Spindle structure of a machine tool

A spindle and machine tool technology, applied in the field of spindle structure, can solve the problems of insufficient tool performance, high production cost, low transmission torque, etc., and achieve stable tool clamping state, reduce machining accuracy, and maintain tool clamping state. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

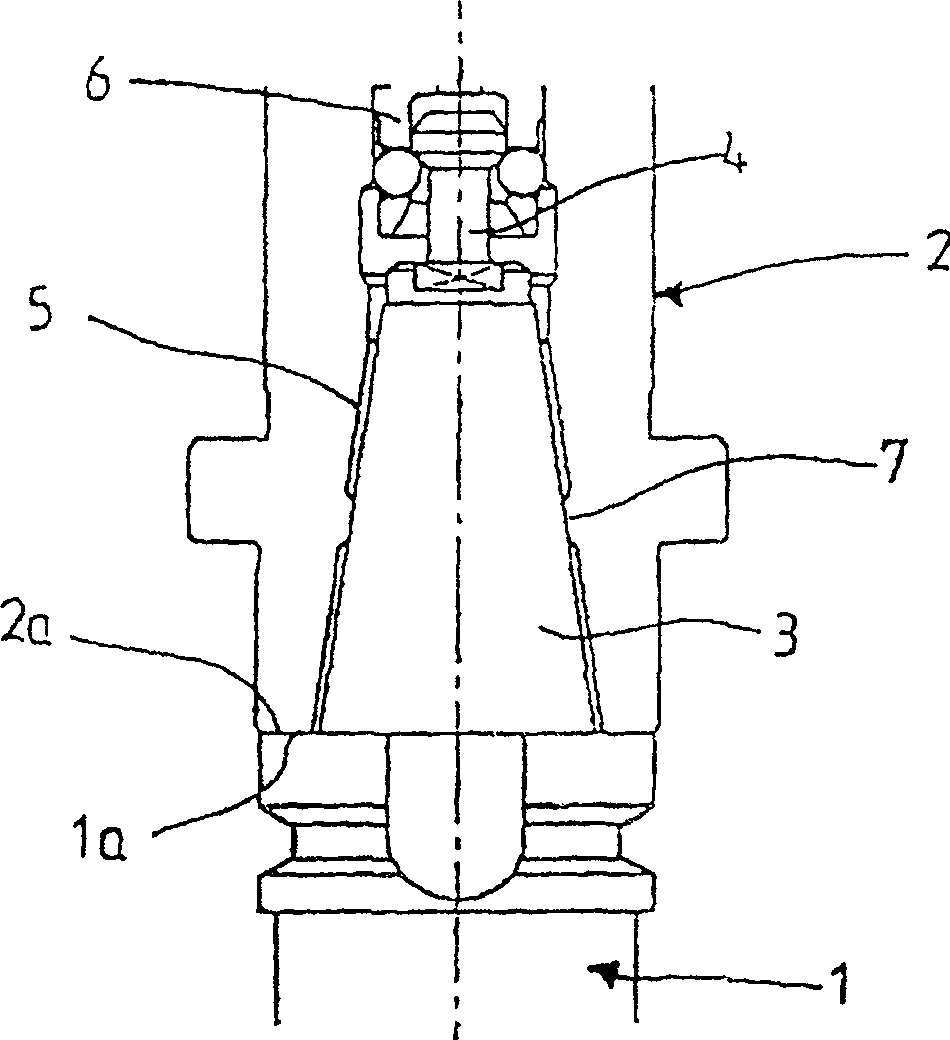

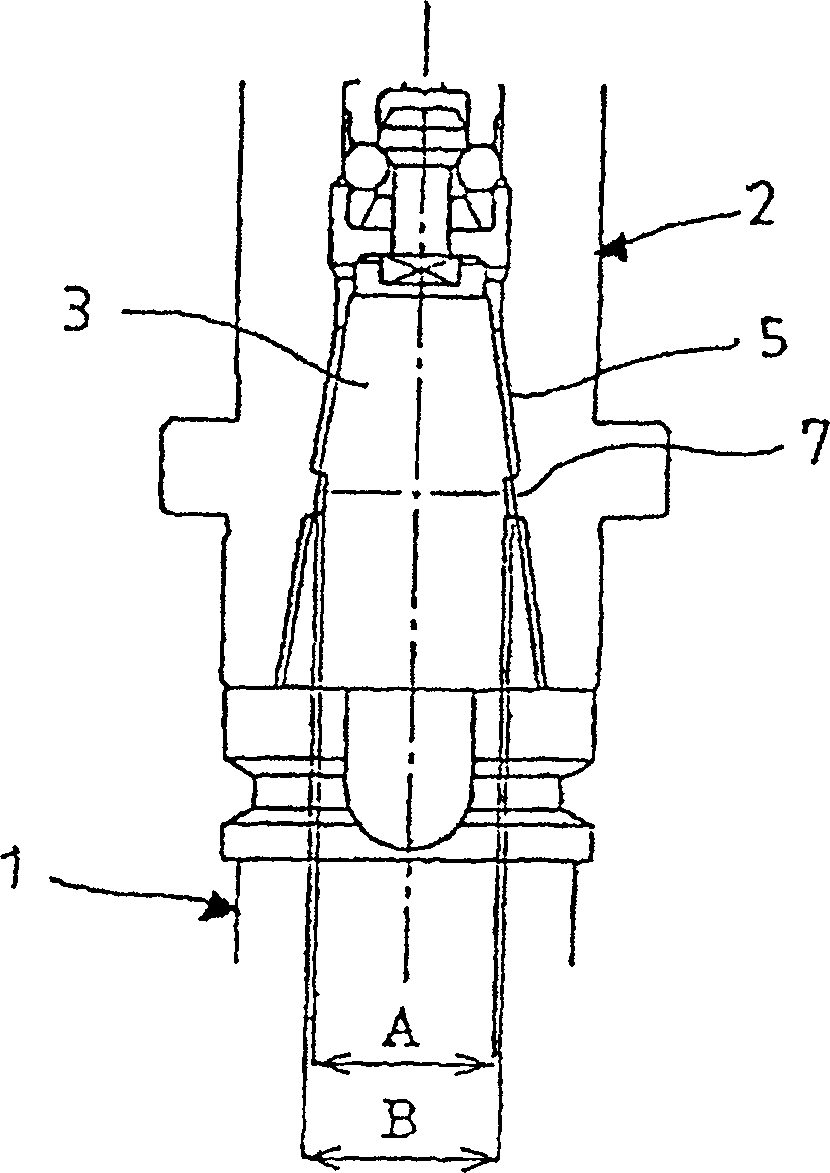

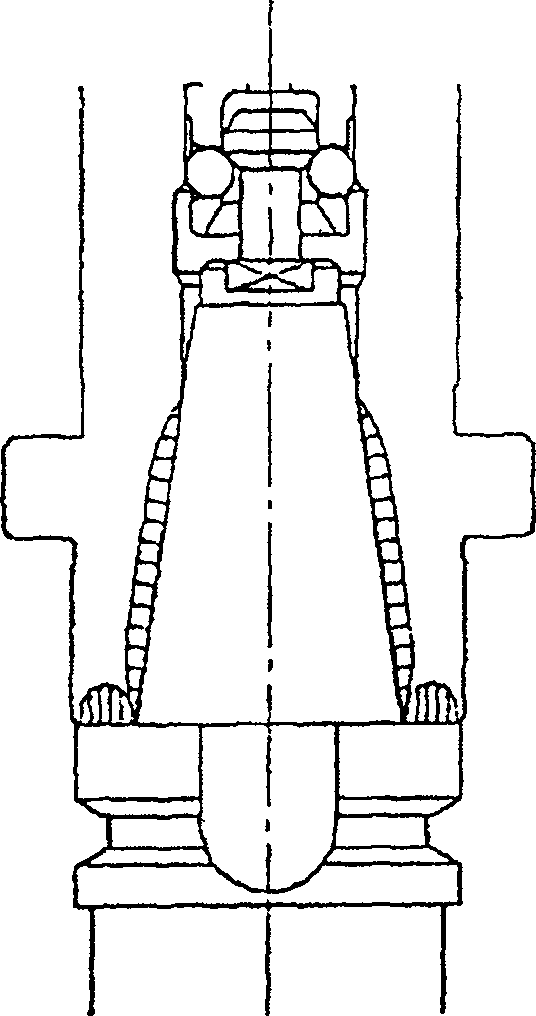

[0027] A first embodiment of a spindle structure of a machine tool according to the present invention will be described with reference to FIG. 1 .

[0028] In the spindle structure shown in Fig. 1, the tool holder 1 with cutting tools and other tools (not shown) installed is installed on the spindle 2 of the machine tool, and the tool is connected to the spindle 2, so that the movement of the spindle 2 can be transmitted to on the knife.

[0029] In the central portion of the end surface 1 a of the tool holder 1 , a convex conical portion 3 is integrally provided, and the central axis thereof coincides with the central axis of the tool holder 1 . On the top of the convex conical portion 3 , a pull bolt 4 is erected along the central axis of the convex conical portion 3 .

[0030] At the central portion of the end surface 2 a of the main shaft 2 , a concave conical portion 5 is formed, the central axis of which coincides with the central axis of the main shaft 2 . At the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com