Patents

Literature

133results about How to "Increase transmission torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

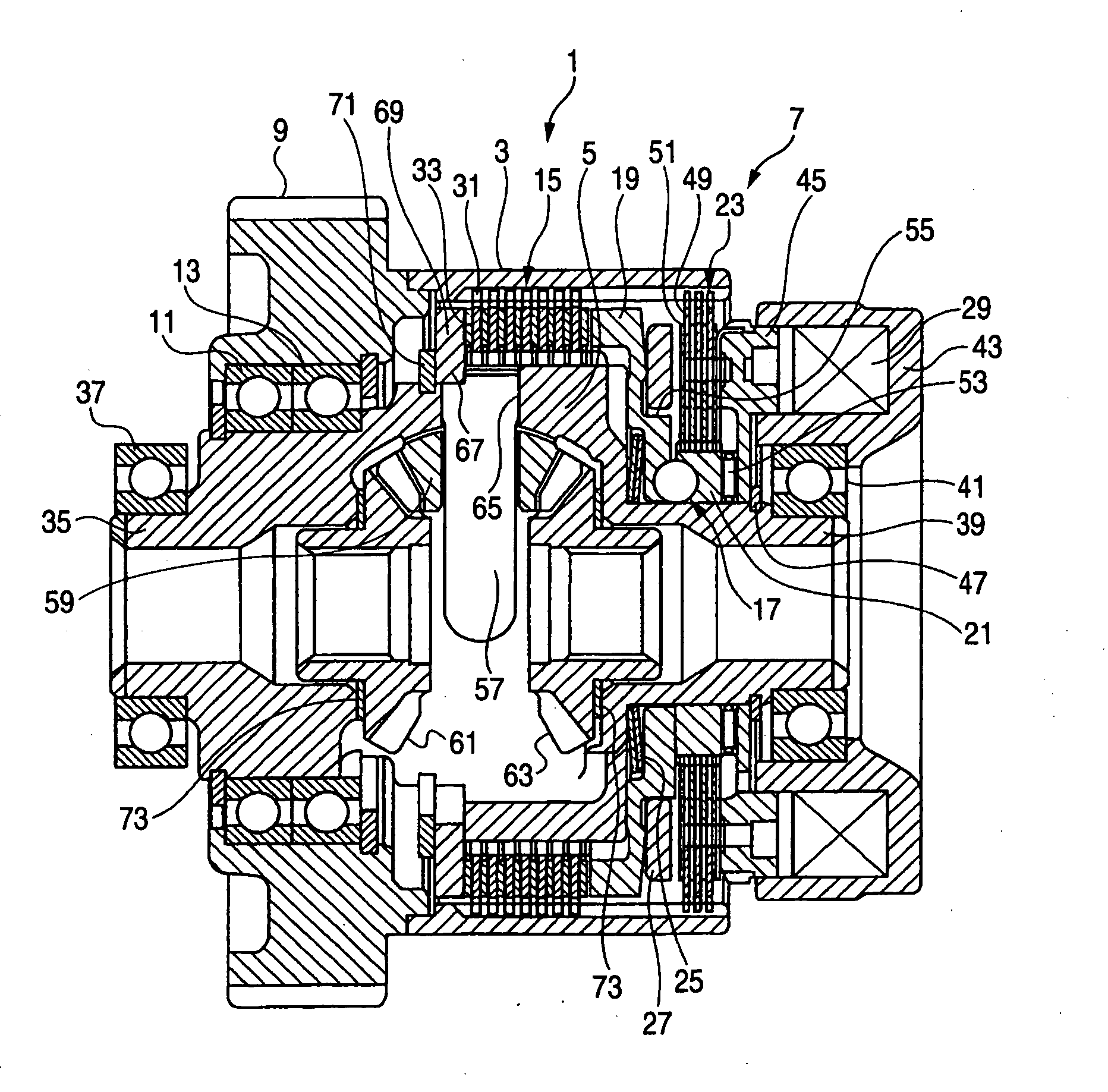

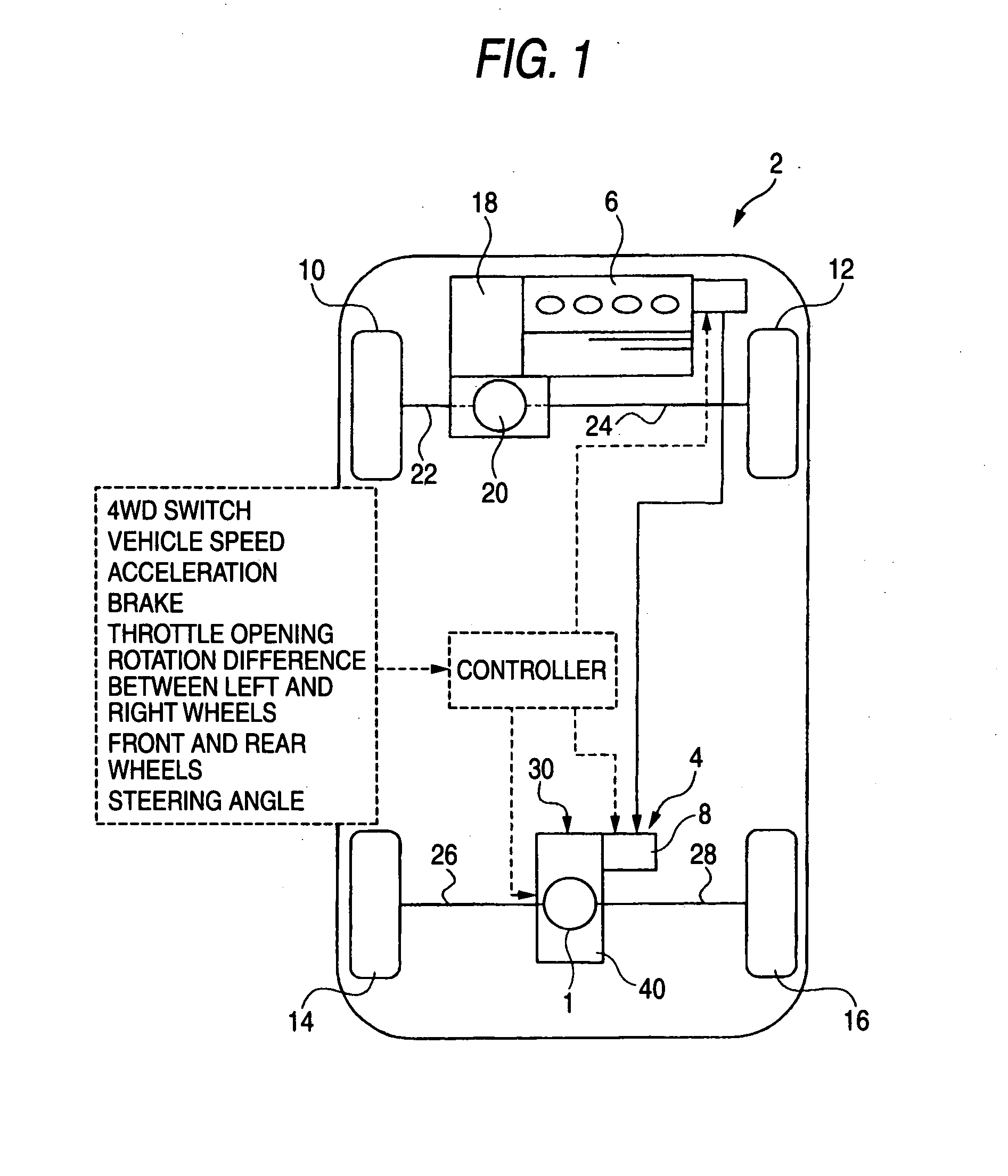

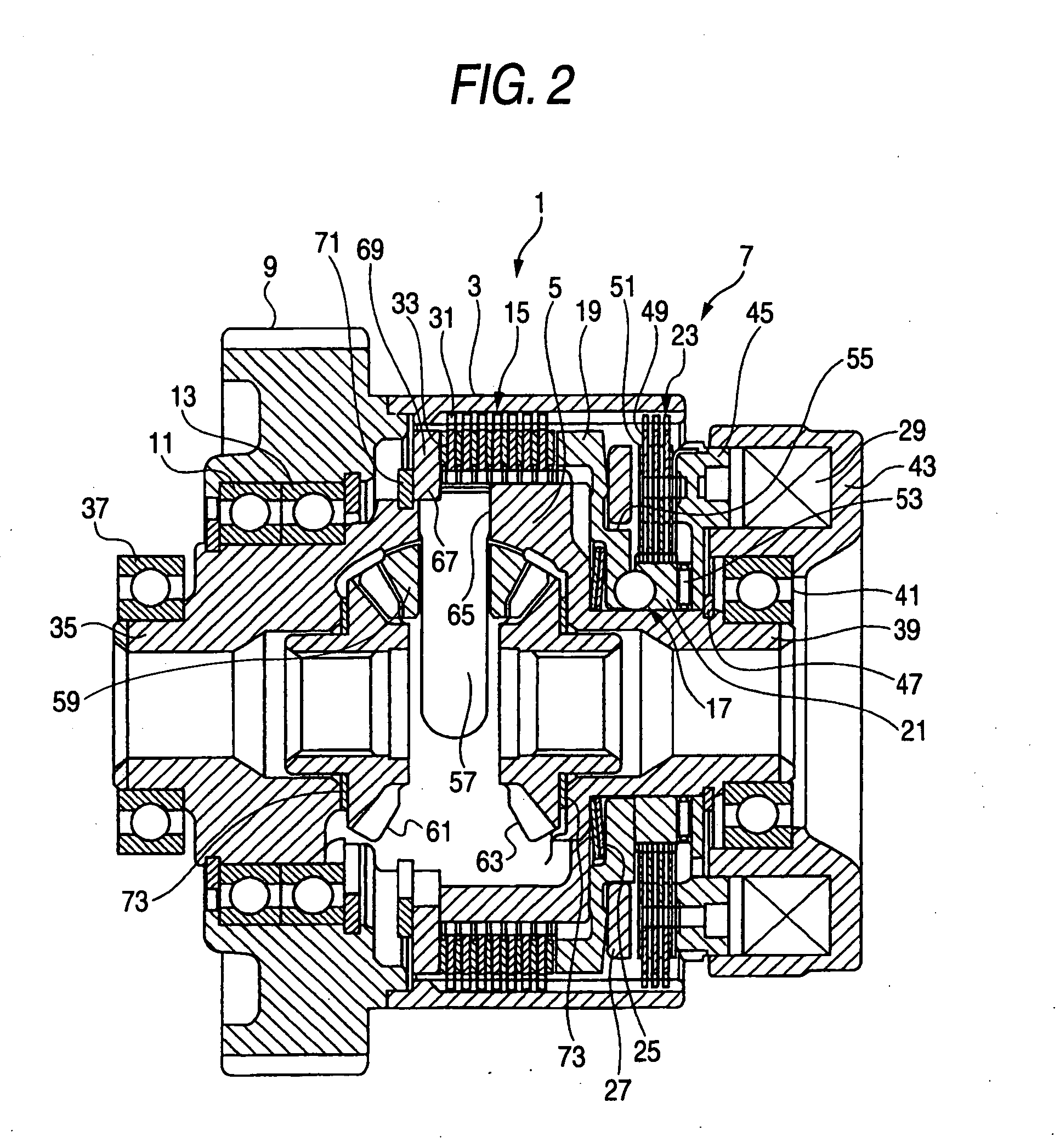

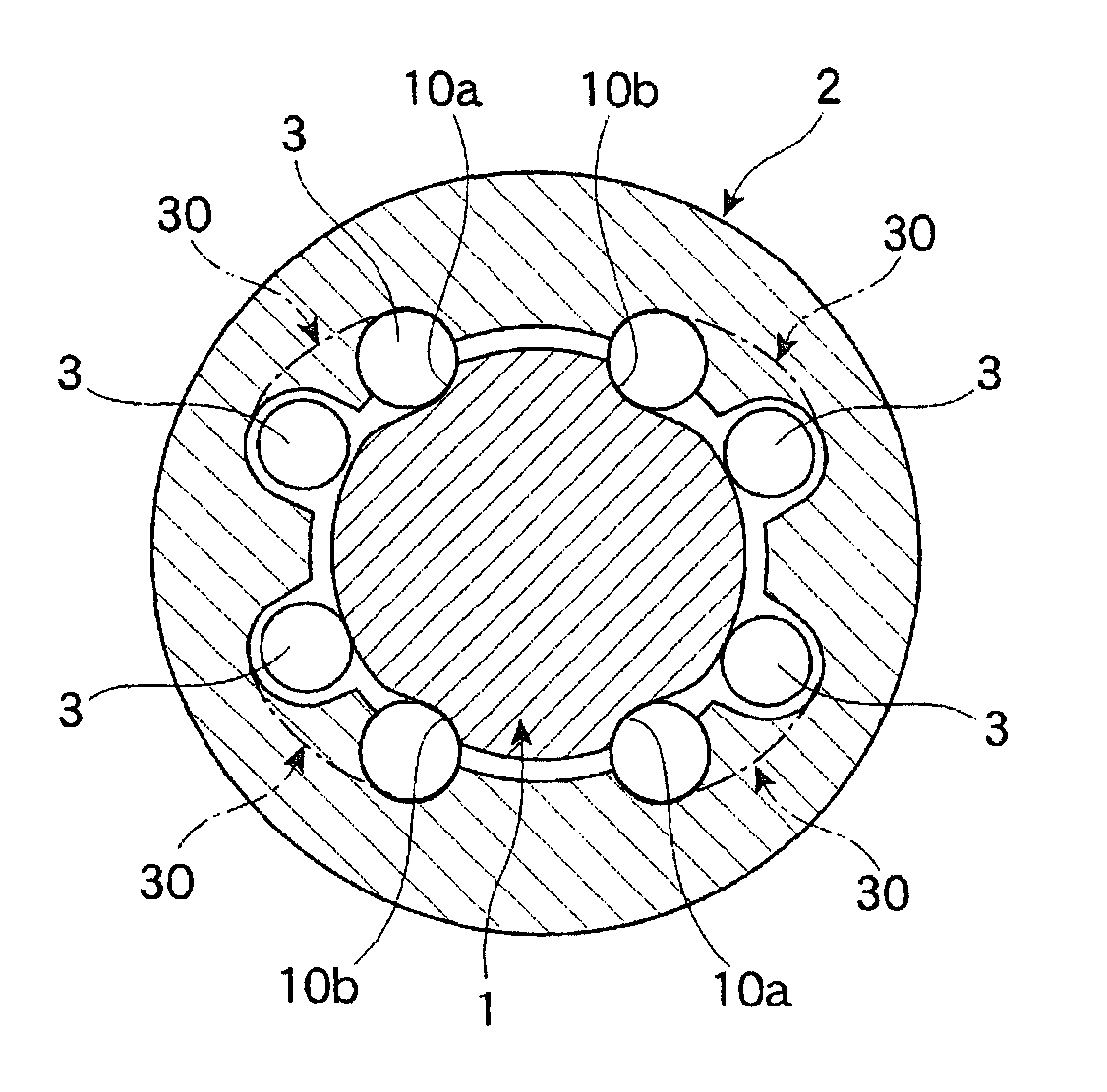

Friction engaging device

InactiveUS20060046890A1Secure strengthReduce and exclude componentMagnetically actuated clutchesDifferential gearingsChemical adsorptionControl theory

An outer plate 31, which is used under a lubricated environment of a differential gear oil including a friction adjuster, is made of a SC tempered material which is subjected to nitriding treatment to suppress chemical adsorption of the friction adjuster. An inner plate 33 has paper on a surface thereof. The outer plate 31 and the inner plate 33 are provided to apply or release the torque between an outer differential case 3 and an inner differential case 5 of a rear differential device 1 having the outer differential case 3 and the inner differential case 5 capable of relatively rotating to the inside and the outside.

Owner:GKN DRIVELINE TORQUE TECHNOLOGY KK

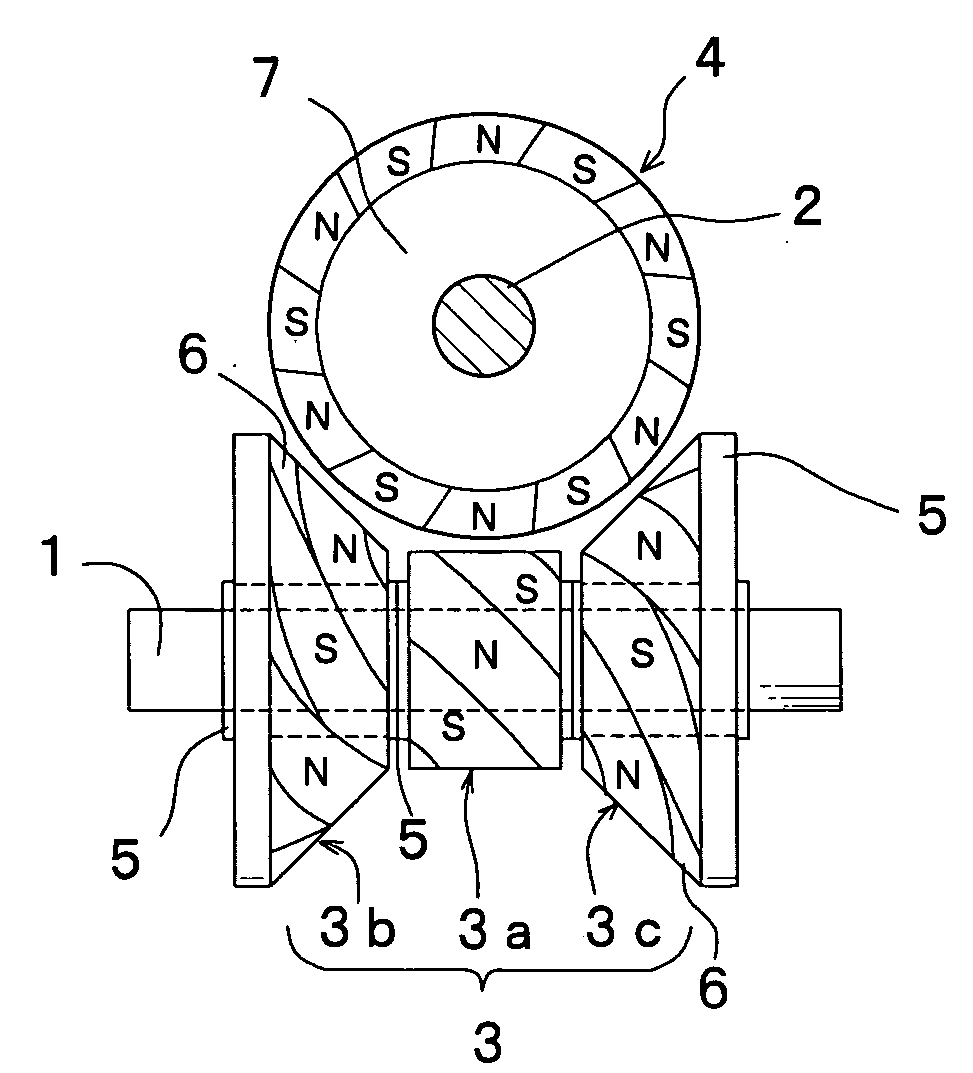

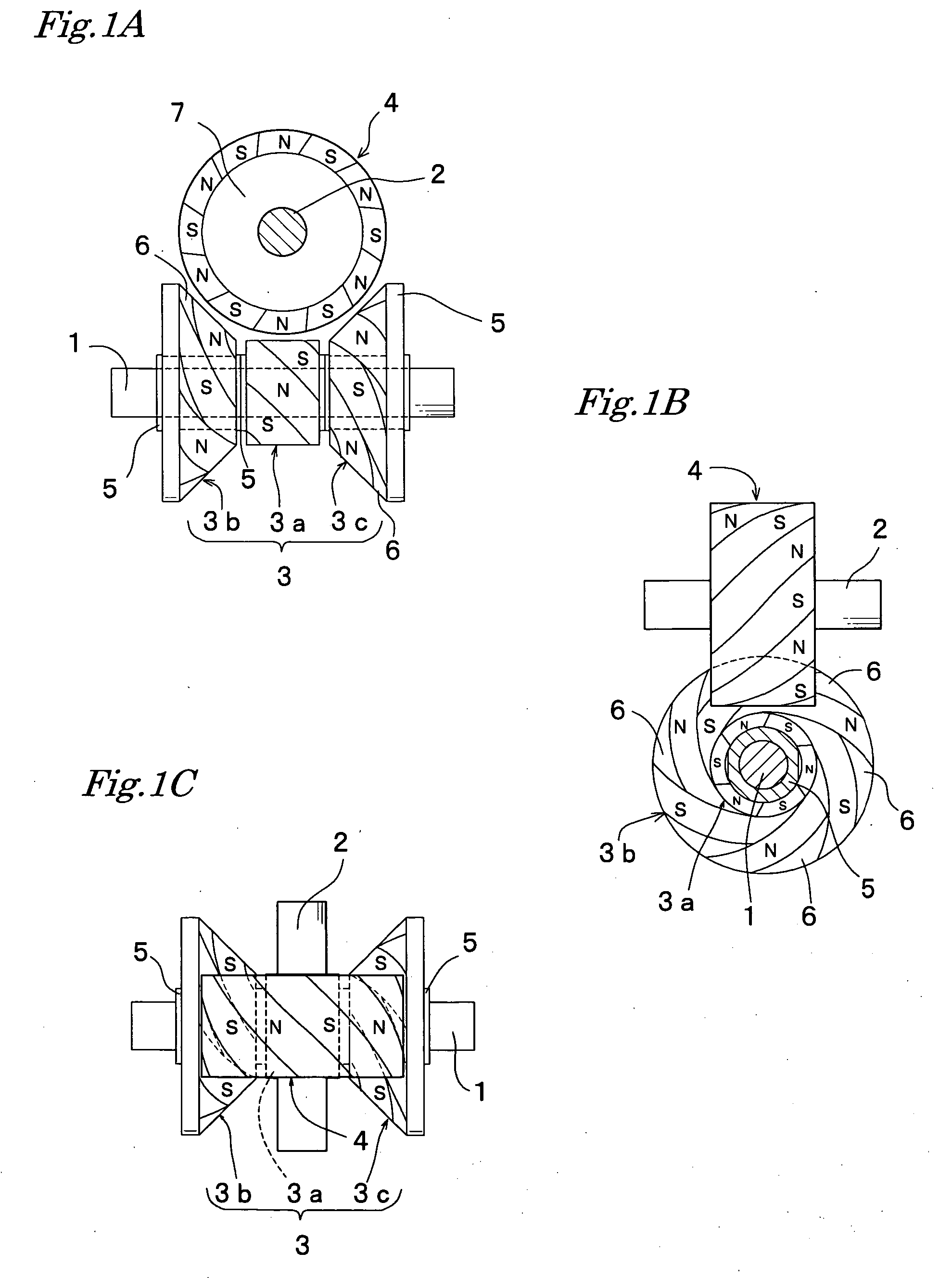

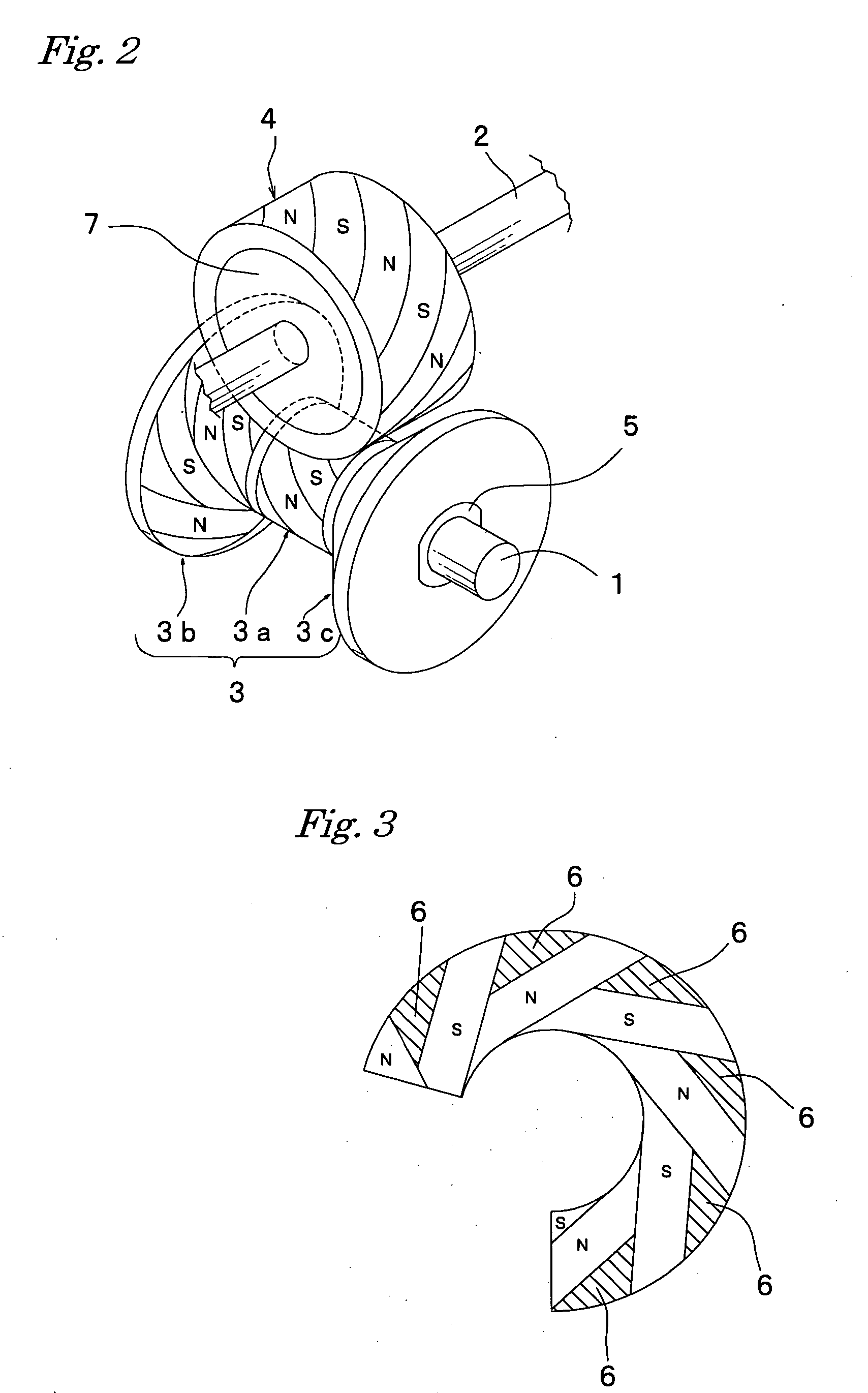

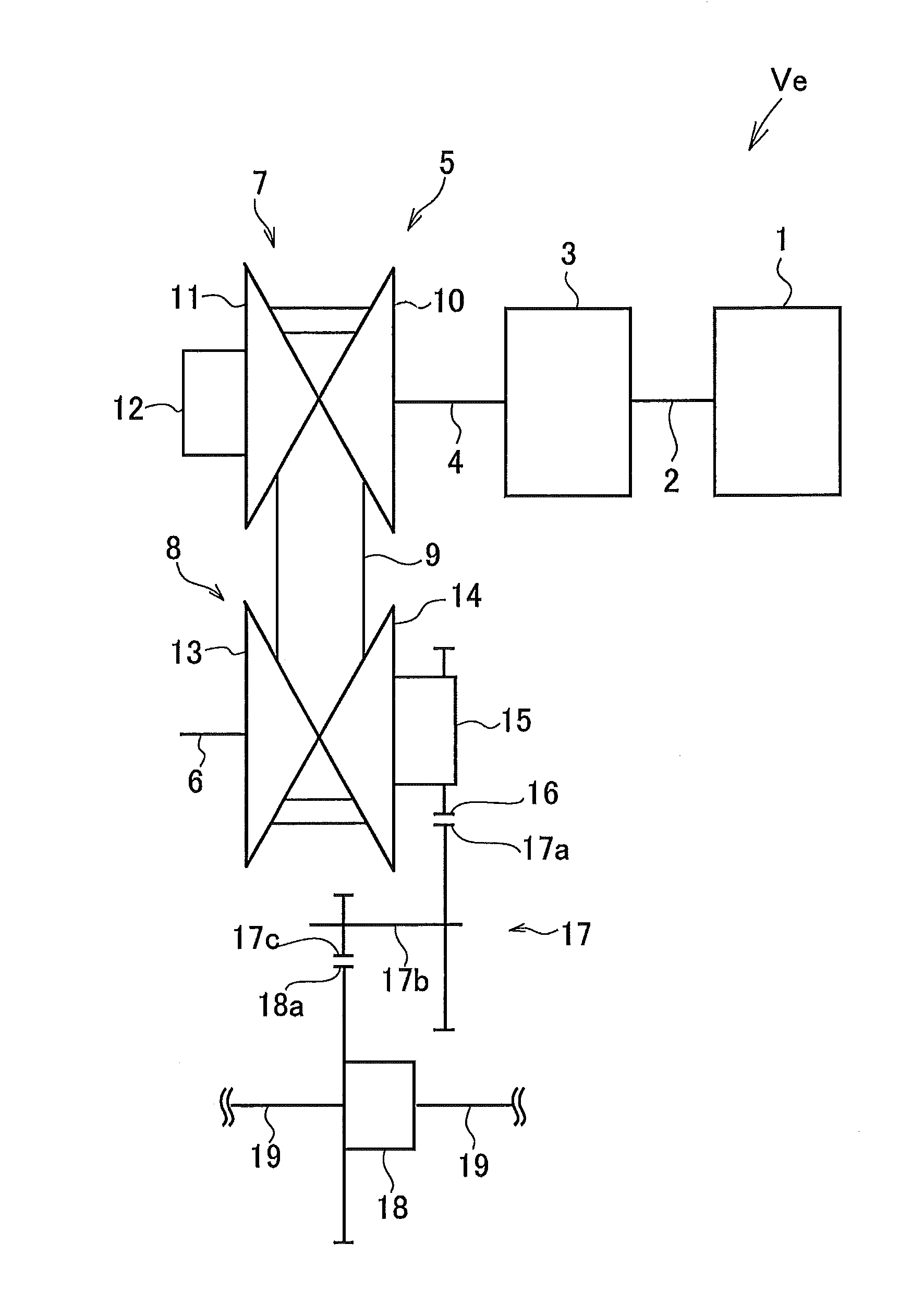

Driving apparatus

InactiveUS20060091748A1Avoid interferenceLoss levelingDynamo-electric brakes/clutchesMechanical energy handlingElectric power transmissionMagnetic tension force

The present invention provides a driving apparatus utilizing magnetic force, which is capable of establishing an enhanced level of higher torque, without enlarging the diameters of the drive magnetic wheel and the follower magnetic wheel, or without installing another transmission system branching off the drive shaft. The driving apparatus where the drive shaft and the follower shaft are arranged in such a manner as crossing each other at right angles, and a non-contact type power transmission mechanism utilizing magnetic force performs power transmission from the drive shaft to the follower shaft, wherein, magnetic wheels are installed respectively on the drive shaft and the follower shaft, each of the magnetic wheels being formed by spirally magnetized into N-pole and S-pole alternately, and plural points are coaxially provided which produce magnetic actions from one magnetic wheel to another magnetic wheel.

Owner:MARUYASU KIKAI KK

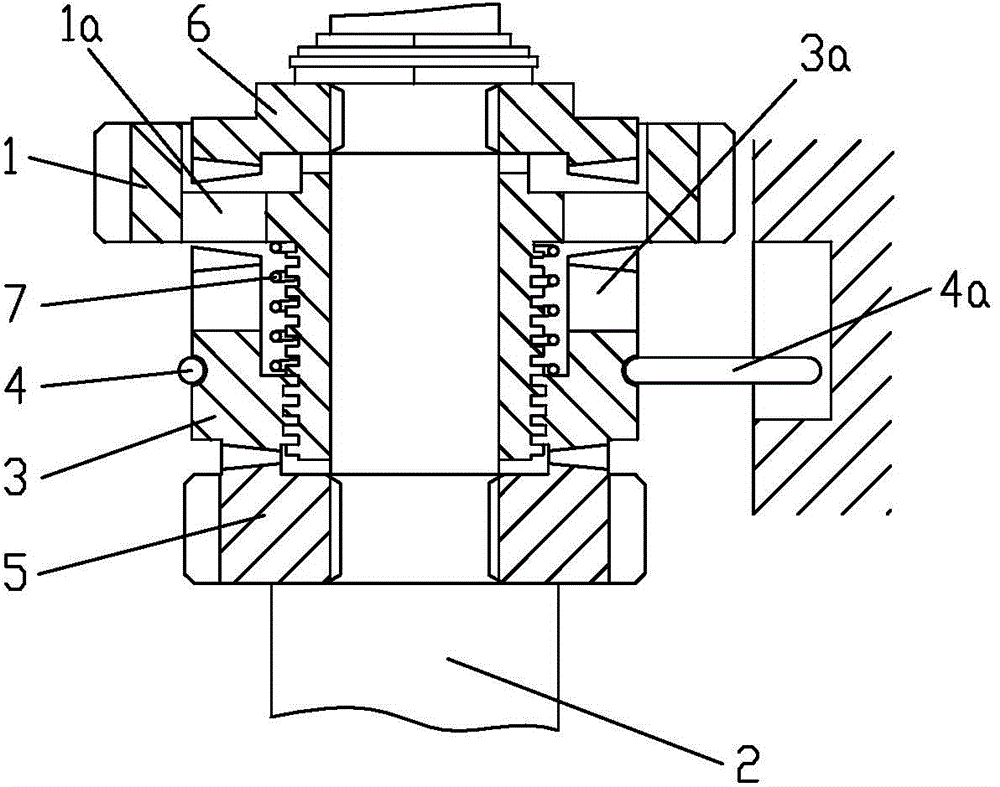

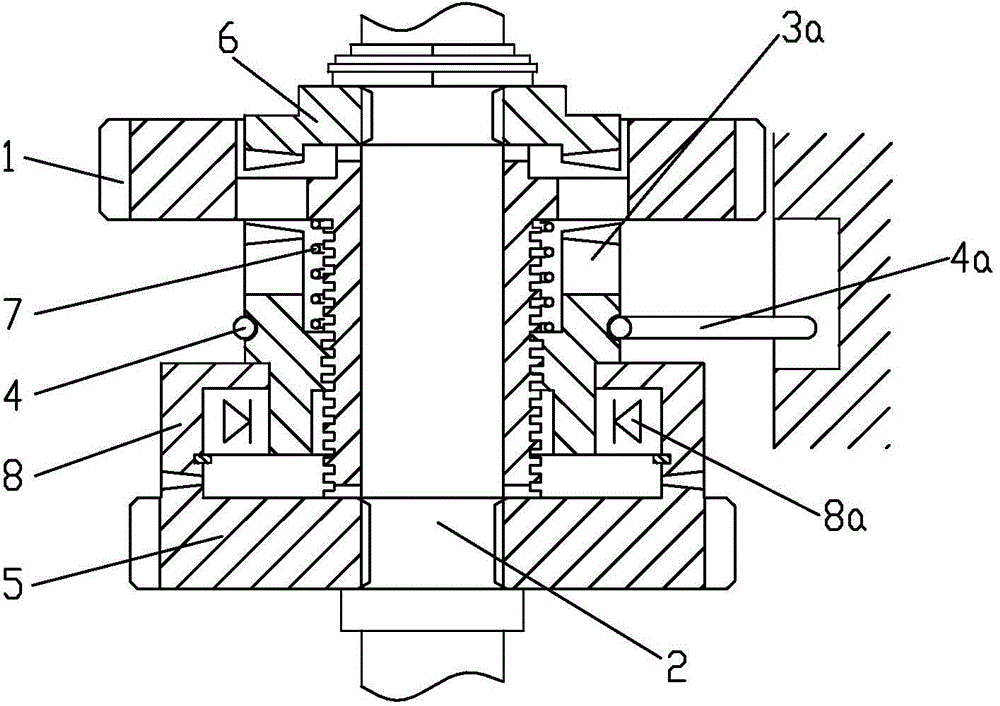

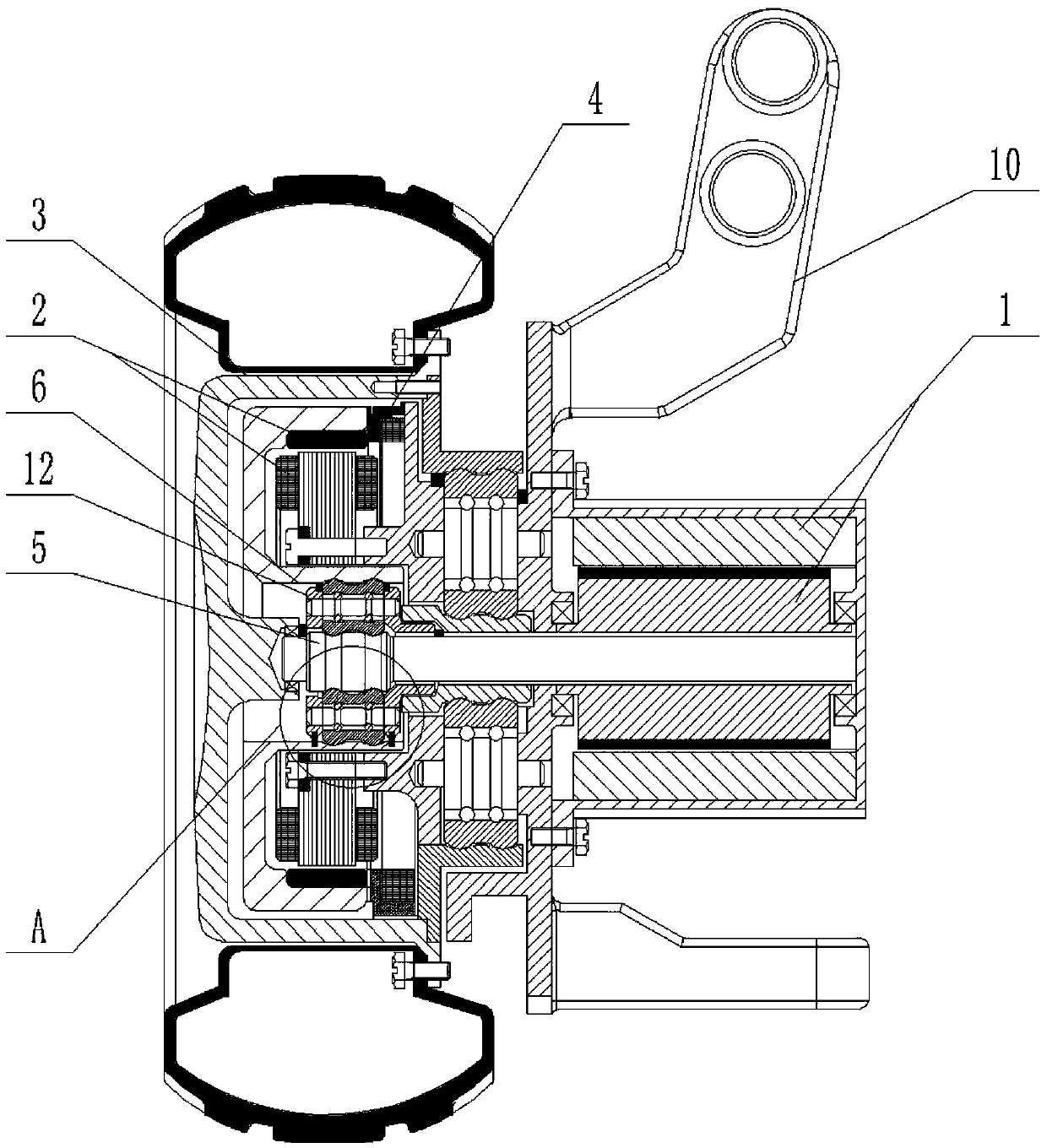

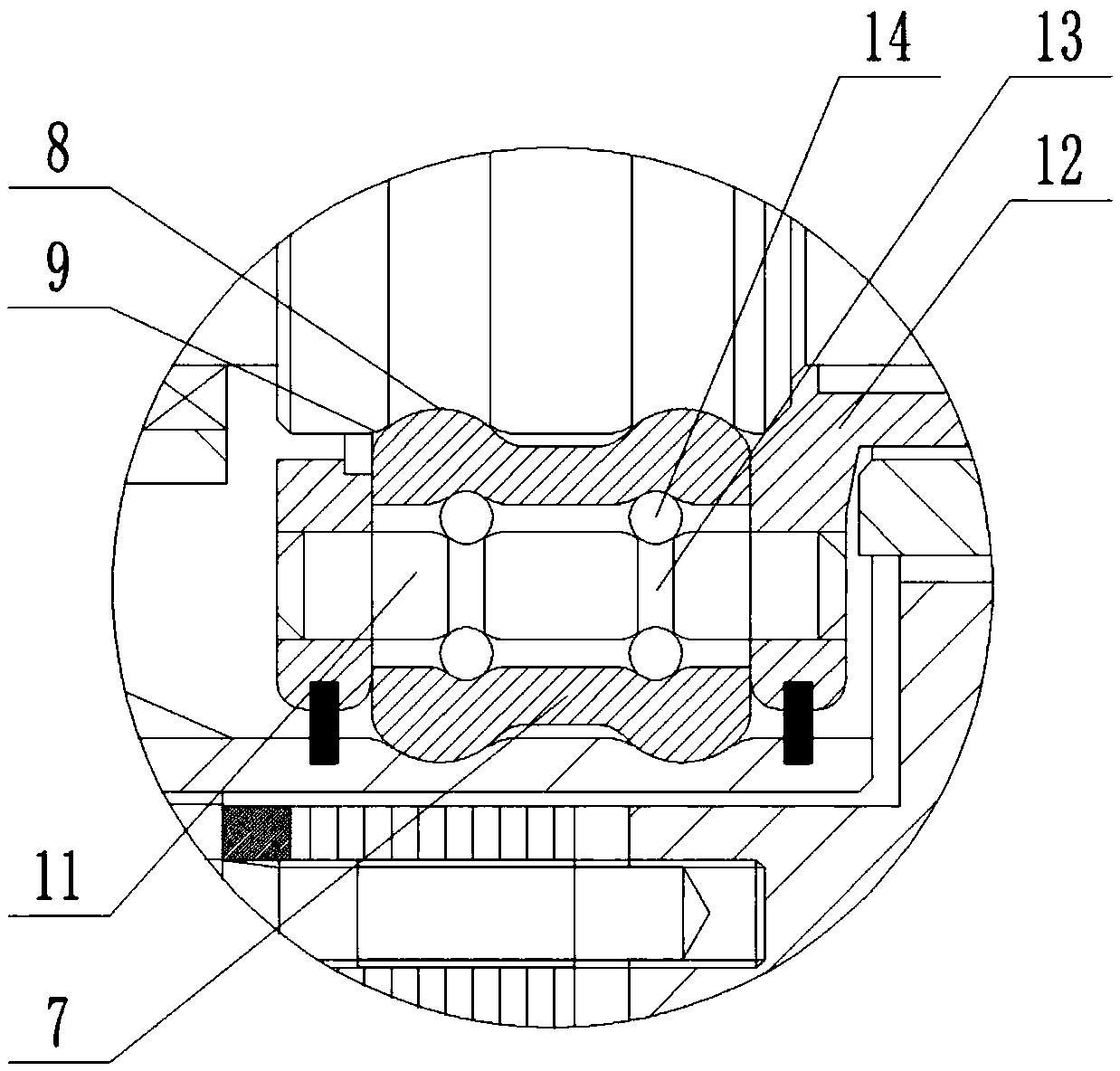

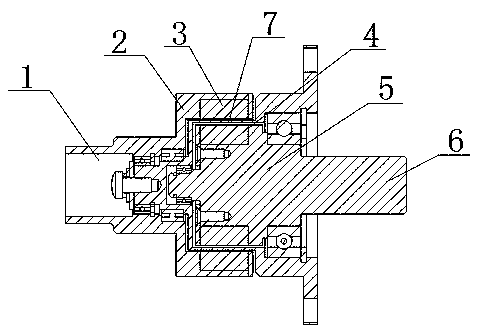

Bidirectional overrunning clutch, speed control device and automatic speed control system

ActiveCN104806656ASmall cross-sectional sizeImprove transmission efficiencyToothed gearingsFreewheel clutchesLow speedAutomatic transmission

The invention discloses a bidirectional overrunning clutch, a speed control device and an automatic speed control system. The bidirectional overrunning clutch comprises a disc-shaped driving part, wherein the disc-shaped driving part can rotatably sleeve a shaft-shaped driven part; a spiral spline sleeve is in spiral spline fit with a journal of the driving part, and a braking device which is used for applying frictional resistance to the spiral spline sleeve is connected to the spiral spline sleeve; a first end surface engagement clutch structure and a second end surface engagement clutch structure are formed between the spiral spline sleeve and the driven part, and the first end surface engagement clutch structure and the second end surface engagement clutch structure are respectively used only for the spiral spline sleeve to drive the driven part to synchronously rotate clockwise and anticlockwise; a bidirectional clutch structure is formed between high and low-speed driven gears of the speed control device and the automatic speed control system. The bidirectional overrunning clutch has the beneficial effects of small cross-sectional dimension, convenience in application, high mechanical efficiency, strong loading capability and long service life; two-gear automatic transmission and reverse output can be realized by the speed control device.

Owner:傅元才

Harmonic-wave speed reducer with improved structure

The invention discloses a harmonic-wave speed reducer with an improved structure of double rigid wheels. Two identical flexible bearings are mounted onto a wave generator. Flexible wheels are circular ring-shaped and mounted onto outer rings of the flexible bearings. The number of internal teeth of a first rigid wheel is greater than that of external teeth of each flexible wheel by two. The first rigid wheel, a rear end cover and an inner ring of a criss-cross roller bearing are connected together as a fixing end of the harmonic-wave speed reducer. The number of internal teeth of a second rigid wheel is the same as that of external teeth of each flexible wheel. The second rigid wheel, a front end cover and an outer ring of the criss-cross roller bearing are connected together as an output end of the harmonic-wave speed reducer.The harmonic-wave speed reducer with the improved structure has a reasonable structure and high load-carrying and impact-resisting capabilities.

Owner:上海鑫君传动科技有限公司

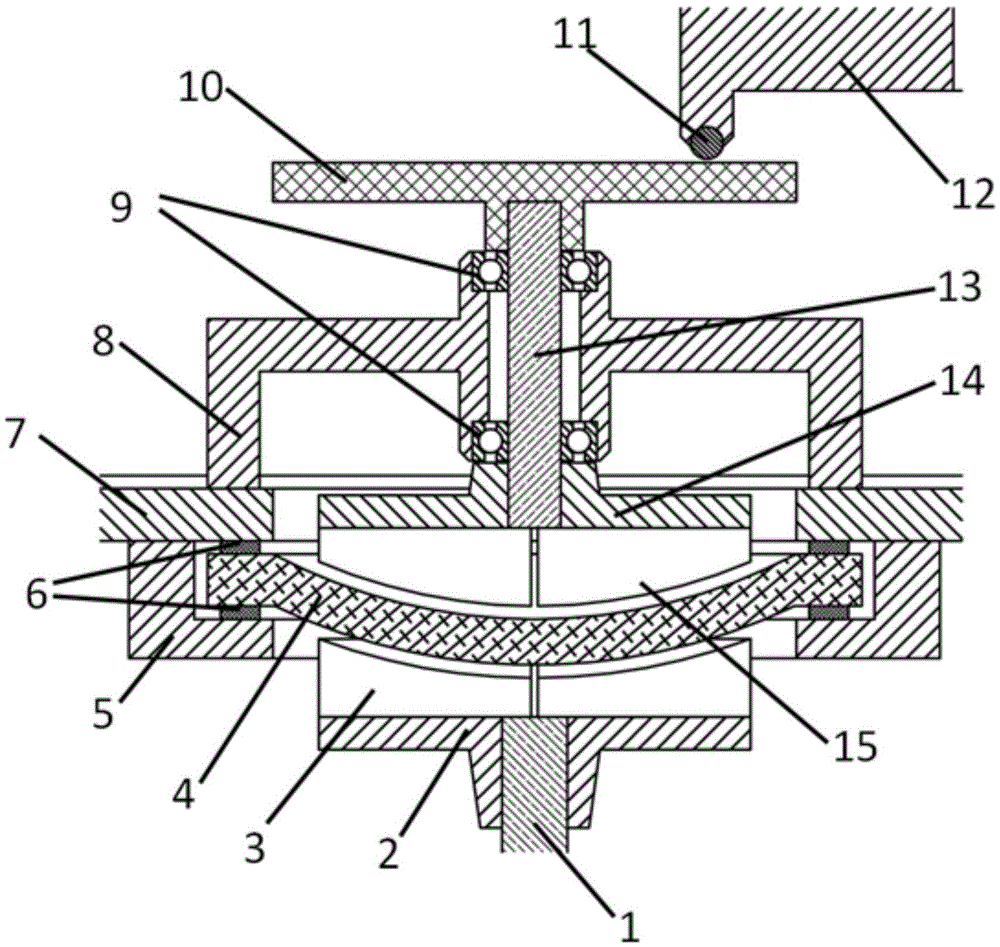

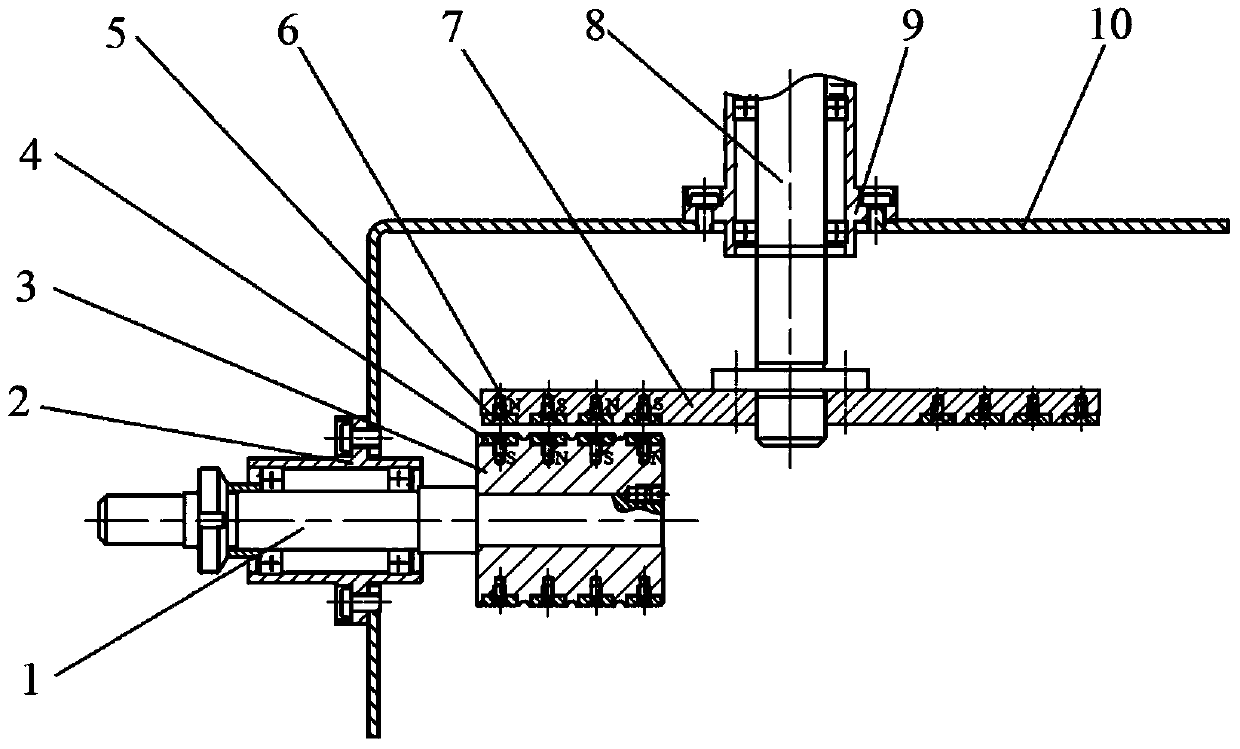

High-vacuum high-speed rotating magnetic transmission device of friction testing machine

ActiveCN105628602AHigh vacuum sealing requirementsReduced eddy current lossUsing mechanical meansInvestigating abrasion/wear resistanceDrive shaftEngineering

The invention relates to a high-vacuum high-speed rotating magnetic transmission device of a friction testing machine. The high-vacuum high-speed rotating magnetic transmission device comprises an outer driving shaft, an inner driven shaft, an inner permanent magnet, an inner permanent magnet fixing seat, an outer permanent magnet, an outer permanent magnet fixing seat, a rotating disc, a bearing support, a quartz separation component and a loading rod. The inner permanent magnet fixing seat is fixed to the lower portion of the inner driven shaft, and the inner permanent magnet is fixed to the lower portion of the inner permanent magnet fixing seat. The outer permanent magnet is opposite to the inner permanent magnet and fixed to the upper portion of the outer permanent magnet fixing seat, the outer permanent magnet fixing seat an the outer driving shaft are fixedly connected, and the inner permanent magnet and the outer permanent magnet are separated through the profiled quartz separation component. The quartz separation component and the bearing support cooperate to seal the inner driven shaft, the inner permanent magnet fixing seat and the inner permanent magnet in a sealed vacuum space. The outer driving shaft and the inner driven shaft are coaxially arranged. The rotating disc and the upper portion of the inner driven shaft are fixedly connected in a sealed mode. The loading rod is arranged above the rotating disc, and a friction test piece on the loading rod makes contact with the rotating disc.

Owner:SHANGHAI JIAO TONG UNIV

Star wheel reducer

InactiveCN101038017AReduce volumeImprove carrying capacityToothed gearingsAgricultural engineeringReducer

The invention relates to a star-wheel speed reducer, which belongs to speed reducer technology field, comprising an input shaft, output shaft, gears, geared ring and a through cover, characterized in that the reducer casing is provided with the input shaft, output shaft, gears, geared ring. The input shaft is equipped with an eccentric sleeve, which is provided with double axial bearings, the eccentric sleeve is provided with two eccentric bearings equipped gears, the two gears are externally connected with tooth rings, the two gears are fixed on an even-carrying plate and the output shaft, the even-carrying plate is provided with a bearing, and a sealing ring is provided between the output shaft excircle and the through cover. The invention is provided with advantages of simple structure, smaller volume, high bearing capacity, low production cost, high transmission accuracy, convenient assemblage and combined application with other types of speed reducers, which can be widely used in speed reducer industry.

Owner:天津百利天星传动有限公司

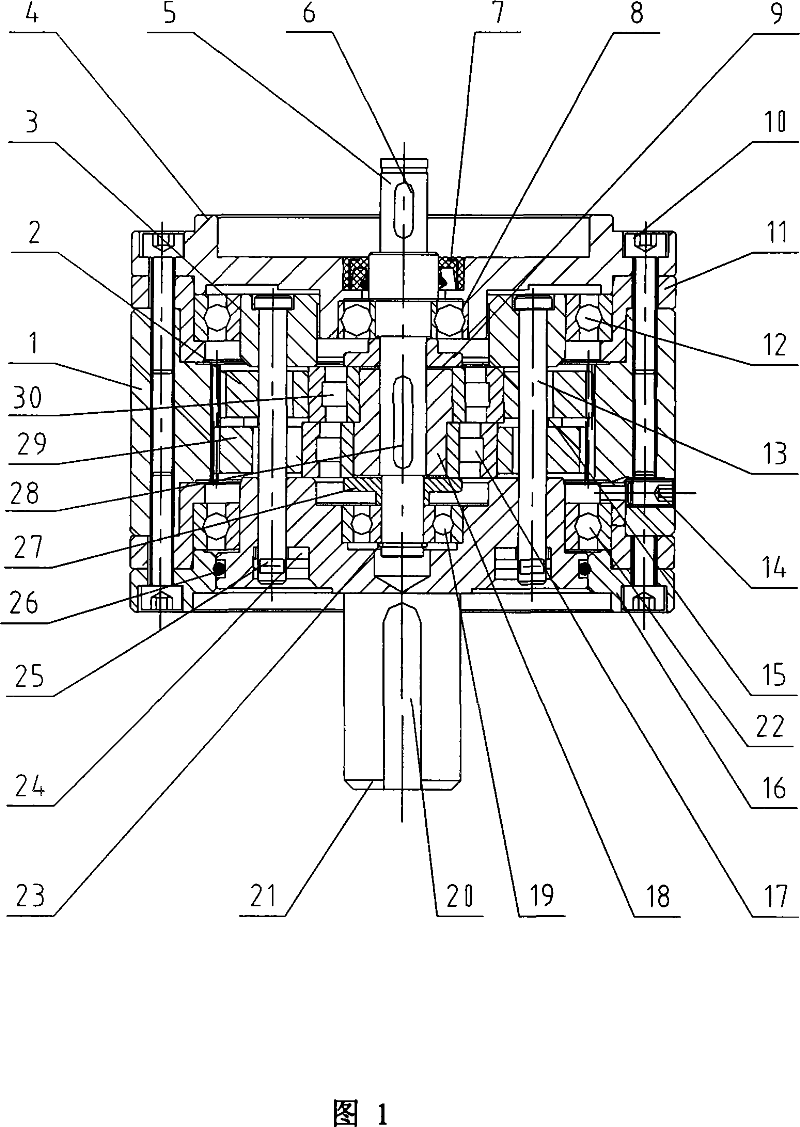

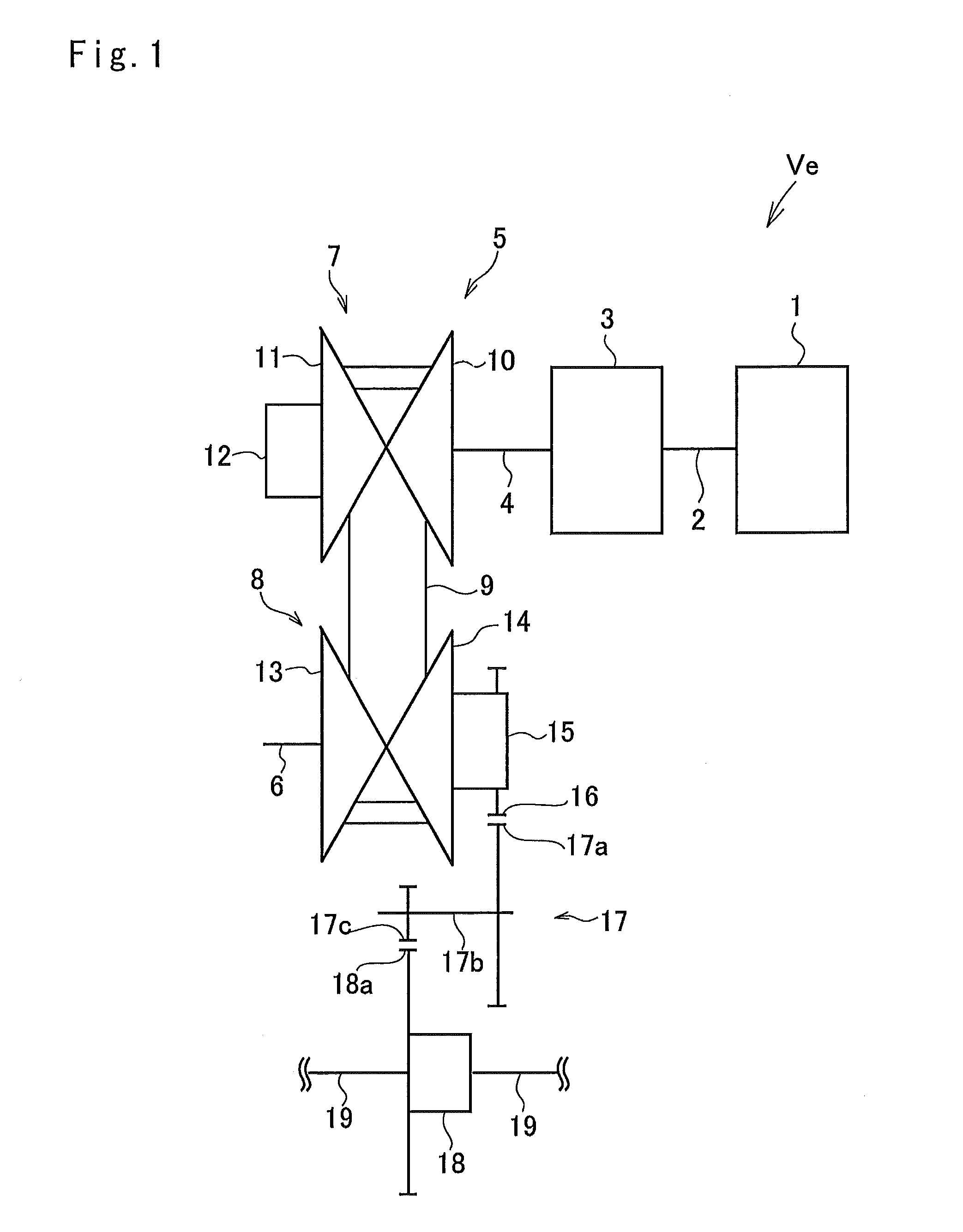

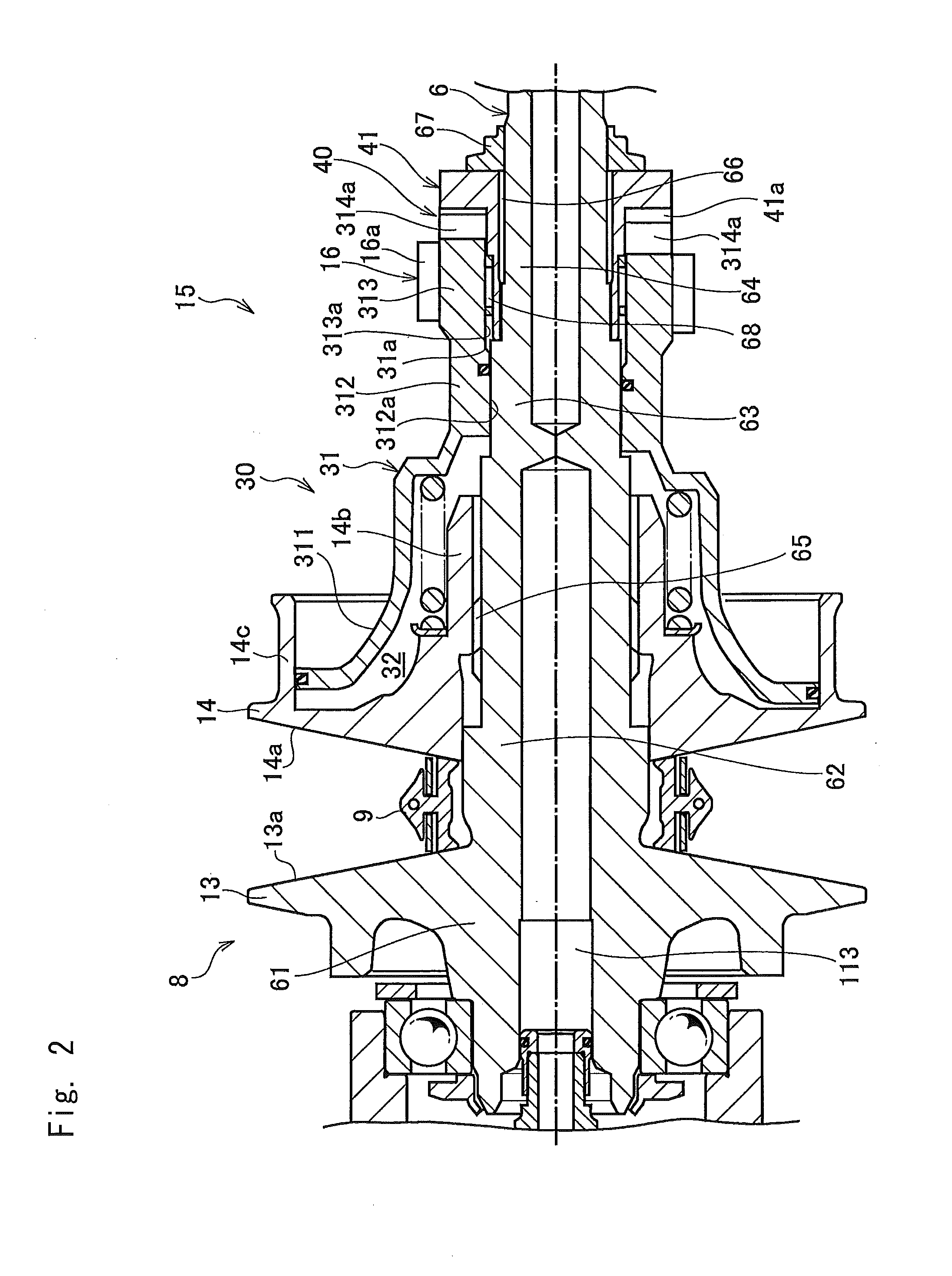

Belt-driven continuously variable transmission

ActiveUS20160131230A1Control damageIncrease transmission torqueGearingGearing controlDrive shaftReciprocating motion

A belt-driven continuously variable transmission adapted to prevent an occurrence of belt slippage is provided. The continuously variable transmission comprises a hydraulic actuator formed on a back side of a movable sheave to change a belt groove between a fixed sheave and a movable sheave, and a torque cam assembly adapted to convert a torque into an axial thrust force by a relative rotation between a pair of cam members contacted to each other. In the belt-driven continuously variable transmission, a piston fitted onto a shaft of the driven pulley while allowing to rotate relatively therewith and to reciprocate thereon is integrated with one of the cam members of driven side and with an output gear for outputting torque of the pulley. The cam member of drive side is fixed in an axial direction on a driven shaft to be rotated integrally therewith.

Owner:TOYOTA JIDOSHA KK

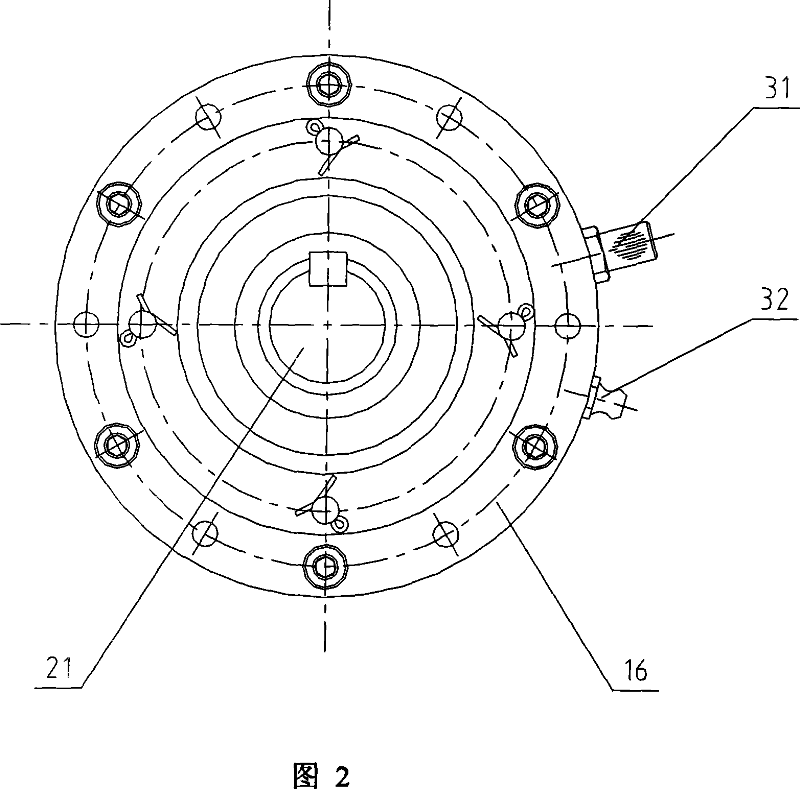

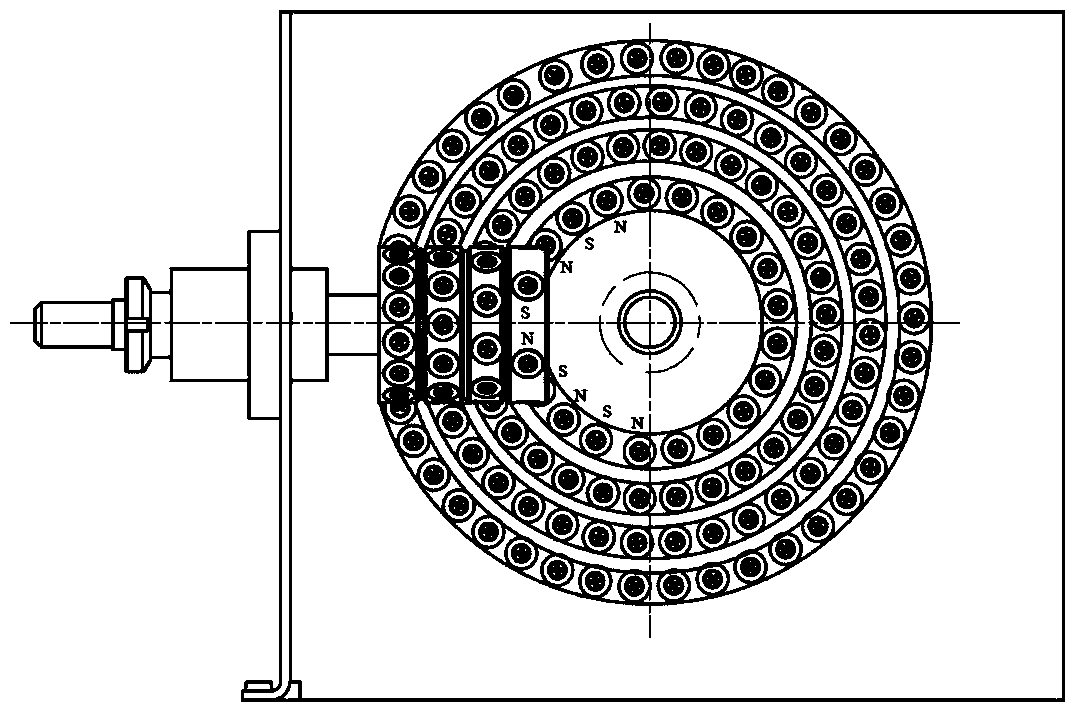

Permanent magnet plane gear mechanism

InactiveCN103427592AReduce manufacturing difficultyIncrease transmission torqueDynamo-electric gearsMagnetic polesElectrical polarity

The invention discloses a permanent magnet plane gear mechanism. The axis of a small cylindrical wheel is in orthogonal layout with the axis of a big round disc. A plurality of circles of concentric permanent magnet blocks are evenly distributed on the plane of the big round disc. A plurality of circles of permanent magnet blocks which have equal diameters and have the opposite polarity with the permanent magnet blocks on the big round disc are correspondingly and coaxially arranged on the cylindrical surface of the small cylindrical wheel. When the permanent magnet plane gear mechanism works, the positions of the minimum air gaps generated when the permanent magnet blocks on the small cylindrical wheel are meshed with the permanent magnet blocks on the big round disc are mutually aligned. A plurality of permanent magnet blocks on a plurality of sets of meshing pairs participate in meshing and the meshing time is non-synchronous. Therefore, the permanent magnet plane gear mechanism not only improves driving torque, but also improves driving stationarity under the condition of loading. In addition, the same round permanent magnet blocks are adopted in the two permanent magnet gears, the manufacturing difficulty of magnetic pole blocks and the permanent magnet gears is reduced.

Owner:DALIAN UNIV OF TECH

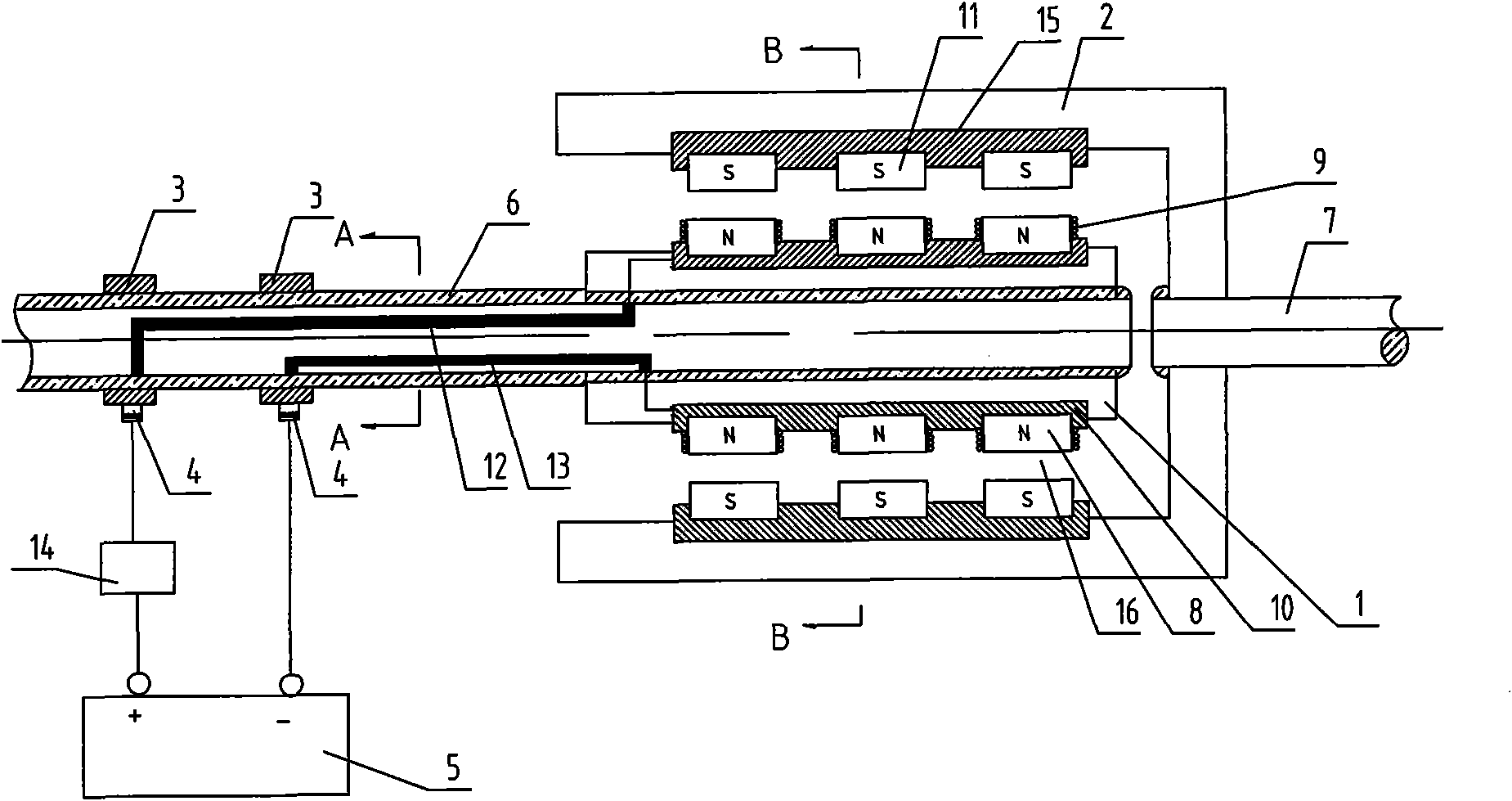

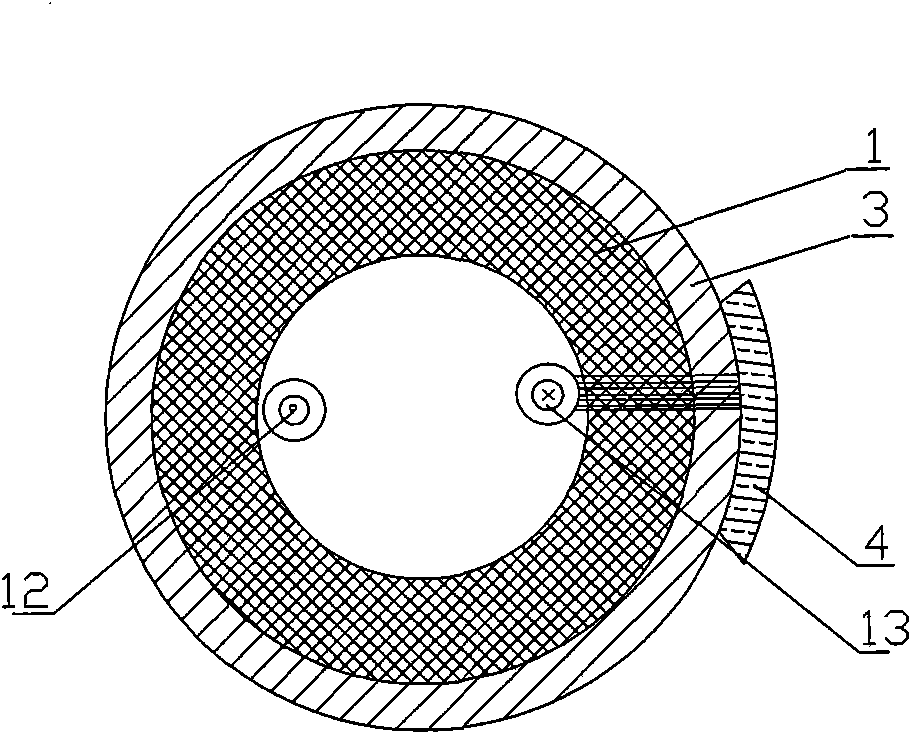

Barrel-type electromagnetic speed regulation system

InactiveCN101860314AReduced precision requirementsIncrease the areaDynamo-electric brake controlSoft magnetEngineering

The invention relates to a barrel-type electromagnetic speed regulation system, which comprises an inner barrel rotor, an outer barrel rotor, conductive slip rings, electric brushes and a DC power supply, wherein the inner barrel rotor is arranged at an input shaft end; the outer barrel rotor is arranged at an output shaft end; the inner barrel rotor and the outer barrel rotor are coaxially nested; the inner barrel rotor is provided with soft magnets of which each is provided with a coil; positions, corresponding to the soft magnets, on the outer barrel rotor are provided with permanent magnets; the input shaft is provided with the conductive slip rings which are matched with the electric brushes; the electric brushes are connected with the anode and the cathode of the DC power supply; the conductive slip rings are connected with the coils by lead wires; and the coils wound by the circumferentially adjacent soft magnets arranged on the inner barrel rotor rotate in opposite directions, while the coils wound by the axially adjacent soft magnets are in the same direction. The barrel-type electromagnetic speed regulation system has the advantages that: the soft magnets on the inner barrel rotor reduce demagnetization and realize control over a rotation speed of the output shaft; and the barrel structure can generate strong electromagnetism, and the areas of the permanent magnets are great, so working efficiency is improved.

Owner:ANSHAN QINYUAN ENERGY SAVING EQUIP MFG

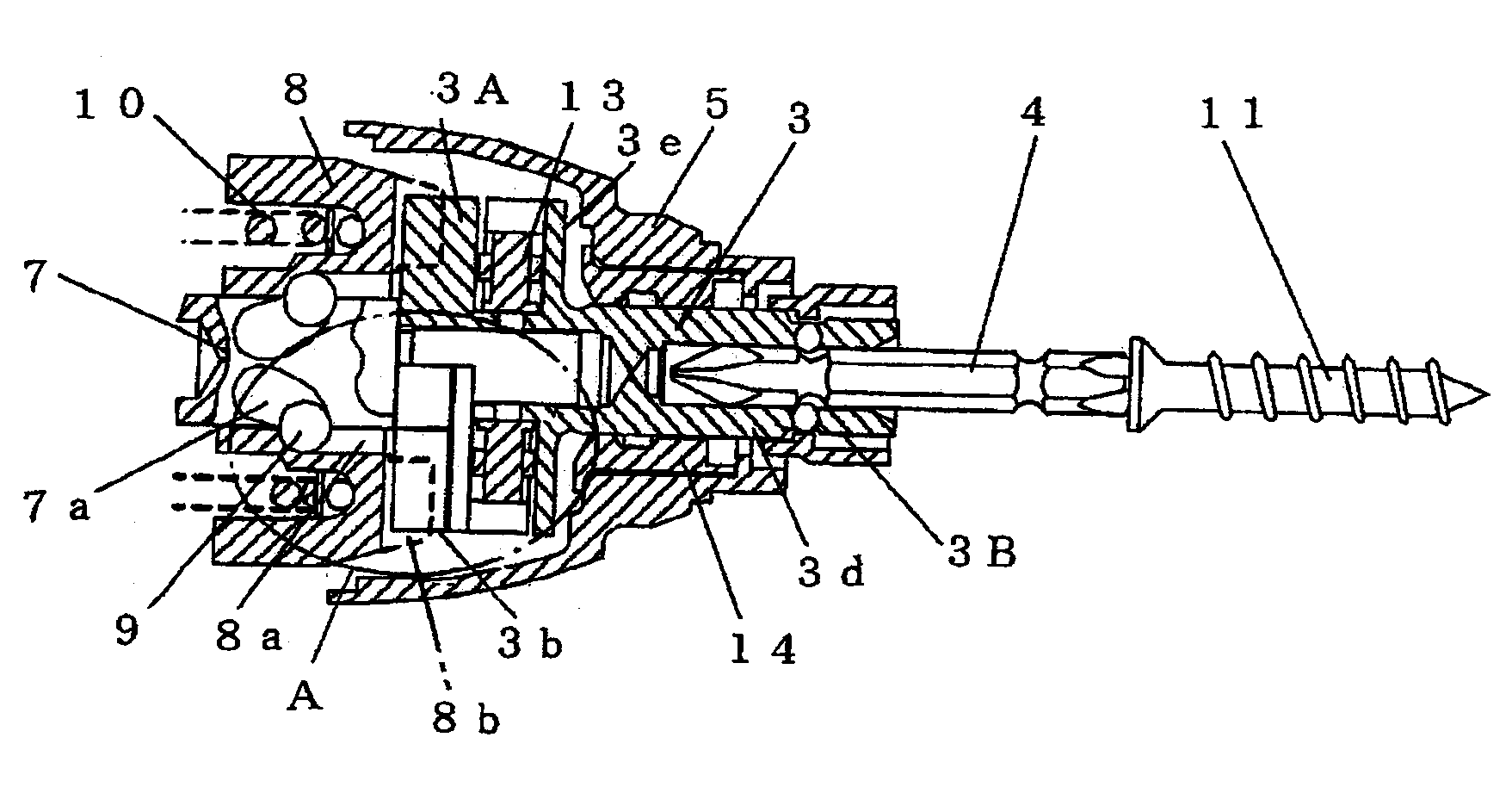

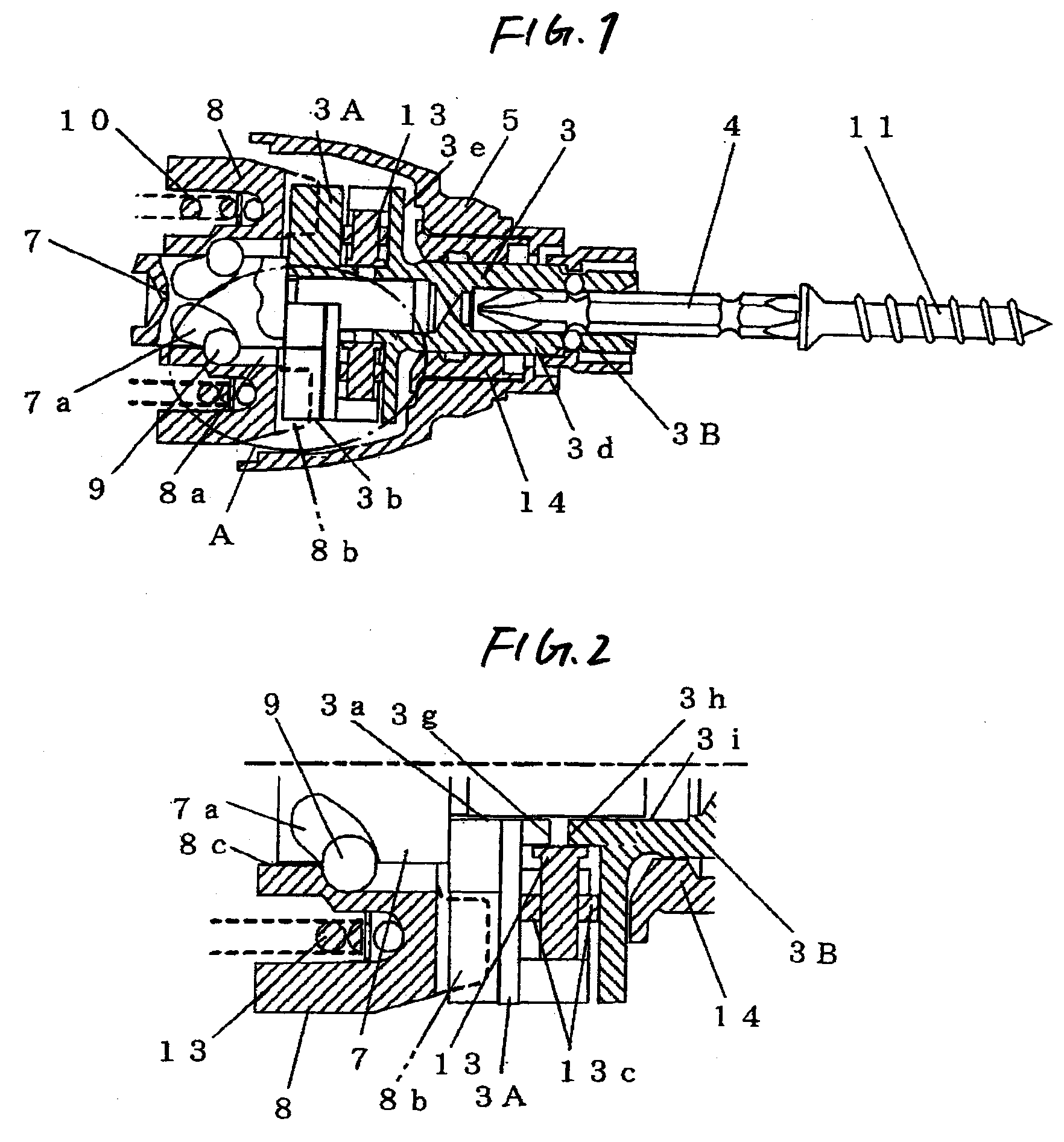

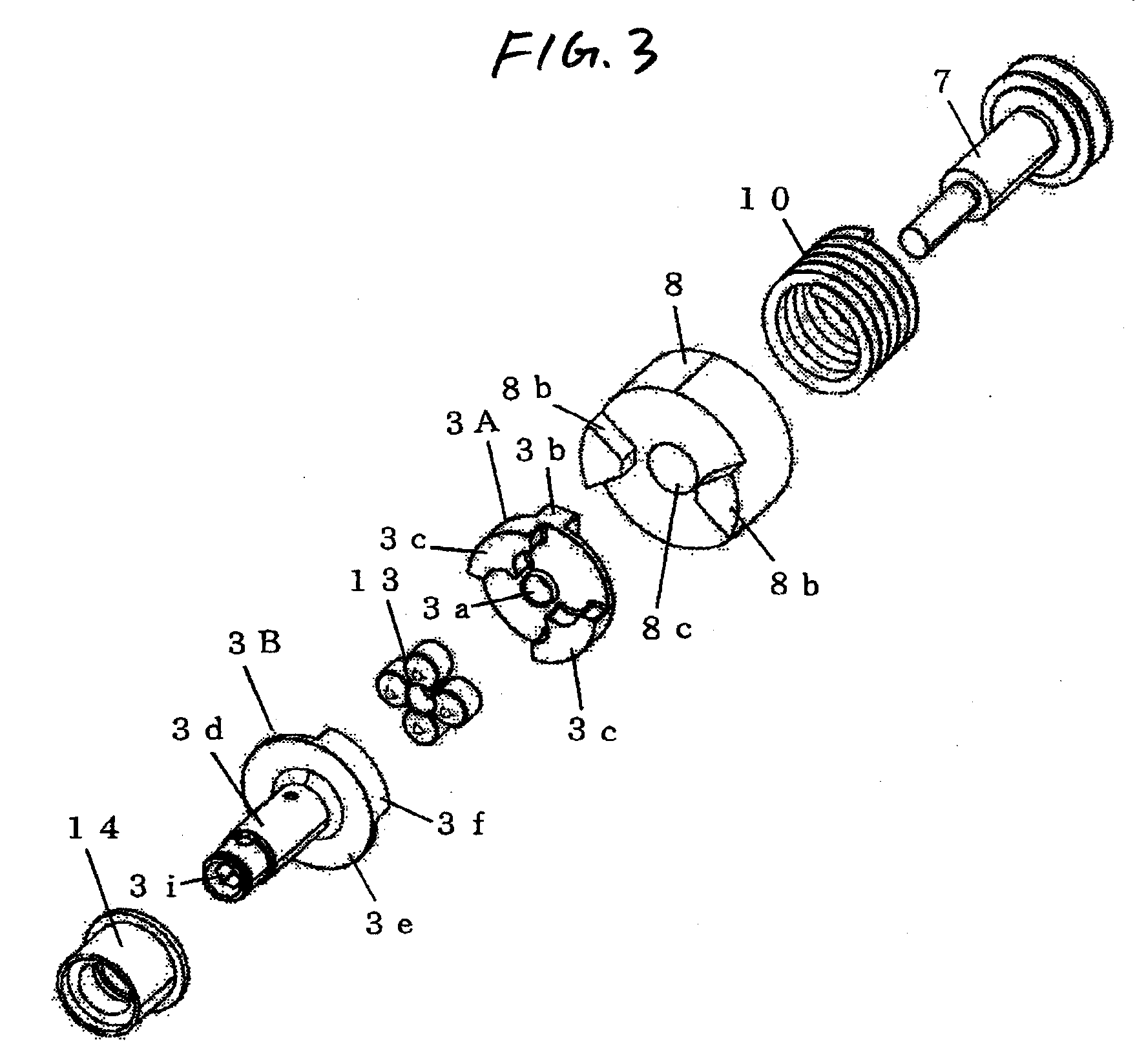

Impact tool

InactiveUS20070179328A1Reduce noiseReduce tightnessHydrocarbonsPower driven toolsEngineeringShock absorber

An impact tool, which can realize the reduction of noise without inviting the reduction of a fastening ability and which can improve the durability of a damper while preventing its damage. The impact tool includes a rotary impact mechanism mounted on a spindle to be rotationally driven by a motor, so that rotary impact is applied to a tip tool by transmitting the rotary impact intermittently from a hammer through an anvil to the tip tool. A plurality of pawls are formed on two half members of the anvil in the axial direction. A rubber damper is disposed in a space between the pawls arranged alternately in the circumferential direction of the two half members. The minimum sectional area of the space formed between the pawls is set larger than the sectional area of the rubber damper.

Owner:KOKI HLDG CO LTD

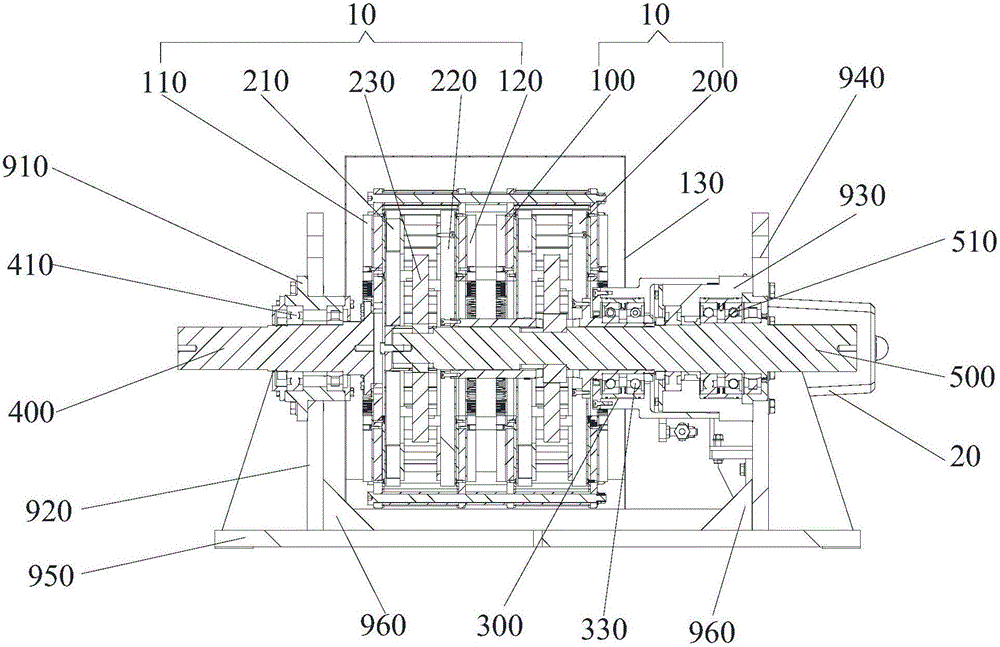

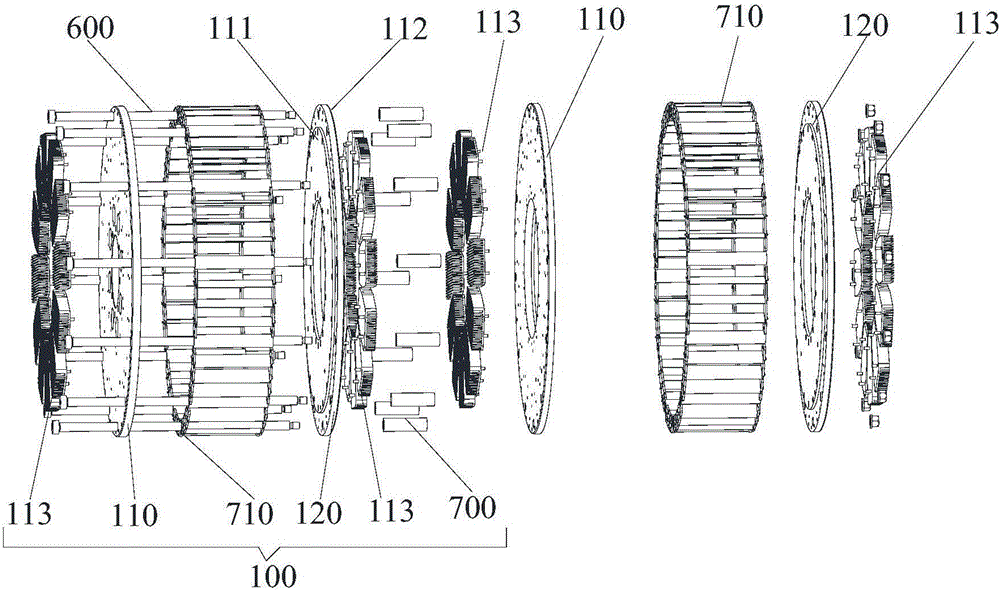

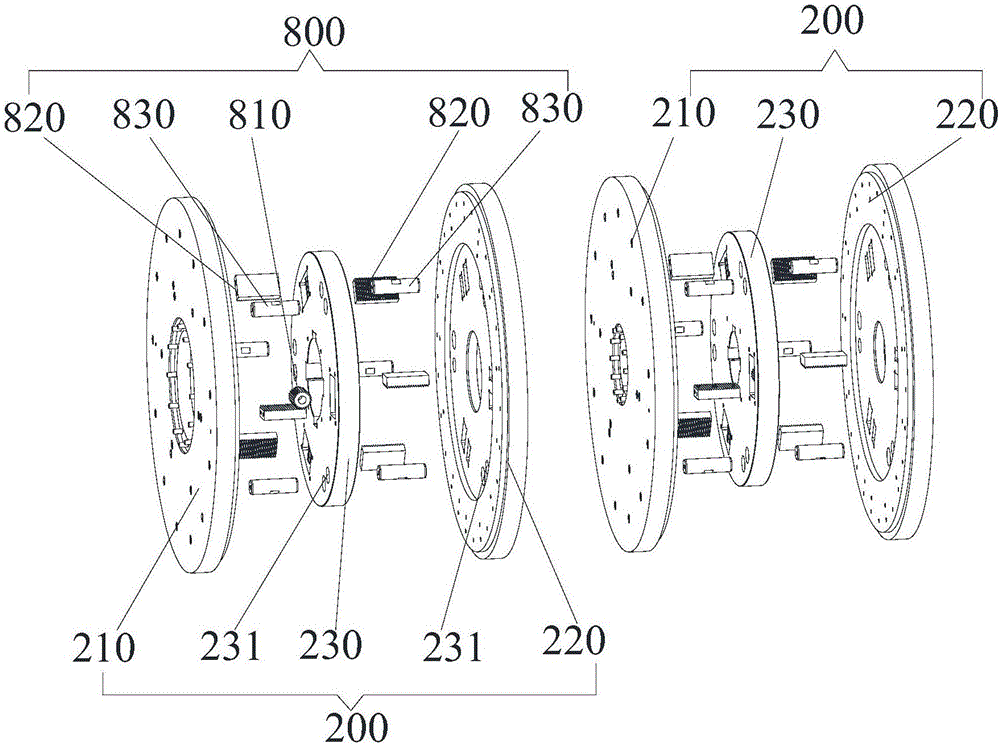

Air-cooled permanent magnet speed regulator

PendingCN106712449ALow calorific valueHigh transmission powerAsynchronous induction clutches/brakesPermanent-magnet clutches/brakesEngineeringMagnet

The invention discloses an air-cooled permanent magnet speed regulator, which comprises at least two rotor assemblies, wherein each rotor assembly comprises an outer rotor member, an inner rotor member and a speed regulating mechanism which is connected with the inner rotor member; the outer rotor members in the at least two rotor assemblies are serially connected in sequence by means of a serial connection member, and each inner rotor member is arranged inside the corresponding outer rotor member; each outer rotor member comprises a first outer rotor disk and a second outer rotor disk, and a first shaft is connected with the first outer rotor disk which is closest to the output end of the first shaft; each inner rotor member comprises a first inner rotor disk, a second inner rotor disk and an intermediate disk, and a second shaft connects the intermediate disks of the at least two rotor assemblies in series; and the first outer rotor disk and the first inner rotor disk are arranged in a manner of facing each other, an air gap is reserved therebetween, the second outer rotor disk and the second inner rotor disk are arranged in a manner of facing each other, and an air gap is reserved therebetween. The air-cooled permanent magnet speed regulator provided by the invention has the advantages of greater transmission torque, simple structure, convenient installation, shaft displacement prevention and easier control of air gap size.

Owner:ANHUI WOLF POWER TECH

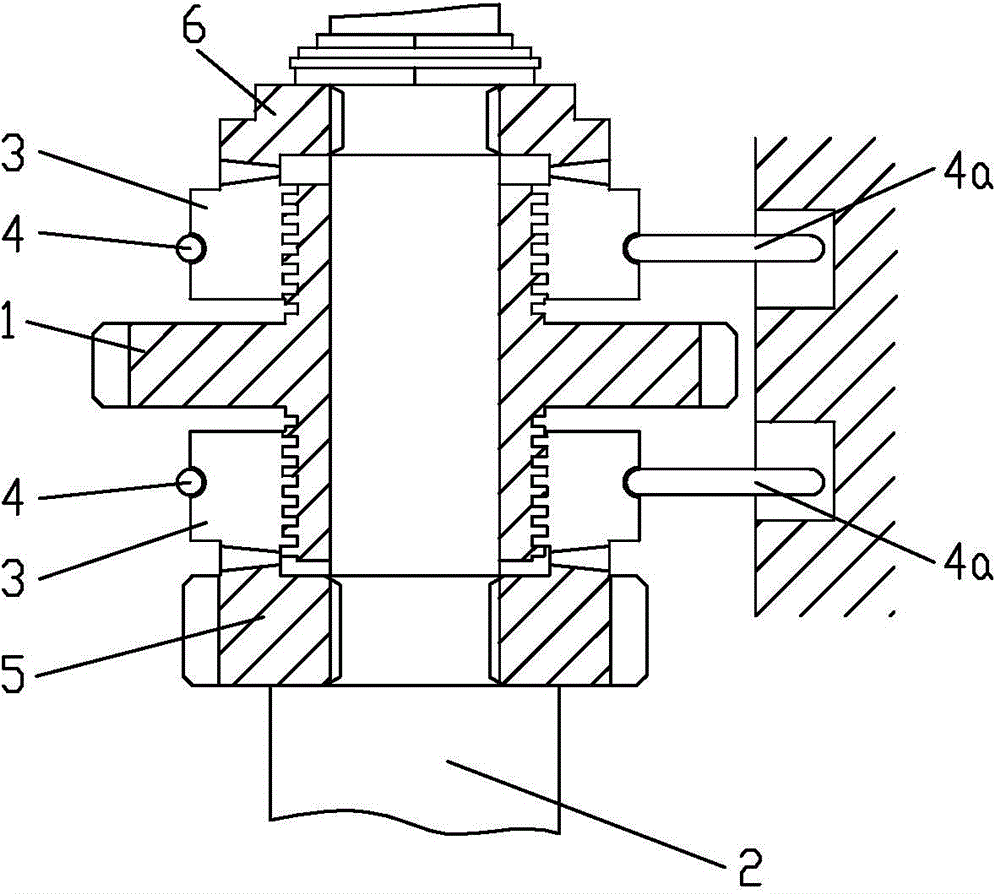

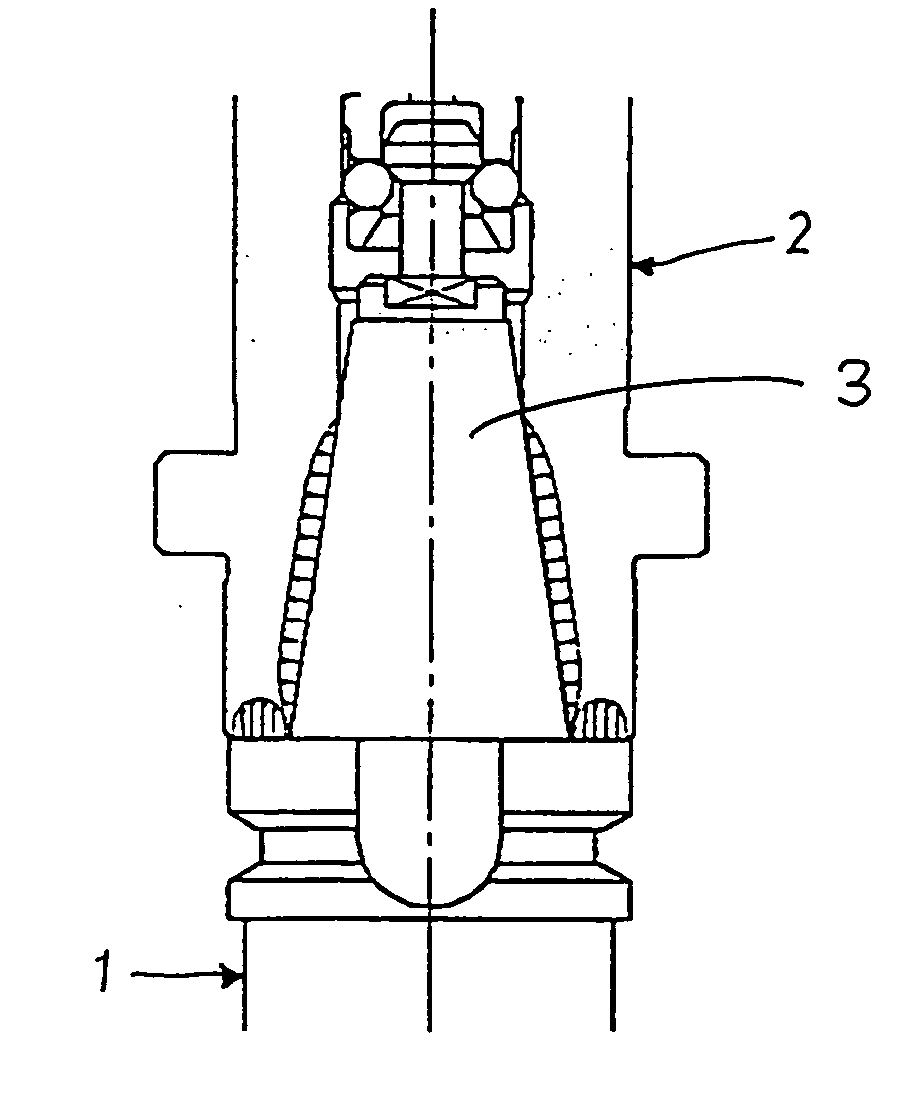

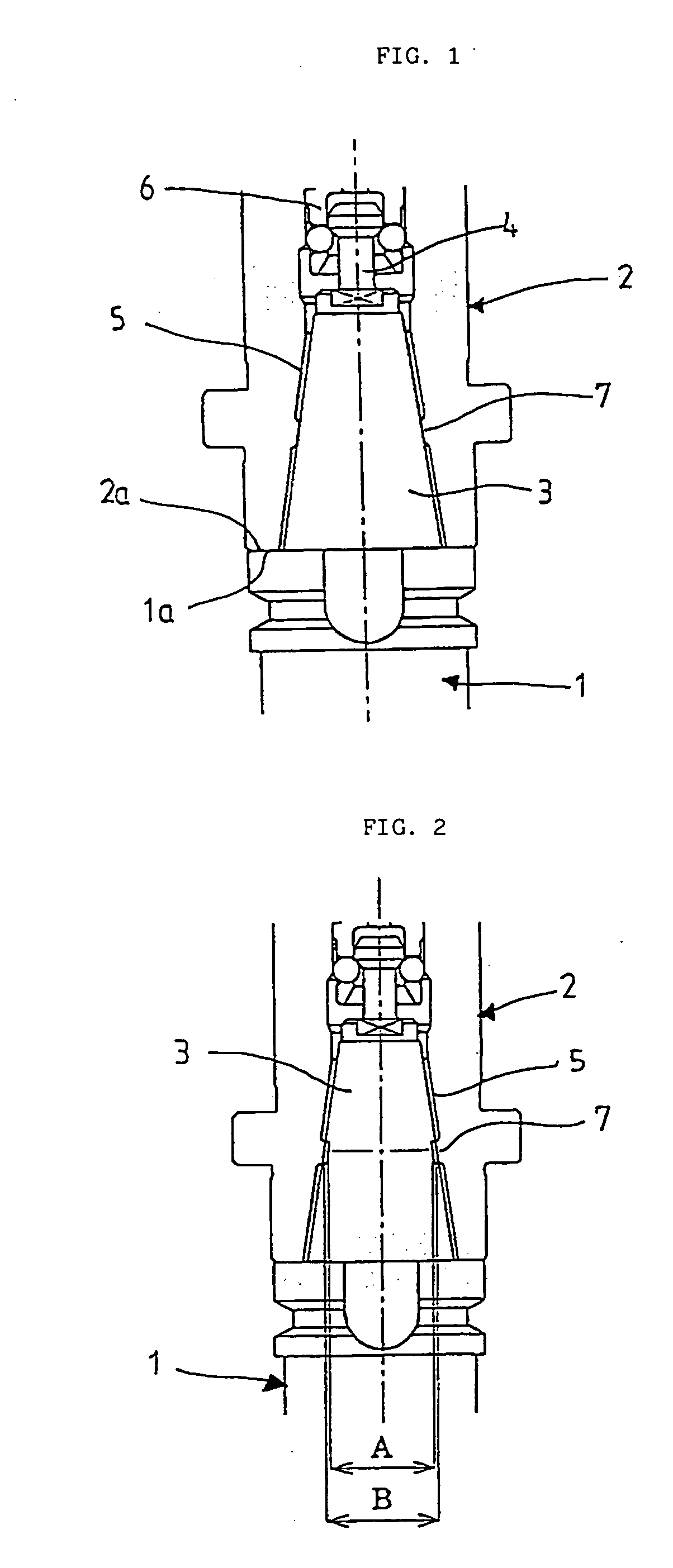

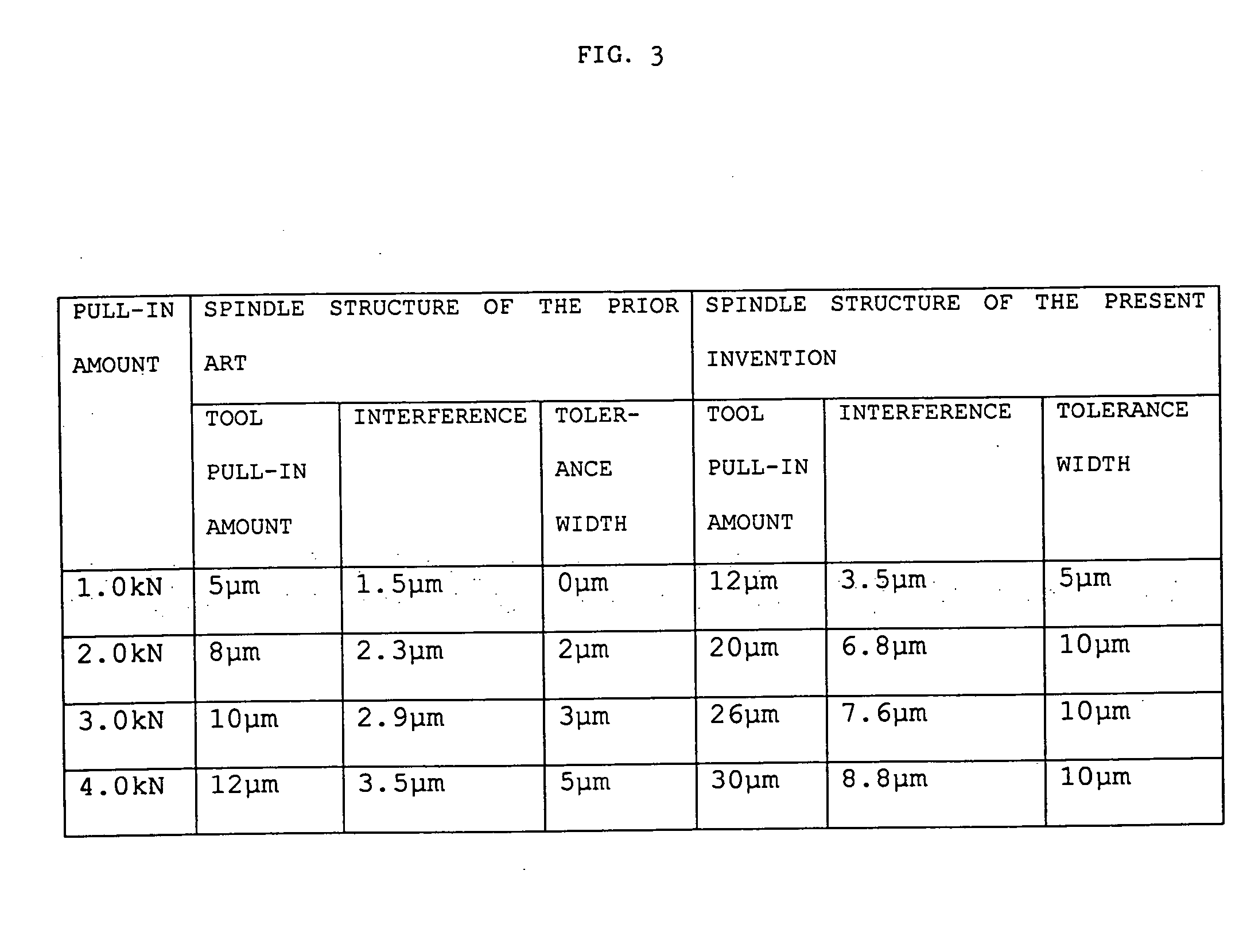

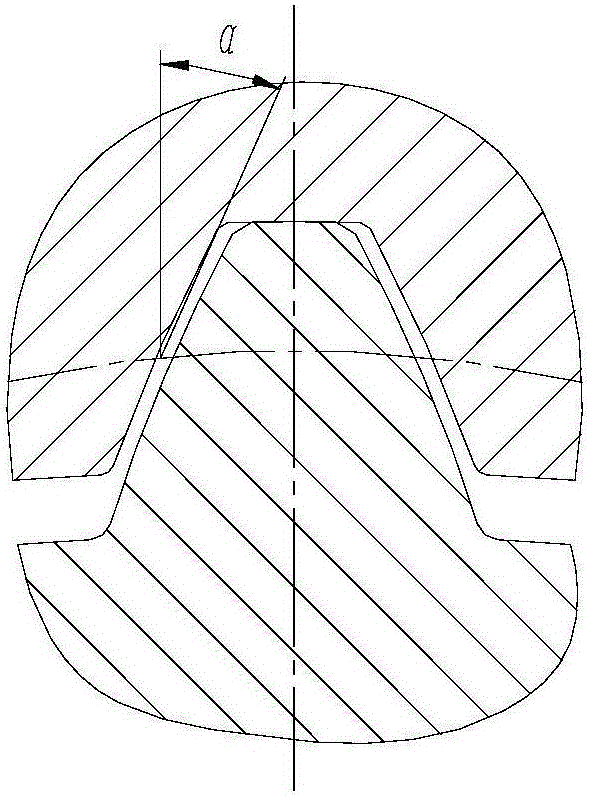

Spindle structure of a machine tool

InactiveUS20050175425A1Stably shackledIncrease transmission torqueThread cutting machinesTransportation and packagingEngineeringMachine tool

A tool holder is attached to a spindle by the contacting of the projecting cone part and end surface of the tool holder with the recessed cone part and end surface of the spindle respectively. A toroidal cone section is provided on the inner side surface of the recessed cone part of the spindle so as to protrude inward. The diameter of the toroidal cone section is formed smaller than the diameter of the section of the projecting cone part of the tool holder that abuts the toroidal cone section.

Owner:FANUC LTD

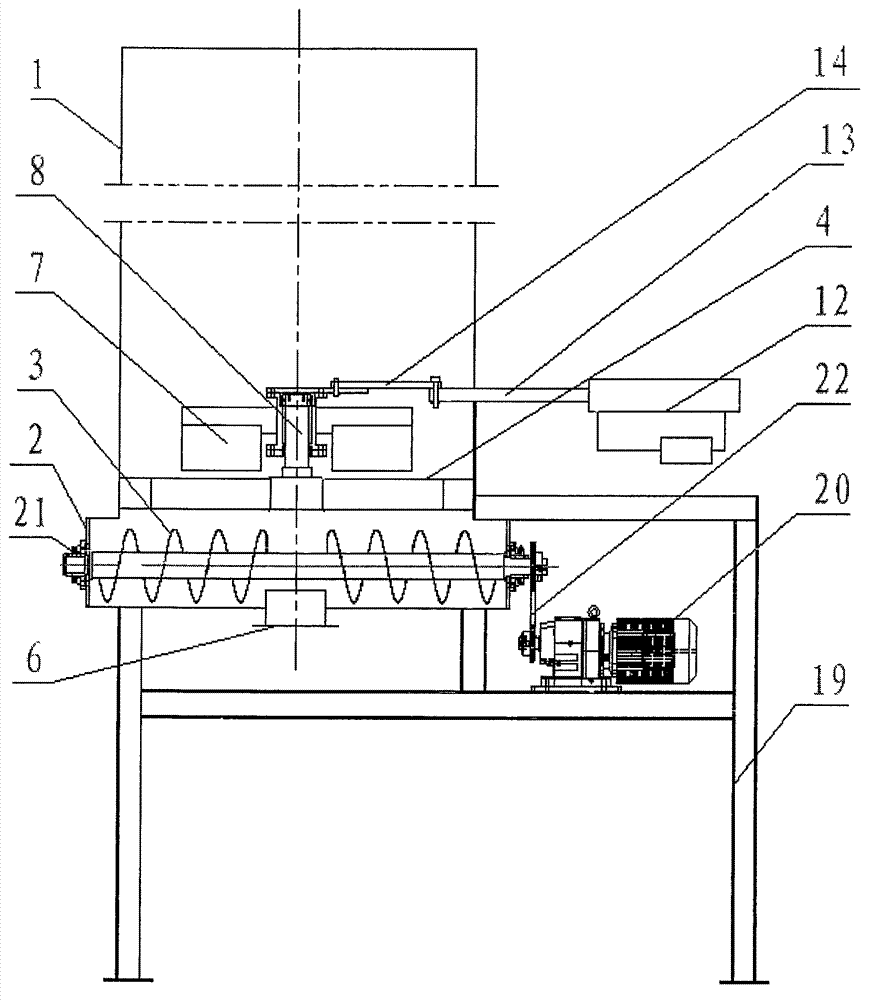

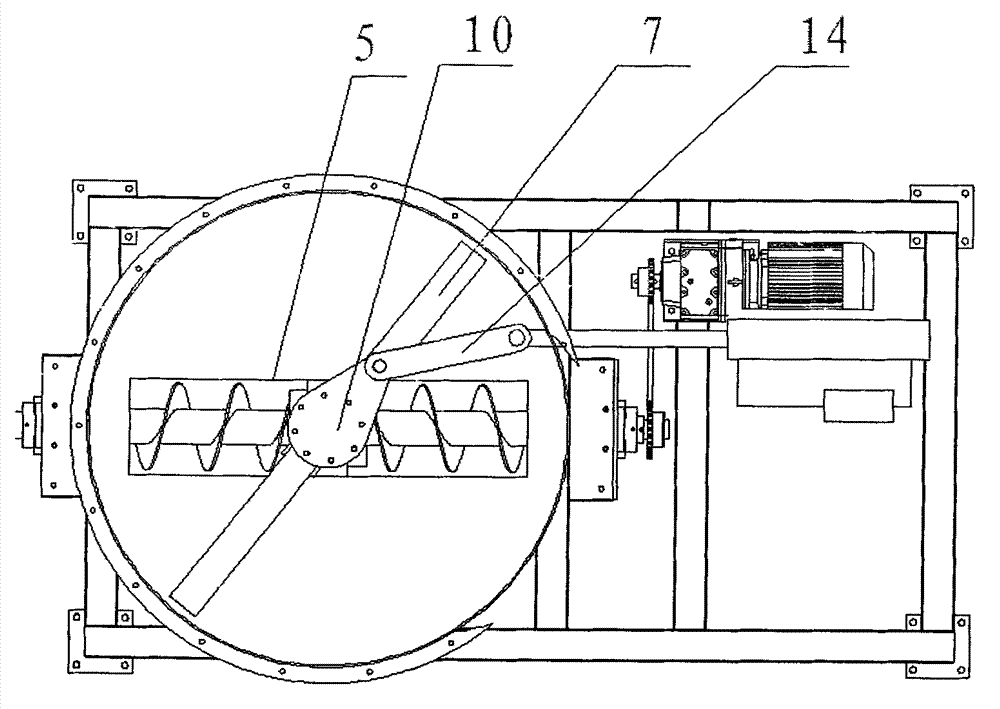

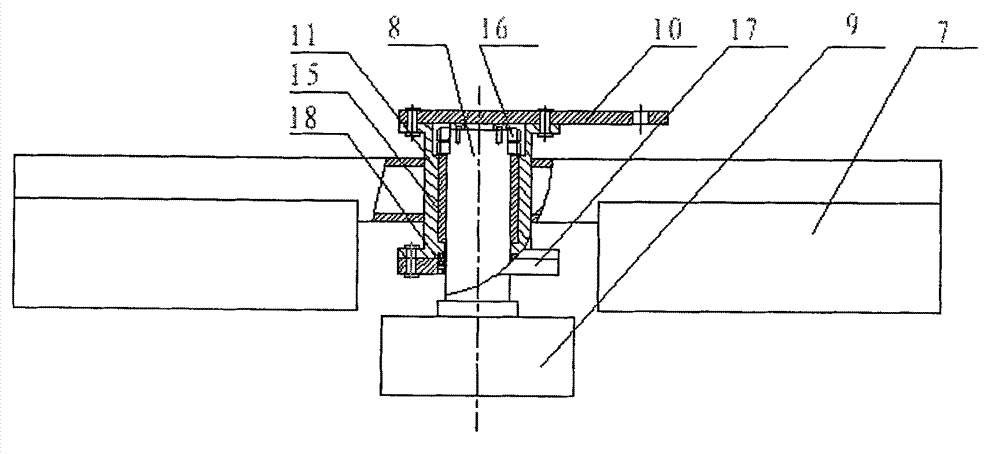

Sludge stock bin with rotary arch breaking mechanism

The invention discloses a sludge stock bin with a rotary arch breaking mechanism. The sludge stock bin comprises a stock bin body, a spiral conveyor (3), an arch breaking mechanism and an arch breaking driving mechanism, wherein the arch breaking mechanism is arranged in the stock bin body, the arch breaking driving mechanism is connected with the arch breaking mechanism, and the spiral conveyor (3) is arranged at the lower part of the stock bin body; the stock bin body comprises an upper bin body (1) and a lower bin body (2), a separation board (4) is arranged between the upper bin body and the lower bin body, a strip-shaped blanking channel (5) is formed in the separation board, and the spiral conveyor is mounted in the lower bin body; and the arch breaking mechanism is the rotary arch breaking mechanism, the rotary arch breaking mechanism comprises scraping plates (7), a rotary assembly and a fixing rod (8), the scraping plates are connected onto the rotary assembly, and the fixing rod is fixed in the center of the separation board. According to the sludge stock bin with the rotary arch breaking mechanism, as direct friction is not caused among the scraping plates and the stock bin body in the rotating process of the scraping plates and the arch breaking can be carried out on the whole stock bin body, the stockpiling phenomenon is hard to occur, and a large amount of energy can be saved.

Owner:CHINA JILIANG UNIV

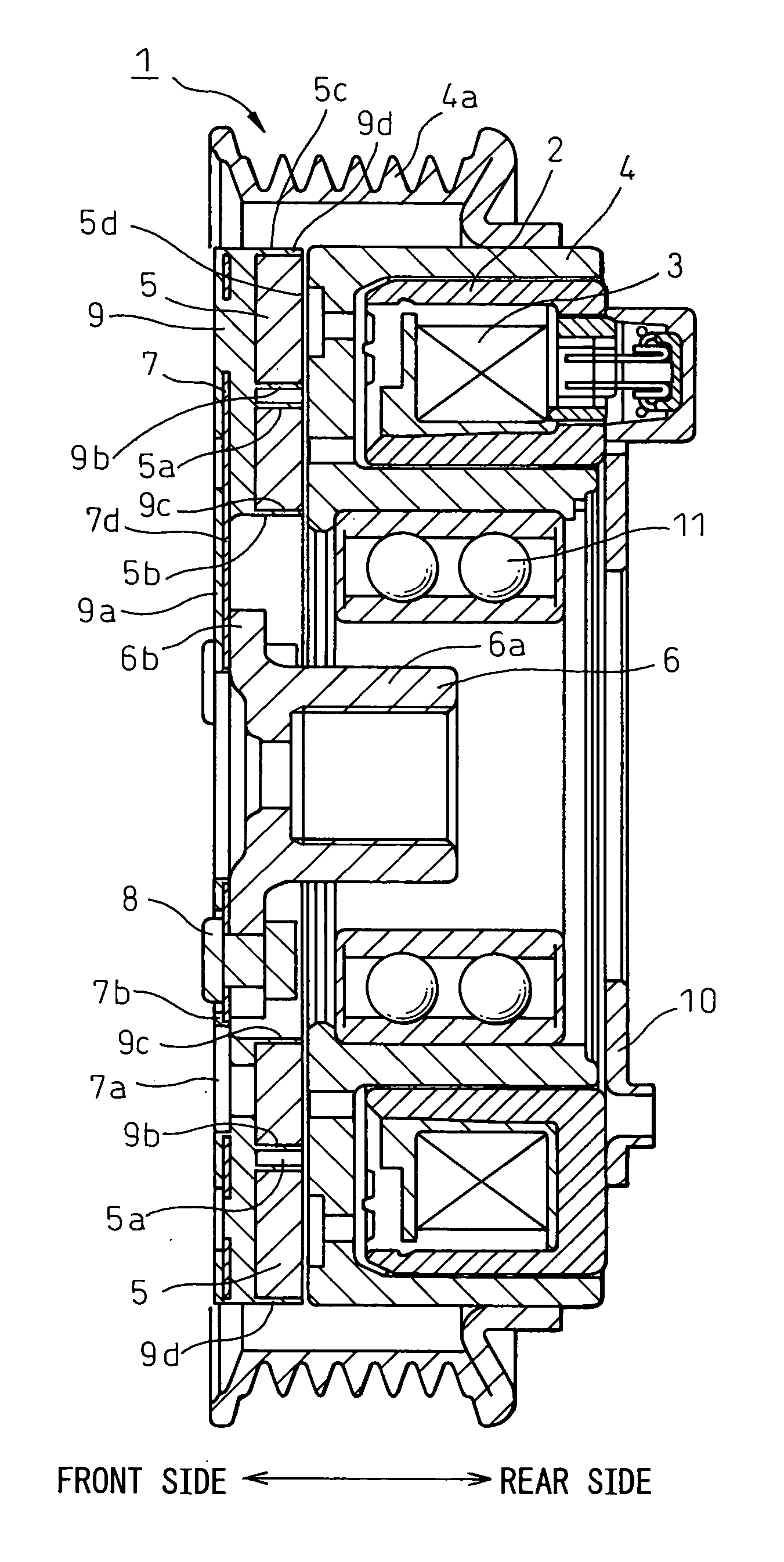

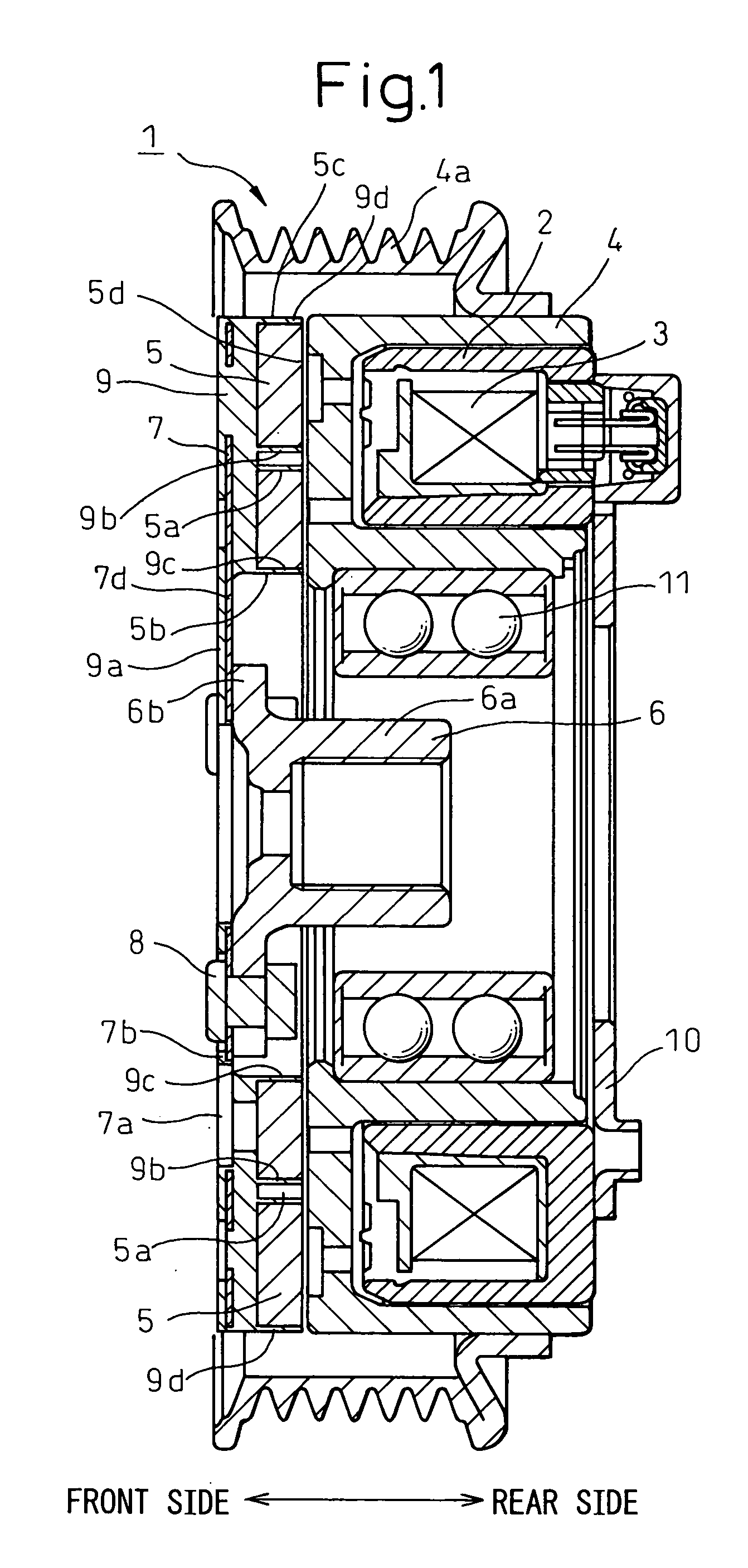

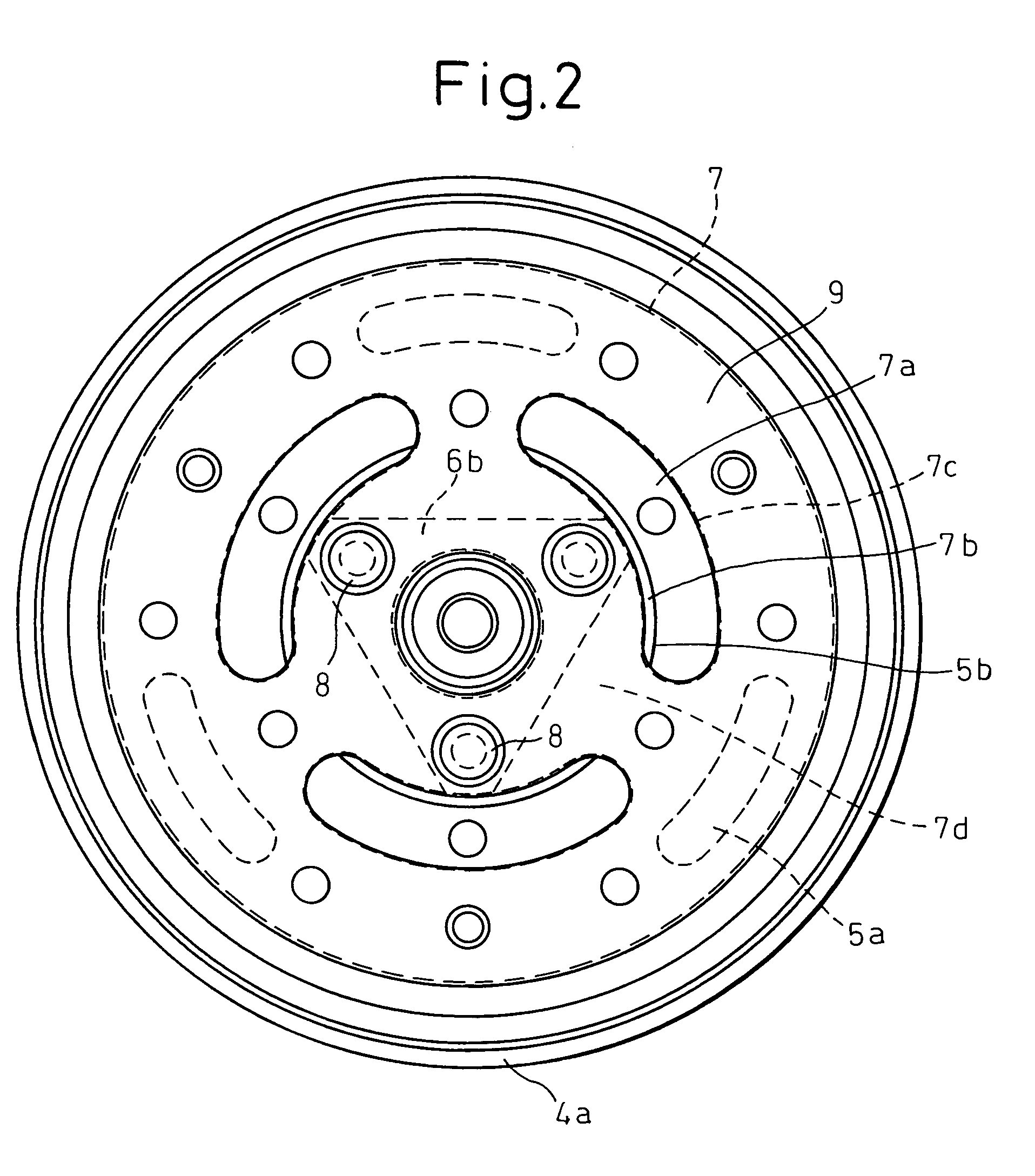

Electromagnetic clutch

InactiveUS20050183923A1Increase the initial torqueReduce necessityLiquid surface applicatorsDrying solid materials with heatElectromagnetic clutchMechanical engineering

An electromagnetic clutch 1 has a construction in which an armature 5 and a plate 7 sandwich an elastic member 9 between them. A spring portion 7d is formed in the plate 7 and an elastic member 9a is so disposed as to cover a front side of the spring portion 7d, too. Elastic members 9b, 9c and 9d are disposed in a thin film form on an inner surface of elongated holes 5a of the armature 5 and the innermost and outermost diameter portions 5b and 5c of the armature 5. The distal end of each elastic member 9b, 9c and 9d is extended to the same plane as an end face 5d of the armature 5 on the rear side or to a position somewhat protruding from the end face on the rear side.

Owner:DENSO CORP

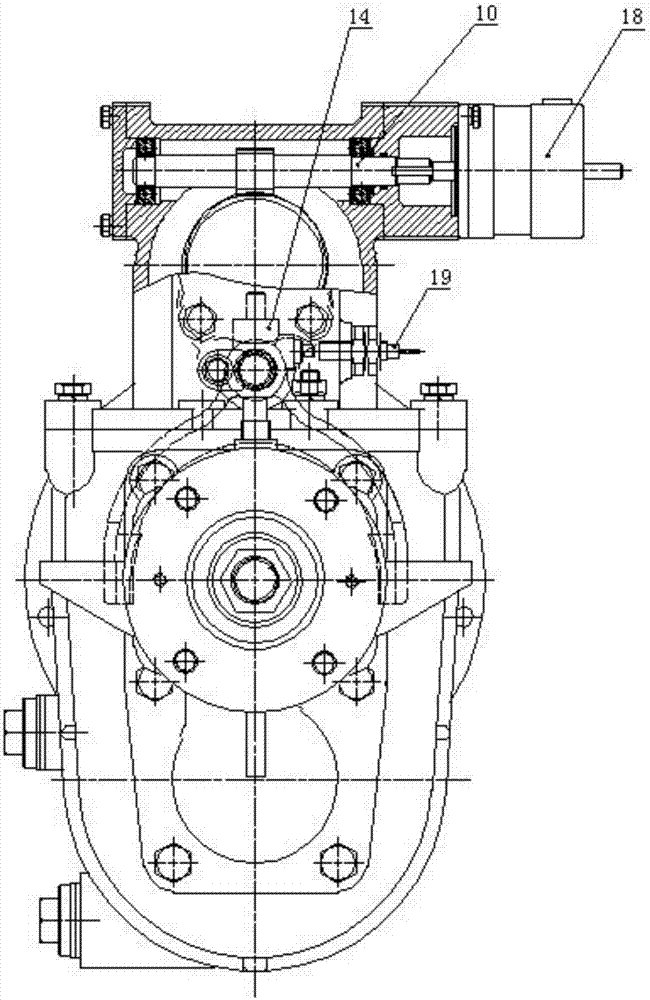

Stepless speed change device with transmission diameter variable wheel hub

ActiveCN103104667AIncrease transmission torqueIncrease powerGearingPortable liftingEngineeringSpeed limit

The invention relates to the field of mechanical transmission stepless speed change devices and particularly relates to a stepless speed change device with a transmission diameter variable wheel hub. The stepless speed change device with the transmission diameter variable wheel hub is characterized by comprising an active diameter variable wheel hub, and a passive diameter variable wheel hub. The active diameter variable wheel hub and the passive diameter variable wheel hub are same in structure. The active diameter variable wheel hub and an input shaft are in coaxial rotation. The passive diameter variable wheel hub and an output shaft are in coaxial rotation. Each two sides of the active diameter variable wheel hub and the passive diameter variable wheel hub have an umbrella-shaped structure. The center portion of each umbrella-shaped structure is hinged with a sliding sleeve. The sliding sleeve is sleeved on the periphery of a pitch varying screw rod. The pitch varying screw rod of the active diameter variable wheel hub is connected with the pitch varying screw rod of the passive diameter variable wheel hub through a synchronous belt to form a synchronous rotation. The active diameter variable wheel hub forms a synchronous rotation with the passive diameter variable wheel hub through a belt. The stepless speed change device with the transmission diameter variable wheel hub has the advantages of being capable of being used for all kinds of stepless speed change devices, improving the transmission torque and power of the stepless speed change devices and improving allowable value of speed limit.

Owner:上海亚仕龙能源科技有限公司

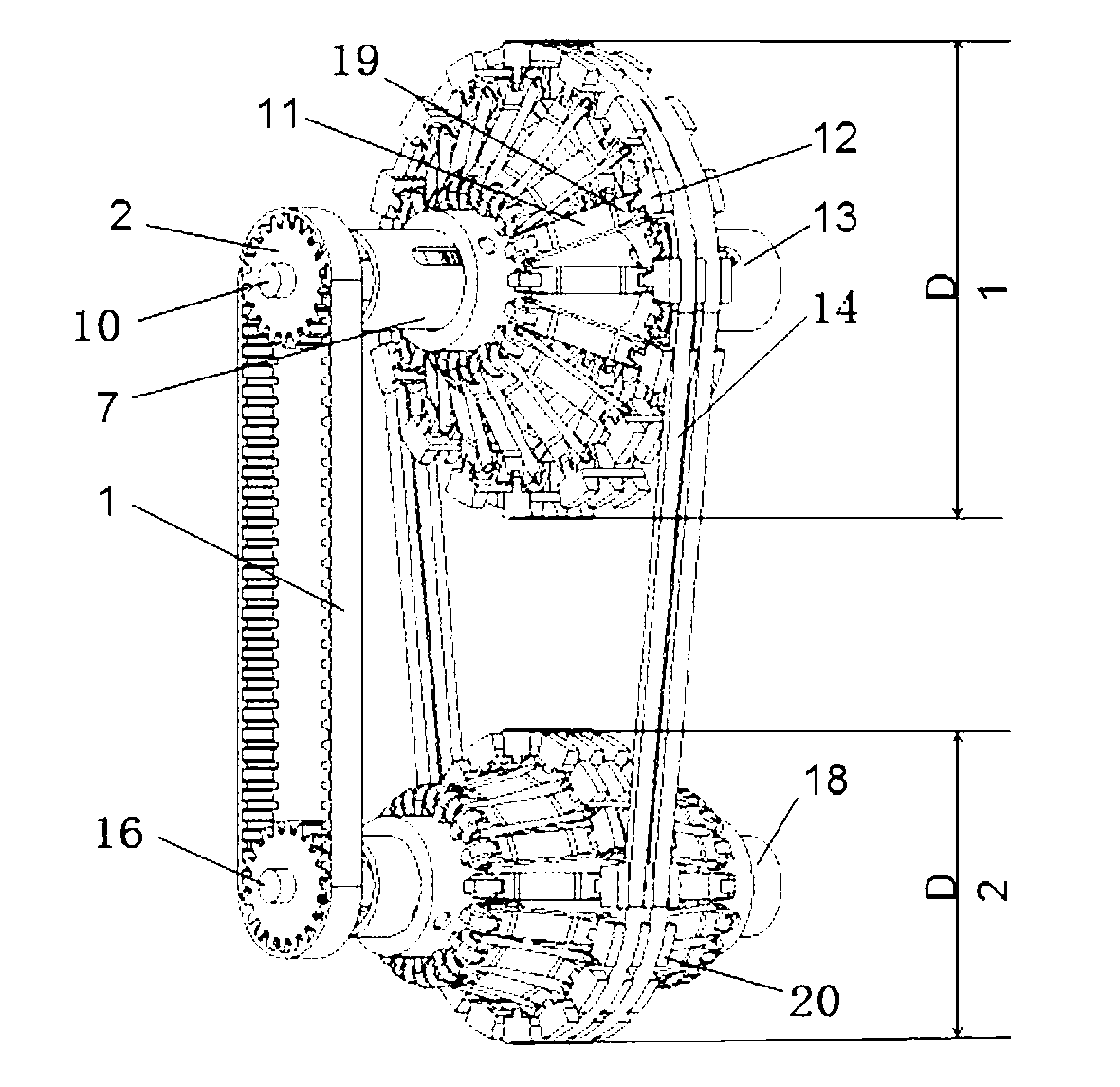

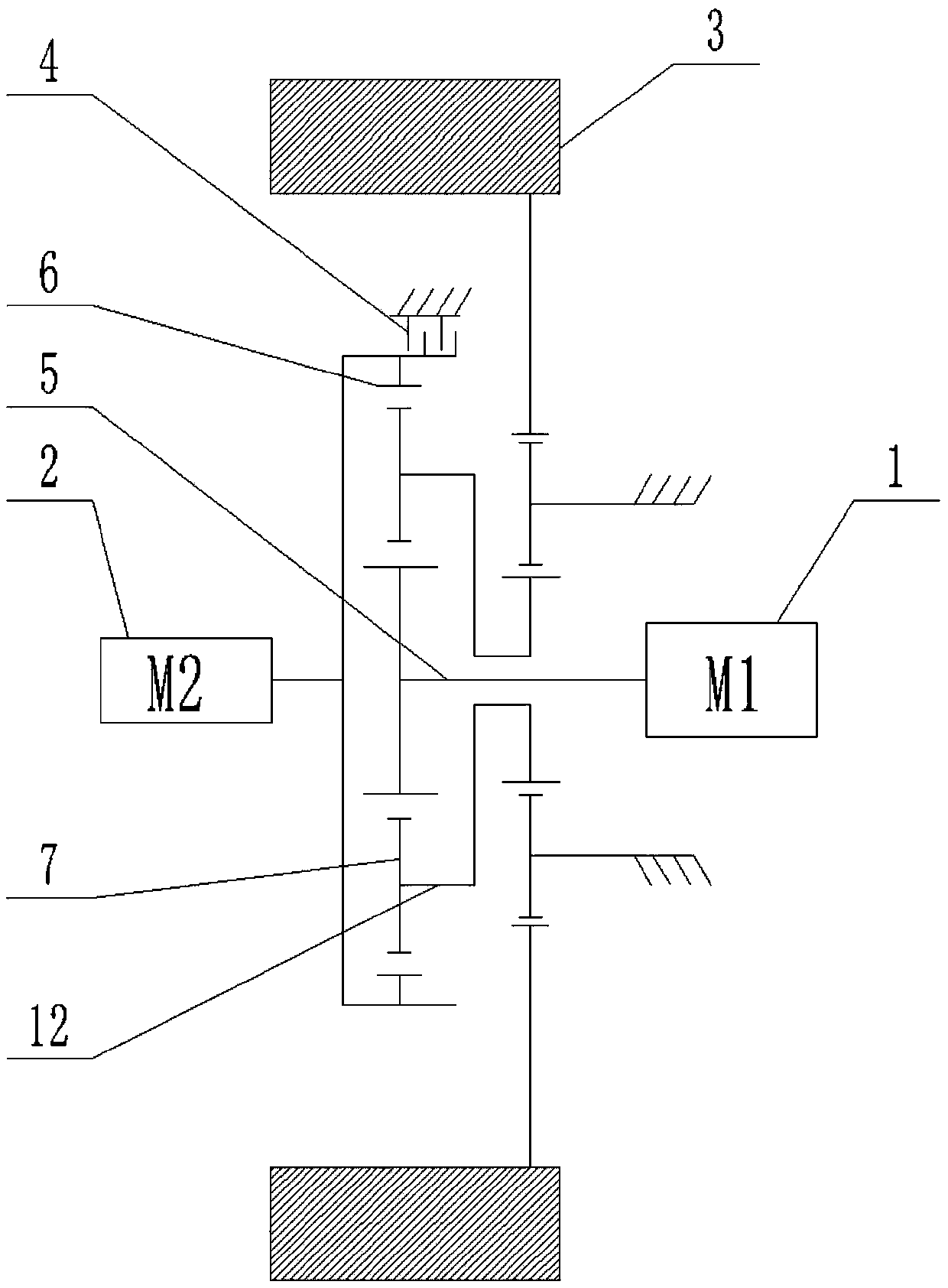

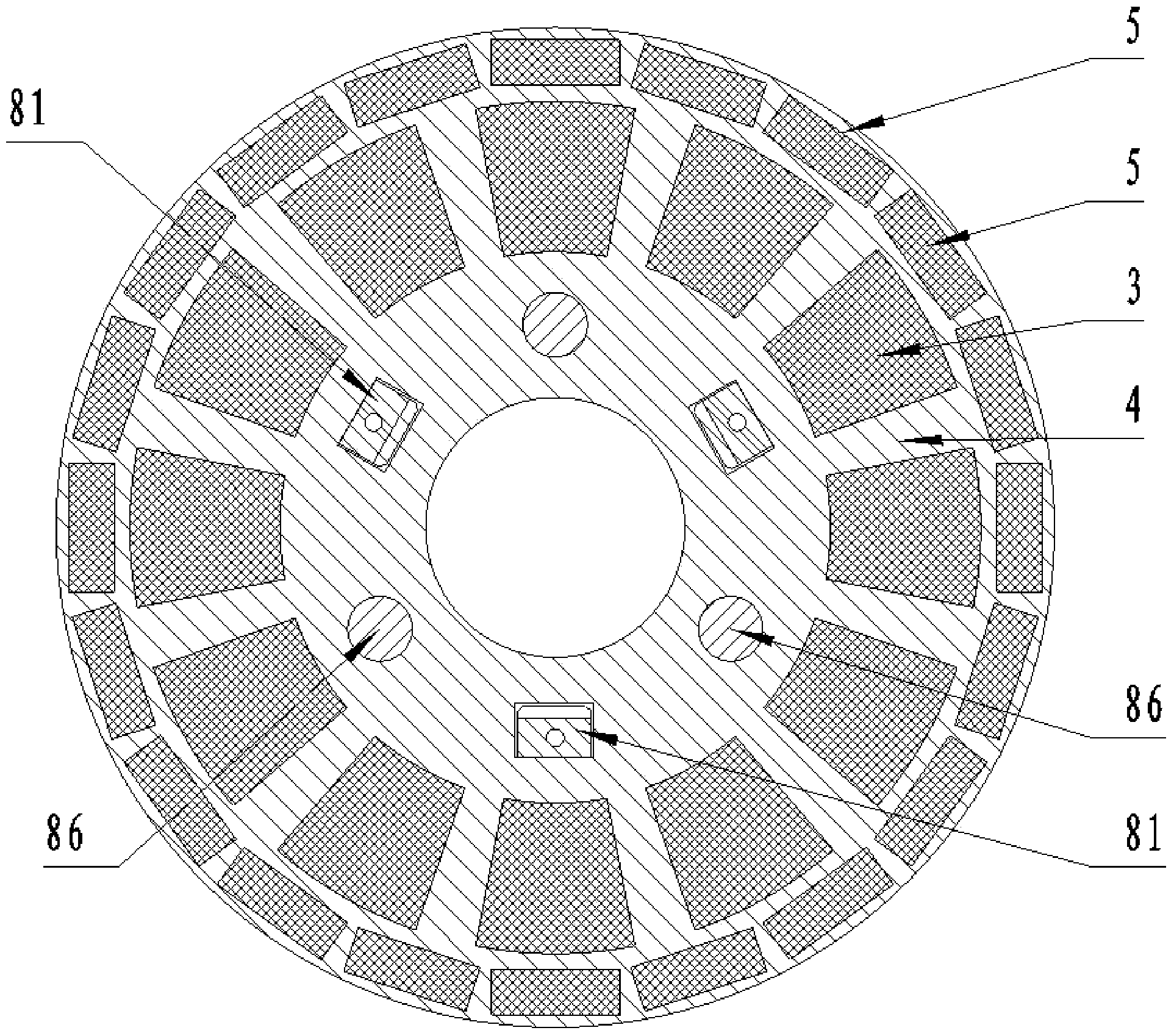

Double-motor coupling planetary traction transmission shaft bearing type deceleration electric hub

InactiveCN109532462ARealize stepless speed regulationSufficient powerMotor depositionControl devicesReduction driveCoupling

The invention discloses a double-motor coupling planetary traction transmission shaft bearing type deceleration electric hub, which comprises a hub, a planetary traction transmission shaft bearing type speed reducer arranged in a hub cavity, a first motor and a second motor. Any sequence combination of a sun gear, a planet carrier and an outer ring in the planetary traction transmission shaft bearing type speed reducer respectively corresponds to a power input end, a power output end and an intermediate transmission part in the planetary traction transmission shaft bearing type speed reducer,the first motor is used for driving the power input end to provide power and driving the hub to rotate through the power output end, and the second motor is used for driving the intermediate transmission part for speed coupling. According to the planetary traction transmission shaft bearing type speed reducer, the cooperation of the two motors is realized through the planetary traction transmission shaft bearing type speed reducer, so that each motor can always work in a high-efficiency working range, the working efficiency of the hub is improved, and the purposes of saving energy and prolonging endurance mileage are achieved.

Owner:CHONGQING UNIV

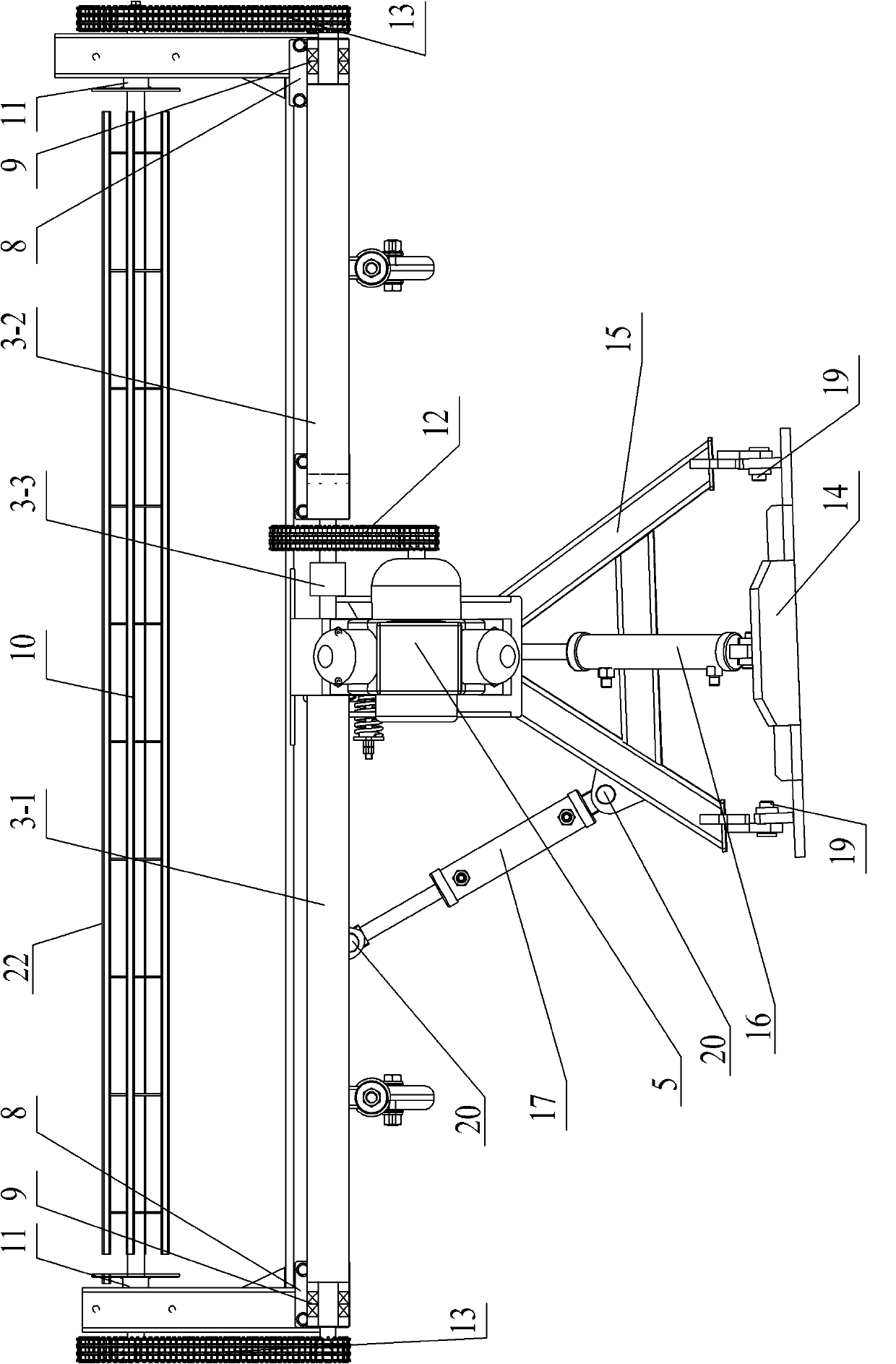

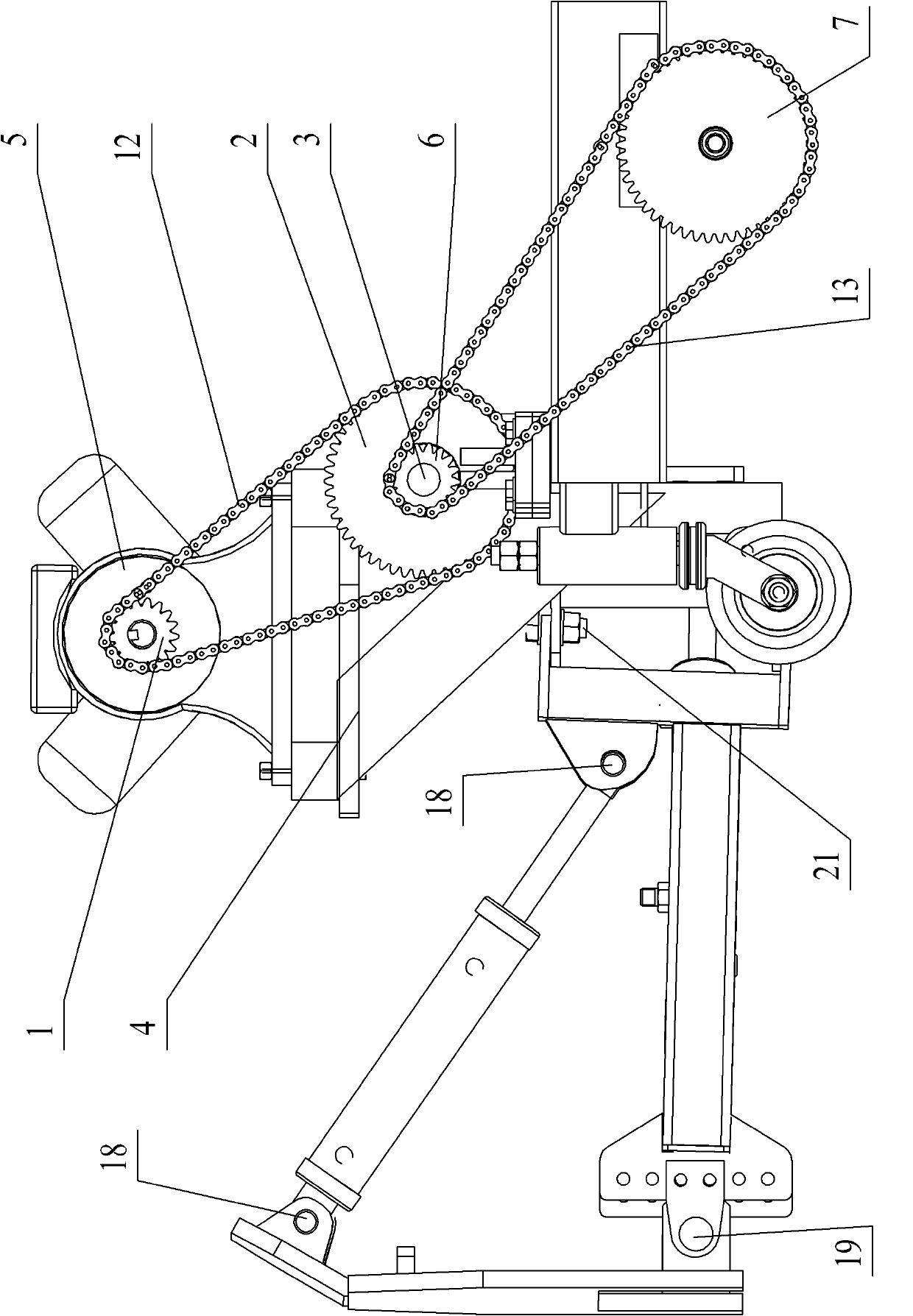

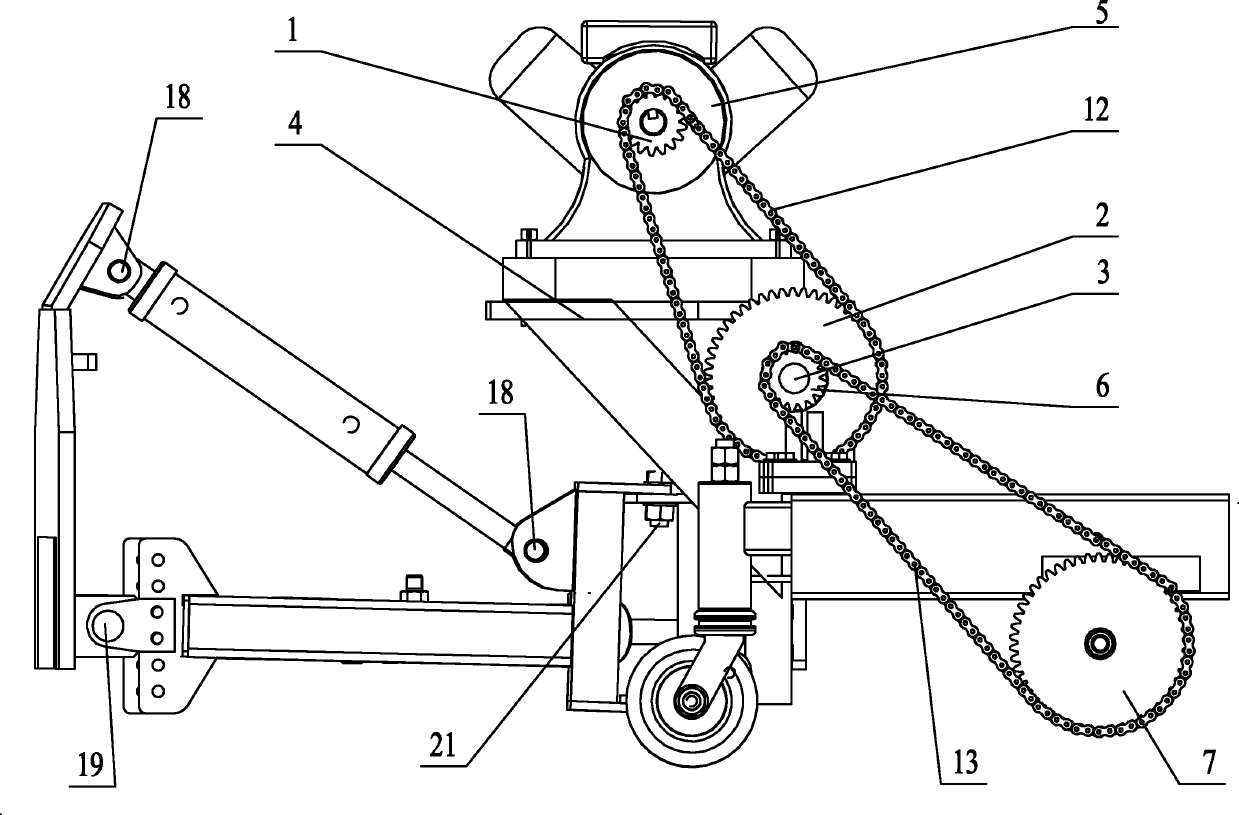

Lifting and swinging hydraulic device for snow remover and snow remover with same

The invention discloses a lifting and swinging hydraulic device for a snow remover and the snow remover with the same, relates to an upper hydraulic device for a snow remover and the snow remover, and solves the problems of high labor intensity of snow removing operation because the conventional snow remover is not provided with the hydraulic device, low transmission efficiency and easy damage of the convention snow remover and the like. The bottom end face of a cylinder body of a lifting oil cylinder is hinged with a vertical plate; one diagonal rod end of the tower bottom end of an A-shaped frame body is hinged with one side of the lower part of the vertical plate, while the other diagonal rod end is hinged with the other side of the lower part of the vertical plate; and a connecting lug on the bottom end face of a cylinder body of a swinging oil cylinder is hinged with a connecting lug on the outside surface of a corresponding diagonal rod on the A-shaped frame body. A snow removing roll is arranged on a rolling brush shaft; a connecting rod end of the lifting oil cylinder is connected with an upright post on the middle part of the rear end of a main framework; and a connecting rod end of the swinging oil cylinder is connected with a side end plate on the main framework. The hydraulic device relieves the labor intensity of the snow removing operation, is safe and reliable, has stable operation, doubles t he torque, and improves the efficiency by 50 percent.

Owner:哈尔滨市环隆卫生工具厂

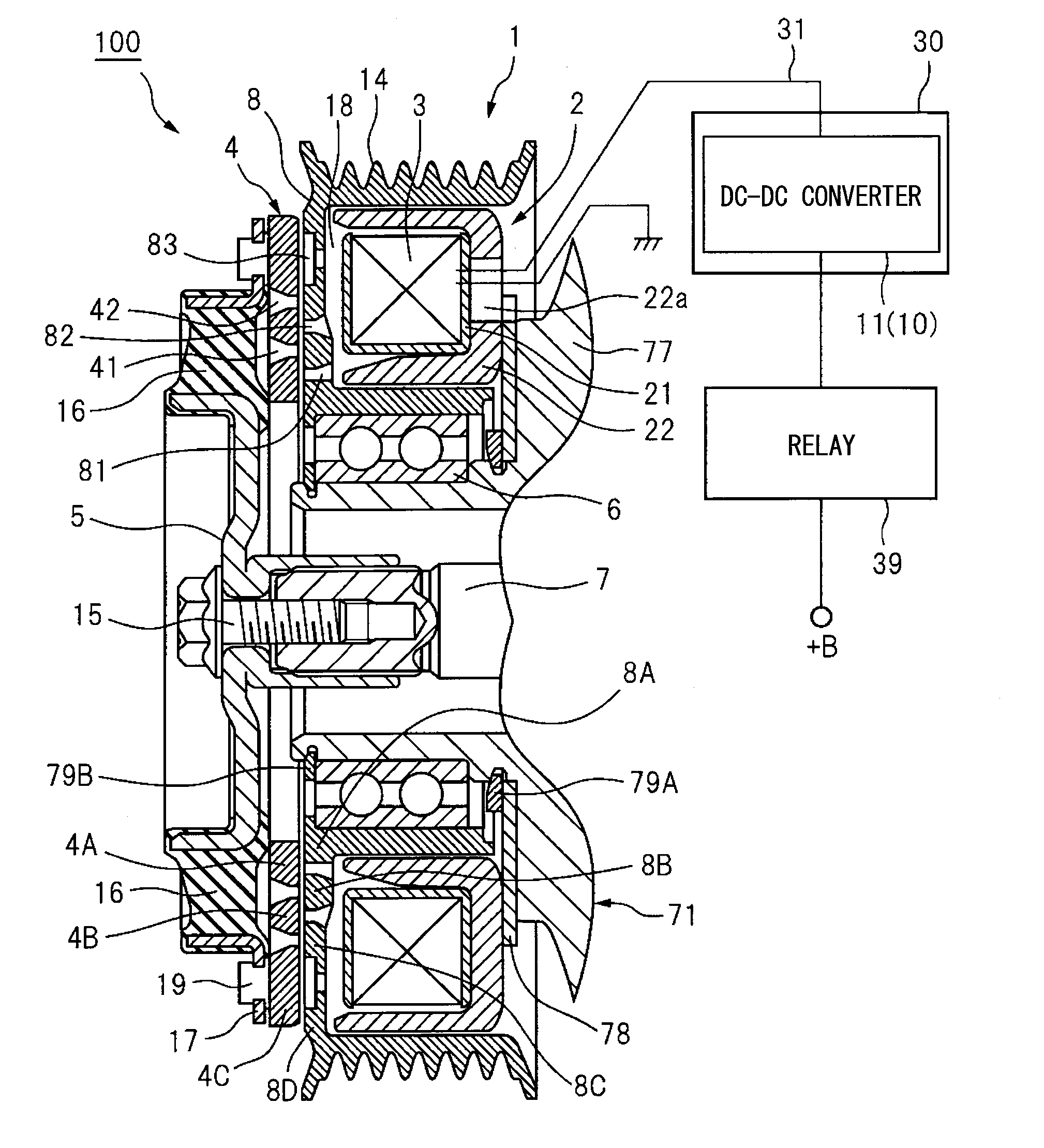

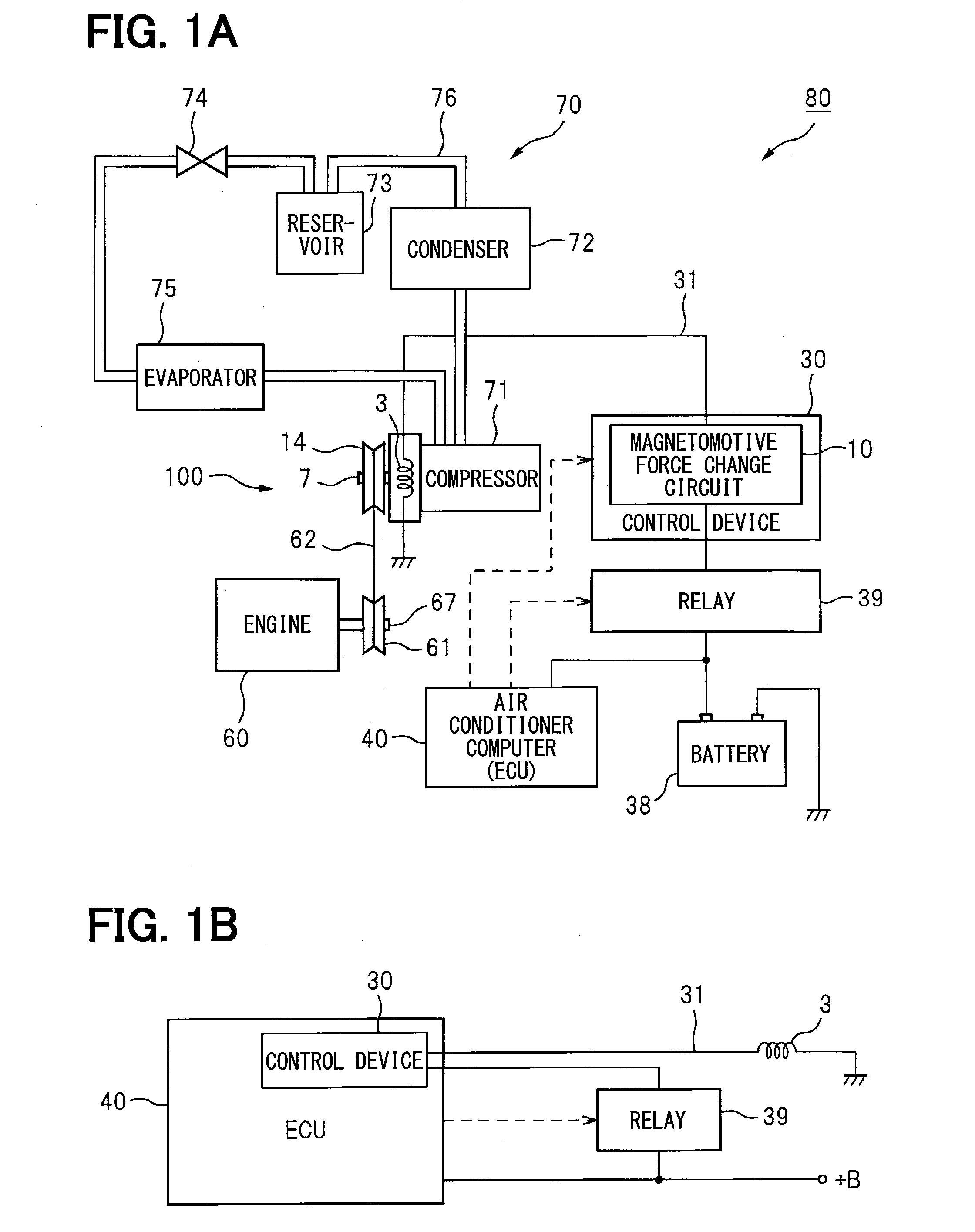

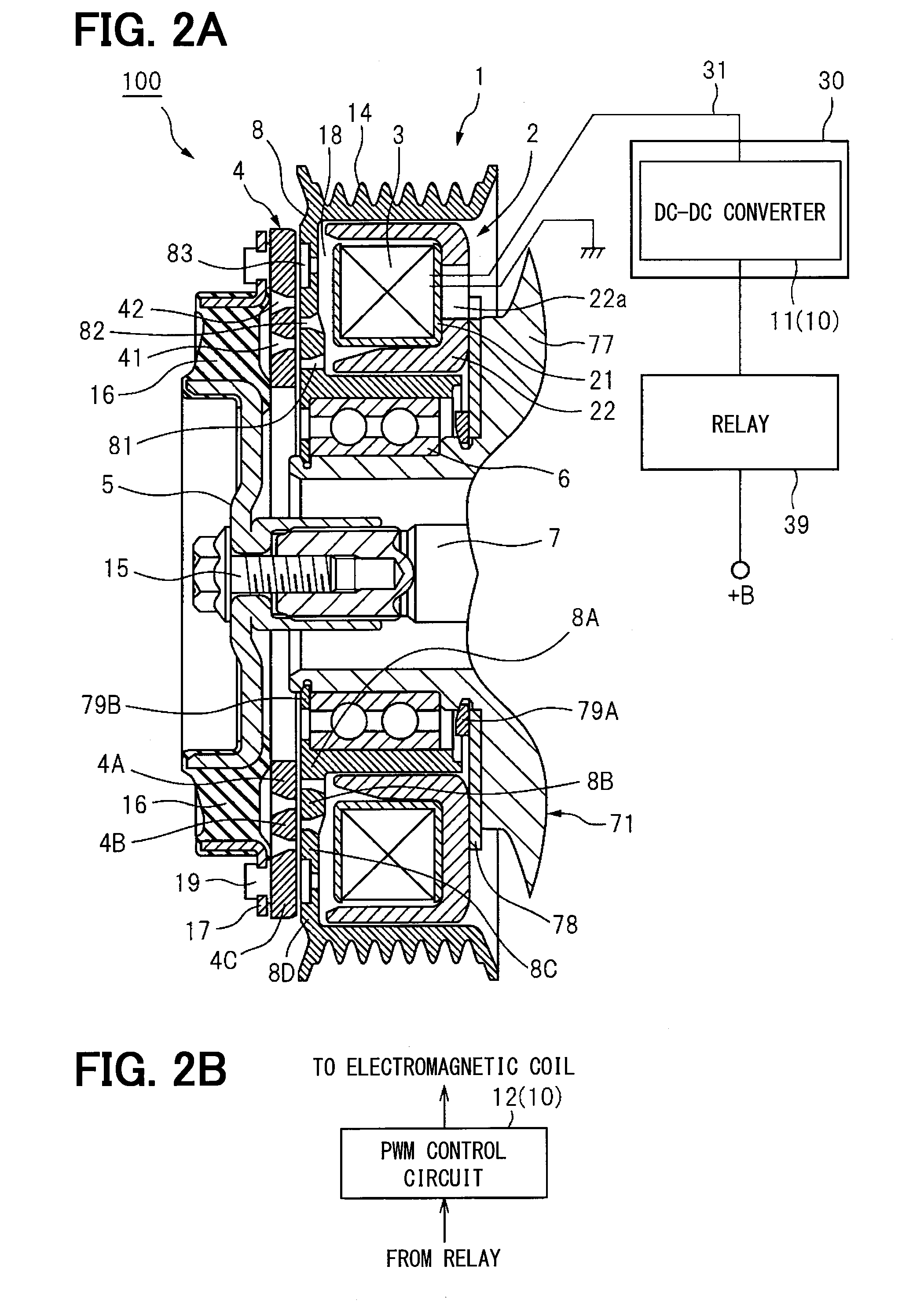

Electromagnetic clutch, electromagnetic clutch control device, and electromagnetic clutch control method

InactiveUS20150300427A1Improve operabilityMinimize power consumptionMechanical actuated clutchesMagnetically actuated clutchesMagnetic fluxMagnetomotive force

An electromagnetic clutch provided with an armature in which two or more non-magnetic sections of differing radii are provided and which is installed on a rotary shaft, a rotor in which three or more non-magnetic section of differing radii that do not overlap with the non-magnetic sections are provided on a friction plate that faces the armature, and which rotates with respect to the rotation shaft by external force, a stator equipped with an electromagnetic coil for fixing the armature to the rotor by applying magnetic flux, which is generated by passage of an electric current, on the friction plate, and a control device for the electromagnetic coil. The control device is provided with a magnetomotive force change circuit for increasing, with a command to start power supply to the electromagnetic coil, the magnetomotive force of the electromagnetic coil above the magnetomotive force of the electromagnetic clutch during normal operation and for returning the magnetomotive force of the electromagnetic coil to the magnetomotive force of the electromagnetic clutch during normal operation when the armature is fixed to the rotor.

Owner:DENSO CORP

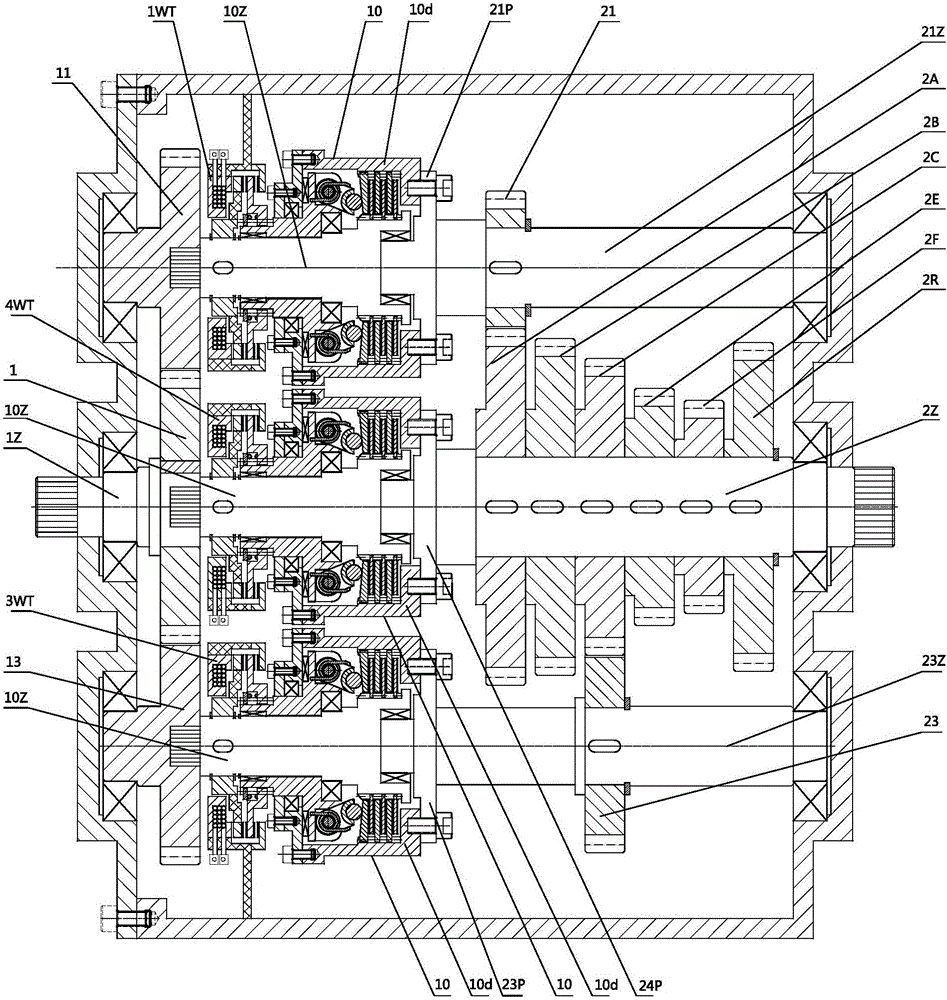

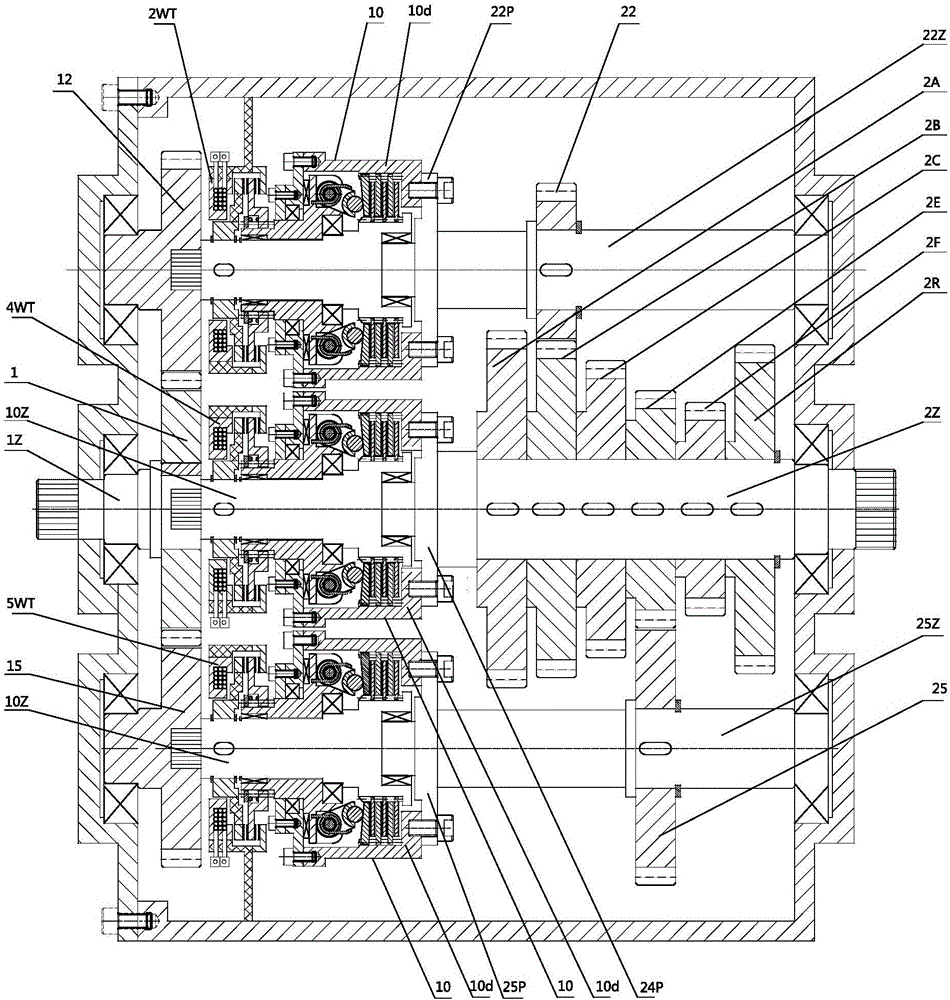

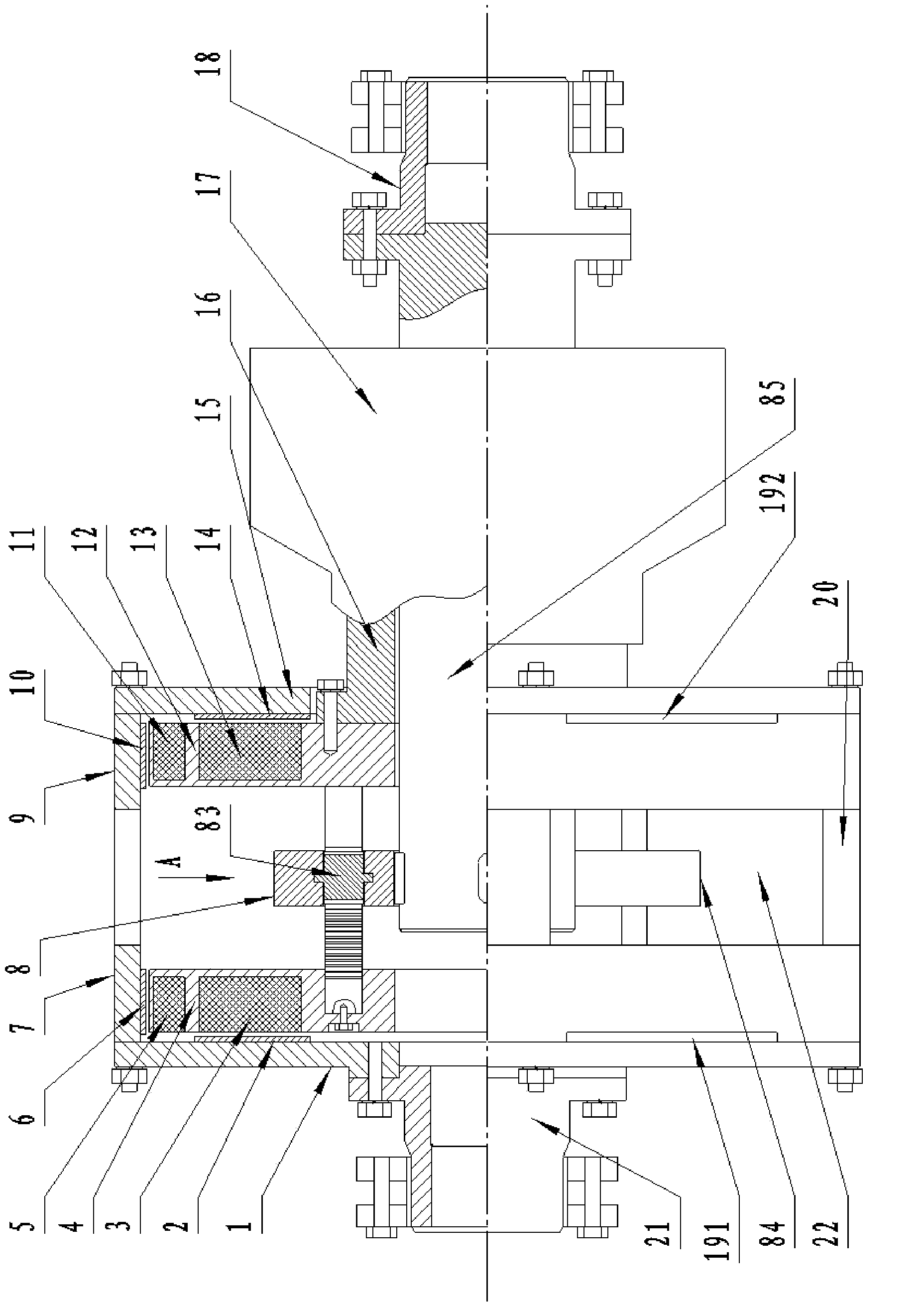

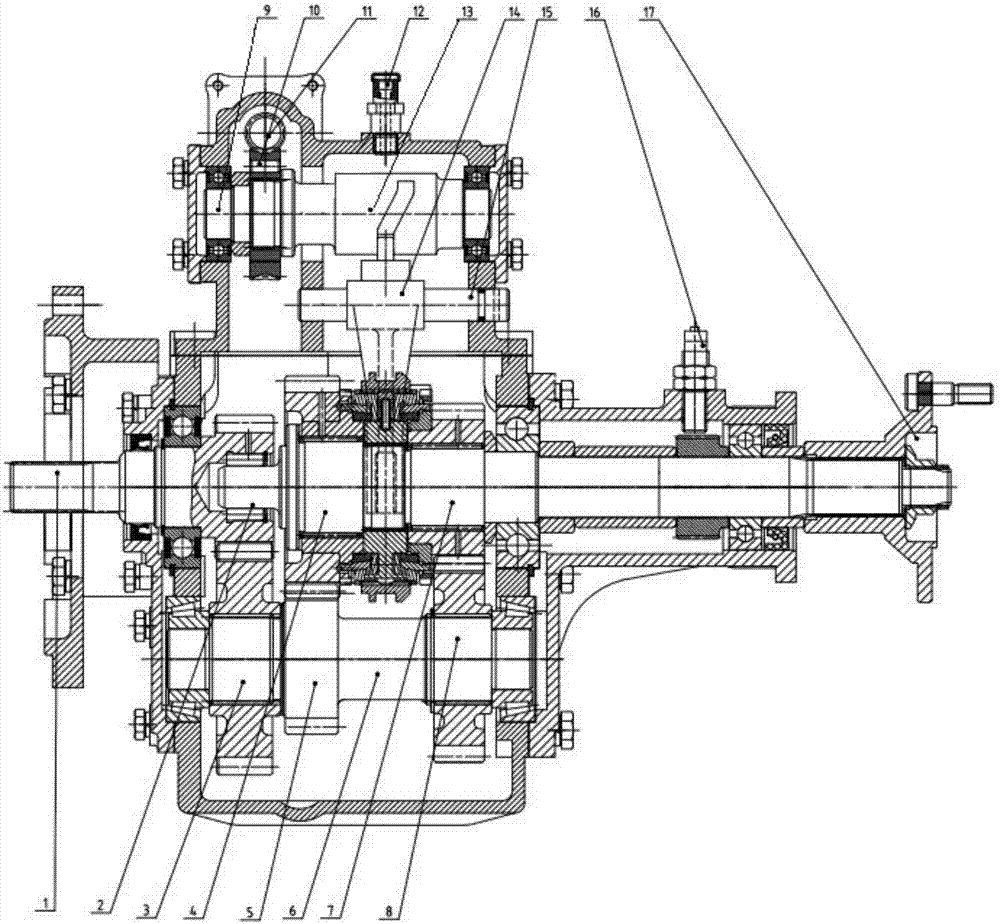

Automotive six-gear automatic transmission with brushless wire-driven centrifugal ball arm jointing devices

ActiveCN106763736ASimple structureLow costToothed gearingsGearing controlAutomatic transmissionGear wheel

The invention discloses an automotive six-gear automatic transmission with brushless wire-driven centrifugal ball arm jointing devices. The brushless wire-driven centrifugal ball arm jointing device is arranged between an input gear of each gear and a driving gear of each gear; by controlling the brushless wire-driven centrifugal ball arm jointing devices to joint and separate, gear control of the automotive six-gear automatic transmission with the brushless wire-driven centrifugal ball arm jointing devices is realized. The transmission disclosed by the invention has the advantages of being compact in structure, capable of gearing dynamically, free of mechanical or hydraulic gearing parts, low in operating energy consumption and the like.

Owner:SHANDONG UNIV OF TECH

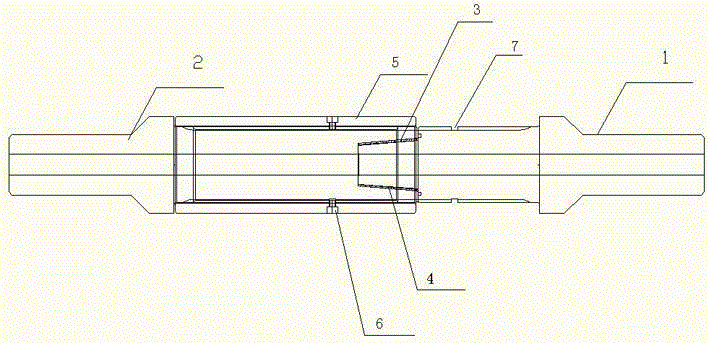

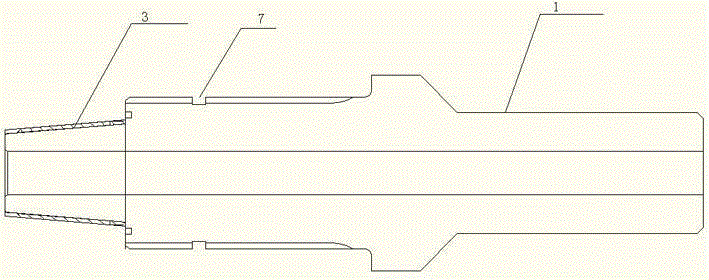

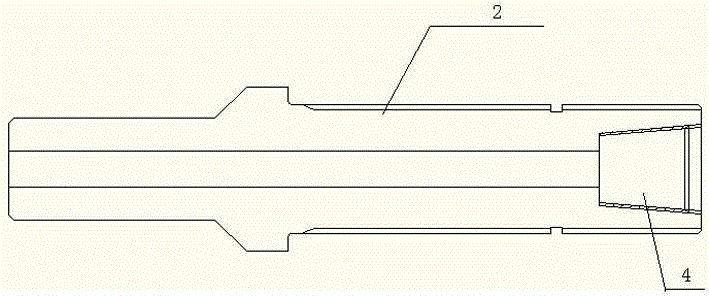

Drill pipe connected through cooperation of taper pipe threads and spline sliding sleeve

InactiveCN105317384AGuaranteed uptimeIncrease transmission torqueDrilling rodsDrilling casingsScrew threadPetroleum engineering

The invention discloses a drill pipe connected through cooperation of taper pipe threads and a spline sliding sleeve. The drill pipe comprises an upper drill pipe body and a lower drill pipe body connected with the upper drill pipe body. A male connector with an outer thread is arranged at a drill pipe connector part of the upper drill pipe body, a female connector with an inner thread is arranged at the drill pipe connector part of the lower drill pipe body, and the male connector and the female connector are connected through threaded fit. The drill pipe further comprises the spline sliding sleeve and a positioning device, the spline sliding sleeve is arranged on the periphery of the drill pipe connector in a sleeving mode, grooves are formed in the upper drill pipe body, holes with the diameter equal to that of the grooves are formed in the spline sliding sleeve and correspond to the grooves one to one, and the positioning device penetrates through the holes and is inserted into the grooves. According to the drill pipe, the upper drill pipe body and the lower drill pipe body can be conveniently connected and demounted; the male taper pipe connector and the female taper pipe connector which are concentrically arranged in the drill pipe are connected through the threads, so that it is ensured that the upper drill pipe body and the lower drill pipe body are closely connected, and it is also ensured that the drill pipe operates stably in the use process; the drill pipe has large transmission torque.

Owner:JIANGSU XINGSHA CONSTR ENG GRP +2

Modular magnetic coupling for underwater propeller

InactiveCN105515335APrevent easy throw-out problemsHigh flux densityPermanent-magnet clutches/brakesCouplingPropeller

The invention provides a modular magnetic coupling for an underwater propeller and belongs to the technical field of coupling devices. The modular magnetic coupling comprises an input shaft, a female connector, a female magnet, a male magnet, a male connector, an output shaft and a spacer sleeve and is characterized in that one end of the input shaft is fixedly connected with the female connector through a screw, and the female magnet is arranged on the surface of the inner wall of the female connector; one end of the output shaft is connected with the male connector, the male magnet is arranged on the surface of the outer wall of the male connector, and the spacer sleeve is arranged between the female connector and the male connector. The modular magnetic coupling has the advantages that a wedge-shaped permanent magnet which has the characteristics of tile-shaped permanent magnets and the characteristics of square permanent magnets is adopted creatively, so that the magnetizing direction can be changed and the direction of the magnetic line of force can be changed gradually, the magnetic flux density of an air gap of the device is maximized so that driving torque can be improved, and meanwhile, the situation that the permanent magnet is thrown away during high-speed rotation can be effectively prevented.

Owner:HEBEI UNIV OF TECH

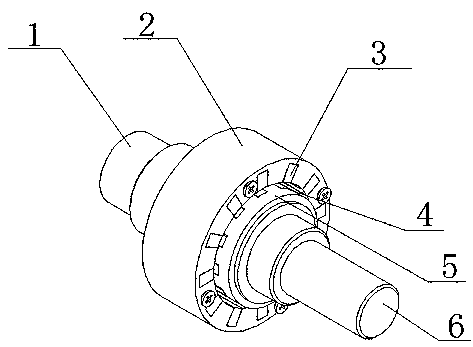

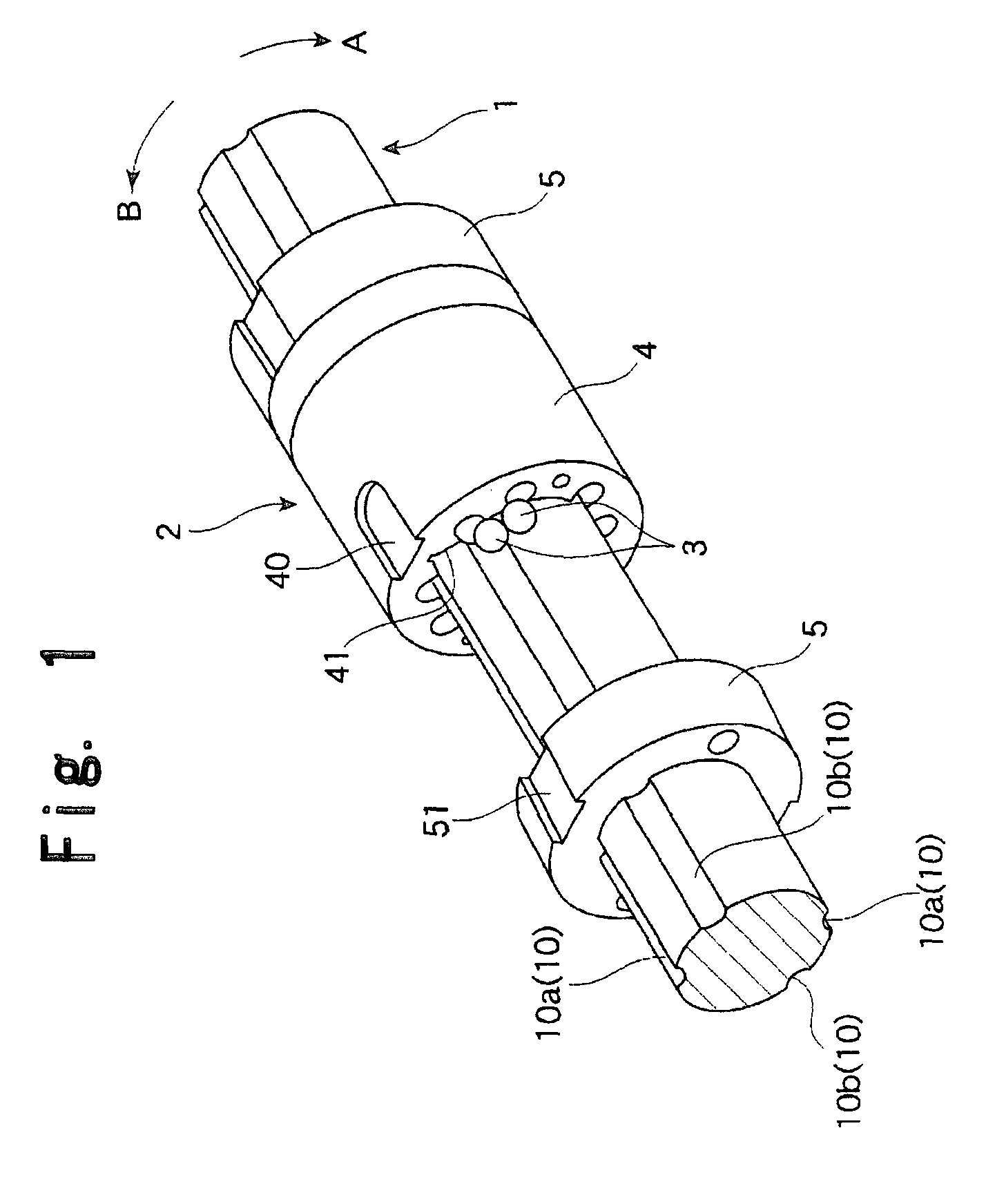

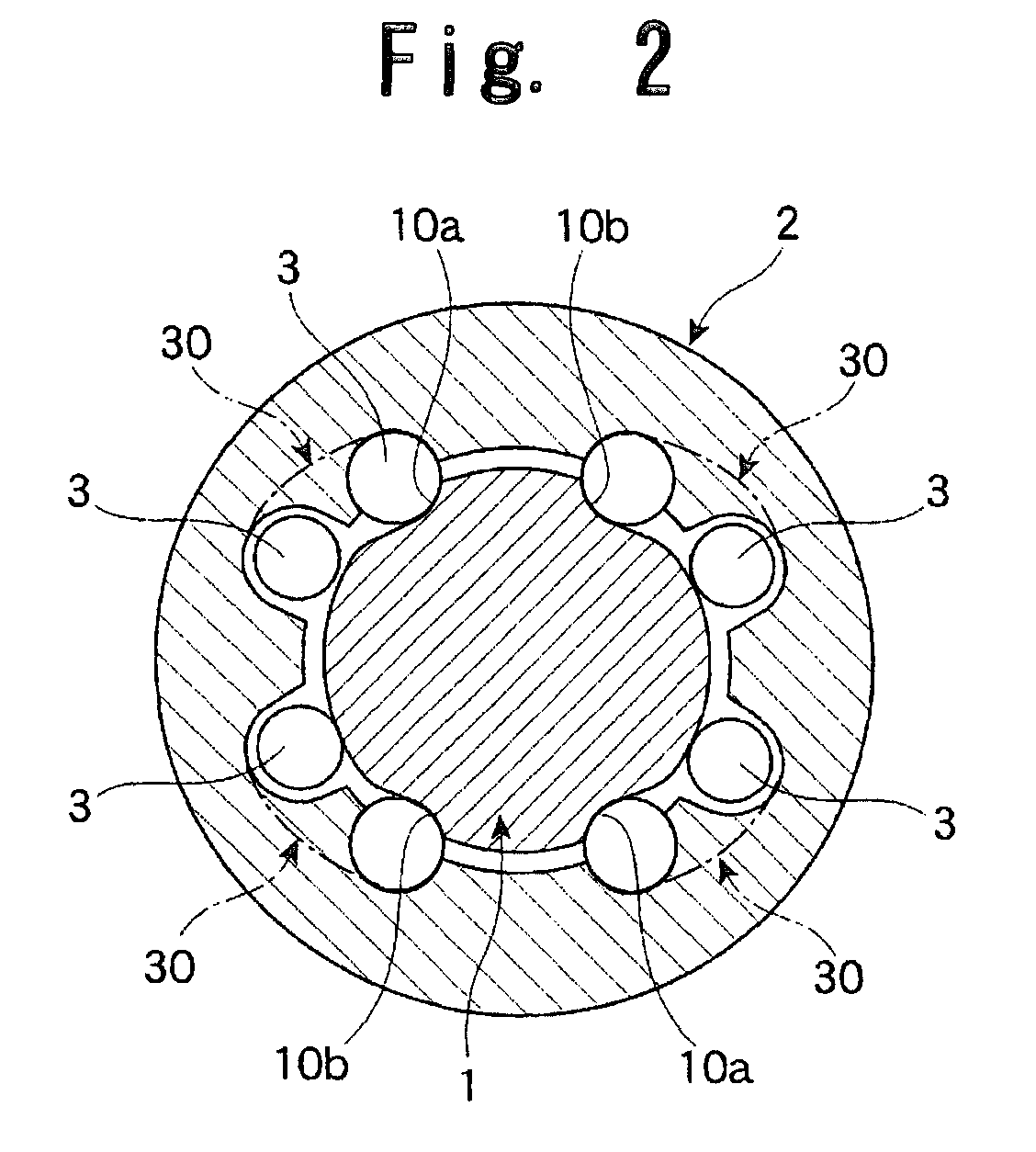

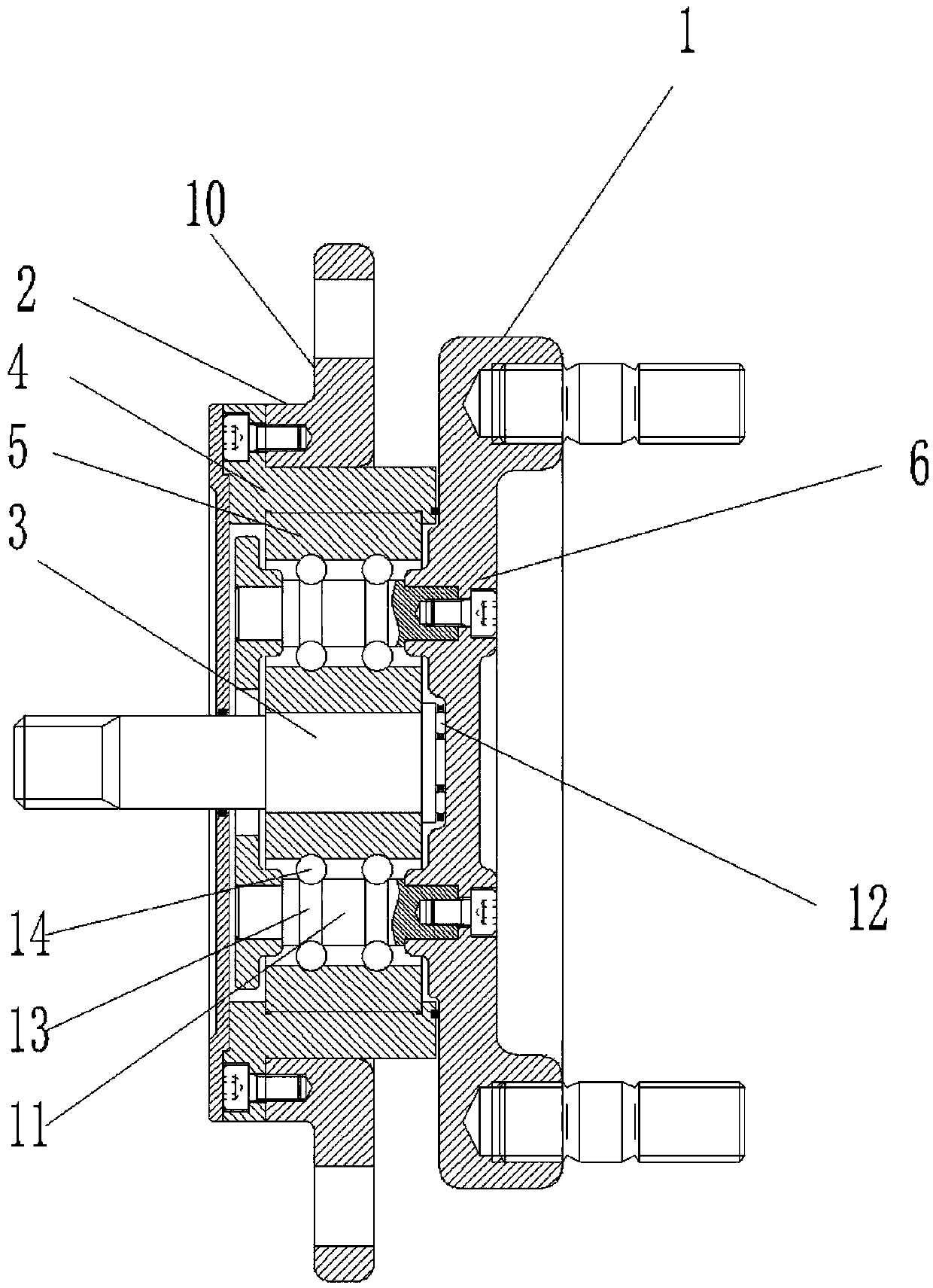

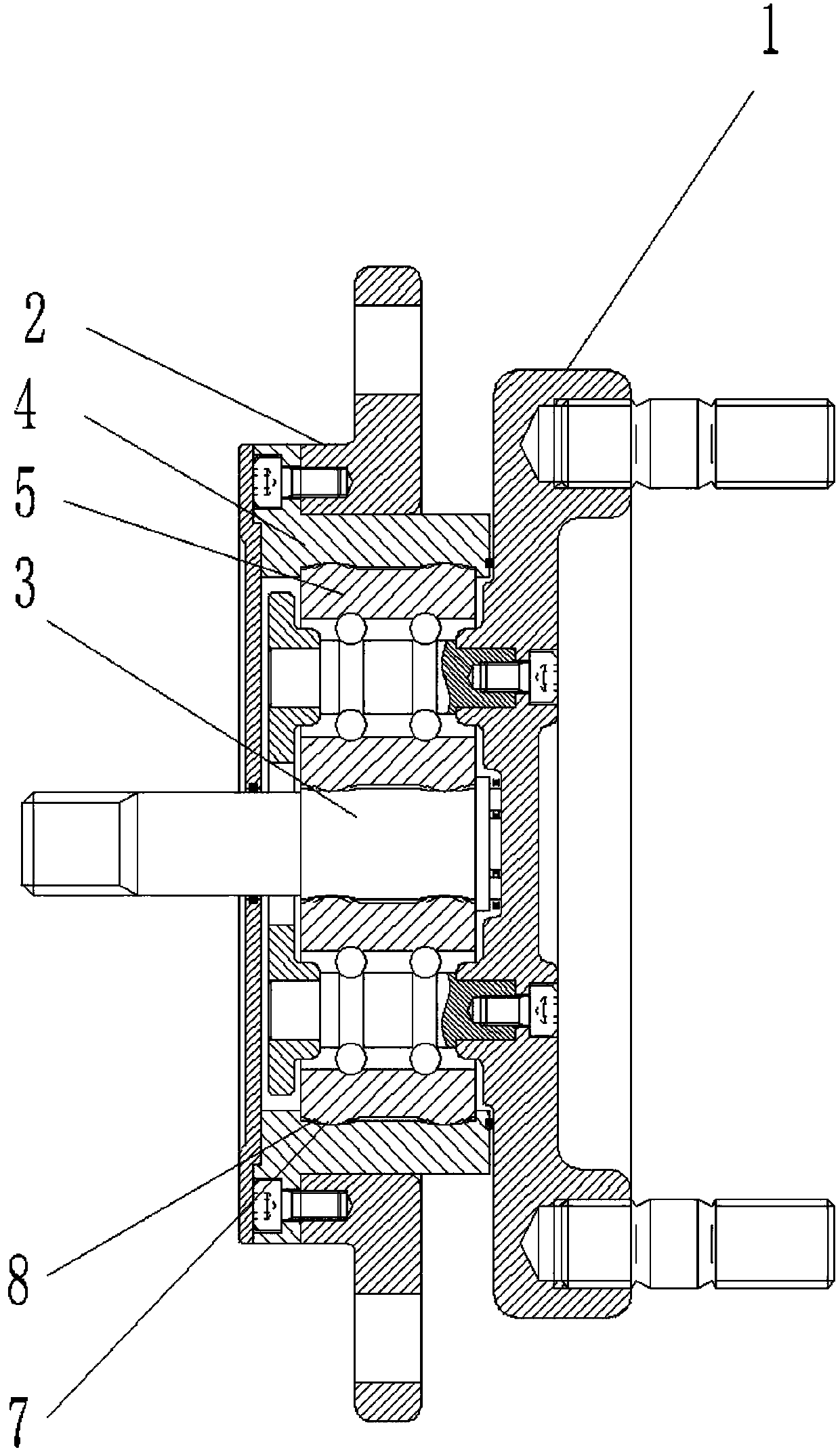

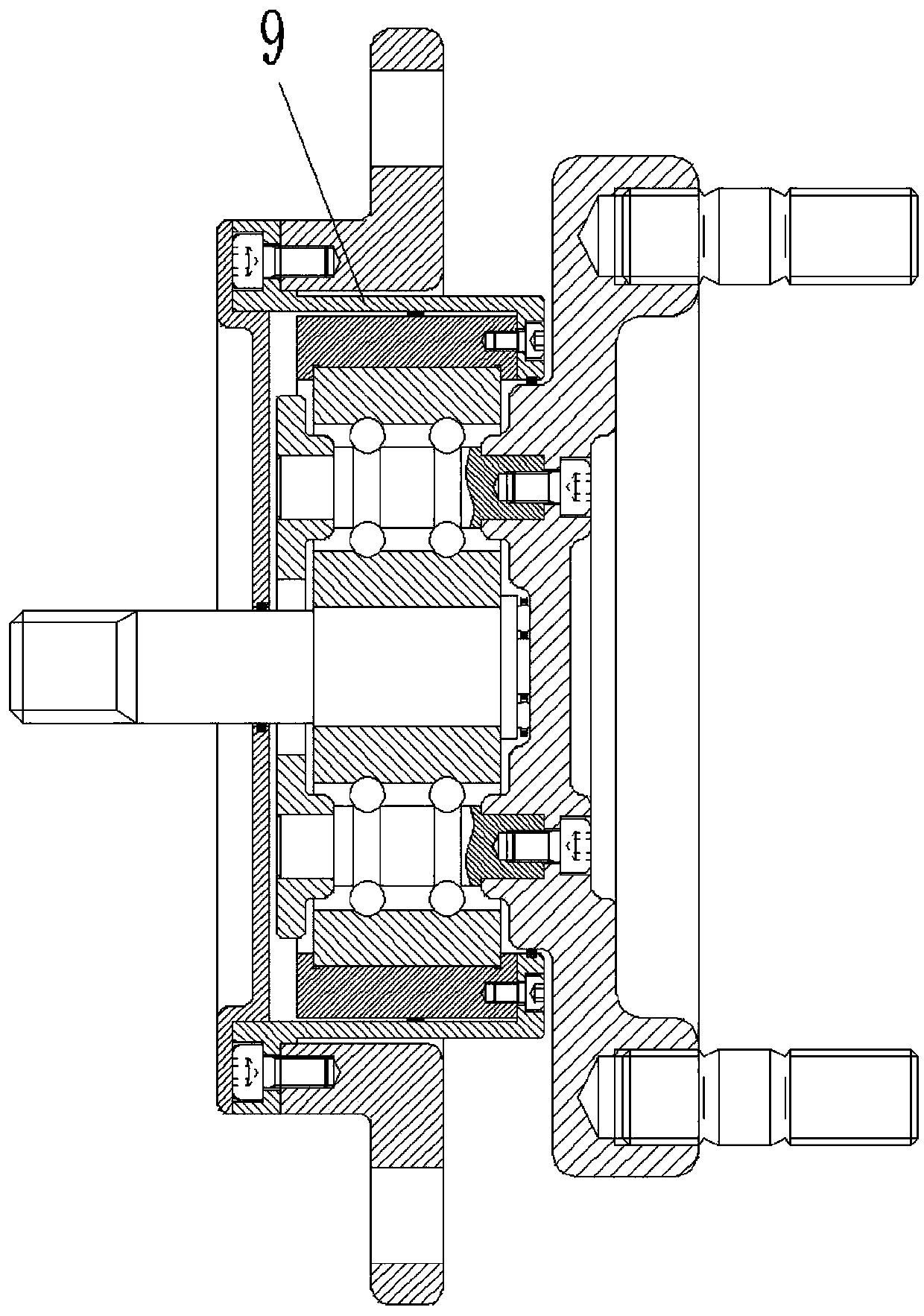

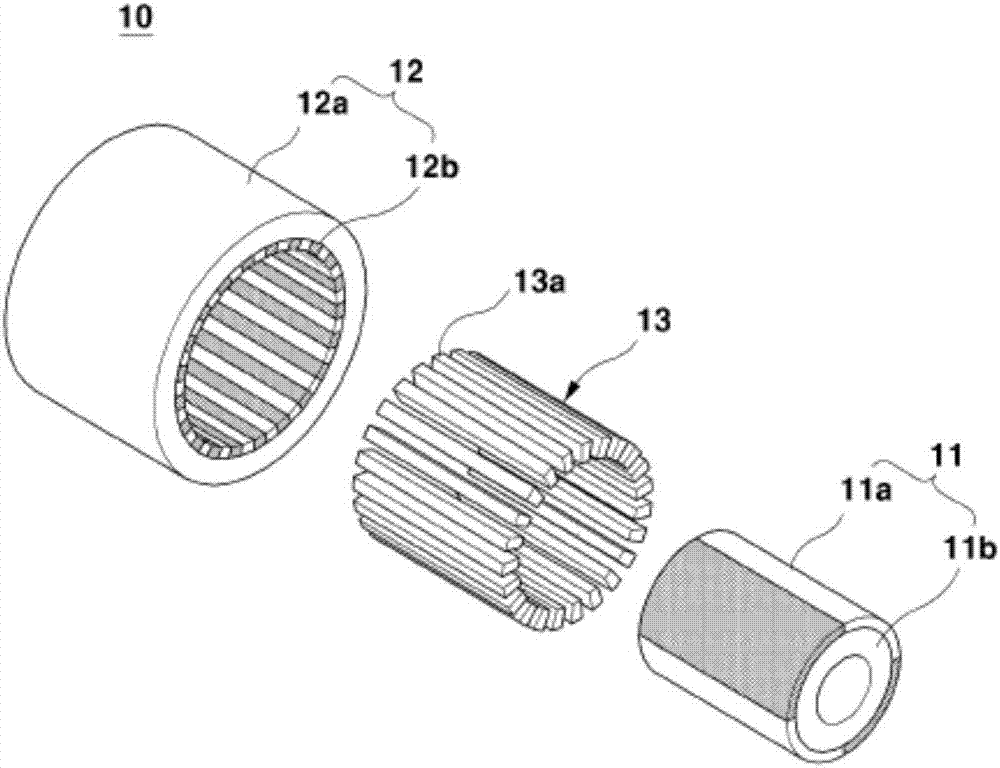

Ball spline device

ActiveUS8123407B2Avoid downsizingMaintain reliabilityYielding couplingLinear bearingsClassical mechanicsStructural engineering

Provided is a ball spline device, in which an outer diameter of a nut member can be downsized to the maximum while sufficiently performing an original function, and which can keep reliability while being capable of being simply manufactured at lower cost without involving time and effort in assembly, in which a nut member has a track groove which is formed on an inner peripheral surface facing a spline shaft, the balls circulating in the track groove, the track groove comprises: a linear load groove formed so as to face the ball rolling groove of the spline shaft; a linear non-load groove provided parallel to the linear load groove; and a pair of ball deflection grooves for communicably coupling the linear load groove and the linear non-load groove with each other so as to allow the balls to intercommunicate therebetween, and the ball deflection grooves forcibly change an advancing direction of the balls rolling in the ball rolling groove and cause the balls to depart from the ball rolling groove with use of a profile of the spline shaft.

Owner:THK CO LTD

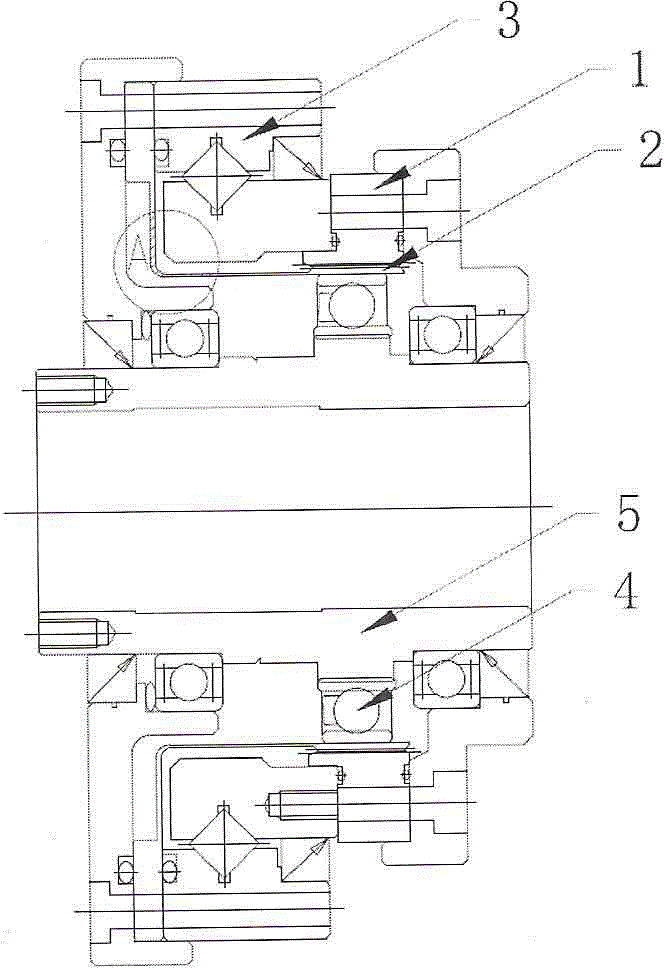

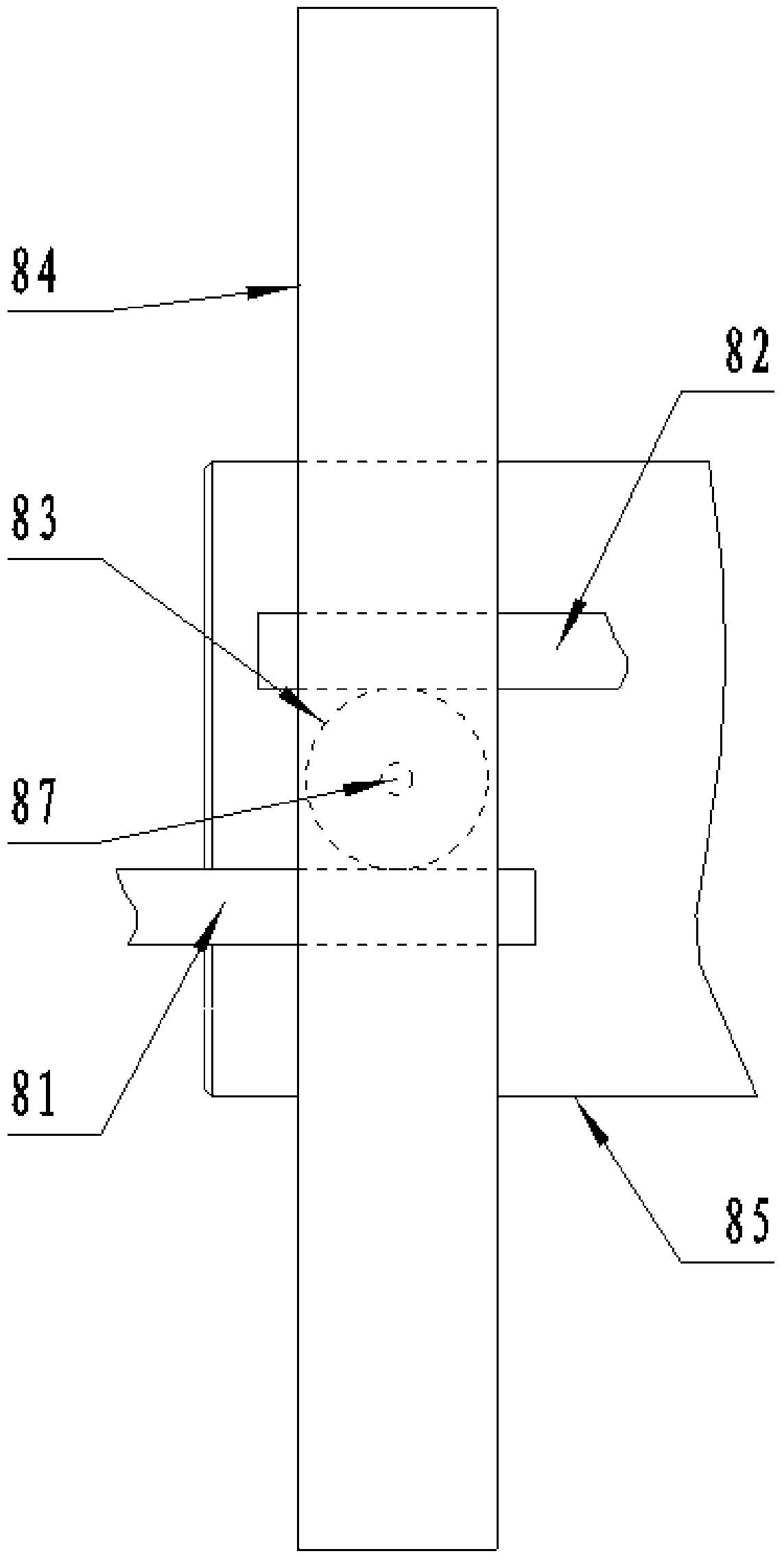

Novel mechanical centrifugal clutch

InactiveCN102478087AIncrease centrifugal controlIncrease transmission torqueAutomatic clutchesControl engineeringCam

The invention relates to a novel mechanical centrifugal clutch. The clutch makes uses of the centrifugal force enlargement principle of a lever and adopts a cam type structure; when the clutch works, firstly centrifugal force acts on the lever, then the lever exponentially enlarges and converts the limited centrifugal force into powerful lever force; and a forcing friction block is reliably combined with and separated from a transmission drum, thereby the centrifugal control force is obviously increased and the transmission torsion and efficiency are substantially improved. The automatic clutch has novel design, simple structure, stable and reliable performance, large torsion, high efficiency, is convenient to manufacture and use and can be widely applied to vehicles, motorcycles and the like needing automatic clutching and automatic gear shifting.

Owner:DALIAN ZHAOYANG SOFTWARE TECH

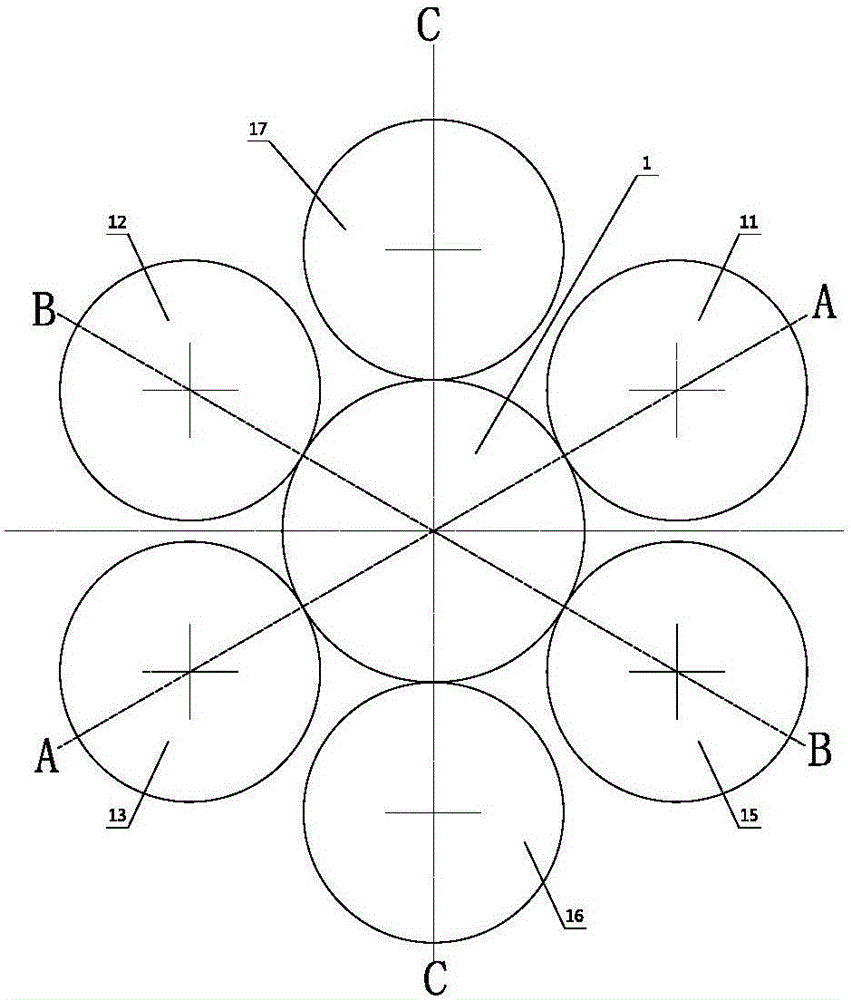

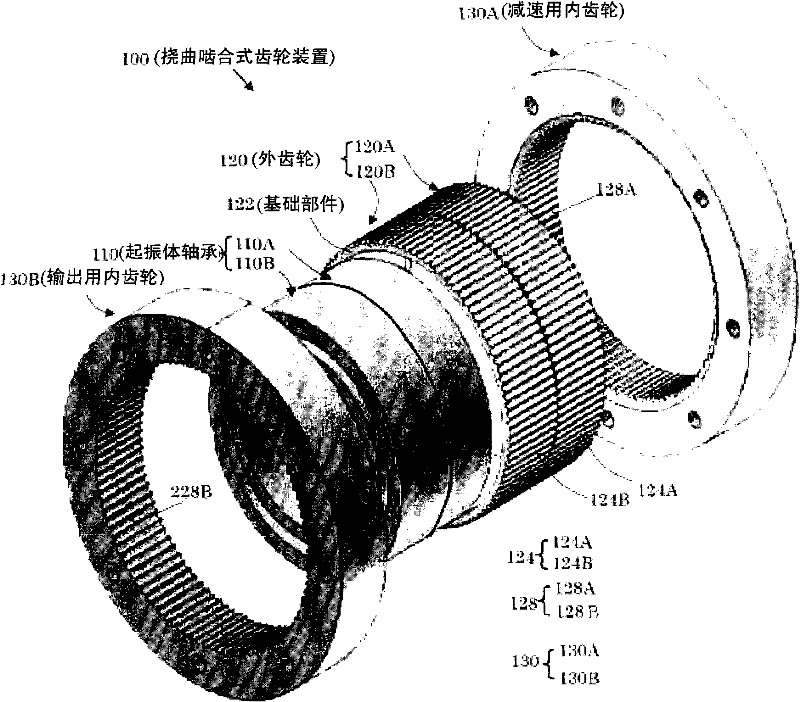

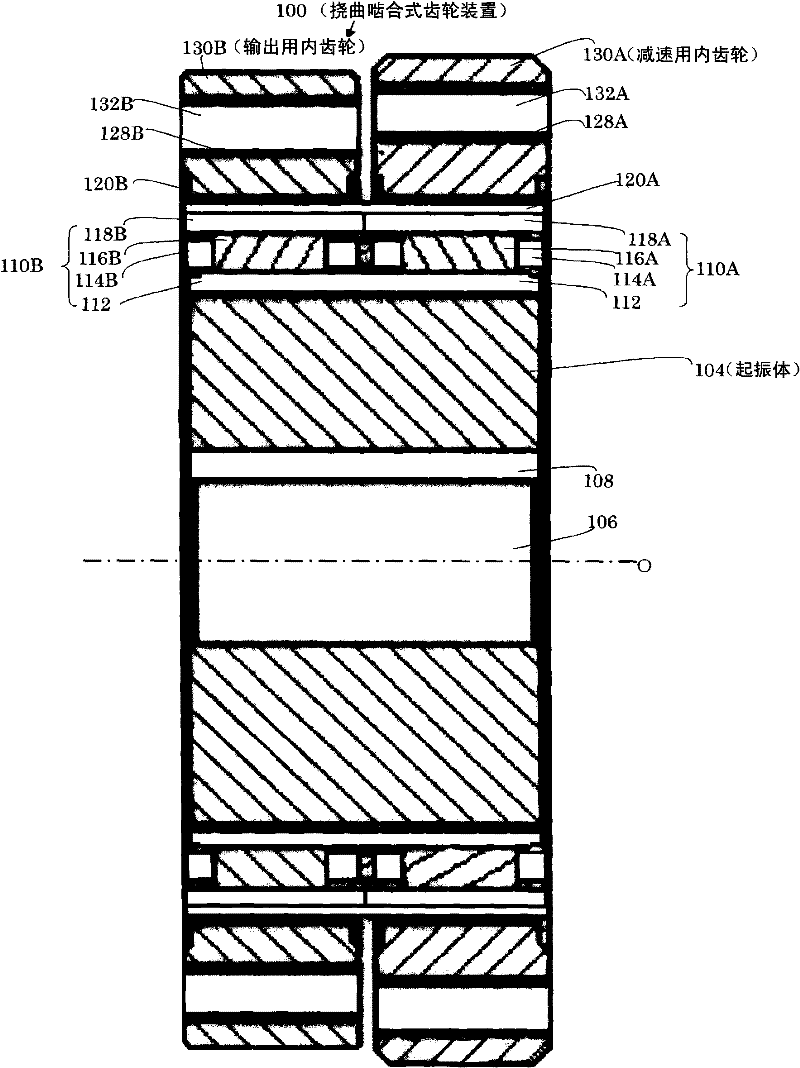

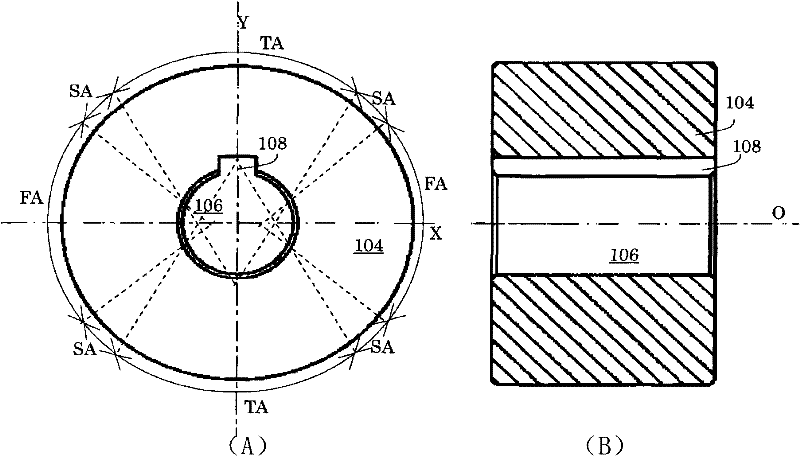

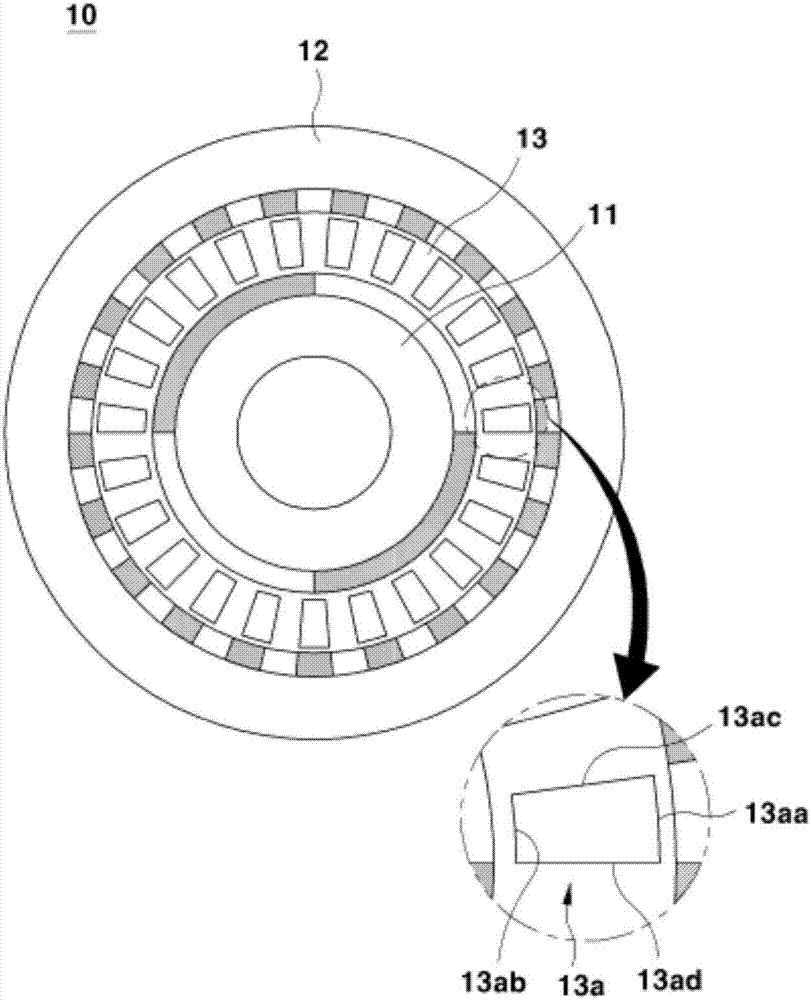

flex mesh gearing

ActiveCN102287484AReduced flexural stressFlexural Stress SuppressionToothed gearingsGear wheelElectrical and Electronics engineering

The invention provides a flexural engage type gear device, which inhibits flexural strain caused by external gear deformation to avoid the gear shape interference between the inner gear and the external gear caused by the external gear deformation, thereby the load torsion is realized to be increased. The flexural engage type gear device (100) provided in the utility model possesses an inner gear (130A), an external gear (120A) and an oscillation starting body (104), wherein the periphery of the oscillation starting body (104) includes an arc-shaped first arc portion (FA) which connects the inner gear (130A) for deceleration with the external (120A) to be in an engagement state, a second arc portion (SA) with curvature radius (r2) smaller than the first arc portion (FA), a third arc portion (TA) with the curvature radius (r3) larger than the first arc portion (FA), enabling the inner gear (130A) and the external gear (120A) be in a non-engagement state. The connection portions of the first arc portion (FA), the second arc portion (SA) and the third arc portion (TA) are respectively share the tangents (T1, T2) of the first arc portion (FA), the second arc portion (SA) and the third arc portion (TA).

Owner:SUMITOMO HEAVY IND LTD

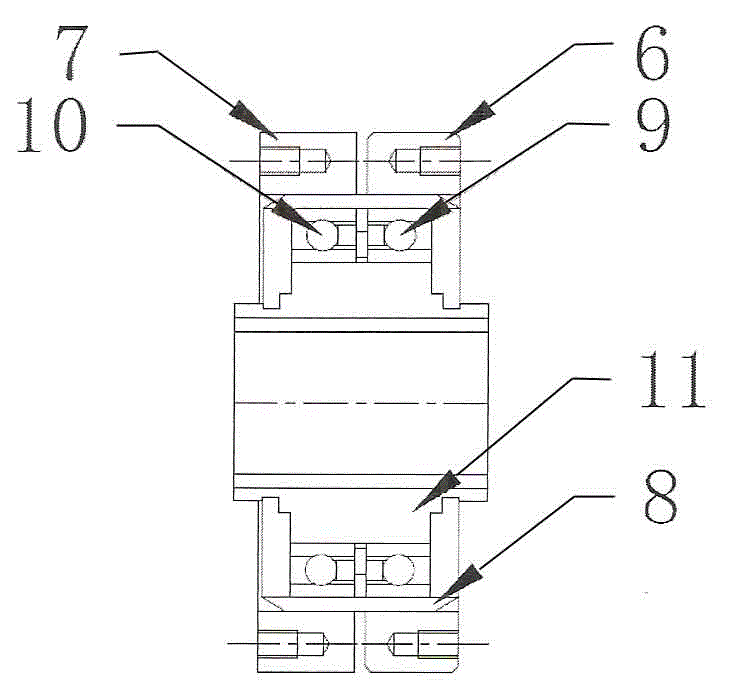

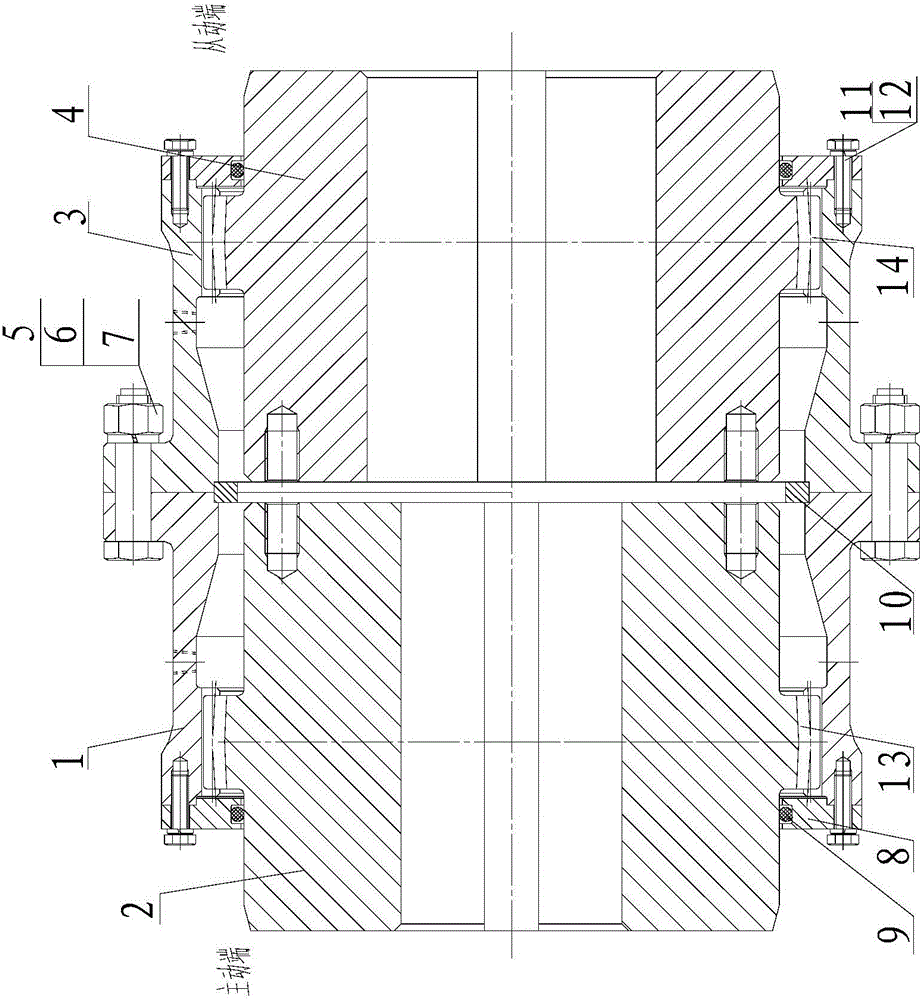

High-performance crowned tooth coupler

ActiveCN105972107AImprove bending strengthImprove contact strengthYielding couplingCouplingEngineering

The invention discloses a high-performance crowned tooth coupler which comprises a driving end inner tooth ring, a driving end outer tooth shaft sleeve, a gear pair connecting the driving end inner tooth ring with the driving end outer tooth shaft sleeve, a driven end inner tooth ring, a driven end outer tooth shaft sleeve, and a gear pair connecting the driven end inner tooth ring with the driven end outer tooth shaft sleeve. The high-performance crowned tooth coupler further comprises combination pressing covers at the two ends, seals, and a connecting structure of a driving end and a driven end, wherein pressure angle alpha between the driving end inner tooth ring and the driving end outer tooth shaft sleeve is 20-30 degrees; and pressure angle alpha between the driven end inner tooth ring and the driven end outer tooth shaft sleeve is 20-30 degrees. With the adoption of the scheme, the carrying capacity of the high-performance crowned tooth coupler is improved, the service life is prolonged, and the production cost is reduced. In addition, the driving end inner tooth ring and the driven end inner tooth ring can be exchanged completely, so that the inventory cost of spare parts is reduced. Furthermore, the quick-worn seals of can be replaced online, so that the maintenance downtime is shortened, and the maintenance labor intensity is reduced.

Owner:TAIER HEAVY IND

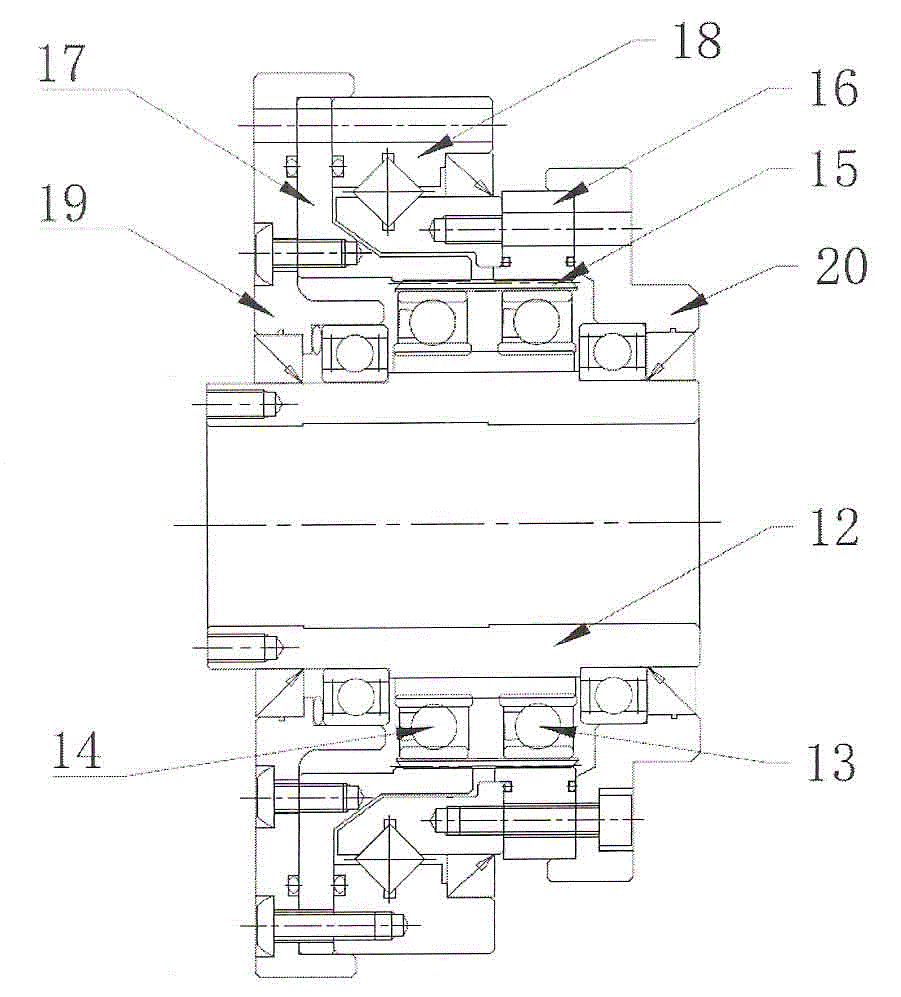

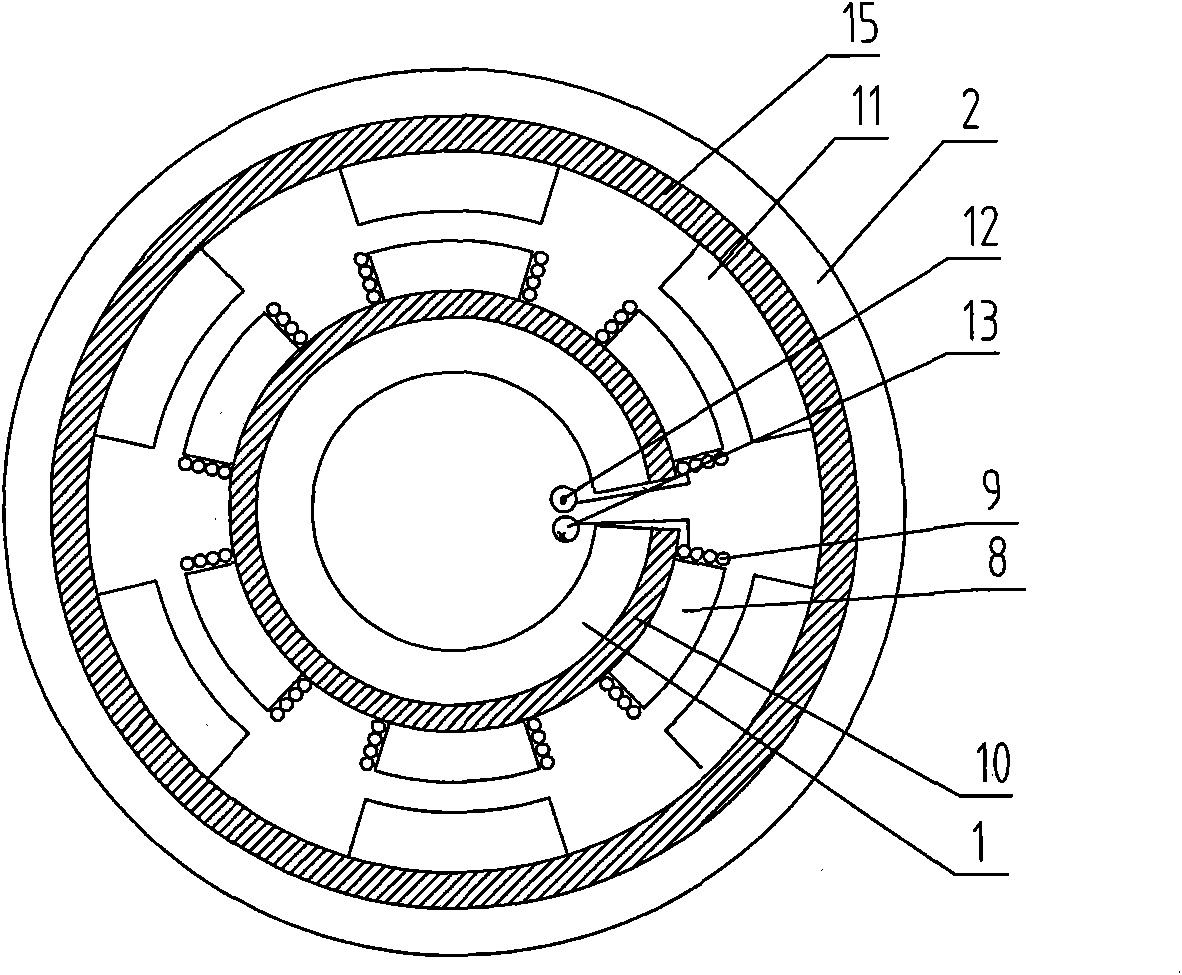

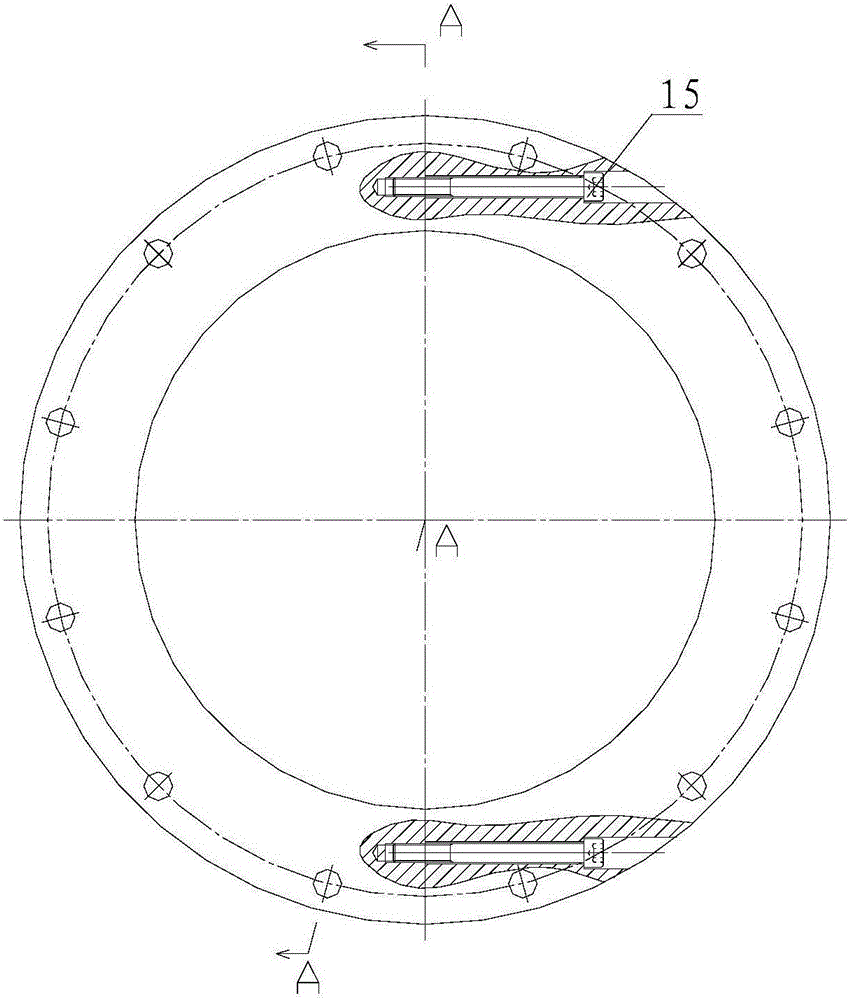

Combined permanent magnet eddy current speed governor

InactiveCN104253523AImprove securityImprove reliabilityDynamo-electric gearsCopper conductorPermanent magnet rotor

The invention provides a combined permanent magnet eddy current speed governor which comprises a conductor rotor and a permanent magnet rotor, wherein the conductor rotor comprises a circumferential fixing sleeve, a first conductor supporting disk (1) and a second conductor supporting disk (15), wherein a first end face conductor (2) is arranged on the inner surface of the first conductor supporting disk (1), and a second end face conductor (14) is arranged on the inner surface of the second conductor supporting disk (15); a radial conductor is arranged on the inner surface of the circumferential fixing sleeve; the permanent magnet rotor comprises a first magnet mounting disk (4) and a second magnet mounting disk (12) which are parallel to each other; end face permanent magnets and radial permanent magnets are arranged on both the first magnet mounting disk (4) and the second magnet mounting disk (12). The combined permanent magnet eddy current speed governor combines a cylinder type structure with a disk type structure, the permanent magnets are simultaneously magnetized in the radial direction and the axial direction, and a copper conductor cuts magnetic lines of force in the radial direction and on the end face to increase electromagnetic damping. Output torque can be easily regulated by a regulating mechanism, and transmission power is greatly increased.

Owner:北京必可测科技股份有限公司

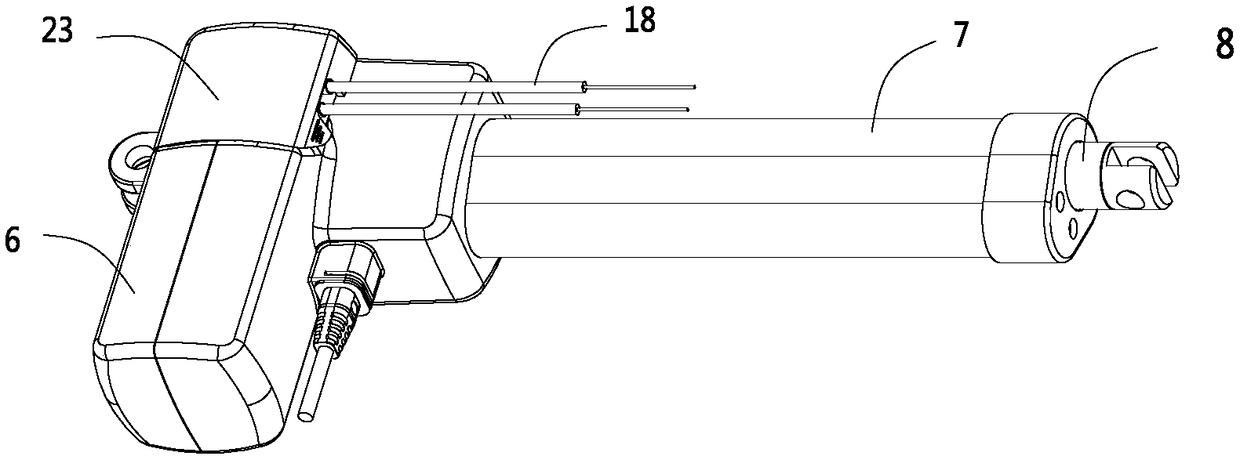

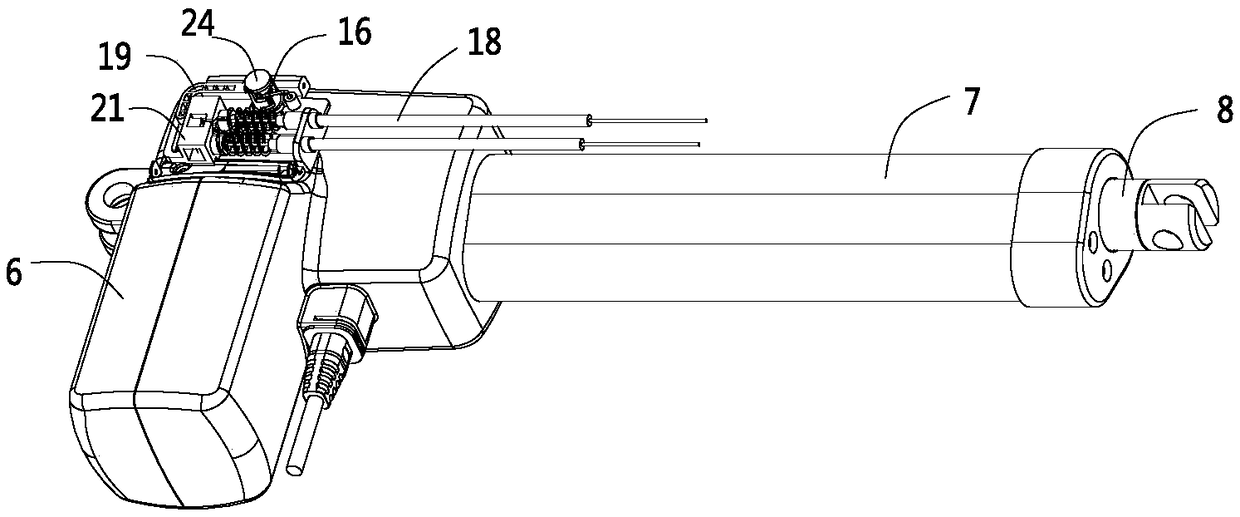

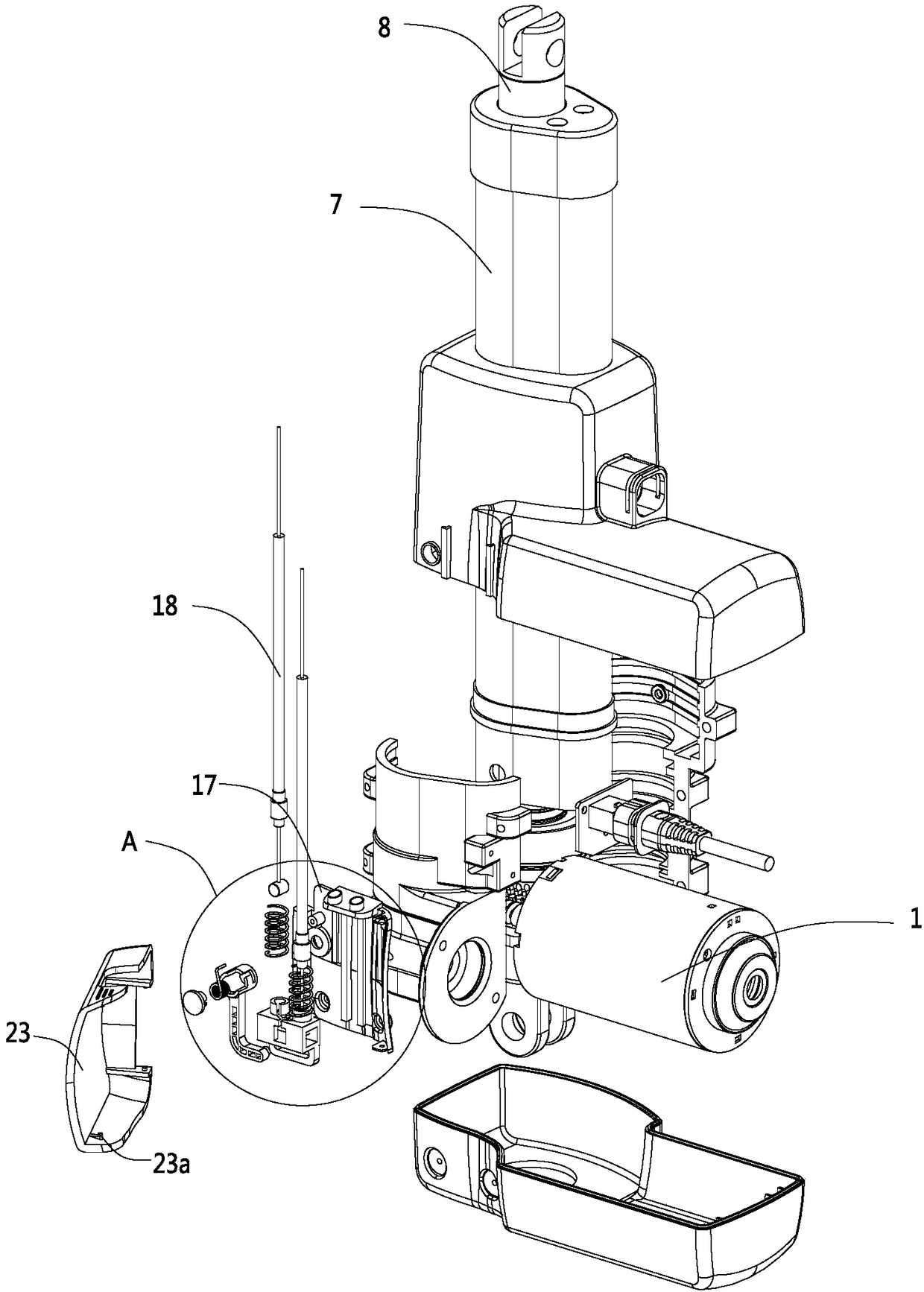

Linear actuator

The invention discloses a linear actuator. The linear actuator comprises a drive motor, a transmission worm, a worm wheel, a lead screw, a nut, a planetary gear assembly and a brake the drive motor isconnected with the transmission worm, the transmission worm drives the worm wheel to rotate, the worm wheel rotate to drives the lead screw to rotate, and the lead screw rotate to drives the nut to move axially. The planetary gear assembly is arranged between the worm wheel and the lead screw, the planetary gear assembly comprises an inner gear ring, a sun gear, a planetary gear and a planet carrier, the sun gear and the worm wheel rotate synchronously, and the planet carrier and the lead screw rotate synchronously. The brake is used for braking the inner gear ring and comprises an outer gearring. The linear actuator has the advantages that when the planetary gear assembly is used for increasing the thrust, release is performed by the planetary gear assembly, and the structure design ismore compact.

Owner:ZHEJIANG JIECHANG LINEAR MOTION TECH

Planetary traction drive bearing type integral reduction hub

InactiveCN109538704AReduce axial sizeImprove compactnessToothed gearingsBearing componentsReduction driveReducer

The invention discloses a planetary traction drive bearing type integral reduction hub which comprises a hub body and a planetary traction drive bearing type reducer; the planetary traction drive bearing type reducer comprises a planetary traction drive gear train collectively formed by a reducer drive inner shaft, a reducer outer ring, a planetary rolling body and a planetary carrier; the planetary rolling body is matched with the reducer drive inner shaft and the reducer outer ring in a friction drive manner; and the power output end of the planetary traction drive gear train is in drive connection to the hub body. The planetary traction drive bearing type integral reduction hub simplifies combination of a wheel-side reducer and a hub bearing, enables the hub bearing to be organically integrated to a planetary traction reduction drive structure, integrates functions of speed reduction and a bearing as well as is simple and compact in structure, small in size and low in processing size.

Owner:CHONGQING UNIV

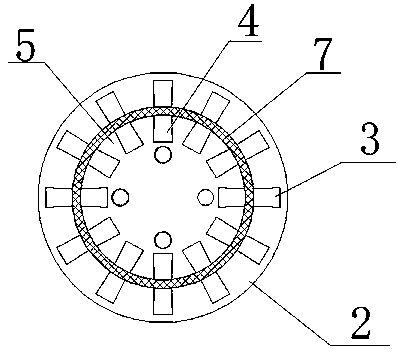

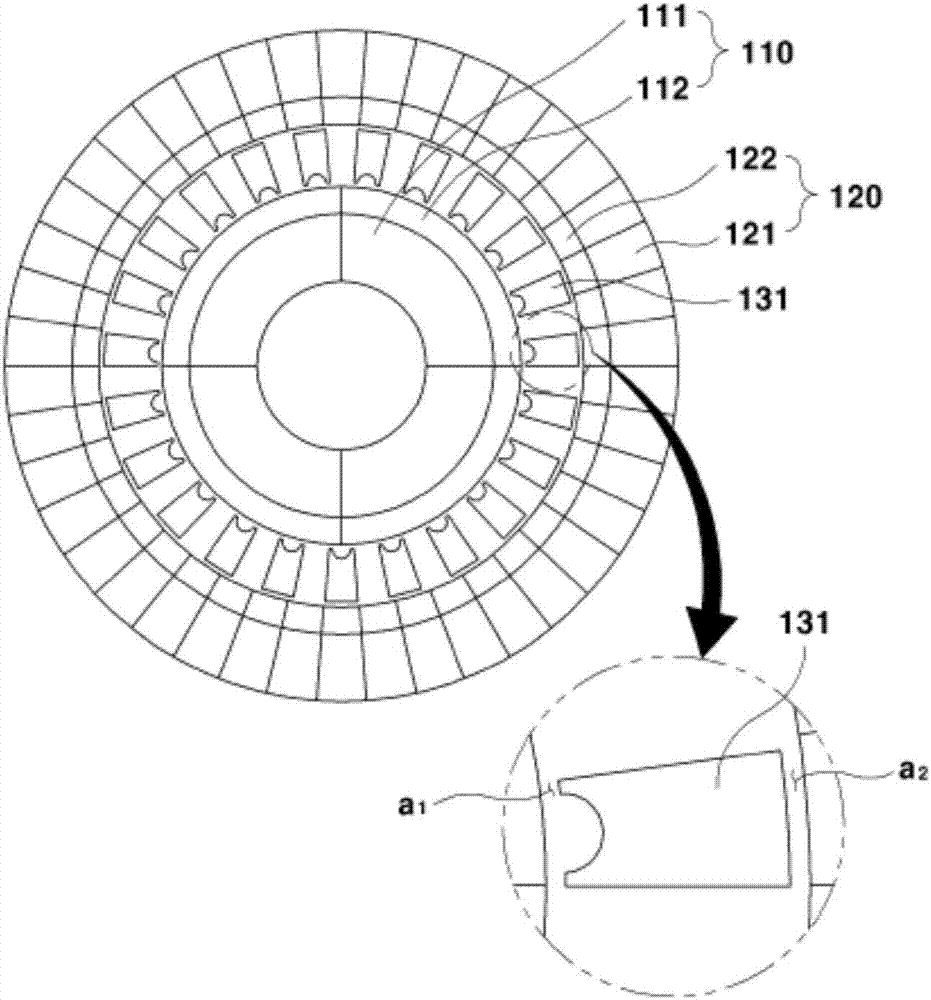

Magnetic gear having pole piece for improving transmitting torque

InactiveCN107196484AGood effectIncrease transmission torquePermanent-magnet clutches/brakesPole pieceEngineering

The present invention relates to a magnetic gear having a pole piece for improving transmission torque characteristics, more specifically, to improve the shape of a pole piece located between an inner rotor and an outer rotor, And to a magnetic piece having a pole piece for improving transmission torque characteristics capable of reducing torque ripple.

Owner:IND ACADEMIC CORP FOUND YONSEI UNIV

Automatic gearbox for electric mini-truck

ActiveCN106949198AConvenient ArrangementSimple layoutToothed gearingsGearing controlEngineeringTruck

The invention belongs to the technical field of gearboxes, particularly relates to a gearbox of reverse input agricultural equipment and discloses an automatic gearbox for an electric mini-truck. The automatic gearbox for the electric mini-truck mainly comprises a clutch, a gearbox shell, a first shaft, a reverse idler shaft, a first-speed driven gear, a first-and-reverse gear hub, a reverse driven gear, a second-speed driven gear, a second-and-third speed gear hub, a third-speed driven gear, a second shaft, a first flange plate, a differential assembly, a second flange plate, a movable gear and the like, wherein the first shaft and the second shaft are sequentially arranged inside the gearbox shell of a hollow structure from bottom to top; a reverse driving gear, a first-speed driving gear, a second-speed driving gear and a third-speed driving gear are sequentially and fixedly connected to the portion, in the gearbox shell, of the first shaft from left to right; and the second shaft is sequentially provided with the reverse driven gear, the first-and-reverse gear hub, the first-speed driven gear, a vertical differential connection shaft, the second-speed driven gear, the second-and-third speed gear hub and the third-speed driven gear. According to the automatic gearbox for the electric mini-truck, the gear shifting operation is easy and convenient, the gear shifting force is small, gear distribution and gear speed are reasonable, the safety performance is good, reliability is high, and the service life is long.

Owner:山东蒙沃变速器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com