Zero-point positioner structure for production assembly line

A zero-point positioning and assembly line technology, applied in the direction of workpiece clamping devices, hand-held tools, manufacturing tools, etc., can solve the problem of low positioning rigidity, achieve good positioning rigidity, simple maintenance, firm radial positioning and axial positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

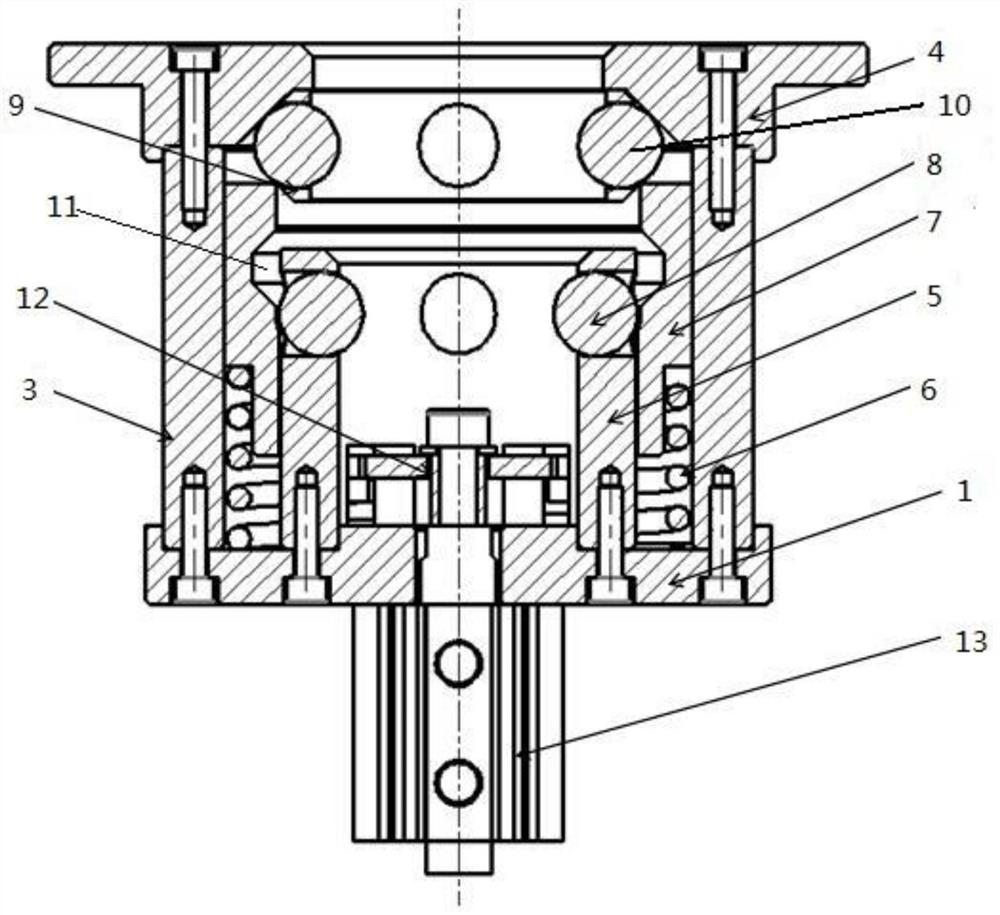

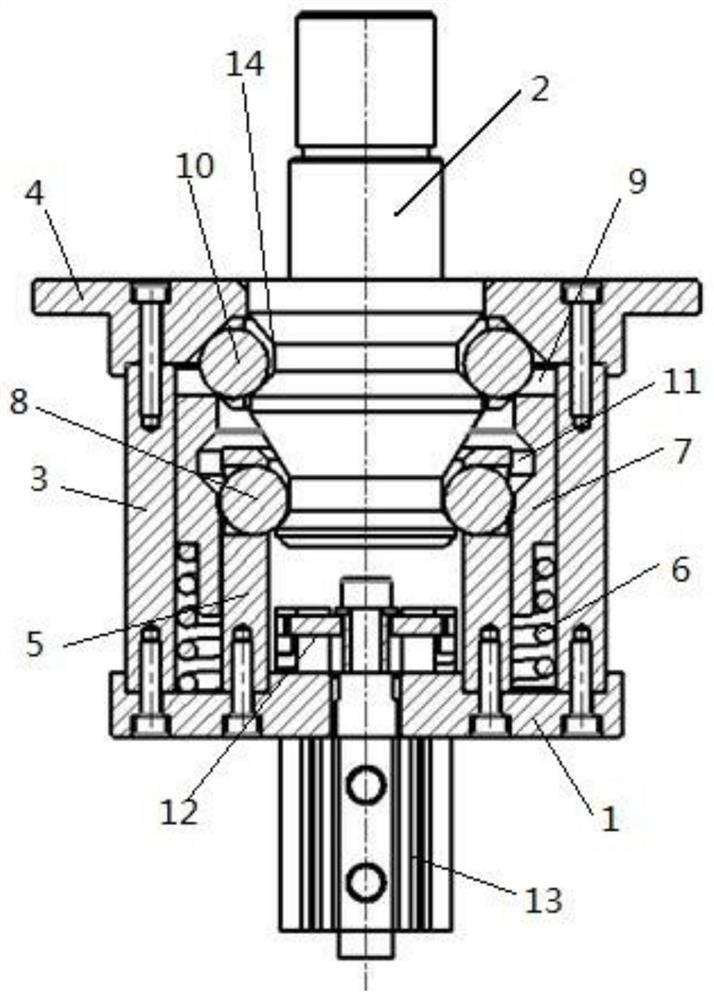

[0028] It can be seen from the accompanying drawings in the specification;

[0029] In a free state: the spring 6 supports the sliding cylinder 7 against the second cage and the four first steel balls 10 , and is in contact with the cover 4 .

[0030] During the downward insertion process of the guide post 2, the inclined plane of the groove 14 of the guide post 2 squeezes the four first steel balls 10 on the second cage, so that the second cage and the first steel balls 10 apply force downward on the slider. 7, the sliding cylinder 76 overcomes the force of the spring 6 and moves down to the bottom point; the four second steel balls 8 on the first ball cage 5 change positions so that the guide posts 2 can all enter the zero positioner smoothly.

[0031] There are eight first steel balls 10 and second steel balls 8 in total, and the slope of the groove 14 in the guide post 2 is a 45° conical surface.

[0032] After the guide post 2 enters, automatic locking is realized, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com