Patents

Literature

50results about How to "The clamping state is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

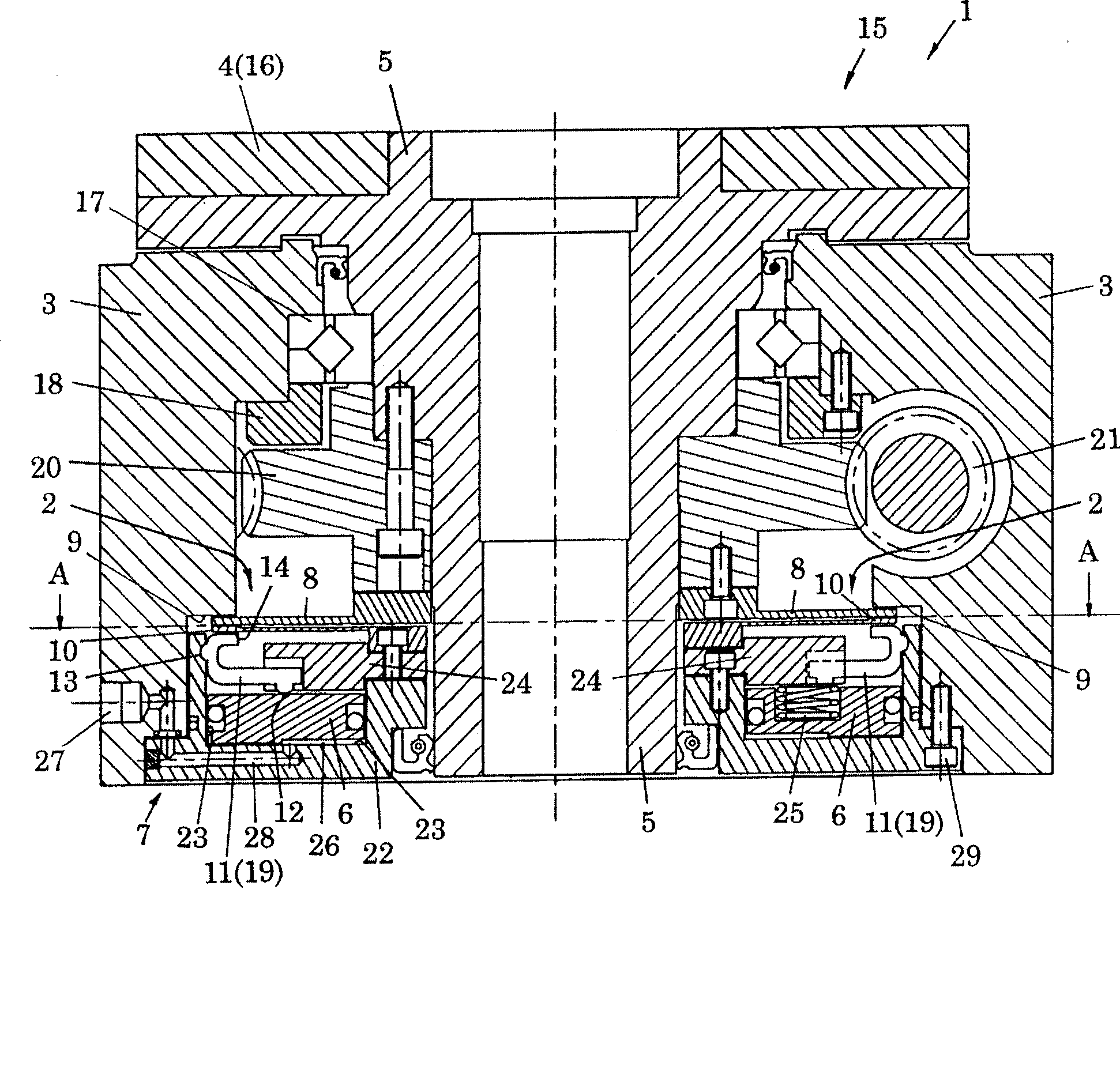

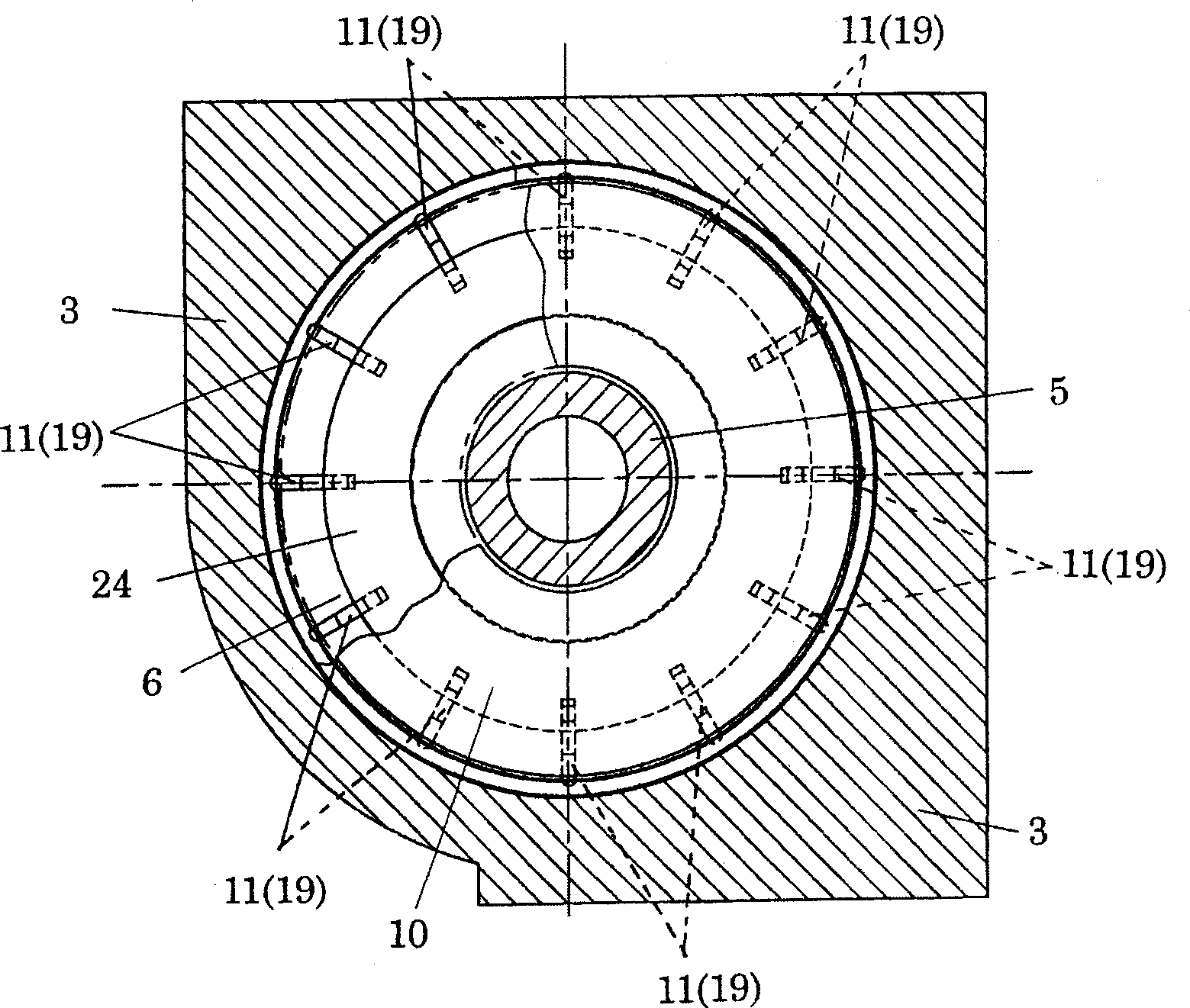

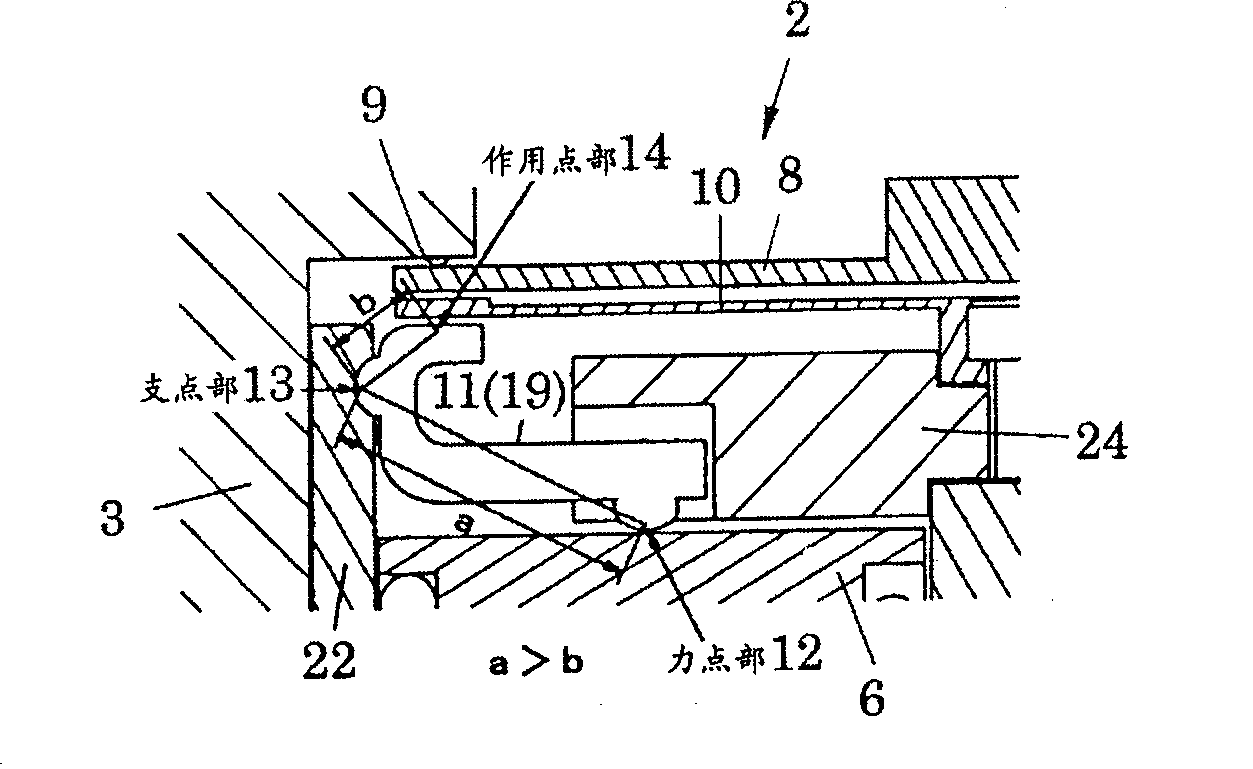

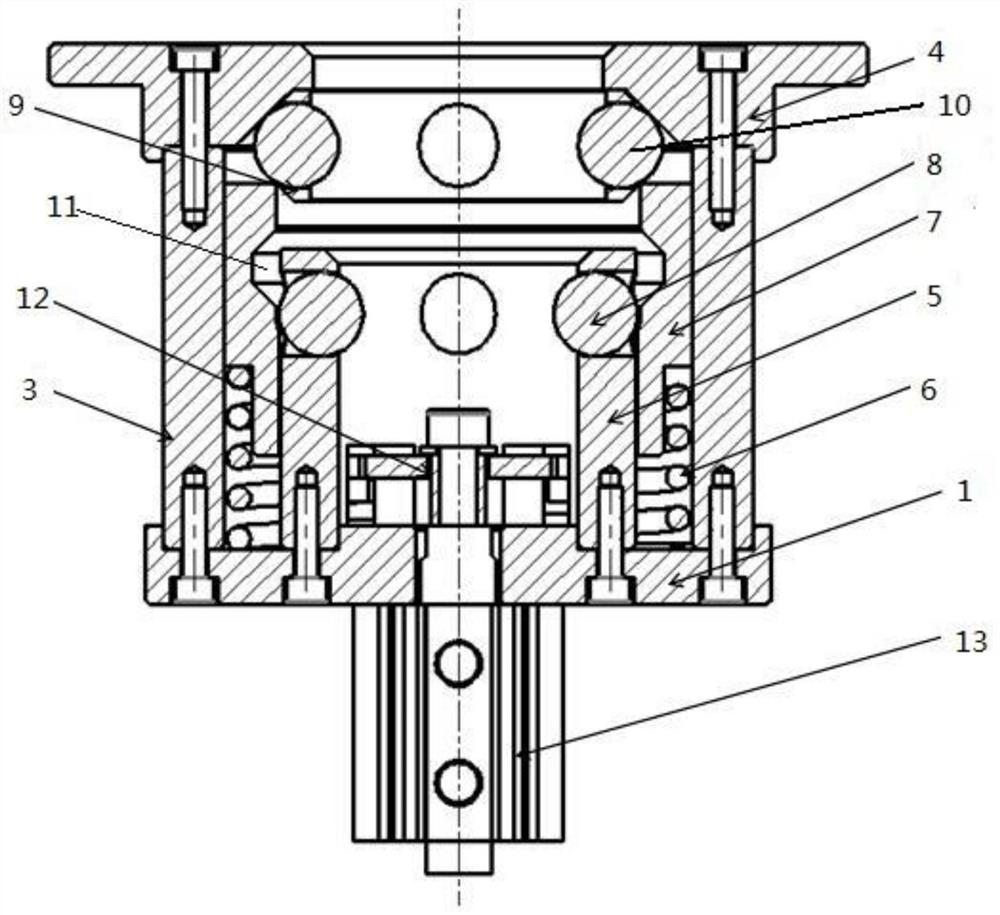

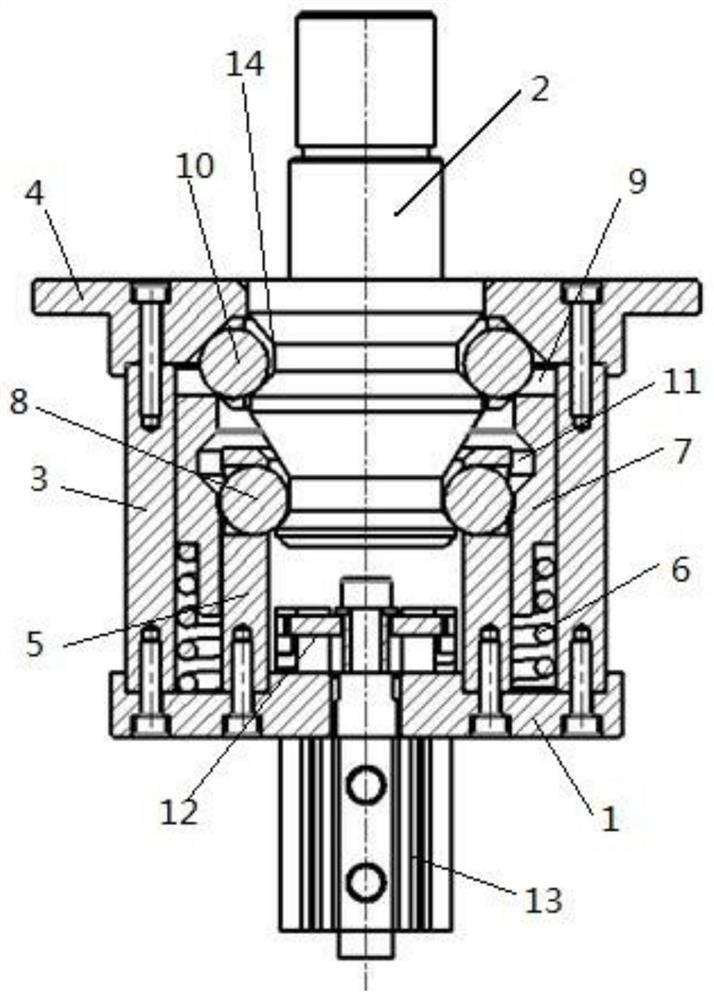

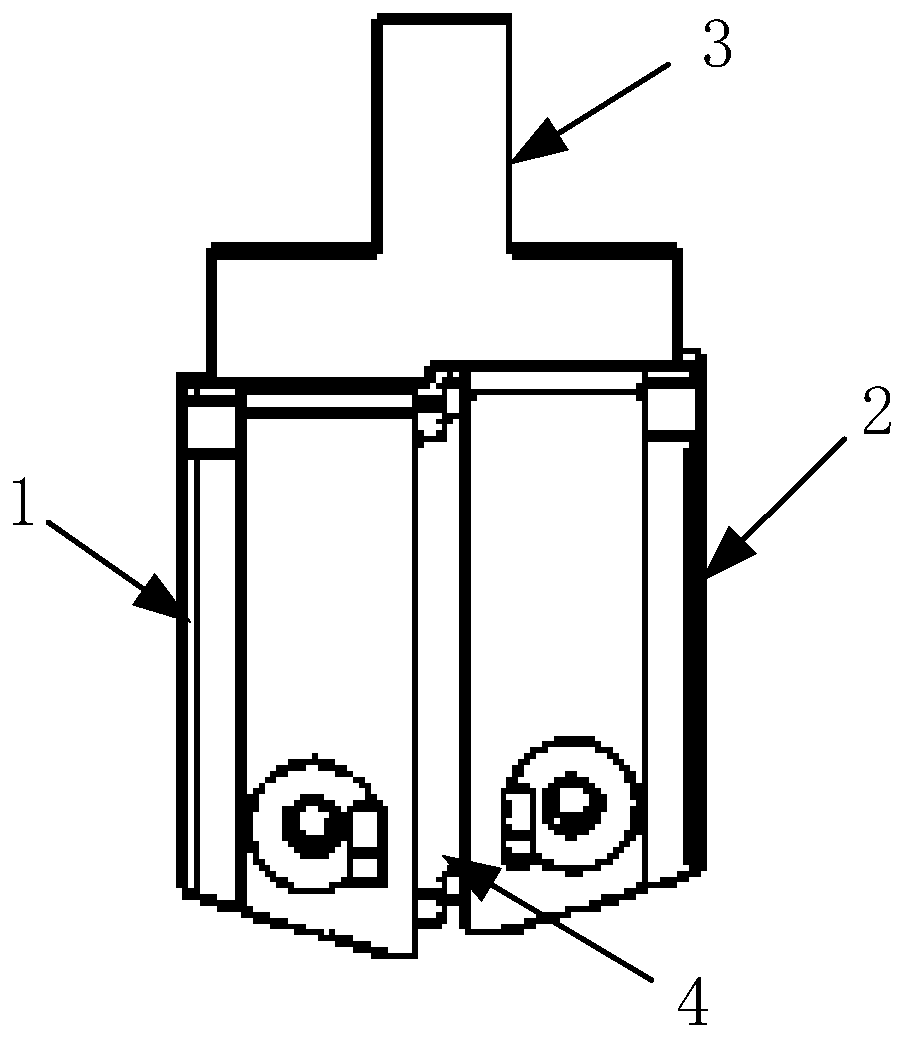

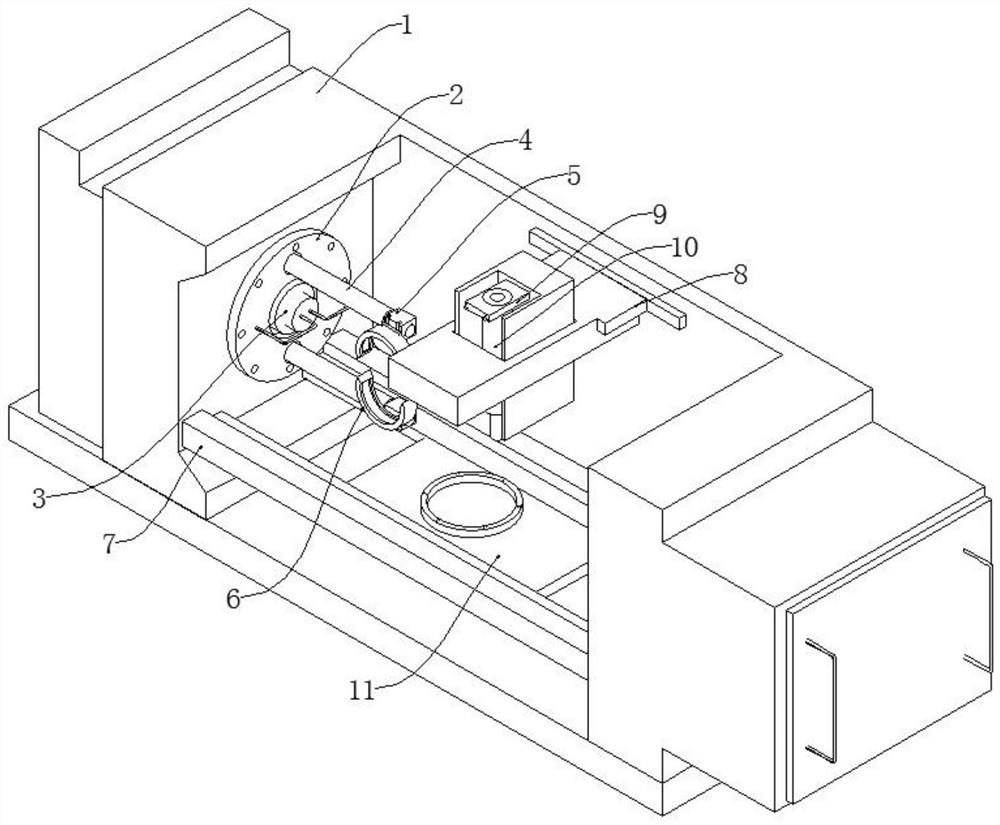

Clamping device for rotation dividing device for machine tool

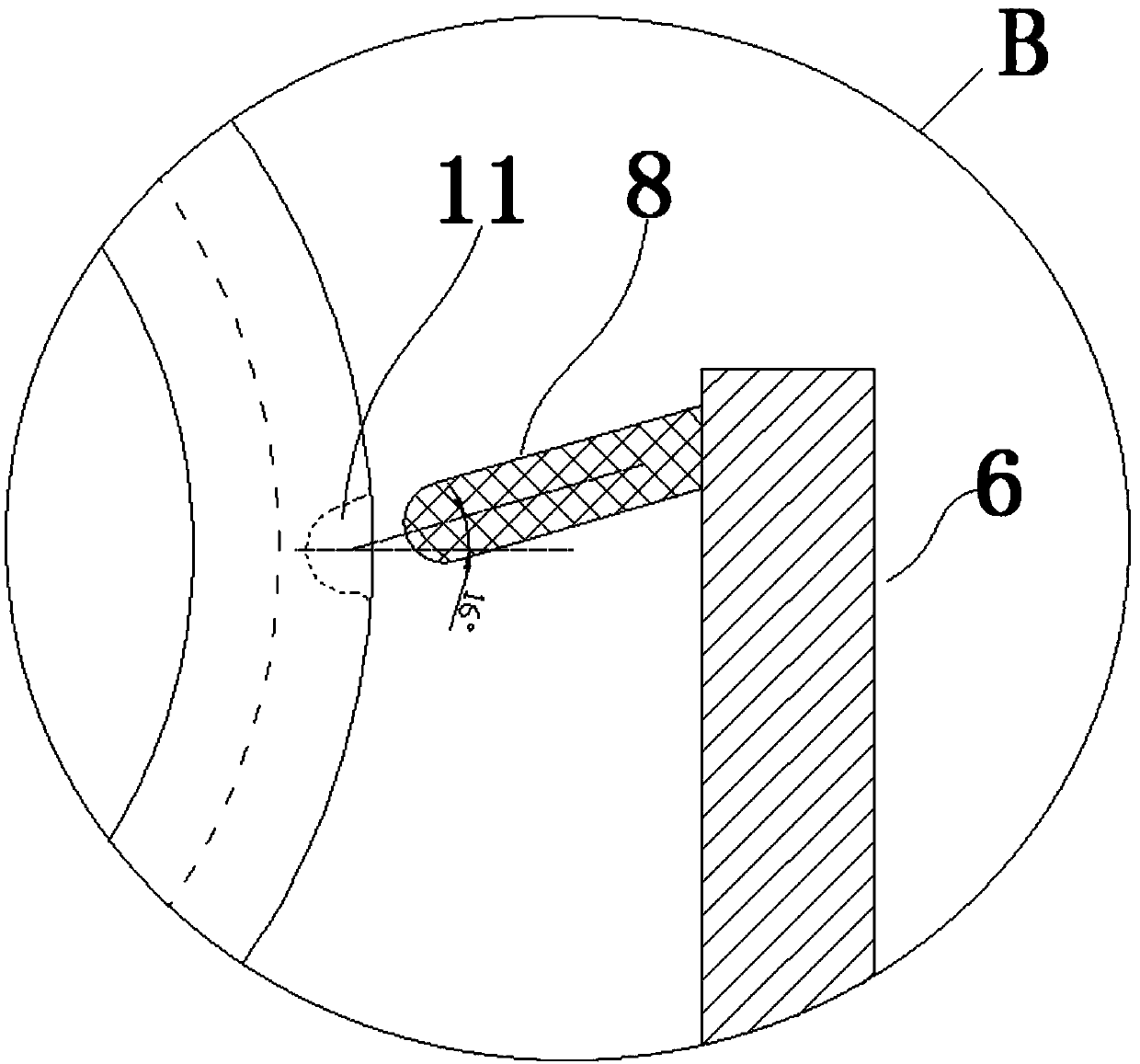

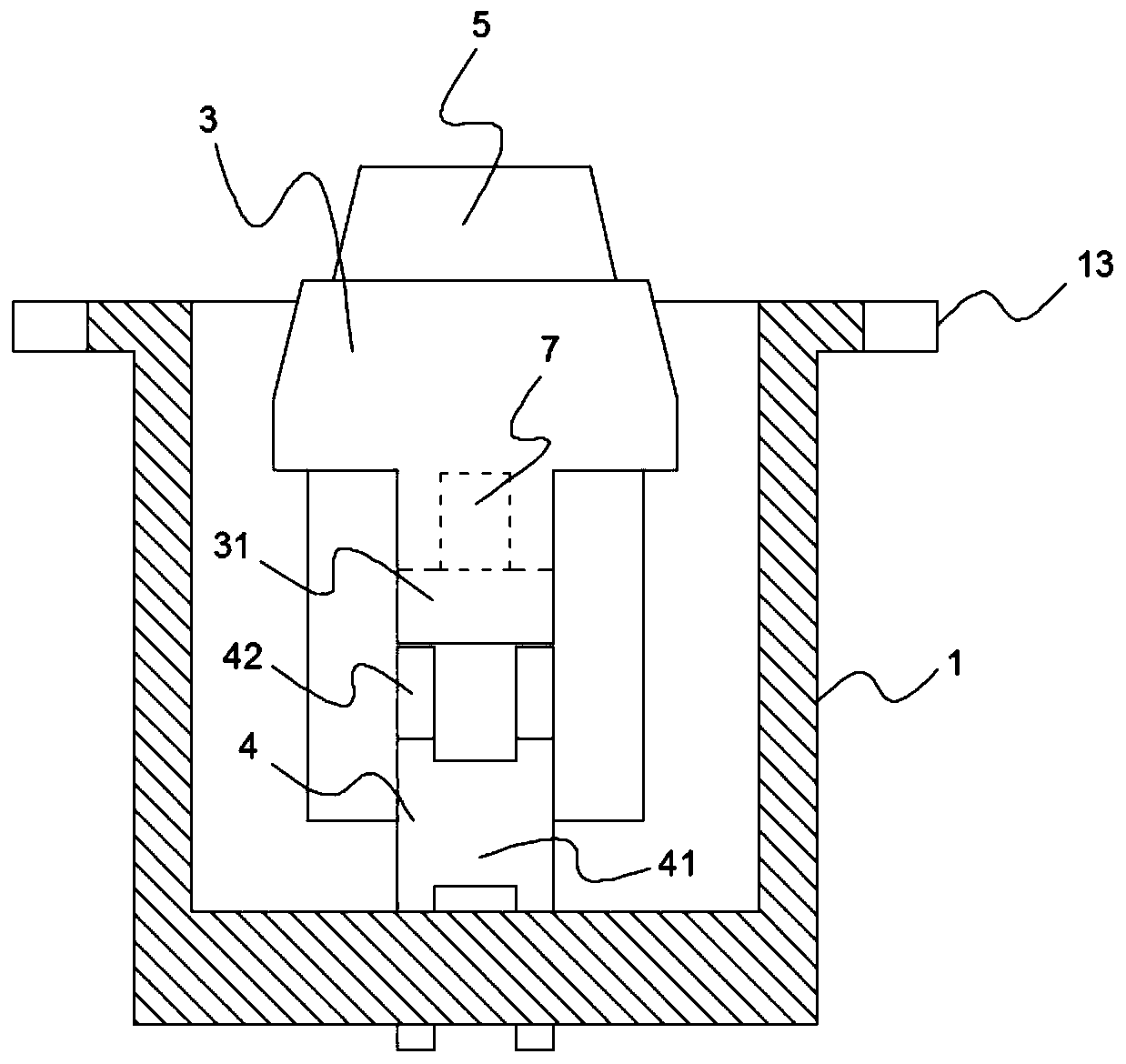

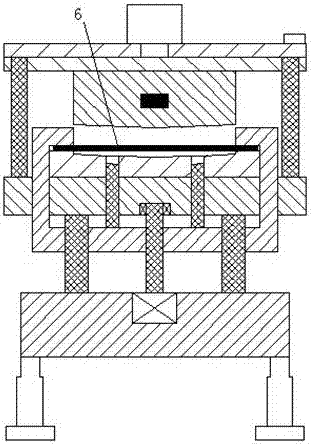

InactiveCN101396797APrevents reduction in machining accuracyMiniaturizationPrecision positioning equipmentMachine tool componentsPistonRotational axis

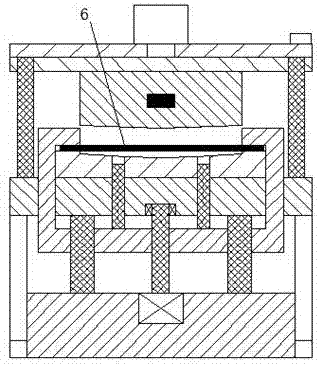

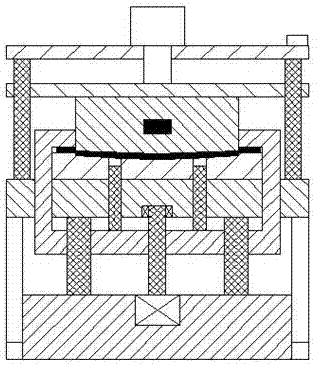

The present invention relates to a clamping device of a rotation indexing device used by a machine tool. The invention provides a clamping mechanism which can endure high-load procession and generates enough clamping force in the clamping device of a rotation indexing device used by a machine tool. The clamping device (2) is provided with a clamping mechanism which is set with a mode of extending along a radius direction of rotation axis (5) and is composed of more than three lever components (11) between a clamping disc (8) and a piston component (6). The pulling force of the piston component (6) is increased through a lever principle and is acted on the clamping disc (8).

Owner:TSUDAKOMA KOGYO KK

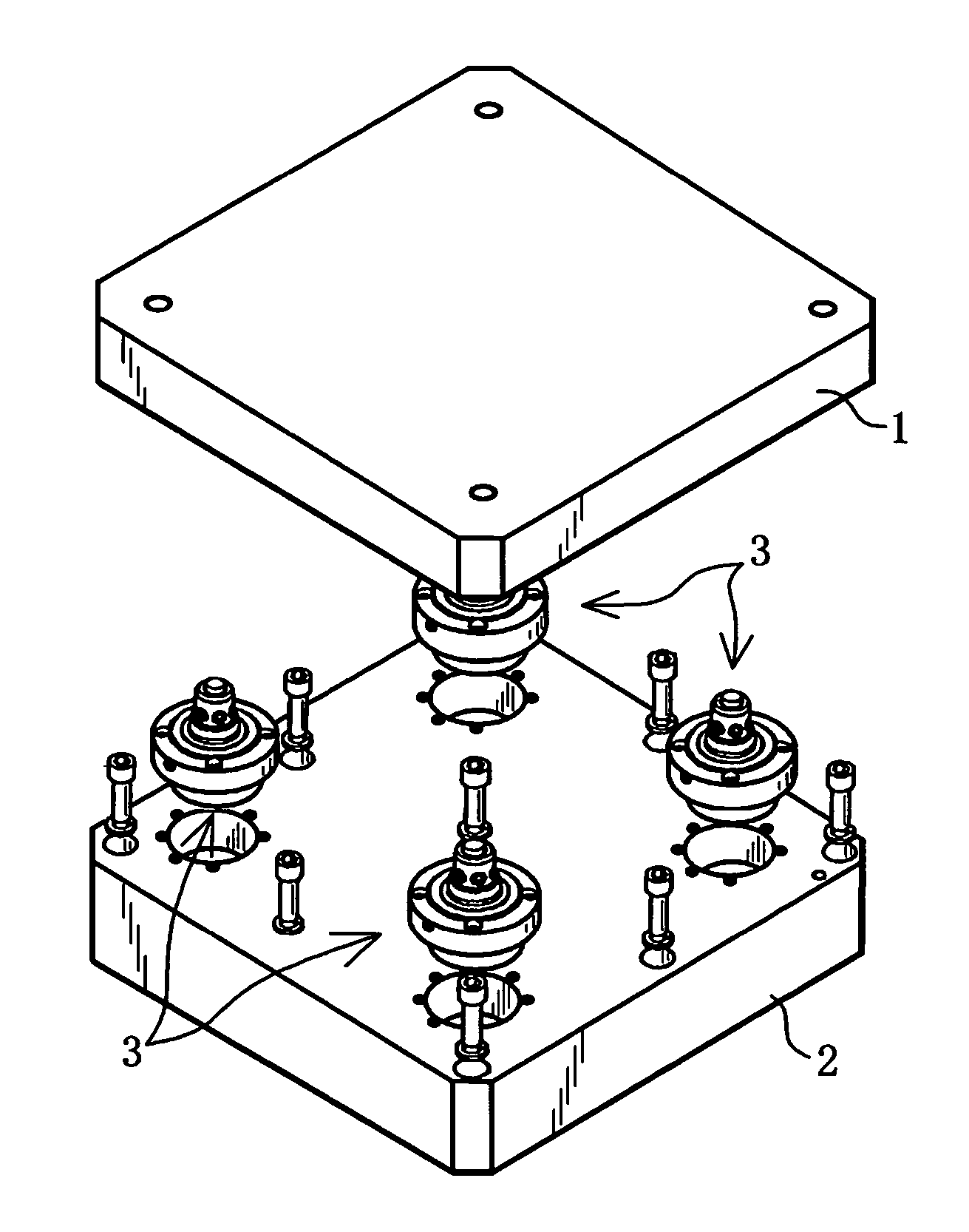

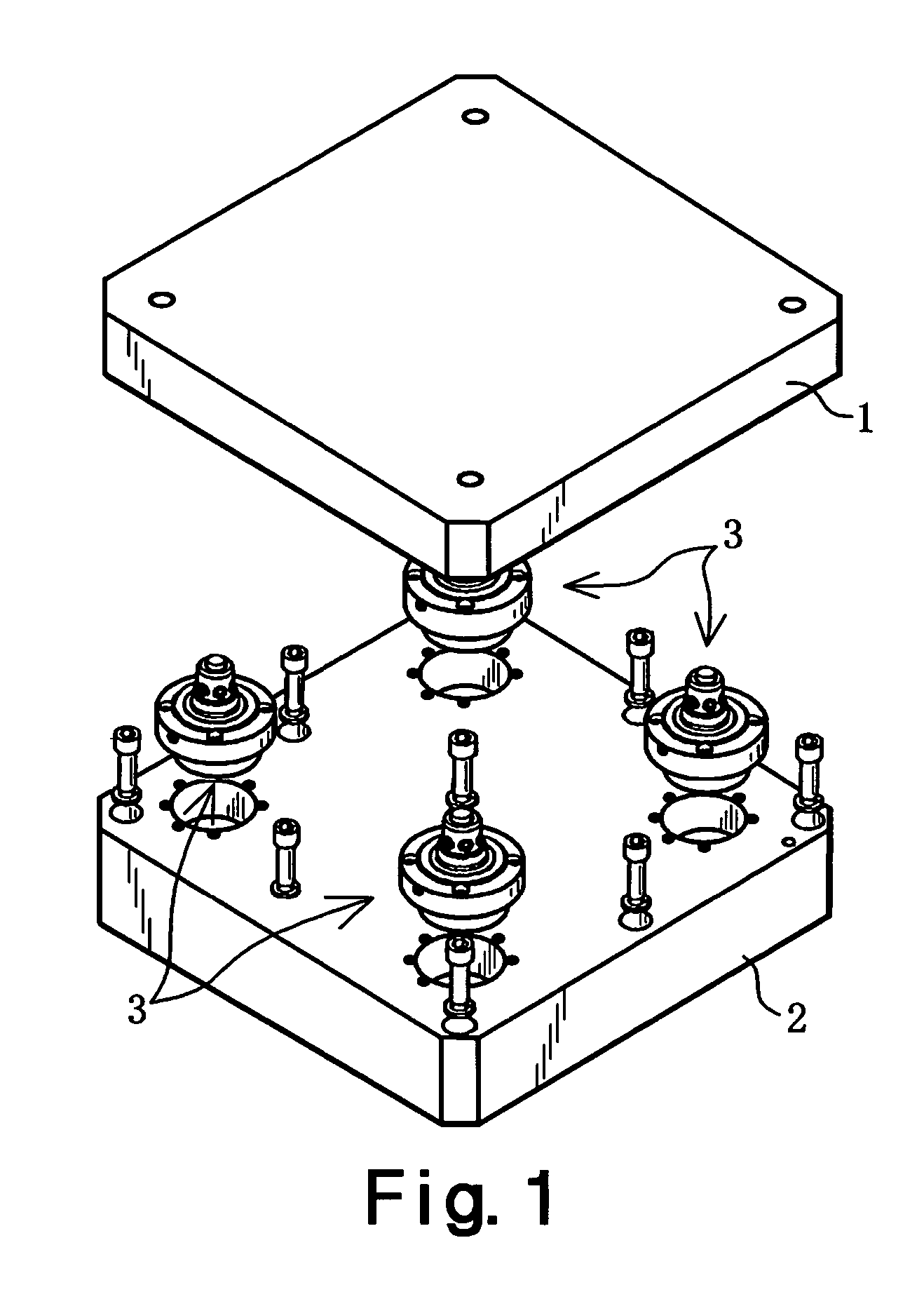

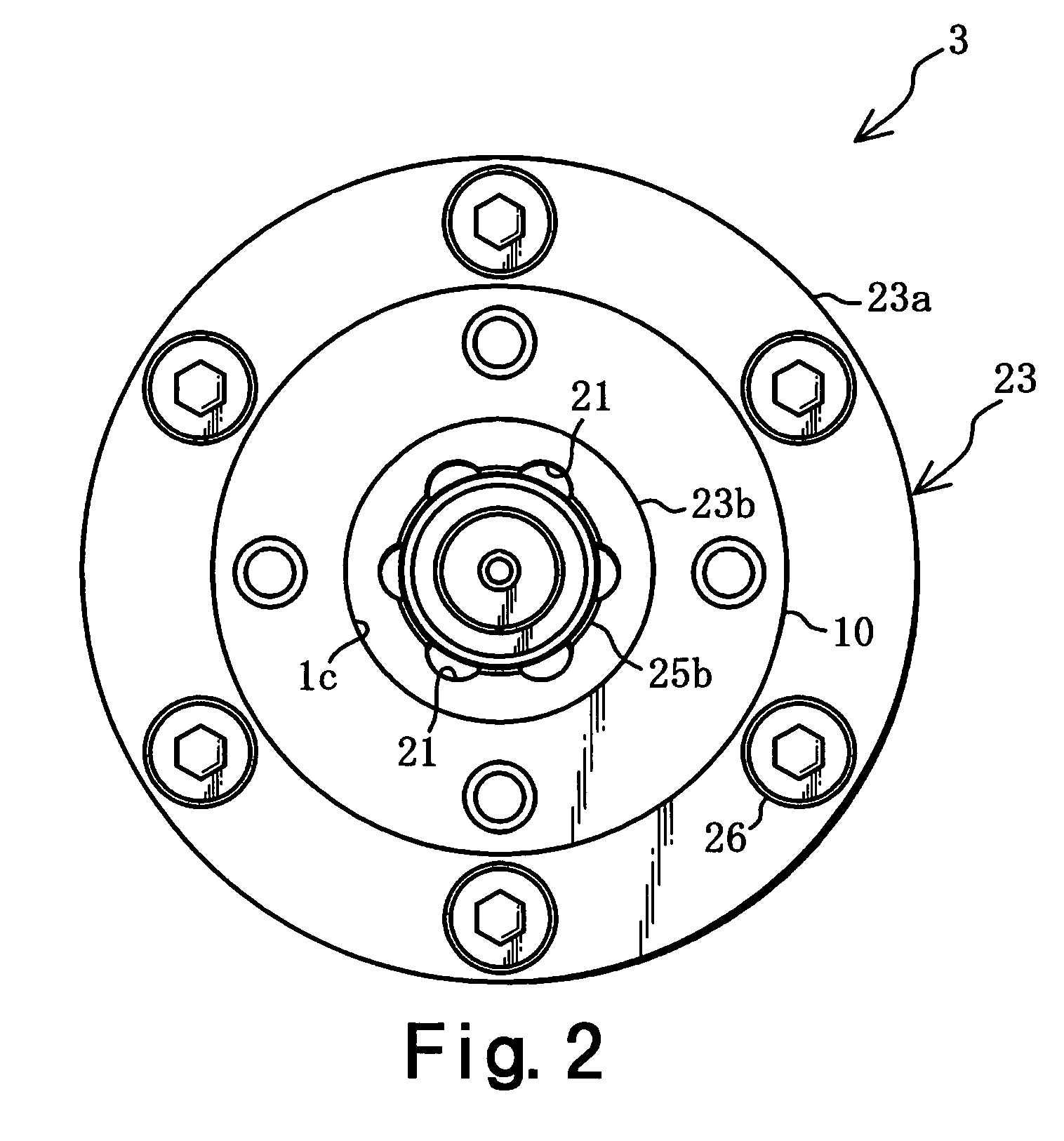

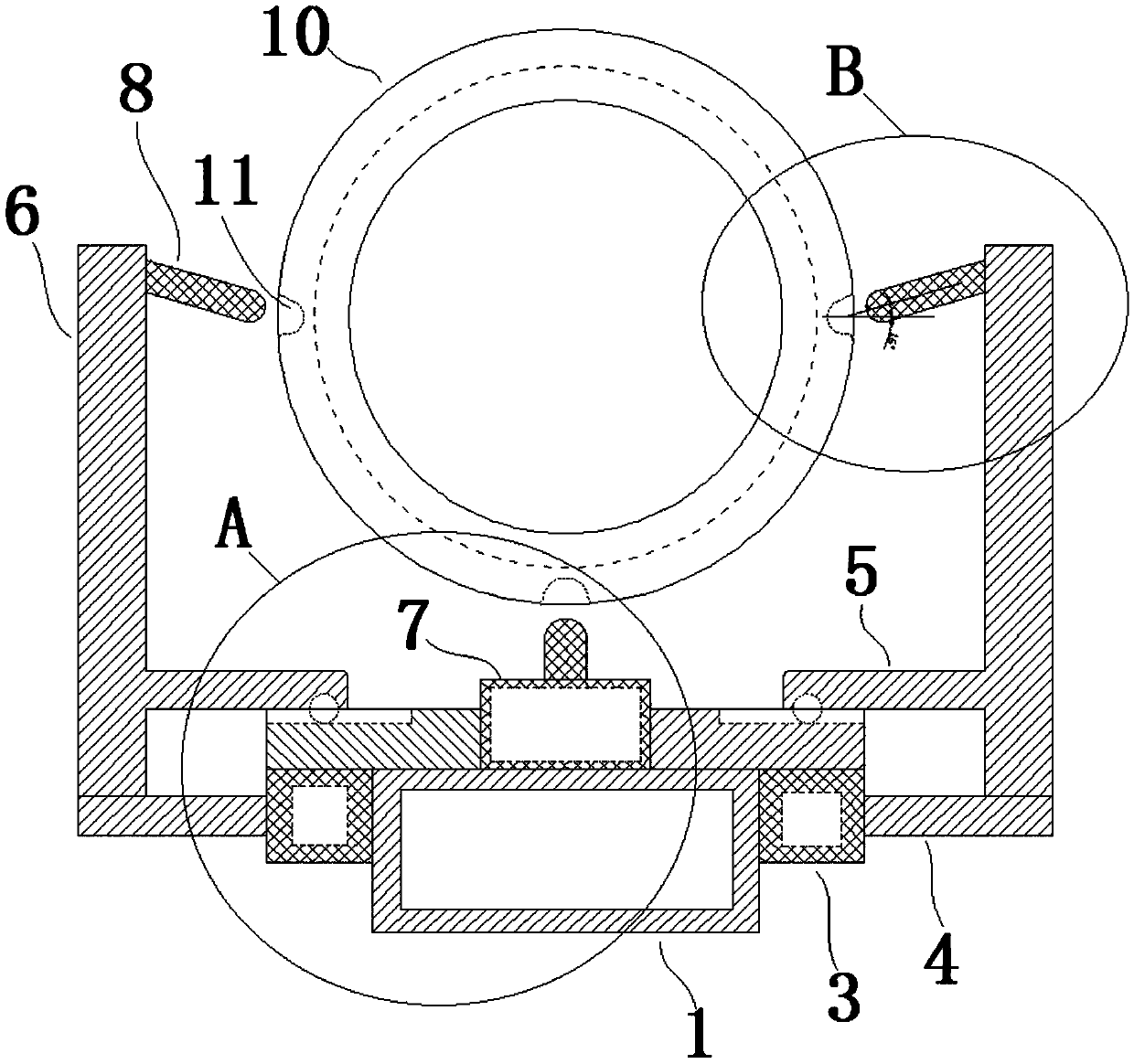

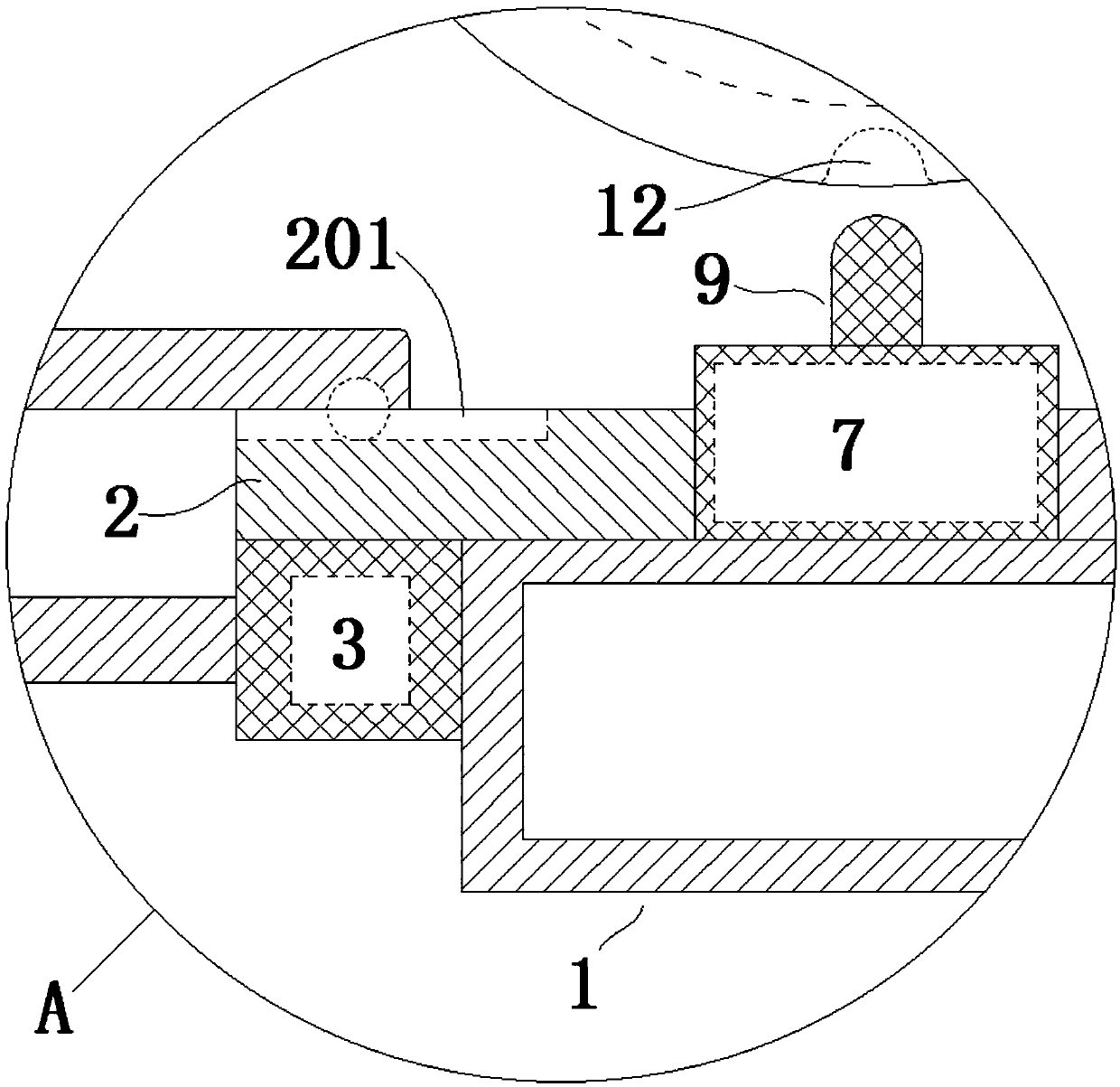

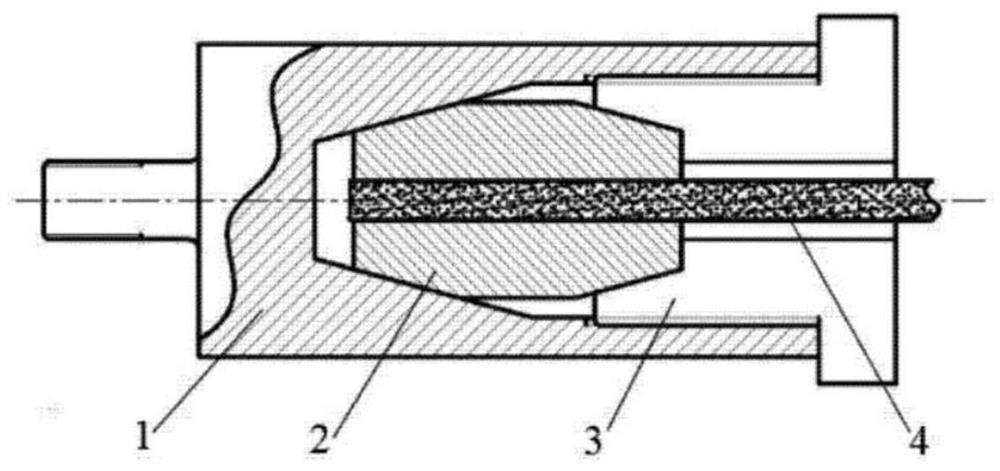

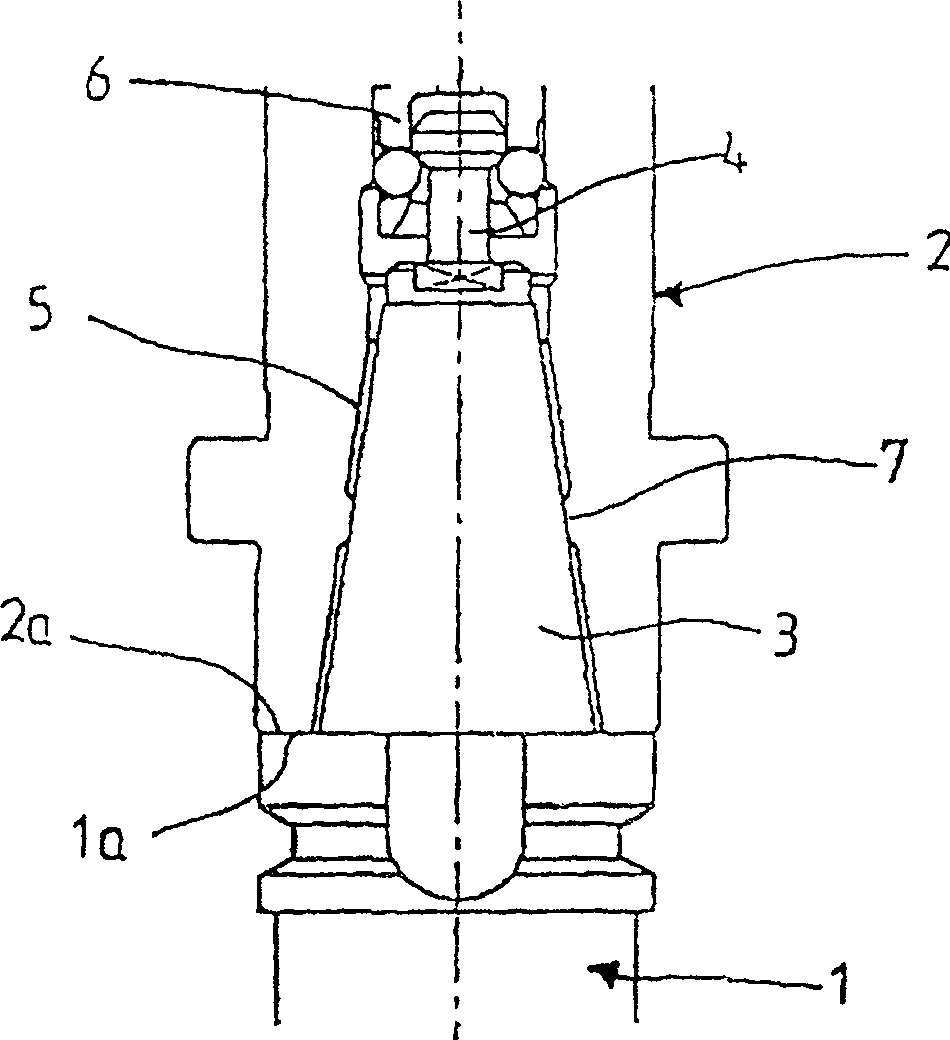

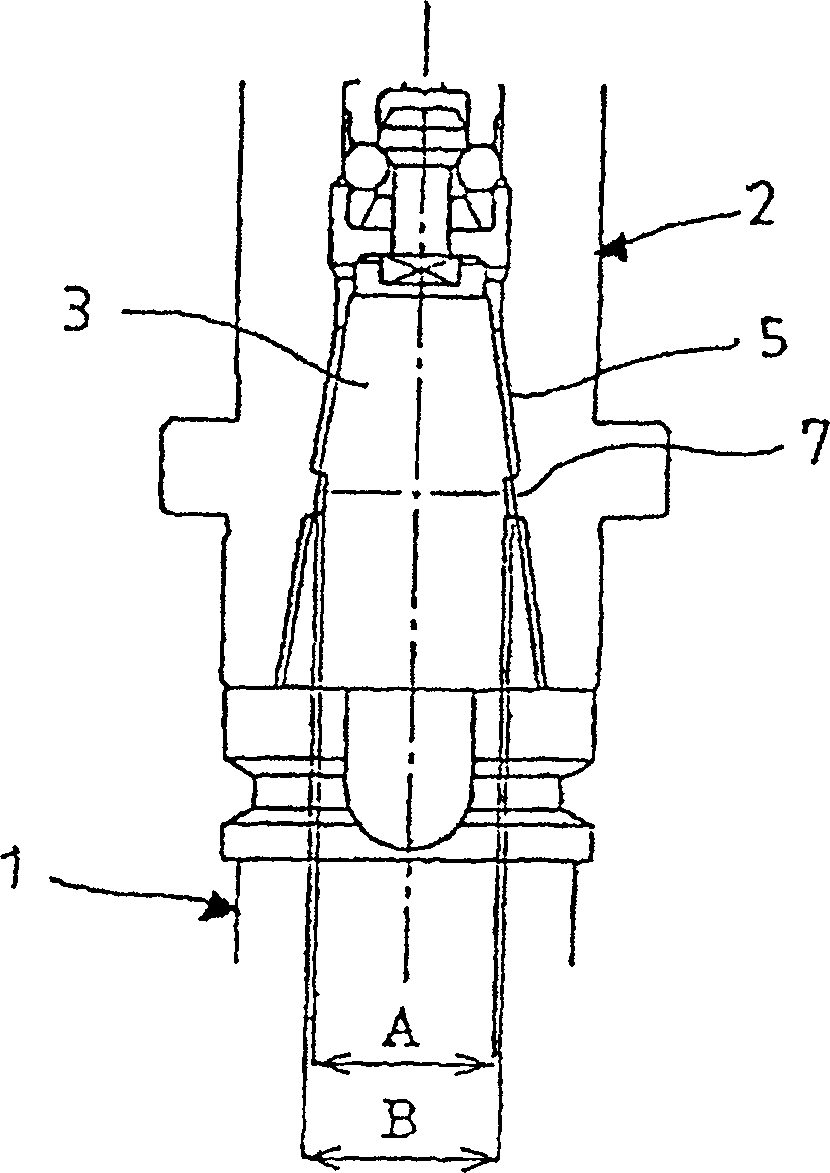

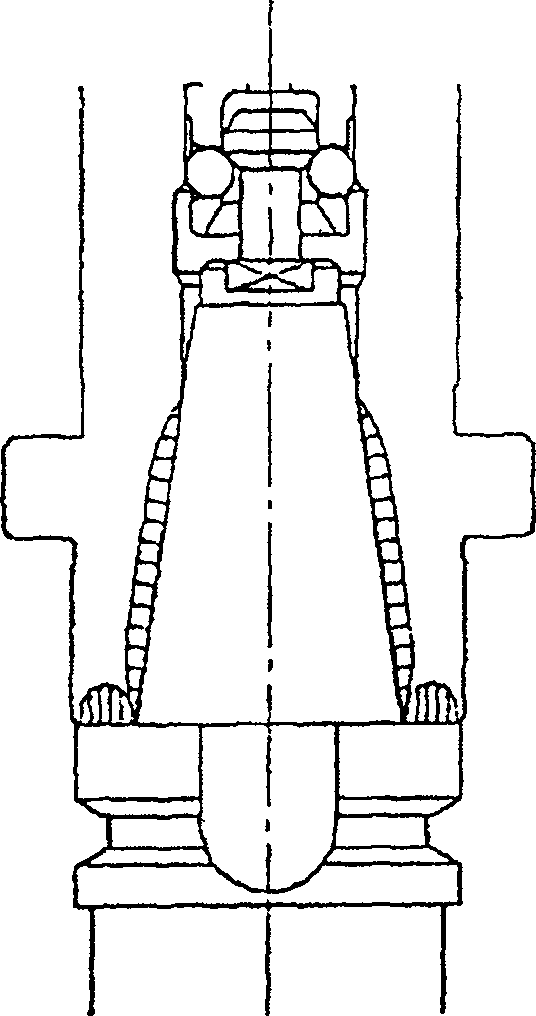

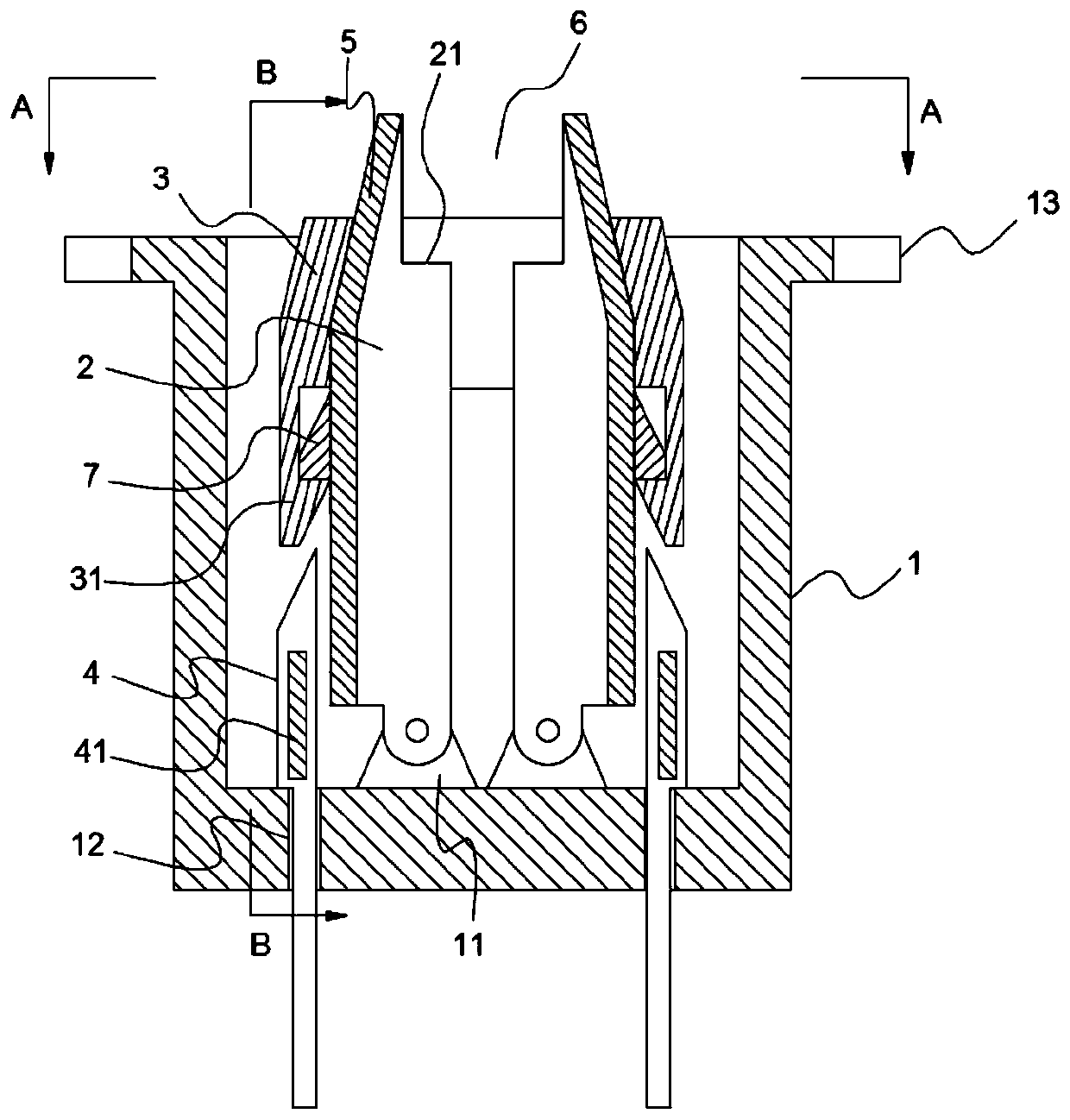

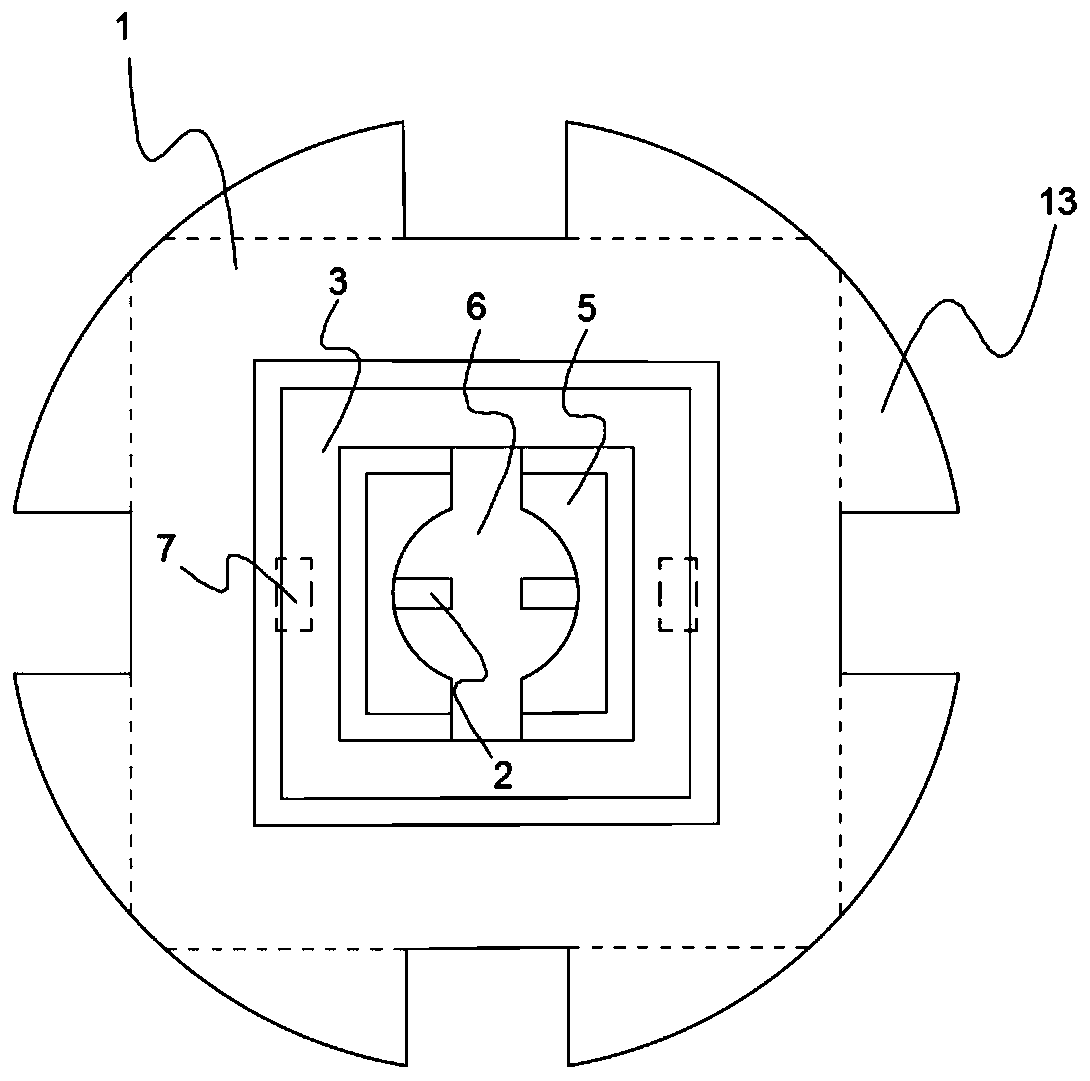

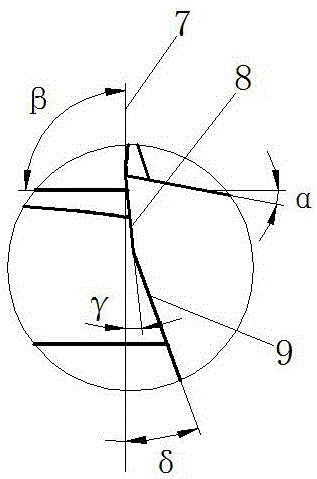

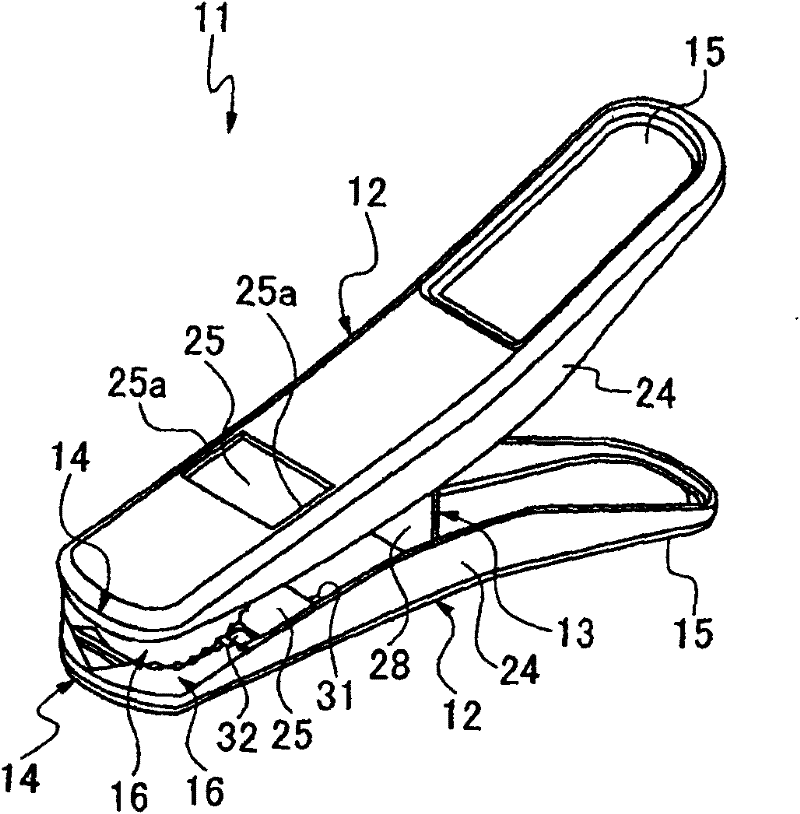

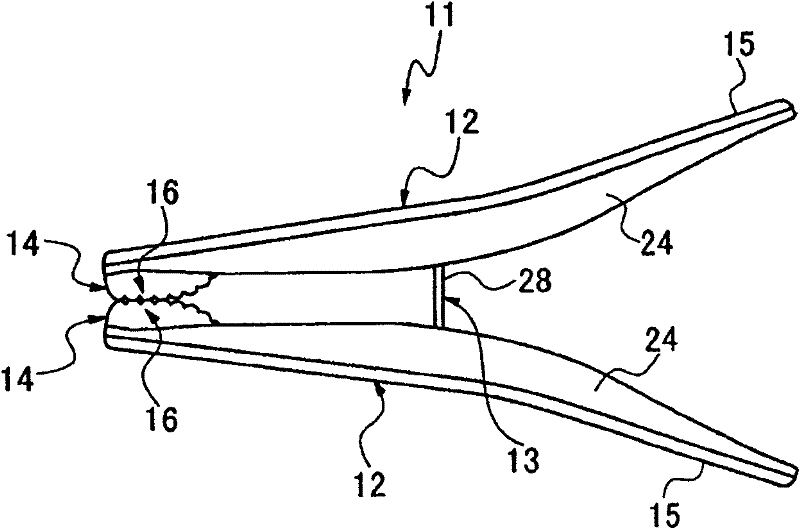

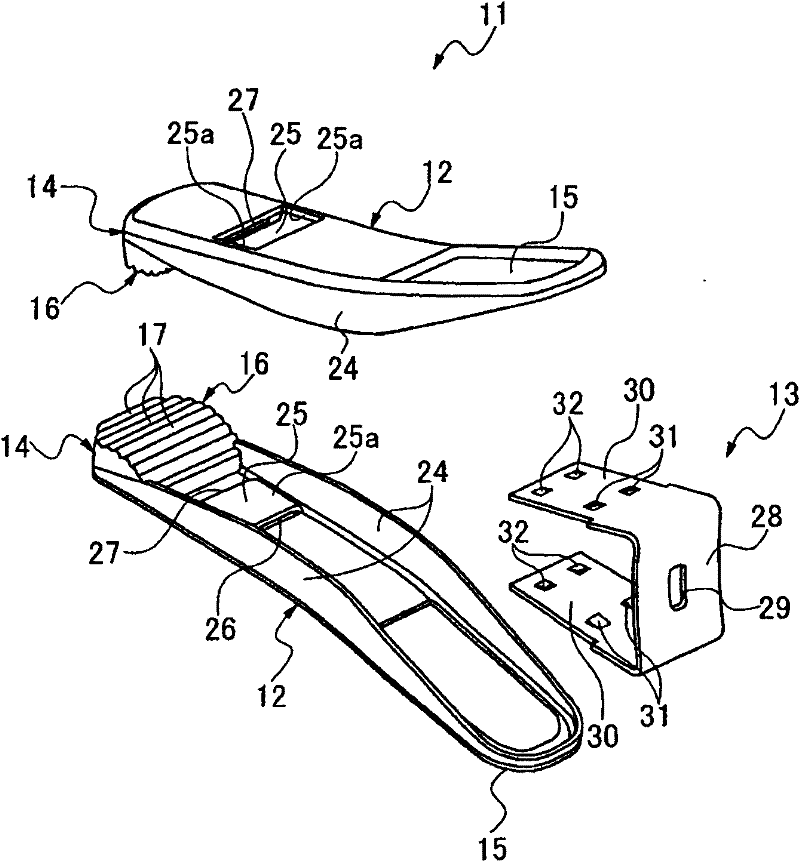

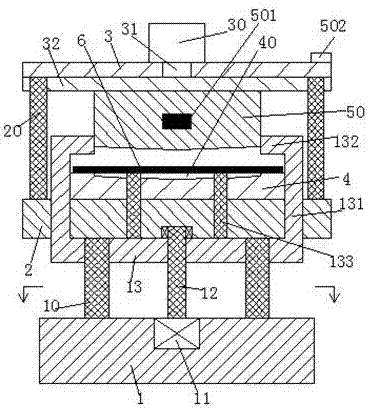

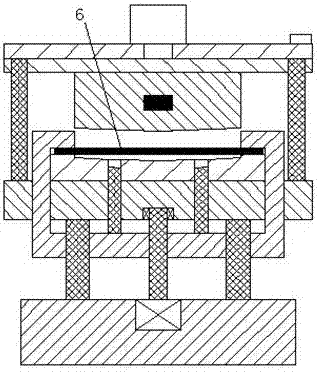

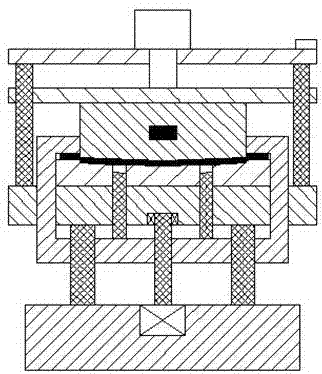

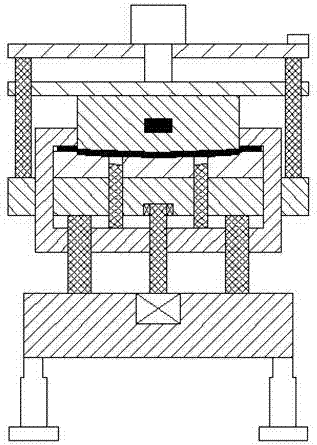

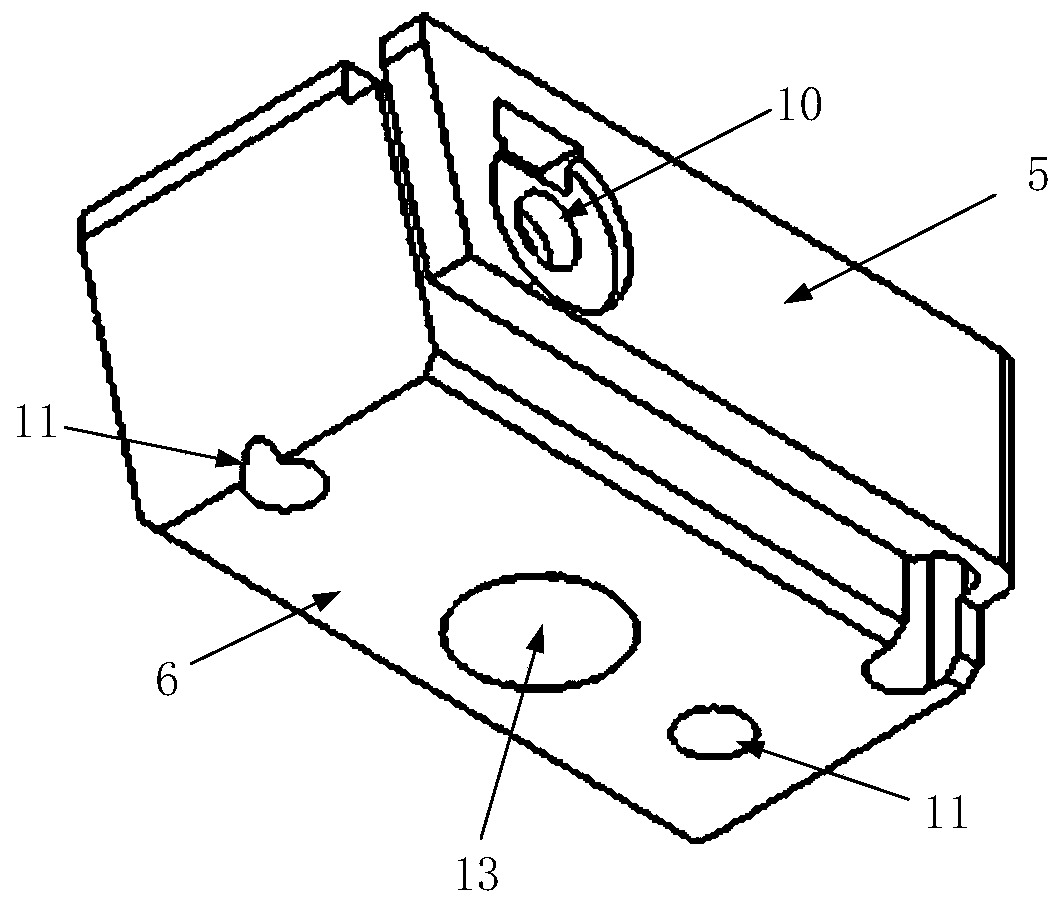

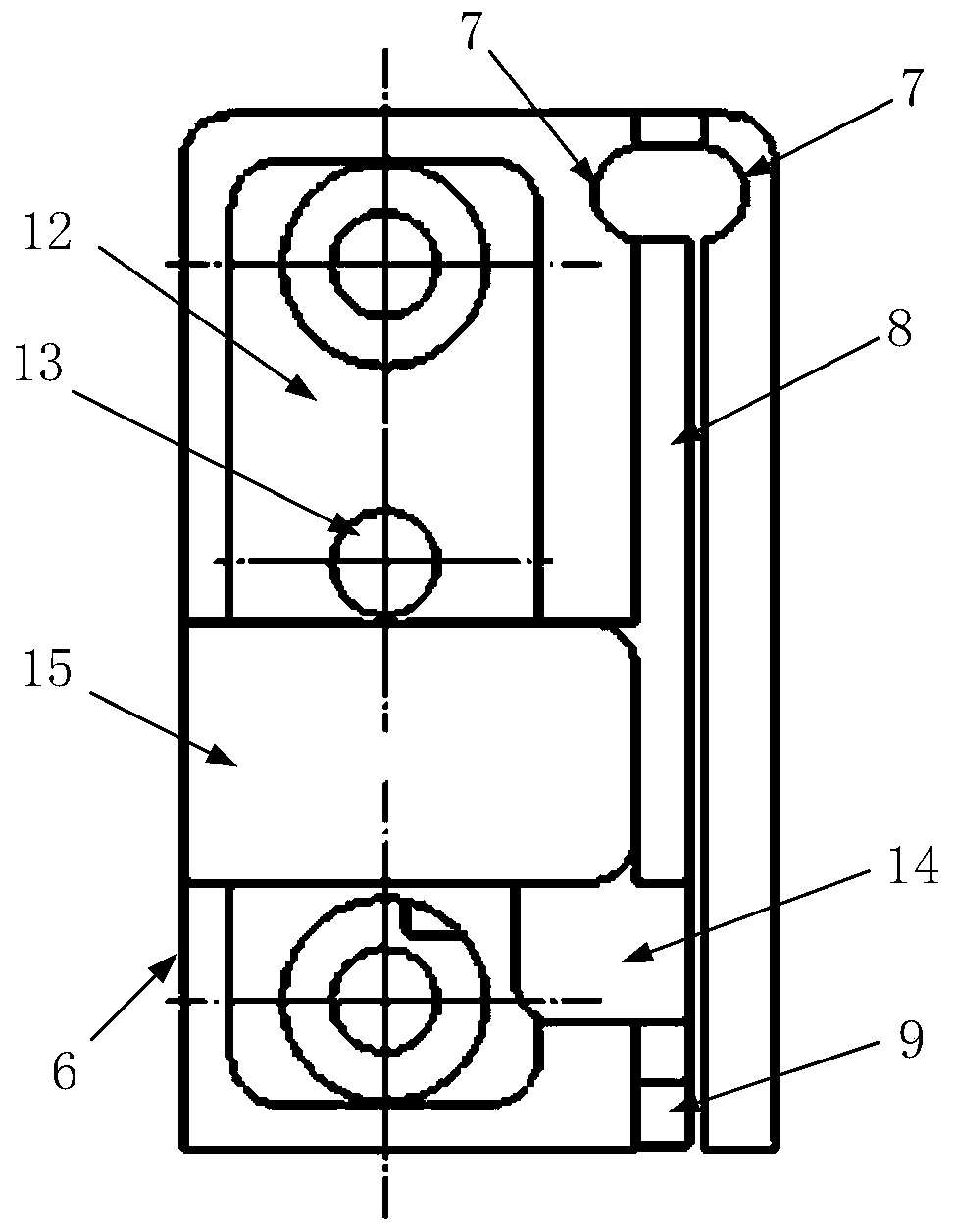

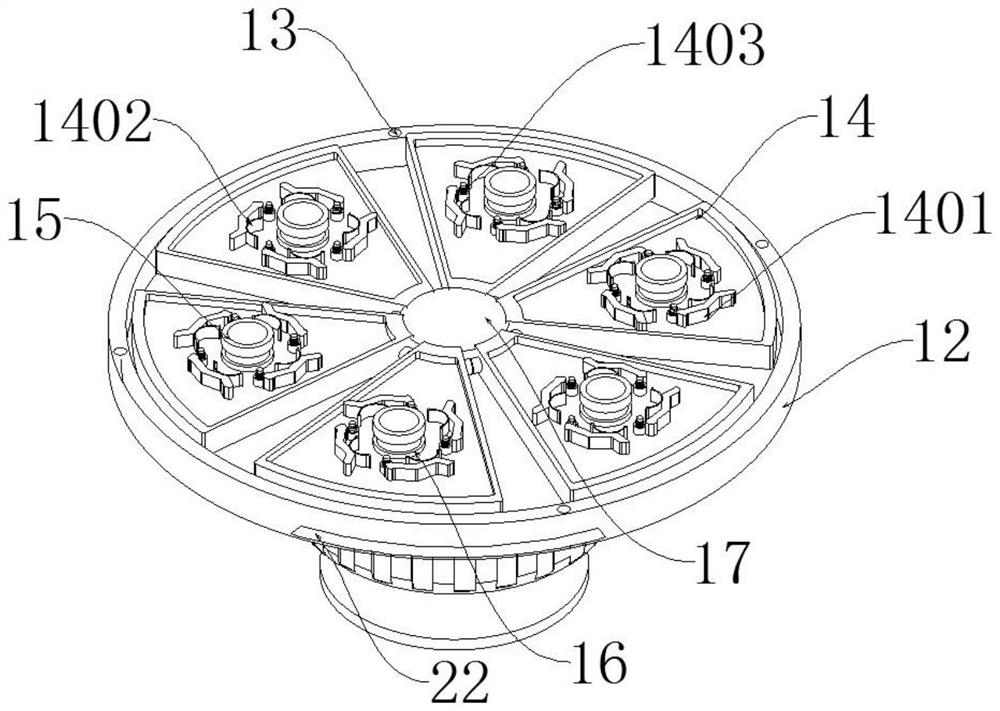

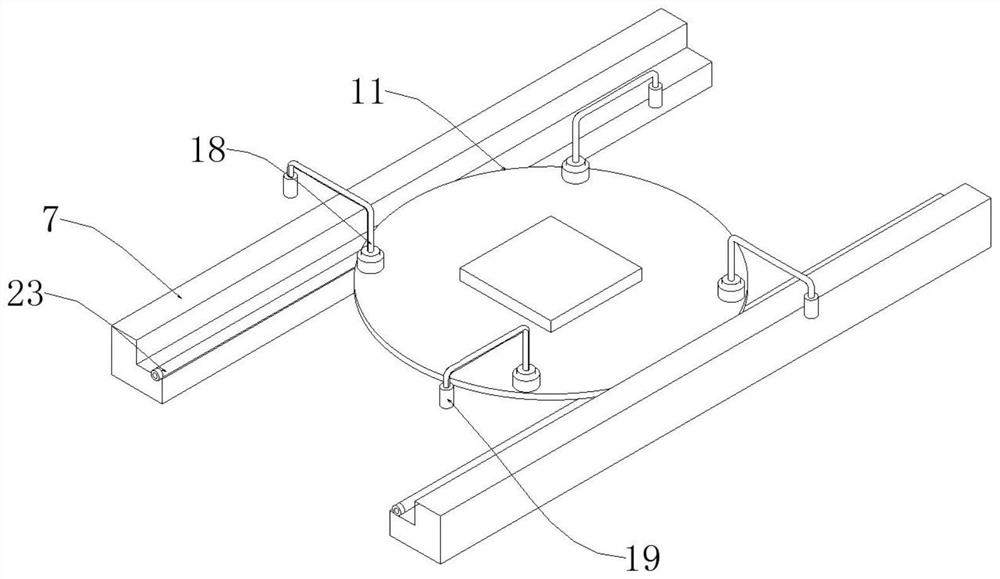

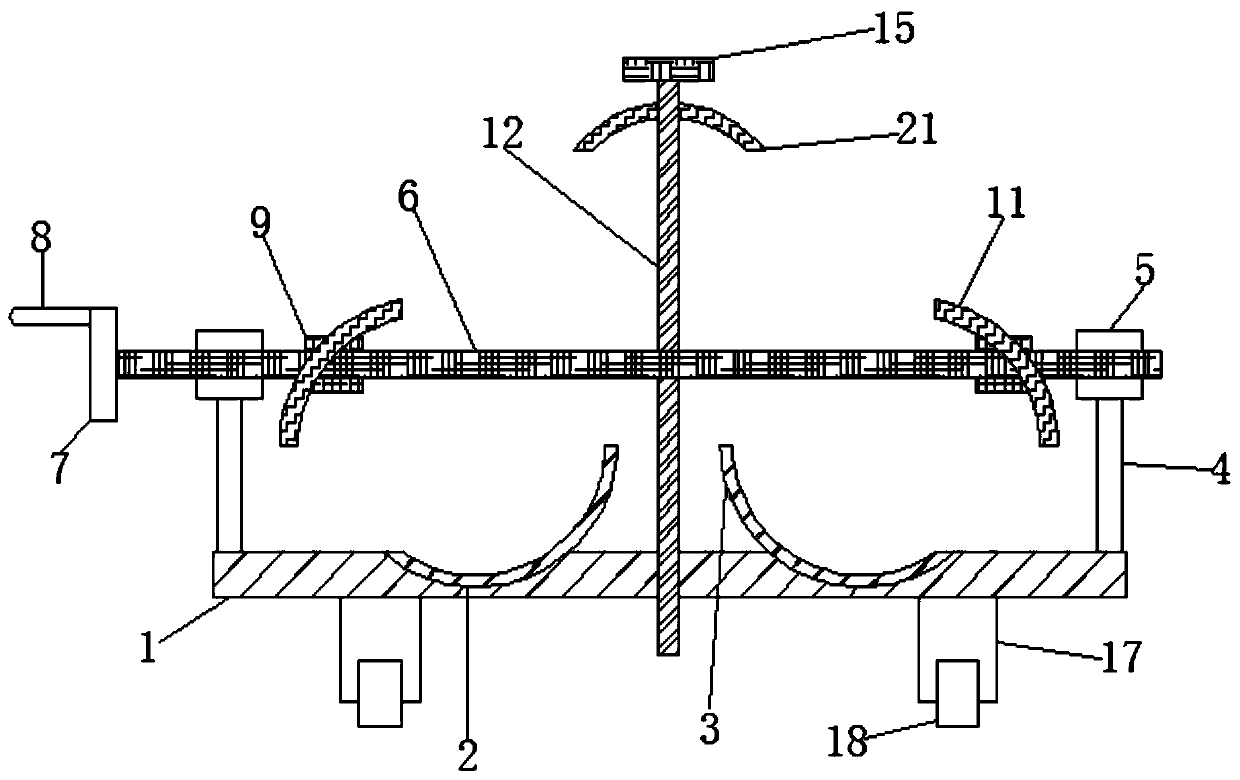

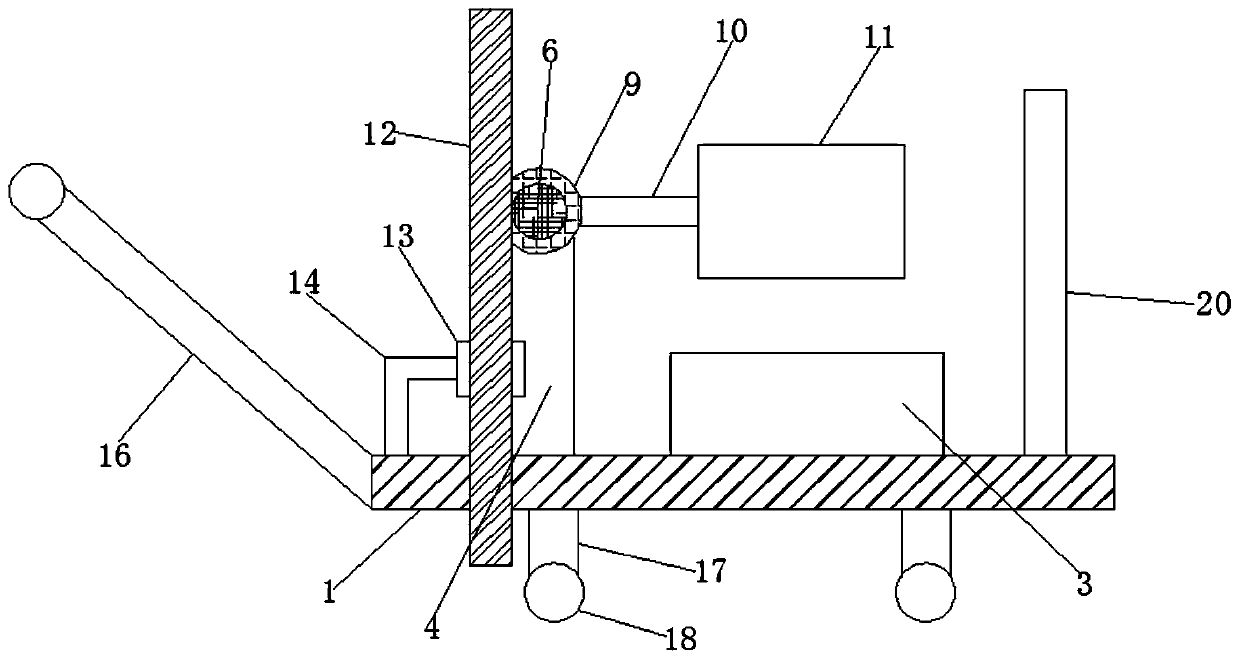

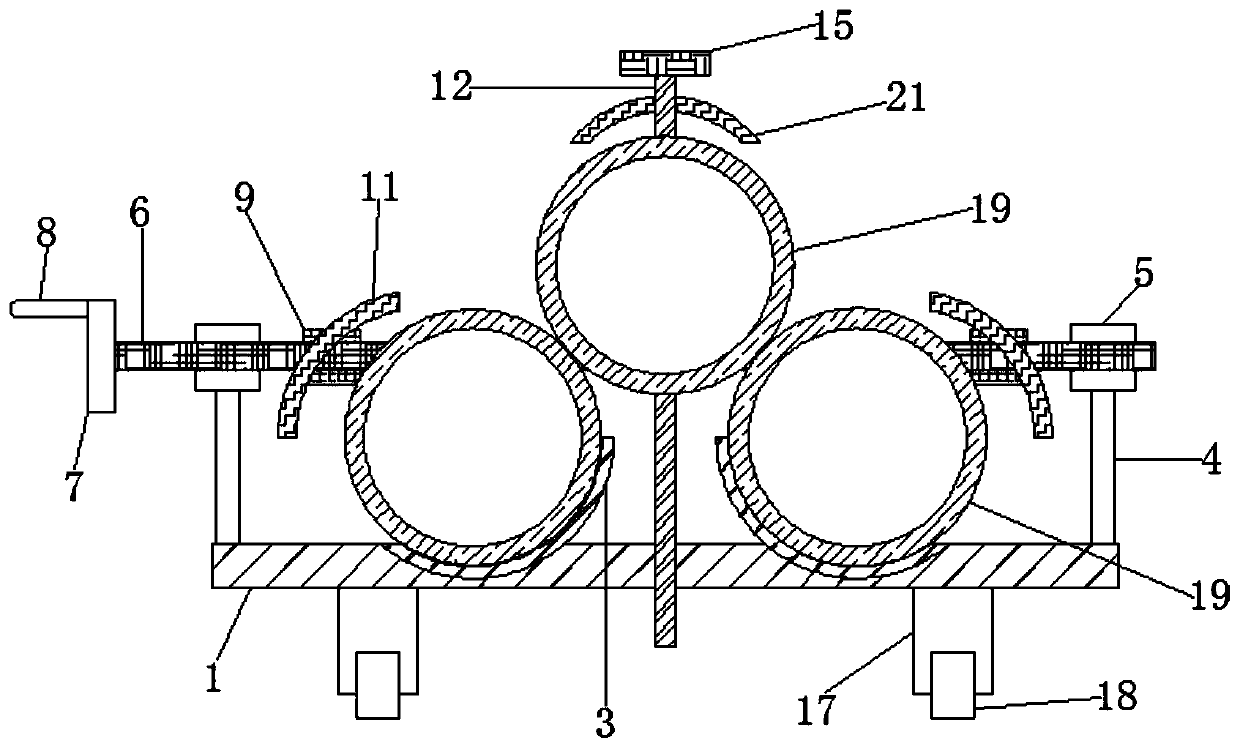

Clamp device

InactiveUS7021615B2The clamping state is stableIncrease the areaLarge fixed membersFriction grip releasable fasteningsEngineeringSteel ball

A clamp device is disclosed which maintains a stable clamped state, even if an object to be fixed, being a work pallet or die, is clamped in a repeated fashion, and which is compact in size and yet capable of clamping the object to be fixed with a large clamping force. In this clamp device (3), a plurality of partial sphere-shaped engaging recess sections (21) are formed in a bush (10), and the clamping mechanism (11) comprises a holding body (23) having a tubular holding section (23b), a plurality of steel balls (24) held movably in the radial direction in the holding section (23b) so as fact to the plurality of engaging recess sections (21), and a piston member (25) inserted movably into an axle hole (28) in the holding section (23b), whereby the plurality of steel balls (24) can be made to engage respectively with the plurality of engaging recess sections (21) by the clamp operating means (12) causing the piston member (25) to move in the axial direction thereof, and the plurality of steel balls (24) can be made to retreat from the engaging recess sections (21) by clamp releasing means (13) causing the piston member (25) to move in the axial direction thereof.

Owner:PASCAL ENG

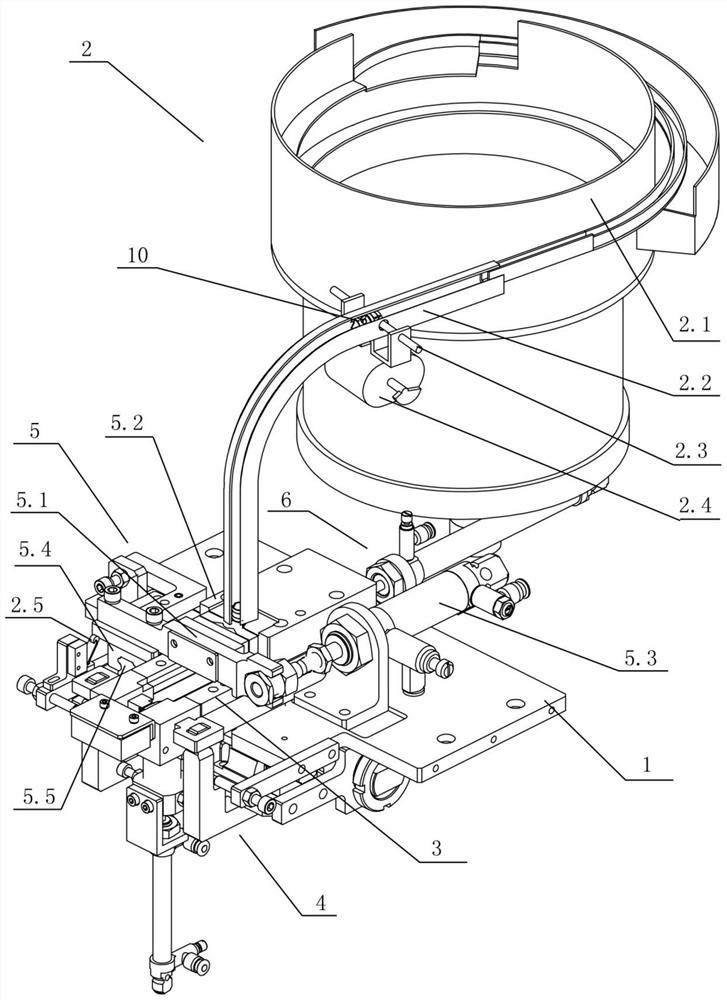

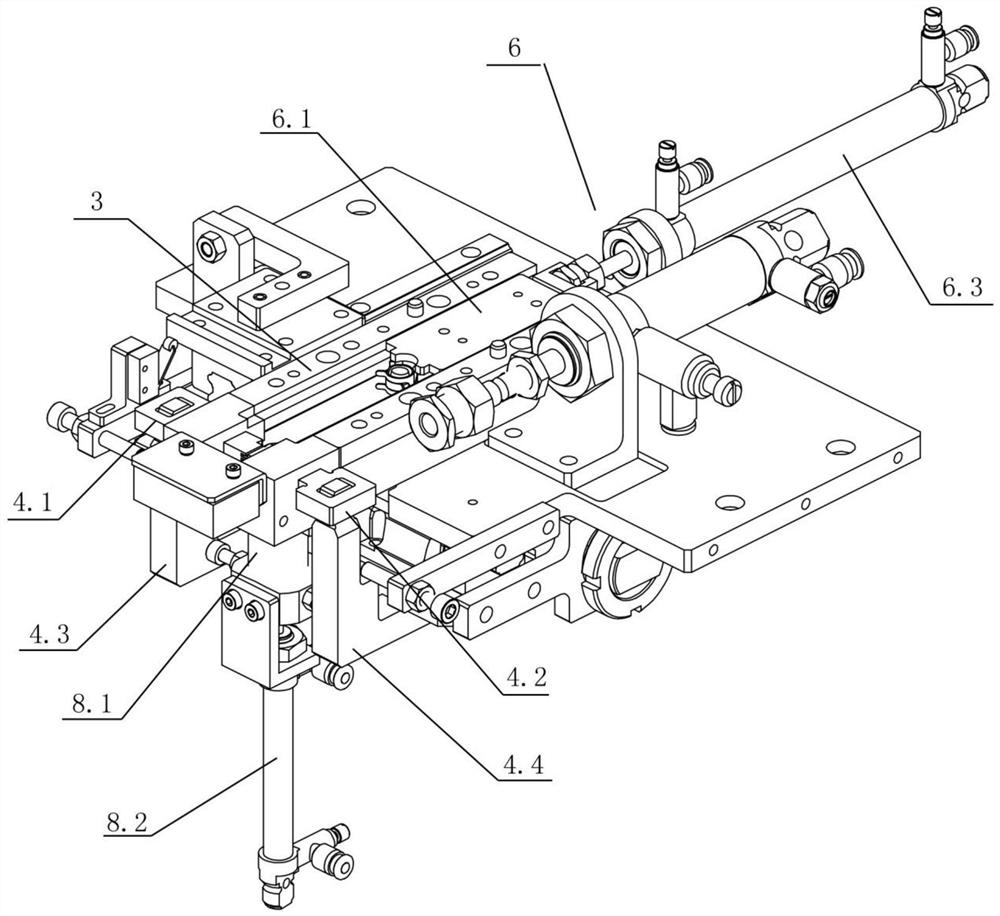

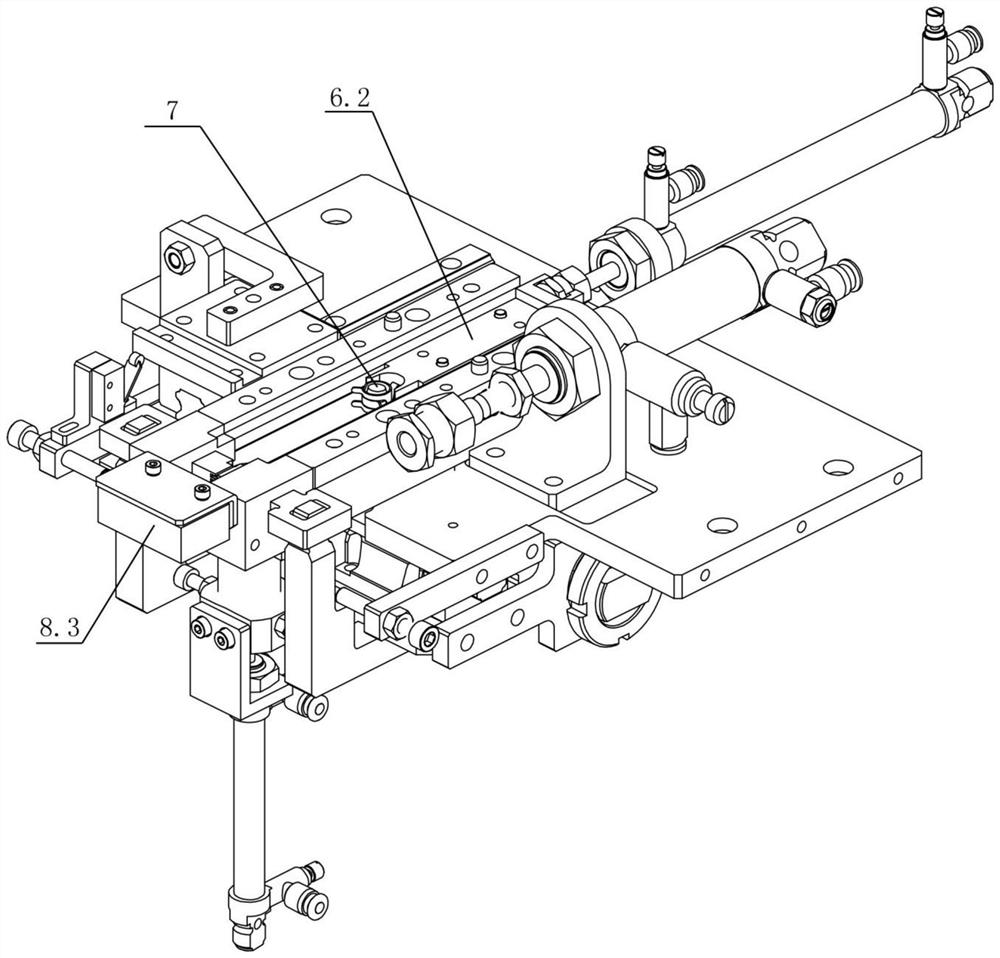

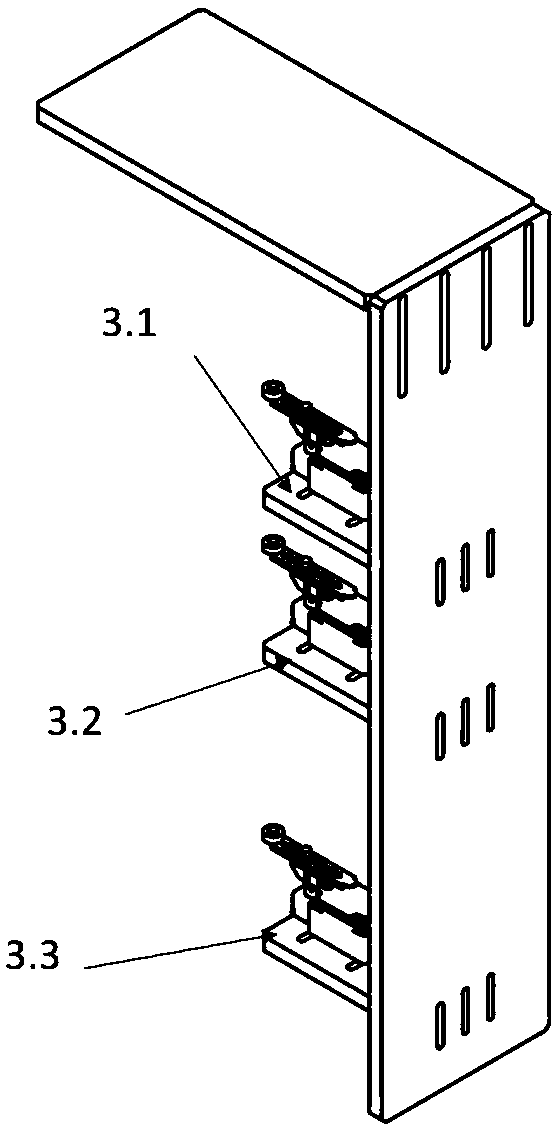

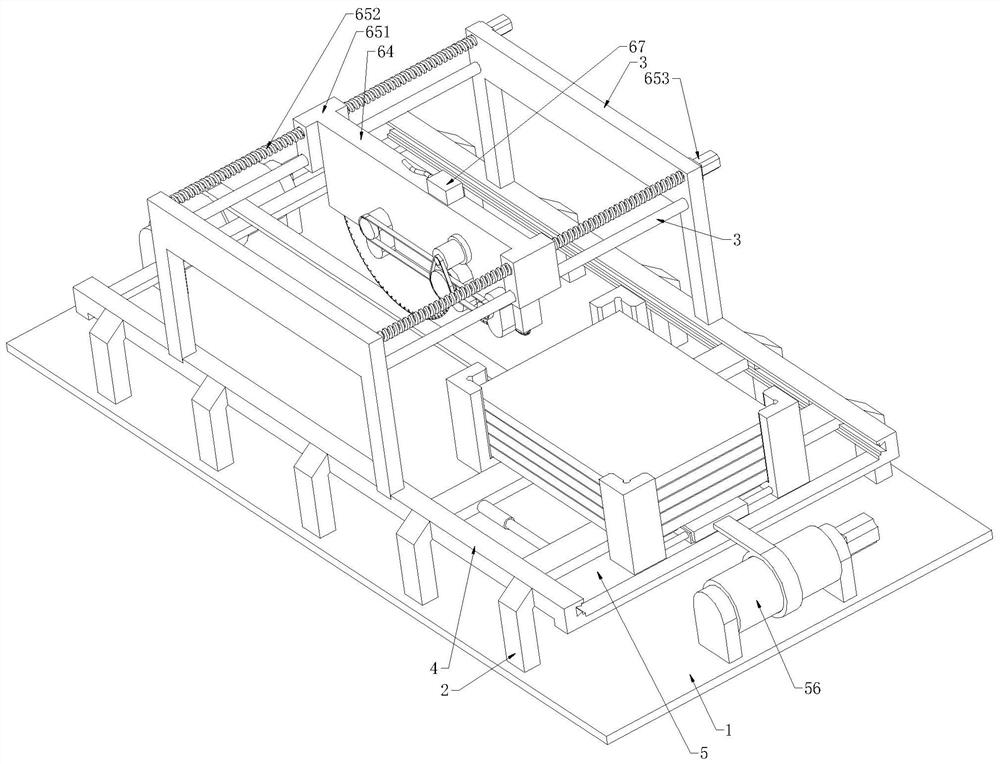

Full-automatic clamp feeding and clamping mechanism

ActiveCN111822964APlay a guiding roleReduce the likelihood of missilesMetal working apparatusControl theoryMechanical engineering

Owner:BORGWARNER AUTOMOTIVE COMPONENTS (NINGBO) CO LTD

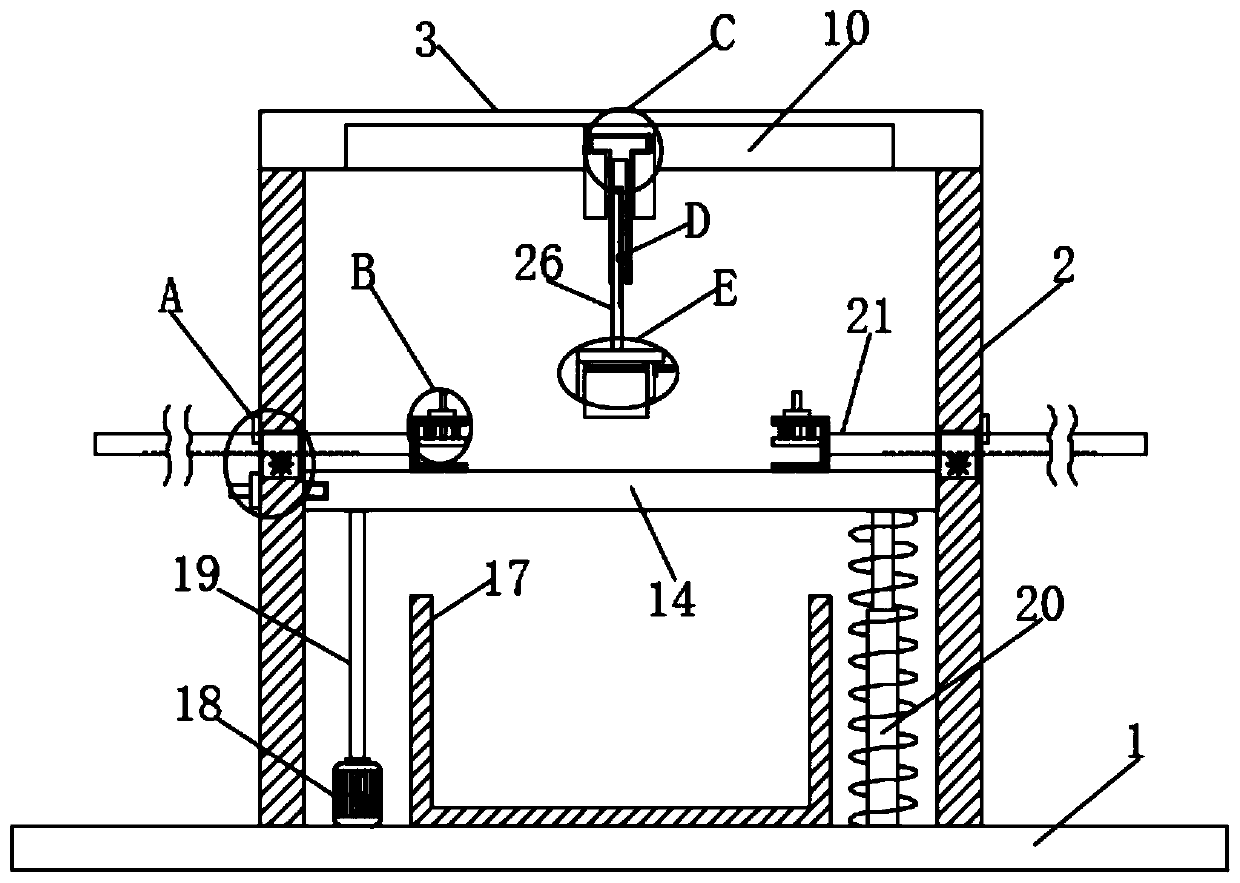

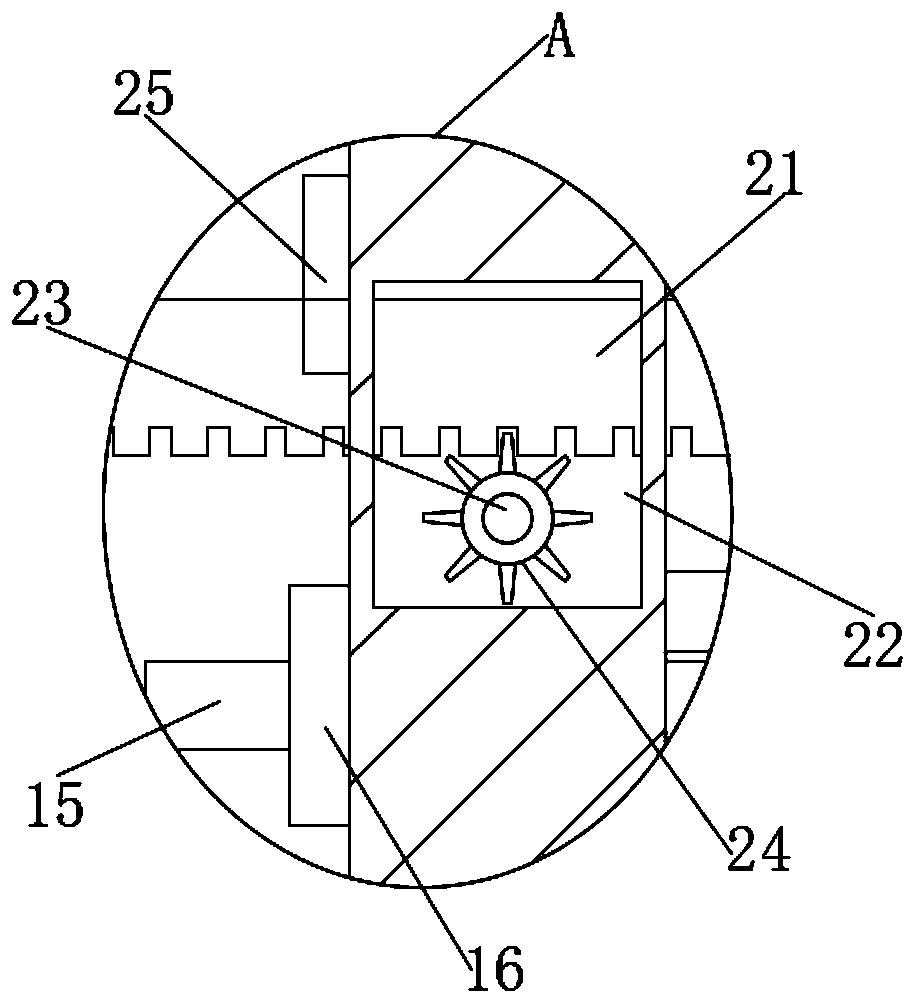

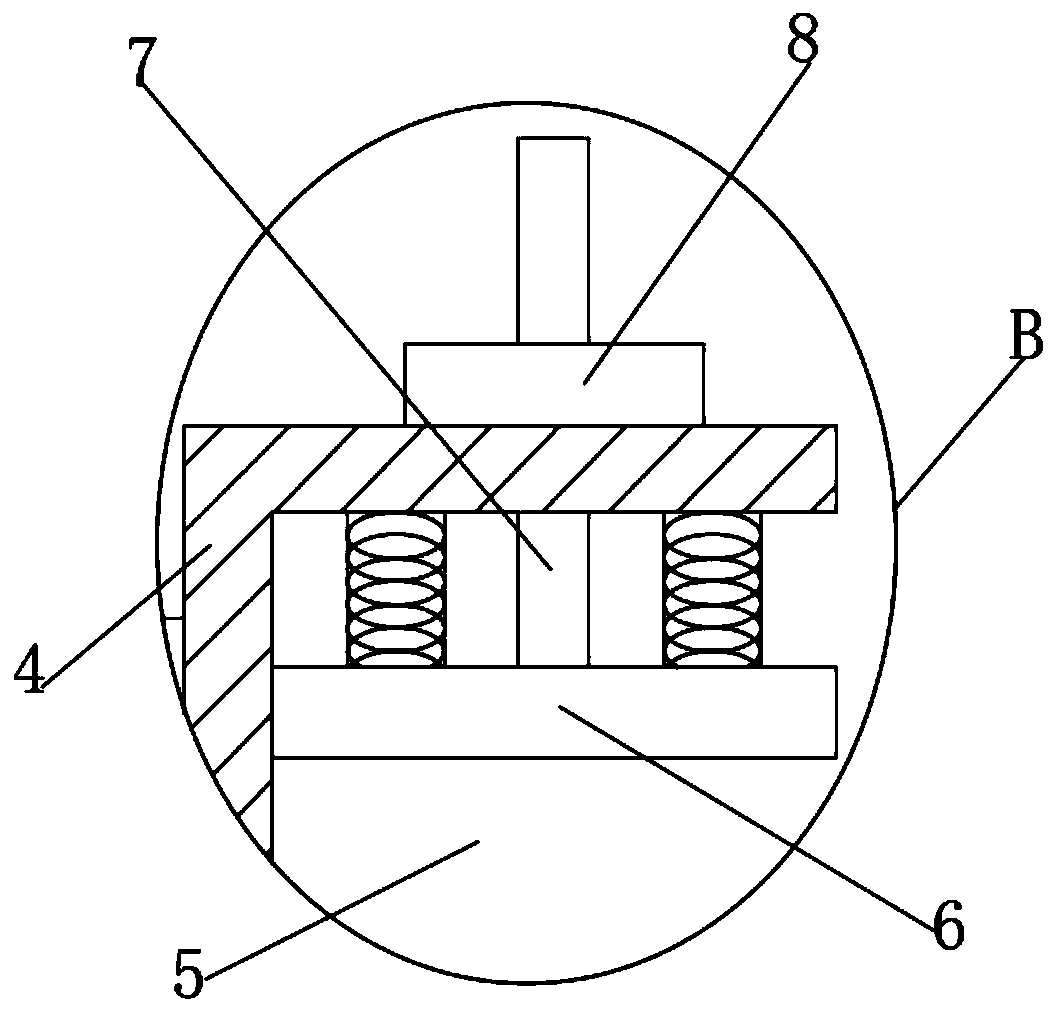

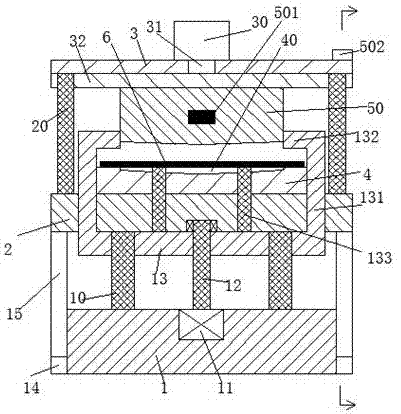

Cotton cloth production cutting device

InactiveCN110258097AThe clamping state is stableStable working conditionSevering textilesCotton clothEngineering

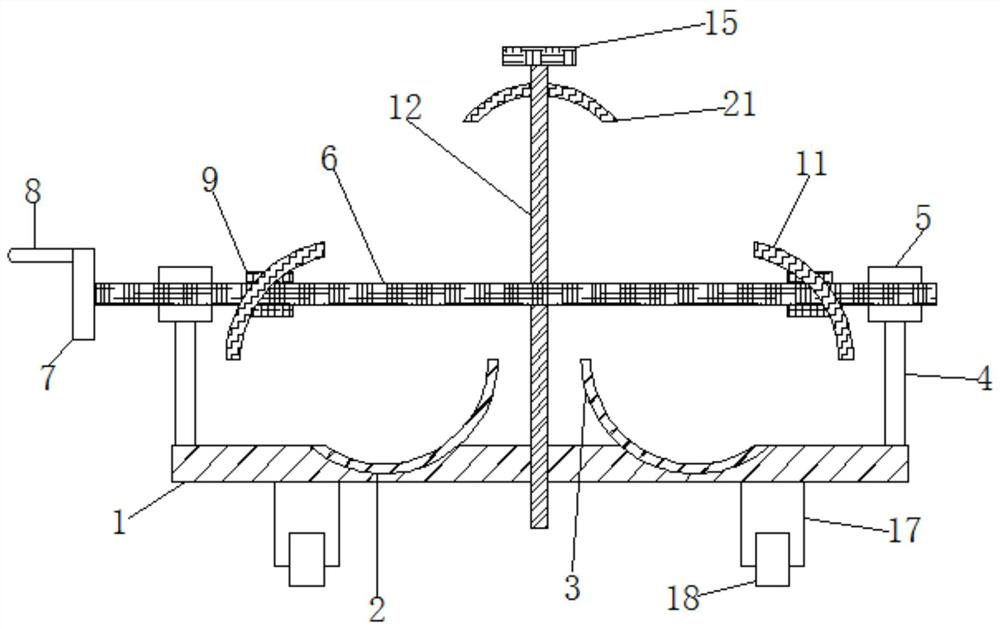

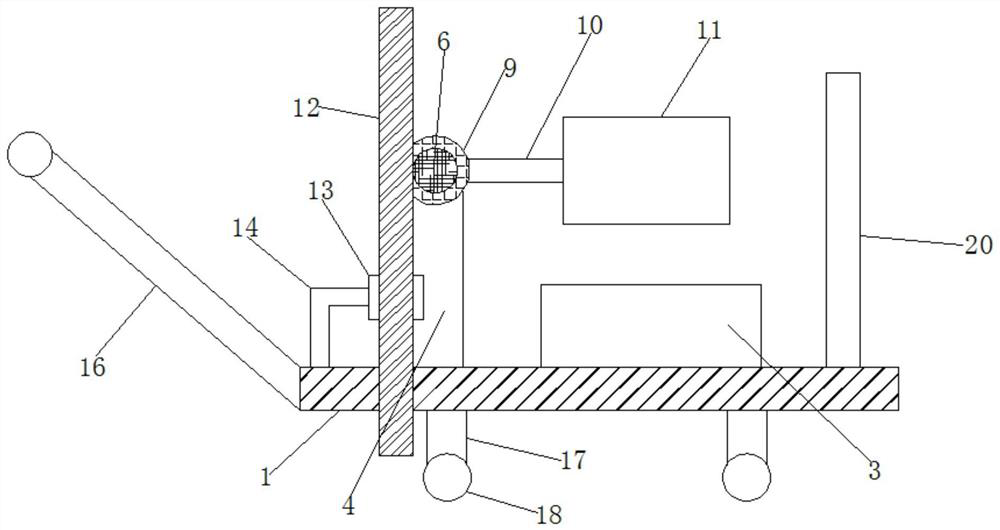

The invention belongs to the field of cotton cloth processing, in particular to a cotton cloth production cutting device. Aiming at the problems that the existing cutting device is not convenient to fix and cut cotton cloth with different thicknesses and lengths when cutting cotton cloth, and the cotton cloth is inconvenient to feed, the following scheme is proposed. The cotton cloth production cutting device comprises a horizontally-arranged base seat, wherein two symmetrically-arranged first support plates are fixedly connected to the upper side wall of the base seat; a horizontally-arranged second support plate is fixedly connected to the upper ends of the two first support plates; two symmetrically-arrange first clamping mechanisms are arranged between the second support plates and the base seat; and the two first clamping mechanisms are both connected with the side walls of the first support plates through a first telescopic mechanism. Cotton cloth with different thicknesses and lengths can be clamped for cutting operation, and the cotton cloth is convenient to feed.

Owner:江苏科沃纺织股份有限公司

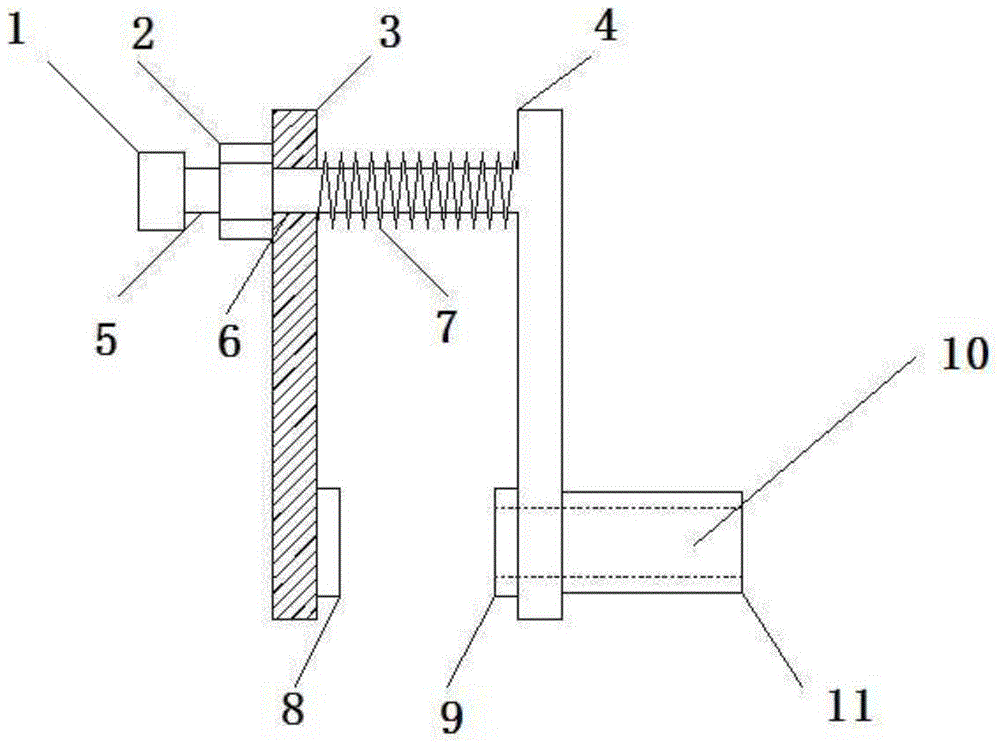

Mobile phone shooting method

The invention provides a mobile phone shooting method. The mobile phone includes a limiting head, a nut, a sliding rod, a fixed rod, a slider bar, a through hole, a reset spring, a first rubber pad, a second rubber pad, an imaging holes and a connecting head. The upper end of the fixed rod is fixedly arranged on the sliding rod, and the lower end of the fixed rod is fixed connected to the offside of the sliding bar and is equipped with the connecting head. A through hole is opened at the top end of the sliding rod, and the slider bar passes through the through hole, and the end of the slider bar away from the fixed rod is fixedly arranged with the limiting head and is located between the limiting head and the sliding rod. The slider bar is equipped with the nut, and the nut is connected to the slider bar by threaded connection. The reset spring is located between the sliding rod and the fixed rod, and is sheathed on the slider bar. The mobile phone shooting method can use a fixture when shooting in the use of the mobile phone to improve the photograph effect of the mobile phone and obtain more stable clamping state.

Owner:TIANJIN TIANYUAN PRODIVITY PROMOTION

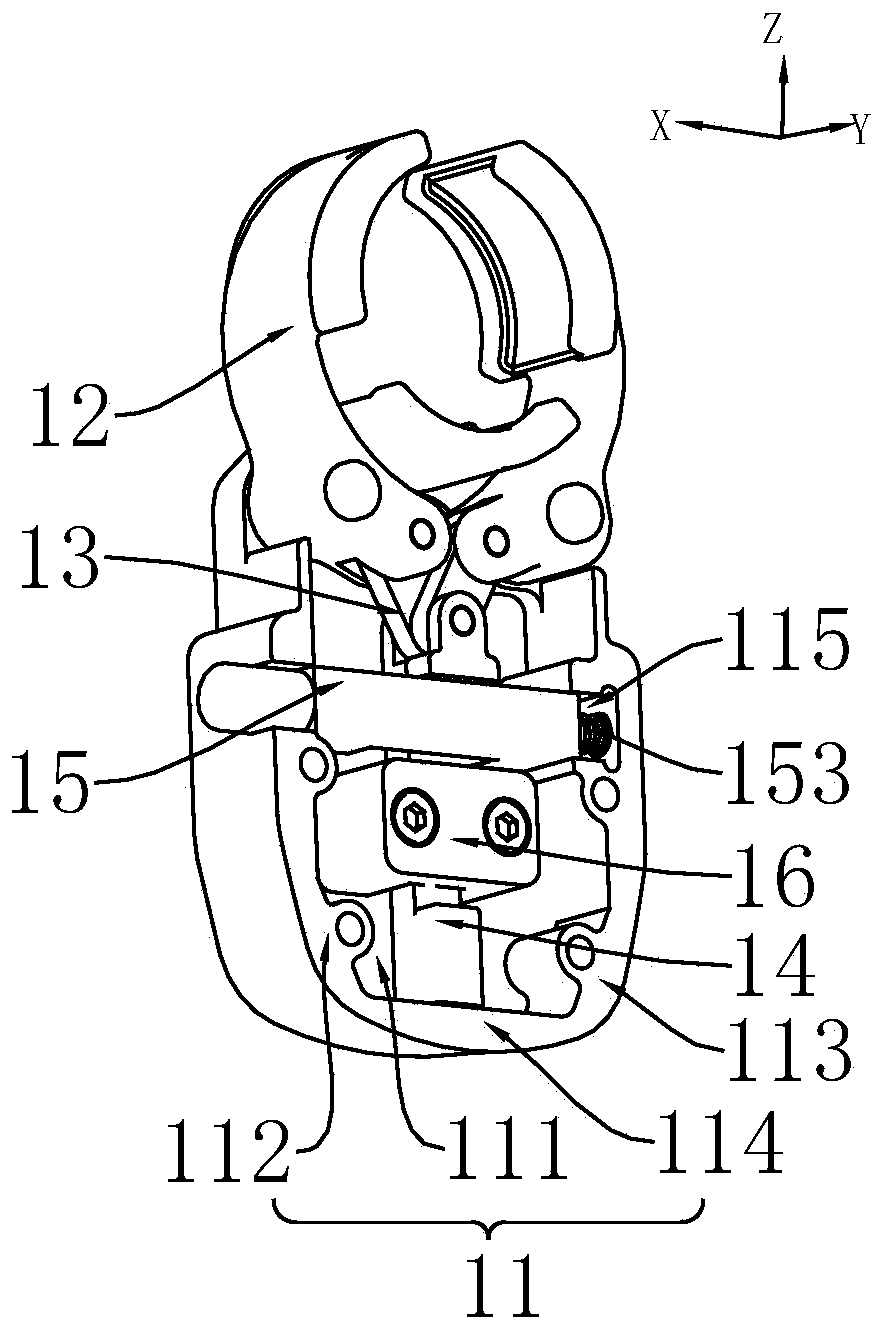

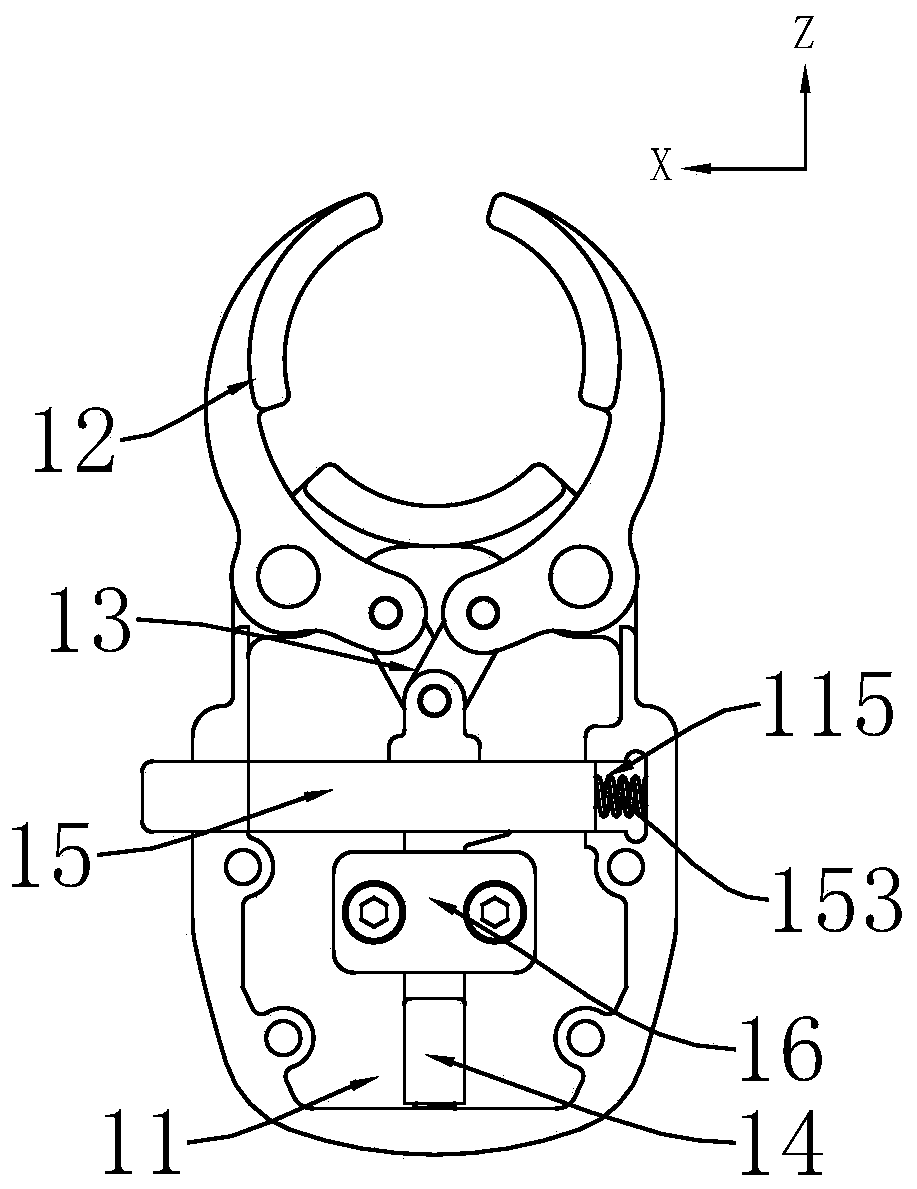

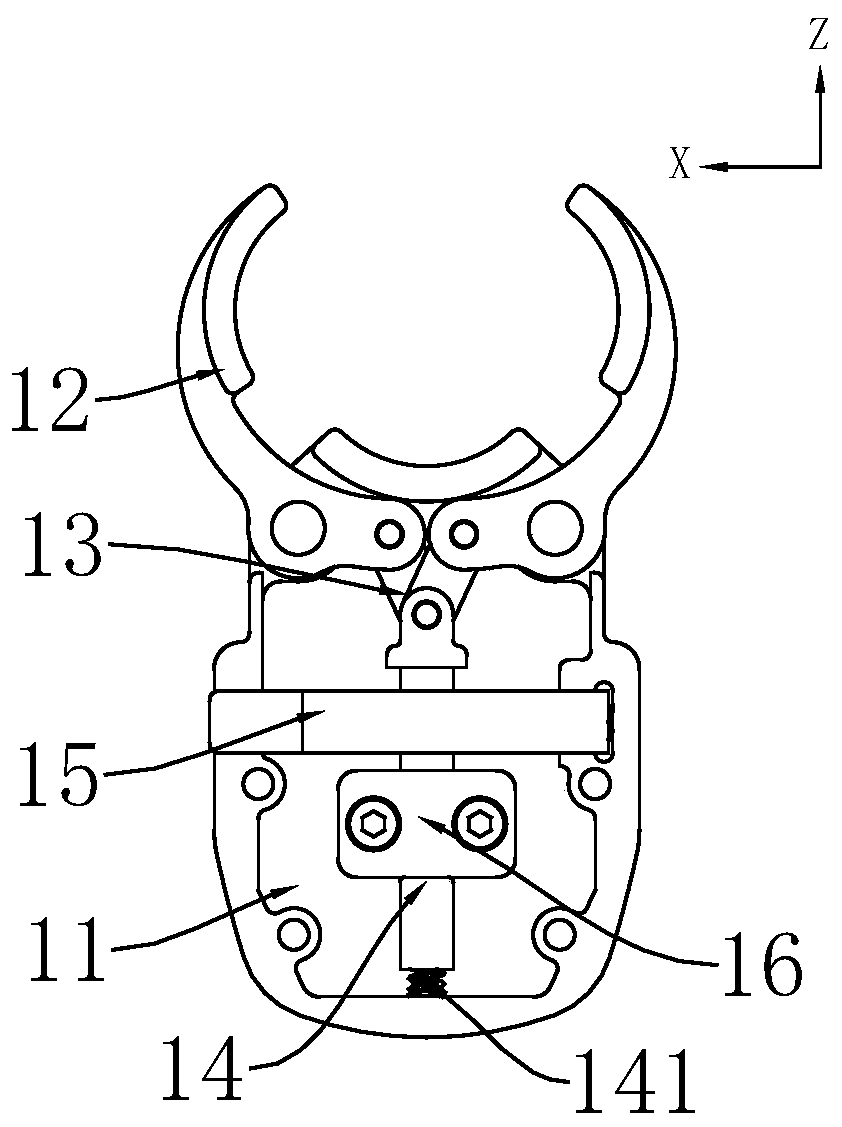

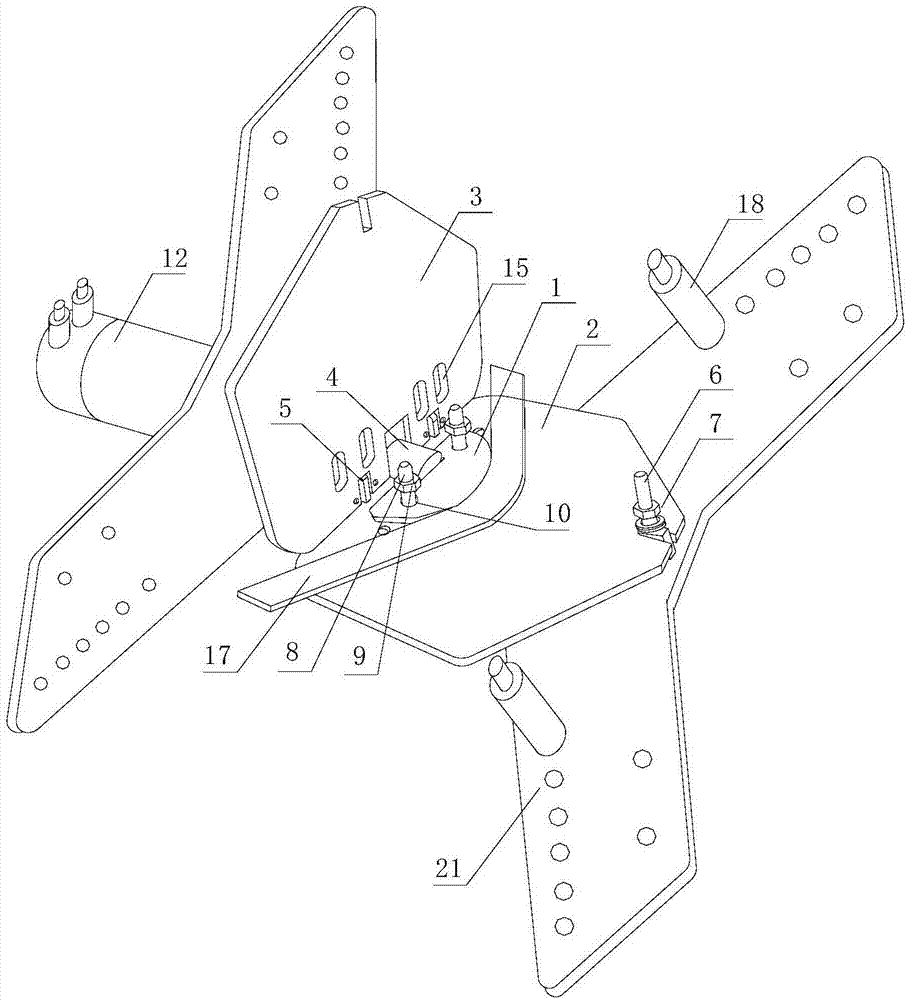

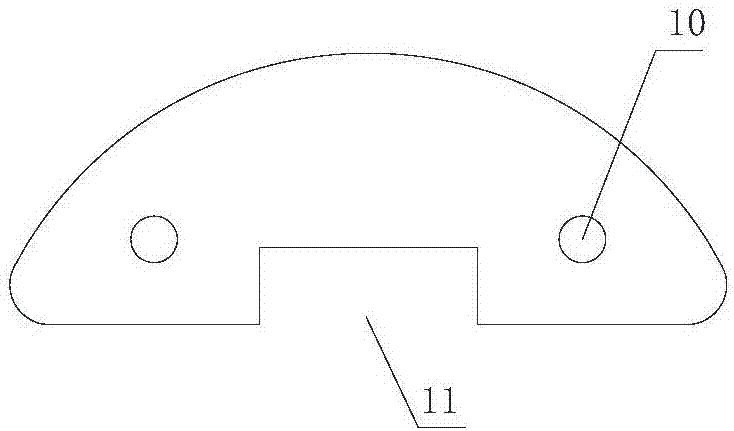

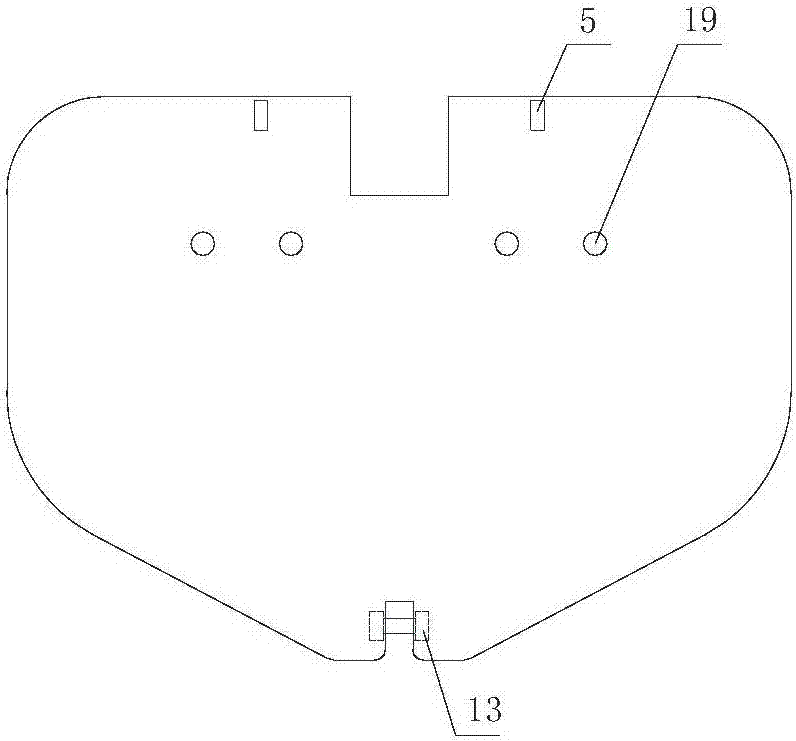

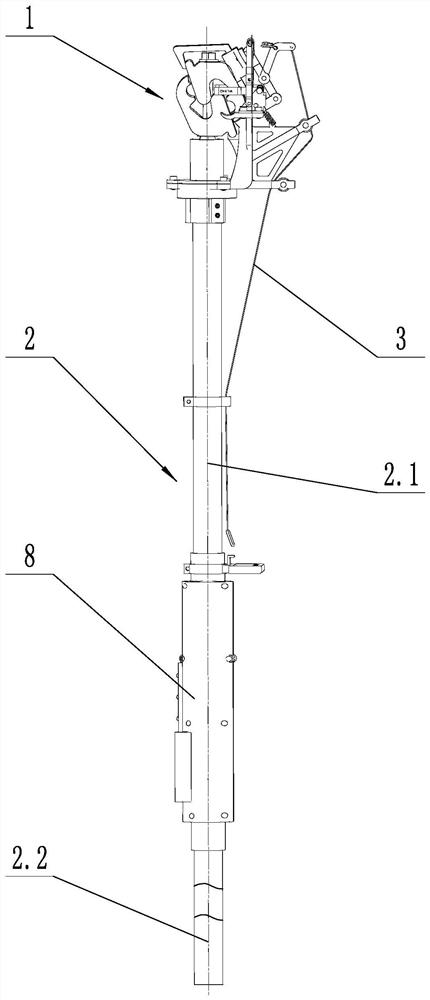

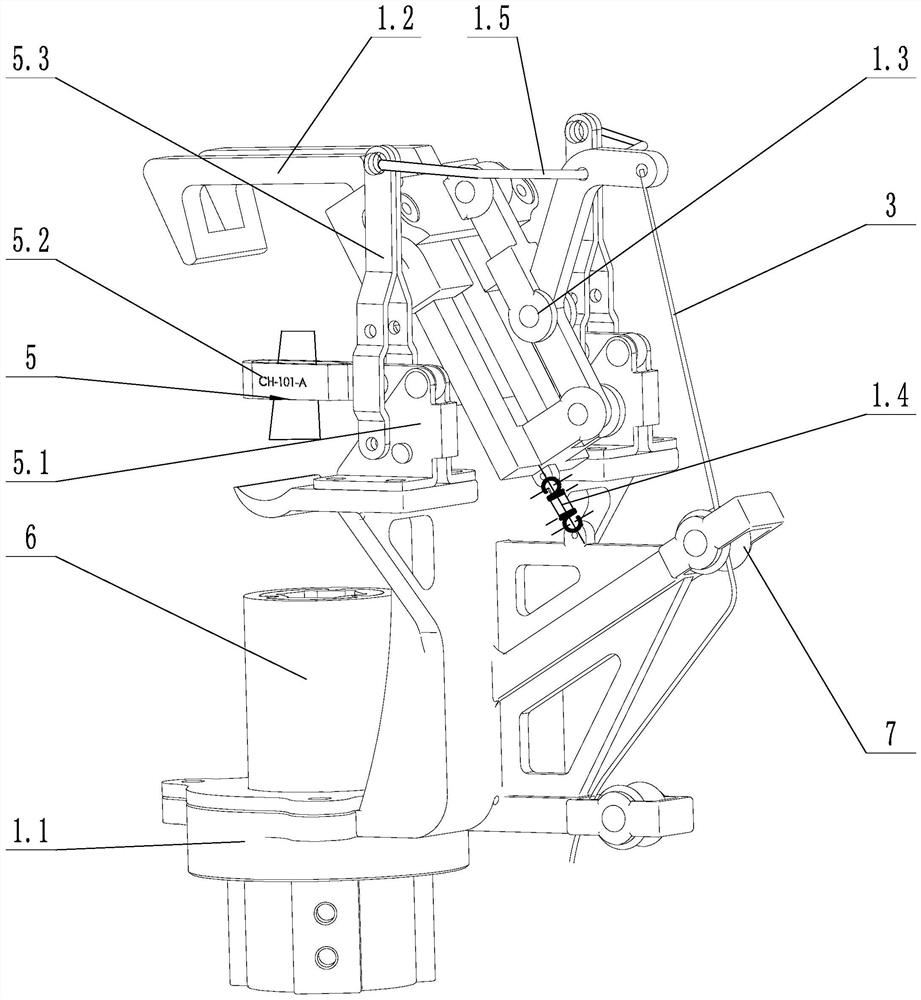

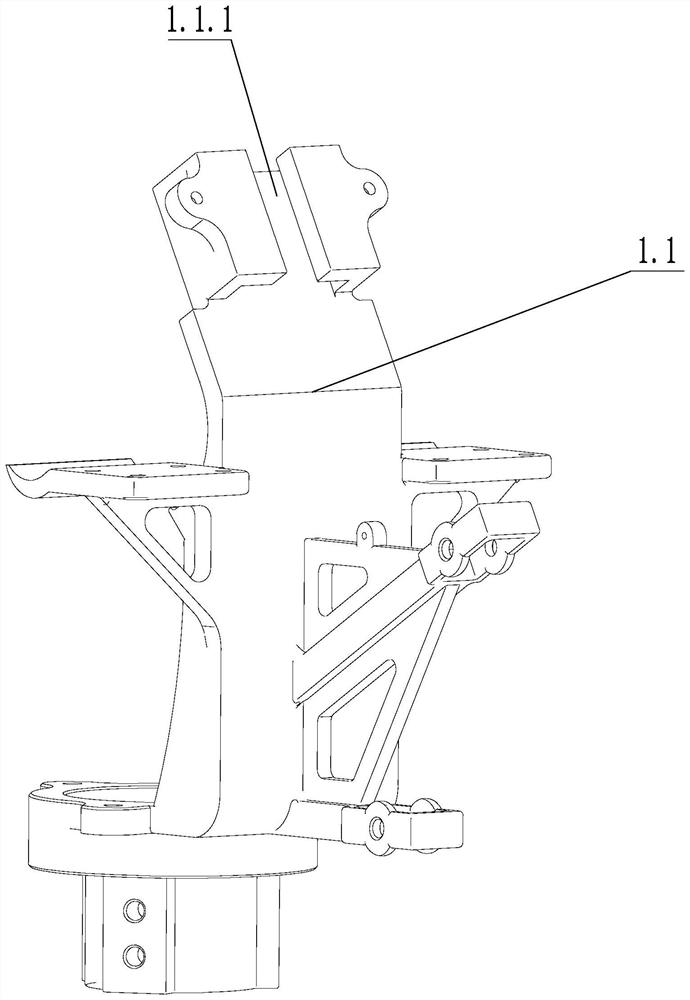

Instrument trocar clamp for surgical robot

PendingCN111529066AThe clamping state is stableAvoid accidental injuryDiagnosticsSurgical manipulatorsSurgical robotEngineering

The invention provides an instrument trocar clamp for a surgical robot and belongs to the technical field of medical instruments. The instrument trocar clamp comprises a base, a first chuck, a secondchuck, a pull rod device and a pull rod control device, wherein the first chuck and the second chuck are connected to the base and are suitable for rotation relative to the base; the pull rod device is connected with the first chuck and the second chuck and drives the first chuck and the second chuck to perform mutual clamping or loosening; the pull rod control device is matched with the pull roddevice; and the first chuck and the second chuck lock or loosen the pull rod device while performing mutual clamping. The pull rod device can drive the first chuck and the second chuck to perform mutual clamping or loosening, and the pull rod control device can lock the pull rod device, so that the clamping state of the first chuck and the second chuck is kept stable, and an accidental injury to apatient is avoided; and furthermore, the first chuck and the second chuck can perform clamping or loosening through pulling the pull rod device, so that the instrument trocar clamp is convenient to operate.

Owner:SUZHOU KANGDUO ROBOT

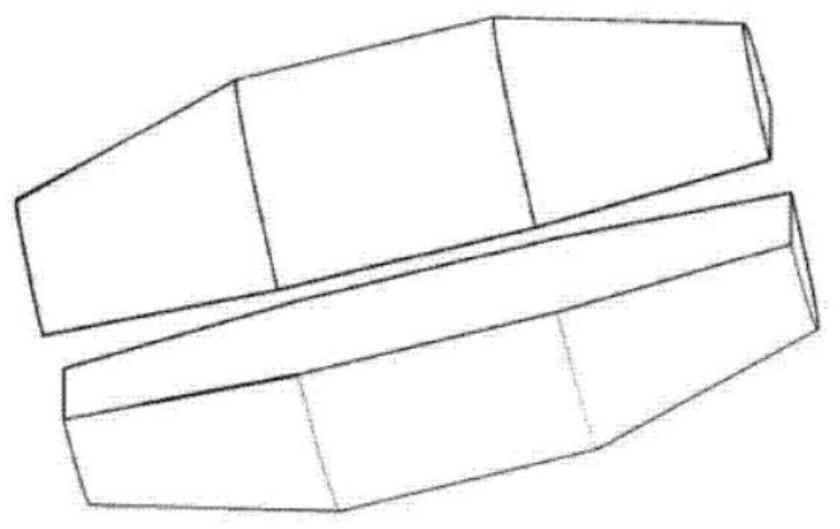

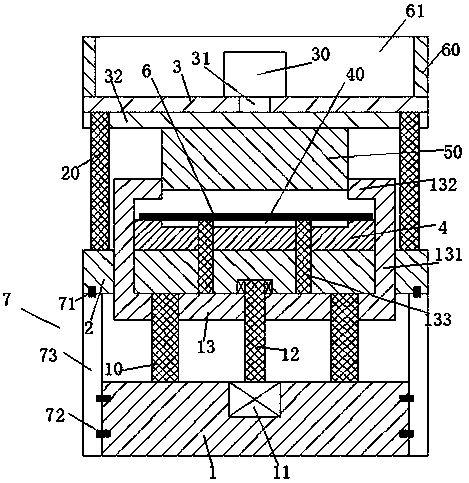

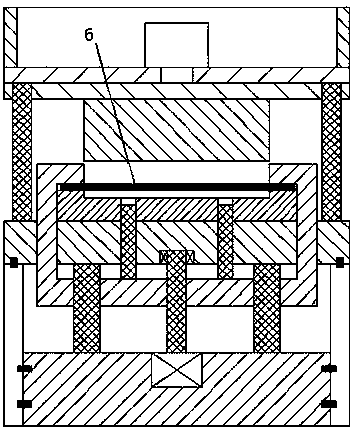

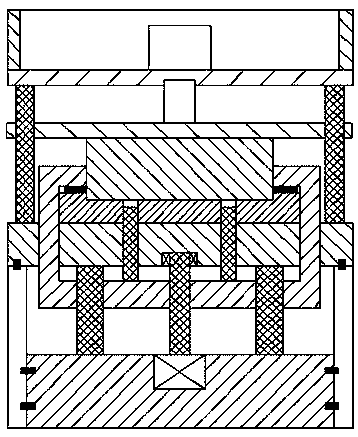

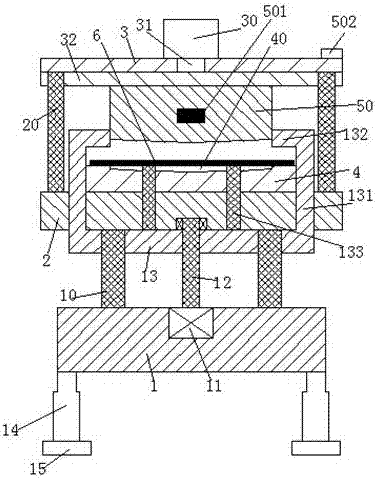

Plane bending forming clamping device and die with clamping device

PendingCN107363136ASolve the problem of low precisionMeet the needs of different anglesShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

The invention discloses a plane bending forming clamping device and a die with the clamping device. The plane bending forming clamping device comprises a first clamping plate, a second clamping plate and an angle forming die piece arranged between the first clamping plate and the second clamping plate. The first clamping plate and the second clamping plate are hinged through a connecting piece. The angle forming die piece arranged between the first clamping plate and the second clamping plate is locked through a locking device via the first clamping plate and the second clamping plate. The angle forming die piece is arranged on the side, close to the connecting piece, of the first clamping plate. The angle forming die piece is arranged on the side, close to the connecting piece, of the first clamping plate. The side, away from the connecting piece, of the angle forming die piece is an arc making contact with a formed piece. The plane bending forming clamping device and the die with the clamping device solve a series of problems that an existing copper (aluminum) row bending tool difficultly bends and forms a copper (aluminum) row plane, the forming angle precision is low, an obtained formed piece is poor in quality stability, scratches exist on the surface of the formed piece, the forming quality is hard to guarantee, applicable occasions are single, and mounting and dismounting procedures are complex.

Owner:大唐国信滨海海上风力发电有限公司

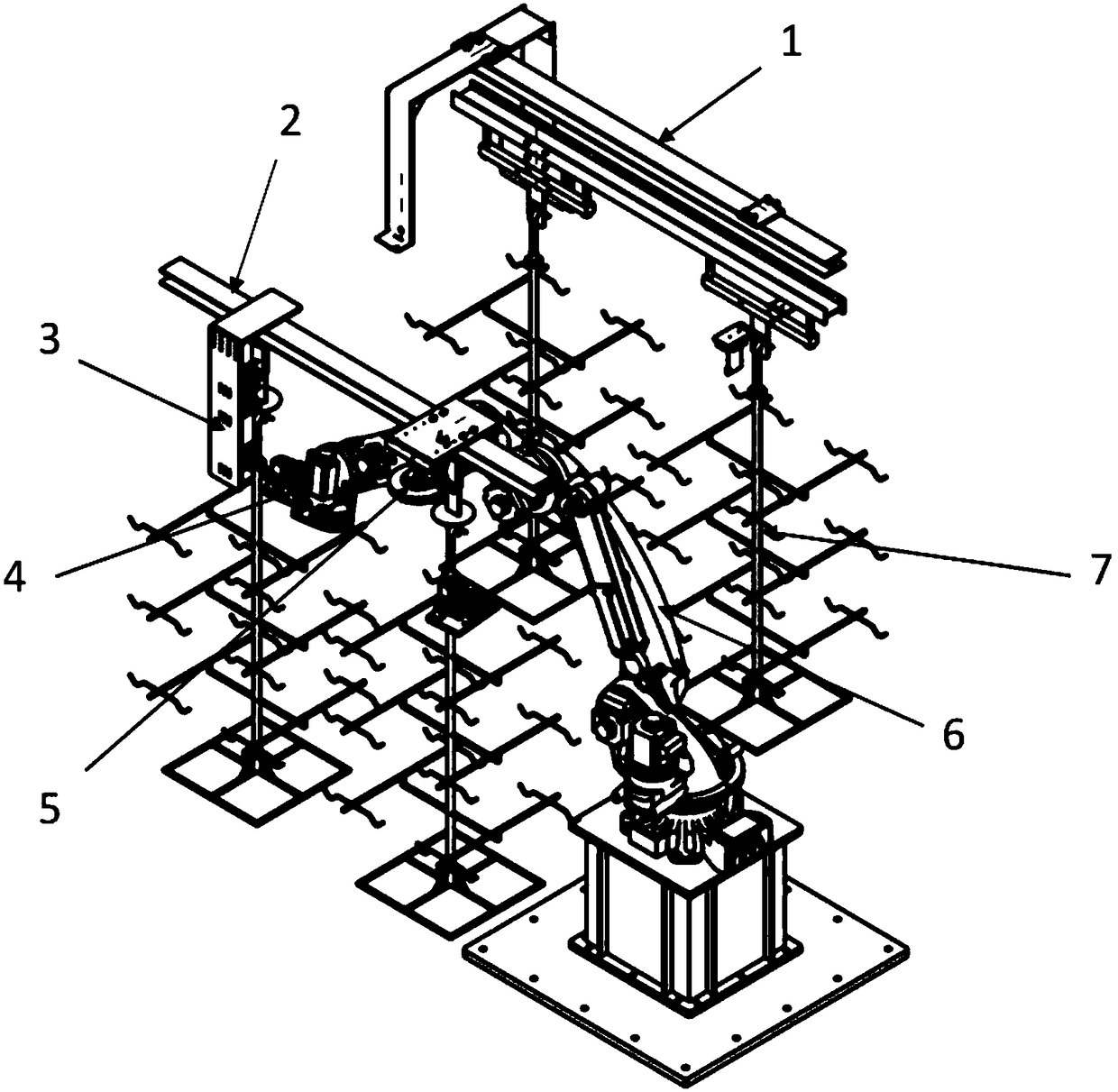

Automobile seat electrophoresis line suspension hanging device and method

ActiveCN108103556AAchieve precision controlThe clamping state is stableElectrolysis componentsElectrophoretic coatingsElectrophoresisCar manufacturing

The invention belongs to the technical field of automobile manufacturing equipment and particularly relates to an automobile seat electrophoresis line suspension hanging device and method. The devicecomprises a first catenary serving as a material hanging line, a second catenary serving as a material incoming line, a detecting mechanism and a robot, wherein the detecting mechanism is used for detecting the position and speed information of a suspension on the second catenary and outputting the detected position and speed information; and the robot comprises a receiving unit, a judgment unit and a clamping jaw mechanism, wherein the receiving unit is used for receiving the position and speed information output by the detecting mechanism, the judgment unit is used for positioning the suspension according to the position and speed information and sending a clamping instruction after positioning, and the clamping jaw mechanism receives the clamping instruction, then takes down the suspension on the second catenary and hangs the suspension on the first catenary. By means of the device, the hanging accuracy and speed of the suspension of an automobile seat electrophoresis line can be guaranteed.

Owner:苏州中藤机电科技有限公司

Bearing ring and its fixing seat mechanism device

InactiveCN107584295AThe clamping state is stableReduce the chance of sheddingBearing componentsPositioning apparatusEngineeringRejection rate

The invention discloses a bearing ring and its fixing seat mechanism device, which relate to the field of bearing processing and workpiece clamping. According to the bearing ring and its fixing seat mechanism device, a first telescopic device is fixedly mounted on both ends of a first substrate, one side surface of the first substrate is fixedly connected with a second substrate, a second telescopic device is fixedly mounted on the second substrate, the first telescopic device is provided with a first telescopic connecting rod, a second connecting rod is vertically connected with the end sideof the first telescopic connecting rod, a second sliding rod and a first reinforcing rod are arranged on the second connecting rod, a second reinforcing rod is arranged on the second telescopic device, and a pair of first fixing slots and a second fixing slot are formed in the bearing ring. As the first fixing slots and the second fixing slot are formed in the bearing ring and the bearing ring canbe clamped and reinforced by the first reinforcing rod and the second reinforcing rod that can be adjusted and matched with each other, the clamping state of the bearing outer ring is more solid, thereby greatly reducing the fall-off rate and rejection rate of workpiece during processing.

Owner:界首市皖俊轴承有限公司

Tensile Fixture and Experimental Method for Split Hopkinson Tie Bar Thin Specimen

ActiveCN111426555BEasy to assembleReduce processing requirementsStrength propertiesWave shapeStress wave

Owner:SOUTHWEST JIAOTONG UNIV

Spindle structure of a machine tool

InactiveCN1654146ALarge margin of errorReduce machining accuracyChucksPositioning apparatusCircular coneEngineering

A tool holder is attached to a spindle by the contacting of the projecting cone part and end surface of the tool holder with the recessed cone part and end surface of the spindle respectively. A toroidal cone section is provided on the inner side surface of the recessed cone part of the spindle so as to protrude inward. The diameter of the toroidal cone section is formed smaller than the diameter of the section of the projecting cone part of the tool holder that abuts the toroidal cone section.

Owner:FANUC LTD

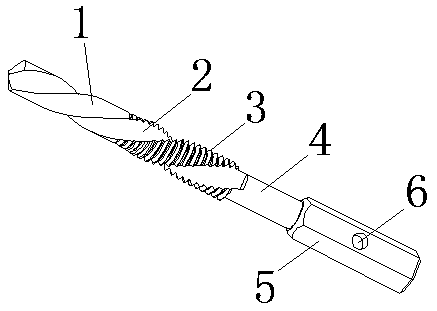

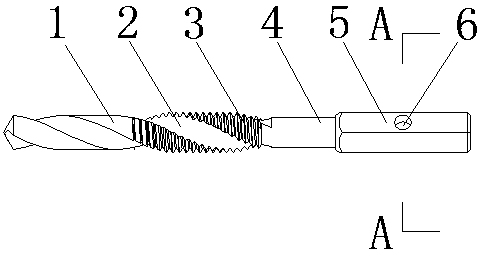

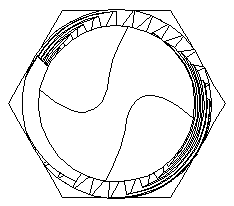

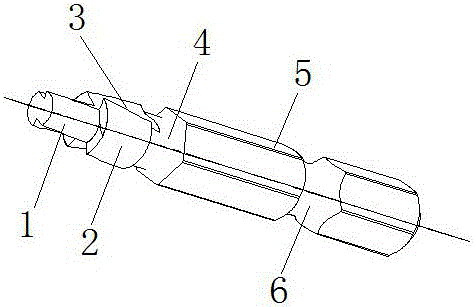

High-machining-precision integrated type hole drilling tapping tool and manufacturing method thereof

InactiveCN107755757AIncrease productivityLarge clamping forceThread cutting toolsTransportation and packagingPrismEngineering

The invention relates to a high-machining-precision integrated type hole drilling tapping tool and a manufacturing method thereof, and belongs to the technical field of machining equipment. The high-machining-precision integrated type hole drilling tapping tool is composed of a working part and a handle part; the working part is jointly formed by a drill bit part, a screw tap part and a chip space, the drill bit part is located at the front end of the integrated type hole drilling tapping tool, the screw tap part is located at the middle portion of the integrated type hole drilling tapping tool and is continuously connected with the drill bit part, and the chip space is continuously arranged on the surfaces of the drill bit part and the screw tap part; a tool avoiding groove is formed between the screw tap part and the handle part, the handle part is in a regular straight prismatic shape, and three positioning holes are formed in the side face of a prism of the handle part; and in theusing process, balls in a clamping device act on the interiors of the positioning holes in a positioned manner, the clamping force of the integrated type tool is greatly reduced, the clamping state ismore stable, swing of the integrated type tool in machining is reduced, the positioning accuracy and the machining accuracy can be obviously improved, and the drilling and tapping production efficiency is improved.

Owner:YANGZHOU SHILI HARDWARE TOOL IND & TRADE CO LTD

Diamond polishing clamp and clamping method thereof

PendingCN110788751AEasy to operateThe clamping state is stableGrinding work supportsStructural engineeringMechanical engineering

The invention discloses a diamond polishing clamp, and relates to the technical field of diamond processing. The diamond polishing clamp comprises a housing, two oppositely-arranged clamping plates, alocking mechanism and an unloading mechanism, wherein the housing of a box body with an open top, the bottom of the clamping plate is hinged into the housing, step structures are arranged at the inner side of the top of the clamping plate, an inner cover shell is arranged at the outer side of the clamping plate, and the step structures located at the two sides, and the inner cover shell encirclean installation groove used for accommodating diamond; a limit block is installed at the outer side of the inner cover shell, the locking mechanism is arranged on the outer surface of the inner covershell in a sleeved manner, and a hook part used for hooking the limit block is arranged at the bottom of the locking mechanism; and the unloading mechanism is arranged below the hook part, and unlocksthe hook part from the limit block. The diamond polishing clamp realizes stable clamping for the diamond, and achieves a great polishing effect.

Owner:杭州超然金刚石有限公司

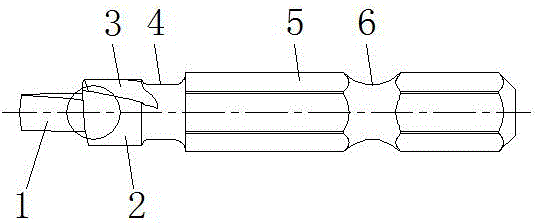

Counterbore countersink drill and machining process thereof

InactiveCN106392149AClear Gripping ForceLarge clamping forceTransportation and packagingTrepanning drillsEngineeringScrew thread

The invention provides a counterbore countersink drill and a machining process thereof and belongs to the technical field of machining equipment. The counterbore countersink drill is composed of a guide column, a counterbore cutting column and a drill handle. A cutter relieving groove is formed between the counterbore cutting column and the drill handle. A coherent chip removing groove with a lead angle Alpha is formed in the surface of the guide column and the surface of the counterbore cutting column, starts at the head of the guide column and ends in the cutter relieving groove. The middle of the drill handle is provided with a rapid receiving groove. The head of the guide column is provided with a guide column opening angle. The end surface of the head of the counterbore cutting column is provided with a first cutting plane composed of a first cutting edge and a second cutting plane composed of a second cutting edge. The first cutting edge and the basal plane form a first relief angle Gamma. The second cutting edge and the basal plane form a second relief angle Delta. The outer circle surface of the guide column and the basal plane form a counterbore cutting column opening angle Beta. According to the counterbore countersink drill and the machining process thereof, the structure is reasonable; the machining process is clear in procedure; the positioning precision and the machining precision of the counterbore countersink drill are significantly improved compared with those of a traditional hole drill and a traditional countersink drill; and the machining efficiency of drilling and countersinking is improved.

Owner:YANGZHOU SHILI HARDWARE TOOL IND & TRADE CO LTD

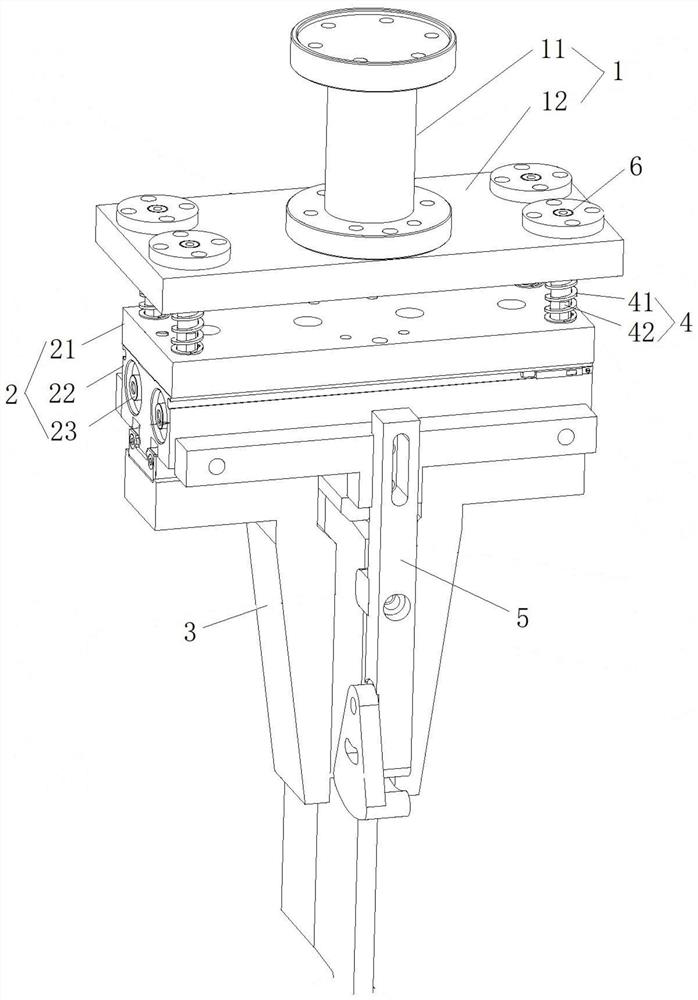

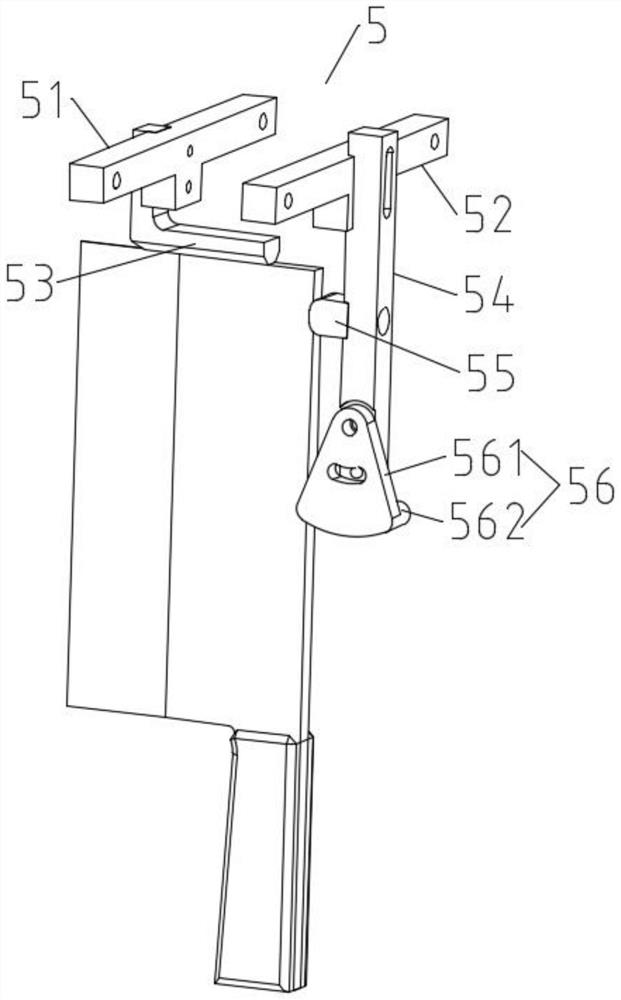

Kitchen knife floating grabbing and clamping device

PendingCN113601546APlay the role of grasping and clampingEffective gripping actionGripping headsEngineeringMachining

The invention relates to a kitchen knife floating grabbing and clamping device. The kitchen knife floating grabbing and clamping device is used for clamping and fixing a kitchen knife to be machined, and comprises a fixed end connected with the tail end of a robot, a clamping piece, and an edge leaning piece, wherein a plurality of floating pieces are arranged between the clamping piece and the fixed end, two clamping plates used for grabbing and clamping the kitchen knife to be machined are arranged on the side, away from the fixed end, of the clamping piece, and the clamping piece is in transmission connection with the clamping plates; and the edge leaning piece for positioning the kitchen knife to be machined is arranged between the two clamping plates, and is fixedly connected with the clamping pieces. According to the kitchen knife floating grabbing and clamping device, the edge leaning piece is arranged between the two clamping plates, the clamping plates can effectively grab and clamp the kitchen knife under the action of the clamping device, kitchen knife machining is facilitated, an edge leaning block can position the kitchen knife, it is effectively guaranteed that the kitchen knife clamping state is stable, subsequent machining treatment of the kitchen knife is facilitated, and the machining quality of the kitchen knife is high.

Owner:重庆智能机器人研究院

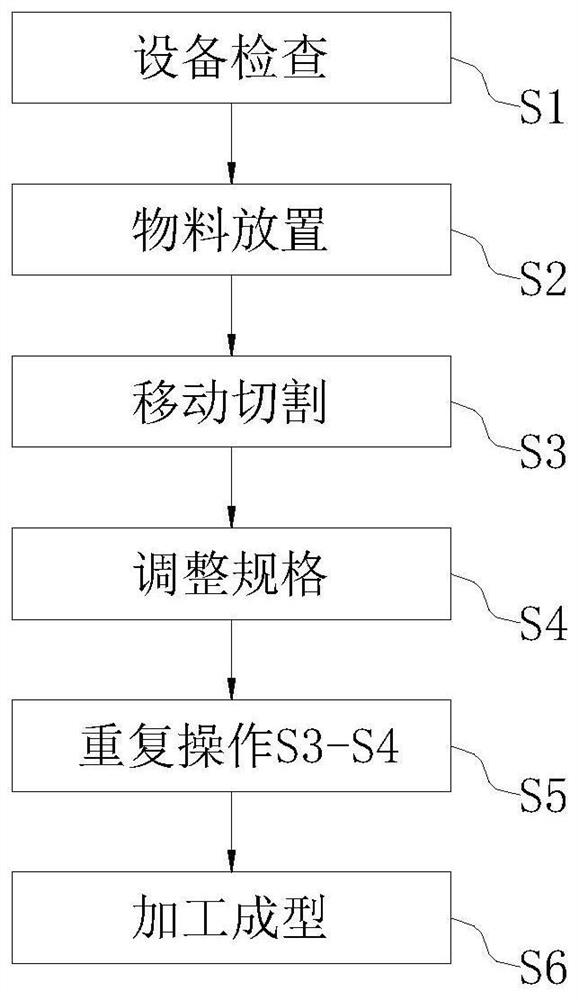

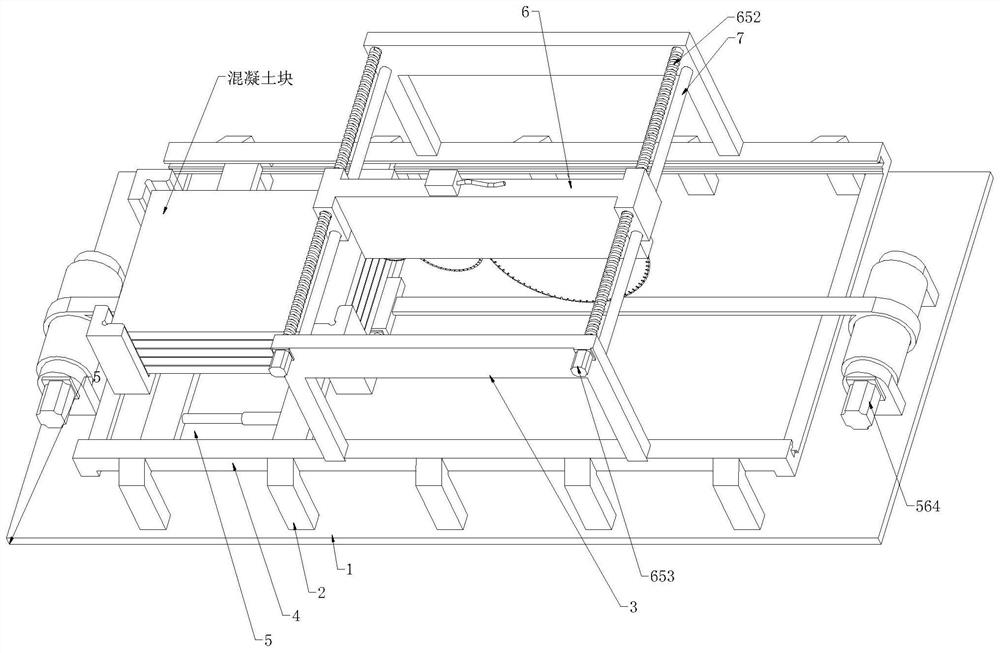

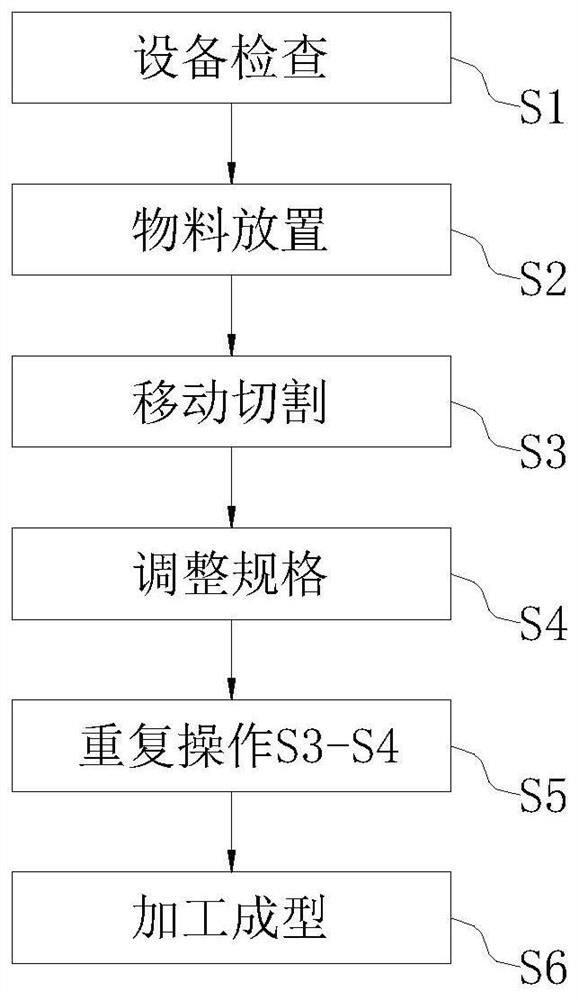

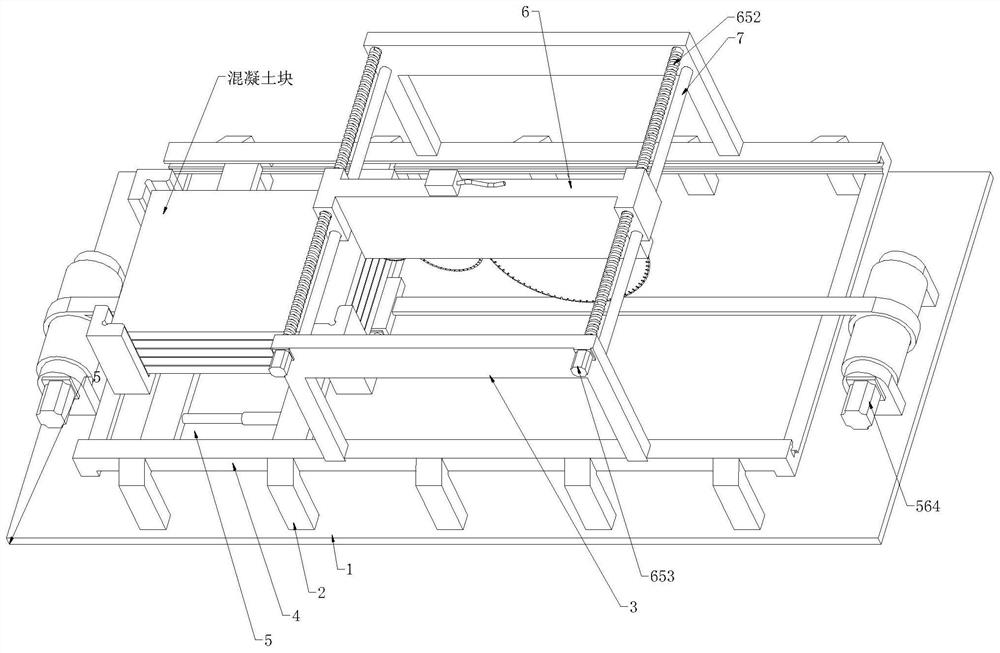

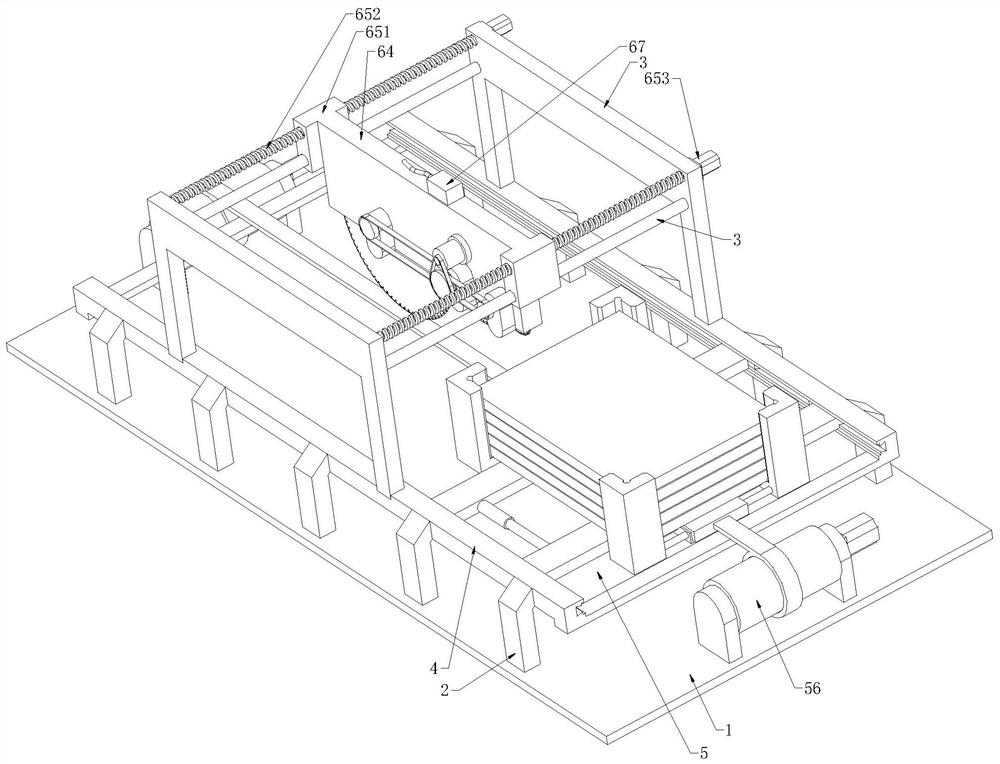

Preparation process of light foam concrete blocks

ActiveCN112757441ALess interventionReduce labor intensityCeramic shaping apparatusManufacturing engineeringFoam concrete

The invention relates to a preparation process of light foam concrete blocks, relates to the technical field of preparation processes of concrete blocks. Processing equipment for foam concrete blocks is adopted in the preparation process of the light foam concrete blocks. The processing equipment comprises a bottom plate, support frames, a mounting frame, a guide rail block, a movable clamping device and a cutting device. According to the preparation process of the light foam concrete blocks, a plurality of concrete blocks are kept in a stable clamping state through the movable clamping device and the cutting device, high-automation graded cutting of the cutting device is matched, the manual intervention degree is reduced, and the cutting is more uniform and stable, so that the effects of reducing the labor intensity of operators and improving the uniformity and precision during cutting are achieved; through the movable clamping device and the cutting device and the matched manual work, the relative positions between the multiple clamped concrete blocks and a first cutting disc, a second cutting disc and a third cutting disc can be adjusted, so that the effect that the concrete blocks are cut and processed into the concrete blocks with different specification requirements is achieved.

Owner:浙江海源新型建材有限公司

Clamping method and fixture for deformed workpiece

InactiveCN110465820AEasy clampingImprove fitWork clamping meansPositioning apparatusIndustrial engineeringConical surface

The invention discloses a clamping method and fixture for a deformed workpiece. According to the clamping method and fixture for the deformed workpiece, the two sides of a fixture main body are provided with connection holes to be used for connecting a tooling, positioning sleeves are put into the connection holes, and in the process of compressing the positioning sleeves, positioning sleeve conical surfaces align the fixture and the tooling automatically; the fixture main body is provided with an air bag, the workpiece and the tooling are made to be closely combined utilizing acting force generated by air bag air inflation on the deformed workpiece, and the whole workpiece is stressed evenly; and when clamping is performed, the workpiece is placed on the tooling, then the fixture is installed on, the fixture, the workpiece and the tooling are fitted together through the positioning sleeves and compressing holes in the two sides of the fixture, the workpiece is adsorbed and fixed afterthe air inflation is performed, and the clamping is finished. By means of the clamping method and fixture for the deformed workpiece, the clamping can be finished by one man operations, and the problem in the prior art of generation of uneven force bearing in workpiece compressing is solved, the workpiece is pressed evenly, the clamping time is short, the clamping state is stable, no machining risk exists, and the efficiency is high.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Clothes washing clamp

InactiveCN101988259BReduced parts countReduce manufacturing costTextiles and paperClothes-pegsEngineeringMechanical engineering

A clothes washing clamp is composed of the following components: a pair of clamping sheets which respectively comprise a clamping part at one end and a clamping handle part at the other end; and a U-shaped elastic member which clamps the clamping sheets in an opposite state and drive the clamping sheets to joint at the clamping part side. The clamping sheets are integrally formed with the metal plates with a preset length. The inside of each metal plate is punched for forming a door part for clamping the elastic member. Two sides of the door part are integrated with the metal plates. A transverse elongated elastic member insertion hole which faces the clamping handle side is formed. Simultaneously a transverse elongated projection hole which faces the clamping part is formed. The elastic member forms a respectively projected stop part 31 and an anti-releasing part. The elastic member is inserted into the door for clamping the stop part at the edge part of the insertion hole. Simultaneously the anti-releasing part is clamped at the edge of the projection hole.

Owner:ランドパイン

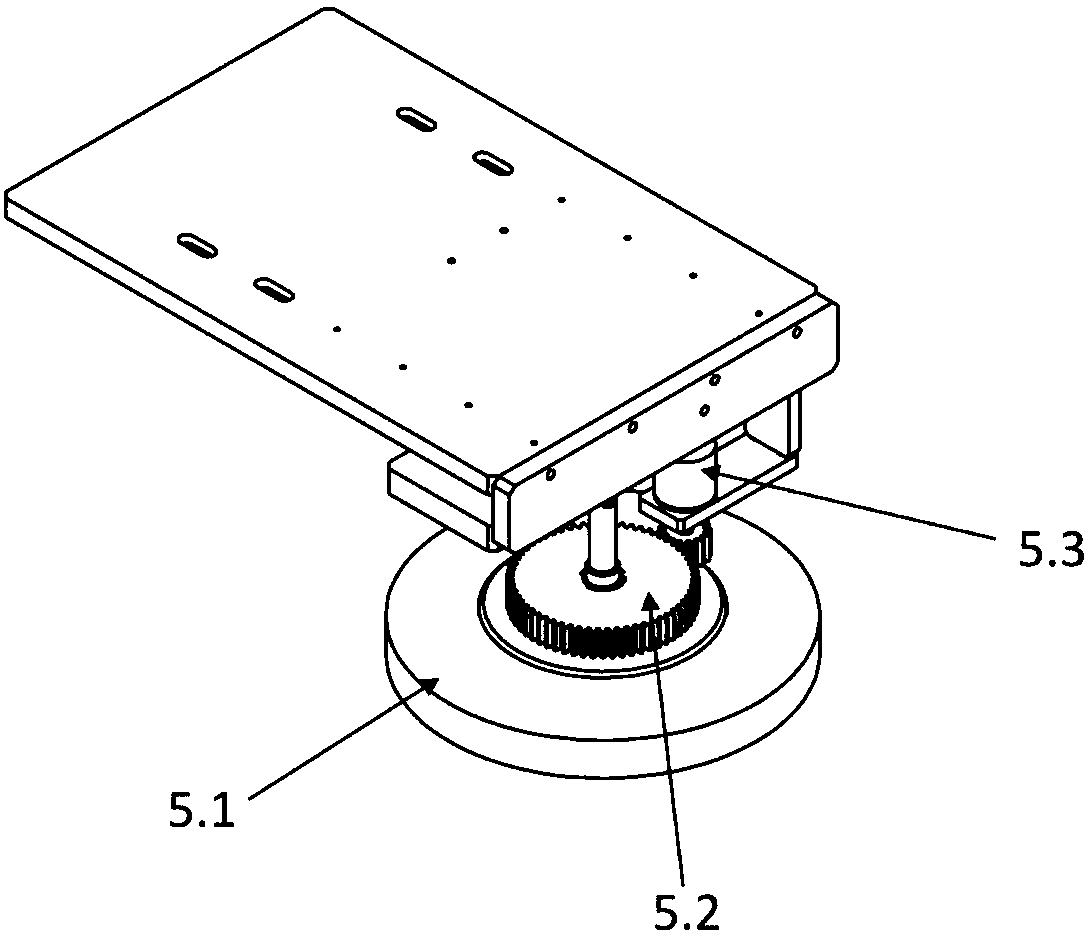

Zero-point positioner structure for production assembly line

ActiveCN114083469AHigh positioning and clamping rigidityEasy to compressWork holdersTotal factory controlPull forceDetent

The invention discloses a zero-point positioner structure for a production assembly line, and relates to the technical field of production equipment, the zero-point positioner structure comprises a base and a guide pillar, the base is fixedly provided with a shell, the upper end of the shell is fixedly provided with a sealing cover, and the upper wall surface of the sealing cover is provided with an insertion hole. A parallel and relative pressing locking mode is adopted, the sections of conical surfaces on the two pressed sides of a steel ball are in a parallel state, the clamping state is stable and firm, acting force in other directions cannot be generated on the steel ball even if the tension of a guide column is increased, the locking force is greatly improved, radial positioning and axial positioning are very firm, and unless an air cylinder is used for opening a sliding barrel, as long as equipment is intact, the sliding barrel can be locked. The locking mechanism can completely lock the special positioning guide column, the zero-point positioning device is suitable for zero-point positioning of a reverse tool, when the positioning guide column is taken out, the guide column can be taken out only by connecting air pressure to the bottom air cylinder, cleaning is convenient, the zero-point positioning device is of a mechanical structure, and the bottom air cylinder is detachable and easy to maintain.

Owner:LIAONING PROVINCIAL COLLEGE OF COMM

Novel plastic plate processing device

A new type of plastic plate processing device is used to process and form thermoplastics, and includes a base, a processing table and a top seat, support plates are fixedly installed on the left and right sides of the base, and uprights are symmetrically arranged on the support plates in the front and rear. The upper end of the column is fixedly connected with the processing table, a mold is fixedly installed on the upper end of the processing table, a mold cavity with an upward port is arranged in the mold, and a plurality of lower guide rods are fixedly installed between the base and the processing table, so A plurality of upper guide rods are fixedly installed between the processing table and the top seat, and a landing plate is slidably installed on the lower guide rod. The upper ends of the two sides of the landing plate are provided with lifting arms, and the upper ends of the lifting arms pass through the processing table. and extending upward, the upper end of the landing arm is provided with a fastening arm extending toward the middle, and a screw rod is threadedly fitted at the midpoint of the landing plate.

Owner:SHENGZHOU BAIEN TRADE

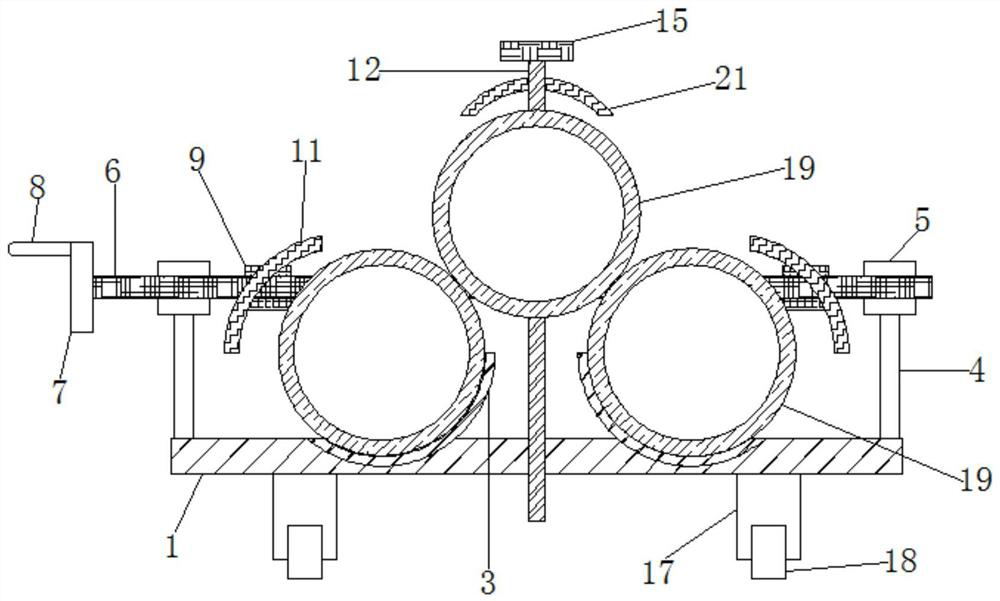

A barrel-shaped container handling device

ActiveCN110667674BRealize the opposite movementPrevent slidingSupporting partsHand carts with multiple axesLogistics managementStructural engineering

The invention relates to the technical field of logistics transportation, and discloses a barrel-shaped container handling device, which includes a bottom plate, an arc groove is opened on the bottom plate, an arc plate is fixedly arranged in the arc groove, and a horizontal fixing sleeve is fixedly arranged above the bottom plate. Two sets of horizontal fixed sleeves are fixedly sleeved on the outside of the screw shaft, and the left and right parts of the screw shaft are sleeved with movable sleeves. The movable sleeve is connected with a horizontal arc-shaped baffle through a connecting rod, and the bottom plate is connected with a vertical shaft in the inner part of the screw shaft. , the vertical axis is fixedly connected with a vertical arc baffle, the inside of the bottom plate is fixedly connected with a push handle, the outside of the bottom plate is fixedly connected with a vertical baffle, and a drum is placed between the arc plate and the vertical arc baffle. The barrel-shaped container handling device can make the horizontal arc-shaped baffles move toward each other, so as to fix and clamp the drum placed on the arc-shaped plate. The setting of the arc-shaped plate can prevent the barrel from being squeezed by the horizontal arc-shaped baffle Sliding, and the vertical arc-shaped baffle on the vertical shaft can keep multiple groups of drums in a stable clamping state.

Owner:江苏昊祥机械科技有限公司

Metal sheet forming device

InactiveCN107309311AEasy loadingStable positionMetal-working feeding devicesShaping safety devicesMetal formingMetal sheet

The invention discloses a metal sheet forming device used for compression forming of metal sheets. The metal sheet forming device comprises a stand, a workbench and a top plate; the upper end of the workbench is fixedly provided with a forming seat; a forming cavity with an upward opening is arranged in the forming seat; at least two lower guide posts are fixedly mounted between the stand and the workbench; at least two upper guide posts are fixedly mounted between the workbench and the top plate; the lower guide posts are slidably provided with a lifting plate; the upper ends of two sides of the lifting plate are provided with lifting arms; the upper ends of the lifting arms pass through the workbench and upwards extend; the upper ends of the lifting arms are provided with clamping arms extending towards the middles; a lifting screw rod is mounted in the center of the lifting plate in a screw thread fit way; at least two through holes communicating with the forming cavity are formed in the forming seat and the workbench; ejecting rods are slidably mounted in the through holes; the lower ends of the ejecting rods are fixedly connected with the lifting plate; and the top plate is also provided with a forming mechanism.

Owner:XINCHANG HAIGE SAISI TRADE

Practical wood plate cutting apparatus

The invention relates to a practical wood plate cutting apparatus, which is used for cutting and molding a wood plate, and comprises a base, a cutting table and a top frame, wherein the upper end of the cutting table is fixedly provided with a model frame, a model cavity with an upward opening part is arranged in the model frame, multiple groups of lower portion position guiding rods are fixedly arranged between the base and the cutting table, multiple groups of upper portion position guiding rods are fixedly arranged between the cutting table and the top frame, a lifting block is arranged onthe lower portion position guiding rods in a sliding manner, lifting arms are respectively arranged on the upper ends of both sides of the lifting block, the upper end of the lifting arm penetrates through the cutting table and upward extends, and is provided with a pressing rod extending toward the middle portion, a screw rod is cooperatively arranged at the middle portion of the lifting block through threads, multiple groups of hole grooves communicated to the model cavity are arranged in the model frame and the cutting table, pushing rods are slidably arranged in the hole grooves, the lowerends of the pushing rods are fixedly connected to the lifting block, and the top frame is provided with a cutting member.

Owner:义乌市源德进出口有限公司

Convenient pipeline bending device

A convenient pipe bending device for bending and forming pipes, including a base, a bending table and an upper table, the upper end of the bending table is fixedly installed with a forming seat, and the forming seat is provided with an opening on the upper part The bottom of the abutment is fixed with a telescopic strut, the lower end of the telescopic strut is fixed with a bottom plate, and several sets of lower guide sliding columns are fixedly installed between the abutment and the bending table. There are several groups of upper guide sliding columns fixedly installed between the curved platform and the upper platform, and undulating plates are installed on the lower guiding sliding columns. The bending table, the upper end of the undulating arm is provided with a sticking arm extending toward the middle, the middle end of the undulating plate is threaded and installed with a screw rod, the forming seat and the bending table are provided with several sets of The opening through which the cavities are connected.

Owner:ZHUJI CITY JIMAILUO IMPORT & EXPORT CO LTD

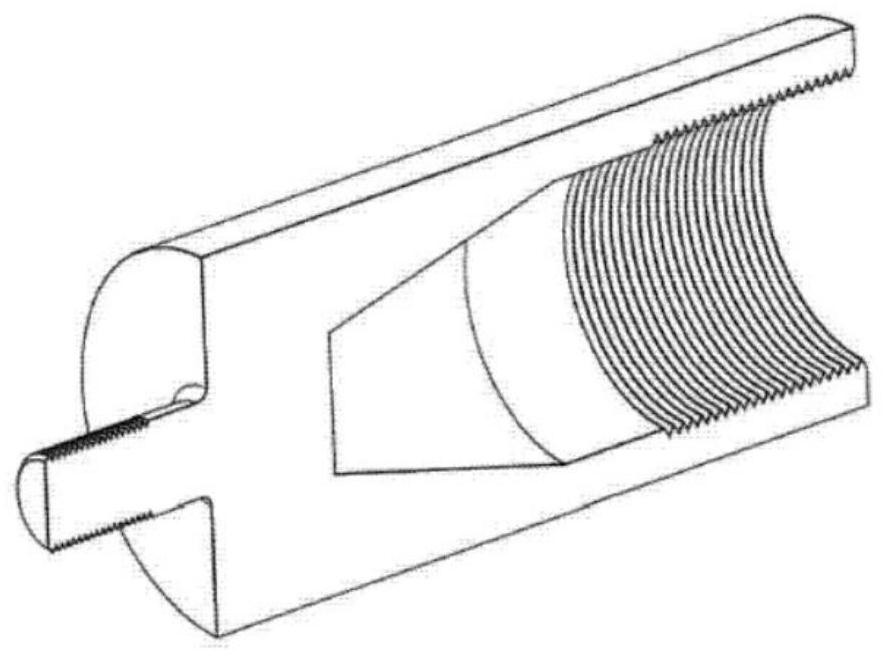

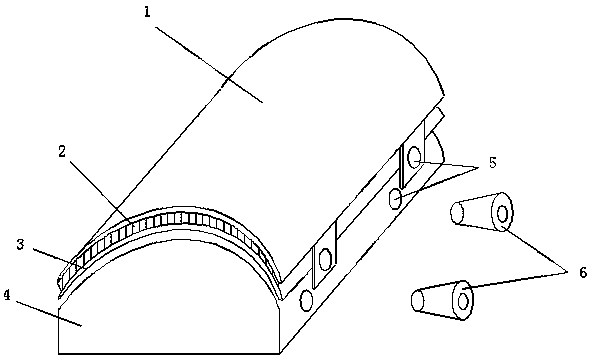

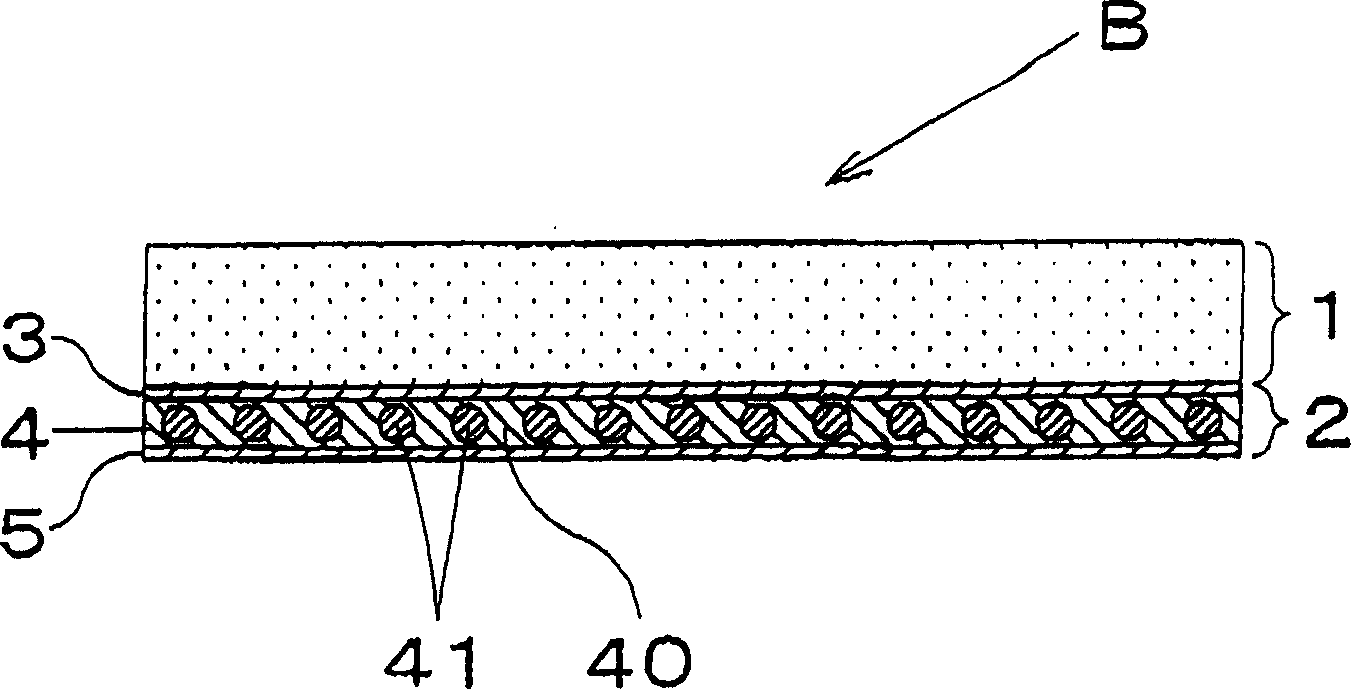

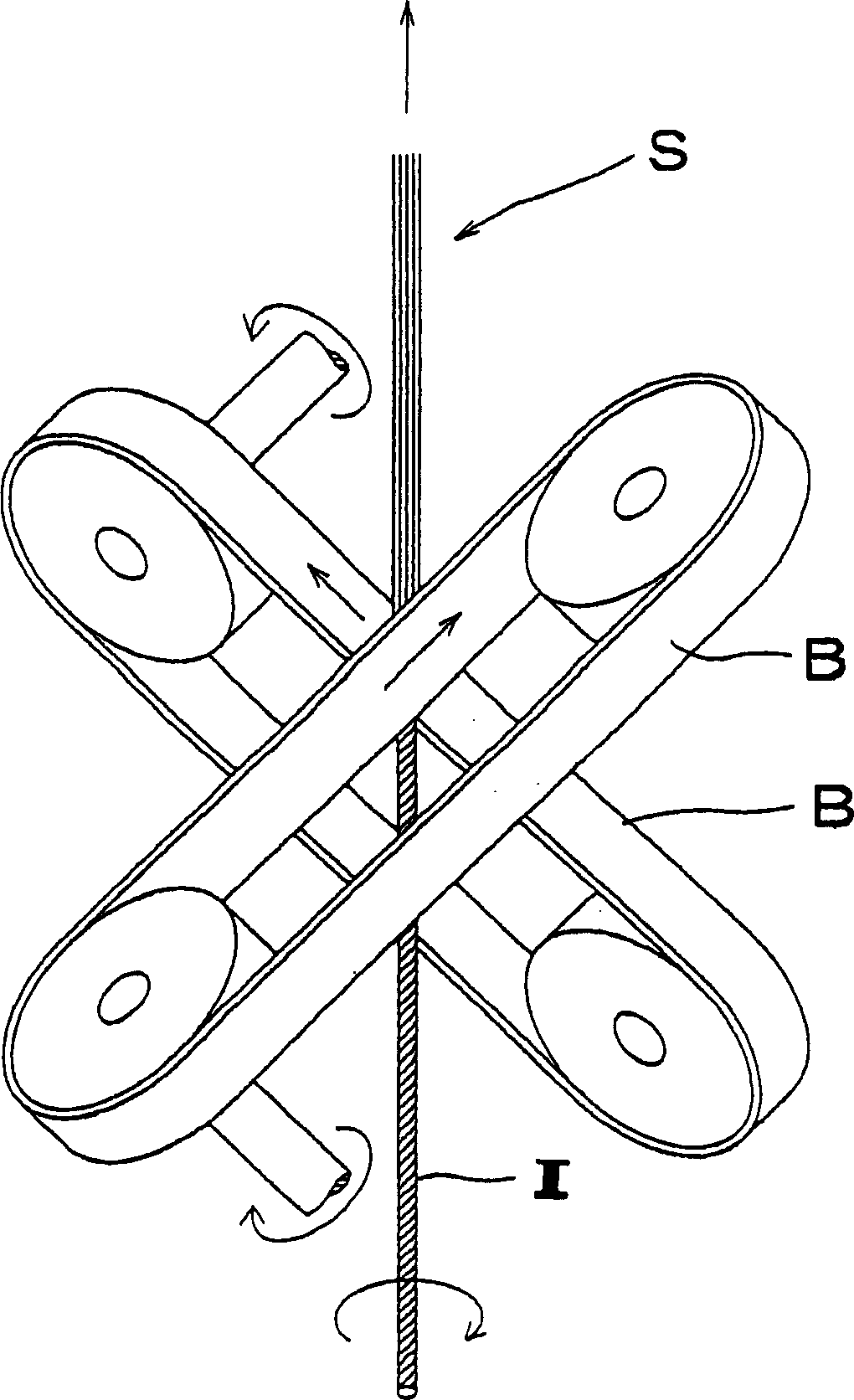

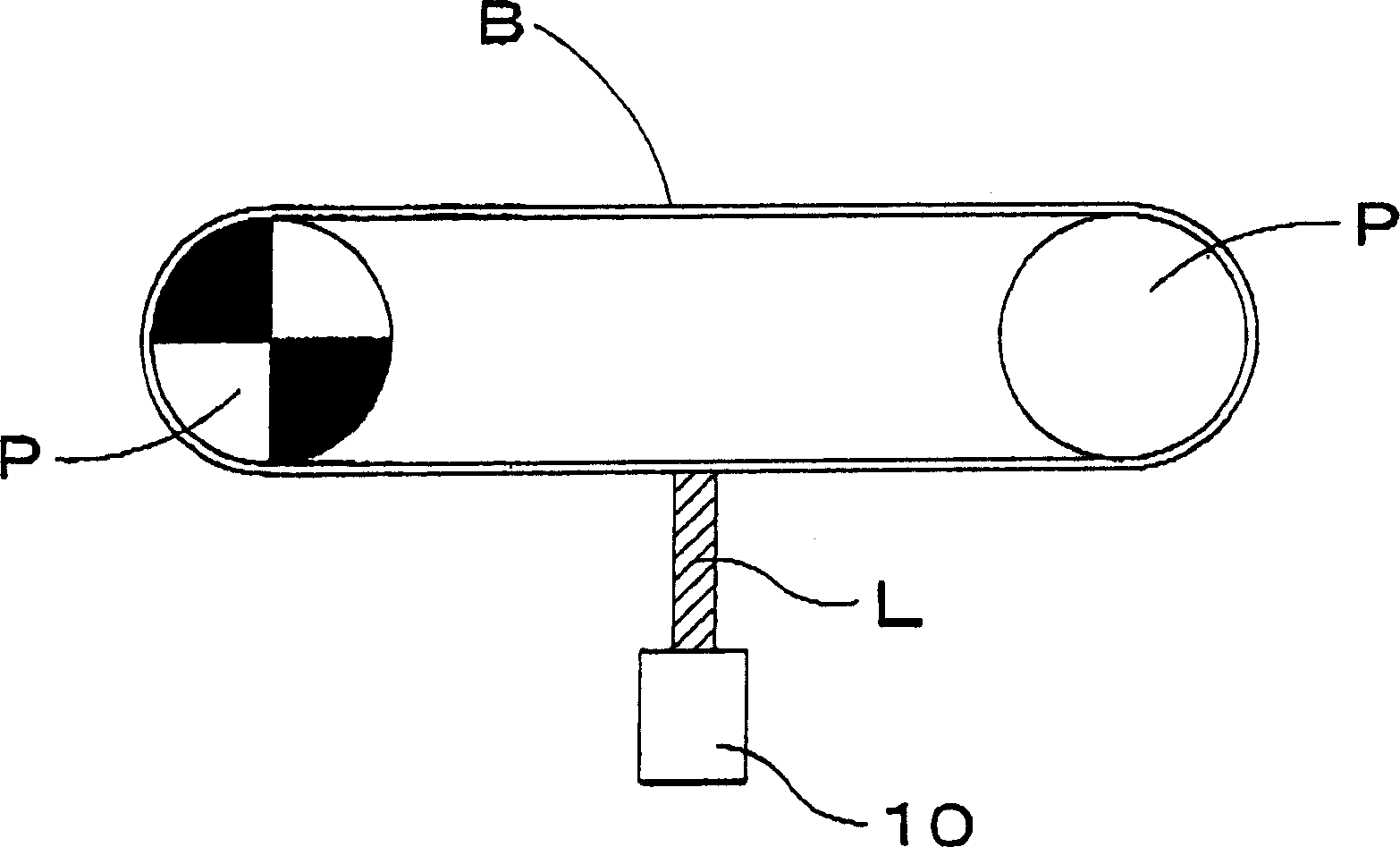

Belt for yarn twisting

InactiveCN1910311AQuality improvementReduce vibrationDriving beltsContinuous wound-up machinesYarnEngineering

A yarn twisting belt formed in an endless loop that ensures longer service life of the belt and stable quality of the yarn, comprising a surface rubber layer 1 that touches yarn to be twisted and a reinforcing layer 2 that is laminated on the surface rubber layer 1, having an intermediate woven fabric 3 provided on the surface rubber layer 1 side of the reinforcing layer 2 while a seamless woven fabric is used as the intermediate woven fabric 3. The seamless woven fabric is elastic in the direction of the belt circumference and rigid in the direction of the belt width. The reinforcing layer 2 comprises the intermediate woven fabric 3 that is constituted from the seamless woven fabric, a core layer 4 constituted from core yarns embedded in the longitudinal direction of the belt, and an external woven fabric 5 that is put on pulleys, while being integrated with the surface rubber layer.

Owner:NITTA CORP

Integrated easy-to-disassemble linbo3 companion fixture

ActiveCN107186616BThe clamping state is stableReduce manufacturing costWork carriersEngineeringLED lamp

The invention discloses an integrated LiNbO3 accompanying sheet clamp easy to detach and mount. The integrated LiNbO3 accompanying sheet clamp comprises a left accompanying sheet clamp body, a right accompanying sheet clamp body and a clamp connecting piece. The left accompanying sheet clamp body and the right accompanying sheet clamp body are fixed to the clamp connecting piece, arranged in a mirror symmetry mode and each comprise a clamping part and a positioning part. The positioning parts are provided with optical fiber positioning grooves for positioning an optical fiber and accompanying sheet arranging grooves for arranging an accompanying sheet. The clamping parts and the positioning parts are screwed up through bolts to fix the accompanying sheet. The front end faces of the left accompanying sheet clamp body and the right accompanying sheet clamp body are designed to be bevels inclining towards the outer sides of the left accompanying sheet clamp body and the right accompanying sheet clamp body correspondingly with the inclination angle being 15 degrees, and the optical fiber end face with the inclination angle being 15 degrees can be ground tacitly. LED arranging grooves are designed in the opposite side faces, close to the accompanying sheet arranging grooves, of the positioning parts of the left accompanying sheet clamp body and the right accompanying sheet clamp body for internally storing LED lamps. The manufacturing cost of a single optical fiber clamp can be reduced, the precision of the optical fiber clamp is improved, the operation and maintenance cost is reduced, and integration is achieved.

Owner:BEIHANG UNIV

A kind of preparation technology of lightweight foam concrete block

ActiveCN112757441BThe clamping state is stableLess interventionCeramic shaping apparatusFoam concreteClassical mechanics

The invention relates to a preparation process of lightweight foamed concrete blocks, and relates to the technical field of the preparation process of concrete blocks, which uses a light foamed concrete block processing equipment, which includes a bottom plate, a support frame, a mounting frame, and a guide rail block, mobile clamping device and cutting device. The invention maintains a stable clamping state for several concrete blocks by moving the clamping device and the cutting device, cooperates with the highly automated graded cutting of the cutting device, reduces the degree of manual intervention, and makes the cutting more uniform and stable, realizing the reduction of operators The labor intensity and the effect of improving the uniformity and accuracy of cutting; by moving the clamping device and cutting device and cooperating with manual work, the distance between the clamped concrete blocks and the first cutting disc, the second cutting disc and the third cutting disc can be adjusted. The relative position between them can achieve the effect of cutting and processing into lightweight foam concrete blocks under different specifications.

Owner:浙江海源新型建材有限公司

An electric integrated operating device for j-shaped wire clamps

ActiveCN110635265BQuick lapQuick unlock actionCoupling device engaging/disengagingCoupling device detailsElectrical and Electronics engineeringBody frame

The invention discloses an electric integrated operating device for a J-shaped wire clamp. The electric integrated operating device comprises a clamping assembly and an insulating rod. The clamping assembly comprises a main body frame, a sliding rod chuck, a connecting rod mechanism and a first telescopic spring. The sliding rod chuck is in sliding connection with the main body frame. The connecting rod mechanism comprises a first connecting rod and a second connecting rod. The second connecting rod comprises a locking rod and an unlocking rod which are connected with each other. A corner is arranged between the locking rod and the unlocking rod; the joint of the locking rod and the unlocking rod is hinged to the first connecting rod; the other end of the first connecting rod is hinged tothe main body frame; the other end of the locking rod is hinged to the sliding rod chuck; the unlocking rod is provided with an unlocking pull rope and a rotating hole, wherein the rotating hole is formed between the unlocking pull rope and the locking rod, and the rotating hole is internally provided with a connecting piece; and one end of the connecting piece is connected with the main body frame. The electric integrated operating device for the J-shaped wire clamp is simple to operate; the clamping state of the clamping assembly is stable and reliable; and unlocking is convenient and rapid.

Owner:国网浙江省电力有限公司桐乡市供电公司

Novel composite high-precision vertical numerical control turning and grinding center

ActiveCN114043245AEasy to installThe clamping state is stableOther manufacturing equipments/toolsTotal factory controlNumerical controlElectric machinery

The invention discloses a novel composite high-precision vertical numerical control turning and grinding center, and particularly relates to the technical field of numerical control machine tools. The novel composite high-precision vertical numerical control turning and grinding center comprises a turning and grinding center main body, a turntable is movably mounted on the left side in the turning and grinding center main body, a motor rotating shaft is mounted on the central axis of the turntable, an adjusting rod is connected to the surface of the turntable in an embedded manner, a sliding seat is arranged at one end of the adjusting rod, and a clamping mechanism is slidably connected to the surface of the sliding seat. Through the arrangement of the clamping mechanism, the clamping mechanism is used for clamping and positioning a workpiece disc, the adjusting rod is in a vertical state before the rotating disc rotates, in this state, the workpiece disc can be more conveniently installed on the inner side of the clamping mechanism, then the adjusting rod is turned over by means of rotation of the rotating disc, and therefore the vertical workpiece disc is adjusted to be in a horizontal state, and are parallel to supporting plates on the surface of a slideway; and a group of movable shafts are mounted in the middle of a folding plate in a penetrating manner, so that the folding plate can be folded and combined conveniently.

Owner:苏州三众精密机械有限公司

Barrel-shaped container carrying device

ActiveCN110667674ARealize the opposite movementPrevent slidingSupporting partsHand carts with multiple axesLogistics managementStructural engineering

The invention relates to the technical field of logistics transportation, and discloses a barrel-shaped container carrying device. The barrel-shaped container carrying device comprises a bottom plate.An arc groove is formed in the bottom plate. An arc plate is fixedly arranged in the arc groove. A transverse fixing sleeve is fixedly arranged above the bottom plate. Two sets of transverse fixing sleeves fixedly sleeve a spiral shaft. Movable sleeves sleeve the left and right portions of the spiral shaft and are connected with transverse arc-shaped baffles through connecting rods. A vertical shaft is connected to the inner portion, located at the spiral shaft, of the bottom plate. A vertical arc baffle is fixedly connected to the vertical shaft. A push handle is fixedly connected to the interior of the bottom plate. A vertical baffle is fixedly connected to the outer portion of the bottom plate. Circular barrels are arranged between the arc plate and a vertical arc-shaped baffle. According to the barrel-shaped container carrying device, the transverse arc-shaped baffles can move towards each other, so that the circular barrels placed on an arc-shaped plate are fixedly clamped. The arc-shaped plate is arranged to prevent the circular barrels from sliding through extrusion of the transverse arc-shaped baffles. The vertical arc-shaped baffle on the vertical shaft can enable the plurality of sets of circular barrels to be in a stable clamping state.

Owner:濉溪初新工业设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com