Remote intelligent speed control axial asynchronous magnetic coupling and speed regulating method

A remote intelligent control, magnetic coupling technology, applied in control systems, control electromechanical transmission devices, energy industry and other directions, can solve the problems of difficult to accurately guarantee accuracy, low transmission efficiency, cumbersome operation, etc., to achieve stable speed and output torque Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

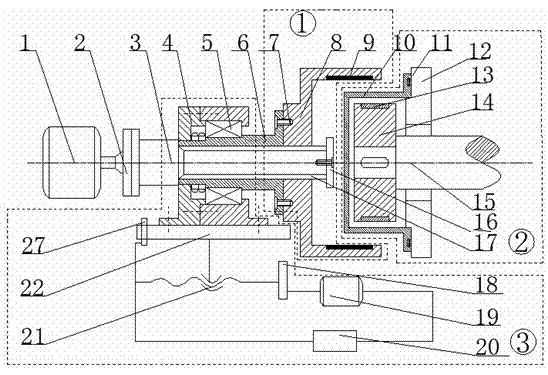

[0030] The working principle of embodiment 1: as figure 1 As shown, when the drive shaft controls the motor 1 and drives the outer rotor 8 to rotate, the permanent magnet 9 arranged on the inner surface of the outer rotor 8 will form a rotating magnetic field in the air gap. According to the principle of electromagnetic induction, the guide bars in the inner rotor 14 13, an induced current will be formed on the surface, and the induced current will induce an induced magnetic field and interact with the magnetic field of the permanent magnet, so that the inner rotor 14 rotates with the outer rotor 8; during the rotation of the outer rotor 8, the remote intelligent controller 20 A command is issued to drive and control the rotation of the motor 19. After being decelerated by the reduction mechanism 18, the rotation motion is converted into a feed motion through the ball screw 21, which drives the worktable 22, the bearing 5, the sleeve 6, and the outer rotor 8 to move left and ri...

Embodiment 2

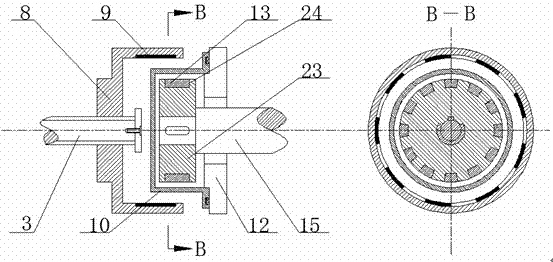

[0031] Embodiment 2: as image 3 As shown, similar to Embodiment 1, the inner rotor assembly ② is composed of the spacer 10 fixed on the base 12, the driven shaft 15, the inner rotor base 23, the guide bar 13 and the end ring 24, the inner rotor base The seat 23 is installed on the driven shaft 15, and the outer surface of the inner rotor base 23 is evenly distributed with deep groove structures along the circumferential direction. Guide bars 13 are placed in the grooves, and end rings 24 are fixed on both sides of the guide bars 13, so that The bars 13 form a closed loop. Since this structure does not require permanent magnet materials on the inner rotor, it is suitable for working under high temperature conditions.

Embodiment 3

[0032] Embodiment 3: as Figure 4 As shown, similar to Embodiment 1, the inner rotor assembly ② is composed of the spacer sleeve 10 fixed on the base 12, the driven shaft 15, the inner rotor inner layer 25, and the inner rotor outer layer 26. The inner rotor inner layer is 25 is a solid rotor, the material is steel or cast iron, and a layer of copper is plated on its outer surface, which is the outer layer 26 of the inner rotor, forming a double-layer cylindrical structure. The structure has the advantages of high transmission performance and good starting performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com