Ninth belt protecting device of heavy belt conveyer

A protection device, belt conveyor technology, applied in conveyor control device, cleaning device, packaging and other directions, can solve the problems of belt tearing, unable to prevent, unable to ensure the normal operation of conveyor and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

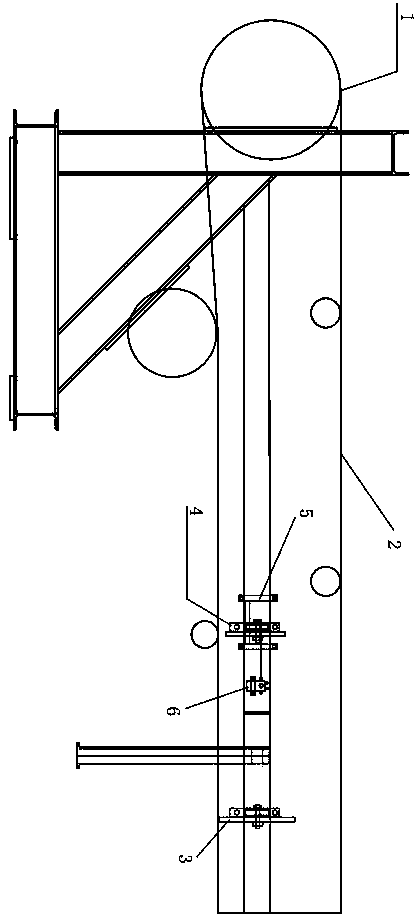

[0013] Such as figure 1 As shown, the ninth belt protection device of the strong belt conveyor of the present invention includes a tail drum 1 and a belt 2, and also includes a first cleaner 3, a second cleaner 4, an angle iron 5 and a pull wire emergency stop switch 6 , the first cleaning device 3 is fixed, close to the belt 2, and the second cleaning device 4 is fixed with a rotating shaft, and the other end is bound with the pull wire emergency stop switch 6 and placed in a 20cm On the angle iron 5 of the stroke, there is a gap of 2-5cm between the second cleaner 4 and the belt 2, and the first cleaner 3 is processed by 80 angle iron, and the belt processing length is 1 meter according to the width of the belt 2 1.2 meters, and use 80*8 iron plates to clamp the belt with a height of 0.2 meters and a length of 1.2 meters, and install it on the belt 2 with clips at an angle of 45 degrees. The second cleaner 4 is processed with 40 angle irons According to the width of the bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com