Patents

Literature

242results about How to "Achieving a soft start" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

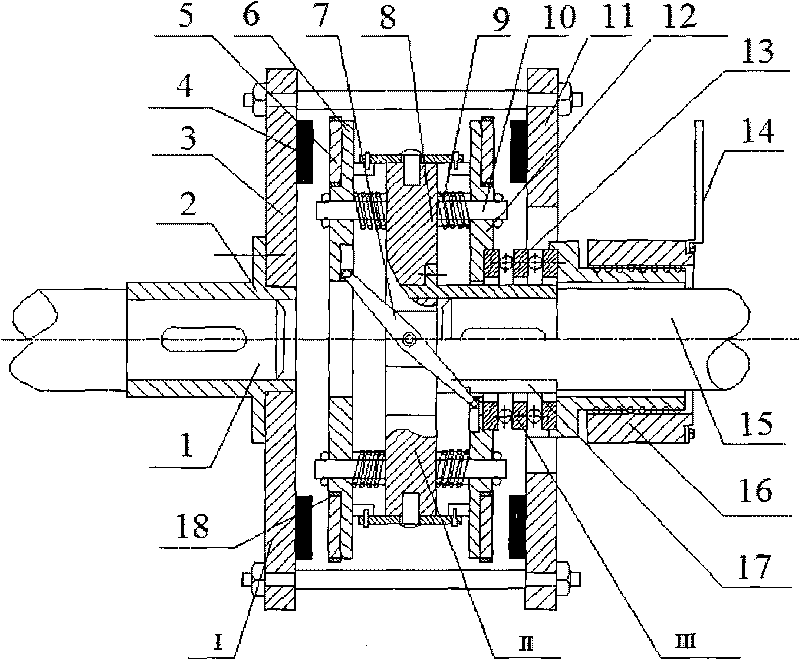

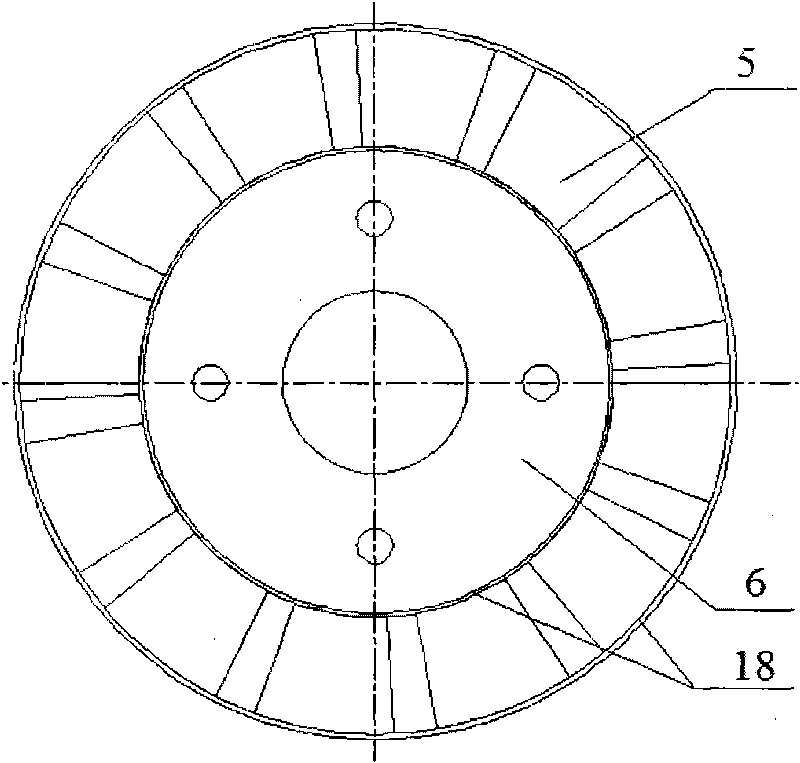

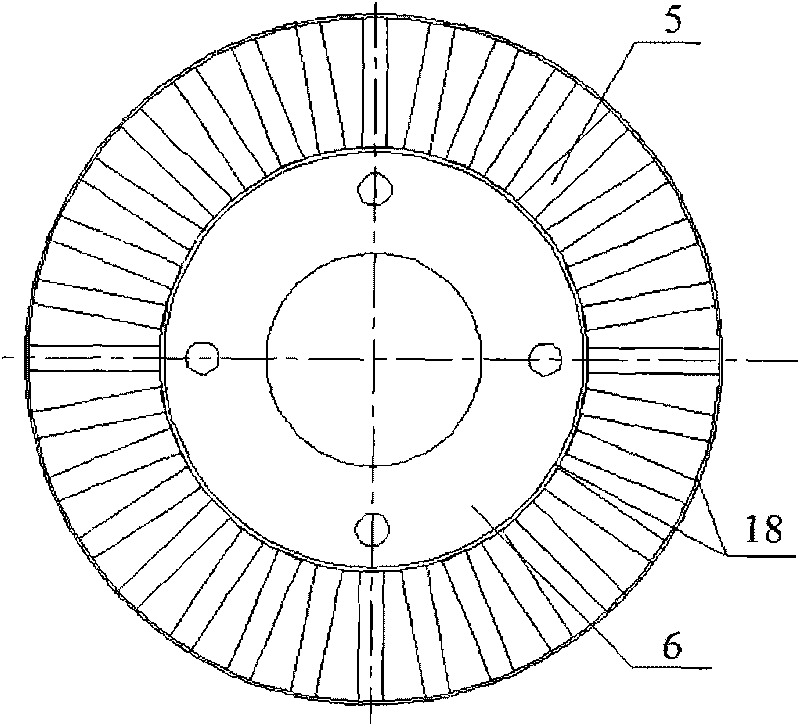

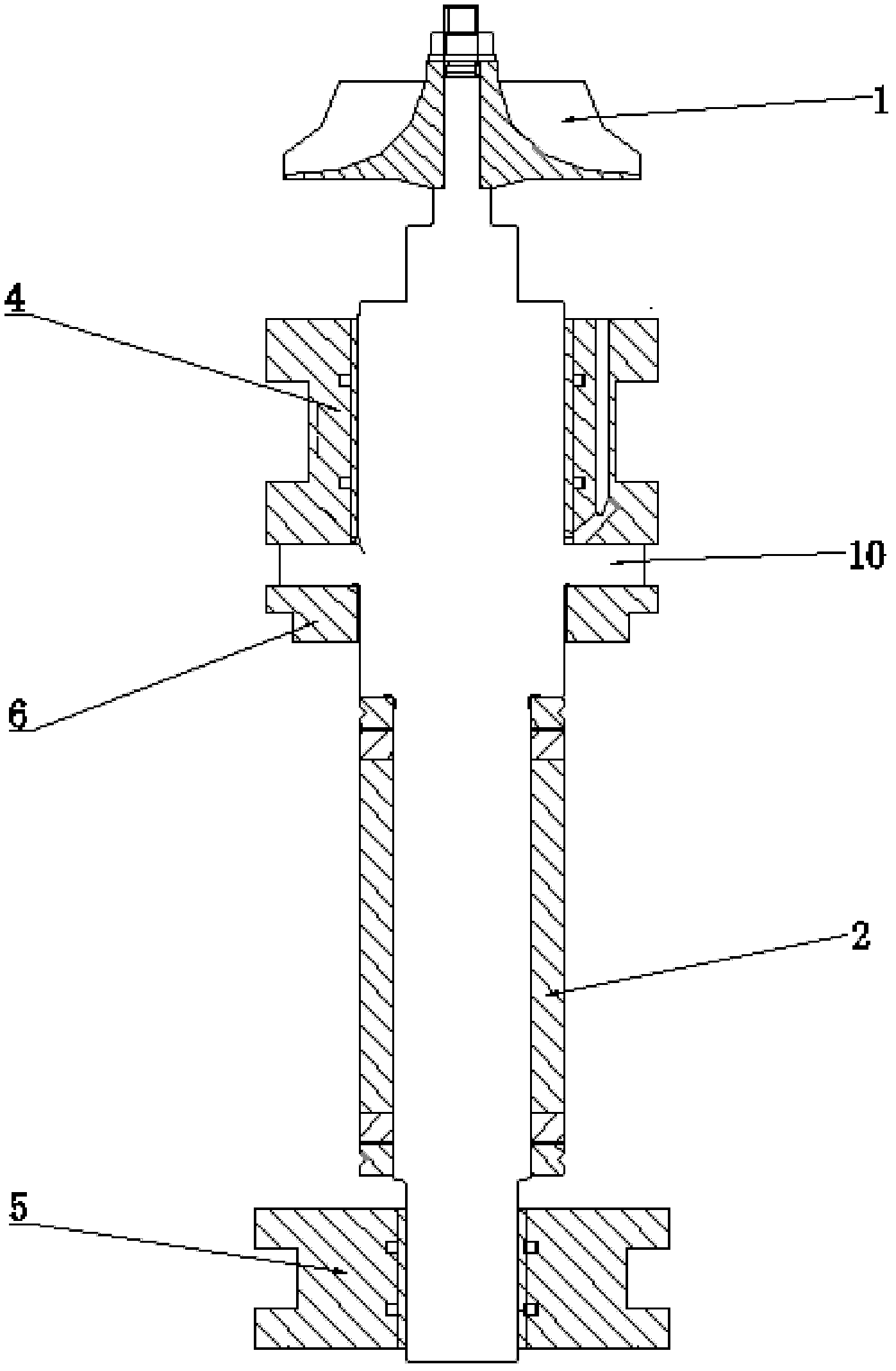

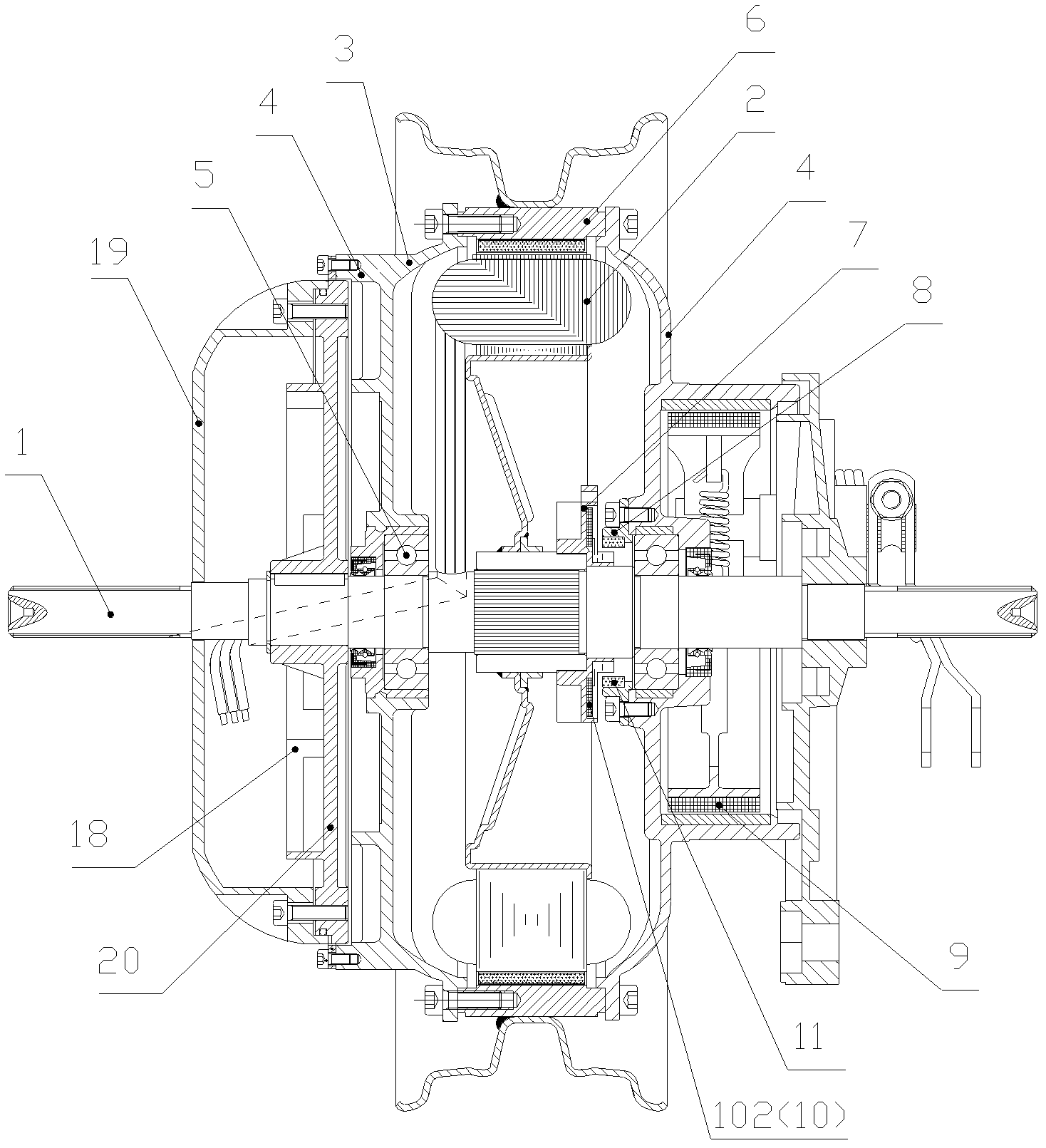

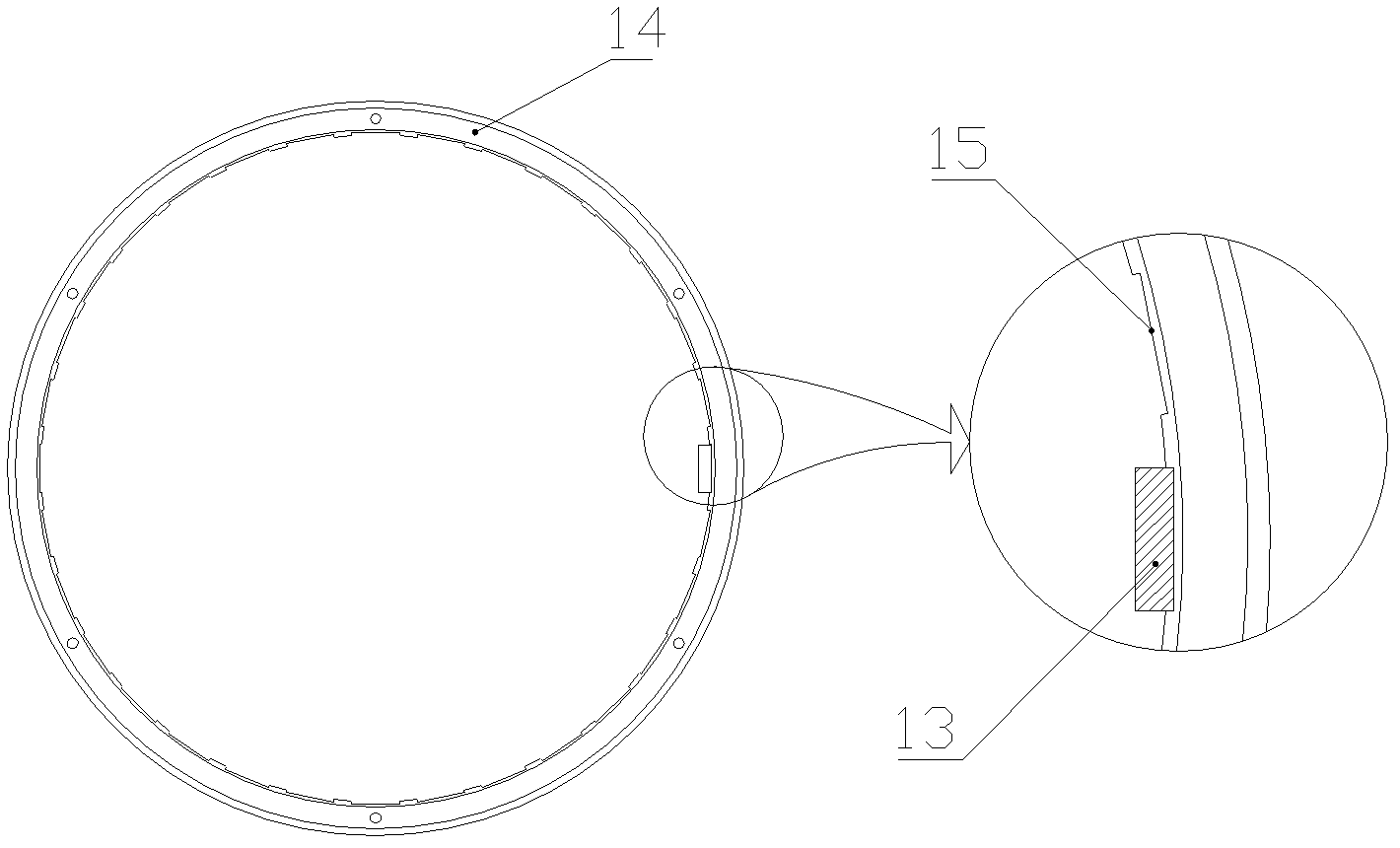

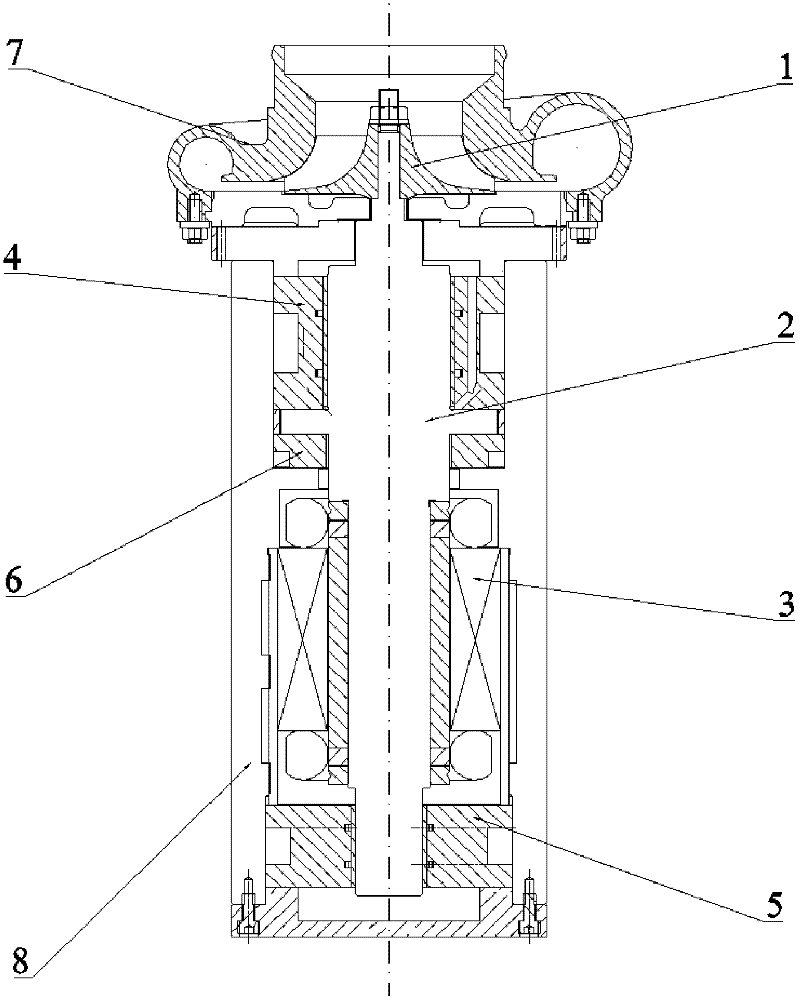

Adjustable-speed magnetic induction coupler

InactiveCN101728930AAchieving a soft startAvoid the phenomenon of rapid heating and burning out the coilDynamo-electric gearsEngineeringCrusher

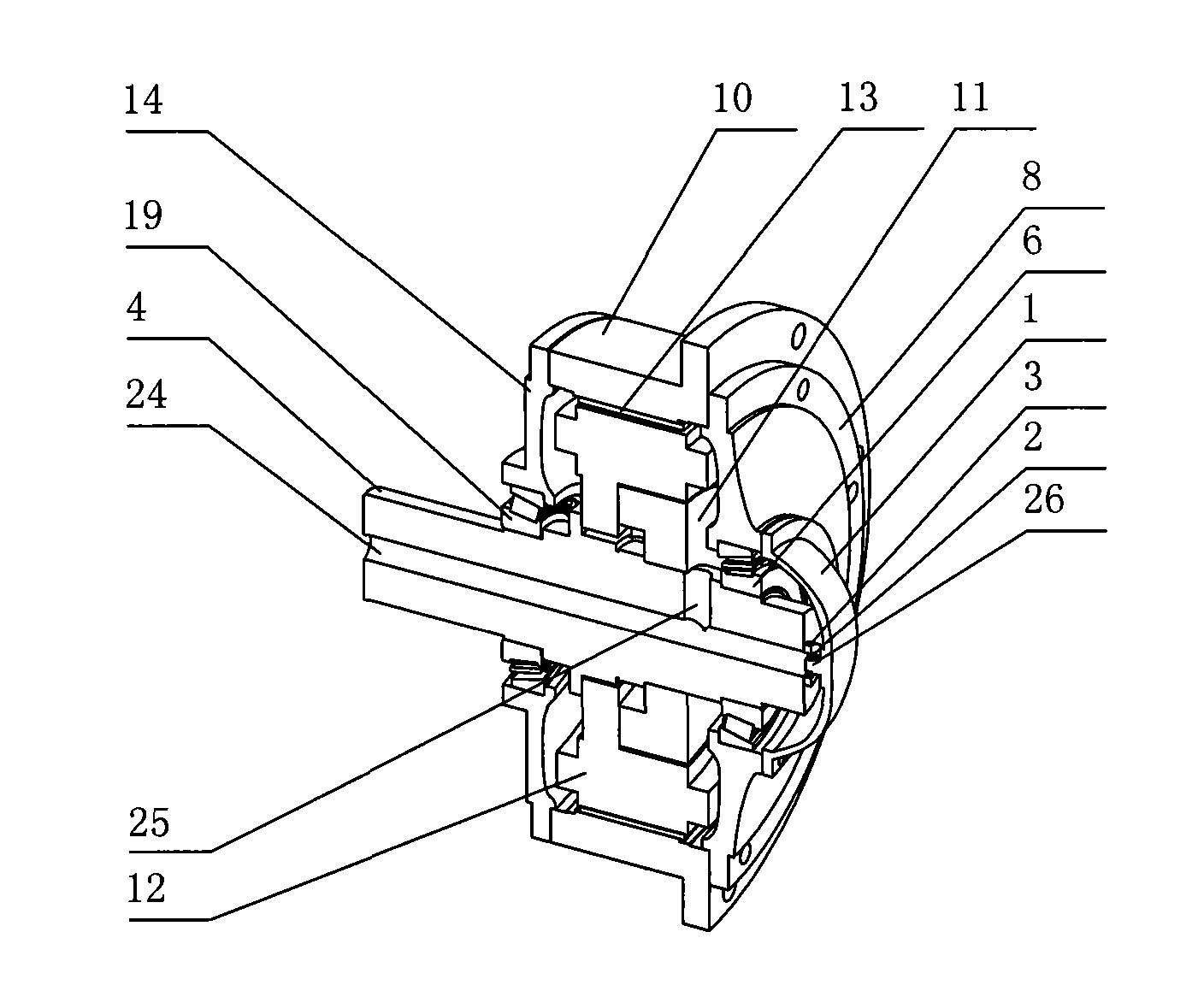

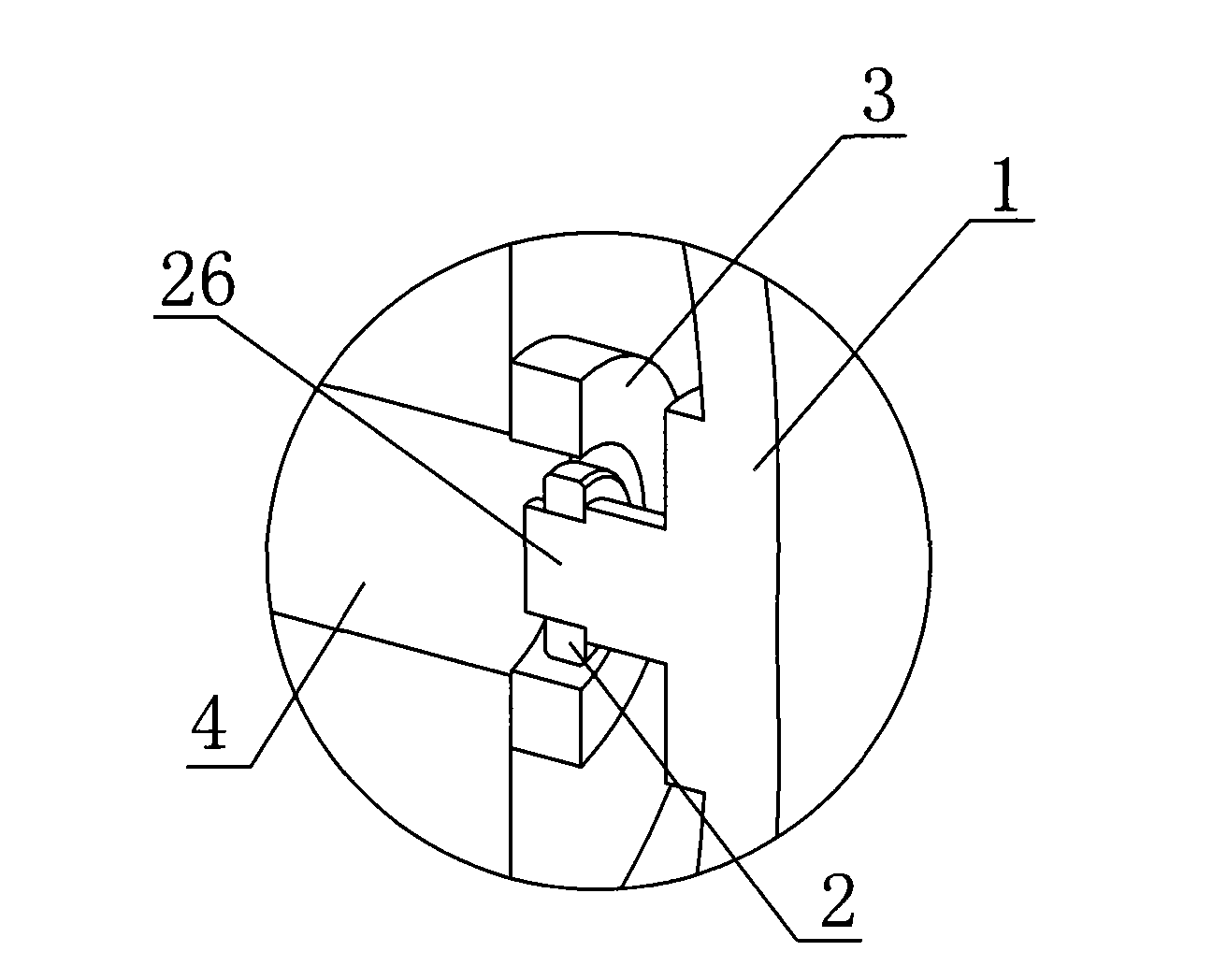

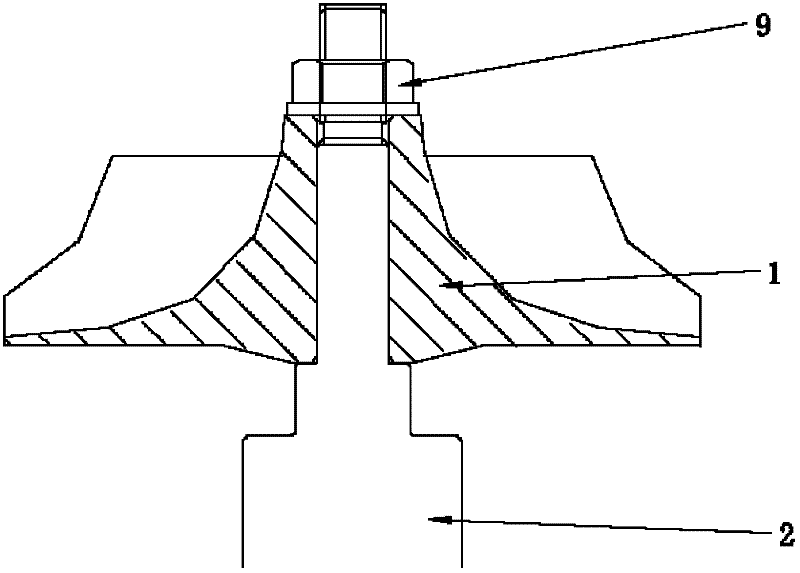

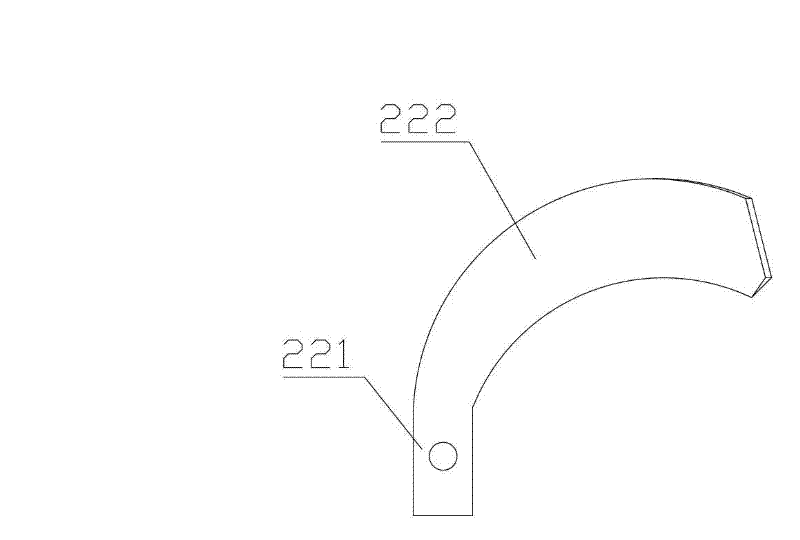

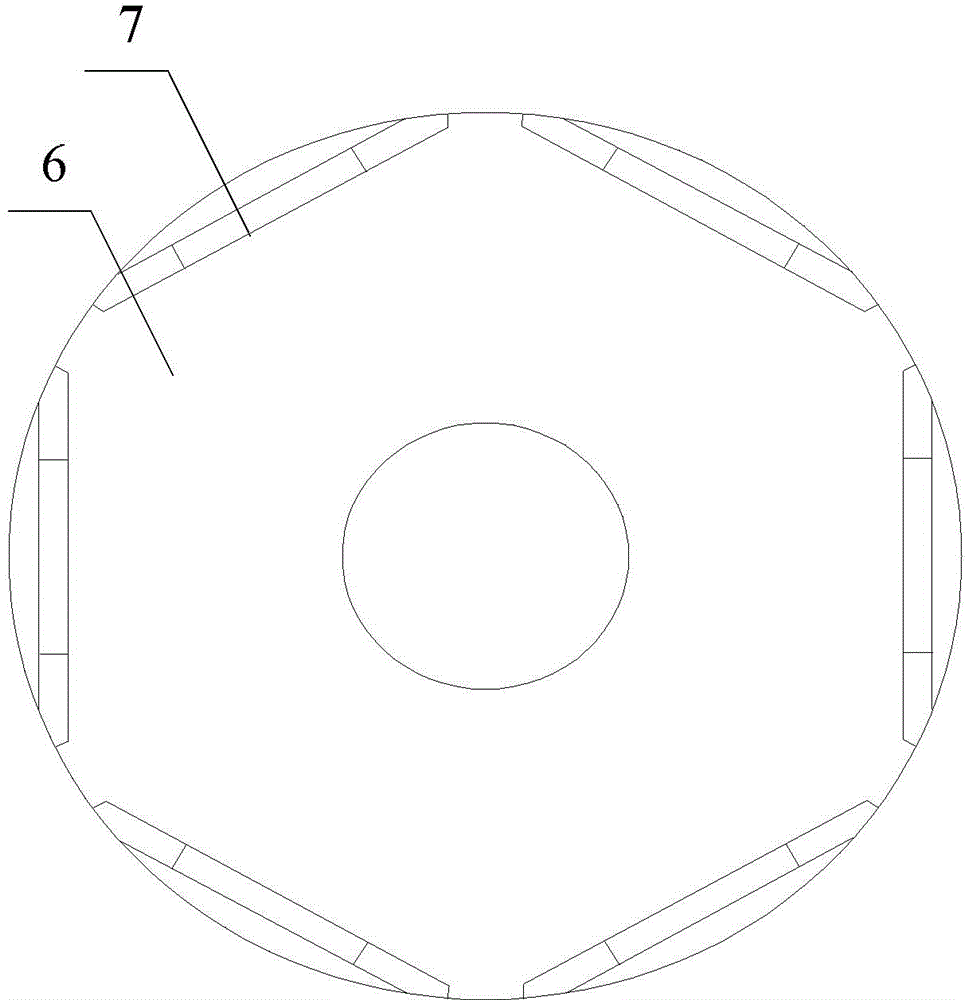

The invention discloses an adjustable-speed magnetic induction coupler, which relates to the technical field of transmission in mechanical engineering, and comprises a driving disk assembly (I) and a driven disk assembly (II), wherein the driven disk assembly (II) comprises a driven disk substrate 1, a driven disk substrate 2, a driven disk substrate 3, sectorial copper plates or rectangular copper bars, a rotary connecting rod, springs, sliding rods and a sleeve 2; the driven disk substrate material is steel disk, the end faces of the driven disk substrates1 and 3 are provided with deep slots of which the depth is greater than half the thickness of the substrates, and the sectorial copper plates or rectangular copper bars, which have the same shape as permanent magnets, are rotationally embedded in the slots; the sliding rods are distributed on the two end faces of the driven disk substrate 2 along a circumferential direction, the springs are sleeved in the sliding rods, and the driven disk substrates 1 and 3 are fixed on the sliding rods and can compress the springs along the sliding rods; and the rotary connecting rods are connected with the driven disk substrates 1 and 3 and are fixed on the driven disk substrate 2 rotationally. The adjustable-speed magnetic induction coupler can be used in power transmission mechanisms between loads and high- vibration motors such as coal mills, crushers and coal belt conveyers and used in transmission systems of other devices.

Owner:常州市长江热能有限公司

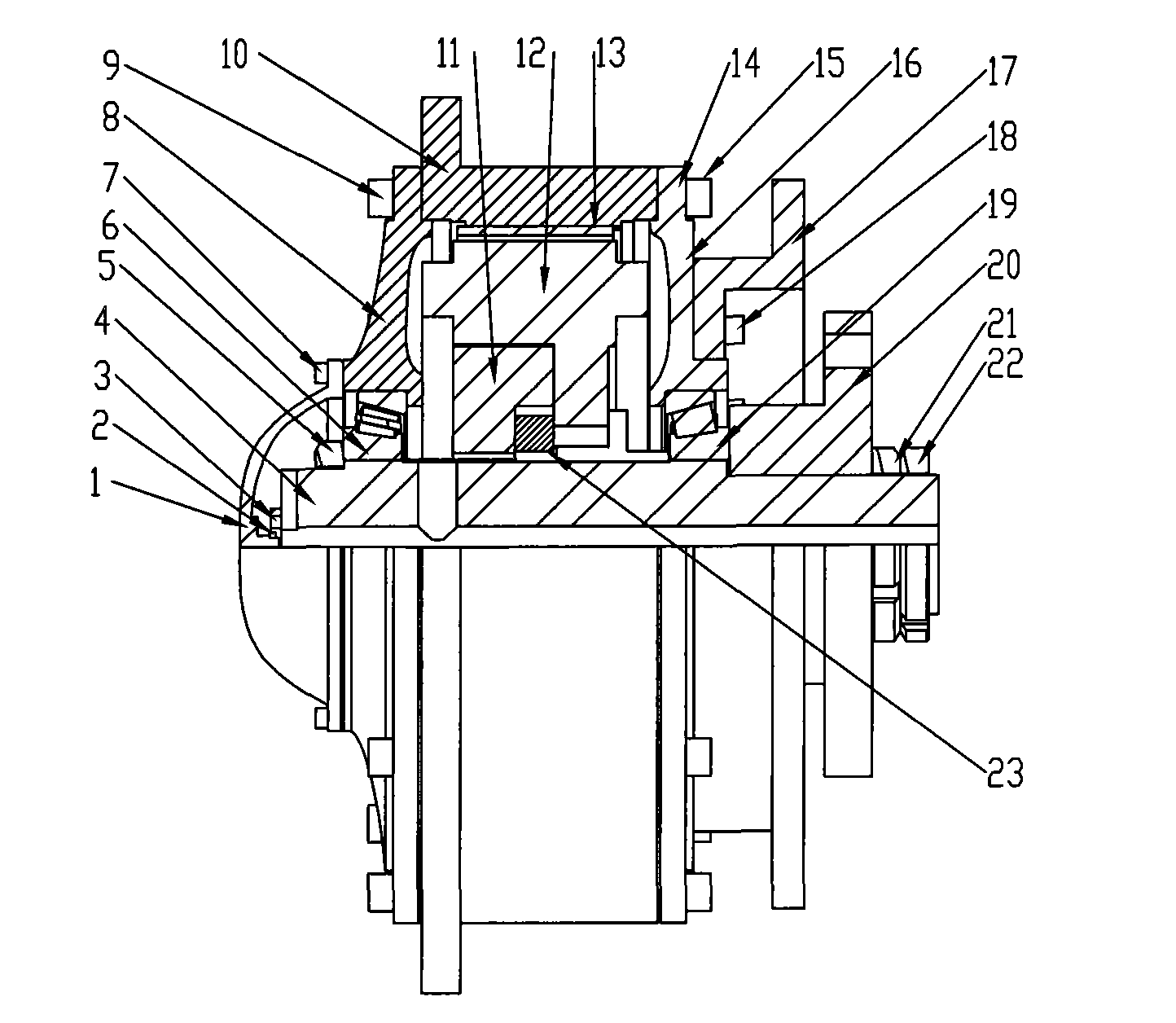

Integrated hub motor and control method thereof

InactiveCN101877524AEasy processing and installationImprove reliabilityElectronic commutation motor controlStructural associationLocation detectionControl theory

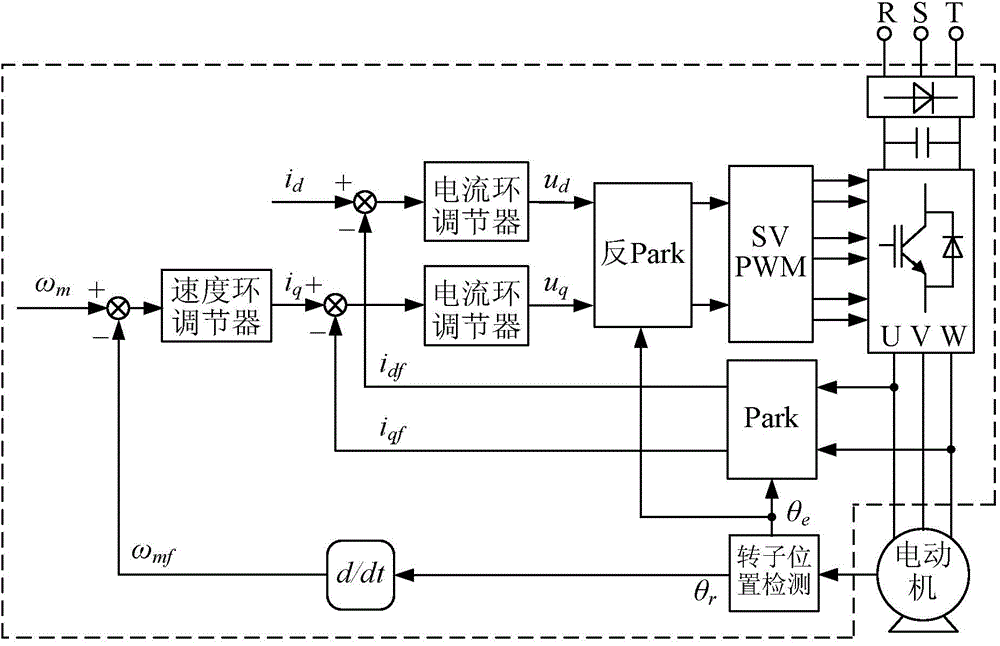

The invention provides an integrated hub motor and a control method thereof. The integrated hub motor comprises a motor shaft and a stator fixed on the motor shaft, wherein the stator is externally sheathed with a rotor casing; the front end and the rear end of the rotor casing are rotatablely fixed on the motor shaft by a rotor end cover and a bearing; two ends of the motor shaft protrude outside the rotor end cover to form a long end and a short end; a bearing end cover is fixed at the outer side of the rotor end cover; and the short end of the motor shaft is covered therein. The invention is characterized in that a bearing end cover shaft is arranged in the middle part of the bearing end cover in a protruding mode towards the direction of the motor shaft, and a position detection device is arranged at the corresponding position of the end part of the motor shaft and the bearing end cover shaft; the motor shaft is sheathed with a servo controller; and the position detection device senses rotation of the bearing end cover shaft and transmits the sensed signal to the servo controller to finally obtain the rotating angle or position of the rotor after being processed by the servo controller, thus achieving accurate control of the motor. The invention has the advantages of simple structure, energy conservation, good starting characteristic, small volume and high efficiency.

Owner:杭州桐聚科技有限公司

Remote intelligent speed control axial asynchronous magnetic coupling and speed regulating method

InactiveCN102647059ASmooth speed and output torqueRealize remote controlEnergy industryDynamo-electric machinesPetrochemicalMagnet

The invention relates to a magnetic coupling, in particular to a remote intelligent speed control axial asynchronous magnetic coupling and a speed regulating method. The meshing area between a permanent magnet and a conductor can be well adjusted by taking a remote intelligent controller to drive and control a motor to rotate, and in such way, the volume of the output torque is changed and precise speed change is realized. According to the invention, the application range of the magnetic coupling is expanded. The remote intelligent speed control axial asynchronous magnetic coupling is suitable for working under the situations with violent vibration, dust and impurities and other harsh conditions. The remote intelligent speed control axial asynchronous magnetic coupling can be widely used in the petrochemical industry, metallurgical industry, mining industry and the like.

Owner:JIANGSU UNIV

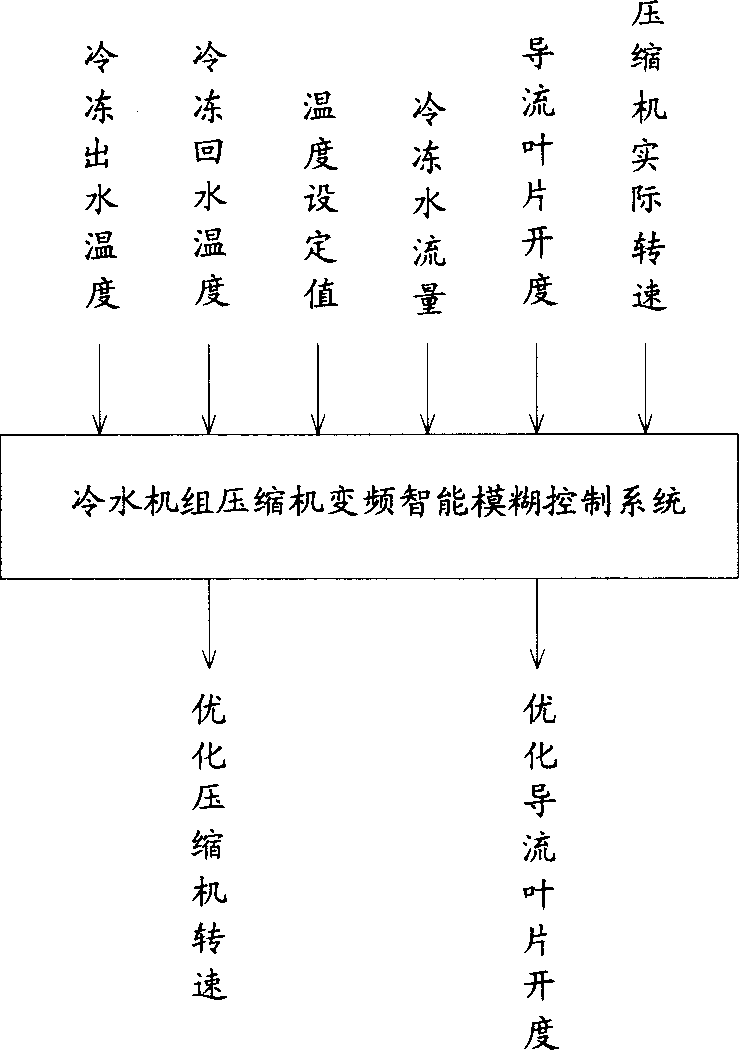

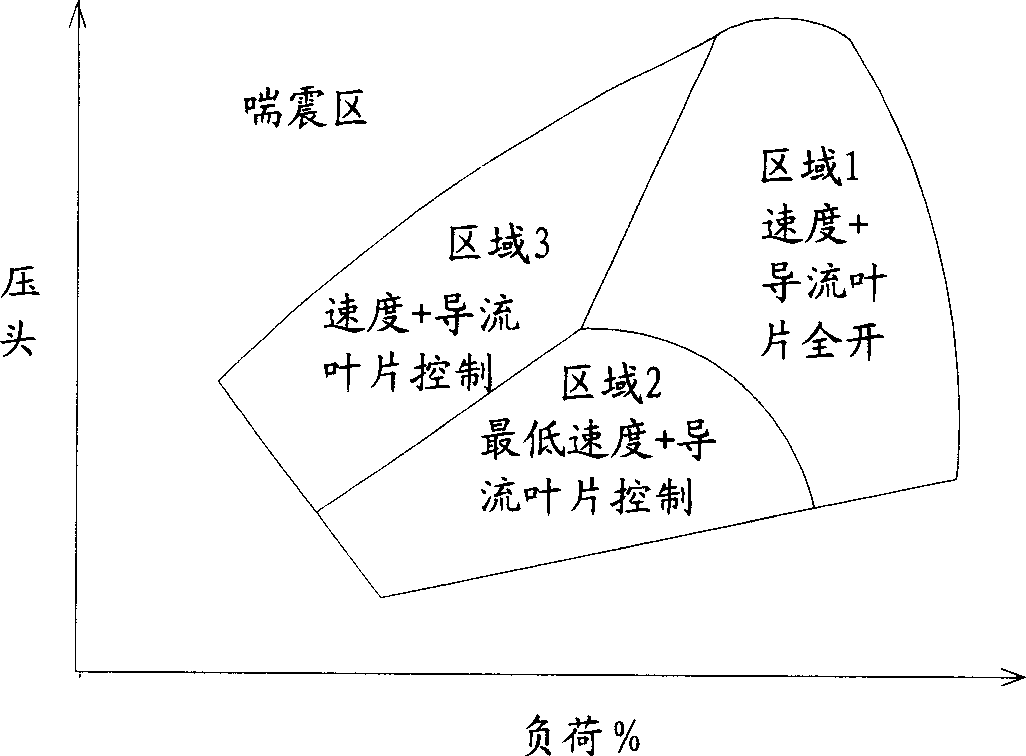

Compressor variable frequency energy saving reforming method of constant speed centrifugal water cooling machine set

InactiveCN1904503AImprove work efficiencyImprove unloading abilitySpace heating and ventilation safety systemsSpace heating and ventilation control systemsControl systemFuzzy control system

This invention relates to a kind of constant speed centrifugal water chilling unit compressor conversion energy-saving reforming energy-saving. It collects the refrigeration outer water's temperature; the temperature set value, the refrigeration backwater's temperature, the refrigeration water's flux, the guide vane's jaw opening, the compressor's real rotate speed and parameter of the unit. Through the water chilling unit compressor conversion intelligence fuzzy control system, it optimizes the compressor's rotate speed and the guide vane's jaw opening. This can make the unit always in the best operation even on all kinds of work conditions especially on partly overload condition. At the same time it improves the compressor's efficiency and reduces the cooling unit's energy consumption for work. It saves the energy of central air condition water chilling unit and has economic operation; the result of save energy is above 30% every year.

Owner:周锋

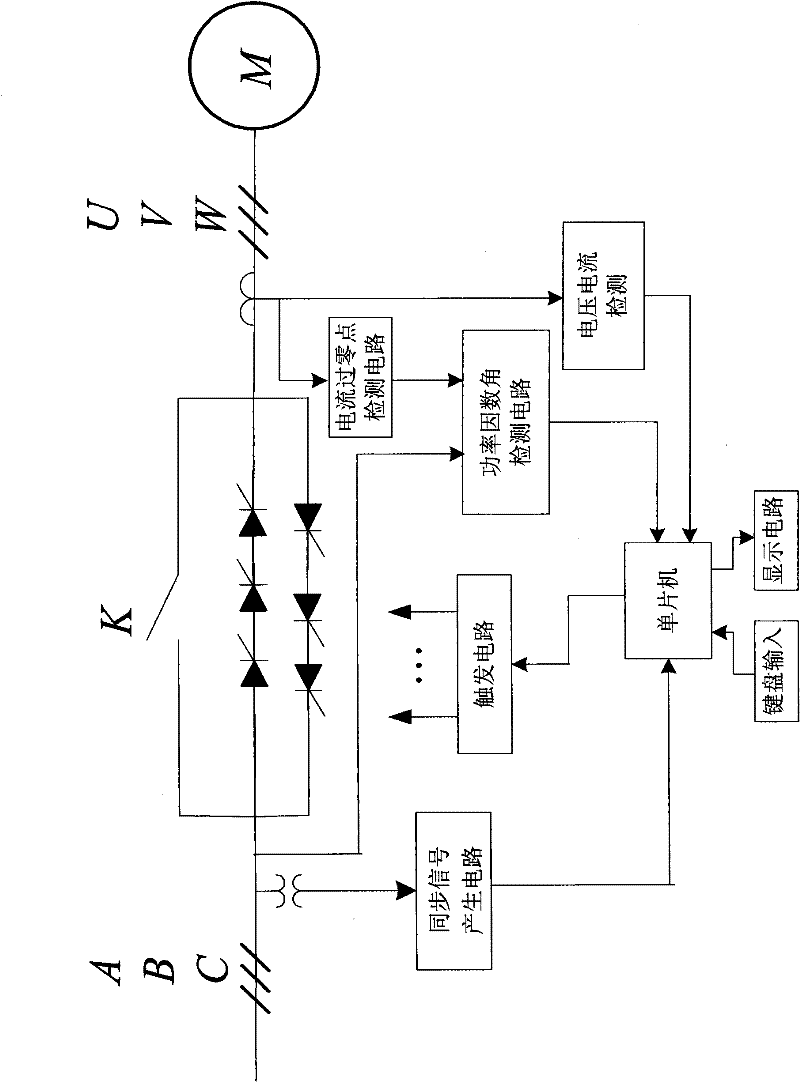

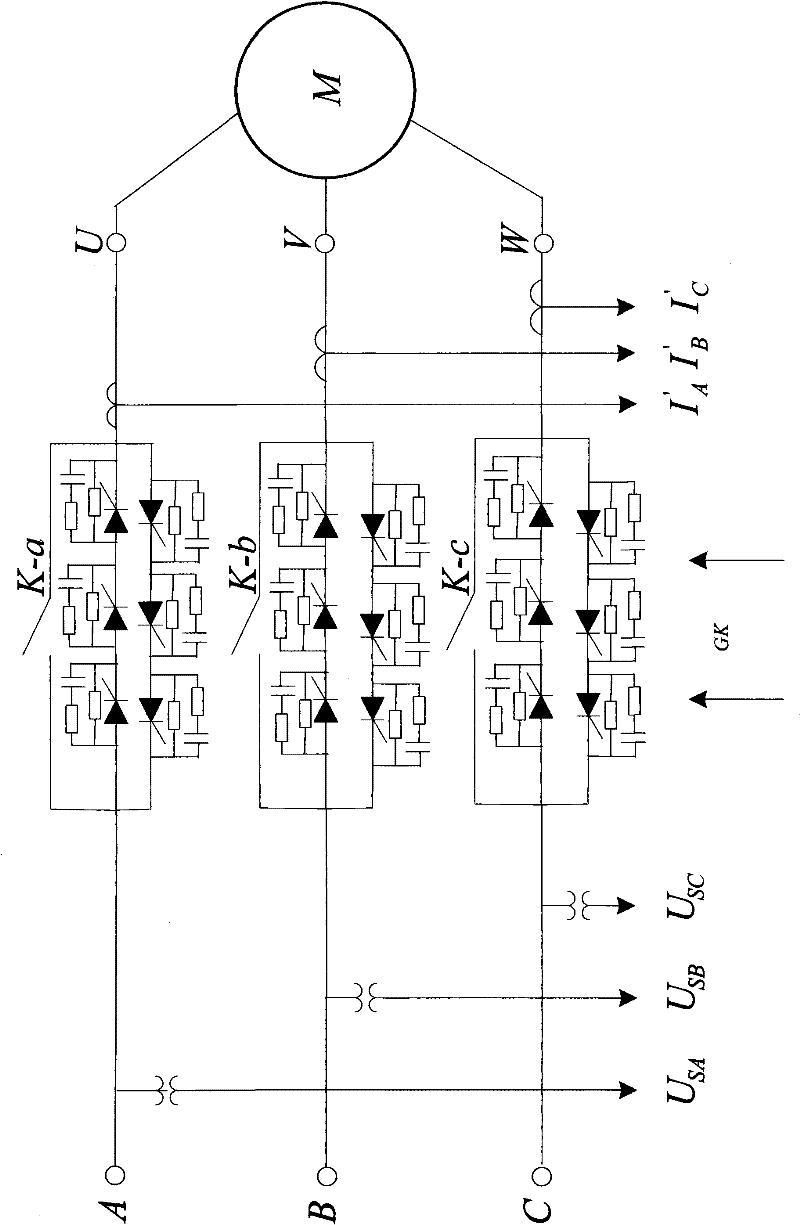

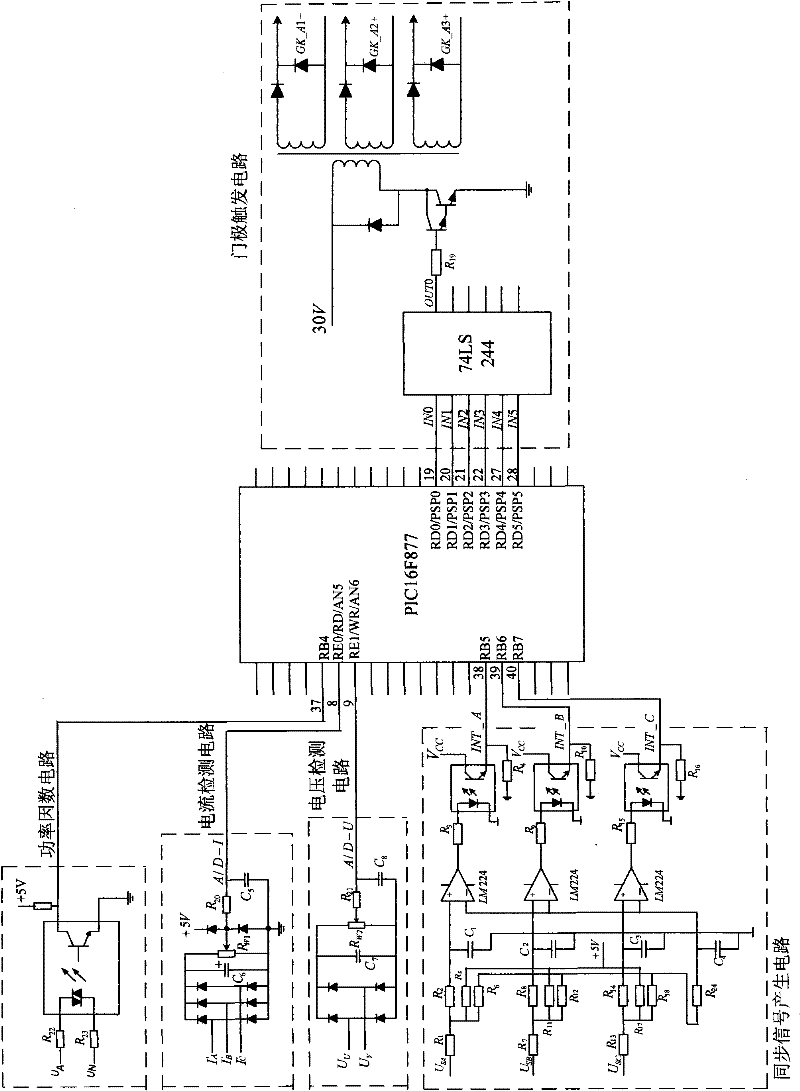

Energy-saving soft-start device for high-voltage asynchronous motor

InactiveCN102185543AAchieving a soft startRealize energy-saving operationPolyphase induction motor starterHigher PowerPower circuits

The invention relates to the technical field of applications of high-voltage asynchronous motors and discloses an energy-saving soft-start device for a high-voltage asynchronous motor. The device is used for solving the problem that a soft starter occupies a larger space in the prior art and other problems. The technical scheme is as follows: the energy-saving soft-start device is characterized by comprising a signal detection processing circuit, a synchronous signal circuit, a control circuit, a trigger signal power amplifying circuit, a power execution circuit and a power circuit for providing more than one path of DC (direct-current) power supply, wherein the power execution circuit comprises three large groups of components which are in series connection between a terminal of a three-phase high-voltage AC (alternating-current) power supply and a terminal of the high-voltage asynchronous motor; each large group of components comprises two small groups of high-power thyristors which are connected in parallel in the opposite directions; and more than three high-power thyristors are connected in series in the same direction in each small group and two ends of each high-power thyristor are connected with circuits with voltage-sharing, protection and absorption effects in parallel. The energy-saving soft-start device has the beneficial effects of realizing the soft start and energy-saving running under a low load factor.

Owner:SHANGHAI MARITIME UNIVERSITY

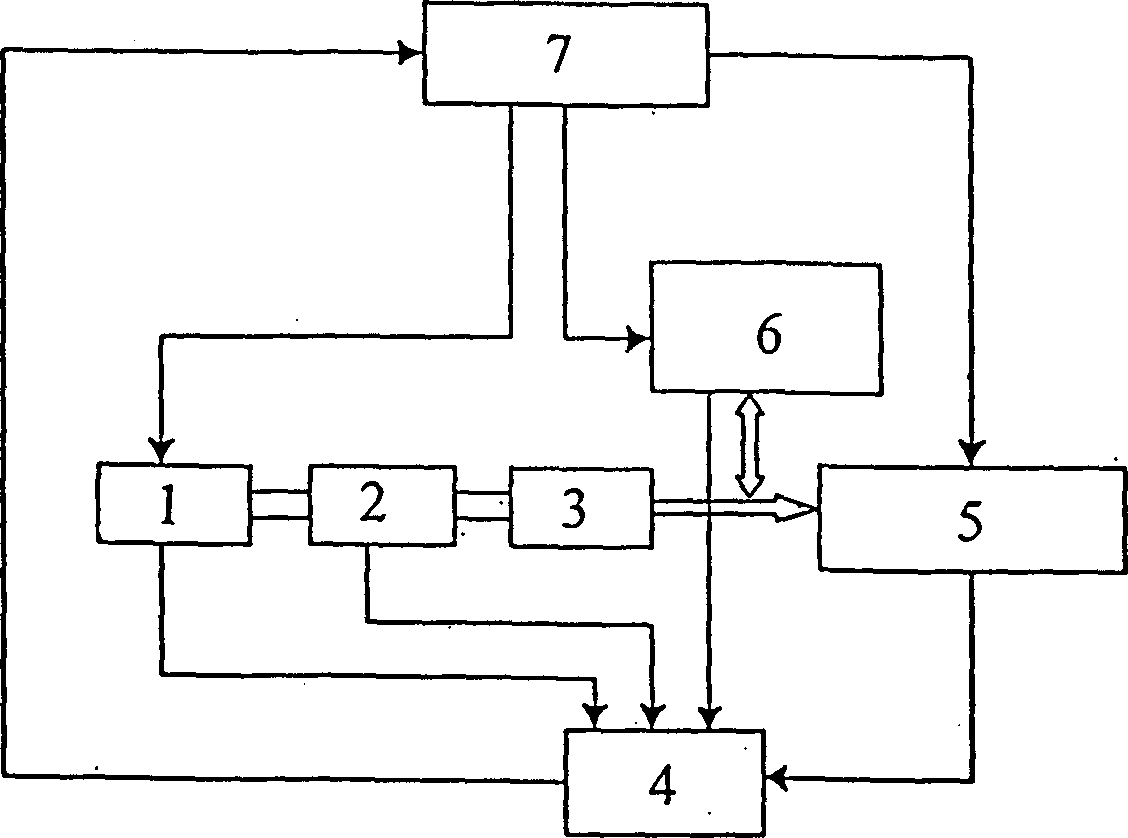

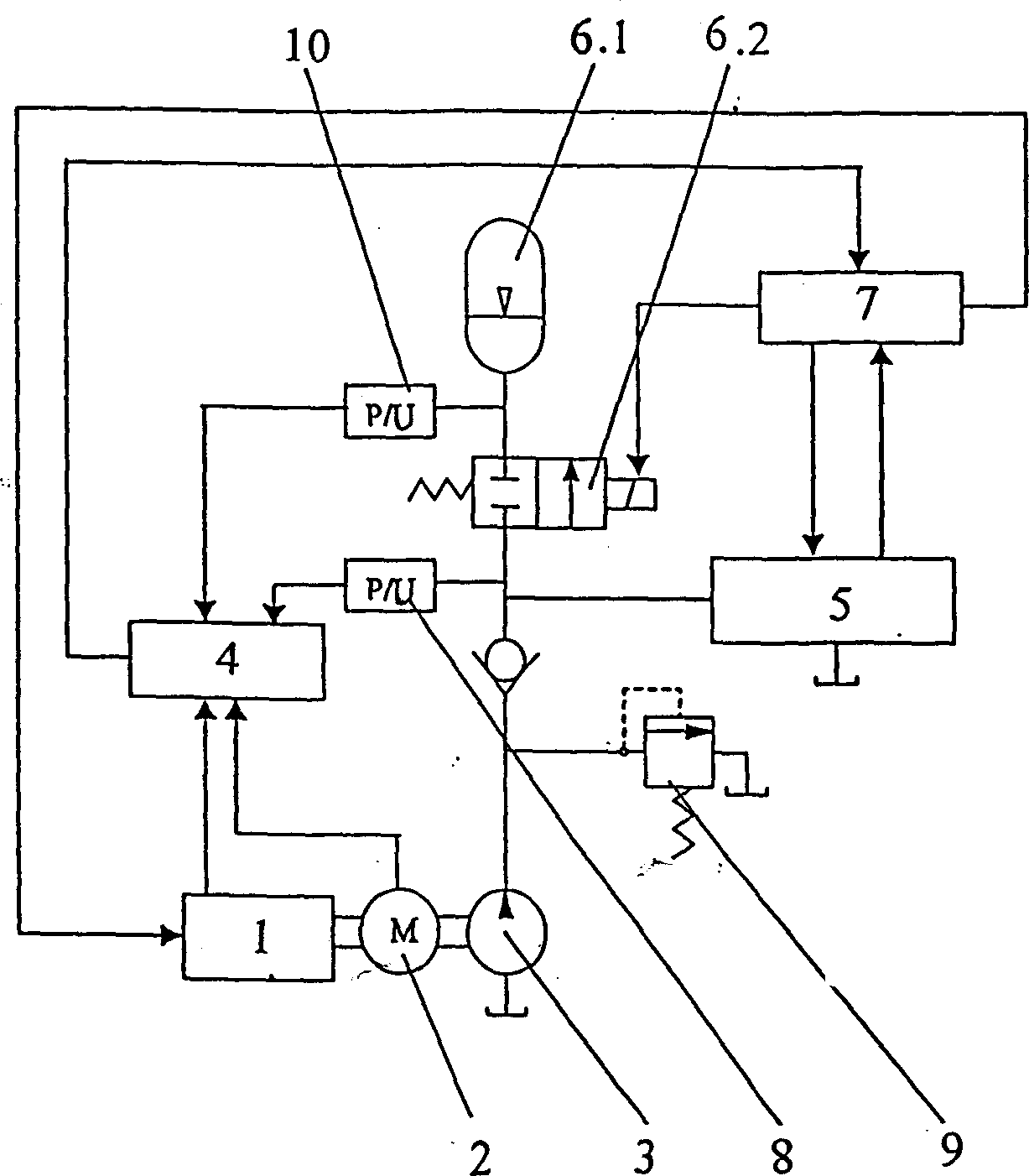

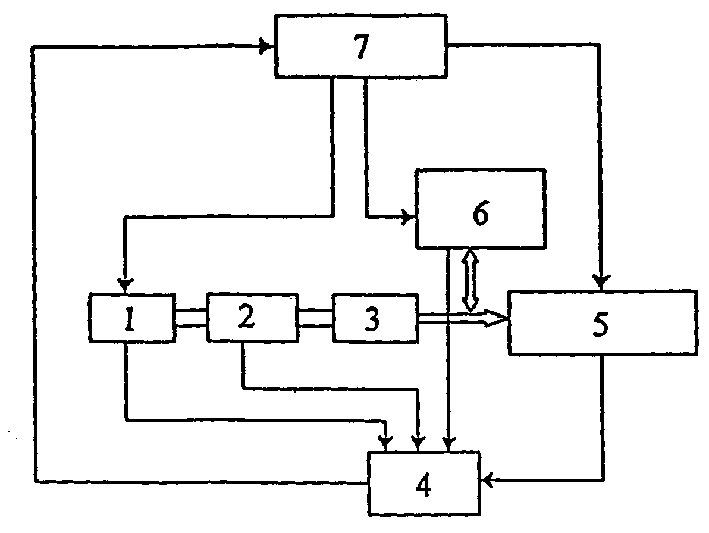

Electro-hydraulic control system and method based on frequency-conversion speed regulation

InactiveCN1391146AIncrease lossReduce lossFluid pressure controlFlow controlFrequency changerEnergy regulation

An electro-hydraulic control system based on frequency conversion type speed regulation is composed of frequency converter used to change rotation speed of pump, motor hydraulic pump, feedback unit for detection, hydraulic control system, energy regualting unit, and controller. The motor and hydraulic control valve are controlled by frequency converter. The electro-hydraulic control valve, energy regualting unit and frequency converter are controlled by controller. Its advantages are high efficiency, saving energy and high response speed.

Owner:ZHEJIANG UNIV

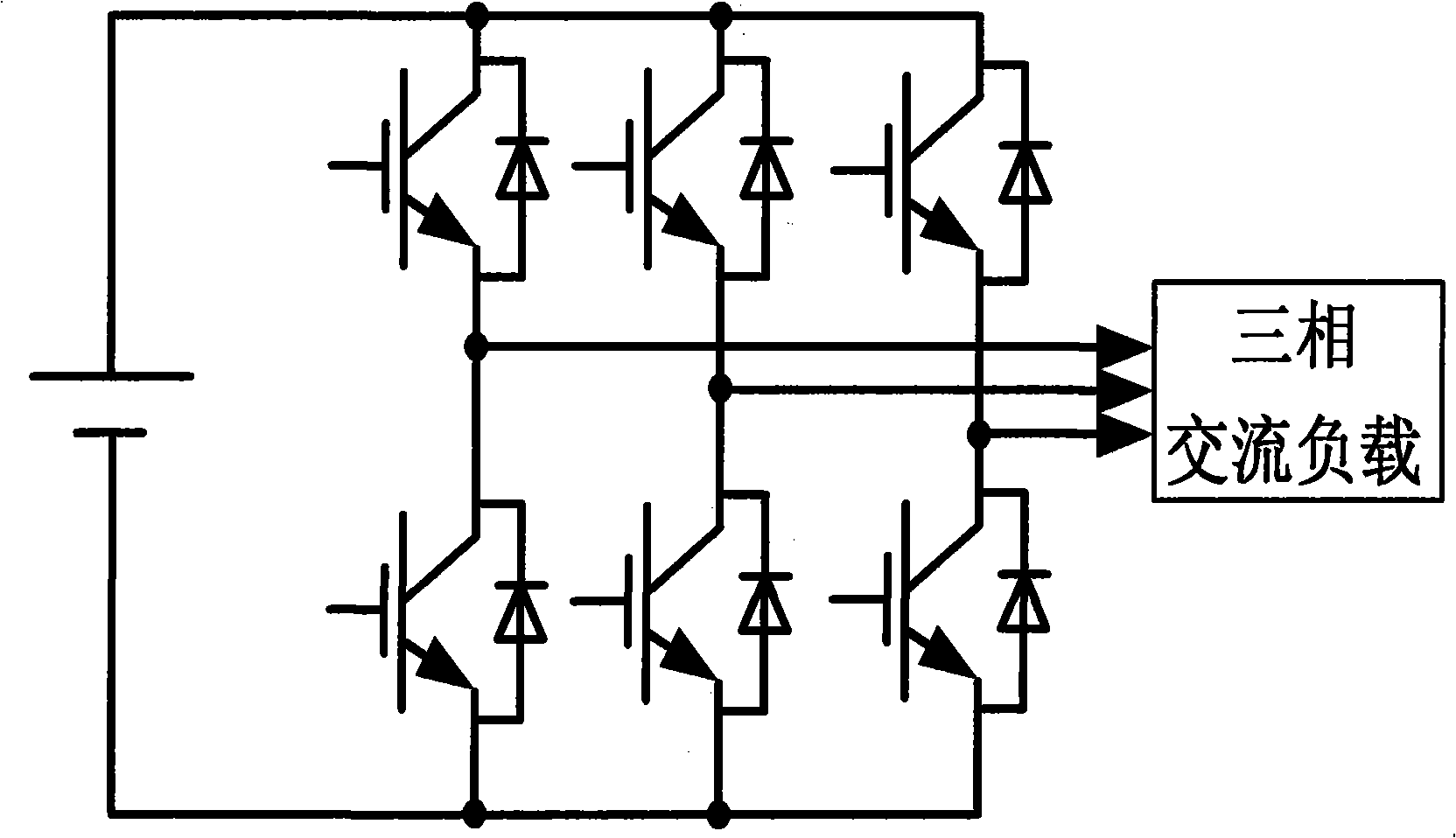

Z source reverser and soft start method

InactiveCN101267168AAchieving a soft startSimple structureAc-dc conversionZ-source inverterCapacitor voltage

The present invention provides a z-source inverter and its soft starting method, belonging to power electronic converter. The inverter main circuit is composed of a DC voltage source, a three-phase inverter bridge, a z-source network, a power diode, characterized in that the positive end of the three-phase inverter bridge is connected to the cathode of the DC voltage source, the negative end of the three-phase inverter bridge is connected to the Z source network. Compared with the voltage source type and the current source type inverter, the Z source inverter realizes pressure raising change function, and the upper and the lower switch tubes of the same bridge arm are directly passing, so the dead zone does not need, the circuit structure is simple, having high credibility. Compared with the traditional Z source inverter, the capacitor voltage of the Z source network in the Z source inverter has small stress, and realizing the soft start of the transformer, avoiding the problems of large voltage and current when the traditional Z source inverter starts, the work of the transformer is safe and credible, and having light volume and weight.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

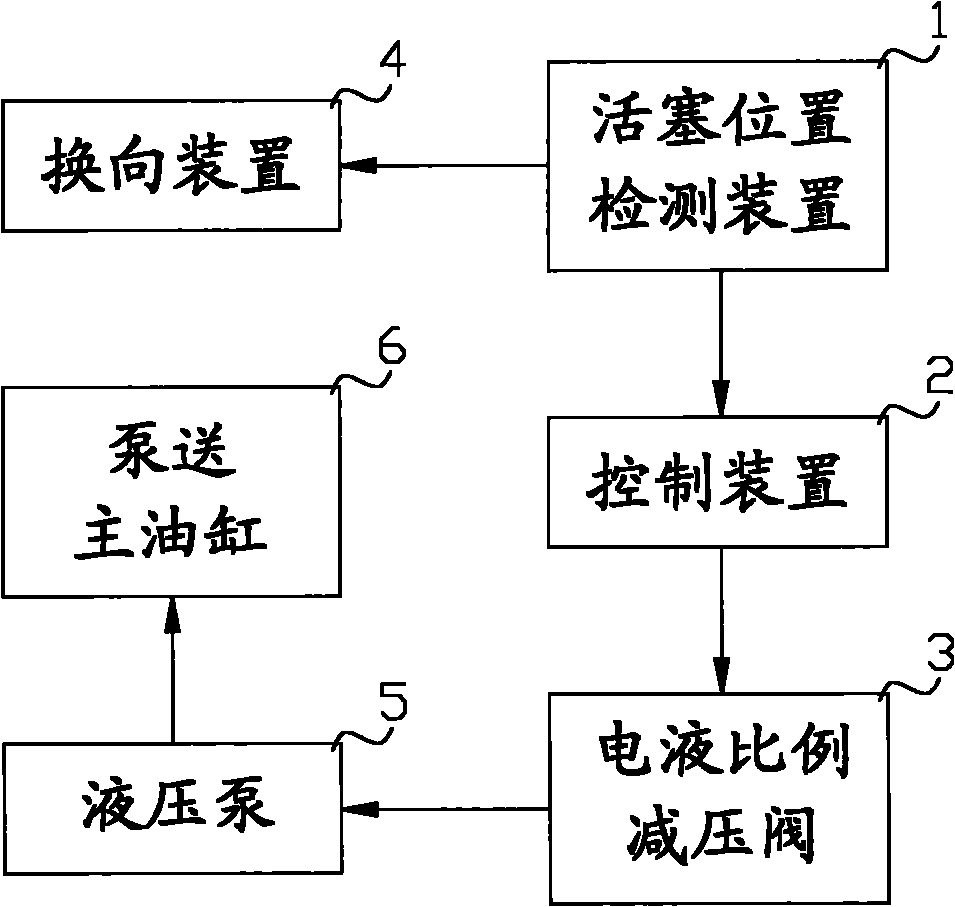

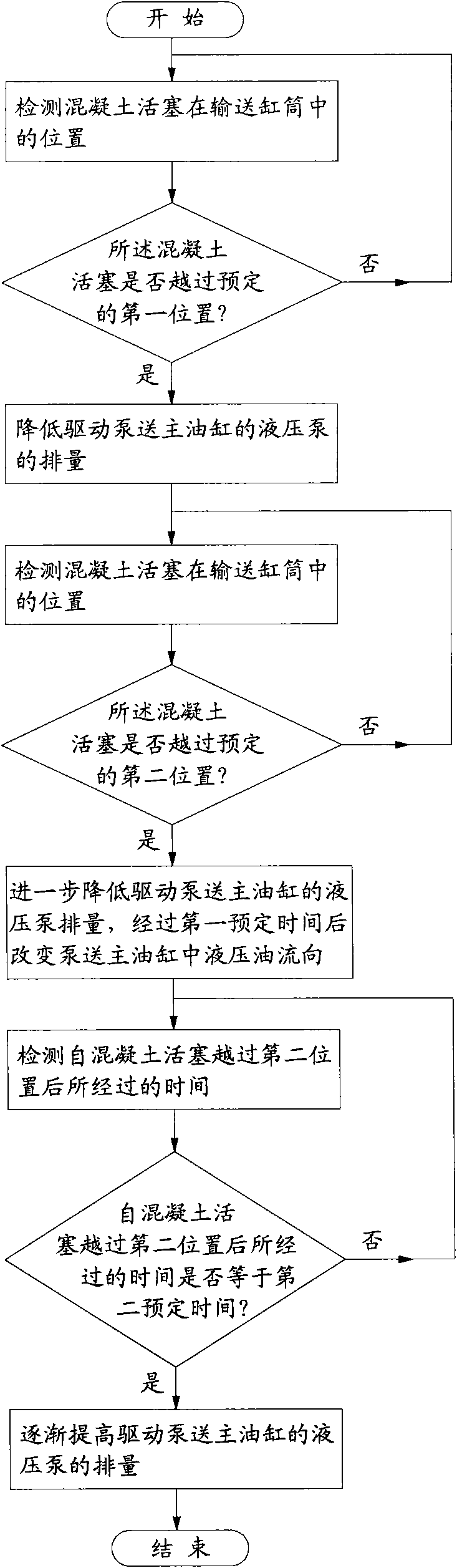

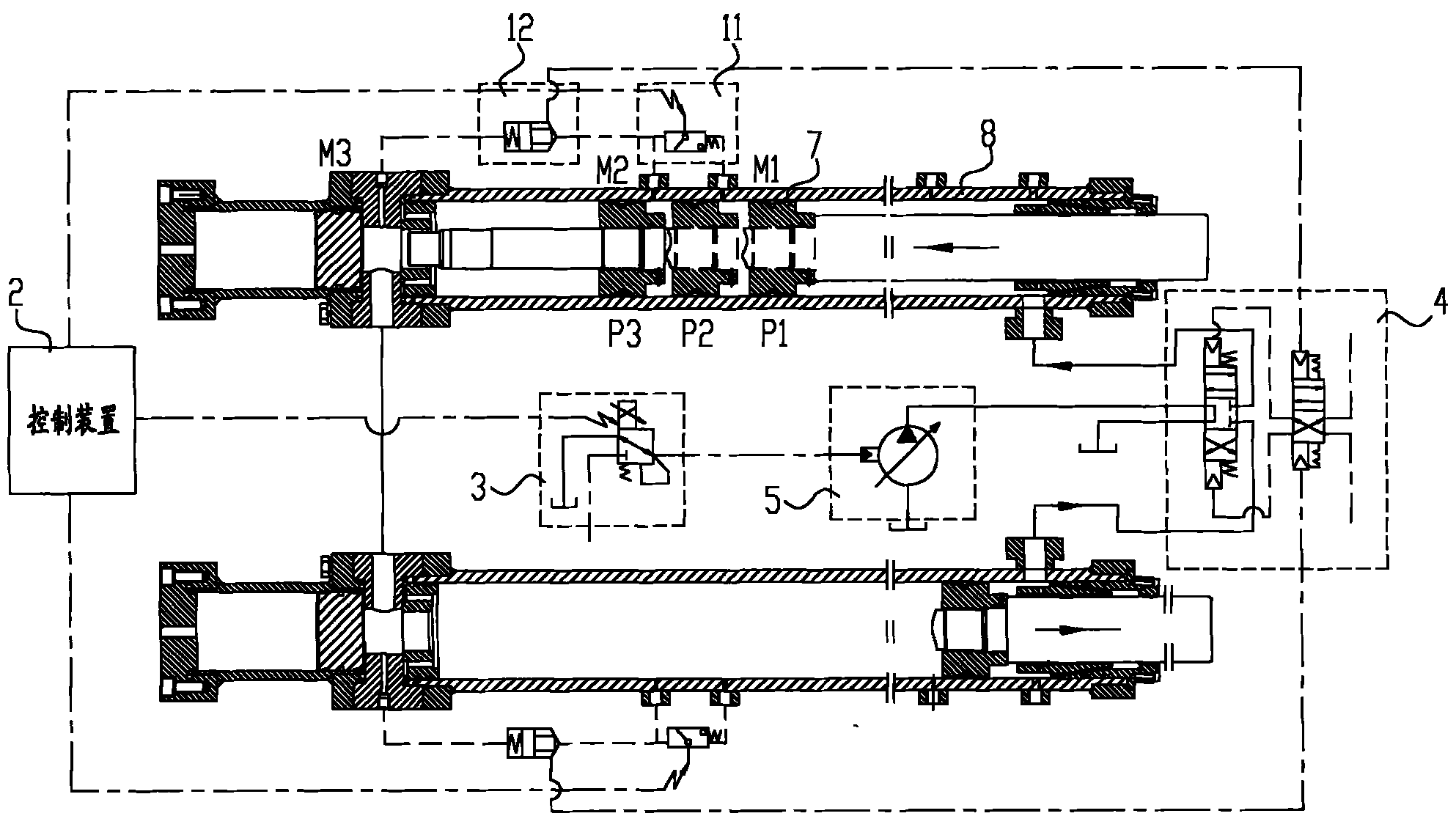

Concrete pump truck and concrete delivery pump exchange system

InactiveCN101793247ARealize pre-decelerationReduce displacementPump controlBuilding material handlingHydraulic pumpStructural engineering

The invention discloses a concrete delivery pump exchange system. After a concrete piston passes over the first position near the stroke end of the piston, the delivery capacity of the hydraulic pump of a pumping main cylinder is reduced so as to realize the pre-deceleration of the concrete piston; after the concrete piston passes over the second position further near the stroke end of the piston, the delivery capacity of the hydraulic pump can be reduced once again, so that the delivery capacity of the hydraulic pump remains a lower level; and then, when the delivery capacity of the hydraulic pump is lower, even close to zero drainage, the flow direction of the hydraulic oil in the pumping main cylinder is changed via an exchange device, thus the impact and the vibration caused by the direction change of the hydraulic oil in the pumping main cylinder are effectively reduced, and the stability of the concrete pump car in the working process can be greatly enhanced.

Owner:XCMG CONSTR MACHINERY

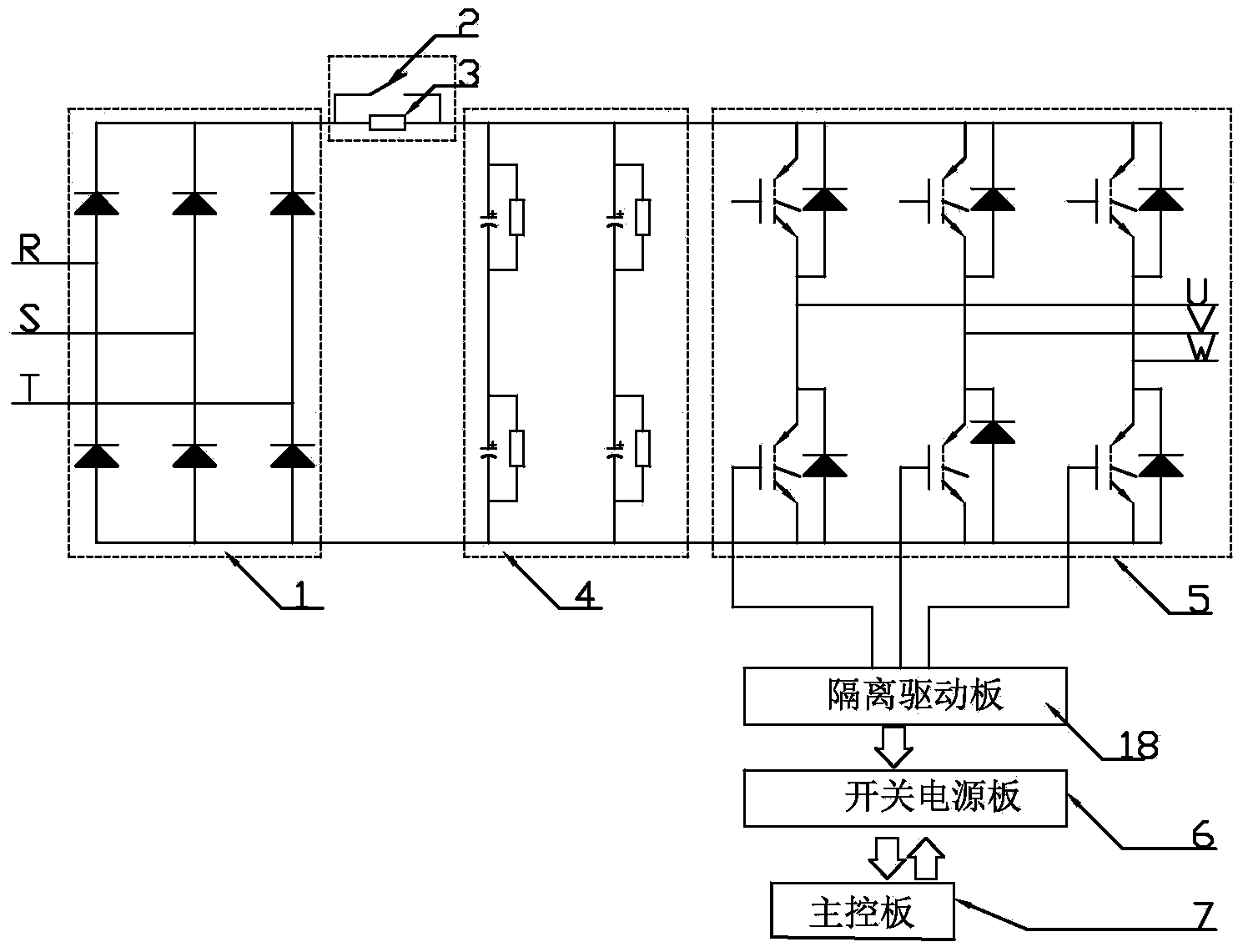

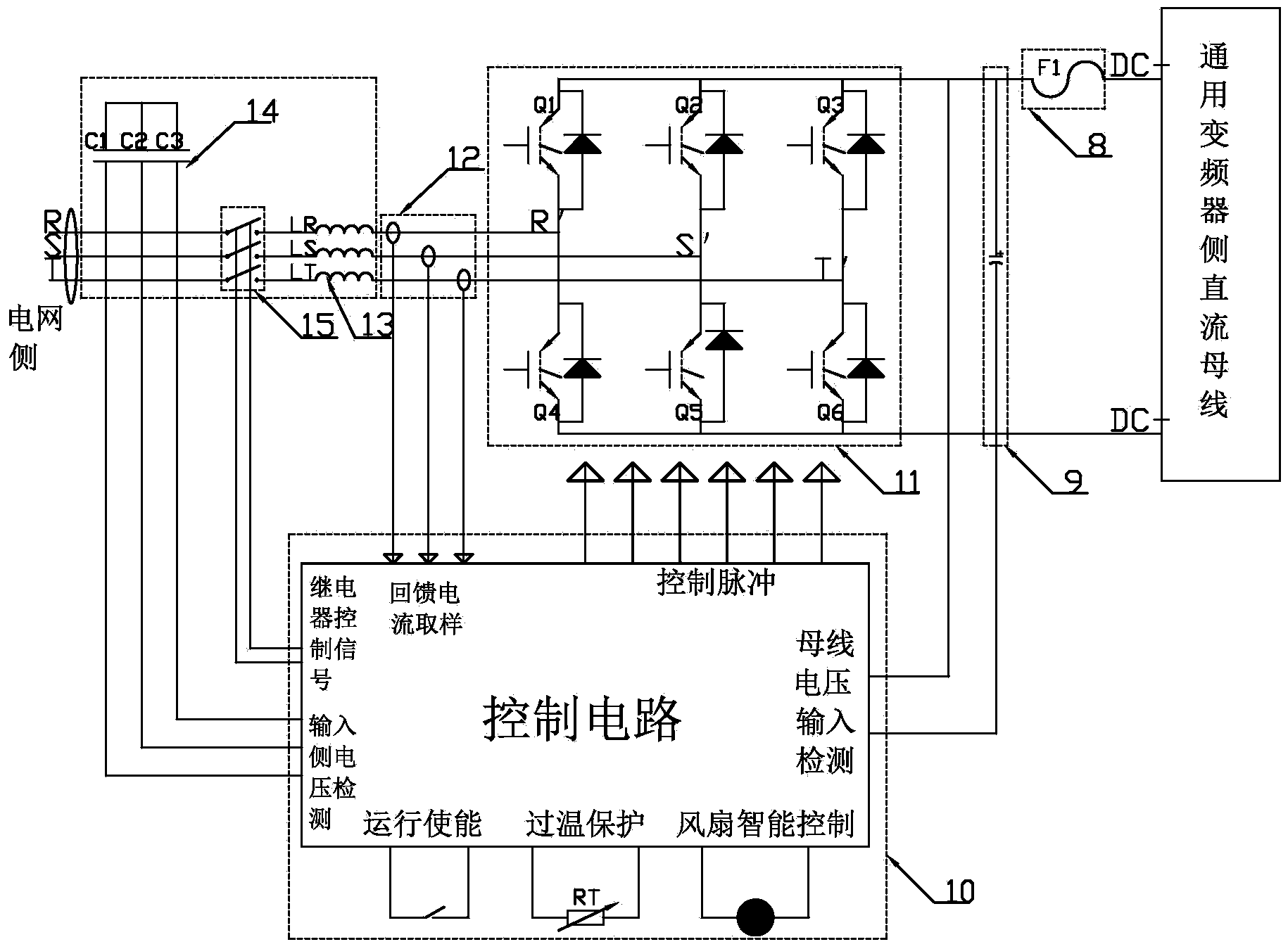

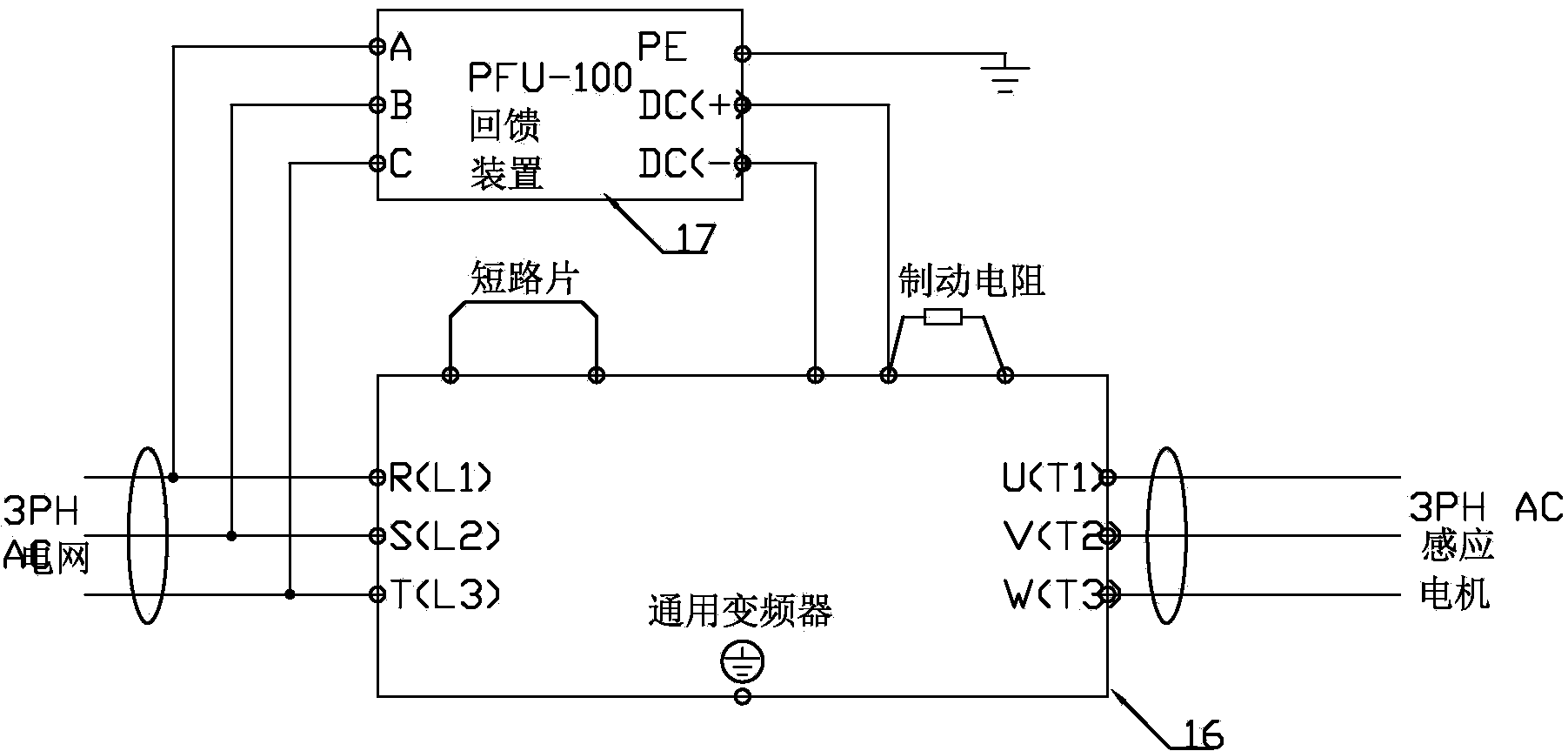

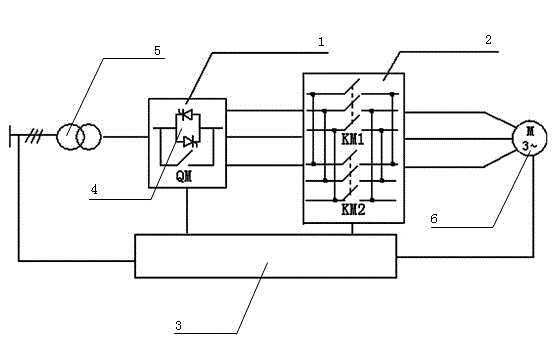

Four-quadrant frequency converter

InactiveCN103825470AReduce manufacturing costIncreased installation flexibilitySingle network parallel feeding arrangementsAc-ac conversionFrequency changerExternal energy

The invention belongs to the technical field of frequency converters and provides a four-quadrant frequency converter. According to the four-quadrant frequency converter, a frequency converter is arranged between a power grid and an induction motor; an energy feedback unit is arranged at a direct current (DC) busbar side of the frequency converter; a negative pole end DC- of a direct current busbar on the frequency converter is electrically connected with the DC- of the energy feedback unit; the DC+ on the frequency converter is electrically connected with DC+ of the energy feedback unit; three-phase alternating current output of the energy feedback unit is connected to input sides R, S and T of the frequency converter in parallel; a PE (Protecting Earthing) terminal of the energy feedback unit is reliably connected to the ground; when the busbar voltage of the frequency converter is detected by the energy feedback unit to be up to a set valve, feedback electric energy is converted to power frequency and transferred to the power grid to carry out energy saving regulation. The four-quadrant frequency converter provided by the invention has the advantages that through an external energy feedback device, the electric energy produced by the motor is added to the input end to the frequency converter after feedback and an electric reactor is additionally arranged to avoid the harmonic pollution, so that the power factor is greatly improved and the efficient utilization ratio of the electric energy is realized.

Owner:ZHEJIANG NEW FOLINN ELECTRIC

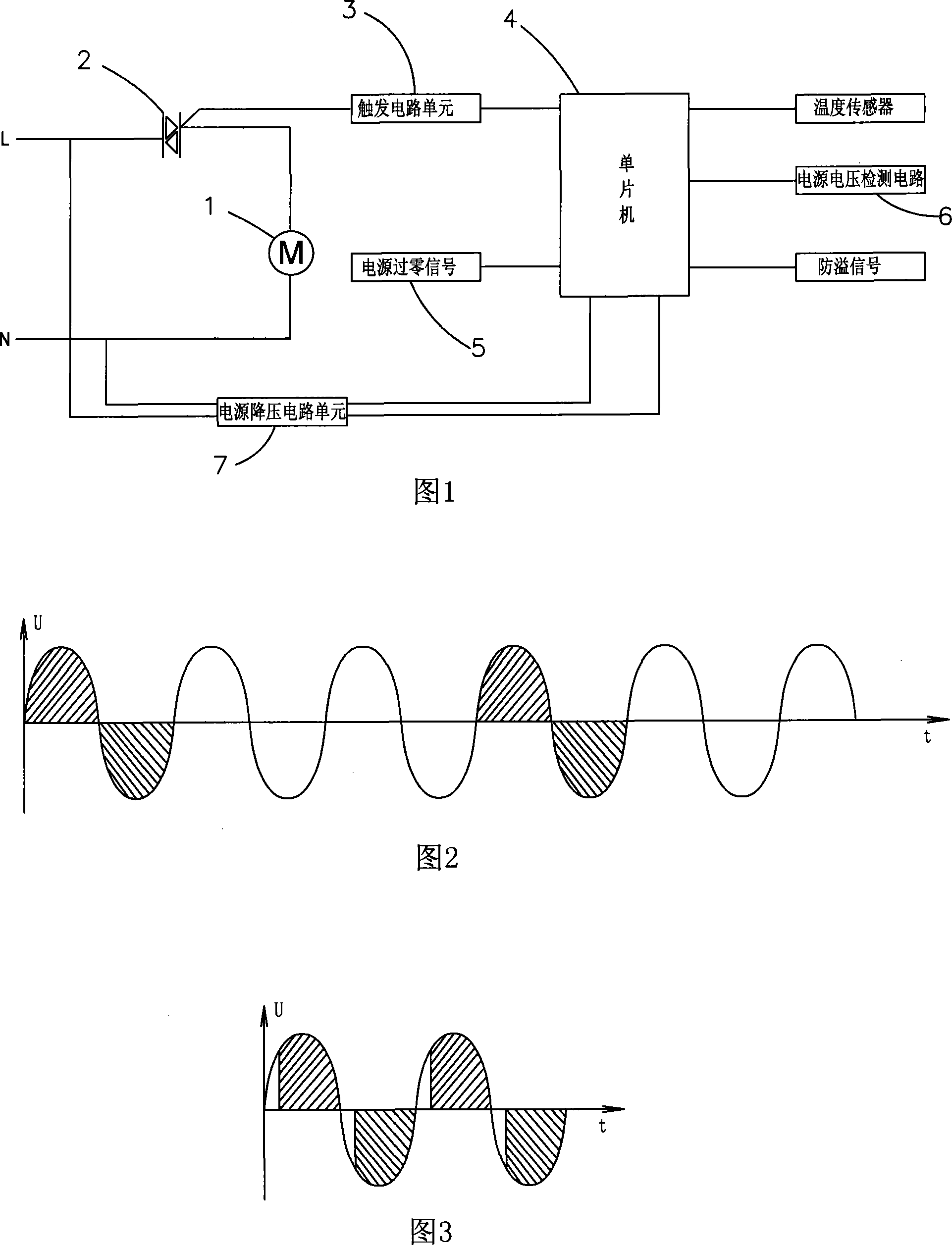

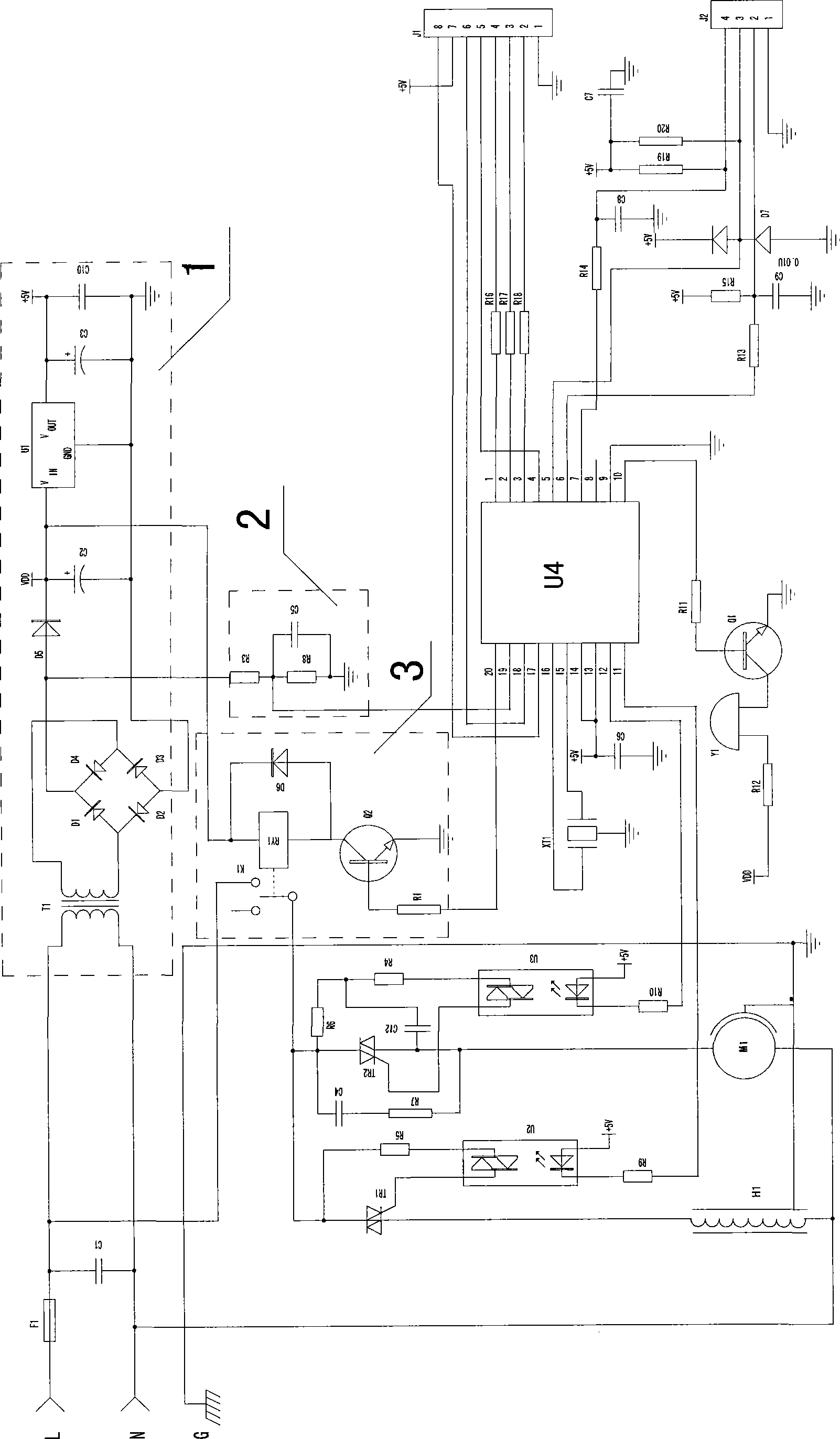

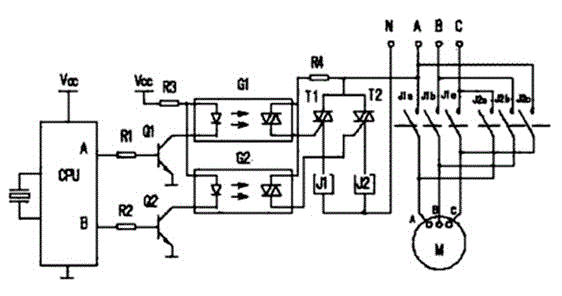

Soybean milk machine controlling circuit capable of starting electric machine softly

ActiveCN101223962AAchieving a soft startReduce shockBeverage vesselsFood preparationMicrocontrollerMicrocomputer

The invention relates to a soya bean milk maker circuit with motor soft start function, which comprises a motor, a silicon-controlled switch which is connected with the motor at an output end, a trigger circuit unit connected with a control end of the silicon-controlled switch, a single chip microcomputer connected with the trigger circuit unit, a zero-crossing detecting unit connected with the single chip microcomputer and a power and voltage detecting unit connected with the single chip microcomputer. An input end of the silicon-controlled switch is connected with one pole of a power, with the other pole of the power being connected with the motor at one end that is not connected with the silicon-controlled switch; the power and voltage detecting unit is connected with two poles of the power; the single chip microcomputer is connected with the power through a power step-down circuit unit. The soya bean milk maker circuit with motor soft start function of the invention controls the motor under the condition that the trigger circuit unit controls the silicon-controlled switch, thereby realizing soft start, and when the motor is started, shock impact of the motor on electric network is reduced and sudden noise caused by starting the motor becomes stable, thus reducing acoustical irritation to human body; in addition, the motor is provided with various voltage for regulating rev of the motor, thereby meeting requirements for different crushing degrees determined by bean materials and users, reducing the noise of the motor, prolonging the service life of the motor and increasing discharging rate.

Owner:SHENZHEN LONGOOD INTELLIGENT ELECTRIC

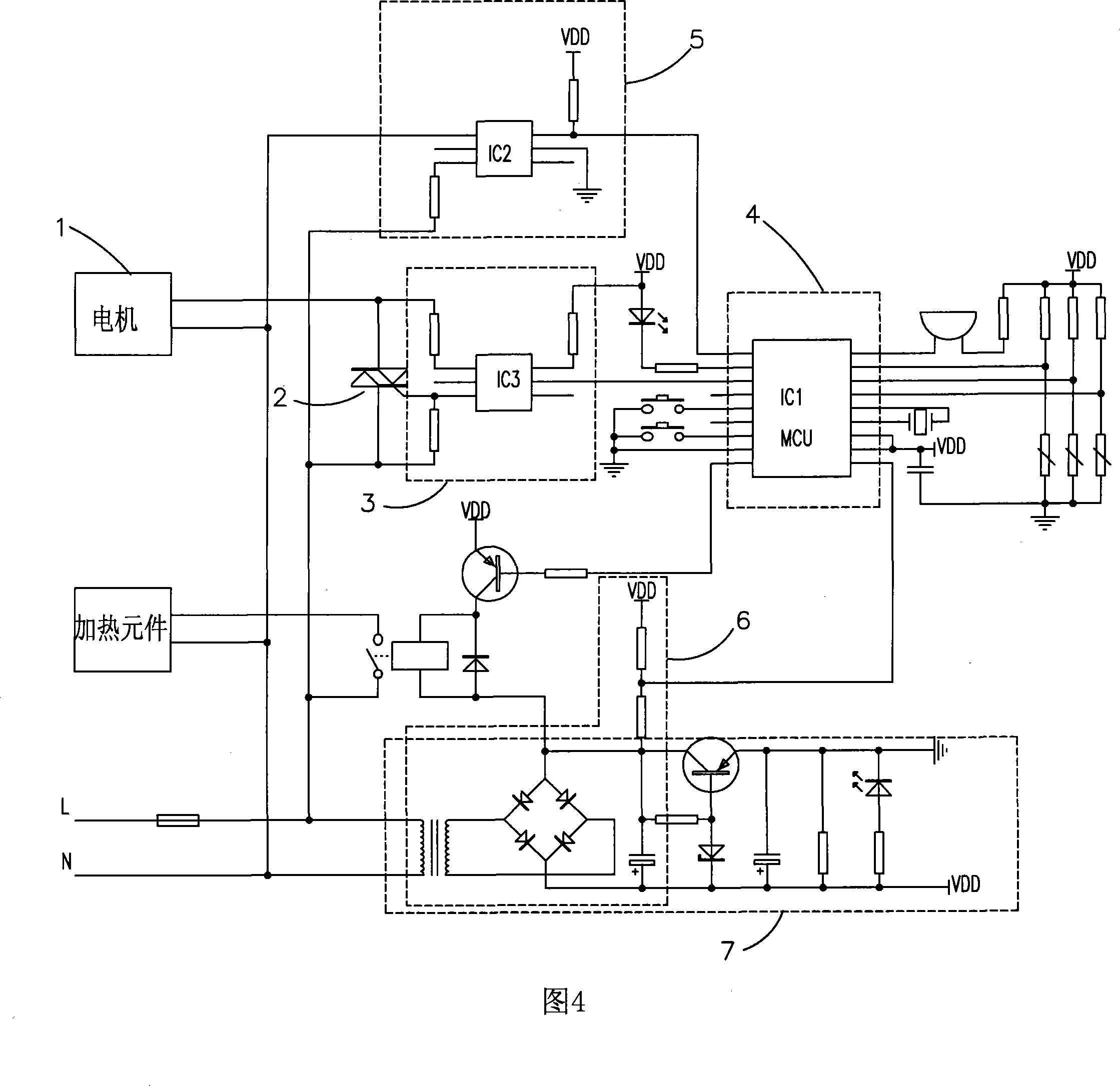

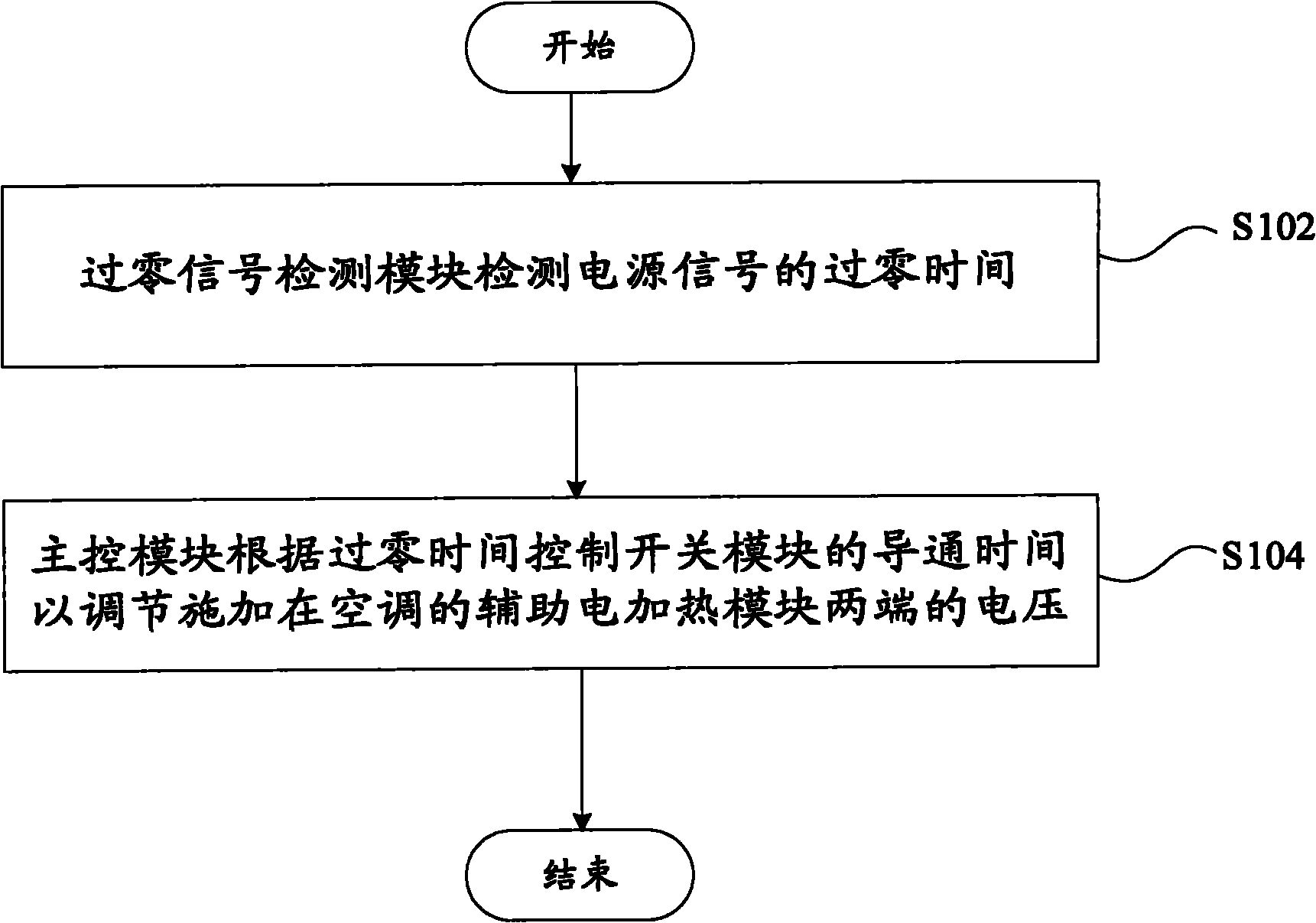

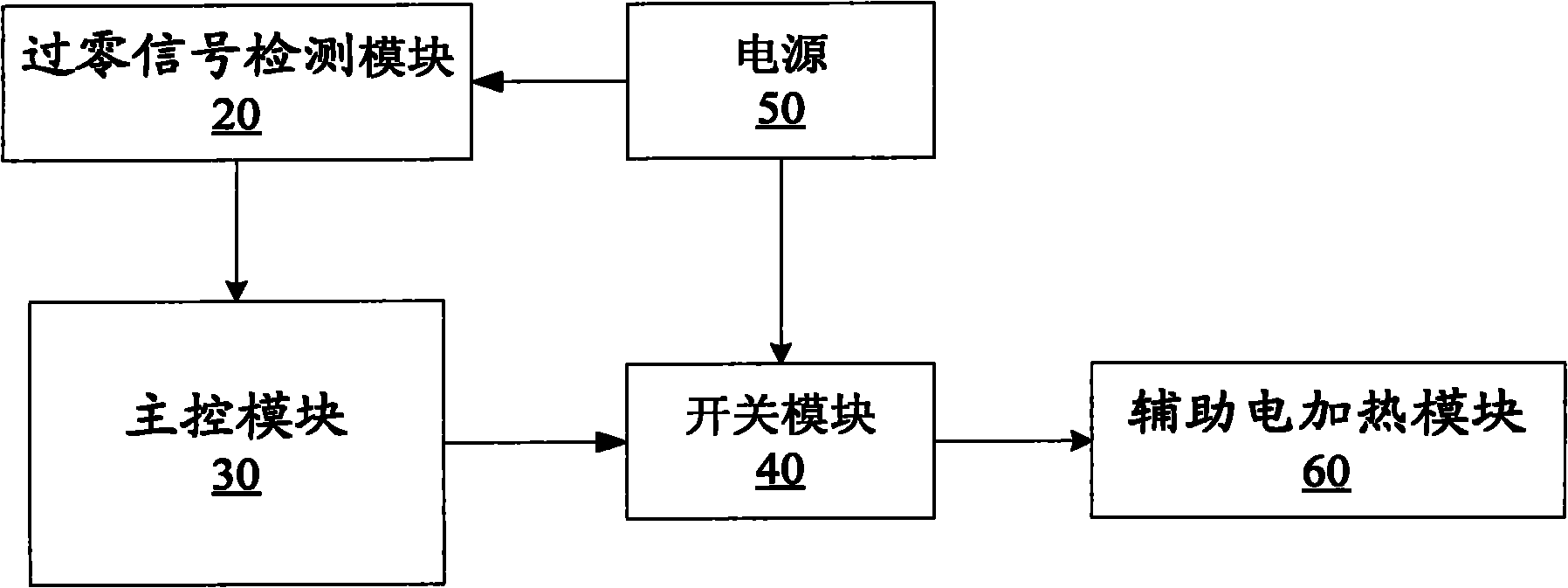

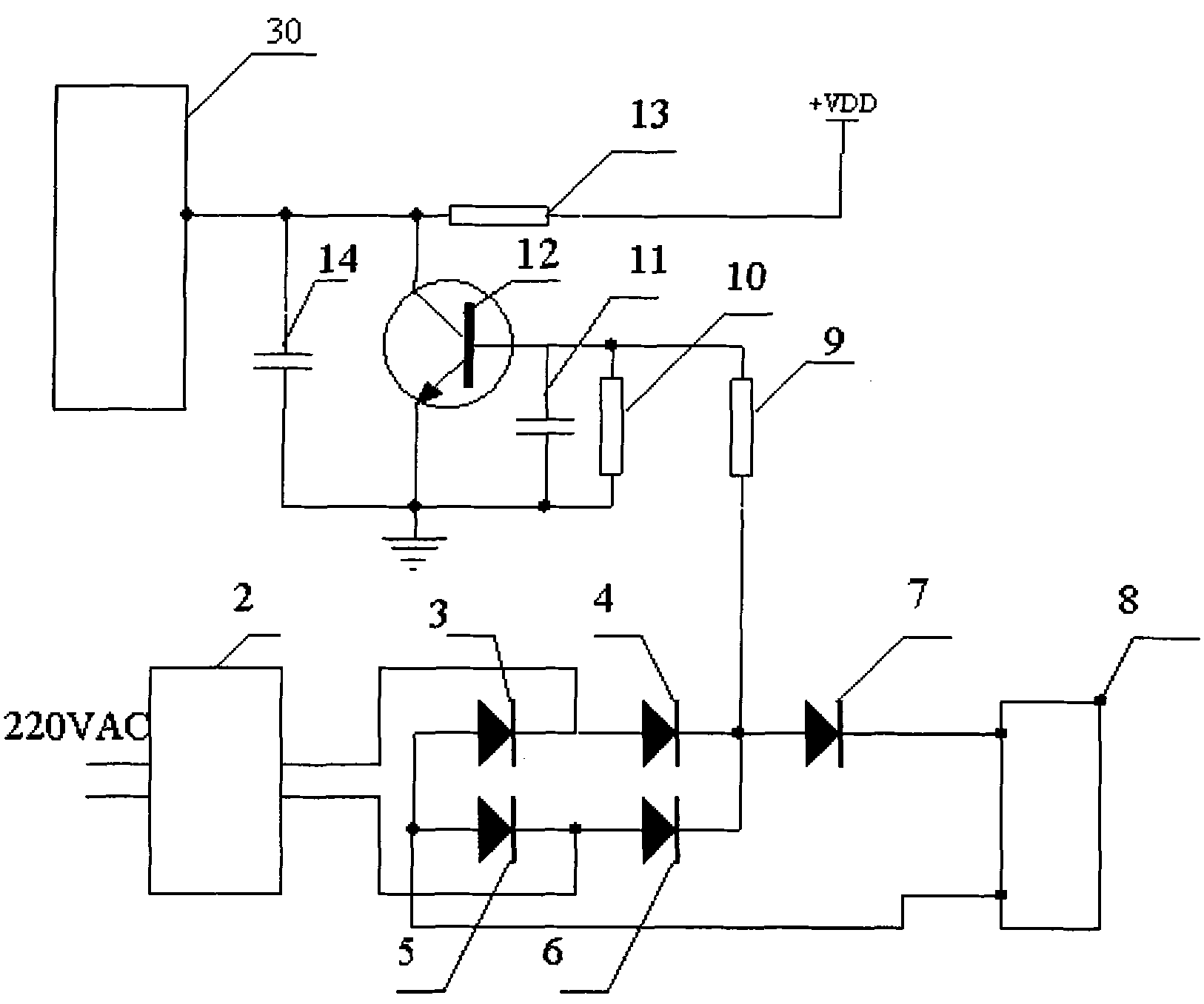

Control method and device for assistant electrical heating of air conditioner

ActiveCN102003767AGood energy saving effectImprove comfortMechanical apparatusSpace heating and ventilation safety systemsElectricityVoltage

The invention provides control method and device for assistant electrical heating of an air conditioner. The method comprises the following steps: an over-zero signal detecting module detects the over-zero time of electric source signals; and a main control module controls the conducting time of a switch module according to the over-zero time to adjust voltage applied to both ends of an assistantelectrical heating module of the air conditioner.

Owner:GREE ELECTRIC APPLIANCES INC

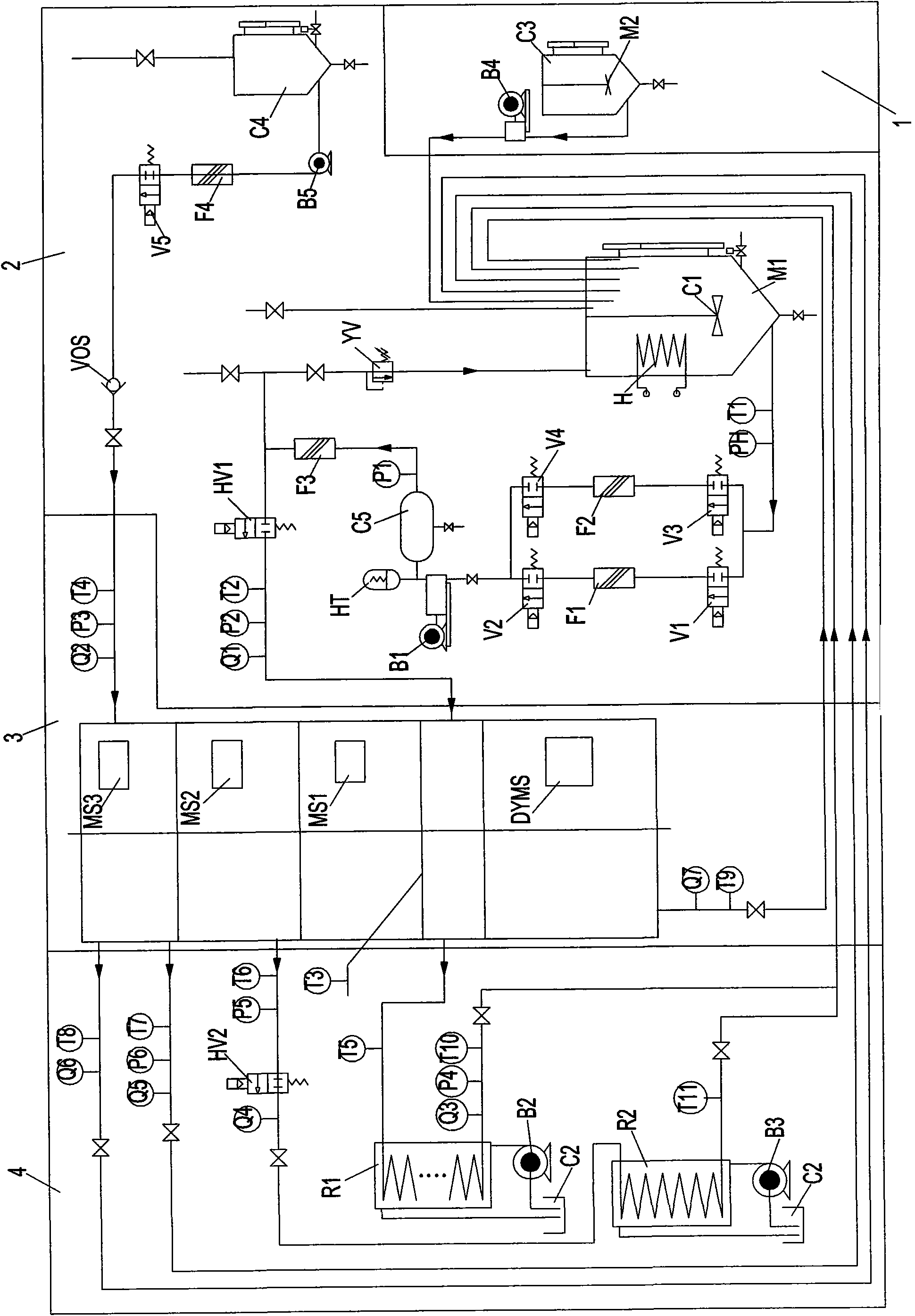

Mechanical seal test system for nuclear main pump

ActiveCN101639396ARealize stepless speed regulationAchieving a soft startFluid-tightness measurement using fluid/vacuumBuffer tankSystem pressure

The invention discloses a mechanical seal test system for a nuclear main pump, which is characterized in that the system comprises a medium concentration control zone, an injection medium processing zone, a frame zone and a reflux medium post processing zone. A test main shaft is used as a driven component in the frame zone; the test shaft is provided with a fluid static pressure seal or a fluid dynamic pressure seal or a fluid dynamic-static pressure combined seal. In the injection medium processing zone, a seal medium flow passage located between a low pressure container and a system seal cavity is respectively provided with a high pressure pump, a high pressure buffer tank and an energy accumulator, which are connected in series with a switchable magnetic filter, an organic filtering film and used,for providing a system pressure source; in the reflux medium post processing zone, a long pipe throttling cooler with a back pressure value is arranged at an outlet of the system seal cavity. The invention not only can simulate a fluid static pressure mechanical seal test for the nuclear main pump, but also can simulate a fluid dynamic pressure mechanical seal test for the nuclear mainpump, at the same time, the invention further can simulate a fluid dynamic-static pressure combined mechanical seal test for the nuclear main pump.

Owner:HEFEI GENERAL MACHINERY RES INST

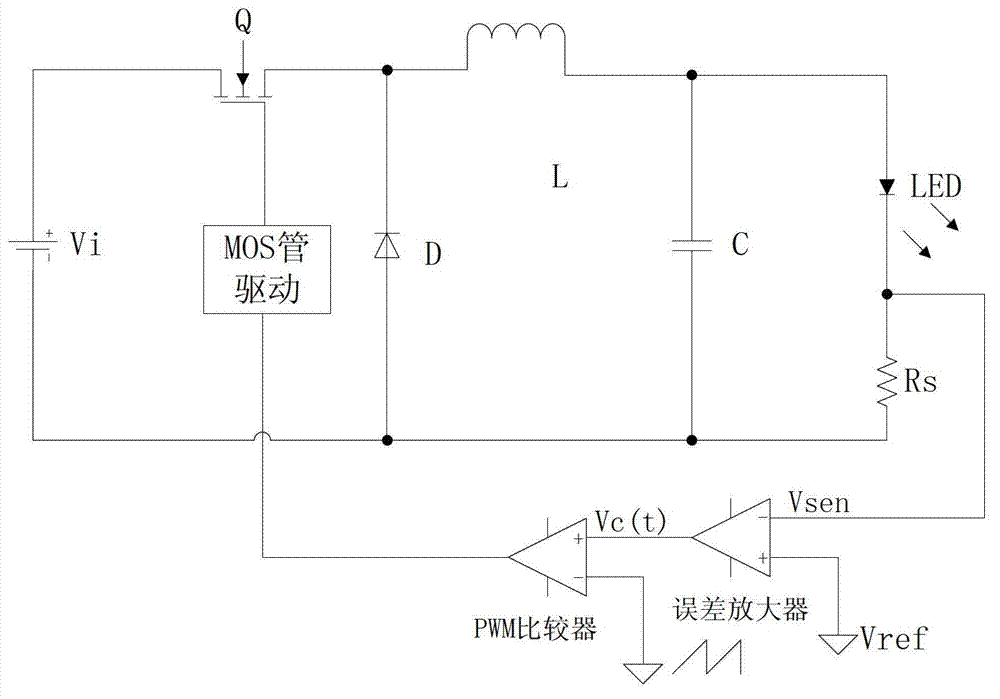

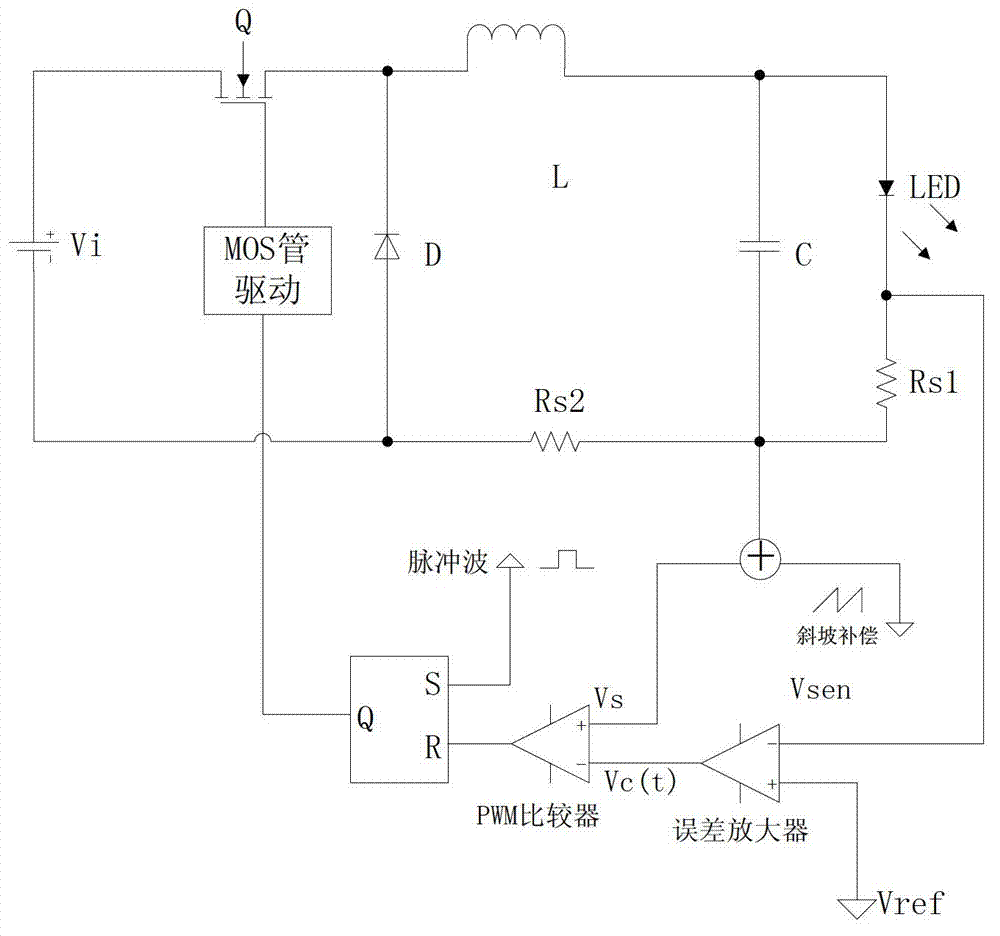

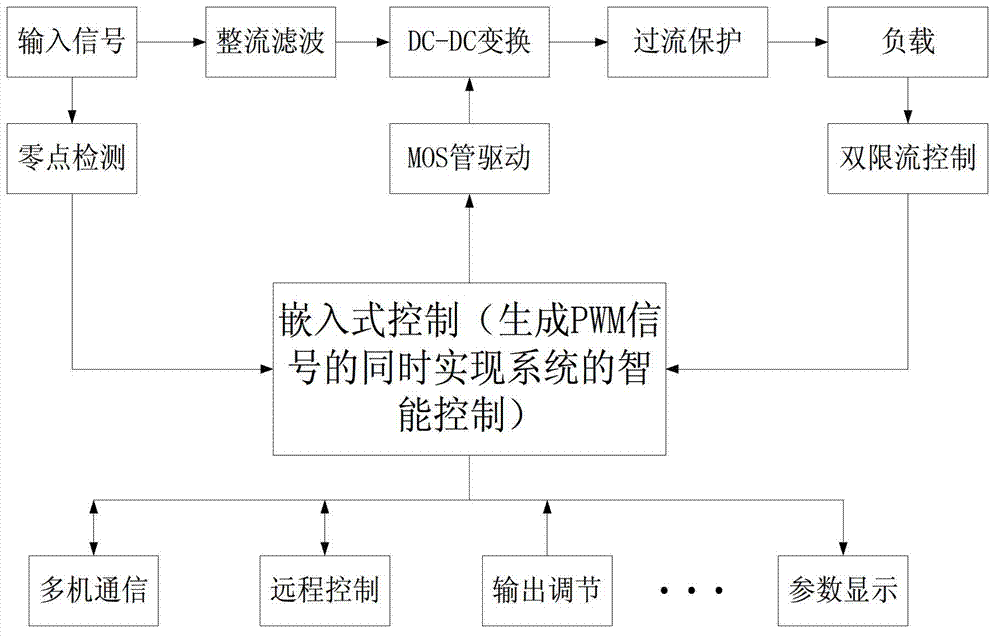

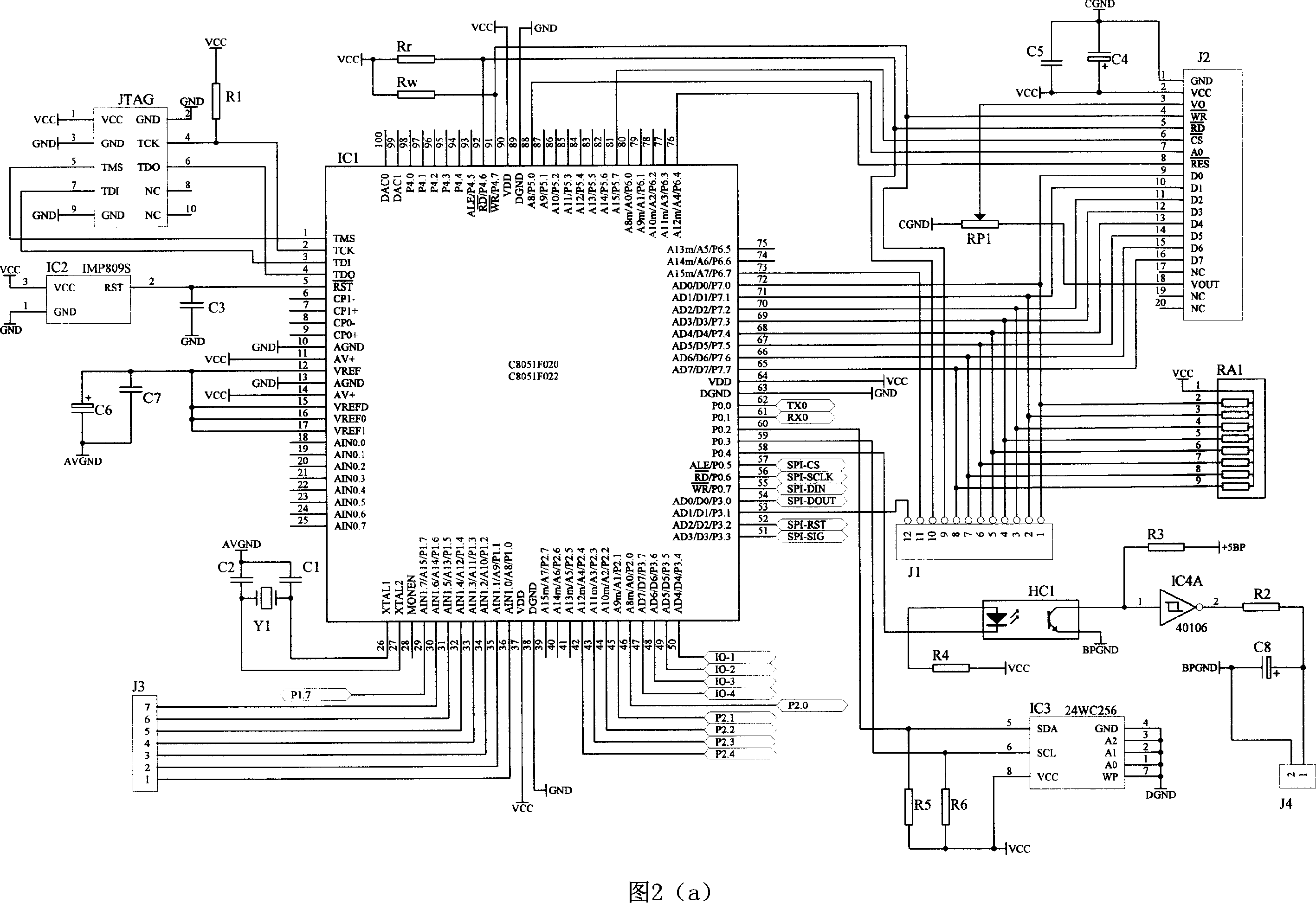

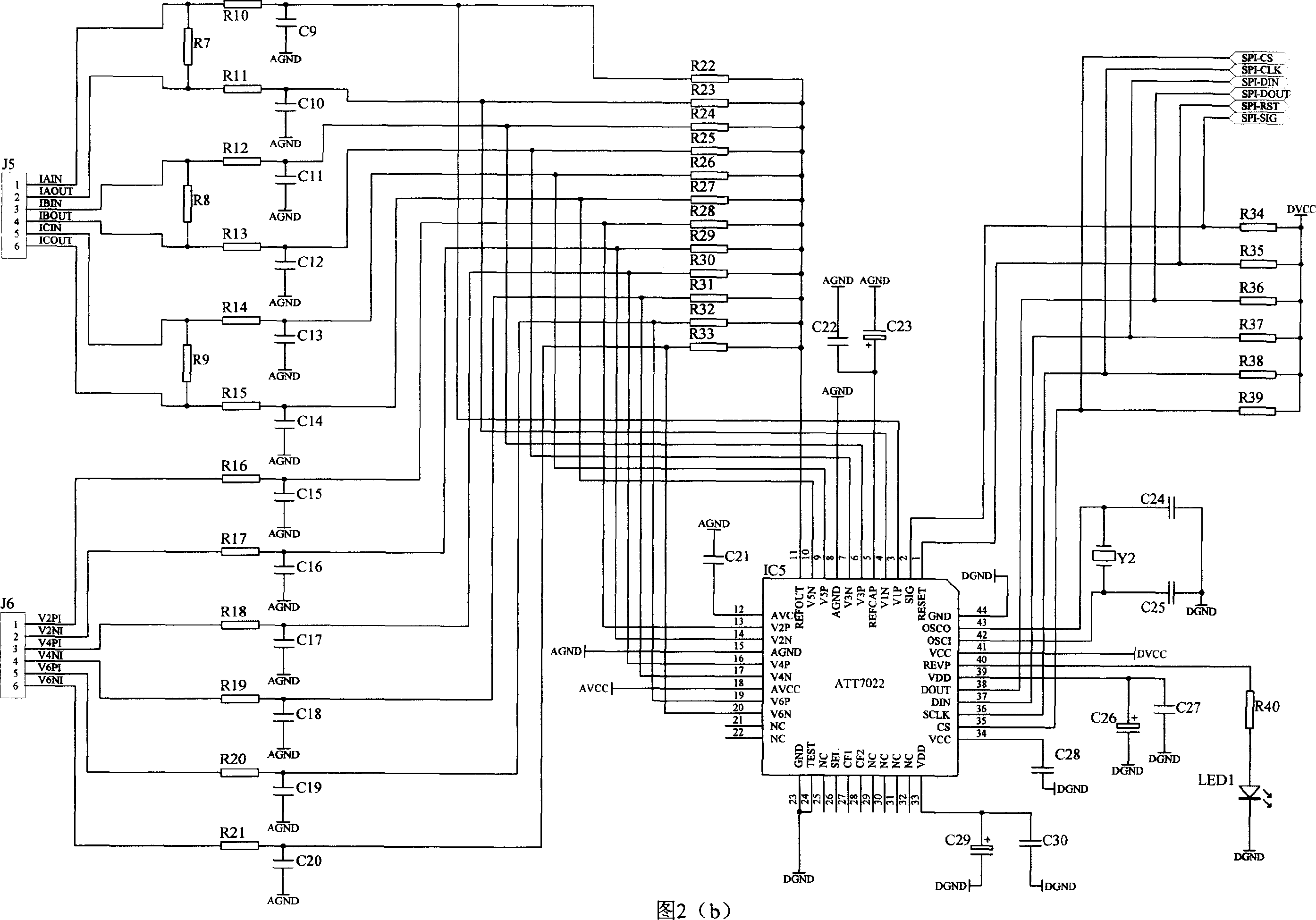

Intelligent constant-current driver realized by embedded chip and control method of intelligent constant-current driver

ActiveCN102769981AExpand the input rangeImprove efficiencyElectric light circuit arrangementEnergy saving control techniquesColor changesConstant current

The invention relates to an intelligent constant-current driver realized by an embedded chip and a control method of the intelligent constant-current driver. The intelligent constant-current driver realized by the embedded chip is characterized by comprising a rectifying filter module, a null-point detecting module, a DC (direct current)-DC conversion module, an overcurrent protection module, a double-limit-current control module, an MOS (metal oxide semiconductor) tube driving module, an embedded intelligent control module and a function extension module based on the embedded chip. The constant-current driver is large in input range, high in efficiency, upgradable, simple in circuit structure, adjustable in output current and rich in extended functions, and is an intelligent constant-current control system. Meanwhile, when the load is an LED array, light dimming, color changing and flickering control and the like can be realized by the system. Therefore, the intelligent constant-current driver can be used for realizing devices for LED lighting, LED alarm lamps and LED displaying and the like.

Owner:深圳市益力盛电子有限公司

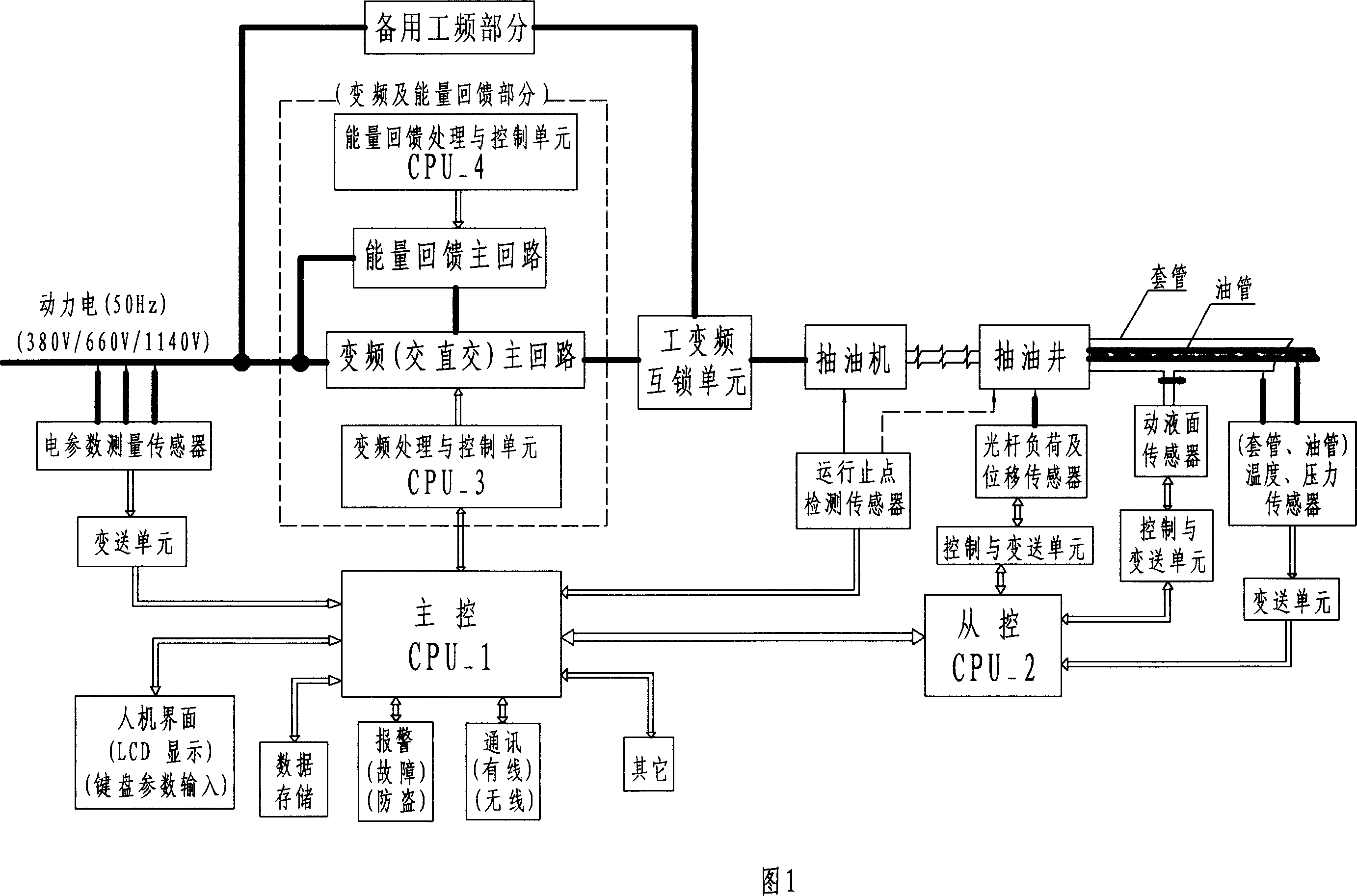

Smart synergetic controller for oil pump

InactiveCN1978865ARealize artificial intelligenceRealize automatic controlComputer controlFluid removalClosed loopPower grid

The invention relates to pumping unit intelligent multiplier controller. It mainly includes light and strong current parts. Its feature is that dynamic liquid level transducer and polished rod load and displacement transducer are connected with the CPU to realize exact closed-loop control for the pumping well. The light current part includes main control CUP and controlled CPU; the strong current part includes energy feedback, stand by power frequency, and power frequency conversion interlocking parts. The invention can increase pumping well system efficiency, realize its energy saving and consumption reducing, increase both production and income, input-output ratio, and economic benefit, can be suited for oil field electric network specificity and pumping well variability.

Owner:王洪亮 +1

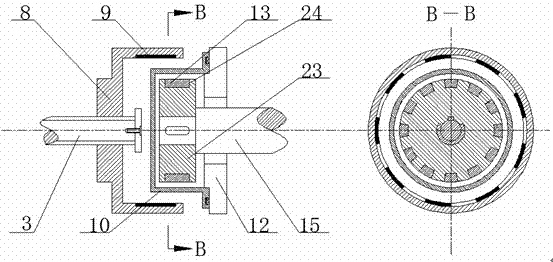

Air-suspension air-supply-adjustable air blower directly driven by high-speed electric machine

ActiveCN102200136AReduced noise and mechanical lossesImprove machine efficiencyPump componentsPump installationsSynchronous motorImpeller

The invention discloses an air-suspension air-supply-adjustable air blower directly driven by a high-speed electric machine. The air blower comprises a compressor impellor, a permanent magnetic synchronous motor rotor, a motor stator, a front radial air bearing, a rear radial air bearing, an axial thrust air bearing, a scroll and a motor shell; one end of the permanent magnetic synchronous motor rotor is connected with the compressor impellor; the rotor stator drives the permanent magnetic synchronous motor rotor to rotate; the front radial air bearing, the rear radial air bearing and the axial thrust air bearing support the permanent magnetic synchronous motor rotor in a suspension mode; the scroll is arranged at the periphery of the compressor impellor; and the motor shell is positioned at the peripheries of the motor stator, the front radial air bearing, the rear radial air bearing, the axial thrust air bearing and the permanent magnetic synchronous motor rotor. According to the invention, through driving the compressor impellor directly by the permanent magnetic synchronous motor rotor of the high-speed electric machine, a complex and expensive speeding system is omitted, noises and mechanical loss are reduced, the integral machine efficiency can be improved, the system is simple, and the air blower provided by the invention is convenient to install and transport.

Owner:宁波虎渡能源科技有限公司

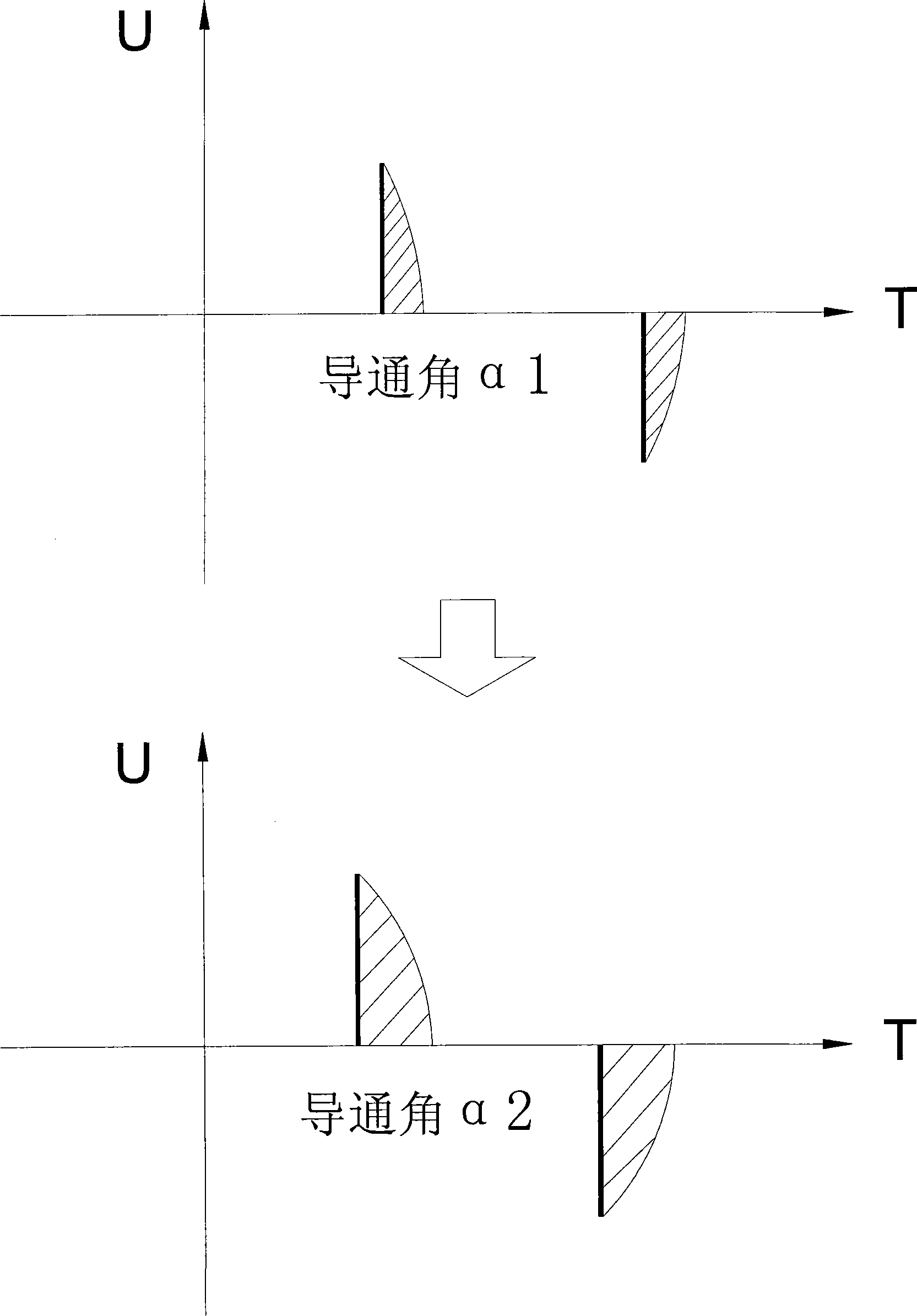

Method for soy bean milk making machine soft starting and soft closing and control circuit for implementing the method

InactiveCN101478276AReduce shock torqueImprove running stabilityStarter detailsFood preparationPhase shiftedZero crossing

The invention discloses a motor soft-starting method of a soymilk machine. Controlled silicon is used as a booster that is connected between a power supply and an electric motor; in AC with T period, an AC zero-crossing signal is detected and taken as a sync signal, the conduction angle magnitude is changed in a phase-shift trigger manner, so that the electric motor obtains voltage that varies continuously. The motor soft-starting method really realizes the soft-starting and soft turning-off of the electric motor in the soymilk machine, reduces the impact of sudden increase and sudden decrease of the voltage on the electric motor and a power grid, leads the rotation speed of the electric motor in the soymilk machine to change smoothly when starting or turning off, reduces the impact torque of the electric motor on loaded machinery, increases the operating stability of the soymilk machine, and prolongs the service life of the electric motor.

Owner:KINGCLEAN ELECTRIC

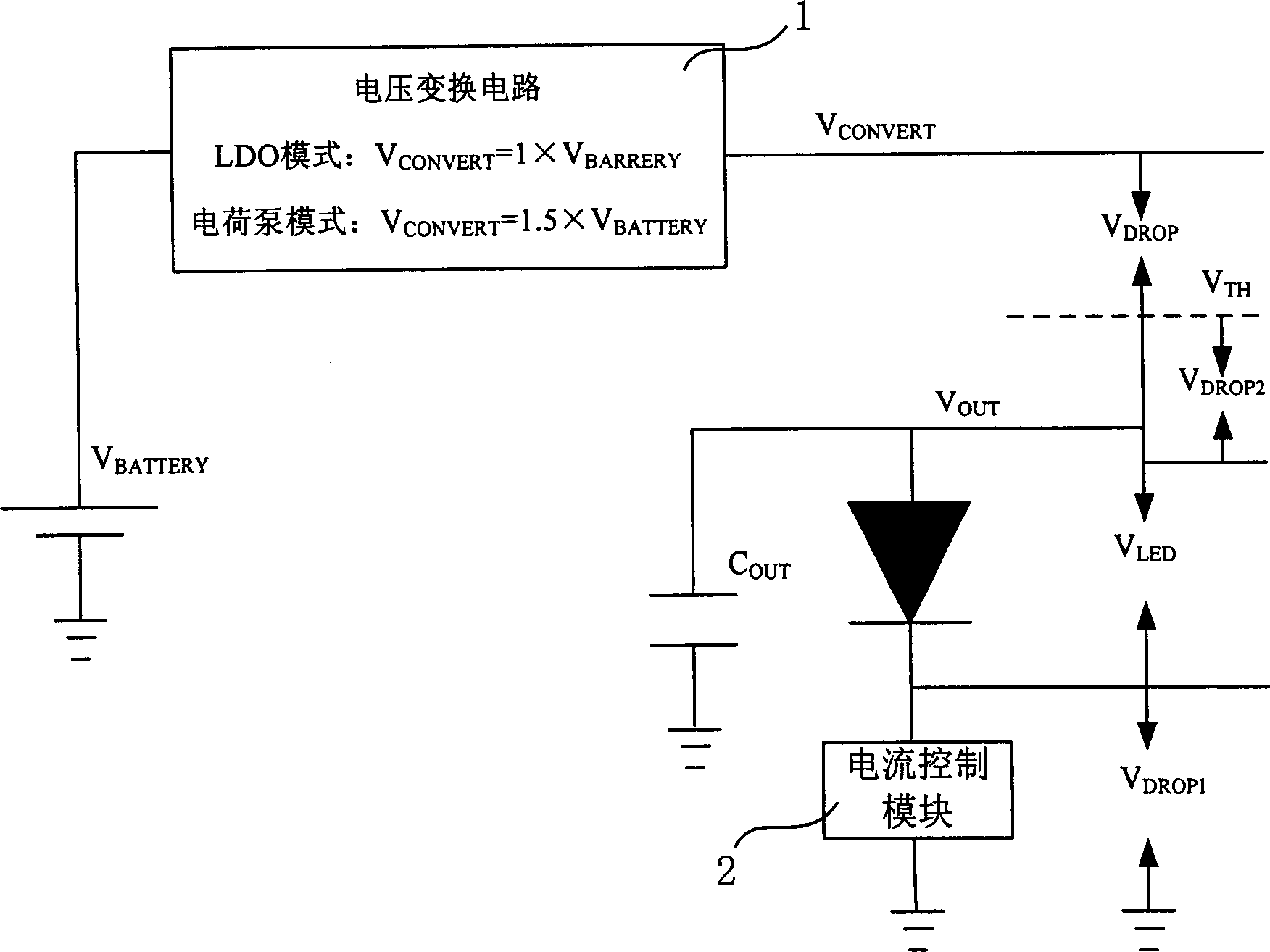

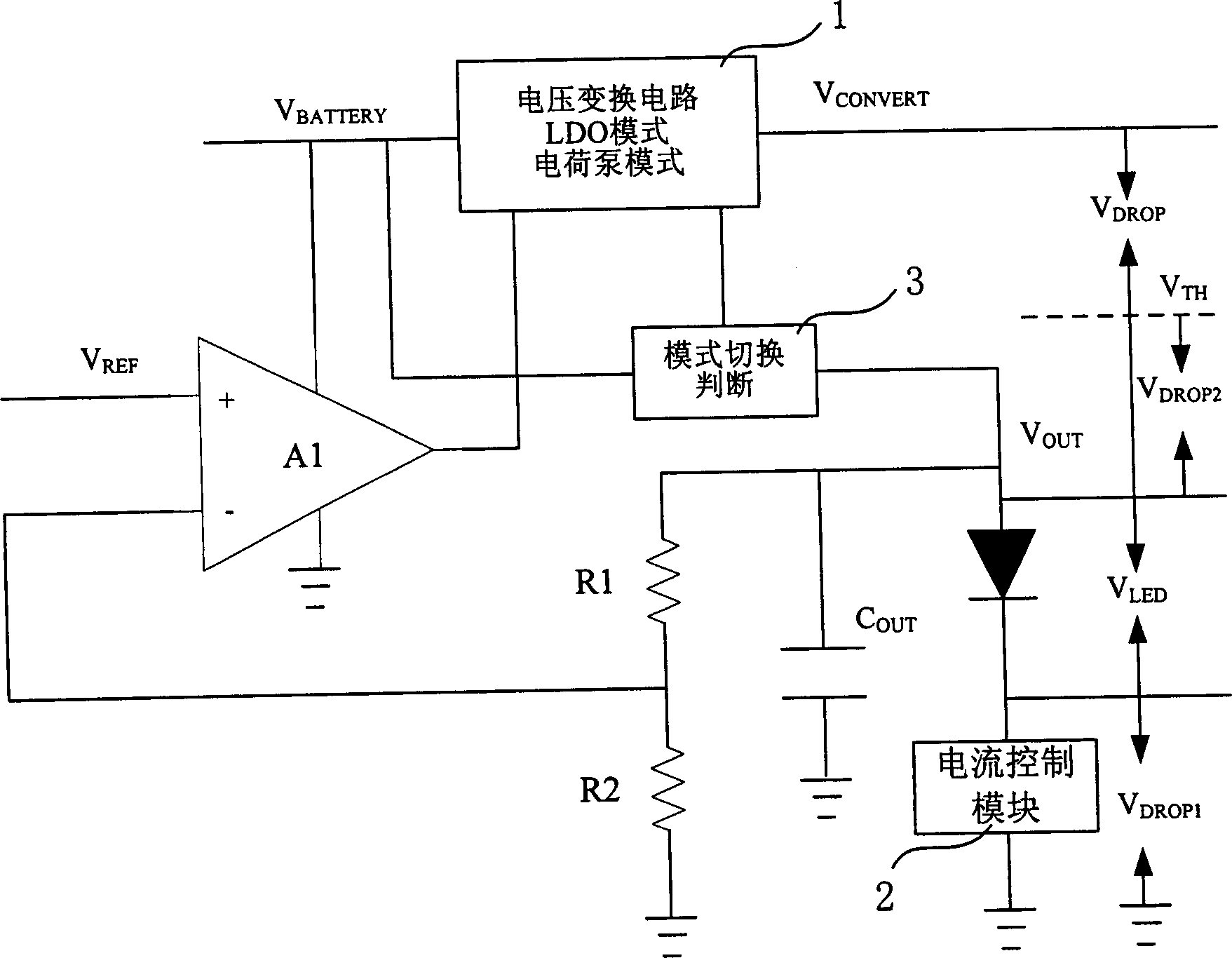

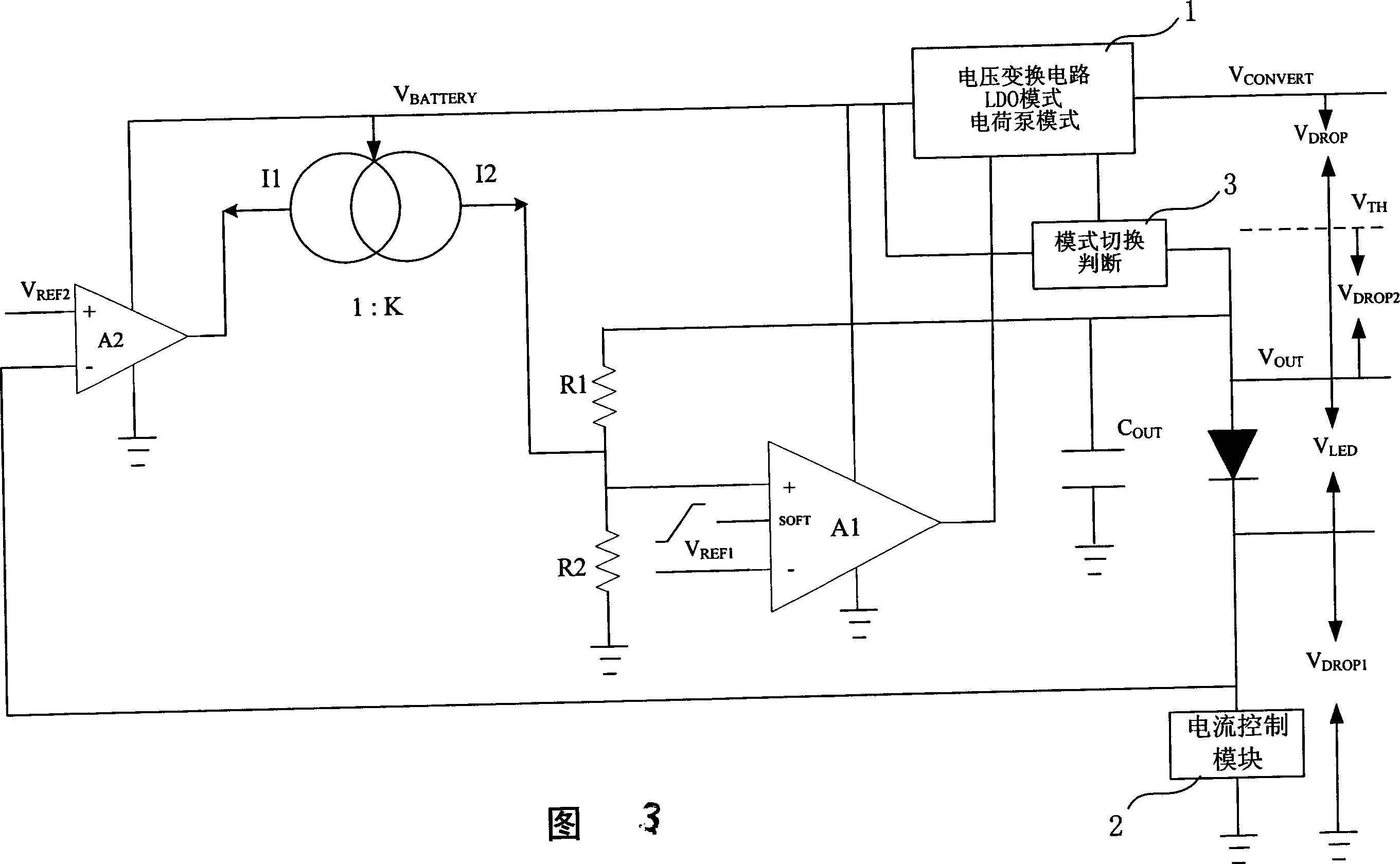

Parallel connection LED drive circuit with adaptive mode switching

InactiveCN1801300AImprove conversion efficiencyAchieving a soft startStatic indicating devicesElectric light circuit arrangementVoltage referenceEngineering

Disclosed is a parallel LED driving circuit with self-adapting switching mode which comprises: current control module; operation amplifier (A1); resistors (R1, R2); a feedback control loop which includes a second operation amplifier (A2) and current mirrors (I1, I2) connected with A2. The invention is characterized in that: the voltage difference that is amplified by A2 between voltage (VDROP1) and reference voltage (VREF2) on the current control module controls the current of current mirror (I2) that flows through the resistor (R2); voltage on R2 is amplified by amplifier (A1) and fed back to the negative terminal of the second amplifier (A2) to ensure the voltage value (VDROP1) equals the reference voltage value (VREF2).

Owner:CHIPHOMER TECH SHANGHAI

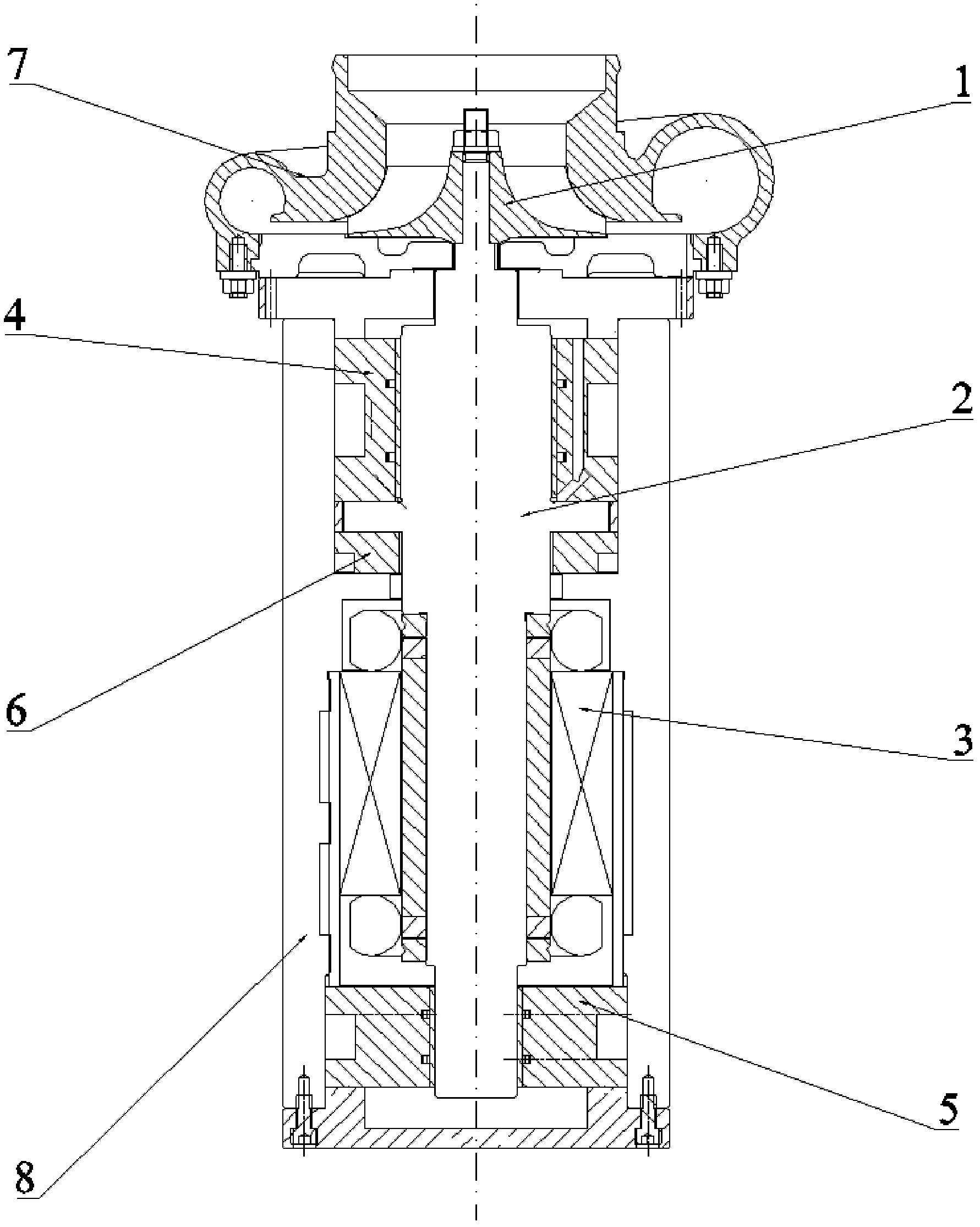

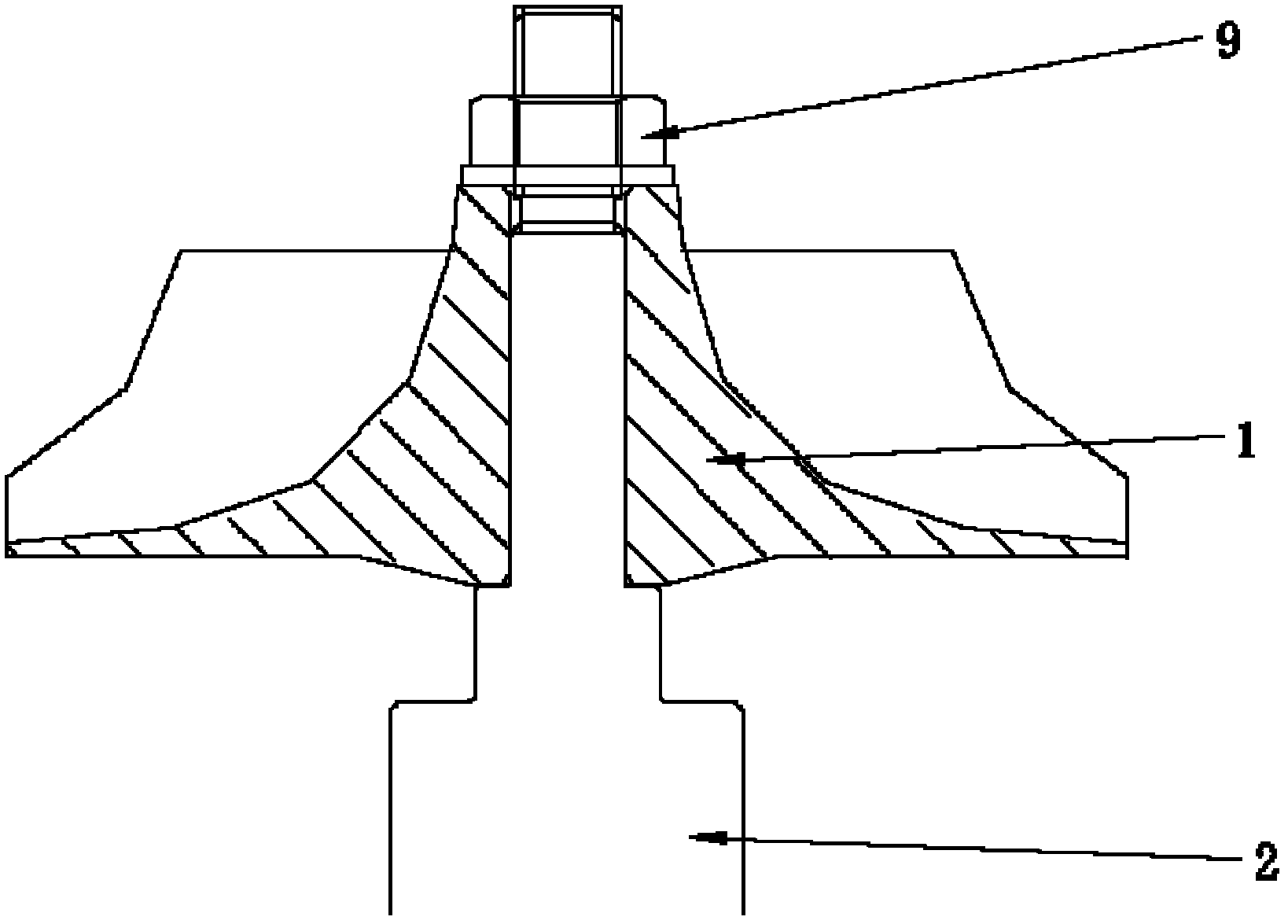

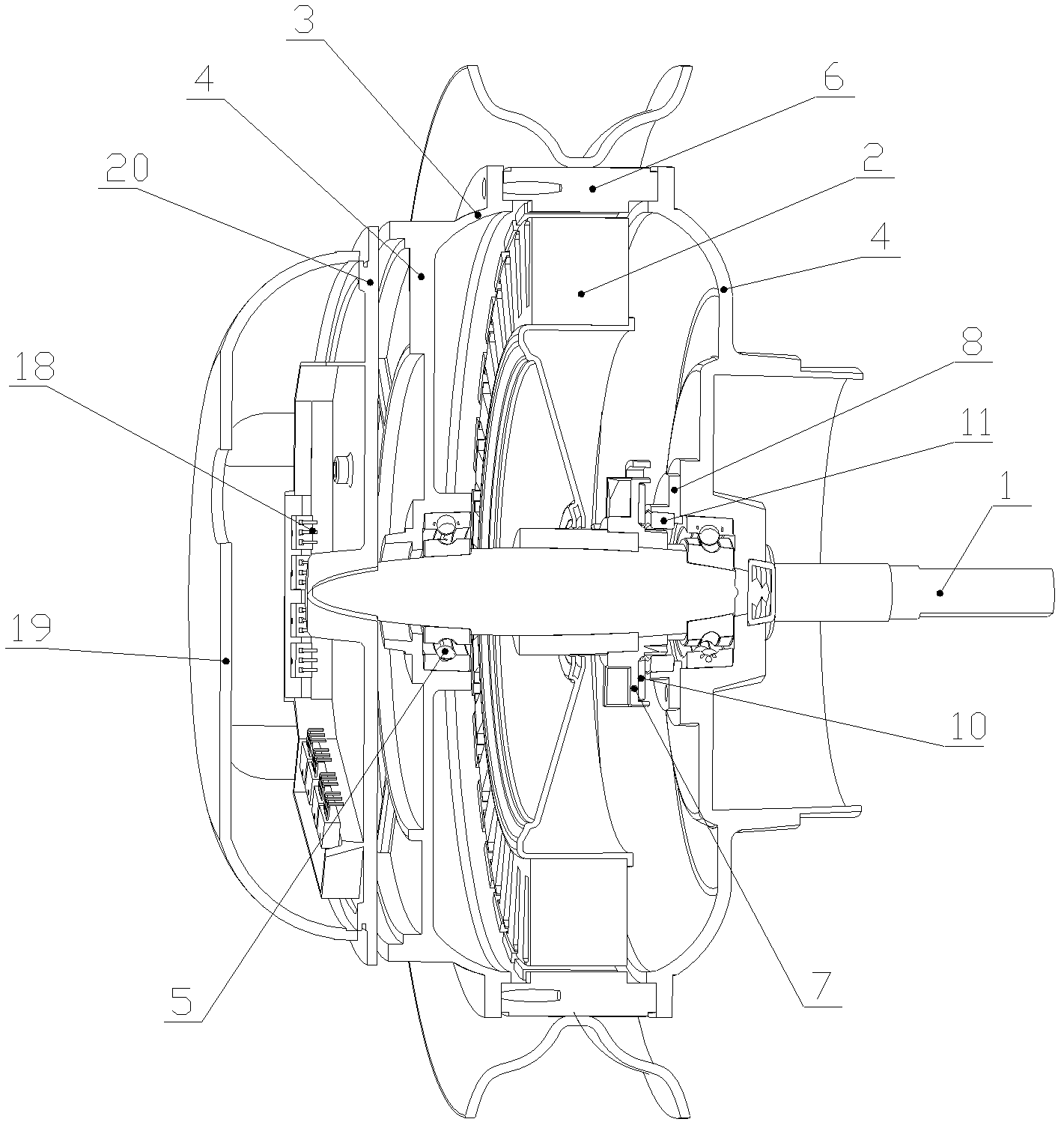

Wheel hub motor and control method thereof

InactiveCN103023259AEasy to install and processImprove reliabilityElectronic commutation motor controlStructural associationMotor shaftEngineering

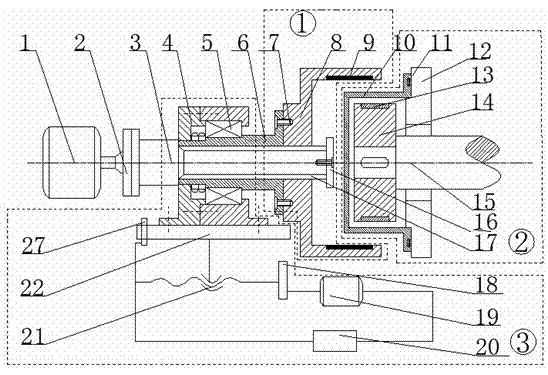

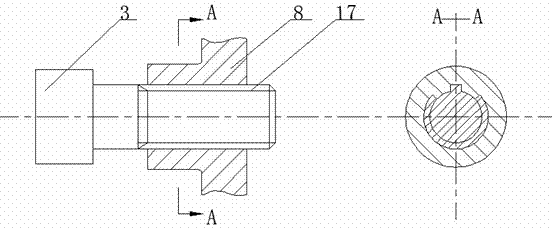

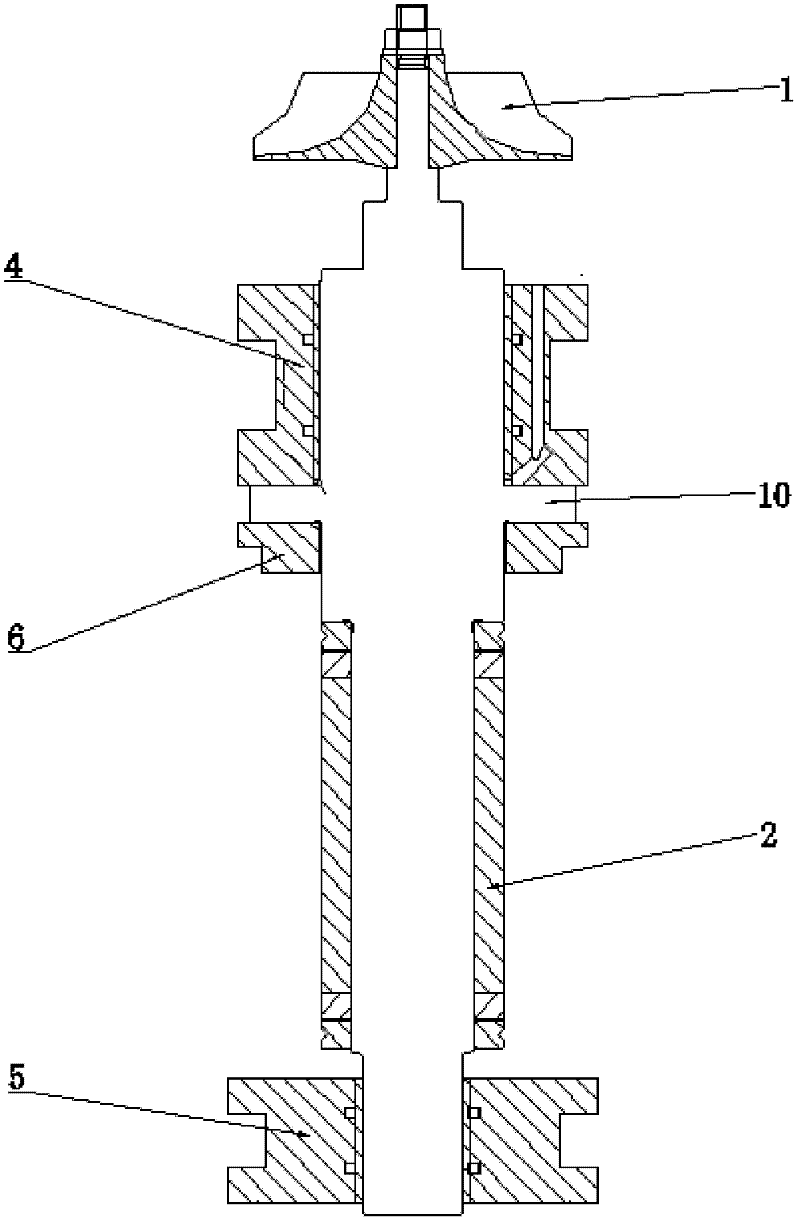

The invention relates to a wheel hub motor and a control method thereof. The wheel hub motor comprises a motor shaft (1) and a stator (2), wherein a rotor shell (3) is sleeved outside the stator (2), and the front end and the back end of the stator (2) are rotatablely fixed on the motor shaft (1) through a rotor end cover (4) and a bearing (5); the outer side of the rotor end cover (4) is connected with a hub brake component (9); the rotor shell (3) is connected with a wheel hub (6); a position detection device is arranged at a position corresponding to the wheel hub motor, and comprises a retainer (7) which is fixed on the motor shaft (1) and a magnetic steel ring (11) which is fixed on the rotor end cover (4); a plurality of Hall elements (10) are arranged on the retainer (7); a servo controller (18) is arranged on the motor shaft (1); and the rotor end cover 94) and the motor shaft (1) rotate relatively. The wheel hub motor is simple in structure, energy-saving, high in starting characteristic, small in size, and high in efficiency.

Owner:ZHEJIANG ZHONGKE DERUN TECH

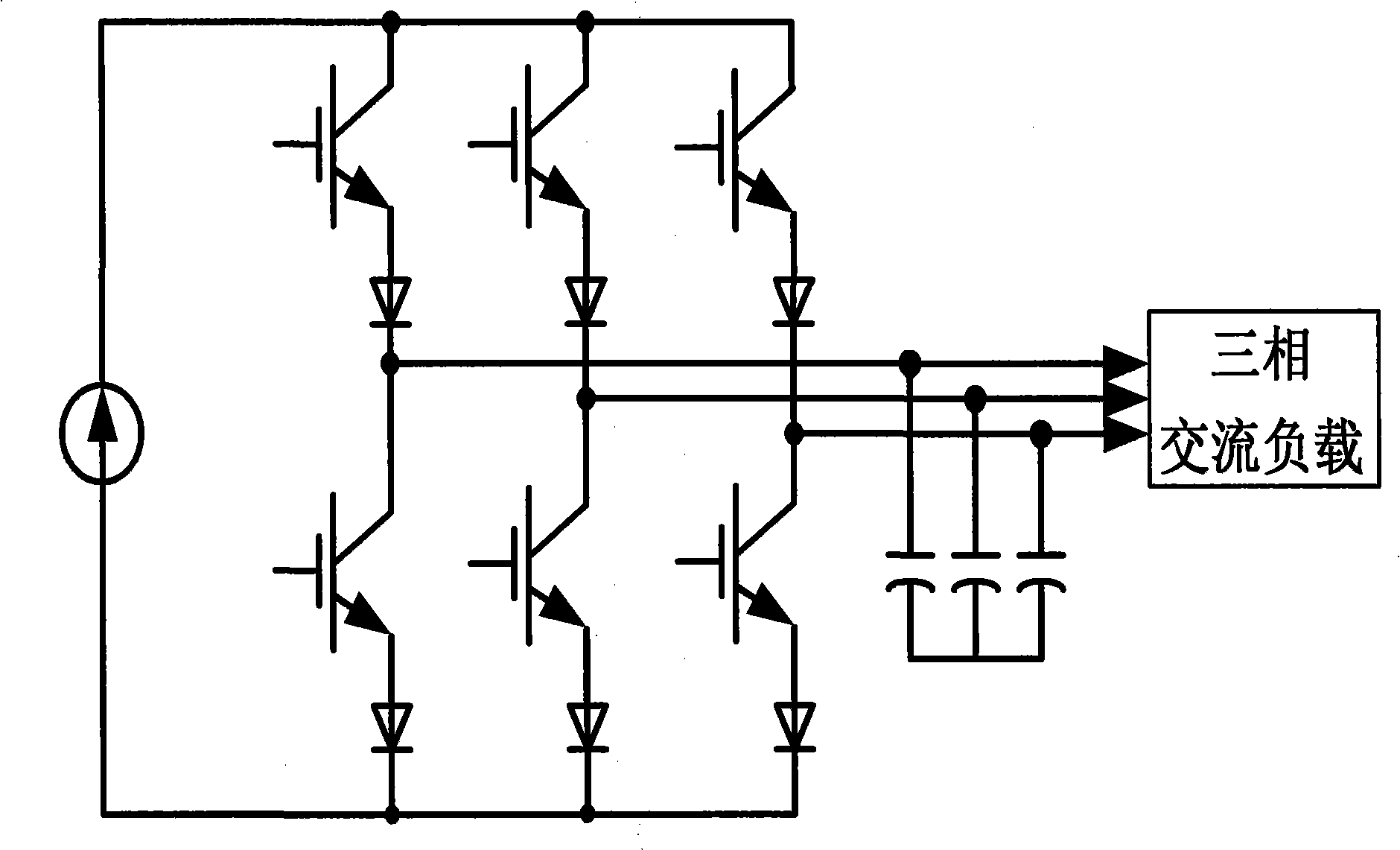

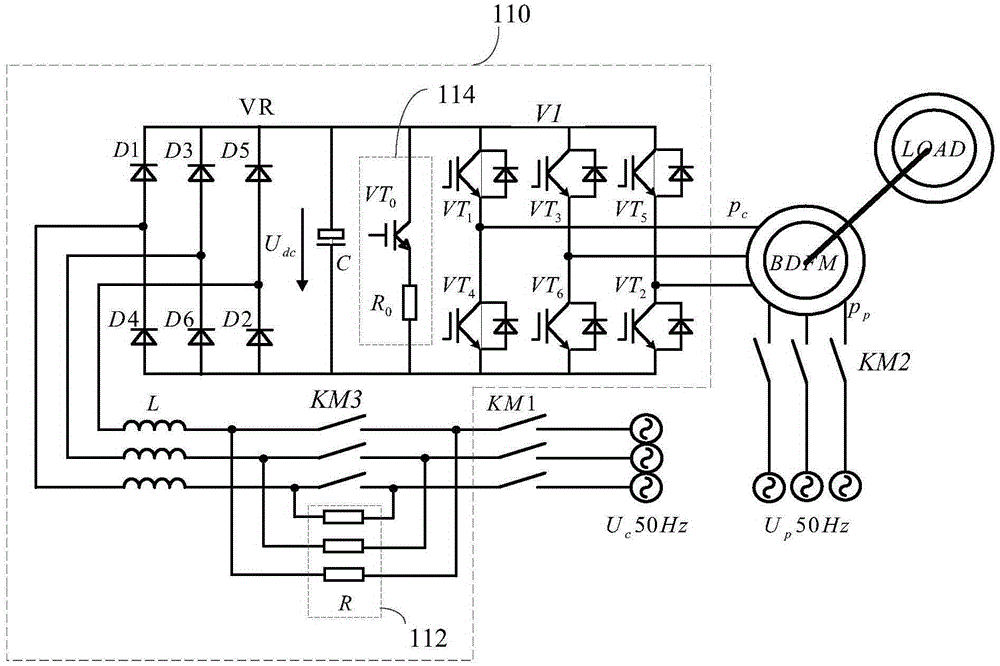

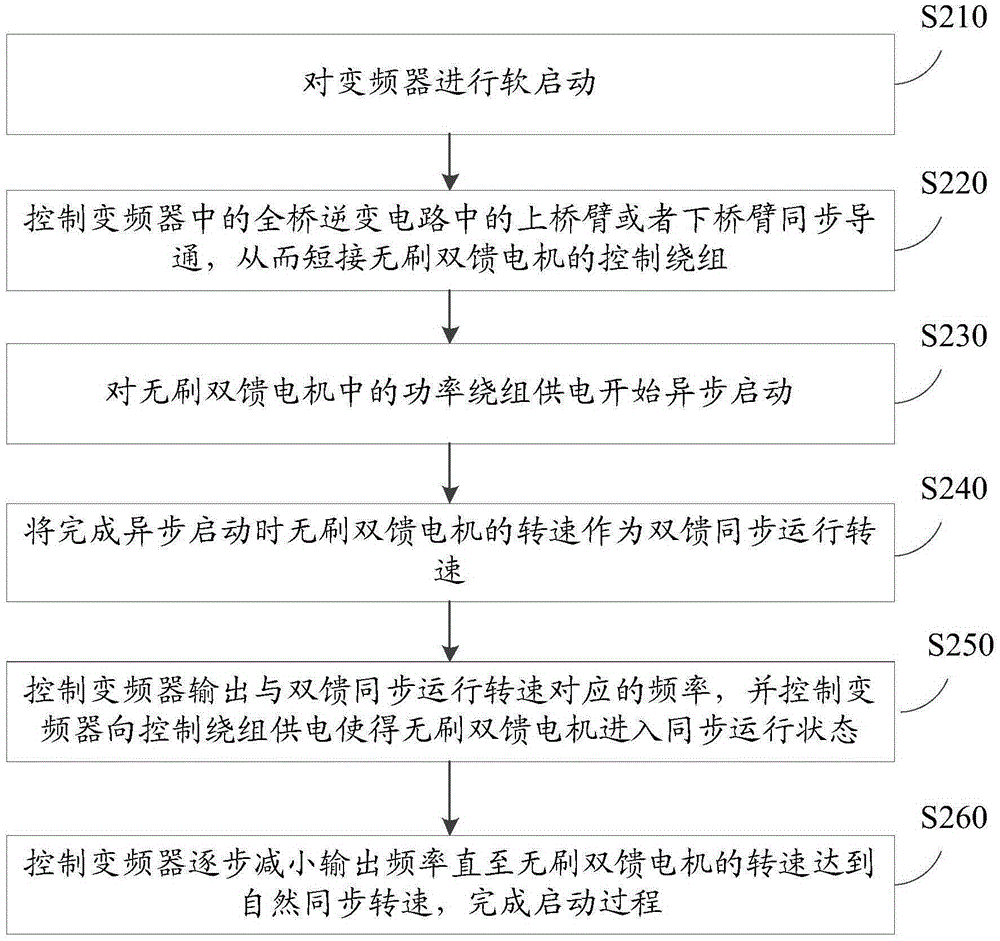

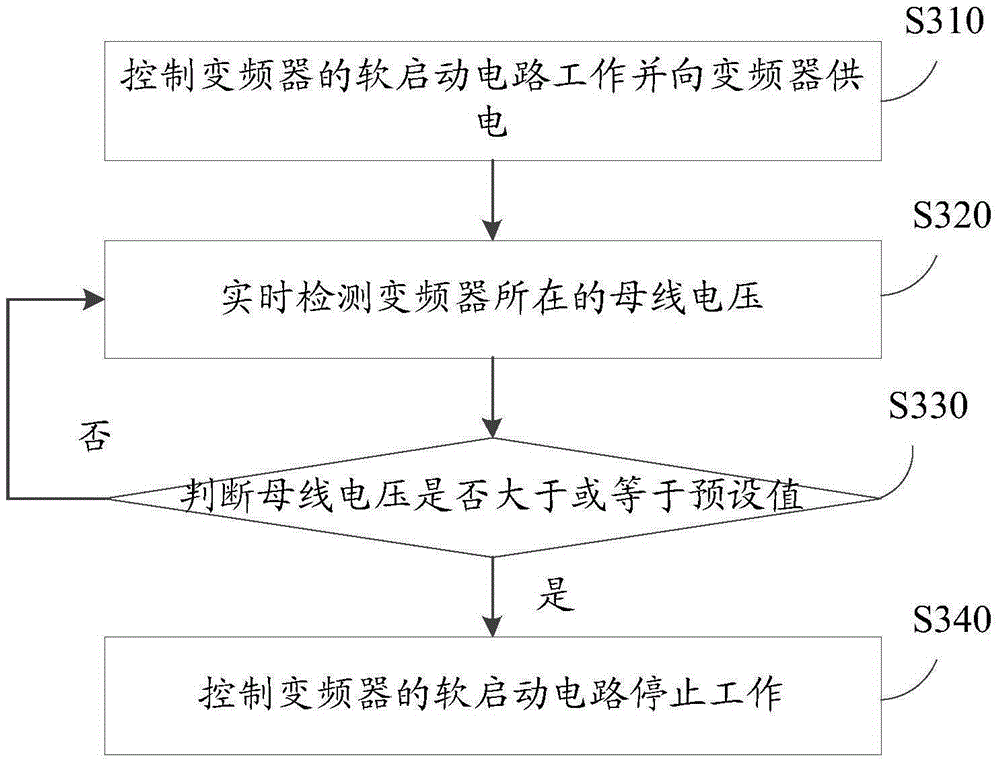

Starting control system and method of brushless double-fed motor

The invention relates to a starting control method of a brushless double-fed motor. The starting control method comprises the following steps of carrying out soft starting on a frequency converter; controlling an upper bridge arm or a lower bridge arm in a full-bridge inverter circuit in the frequency converter to be synchronously conducted so as to make a control winding of the brushless double-fed motor short-connected; supplying power to a power winding in the brushless double-fed motor and beginning asynchronous starting; taking a rotational speed of the brushless double-fed motor already subjected to asynchronous starting as a double-fed synchronous running rotational speed; controlling the frequency converter to output a frequency corresponding to the double-fed synchronous running rotational speed, and controlling the frequency converter to supply power to the control winding so that the brushless double-fed motor enters a synchronous running state; and controlling the frequency converter to gradually reduce the output frequency until the rotational speed of the brushless double-fed motor reaches a natural synchronous rotational speed, and completing the starting process. With the above starting control method of the brushless double-fed motor, the reduction of the device cost and volume isfacilitated. The invention also relates to a starting control system of the brushless double-fed motor.

Owner:EAST GRP CO LTD

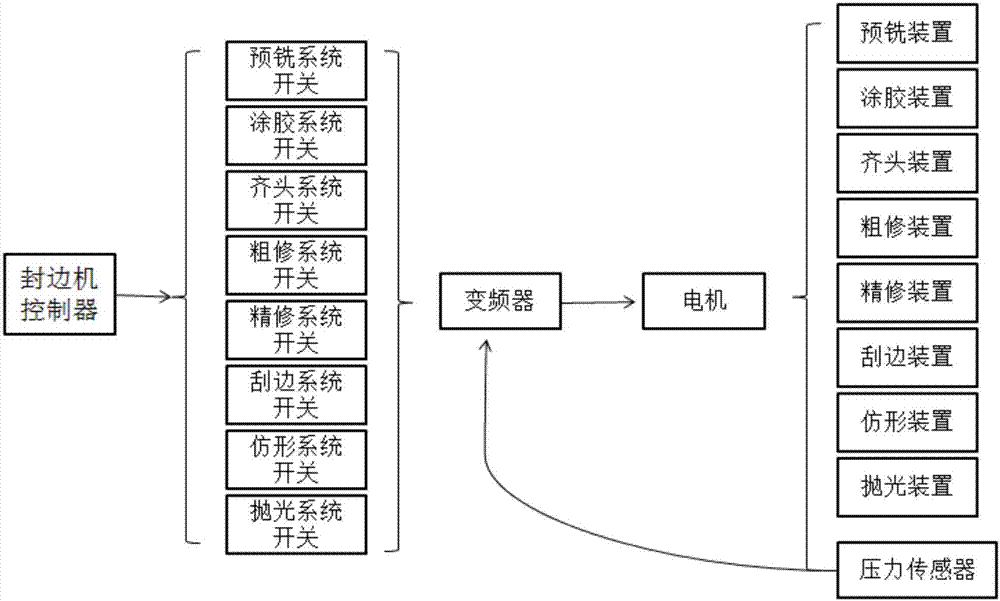

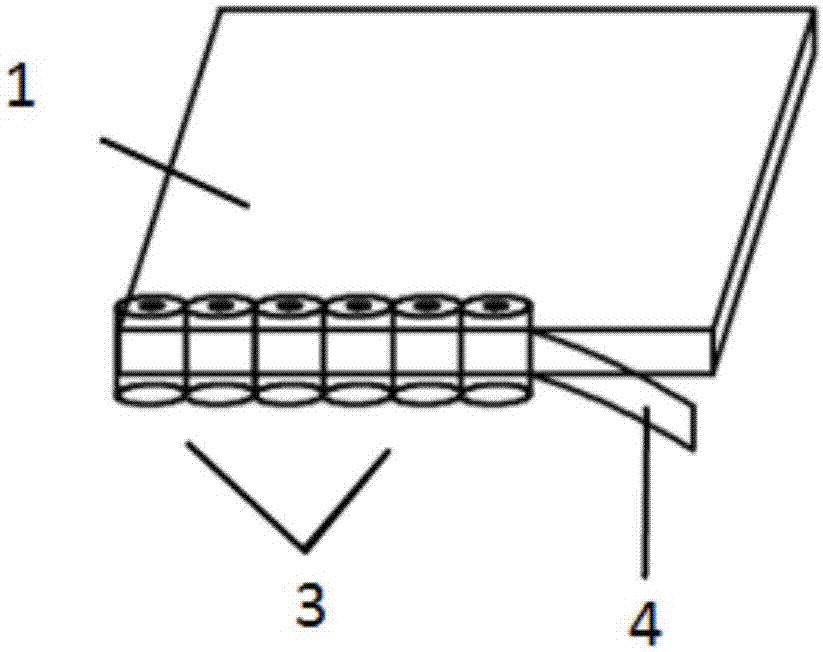

Variable frequency full-automatic edge bonding machine

InactiveCN107450465AExtended service lifeAchieving a soft startProgramme control in sequence/logic controllersNumerical controlFrequency changer

The invention discloses a variable frequency full-automatic edge bonding machine including a controller, a frequency changer, a sensor, a motor and a host. The frequency changer is connected with a control system and the motor and is used for regulating the rotation speed of the motor and protecting the safety of the motor. The host includes devices for working procedures of pre-milling, gluing, flushing, rough trimming, fine trimming, edging, profiling and polishing. The variable frequency full-automatic edge bonding machine mainly adopts a flexible modularized design. The working table of the host mainly includes eight working procedures. In the whole cyclic processing process, the variable frequency full-automatic edge bonding machine adopts a PLC numerical control device and a machine tool pneumatic control device. A PLC controller sends signals of corresponding working procedures and the frequency changer drives the motor, so that the motor on the working table of the host starts to work. The main motor employs frequency changer drive and is provided with built in optimized control programs. Different parameters during the operation process of the motor can be adjusted automatically according to real time operation load of the variable frequency full-automatic edge bonding machine, so that the shaft power of the motor can be optimized.

Owner:QINGDAO HENGRUN XIANG MACHINERY MFG CO LTD

Air-suspension air-supply-adjustable air blower directly driven by high-speed electric machine

ActiveCN102200136BSimple structureImprove power densityPump componentsPump installationsImpellerSynchronous motor

The invention discloses an air-suspension air-supply-adjustable air blower directly driven by a high-speed electric machine. The air blower comprises a compressor impellor, a permanent magnetic synchronous motor rotor, a motor stator, a front radial air bearing, a rear radial air bearing, an axial thrust air bearing, a scroll and a motor shell; one end of the permanent magnetic synchronous motor rotor is connected with the compressor impellor; the rotor stator drives the permanent magnetic synchronous motor rotor to rotate; the front radial air bearing, the rear radial air bearing and the axial thrust air bearing support the permanent magnetic synchronous motor rotor in a suspension mode; the scroll is arranged at the periphery of the compressor impellor; and the motor shell is positionedat the peripheries of the motor stator, the front radial air bearing, the rear radial air bearing, the axial thrust air bearing and the permanent magnetic synchronous motor rotor. According to the invention, through driving the compressor impellor directly by the permanent magnetic synchronous motor rotor of the high-speed electric machine, a complex and expensive speeding system is omitted, noises and mechanical loss are reduced, the integral machine efficiency can be improved, the system is simple, and the air blower provided by the invention is convenient to install and transport.

Owner:宁波虎渡能源科技有限公司

Slipping type all-hydraulic turner

InactiveCN102653480ASave work spaceLow costClimate change adaptationOrganic fertiliser preparationClutchFault rate

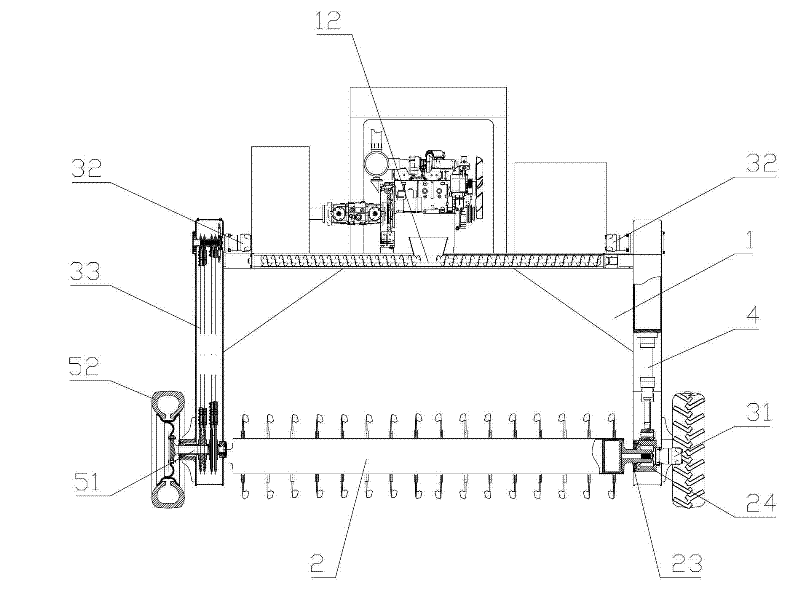

The invention discloses a slipping type all-hydraulic turner, comprising a turner body, wherein the turner body is provided with a drive assembly; a turning mechanism is further arranged at the lower part of the turner body; the turning mechanism comprises a turning cylinder; the drive assembly comprises a hydraulic motor for driving the turning cylinder to rotate; and the turning cylinder is provided with a regulating component which is used for connecting the turning cylinder and the turner body and simultaneously regulating the height of the turning cylinder relative to the turner body. The slipping type all-hydraulic turner is powered by hydraulic pressures, members, such as a clutch and a gear box are cancelled, stepless speed changing is realized, the fault rate is greatly reduced, and the technical problems that the traditional turner has big turning radius, large size, high fault rate, low turning efficiency, poor turning effect and the like are solved.

Owner:浙江濠泰机械有限公司

Starting control method for input-series output-quasi-parallel multiplexed output converter

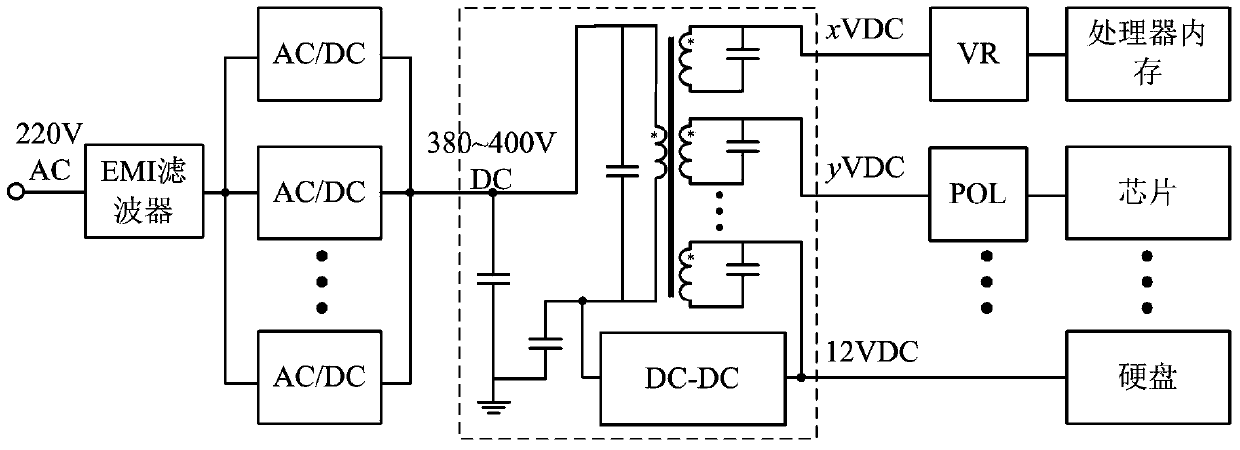

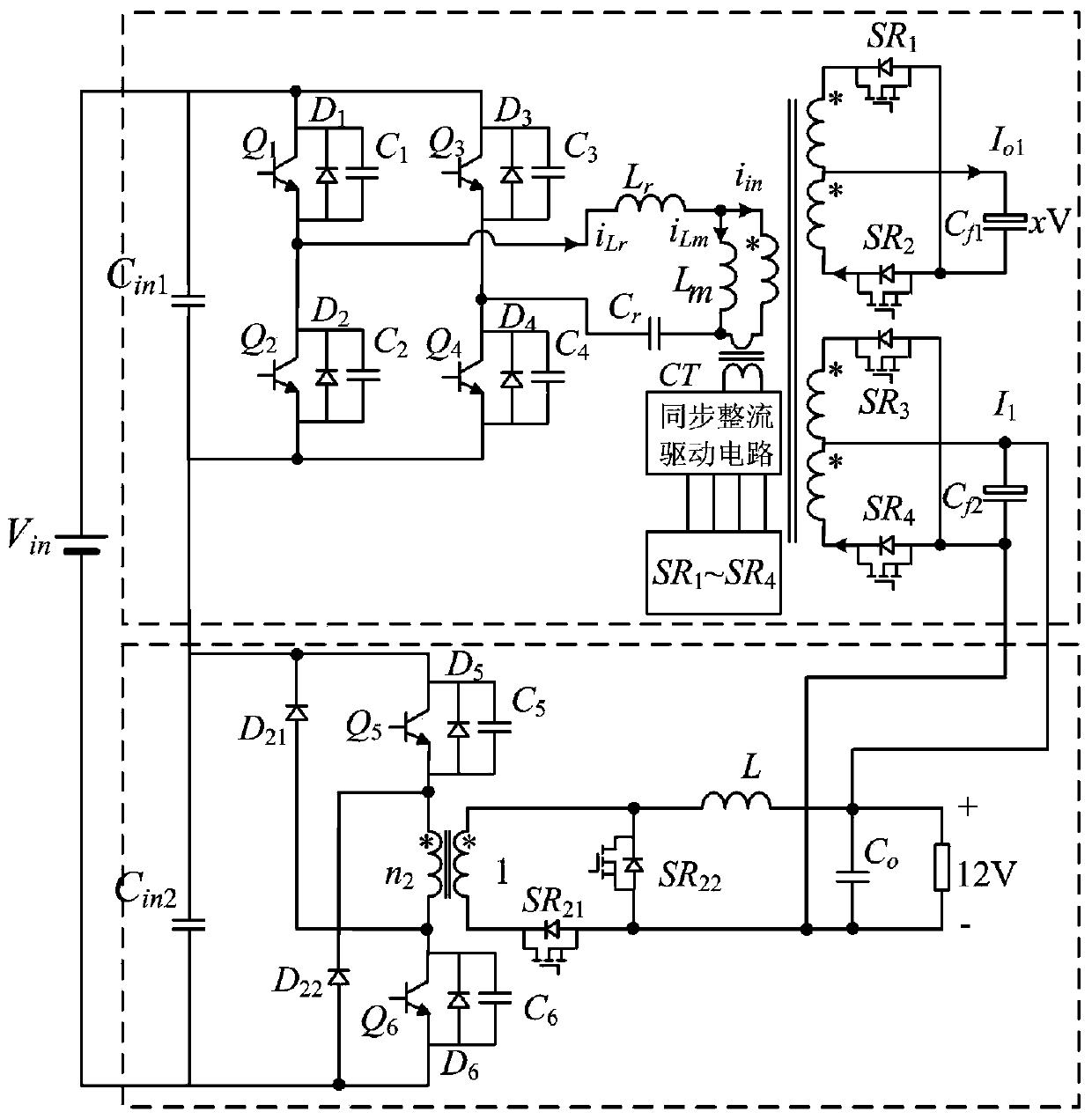

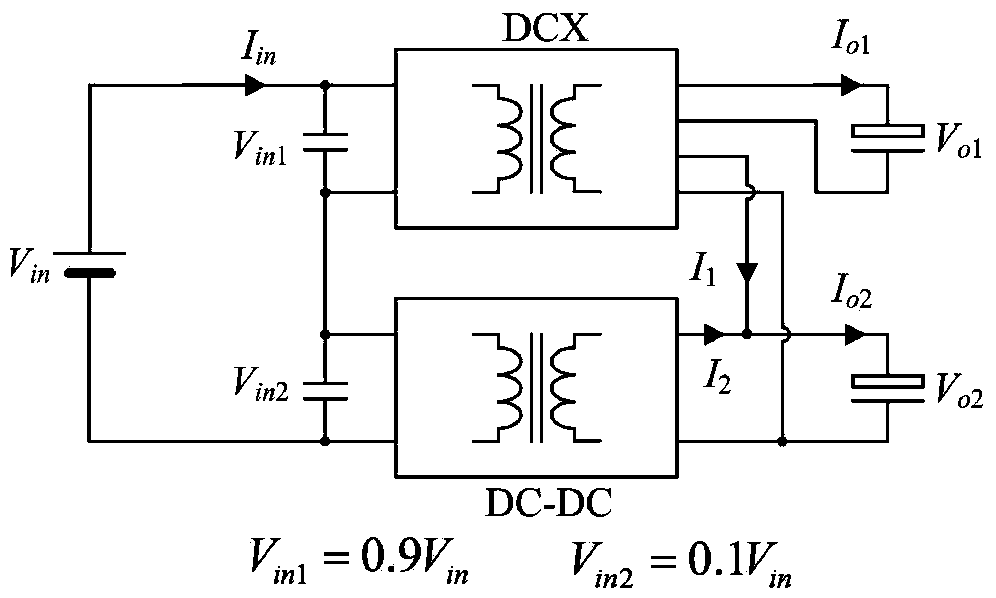

ActiveCN103812321AAvoid high input voltageAchieving a soft startPower conversion systemsĆuk converterElectric energy

The invention discloses a starting control method for an input-series output-quasi-parallel multiplexed output converter and belongs to the field of the electrical energy transformation. The starting control method mainly includes initializing a system of a single chip and initializing PWM when starting up, waiting for establishing an input voltage, making the PWM enable interrupts, making a DCX open a duty ratio, regulating a feedback reference voltage value, regulating a switching frequency of the DCX, and regulating a duty ratio of the DCX and a closed loop PI regulating program of a DC-DC converter so as to realize the soft starting of a circuit and avoid the circuit damage due to unbalanced voltage distribution when starting.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

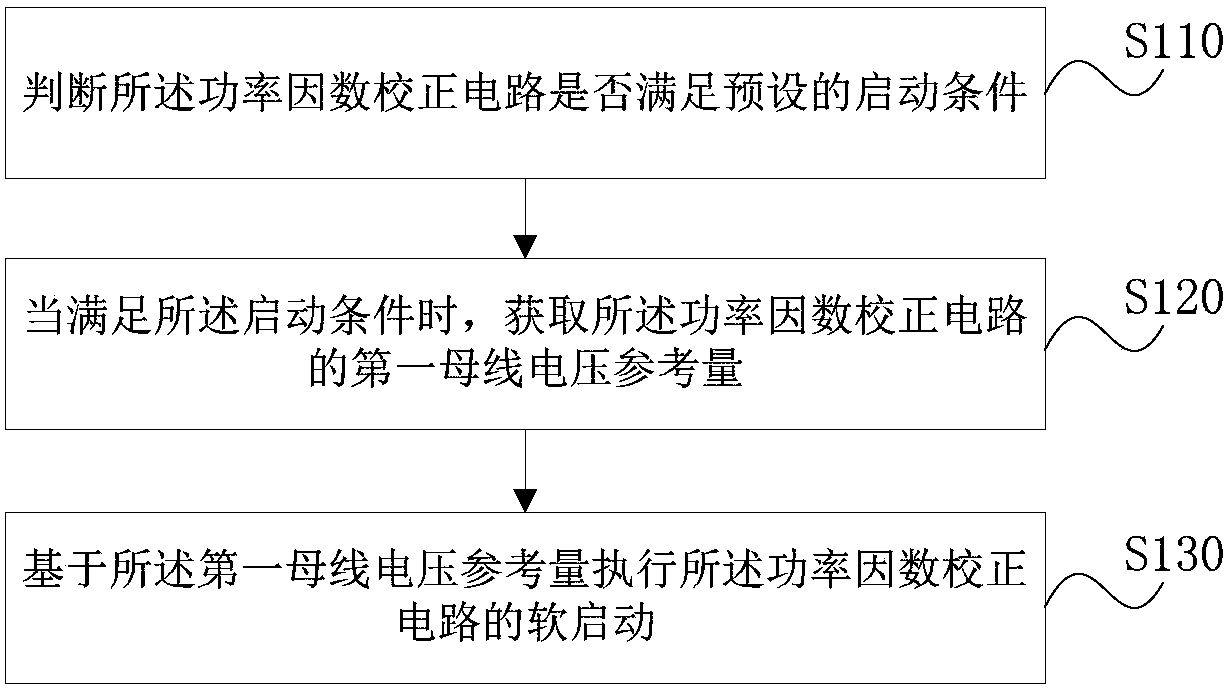

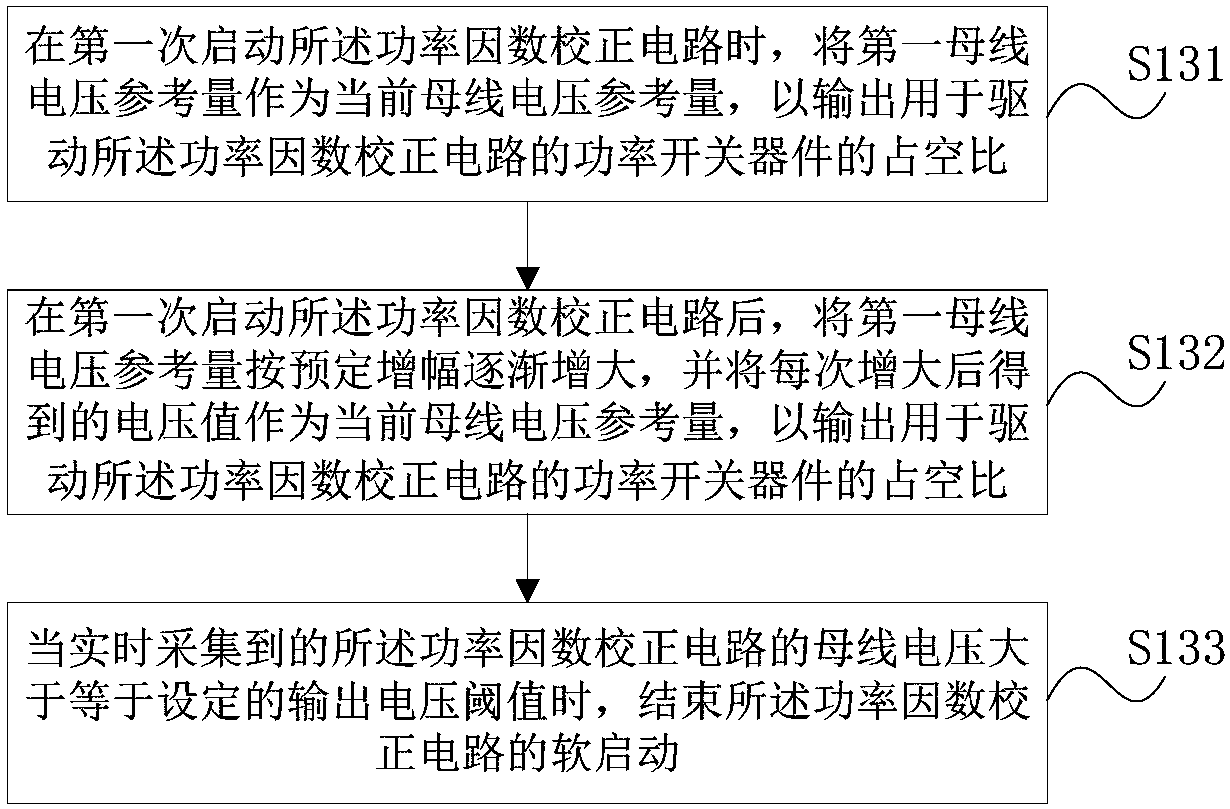

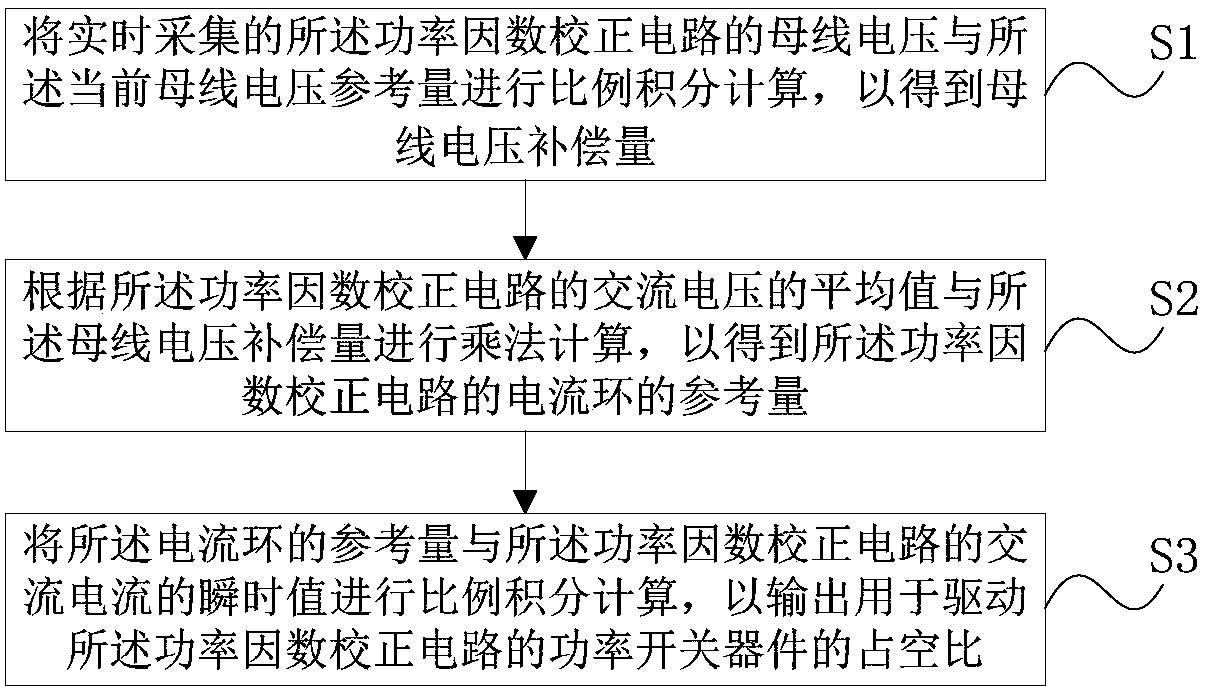

Power factor correction circuit soft start method and device, circuit and electric appliance

ActiveCN108075633AGuaranteed reliabilityImprove reliabilityPower conversion systemsElectrical resistance and conductanceEngineering

The invention provides a power factor correction circuit soft start method and device, a circuit and an electric appliance. The method comprises the following steps: judging whether the power factor correction circuit meets a preset start condition; when the power factor correction circuit meets the preset start condition, obtaining a first bus voltage reference quantity of the power factor correction circuit; and carrying out soft start on the power factor correction circuit based on the first bus voltage reference quantity. The provided scheme can realize soft start of the PFC circuit without starting a resistor and a relay, thereby reducing circuit cost and improving reliability of the control circuit.

Owner:GREE ELECTRIC APPLIANCES INC +1

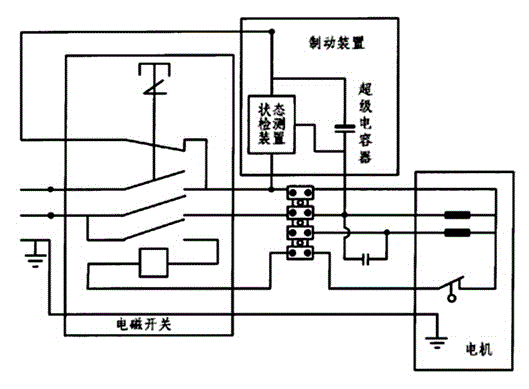

Three-phase asynchronous motor electric-braking device and control method thereof

ActiveCN102882441AFast brakingReduce shockAc motor stoppersPolyphase induction motor starterThree phase asynchronous motorThree-phase

The invention discloses a three-phase asynchronous motor electric-braking device and a control method thereof. The three-phase asynchronous motor electric-braking device comprises a thyristor voltage regulator, a braking actuator and a control and status monitor. The thyristor voltage regulator is connected with a brake actuator and a three-phase alternating-current power source, the braking actuator is connected with a motor, and the control and status monitor is connected with the braking actuator, the three-phase alternating-current power source and the motor respectively. Besides, the thyristor voltage regulator comprises a bypass contactor and at least one thyristor valve group which are in parallel connection. The braking actuator comprises a forward contactor and a reverse contactor which are in parallel connection. The control and status monitor changes input voltage of the stator of the motor by controlling the thyristor valve group. The electric-braking device is simple in structure, reliable and safe in performance and applicable to quick, accurate and smooth brake stop in a three-phase asynchronous motor driving system.

Owner:ZHUZHOU NAT ENG RES CENT OF CONVERTERS

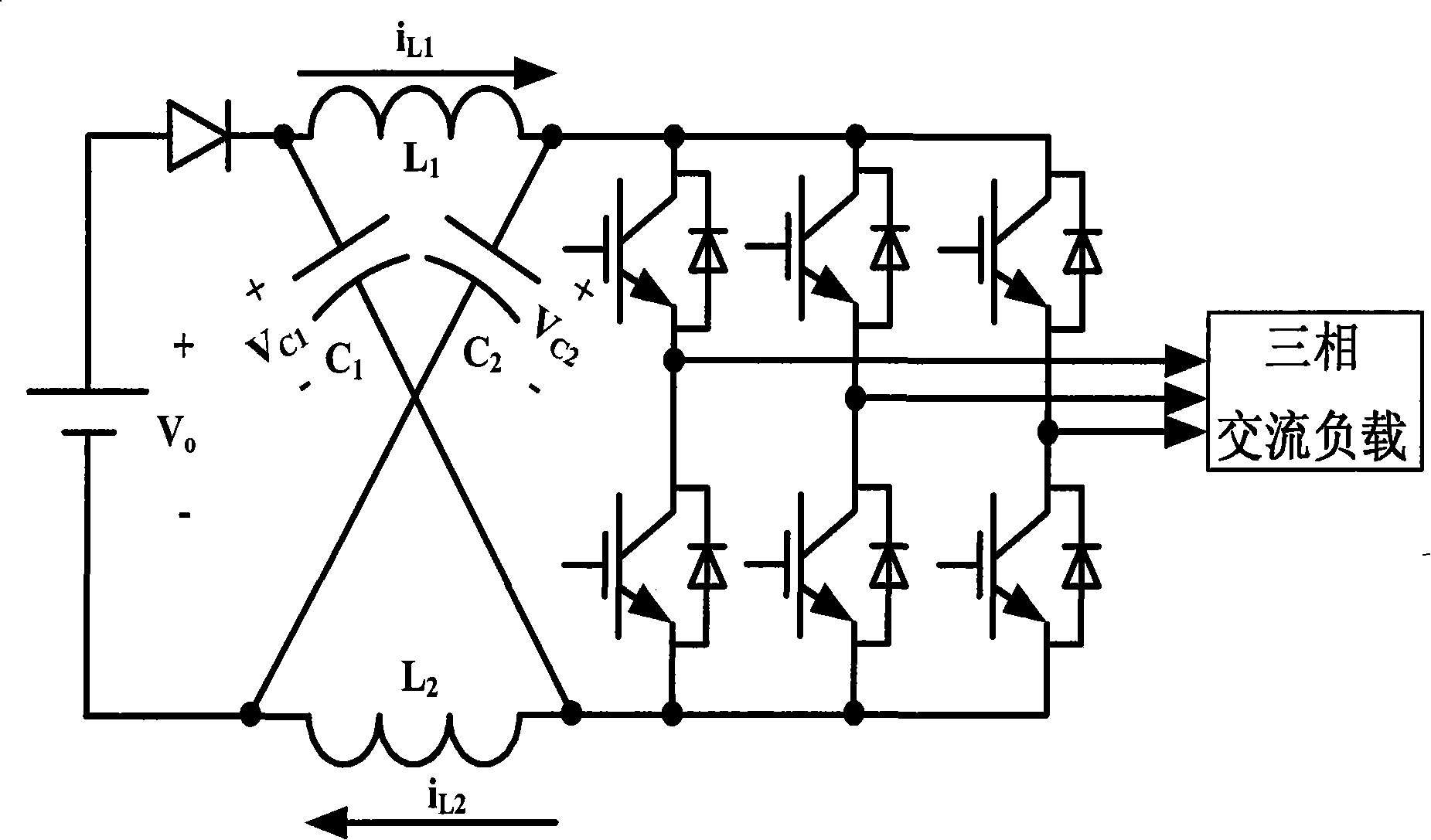

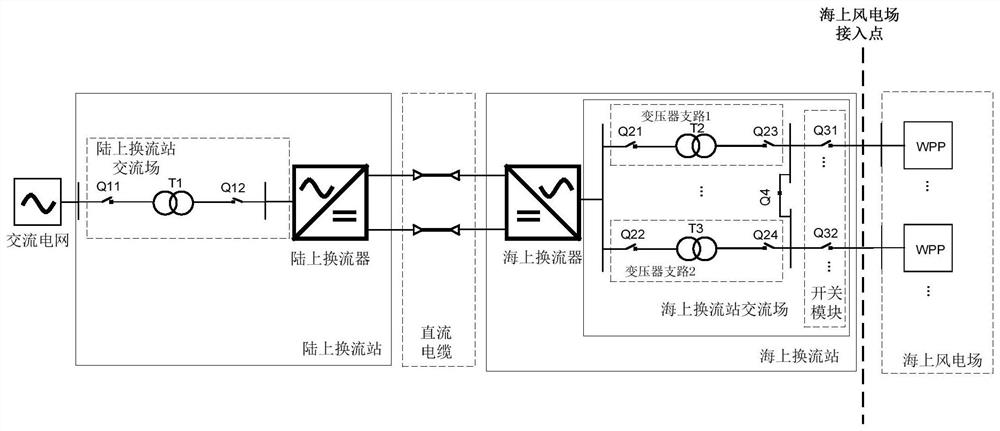

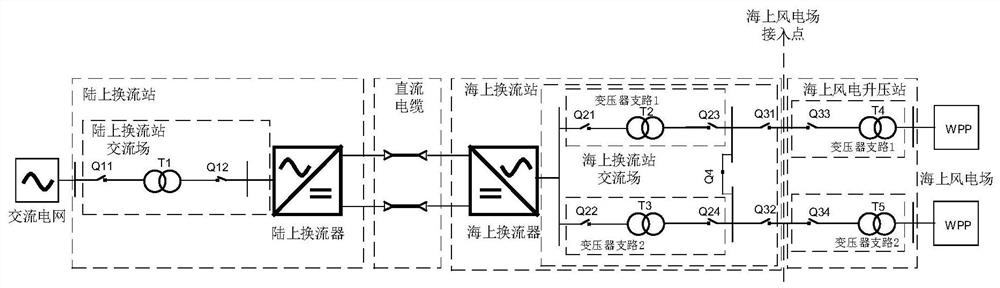

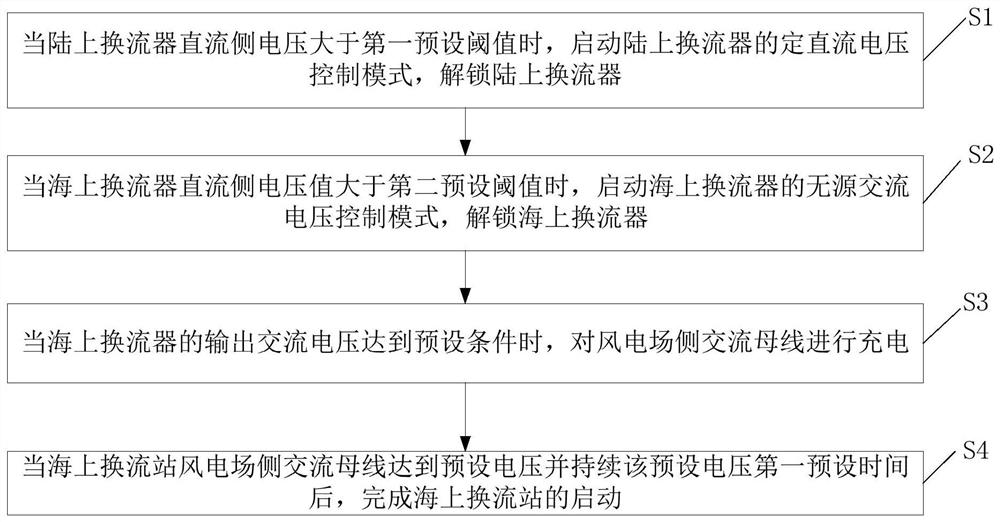

Offshore wind power flexible direct-current grid-connected system and starting method thereof

ActiveCN112600246AReliable startImprove the level of safe operationElectric power transfer ac networkSingle network parallel feeding arrangementsMarine engineeringAC - Alternating current

The invention discloses an offshore wind power flexible direct-current grid-connected system and a starting method thereof. The offshore wind power flexible direct-current grid-connected system comprises an alternating-current power grid, an onshore converter station, a direct-current cable, an offshore converter station and an offshore wind power plant, wherein the onshore converter station comprises an onshore converter station alternating-current field and an onshore converter, wherein the offshore converter station comprises an offshore converter and an offshore converter station alternating current field; the alternating-current power grid is connected with the alternating-current side of the onshore converter through an onshore converter station alternating-current field, the direct-current side of the onshore converter is connected with the direct-current side of the offshore converter through a direct-current cable, and the alternating-current side of the offshore converter isconnected with the offshore wind power plant through an offshore converter station alternating-current field. According to the starting method provided by the invention, soft starting of a plurality of transformers of the converter station is realized by controlling rising and falling of the slope of the alternating-current voltage of the offshore converter and cooperating with corresponding switching operation, operation cost is saved, and the safe operation level of a wind power direct-current grid-connected system is effectively improved.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

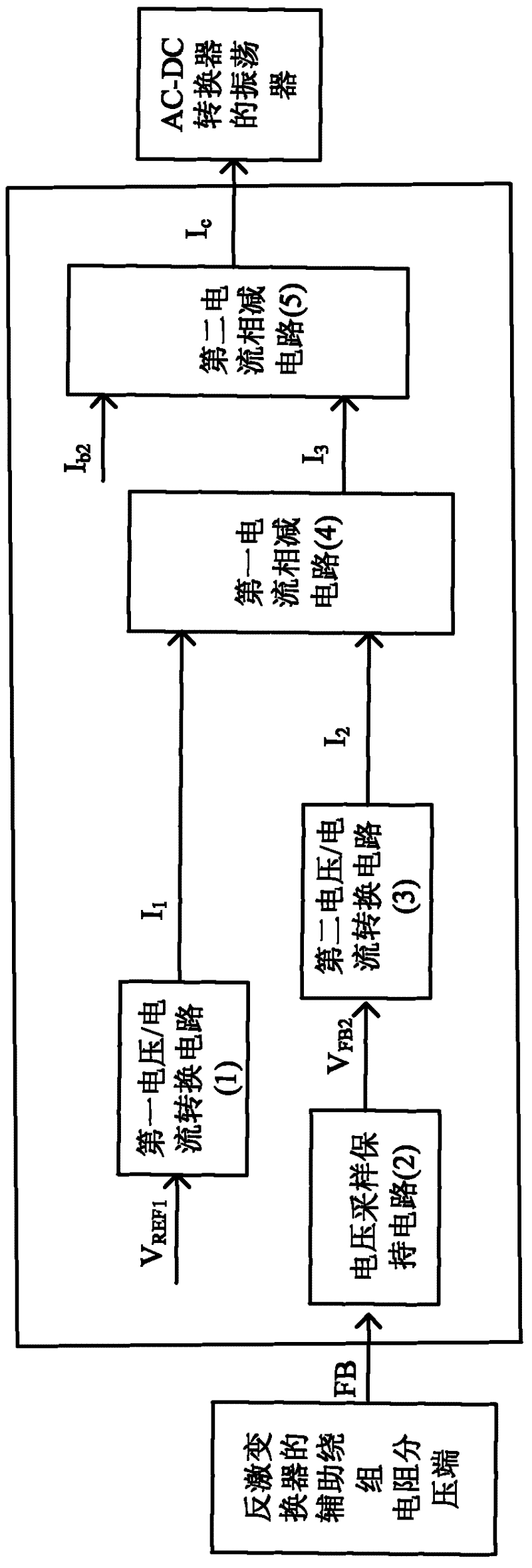

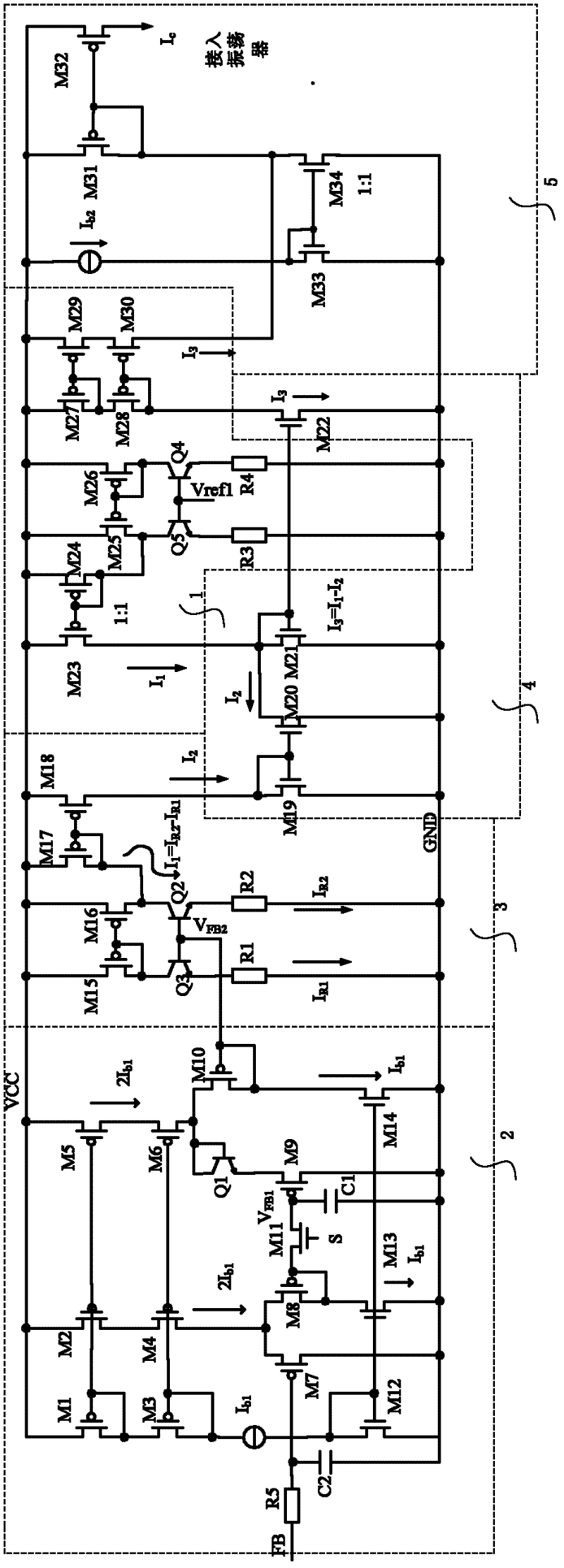

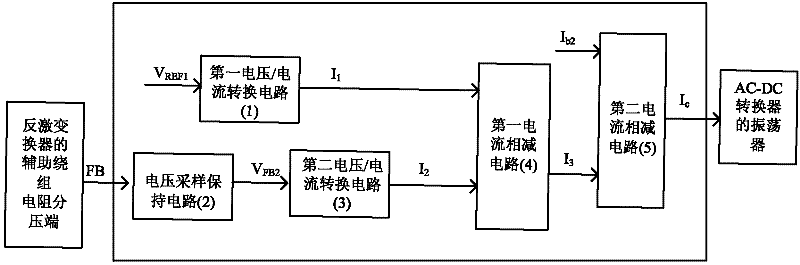

pfm constant current control circuit applied in ac-dc converter

InactiveCN102291021AThe peripheral circuit is simpleCost-effectiveAc-dc conversionSecondary loopConductor Coil

The invention discloses a PFM constant-current control circuit applied in AC-DC converters, which mainly solves the problem that: since constant current in the prior art needs a photocoupler and a secondary loop control circuit, the application circuit is complex, and the cost is high. The PFM constant-current control circuit comprises a first voltage / current conversion circuit, a voltage sampling and retaining circuit, a second voltage / current conversion circuit, a first current subtraction circuit and a second current subtraction circuit. The voltage sampling and retaining circuit samples the change of output voltage by means of the feedback of a resistor voltage-dividing end of an auxiliary winding of a flyback converter, the voltage / current conversion circuits and the current subtraction circuits are utilized to convert the sampled voltage change of the resistor voltage-dividing end into current change, the current, the output magnitude of which is in direct proportion to the frequency of an oscillator, is used as the working current of the oscillator of an AC-DC converter, and when the load is changed, the magnitude of input power is regulated in order to realize constant current. The PFM constant-current control circuit can simplify application circuits and reduce the system cost, and can be used in the designs of constant-current constant-voltage AC-DC converters.

Owner:XIDIAN UNIV

Non-damping winding permanent-magnet synchronous motor grid connection method

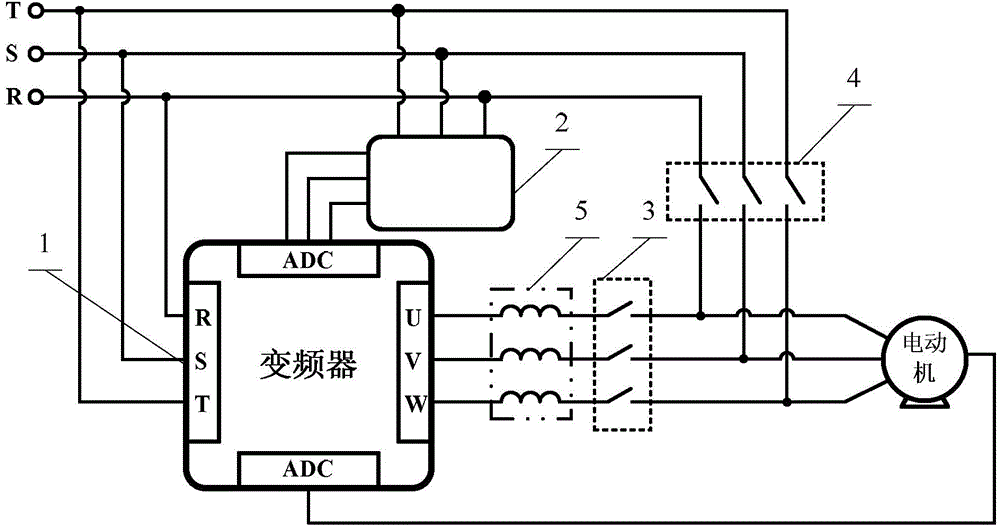

ActiveCN104158228AAchieving a soft startReduce capacitySingle network parallel feeding arrangementsFrequency changerVoltage amplitude

The invention discloses a non-damping winding permanent-magnet synchronous motor grid connection method and belongs to the technical field of motor grid connection. The method aims to solve the problems that a non-damping winding permanent-magnet synchronous motor can be only used on a variable-frequency speed control occasion and does not have the power frequency operating capacity of a power grid. According to the method, the non-damping winding permanent-magnet synchronous motor is soft started under the control of a frequency converter, and then, the frequency converter is regulated, wherein firstly, the fundamental frequency of the voltage of the output end of the frequency converter is made to be consistent with the frequency of a power grid; secondly, the difference between the fundamental amplitude of the voltage of the output end of the frequency converter and the voltage amplitude of the power grid is made to be within a preset threshold range; finally, the fundamental phase of the voltage of the output end of the frequency converter is made to be consistent with the phase of the voltage of the power grid; next, the switch-on time moment of a second contact is made to be later than the switch-off time moment of a first contact under the control of the frequency converter, and the operating state that the non-damping winding permanent-magnet synchronous motor is soft started is switch to the power grid operating state. The non-damping winding permanent-magnet synchronous motor grid connection method is used for grid connection of the non-damping winding permanent-magnet synchronous motor.

Owner:中安星瑞航空科技有限公司

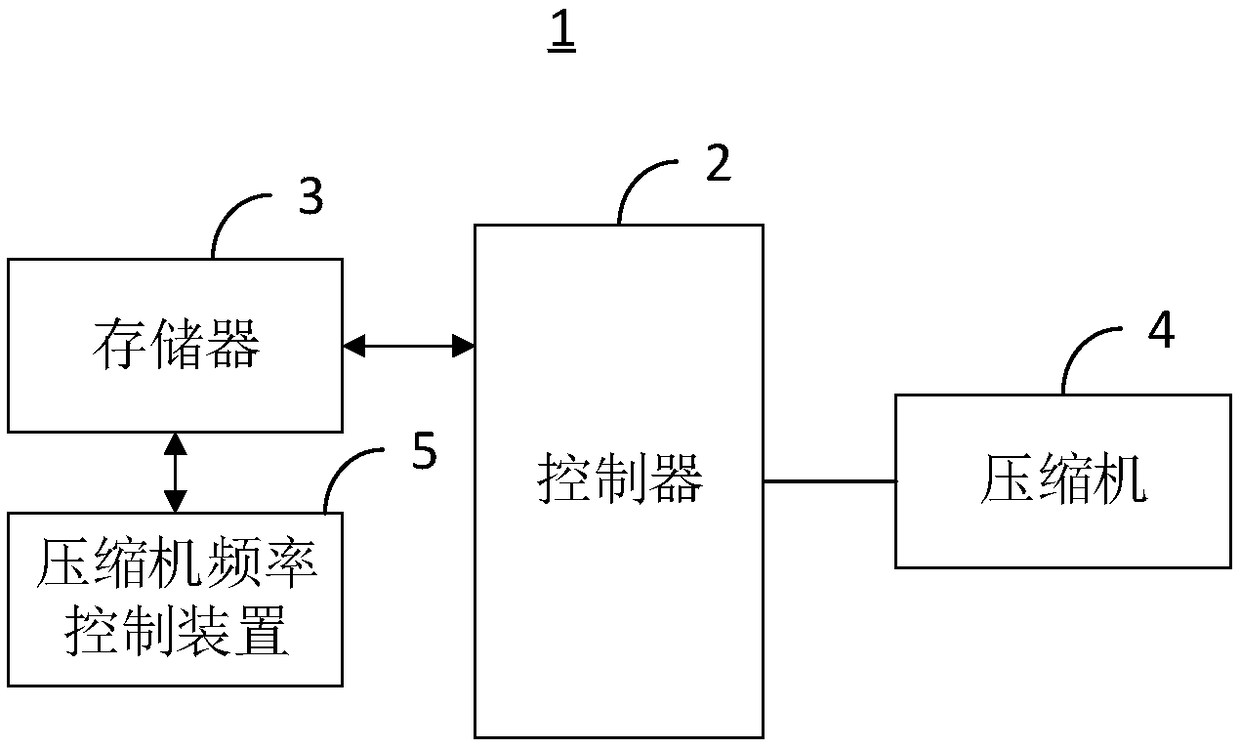

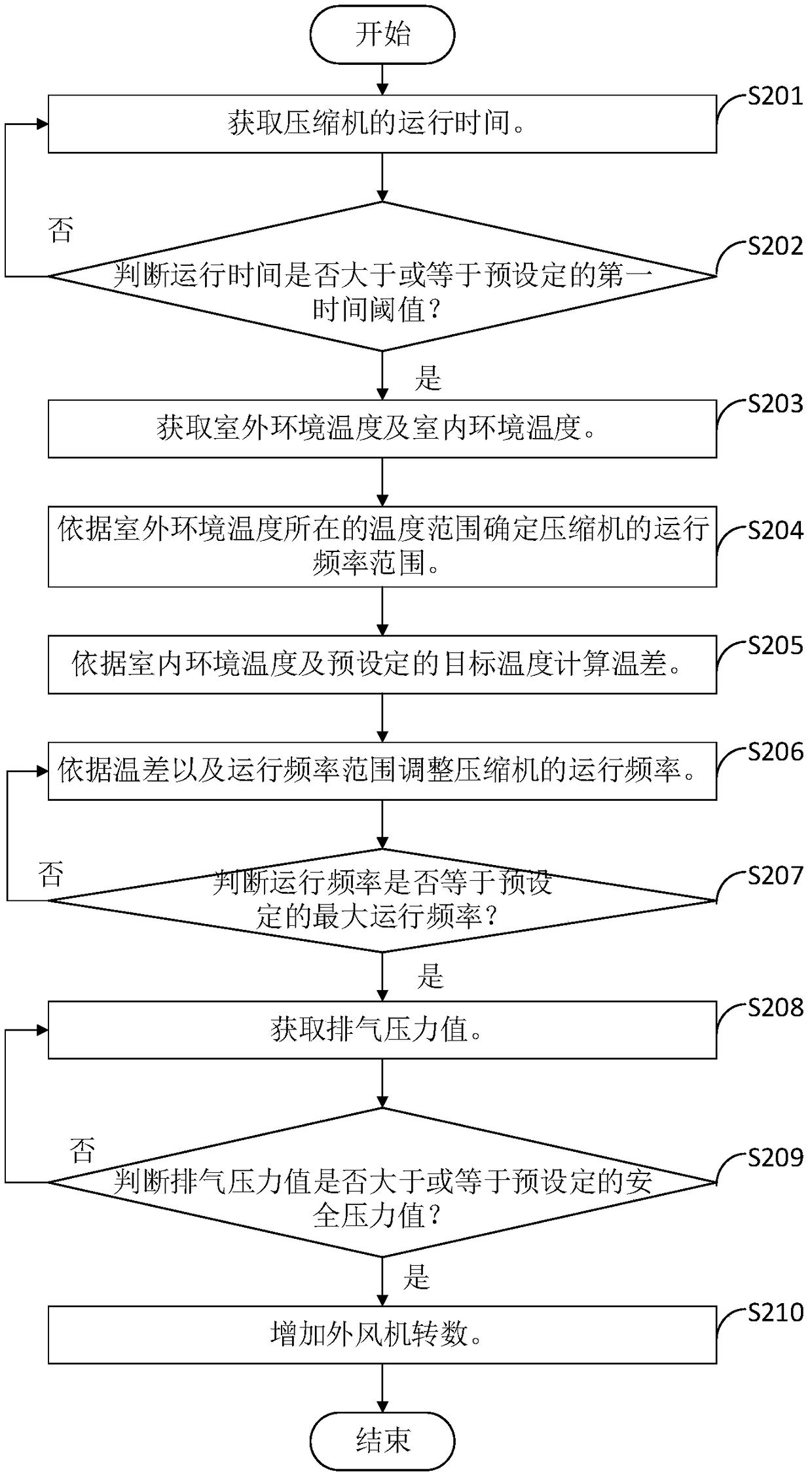

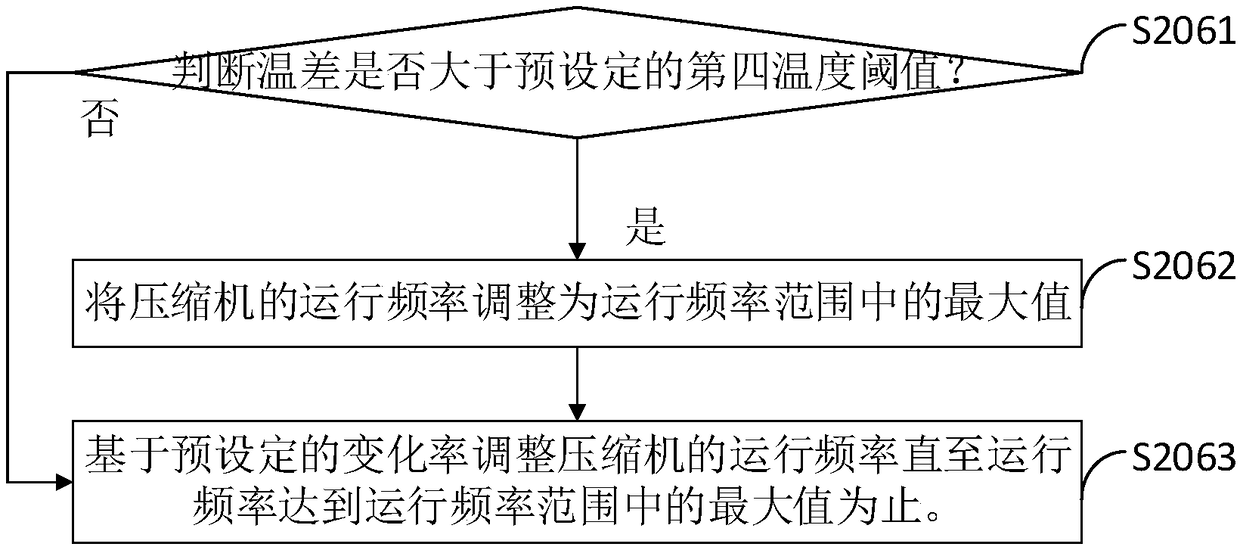

Compressor frequency control method and device, and air conditioner

InactiveCN109099553AAchieving a soft startAvoid the effects of longevityMechanical apparatusSpace heating and ventilation safety systemsEngineeringTemperature difference

The invention provides a compressor frequency control method and device, and an air conditioner, and relates to the technical field of air conditioners. According to the compressor frequency control method and device, by obtaining the operating time of a compressor, when the operating time is larger than or equal to a preset first time threshold value, the outdoor environment temperature and the indoor environment temperature are obtained; then, the operating frequency range of the compressor is determined according to the temperature range of the outdoor environment temperature; then, according to the indoor environment temperature and the preset target temperature, the temperature difference is calculated; and finally, according to the temperature difference and the operating frequency range, the operating frequency of the compressor is adjusted. By applying the steps, after the compressor is started, the operating frequency of the compressor can rise slowly in a segmental mode, softstarting of the compressor is achieved, and thus influences of the situation that the compressor has continuously operated at the high frequency since starting on the life of the compressor are avoided.

Owner:NINGBO AUX ELECTRIC

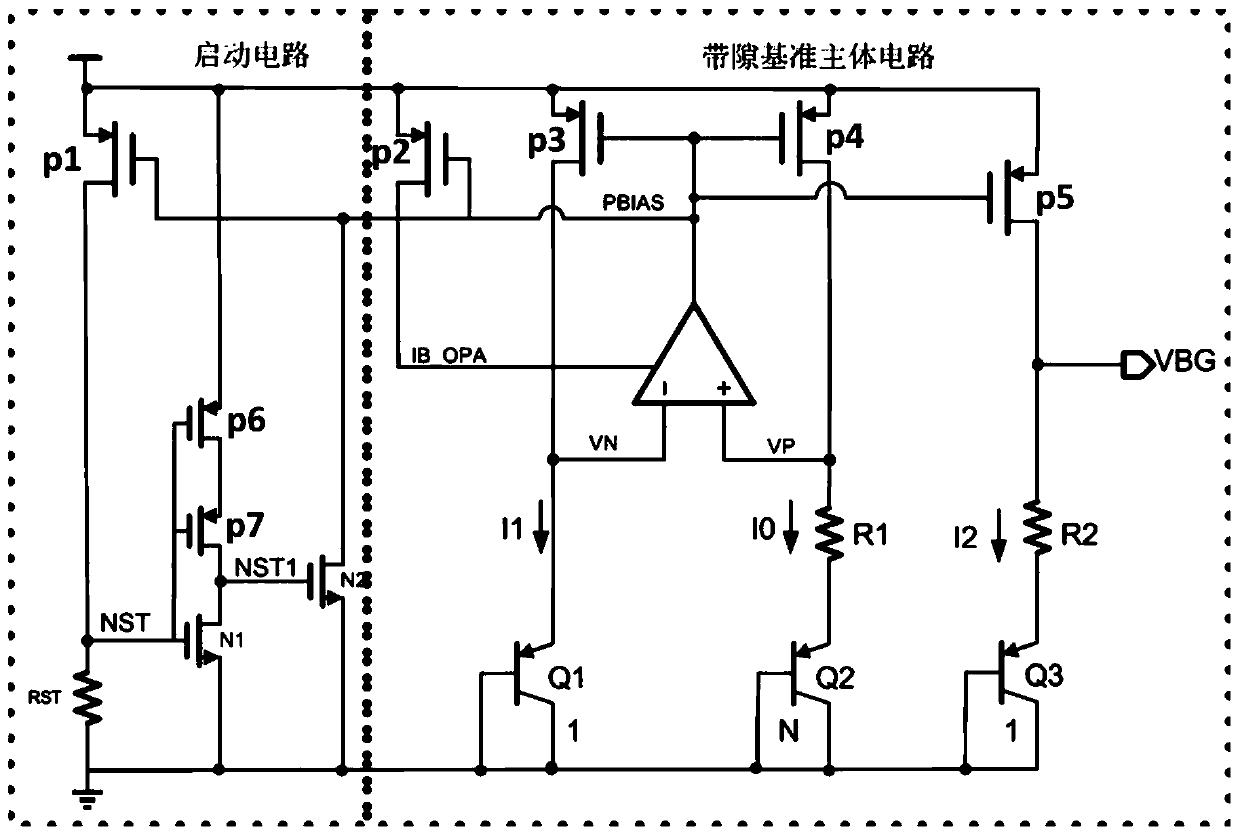

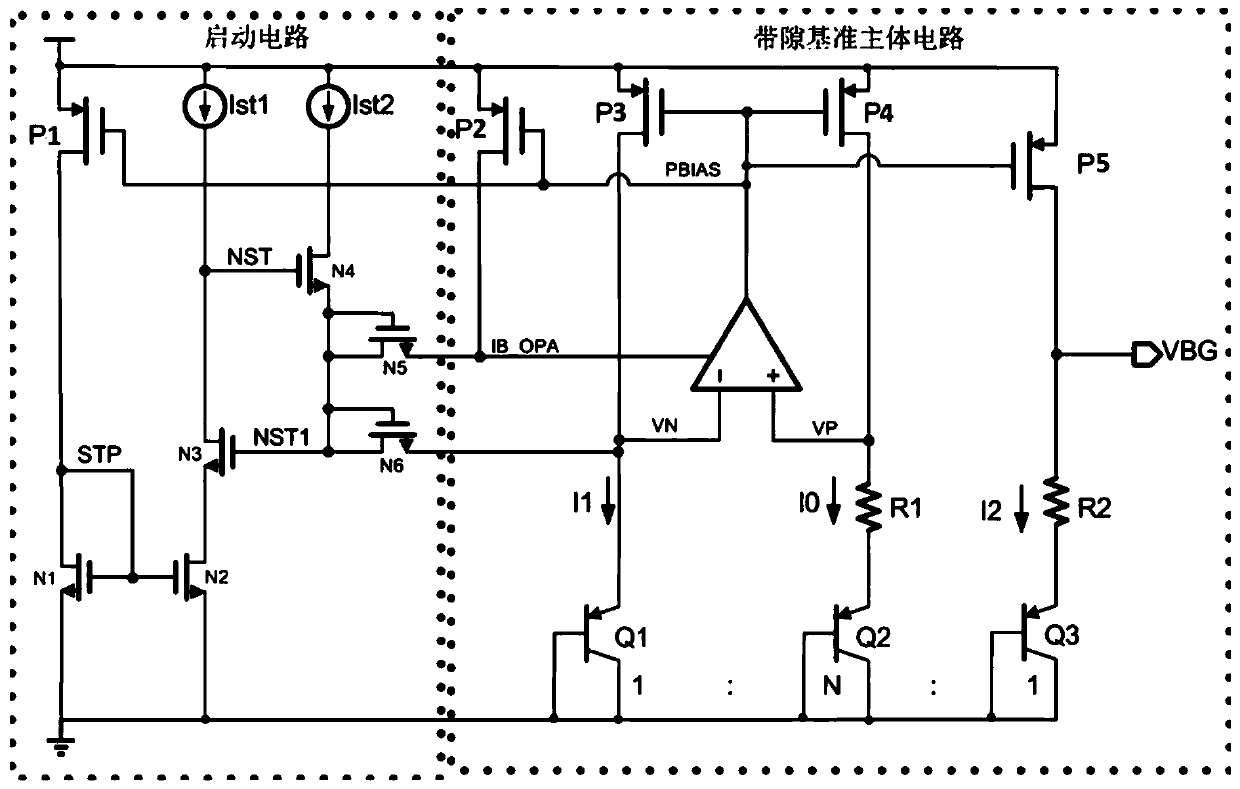

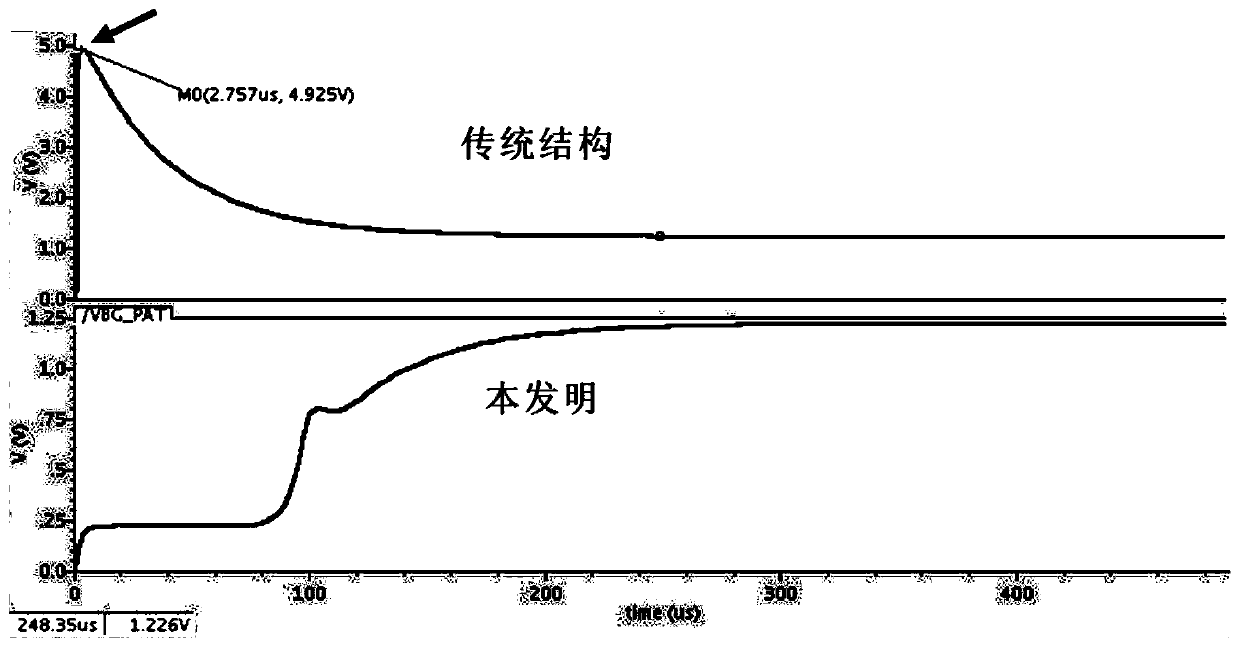

Starting circuit of band-gap reference source

ActiveCN110568898AAchieving a soft startAccuracy is not affectedElectric variable regulationElectrical currentVoltage

The invention discloses a band-gap reference source circuit. The band-gap reference source circuit comprises a band-gap reference source main body circuit and a starting circuit. The starting circuitprovides starting current for a main circuit of the band-gap reference source. The starting circuit comprises a first starting current and a second starting current, the starting currents are generally generated by a current bias circuit, the starting circuit can be completely switched off, no leakage current exists, and the precision of the output voltage of the band-gap reference source circuitis not affected. The circuit provided by the invention has the advantages that the soft start of the circuit can be achieved and the output voltage does not overshoot.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com