Parallel connection LED drive circuit with adaptive mode switching

A technology of LED driving and mode switching, applied in the direction of electric lamp circuit layout, electric light source, lighting device, etc., can solve the problem of efficiency loss, not taking into account the LED conduction voltage drop, etc., achieve high conversion efficiency, achieve soft start and overtime The effect of pressure protection and strong implementability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

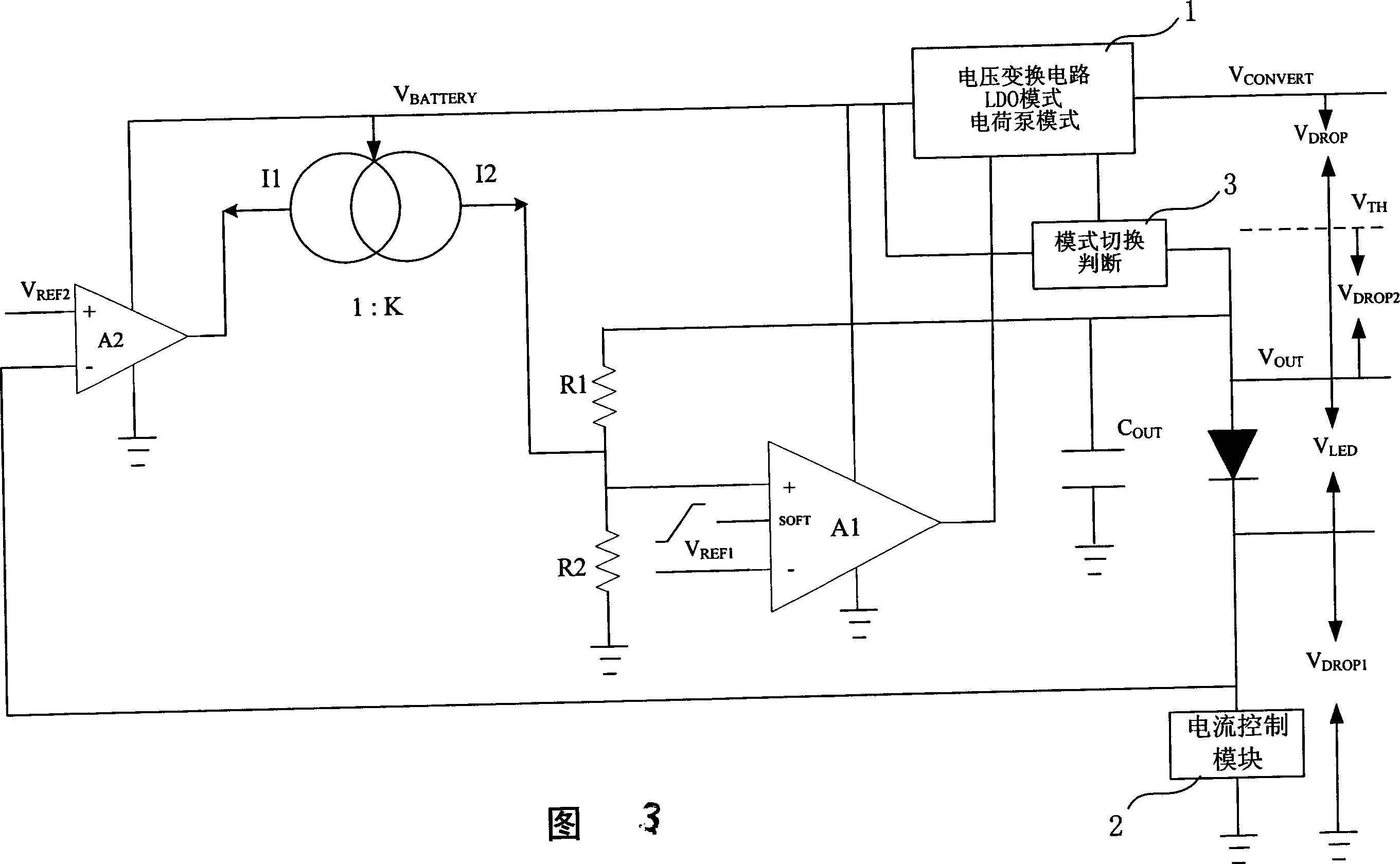

[0036] As shown in Figure 3, in the circuit of the present invention, V DROP1 The voltage is set to a fixed, relatively small voltage value, generally between 200-400mV, so V OUT Voltage is no longer a fixed voltage value. According to Equation 1, the mode switching voltage V TH It is no longer a fixed voltage, but will be adjusted according to the forward voltage drop of the LED.

[0037] According to the mode switching criterion given in Equation 2, it can be seen that: through the mode switching voltage V TH According to the adaptive change of the load LED characteristics, the adaptive control of mode switching is realized.

[0038] As shown in Figure 3, the present invention, that is, a parallel LED drive circuit with adaptive mode switching, includes a voltage conversion circuit 1, a mode switching judgment circuit 3, a current control module 2, an operational amplifier A1, and voltage dividing resistors R1 and R2 , capacitance C out , and a feedback control loop, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com