Energy-saving soft-start device for high-voltage asynchronous motor

An asynchronous motor, soft start technology, applied in the direction of motor generator/starter, starter of a single multi-phase induction motor, etc., can solve the problems of power factor cannot be automatically improved, consumption, large footprint, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

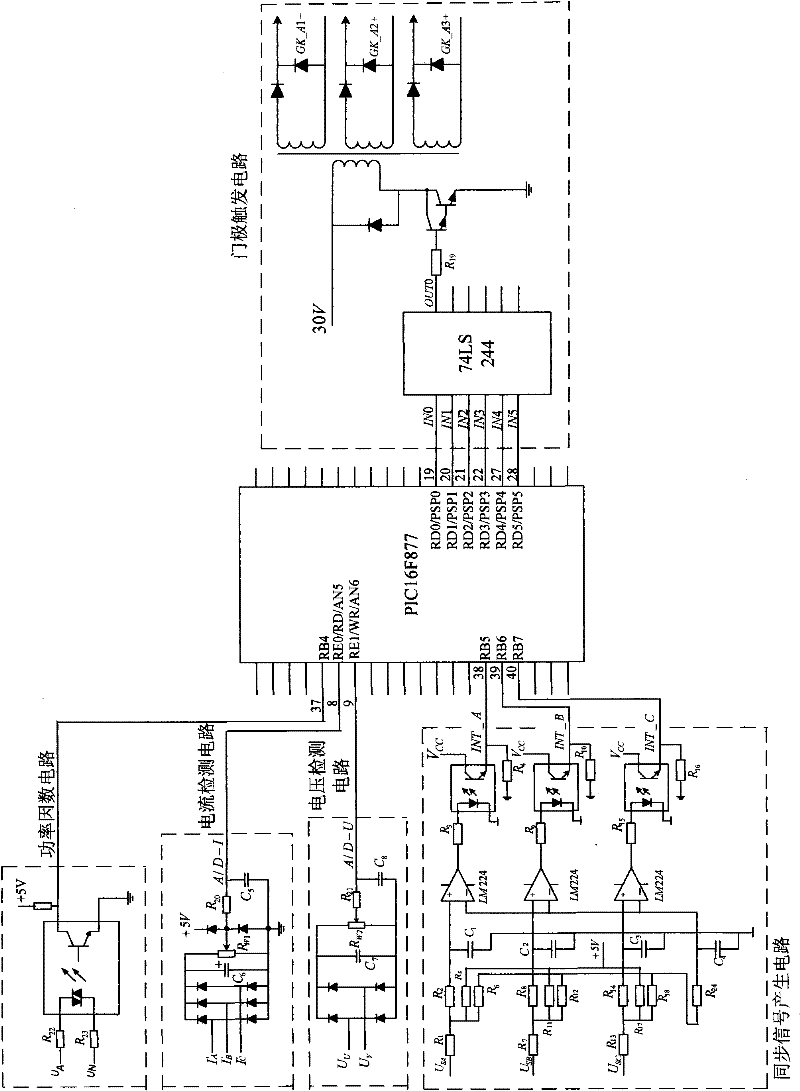

[0095] This embodiment further illustrates the device of the present invention by introducing a specific circuit.

[0096] The hardware circuit in this embodiment uses Figure 1 to Figure 9 as well as Figure 17 In addition, the circuit of this embodiment also has a display unit, a keyboard input circuit, and a remote control circuit, which are omitted in the figure, and the DC power supply circuit is not drawn in detail. Some of the content omitted and not drawn in detail above are common and well-known technical means in this technical field, and related books are flooded in libraries and bookstores. Repeat the description again in order to have enough space to describe the technology of the present invention in detail.

[0097] Combine below Figure 1 to Figure 9 as well as Figure 17 The circuit in this embodiment will be described in detail.

[0098] about figure 1 , figure 2 and image 3 instruction of.

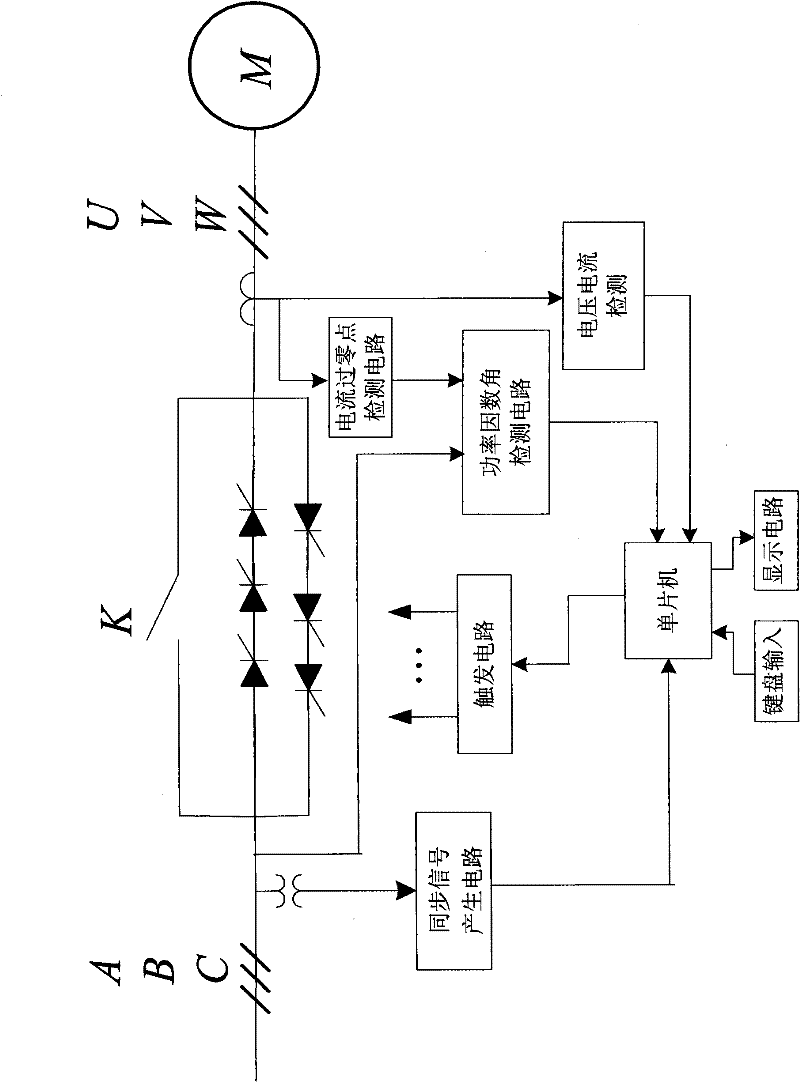

[0099] figure 1 It is the electrical principle block di...

Embodiment 2

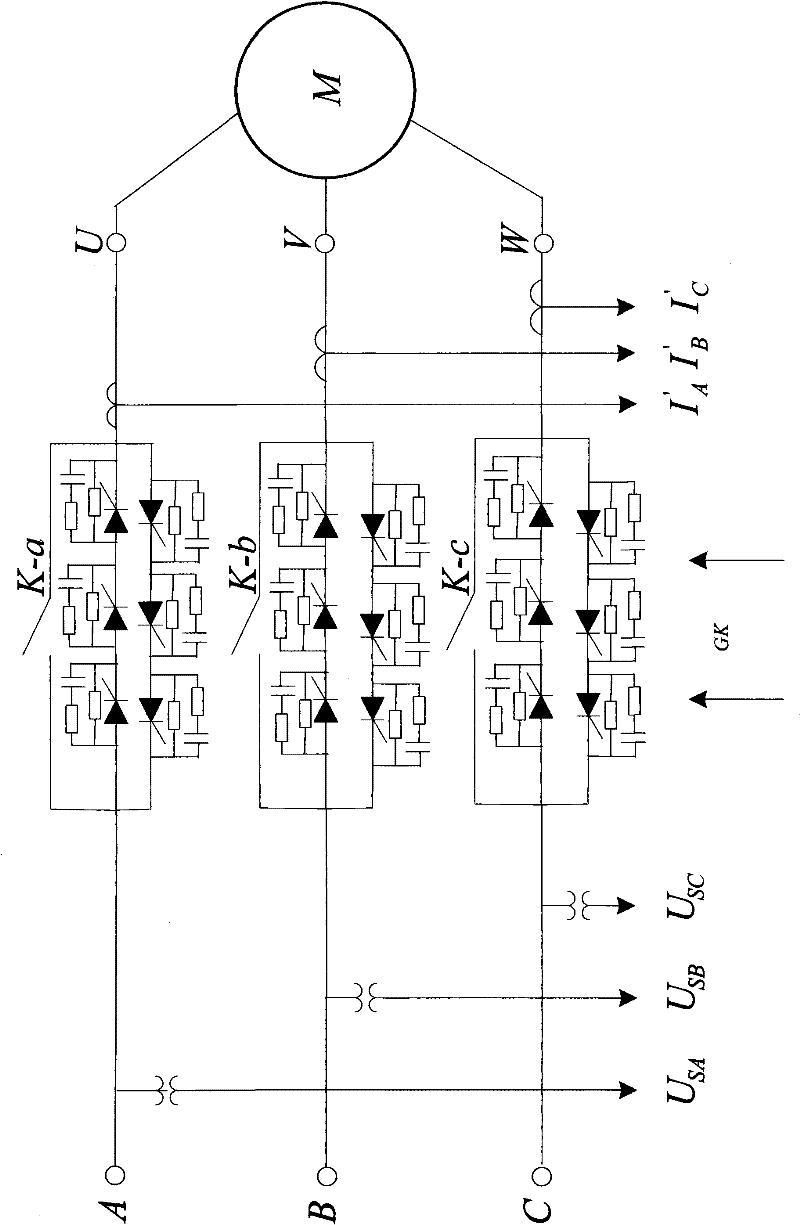

[0163] combine Figure 18 Be explained. right first Figure 18 The labels in are explained: A is the first phase sequence in the three-phase alternating current, that is, the phase sequence of the A phase, and is also expressed as the terminal of the A phase; B is the second phase sequence in the three-phase alternating current, that is, the phase sequence of the B phase , which is also expressed as the B-phase terminal; C is the third phase sequence in the three-phase AC, that is, the C-phase phase sequence, and is also expressed as the C-phase terminal; M is the internal Y-connected motor; U is the soft The output end of the starter, that is, the input end of the motor, is located on the A-phase line; V is the output end of the soft starter, that is, the input end of the motor, and is located on the B-phase line; W is the output end of the soft starter, that is, the motor The input terminal is located on the C-phase line; N is the neutral terminal of the three-phase AC pow...

Embodiment 3

[0169] combine Figure 19 Be explained. right first Figure 19 The labels in are explained: A is the first phase sequence in the three-phase alternating current, that is, the phase sequence of the A phase, and is also expressed as the terminal of the A phase; B is the second phase sequence in the three-phase alternating current, that is, the phase sequence of the B phase , which is also expressed as the B-phase terminal; C is the third phase sequence in the three-phase AC, that is, the C-phase phase sequence, and is also expressed as the C-phase terminal; M is the internal Y-connected motor; U is the soft The output end of the starter, that is, the input end of the motor, is located on the A-phase line; V is the output end of the soft starter, that is, the input end of the motor, and is located on the B-phase line; W is the output end of the soft starter, that is, the motor The input terminal of is located on the C-phase line; N is the neutral wire terminal of the three-phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com