Tensile Fixture and Experimental Method for Split Hopkinson Tie Bar Thin Specimen

A separate, test-piece technology, applied in the research field, can solve problems such as the looseness of the main clamp body and the auxiliary clamp body, high processing precision requirements for the reinforcement sheet, and easy gaps in the thread fit, so as to avoid waveform clutter and ensure integrity The effect of stability and clamping state stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by those skilled in the art without making creative efforts belong to the protection scope of the present invention.

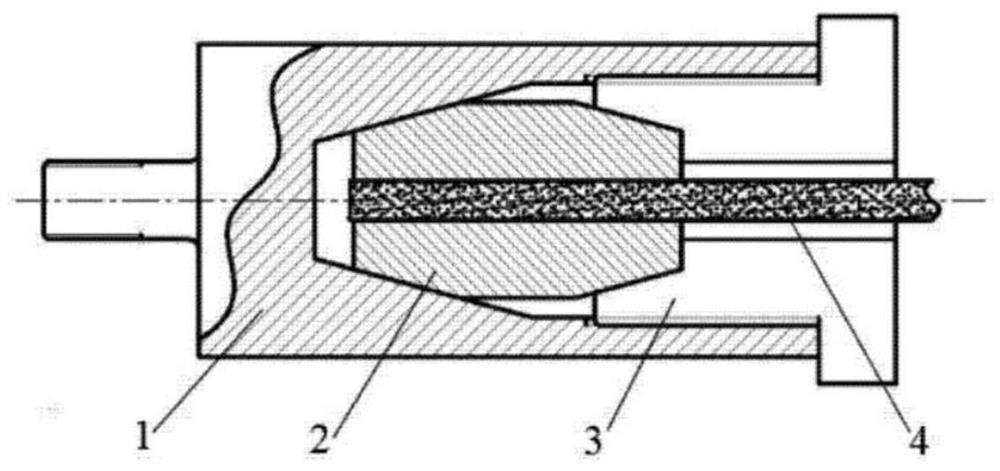

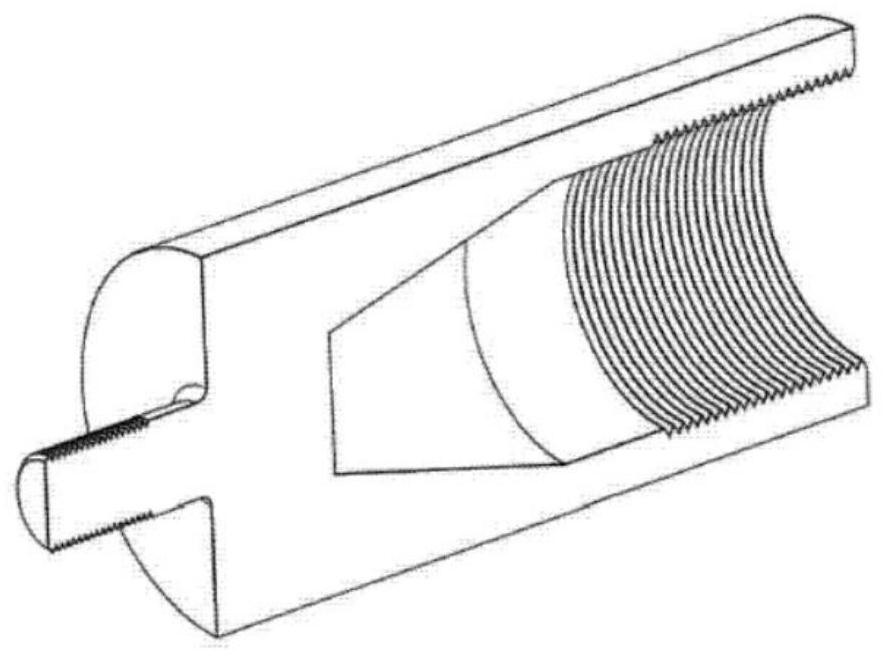

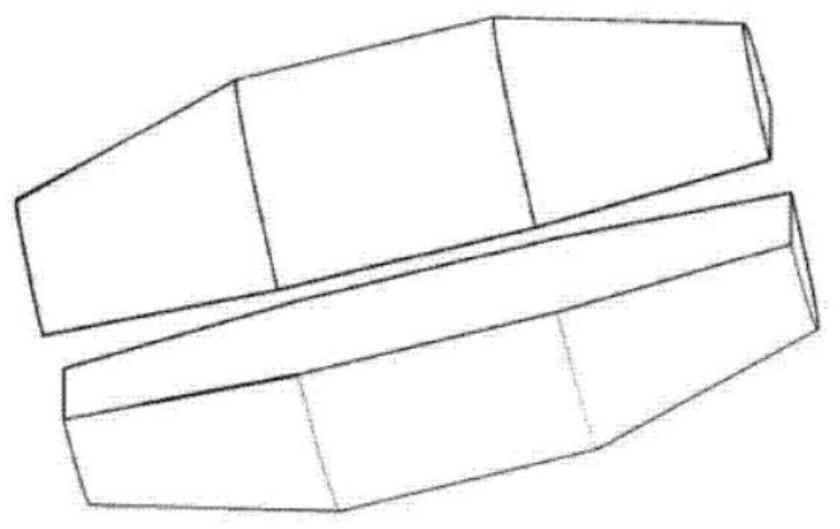

[0074] refer to Figure 20-24 , the present invention provides a split-type Hopkinson pull rod sheet-like test piece dynamic tensile test fixture with simple structure, convenient assembly and low processing requirements, which can effectively solve the slipping of the sheet-like test piece during the test process and ensure the fastening of the fixture and the test piece The stability of the test ensures the integrity of the waveform propagation during the test, avoids interference with the stress wave, and effectively improves t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com