Clamping method and fixture for deformed workpiece

A workpiece and tooling technology, which is applied in the field of mechanical processing, can solve problems such as unstable adsorption state of workpieces, high technical requirements for personnel, uneven force, etc., and achieve good bonding between workpieces and tooling, high efficiency, and simple clamping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A clamping method for deformed workpieces of the present invention, the steps are:

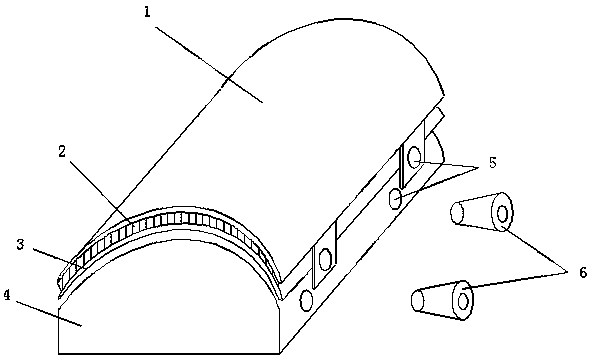

[0030] Setting tooling 4 and fixture body 1 with a mating curved surface adapted to the shape required by the workpiece;

[0031] The deformed workpiece 3 is installed on the tooling 4

[0032] Air bag 2 is placed on deformed workpiece 3;

[0033] Cover the airbag 2 with the clamp body 1;

[0034] Connect and fix the tooling 4 with the fixture main body 1;

[0035] Inflate the airbag to make the deformed workpiece fit well with the tooling;

[0036] The tooling opens the vacuum adsorption device to absorb the deformed workpiece;

[0037] After the positioning sleeve, air bag and fixture are removed, the workpiece is processed.

[0038] The tooling 4 of the present invention is connected and positioned with the fixture main body 1 through a tapered positioning sleeve 6 . The air bag 2 is provided on the lower surface of the jig main body 1 .

Embodiment 2

[0040] A clamping fixture for a deformed workpiece according to the present invention comprises a fixture main body 1, an air bag 2 and a tooling 4; the tooling 4 and the fixture main body 1 have a curved surface adapted to the required shape of the workpiece; when clamping the workpiece, the deformed workpiece 3 is installed on the tooling Above, the airbag 2 is placed on the deformed workpiece 3, the fixture main body 1 covers the airbag 2, and the tooling 4 is connected and fixed with the fixture main body 3. Both sides of the tooling 4 and the fixture body 1 are provided with connecting holes, and the positioning tooling and the fixture body are connected through the positioning sleeve 6 arranged in the connecting hole 5 . A through hole is formed in the center of the positioning sleeve 6 for installing screws to fix the fixture main body 1 .

Embodiment 3

[0042] A clamping fixture for a deformed workpiece of the present invention, the deformed workpiece 3 is cleaned and placed on the surface of the tooling 4, the clamp 1 is covered on the workpiece, the positioning sleeve 6 is placed in the connecting plate 5, and screws are placed in the positioning sleeve 6 And lock it. During the locking process, the tapered surface of the positioning sleeve 6 automatically fits the fixture with the workpiece and the tooling. By inflating the air bag 2 installed on the surface of the fixture, the deformed workpiece 3 fits well with the tooling 4. Vacuum absorbs the deformed workpiece, and the workpiece can be processed after the positioning sleeve and the fixture are removed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com