Nattokinase-containing micro-emulsion and preparation method thereof

A technology of nattokinase and microemulsion is applied in the directions of food ingredients as emulsifier, food forming, function of food ingredients, etc., can solve the problems such as easy inactivation of nattokinase, achieve simple and feasible preparation process, low cost, High bioavailability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The present invention will be further described below in conjunction with specific embodiments and attached tables, but the following content should not be interpreted as limiting the scope of protection of the invention to any extent.

[0025] A kind of microemulsion containing nattokinase of embodiment 1, the mass percent composition of described microemulsion is as follows:

[0026] Nattokinase freeze-dried powder

2g (800FU / g)

Isopropyl myristate

8g

Apple Polyphenol Caprylate

10g

Absolute ethanol

5g

Deionized water

78g

[0027] Its preparation process is:

[0028] S1. Add the freeze-dried nattokinase powder into water and stir to dissolve it, then add absolute ethanol and mix to form a water phase;

[0029] S2. Mix and stir apple polyphenol caprylate and isopropyl myristate at 40° C. to form an oil phase;

[0030] S3. Slowly add the oil phase into the water phase, and stir while adding, until a uniform emuls...

Embodiment 2

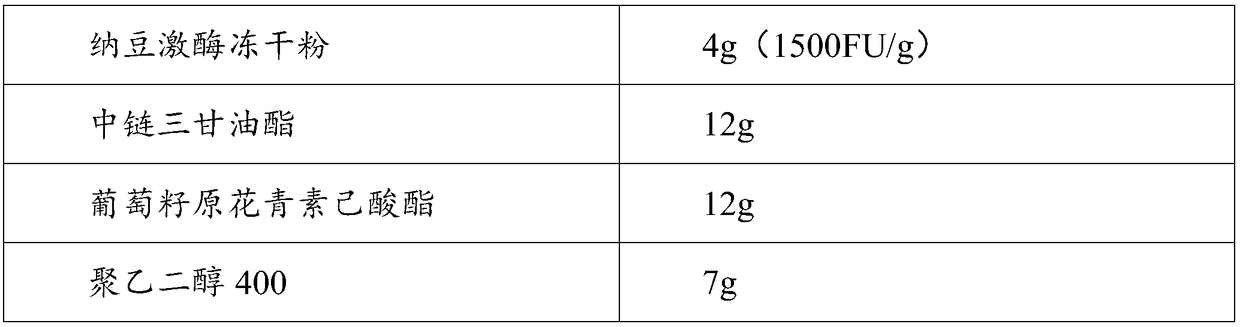

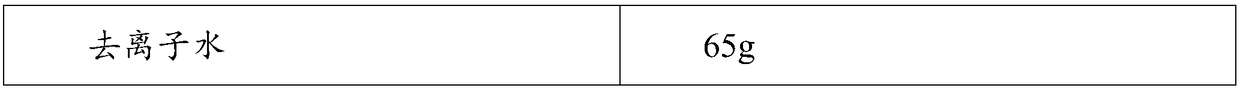

[0031] A kind of microemulsion containing nattokinase of embodiment 2, the mass percent composition of described microemulsion is as follows:

[0032]

[0033]

[0034] Its preparation process is:

[0035] S1. Add the freeze-dried nattokinase powder into water and stir to dissolve it, then add polyethylene glycol 400 and mix to form an aqueous phase;

[0036] S2, mixing medium chain triglycerides and grape seed proanthocyanidin hexanoate at 50°C to form an oil phase;

[0037] S3. Slowly add the oil phase into the water phase, and stir while adding, until a uniform emulsion is formed, filter through a 0.2 μm microporous membrane, sterilize, and separate to obtain a nattokinase microemulsion.

Embodiment 3

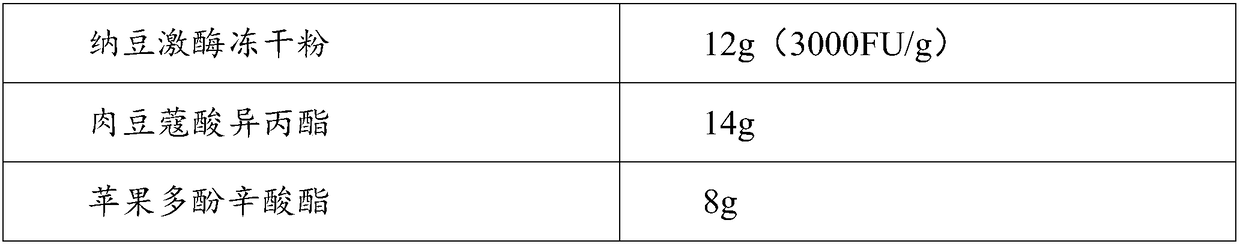

[0038] A kind of microemulsion containing nattokinase of embodiment 3, the mass percent composition of described microemulsion is as follows:

[0039] Nattokinase freeze-dried powder

8g (2000FU / g)

6g

10g

Apple Polyphenol Caprylate

15g

glycerin

6g

Deionized water

55g

[0040] Its preparation process is:

[0041] S1. Add the freeze-dried nattokinase powder into water and stir to dissolve it, then add glycerin and mix to form an aqueous phase;

[0042] S2, mixing and stirring olive oil, corn oil, and apple polyphenol caprylate at 45° C. to form an oil phase;

[0043] S3. Slowly add the oil phase into the water phase, and stir while adding, until a uniform emulsion is formed, filter through a 0.2 μm microporous membrane, sterilize, and separate to obtain a nattokinase microemulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com