Patents

Literature

36results about How to "Avoid downsizing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

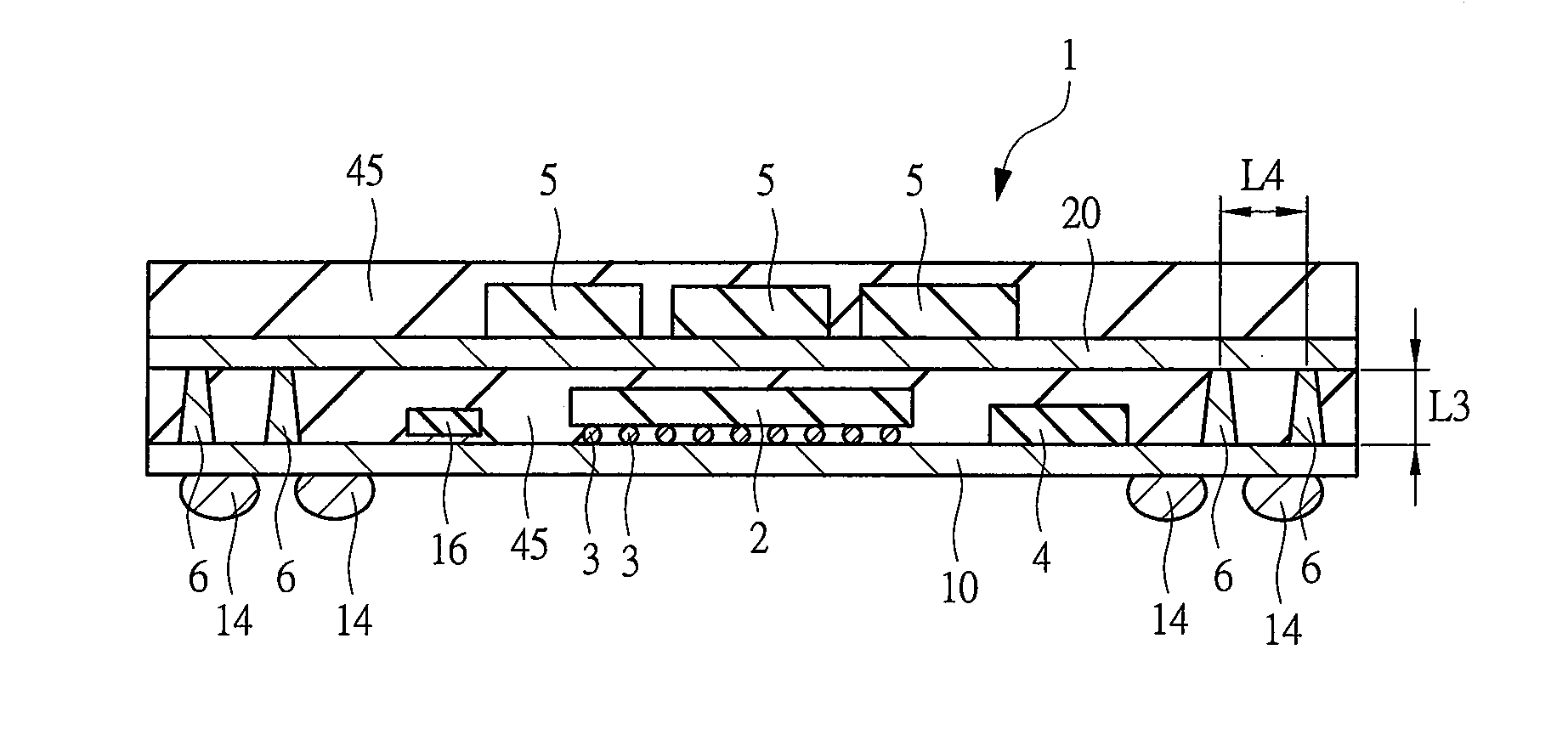

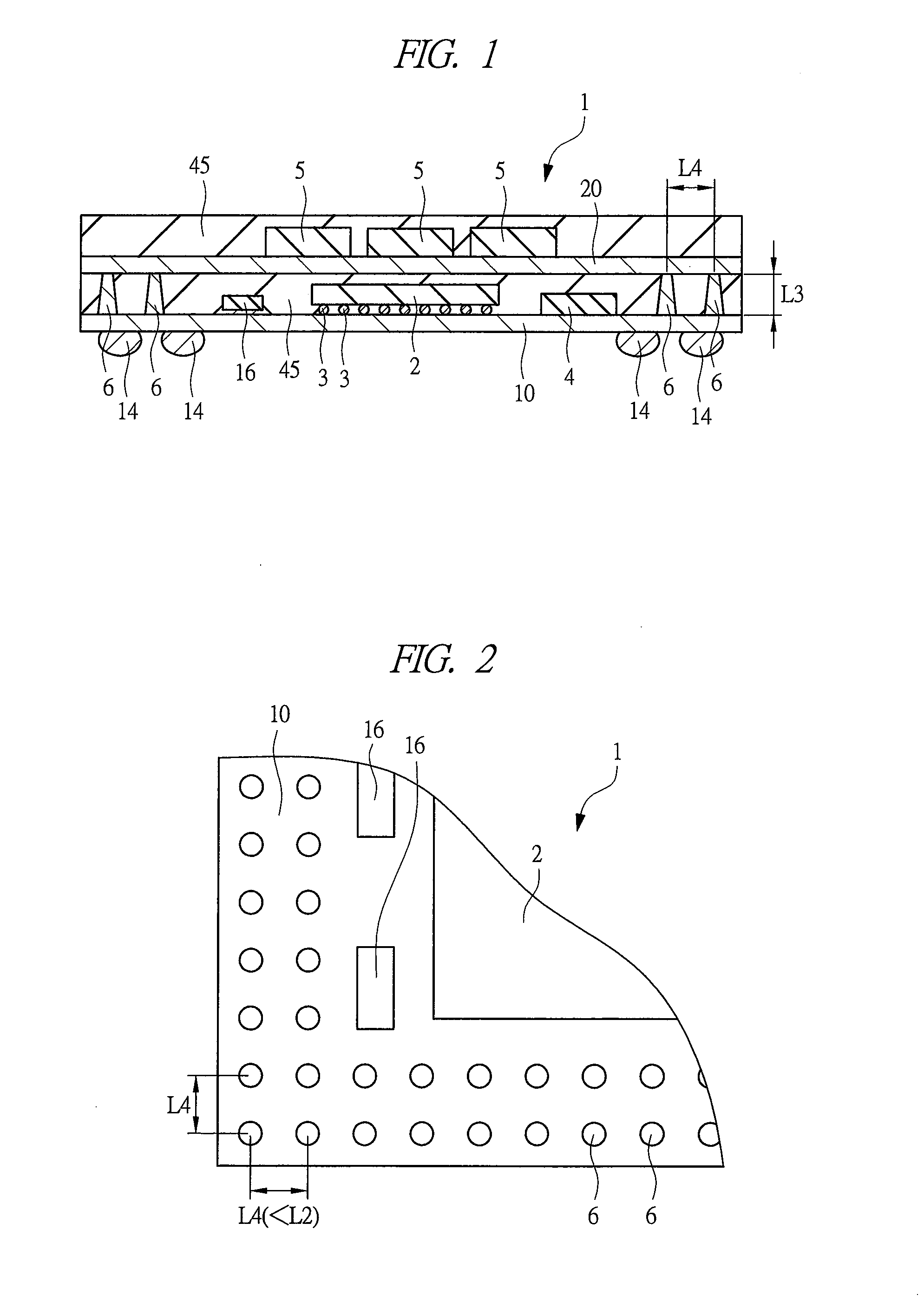

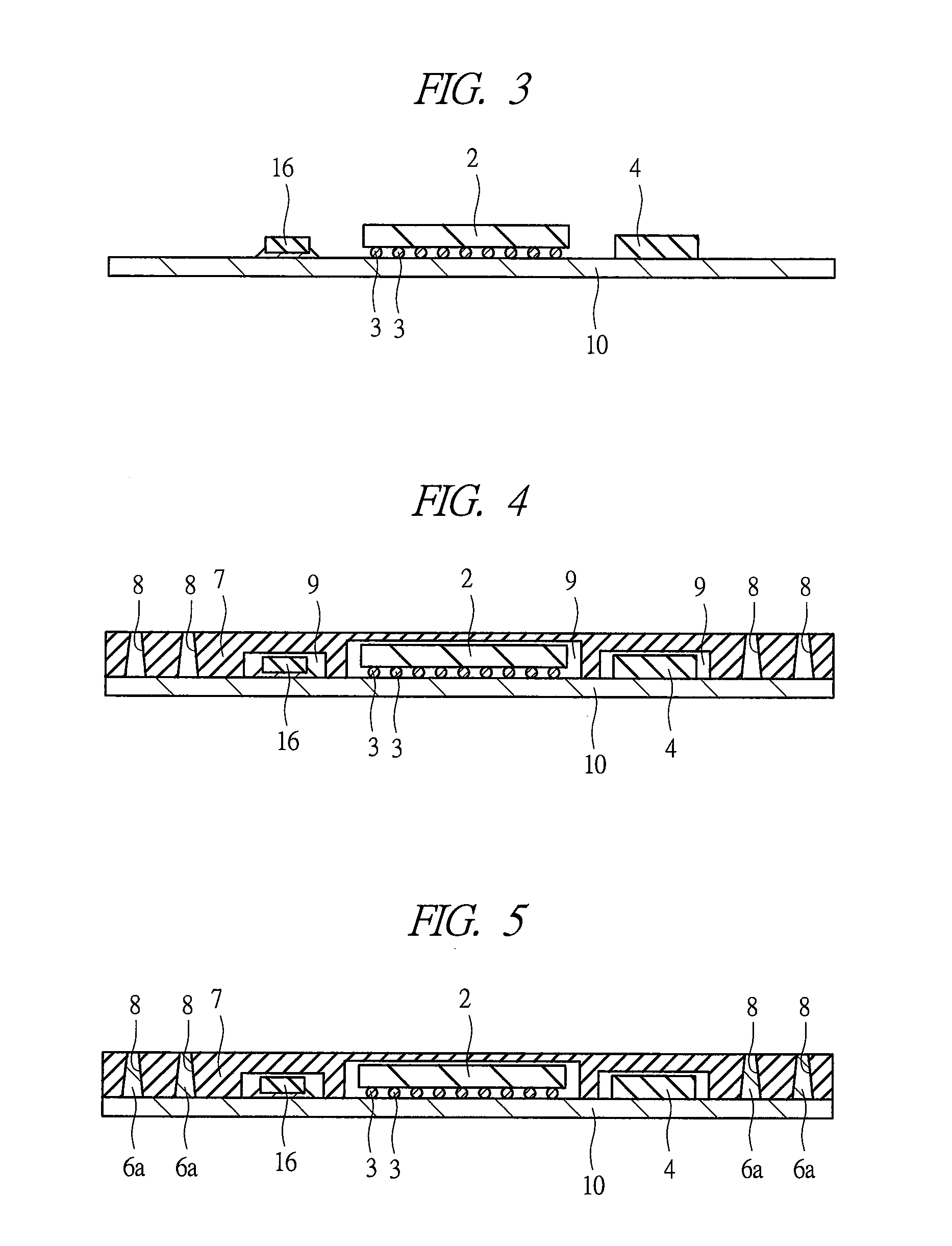

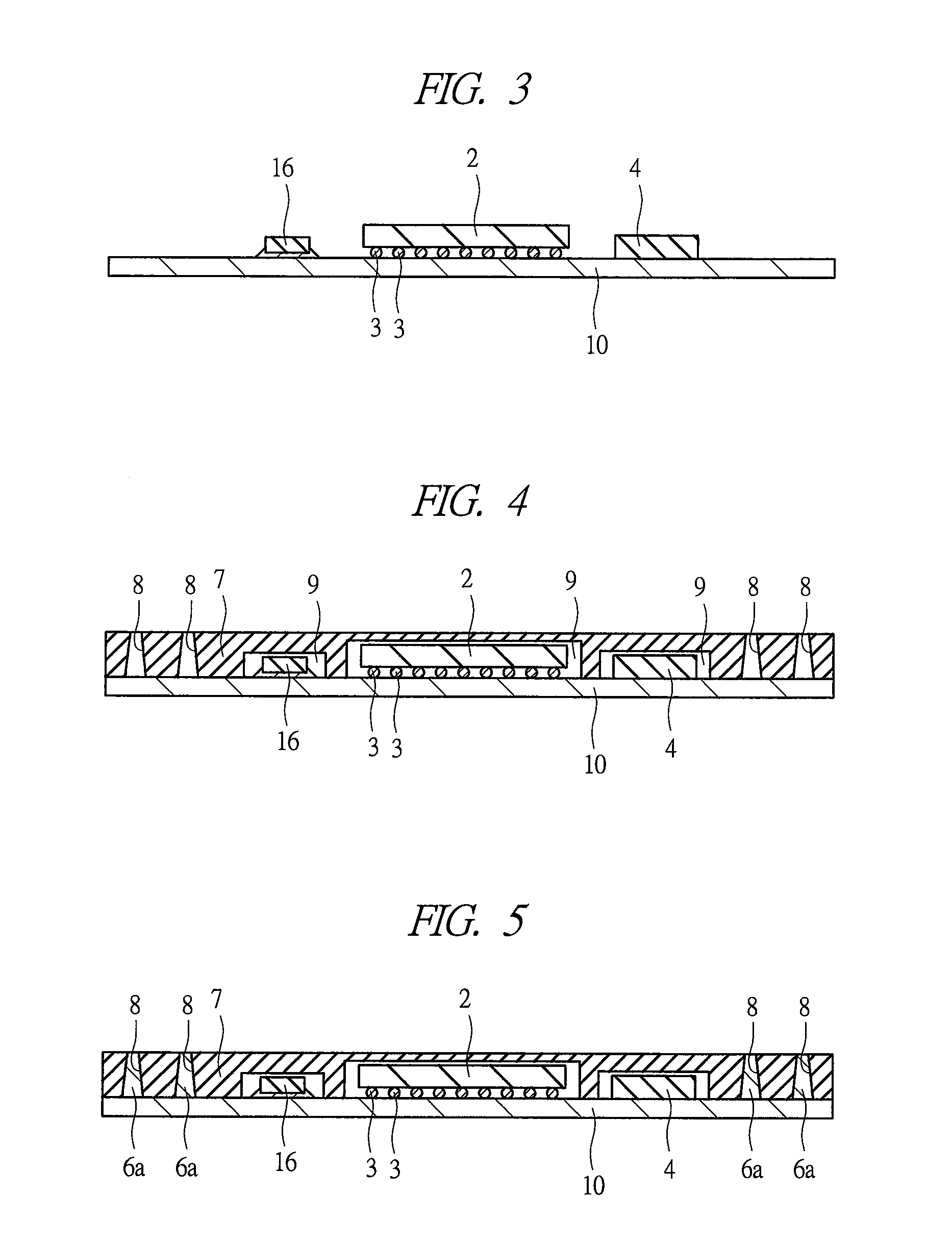

Semiconductor device and method of manufacturing the same

ActiveUS20110128713A1Downsizing and thinningLower Reliability RequirementsSemiconductor/solid-state device detailsPrinted circuit aspectsElectrical connectionSolder ball

In a semiconductor device in which a plurality of wiring substrates each mounting an electronic component are stacked and sealed by a resin, the semiconductor device can be downsized, thinned, and highly reliable, and its manufacturing cost can be reduced. By using a metal paste for electrical connection between the stacked lower-layer side wiring substrate and upper-layer side wiring substrate, a connecting pitch can be smaller than that in a connecting method of using a solder ball including Cu core, and the connection at low temperature can be achieved. Also, by coating a metal paste by a print-coating method or a dispense-coating method, manufacturing steps are simplified, so that the manufacturing cost is reduced.

Owner:RENESAS ELECTRONICS CORP

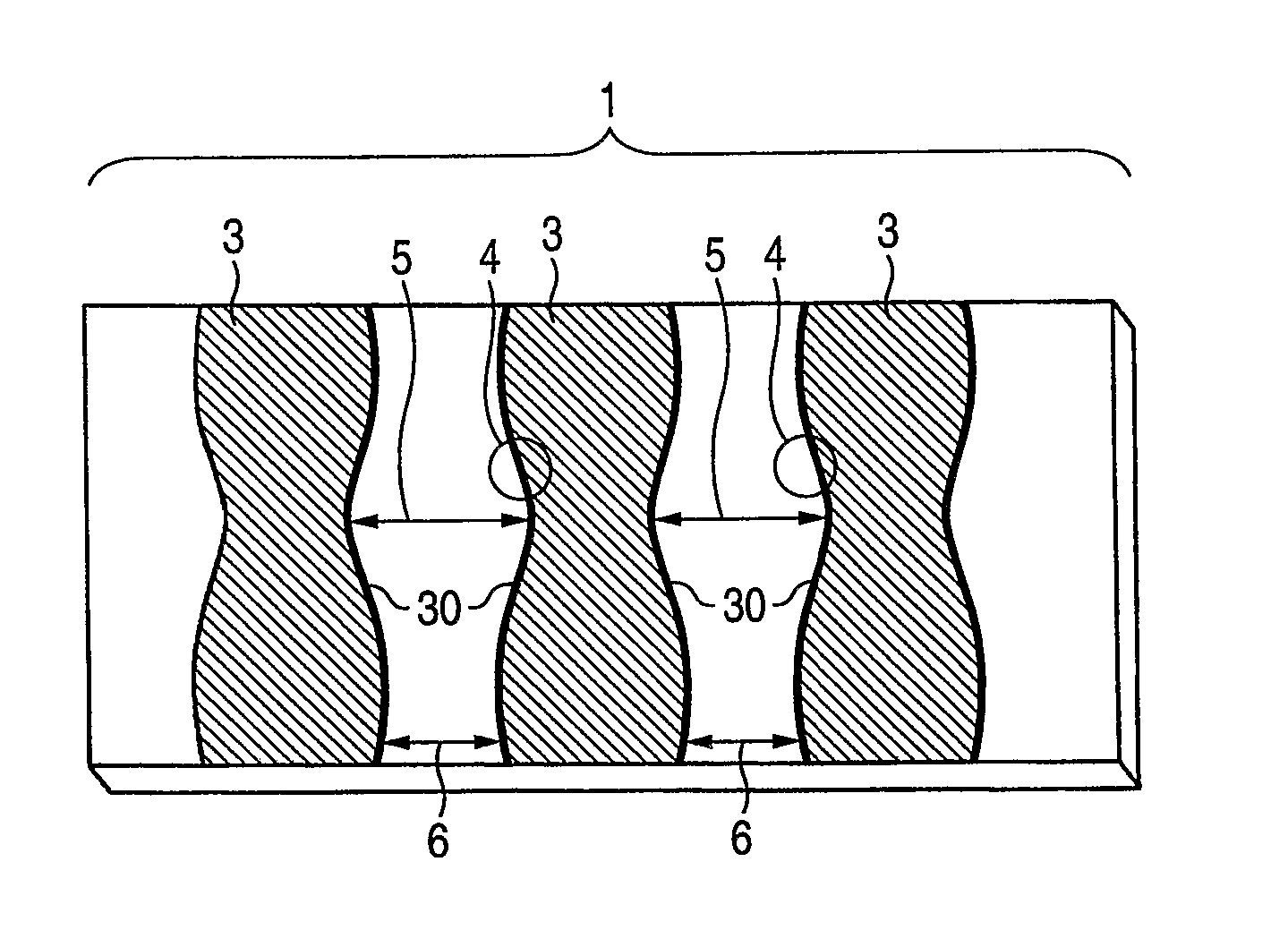

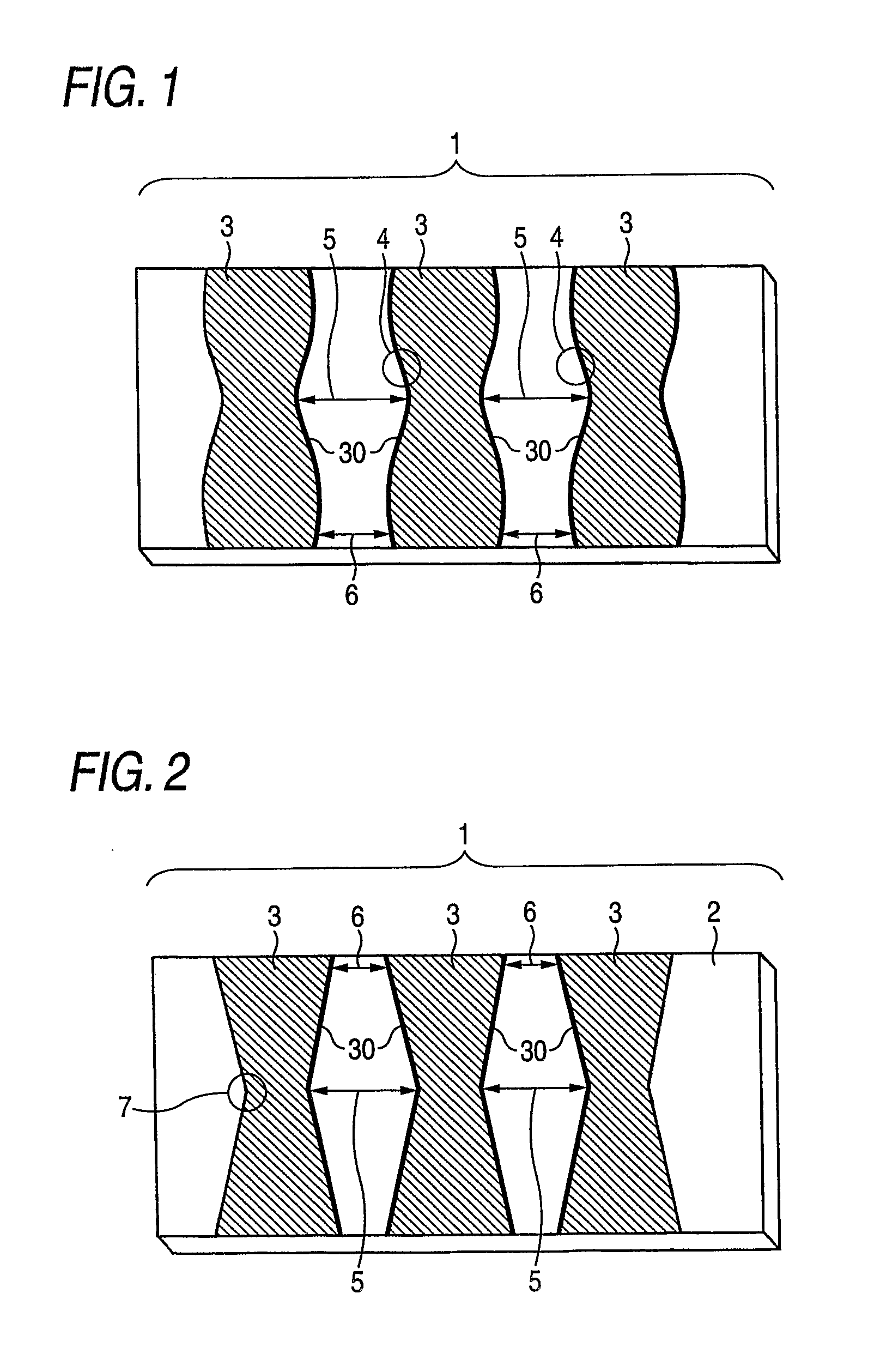

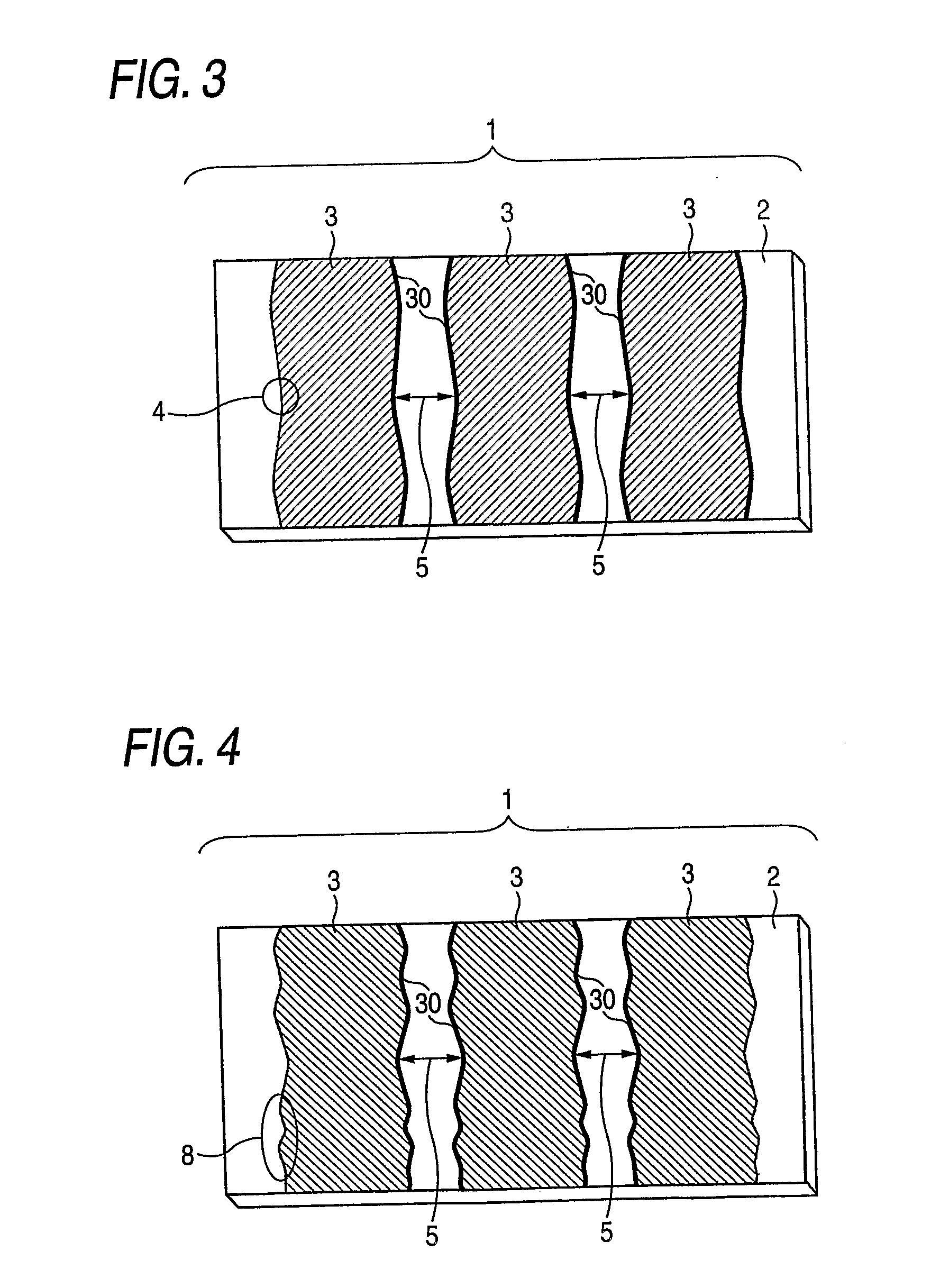

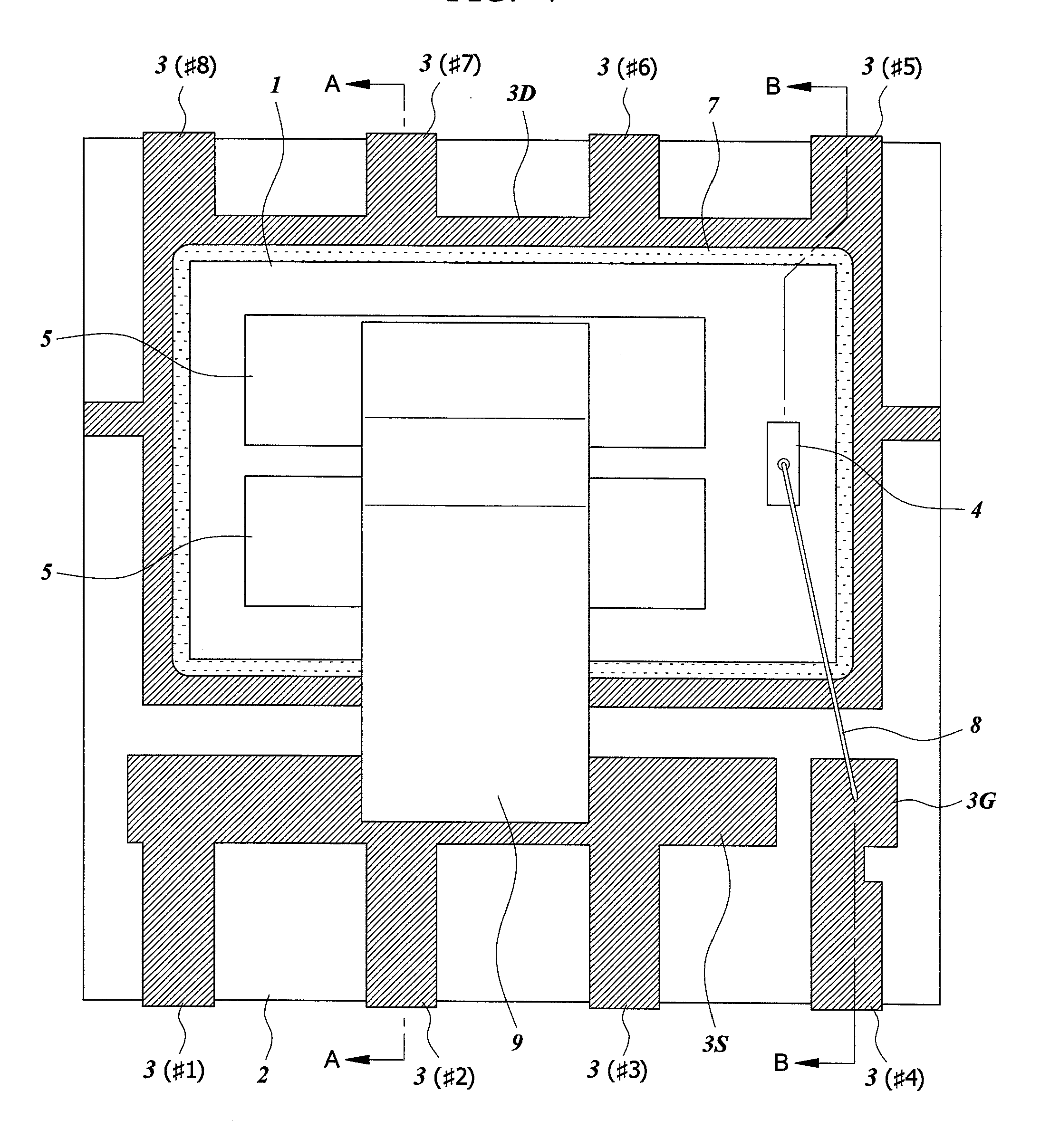

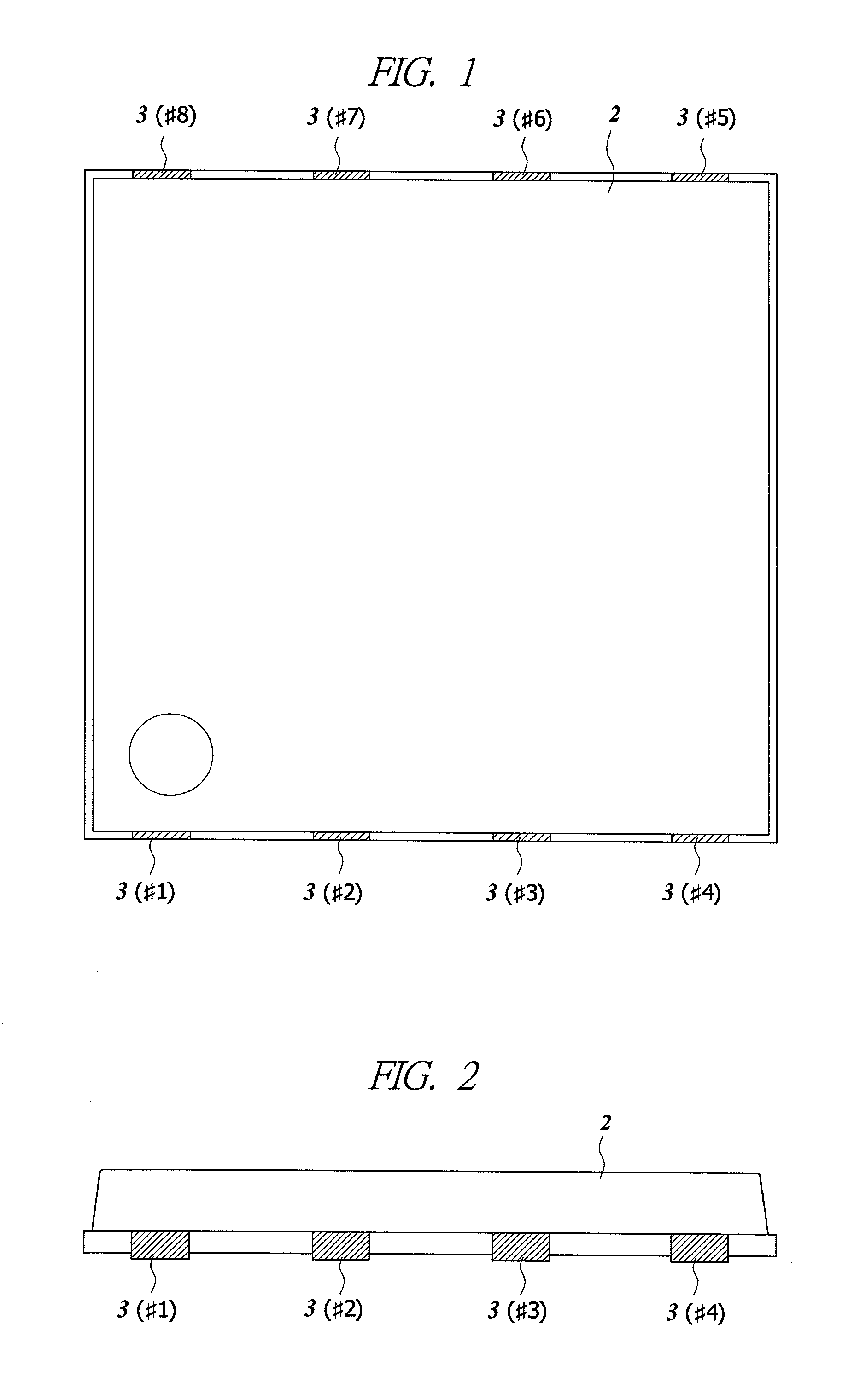

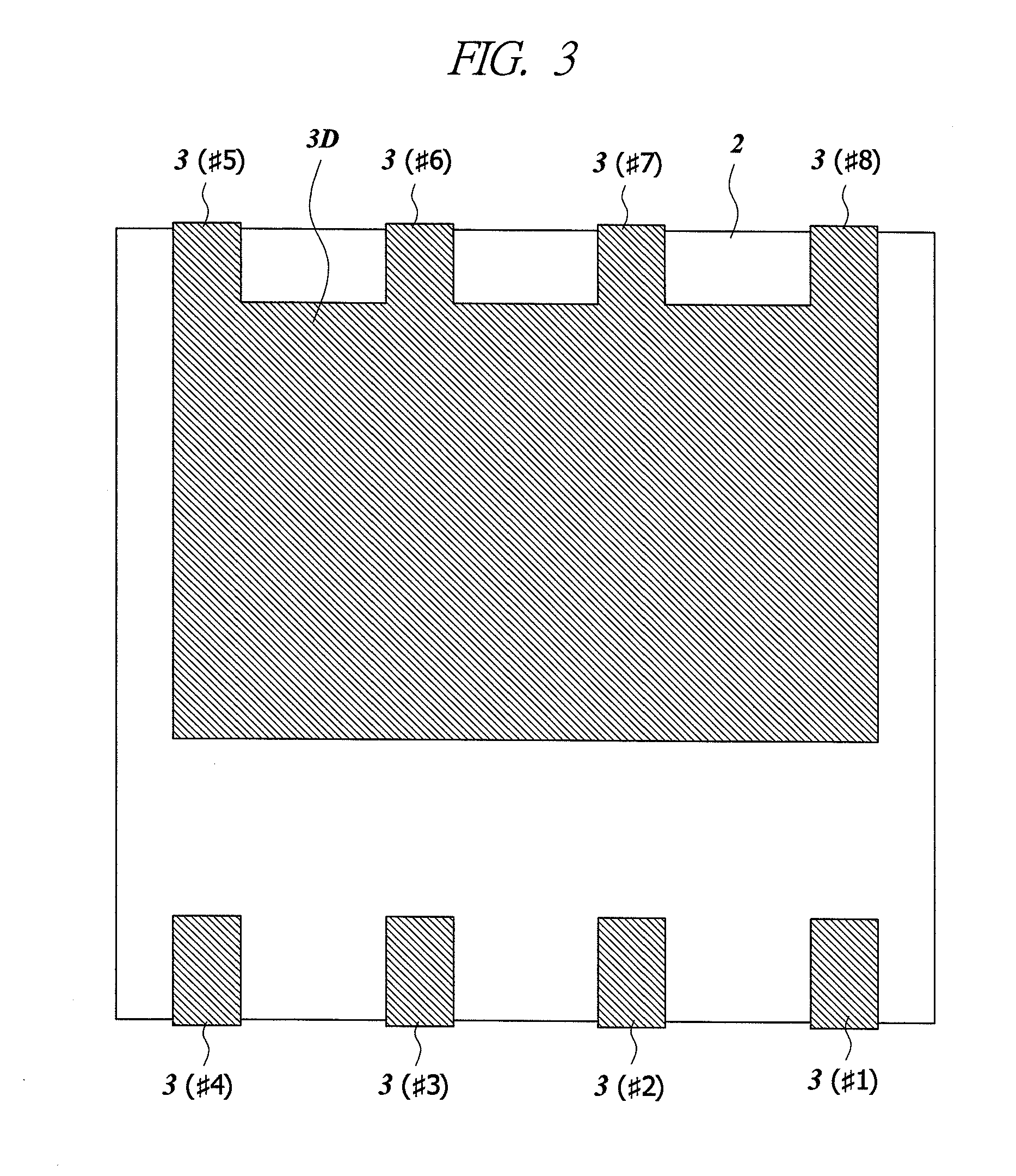

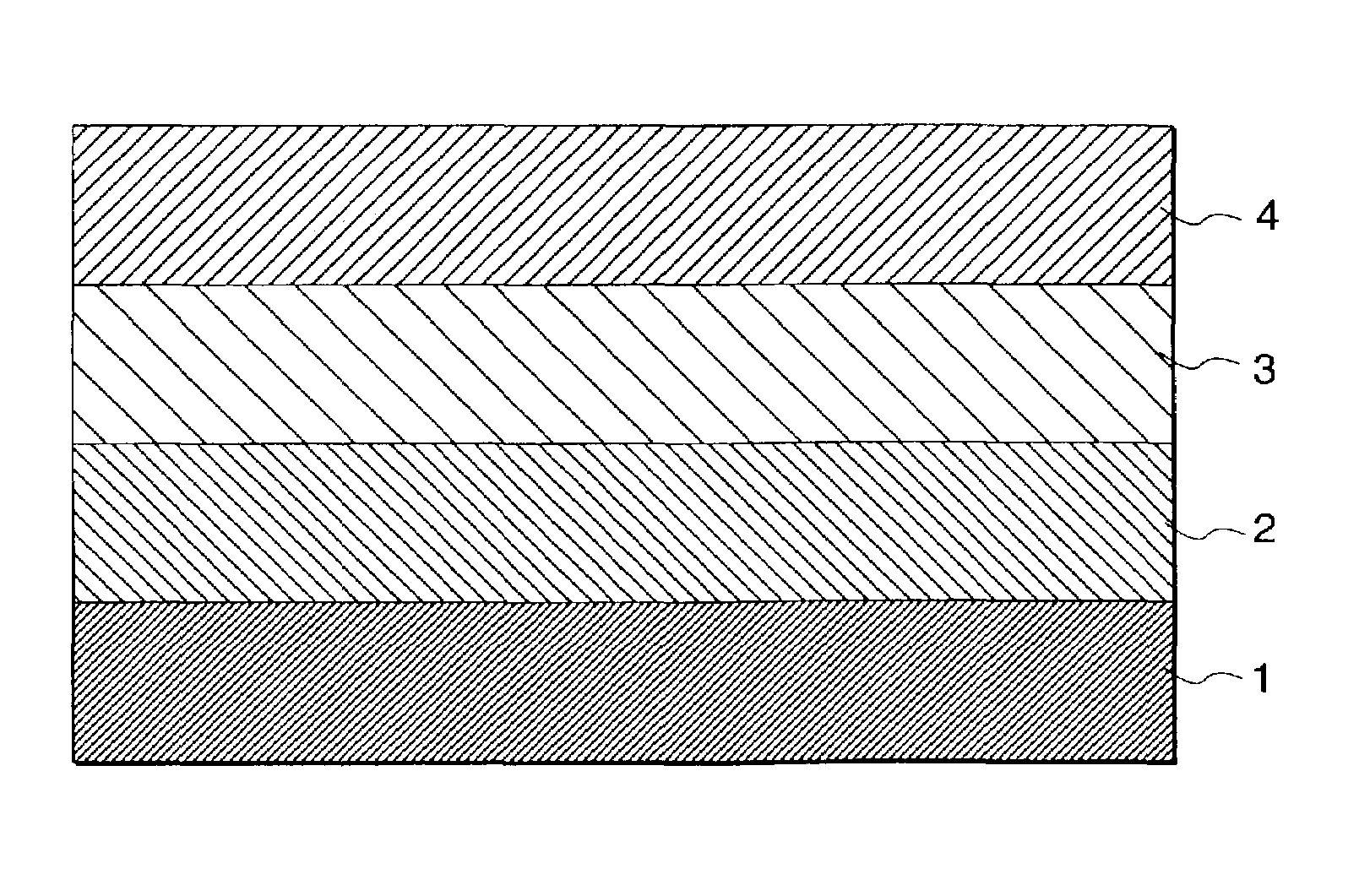

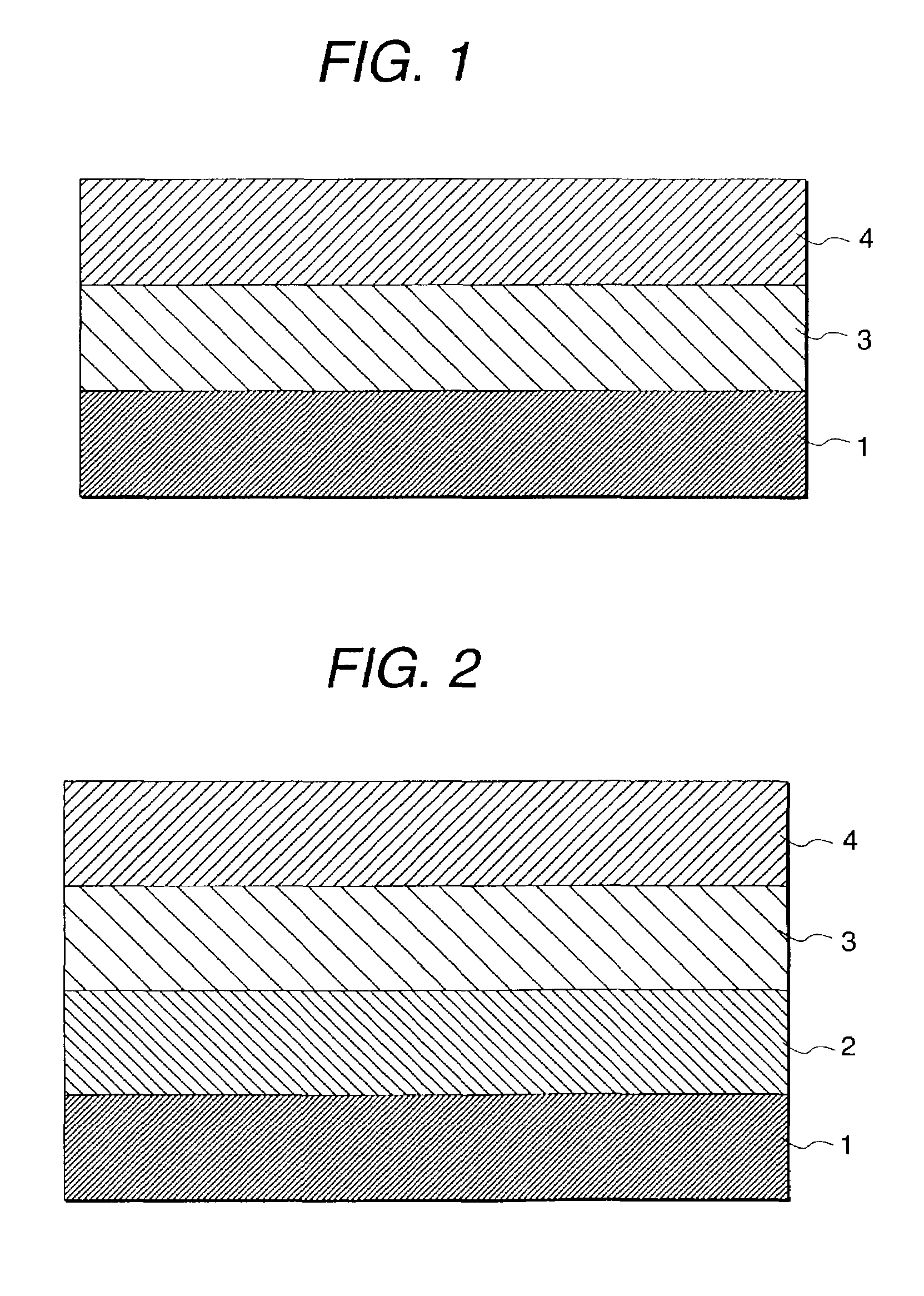

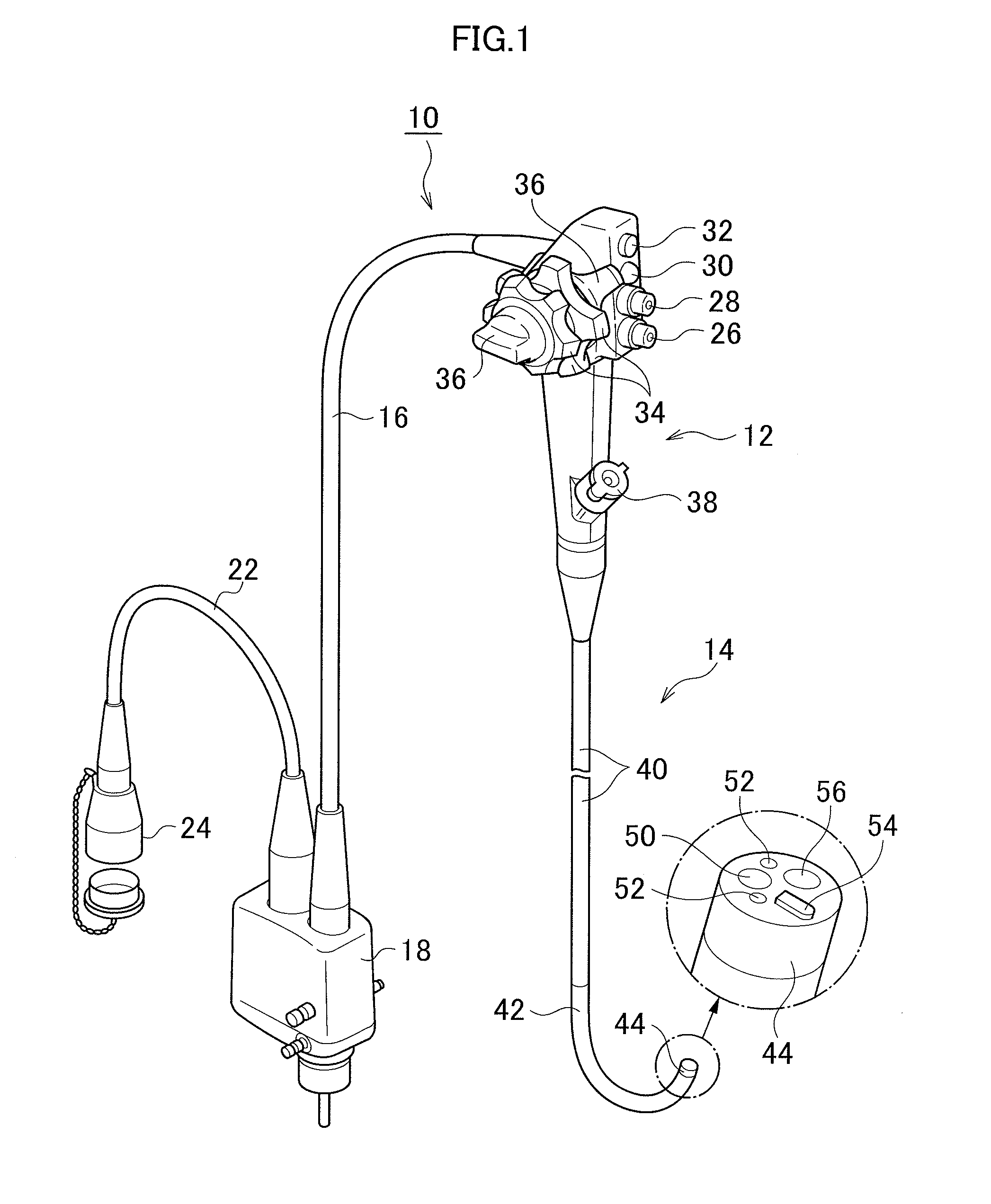

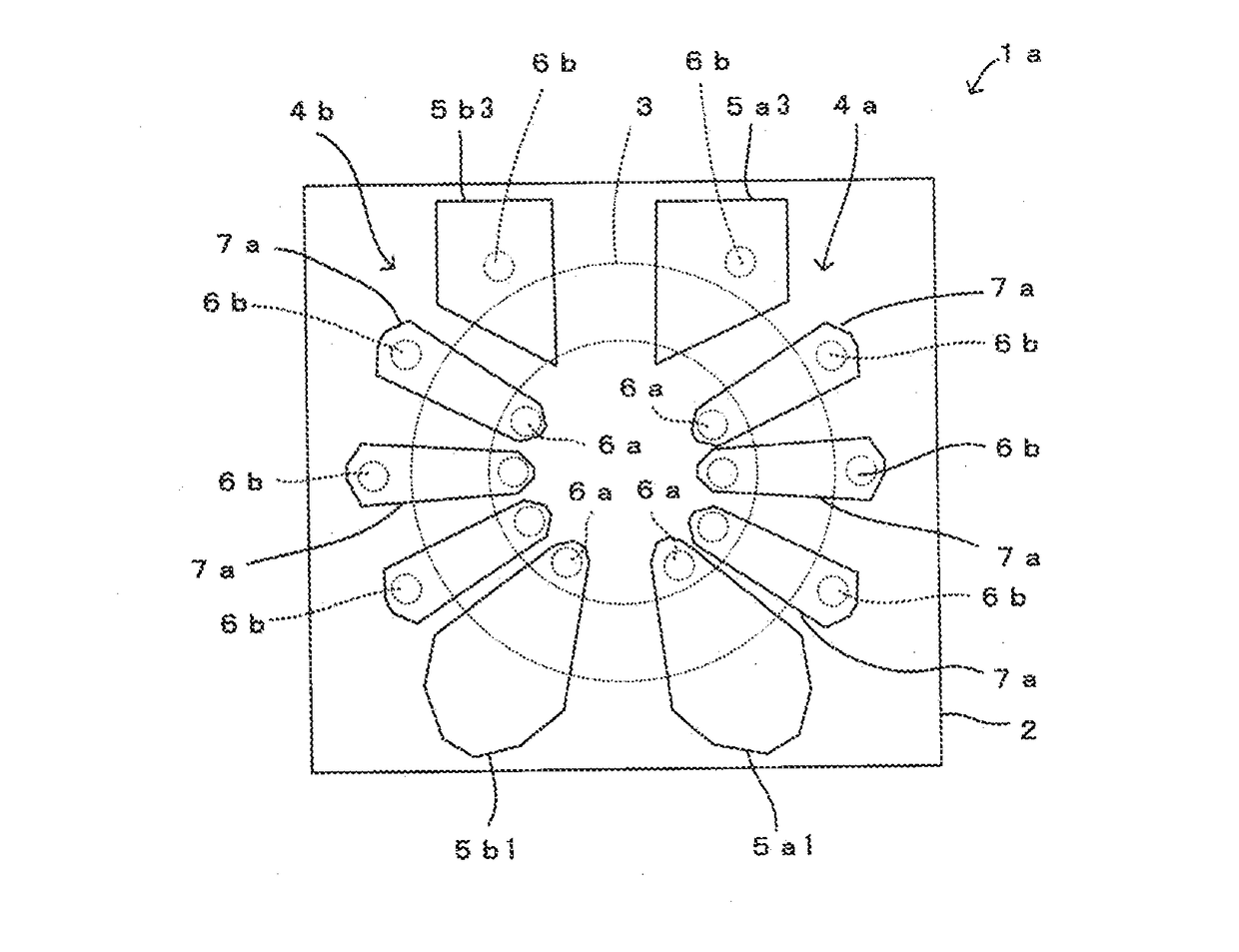

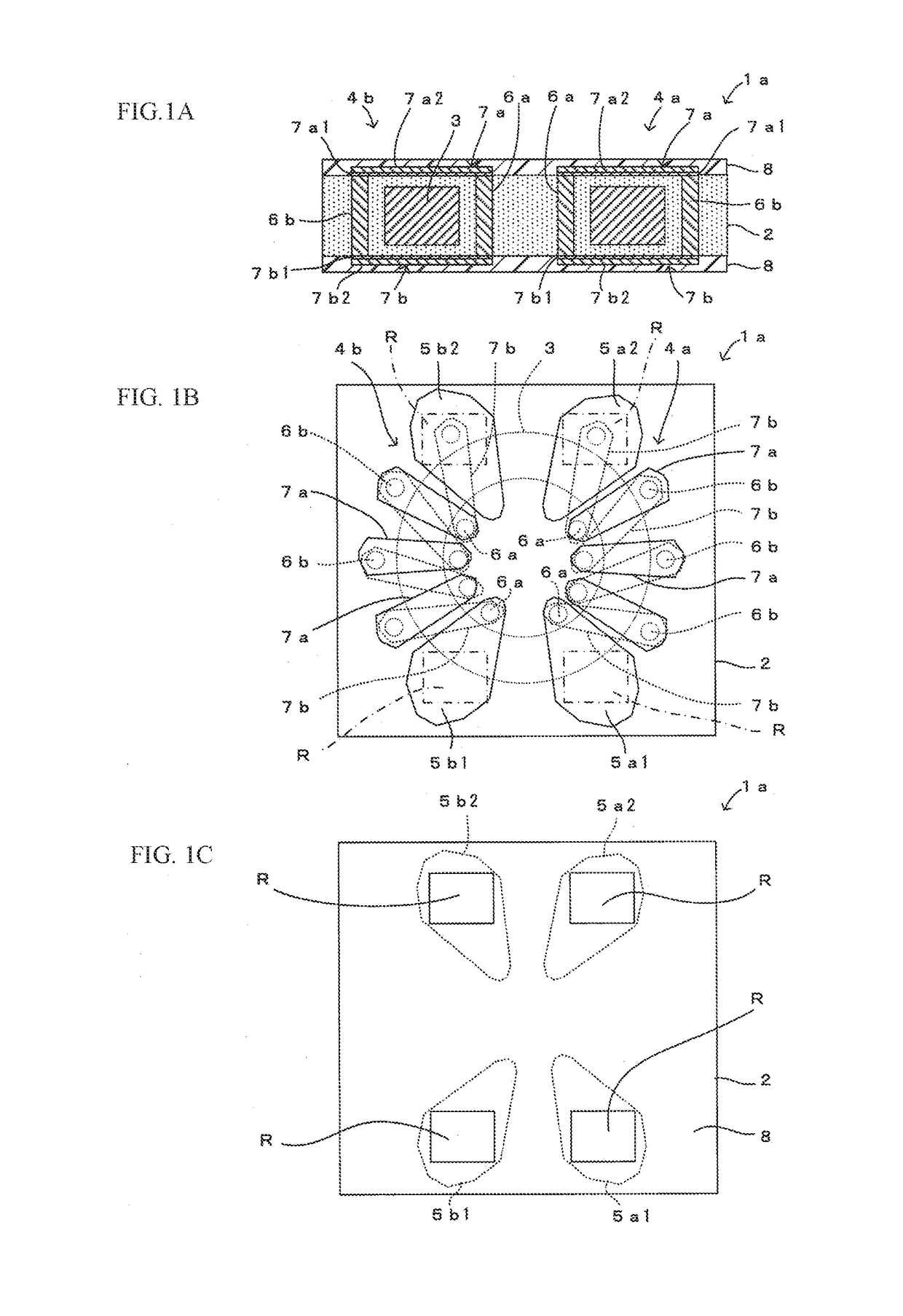

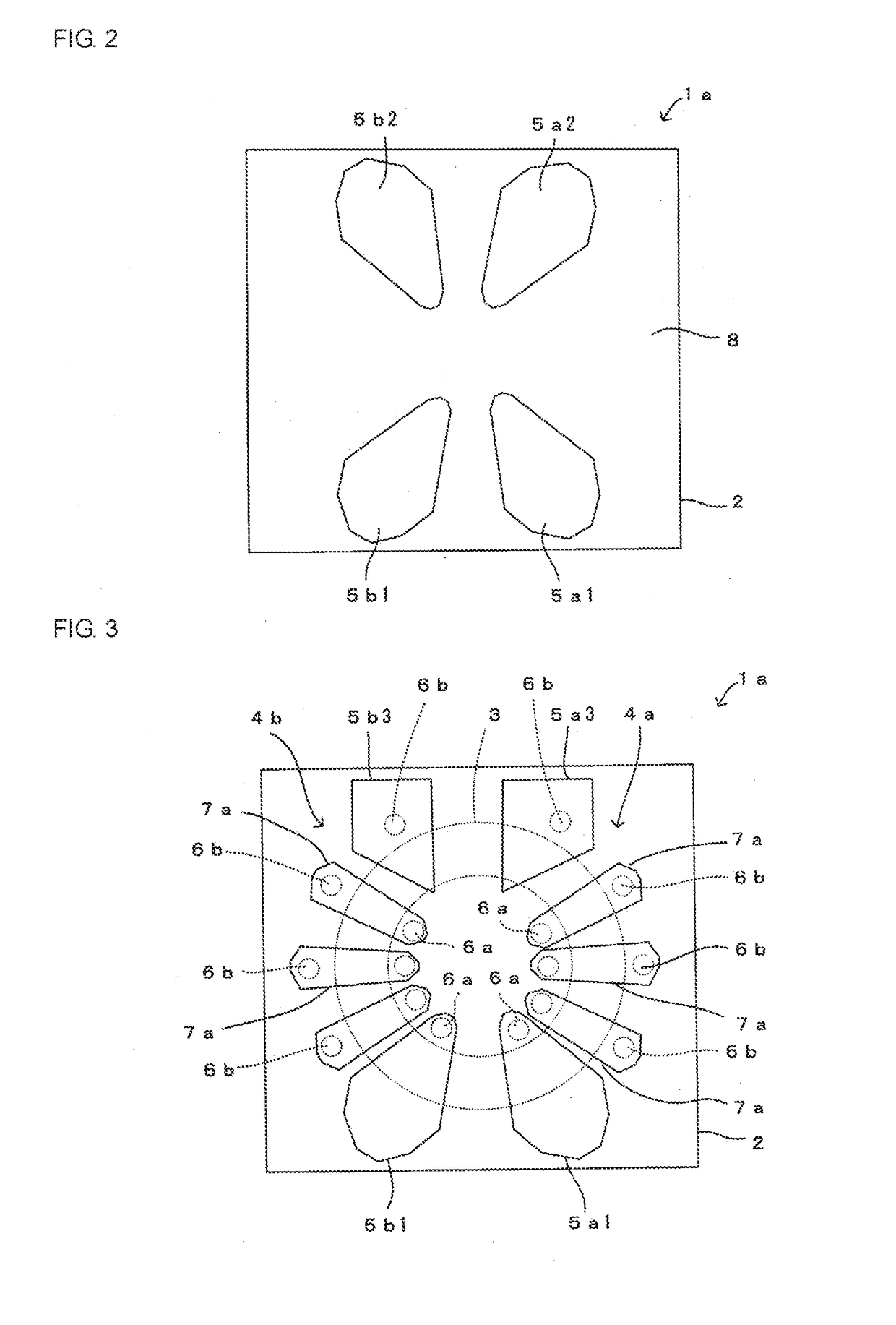

Multi-Layer Capacitor and Mold Capacitor

InactiveUS20080030922A1High withstand voltageDownsizing be hinderMultiple fixed capacitorsFixed capacitor electrodesDielectric substrateElectrical and Electronics engineering

A mulitilayer A capacitor includes a plurality of dielectric substrates (2) which are layered; a pair of terminal electrodes formed on the plurality of dielectric substrates; a plurality of internal electrodes (3) arranged on each of the dielectric substrates and having outer edges (30) opposed apart by a predetermined interval, wherein at least one of the internal electrodes (3) is arranged apart from the adjacent internal electrode (3) by the maximum interval (5) at the center of the outer edges (30).

Owner:PANASONIC CORP

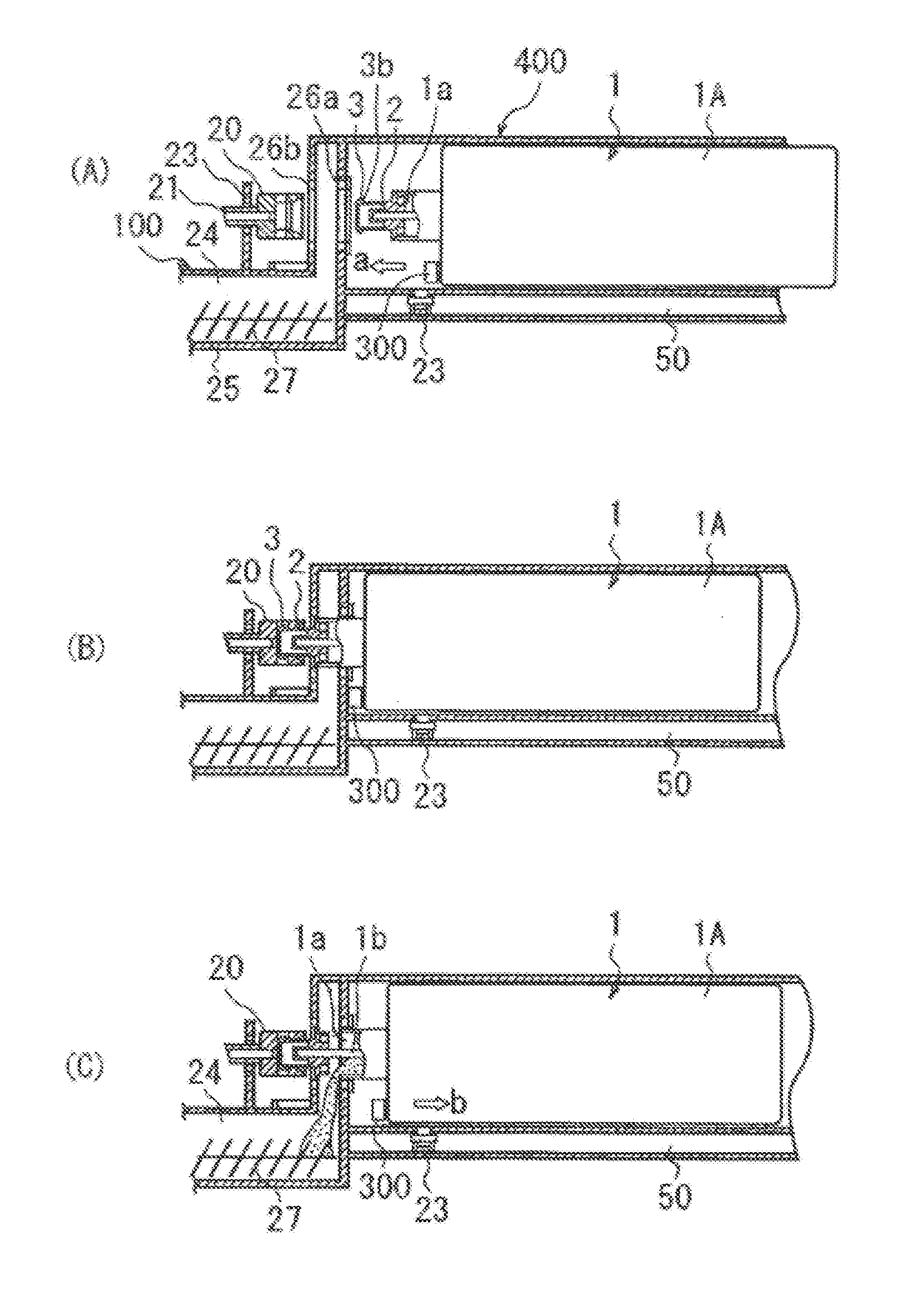

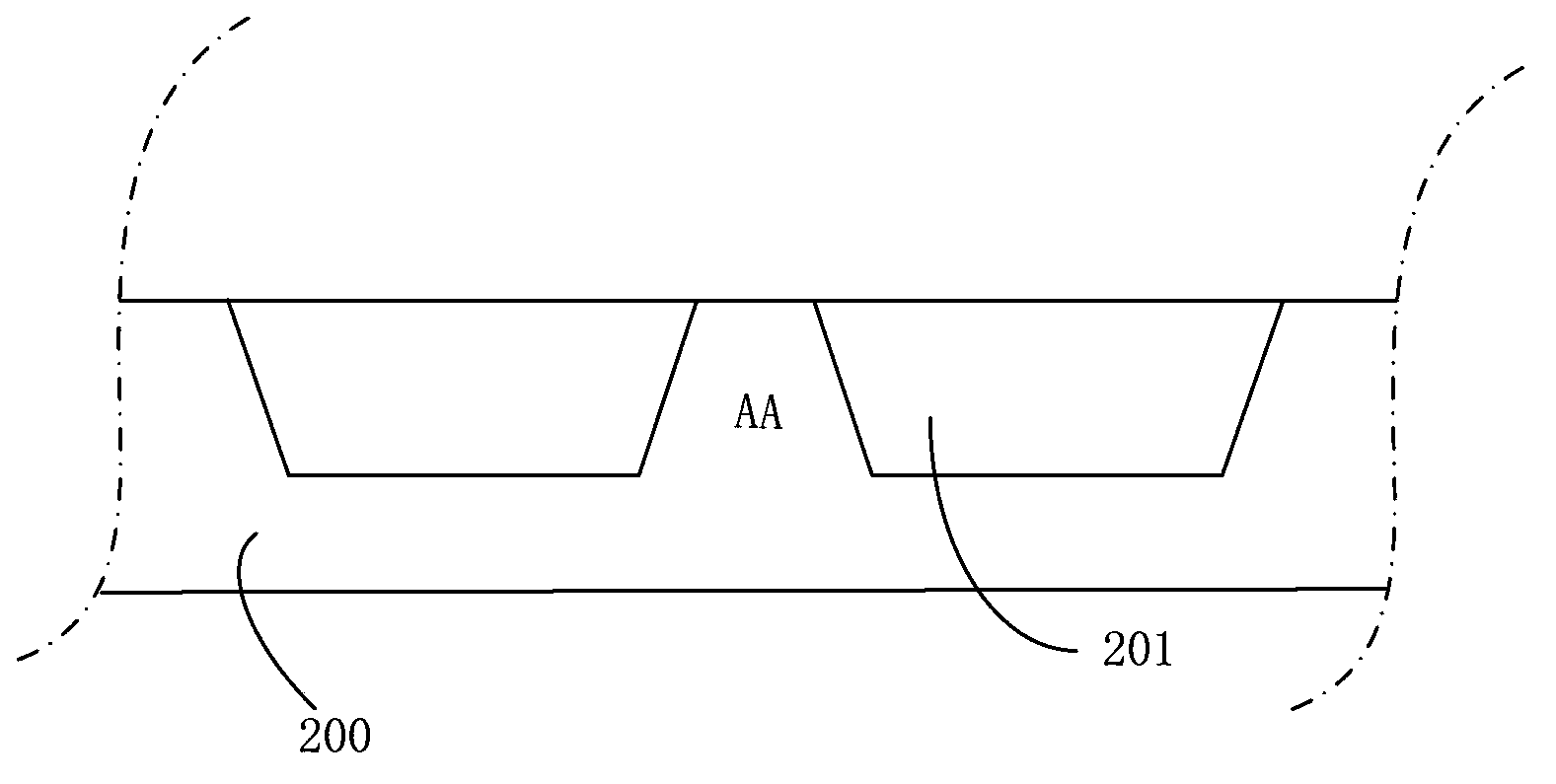

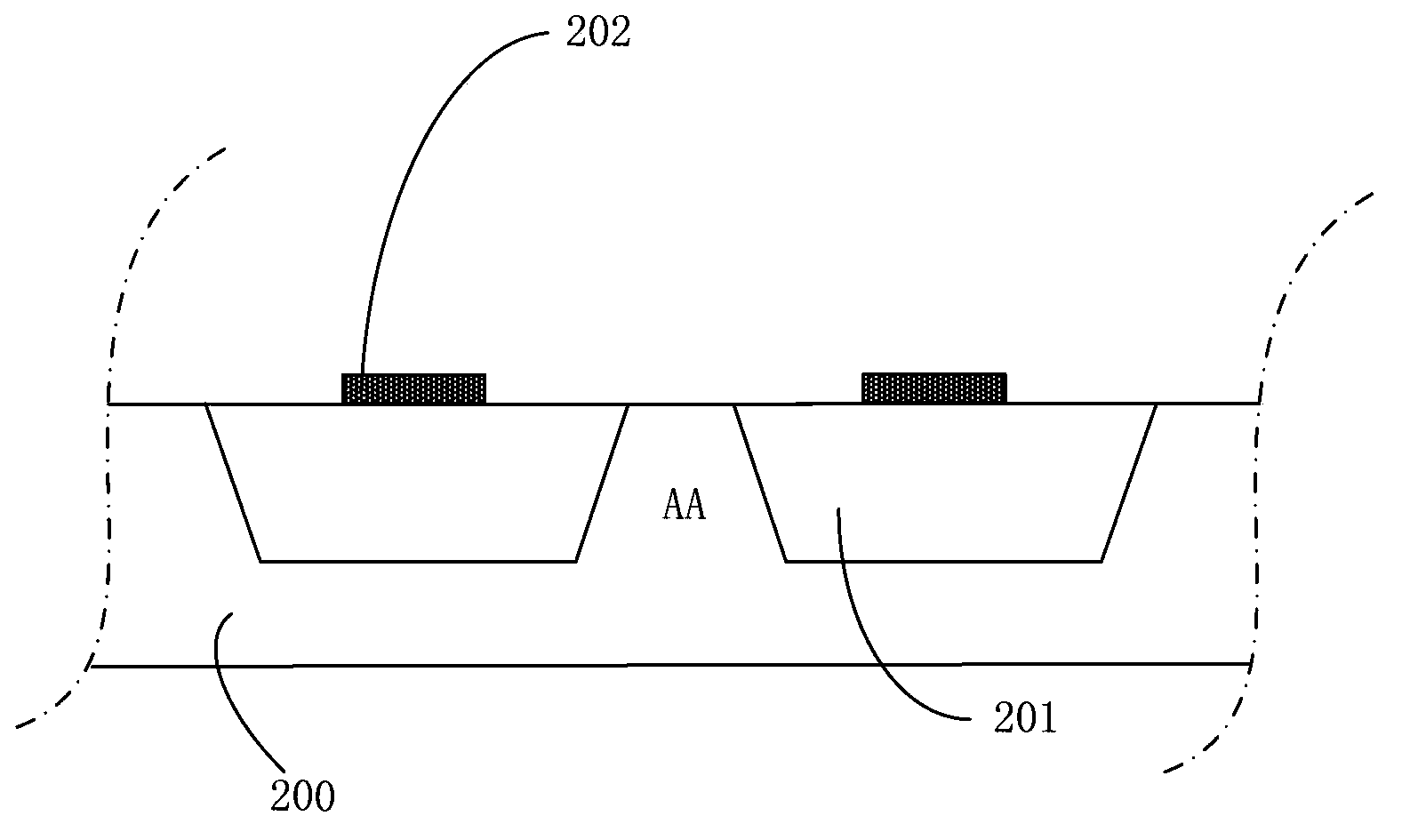

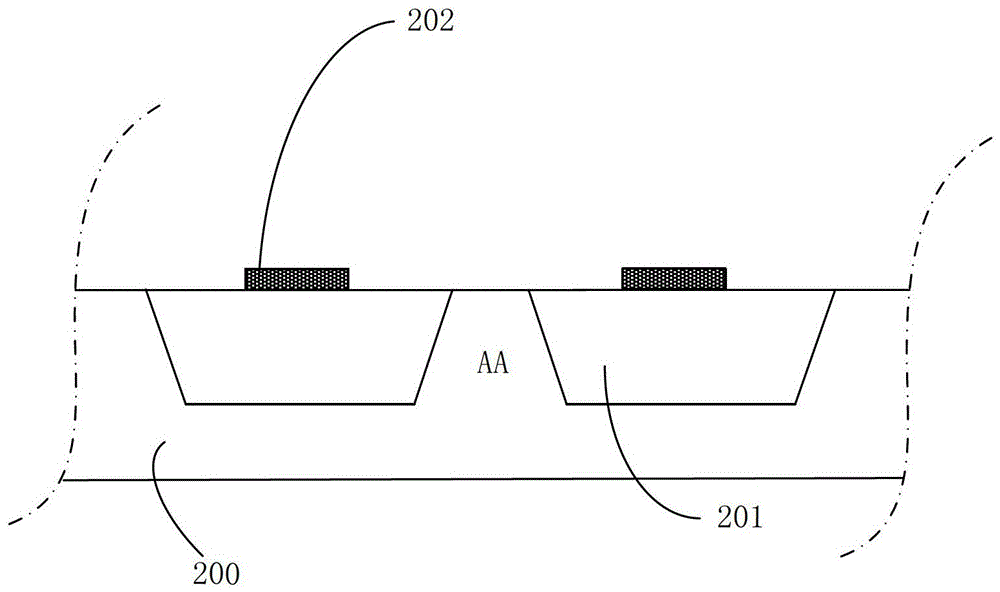

Semiconductor device and method for manufacturing same

InactiveUS20130009300A1Avoid downsizingIncrease the areaSemiconductor/solid-state device detailsSolid-state devicesDevice materialDie bonding

A dug portion (50) in which a die-bonding material is filled is provided to a lower surface of a stamping nozzle (42) used in a step of applying the die-bonding material onto a chip mounting portion of a wiring board. Planar dimensions of the dug portion (50) are smaller than external dimensions of a chip to be mounted on the chip mounting portion. In addition, a depth of the dug portion (50) is smaller than a thickness of the chip. When the thickness of the chip is 100 μm or smaller, a problem of crawling up of the die-bonding material to an upper surface of the chip is avoided by applying the die-bonding material onto the chip mounting portion using the stamping nozzle (42).

Owner:RENESAS ELECTRONICS CORP

Heat-peelable pressure-sensitive adhesive sheet

InactiveUS7163597B2Sufficient efficient contact areaAvoid adhesion failurePaper/cardboard articlesSolid-state devicesMicrosphereExpandable microsphere

A heat-peelable pressure-sensitive adhesive sheet which ensures an efficient contact area even in case where the area of an adherend to be adhered is decreased and thus makes it possible to avoid adhesion failures such as chip-scattering or chipping. The heat-peelable pressure-sensitive adhesive sheet comprises a substrate and a heat-expandable pressure-sensitive adhesive layer containing heat-expandable microspheres, formed on at least one side of the substrate, wherein the surface of the heat-expandable pressure-sensitive adhesive layer before heating has a center line average roughness of 0.4 μm or less.

Owner:NITTO DENKO CORP

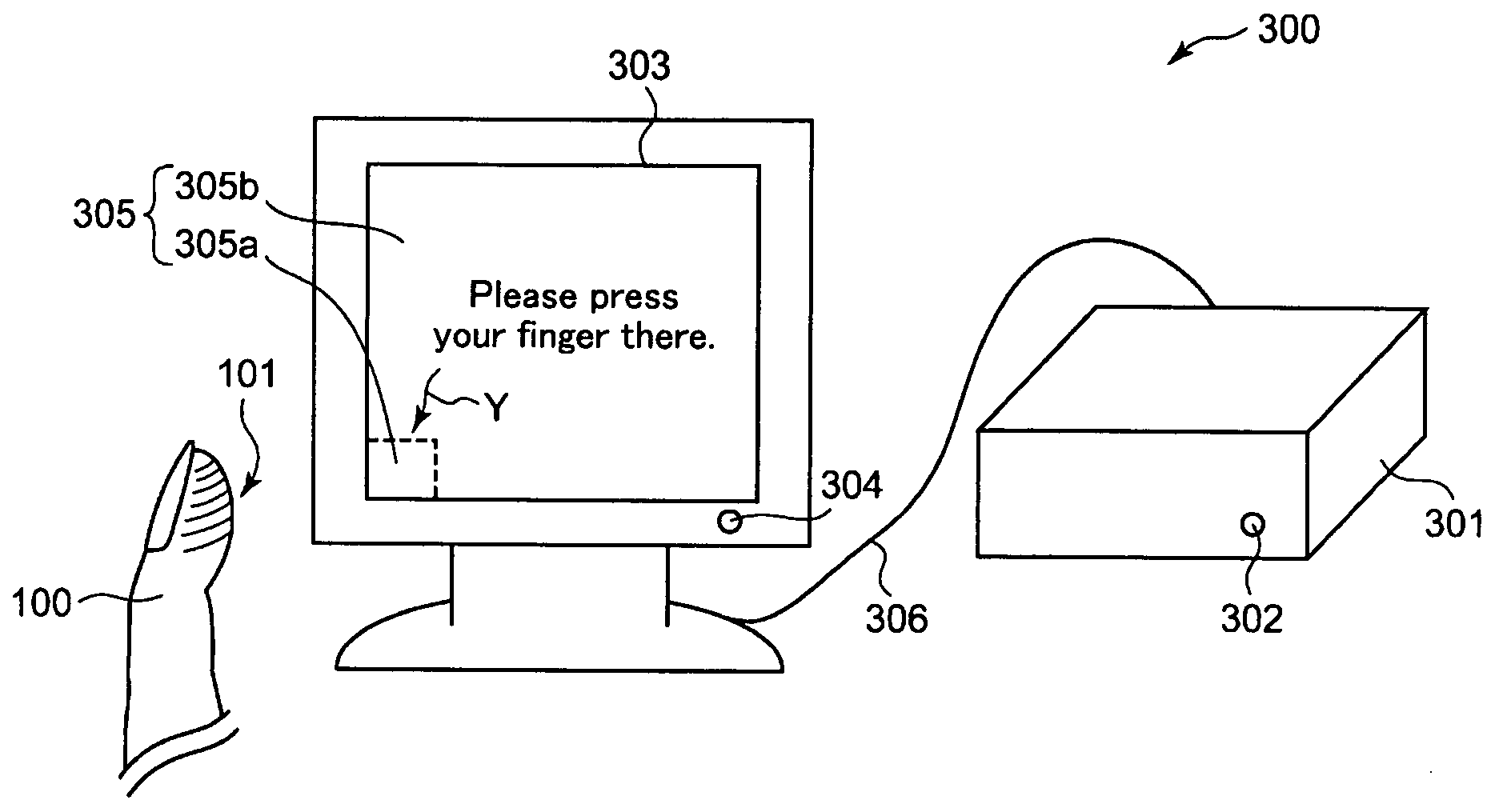

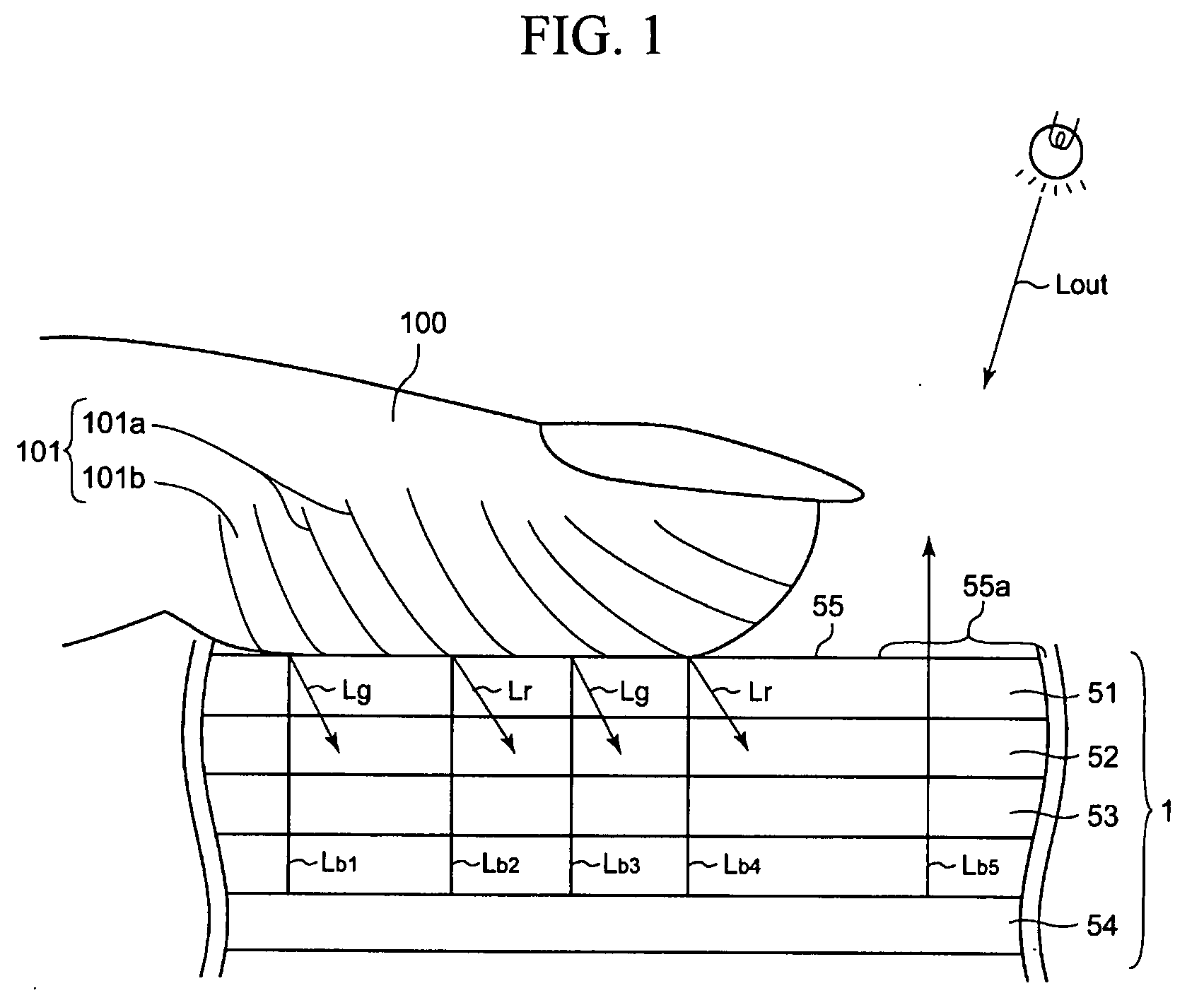

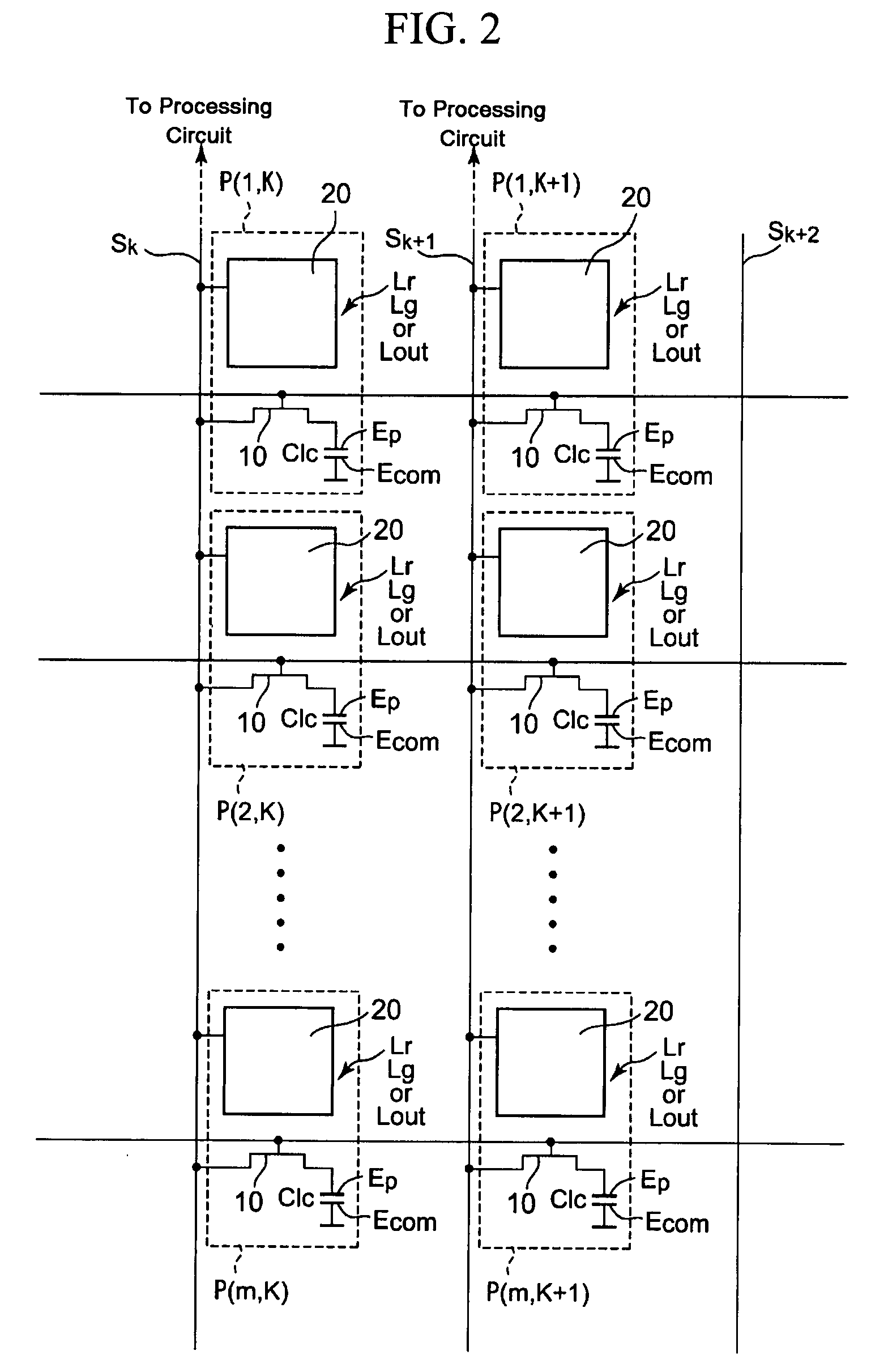

Display Device

InactiveUS20080278459A1Avoid complex processAvoid changeTelevision system detailsStatic indicating devicesDisplay deviceEngineering

A display device which can authenticate fingerprint without a fingerprint sensor device and can be prevented from large size or reduced the size. A display device (1) is provided with a pixel or sub pixel comprising a photo diode (11) for detecting a light from a object, a holding capacitor (13) for holding a voltage (Vn1) corresponding to an intensity of the light detected by the photo diode (11), and a refreshing means (18) for writing a voltage (Vdd or Vss) into the holding capacitor (13) (node N1) on the basis of the voltage Vn1 held in the holding capacitor (13).

Owner:TPO HONG KONG HLDG

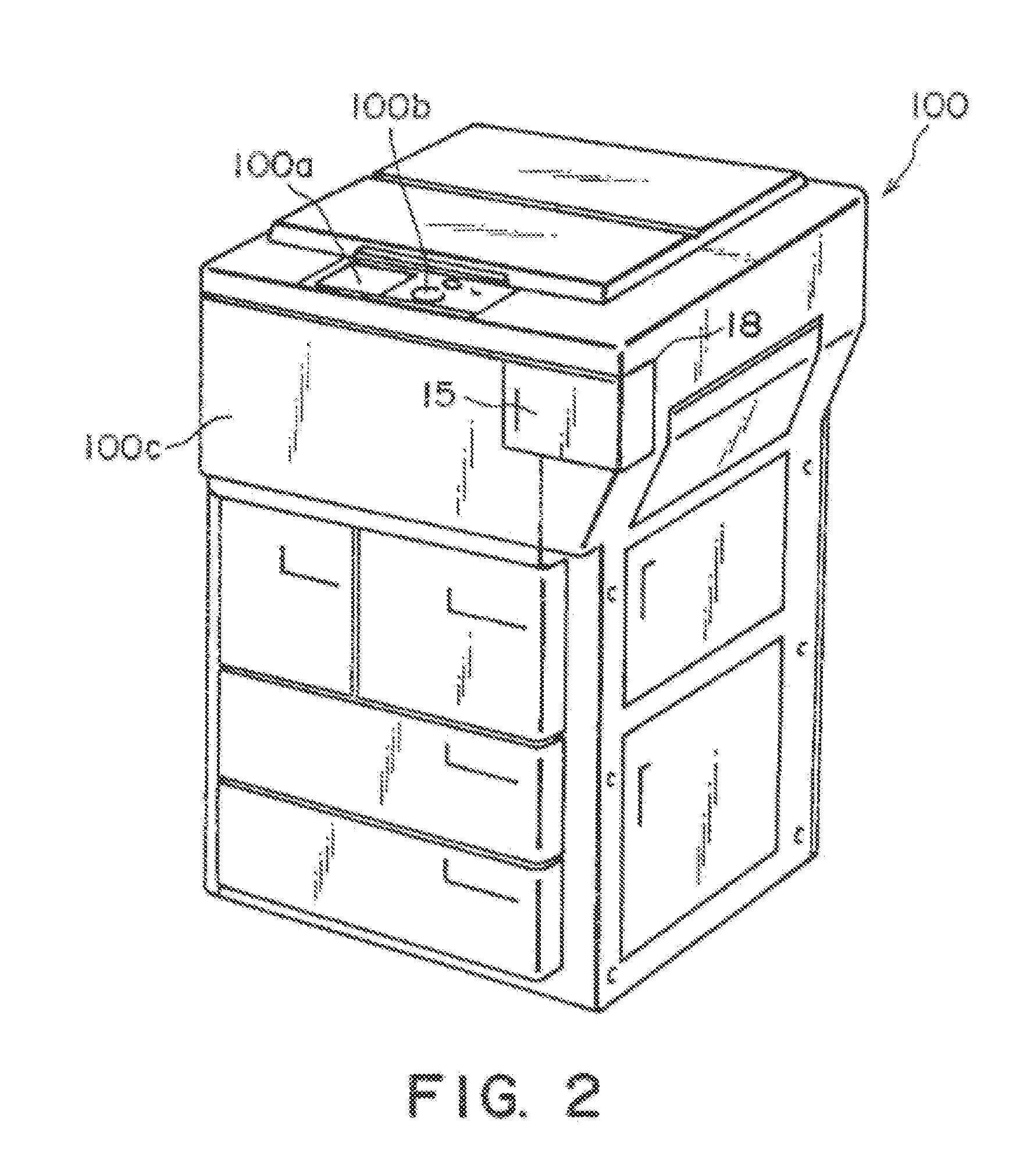

Sealing member, toner accommodating container and image forming apparatus

InactiveUS20160124348A1Simple structureSimple processElectrographic process apparatusCouplingPlastic materials

A toner supply container includes a toner container body including a cylindrical portion and an opening, and a sealing member provided at one axial end portion of the container body. The sealing member is movable relative to the container body in an axial direction and includes a sealing portion provided at a side adjacent the container body and a coupling portion provided at a side remote from the container body. The coupling portion includes a supporting portion provided on the sealing portion, an engaging portion provided at a free end of the supporting portion, and a displacing force receiving portion provided on the supporting portion at a position closer to the container body than the engaging portion. The displacing force receiving portion is displaceable with the supporting portion and has a radially outermost part that is more remote from a rotation axis of the container body than a radially outermost part of the engaging portion. The supporting portion, the engaging portion, and the displacing force receiving portion are made of a plastic material.

Owner:YAMADA YUSUKE +4

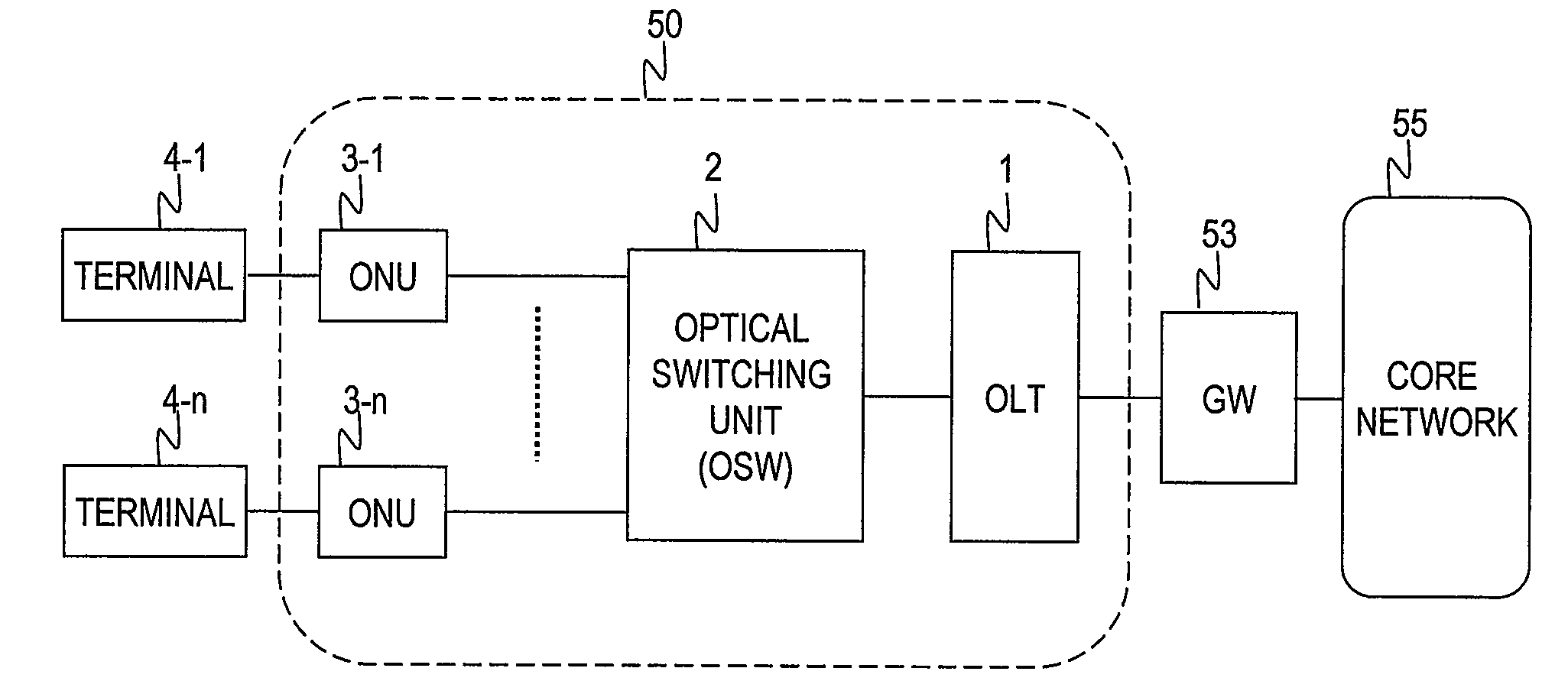

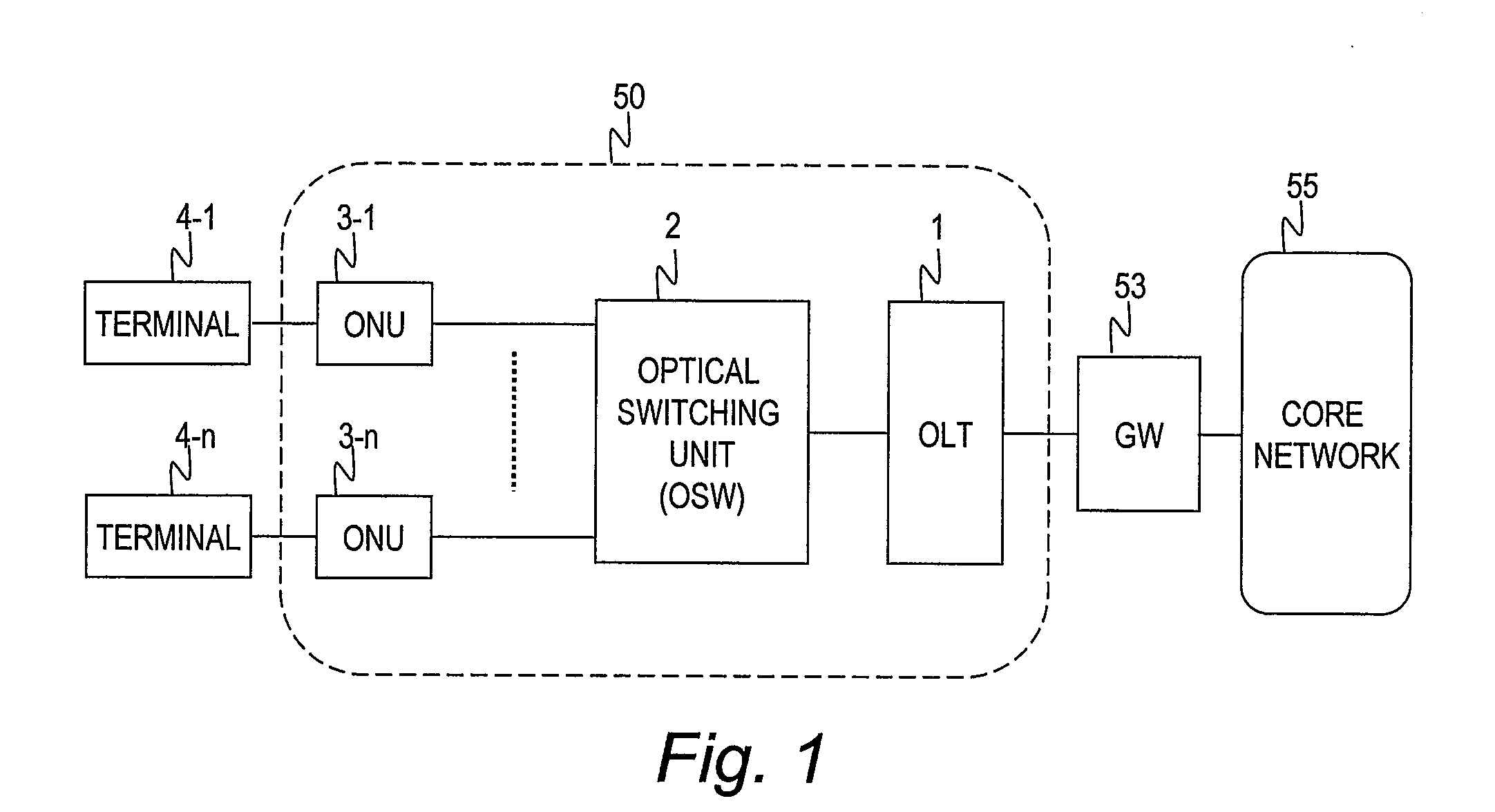

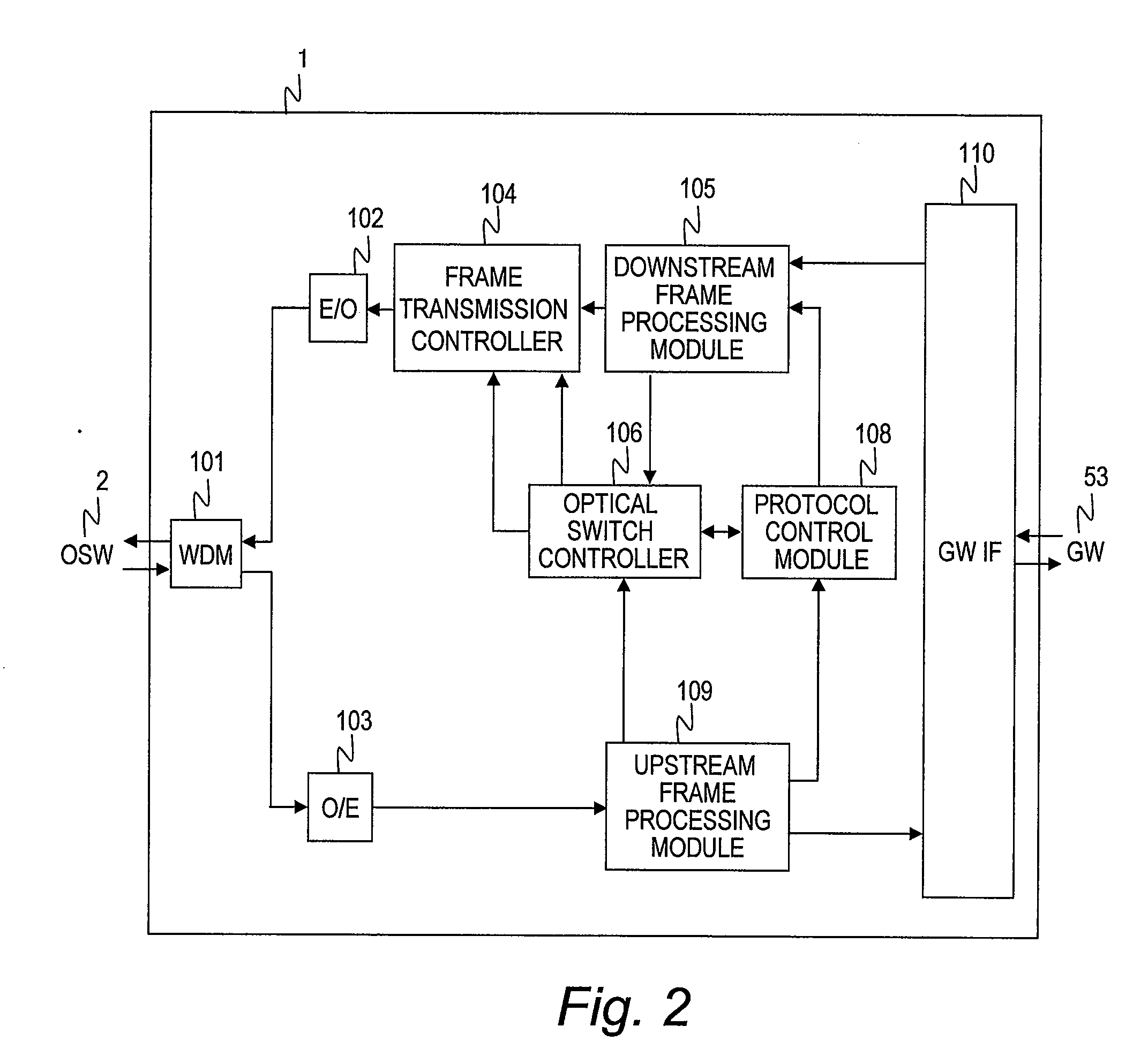

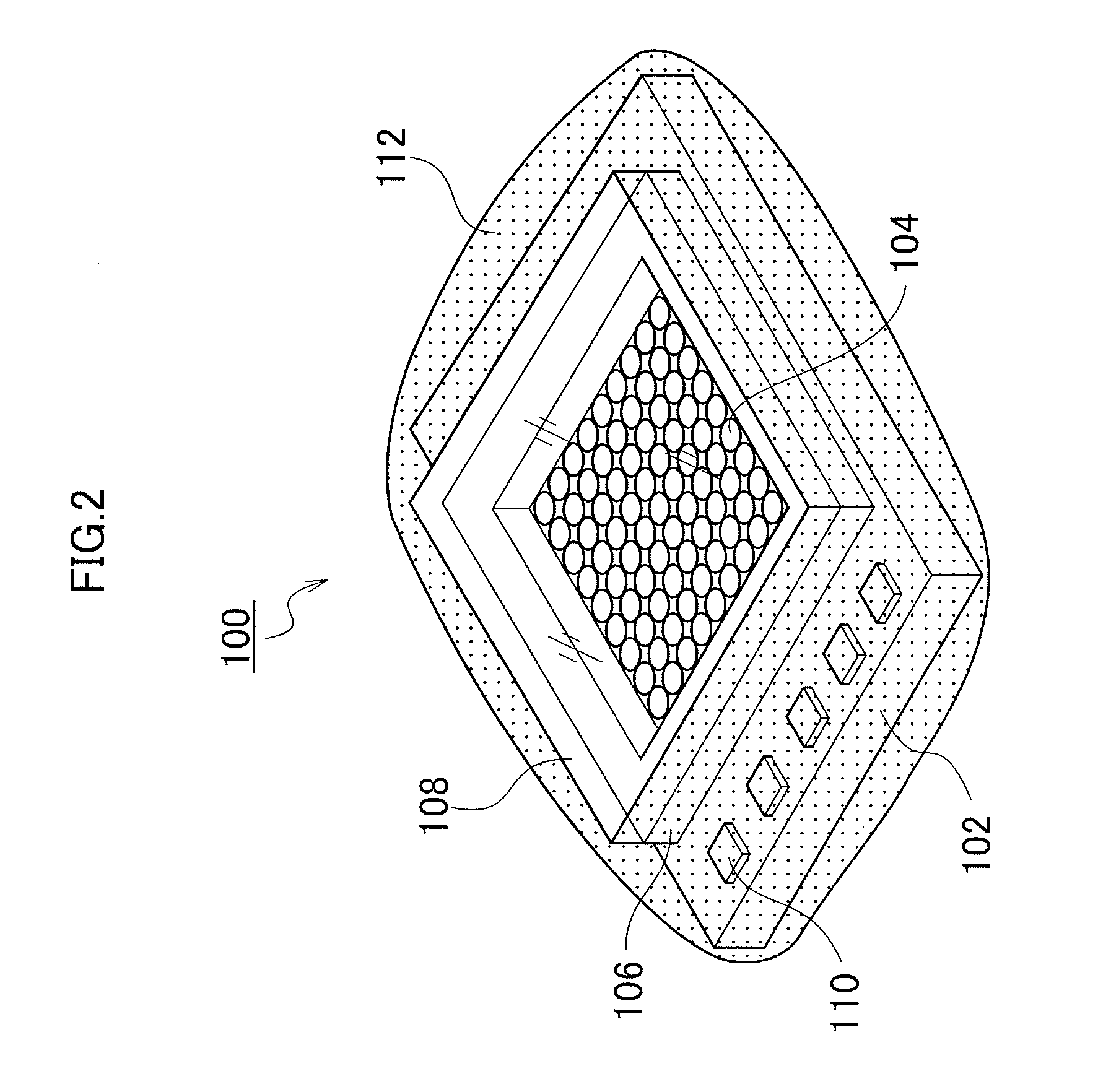

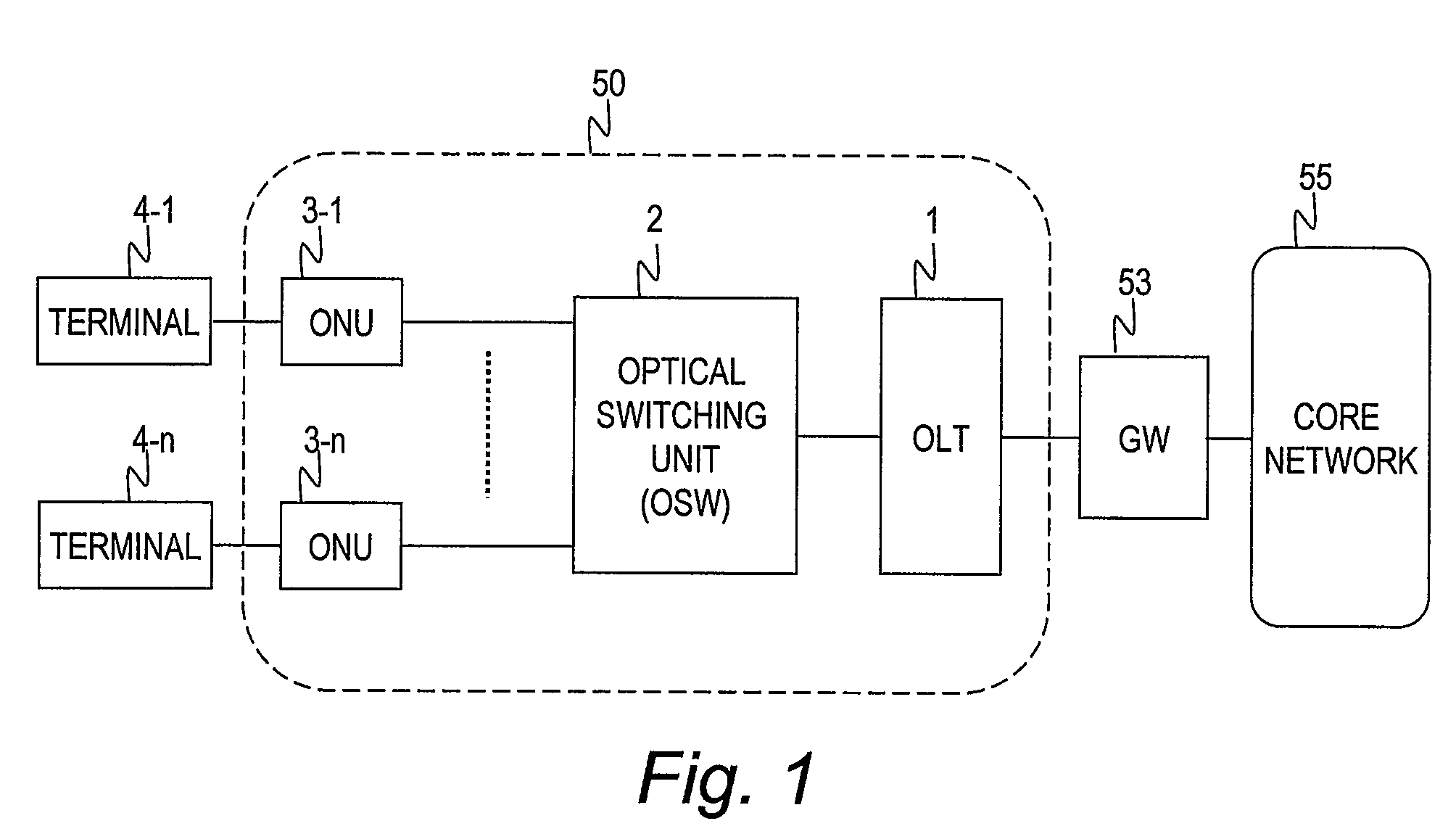

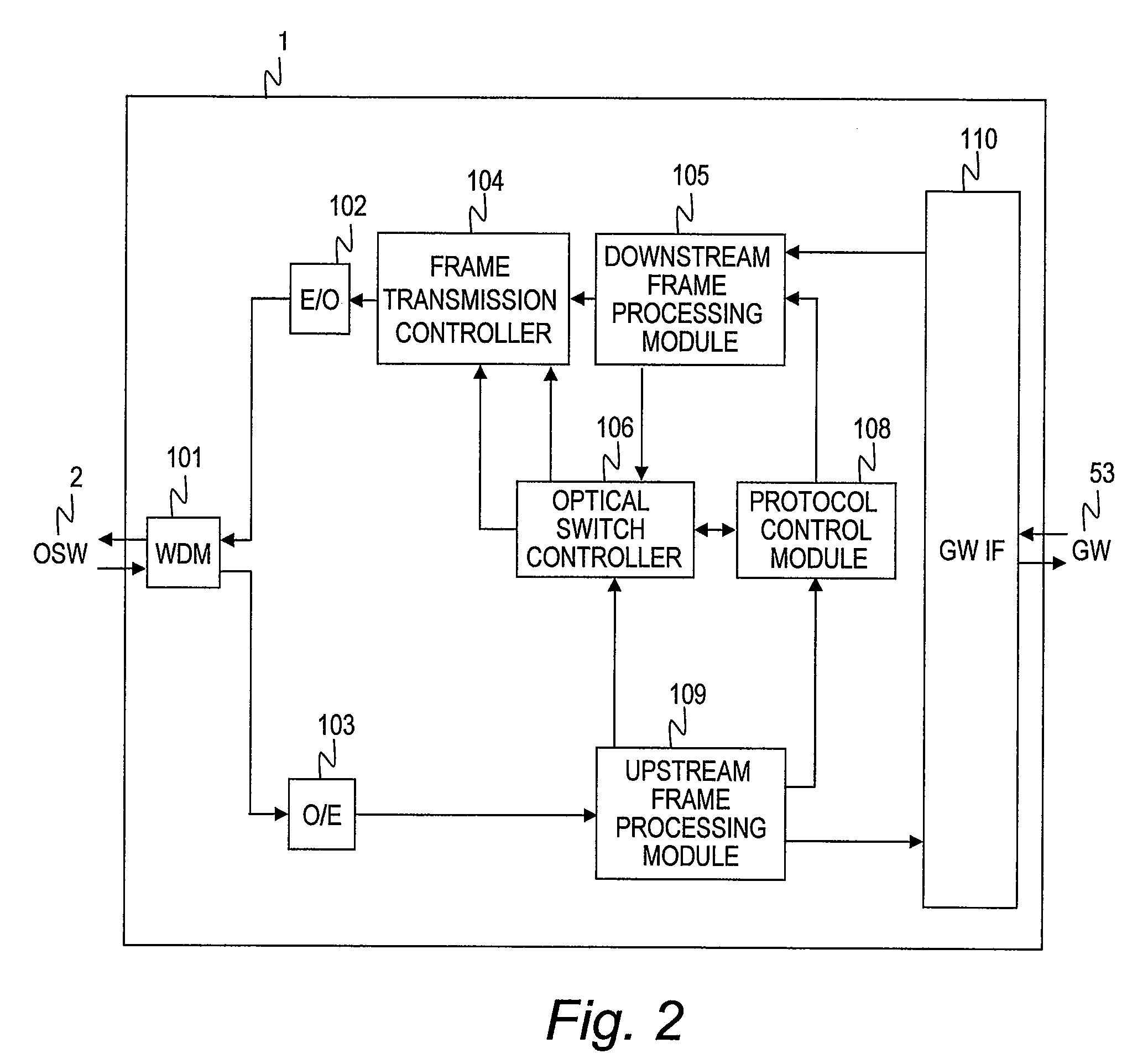

Optical access system, optical switching unit and optical line terminal

InactiveUS20100021160A1Eliminate needSmall sizeMultiplex system selection arrangementsStar/tree networksOptical line terminationOptical communication

Provided is an optical access system, including: an optical line terminal, a plurality of optical network units and an optical switching unit. The optical line terminal sends to the optical switching unit a control frame including a switching time when the optical switching unit is to make a switch from one of the optical communication paths between the optical line terminal and the plurality of optical network units to another, and an identifier of an optical communication path to which the switch is made in order to switch the optical communication paths between the optical line terminal and the plurality of optical network units. The optical switching unit switches the optical communication paths between the optical line terminal and the plurality of optical network units based on the switching time and the identifier of the optical communication path after switching which are included in the control frame.

Owner:HITACHI LTD

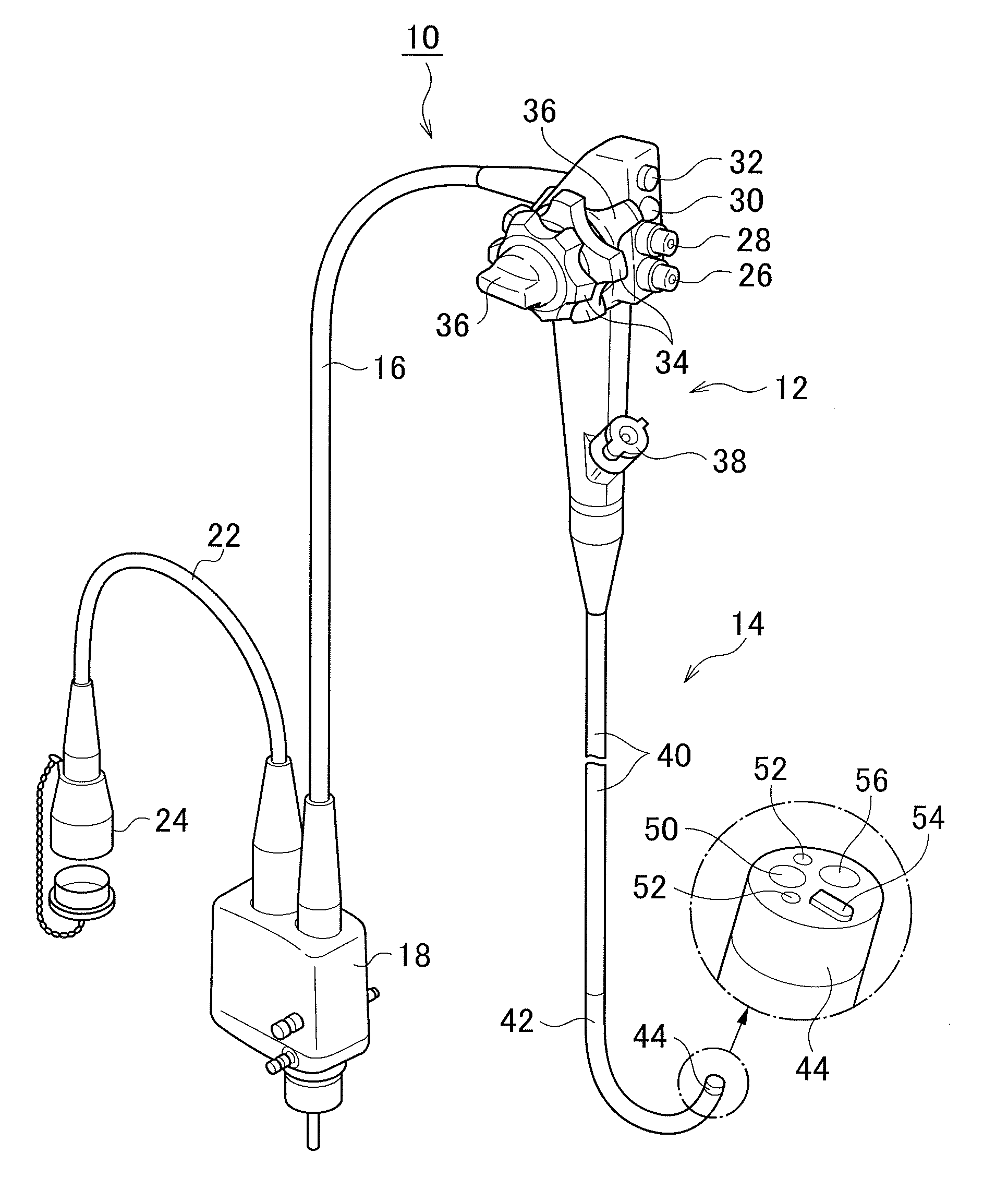

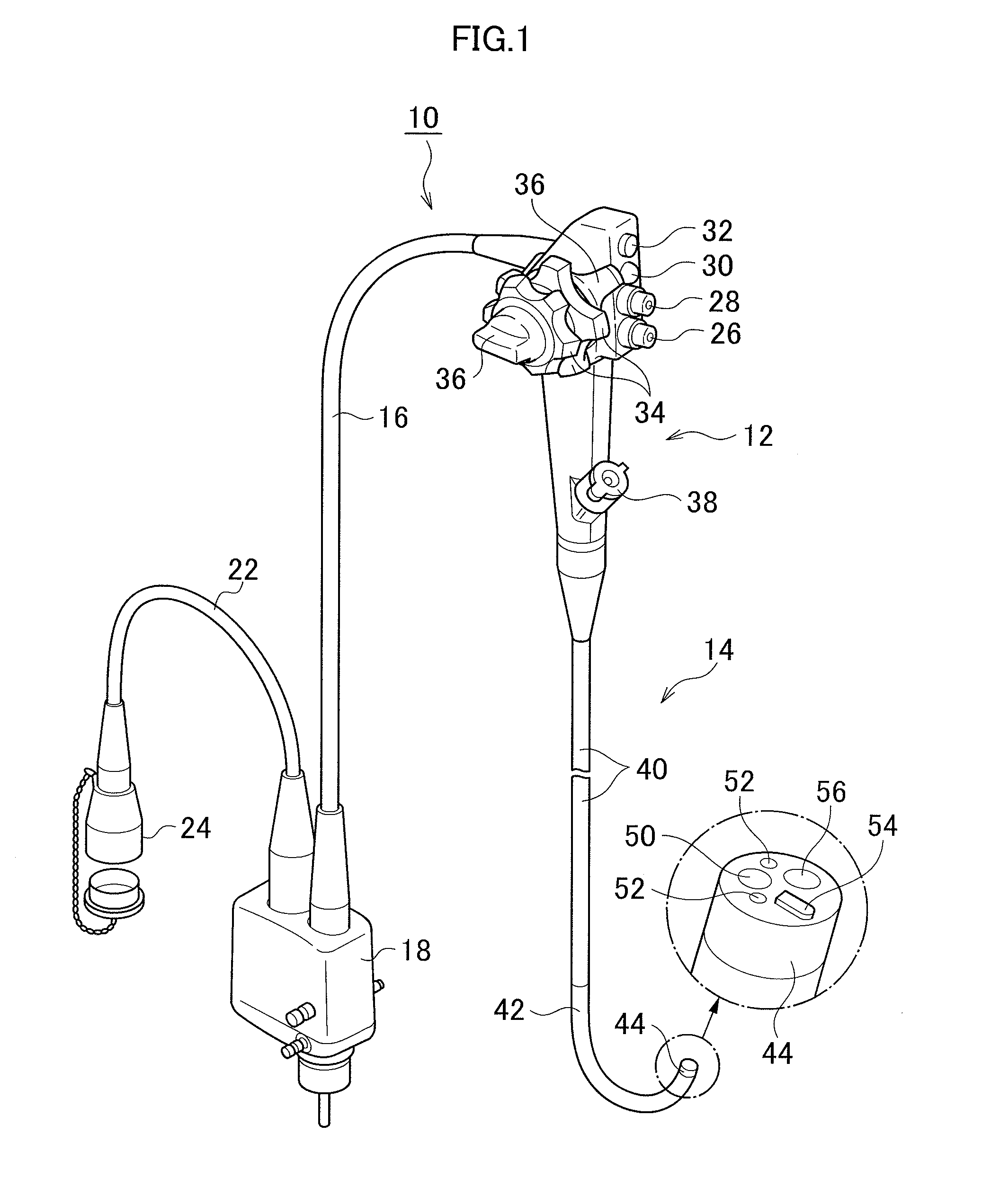

Image pickup device and endoscope

An image pickup device includes: an image pickup element; a spacer surrounding a light receiving surface of the image pickup element; a cover glass attached to the spacer, the cover glass being disposed opposing to the light receiving surface; and an insulative resin configured to thermally couple the image pickup element with the cover glass, and to have a thermal conductivity of not less than 8 W / mK. An endoscope includes: the image pickup device; an image pickup optical system; a drive circuit; a light guide configured to radiate light from a illumination light source; a tubular body configured to accommodate the image pickup device, the image pickup optical system, the drive circuit, the light guide, and a forceps opening; and a first insulative resin having a thermal conductivity of not less than 8 W / mK, and adapted to thermally couple the image pickup device with the drive circuit.

Owner:FUJIFILM CORP

Optical access system, optical switching unit and optical line terminal

InactiveUS8401384B2Avoid downsizingEliminate needMultiplex system selection arrangementsStar/tree networksOptical line terminationOptical communication

Provided is an optical access system, including: an optical line terminal, a plurality of optical network units and an optical switching unit. The optical line terminal sends to the optical switching unit a control frame including a switching time when the optical switching unit is to make a switch from one of the optical communication paths between the optical line terminal and the plurality of optical network units to another, and an identifier of an optical communication path to which the switch is made in order to switch the optical communication paths between the optical line terminal and the plurality of optical network units. The optical switching unit switches the optical communication paths between the optical line terminal and the plurality of optical network units based on the switching time and the identifier of the optical communication path after switching which are included in the control frame.

Owner:HITACHI LTD

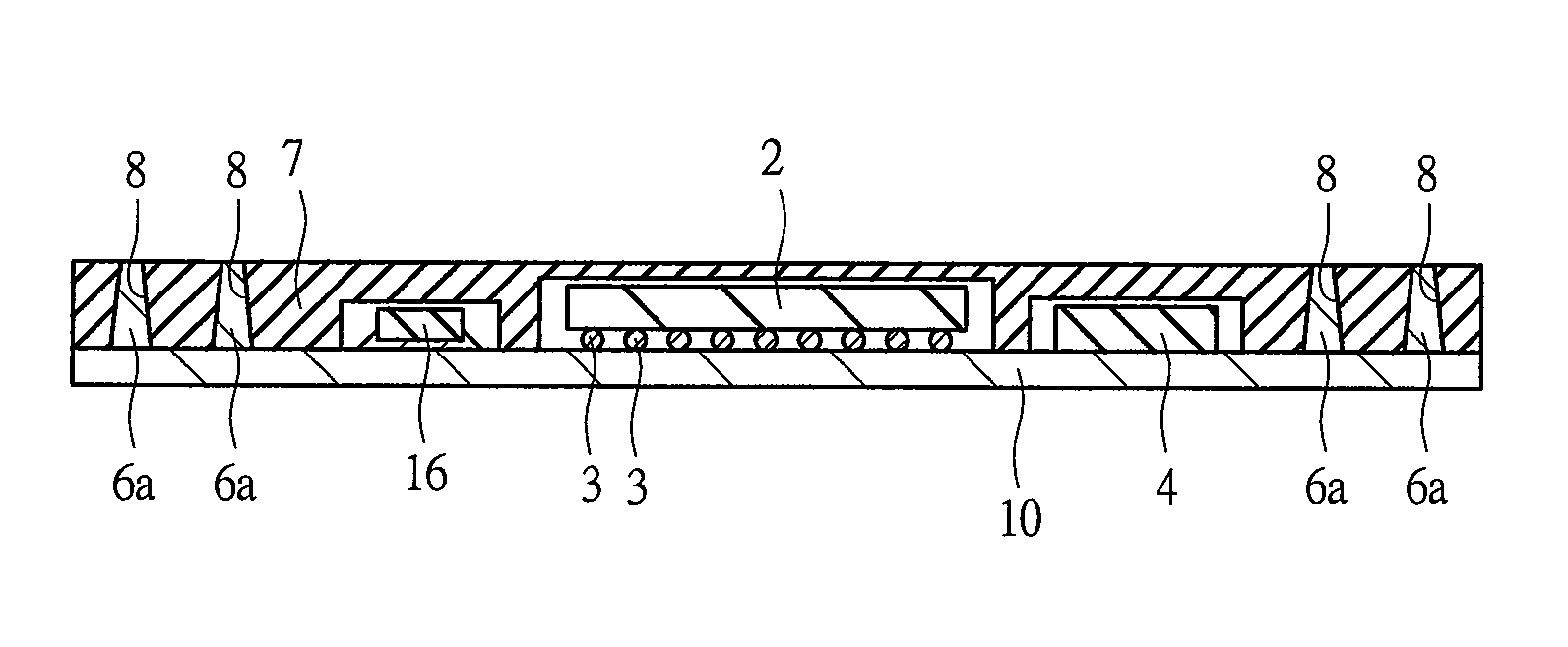

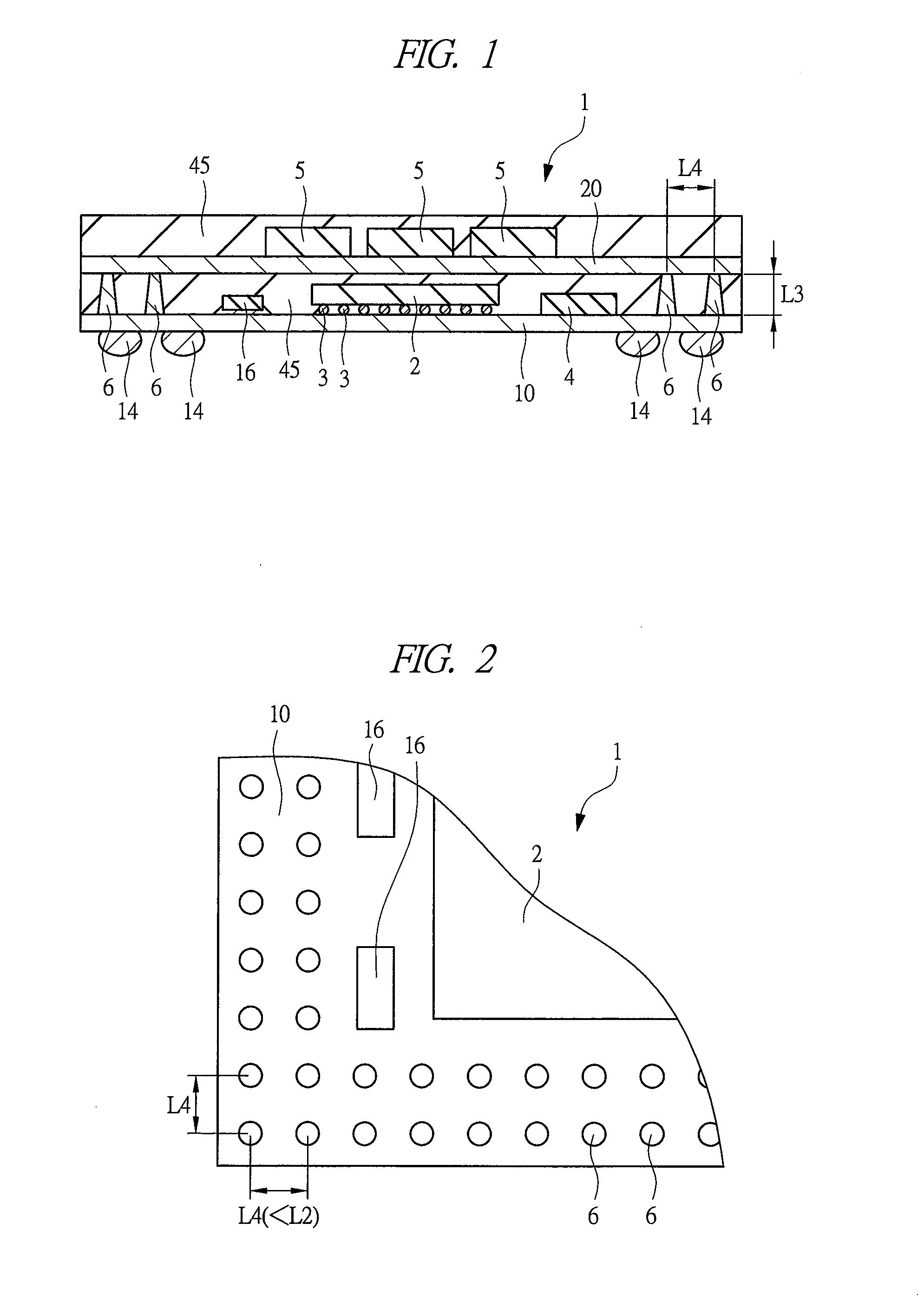

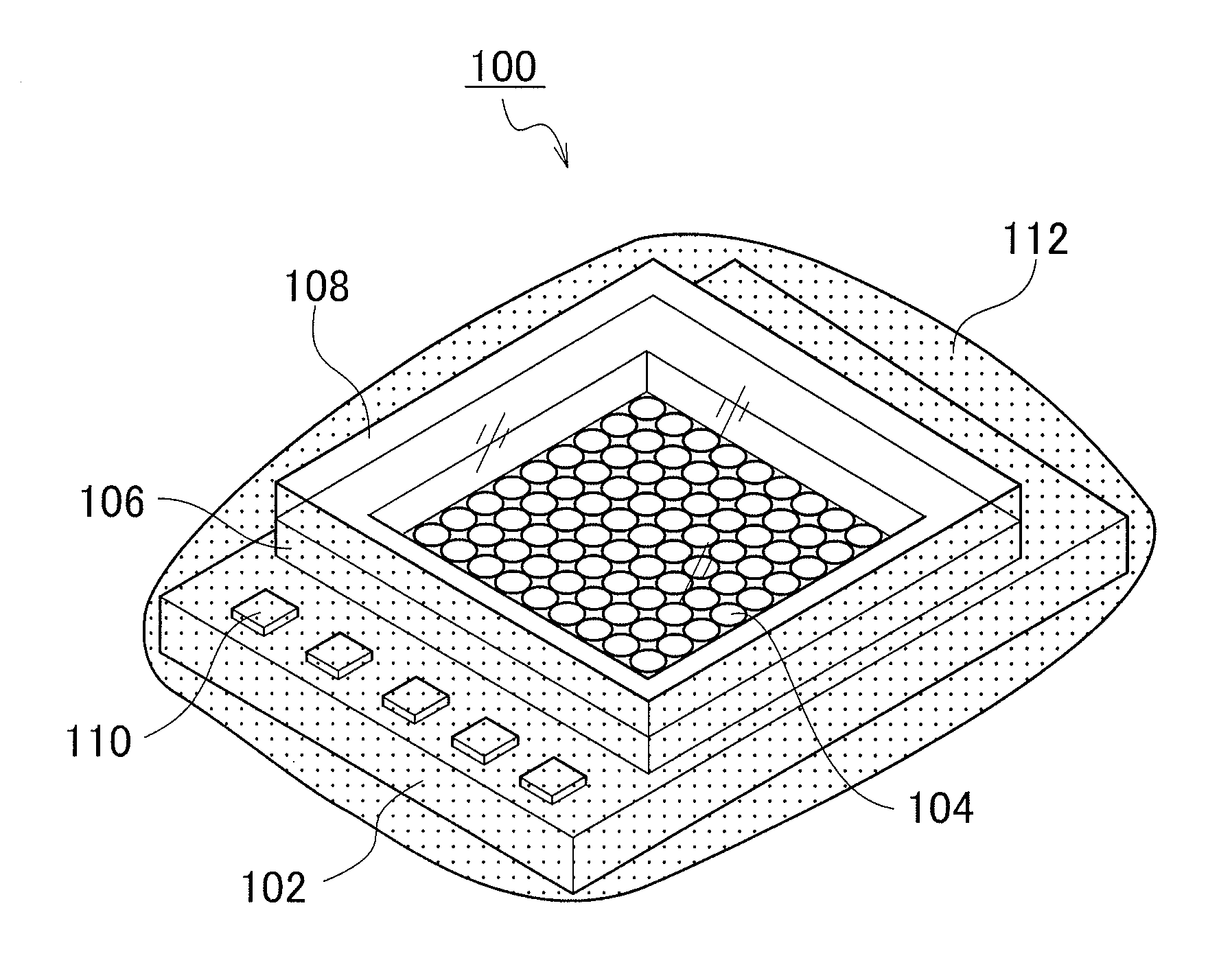

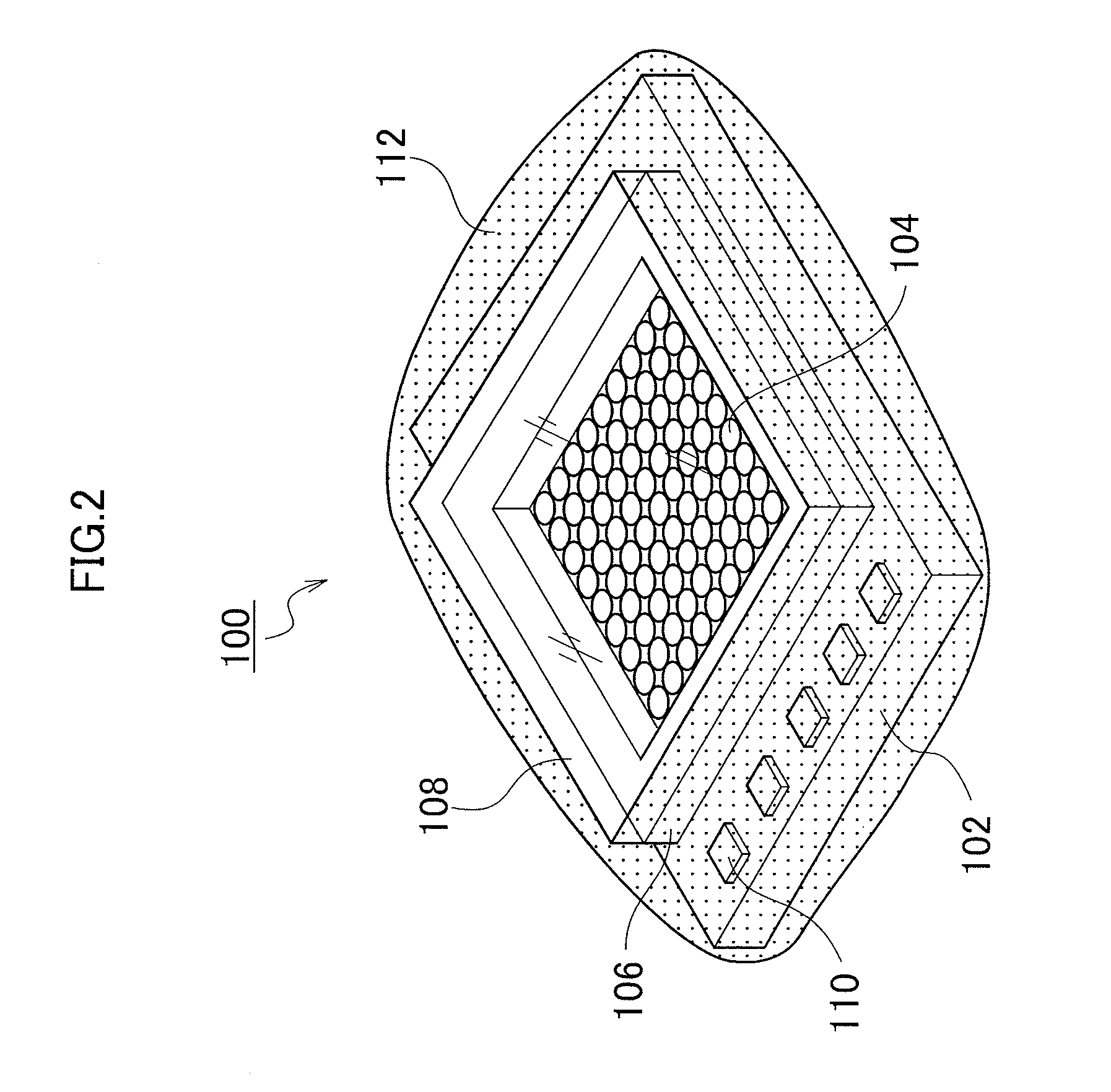

Semiconductor device and method of manufacturing the same

ActiveUS8763242B2Downsizing of the semiconductor device is significantly preventedAvoid downsizingPrinted circuit assemblingSemiconductor/solid-state device detailsConductive pasteMiniaturization

In a method of manufacturing a semiconductor device, a second wiring substrate is stacked over a first wiring substrate using a conductive paste, where each wiring substrate has mounted thereon an electronic component. The conductive paste is hardened to form a metal column which forms an electrical connection between the first wiring substrate and the second wiring substrate. The wiring substrates are sealed with a resin. The semiconductor device can be downsized, thinned, and made highly reliable, and its manufacturing cost can be reduced. By using conductive paste for the electrical connection between the wiring substrates, a connecting pitch can be smaller than that in a connecting method of using a solder ball including Cu core, and a connection at low temperature can be achieved. Also, by coating the conductive paste by a print-coating or dispense-coating method, manufacturing is simplified and the manufacturing cost is reduced.

Owner:RENESAS ELECTRONICS CORP

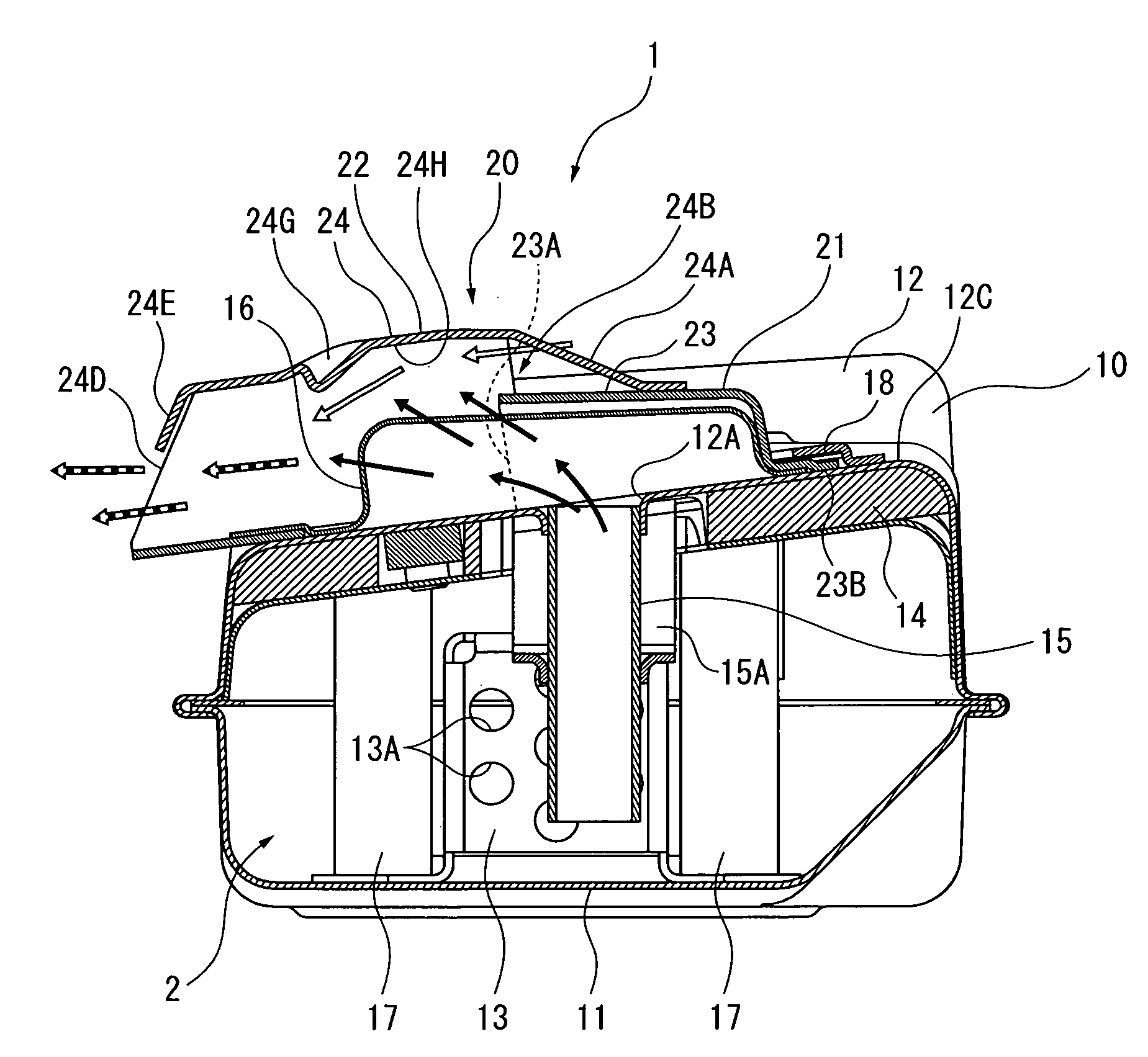

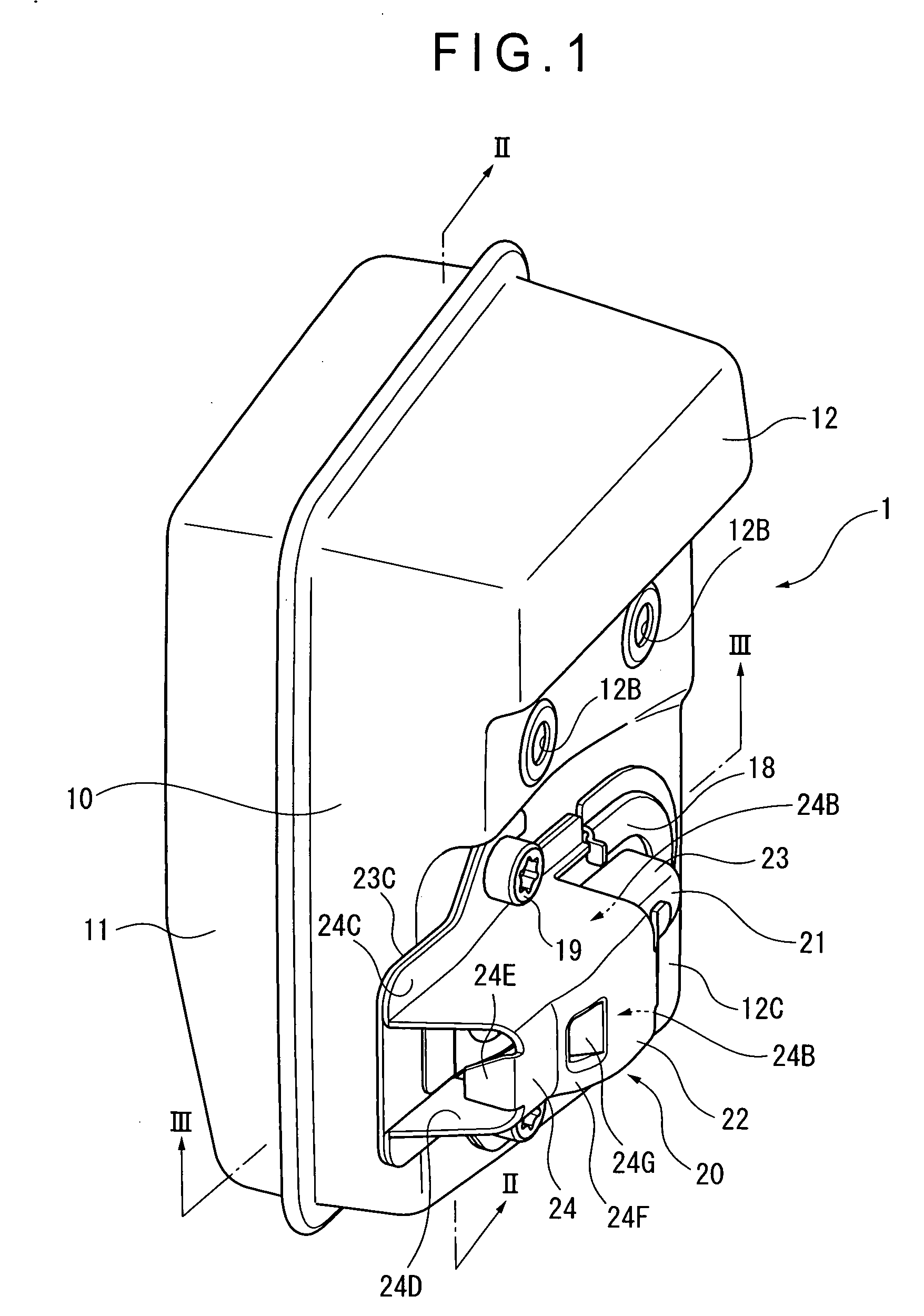

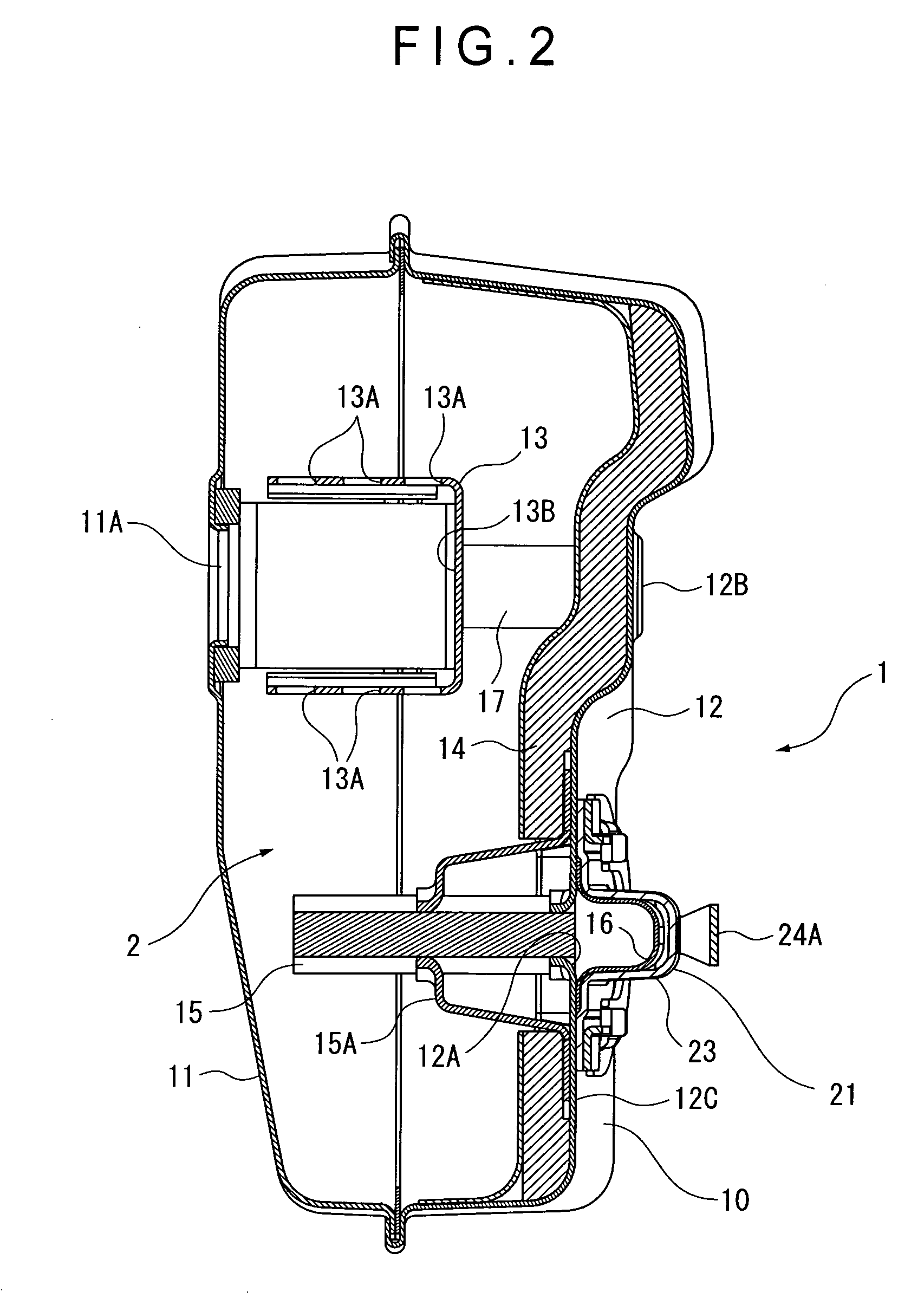

Muffler

InactiveUS20100230205A1Lower temperature of exhaust gasAvoid downsizingExhaust apparatusSilencing apparatusExhaust gasExhaust fumes

Owner:HUSQVARNA ZENOAH

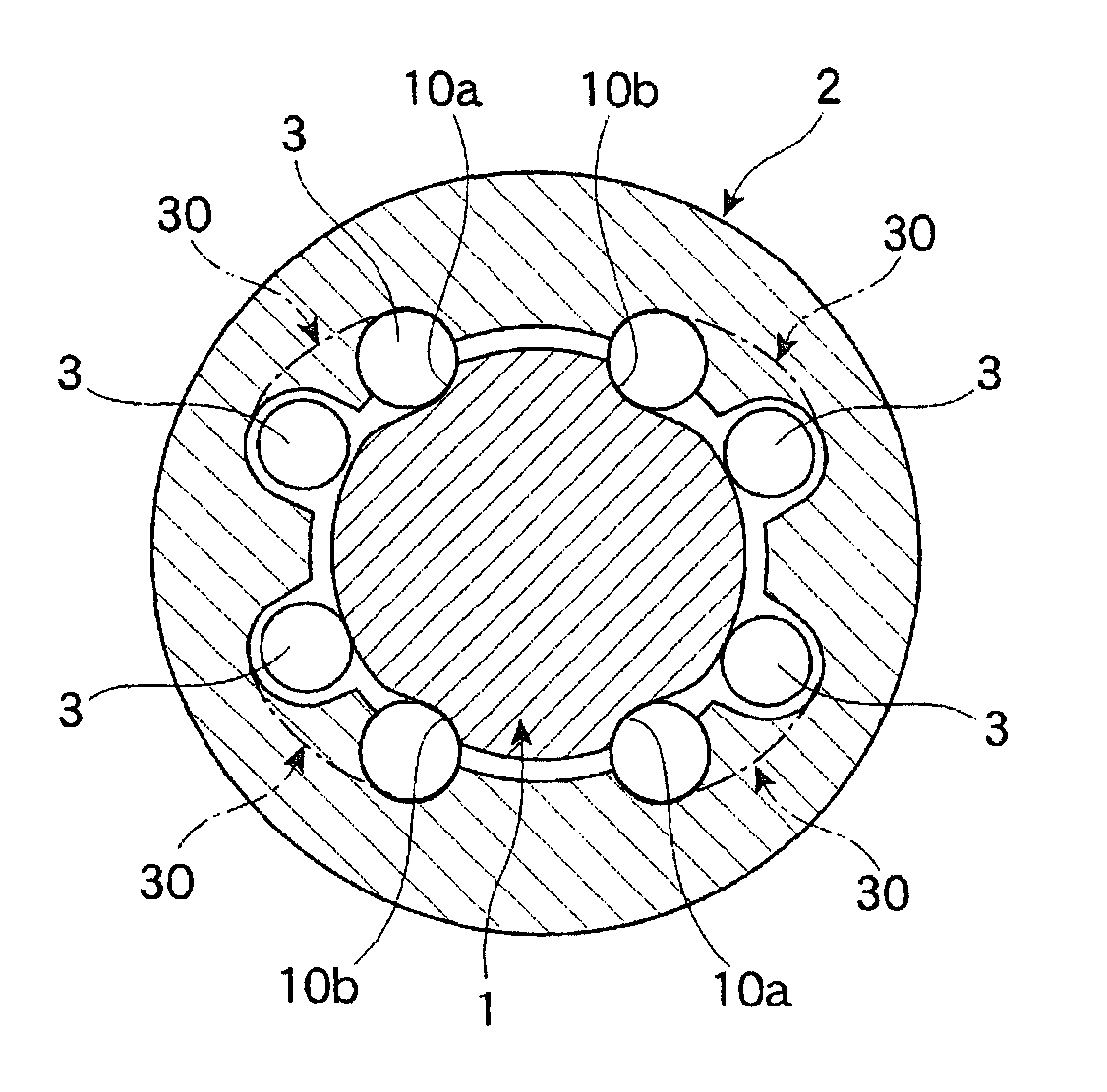

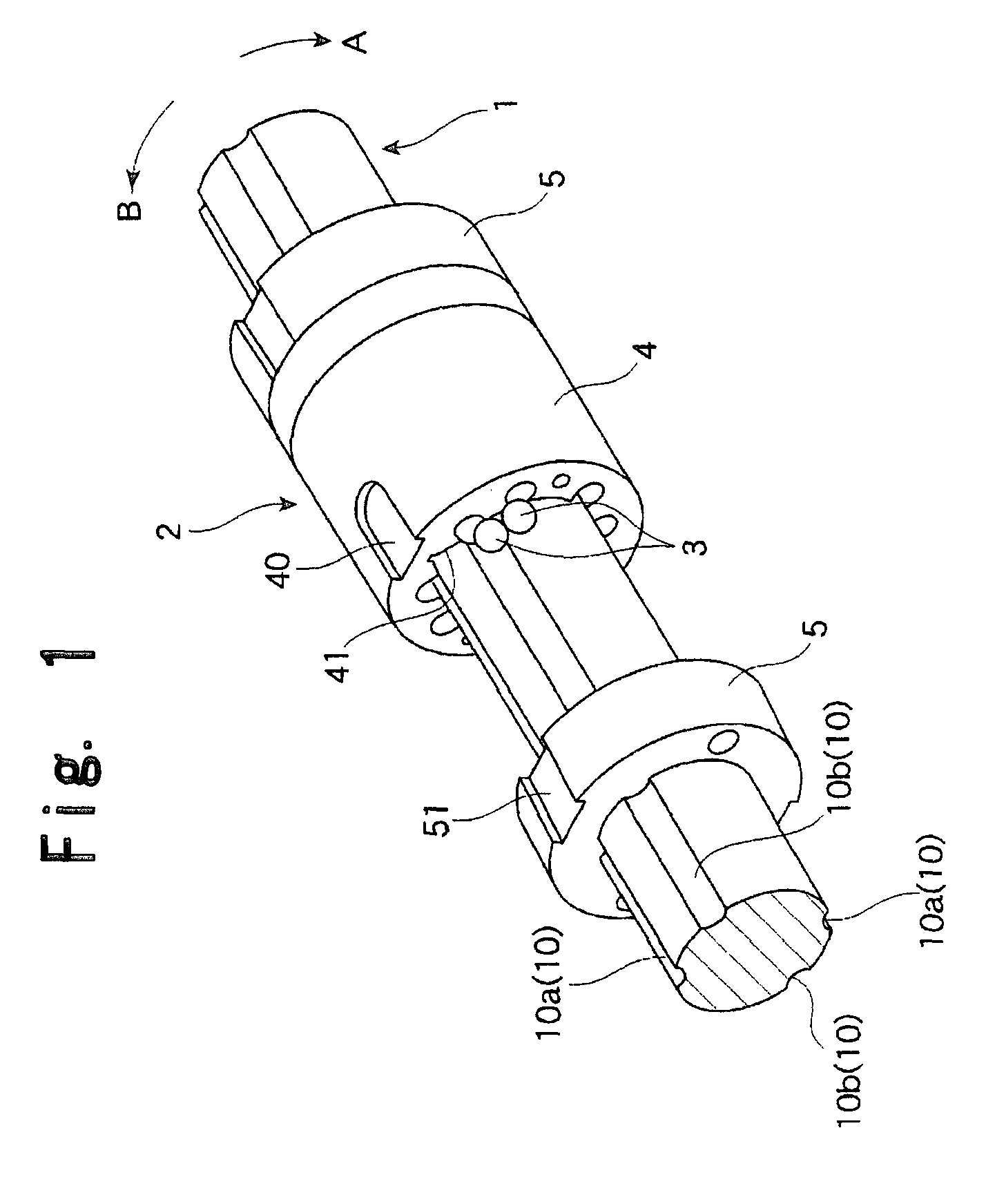

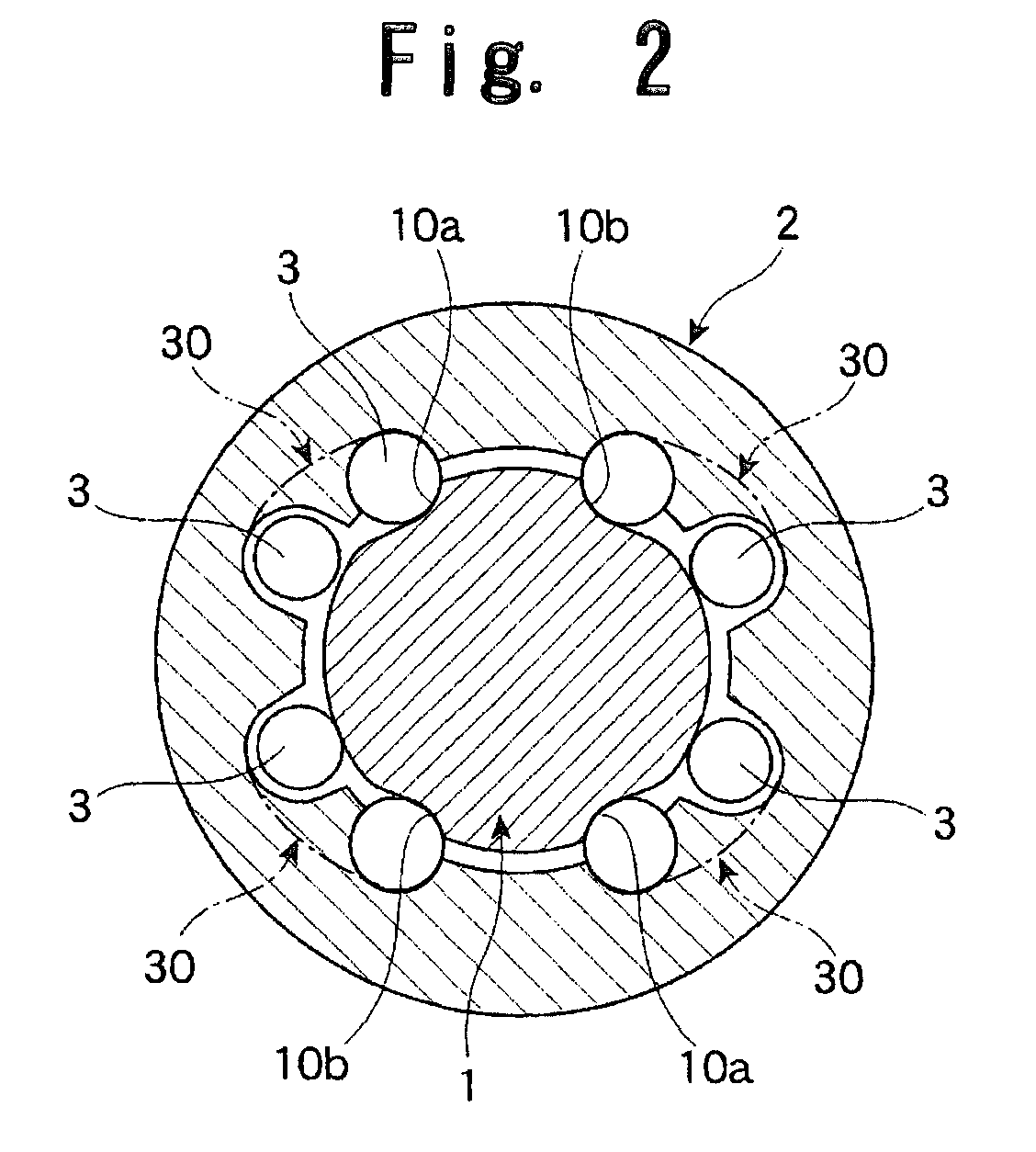

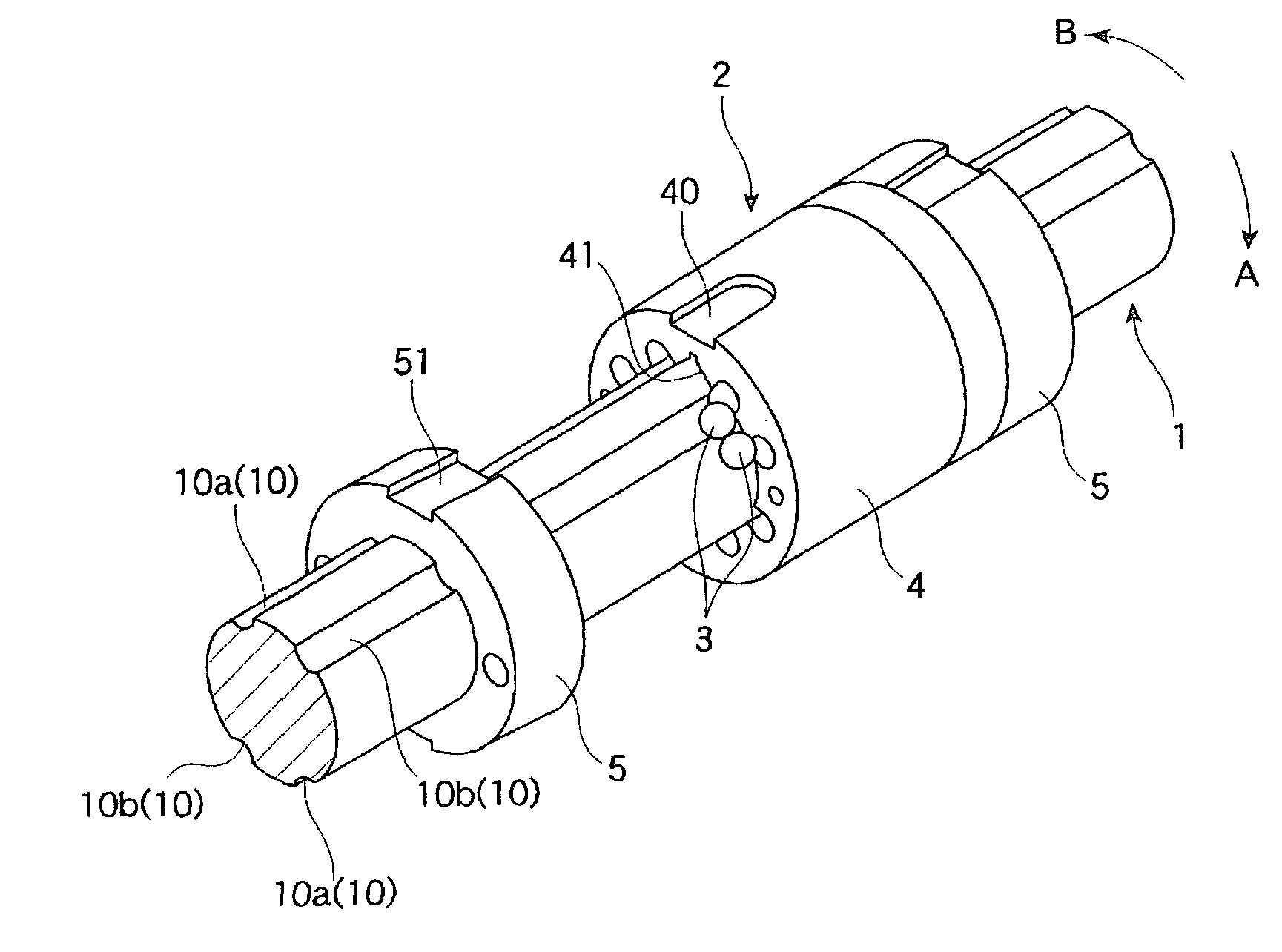

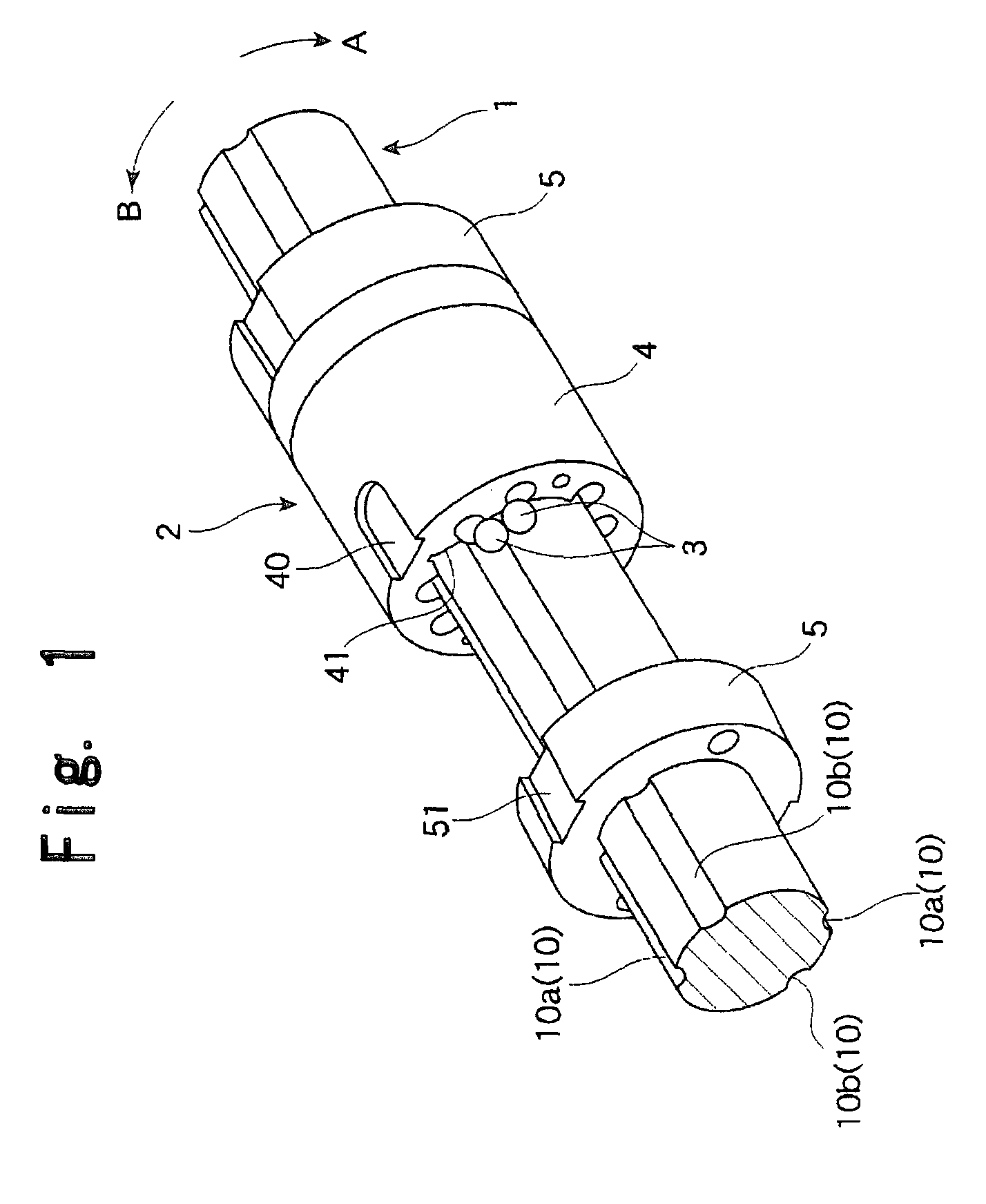

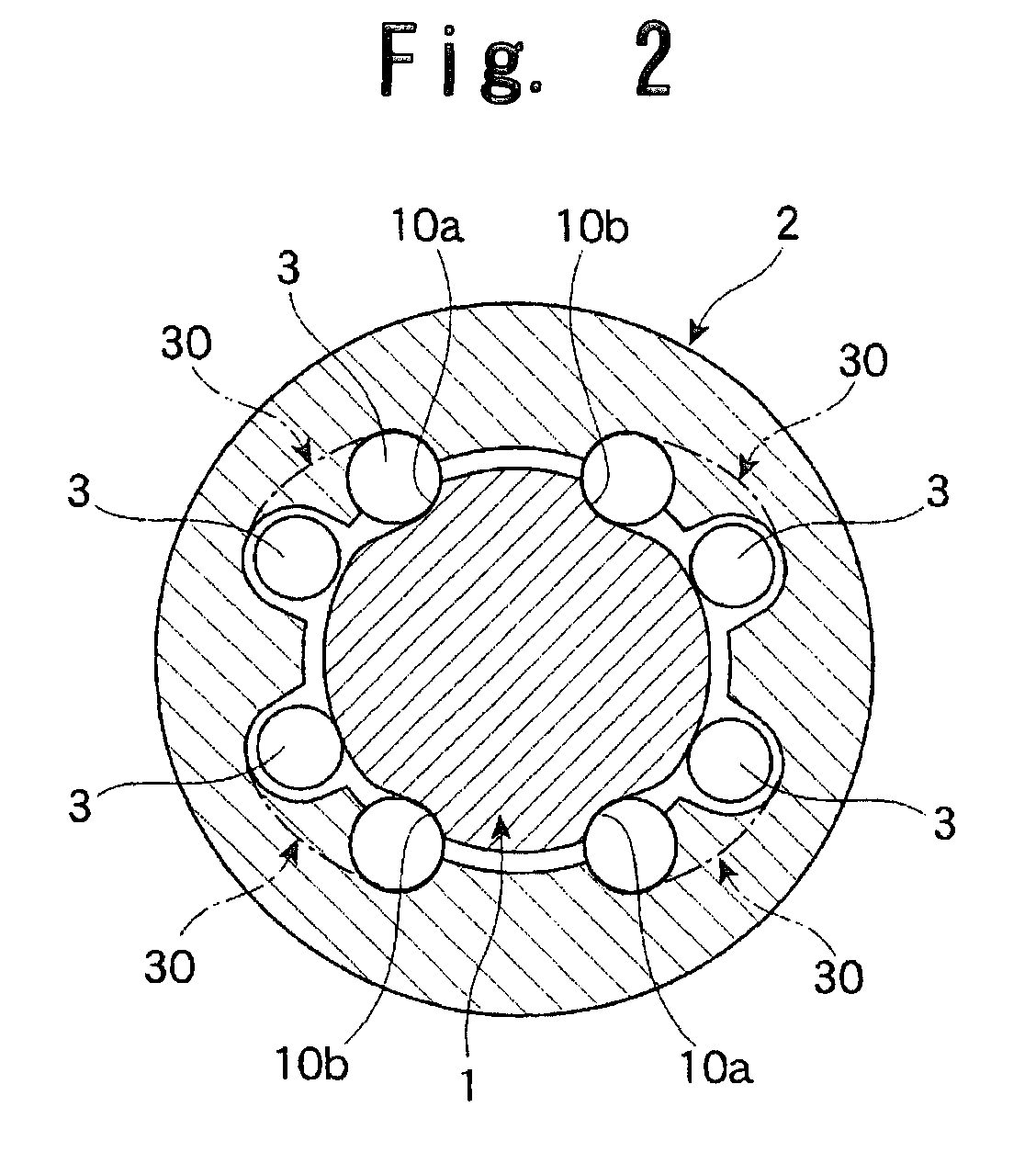

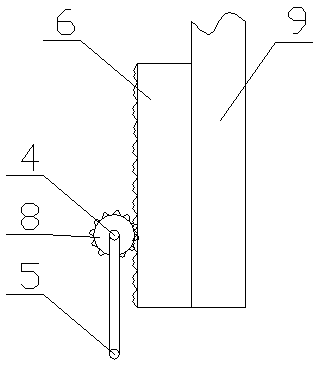

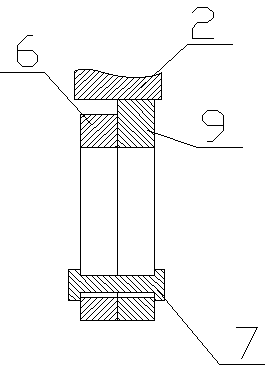

Ball spline device

ActiveUS8123407B2Avoid downsizingMaintain reliabilityYielding couplingLinear bearingsClassical mechanicsStructural engineering

Provided is a ball spline device, in which an outer diameter of a nut member can be downsized to the maximum while sufficiently performing an original function, and which can keep reliability while being capable of being simply manufactured at lower cost without involving time and effort in assembly, in which a nut member has a track groove which is formed on an inner peripheral surface facing a spline shaft, the balls circulating in the track groove, the track groove comprises: a linear load groove formed so as to face the ball rolling groove of the spline shaft; a linear non-load groove provided parallel to the linear load groove; and a pair of ball deflection grooves for communicably coupling the linear load groove and the linear non-load groove with each other so as to allow the balls to intercommunicate therebetween, and the ball deflection grooves forcibly change an advancing direction of the balls rolling in the ball rolling groove and cause the balls to depart from the ball rolling groove with use of a profile of the spline shaft.

Owner:THK CO LTD

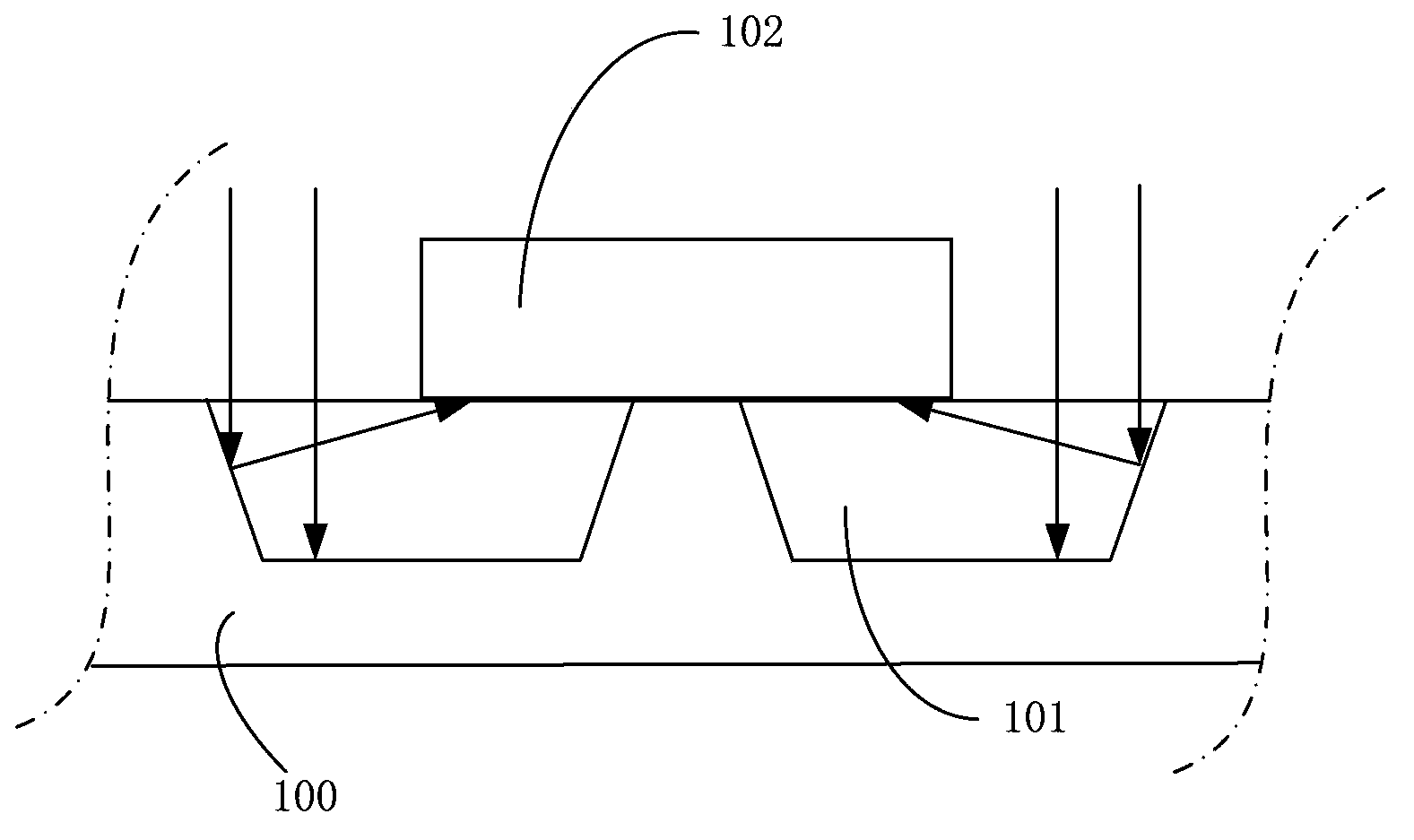

Manufacturing method of semiconductor device

ActiveCN103811294AImprove performanceAvoid downsizingSemiconductor/solid-state device manufacturingPhotoresistIon implantation

The invention provides a manufacturing method of a semiconductor device, and relates to the semiconductor technical field; the method comprises the following steps: S101, providing a semiconductor substrate; S102, forming an antireflective layer in a boundary between a zone wherein ion injection is to be carried out and a zone wherein an ion implantation shielding layer is to be formed on the semiconductor substrate; S103, employing photoresist to form the ion implantation shielding layer on the semiconductor substrate. The manufacturing method of the semiconductor device adds the step in which the antireflective layer is formed in a boundary between the zone wherein ion injection is to be carried out and the zone wherein the ion implantation shielding layer is to be formed; in a process to expose a photoresist film so as to form the ion implantation shielding layer, the reflection light from the semiconductor substrate can be prevented or stopped from entering the photoresist film, so the reflection light cannot cause size reduction of the ion implantation shielding layer, thereby ensuring key size of the ion implantation shielding layer, and improving performance of the semiconductor device.

Owner:SEMICON MFG INT (SHANGHAI) CORP

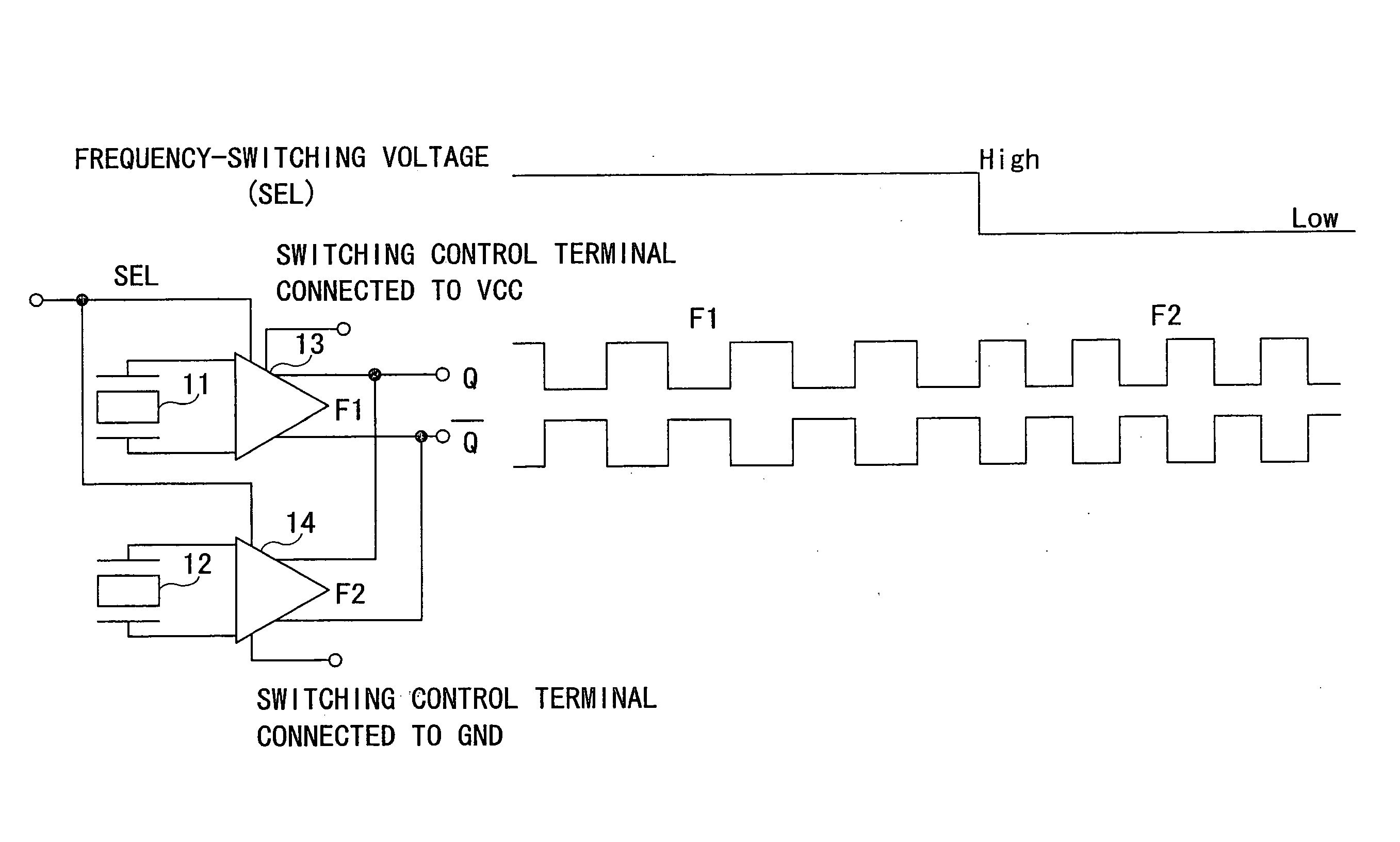

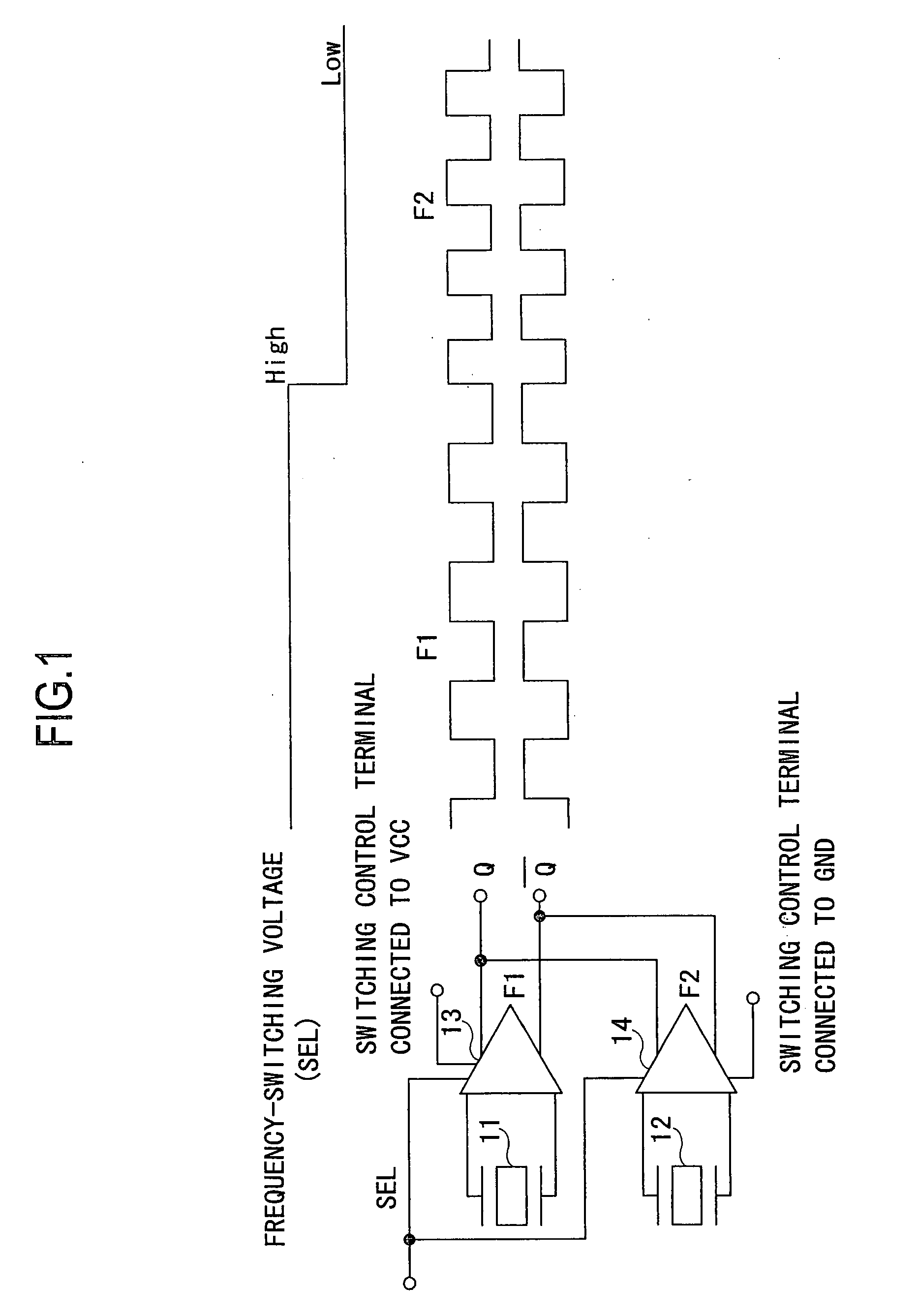

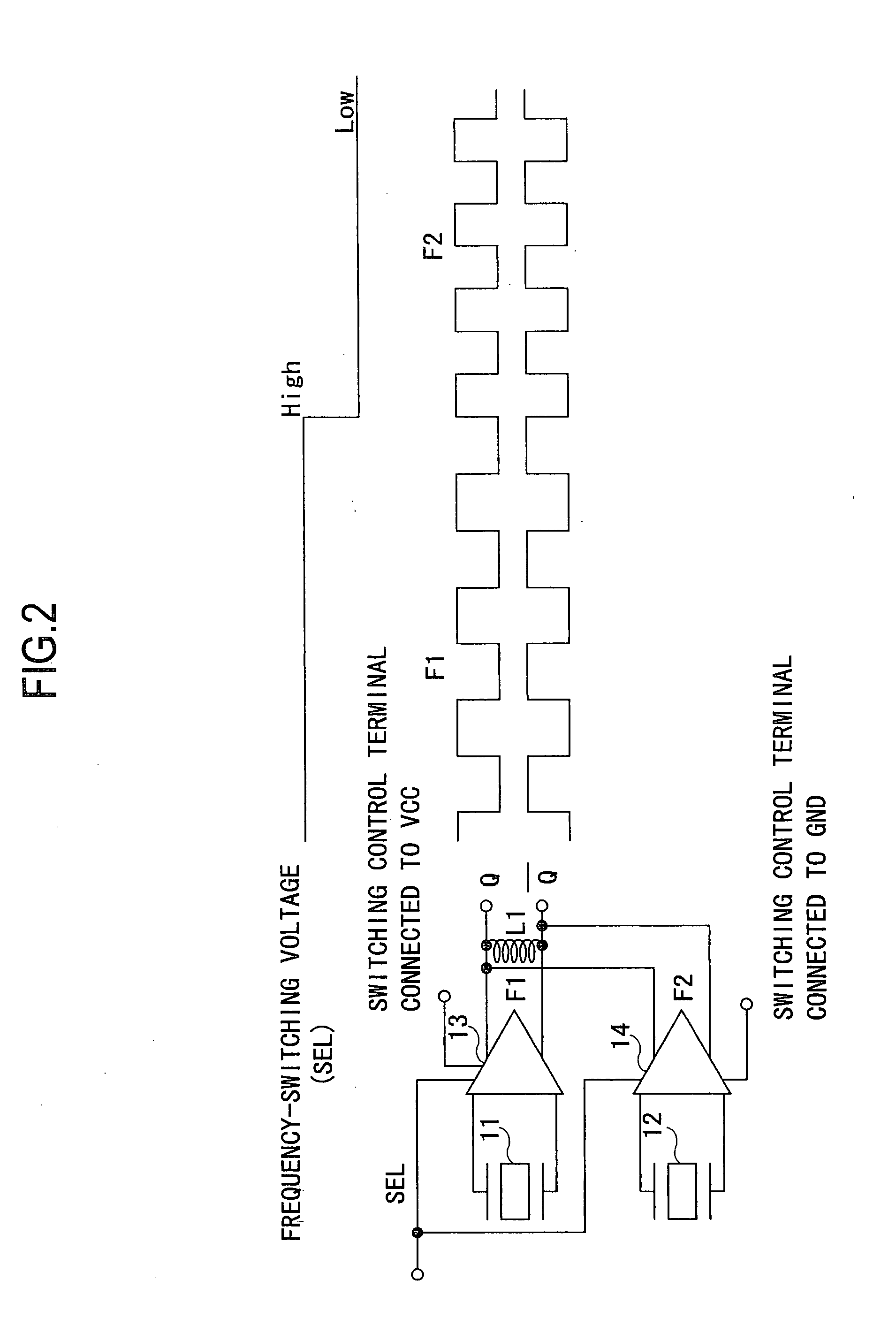

Frequency-selective oscillator

InactiveUS20080074206A1Avoid downsizingGood output voltage characteristicPulse automatic controlElectric pulse generatorInductorQuantum electrodynamics

The object of the present invention is to provide a frequency-selective oscillator capable of outputting two frequencies without hindering the downsizing of the device and capable of obtaining good output voltage characteristics. The frequency-selective oscillator includes a first crystal resonator and a second crystal resonator different in oscillation frequency from each other, and a first oscillation circuit and a second oscillation circuit corresponding to respective crystal resonators, in which a frequency-switching voltage is applied to selector terminals of the first and second oscillation circuits, a supply voltage Vcc is applied to a switching control terminal of the first oscillation circuit, a switching control terminal of the second oscillation circuit is grounded, Q outputs and inverted Q outputs of the oscillation circuits and are respectively connected and output from respective common signal lines. The frequency-selective oscillator can also be such that the common Q output and the common inverted Q output in the above structure are connected through an inductor L1.

Owner:NIHON DEMPA KOGYO CO LTD

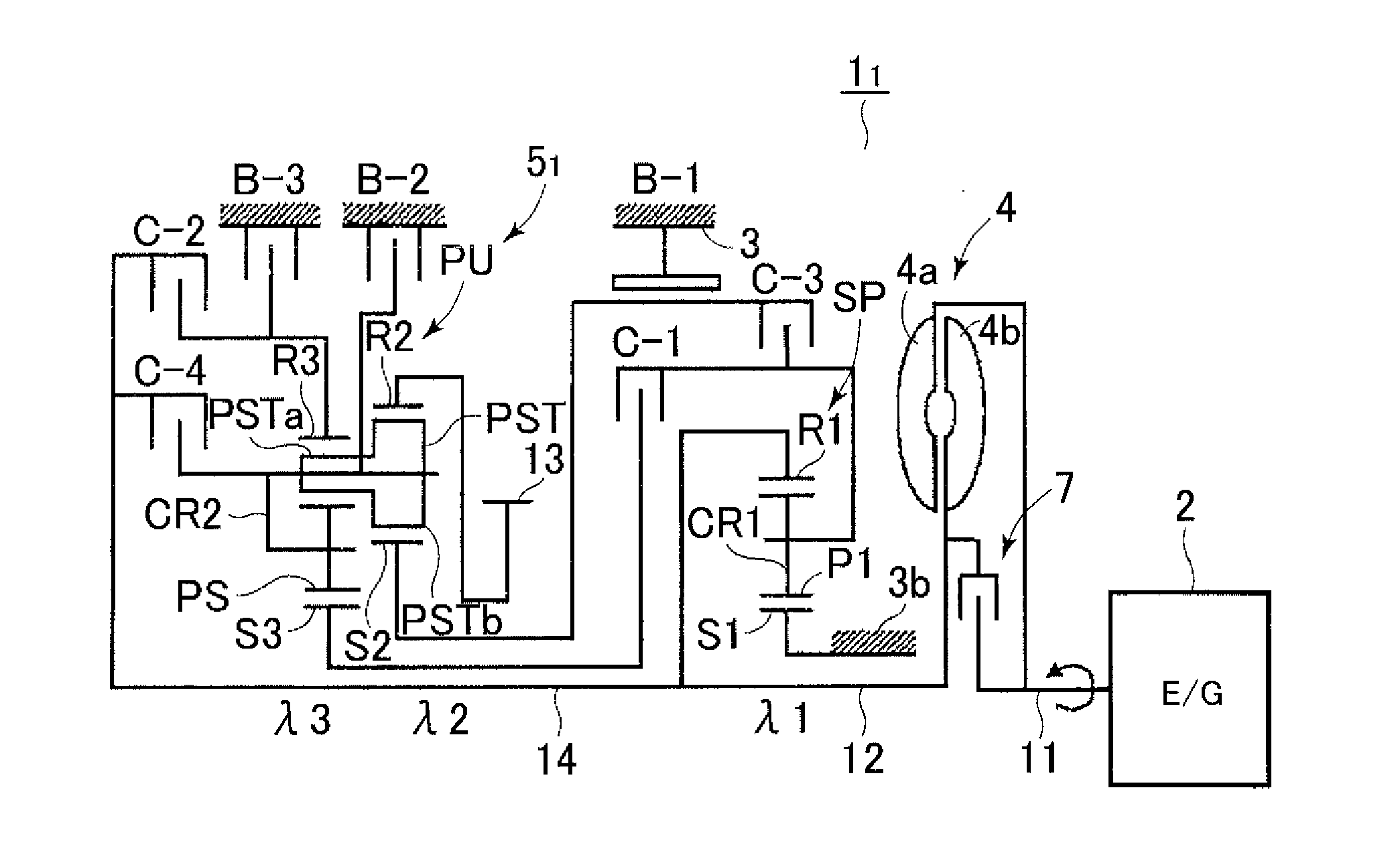

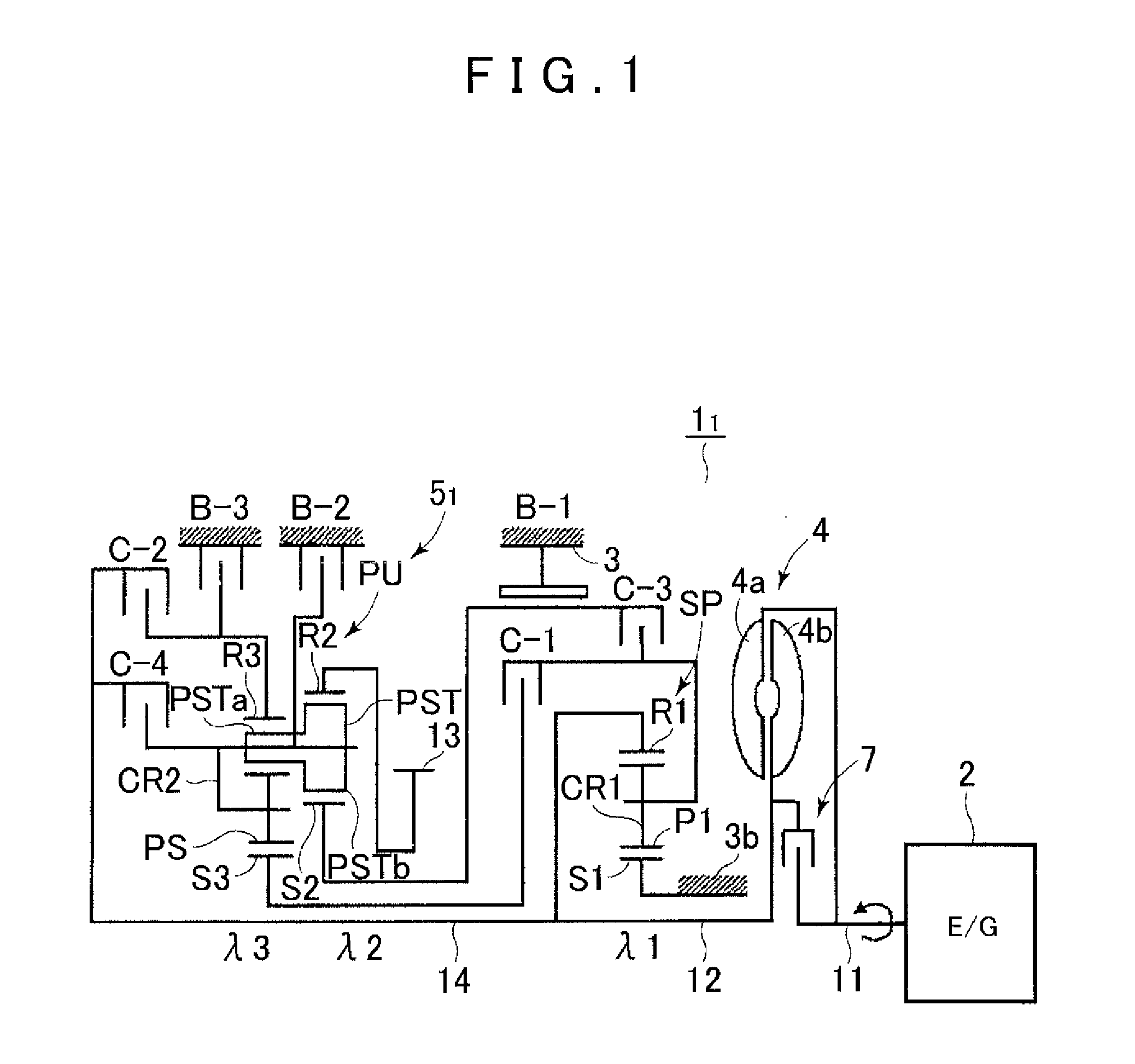

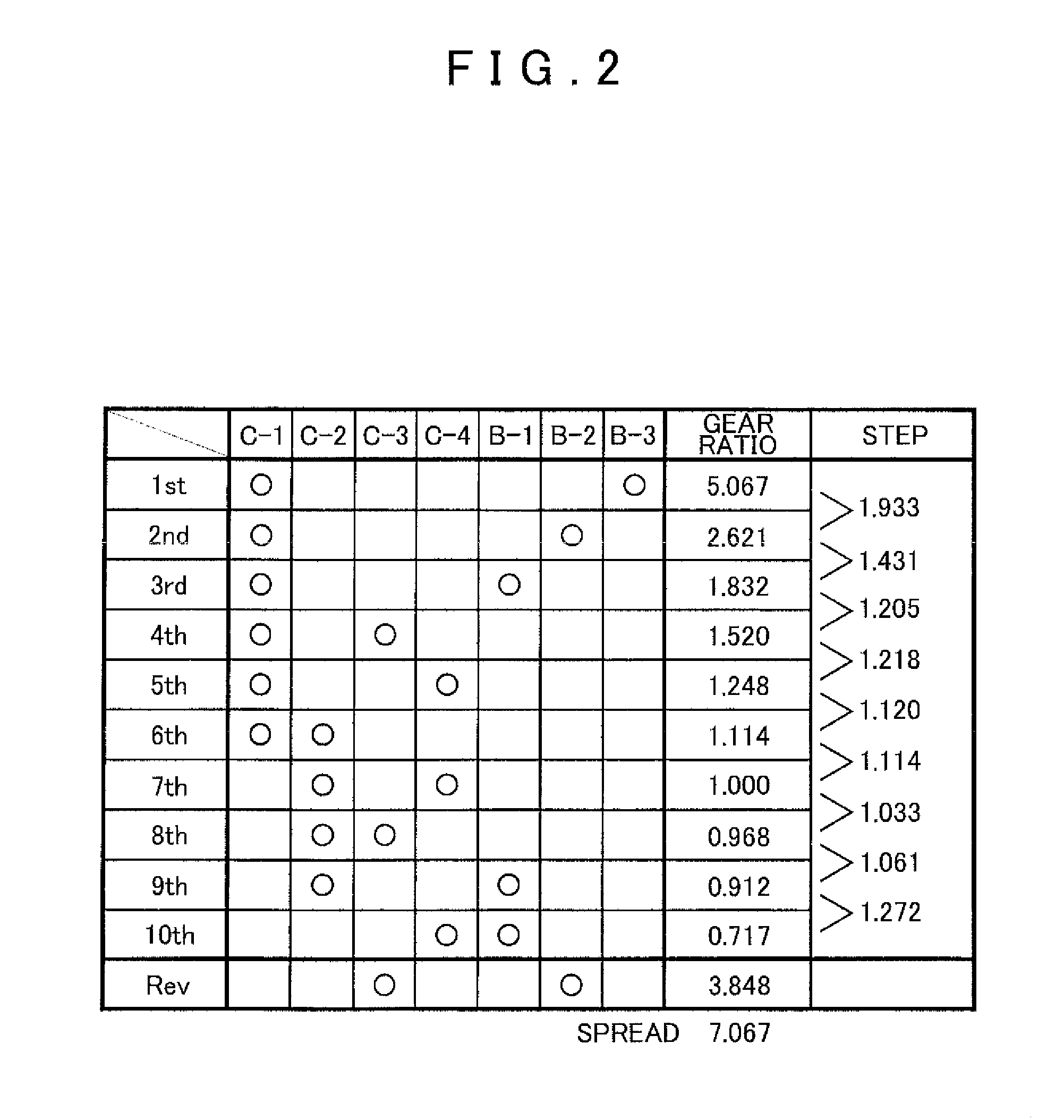

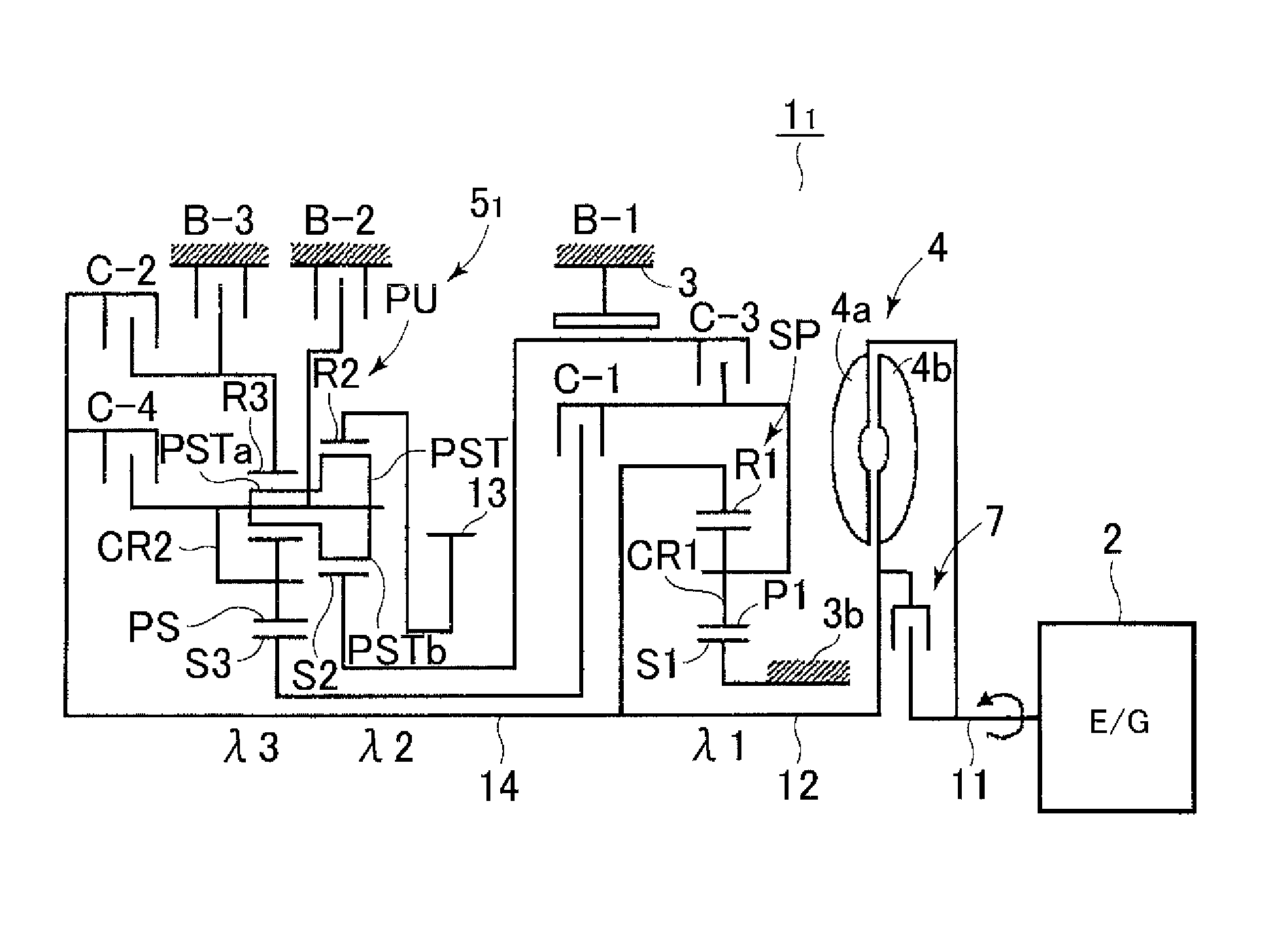

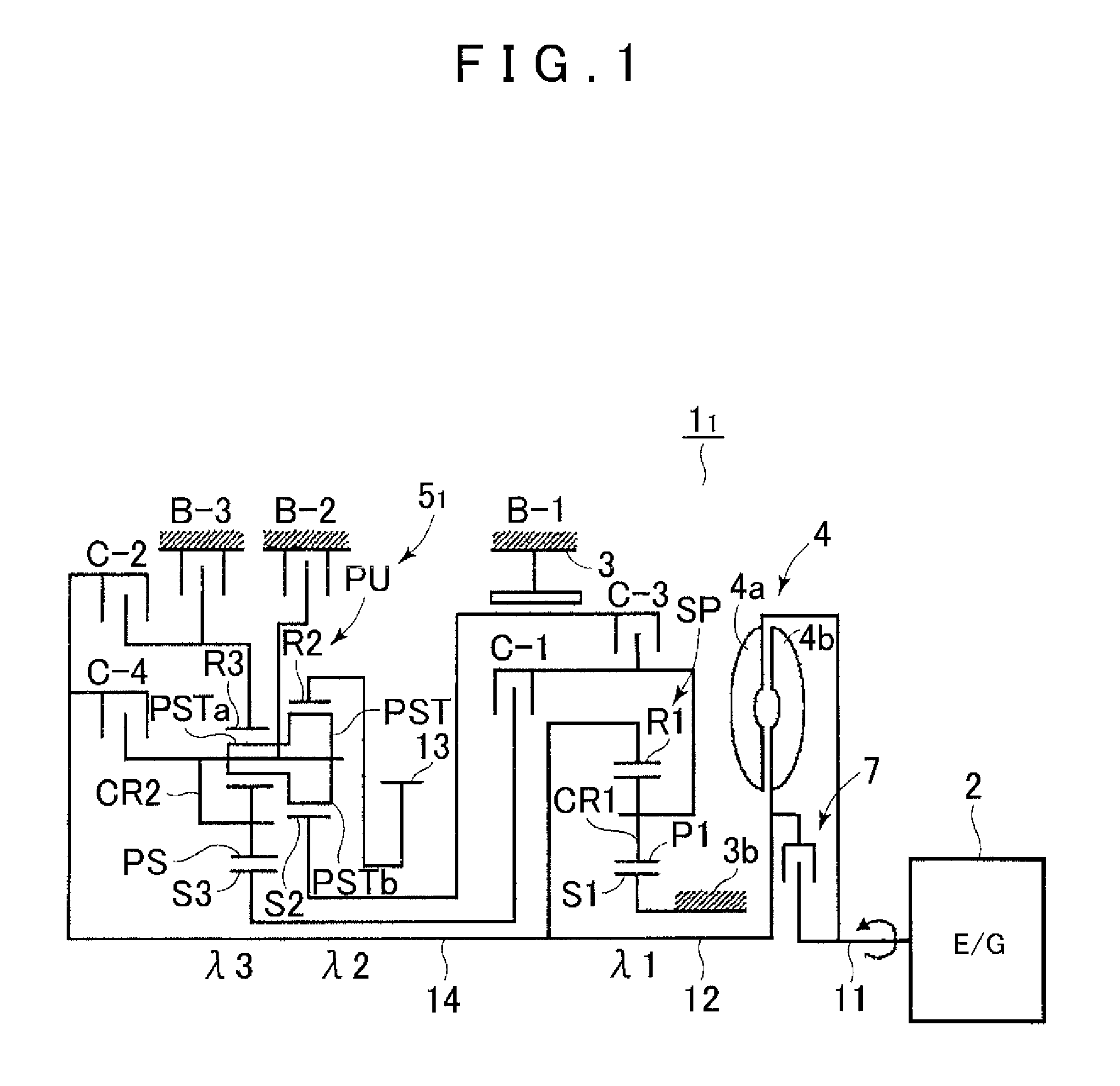

Automatic transmission

InactiveUS20130260948A1Low costIncrease the number ofToothed gearingsTransmission elementsAutomatic transmissionGear wheel

An automatic transmission is configured to achieve at least ten forward speeds and one reverse speeds. This is achieved through the use of two planetary gear sets with a plurality of clutches and brakes configured to operably couple different components of the two planetary gears to achieve different speeds. For example, operation of a first clutch inputs decelerated rotation of a reduction planetary gear to a third sun gear. Operation of a second clutch transmits from an input shaft to a third ring gear, a third clutch inputs decelerated rotation of the reduction planetary gear to the second sun gear, a fourth clutch transmits from the input shaft to the second carrier, a first brake prevents a second sun gear from rotating, a second brake prevents a carrier from rotating, a third brake capable prevents a third ring gear from rotating.

Owner:AISIN AW CO LTD

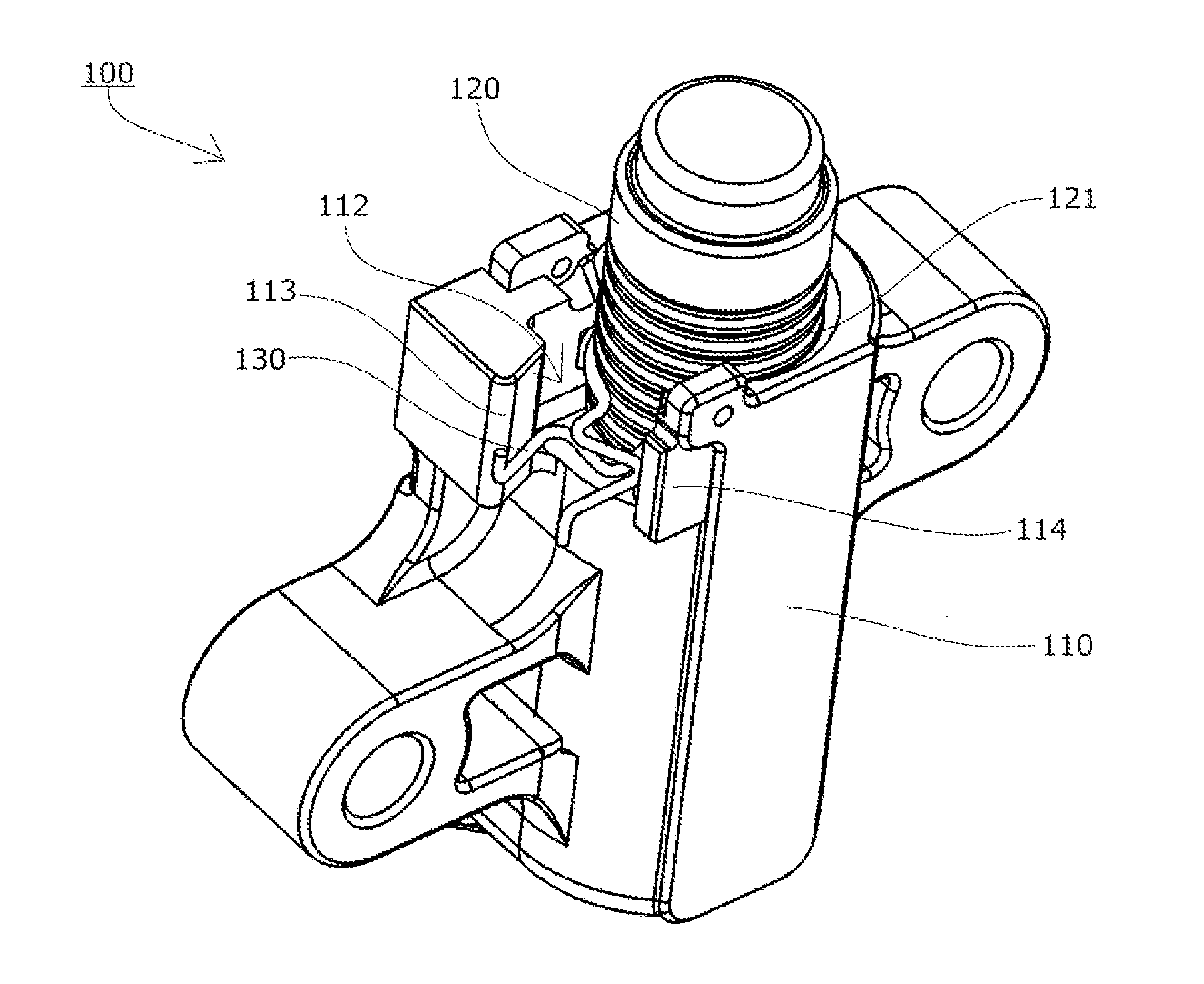

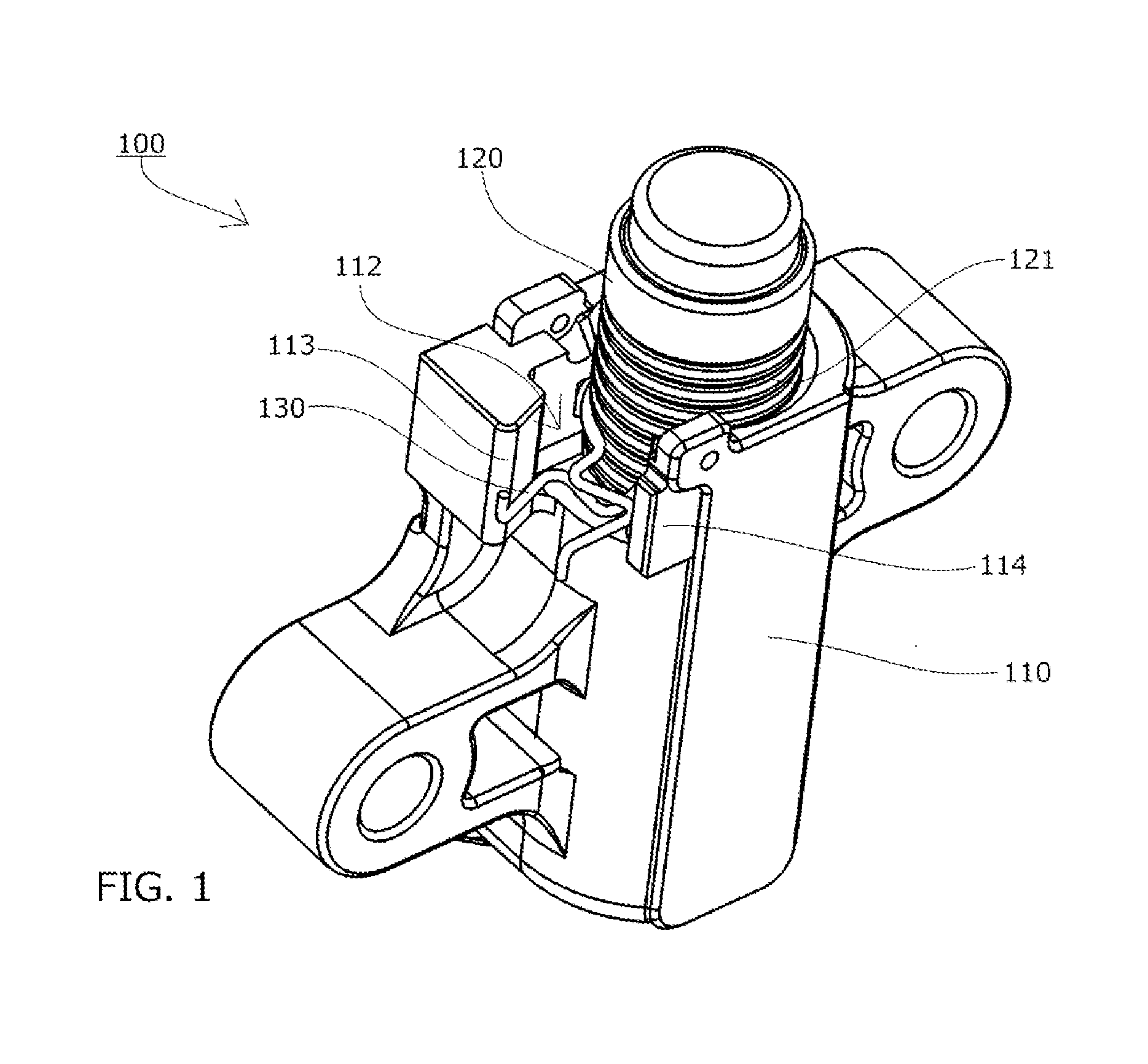

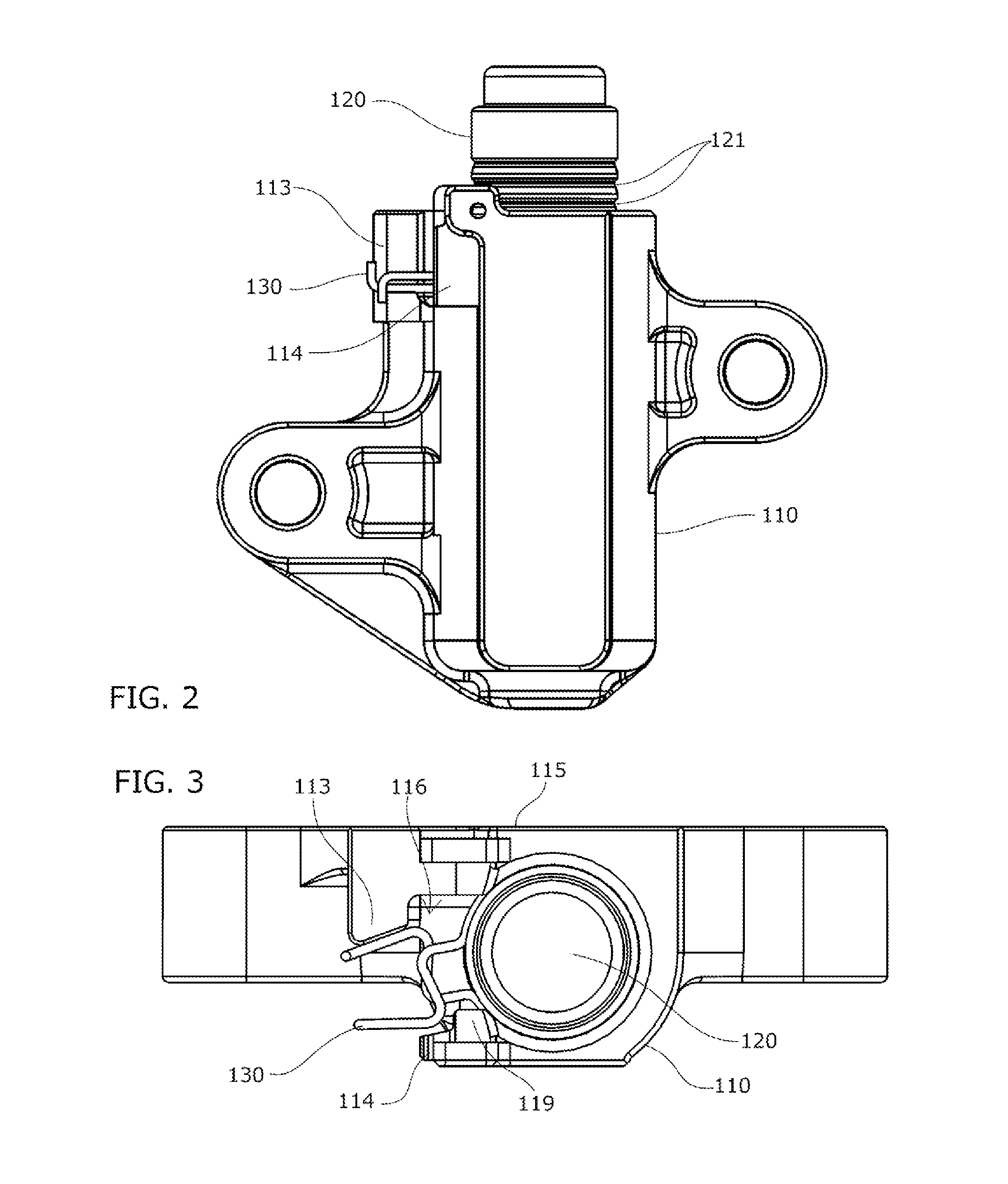

Chain tensioner

An object of the present invention is to provide a chain tensioner which enables operations on an elastic ring member during assembly and maintenance work to be readily performed and which is capable of eliminating protrusion of an operating portion of the elastic ring member in a direction opposite to a mounting surface, with a simple configuration. A ring holding portion 112 provided on an open side of a plunger housing hole 111 includes a pressing projection 113 and a restricting portion 114 which restrict rotation of the elastic ring member 130 and which oppose both outer sides of a pair of operating portions 132 of the elastic ring member 130 in a circumferential direction, and the pressing projection 113 is arranged at a position closer to a mounting surface 115 than the restricting portion 114.

Owner:TSUBAKIMOTO CHAIN CO

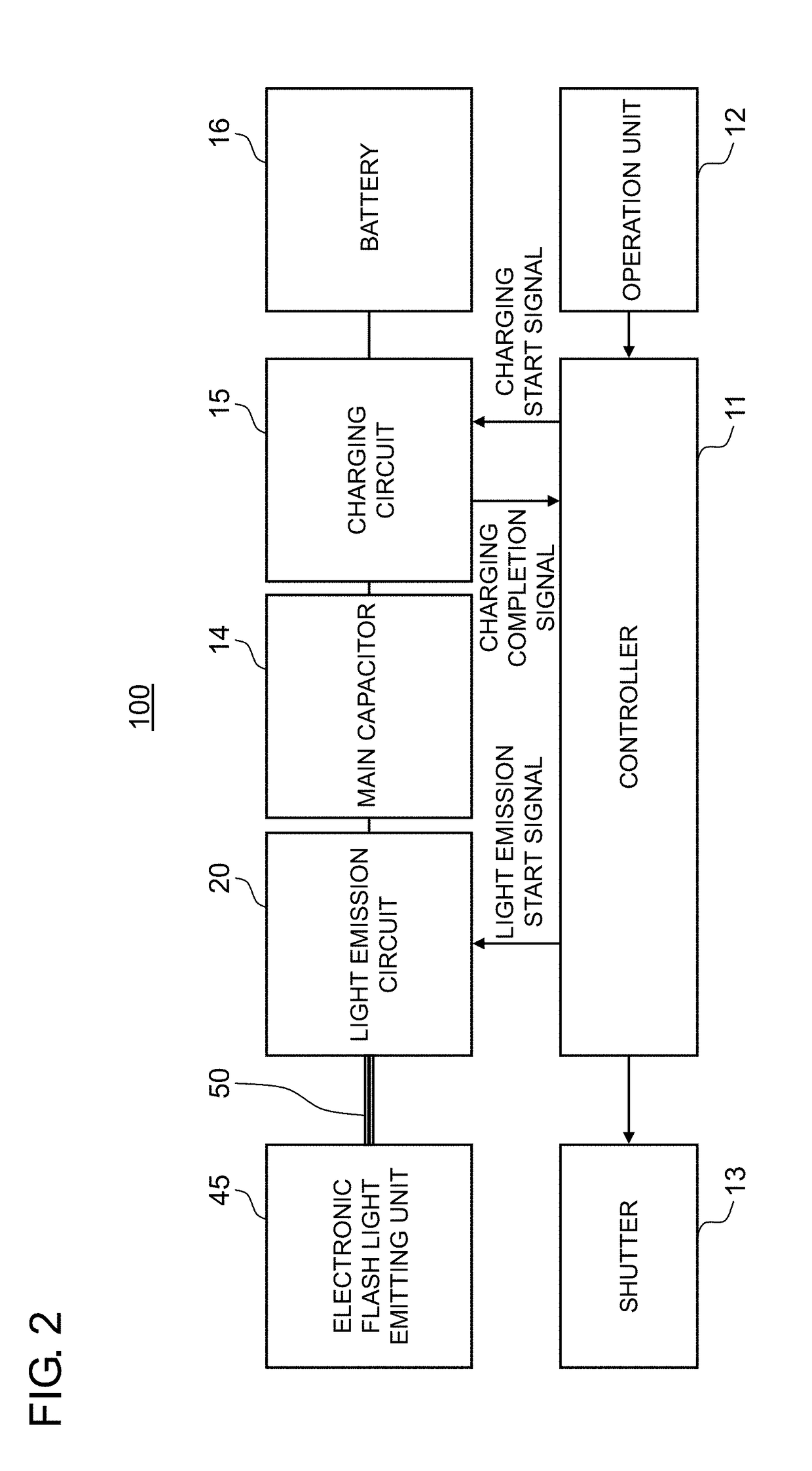

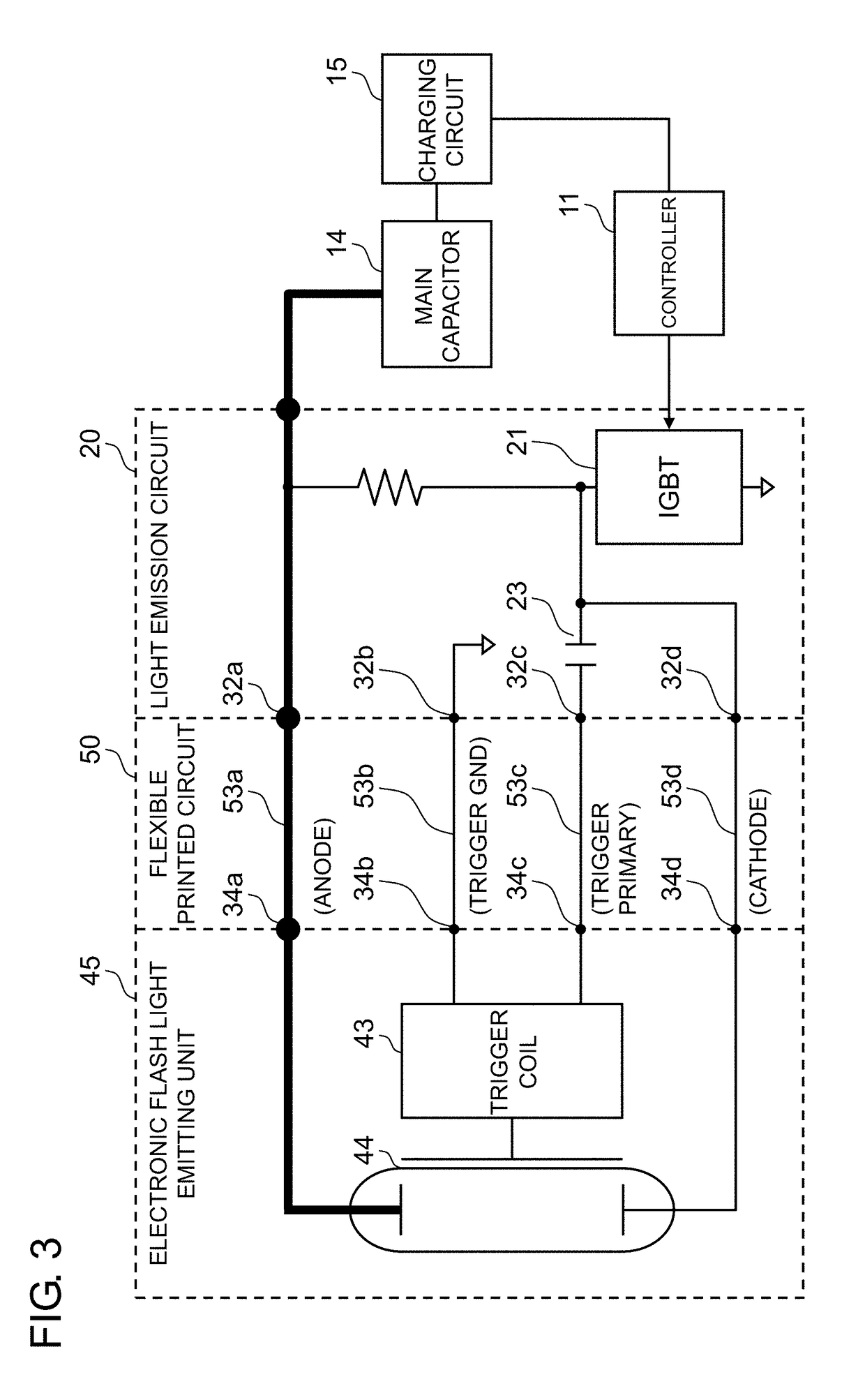

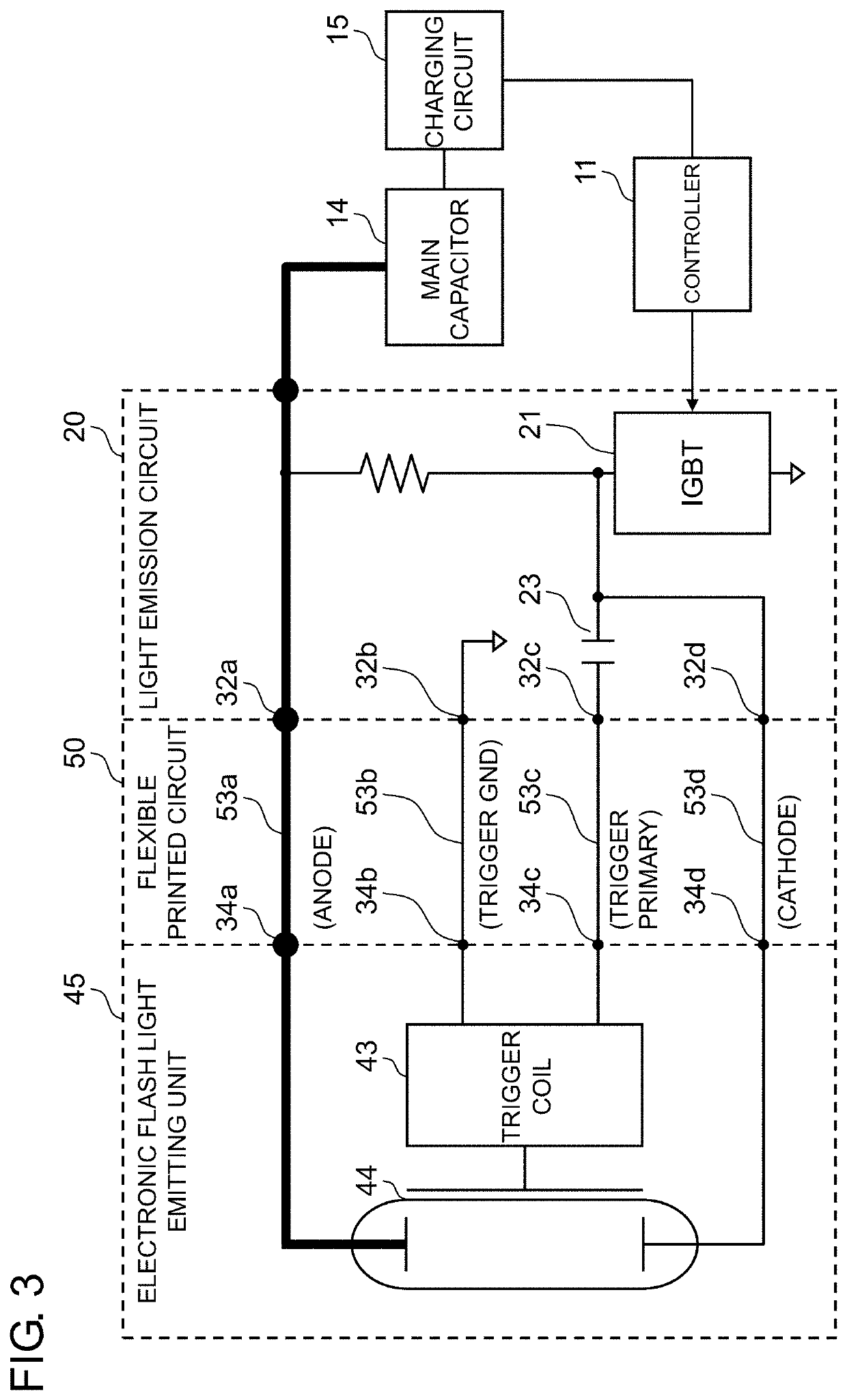

Flexible printed circuit and imaging apparatus including same

ActiveUS20190069413A1Improve insulation performanceReduce thicknessTelevision system detailsCasings/cabinets/drawers detailsEngineeringImaging equipment

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

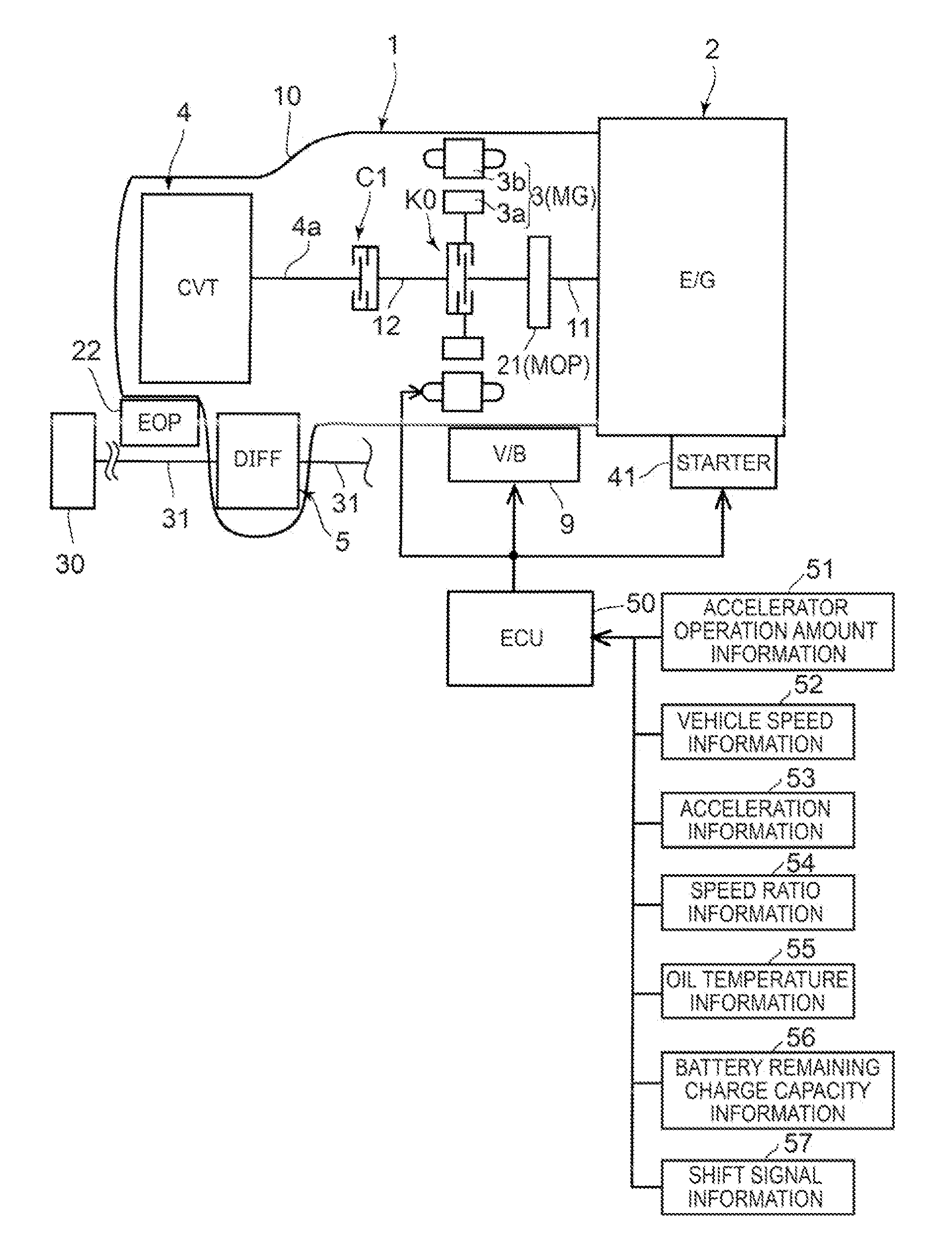

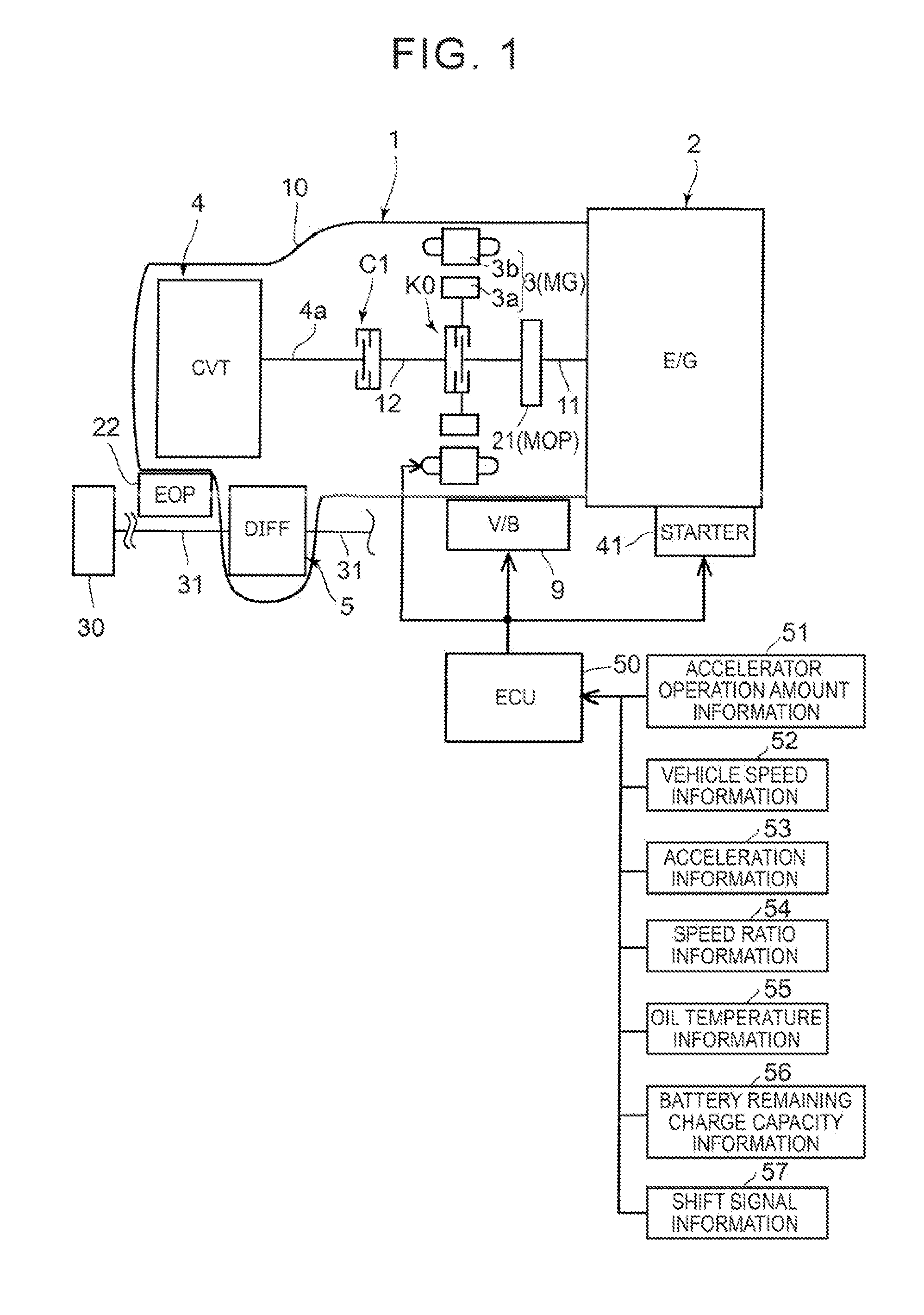

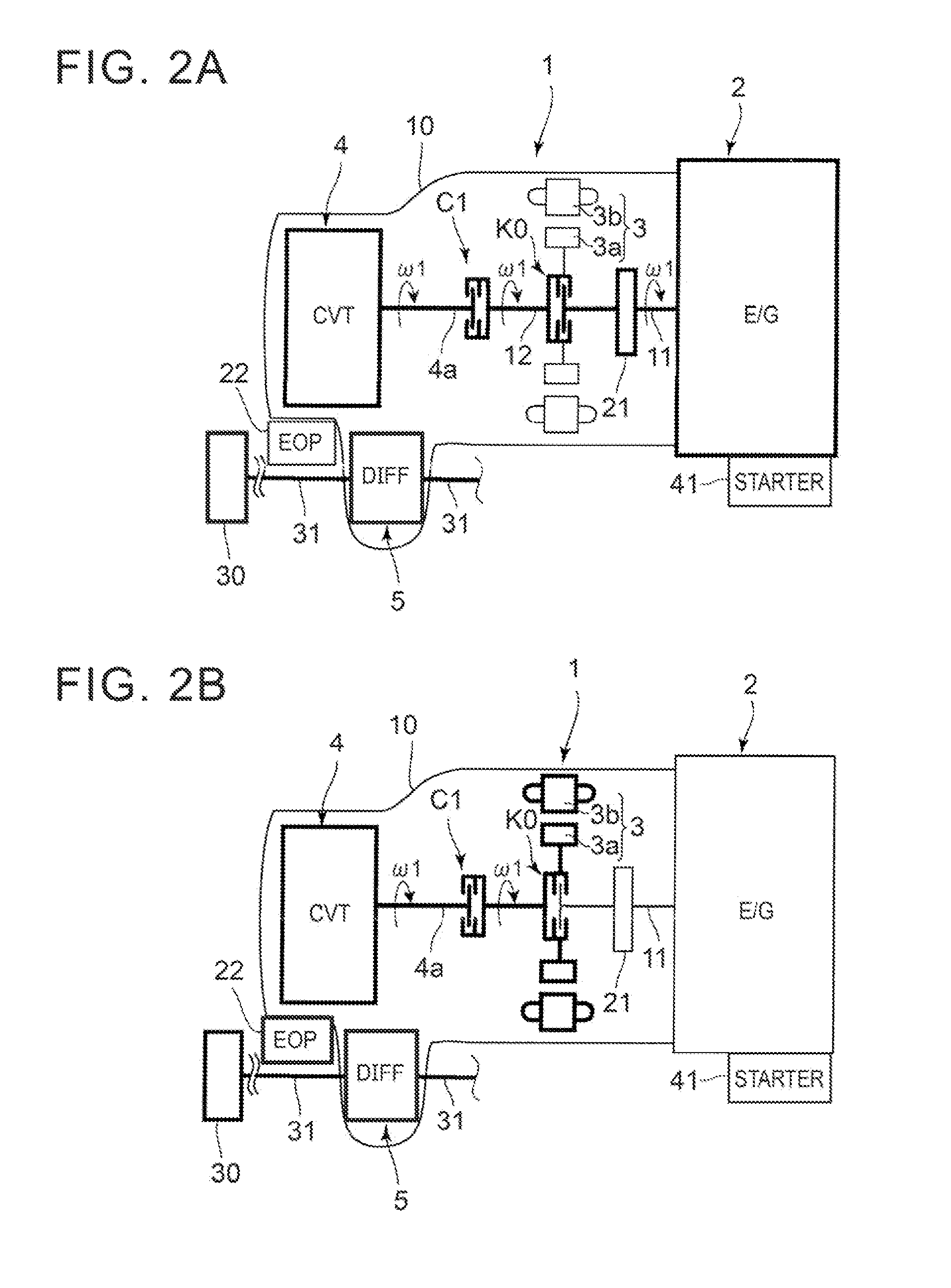

Hybrid drive device

InactiveUS20140190455A1Compact and inexpensive structureSolve the lack of resistanceHybrid vehiclesElectrical controlExternal combustion engineElectric machine

A hybrid drive having a hydraulic control device capable of hydraulically controlling a first clutch, a second clutch, and a continuously variable transmission using a hydraulic pressure generated by at least one of a mechanical oil pump and an electric oil pump. A control section is configured to execute a mechanical oil pump drive mode in which a command to start an internal combustion engine is provided to drive the mechanical oil pump via a first shaft using output rotation of the internal combustion engine during reverse travel in which reverse rotation is output from the rotary electric machine to rotate wheels in reverse via the second shaft, the second clutch, and the continuously variable transmission with the first clutch disengaged and with the second clutch engaged by providing a command to the hydraulic control device.

Owner:AISIN AW CO LTD

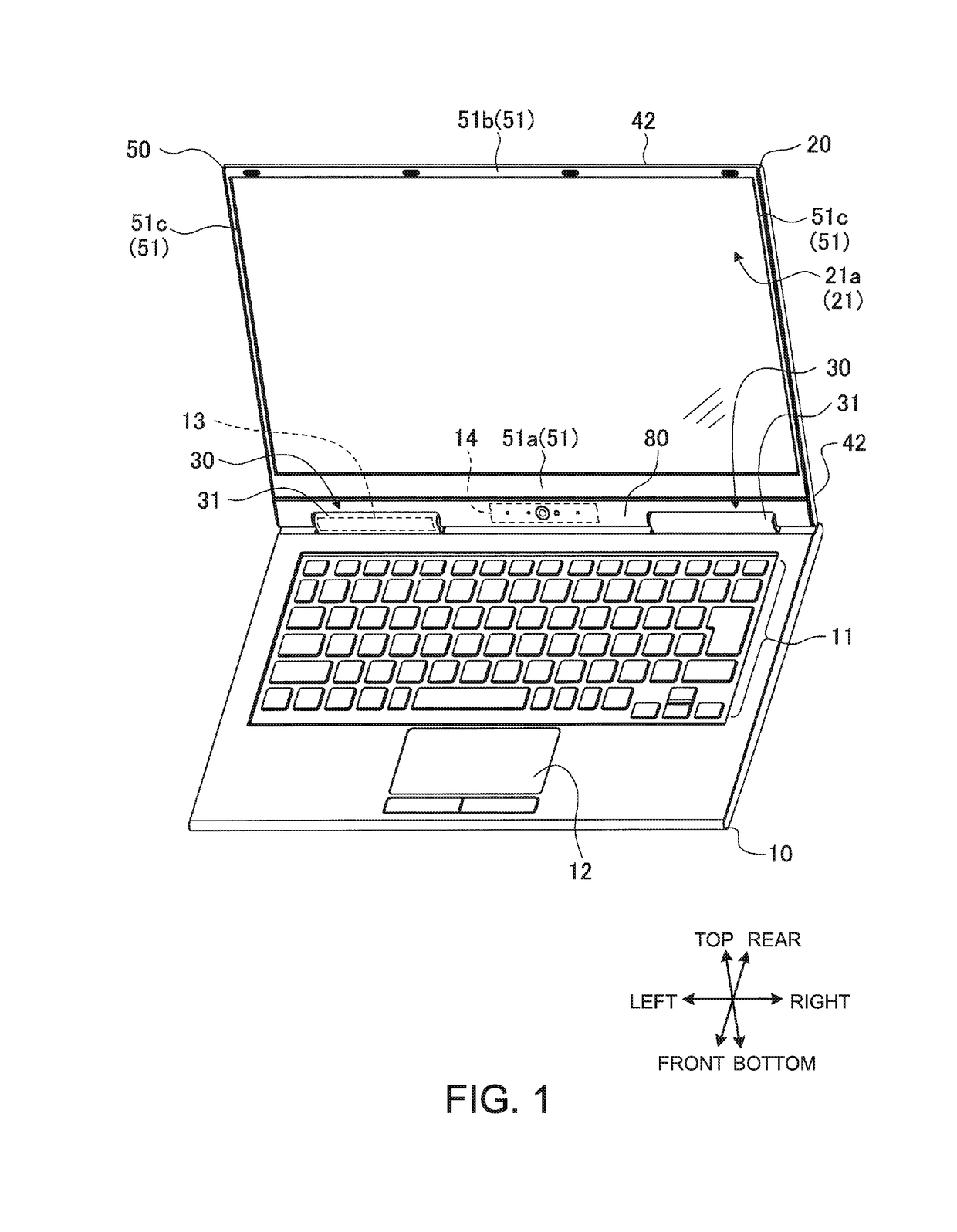

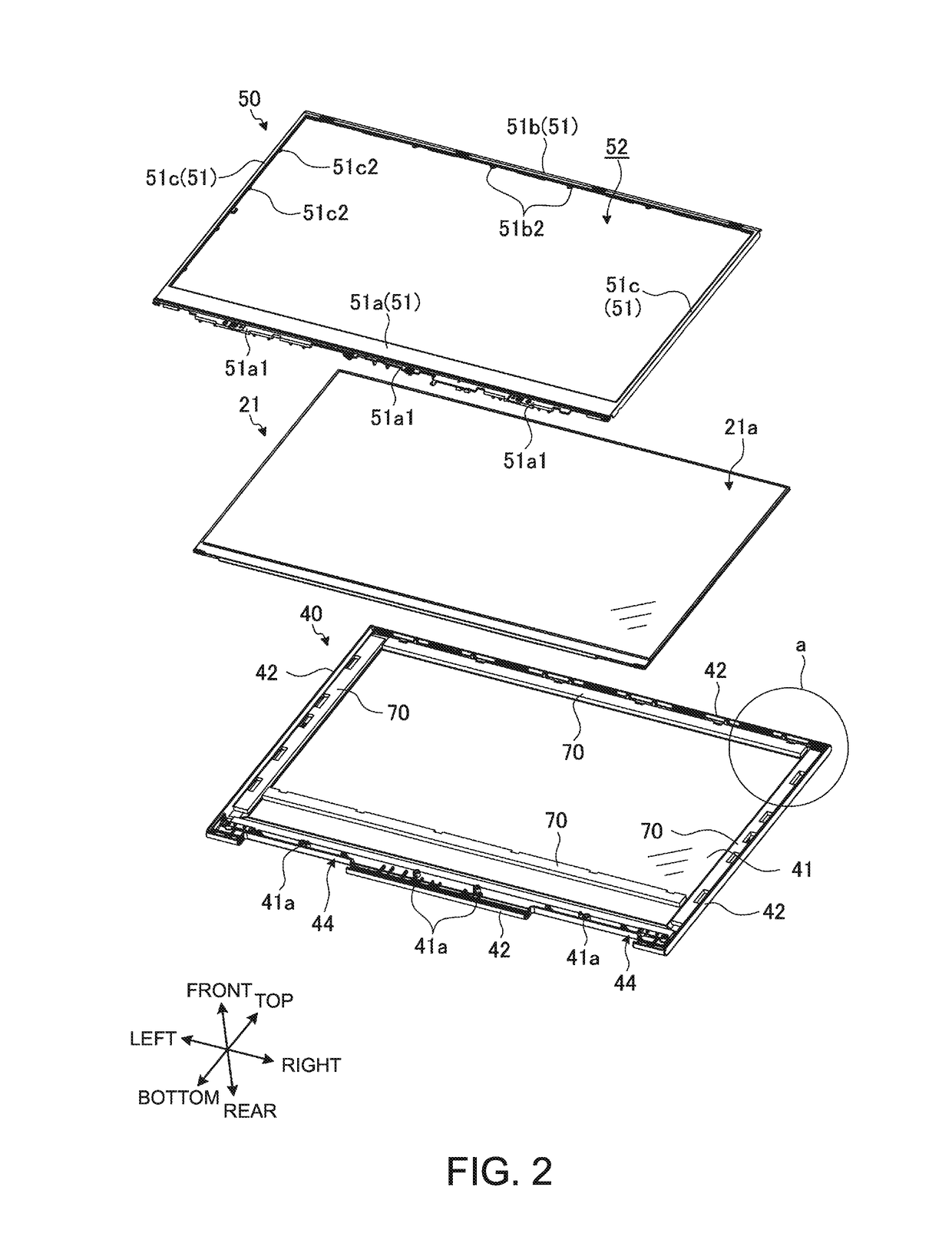

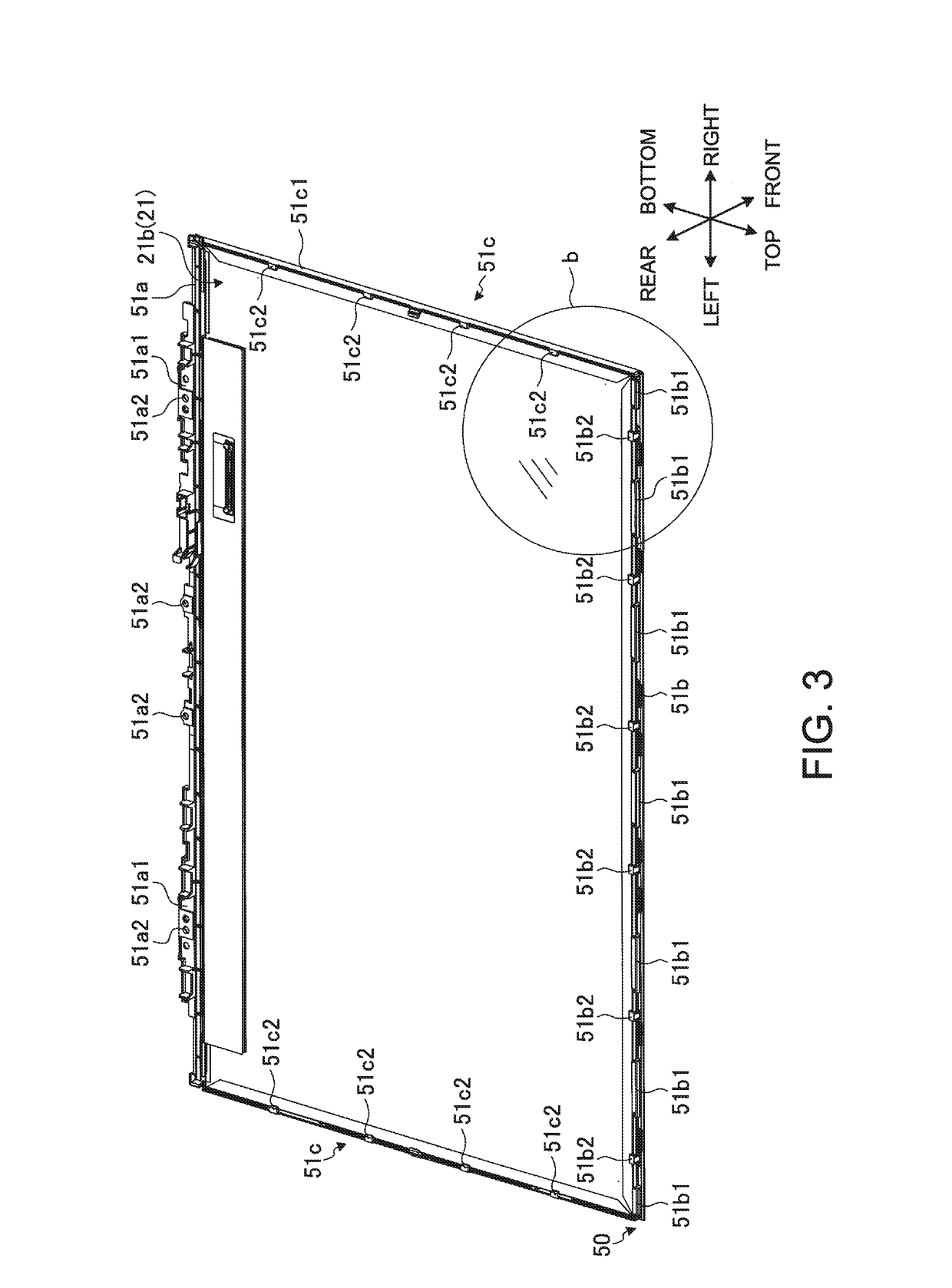

Display device and electronic apparatus

ActiveUS10156866B2Avoid downsizingFacilitate downsizingDetails for portable computersNon-linear opticsDisplay deviceLiquid crystal

In a display device, the display unit chassis is configured by including a peripheral wall section which is disposed to cover the circumference of a liquid crystal panel, and a bezel case section which is disposed between the liquid crystal panel and the peripheral wall section in a state of covering a surface of a peripheral edge of the liquid crystal panel, side-edge sections whose engagement is limited only to the liquid crystal panel are disposed on both of left and right sides of the bezel case section.

Owner:NEC PERSONAL COMPUTERS LTD

Ball spline device

ActiveUS20100098358A1Low costImprove reliabilityYielding couplingLinear bearingsEngineeringMechanical engineering

Provided is a ball spline device, in which an outer diameter of a nut member can be downsized to the maximum while sufficiently performing an original function, and which can keep reliability while being capable of being simply manufactured at lower cost without involving time and effort in assembly, in which a nut member has a track groove which is formed on an inner peripheral surface facing a spline shaft, the balls circulating in the track groove, the track groove comprises: a linear load groove formed so as to face the ball rolling groove of the spline shaft; a linear non-load groove provided parallel to the linear load groove; and a pair of ball deflection grooves for communicably coupling the linear load groove and the linear non-load groove with each other so as to allow the balls to intercommunicate therebetween, and the ball deflection grooves forcibly change an advancing direction of the balls rolling in the ball rolling groove and cause the balls to depart from the ball rolling groove with use of a profile of the spline shaft.

Owner:THK CO LTD

Laser lamp with integral heat radiation function

The invention relates to the technical field of laser lamps, in particular to a laser lamp with an integral heat dissipation function. A laser lamp box and a shell body are integrally designed. The heat radiation effect of the whole laser lamp is achieved through the process of heat transfer between the bottom shell of the laser lamp box and the outside. The possibility of the outside air and water entering the shell body of the lamp box is avoided. Moreover, a heat radiation fin group with an adjustable heat radiation area is added at the bottom of the laser lamp box. Thus, the volume is reduced under the condition of needing less heat radiation while the function of fast heat radiation is achieved.

Owner:西安名都光电科技有限公司

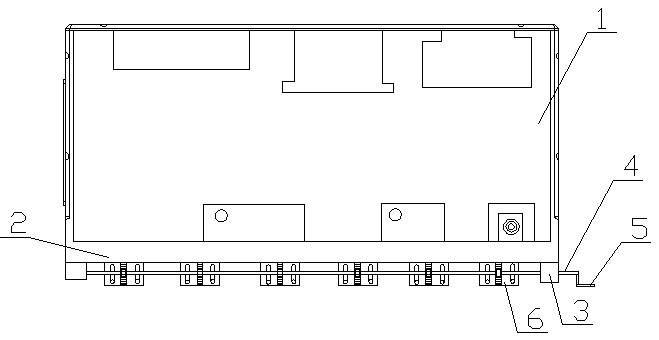

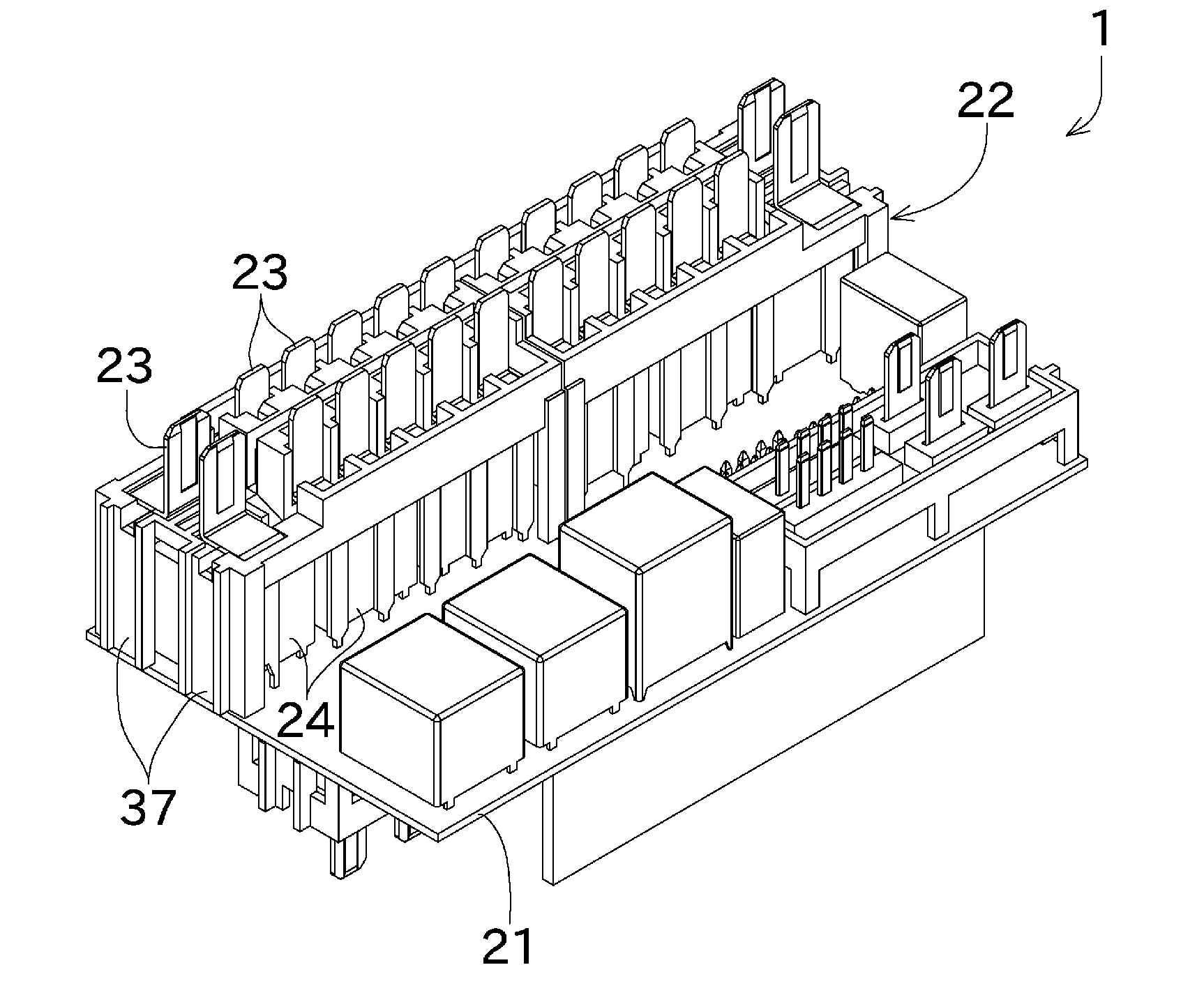

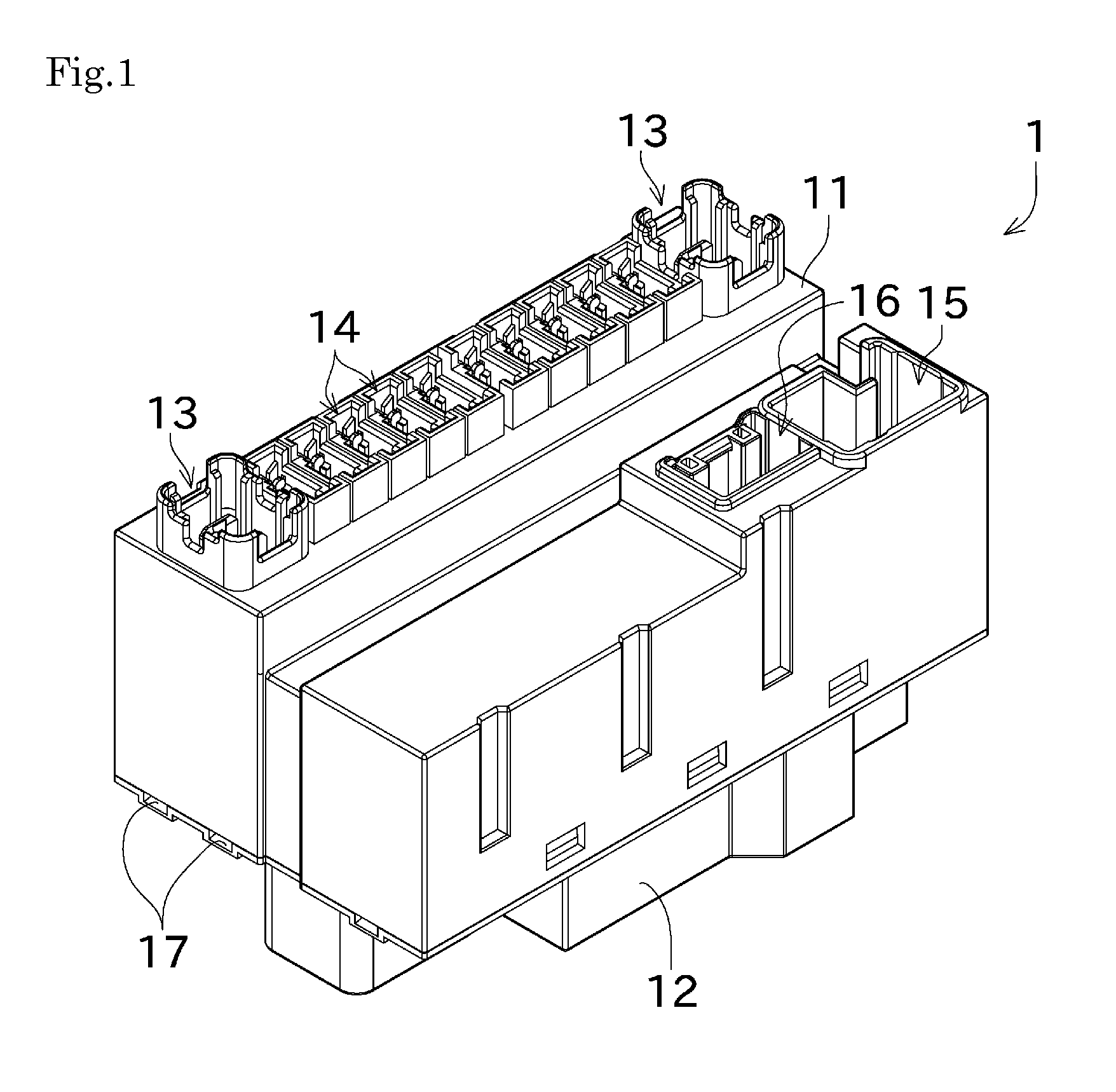

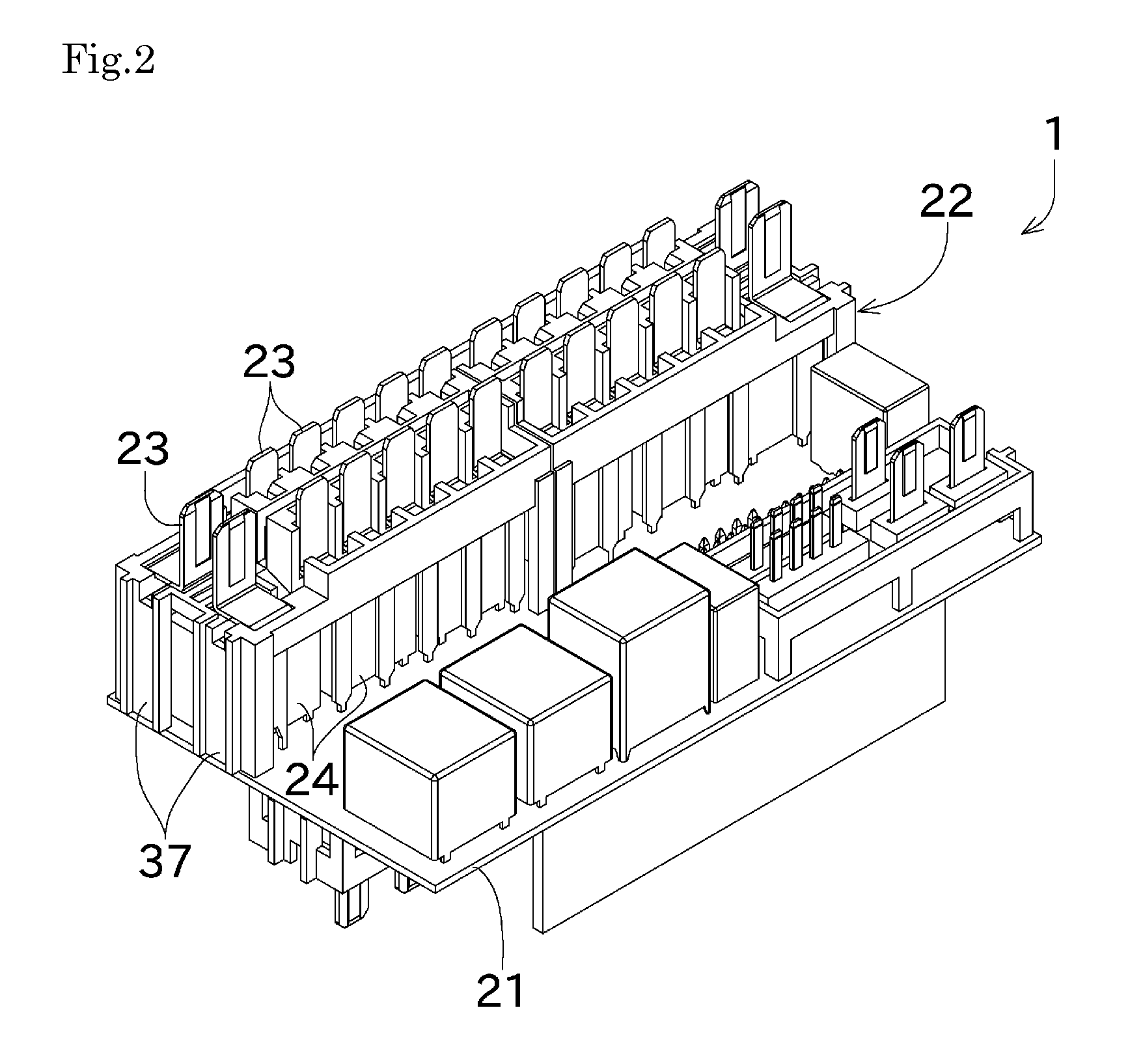

Electrical connection box

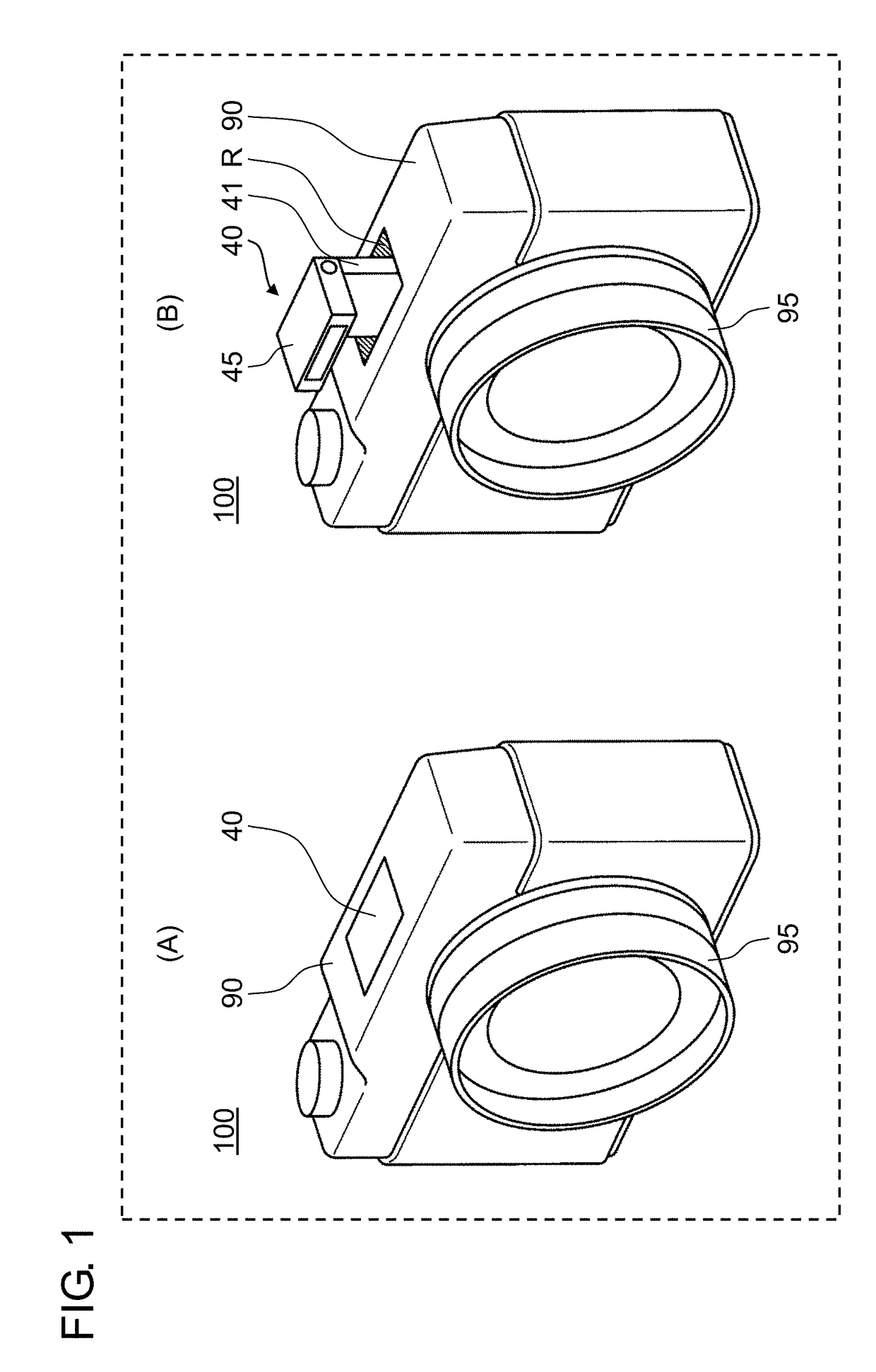

ActiveUS20160073534A1Increase the use of spaceElectrical connectionElectric/fluid circuitMultiple connection subassembliesElectrical connectionElectronic component

Provided is an electrical connection box that achieves downsizing by means of efficient arrangement of electronic components and terminals on a board. An electrical connection box (1) includes a board (21), a terminal holder (22), flat-plate terminals (23), and electronic components (24). The terminal holder (22) is mounted to the board (21). The flat-plate terminal (23) includes a first portion (41), a second portion (42), and a third portion (43). The first portion (41) is connected to the board (21), and extends substantially perpendicularly from the board (21). The second portion (42) is connected to the first portion (41), and extends substantially in parallel with the board (21). The third portion (43) is connected to the second portion (42), is connectable to a connector, and extends substantially perpendicularly to the board (21). The electronic component (24) is arranged between the second portion (42) of the flat-plate terminal (23) and the board (21).

Owner:FURUKAWA ELECTRIC CO LTD +1

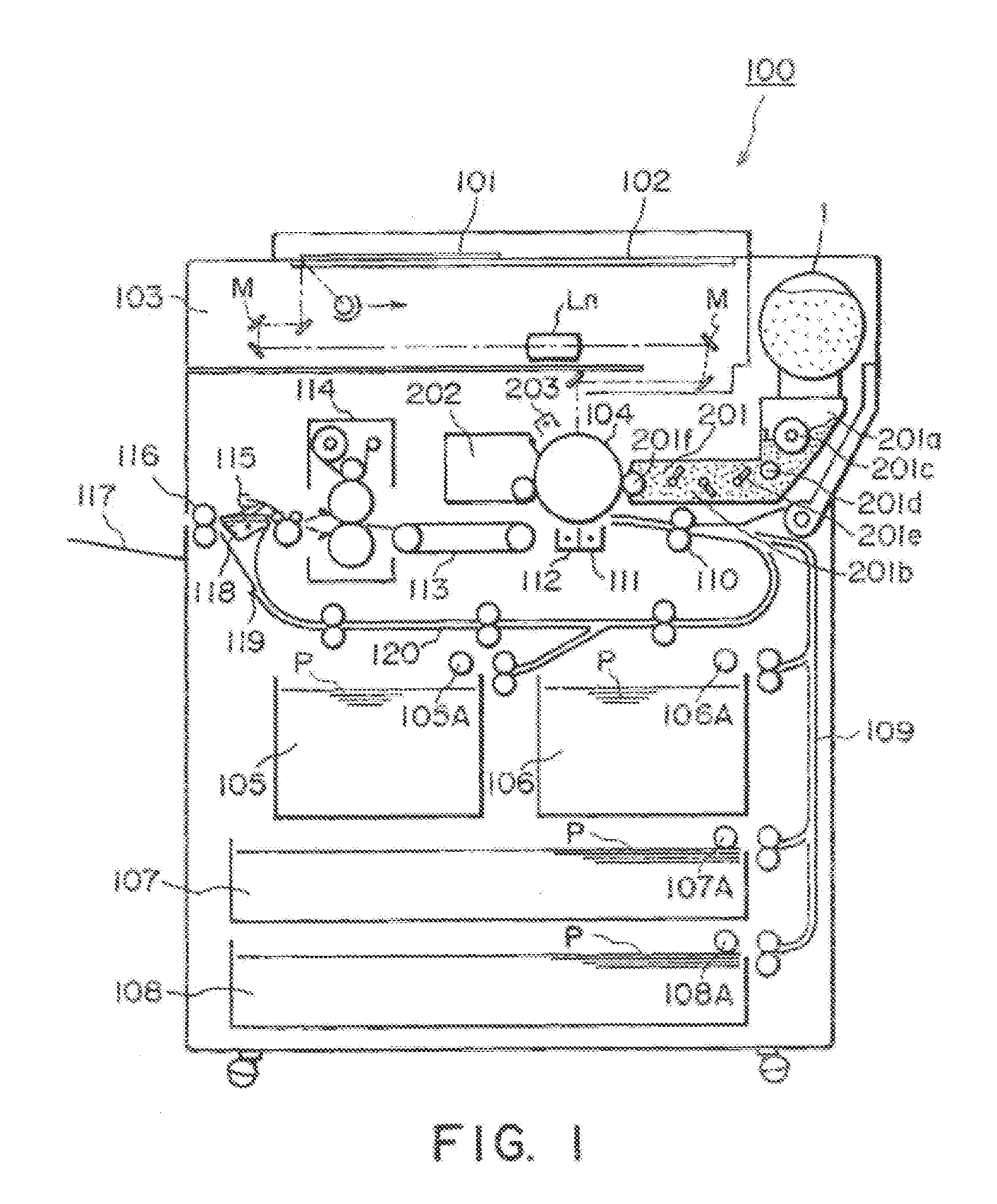

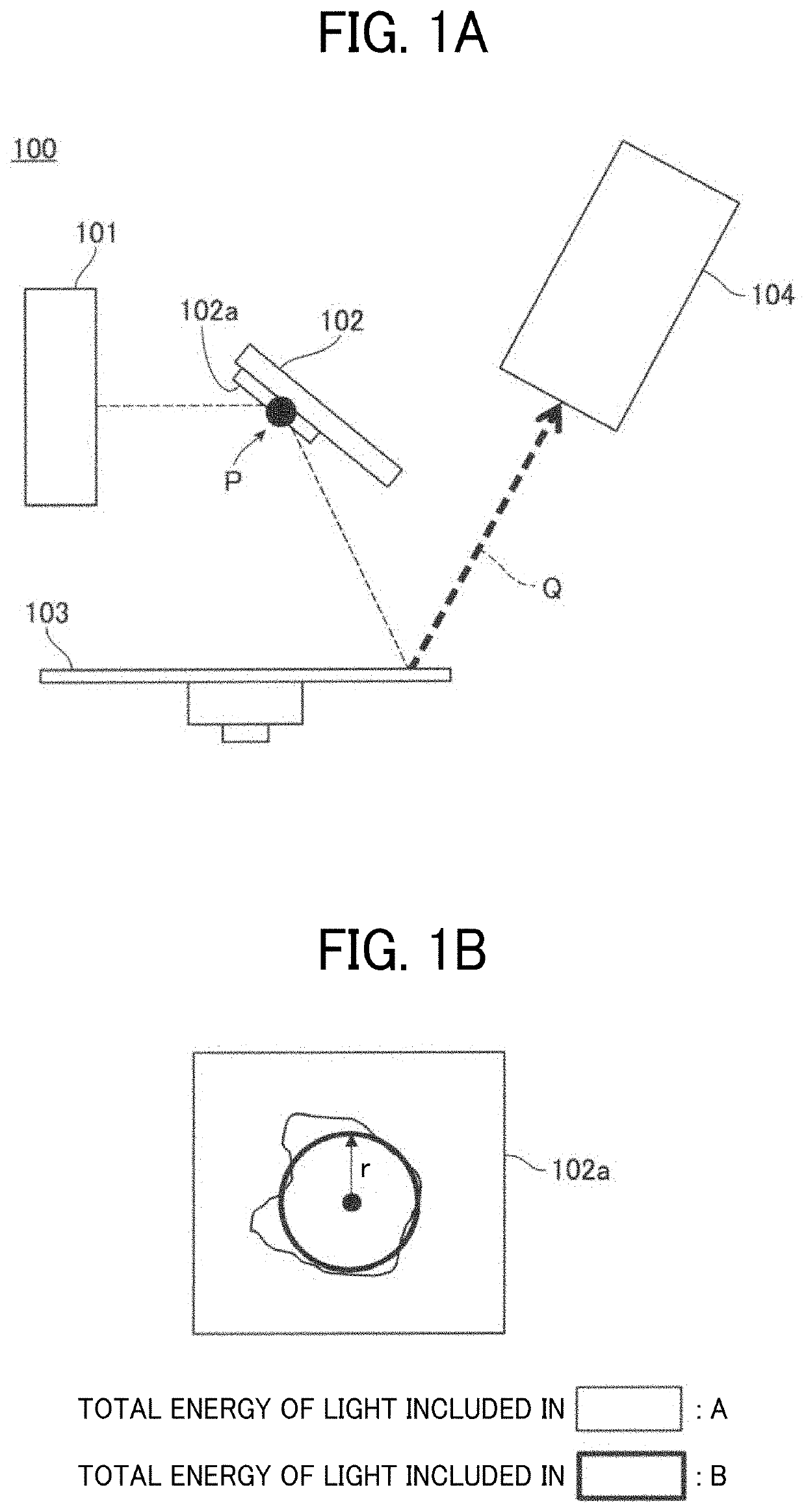

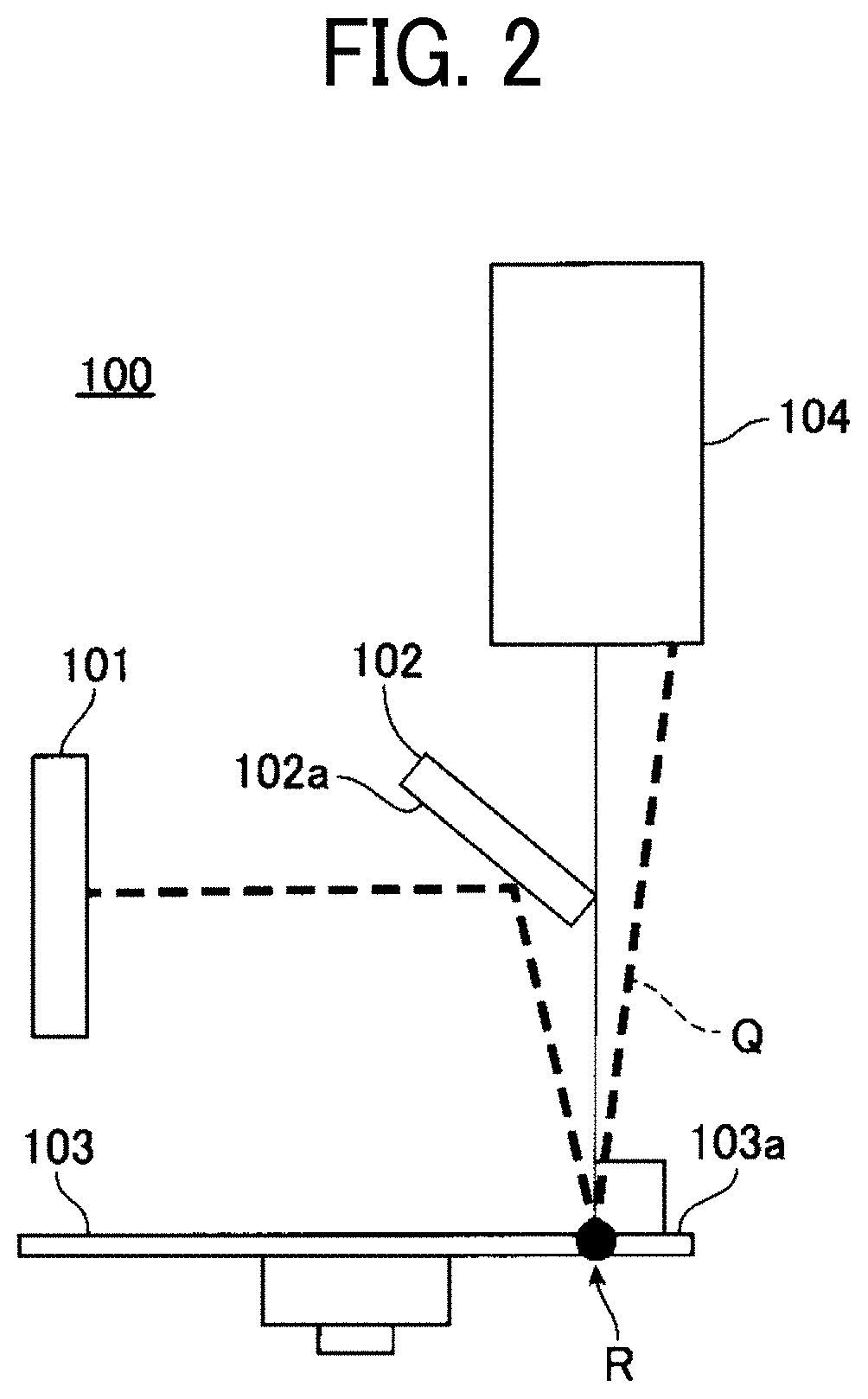

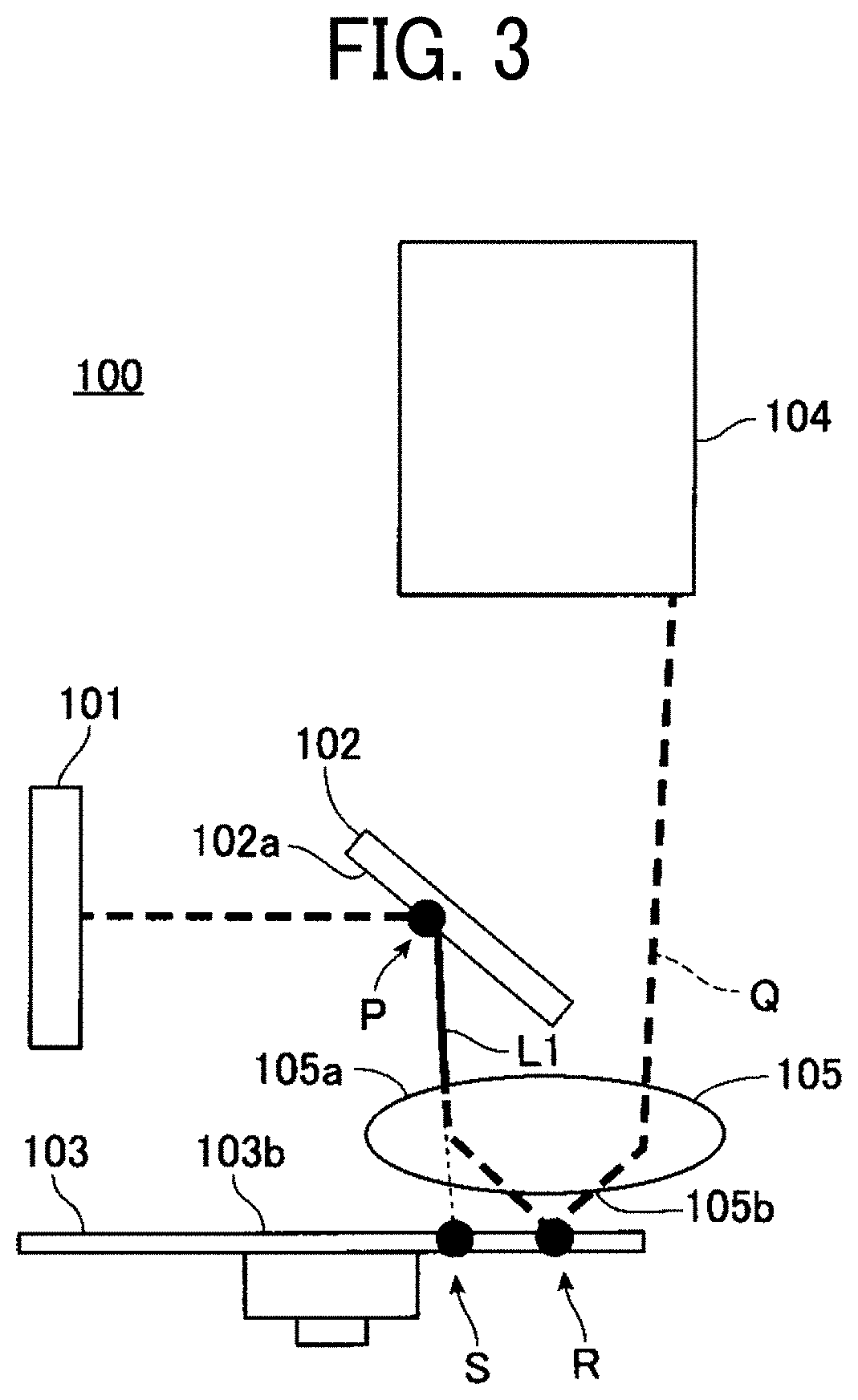

Light-source device and image forming apparatus including same

PendingUS20210136336A1Downsizing of the device bodyLow costProjectorsColor photographyLight fluxLight beam

A light-source device includes an excitation light source, an optical member, and a wavelength converter. The excitation light source is configured to emit first color light. The optical member has a reflecting surface configured to reflect the first color light emitted from the excitation light source. The wavelength converter includes a wavelength conversion member on which the first color light reflected by the optical member is incident. The wavelength conversion member is configured to convert at least part of the first color light into second color light having a wavelength different from a wavelength of the first color light and emit the second color light. A center of the first color light on the reflecting surface of the optical member does not intersect with a light flux of the first color light emitted from the wavelength converter.

Owner:RICOH KK

Automatic transmission

InactiveUS8771130B2Increase the number ofAvoid downsizingToothed gearingsTransmission elementsAutomatic transmissionGear wheel

Owner:AISIN AW CO LTD

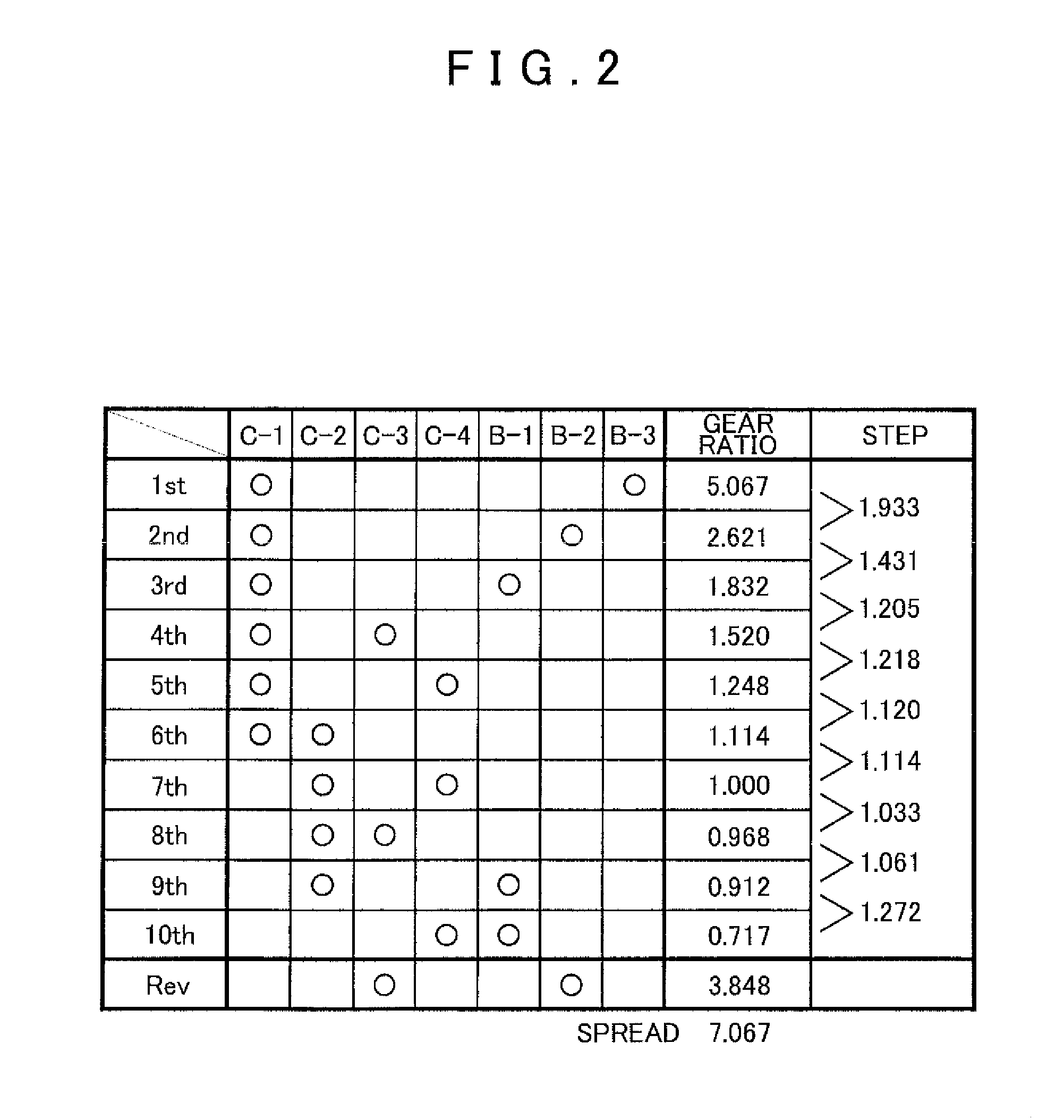

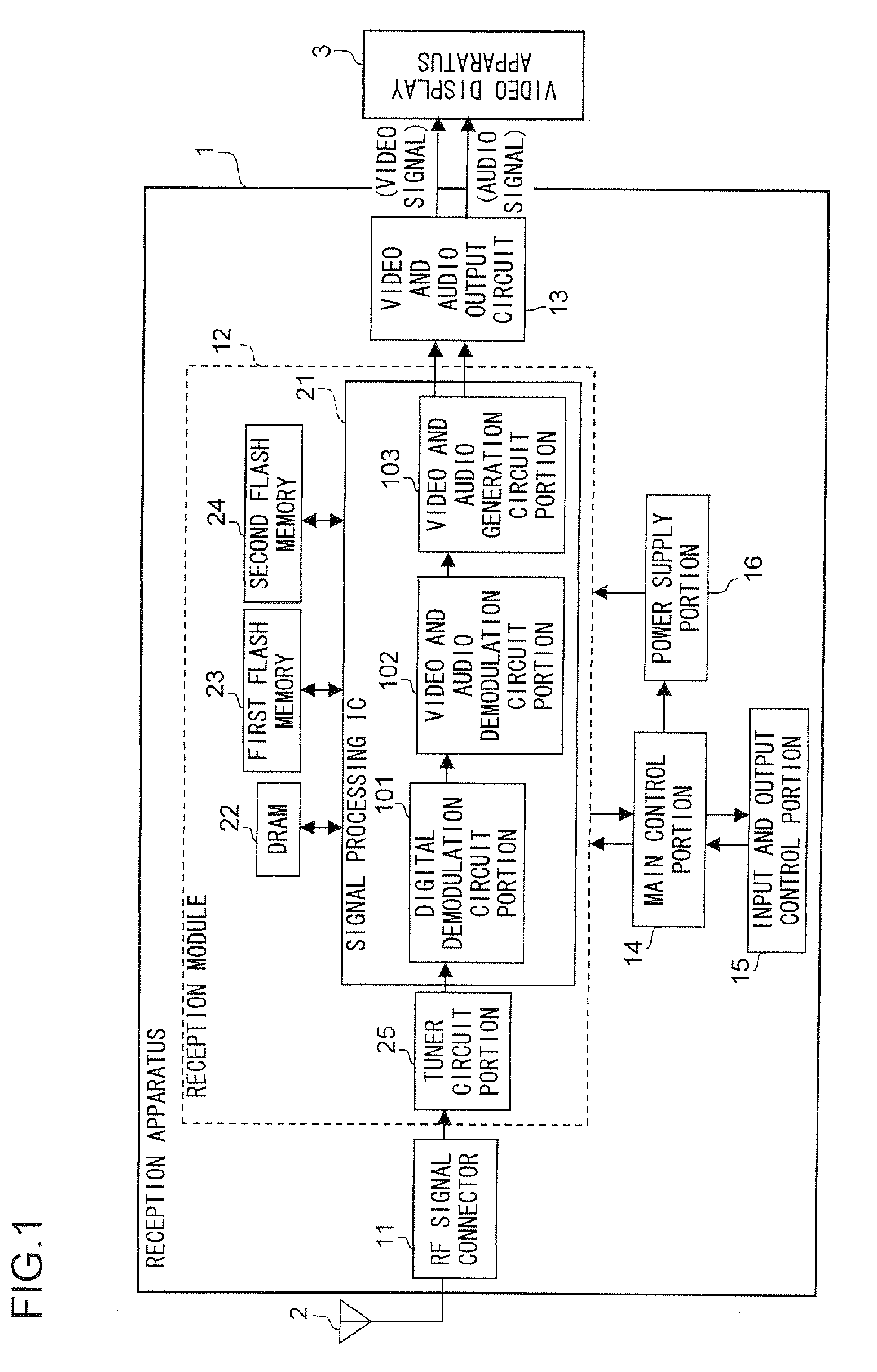

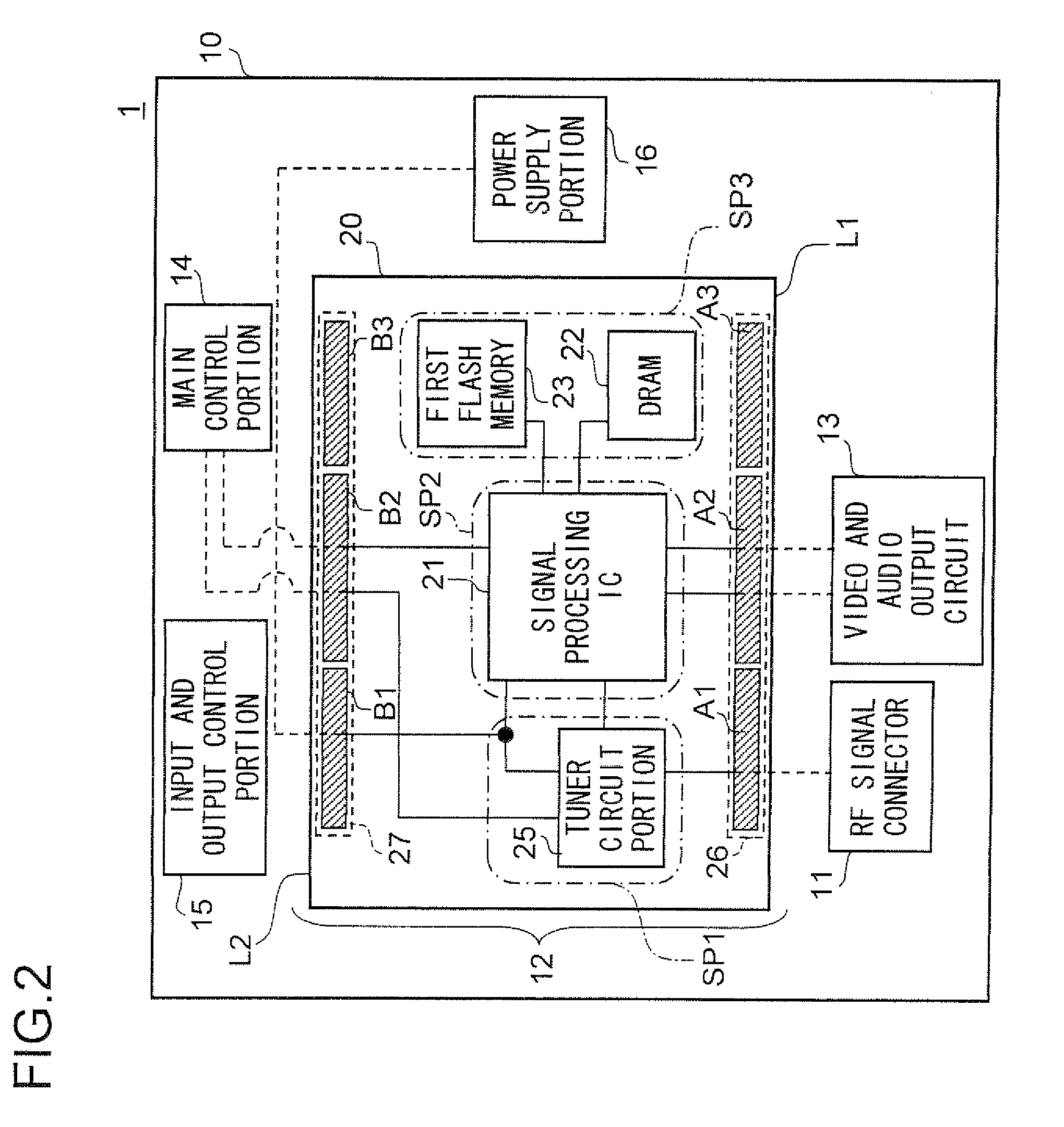

Reception module and reception apparatus including the same

InactiveUS20100203856A1Reduce the impact of noiseAvoid downsizingBroadcast receiving circuitsTransmissionMiniaturizationEngineering

A reception module includes a tuner for performing a tuning process on a received broadcasting signal, a signal processing device for performing a predetermined process on the broadcasting signal after the tuning process, a first memory which is used as a working region for the signal processing device, and a second memory which stores a program for operating the signal processing device, in which the individual elements are disposed on the same component side of a circuit board, and the tuner is disposed in a first space on the component side, the signal processing device is disposed in a second space that is located substantially in the middle on the component side, the first memory and the second memory are disposed in a third space on the component side, and the first space and the third space are located on the opposite sides with respect to the second space. The reception module is capable of suppressing influence of noise generated by the memory to operations of the tuner as much as possible with a main component group and without preventing downsizing as much as possible.

Owner:SHARP KK

Flexible printed circuit and imaging apparatus including same

ActiveUS10973128B2Avoid downsizingIncreasing the thicknessTelevision system detailsCasings/cabinets/drawers detailsHermetic sealConductive materials

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Coil component

ActiveUS20170221624A1Reduce connection strengthAvoid downsizingTransformers/inductances coils/windings/connectionsFixed signal inductancesMetalExternal connection

A coil component includes an insulating layer in which a magnetic core is embedded, coil electrodes wound around the magnetic core, external connection pad electrodes that are provided on the upper surface of the insulating layer and are connected to the coil electrodes. Each of the coil electrodes includes a plurality of inner metal pins standing in the insulating layer, a plurality of outer metal pins standing in the insulating layer, a plurality of upper wiring patterns formed on the upper surface of the insulating layer, and a plurality of lower wiring pattern formed on the undersurface of the insulating layer. Each of the pad electrodes is directly connected to the upper end surface of the inner metal pin or the outer metal pin, and has, in plan view, an area larger than that of the single upper wiring pattern or the single lower wiring pattern.

Owner:MURATA MFG CO LTD

Image pickup device and endoscope

An image pickup device includes: an image pickup element; a spacer surrounding a light receiving surface of the image pickup element; a cover glass attached to the spacer, the cover glass being disposed opposing to the light receiving surface; and an insulative resin configured to thermally couple the image pickup element with the cover glass, and to have a thermal conductivity of not less than 8 W / mK. An endoscope includes: the image pickup device; an image pickup optical system; a drive circuit; a light guide configured to radiate light from a illumination light source; a tubular body configured to accommodate the image pickup device, the image pickup optical system, the drive circuit, the light guide, and a forceps opening; and a first insulative resin having a thermal conductivity of not less than 8 W / mK, and adapted to thermally couple the image pickup device with the drive circuit.

Owner:FUJIFILM CORP

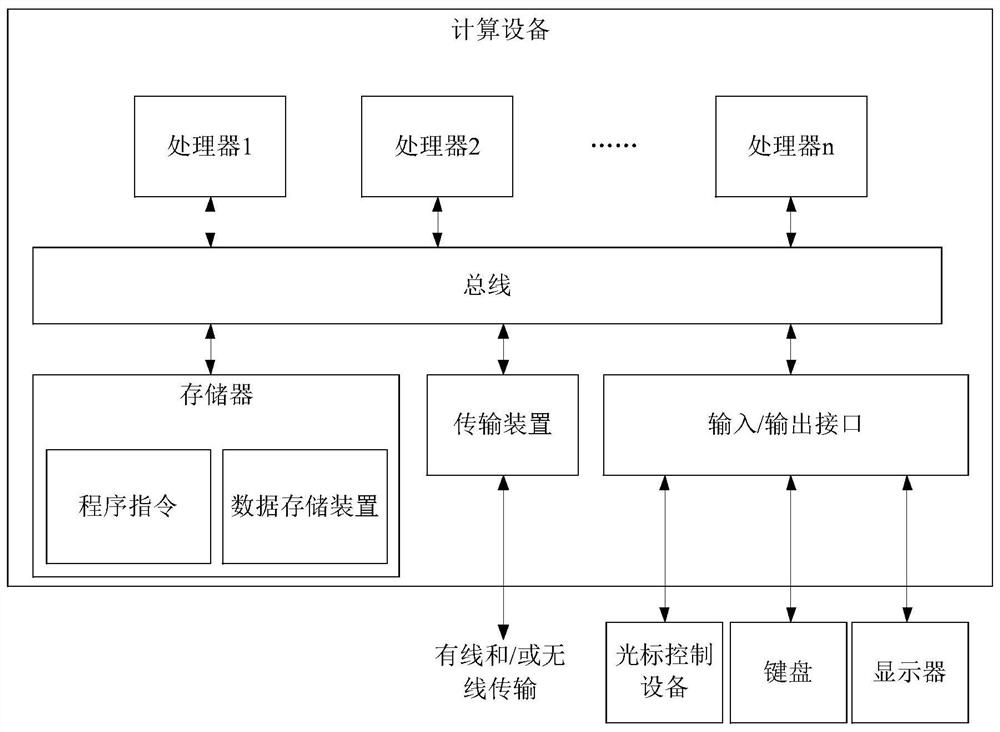

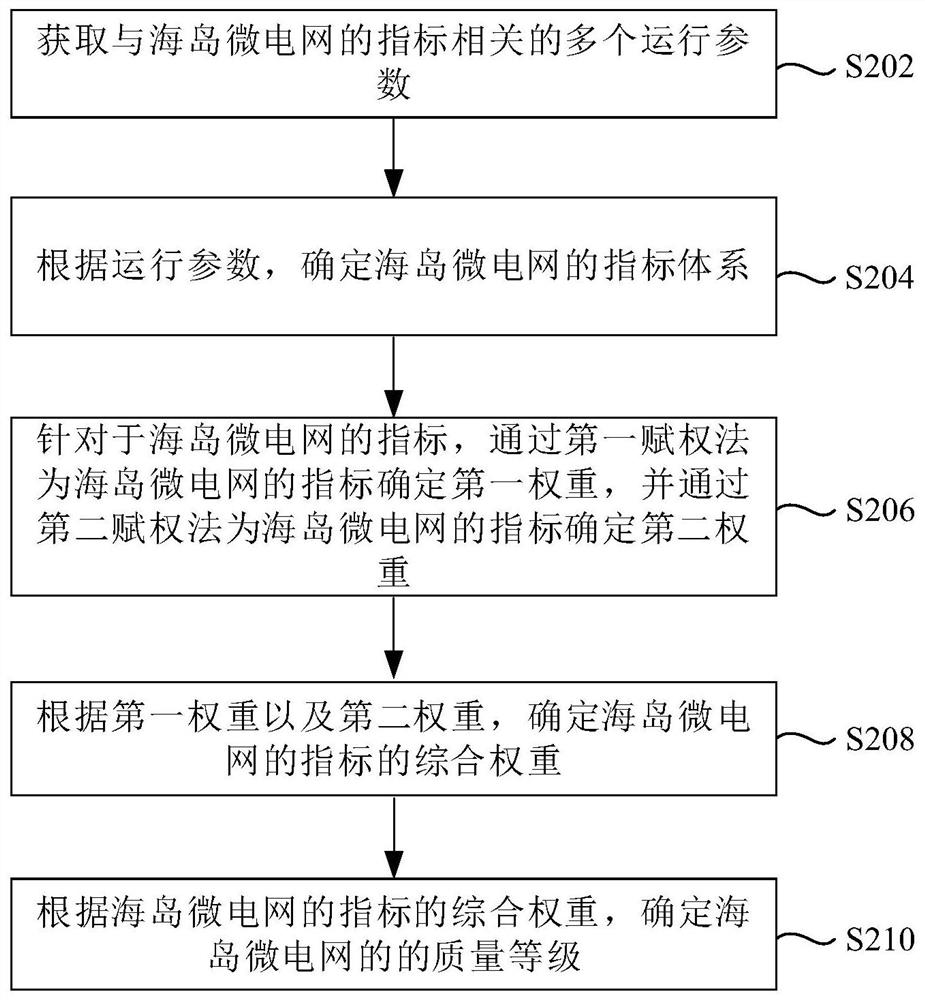

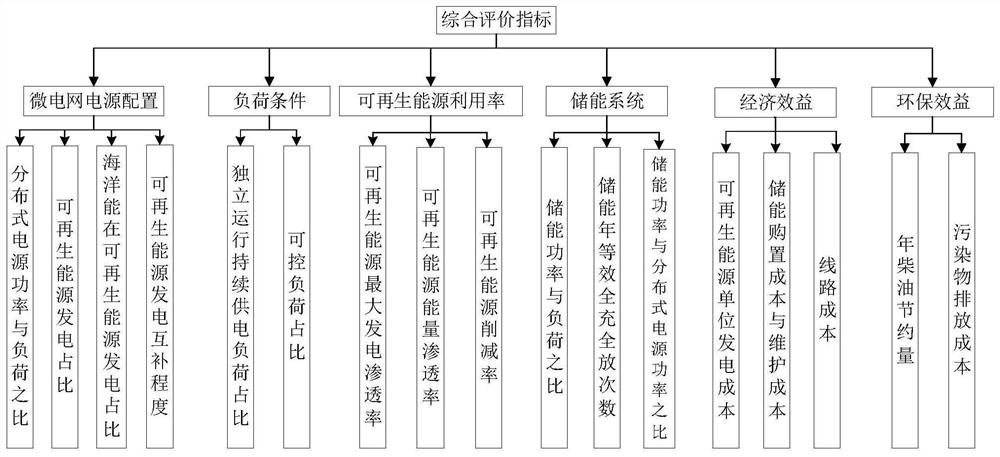

A method and device for determining quality level for index of island microgrid

PendingCN112348309AWell structured and comprehensiveAvoid excessive magnification of the importance of indicatorsResourcesComplex mathematical operationsQuality levelMicrogrid

The invention discloses a method and a device for determining a quality level for an index of an island microgrid. The method comprises the following steps: acquiring a plurality of operating parameters related to indexes of the island microgrid; determining an index system of the island microgrid according to the operation parameters; for the indexes of the island microgrid, determining a first weight for the indexes of the island microgrid through a first weighting method, and determining a second weight for the indexes of the island microgrid through a second weighting method; determining acomprehensive weight of an index system of the island microgrid according to the first weight and the second weight; and determining the quality level of the island microgrid according to the comprehensive weight of the indexes of the island microgrid.

Owner:STATE GRID SHANGHAI ENERGY INTERCONNECTION RES INST CO LTD +3

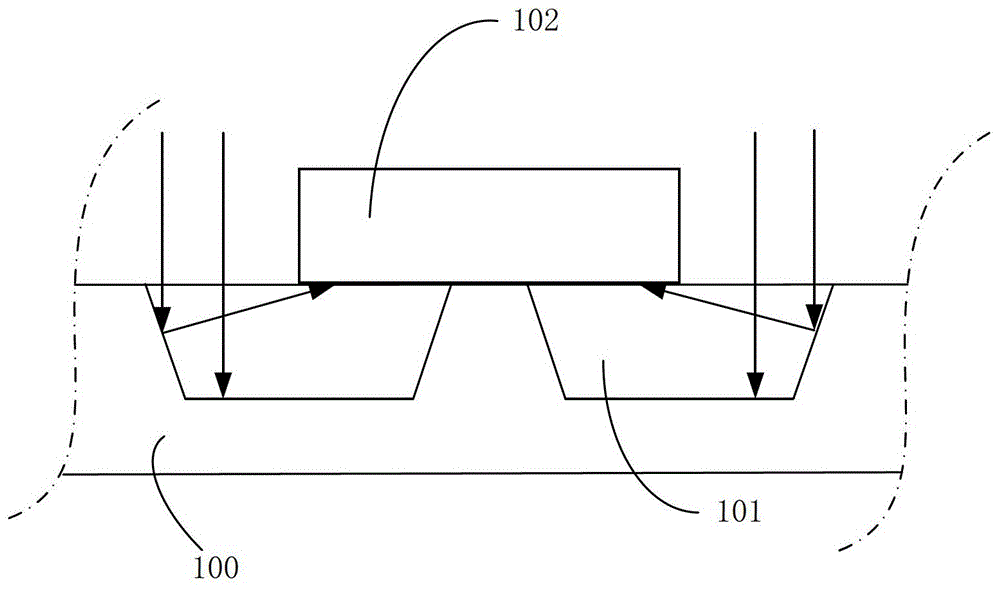

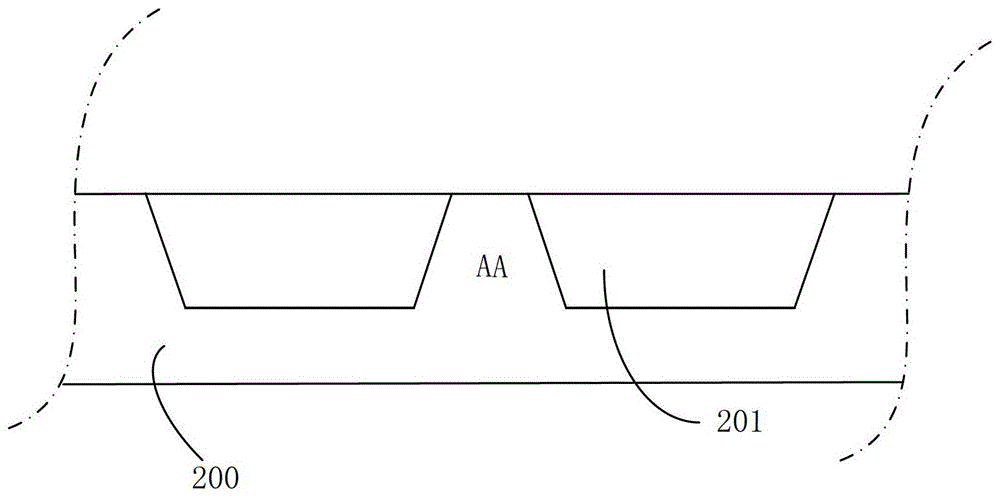

A method of manufacturing a semiconductor device

ActiveCN103811294BImprove performanceAvoid downsizingSemiconductor/solid-state device manufacturingPower semiconductor devicePhotoresist

The invention provides a manufacturing method of a semiconductor device, and relates to the semiconductor technical field; the method comprises the following steps: S101, providing a semiconductor substrate; S102, forming an antireflective layer in a boundary between a zone wherein ion injection is to be carried out and a zone wherein an ion implantation shielding layer is to be formed on the semiconductor substrate; S103, employing photoresist to form the ion implantation shielding layer on the semiconductor substrate. The manufacturing method of the semiconductor device adds the step in which the antireflective layer is formed in a boundary between the zone wherein ion injection is to be carried out and the zone wherein the ion implantation shielding layer is to be formed; in a process to expose a photoresist film so as to form the ion implantation shielding layer, the reflection light from the semiconductor substrate can be prevented or stopped from entering the photoresist film, so the reflection light cannot cause size reduction of the ion implantation shielding layer, thereby ensuring key size of the ion implantation shielding layer, and improving performance of the semiconductor device.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com