Novel hydraulic driving system for scraper conveyer

A scraper conveyor and drive system technology, applied in conveyors, transportation and packaging, etc., can solve the problems of disassembly, maintenance, wear, and seal failure, so as to improve system reliability and economy, and reduce equipment investment. , the effect of reducing the height of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

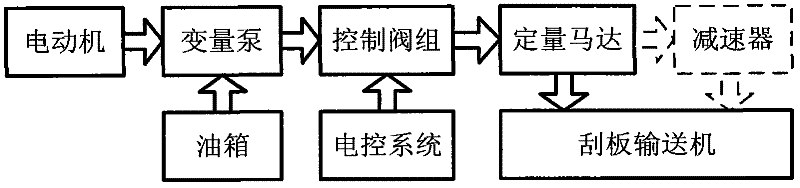

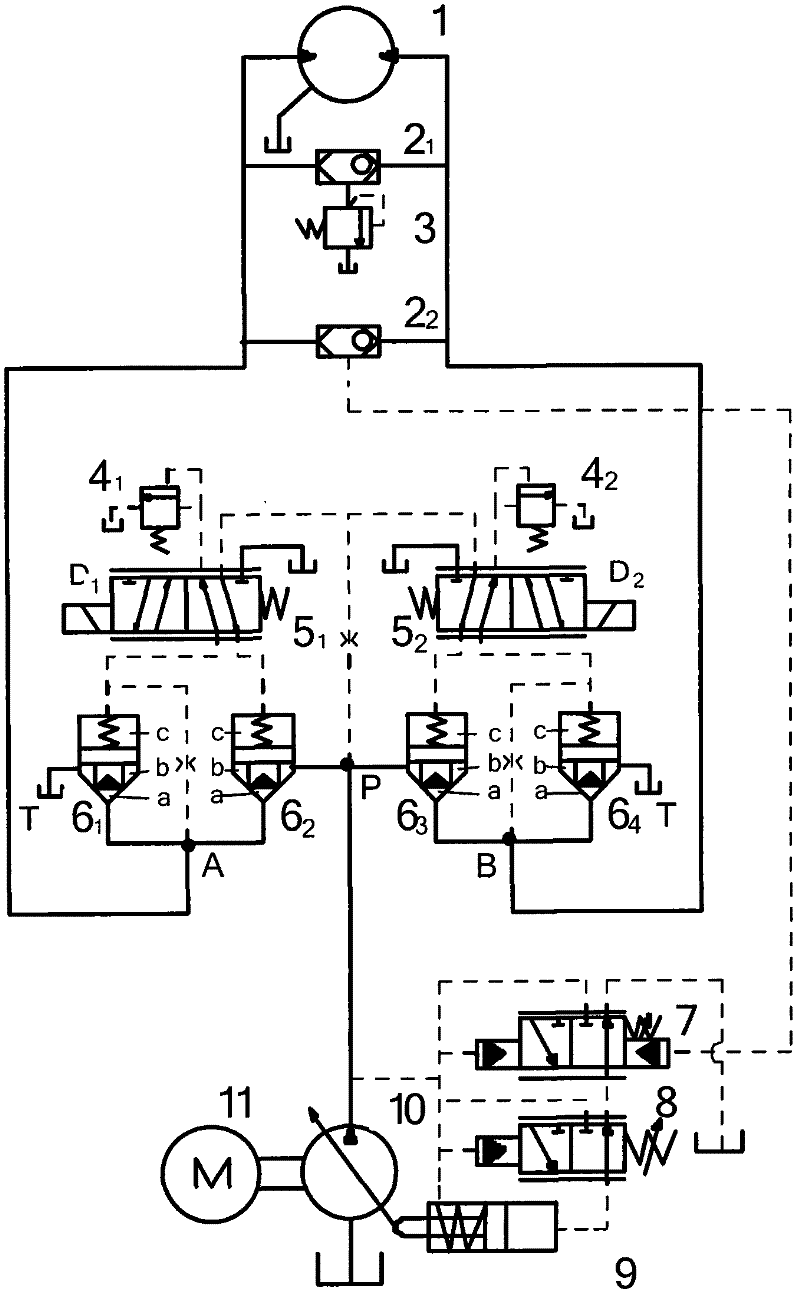

[0010] Depend on figure 1 , 2 As shown, the new hydraulic drive system of the scraper conveyor includes an oil tank and an electric control system, which is characterized by: a hydraulic motor 1, a shuttle valve, a safety valve 3, an overflow valve, a proportional reversing valve, a flow type cartridge valve, Load sensing valve 7, pressure cut-off valve 8, variable piston 9, variable pump 10, and motor 11; the output shaft of hydraulic motor 1 is connected to the sprocket shaft of the scraper conveyor, and the two ends of hydraulic motor 1 are connected in parallel with the first shuttle valve 2 1 and the second shuttle valve 2 2 , the first shuttle valve 2 1 The outlet is connected in series with safety valve 3 and the second shuttle valve 2 2 The outlet of the load sensing valve 7 is connected in series to the right chamber of the control end, the oil outlet of the load sensing valve 7 is connected with the oil outlet of the pressure cut-off valve 8, and the right end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com