Laser lamp with integral heat radiation function

A laser lamp, integrated technology, applied in the field of laser lamps, can solve the problems of waste of material resources, bulky, increased light attenuation, etc., to achieve the effect of increasing rapid heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

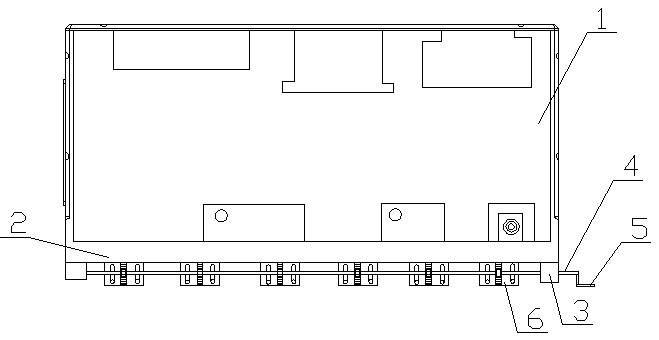

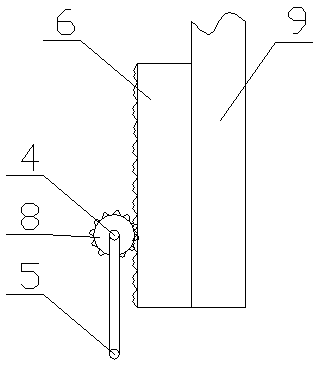

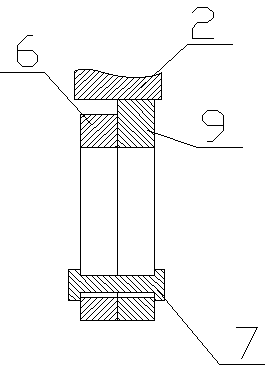

[0028] Embodiment: In the use of the present invention, usually in a relatively good and cold environment, the light box 1 and the base 2 are integrally designed or produced, so the heat dissipation inside the light box can be directly transferred out through the heat conduction of the base 2, and the base 2. The cooling assembly at the lower end and the fixing piece 9 dissipate the heat. At this time, the space volume occupied by the overall laser light box can be relatively small. Turn the handle 5, the handle 5 will drive the connecting rod 4 to rotate, and the rotation of the connecting rod 4 will drive the pinion 8 on the connecting rod 4 to rotate, and the pinion 8 will drive the heat sink 6 meshed with it to the relative fixed plate 9 When the cooling fin 6 moves up and down relative to the fixed fin 9, the area of the heat dissipation assembly will increase, because the contact area between the cooling fin 6 and the fixed fin 9 will gradually leak out, so the heat dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com