Adjustable-speed magnetic induction coupler

A magnetic induction and coupling technology, applied in electrical components, electromechanical devices, electromechanical transmission devices, etc., can solve problems such as reduced efficiency, increased rotor loss, and inconspicuousness, so as to improve the transmitted torque and avoid vibration interference. , to achieve the effect of adjustable speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

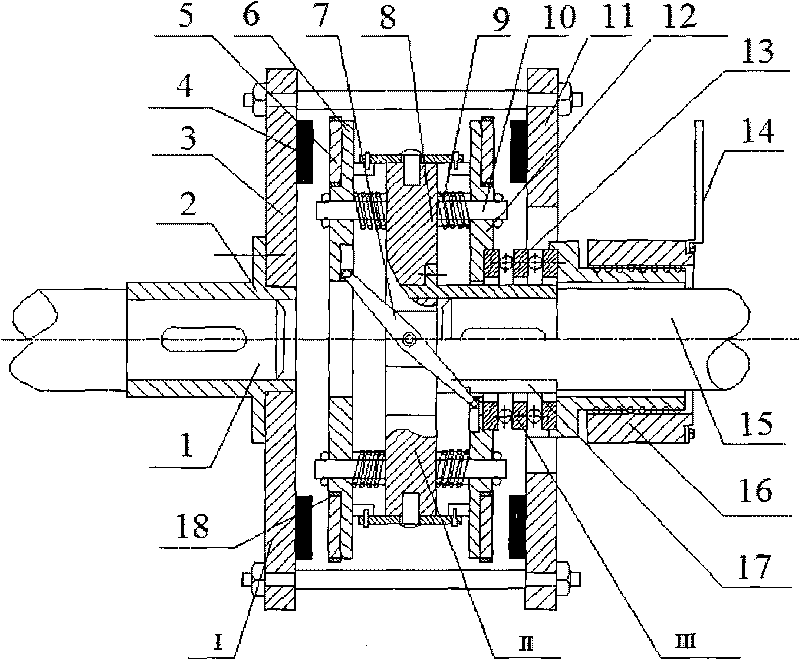

[0027] The overall structure of the present invention is as figure 1 As shown, the device is mainly composed of a driving disc assembly (I), a driven disc assembly (II) and a speed regulating device assembly (III). The driving disc assembly (I) is connected with the driving shaft through a flat key; the driven disc assembly (II) is installed at one end of the driven shaft; the speed regulating device assembly (III) is connected with the driven disc assembly (II).

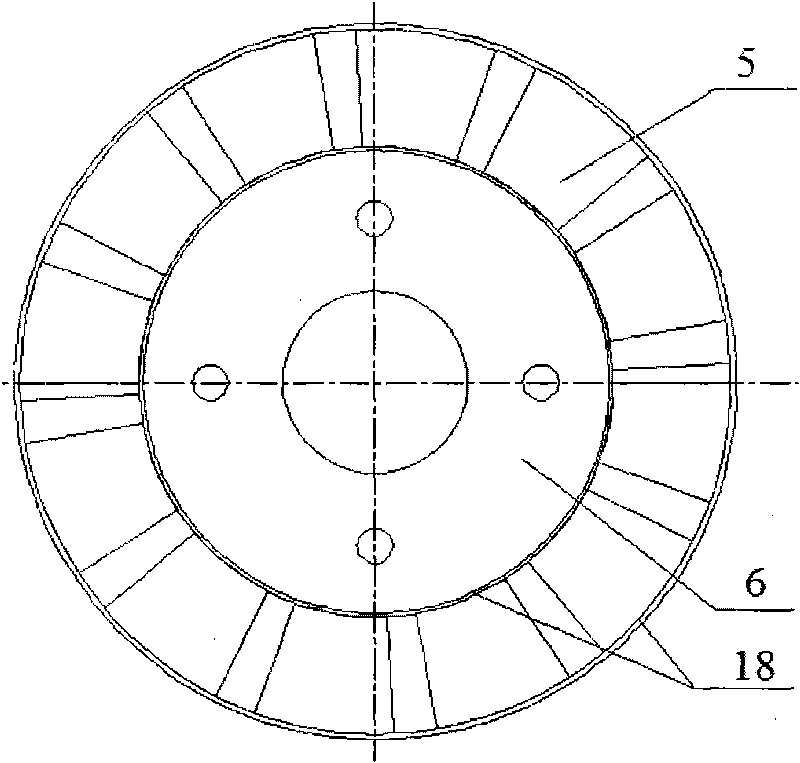

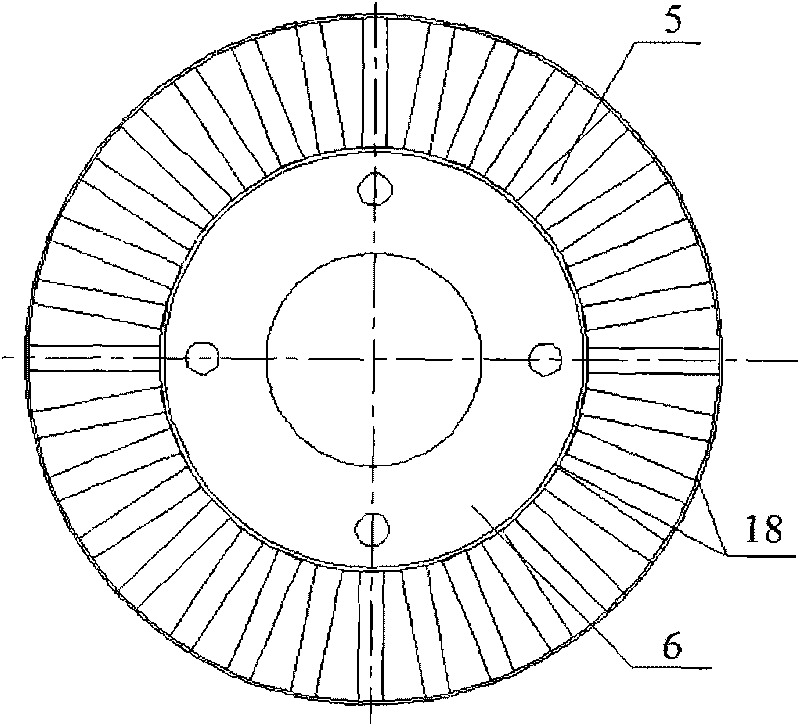

[0028] Concrete structure of the present invention: drive disc assembly (I) such as figure 1 As shown, it includes a sleeve 1 (2), two drive disc substrates 3, 11 and permanent magnets 4; the permanent magnets 4 are closely arranged and bonded on the end faces of the substrates 3, 11 according to the even-numbered N pole and S pole. The S pole can be a single pole, or multiple ring magnets with the same polarity and size, and the two drive disc bases are connected by screws; the driven disc assembly (II) includes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com