Circuit of pulping machine

A pulping machine and circuit technology, which is applied in dairy products, food preparation, electrical program control, etc., can solve the problems of pulping material paste tube, motor failure, and unfavorable health of consumers, so as to improve pulp yield and pulp body delicious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

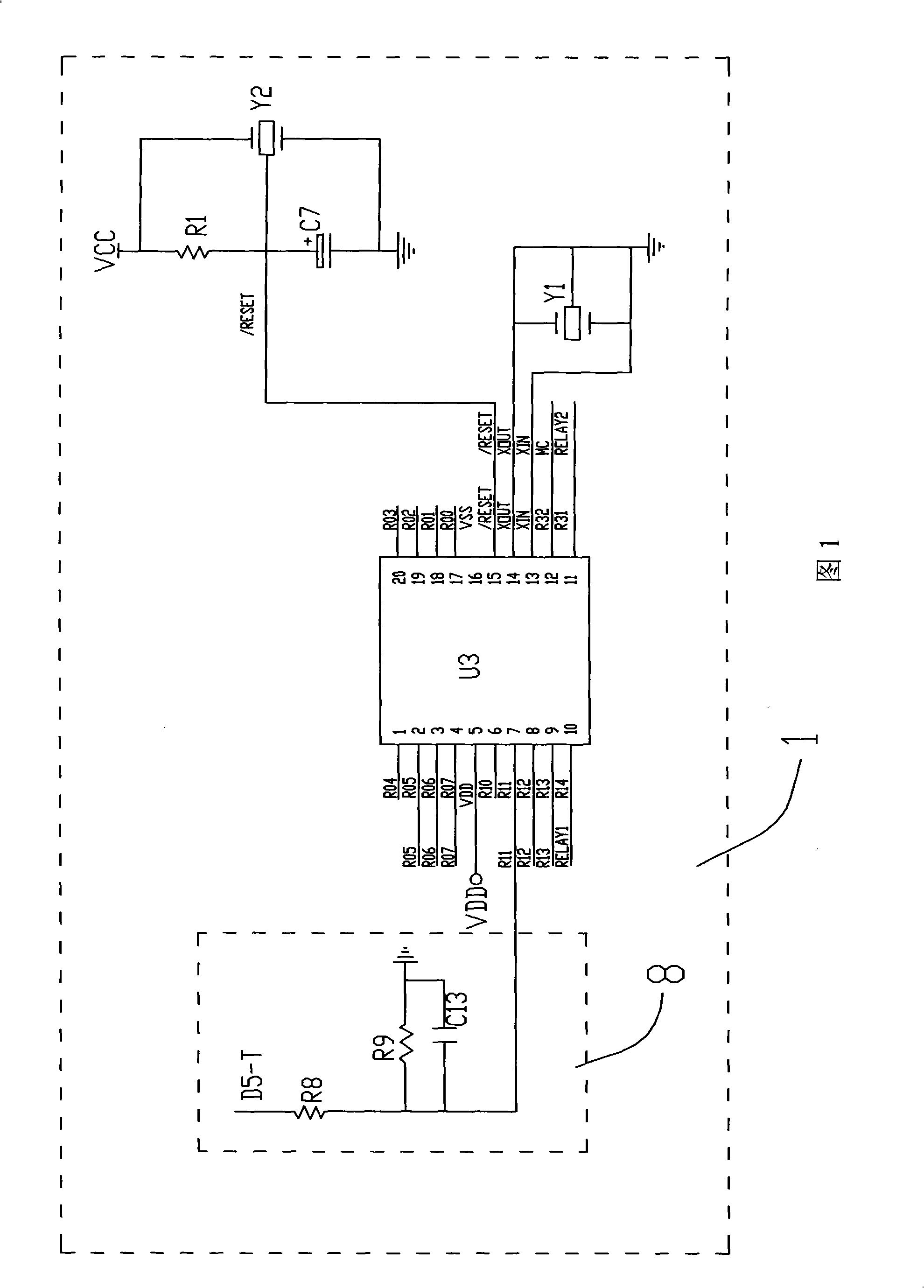

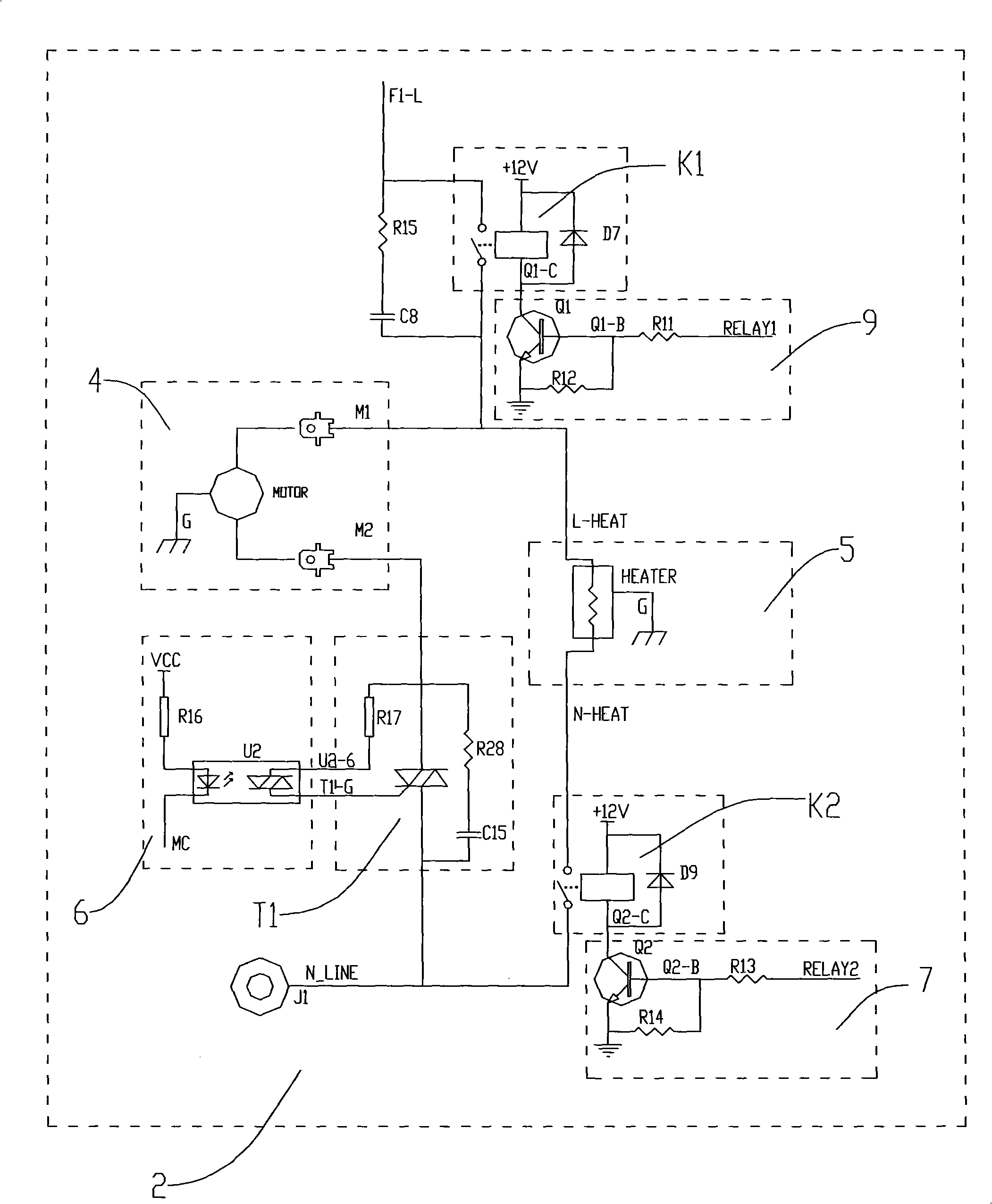

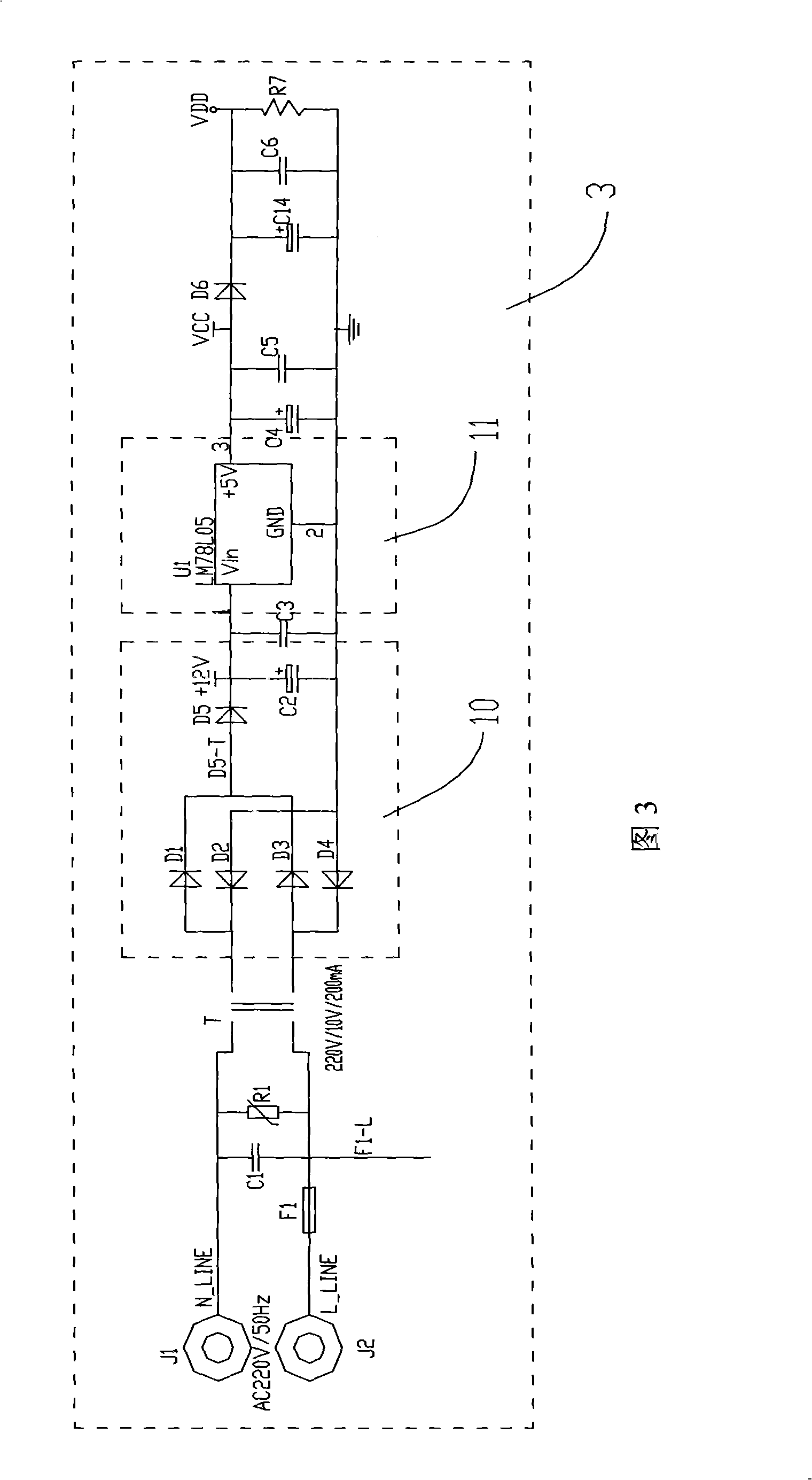

[0014] As shown in Fig. 1 to Fig. 3, it is a circuit diagram of a preferred embodiment of the circuit of the present invention. Including a central processing chip U3, a zero-crossing detection circuit 8 connected to the central processing chip U3 for detecting power signals, a first relay K1 connected to the central processing chip U3 and a first relay control circuit 9, connected to the central processing chip U3 The second relay K2 and the first relay control circuit 7, and the optocoupler control circuit 6 connected to the central processing chip U3 for controlling the opening and closing of the triac T1.

[0015] FIG. 1 is a circuit diagram of the control unit 1 of the present invention. In this embodiment, the central processing chip adopts a single-chip microcomputer, the model is SN8P2613, and the crystal oscillator frequency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com