Clothes washing clamp

A technology of clamping handles and clamping pieces, which is applied in the field of laundry clips, can solve the problems of increased production costs, large number of parts, and complicated operations, and achieve the effects of stable clamping state, small number of parts, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

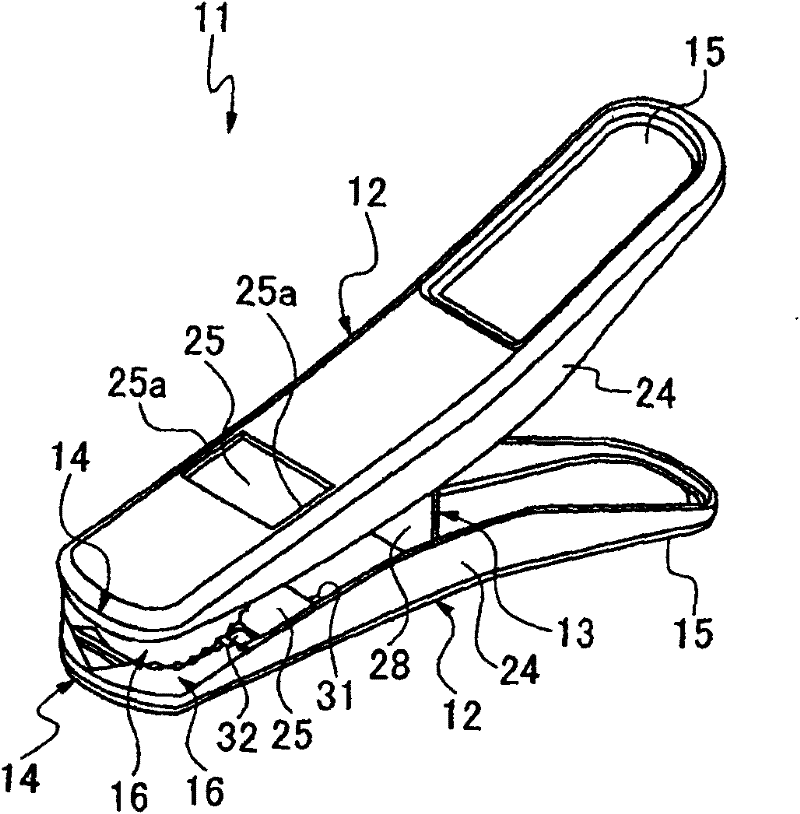

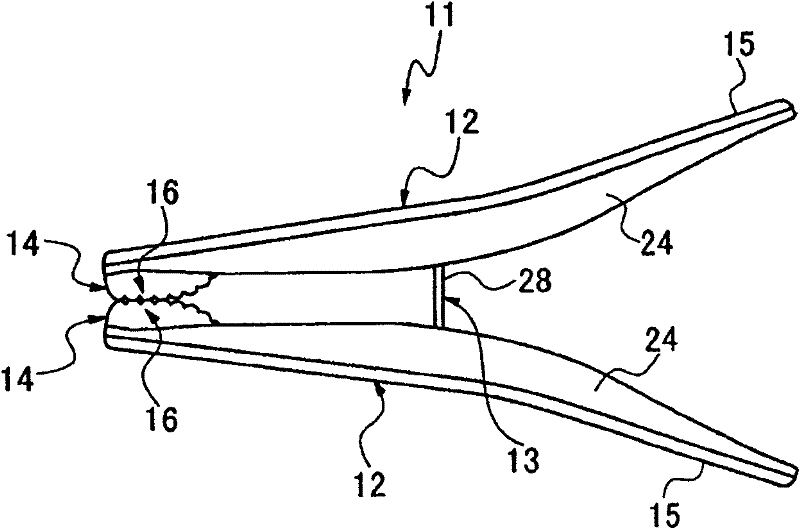

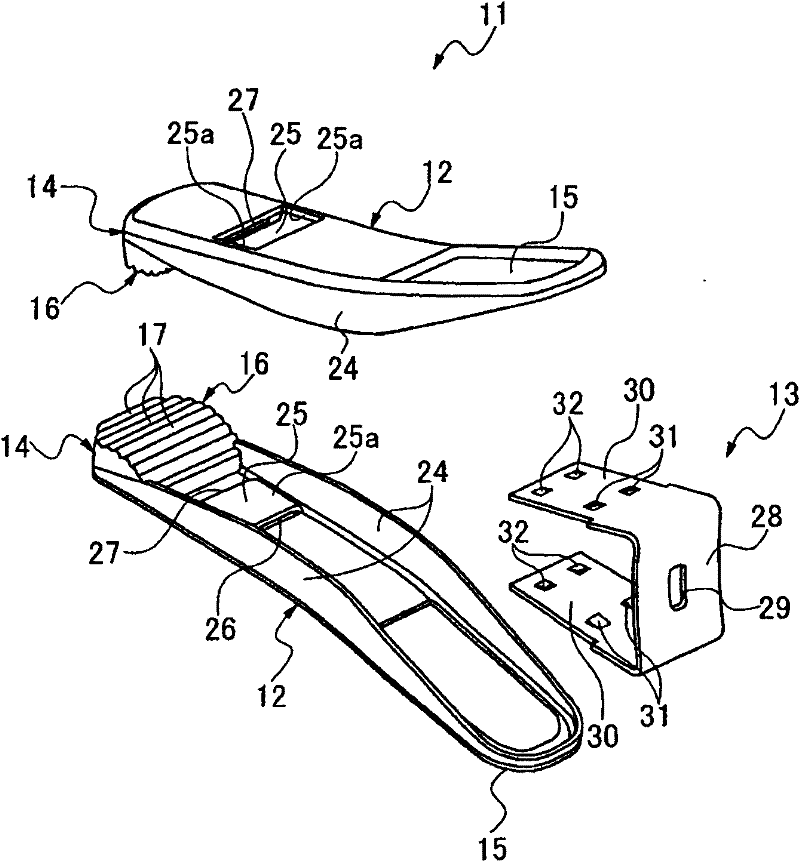

[0026] The structure of "washing clip" of the present invention, at first, Figure 1 to Figure 4 The laundry clip 11 is composed of a pair of clamping pieces 12 and an elastic member 13 that locks the clamping pieces 12 in a facing state.

[0027] The clamping piece 12 is integrally formed by drilling a metal plate with a predetermined length and width, and has a clamping portion 14 at one end and a clamping handle portion 15 at the other end. The metal plate used here is specifically, for example, aluminum, stainless steel, iron, etc., and aluminum which is lightweight and rigid is particularly preferable.

[0028] A first embodiment of the clamping portion 14 will be described below. Such as image 3 As shown, the swelling part 16 made of rubber or synthetic resin is a separate component, and the swelling part 16 is installed on the inner side of one end of the clamping piece 12 by sticking or other appropriate methods. Several concavo-convex portions 17 are formed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com