Variable frequency full-automatic edge bonding machine

An edge banding machine, fully automatic technology, applied in the direction of program control, control/regulation system in instruments, sequence/logic controllers, etc., can solve the problems of low safety factor, high energy consumption, poor stability, etc., and achieve extended use. Longevity, stable equipment operation, and the effect of eliminating current impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

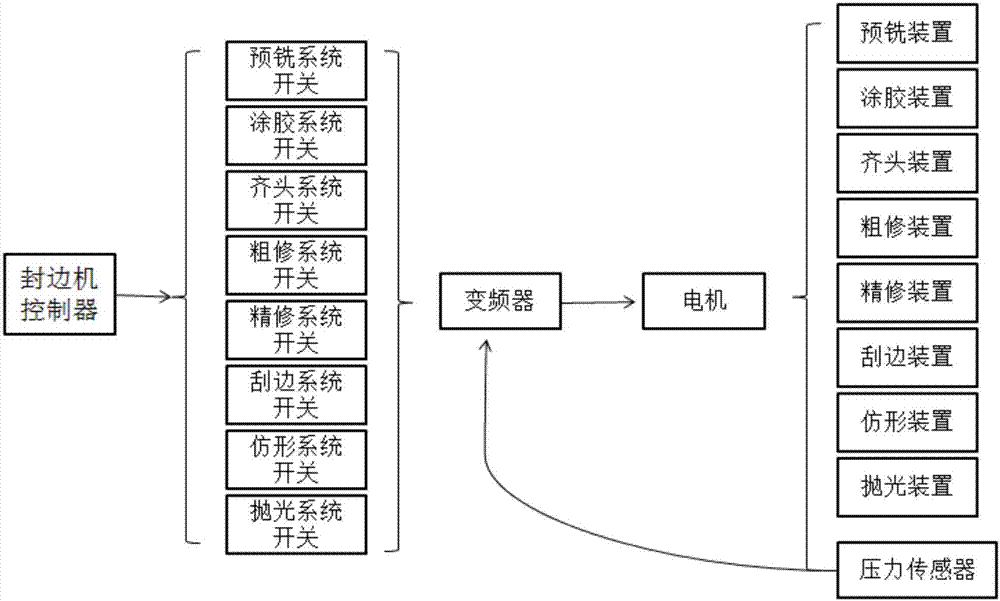

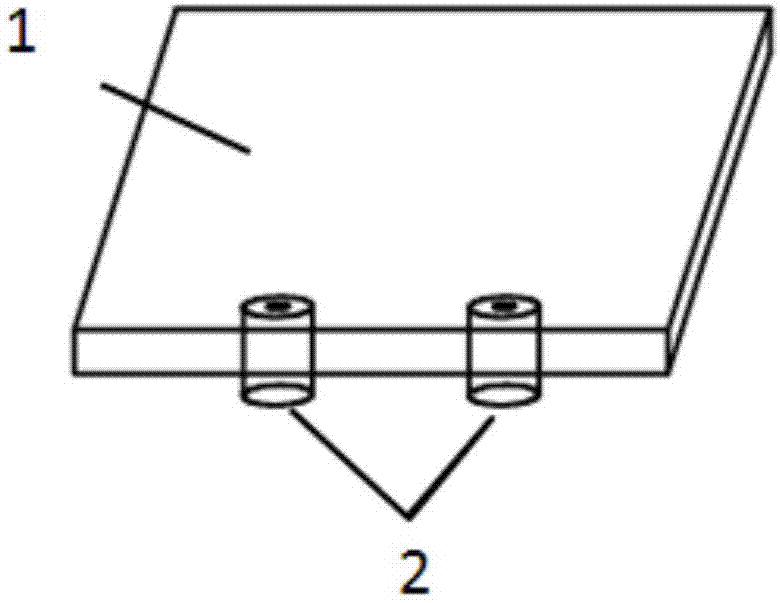

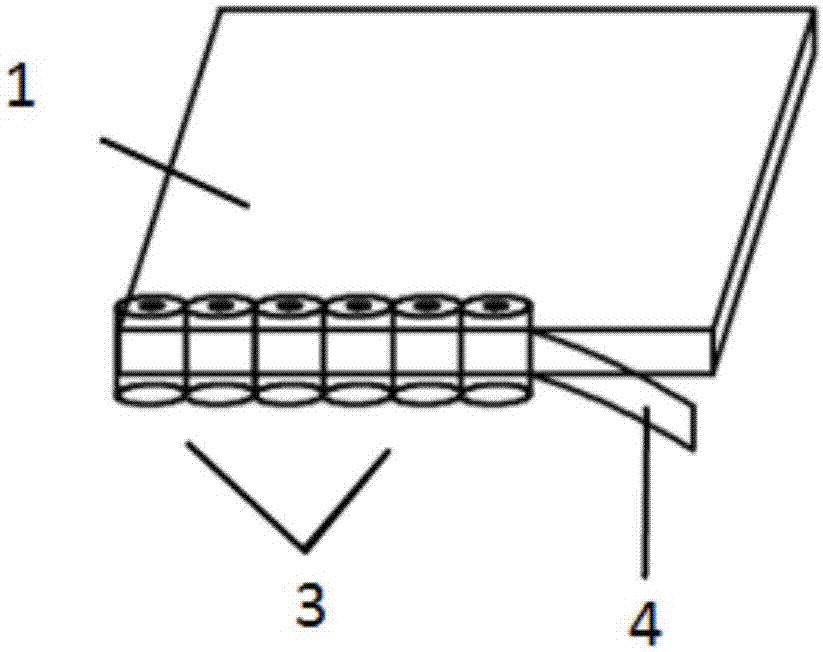

[0034] A frequency conversion automatic edge banding machine, including a controller, a frequency converter, a motor and a main machine, the frequency converter is connected with the control system and the motor, used to adjust the speed of the motor and protect the safety of the motor, the main machine includes pre-milling, gluing , Qi head, rough repair, fine repair, scraping, profiling, polishing process. The frequency conversion automatic edge banding machine of the present invention mainly adopts flexible and unit modular design, and the host workbench mainly includes 8 processes. During the whole cycle processing process, the whole machine adopts PLC numerical control device and machine tool pneumatic control device. The PLC controller sends a signal corresponding to the process, the frequency converter drives the motor, and the motor that drives the host workbench starts to work. The main motor is driven by a frequency converter, with an optimized control program built ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com