Pad holder for brake pad holder and brake pad holder

A technology of brake linings and retaining devices, applied to brakes with brake parts, brakes with pressed braking surfaces, parts of brakes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

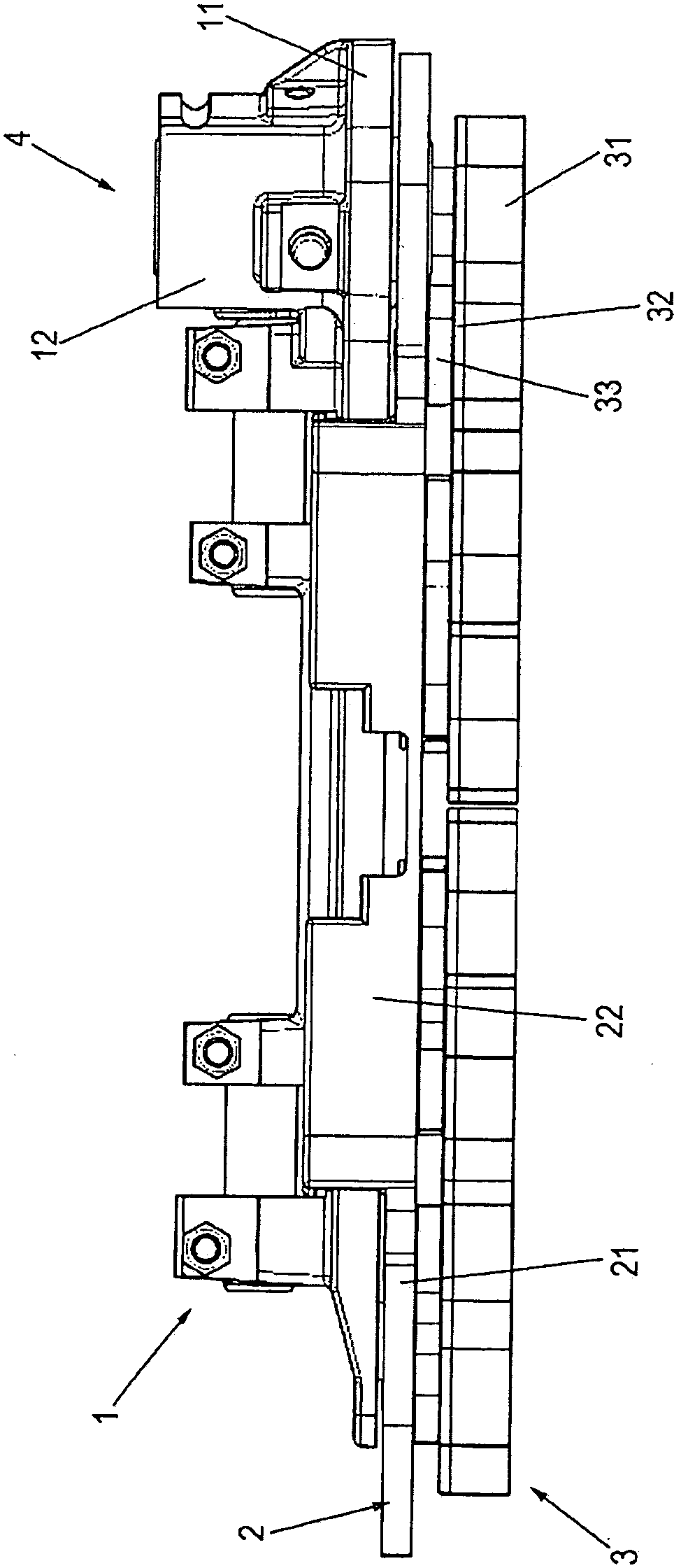

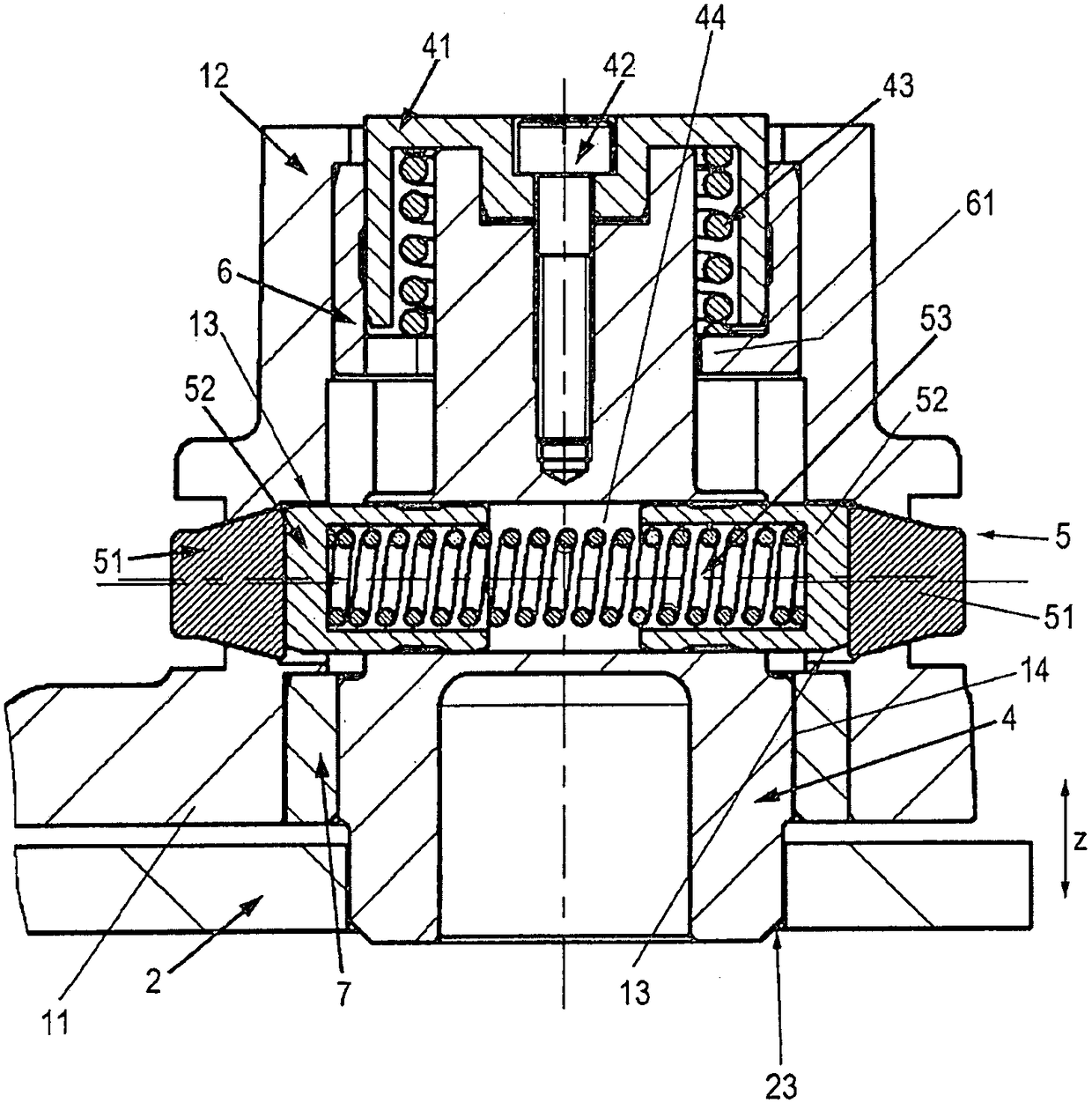

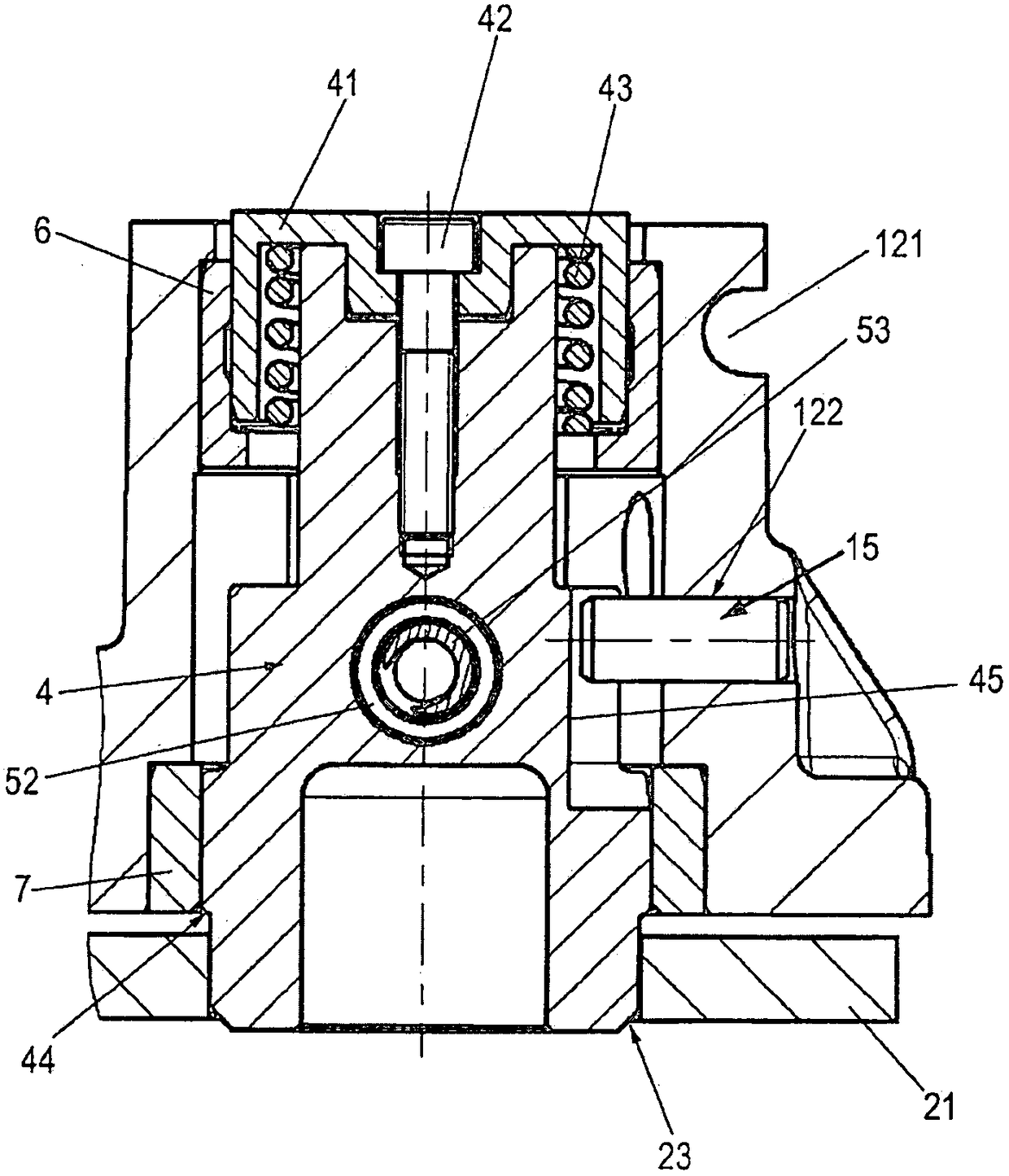

[0049] exist figure 1 A first embodiment of a brake lining retaining device according to the invention is shown in FIG. 2 , which comprises a lining retainer 1 and a lining carrier 2 fastened thereto.

[0050] The lining holder 1 here has a plate-shaped base 11 . Arranged on the base 11 is a receptacle 12 in which the locking element 4 , which is preferably formed as a pin, is guided along the movement direction z at an angle to the plane of the base 11 . In this case, the locking element 4 is preferably guided perpendicular to the plane of the base 11 in the receptacle 12 . However, an angular position of the locking element 4 relative to the plane of the base 11 that differs from the vertical is also conceivable, in particular in an angular range of approximately 60° to 120°.

[0051] The lining carrier 2 has a lining carrier plate 21 on which at least one friction lining 31 , preferably a plurality of friction linings 31 is held.

[0052] exist figure 1 In the embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com