Anti-explosion water-cooling supercharger

A supercharger, water-cooled technology, used in machines/engines, engine components, internal combustion piston engines, etc., can solve the problems of unadjustable supercharging pressure, low supercharger efficiency, insufficient supercharging pressure, etc., and achieve supercharging pressure. Adjustable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

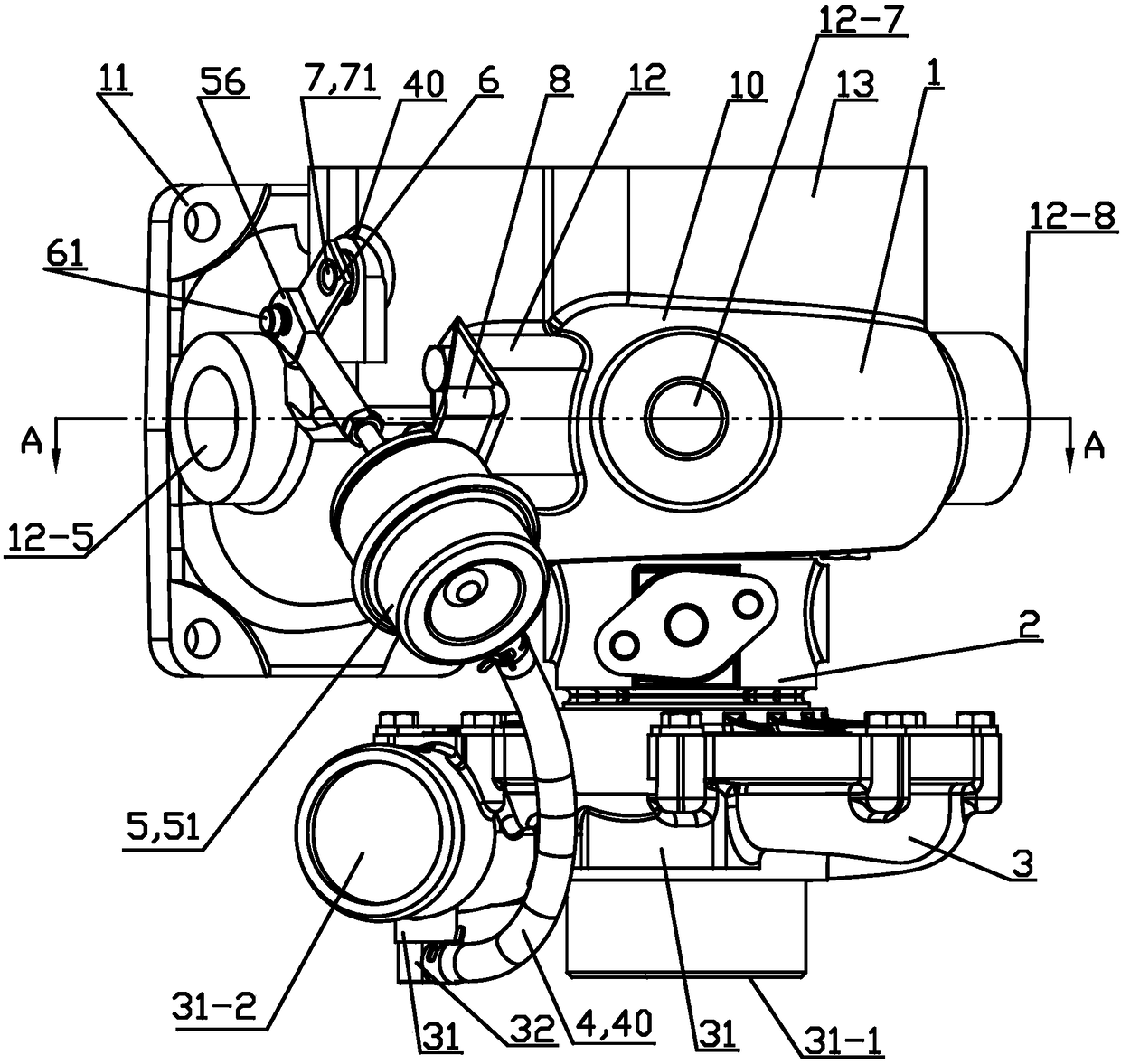

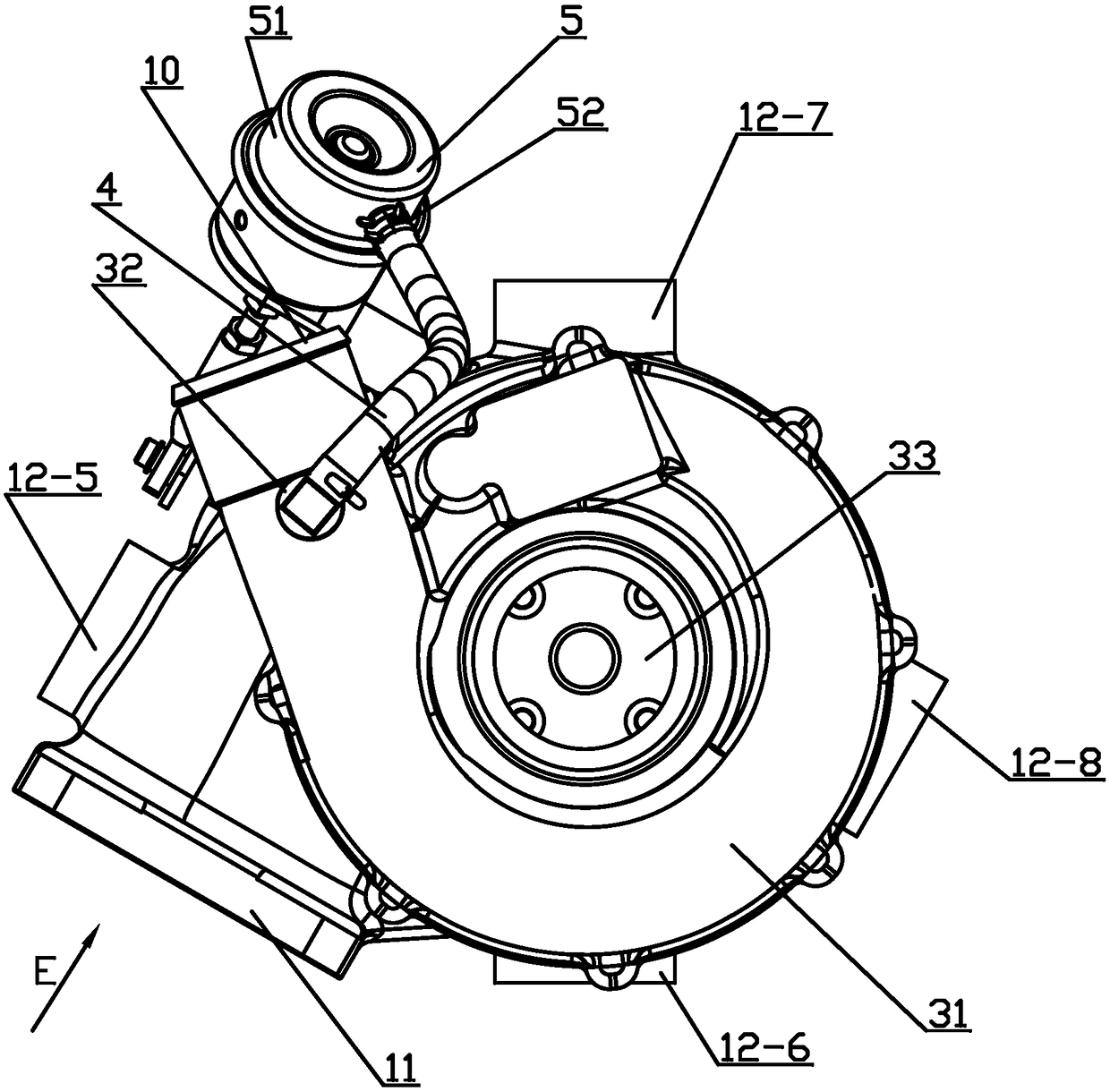

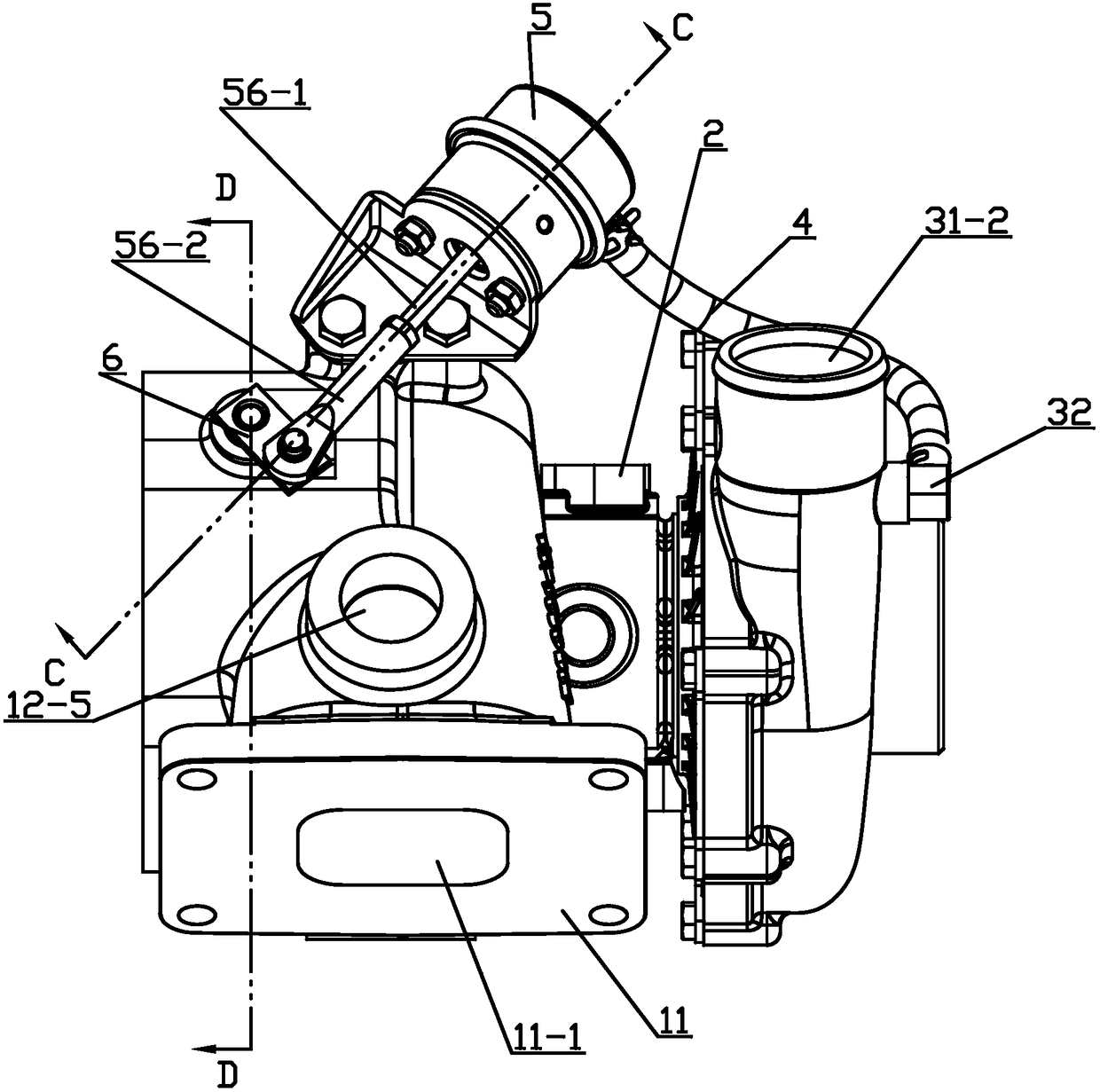

[0034] See figure 1 , Figure 5 with Figure 10 , the explosion-proof water-cooled supercharger of this embodiment includes a turbine 1 , an intermediate body 2 , a compressor 3 and a wastegate mechanism 40 . The turbine 1, the intermediate body 2 and the compressor 3 are fixedly connected in sequence from front to back. The wastegate mechanism 40 is connected between the compressor 3 and the turbine 1 . The wastegate mechanism 40 includes a silicone tube 4 , a diaphragm valve 5 , a rocker arm 6 , a wastegate valve 7 and a diaphragm valve bracket 8 . The intermediate body 2 is an integral piece made of steel, and is provided with an internal cavity communicating with the front and back, and is provided with a front connection port 22 and a rear connection port 21 .

[0035] See Figure 10 with Figure 5 , the turbomachine 1 has a volute 10 and a turbine 15, the volute 10 and the turbine 15 are all made of steel as one piece. A turbine 15 is rotatably connected in the vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com