Patents

Literature

379results about How to "Realize stepless speed regulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

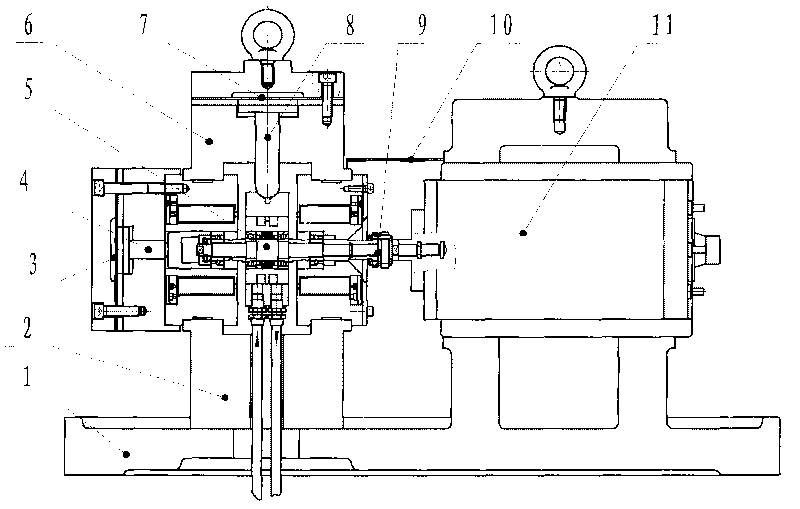

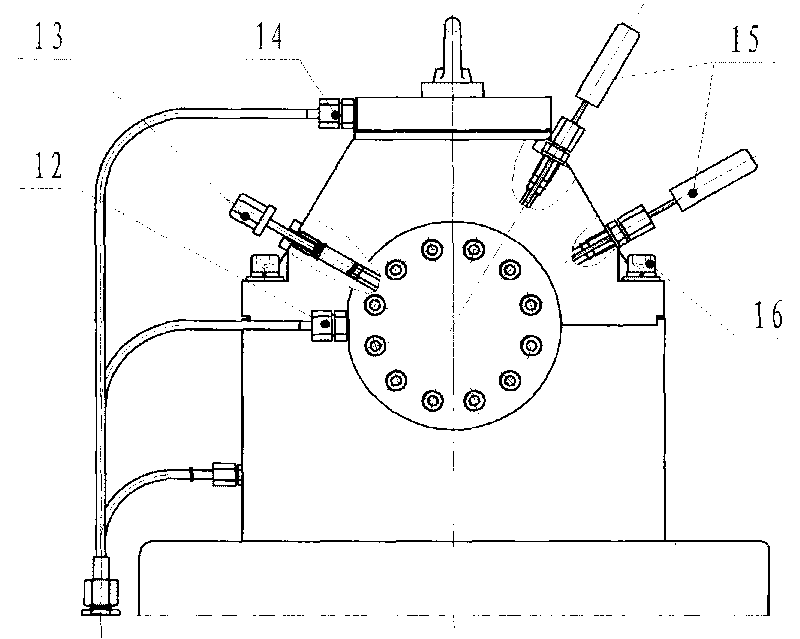

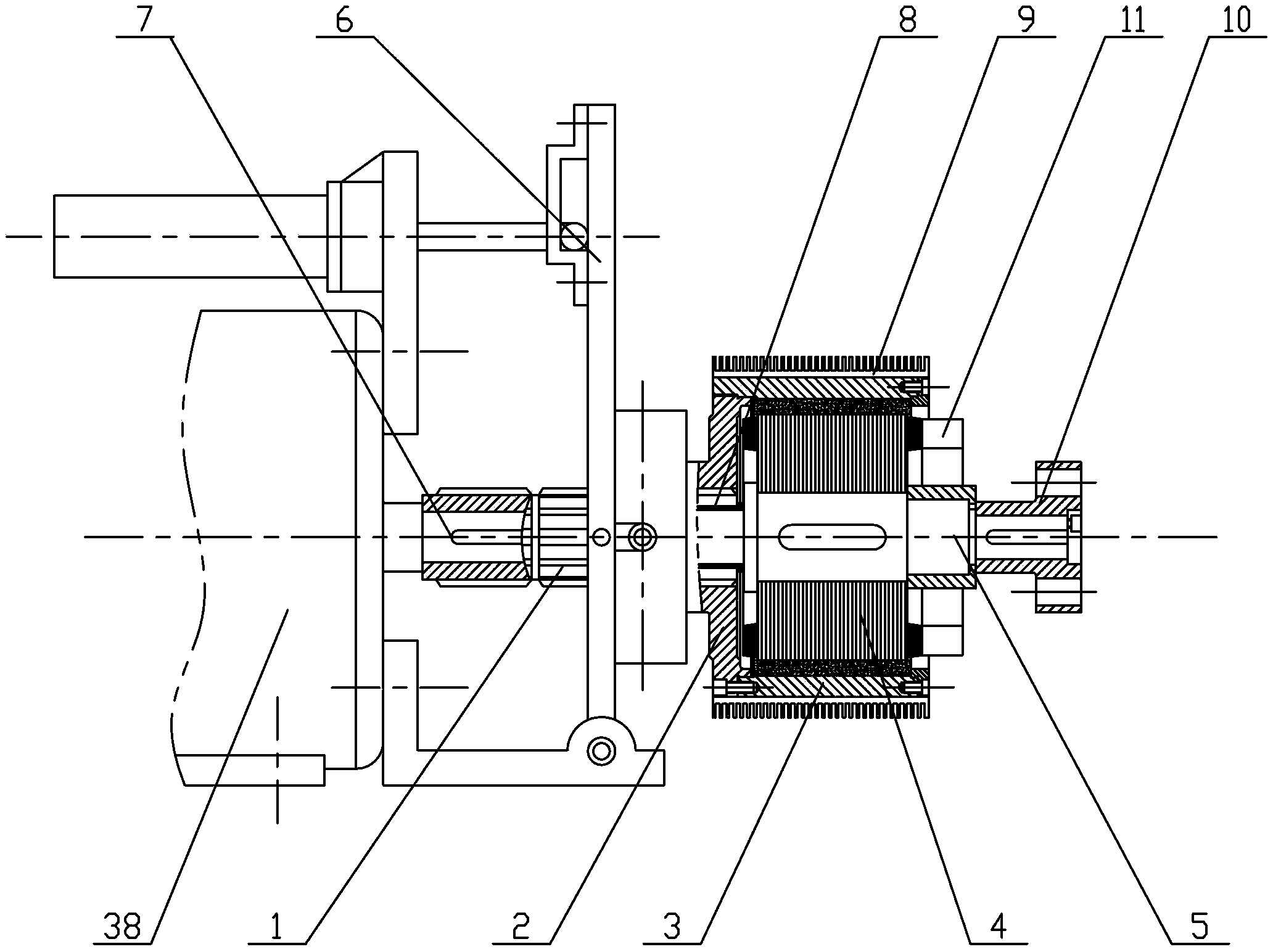

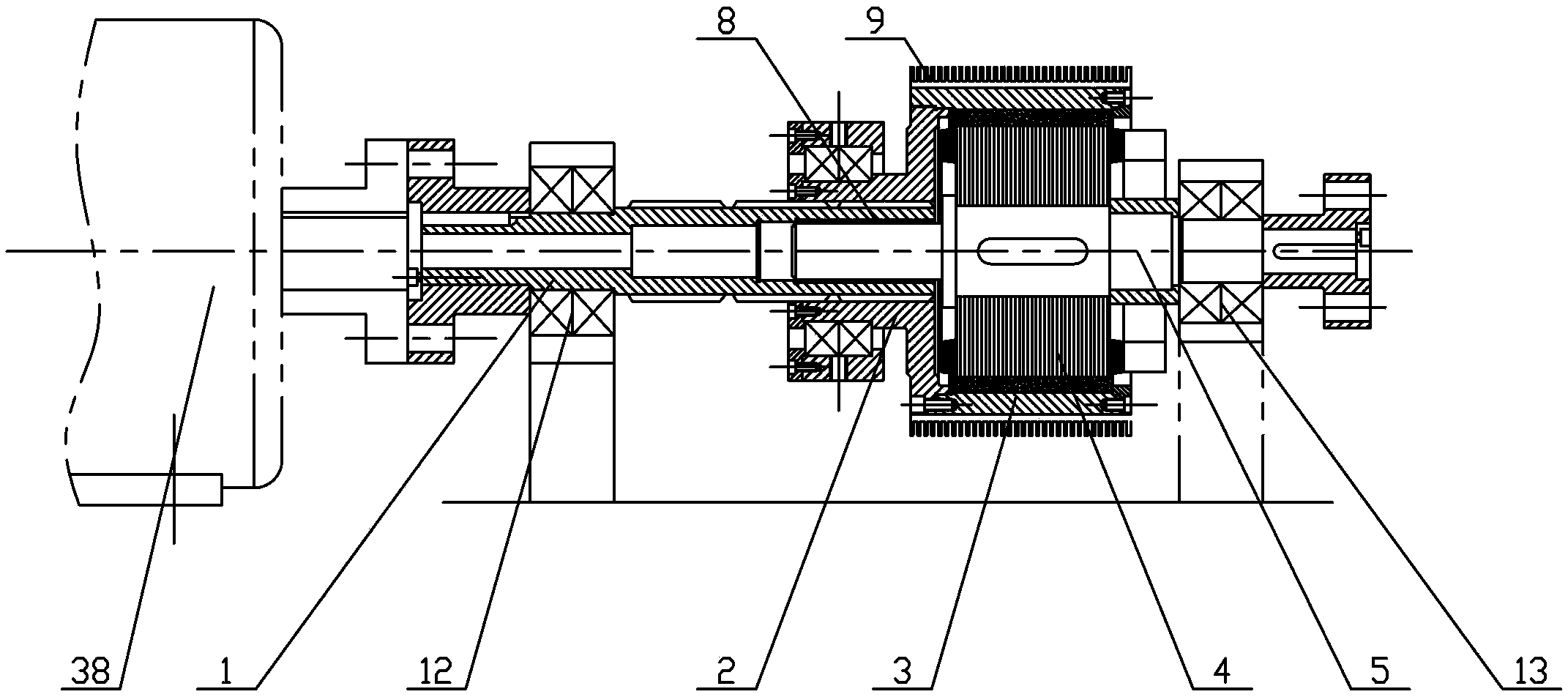

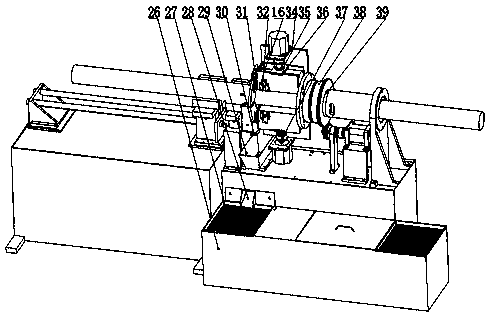

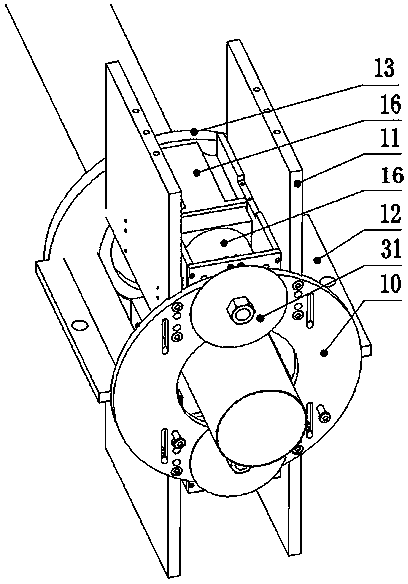

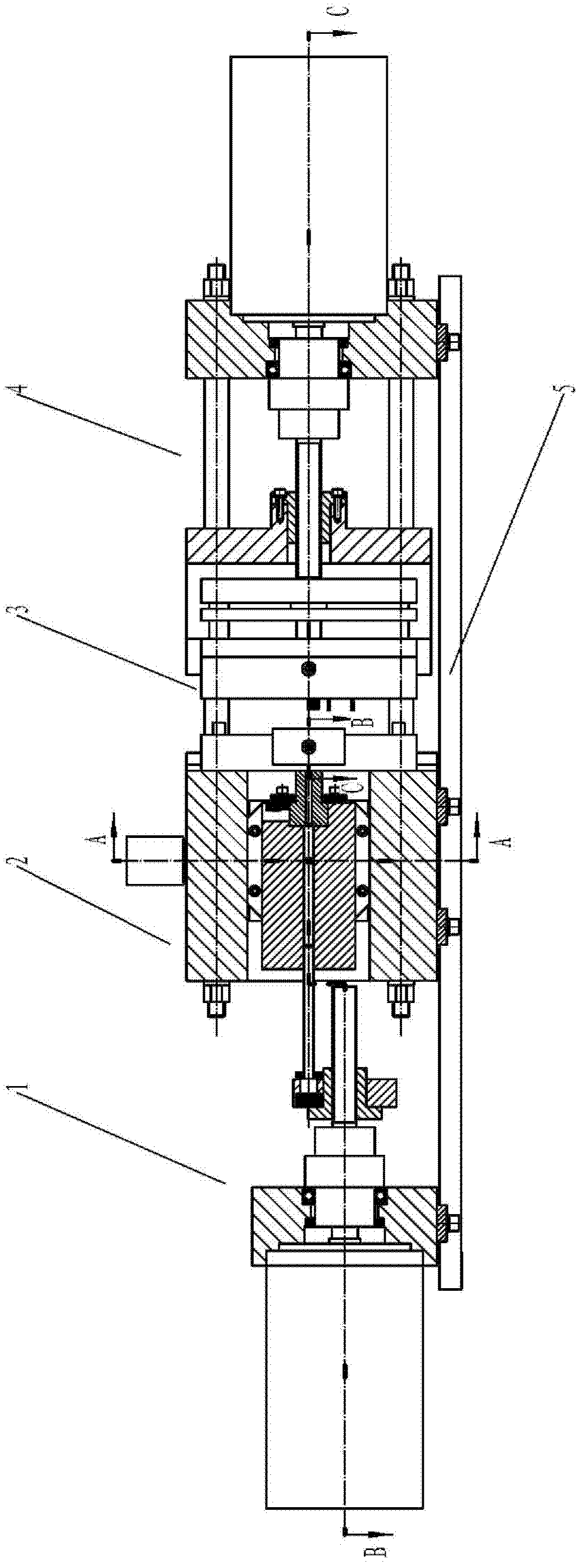

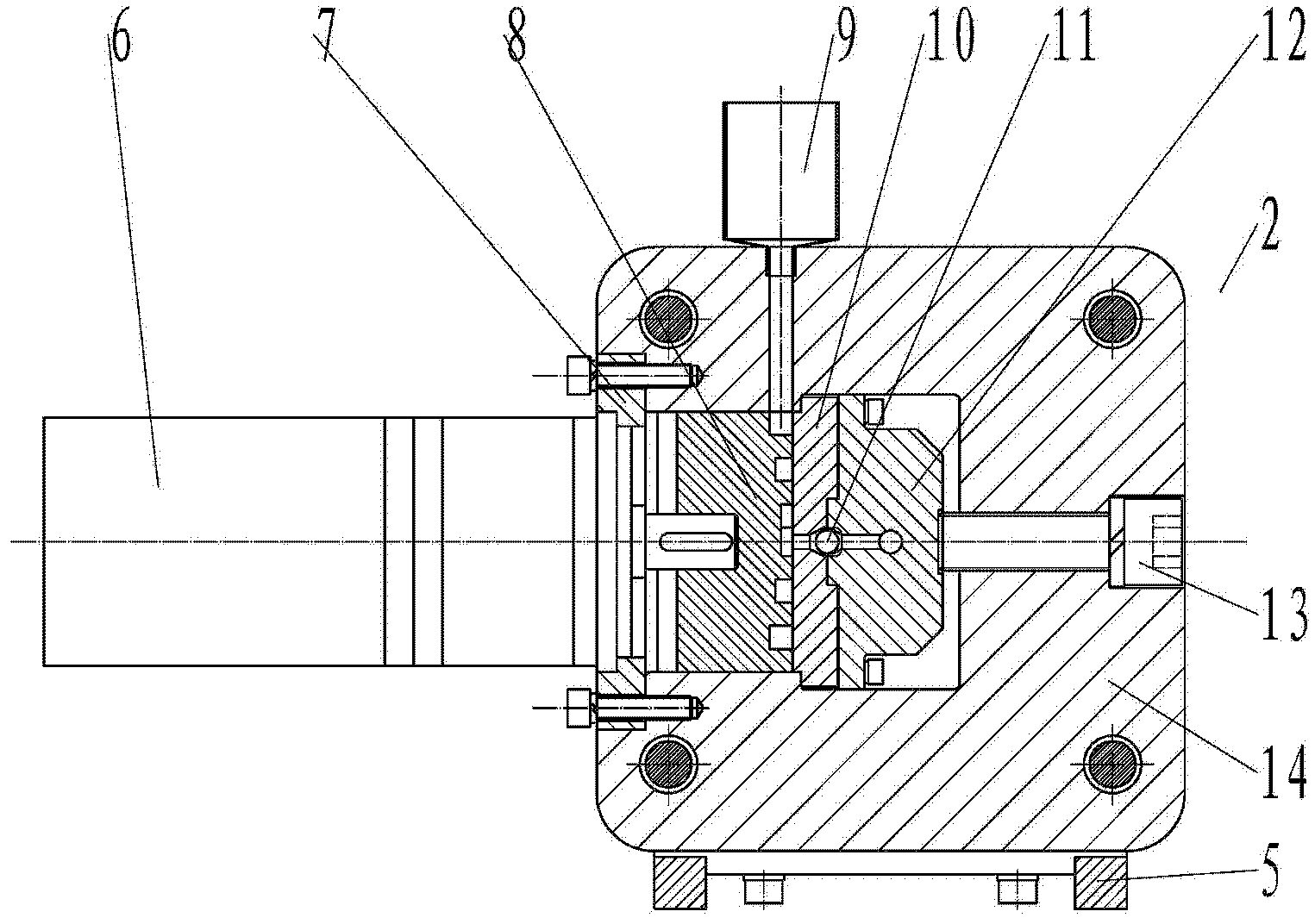

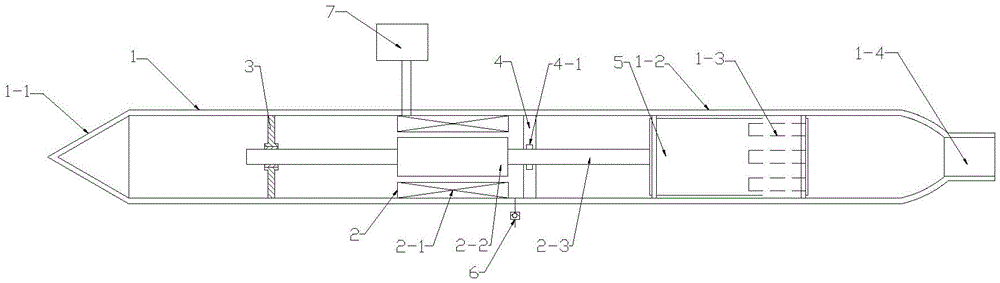

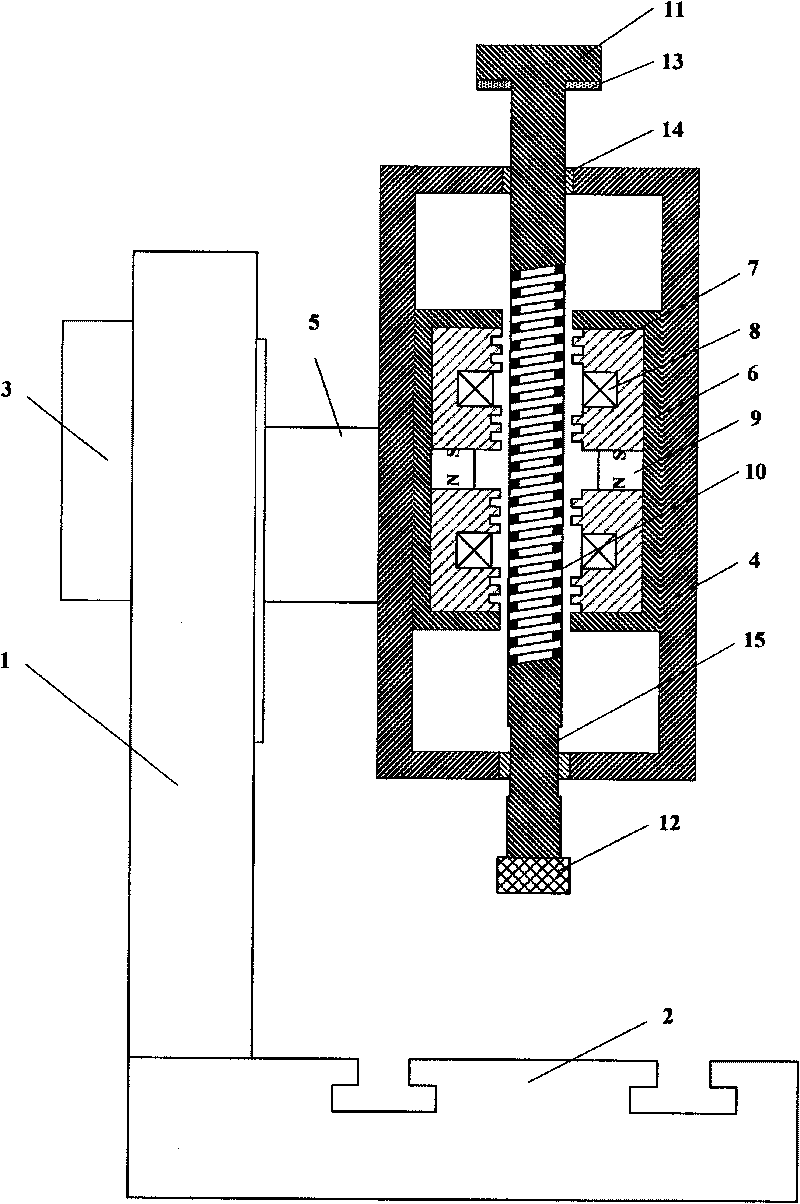

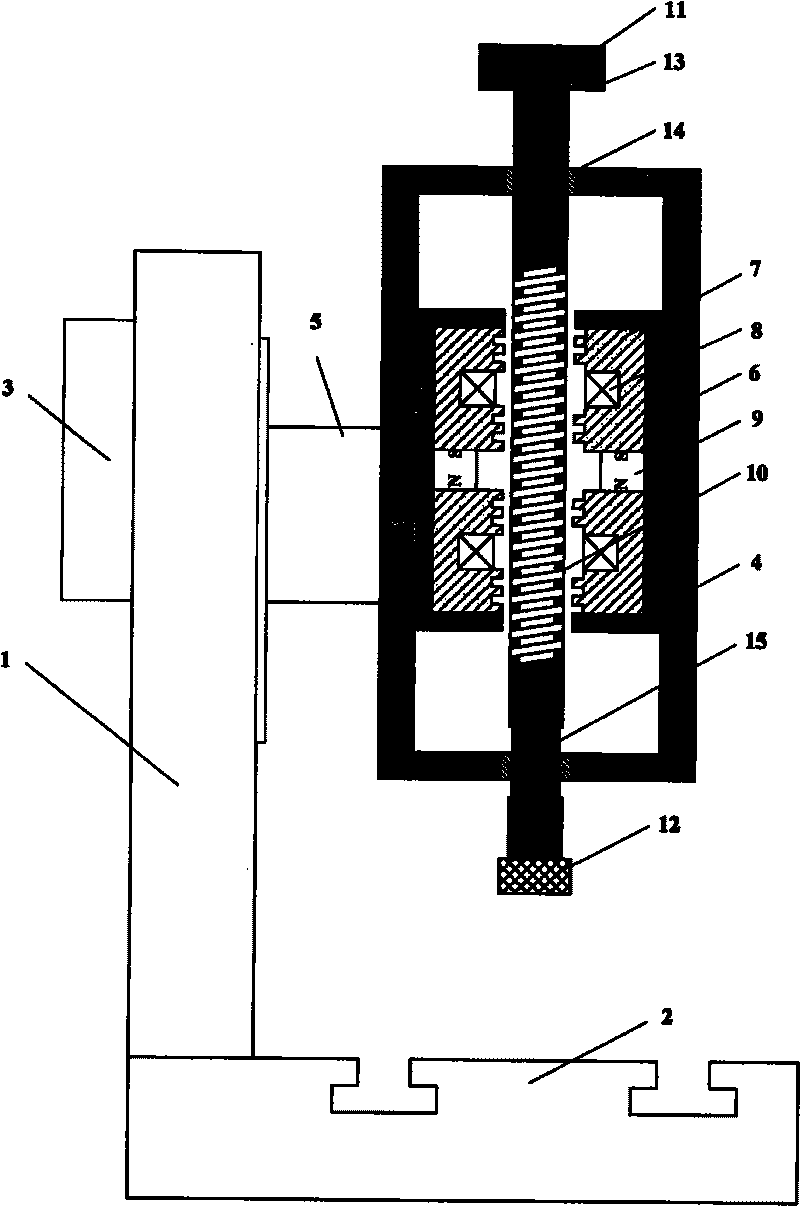

High-speed dynamic simulation test method for electric mainshaft bearing

ActiveCN101975659AEasy to achieve high speedRealize stepless speed regulationMachine bearings testingComputer databasePetroleum engineering

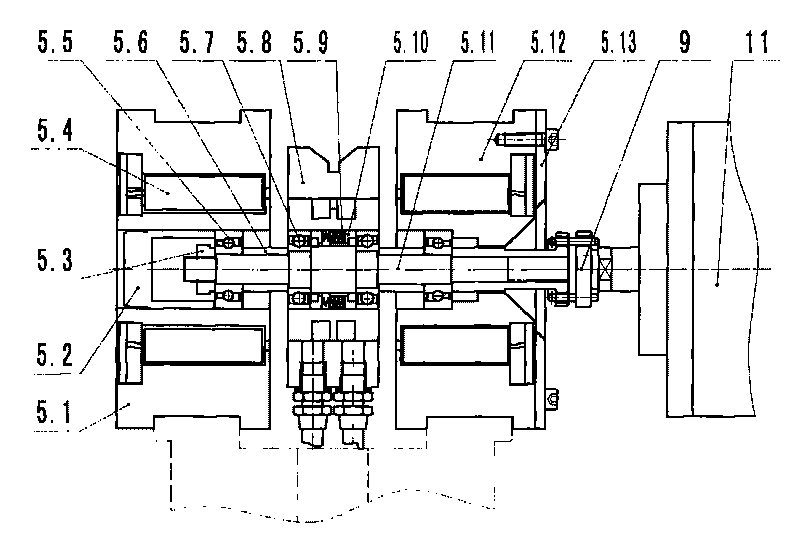

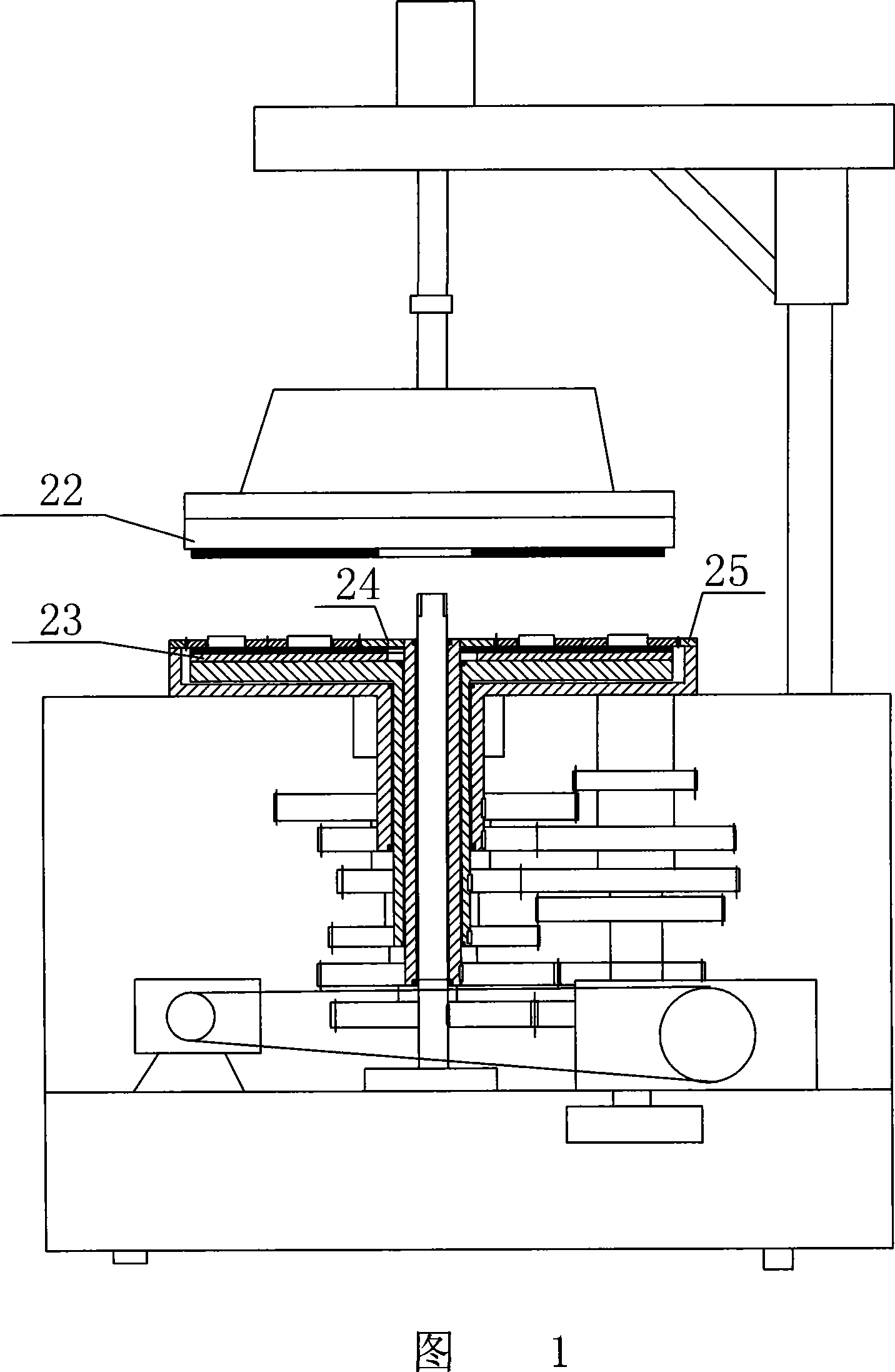

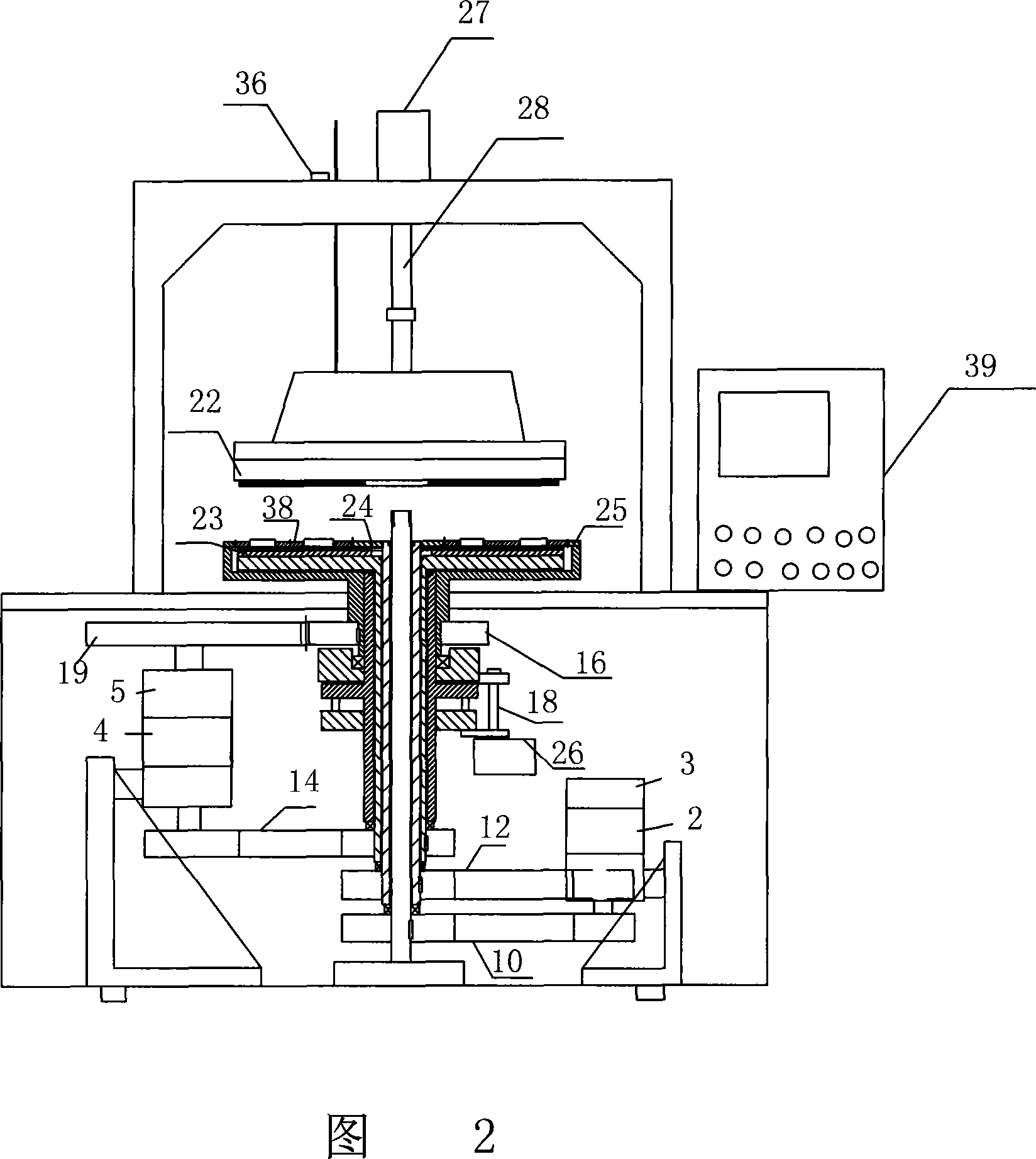

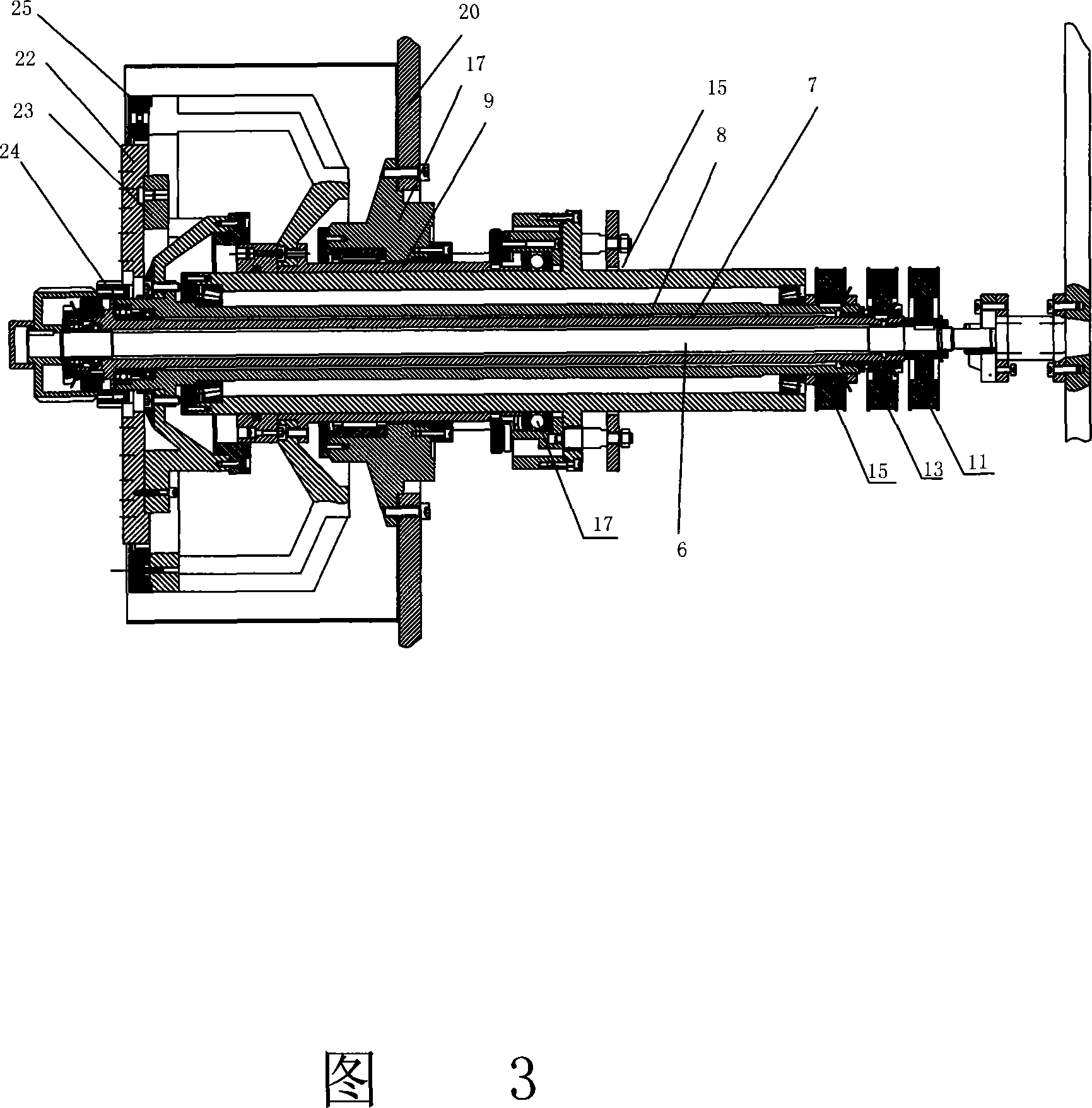

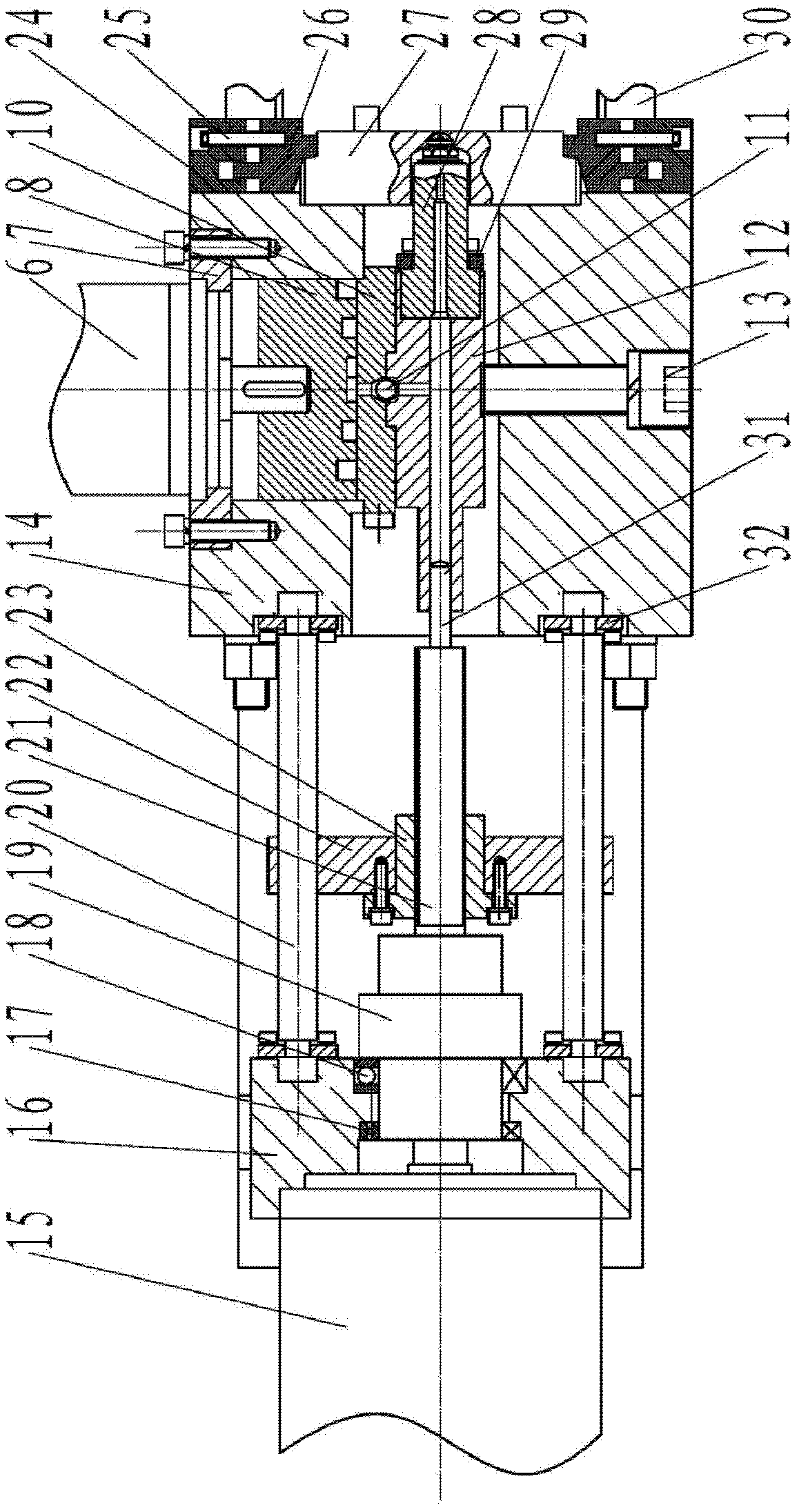

The invention relates to a high-speed dynamic simulation test method used for an electric mainshaft bearing. The electric mainshaft bearing comprises a frame, a main body pedestal, an axial loading cylinder, a test head assembly, a main body gland, a radial loading cylinder, a shaft coupling, a protecting hood, an electric mainshaft, a lubricating oil pipe, an axial loading oil pipe, a vibration sensor, a radial loading oil pipe and a temperature sensor and also a final assembly of all the parts. A hydraulic loading system is started to provide pressure oil to the axial loading cylinder and the radial loading cylinder, the electric mainshaft drives a test mainshaft to rotate, the radial loading cylinder exerts radial force on a first test accompanying bearing and a second test accompanying bearing through a radial loading sleeve, and the radial loading cylinder exerts axial force on a first test bearing and a second test bearing through an axial loading sleeve. The entire test is controlled by a computer to display parameters of the rotating speed, the axial load and the radial load, the oil pressure, the cooling water temperature, the bearing temperature, the bearing vibration, the power current of the electric mainshaft and the test time, and the parameters are saved in a computer database and analyzed.

Owner:国创(洛阳)轴承产业技术研究院有限公司

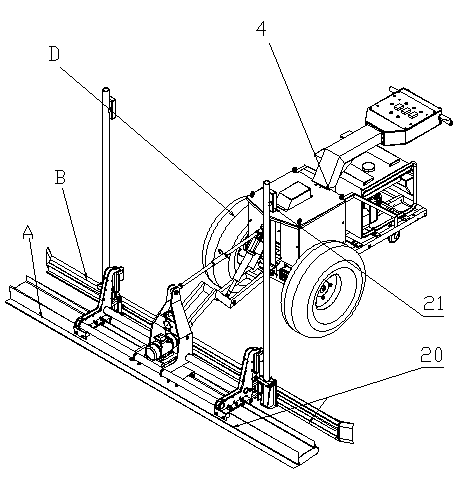

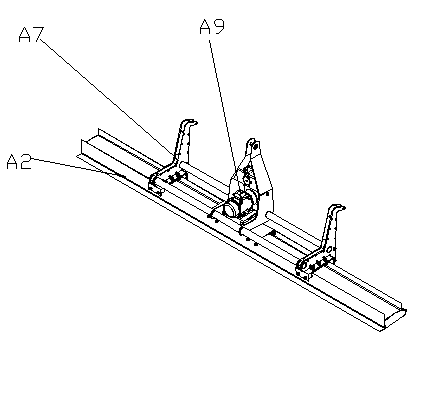

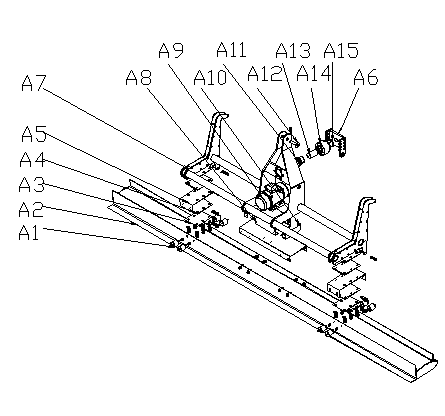

All-electric driven concrete laser leveler

InactiveCN102797214ASimple and lightweight structureReduce weightBuilding constructionsRoads maintainenceLaser transmitterEngineering

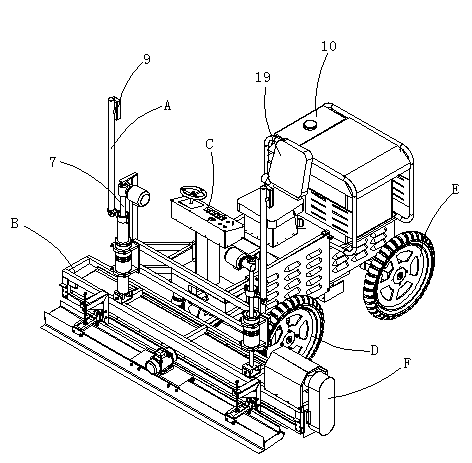

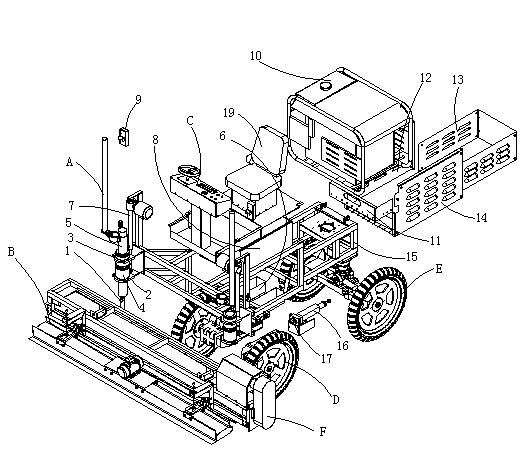

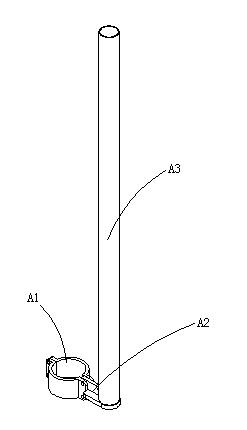

The invention discloses an all-electric driven concrete laser leveler. The all-electric driven concrete laser leveler comprises a vibrating plate module, a scraping plate module, a pull rod module, a walking mechanism, a central control box, a horizontal sensor, a protective shell, a frame, a control panel, a power generator unit, a caster, a power generator unit bottom plate, a pull rod pin, an electric cylinder pin, a motor protective plate, an electric cylinder, a first connecting rod pin, a second connecting rod pin, a connecting rod welding body, an electric push rod, a third connecting rod pin, an electric cylinder connecting rod, a laser transmitter, a vibrating scraping plate module, a laser receiver and other main parts. As an advanced laser control technology and a computer controlled servo driving technology are adopted in the whole machine and the original hydraulic driving system is replaced with an all-electric driving system, the all-electric driven concrete laser leveler disclosed by the invention has the advantages of high automation degree, high construction efficiency, high accuracy, light weight, simplicity in operation, less construction personnel, low construction cost and so on, and is suitable for places with comparatively small loads, such as terraces laid with double-layer reinforcing meshes, floor terraces and so on.

Owner:张晓军

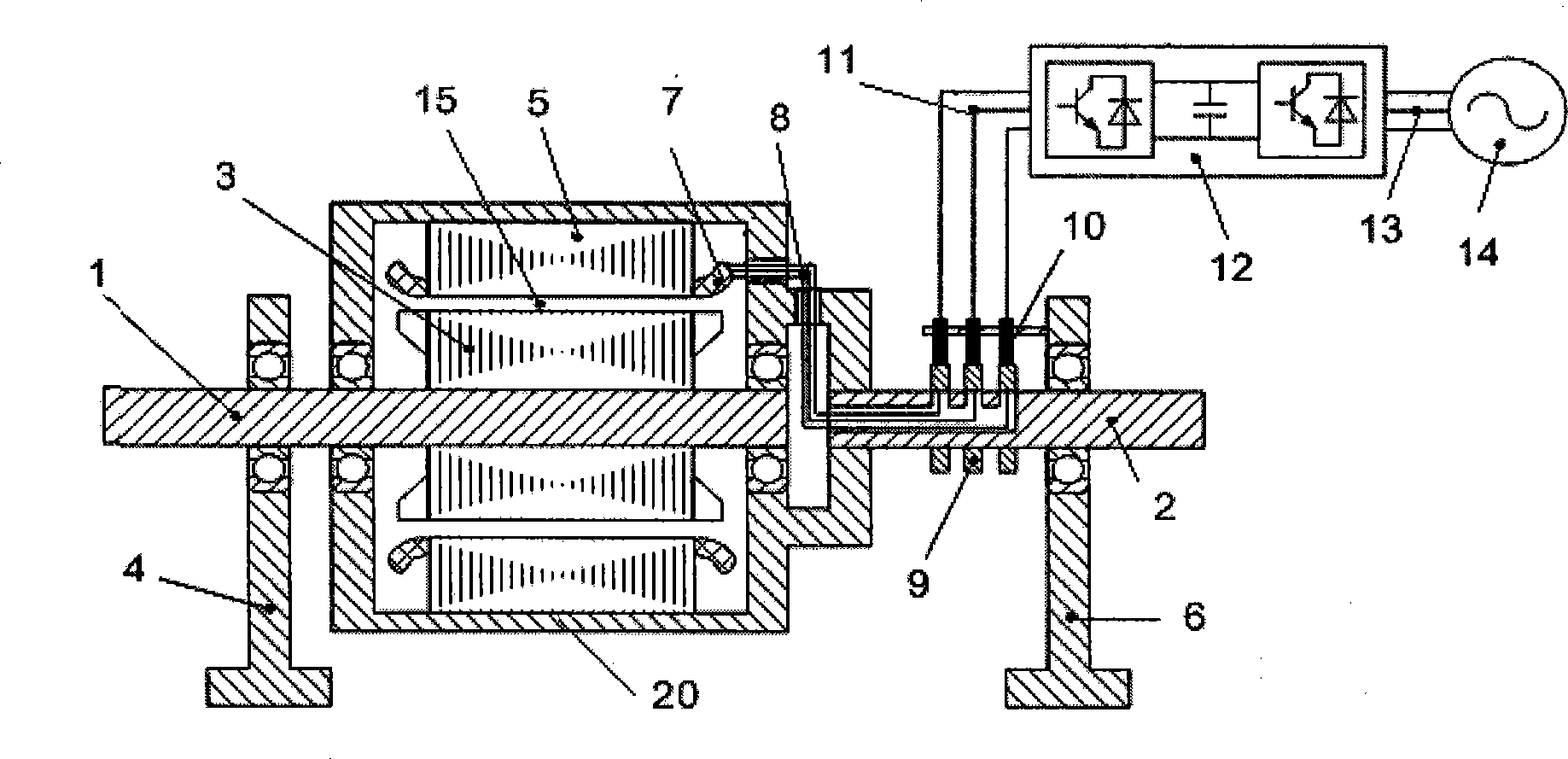

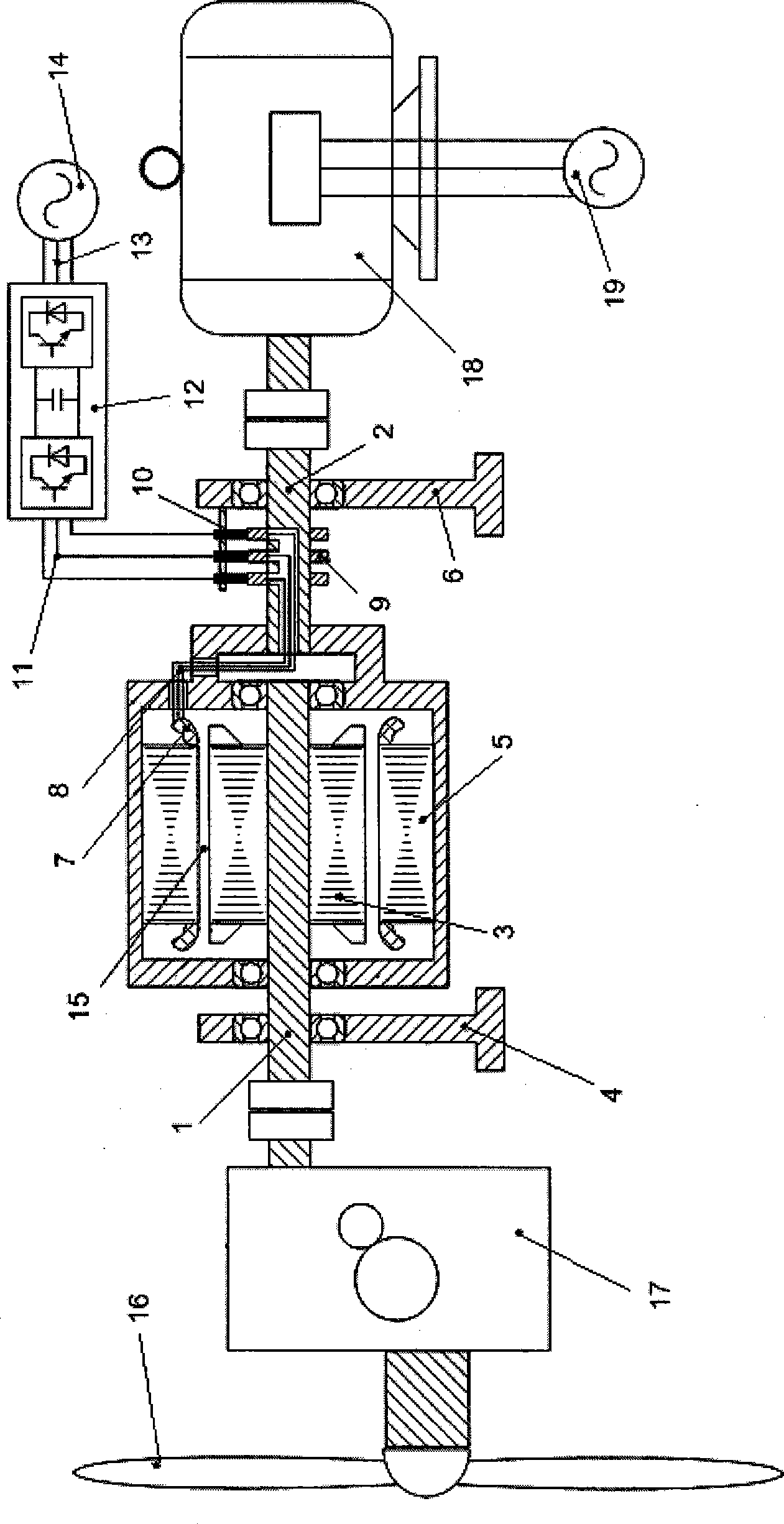

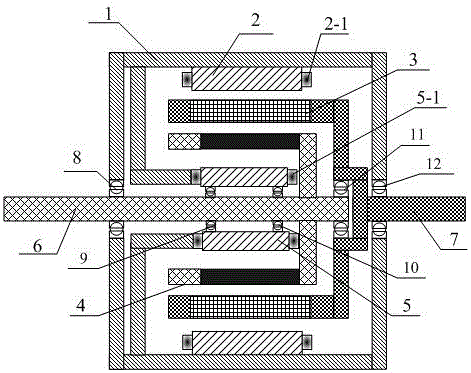

Variable-frequency control electromagnetic torsion coupler and use thereof

InactiveCN101465592AHard mechanical propertiesRealize stepless speed regulationDynamo-electric gearsDynamo-electric gear controlFrequency changerAlternating current

The invention relates to a variable-frequency speed-regulating magnetic torque coupler which is characterized in that: the coupler comprises a shell, and an inner rotor mechanical axis and an outer rotor mechanical axis are arranged in the shell; the inner rotor mechanical axis is connected with an inner rotor which is supported on a static bearing frame of the inner rotor, and the outer rotor mechanical axis is connected with an outer rotor which is supported on the static bearing frame of the outer rotor; an electromagnetic coupling working air gap is formed between the inner rotor and the outer rotor; the outer rotor is internally provided with an armature winding which is connected with a group of three-phase static electric brushes by three drainage slipping rings; the three-phase static electric brush is connected with the output end of a frequency converter, and the input end of the frequency converter is connected with a three-phase alternating-current electric fence. As a variable-frequency speed-regulating technology is introduced in a simple electric transmission system, non-contact torque transmission and stepless speed regulation between two rotary mechanical shafts can be realized by utilizing the principle of variable-frequency motors. The variable-frequency speed-regulating magnetic torque coupler can be widely applied to transmission systems.

Owner:TSINGHUA UNIV

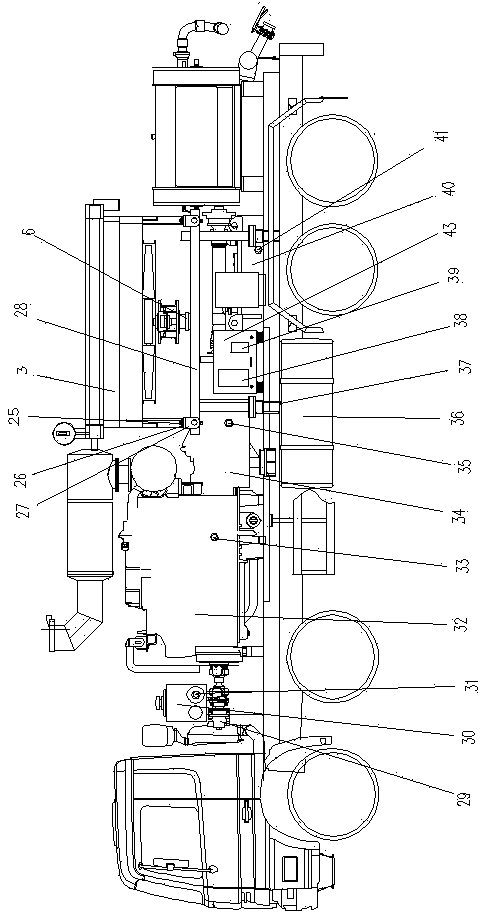

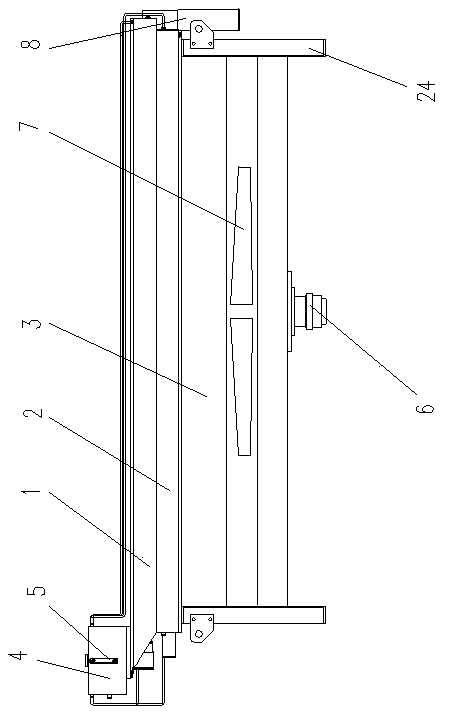

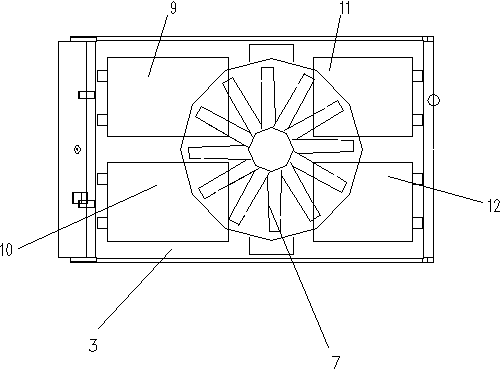

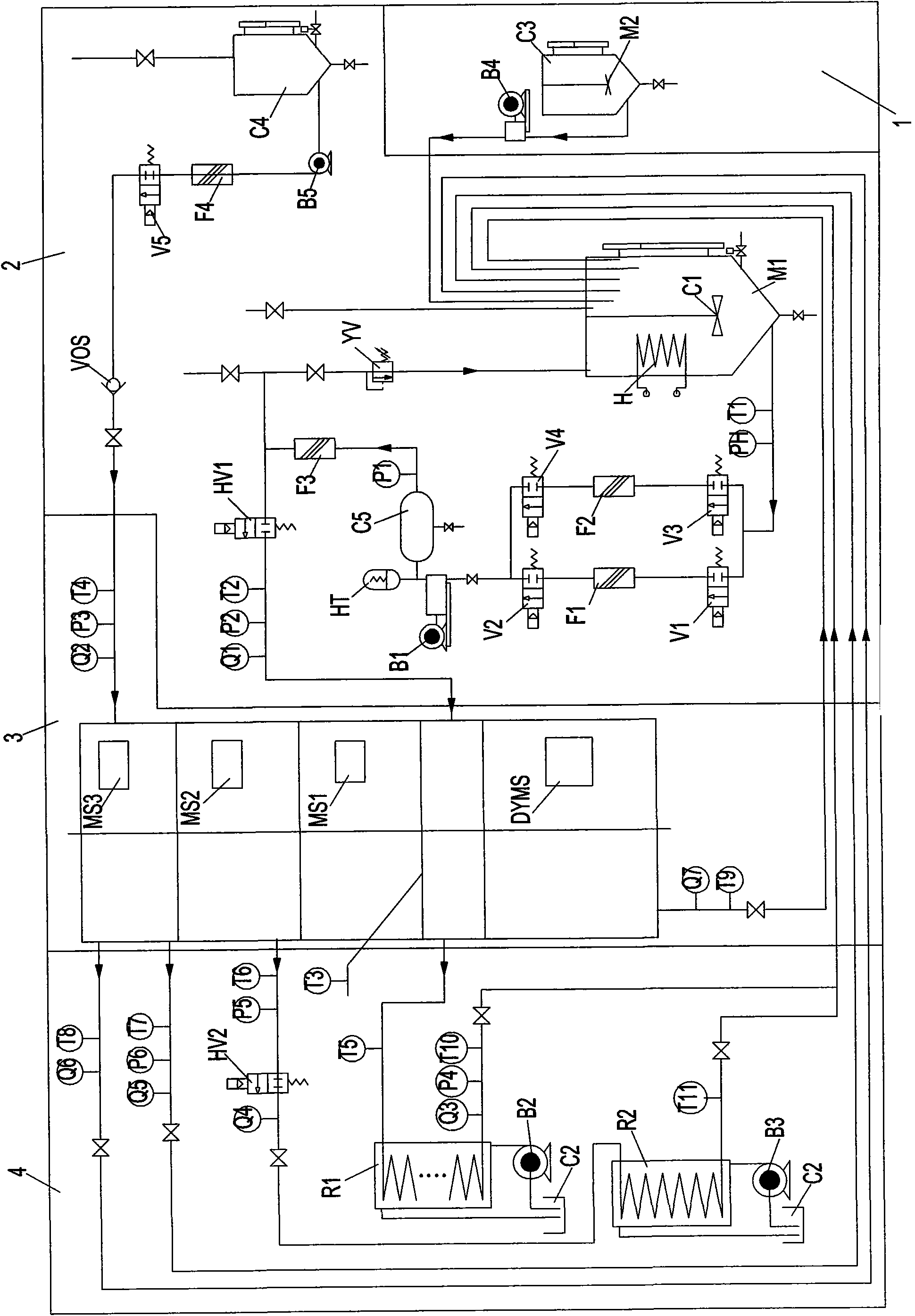

Cooling device of fracturing truck

InactiveCN104196613AMeet quality requirementsMeet the installation space requirementsCoolant flow controlGear lubrication/coolingFuel tankHydraulic pump

The invention provides a cooling device of a fracturing truck. A support of the integrated cooling device of the fracturing truck is connected with a connection base and a chassis crossbeam connection frame through a shock pad by means of a bolt, a control device and a lubrication oil tank provided with a lubrication oil temperature sensor are arranged below the chassis crossbeam connection frame, a fuel tank provided with a fuel temperature sensor is arranged at the lower portion a truck crossbeam, the upper front portion of the truck crossbeam is provided with a hydraulic oil tank provided with a hydraulic oil temperature sensor, an electrically-controlled volume adjustable hydraulic pump is arranged at the lower portion of the hydraulic oil tank, the electrically-controlled volume adjustable hydraulic pump is connected with an engine provided with a water temperature sensor, and the other side of the engine is provided with a transmission tank provided with a transmission tank oil temperature sensor. A horizontal heat sink is respectively provided with an engine water-cooling device, a power end cooling device, a hydraulic cooling device, a fuel cooling device and a transmission tank cooling device. According to the cooling device of the fracturing truck, a horizontal structure and a concentrated heat dissipation mode are adopted, a pipeline of a cooling system is arranged reasonably, and the requirements for the weight and installation space of vehicle-mounted fracturing equipment are met.

Owner:SJ PETROLEUM MACHINERY CO LTD SINOPEC

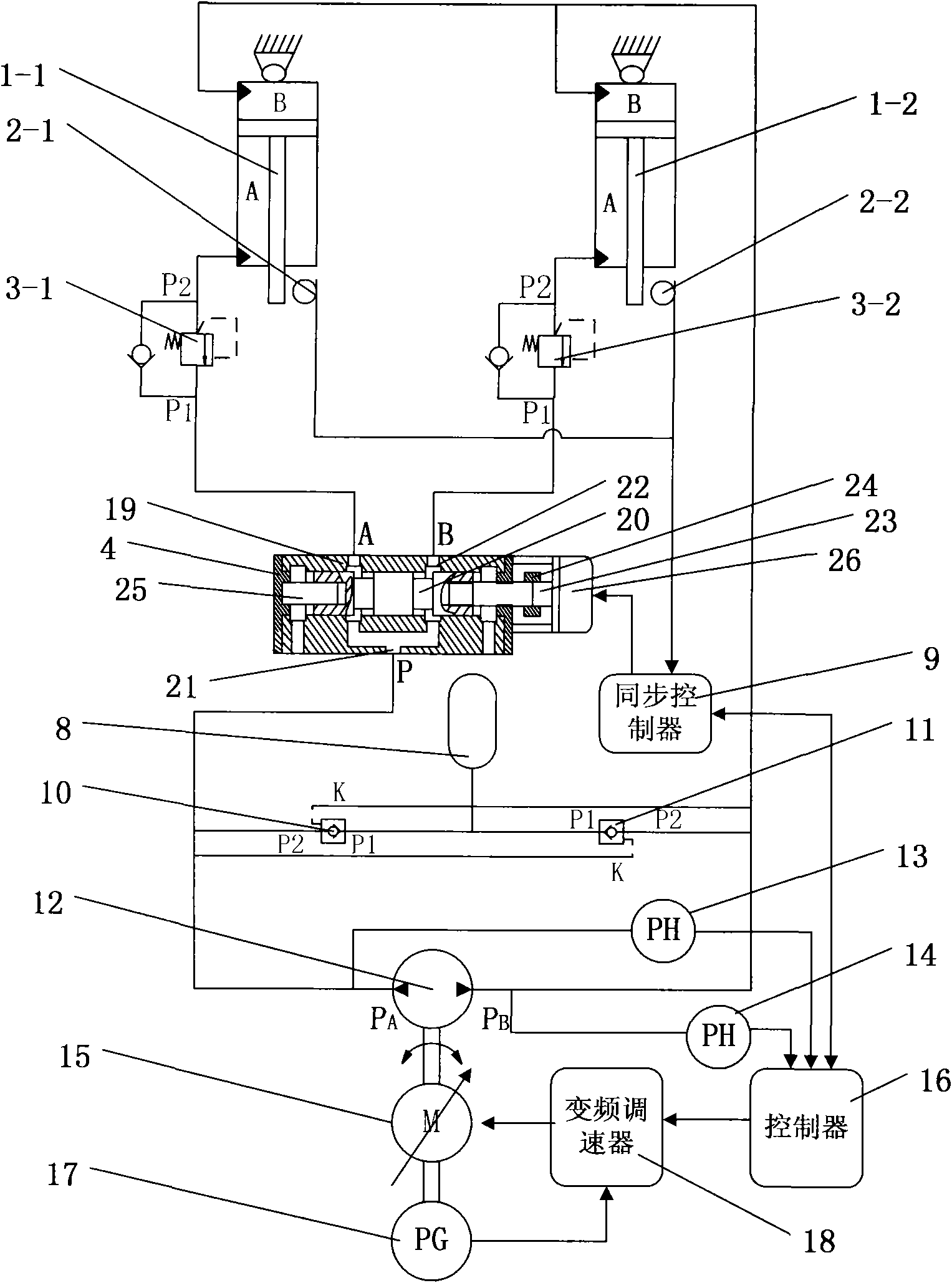

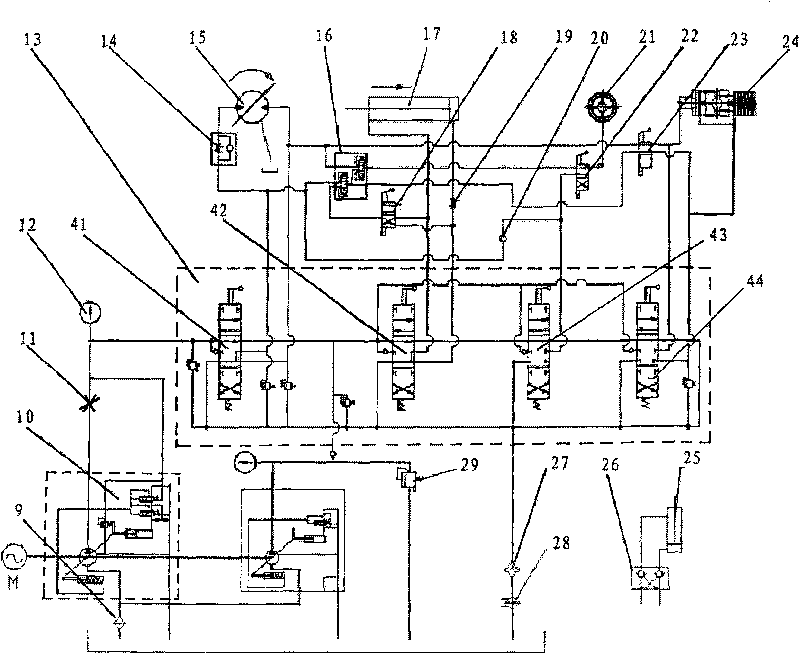

Digital electric-hydraulic synchronous control system

InactiveCN101571155AThrottle control responds quicklyIntelligentFluid-pressure actuator componentsHydraulic pumpFuel tank

The invention discloses a digital electric-hydraulic synchronous control system, which comprises a hydraulic actuating mechanism, a digital synchronous control mechanism for performing synchronous control on the hydraulic actuating mechanism, an electric-hydraulic power source for providing power oil for the hydraulic actuating mechanism and the digital synchronous control mechanism, and an electric-hydraulic control system for controlling the power source and the synchronous control mechanism. The hydraulic actuating mechanism is a hydrocylinder; the electric-hydraulic power source comprises an oil storage tank, a double-acting hydraulic oil pump and a driving motor; the electric-hydraulic control system comprises a detector for detecting the oil pressure of the hydraulic oil pump and the rotating speed of the motor respectively and a variable frequency speed regulator and a controller for controlling the motor; and the digital synchronous control mechanism comprises a digital synchronization valve, a digital synchronization controller and a displacement transducer for detecting the displacement of an output shaft of the hydrocylinder. The digital electric-hydraulic synchronous control system has the advantages of simple structure, simple and convenient use and operation, good use effect, energy conservation and no oil leakage, and can achieve the aims of stepless speed regulation and high-precision synchronization according to operating characteristic requirements of different types of controlled objects.

Owner:薛国光

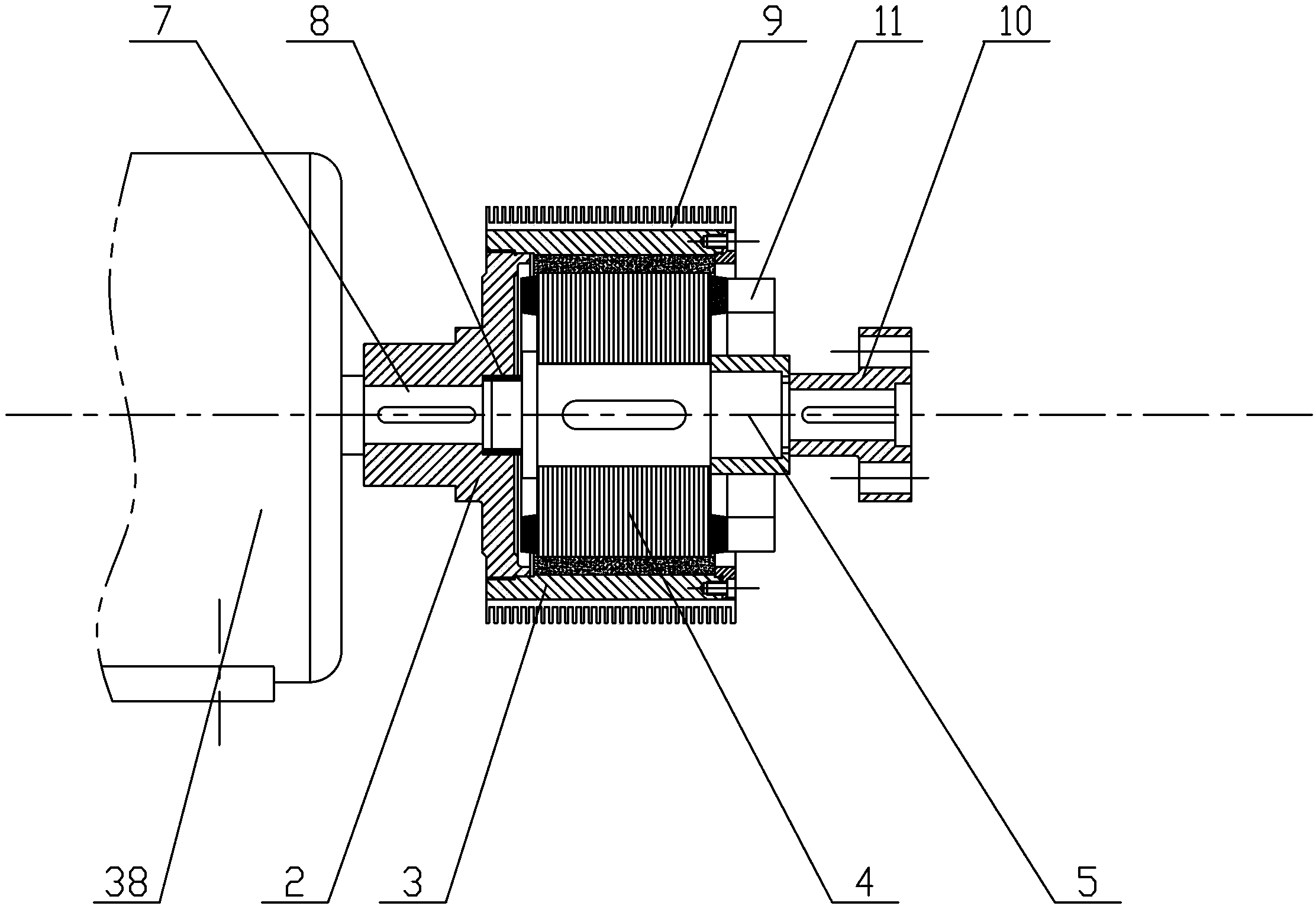

High-temperature high-speed test method for sealed bearing

InactiveCN101718625AImprove the state of stressEasy to achieve high speedMachine bearings testingElectricityComputer control system

The invention relates to a high-temperature high-speed test method for a sealed bearing, which comprises the following steps of: firstly designing a testing device, installing two sets of testing accompanying bearings on a testing main shaft, and pretightening through a set of spring and a pressure ring; installing the two sets of testing bearings at the left end and the right end of the testing main shaft, connecting an electric main shaft through a shaft coupling and additionally covering a shield; starting cooling circulating water, adding cooling water into a loading sleeve, starting a hydraulic station, an electric main shaft variable-frequency driving system and a computer control system, applying 20-30 percent of the maximum axial test load and 20-30 percent of the maximum radial test load to the testing bearings, starting the electric main shaft to reach 15-20 percent of the highest rotational speed and running for 15-25 minutes after the heating temperature reaches a set value, and then sequentially adding axial loads and radial loads and increasing the rotational speed of the electric main shaft so as to reach the highest rotational speed when the power consumption current of the electric main shaft tends to be steady; and carrying out computer data processing for the data and images in different time periods of the whole testing process and working out a test conclusion.

Owner:LUOYANG BEARING SCI & TECH CO LTD

Accurate doublefaced polisher

InactiveCN101049678ACompact structureReduce the impact of impactPolishing machinesGrinding drivesElectric machineryMachining process

A precise dual-surface polishing machine is composed of machine frame, mainshaft and its drive mechanism, upper polishing disc and its drive unit, lower polishing disc, internal and external toothed rings, planetary gear for holding workpiece, 4 coaxial frequency-conversion motors fro respectively driving coaxial upper and lower polishing discs and external and internal toothed rings, pressure regulating sensors, and pressure regulating valves.

Owner:ZHEJIANG UNIV OF TECH

Complete equipment system for gas hydrate simulate composition and decomposition and reaction kettle

InactiveCN1762565ANo stress corrosionHigh degree of visualizationLiquid-gas reaction processesPressure vessels for chemical processOcean bottomDecomposition

The invention relates to analogue synthesis to gas hydrate in seabed and opposite device as well as the kettle in device system. Wherein, the reaction kettle as the core part can bear pressure and temperature of 3000m water depth, and has high visualization degree and capacity. The system needs low cost, has sufficient monitor method, can take analysis to analogue synthesis and decomposition for gas hydrate in seawater and sand in sea bed, and plays an important role in prospecting gas hydrate. The opposite device comprises: an analogue gas-distribution system for natural gas, a high-pressure pressurizing system for natural gas, a high-pressure visual reaction kettle, a temperature control system for cooling and bath, a parameter control desk, a computer data acquisition system, and a magnetic-force stir system.

Owner:NANJING UNIV OF TECH

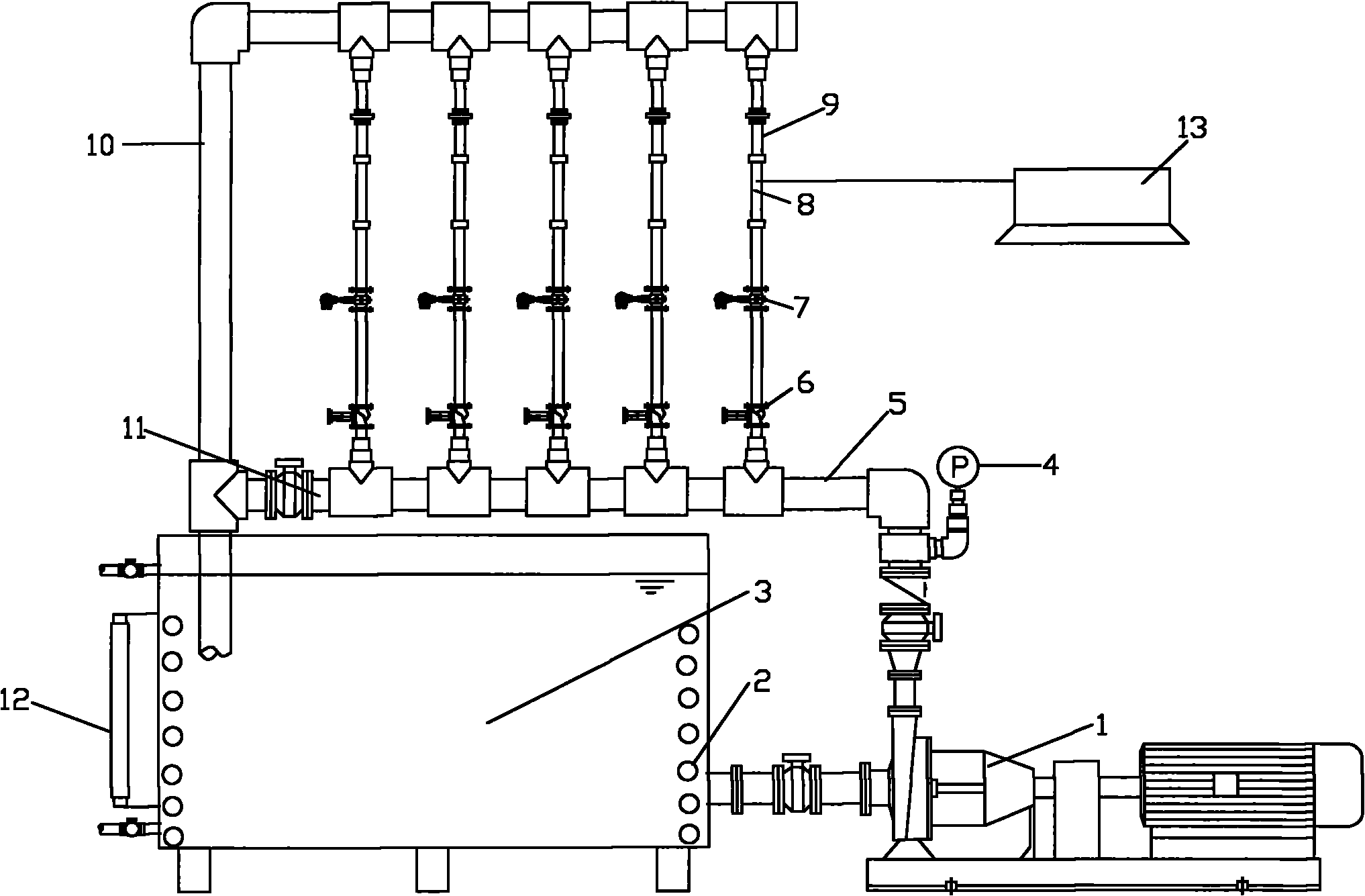

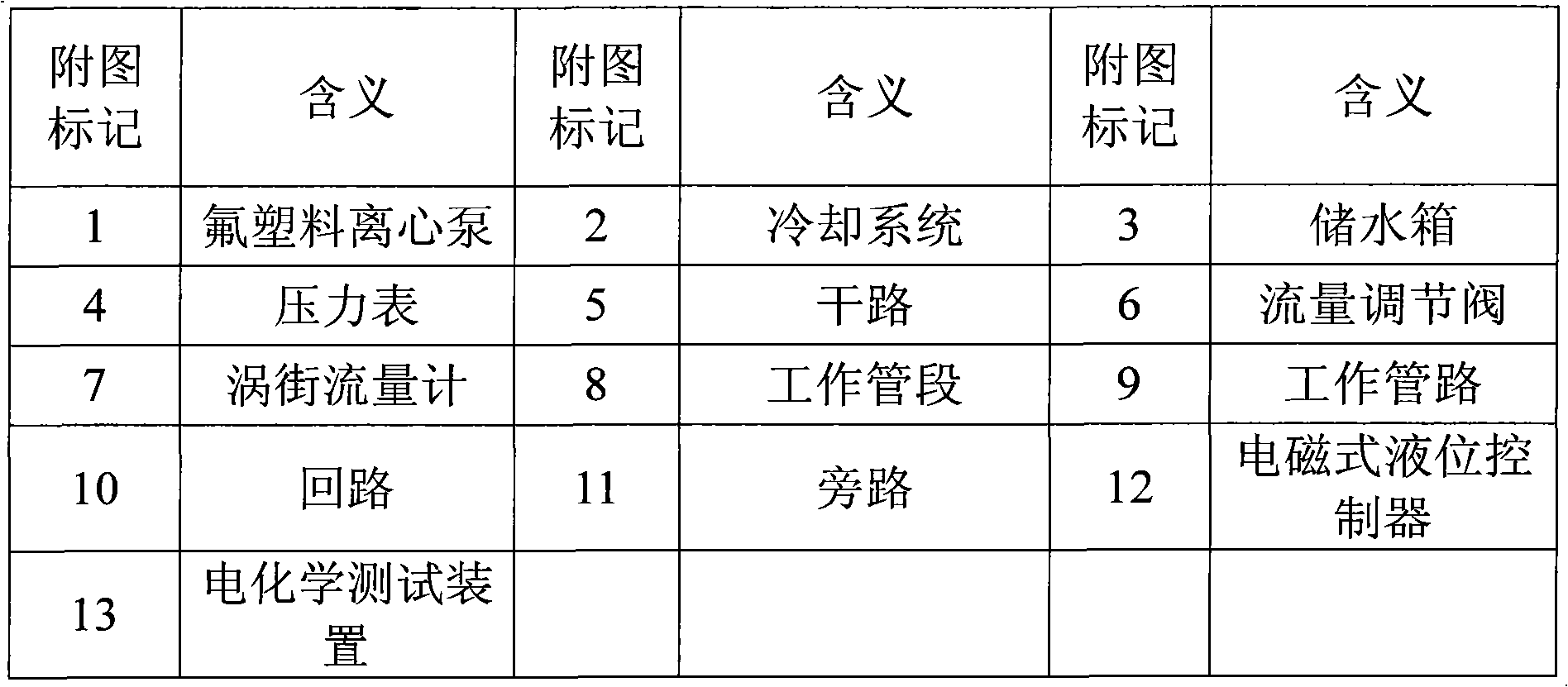

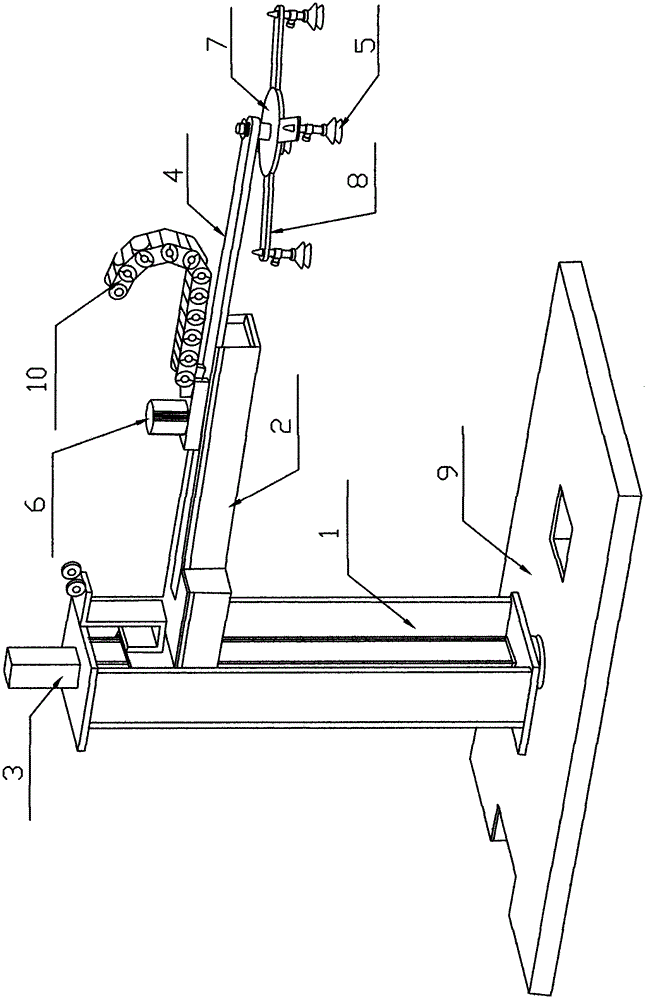

Erosion corrosion test device of seawater piping system metal member

InactiveCN101975744AShorten test timeReduce test costsWeather/light/corrosion resistanceCentrifugal pumpPiping

The invention relates to an erosion corrosion test device of a seawater piping system metal member, comprising a fluoroplastic centrifugal pump and a water storage tank, wherein the inner side wall of the water storage tank is provided with a cooling system; the inlet of the fluoroplastic centrifugal pump is connected with the water storage tank, and the outlet main line of the fluoroplastic centrifugal pump is connected with a plurality of parallel-connected working pipelines; each working pipeline is sequentially connected in series with a flow regulating valve, a vortex street flowmeter and a working pipe section; the outlet ends of the plurality of parallel-connected working pipelines are communicated with the water storage tank through loops; the outlet main line of the fluoroplastic centrifugal pump is also provided with a by-pass; the by-pass is communicated to the water storage tank; and the working pipe section is also electrically connected with an electrochemical test device. The erosion corrosion test device can realize the erosion corrosion resistant property tests of different pipe samples under approximately completely consistent test conditions of a same medium, same temperature, same flow velocity, and the like and can also be used for researching the erosion corrosion resistant property of a same material under the conditions of different mediums and flow velocities.

Owner:苏州有色金属研究院有限公司

Intelligent robot capable of high-speed feeding and discharging

InactiveCN104440898AReduce volumeSmall inertia forceProgramme-controlled manipulatorGripping headsBall screwManipulator

The invention relates to an intelligent robot capable of high-speed feeding and discharging. An existing feeding and discharging device is complicated to operate. Accordingly, the intelligent robot capable of high-speed feeding and discharging comprises a stand column and a cross arm, wherein the stand column s provided with a vertical linear guide rail, a lifting block is arranged on the vertical linear guide rail, the cross arm is fixed to the lifting block, the lifting block is driven by a ball screw pair, lead screws of the ball screw pair are driven by a lifting servo motor and sleeved with nuts of the ball screw pair, and the nuts and the lifting block are fixed together. The cross arm is provided with a horizontal linear guide rail provided with a slide block, a telescopic arm is fixed to the slide block, a sucker rack or a manipulator grabbing device is fixed to the front end of the telescopic arm, the slide block is driven by a ball screw pair, lead screws of the ball screw pair are driven by a telescopic serve motor and sleeved with nuts of the ball screw pair, and the nuts and the slide block are fixed together. The intelligent robot has the advantages of being convenient to use, safe and efficient, thereby being suitable for various production enterprises needing workpiece carrying.

Owner:范克健

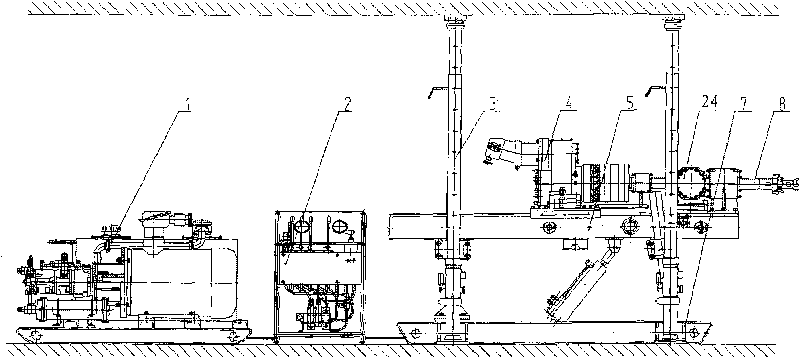

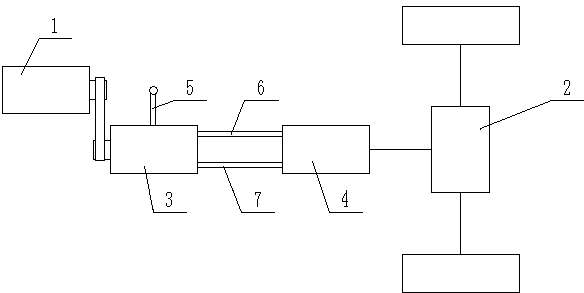

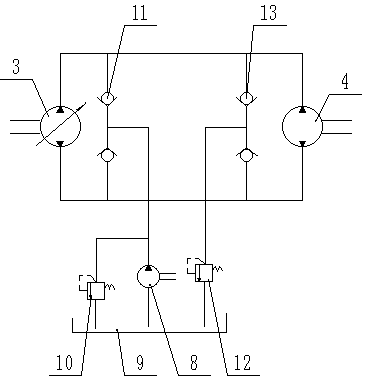

Mining linkage all-hydraulic drilling machine

ActiveCN101705785AReduce auxiliary timeSimple and fast operationDrilling rodsConstructionsHydraulic motorEngineering

The invention discloses a mining linkage all-hydraulic drilling machine which comprises a pump station system, a power head, a base, a machine frame, an upright post, a gripper, a drilling tool, a drilling machine thrust cylinder and a hydraulic linkage system, the hydraulic linkage system comprises a multiway valve unit and a linkage unit, the pump station system is connected with the linkage unit by the multiway valve unit, the linkage unit comprises an advance and retreat pole hand-operated direction valve, a cartridge linkage / single acting hand-operated direction valve and a gripper linkage / single acting hand-operated direction valve, the multiway valve unit comprises thrust cylinder valve leaves, hydraulic cartridge valve leaves, gripper valve leaves and hydraulic motor valve leaves.The invention adopts hydraulic linkage function, thus reducing auxiliary time of drilling machine operation, and leading the drilling machine operation to be more convenient. The drilling machine is compact in structure, light in weight and easy to transport in the pit.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

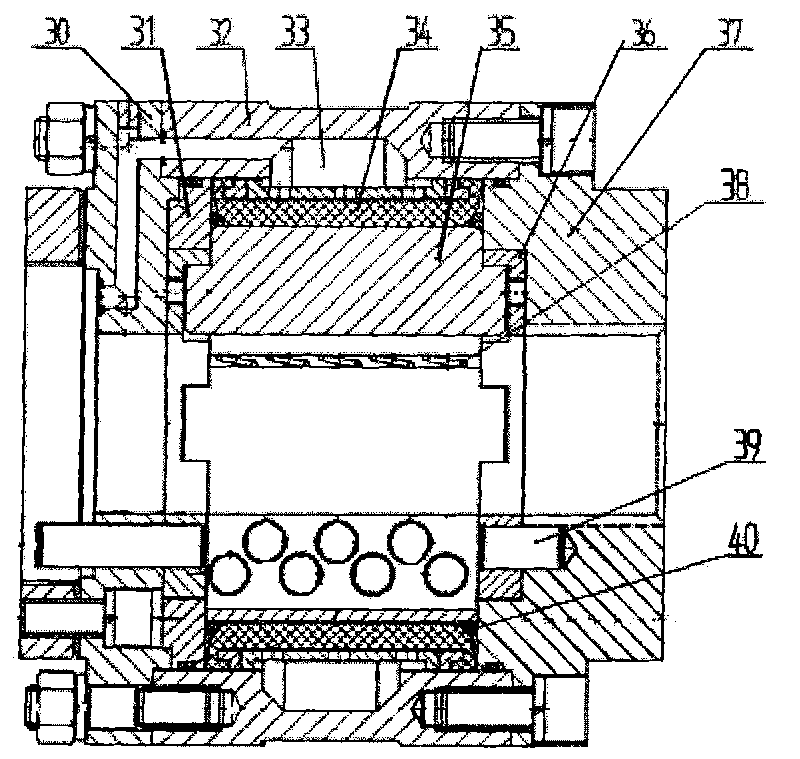

Magnetic coupler

ActiveCN103401398ASmall moment of inertiaImprove reliabilityDynamo-electric gearsElectric machineControl theory

The invention discloses a magnetic coupler which comprises a power input shaft, connecting flanges, permanent magnet outer rotor assemblies, cage type inner rotors, a power output shaft and a mechanical speed adjustment device, wherein the permanent magnet outer rotor assemblies have hollow cup-shaped structures, are sleeved outside the cage-type inner rotors and realize transmission of torque under the coupling action of an air gap magnetic field between the permanent magnet outer rotor assemblies and the cage-type inner rotors; the mechanical speed adjustment device can change axial air gap areas between the permanent magnet outer rotor assemblies and the cage-type inner rotors according to a lever theory, thus realizing stepless speed variation for load rotating speed. According to the magnetic coupler, a method for designing the number of pole pairs of the permanent magnet outer rotor assemblies is provided on the basis of a minimum torque ripple rule, so that the thickness of yokes and the rotating inertia of the coupler are reduced. The cage-type inner rotors can adopt structures which are the same as or similar to that of the conventional motor cage rotor iron core. The magnetic coupler disclosed by the invention can be coaxially connected with a load and can be used as a belt wheel adapter matched with a belt wheel.

Owner:DALIAN JIAOTONG UNIVERSITY

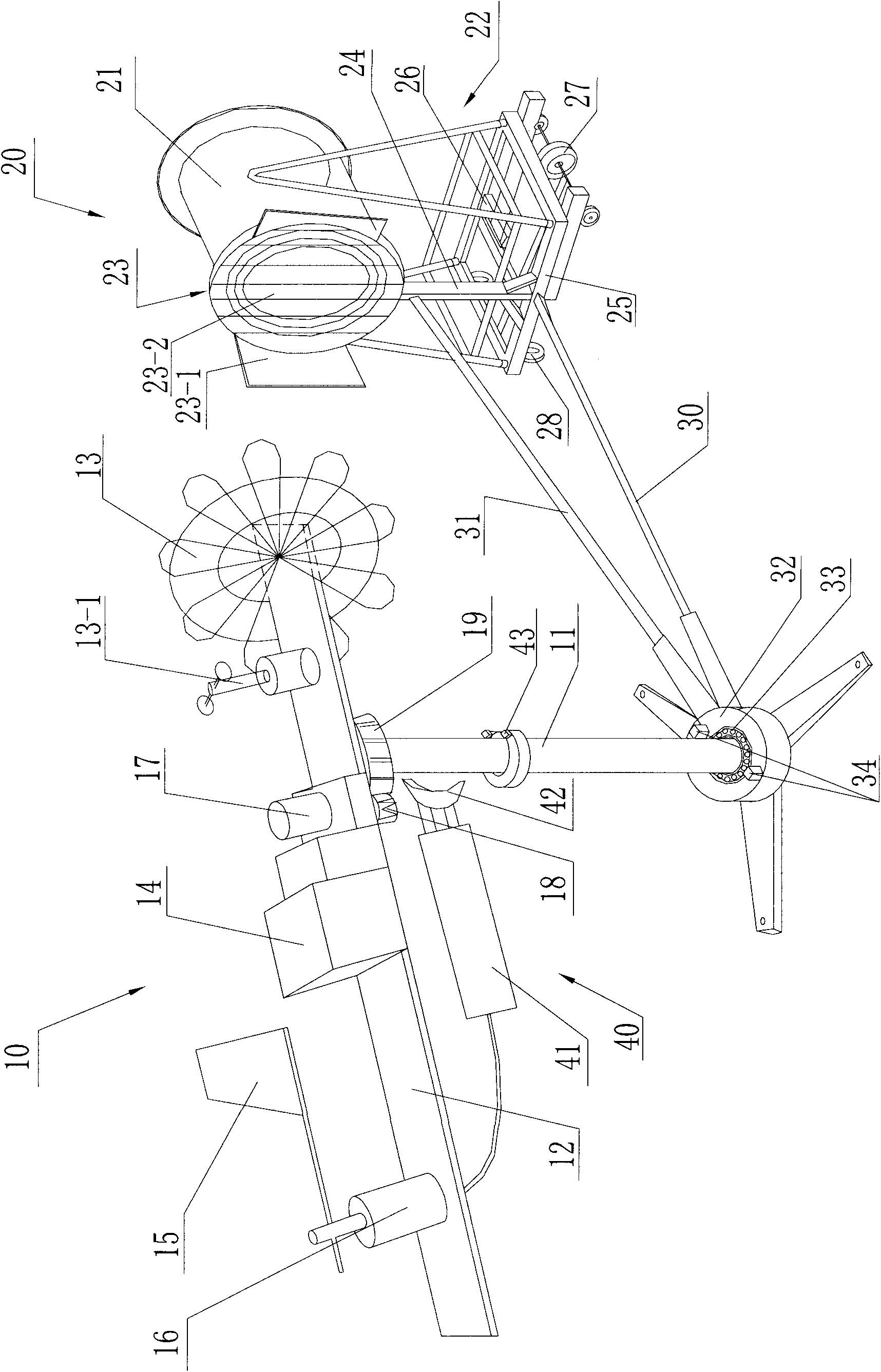

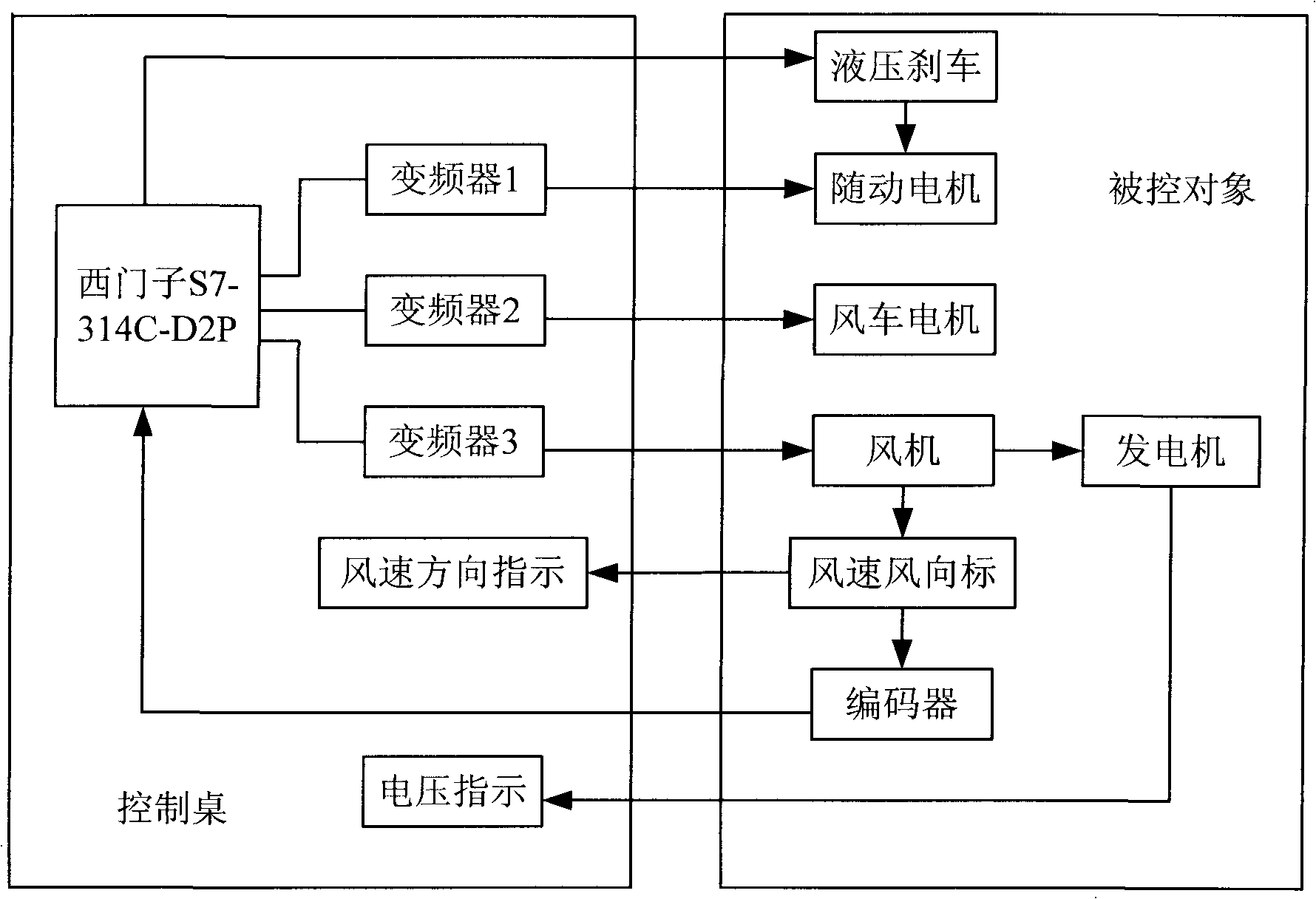

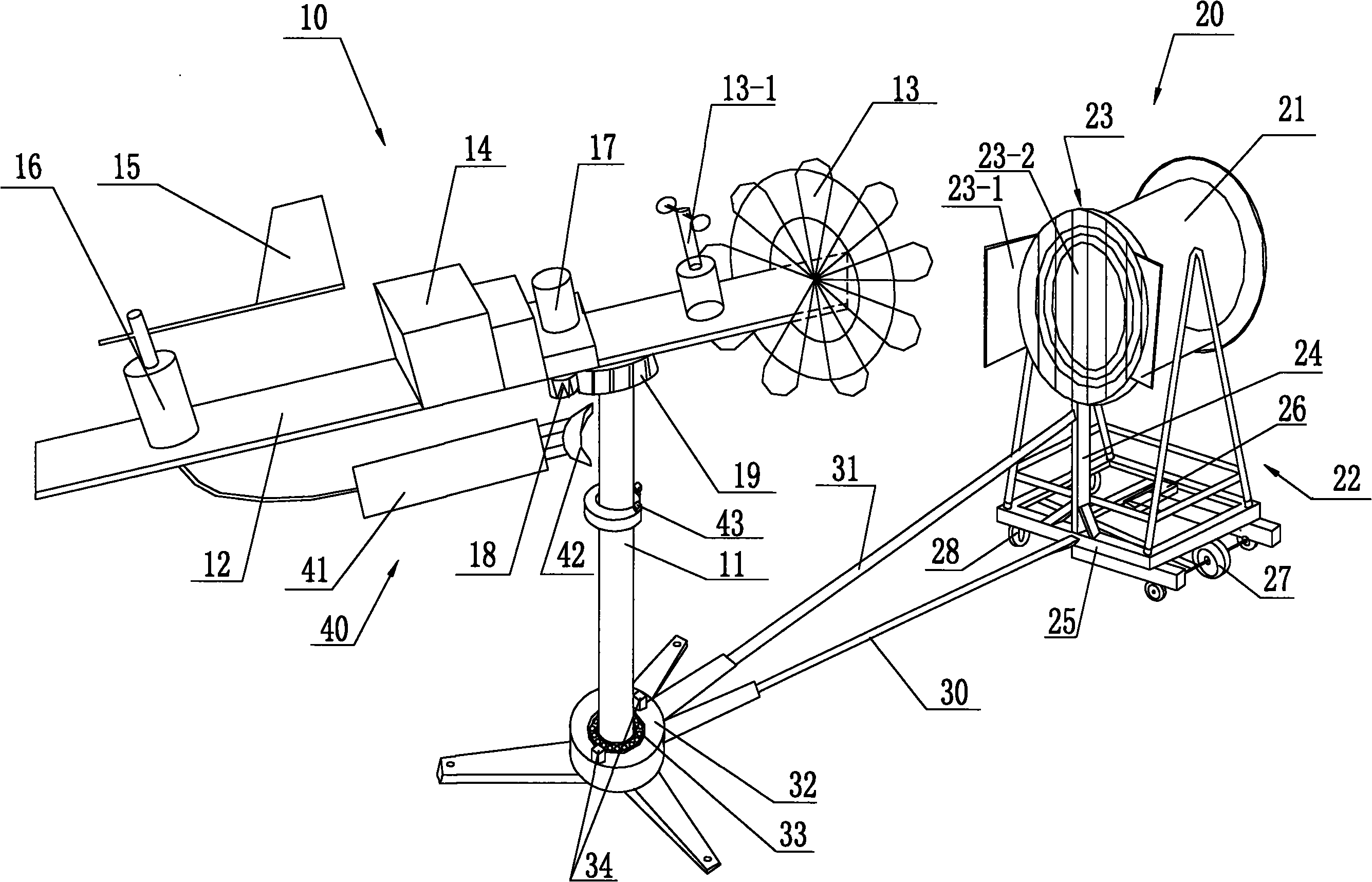

Wind direction tracking wind power generation simulating device

ActiveCN101839220ASave spaceExtended service lifeWind motor controlMachines/enginesWind forceImpeller

The invention provides a wind direction tracking wind power generation simulating device, which can solve the problem that the prior art lacks a wind power generation test device used for experimental teaching. The invention has the technical scheme that the wind direction tracking wind power generation simulating device comprises a wind power generation system and a wind source system which are controlled by a control system, wherein the wind power generation system comprises a fixed column, the column is provided with a cross beam which can rotate around the column, and the cross beam is provided with a generator set consisting of impellers and a generator; and the wind source system comprises a windmill and a fan, and the windmill drives the fan to rotate around the wind power generation system. The invention simulates the actual wind power generation device via a lab device, can detect the coming direction of the wind in real time, automatically regulates the direction of the windward side of the generator blade according to the existing wind direction so as to make the blade always face the coming direction of the wind, transfers the existing wind energy into electric energy to the maximum extent, and fills the gap in the market when being used as a teaching instrument.

Owner:青岛金博士自动化技术有限公司

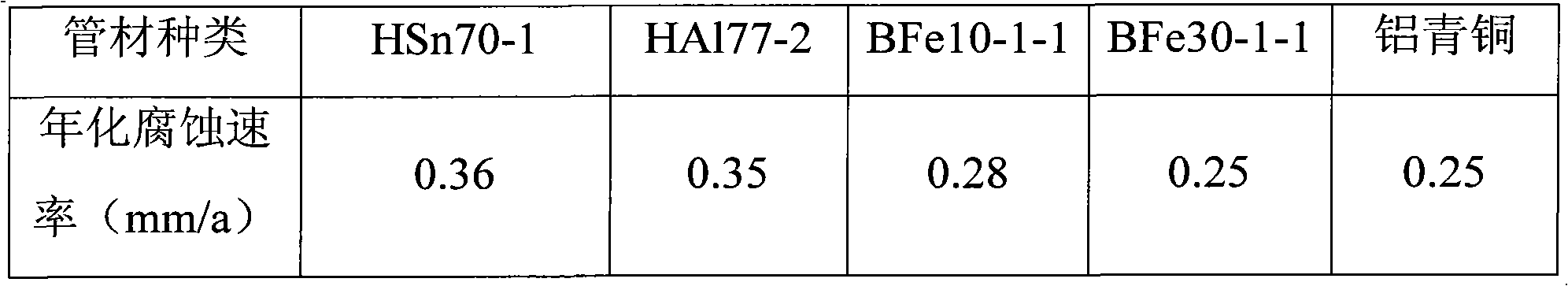

Magnetorheological polishing solution rheology testing device

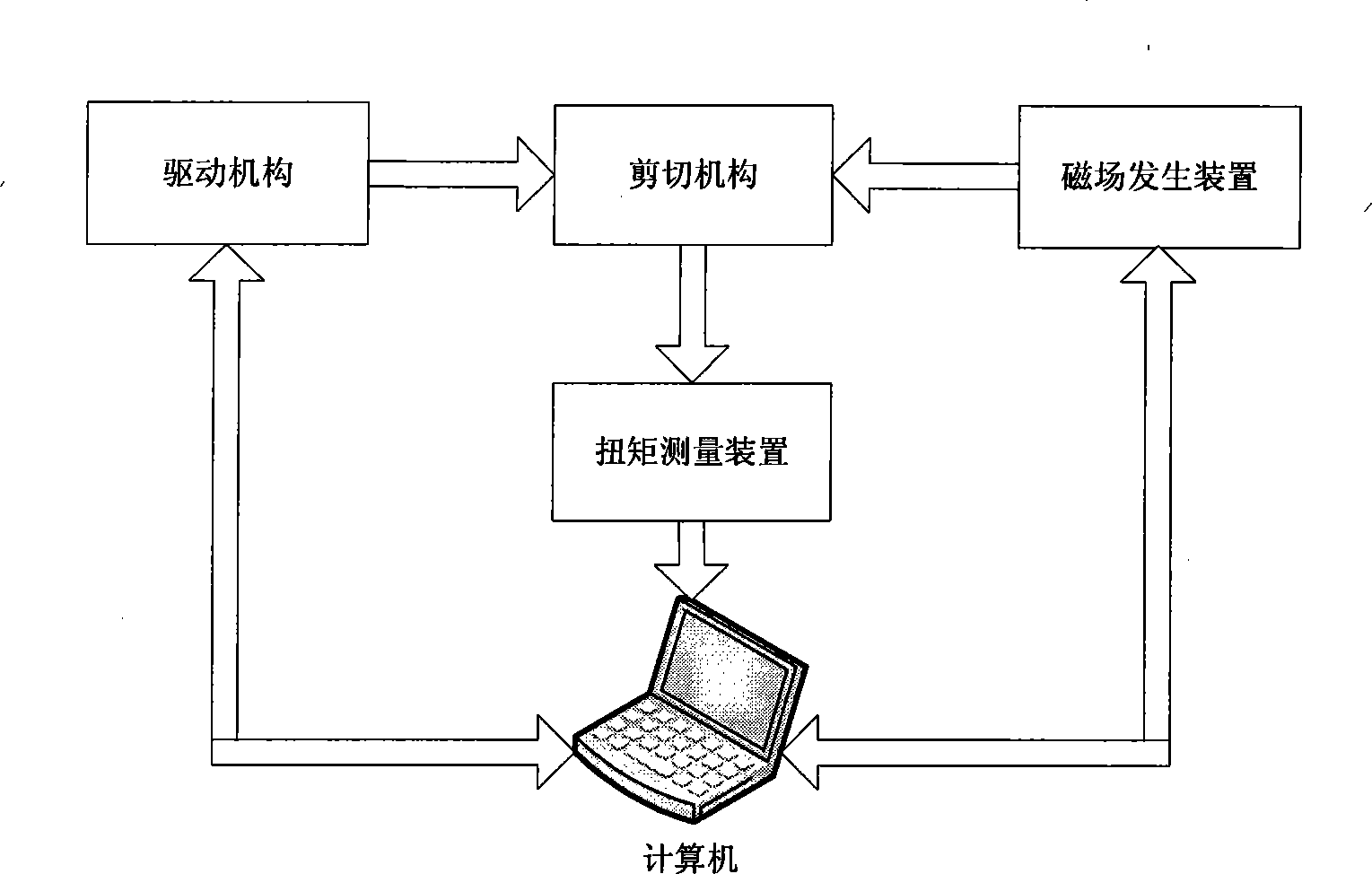

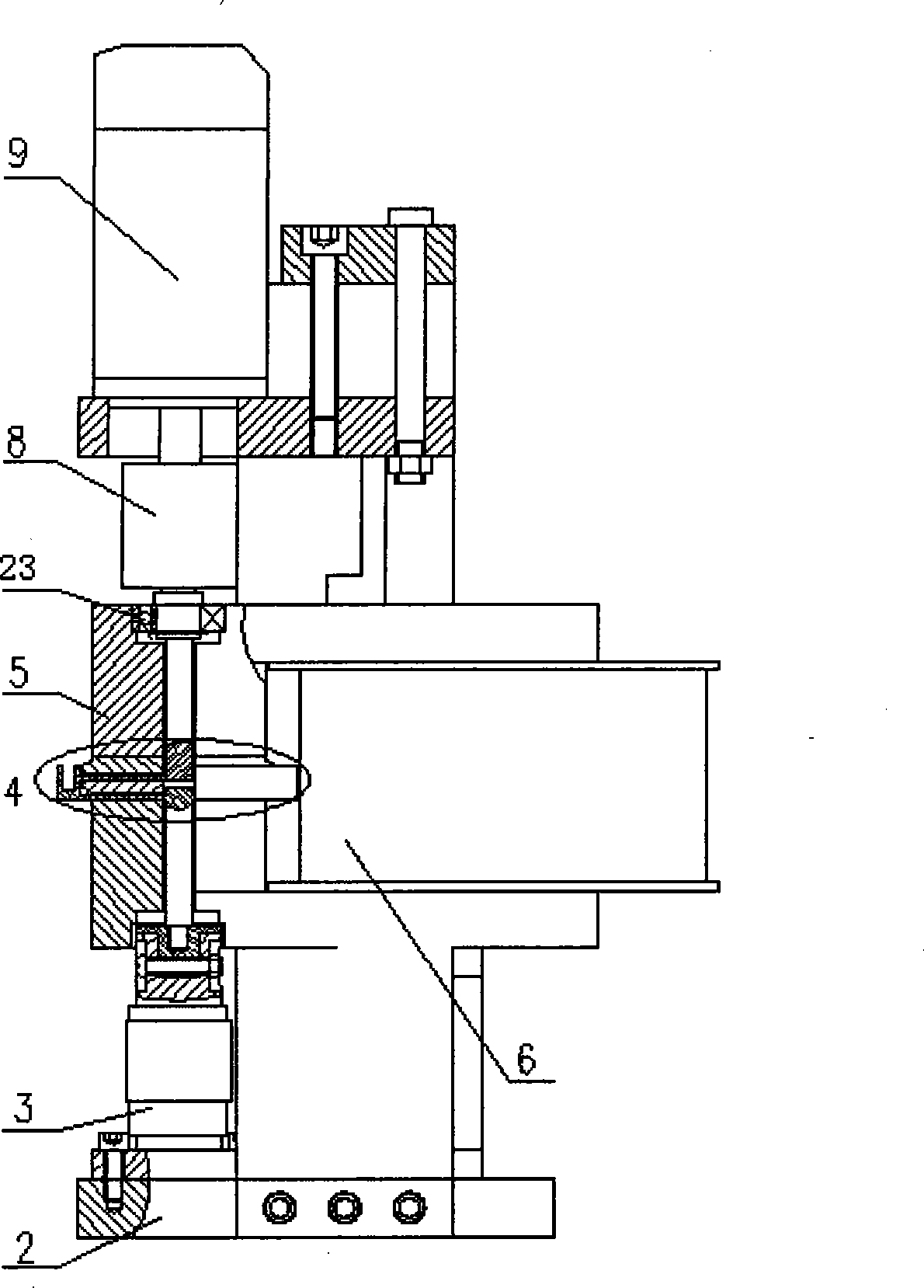

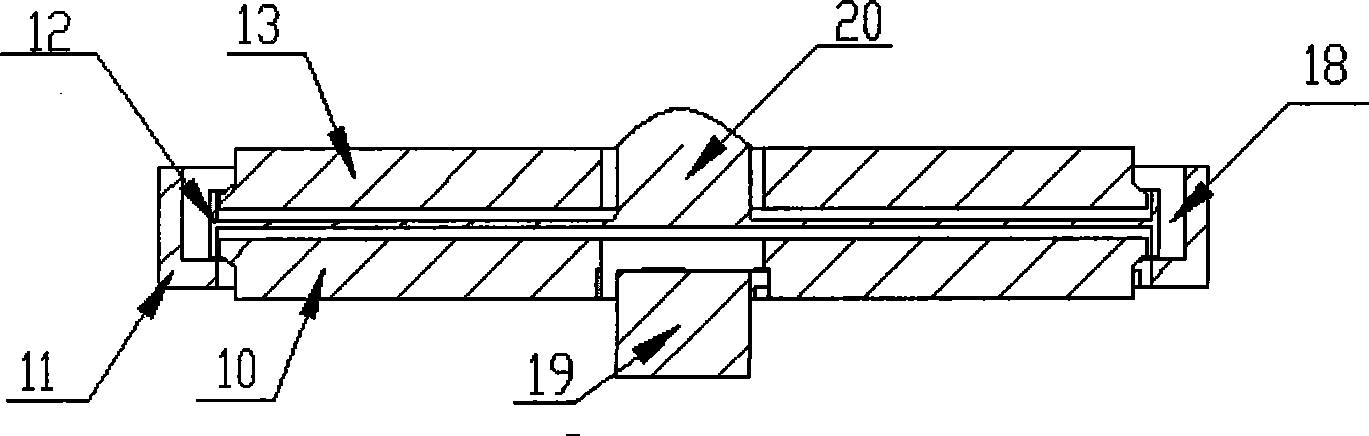

InactiveCN101246109ATest stableCompact structureFlow propertiesMaterial strength using steady shearing forcesEngineeringMagnetic field

A magnetic rheology polishing solution rheology testing device comprises a computer, a bracket, a torque measuring device fixed on the bracket, a magnetic field generating device, a shearing mechanism and an actuating device, the torque measuring device, the magnetic field generating device and the actuating device are connected with the computer, the shearing mechanism arranged in the magnetic field generating device comprises a shearing ring and a fixed ring, the shearing ring is fixed on the upper side of the fixed ring, the shearing ring and the external circumference on the fixed ring are respectively arranged with a shearing ring edge and a fixed ring edge which have a certain height, a liquid storing groove which is used for storing the magnetic rheology polishing solution is formed between the shearing ring edge and the fixed ring edge, the upper side of the center of the shearing edge which is discal is arranged with a rotation axis connected with the actuating device, and the lower side of the center of the fixed ring is arranged with a connecting axis connected with the torque measuring device. The invention has the advantages of simple and compact structure, low cost, convenient controlling, stable testing, high precision and the like.

Owner:NAT UNIV OF DEFENSE TECH

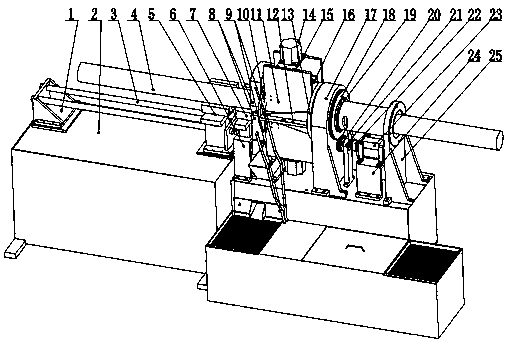

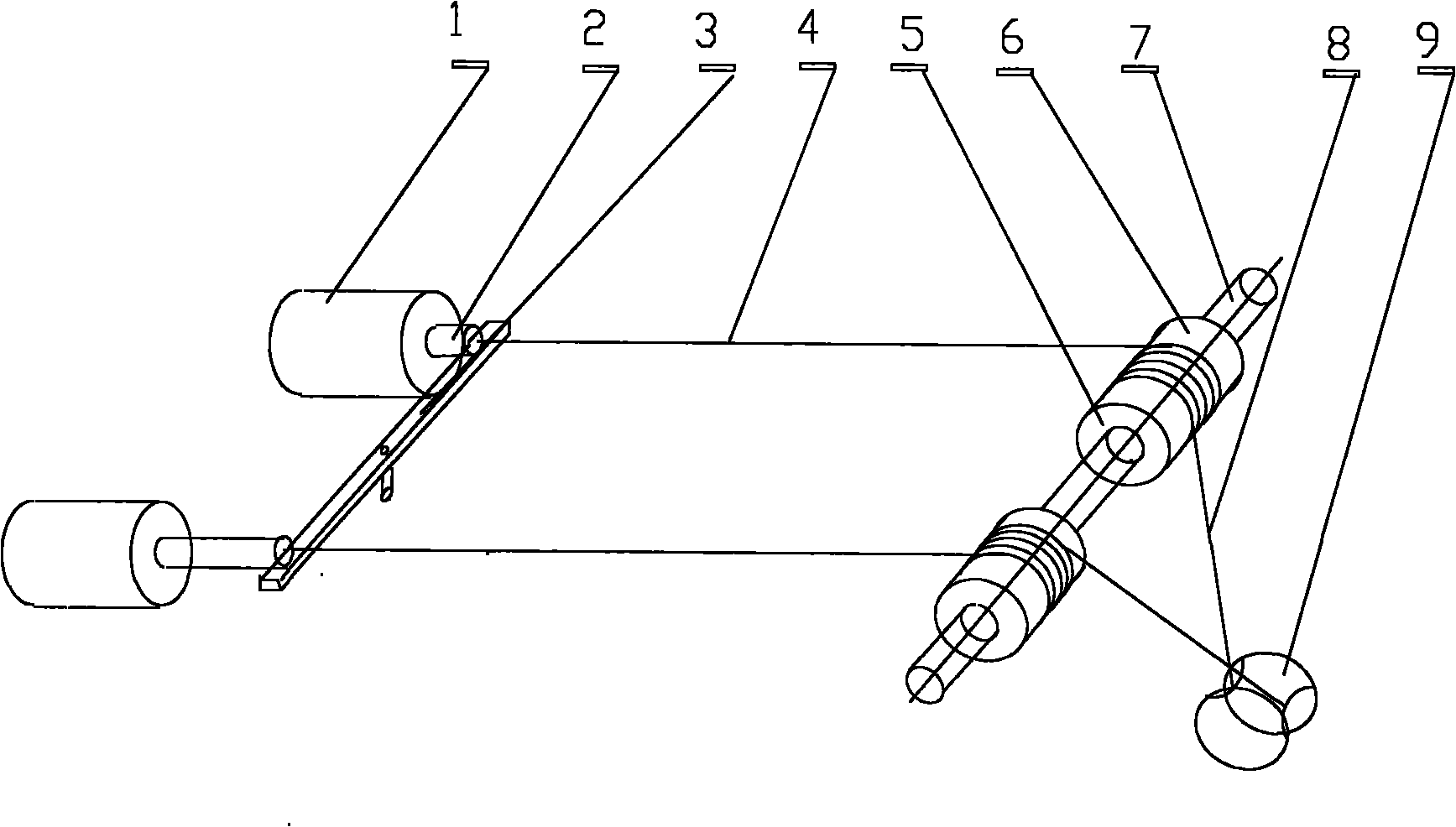

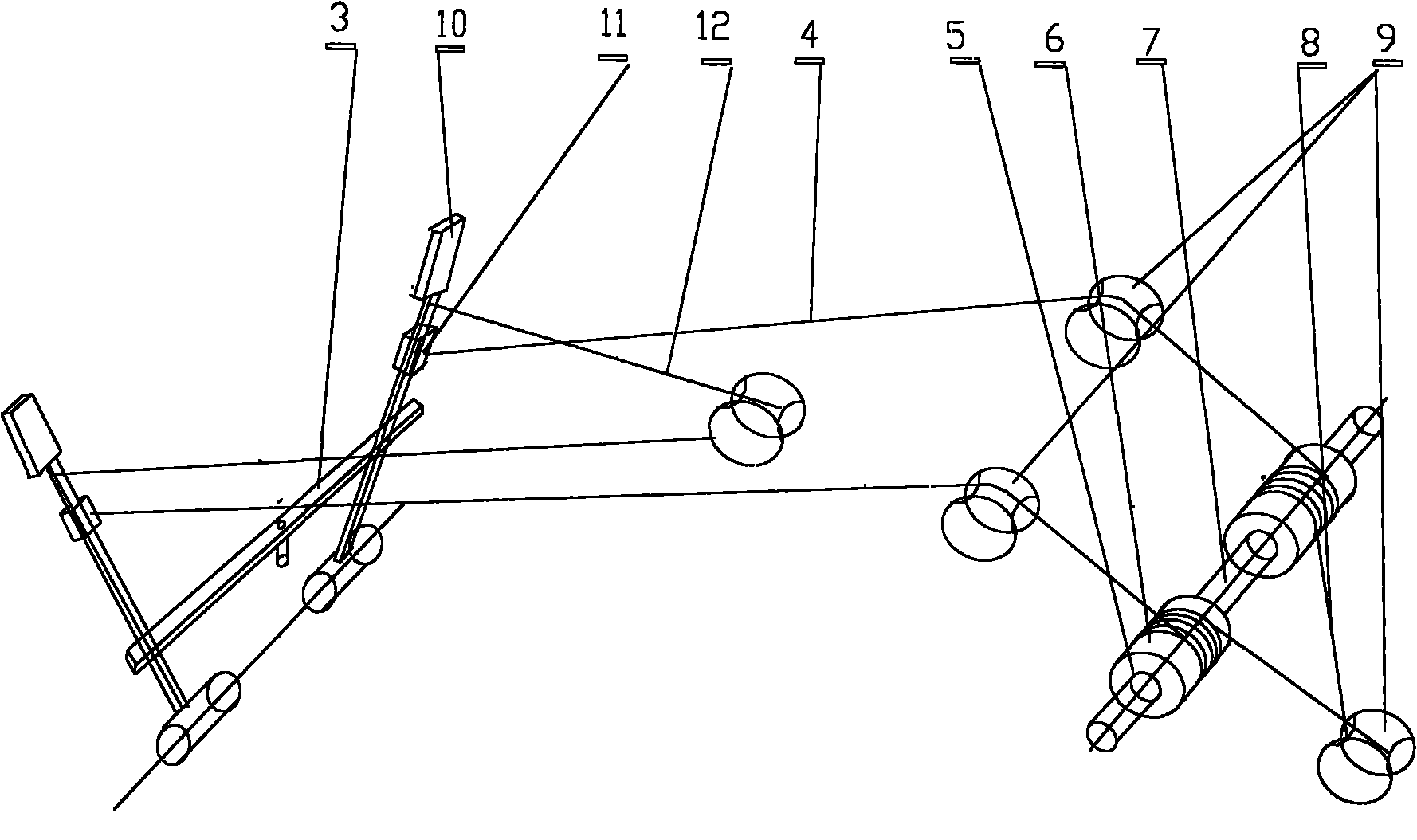

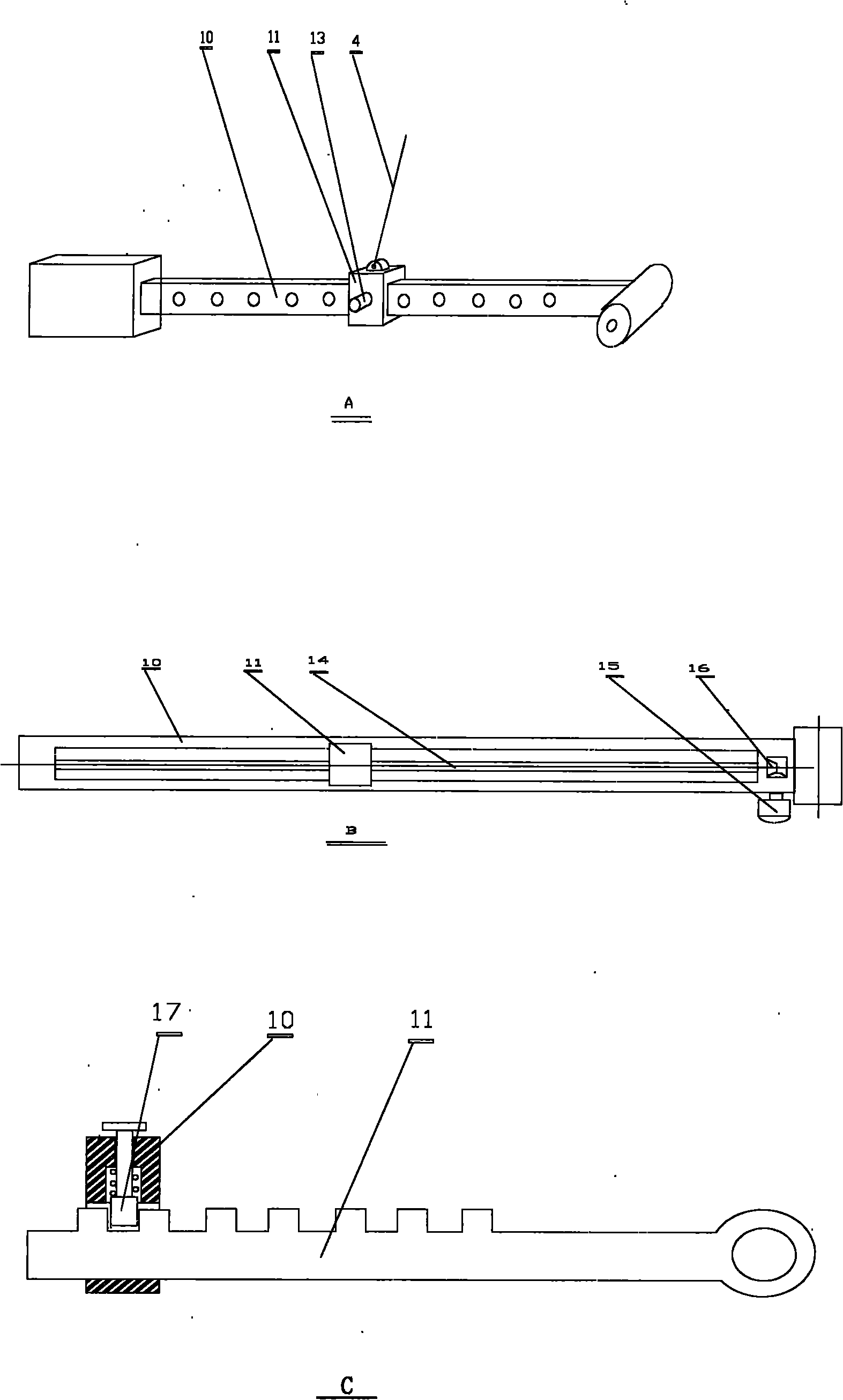

Device and method for thin wall stainless steel pipe double-cutter symmetric planetary automatic cutting

The invention discloses a device and a method for thin wall stainless steel pipe double-cutter symmetric planetary automatic cutting. According to the invention, cutting cutters are fixed on autorotation motors; the autorotation motors and the cutting feed adopt servo motors to achieve step-less speed regulation of cutting rotating speeds and a feed speed; rotating cutter discs are connected with the servo motors controlling the autorotation of the milling cutters by adopting guide rails to achieve the functions of cutting feed guiding and wound tube rotating cutting; through the arrangement that the two cutters are symmetric, in the cutting process, the cutting efficiencies of the two cutters are improved, the abrasion speed of the cutters is lowered, cutting force for a tube is symmetrical, the plastic deformation is relatively uniform, and the notch verticality is improved; through the adoption of PLC control, the problems of electric wire winding is solved through automatic regulation of autorotation and revolution of the cutters and cutting speed of cutting feed according to a cutting material, the size of the tube diameter, and the thickness of the tube; meanwhile, the problems of poor contact, abrasion, oxidation, short service life and the like caused by the form of adopting a carbon brush are solved.

Owner:HUBEI UNIV OF TECH

All-electric micro precise injection moulding machine

The invention discloses an all-electric micro precise injection moulding machine, which belongs to the field of high molecular material forming mechanism. The micro precise injection moulding machine mainly consists of an end-face plasticizing part, a plunger injection part, a mold-closing part, a mold and a machine frame. The all-electric micro precise injection moulding machine of the invention adopts the side feeding way; a plunger, a machine cylinder and a hot runner nozzle are arranged on one line; and a check valve is assembled; the injection resistance is low and the pressure loss is less; the end-face spiral disc plasticizing materials are used, so that the problems, such as difficult processing, low intensity and the like, of the traditional small-sized screws are solved basically; a servo motor is used to drive a ball screw pair to inject the plunger and open and close the mold, so that the accurate control of action positions and stepless speed regulation can be realized. The all-electric micro precise injection moulding machine disclosed by the invention combines the advantages of traditional micro injection forming technology, the end-face pre-plastication technology, the hot runner technology and the electric servo driving technology, and has the advantages of well plasticizing and mixed melting effects, high material utilization rate, less pressure loss and relatively simple structure.

Owner:BEIJING UNIV OF CHEM TECH

Concrete laser leveling machine driven by driving type pure electric power

ActiveCN103276655ASimple and lightweight structureReduce resistanceRoads maintainenceControl systemElectric machine

The invention relates to a concrete laser leveling machine driven by driving type pure electric power. The laser leveling machine comprises a machine skeleton, a machine power system, a control system, a laser measuring and controlling system and a leveling head capable of feeding automatically, wherein the leveling head can be connected and matched with the front end of the machine skeleton through an electric pusher capable of ascending or descending; the leveling head comprises a vibration plate, a vibration plate installation seat, a vibration motor installation seat, a vibration motor, a connection assembly, a steel rope and a spiral feeding mechanism, wherein the vibration motor is mounted on the vibration motor installation seat and is connected and matched with the vibration plate; the vibration plate is mounted on the vibration plate installation seat; the connection assembly is fixed on the side surface of the spiral feeding mechanism; and the vibration plate installation seat is suspended on the connection assembly through the steel rope and is movably matched with the spiral feeding mechanism through the connection assembly. The spiral feeding mechanism of the machine can automatically clear concrete accumulated in front of a scraper, thereby reducing working resistance; and at the same time, the spiral feeding mechanism is provided with the scraper, thereby keeping the accuracy of the surface elevation of the concrete.

Owner:上海捷舟工程机械有限公司

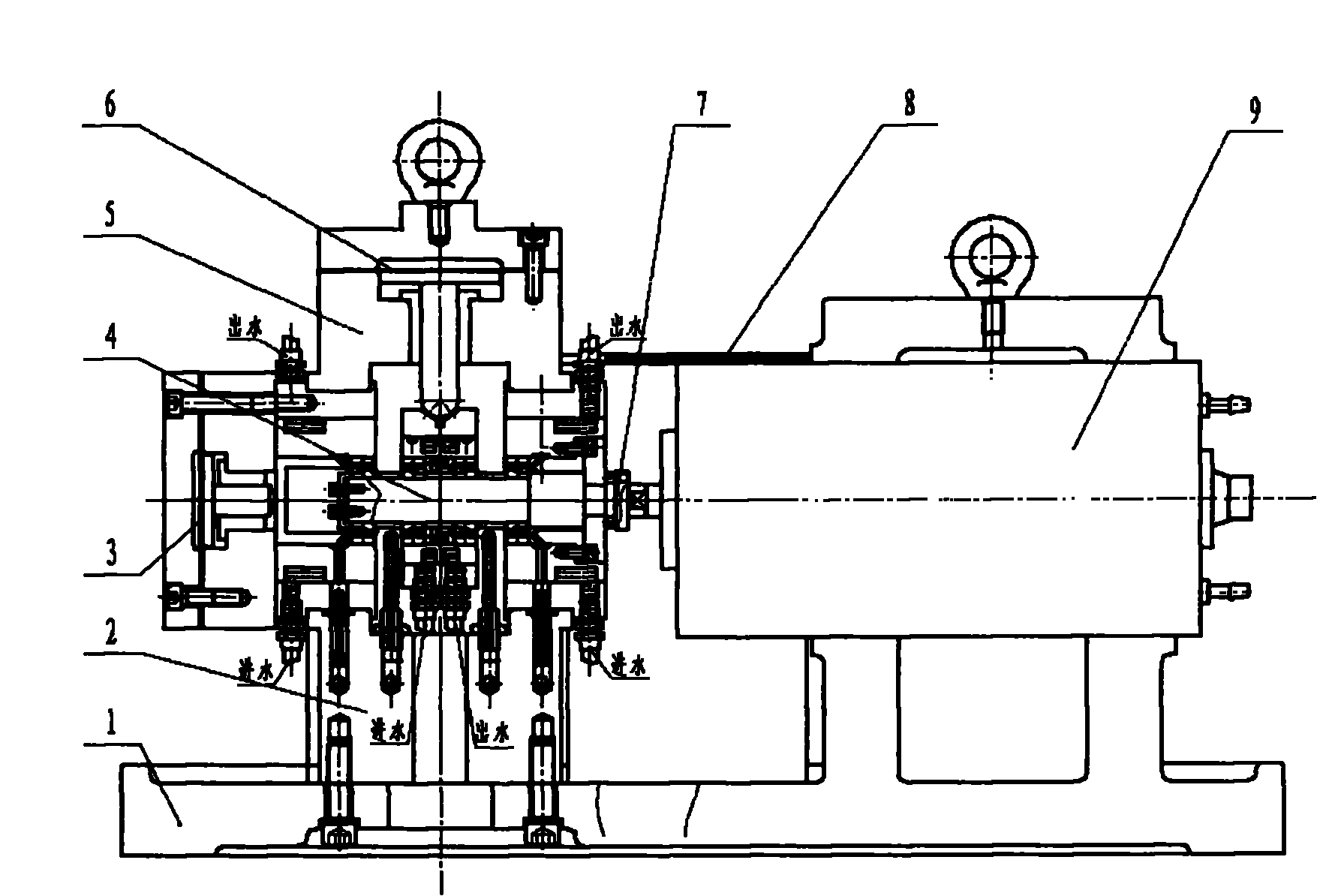

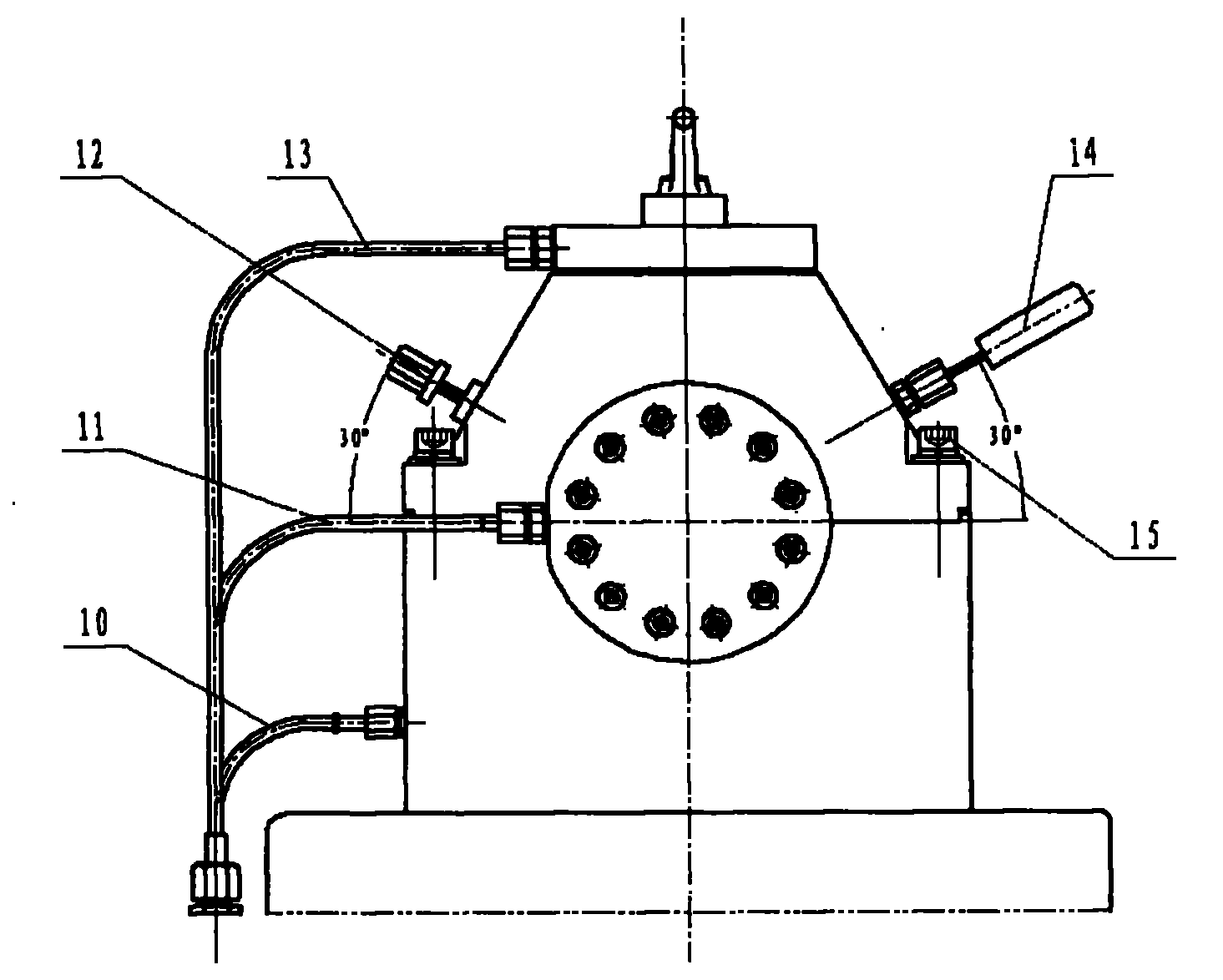

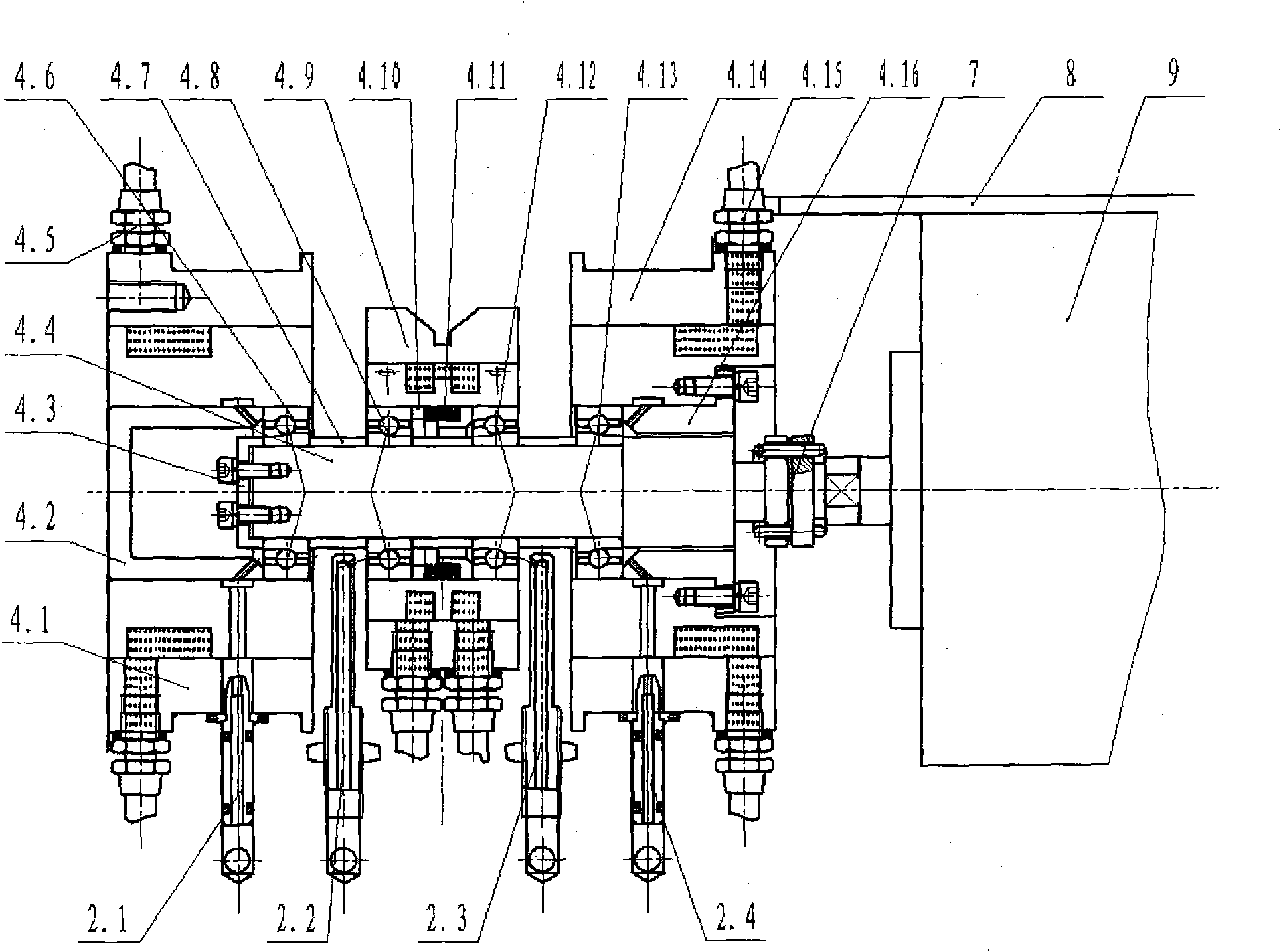

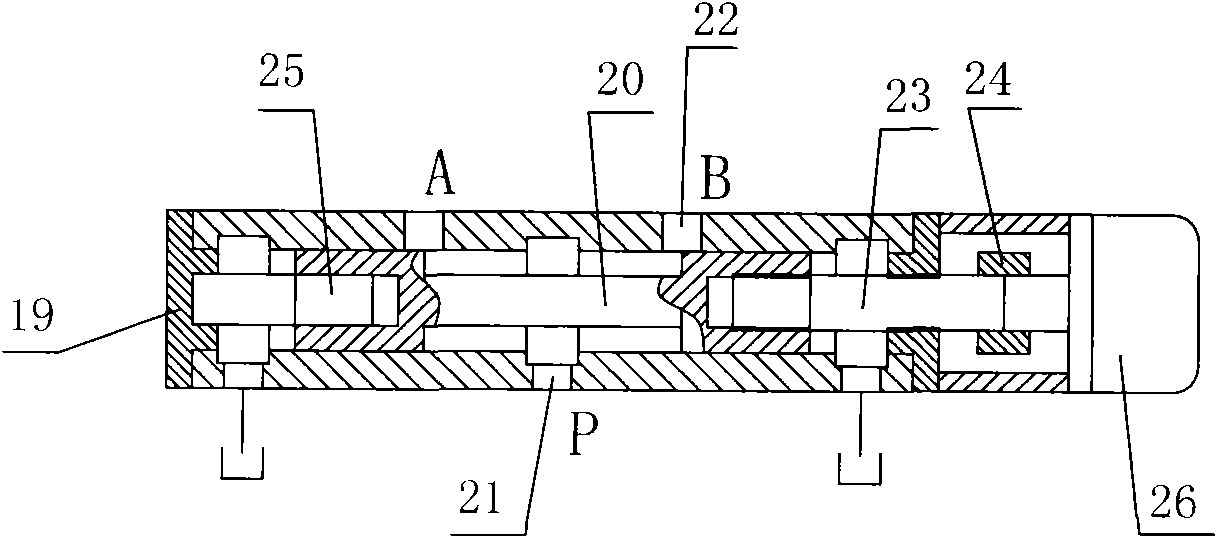

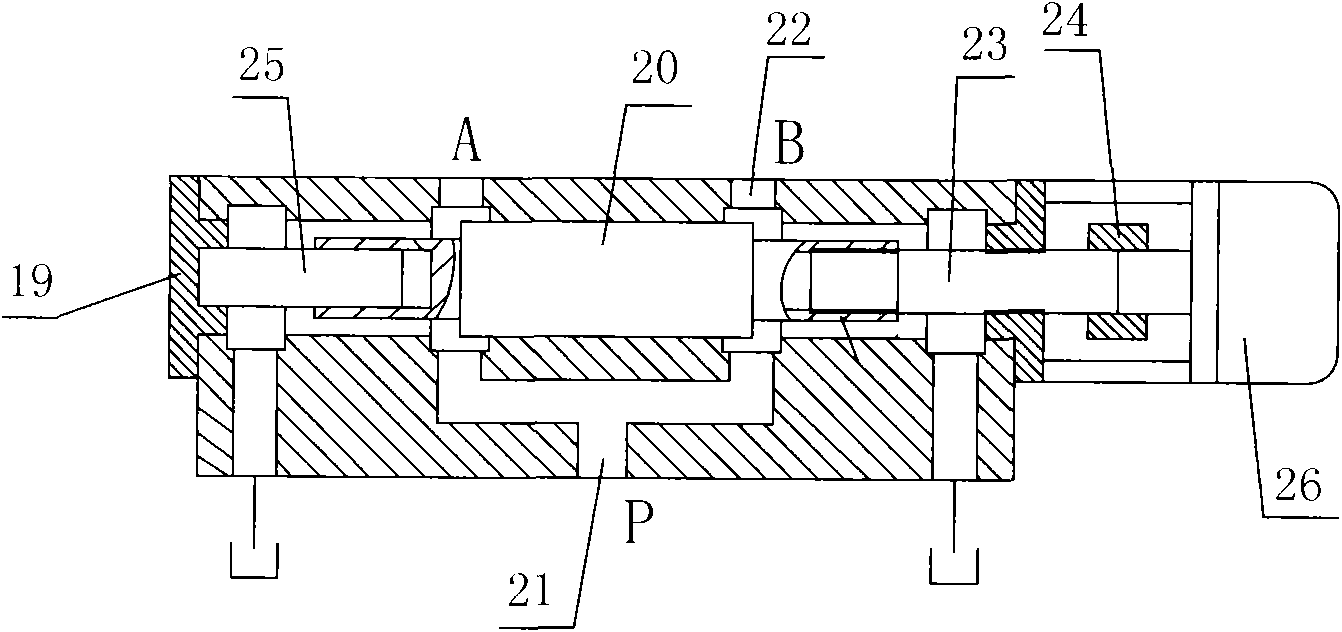

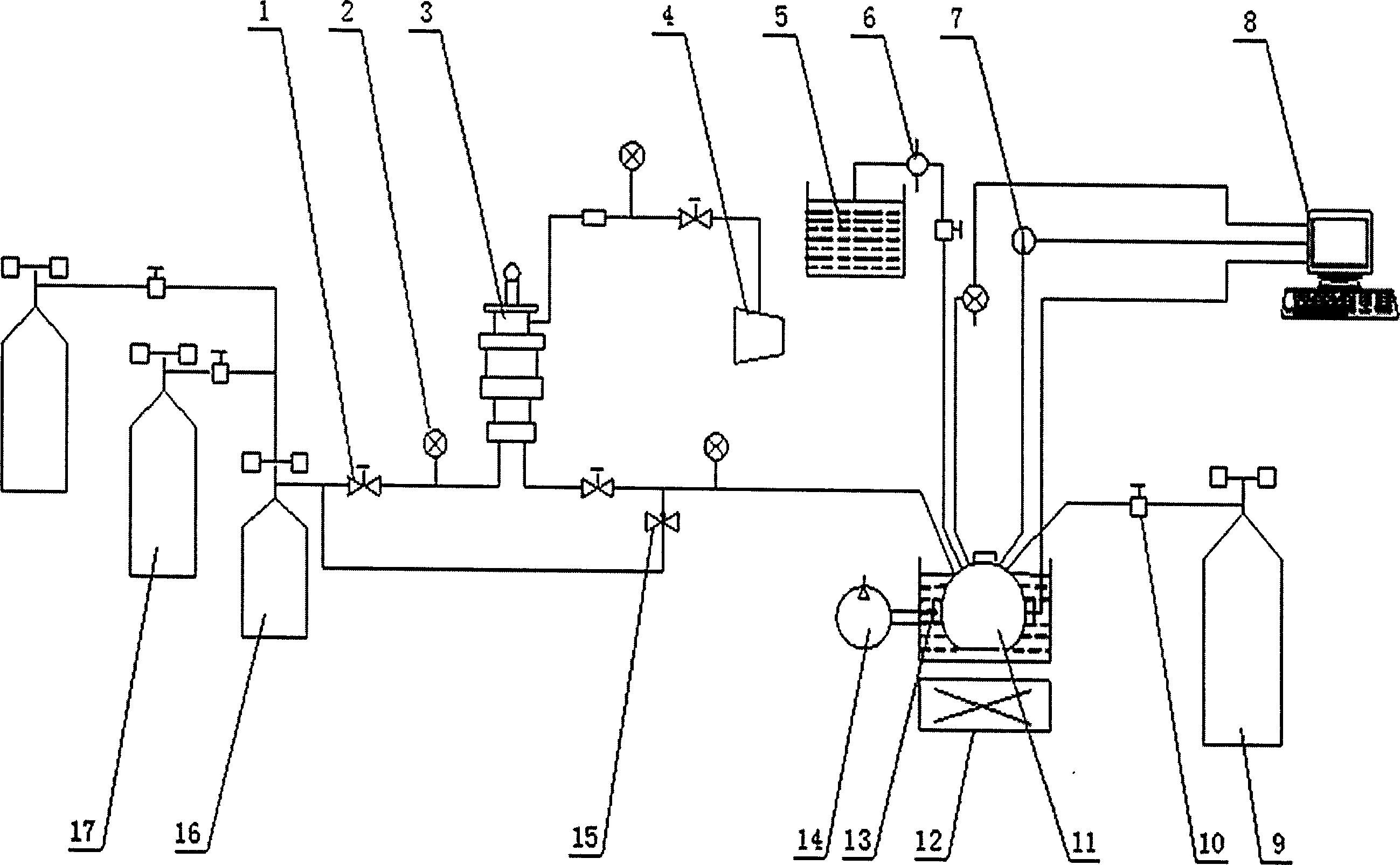

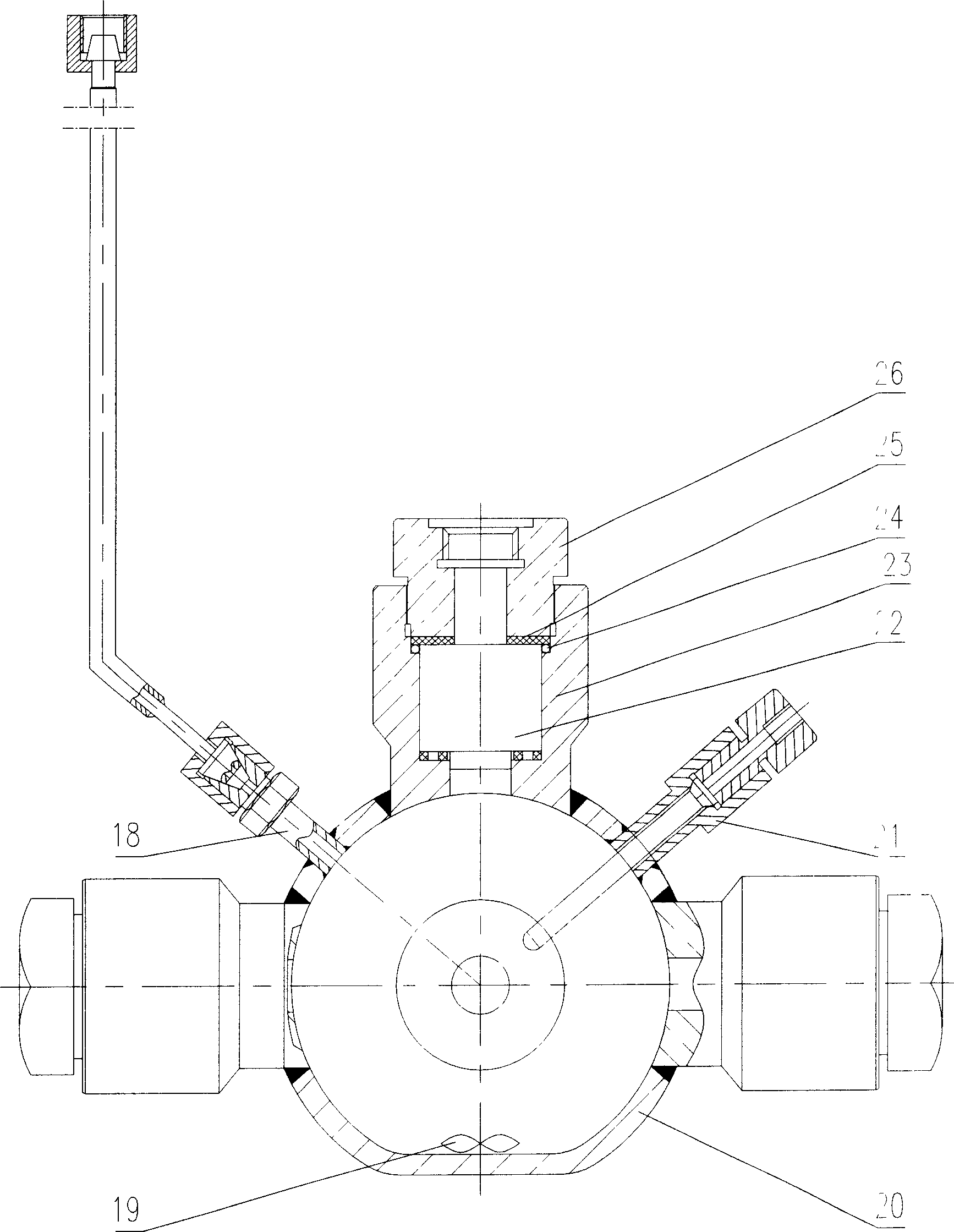

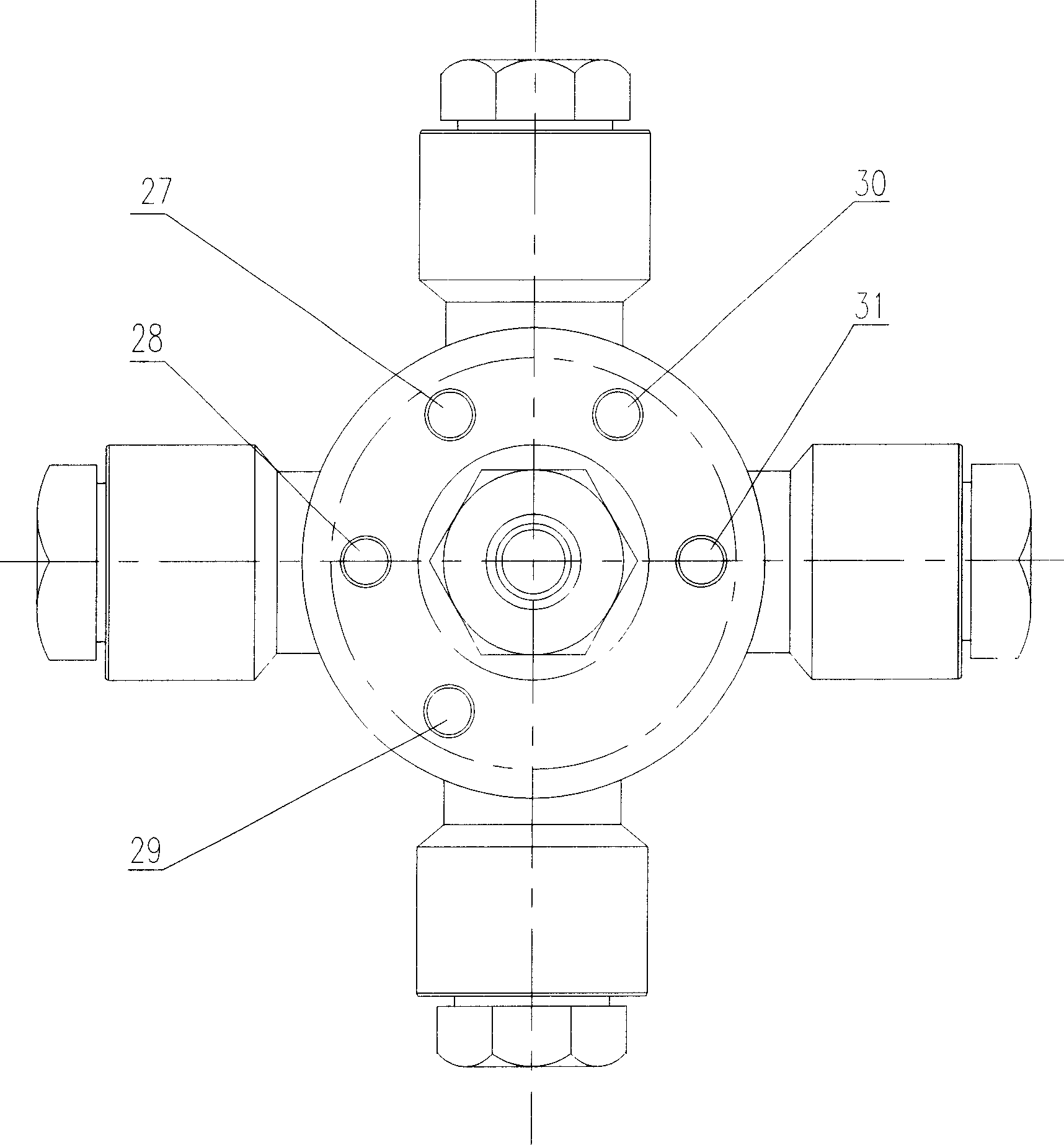

Mechanical seal test system for nuclear main pump

ActiveCN101639396ARealize stepless speed regulationAchieving a soft startFluid-tightness measurement using fluid/vacuumBuffer tankSystem pressure

The invention discloses a mechanical seal test system for a nuclear main pump, which is characterized in that the system comprises a medium concentration control zone, an injection medium processing zone, a frame zone and a reflux medium post processing zone. A test main shaft is used as a driven component in the frame zone; the test shaft is provided with a fluid static pressure seal or a fluid dynamic pressure seal or a fluid dynamic-static pressure combined seal. In the injection medium processing zone, a seal medium flow passage located between a low pressure container and a system seal cavity is respectively provided with a high pressure pump, a high pressure buffer tank and an energy accumulator, which are connected in series with a switchable magnetic filter, an organic filtering film and used,for providing a system pressure source; in the reflux medium post processing zone, a long pipe throttling cooler with a back pressure value is arranged at an outlet of the system seal cavity. The invention not only can simulate a fluid static pressure mechanical seal test for the nuclear main pump, but also can simulate a fluid dynamic pressure mechanical seal test for the nuclear mainpump, at the same time, the invention further can simulate a fluid dynamic-static pressure combined mechanical seal test for the nuclear main pump.

Owner:HEFEI GENERAL MACHINERY RES INST

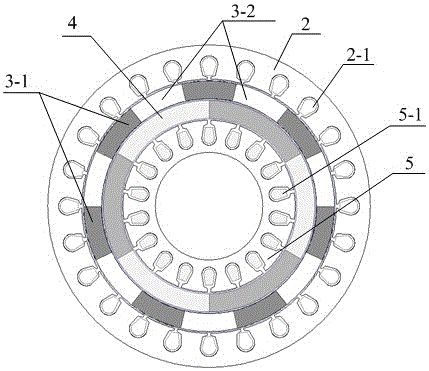

Modulation type brushless permanent magnet dual-rotor motor for hybrid electric vehicle

ActiveCN105978268AImprove power densitySimple structureDynamo-electric machinesPermanent magnet rotorElectric machine

The invention discloses a modulation type brushless permanent magnet dual-rotor motor for a hybrid electric vehicle. The modulation type brushless permanent magnet dual-rotor motor comprises a machine base, wherein a stator, an adjustable magnetic ring rotor, a permanent magnet rotor, an internal stator and an output shaft are arranged in the machine base from outside to inside in sequence; the adjustable magnetic ring rotor is connected to the output shaft of the adjustable magnetic ring rotor to directly drive vehicle wheels; the permanent magnets in the permanent magnet rotor are radially magnetized, and the polarities of the adjacent permanent magnet are opposite; the windings placed on the stator and the internal stator are all three-phase distributed type or concentrated windings; and the adjustable magnetic ring rotor comprises a magnetic conducting material and a non-magnetic-conducting material which are uniformly staggered in a circumferential direction. The modulation type brushless permanent magnet dual-rotor motor provided by the invention is combined with the concentric type magnetic gear design based on magnetic field modulation; a modulation type motor is introduced to a hybrid power synthetic system; the coupling and distribution of the hybrid power, and the stepless speed change of the vehicle are realized; a combination of an electric brush and a collecting ring is omitted, and a part of mechanical gears in the existing system are replaced; due to the radial concentric type arrangement structure, the space utilization ratio is improved; and meanwhile, the power density of the motor, and the transmission efficiency and operational reliability of the system are improved.

Owner:YANGZHOU UNIV

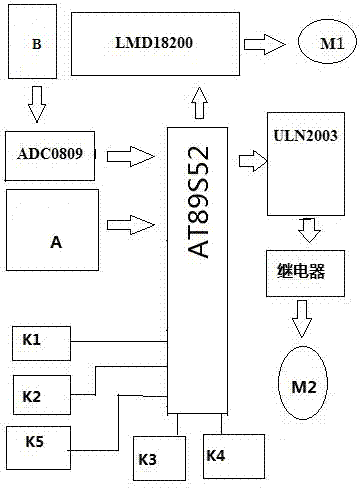

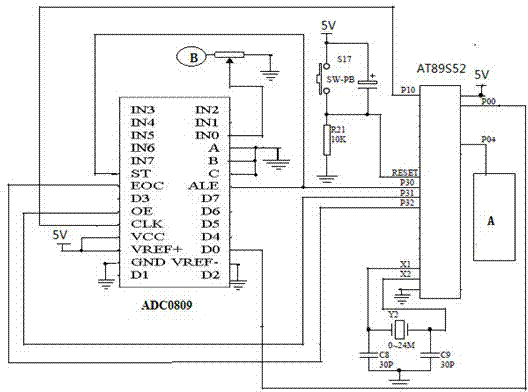

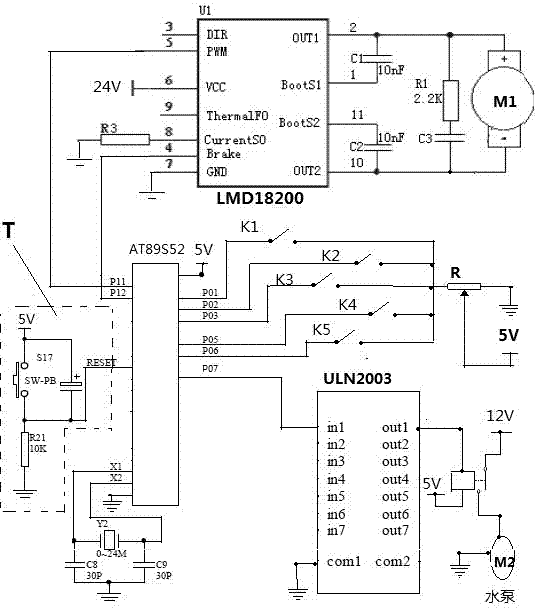

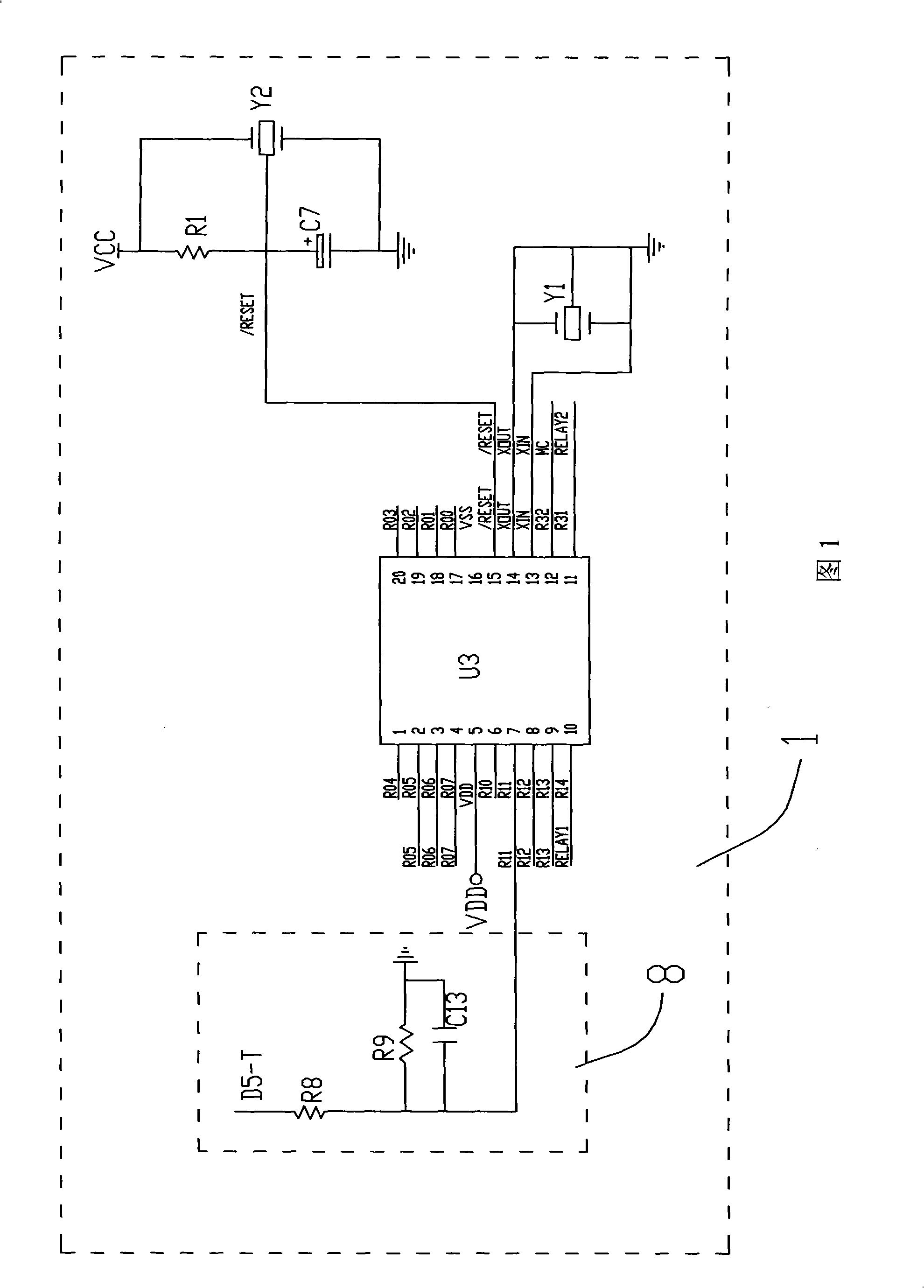

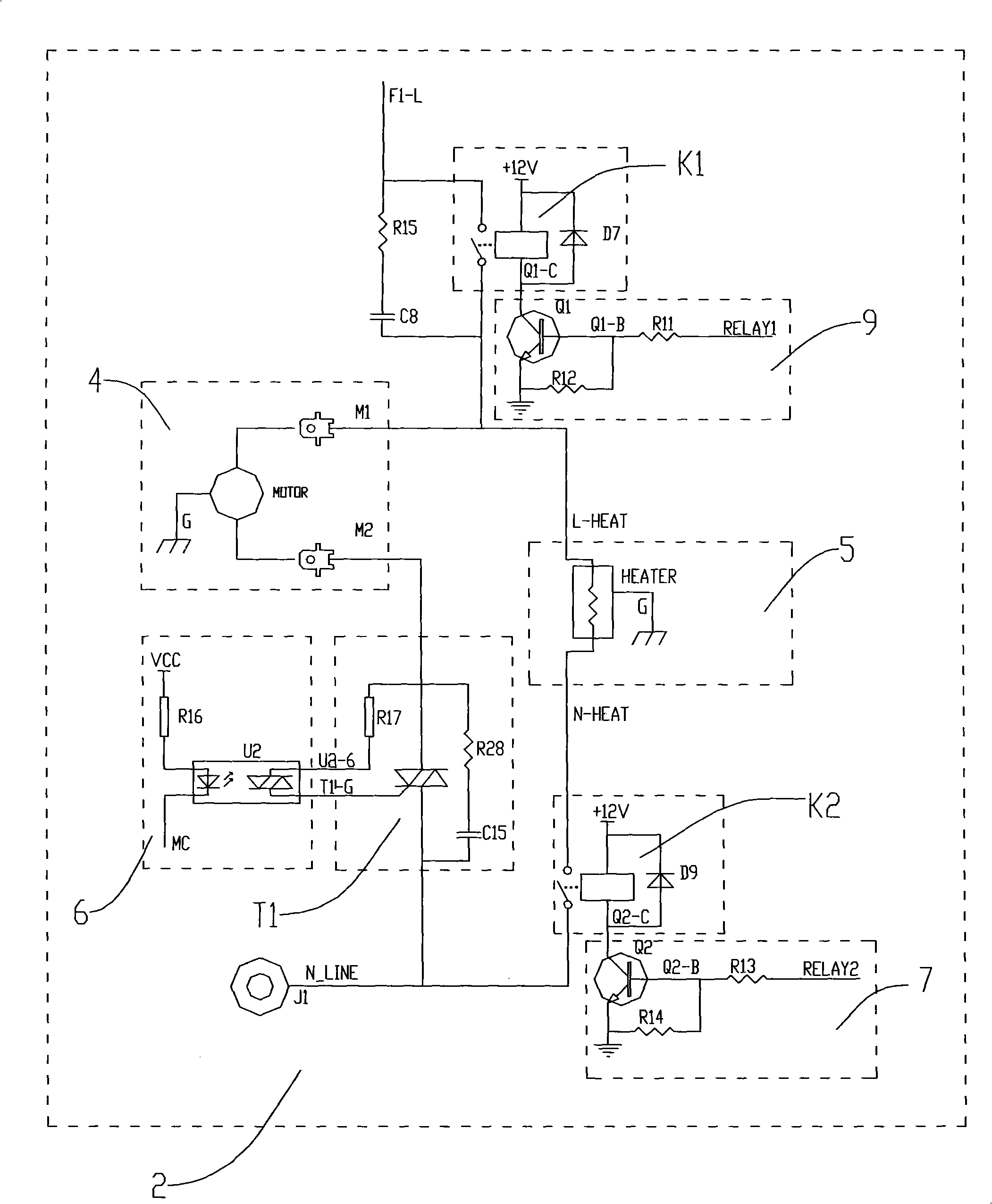

Intelligent stepless speed change control system for windscreen wiper

ActiveCN102887131AAchieve closureRealize stepless speed regulationVehicle cleaningMicrocontrollerAutomatic control

The invention relates to a windscreen wiper control system, in particular relates to an intelligent stepless speed change control system for a windscreen wiper, and belongs to the technical field of windscreen wiper control. The intelligent stepless speed change control system for the windscreen wiper mainly comprises a raining monitoring sensor module, a rainfall detecting sensor and a windscreen wiper; the raining monitoring sensor module and the windscreen wiper are mounted on the surface of a windscreen of a car; the rainfall detecting sensor is mounted in a rainwater leaking part below the windscreen; the raining monitoring sensor module is connected with a single chip AT89S5S2; the rainfall detecting sensor is connected with the single chip AT89S5S2 through a chip ADC0809; the windscreen wiper is connected with the single chip AT89S5S2 through a chip LMD 18200; and the power of the intelligent stepless speed change control system for the windscreen wiper is provided with a car storage battery. According to the intelligent stepless speed change control system for the windscreen wiper provided by the invention, the raining monitoring sensor module and the rainfall detecting sensor are adopted for detecting, therefore, high detecting precision is achieved; and moreover, the sensors are unique in design and low in cost; the single chip performs PWM (Pulse Width Modulation) control to a motor of the windscreen wiper, so that real stepless speed change can be achieved; and the manual control and automatic control are combined, thus high humanization is embodied.

Owner:昆明理工大学设计研究院有限公司

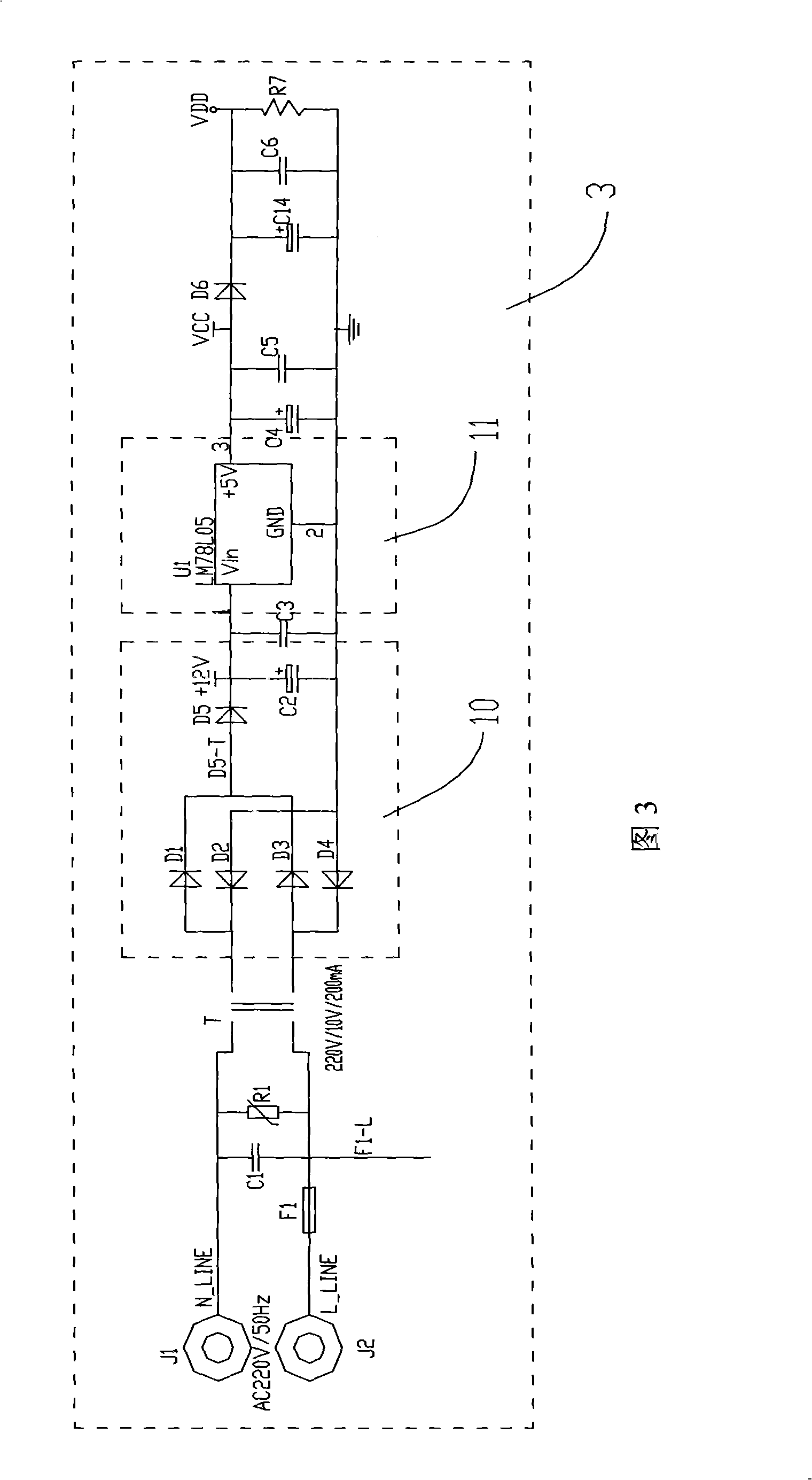

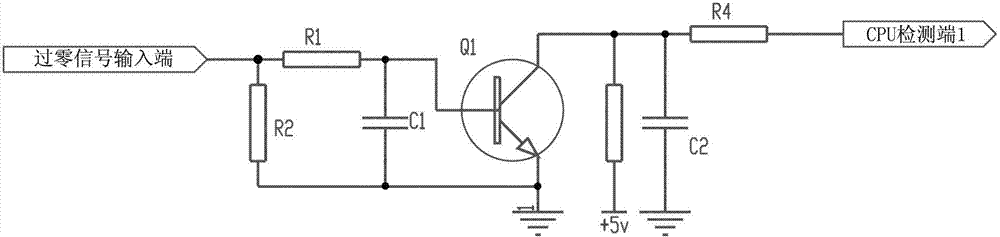

Circuit of pulping machine

ActiveCN101354573ATo achieve the purpose of not burningRealize stepless speed regulationProgramme control in sequence/logic controllersFood preparationDIACSlow-start

The invention relates to a circuit of a pulper. The circuit of a pulper comprises a control unit, an execution unit and a power source unit, wherein the control circuit comprises a central processing chip; the execution unit comprises an electric machine and an electric heating device which are connected in parallel; the electric machine is connected in series with a bidirectional thyristor, while the electric heating device is connected in series with a second relay; the central processing chip is connected with the bidirectional thyristor through a light-coupled control circuit and the electric heating device through a second relay control circuit; and the control unit also comprises a zero-crossing detection circuit connected with the central processing chip for detecting a power source signal. Because the circuit is provided with the bidirectional thyristor and the zero-crossing detection circuit, stepless speed regulation can be realized to reach the goal of slow start, slow stop or slow stirring. Moreover, because the pulper controlled by the circuit can carry out crushing and stirring to pulp-preparing materials while heating the materials, and prevents the materials from sticking on a tube and a bottom, and the pulper can also improve pulp yield and ensures that the manufactured pulp is more delicious.

Owner:MIDEA GRP CO LTD

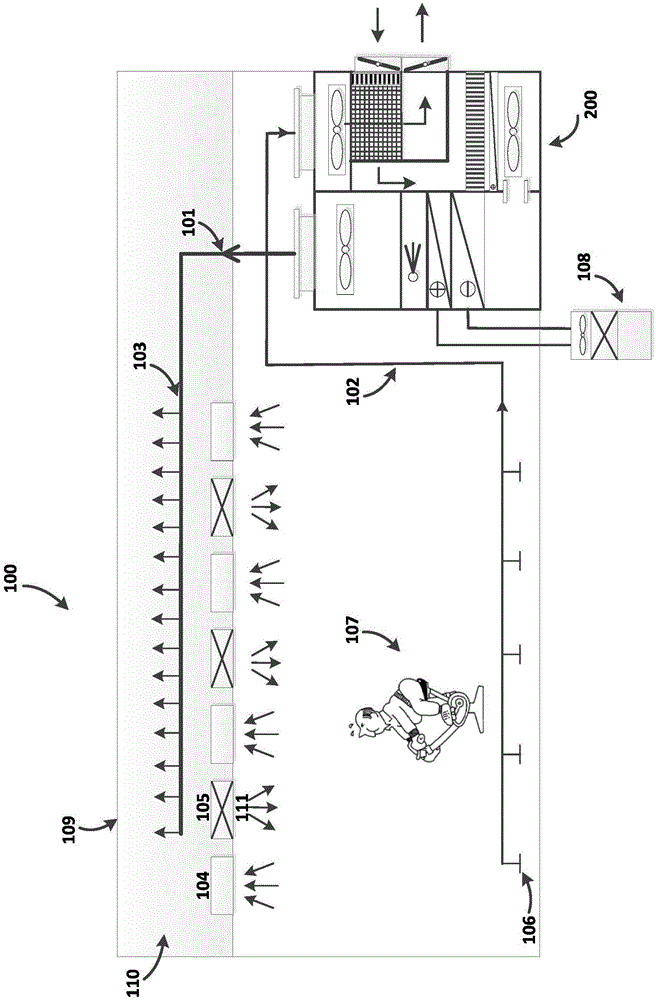

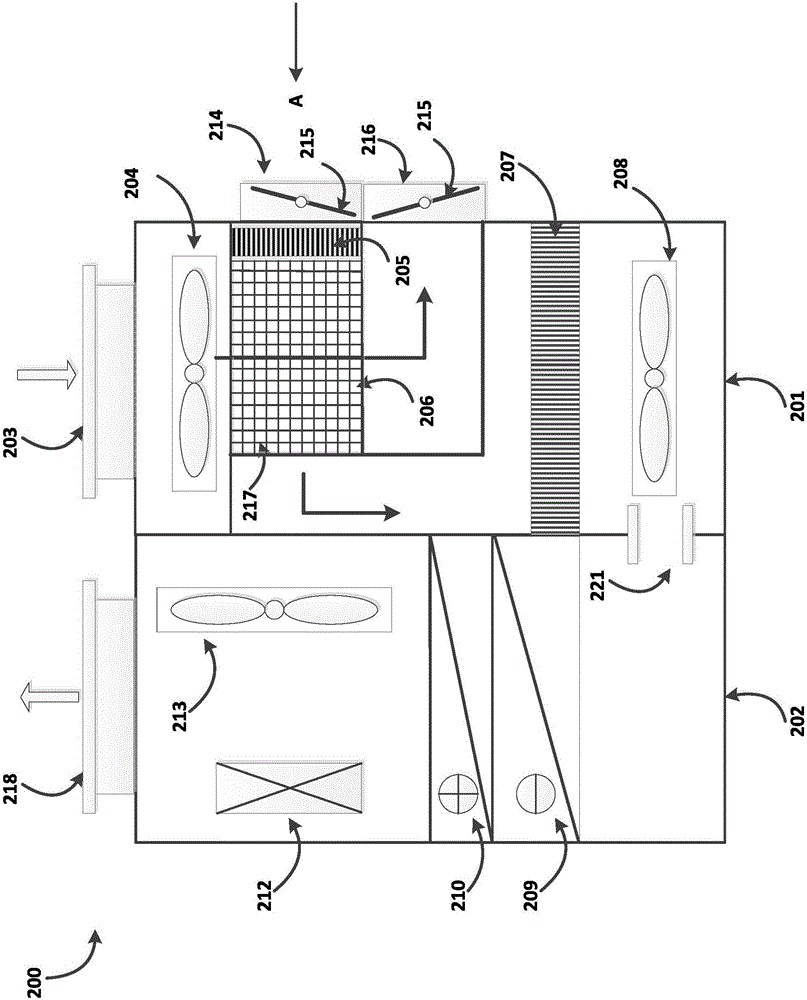

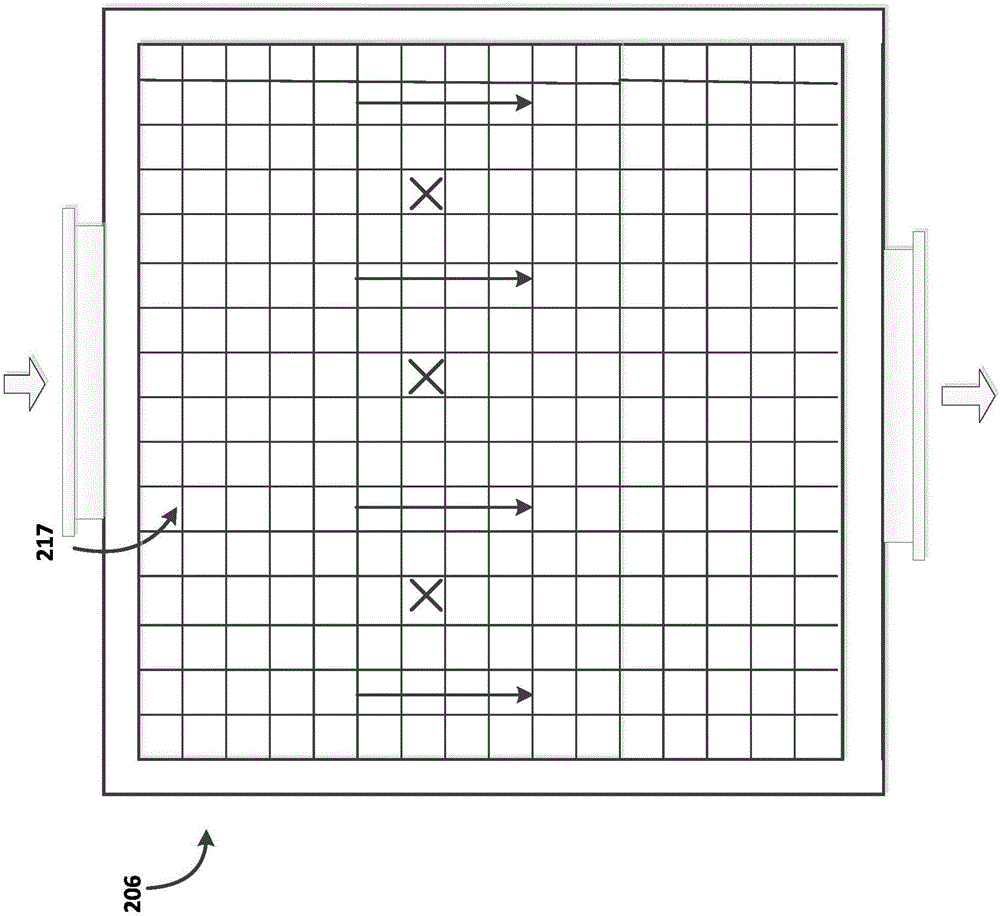

Upper-supply and upper-return type air purification system

InactiveCN106403137AReduce equipment costsReduce installation costsEnergy recovery in ventilation and heatingMechanical apparatusAir treatmentAir purification

The invention relates to an upper-supply and upper-return type air purification system which comprises a gym air exhaust and ventilation integrated cabinet, an air supply ceiling and an exhaust port, wherein the gym air exhaust and ventilation integrated cabinet is used for inputting fresh air and air to be exhausted, treating the fresh air and the air to be exhausted and outputting the fresh air and the air to be exhausted; the air supply ceiling is used for evenly mixing the induced fresh air and returned air, filtering the induced fresh air and the returned air and outputting the induced fresh air and the returned air into a room; and the exhaust port is used for outputting the air to be exhausted in the room to the outside through the gym air exhaust and ventilation integrated cabinet. Through the air purification system, a plurality of treatment functions including ventilation, exhaust, dehumidification, temperature adjustment, purification and the like are achieved at a time, and waste heat / waste cold is utilized so that energy saving can be achieved, the fresh air treatment function and the returned air treatment function are completely separated, and energy saving is achieved; through a fan filter unit (FFU) installed in the position of the air supply ceiling, fresh air is input into the room (upper supply), returned air is sucked through an air return port in the position of the air supply ceiling (upper return), and an independently arranged air return treatment device, an air return pipeline and a passageway are completely omitted; and the returned air and the fresh air can be evenly mixed, and the outlet air quality is improved.

Owner:殷晓冬

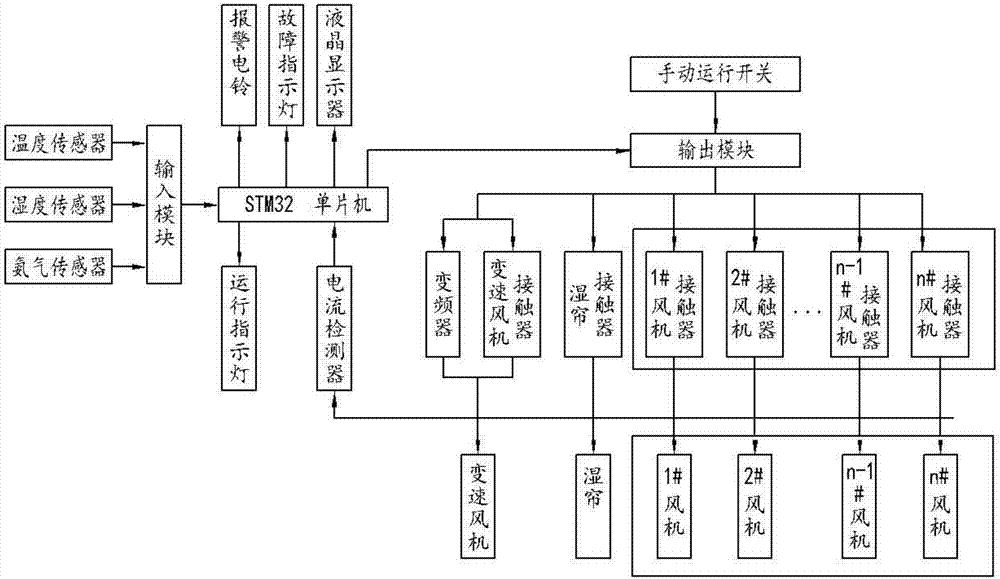

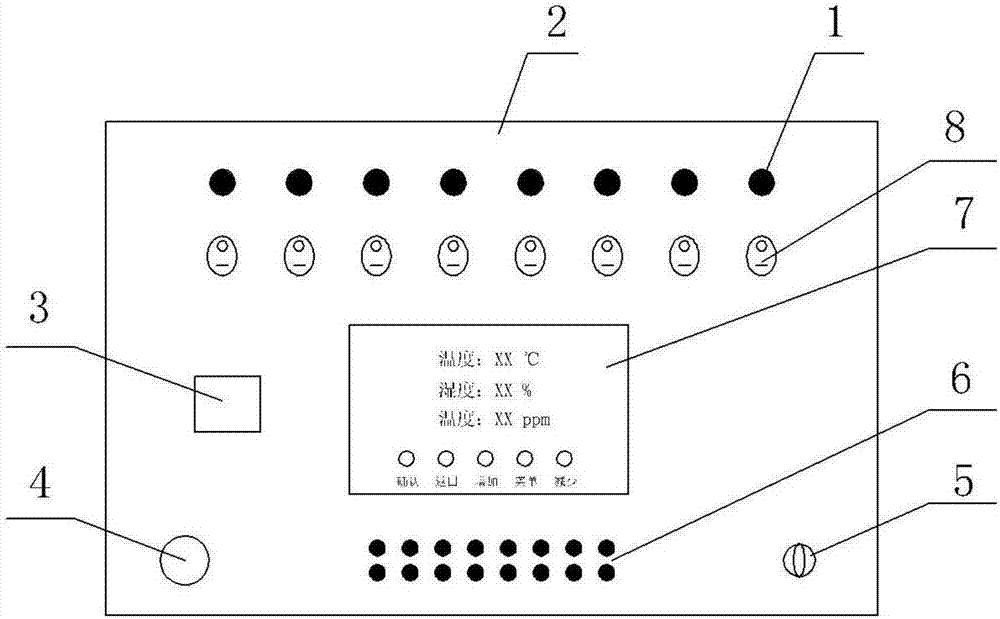

Hog house environment intelligent control system

InactiveCN106933279ARealize stepless speed regulationStrong speed regulation abilitySimultaneous control of multiple variablesPig farmsEngineering

The invention provides an intelligent control system for pig house environment, which belongs to the technical field of pig farm breeding equipment, including STM32 single-chip microcomputer, operation panel, sensor, input module, output module, frequency converter, variable frequency fan contactor, variable speed fan, wet curtain contact device, cooling pad, constant speed fan contactor and constant speed fan. The temperature, humidity and ammonia control parameters of the pig house environment automation control system of the present invention can be adjusted by themselves, and different houses can adjust the control range of temperature, humidity and ammonia according to the needs, so as to give pigs a suitable growth environment, Guarantee the health and growth speed of pigs, and increase the economic benefits of the farm; the system of the present invention adopts highly intelligent and humanized design, fully automatic operation control according to the set parameters, no need for on-site personnel, 24-hour all-weather operation, one-time input, benefit for ten years.

Owner:安徽国农畜牧科技有限公司

Electromagnetic piston propeller

InactiveCN104554685AReduce consumptionPlay a power-saving effectPropulsive elementsReciprocating motionStator coil

The invention discloses an electromagnetic piston propeller, and relates to ship power. The electromagnetic piston propeller has the advantages that a piston can do work in a reciprocating manner by the aid of electromagnetic force, so that water which flows into a piston barrel can be discontinuously drained, and reacting force can be generated; one end of the piston barrel is closed by an umbrella-shaped cap, the other end of the piston barrel is connected with a barrel which comprises a necked nozzle, and the inside of the piston barrel is divided into two portions for a linear motor and the piston by a partition plate; a rotor of the linear motor can reciprocate via a combination of a shaft and the piston under the effect of movable electromagnetic fields generated by an electrified stator coil, so that the piston can discontinuously carry out water suction and pressurization operation; water flow is constrained in the piston barrel, and accordingly the electromagnetic piston propeller is low in energy loss and high in water pressure.

Owner:徐建宁

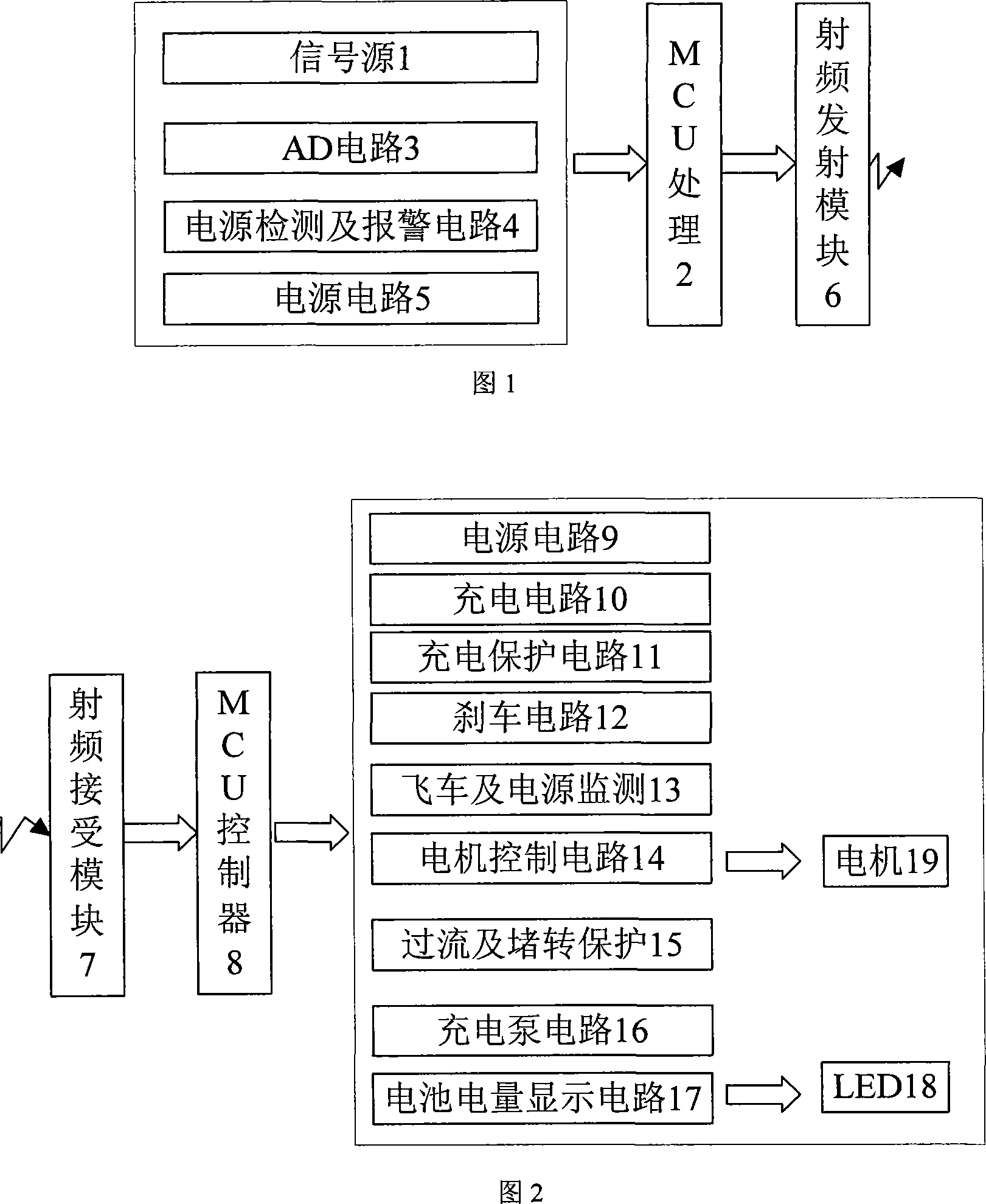

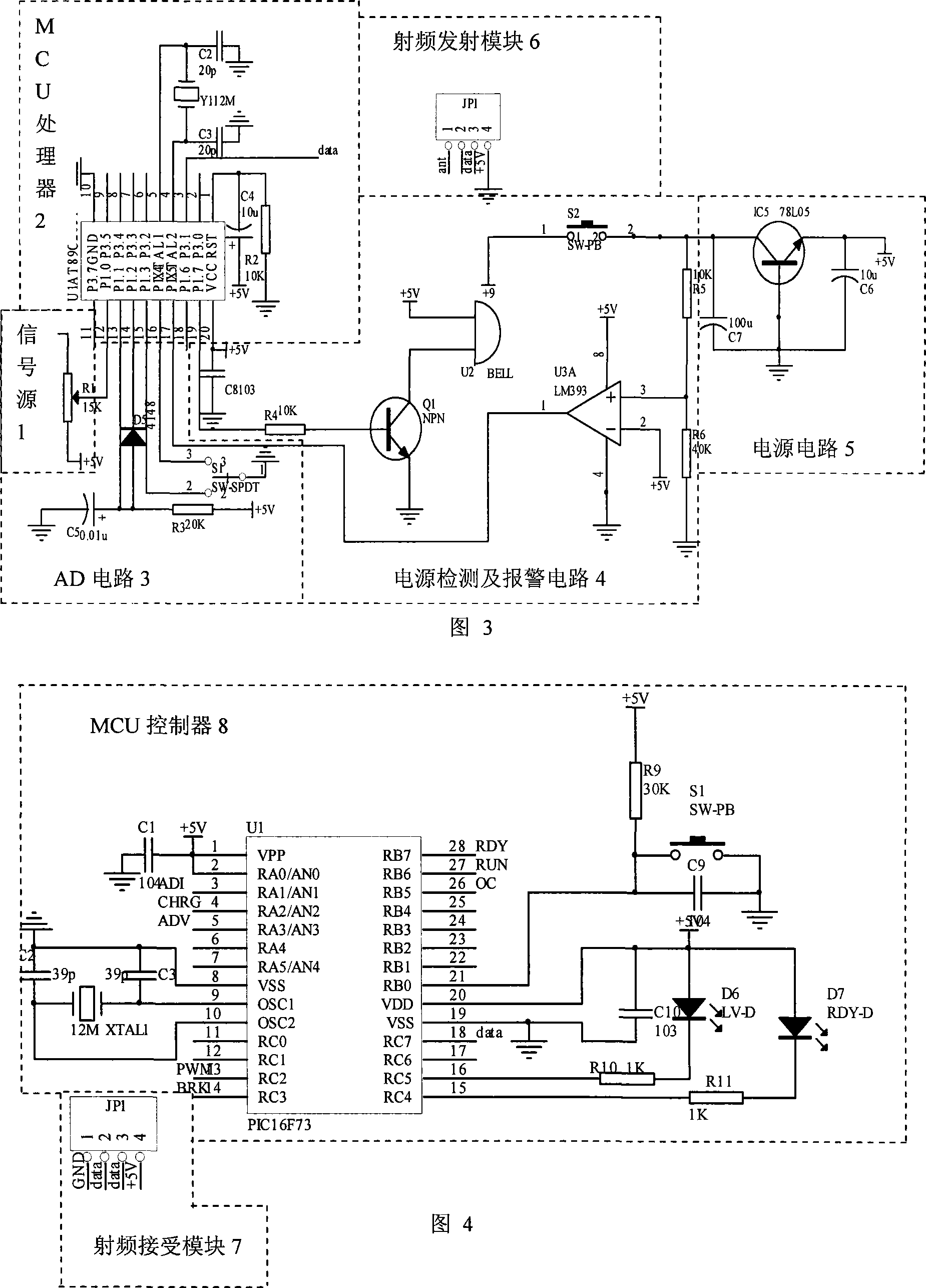

Electric scooter radio remote controller and controller thereof

InactiveCN101131585ANo controlRealize stepless speed regulationTransmission systemsElectric vehicle charging technologyOperating instructionRemote control

This invention is a sort of control device which controls the operation of the dynamo-electric sliding vane bus. It is this device which controls the operation of the dynamo-electric sliding vane bus by the remote control technique. According to the techno-method offered by this invention this invention consists two parts, this first part is the remote control emission, the request of the transmitted power of this part is high, the transmitted power of processor reaches 10 milliwatt, the transmission distance is in the range of 10 meter. The second part if the control of the remote control receiver, this part realizes the control to the operation of the electromotor of the sliding vane bus. This remote controller uses the digit control signal of the radio-frequency transmission to control the sliding vane bus; it realizes the infinite speed regulating control to the electromotor of the sliding vane bus. The controller is the actuating mechanism of the operating instruction of the controller, it controls the operating mode of the electromotor, and it carries out the infinite speed variation of the electromotor and the braking. It progresses the monitor to the estate of the electromotor, it the fly-bus happens or the people deviates the sliding vane bus, stop the operation of the sliding vane bus, and stop the answer to the control signal of the remote controller.

Owner:JIANGNAN UNIV

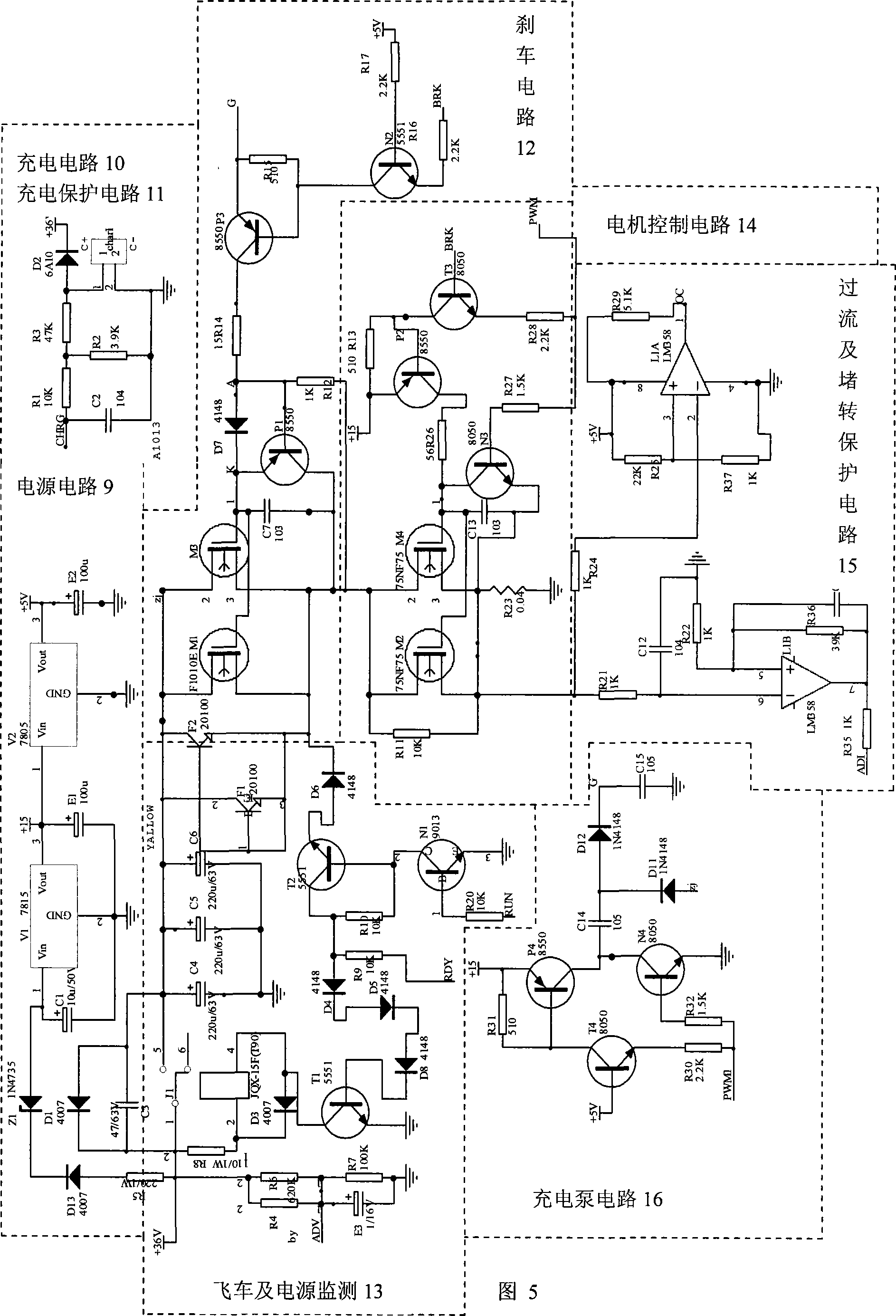

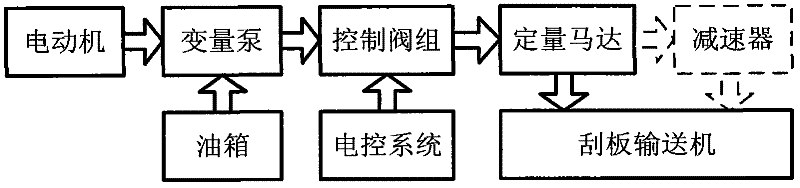

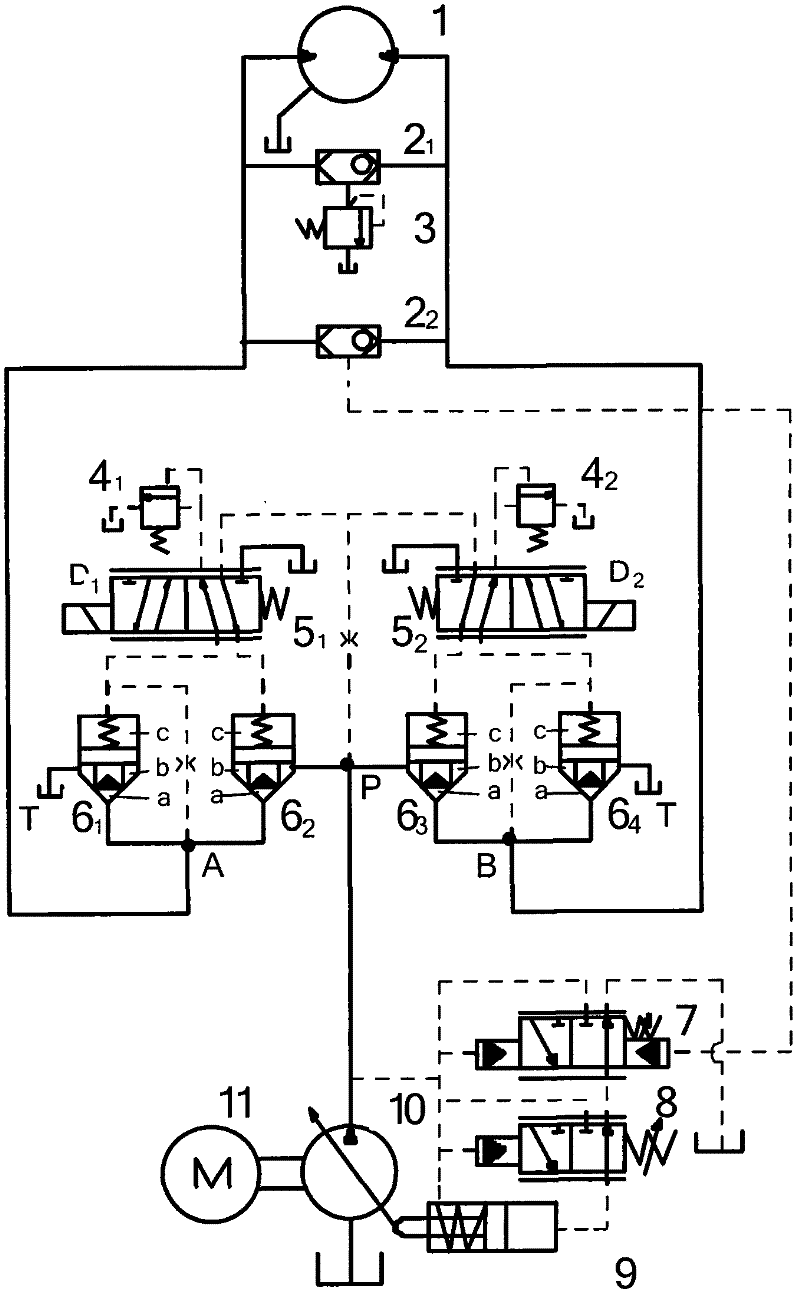

Novel hydraulic driving system for scraper conveyer

The invention relates to a hydraulic driving system, in particular to a novel hydraulic driving system for a scraper conveyer, which aims to the overcome the defect that as the existing scraper conveyer is commonly driven by a two-speed motor, a single speed motor plus a hydraulic coupling, a variable-frequency motor and the like, when a motor, a transmission device and a chain wheel are connected with one another, the tail part is suspended, resulting in easy generation of vibration, abrasion, invalid sealing and the like. The novel hydraulic driving system consists of a hydraulic motor, a shuttle valve, a safety valve, an overflow valve, a proportional reversing valve, a flow type cartridge valve, a load sensing valve, a pressure cutoff valve, a variable piston, a variable pump and a motor. The novel hydraulic driving system has the beneficial effects that the soft start of the scraper conveyer is realized by applying a load sensing system, a variable pump-quantitative motor type volume speed control circuit and a flow type proportional cartridge valve control element; the rotating speed of the hydraulic motor can be controllable, can also be subjected to stepless speed regulation within a certain scope and is not affected by load change and motor rotating speed fluctuation; and the working requirements on high pressure and large flow rate of the system are satisfied, and equipment operation and braking are ensured to be stable and reliable.

Owner:CHINA COAL ZHANGJIAKOU COAL MINING MACHINERY

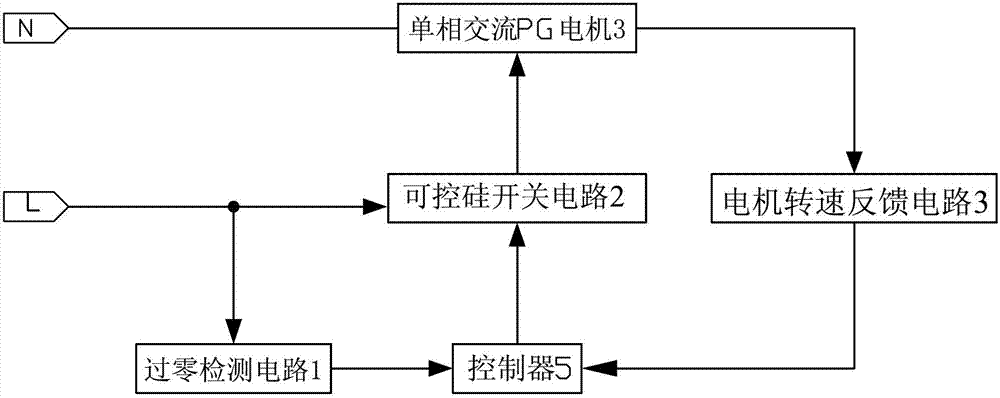

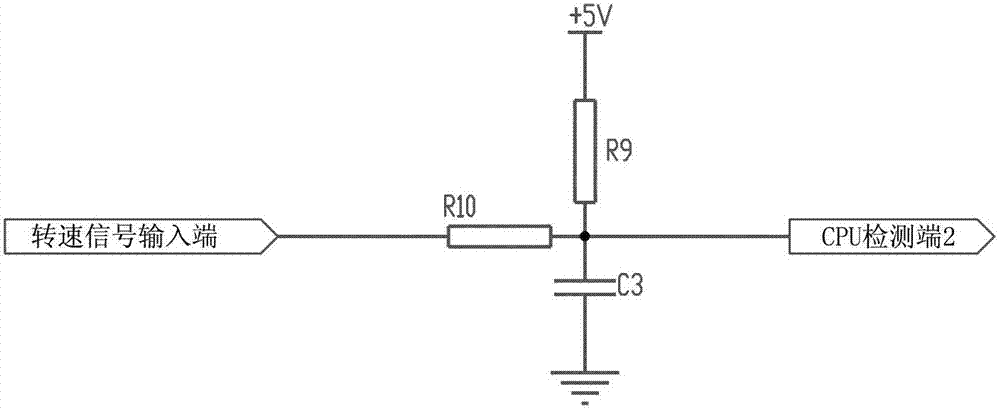

Upper alternating current draught fan speed regulating system of gas water heater

InactiveCN103036501AChange speed effectRealize stepless speed regulationAC motor controlMotor speedElectric machine

The invention discloses an upper alternating current draught fan speed regulating system of a gas water heater. The upper alternating current draught fan speed regulating system of the gas water heater comprises a controller, a single phase alternating current program guidance (PG) motor, a controllable transwitch circuit, a motor speed feedback circuit and a zero cross detection circuit, wherein the controllable transwitch circuit, the motor speed feedback circuit and the zero cross detection circuit are respectively connected with the controller. The upper alternating current draught fan speed regulating system of the gas water heater aims at achieving stepless speed regulating of the single phase alternating current PG motor through controlling the size of an electrical angle between the controllable transwitch circuit which is connected with the single phase alternating current PG motor and an alternating current zero crossing point, a well-matched state of gas and air is achieved, and the defects of a draught fan with fixed gears has limited gears are overcome, and problems that burning instability and flameouts of a water heater when air quality is too large or too small and the like are solved.

Owner:ZHONGSHAN INSE GROUP

Hydraulic stepless speed-change transmission mechanism

InactiveCN103899724ASimple structureOptimize structure layoutFluid gearingsControl devicesHydraulic motorControl engineering

The invention discloses a transmission mechanism, and particularly discloses a hydraulic stepless speed-change transmission mechanism suitable for farm machines. The hydraulic stepless speed-change transmission mechanism comprises an engine and a rear axle walking mechanism and further comprises a variable pump and a hydraulic motor, an output shaft of the engine is connected with an input shaft of the variable pump, a high-pressure cavity of the variable pump is communicated with an oil inlet of the hydraulic motor through a first oil way, a low-pressure cavity of the variable pump is communicated with an oil outlet of the hydraulic motor through a second oil way, a closed loop is formed by the variable pump and the hydraulic motor, an output shaft of the hydraulic motor is connected with an axle package of the rear axle walking mechanism, and a gear controlling rod is installed on the variable pump and fixed on a swash plate of the variable pump. The hydraulic stepless speed-change transmission mechanism is simple and reasonable in structure, original complex mechanical speed adjustment is replaced by hydraulic speed adjustment transmission, the pausing feeling during gear shifting is avoided, driving is smooth, stepless speed adjustment can be achieved, the speed adjustment range is large, operation is convenient to achieve, the structure layout is simple, practicability is high, and energy is saved.

Owner:交城县华昌泰机械制造有限公司

Electromagnetic lead screw driving type precise-punching presser

The invention discloses an electromagnetic lead screw driving type precise-punching presser which comprises a presser body, a working platform, a controller and a stand, wherein the presser body is fixed on the working platform; the stand is arranged above the working platform, and is movably connected with the stand through a connecting plate. The stand is provided with an electromagnetic lead screw system which comprises an electromagnetic nut and a punch shaft. The electromagnetic nut is fixed on the stand, and comprises two circular cores. Each circular core is divided into two parts by a coil. A circular permanent magnet is clamped between the two cores. The punch shaft penetrates through the stand and the electromagnetic nut, and has a gap with the electromagnetic nut. Threads which have the same pitch are processed at the inner hole side of the circular core and the part of the punch shaft. The controller is used for controlling the density, the frequency and the phase of the current in the coil. The invention has the advantages of adjustable speed and punch force, quick response, high guiding and positioning precision, simple structure, convenient control, less component consumption, low noise, convenient maintenance and long service life.

Owner:ZHEJIANG UNIV

Mechanical mechanism for converting reciprocating motion power into rotary power

InactiveCN101832377AImprove mechanical efficiencyConvenient stepless speed regulation or stepped speed regulationGearingClutchHuman power

The invention discloses a mechanical mechanism which converts reciprocating motion power into rotary power for output and can realize stepless speed regulation. A power source pulls a rope; the rope pulls a rope drum to rotate; and the rope drum drives a power output shaft to rotate through an overrunning clutch; or the power source drives an oscillating bar to oscillate; a rope tractor on the oscillating bar pulls the rope; the rope pulls the rope drum to rotate; and the rope drum drives the power output shaft to rotate through the overrunning clutch. Because the position of the rope tractor on the oscillating bar can be adjusted, the rotating ratio of the moment to the speed between the power source and the power output shaft can be adjusted by adjusting different positions of the rope tractor on the oscillating bar. The mechanical mechanism has the advantages of high efficiency and simple structure, and capacity of realizing the stepless speed regulation; and the power source can be a cylinder or human power or animal power. The mechanical mechanism can be applied to internal combustion engines, bicycles, and other machinery, or can be applied to equipment needing the stepless speed regulation.

Owner:陈悦文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com