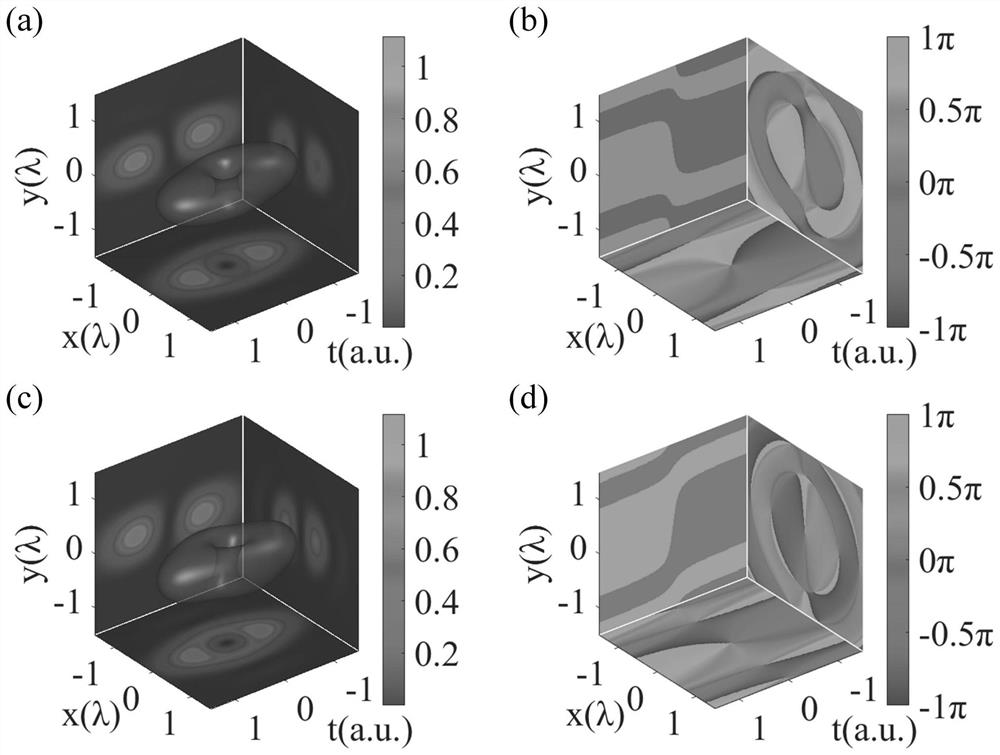

Method for regulating and controlling orientation of focal field space-time wave packet orbital angular momentum rotation axis

InactiveCN113759575ARealize regulationControl directionRadiation/particle handlingNon-linear opticsSpin angular momentum of lightHigh numerical aperture

The invention discloses a method for regulating and controlling the orientation of a focal field space-time wave packet orbital angular momentum rotation axis. The method comprises steps of carrying out targeted preprocessing operation of a circular polarization incident wave packet according to an expected topological charge number; taking the preprocessed circular polarization space-time wave packet as an incident field of a strong focusing system, and obtaining a vector space-time optical vortex on a focal plane through focusing of a high numerical aperture objective lens; after the spin angular momentum of the circularly polarized incident wave packet is focused by a lens, longitudinal orbital angular momentum with the topological charge number of + 1 or -1 being induced, and the longitudinal orbital angular momentum being mutually coupled with transverse orbital angular momentum in focal field space-time optical vortex; for transverse polarization components (namely x and y components) of focusing vector space-time optical vortex, the cross sectional area of a space-time plane in a wave packet can be changed by controlling the pulse width, and then the density ratio of longitudinal and transverse orbital angular momentum is changed, so the orientation of a total orbital angular momentum rotation axis in the transverse polarization components is controlled. According to the invention, the orientation of an orbital angular momentum rotation axis of a transverse polarization component is regulated and controlled, and a longitudinal polarization component with a complex vortex structure is generated.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

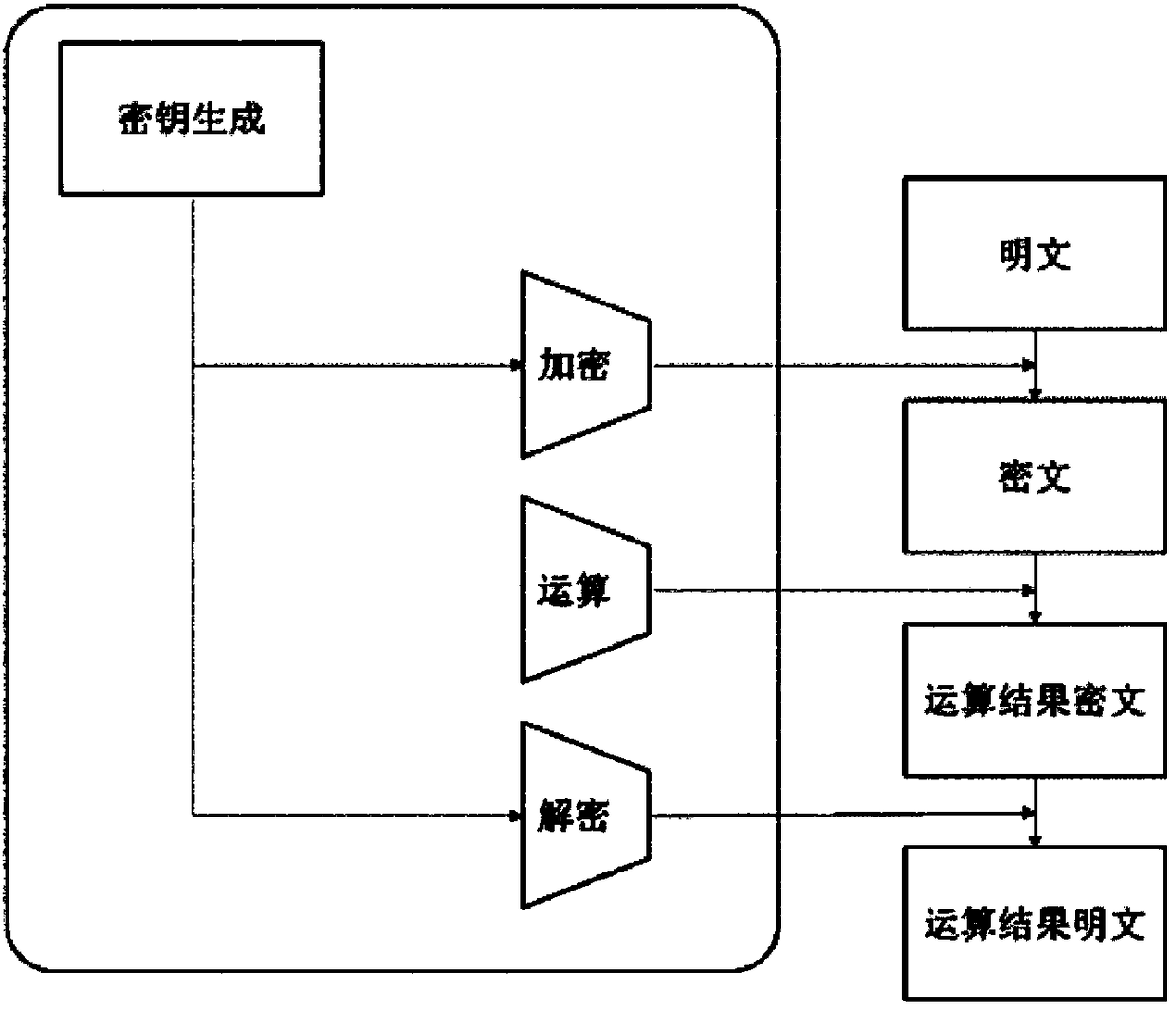

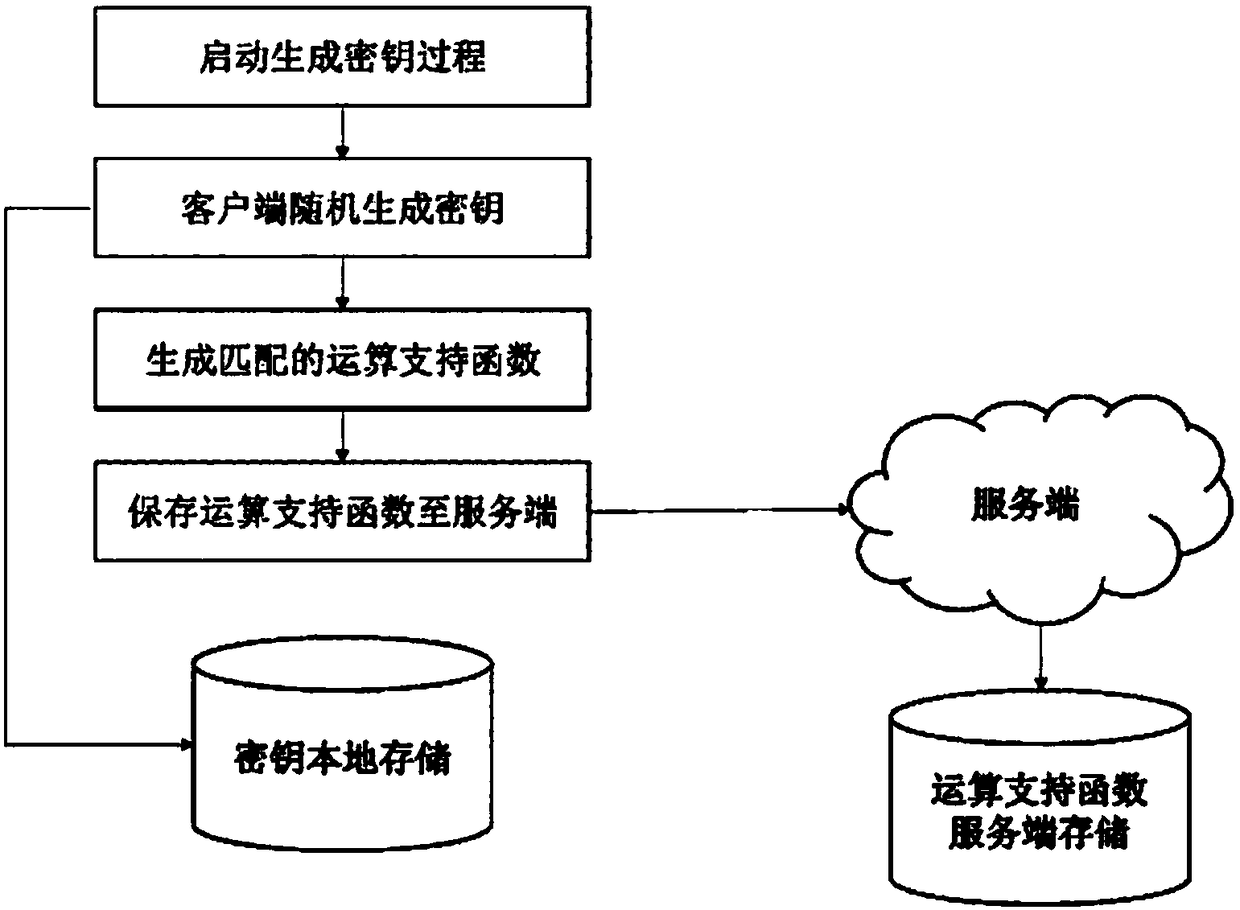

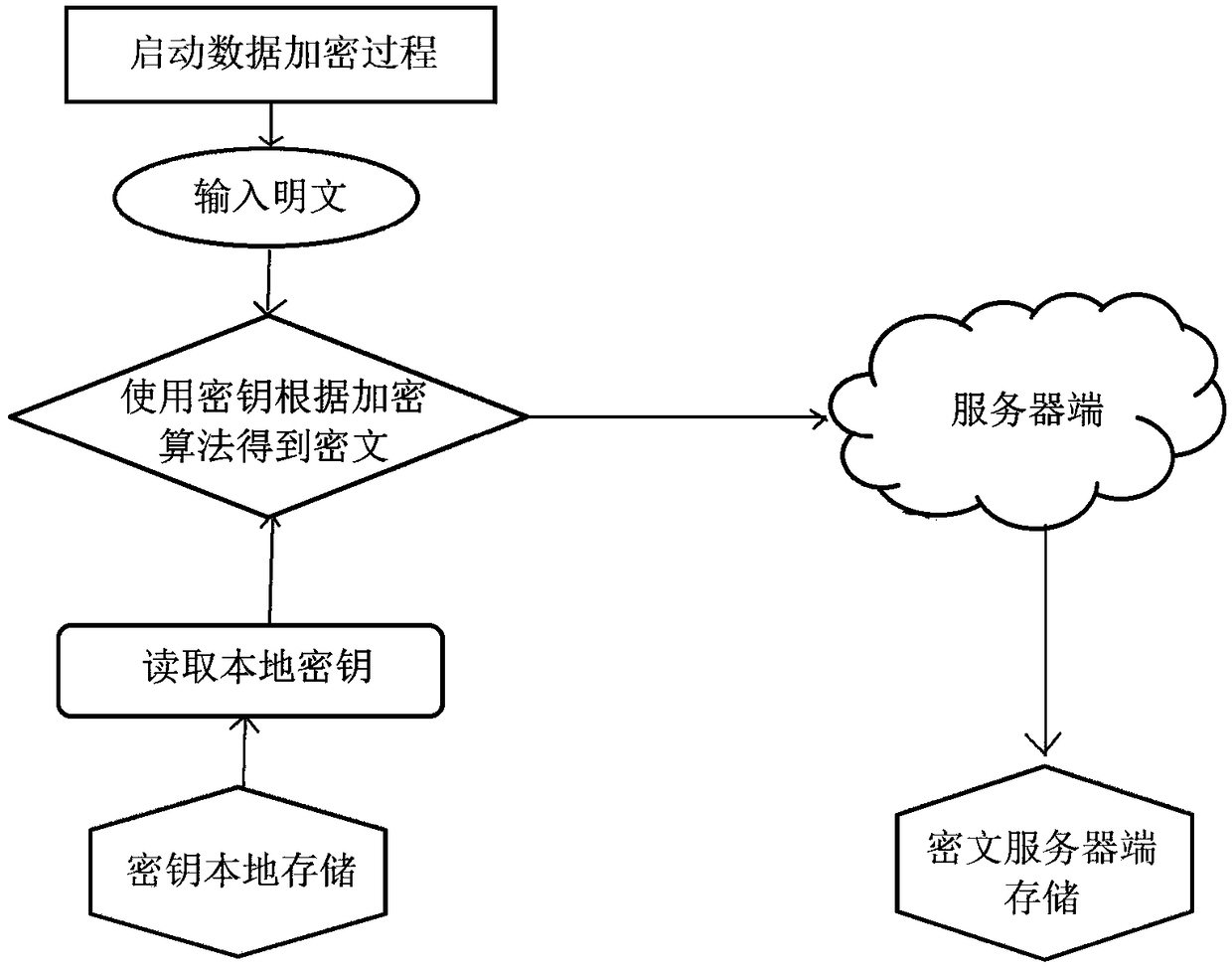

Precision control and accumulated error eliminating method applied to fully homomorphic encryption

ActiveCN108809619AAchieve precision controlGuaranteed accuracyKey distribution for secure communicationPublic key for secure communicationPlaintextCiphertext

The invention discloses a precision control and accumulated error eliminating method applied to fully homomorphic encryption. The method comprises the following steps of splitting a plaintext; encrypting each constituent part and computing to acquire a result ciphertext; performing homomorphic comparison computation on the result ciphertext; performing a reserving operation or a carrying and reserving operation via a comparison computation result; and acquiring a result plaintext via decryption and rounding operations, thus achieving precision control on a polynomial fully-homomorphic encryption method based on coefficient mapping conversion. After such operation, each byte part of the computation result ciphertext can be controlled within a precision range of an original scheme, and afterthe decryption and rounding operations, the result plaintext can be completely accurate. The single ciphertext computation can be completely accurate, and the any times of continuous ciphertext computation also can be completely accurate.

Owner:上海麟羿信息科技有限公司

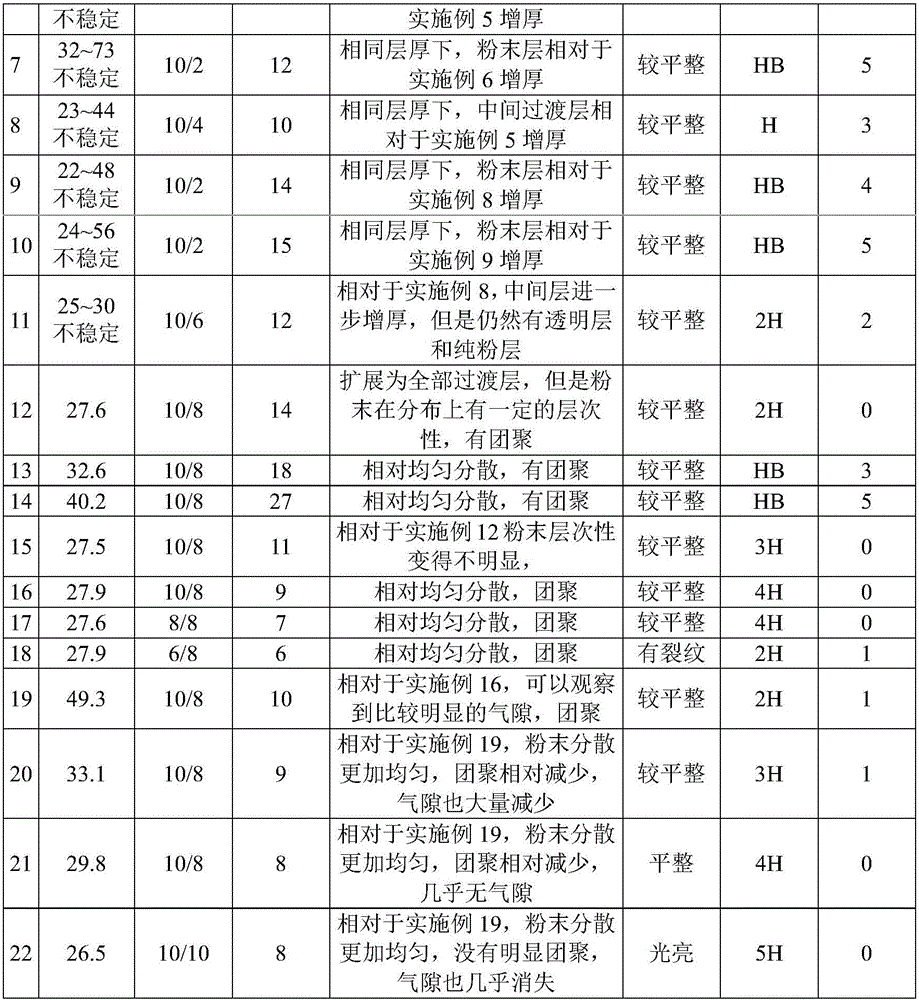

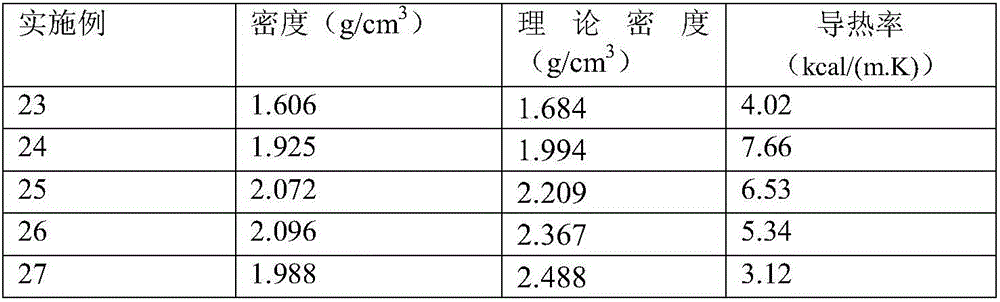

Thermally conductive slurry as well as preparation method and application thereof

ActiveCN105778431AImprove stabilityGuaranteed print jetting requirementsAdditive manufacturing apparatusBoiling pointDiluent

The invention discloses thermally conductive slurry as well as a preparation method and application thereof. The thermally conductive slurry consists of the following raw materials in parts by mass: 1 part of photo-thermal dual-curing resin, 1.5-4 parts of a diluent and 0.5-4 parts of aluminum powder, wherein the photo-thermal dual-curing resin is resin containing an acrylic group; the boiling point of the diluent is 80-150 DEG C, the viscosity is 1mPa.s-2mPa.s, the surface tension is 20 mN / m-30mN / m, and the diluent is easy to volatize; and the grain size of the aluminum oxide powder is 1-2mu m. The thermally conductive slurry disclosed by the invention adopts the photo-thermal dual-curing resin as curing matrix, so that the problem that deep curing cannot be carried out due to the fact that light is scattered, refracted and absorbed by the filler can be made up by thermal curing. Meanwhile, the method of mutually regulating by the diluent / a thixotropic agent is adopted, so that the slurry has good stability while meeting the jetting requirements of 3D inkjet printing.

Owner:ZHEJIANG UNIV OF TECH

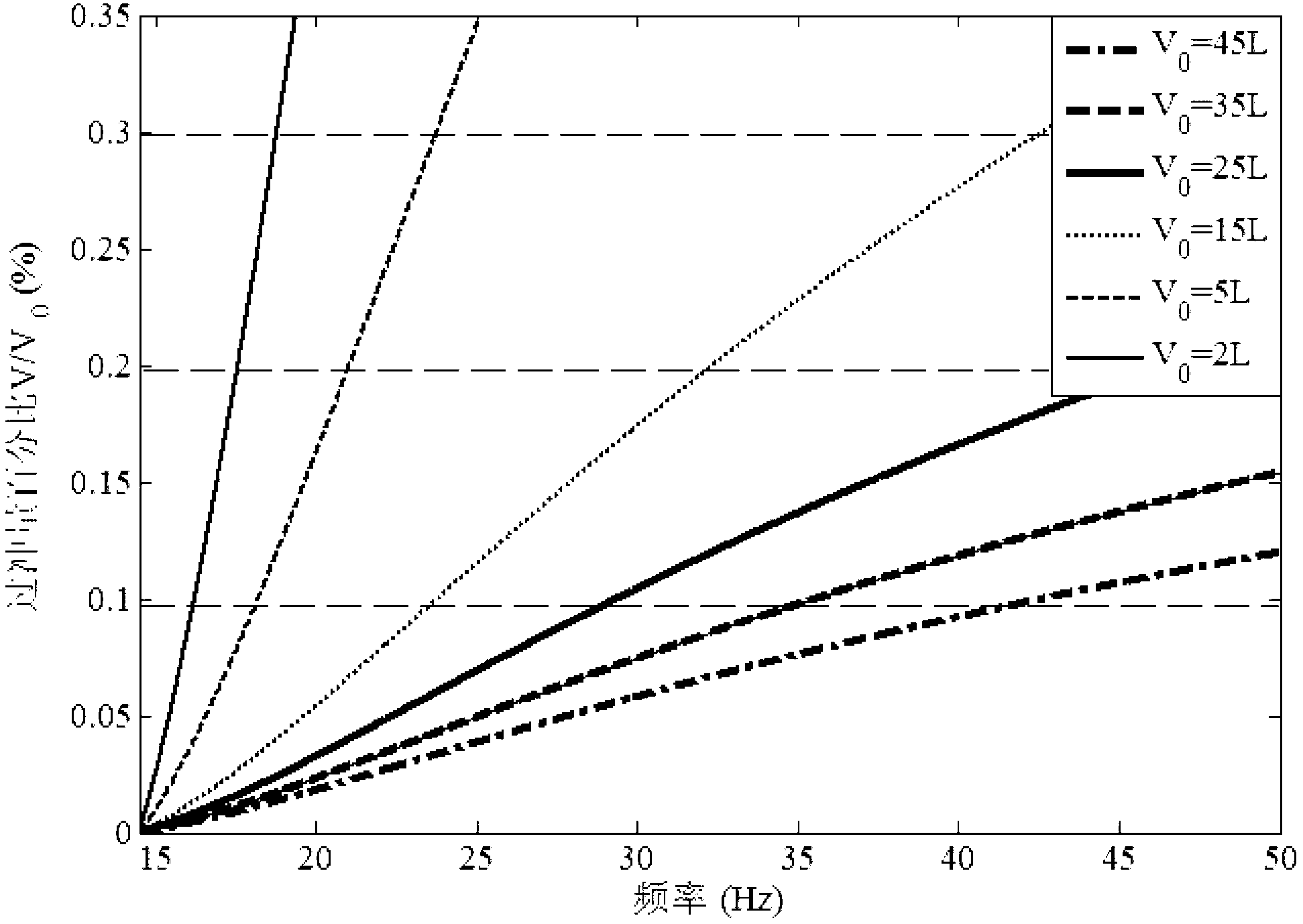

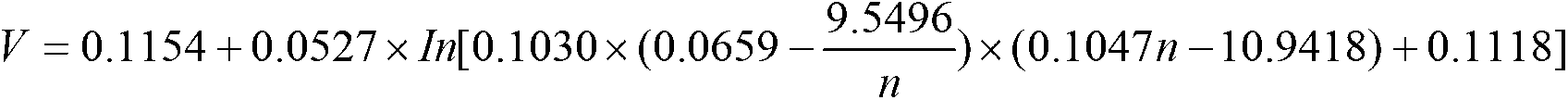

Liquid filling accuracy control method for liquid filling quantity smaller than minimum measured quantity

ActiveCN103058119AControl speedAchieve precision controlLiquid transferring devicesLiquid dispensingControl systemEngineering

The invention provides a liquid filling accuracy control method for liquid filling quantity smaller than minimum measured quantity. The method is characterized by including: drawing a relation curve between over-filling percentage of a liquid filling machine and buffer frequency of a variable frequency motor in a variable frequency hydraulic control system of the liquid filling machine, and performing accuracy control to the liquid filling machine during quantitative liquid filling according to the relation curve. The over-filling percentage is the ratio of over-filling quantity V to preset filling quantity V0. The over-filling quantity V is obtained according to an equation: V=0.1154+0.0527*In[0.1030*(0.0659-9.5496 / n)*(0.1047n-10.9418)+0.1118], wherein n is buffer speed of the variable frequency motor; buffer frequency f is equal to n / 60. Aiming at different filling quantities during actual liquid filling, different buffer frequencies can be selected, the over-filling percentage V / V0 can be controlled with a smaller range of errors, and accordingly liquid filling accuracy control for quantitative liquid filling with the liquid filling quantity smaller than the minimum measured quantity is achieved.

Owner:FOSHAN HAIZHUORUI FLUID CONTROL ENG

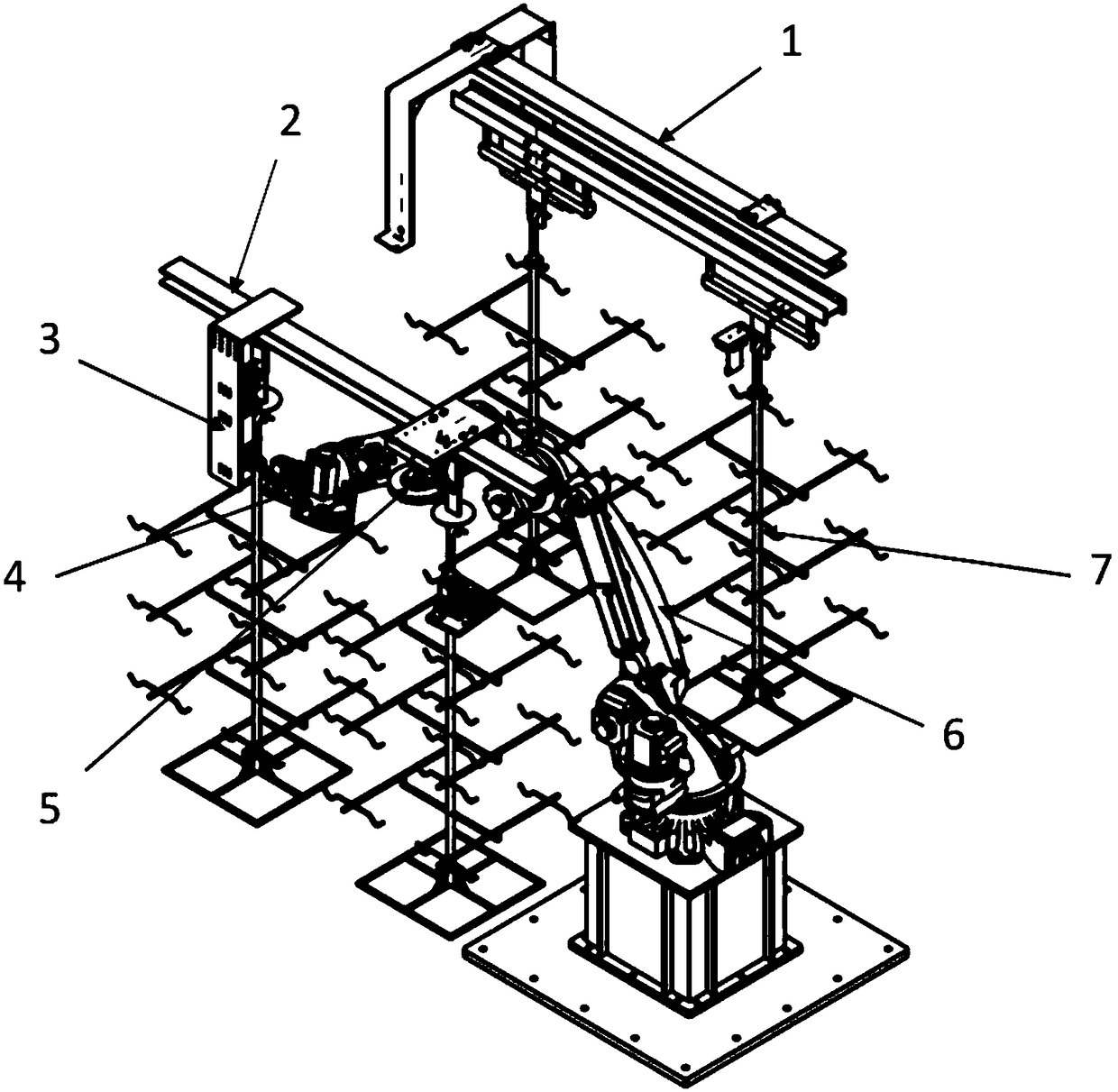

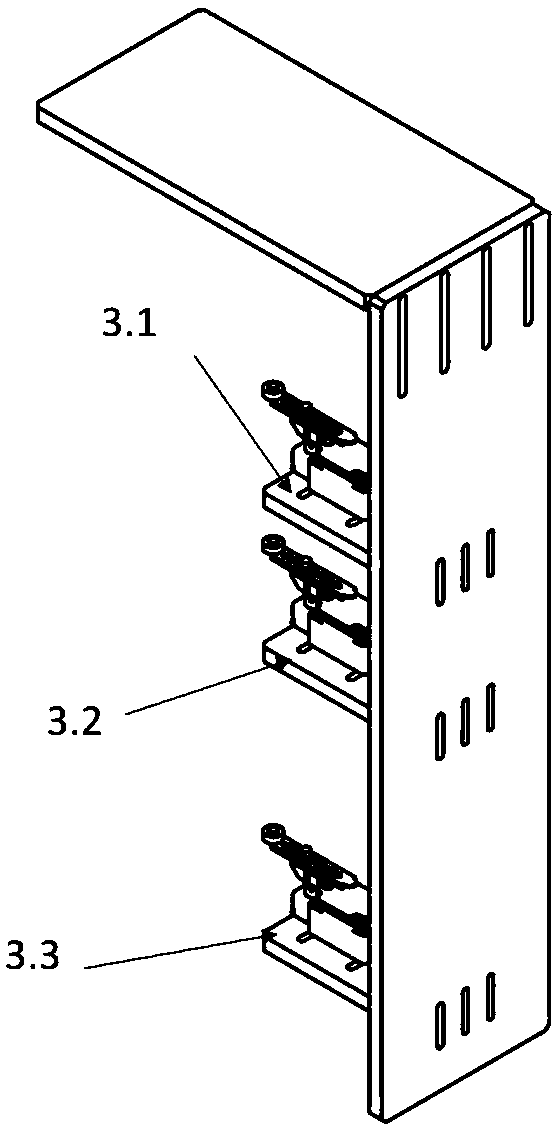

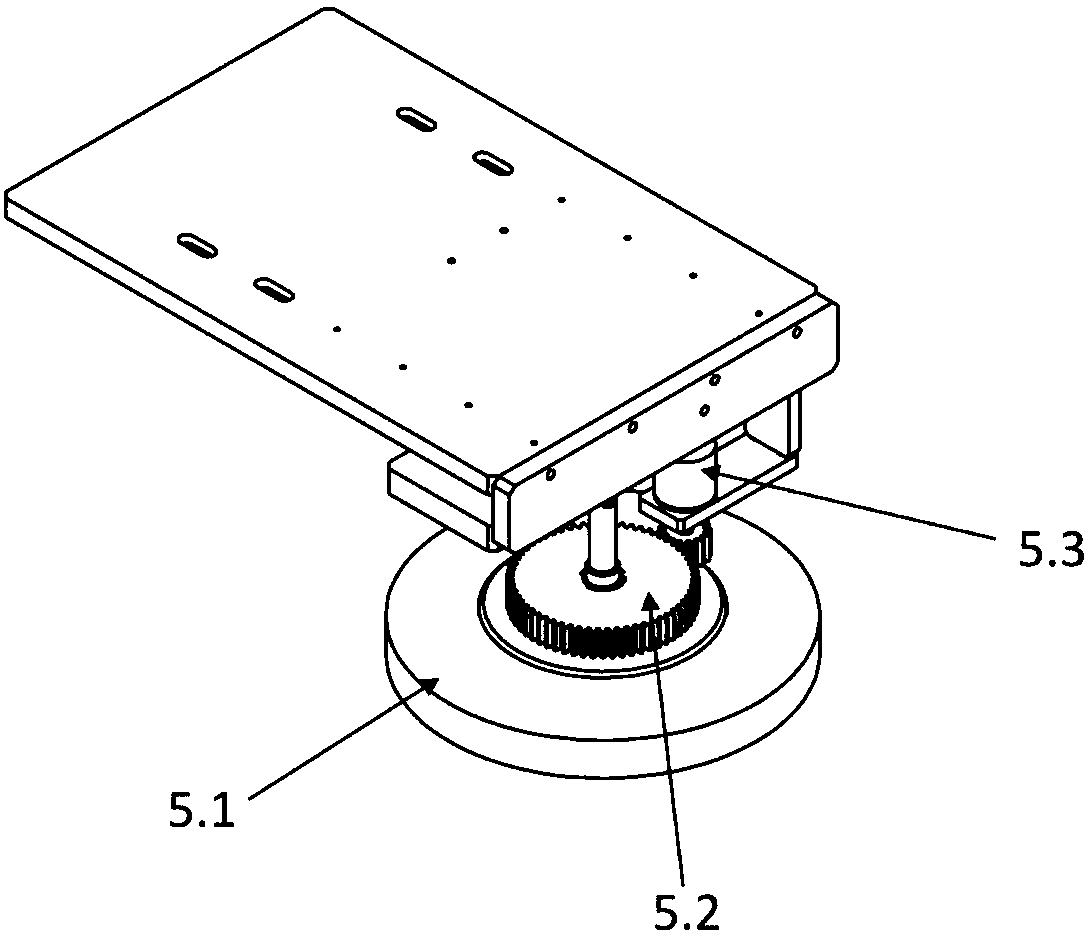

Automobile seat electrophoresis line suspension hanging device and method

ActiveCN108103556AAchieve precision controlThe clamping state is stableElectrolysis componentsElectrophoretic coatingsElectrophoresisCar manufacturing

The invention belongs to the technical field of automobile manufacturing equipment and particularly relates to an automobile seat electrophoresis line suspension hanging device and method. The devicecomprises a first catenary serving as a material hanging line, a second catenary serving as a material incoming line, a detecting mechanism and a robot, wherein the detecting mechanism is used for detecting the position and speed information of a suspension on the second catenary and outputting the detected position and speed information; and the robot comprises a receiving unit, a judgment unit and a clamping jaw mechanism, wherein the receiving unit is used for receiving the position and speed information output by the detecting mechanism, the judgment unit is used for positioning the suspension according to the position and speed information and sending a clamping instruction after positioning, and the clamping jaw mechanism receives the clamping instruction, then takes down the suspension on the second catenary and hangs the suspension on the first catenary. By means of the device, the hanging accuracy and speed of the suspension of an automobile seat electrophoresis line can be guaranteed.

Owner:苏州中藤机电科技有限公司

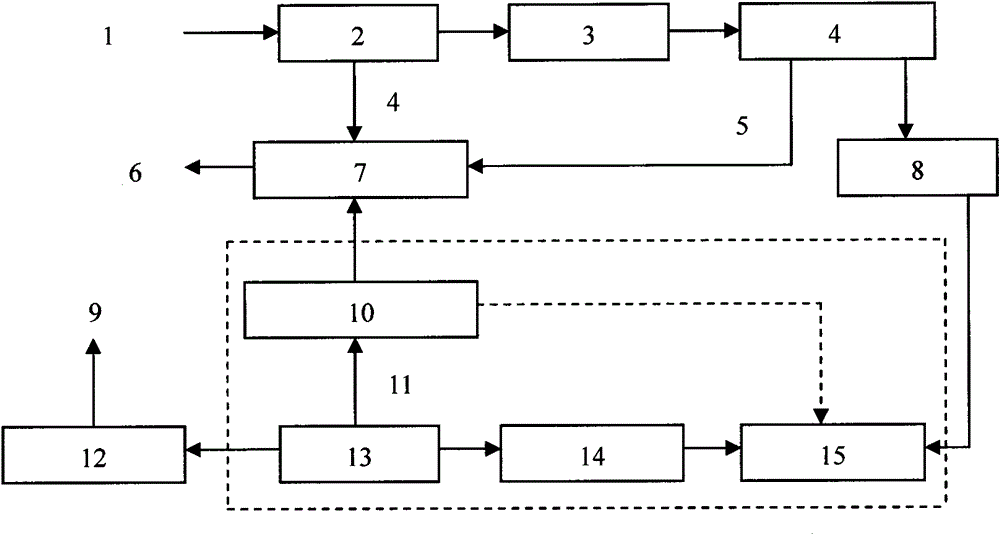

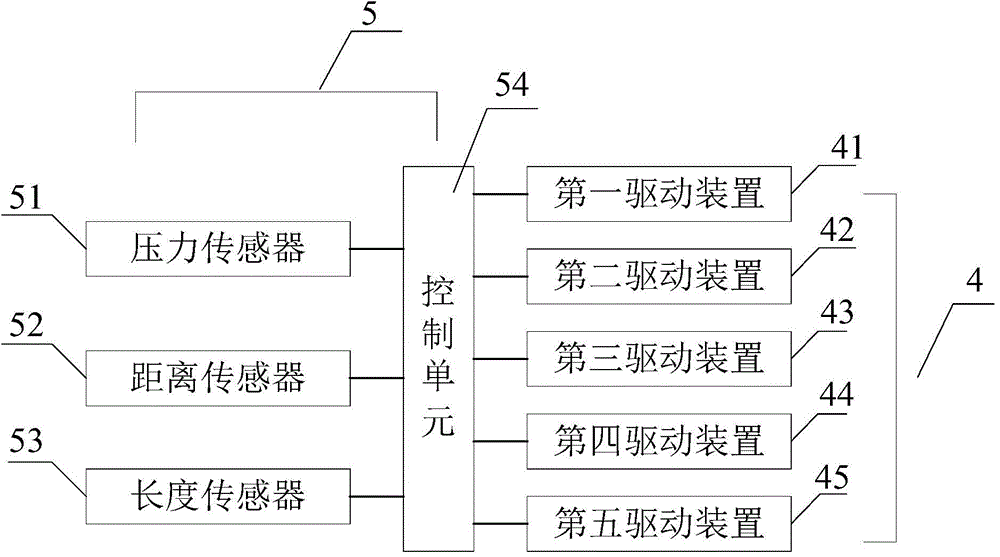

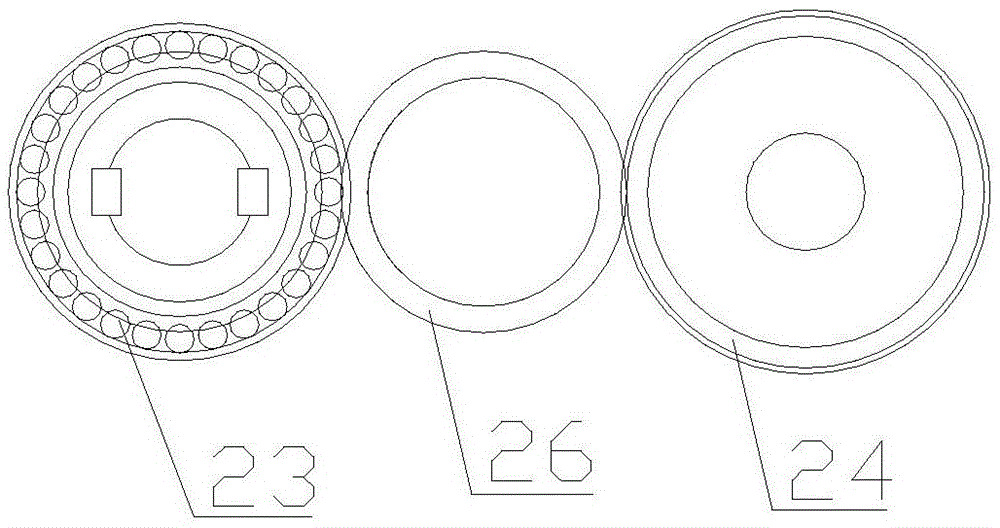

Resource recovery-based automatic corrugated board glue making system

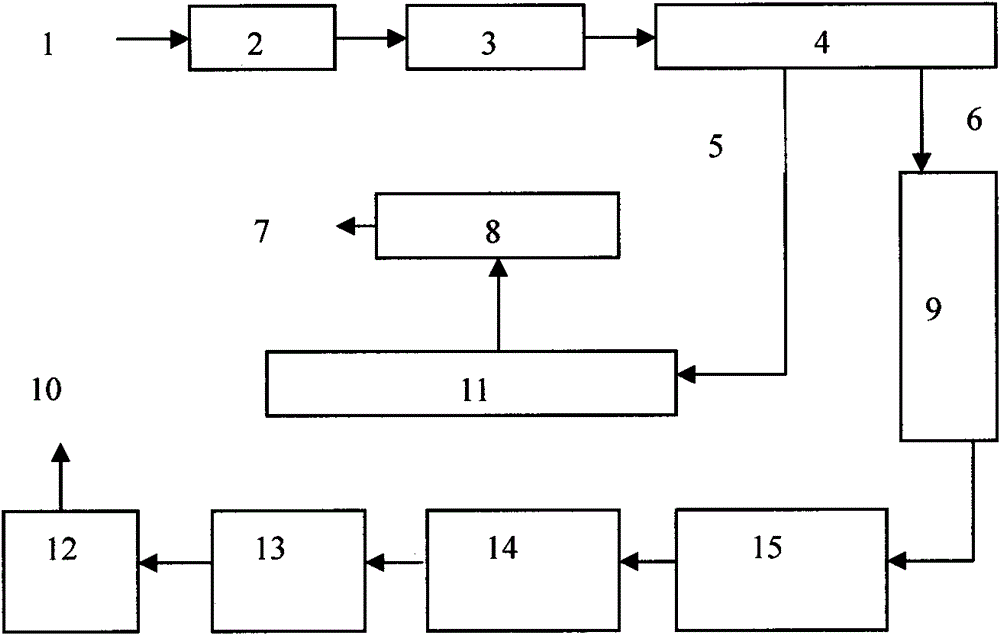

InactiveCN102796467AEasy to adjustThe running screen is accurate and clearStarch adhesivesCycle controlSoftware

The invention discloses a full-automatic glue making system for improving corrugated board glue making performance and resource recovery. The system mainly comprises two aspects, namely a full-automatic corrugated board glue making system and a resource recovery-based corrugated board glue making recycle process (a domestic wastewater recovery process flow diagram is shown as figure 1). The full-automatic corrugated board glue making system mainly comprises software and hardware equipment of the glue making system, and matched large and small cycle control systems; by high process control over pasting temperature, viscosity, solid content and glue temperature, unstable glue quality caused by human factors is radically avoided, the high quality of products is ensured, and high efficiency and low consumption in the production process are ensured. The resource recovery-based corrugated board glue making recycle process mainly comprises steps of using the treated domestic wastewater as production water for the automatic glue making process and treating and recycling glue making wastewater. By the two aspects, water for the whole production system is organically cycled, so that cyclic production is realized, water resources are recycled, the full-automatic glue making system accords with low-carbon production and environmental protection concepts supported by China, and a green idea is combined into the glue making system.

Owner:黄遂兢

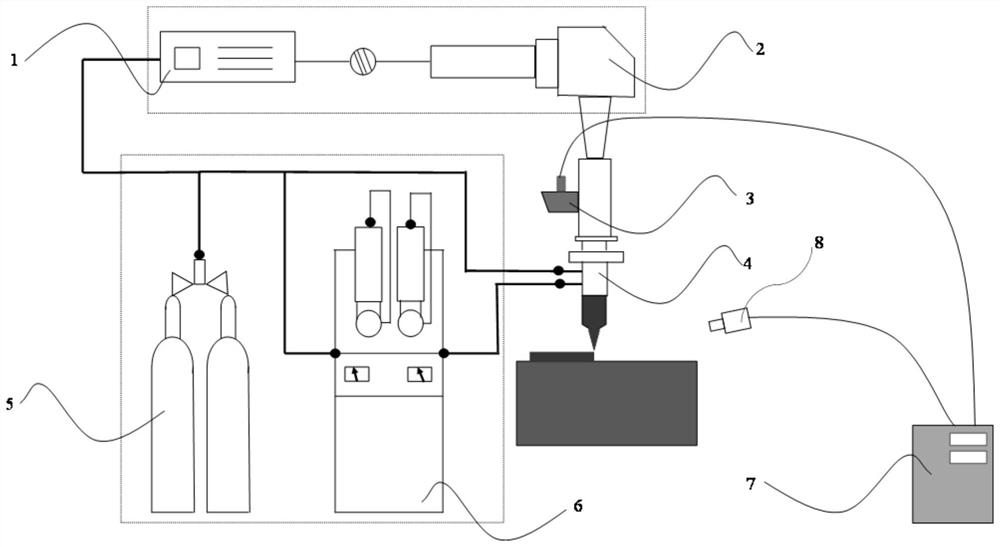

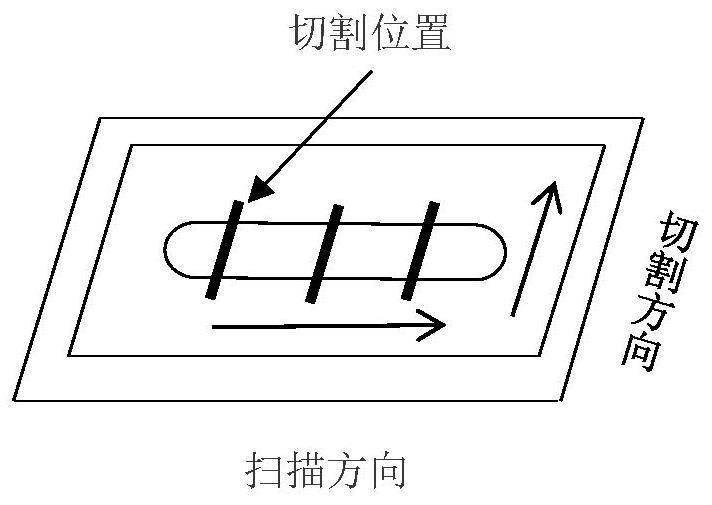

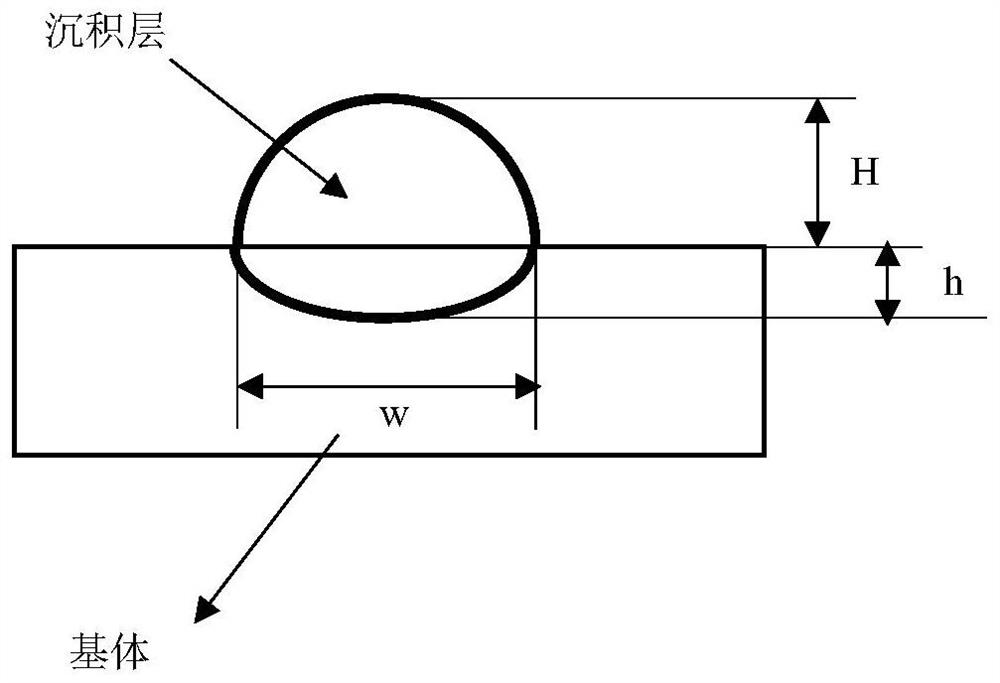

Method for predicting geometrical characteristics of laser melting deposition layer

ActiveCN114346260AGuaranteed accuracyAchieve precision controlAdditive manufacturing apparatusIncreasing energy efficiencyNumerical modelsFinite element software

The invention discloses a geometric feature prediction method for a laser melting deposition layer. A coaxial powder feeding type laser deposition manufacturing numerical calculation model is established based on a VOF method and a powder feeding equation; integrating the development program with Fluent finite element software; carrying out multiple groups of single-channel single-layer melting deposition experiments, carrying out online real-time monitoring on the geometric characteristics and the temperature of the molten pool based on an online real-time monitoring system, preparing a deposition layer sample, extracting the geometric characteristics of the deposition layer, and verifying the accuracy of the numerical model through the geometric characteristics of the molten pool, the temperature of the molten pool and the geometric characteristics of the deposition layer sample; based on the process parameter and sedimentary layer geometric feature database, establishing a prediction model of the process parameters and the sedimentary layer geometric features by using a Gaussian process regression machine learning method; and performing feedback correction on the sedimentary layer geometric feature prediction model based on a small amount of experimental data. According to the method, the prediction model of the process parameters and the geometric features of the sedimentary layer can be quickly and accurately established, the process cost is low, the efficiency is high, and the prediction precision is controllable.

Owner:DALIAN UNIV OF TECH

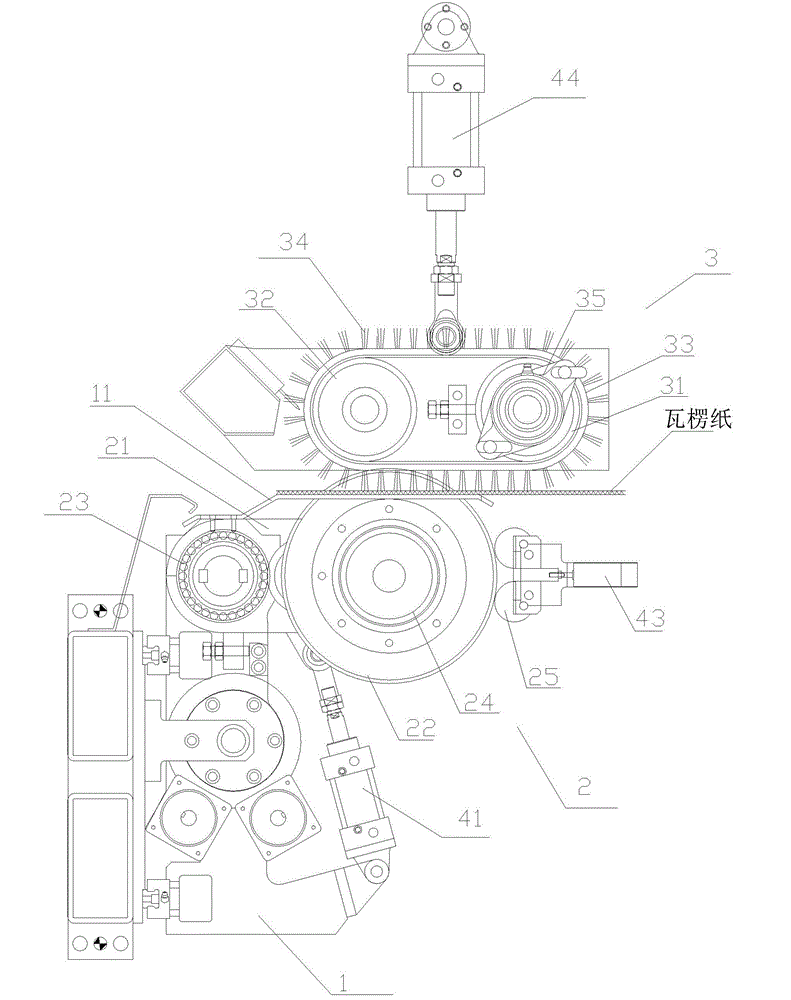

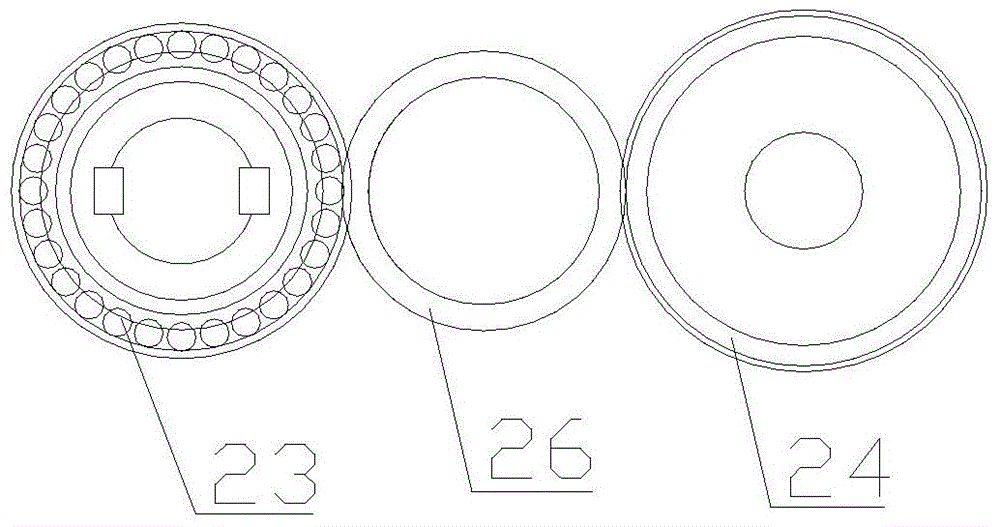

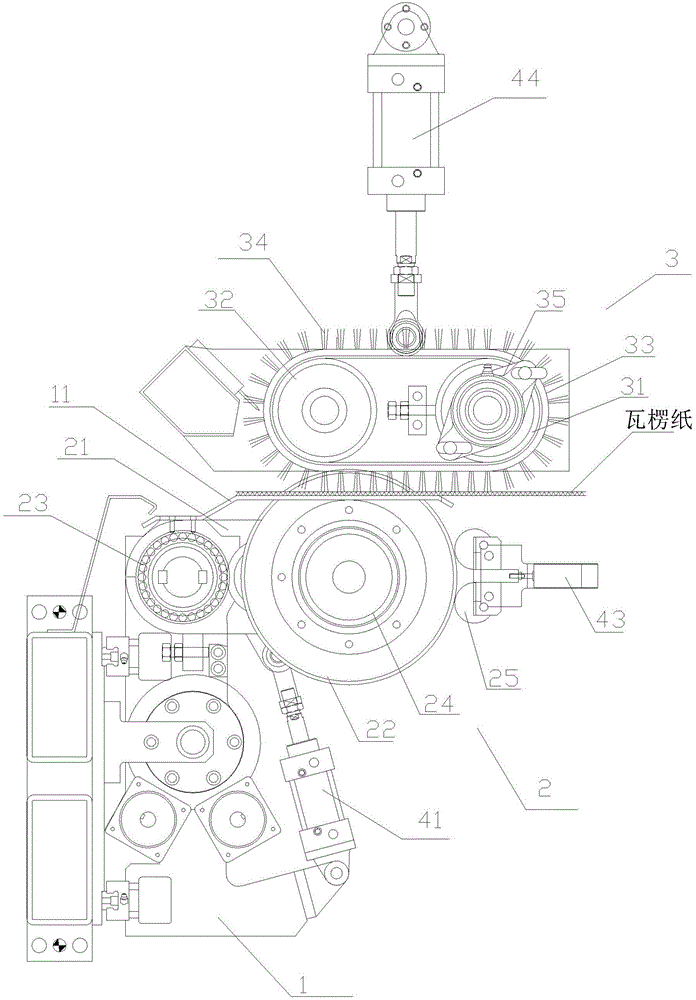

Distance self-adjusting type corrugated paper cutter

ActiveCN104589385AExtended service lifeRegular grindingMetal working apparatusDrive wheelEngineering

The invention provides a distance self-adjusting type corrugated paper cutter which comprises a base, a blade mechanism, a brush base, a driving mechanism and a control module. A cutter clamping plate is arranged at the top of the base. A cutter clamping gap is arranged on the cutter clamping plate. The blade mechanism comprises a cutter rest, a blade, a driving wheel, a driven wheel and a grinding wheel. The cutter rest can be arranged on the base in a vertical-rotating mode. The blade is arranged on the cutter rest in a rotatable mode through the driven wheel and corresponds to the cutter clamping gap in position. The driving wheel is arranged on the base in a rotatable mode. The driving wheel is connected with the driven wheel and drives the driven wheel to rotate. The tool rest has a first position state and a second position state. Under the first position state, the blade is placed below the cutter clamping plate. Under the second position state, the blade penetrates through the cutter clamping gap. The grinding wheel has two position states of grinding and retreating. Under the grinding state, the grinding wheel is in contact with the blade. Under the retreating state, the grinding wheel is far away from the blade. The distance self-adjusting type corrugated paper cutter is easy to operate, reasonable in design, high in working efficiency and good in cutting quality.

Owner:ANHUI TIANXIANG PACKING MASCH CO LTD

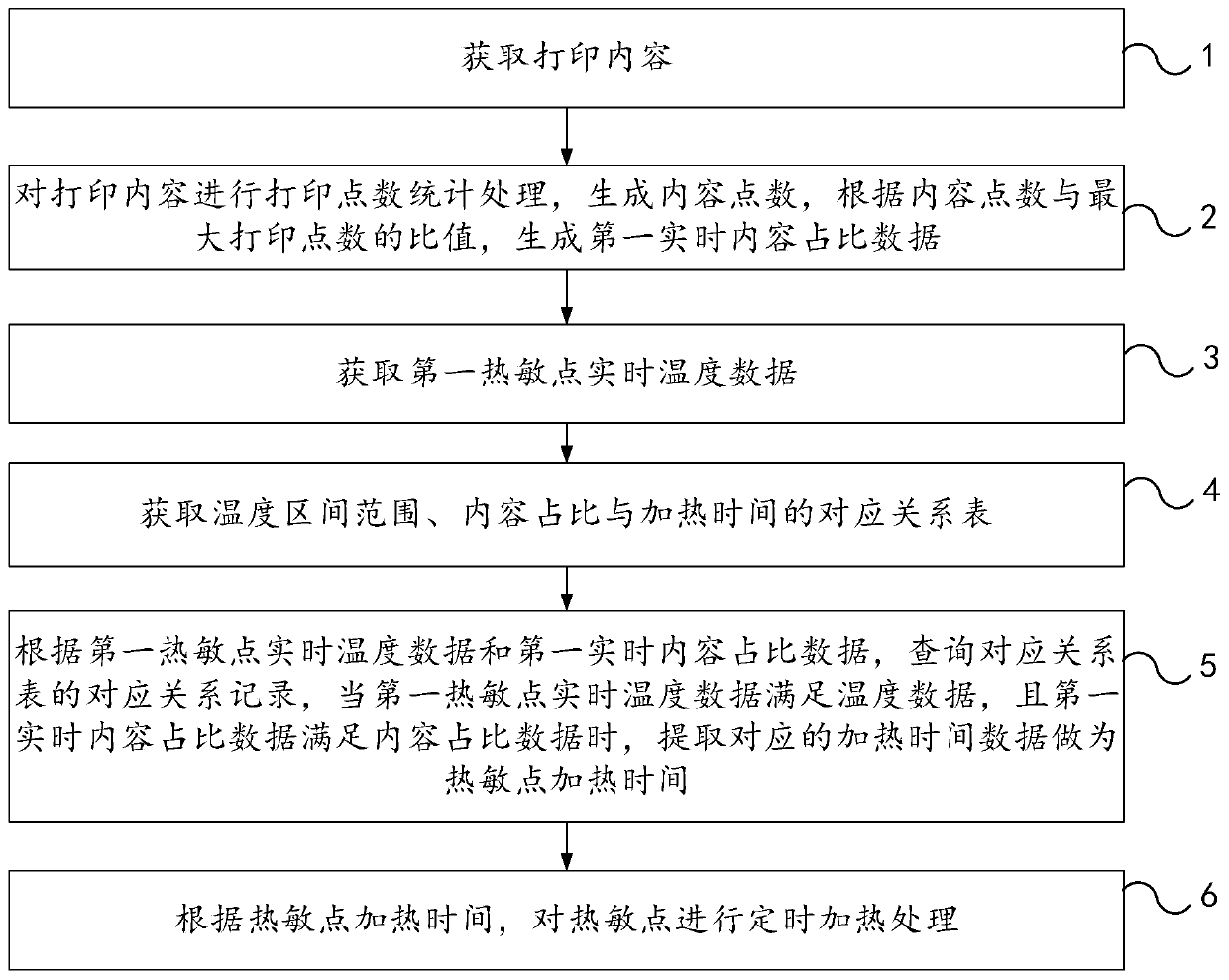

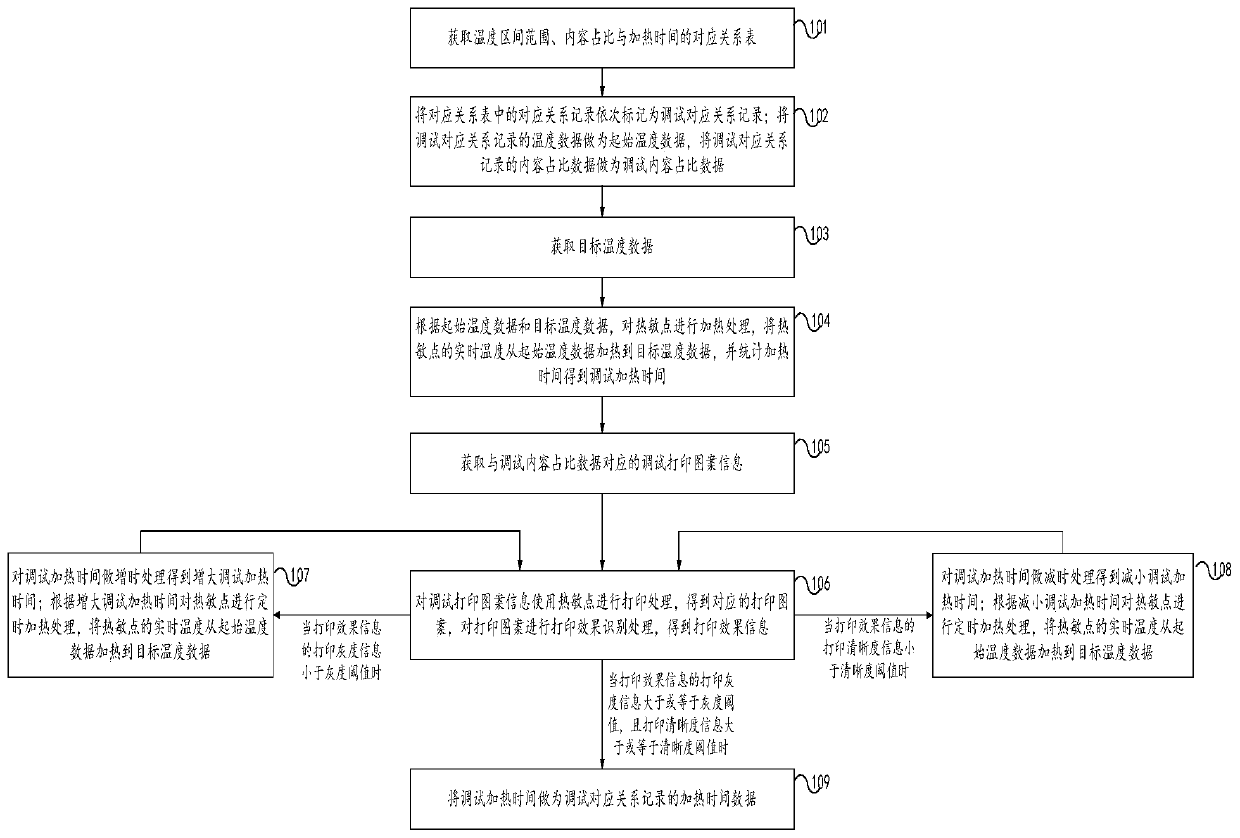

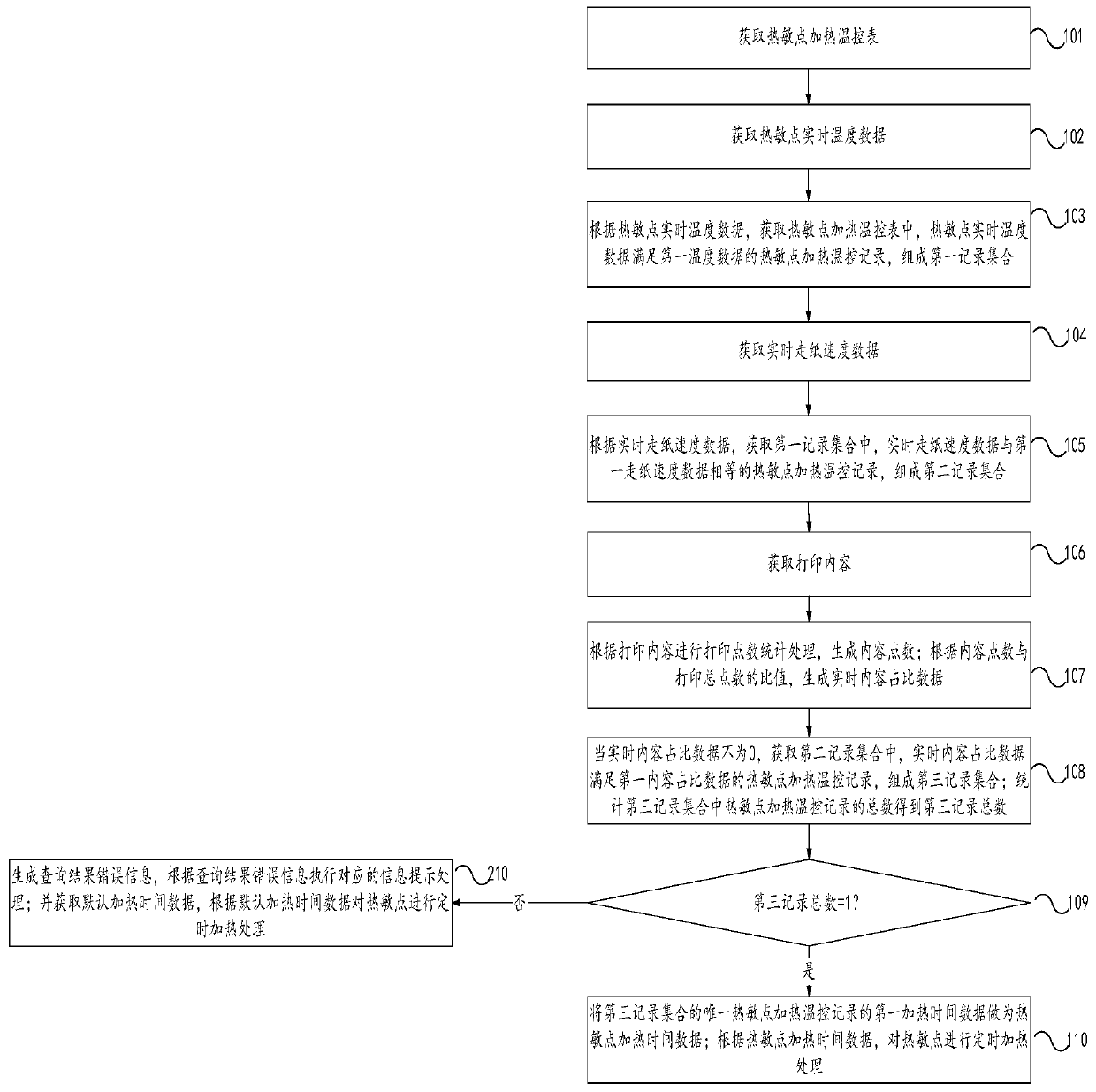

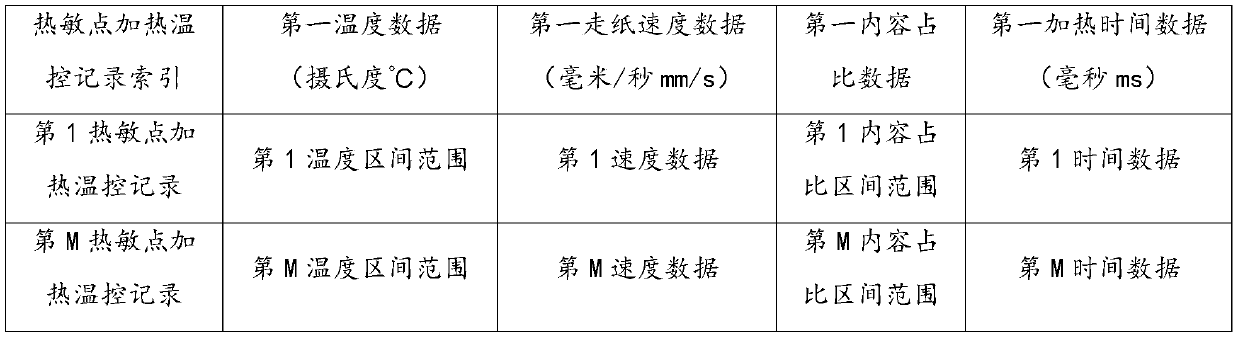

Method for heating thermosensitive points according to temperature interval range and content proportion

ActiveCN111483246AAchieve precision controlImprove stabilityThermographyDigital output to print unitsThermodynamicsHeating time

The embodiment of the invention relates to a method for heating thermosensitive points according to a temperature interval range and a content proportion. The method comprises the following steps thatprint content is obtained; first real-time content proportion data are obtained according to the ratio of the content point number of the print content to the maximum print point number; first thermosensitive point real-time temperature data are obtained; a corresponding relation table among the temperature interval range, the content proportion and heating time is obtained; according to the first thermosensitive point real-time temperature data and first real-time content proportion data, corresponding relation records in the corresponding relation table are searched, and when the first thermosensitive point real-time temperature data conform to temperature data and the first real-time content proportion data conform to content proportion data, corresponding heating time data are extracted to be as thermosensitive point heating time; and according to the thermosensitive point heating time, timing heating treatment is carried out on the thermosensitive points. According to the method,the thermosensitive point heating time data can be dynamically adjusted, the precision control over the thermosensitive point heating process is realized, and the stability of thermosensitive printing is improved.

Owner:SHENZHEN CAREWELL ELECTRONICS

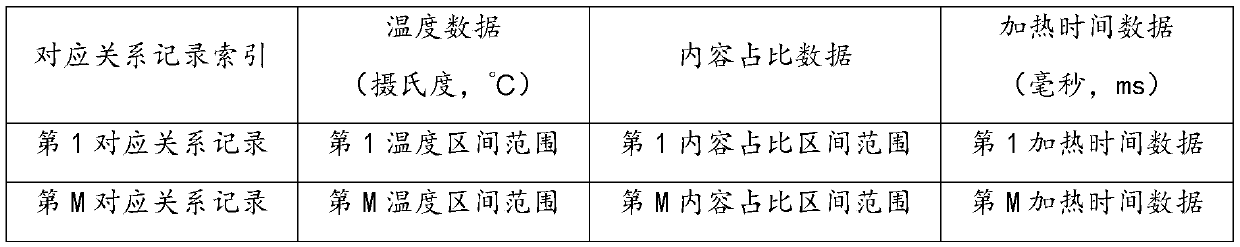

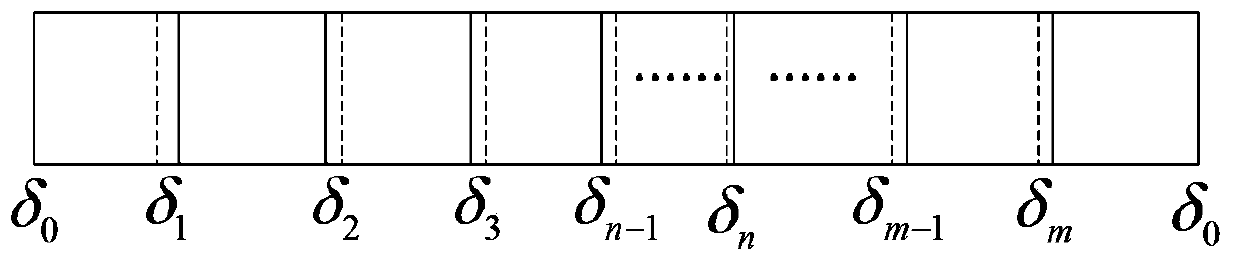

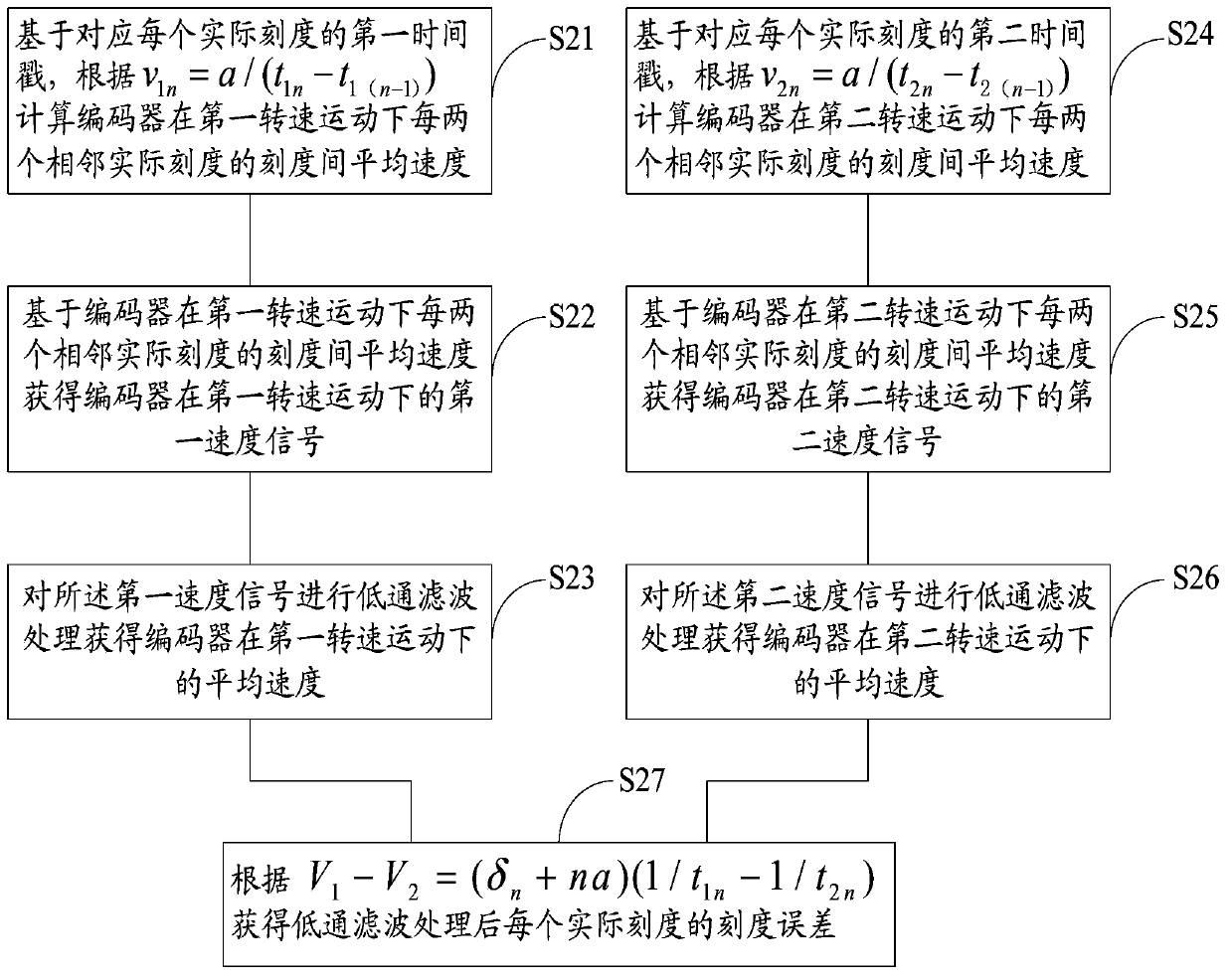

Method for obtaining encoder scale graduation error

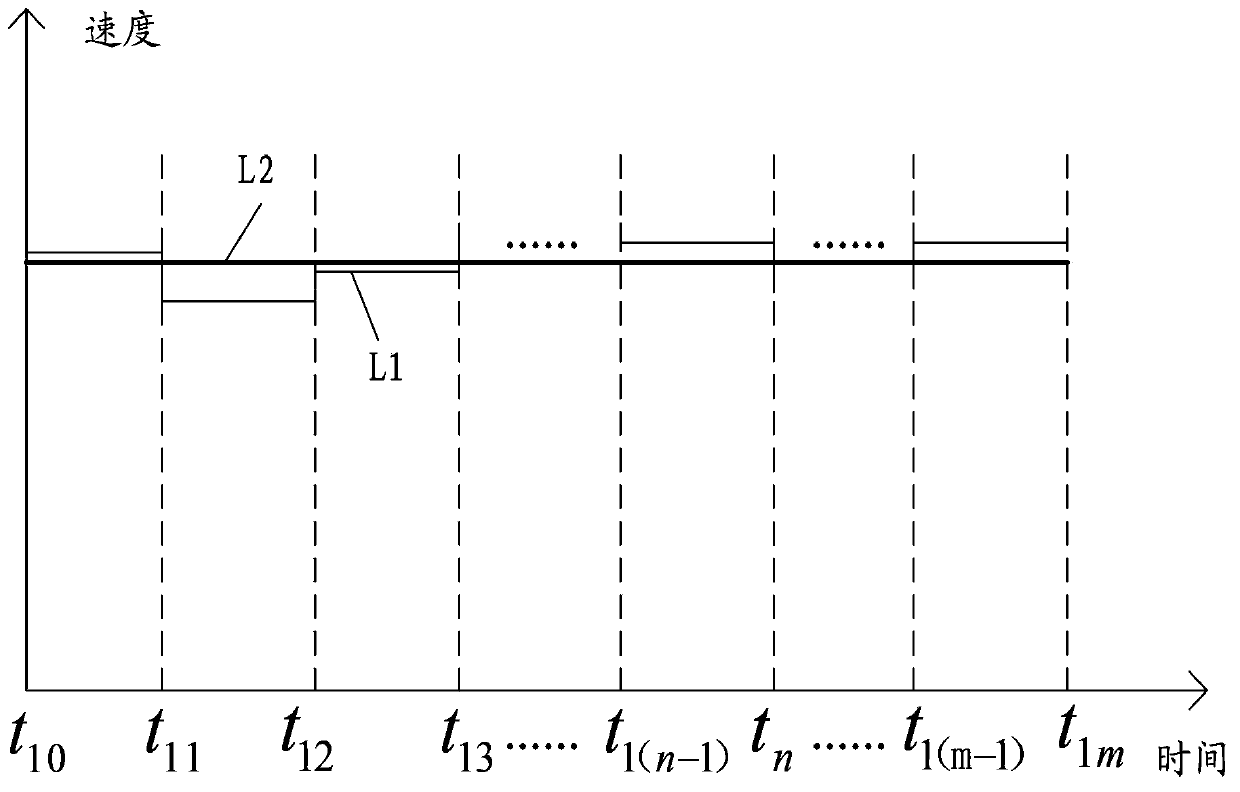

Provided is a method for obtaining encoder scale graduation error. The method comprises the following steps: calculating the average speed between the graduations of every two adjacent actual graduations when an encoder moves at a first rotating speed and at a second rotating speed according to a first time stamp and a second time stamp corresponding to each actual graduation; obtaining a first speed signal when the encoder moves at the first rotating speed and a second speed signal when the encoder moves at the second rotating speed according to the average speed between the graduations of every two adjacent actual graduations when the encoder moves at the first rotating speed and at the second rotating speed; carrying out low-pass filtering process on the first speed signal and the second speed signal to obtain the average speed of the encoder at the first rotating speed and at the second rotating speed; and obtaining the graduation error of each actual graduation according to V1 - V2 = (delta n + na) ( 1 / t1n- 1 / t2n). According to the method for obtaining the encoder scale graduation error provided in the technique method of the invention, the cost in obtaining the encoder scale graduation error can be reduced, and high-precision graduation error can be obtained.

Owner:联影(常州)医疗科技有限公司

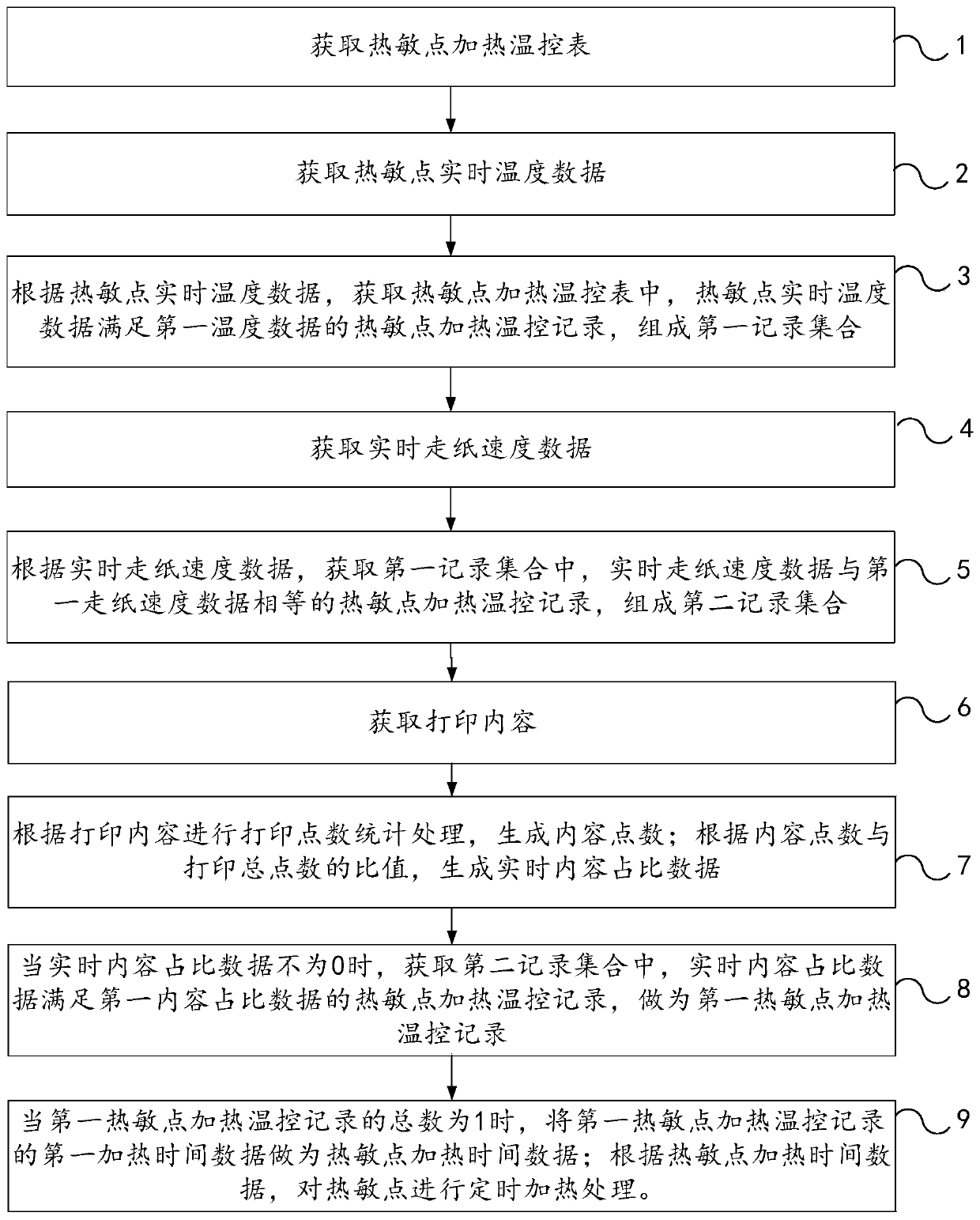

Method for heating thermosensitive point

ActiveCN111483247AImprove stabilityAchieve precision controlThermographyDigital output to print unitsProcess engineeringHeating time

The embodiment of the invention relates to a method for heating a thermosensitive point. The method comprises the steps that a thermosensitive point heating temperature control table is obtained; real-time temperature data of the thermosensitive point is obtained; a first record set corresponding to the real-time temperature data of the thermosensitive point in the thermosensitive point heating temperature control table is obtained; real-time paper feeding speed data is obtained; a second record set corresponding to the real-time paper feeding speed data in the first record set is obtained; real-time content proportion data of the printing content is obtained; a first thermosensitive point heating temperature control record corresponding to the real-time content proportion data in the second record set is obtained; the first heating time data of the first thermosensitive point heating temperature control record is taken as thermosensitive point heating time data; and timing heating treatment is carried out on the thermosensitive point according to the thermosensitive point heating time data. According to the method, on the basis of the thermosensitive point heating temperature control table, precision control over the thermosensitive point heating process is achieved, and the thermosensitive printing stability is improved.

Owner:SHENZHEN CAREWELL ELECTRONICS

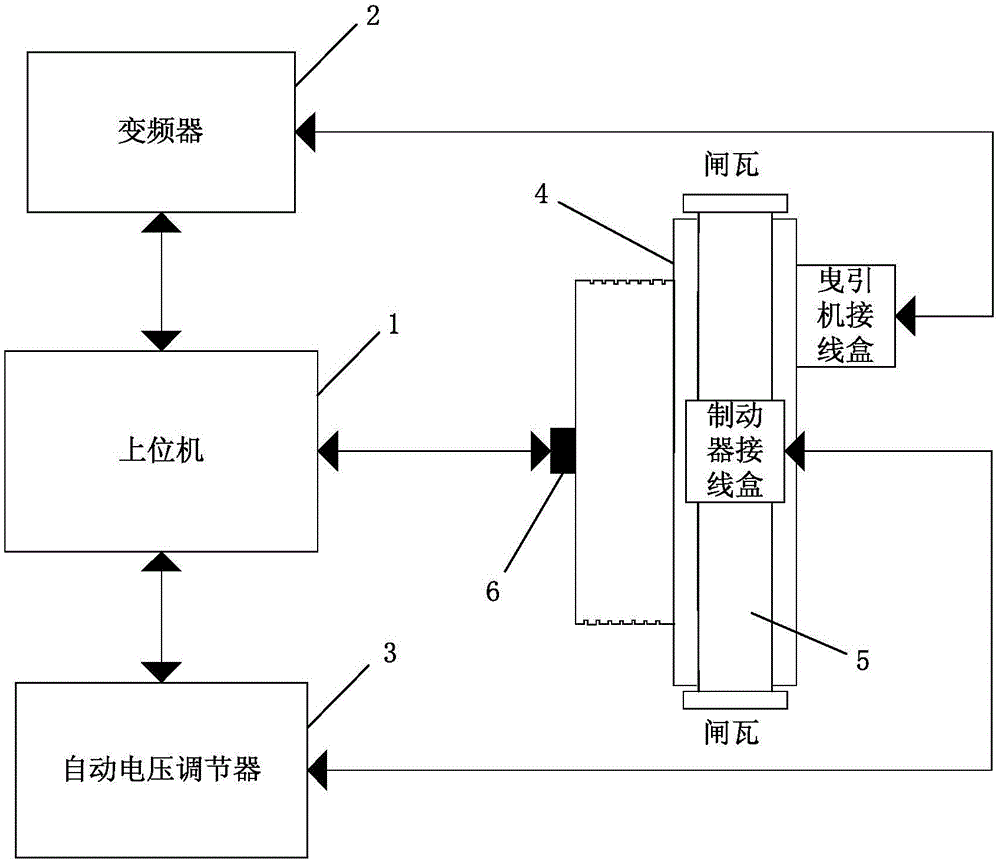

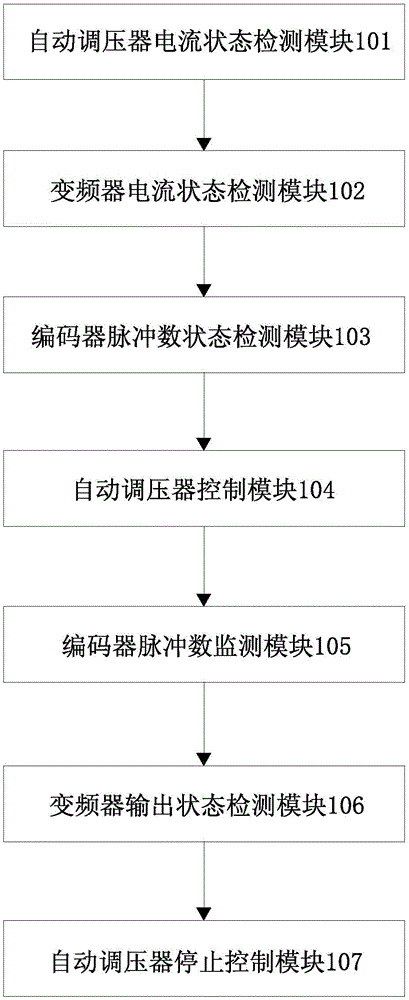

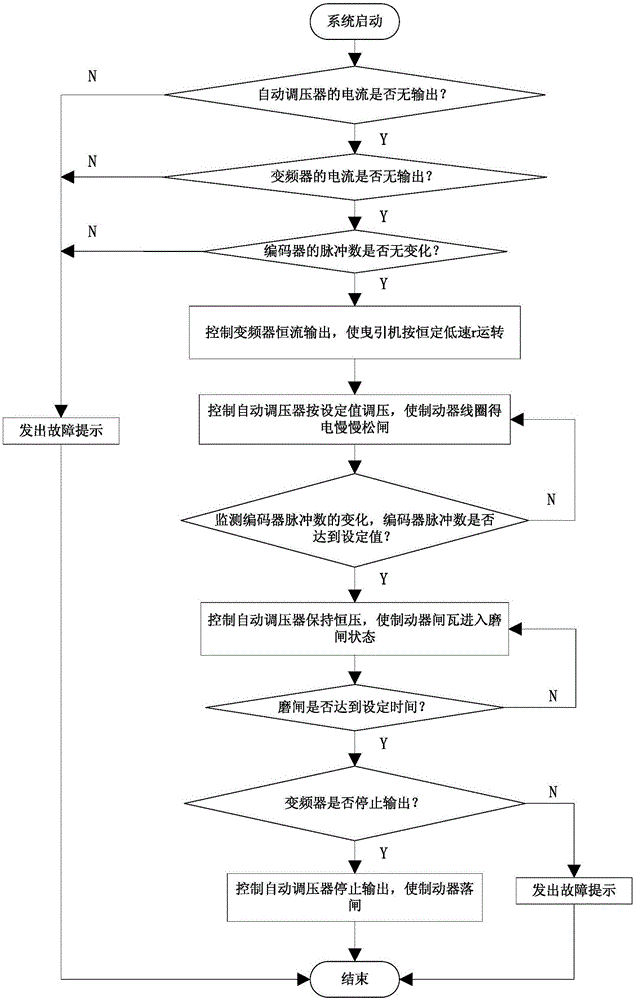

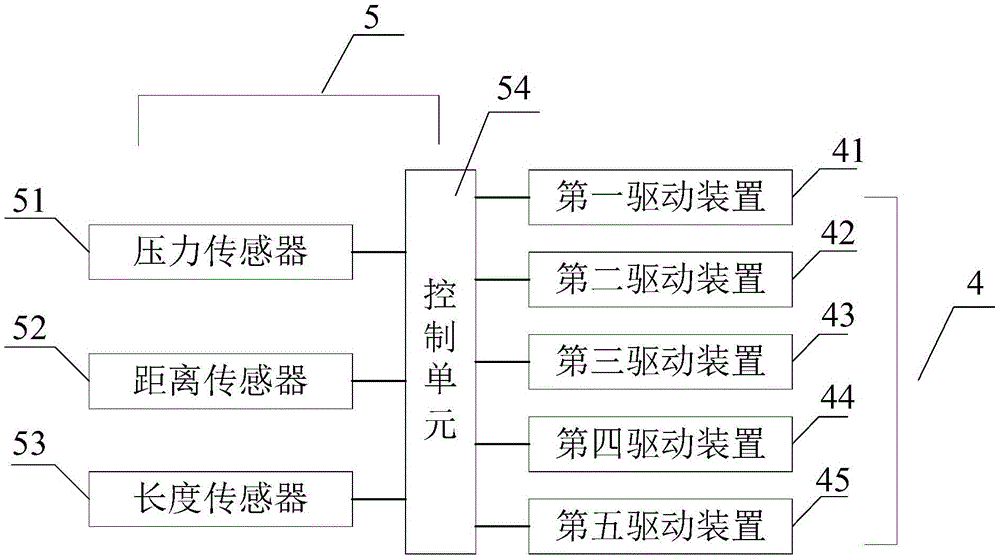

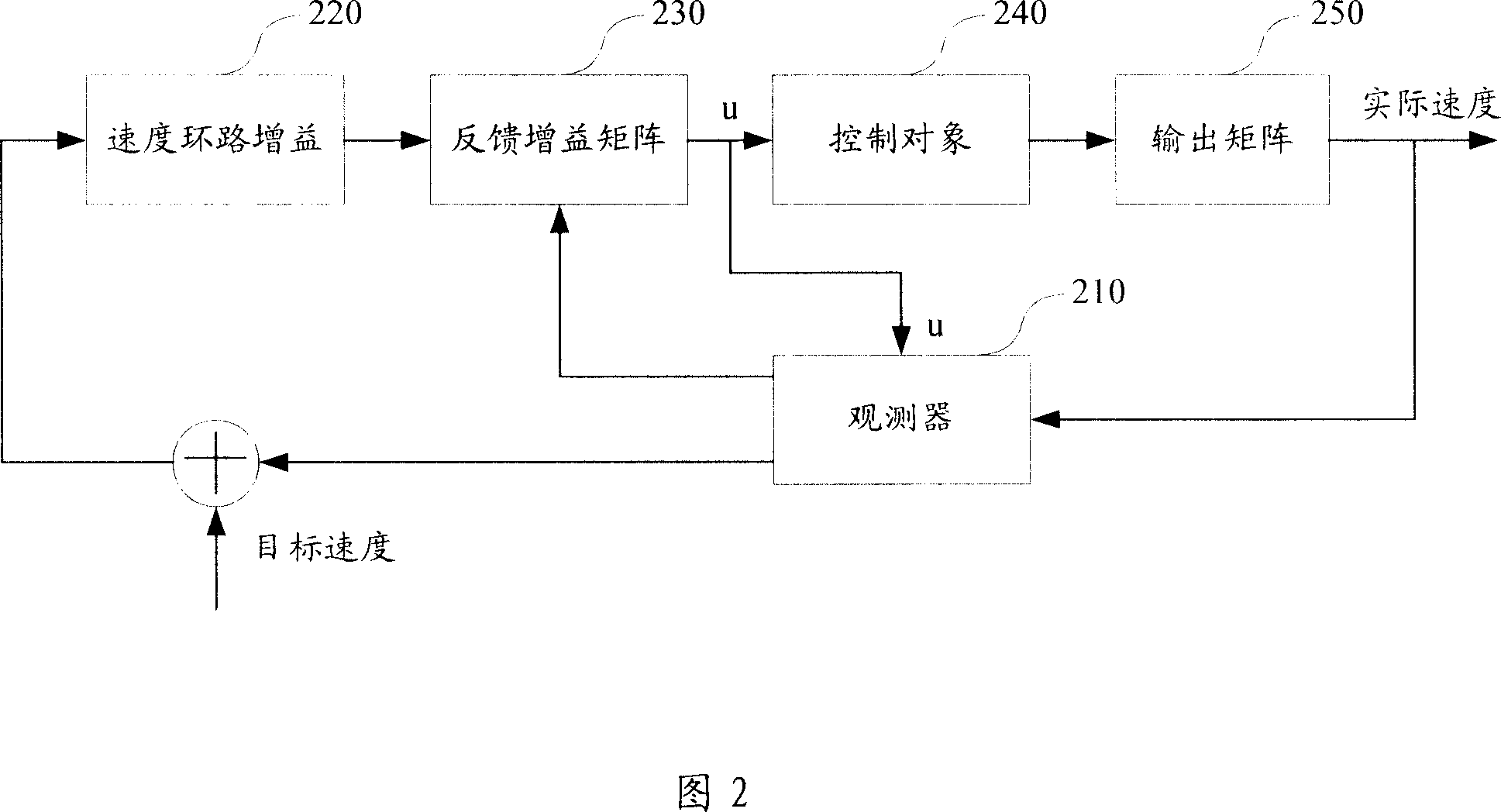

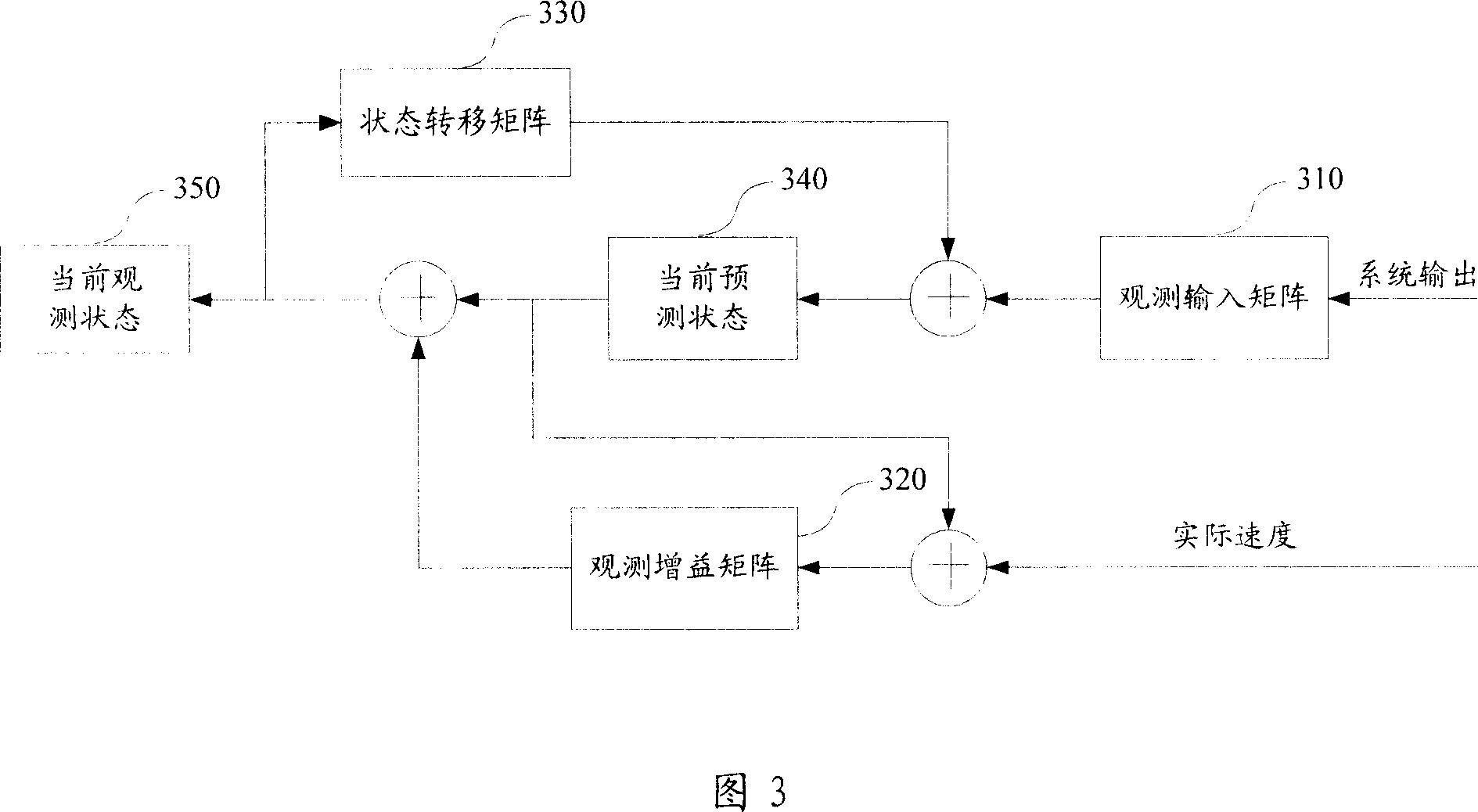

Elevator traction machine brake precision control system and method

ActiveCN105152065APrevents a drop in braking forceAchieve precision controlHoisting equipmentsFrequency changerPulse number

The invention discloses an elevator traction machine brake precision control system and method. The system comprises an upper computer. The upper computer comprises an automatic voltage regulator current state detection module, a frequency converter current state detection module, an encoder pulse number state detection module, an automatic voltage regulator control module, an encoder pulse number monitoring module, a frequency converter output state detection module and an automatic voltage regulator stop control module. A frequency converter, an automatic voltage regulator, a traction machine, a brake and an encoder are controlled by the upper computer. The elevator traction machine brake precision control system and method have the advantages that the cost is low, the reliability is high, operation is convenient, and the structure is simple. The brake control precision is improved on the traction machine achieving complete machine installation directly on the existing production conditions, no other tool equipment needs to be specially designed for carrying out precision machining on the brake, installation and debugging are easy, and the system and method can be widely applied to brake production.

Owner:GUANGZHOU GUANGRI ELEVATOR IND

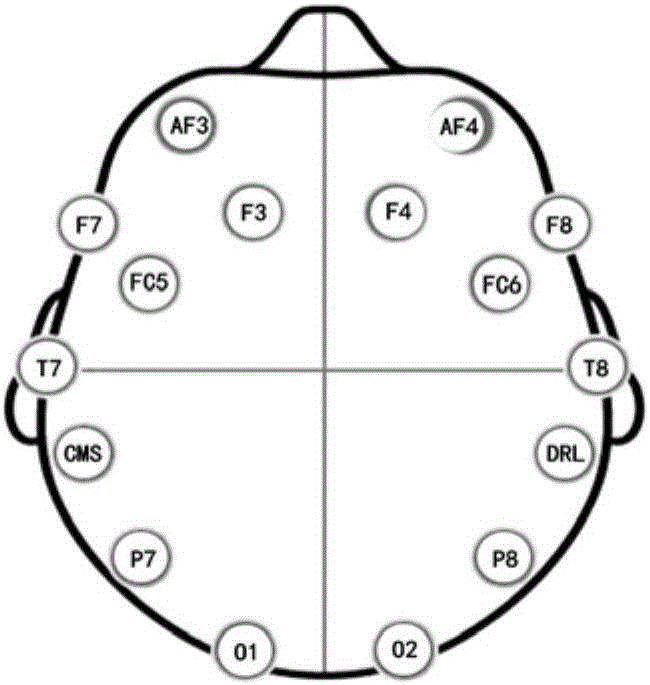

Parallel multi-modal brain control method for complete grabbing operation of artificial hand

ActiveCN105676639AAchieve precision controlImprove accuracyAdaptive controlInformation transmissionAnimation

The invention discloses a parallel multi-modal brain control method for complete grabbing operation of an artificial hand. On the basis of intelligent artificial hand control methods in the prior art that use EEG signals, the method integrates the reliability of a brain control paradigm that is evoked by vision on the basis of scene animations and of a brain control paradigm that is driven by expressions to improve the correct rate of complete grabbing operation of an artificial hand. EEG signals generated by visual evocation when a subject looks at different scene animations and EEG signals generated by different expressions are used as control information sources at the same time. By increasing individual differences between different types of EEG signals, the method achieves precise control of the artificial hand and further improves the accuracy and information transmission rate of a brain control artificial hand system.

Owner:XI AN JIAOTONG UNIV

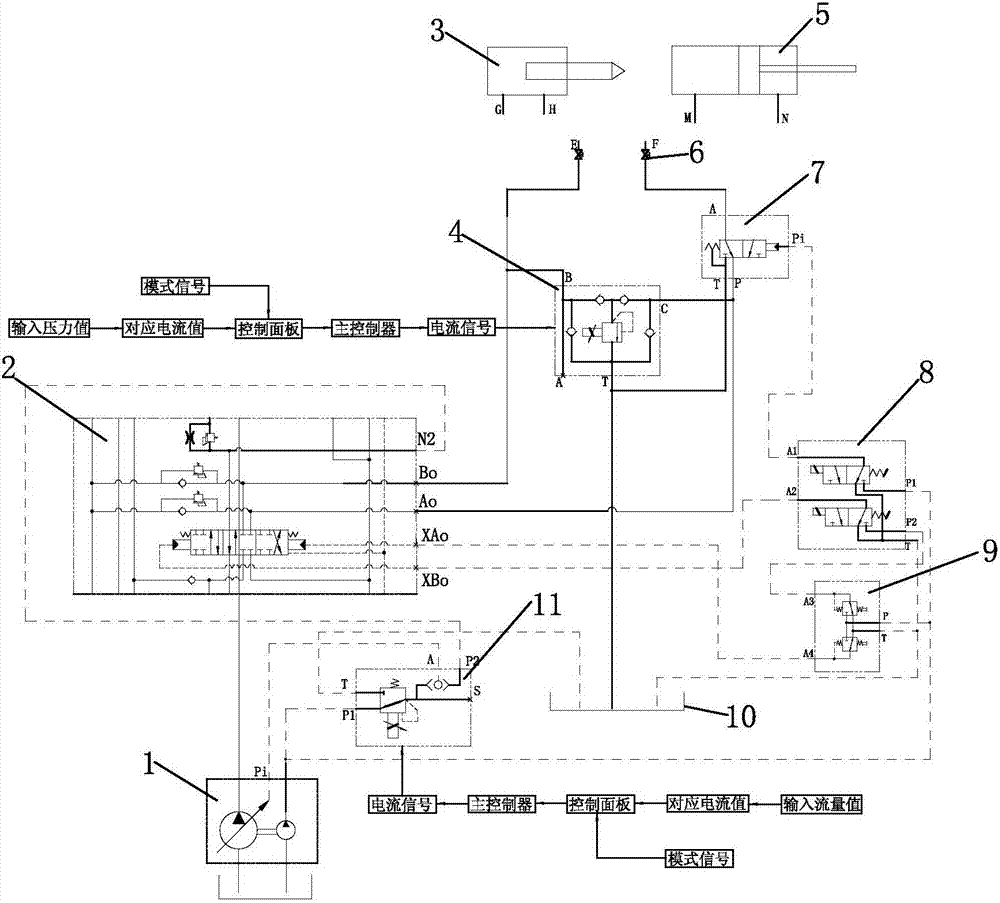

Excavator multifunctional machine tool flow and pressure control system

PendingCN107956233AMeet the use requirementsSimple and reliable adjustmentSoil-shifting machines/dredgersMachineElectric control

The invention discloses an excavator multifunctional machine tool flow and pressure control system. The system comprises a main pump, a main control valve, a current-limiting electromagnetic valve, anelectromagnetic valve set, a bidirectional foot valve, a hydraulic control reversing valve, a proportional overflow valve, a stop valve, a one-way machine tool, a bidirectional machine tool, a hydraulic oil tank, a main controller, a control panel and related hydraulic pipelines and electric wire harnesses; and the control panel transmits electrical signals to the main controller, and the main controller separates out four paths of current signals to control the proportional overflow valve, the current-limiting electromagnetic valve, and an A1-connected electromagnetic valve and an A2-connected electromagnetic valve of the electromagnetic valve set correspondingly. According to the system, on the basis of an original multifunctional machine tool hydraulic pipeline, the electro-hydraulic proportional technology and the electric control technology are combined, so that the accurate control over the hydraulic system flow and pressure is realized, the operator only needs to manually inputthe required flow and pressure values on the control panel, and then the system can be used by the different machine tools.

Owner:XCMG EXCAVATOR MACHINERY

A self-adjusting distance corrugated paper cutting machine

ActiveCN104589385BAffecting workGuaranteed work performanceMetal working apparatusDrive wheelKnife blades

The invention provides a distance self-adjusting type corrugated paper cutter which comprises a base, a blade mechanism, a brush base, a driving mechanism and a control module. A cutter clamping plate is arranged at the top of the base. A cutter clamping gap is arranged on the cutter clamping plate. The blade mechanism comprises a cutter rest, a blade, a driving wheel, a driven wheel and a grinding wheel. The cutter rest can be arranged on the base in a vertical-rotating mode. The blade is arranged on the cutter rest in a rotatable mode through the driven wheel and corresponds to the cutter clamping gap in position. The driving wheel is arranged on the base in a rotatable mode. The driving wheel is connected with the driven wheel and drives the driven wheel to rotate. The tool rest has a first position state and a second position state. Under the first position state, the blade is placed below the cutter clamping plate. Under the second position state, the blade penetrates through the cutter clamping gap. The grinding wheel has two position states of grinding and retreating. Under the grinding state, the grinding wheel is in contact with the blade. Under the retreating state, the grinding wheel is far away from the blade. The distance self-adjusting type corrugated paper cutter is easy to operate, reasonable in design, high in working efficiency and good in cutting quality.

Owner:ANHUI TIANXIANG PACKING MASCH CO LTD

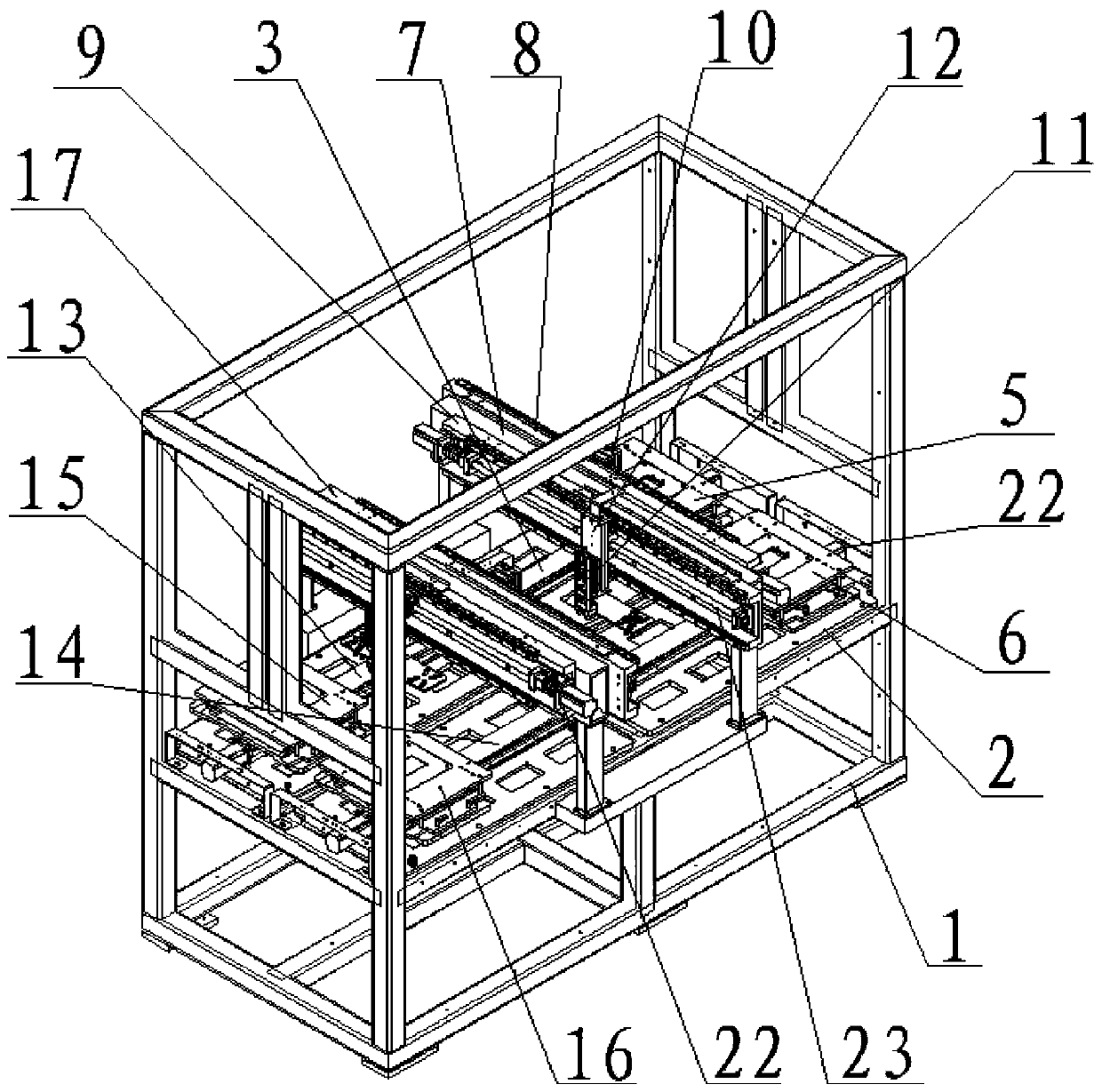

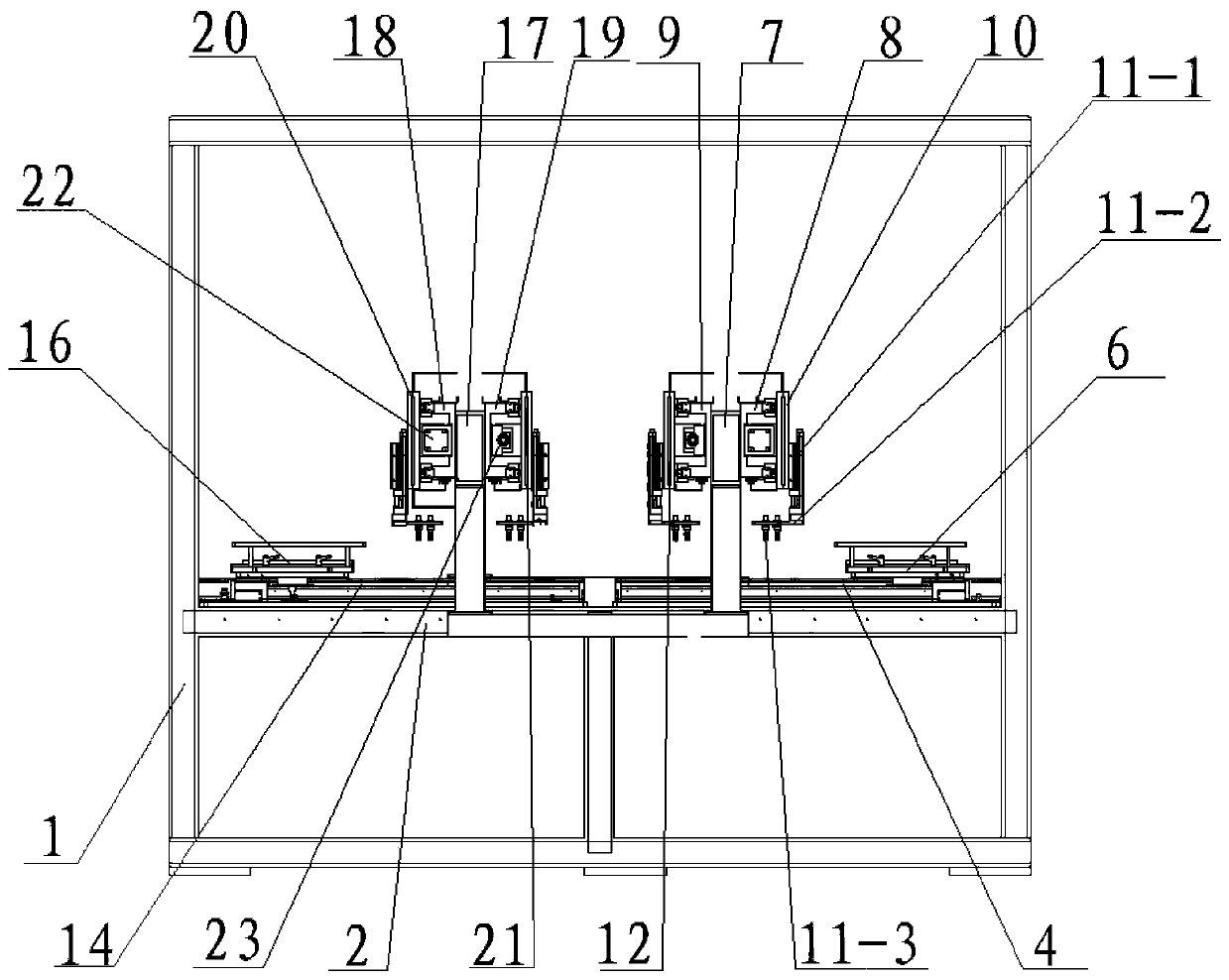

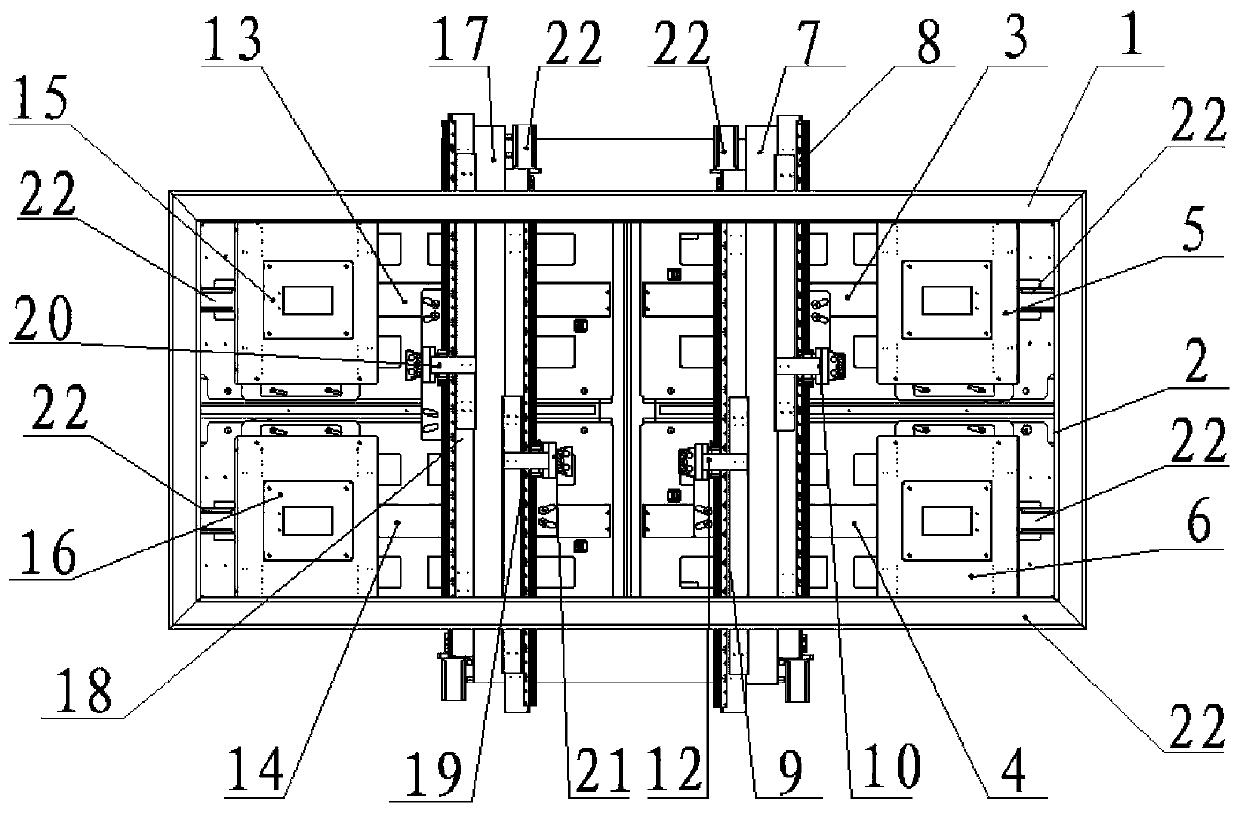

Multi-station rapid feeding and discharging structure

PendingCN109761041AIncrease productivityGood effectConveyor partsProduction lineBiochemical engineering

The invention relates to a multi-station rapid feeding and discharging structure comprising a machine frame. A work table which is horizontally arranged is fixedly arranged on the machine frame. A first module and a second module are arranged on the upper end face of the work table. A first jig is arranged on the first module in a sliding manner. A second jig is arranged on the second module in asliding manner. A first feeding and discharging frame body is fixedly arranged on the machine frame. A first guide rail and a second guide rail are arranged on the two sides of the first feeding and discharging frame body correspondingly. A first feeding and discharging module is arranged on the first guide rail. A feeding and discharging mechanical hand assembly is arranged at the bottom end of the first feeding and discharging module. A second feeding and discharging module is arranged on the second guide rail. A feeding and discharging mechanical hand assembly is arranged at the bottom endof the second feeding and discharging module. By means of the multi-station rapid feeding and discharging structure, the actual time required by the step of working procedure is shortened according tothe work time of products at jig work stations, the influences of the long-time working procedure on a whole production line are greatly compressed, the production efficiency is improved, and a goodeffect is achieved.

Owner:BEIJING C&W ELECTRONICS GRP

Temperature bending deformation measurement of surface piezoelectric composite material

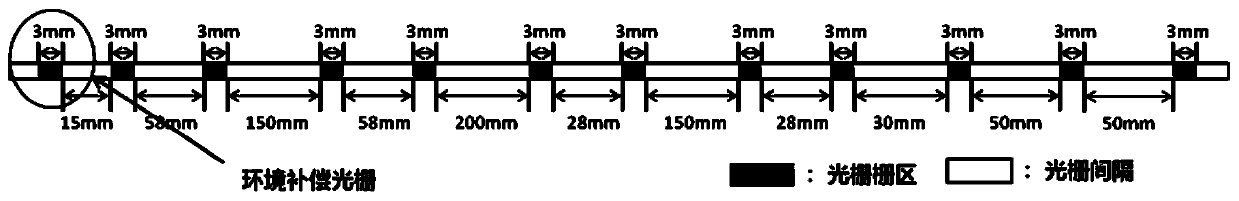

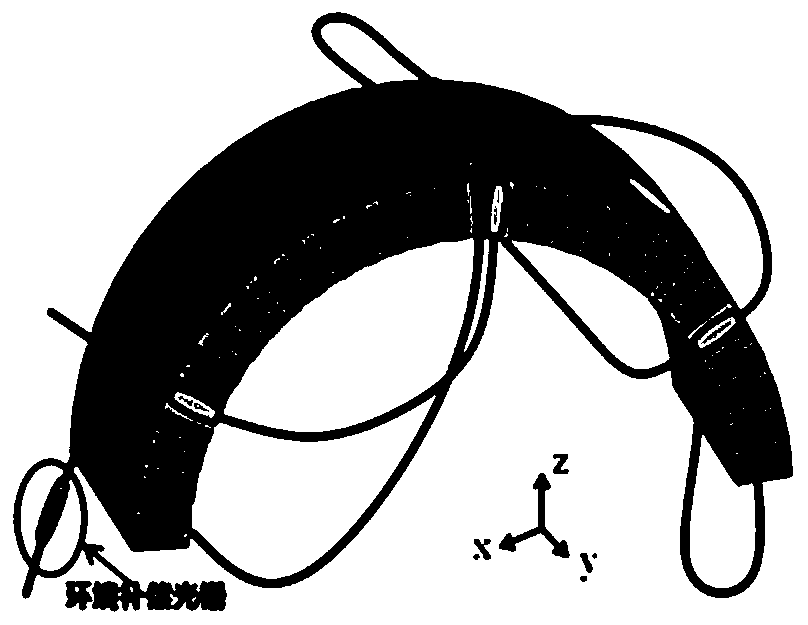

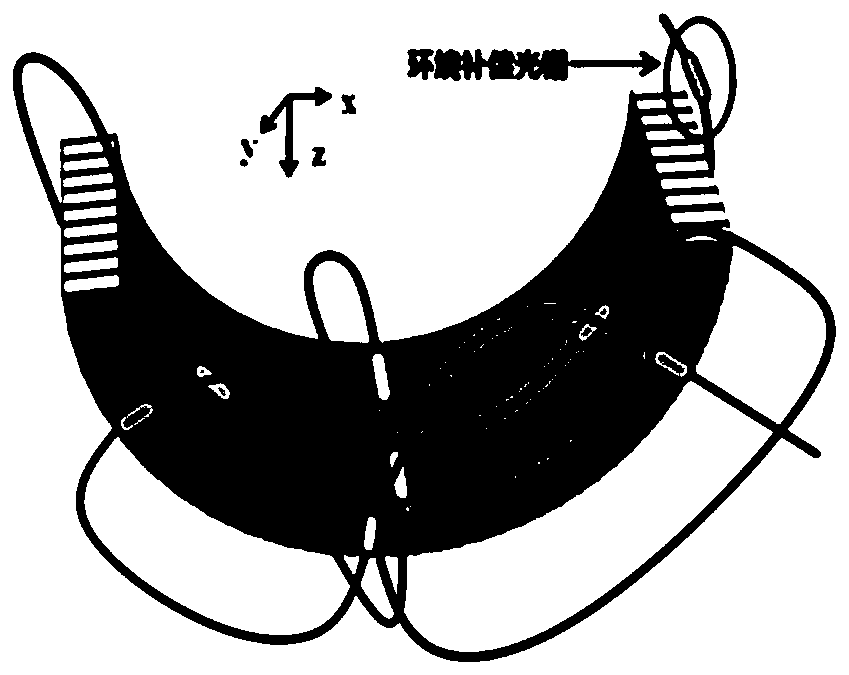

ActiveCN110836643ASolve the problem of temperature deformation quantitative testImprove environmental adaptabilityUsing optical meansMaterial thermal analysisFiberGrating

The invention provides temperature bending deformation measurement of a surface piezoelectric composite material. The temperature bending deformation measurement is implemented according to the stepsof providing a fiber formed with gratings; determining a measured position of a to-be-measured surface sample, and closely attaching each grating onto each surface of the to-be-measured sample by a pasting mode; measuring a length of a bonding region where the fiber at the measured position and the to-be-measured sample are pasted; changing an environmental temperature, monitoring a wavelength ofgrating reflection light under each temperature, and calculating strain of each fiber grating according to a relation between wavelength change quantity of the grating reflection light and the fiber grating to obtain measurement strain of each measured position; and obtaining an average strain value of the to-be-measured sample under each temperature according to the grating length of each measured position, the length of the bonding region and the corresponding measurement strain. By the method, a reliable basis is provided for detection of the piezoelectric composite material for a transducer, meanwhile, an effective check means is provided for improvement of a design and preparation process of the surface piezoelectric composite material, and the environmental adaptability of the transducer and a sonar system can be improved.

Owner:中国人民解放军海军七0一工厂

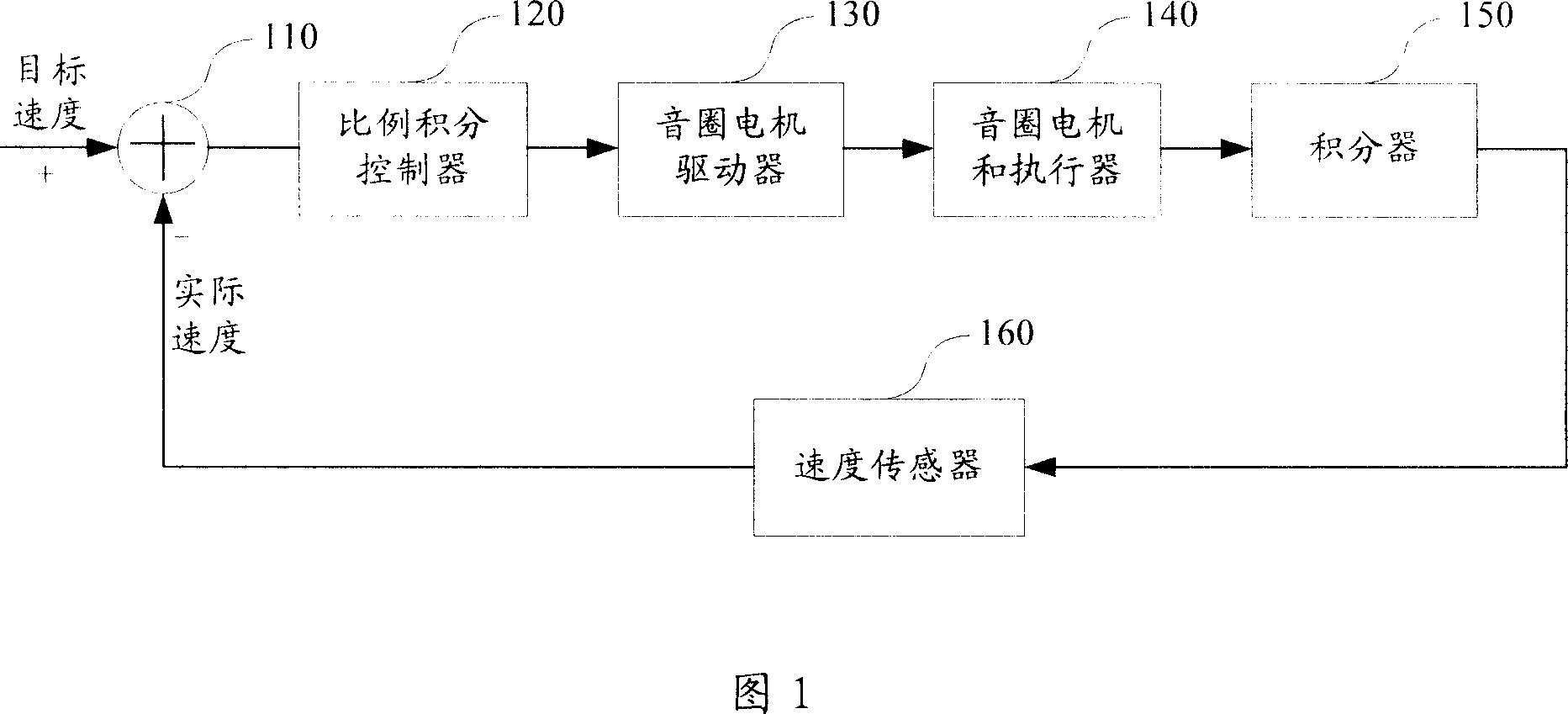

Hard disk magnetic head load method capable of compensating friction force

InactiveCN1959834AAchieve precision controlEasy to controlDisposition/mounting of recording headsDriving/moving recording headsControl systemControl quality

A method for loading hard-disc magnetic head to compensate frictional force includes setting object loading speed and current parameter value by system when loading command is received by hard-disc magnetic head, obtaining current actual loading speed and parameter of next time according to said current parameter value, regulating loading speed of head-disc magnetic head as per current actual loading speed till hard-disc magnetic head is loaded on disc.

Owner:重庆禾兴江源科技发展有限公司

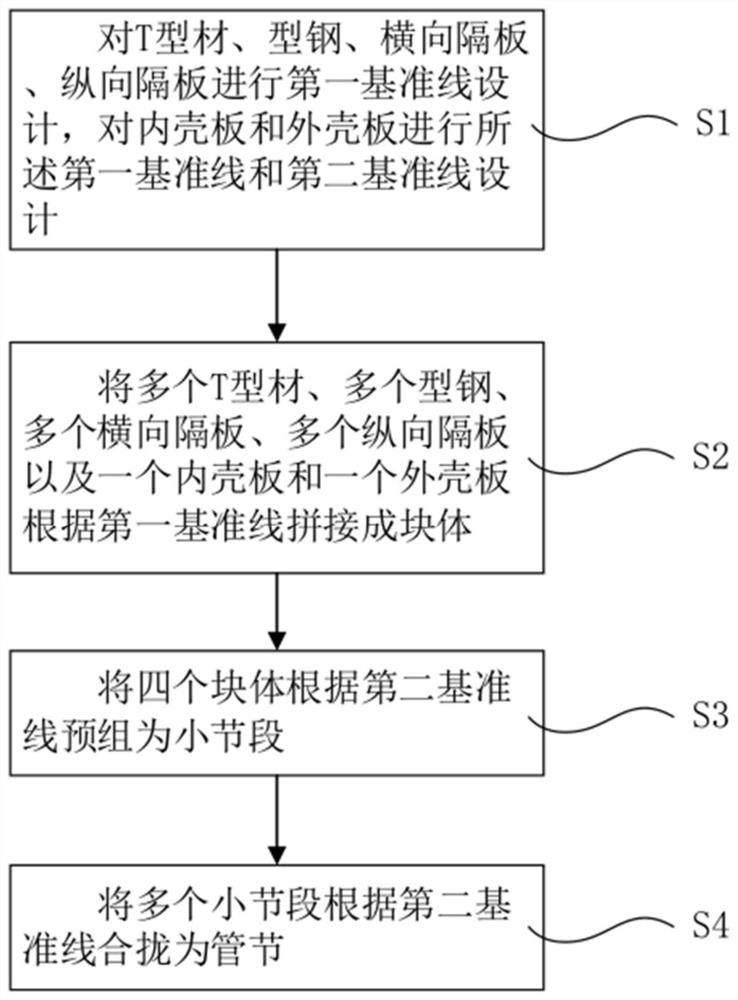

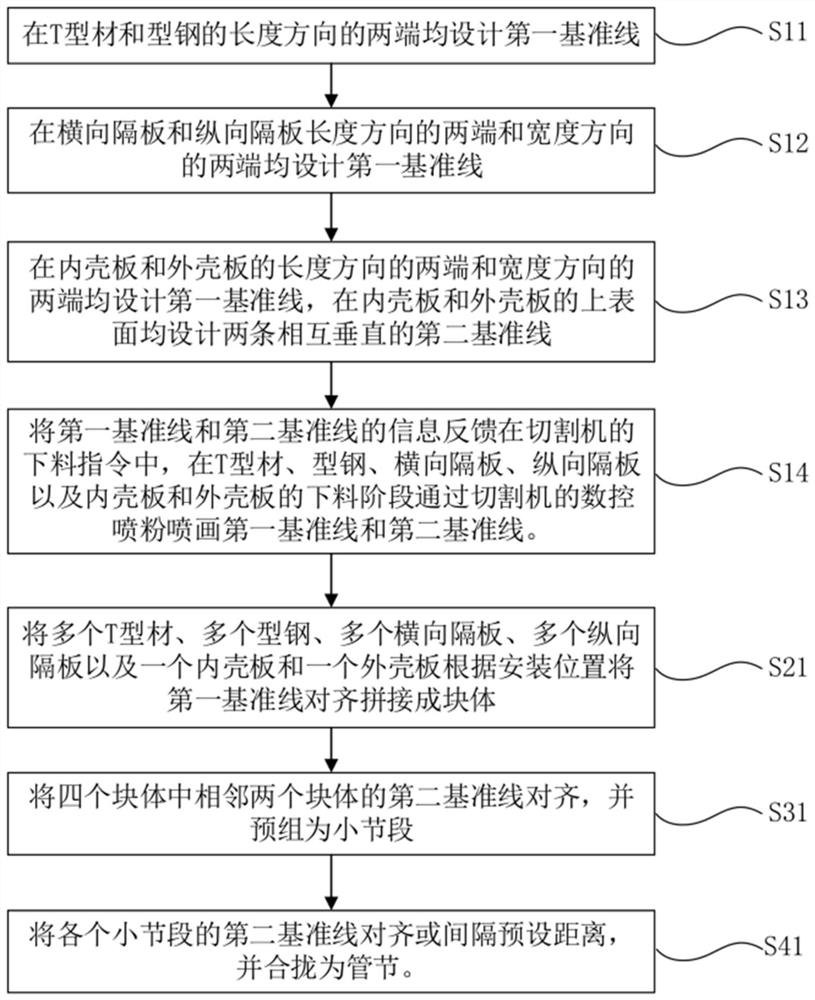

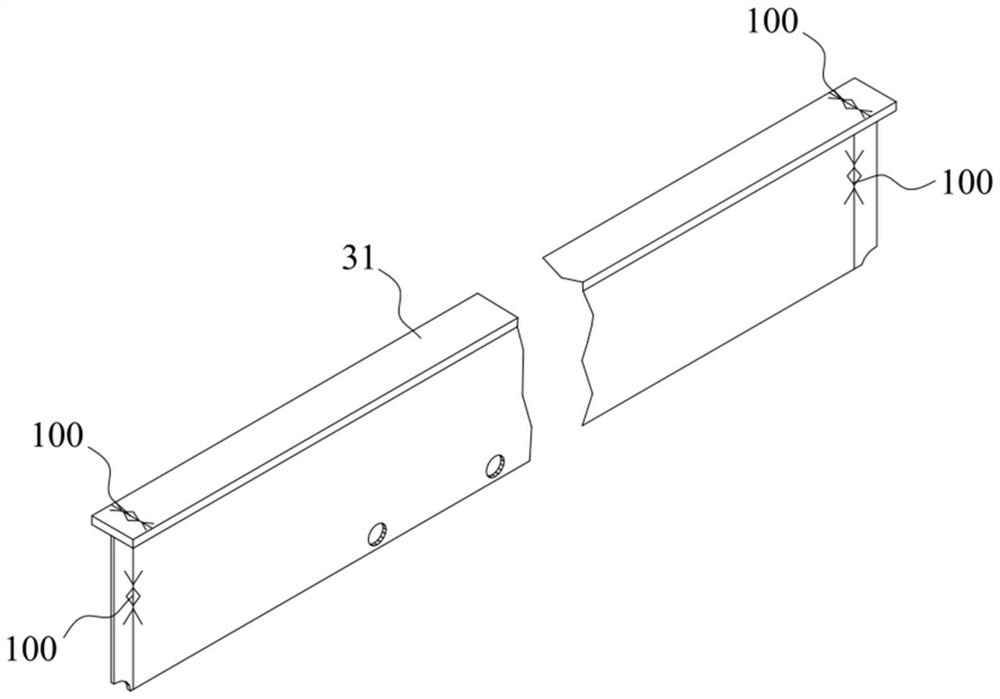

Manufacturing method of immersed tube tunnel steel shell tube section and immersed tube tunnel steel shell tube section

InactiveCN112064680AAchieve precision controlSimplify location targetingArtificial islandsUnderwater structuresPhysicsEngineering

The invention discloses a manufacturing method of an immersed tube tunnel steel shell tube section and the immersed tube tunnel steel shell tube section, and relates to the technical field of large steel structure manufacturing engineering. The manufacturing method comprises the following steps that S1, first datum line design is conducted on T-shaped profiles, profile steel, transverse partitionplates and longitudinal partition plates, and first datum line design and second datum line design are conducted on inner shell plates and outer shell plates; S2, a plurality of T-shaped profiles, a plurality of pieces of profile steel, a plurality of transverse partition plates, a plurality of longitudinal partition plates, an inner shell plate and an outer shell plate are spliced into a block body according to the first datum line; S3, four blocks are pre-assembled into a small section according to the second datum line; and S4, multiple small sections are folded into a tube section according to the second datum line. Splicing is carried out according to the first datum line, so that parts do not need to be measured, operation is simplified, accurate positioning of all the parts is guaranteed, and precision control over block splicing is achieved.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com