Novel composite high-precision vertical numerical control turning and grinding center

A high-precision, turning-grinding technology, applied in the field of CNC machine tools, can solve problems such as insufficient precision, small number of workpieces, and inability to locate and process multiple sets of workpieces, and achieve stable and accurate processing, stable clamping status, and improved work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

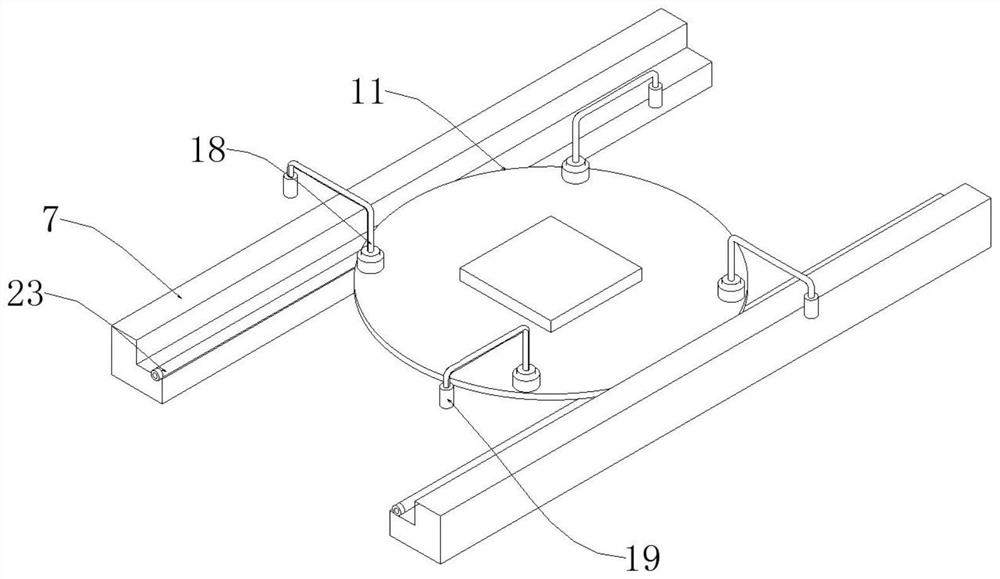

[0055] The embodiment is specifically: through the setting of the moving mechanism 21, the azimuth movement and adjustment of the grinding drive mechanism 10 can be carried out. The mounting seat 9 will move along the guide rod 24 under the push of the first hydraulic push rod 25, and the mounting seat 9 will move along the guide rod 24. The movement of 9 is to move the grinding drive mechanism 10 in the general direction, and the moving mechanism 21 is to move the grinding drive mechanism 10 in a more precise small direction, so that the combination of the two greatly improves the accuracy of the equipment.

[0056] according to Figure 7 As shown, the external shape of the moving mechanism 21 is cross-shaped, and the rotating coupling 2103 and the shifting plate 2104 form a rotational connection.

[0057] The specific embodiment is: the cross-shaped moving mechanism 21 can make the grinding driving mechanism 10 adjust in multiple directions, and increase the flexibility of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com