Barrel-type electromagnetic speed regulation system

An electromagnetic speed regulation and cylinder type technology, which is applied in the direction of control system, electrical components, control electromechanical brake, etc., can solve the problems of increased design difficulty, limited speed regulation range, small size of magnet, etc., to reduce demagnetization phenomenon and reduce circuit magnetism Resistance, improve the effect of transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

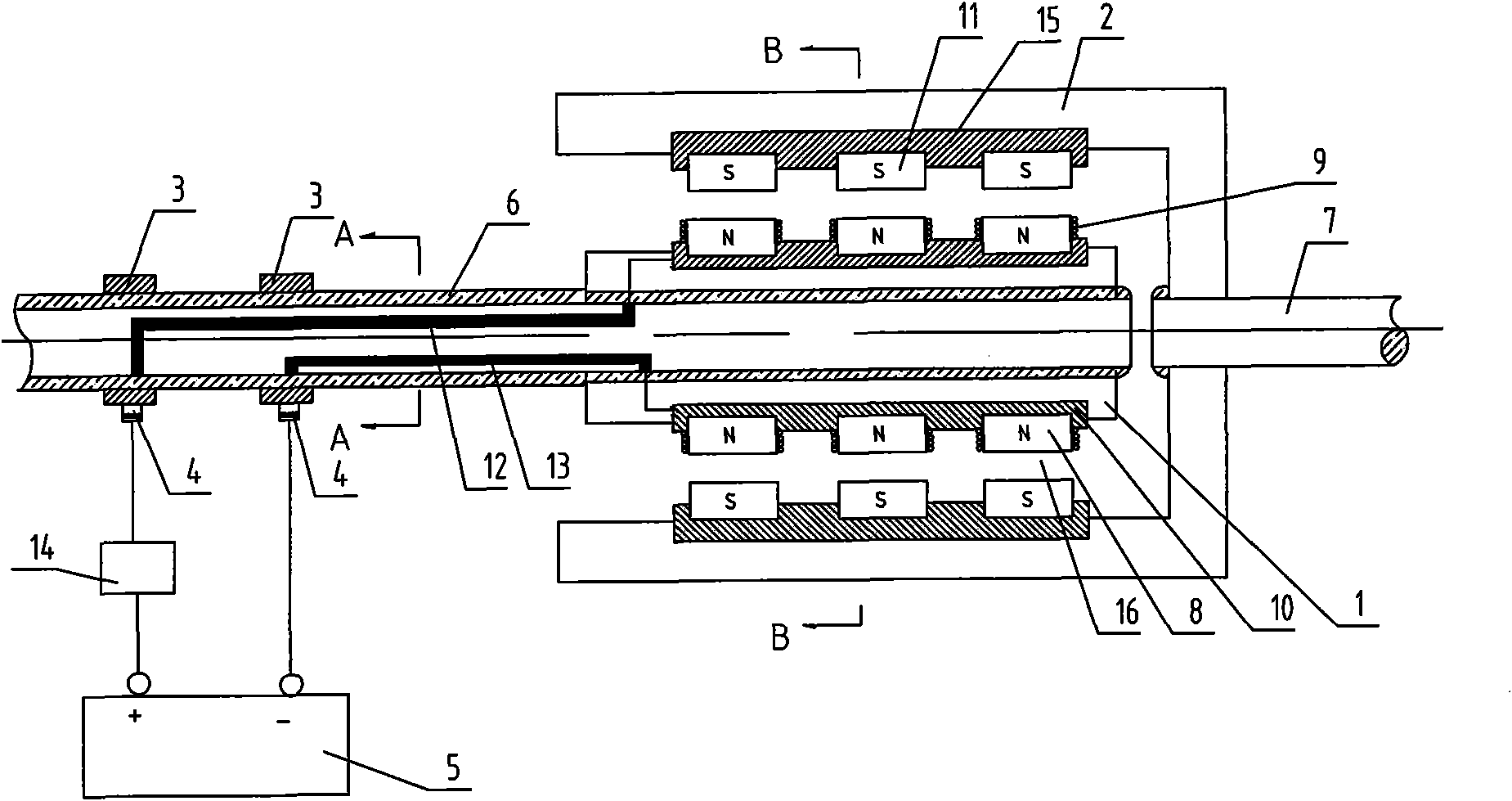

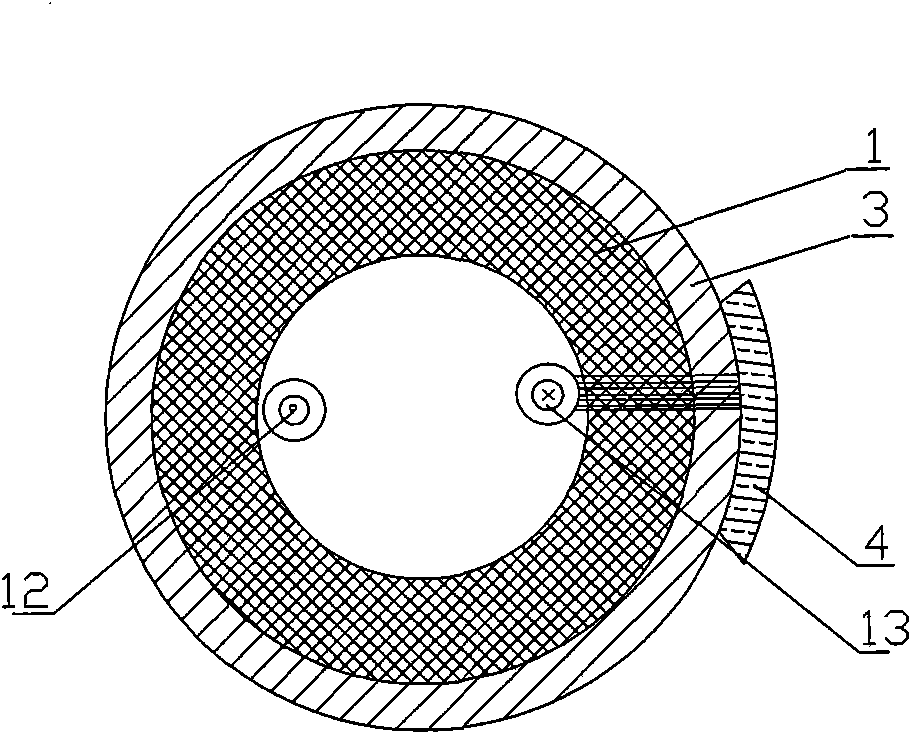

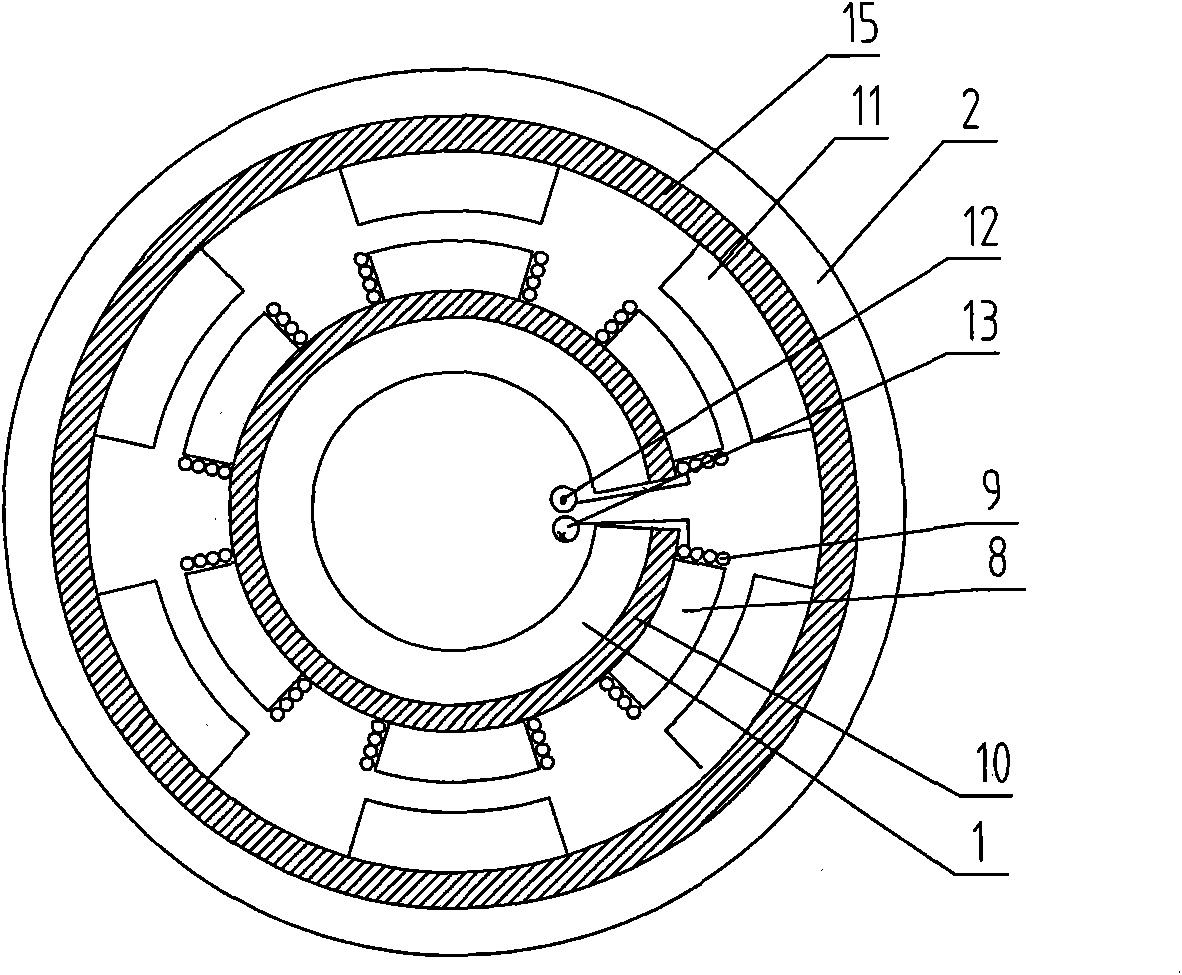

[0016] See figure 1 , figure 2 , a cylindrical electromagnetic speed control system, including an inner drum rotor 1, an outer drum rotor 2, a conductive slip ring 3, a brush 4, a DC power supply 5, the inner drum rotor 1 is arranged at the end of the input shaft 6, and the input shaft 6 is hollow Structure, the outer cylinder rotor 2 is arranged at the end of the output shaft 7, the inner cylinder rotor 1 is coaxially nested with the outer cylinder rotor 2, the inner cylinder rotor 1 is provided with a soft magnet 8, the soft magnet 8 is provided with a coil 9, There is also an iron lining 10 between the magnet 8 and the inner cylinder rotor 1, and a permanent magnet 11 is provided on the outer cylinder rotor 2 at the position corresponding to the soft magnet 8. There is a certain air gap 16 between the soft magnet 8 and the permanent mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com