Bearing ring and its fixing seat mechanism device

A mechanism device and bearing ring technology, which is applied to positioning devices, bearing components, shafts and bearings, etc., can solve the problems of loose workpiece clamping, high shedding rate and high scrapping rate, achieve firm clamping state and reduce workpiece shedding. rate and reject rate, the effect of strengthening the firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

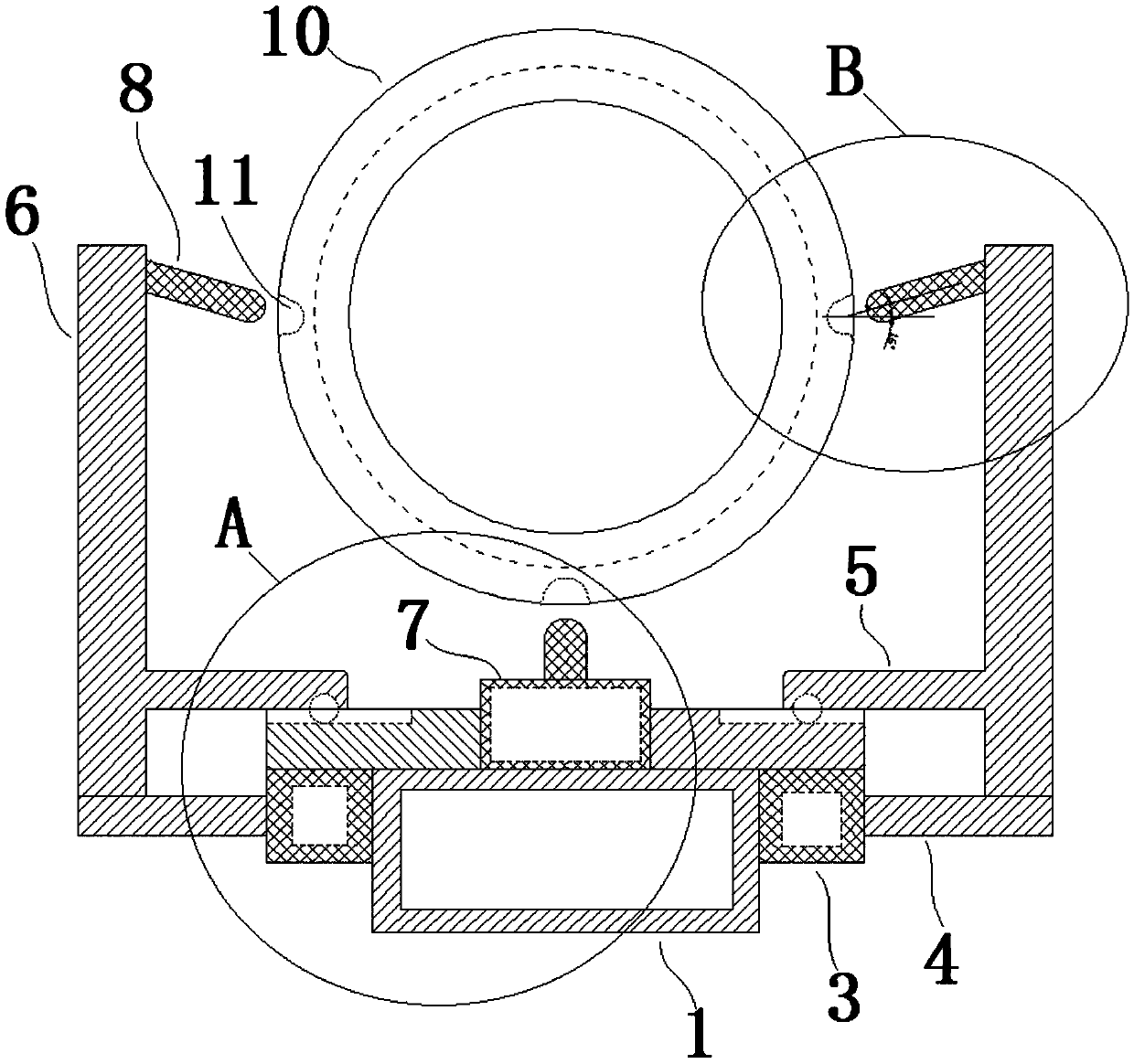

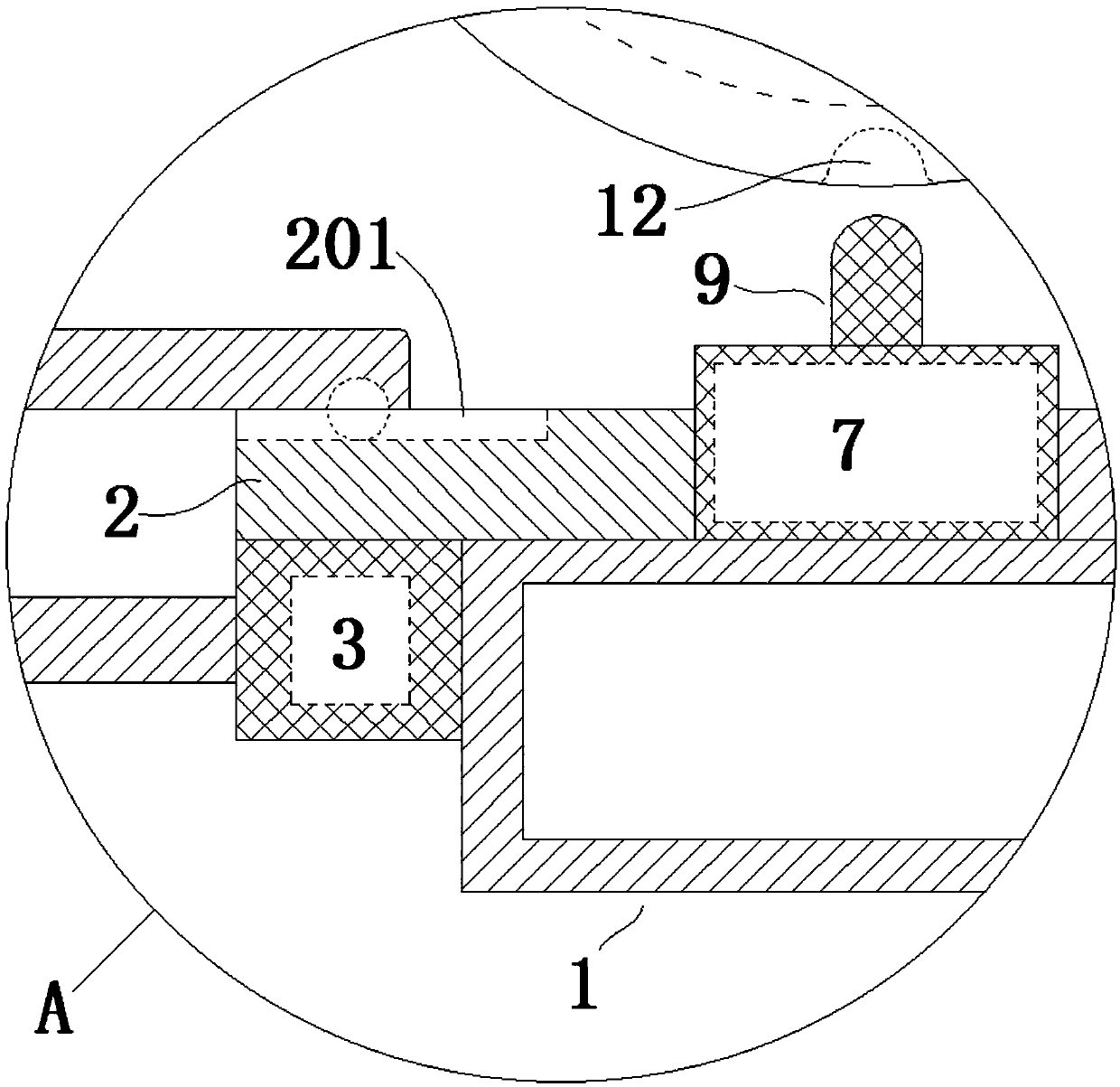

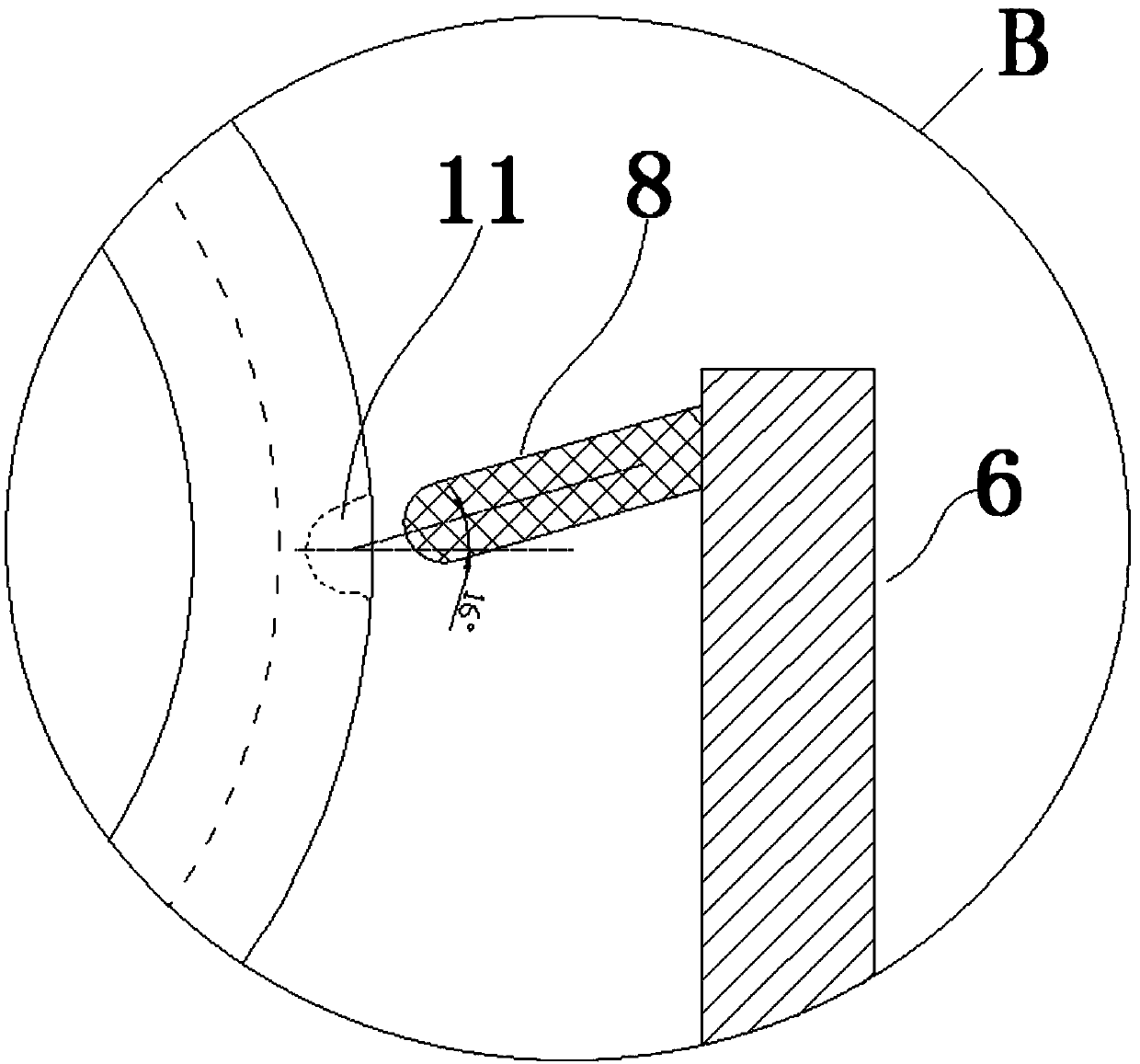

[0024] The present invention comprises a first base plate 1 and a bearing ring 10, first telescopic devices 3 are fixedly installed on both ends of the first base plate 1; a second base plate 2 is fixedly connected to one side of the first base plate 1; the second base plate 2 A second telescopic device 7 is fixedly installed on the top; the first telescopic device 3 is provided with a first telescopic connecting rod 4; the end side of the first telescopic connecting rod 4 is vertically connected with a second connecting rod 6; on the second connecting rod 6 Including the second sliding rod 5 and the first reinforcing rod 8; the angle between the first reinforcing rod 8 and the horizontal plane is 5-30 degrees; the second telescopic device 7 is provided with the second reinforcing rod 9; the bearing ring 10 is provided with There are a pair of first fixing slots 11 and a second fixing slot 12 .

[0025] The second substrate 2 is provided with a substrate chute 201 structure; o...

specific Embodiment 2

[0029] The bearing ring is clamped in a traditional way and the device of the present invention is used to perform corresponding clamping operations.

[0030] Table 1: The bearing ring is clamped by a traditional clamping device.

[0031]

[0032]

[0033] Table 2: The device of the present invention is used to clamp the bearing ring.

[0034] Bearing ring diameter / mm

[0035] It can be seen from the above two tables that the overall performance of the clamping and processing operation of the bearing ring by the device of the present invention is significantly better than that of the traditional bearing ring clamping method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com