A modular decorative wall panel and its assembly method

A modular and wall panel technology, applied in covering/lining, construction, building construction, etc., achieves the effects of simple disassembly, time-saving and labor-saving construction period, and reduced wall flatness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

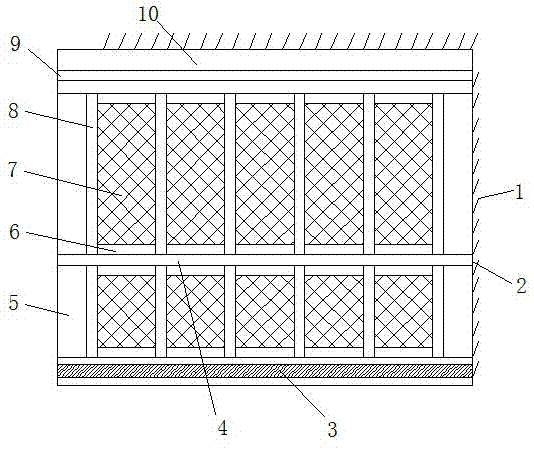

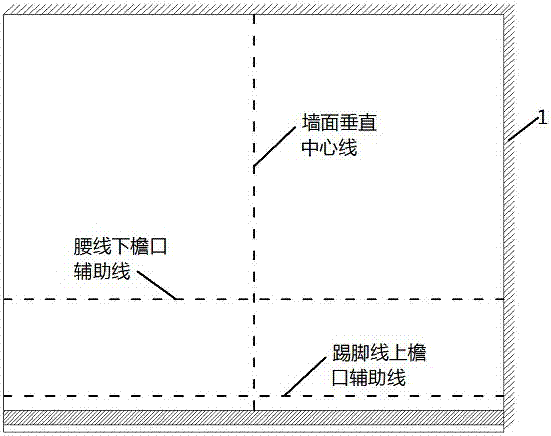

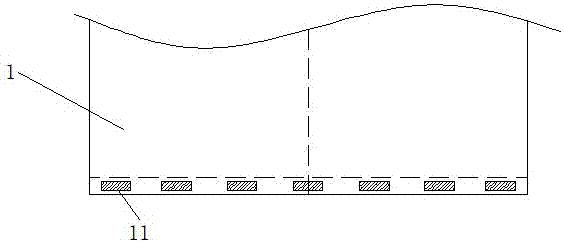

[0043] Such as figure 1 As shown, a modular decorative wall panel includes a wall 1, a modular whole 2, a waistline 4, a standard frame 7, a vertical partition 8, a horizontal partition 6, a baseboard 3, and clips 11 , adjusting plate 5, adjusting hanging plate 9 and top line 10, the surface of the wall 1 is provided with a modular body 2, and the modular body 2 is evenly distributed with standard frames 7 from the middle to both sides, and the left and right ends of the standard frame Both are provided with a vertical partition bar 8, and the bottom and top of the standard frame 7 are provided with a horizontal partition bar 6, and the surface of the wall body 1 is drawn with a vertical center line of the wall surface, a cornice auxiliary line under the waistline, and kicking The cornice auxiliary line on the foot line, the waist line 4 is provided at the cornice auxiliary line under the waist line of the modular whole 2, the skirting line 3 is provided at the bottom of the m...

Embodiment 2

[0052] The modular decorative wall panel and its assembly method according to this embodiment are basically the same as Embodiment 1, the difference is that: this embodiment does not need to install a horizontal partition 6 (see Figure 10 ), the installation step of the horizontal partition 6 is omitted during the installation process, and the standard frame 7 is embedded in the notch 13 provided by the vertical partition 8, skirting line 3 and waist line 4.

Embodiment 3

[0054] The modular decorative wall panel and its assembly method according to this embodiment are basically the same as Embodiment 1, the difference is that: this embodiment does not need to install the waistline 4 (see Figure 11 ), the installation step of the waistline 4 is omitted during the installation process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com