Patents

Literature

134 results about "Jaw opening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Jaw opening involves multiple muscles, including the suprahyoid muscle group. Some suprahyoid muscles are involved not only in hyoid elevation but also in jaw opening, by virtue of pulling the lower jaw down by contraction of the muscles.

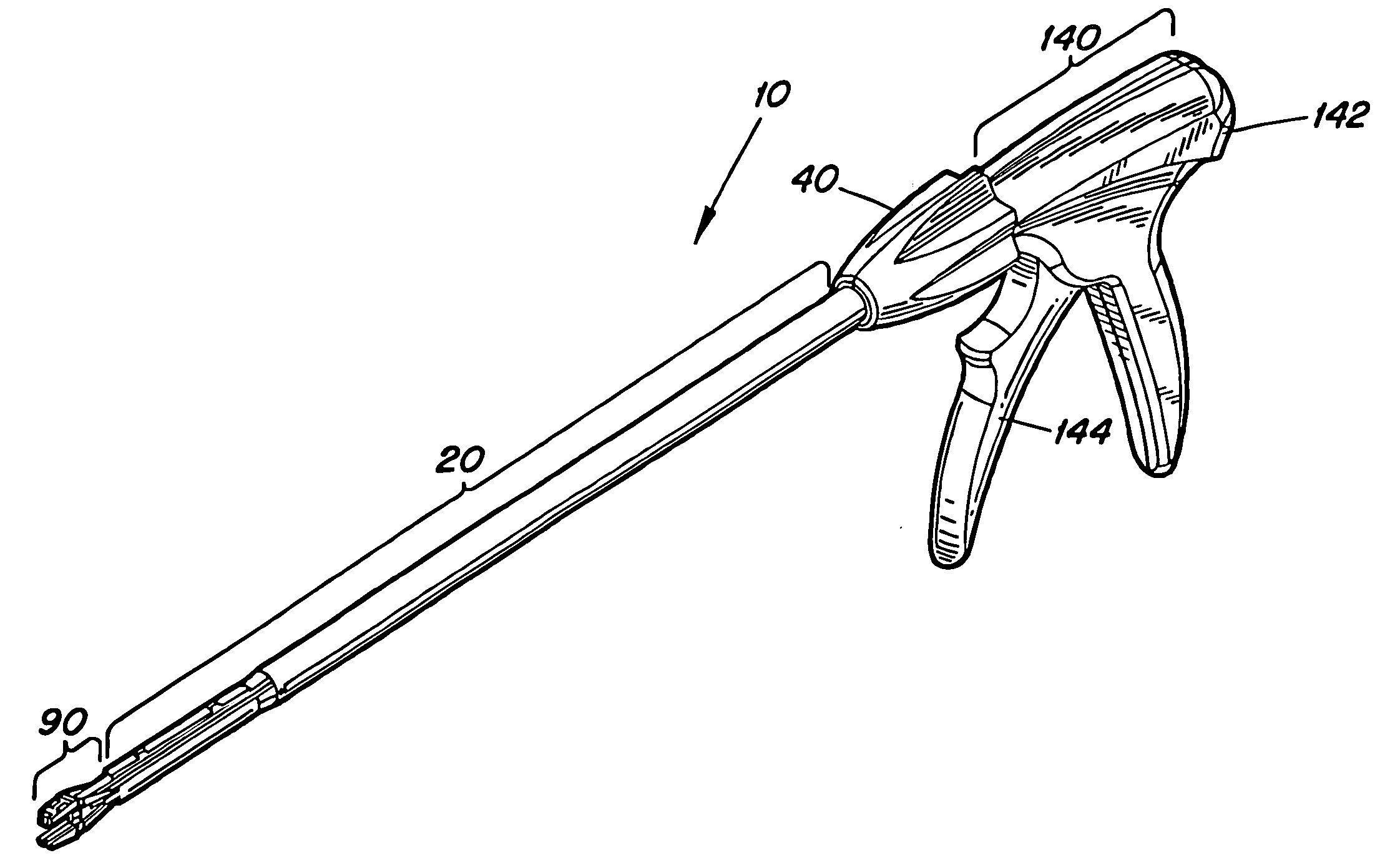

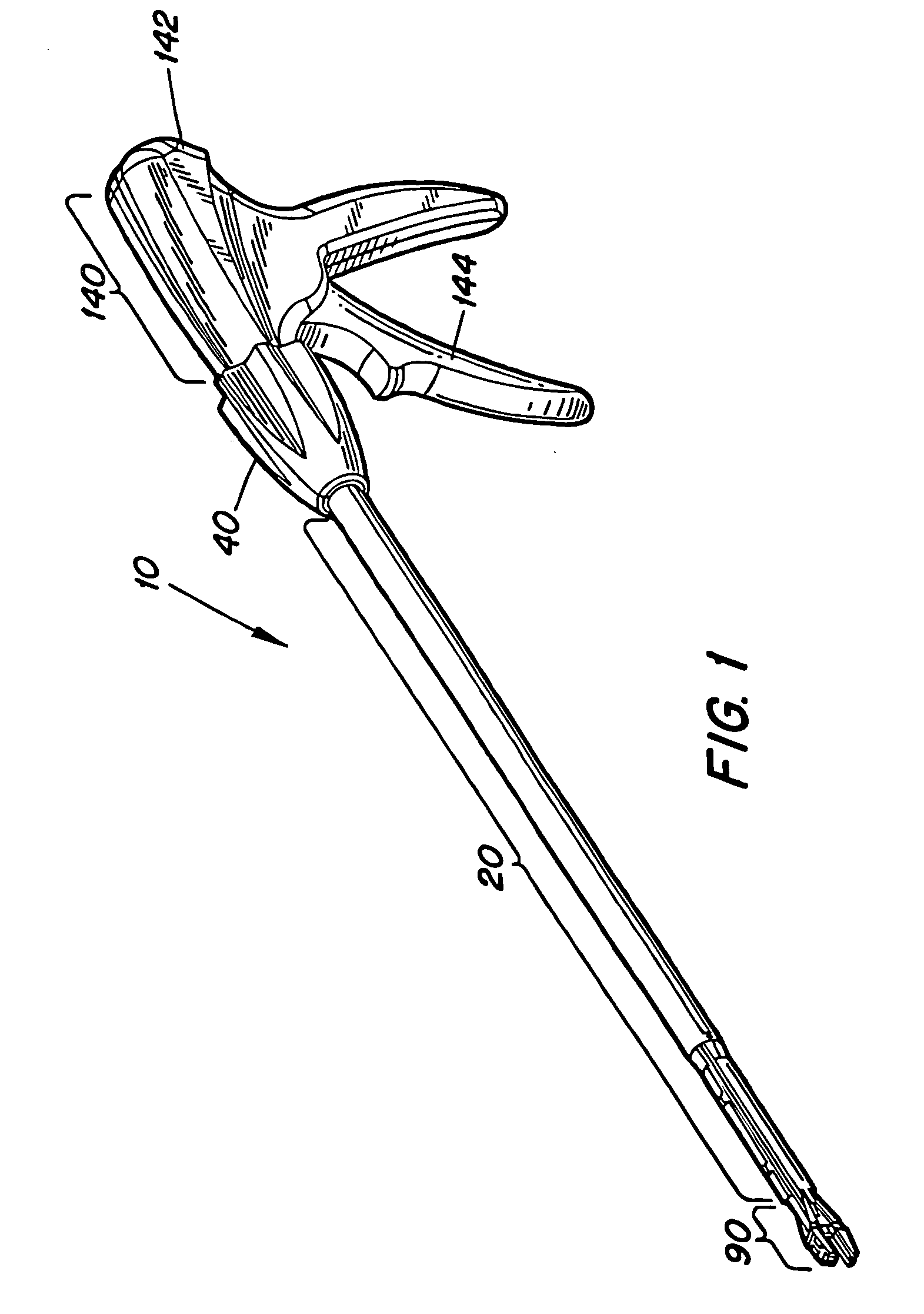

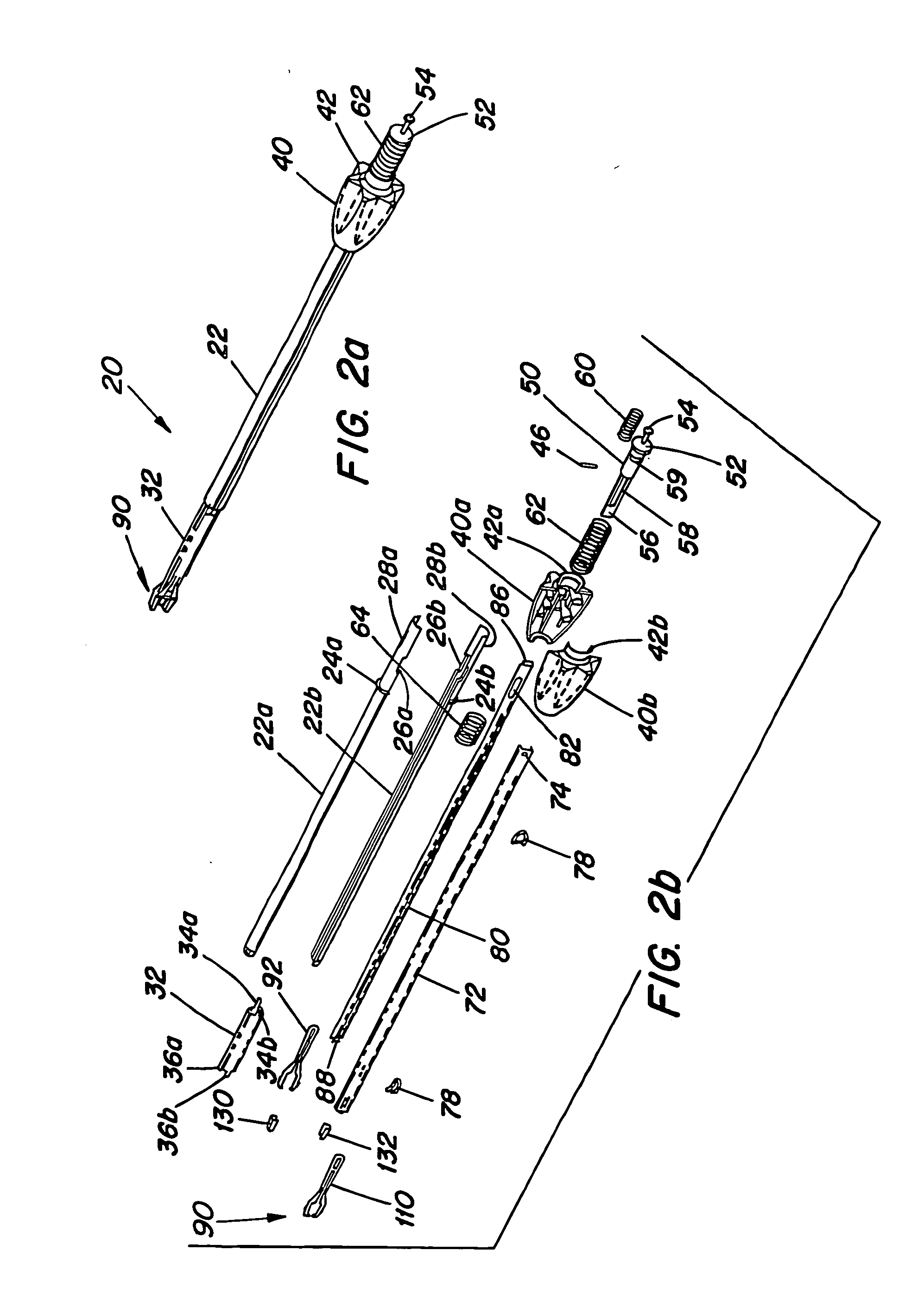

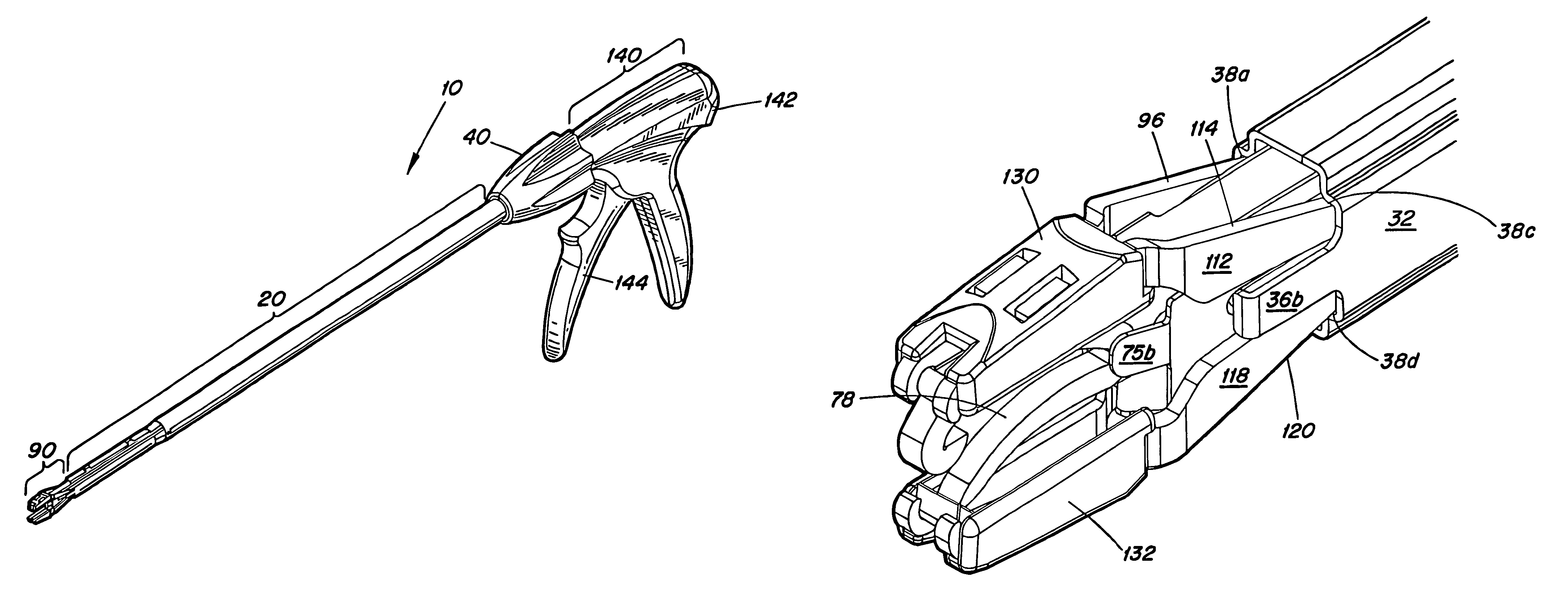

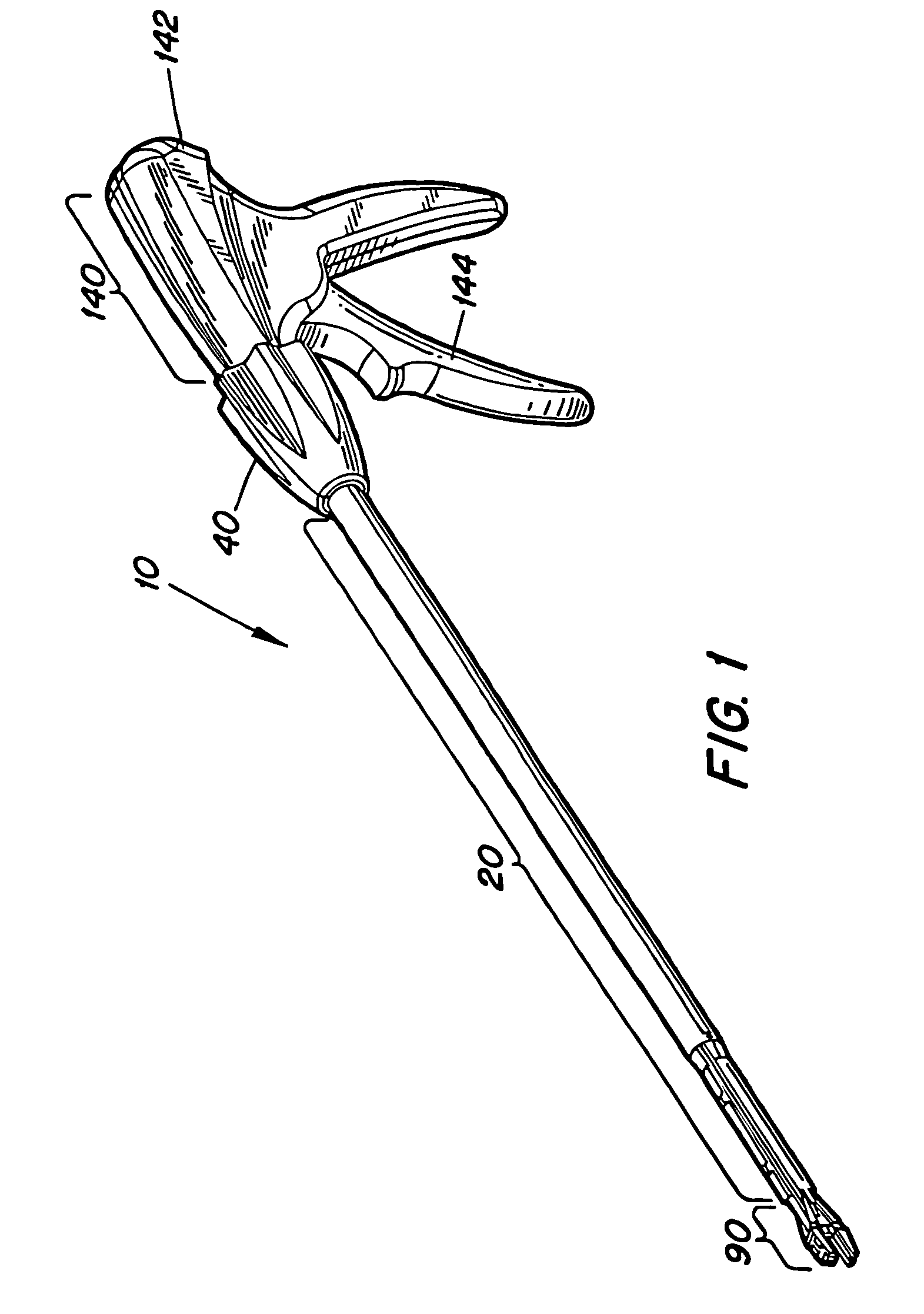

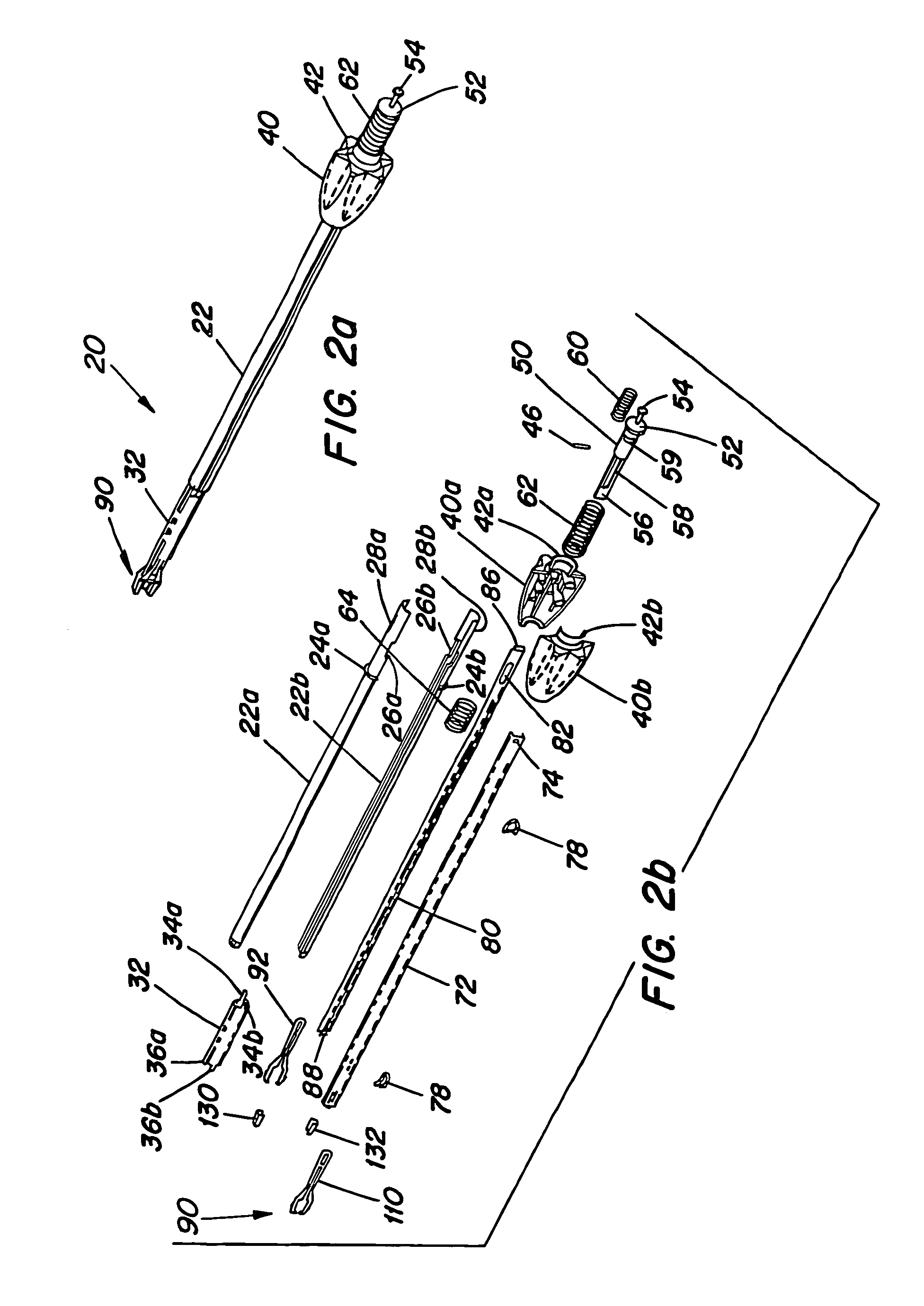

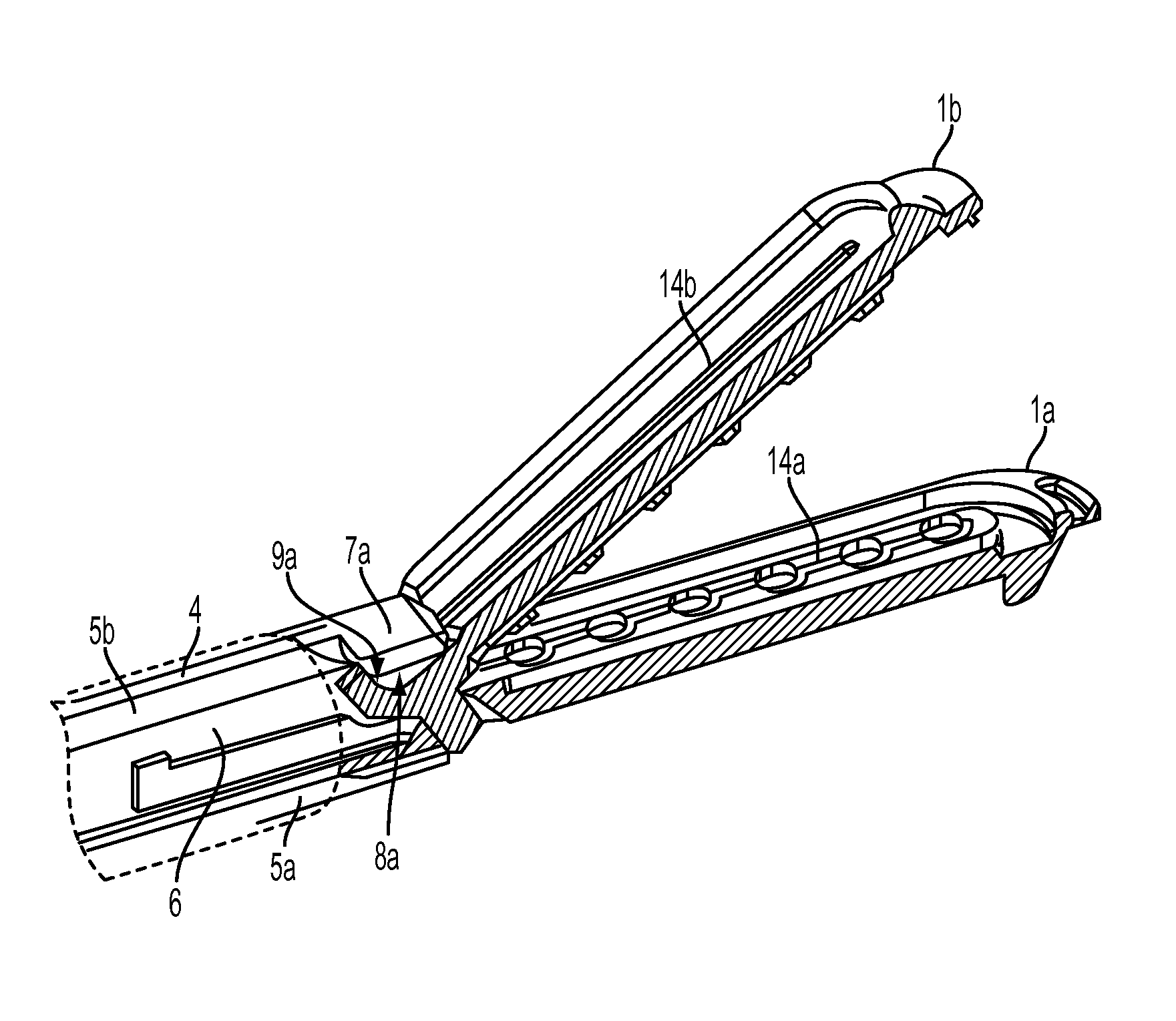

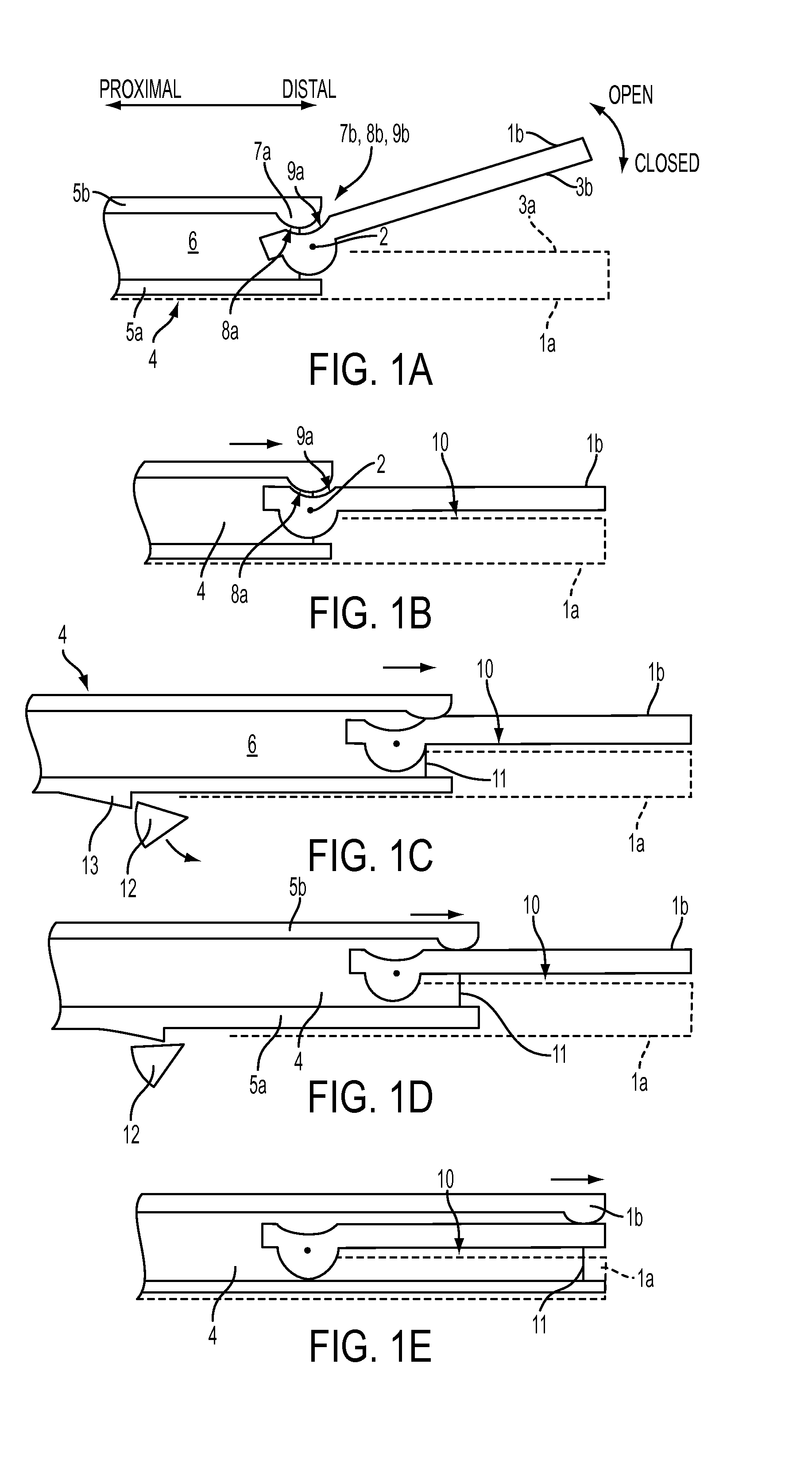

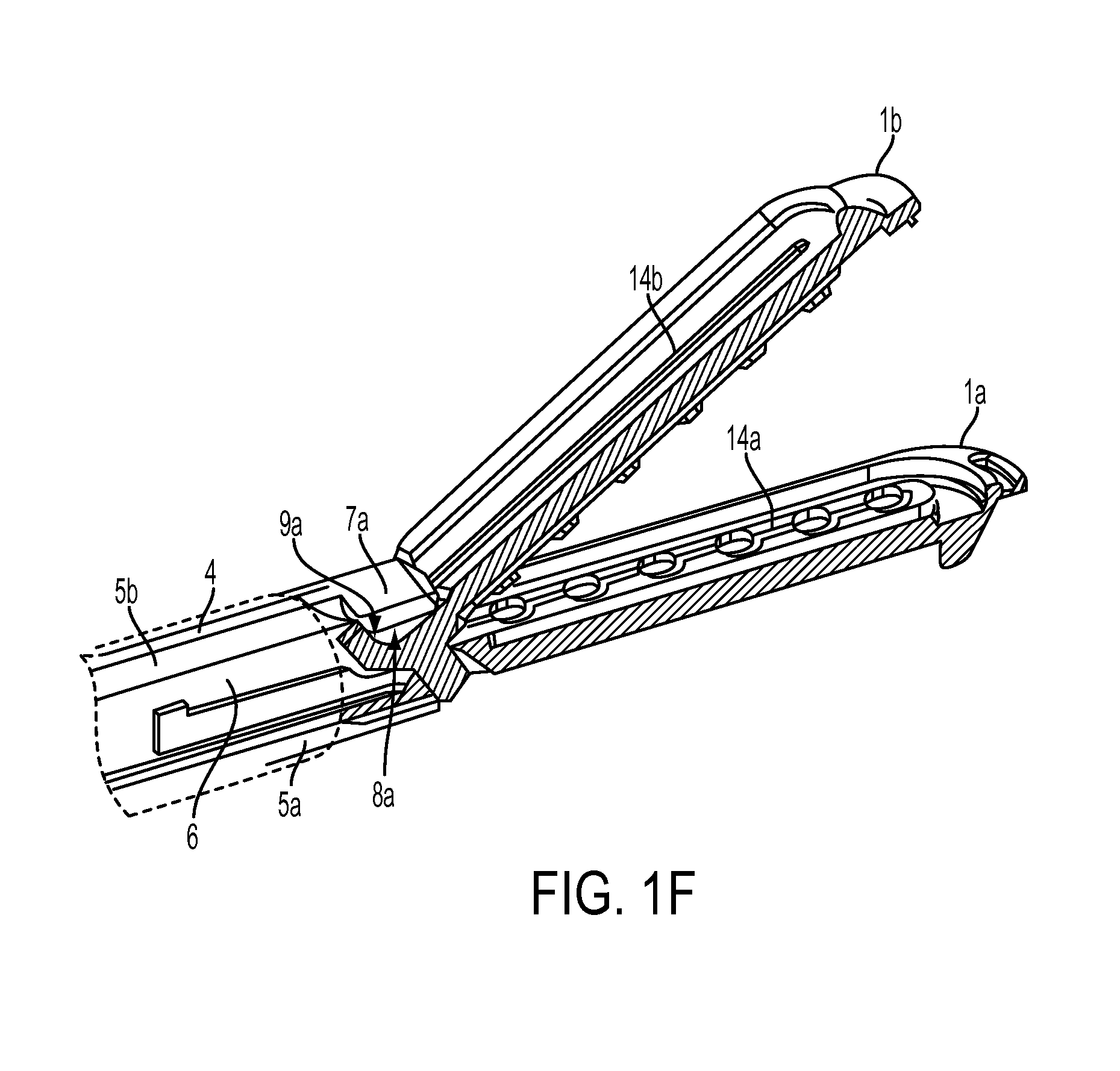

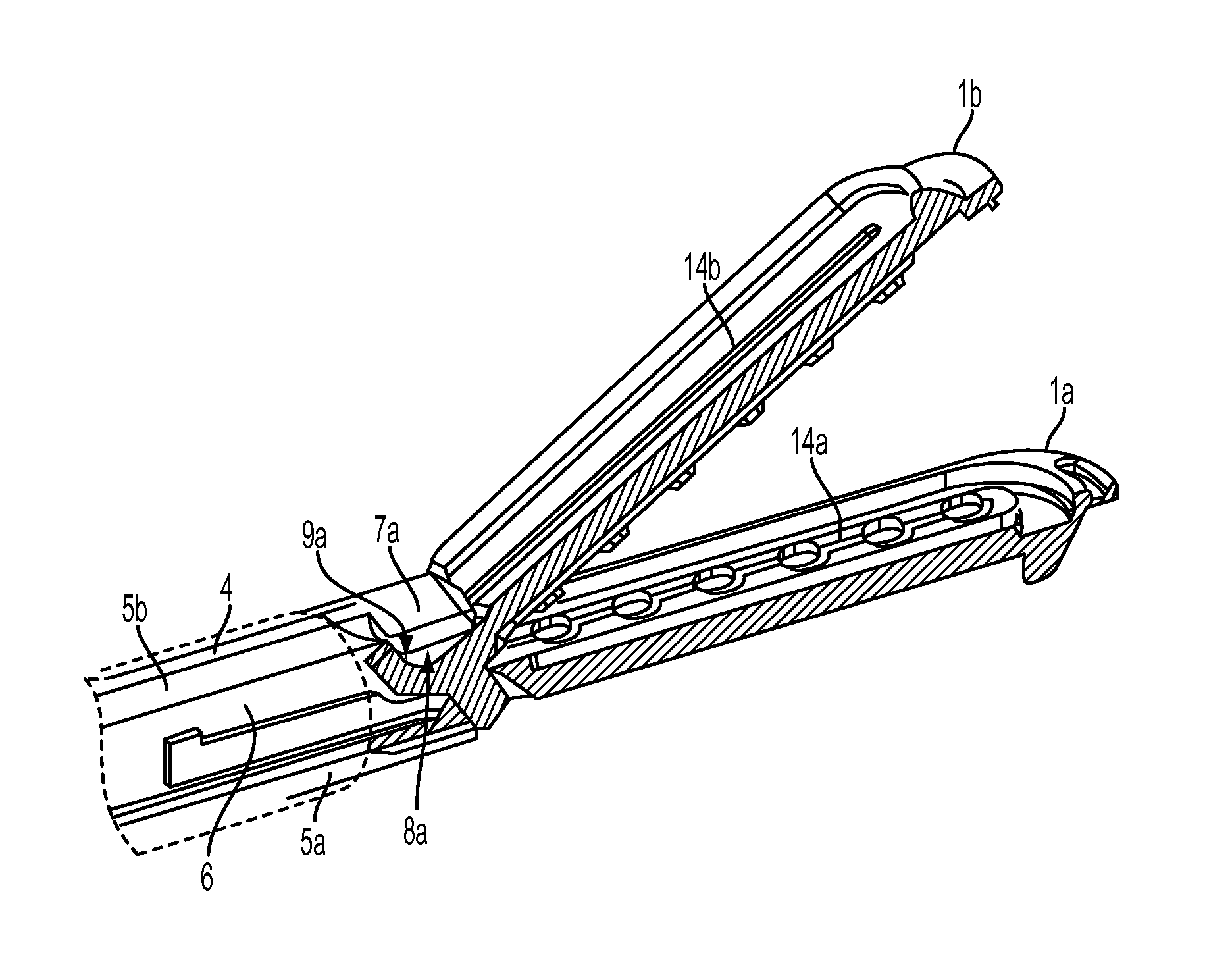

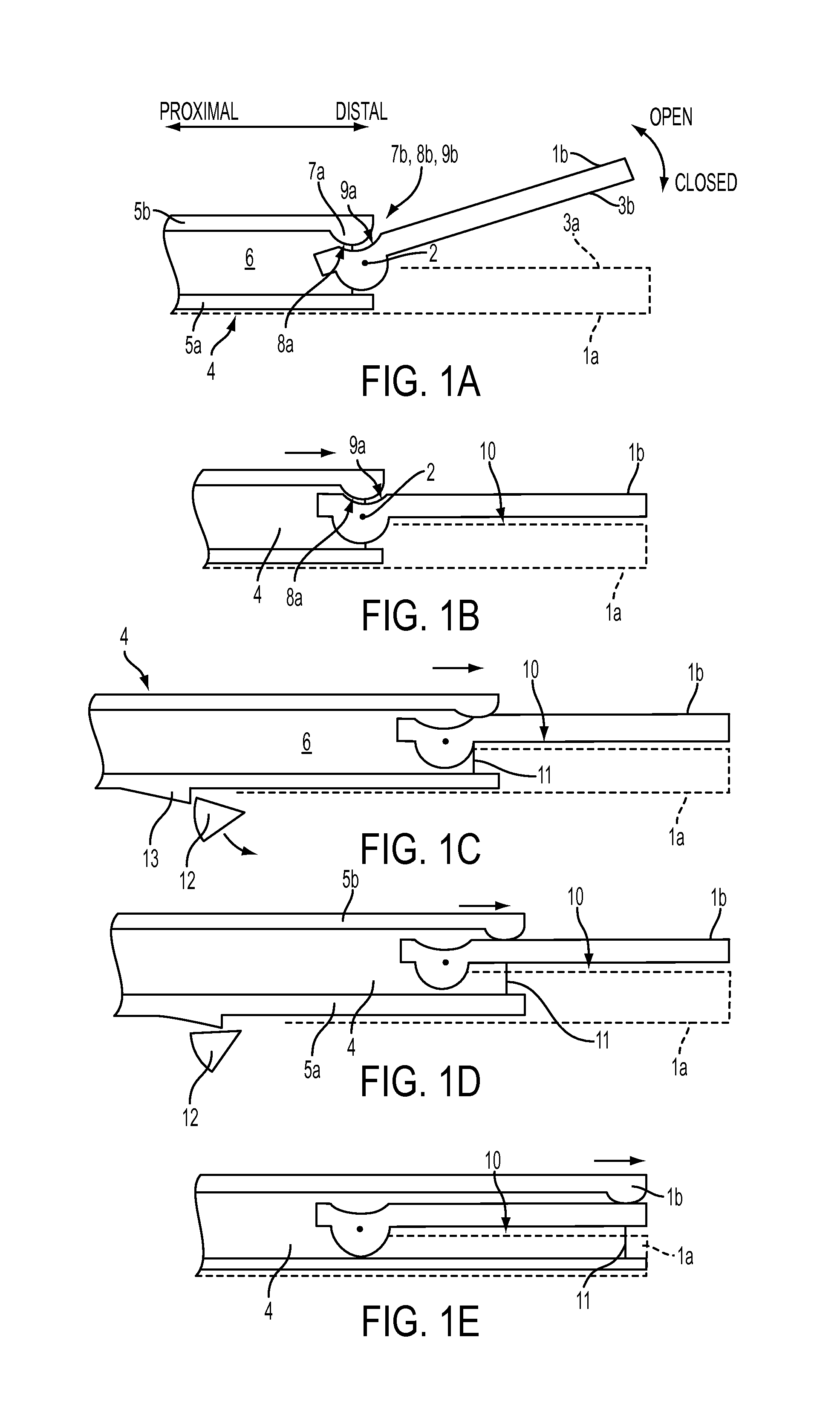

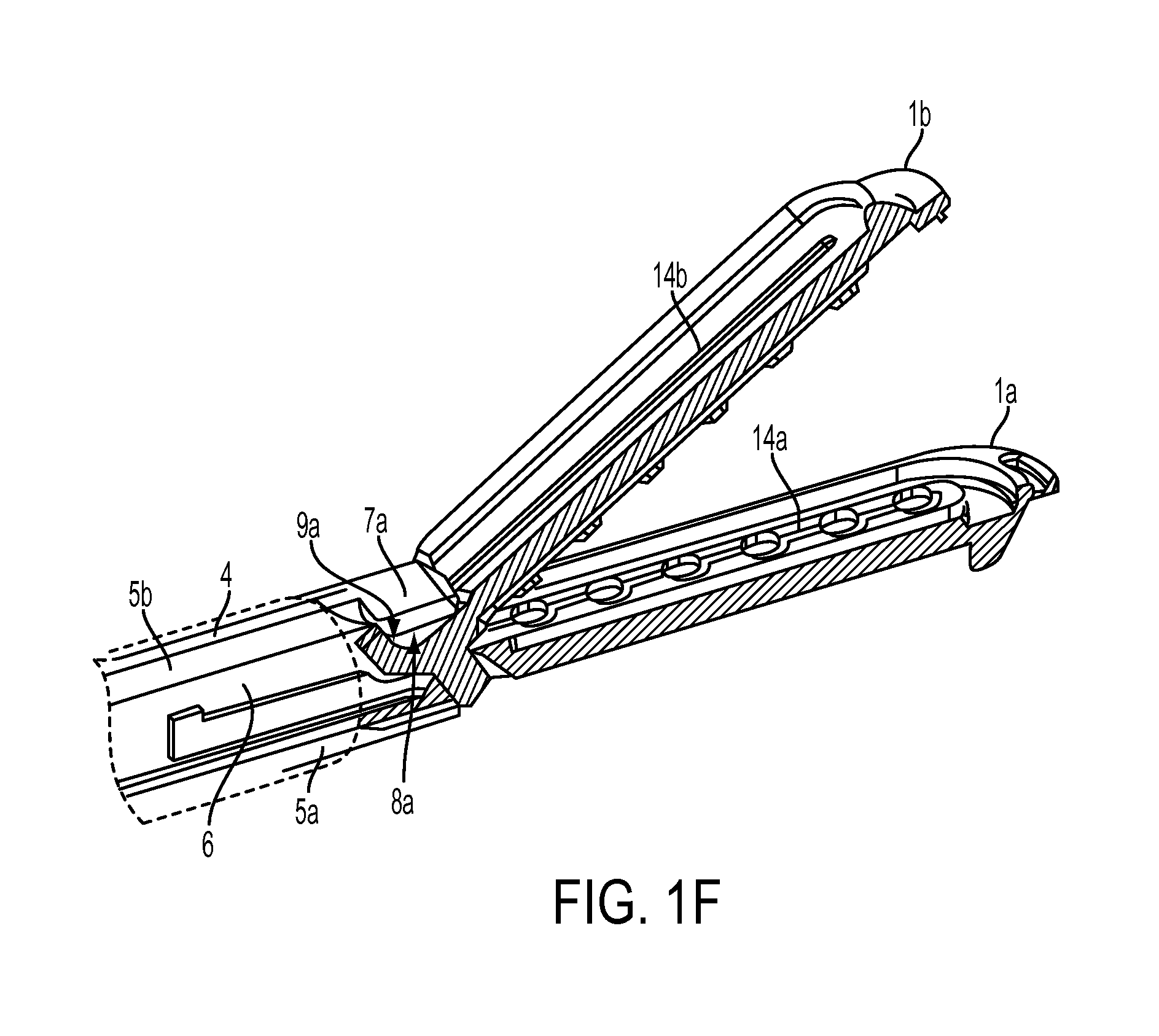

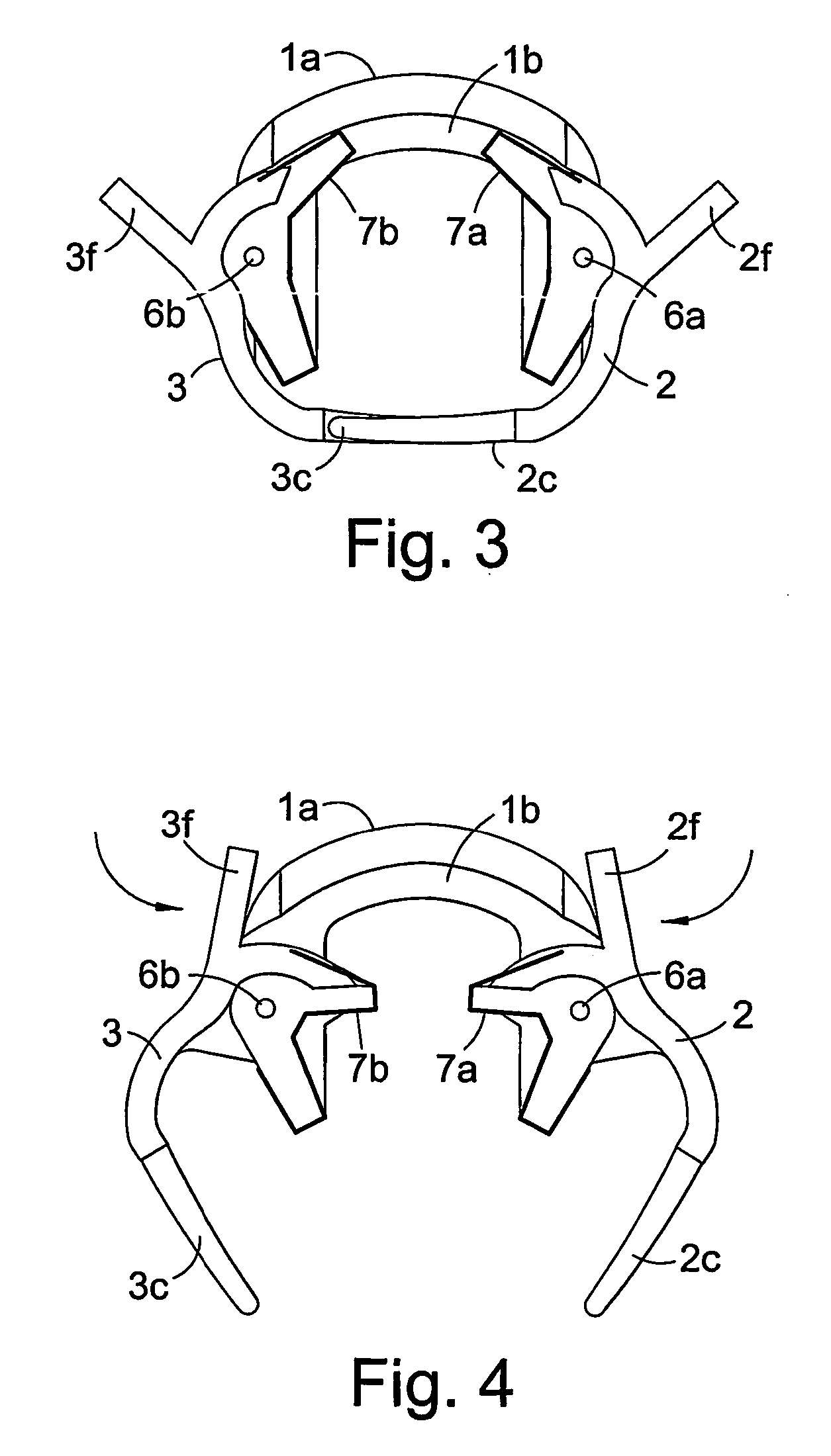

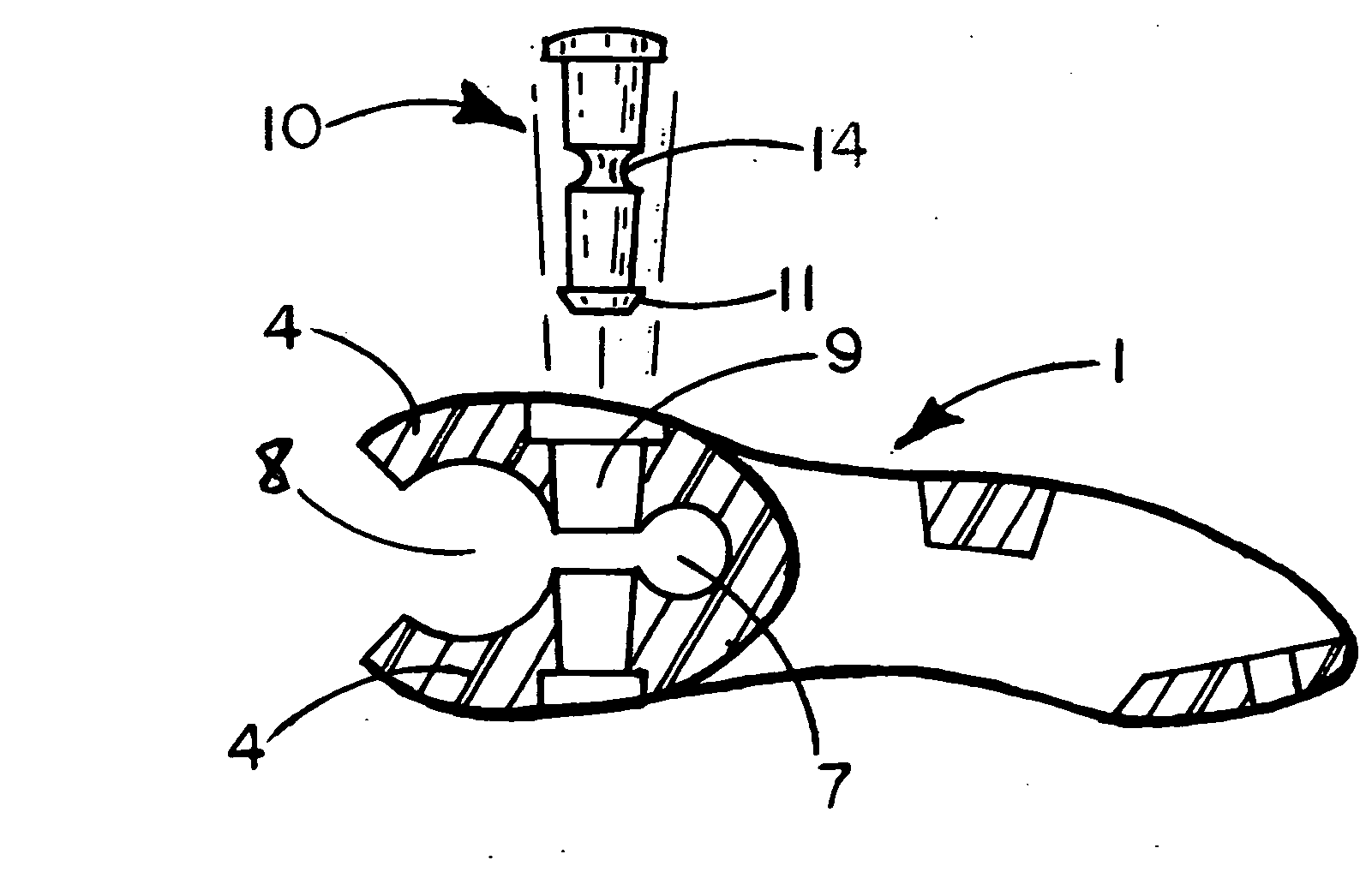

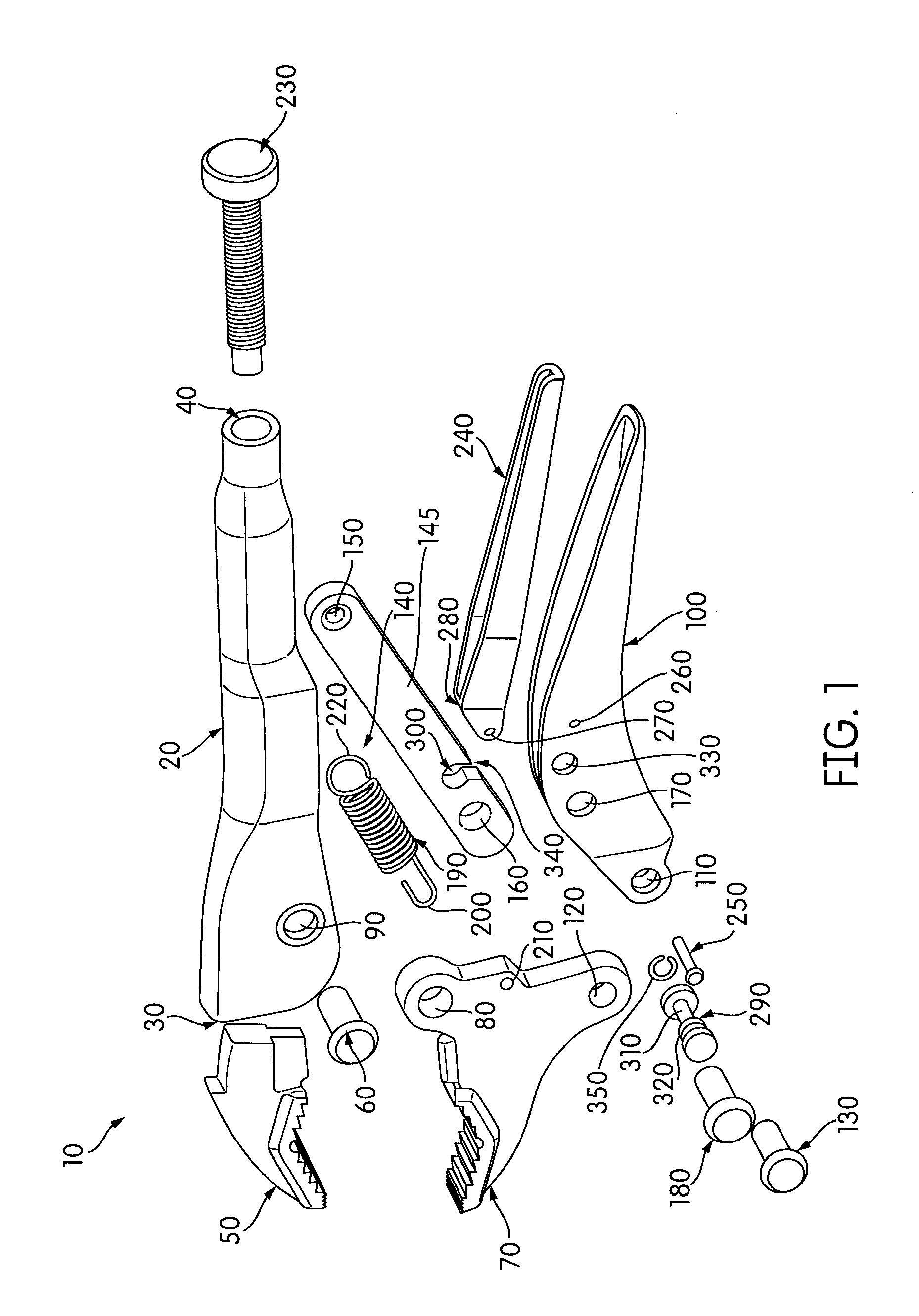

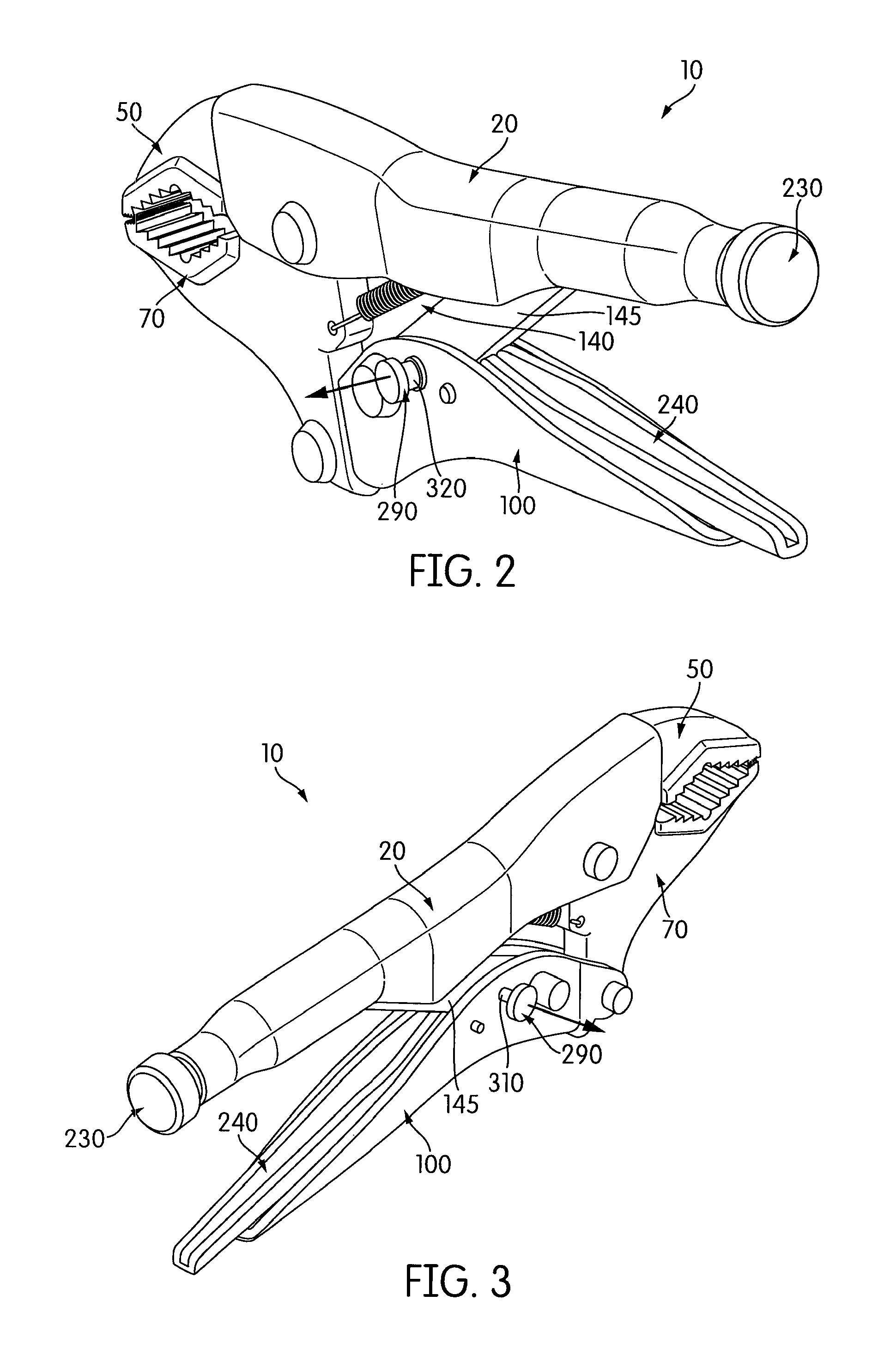

Endoscopic clip applying apparatus with improved aperture for clip release and related method

ActiveUS20050171560A1Increase widthFacilitated releaseSurgical forcepsWound clampsEndoscopic clippingSacroiliac joint

An apparatus for applying surgical clips includes a jaw assembly and a jaw opening member. The jaw assembly includes first and second opposing pivotable jaw members that define a variable-width jaw aperture therebetween for receiving a clip. The jaw opening member is movable into engagement with the first and second jaw members for increasing the width of the jaw aperture, thereby improving the release of a clip from the jaw assembly.

Owner:TELEFLEX MEDICAL INC

Endoscopic clip applying apparatus with improved aperture for clip release and related method

ActiveUS7585304B2Increase widthFacilitated releaseSurgical forcepsWound clampsEndoscopic clippingSurgical Clips

An apparatus for applying surgical clips includes a jaw assembly and a jaw opening member. The jaw assembly includes first and second opposing pivotable jaw members that define a variable-width jaw aperture therebetween for receiving a clip. The jaw opening member is movable into engagement with the first and second jaw members for increasing the width of the jaw aperture, thereby improving the release of a clip from the jaw assembly.

Owner:TELEFLEX MEDICAL INC

Surgical instrument control

ActiveUS20130267950A1Surgical instruments for heatingEndoscopic cutting instrumentsRange of motionInput control

In a surgical instrument, a reciprocating element controls jaw opening and closing as it moves over a first range of motion and cuts tissue clamped between the jaws as it moves over a second range of motion. A first control input controls the reciprocating element's motion over the first range of motion, and a second control input controls the reciprocating element's motion over the second range of motion. As a result, over control by the first control input will not result in inadvertent tissue cutting.

Owner:INTUITIVE SURGICAL OPERATIONS INC

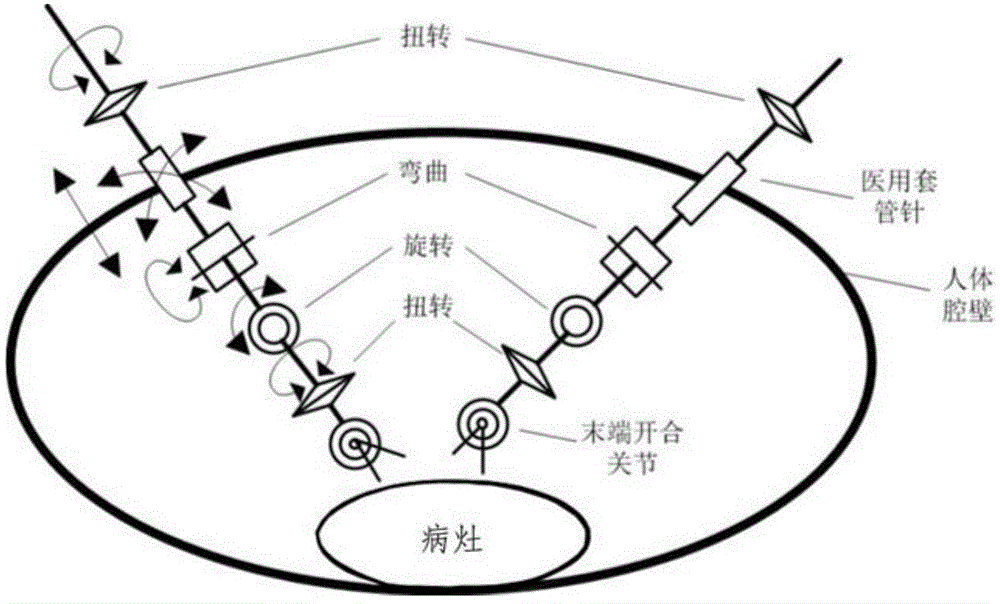

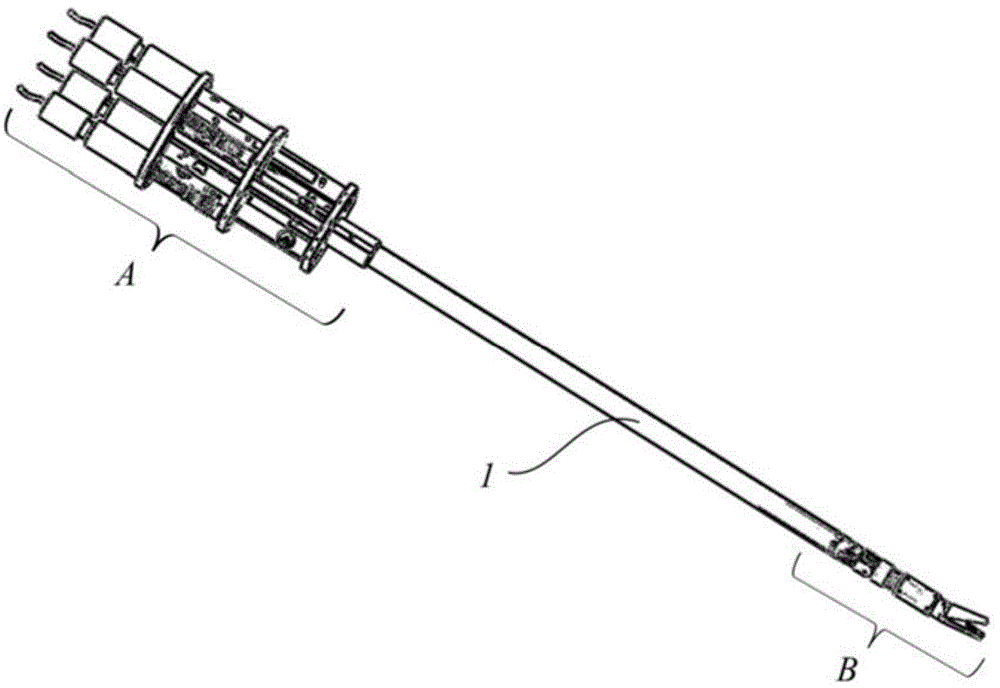

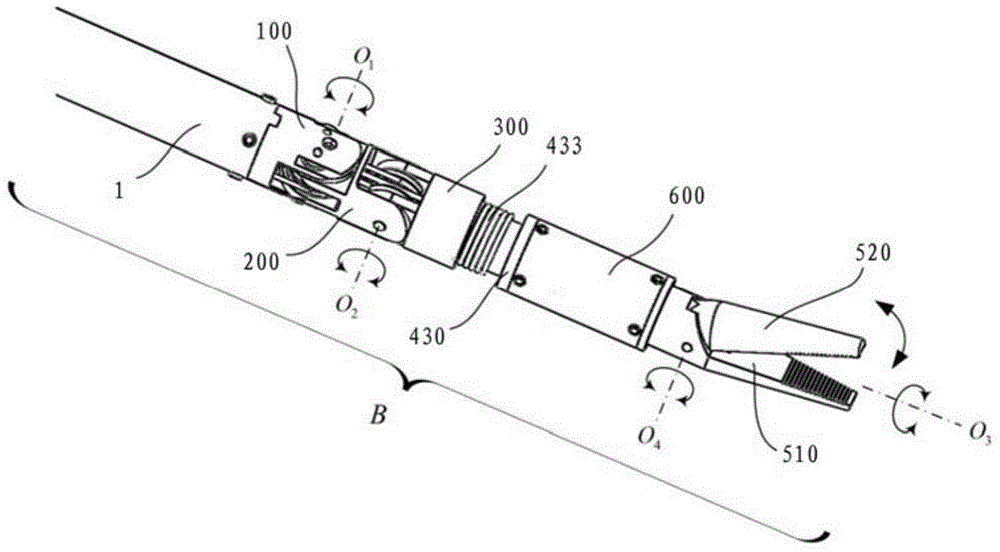

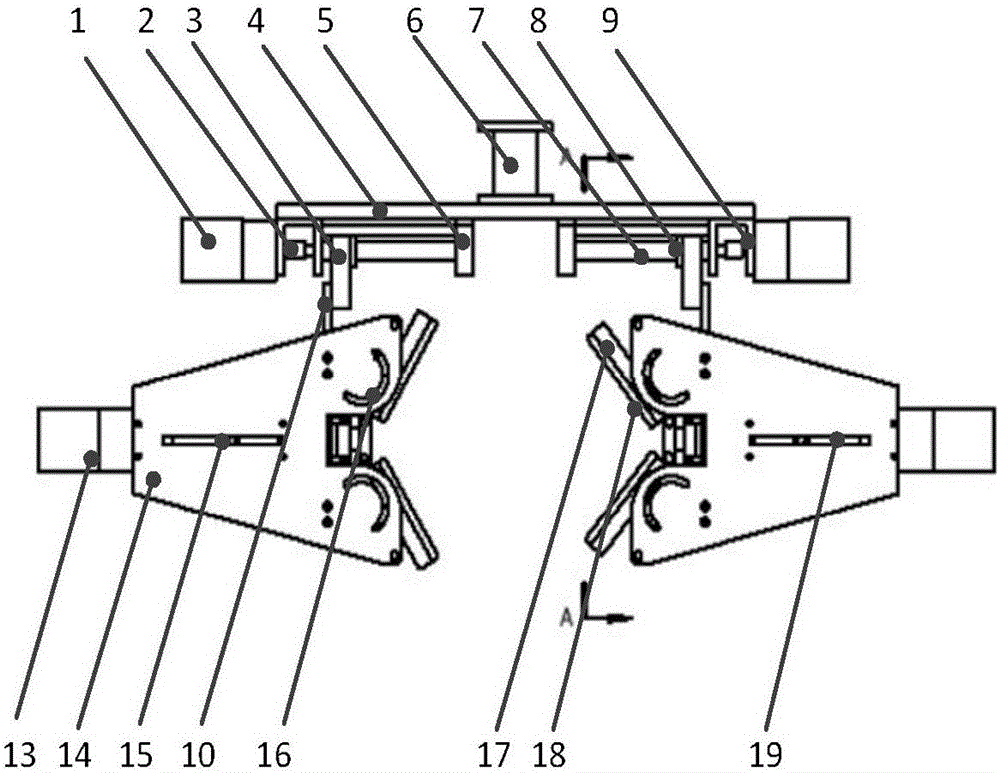

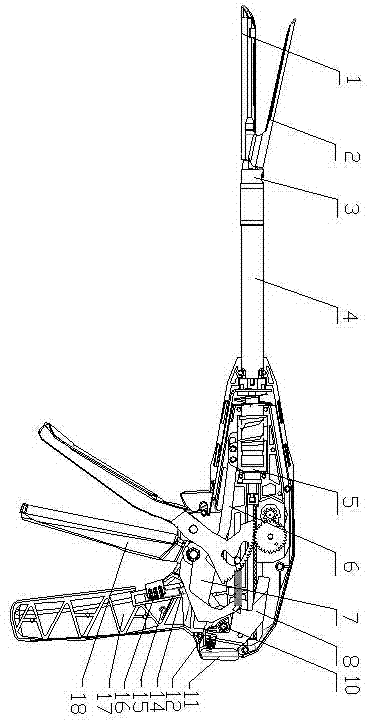

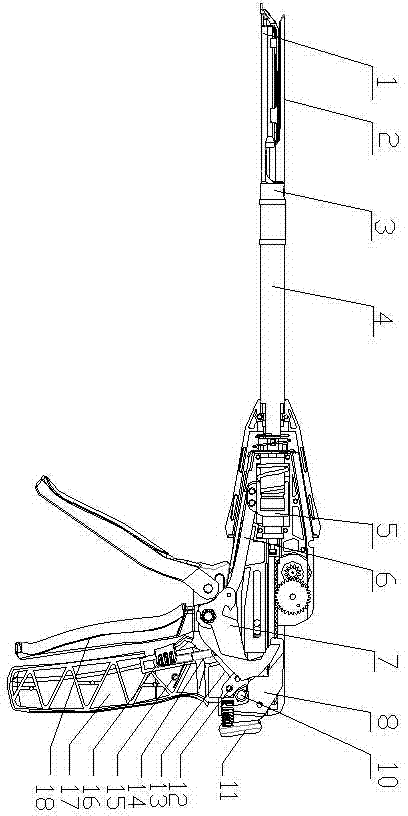

Surgical instrument tail end structure of minimally invasive surgery robot

ActiveCN104434318AAchieving bending freedomAchieving Torsional FreedomDiagnosticsSurgeryLess invasive surgeryEngineering

The invention provides a surgical instrument tail end structure of a minimally invasive surgery robot. A first joint rotating base back end is fixedly connected with a connecting cylinder front end of a surgical instrument, a first joint rotating base front end is hinged to a second joint rotating base back end, and accordingly a bending freedom degree is achieved. A second joint rotating base front end and a third joint rotating base back end are hinged, and a rotating freedom degree is achieved. A third joint rotating shaft back end is arranged at a third joint rotating base front end through a bearing to achieve a torsion freedom degree. The back end of a jaw fixing part is fixedly connected with the front end of a third joint rotating shaft, a jaw moving piece is hinged to the jaw fixing part, and accordingly a jaw opening freedom degree is achieved. The four freedom degrees are controlled by a steel wire rope connected into a cylinder, the four freedom degrees simulate moving functions of all doctor arm joints of shoulder joints, elbow joints and wrist joints, and accordingly the safety of minimally invasive surgery is effectively improved.

Owner:SHANGHAI JIAO TONG UNIV

Surgical instrument control

ActiveUS9144456B2Surgical instruments for heatingEndoscopic cutting instrumentsRange of motionInput control

In a surgical instrument, a reciprocating element controls jaw opening and closing as it moves over a first range of motion and cuts tissue clamped between the jaws as it moves over a second range of motion. A first control input controls the reciprocating element's motion over the first range of motion, and a second control input controls the reciprocating element's motion over the second range of motion. As a result, over control by the first control input will not result in inadvertent tissue cutting.

Owner:INTUITIVE SURGICAL OPERATIONS INC

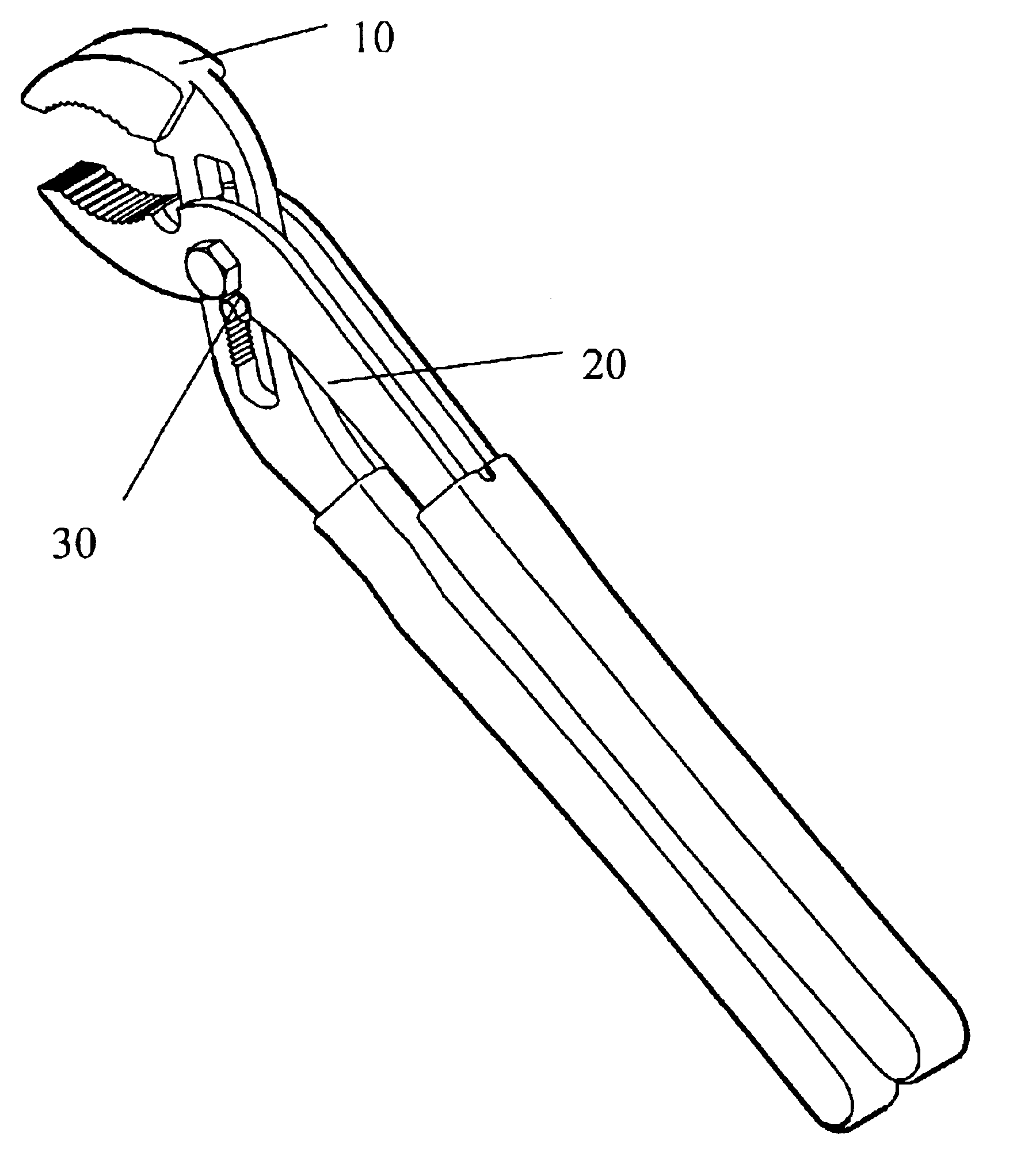

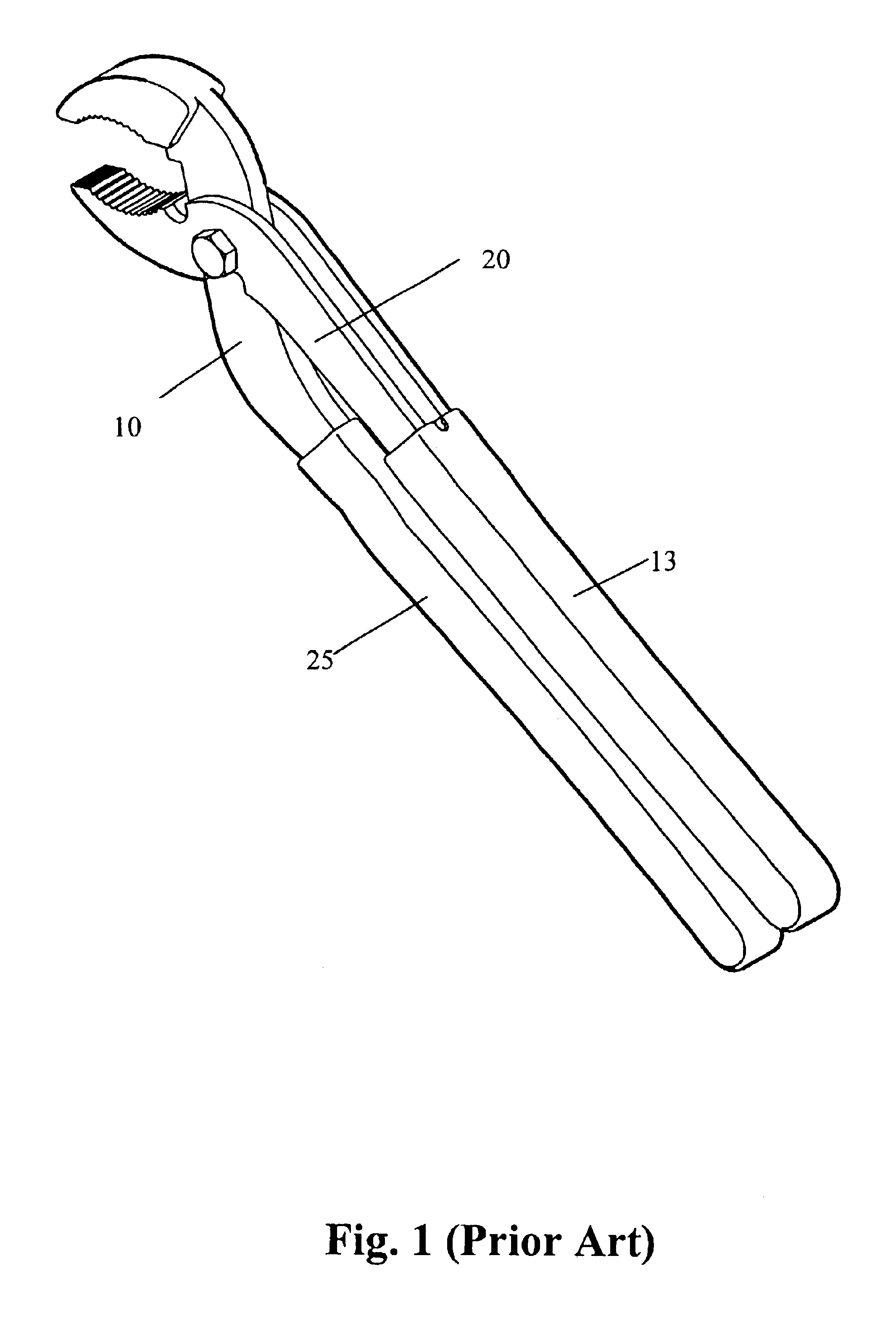

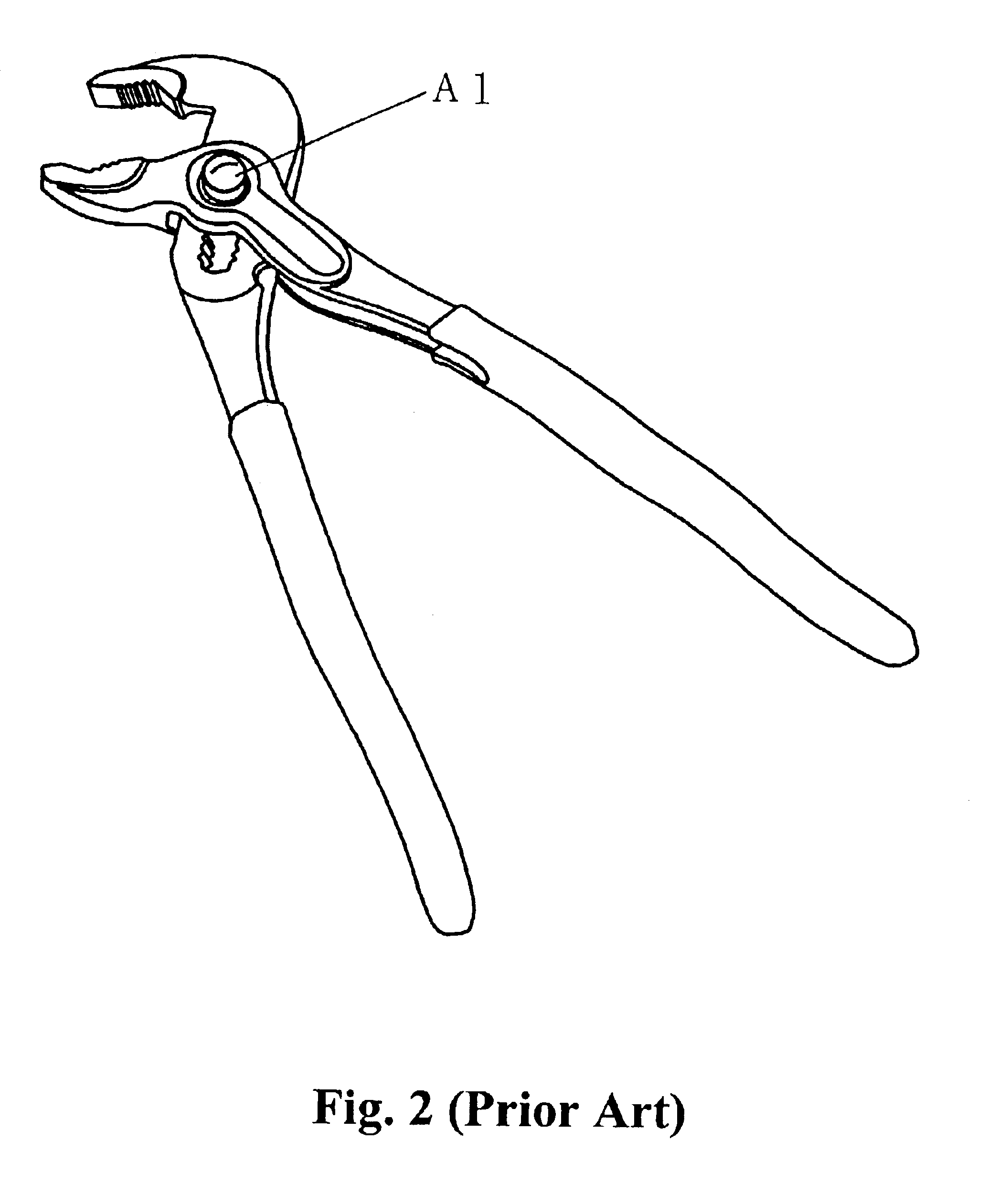

Pliers with movable joint

A pair of pliers mainly includes a first body part having predetermined length, thickness, and shape; a second body part having length, thickness, and shape adapted to work with that of the first body part; and a joint pivotally connecting the first and the second body part together at a predetermined position. The joint is movable within a defined range to enable quick adjustment of jaw opening of the pliers, and is locked in place once it is moved to a desired position.

Owner:KING LUGGER

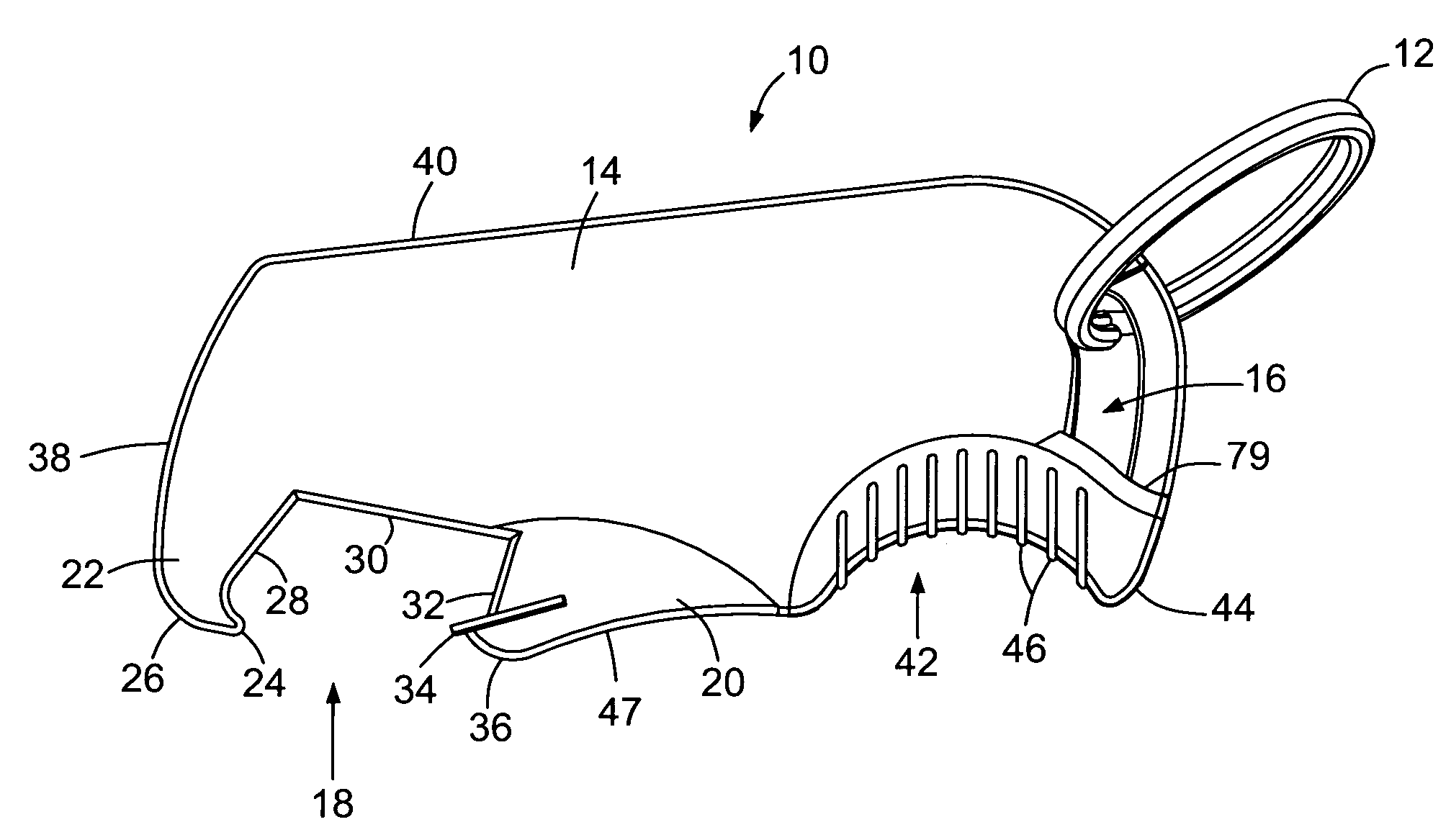

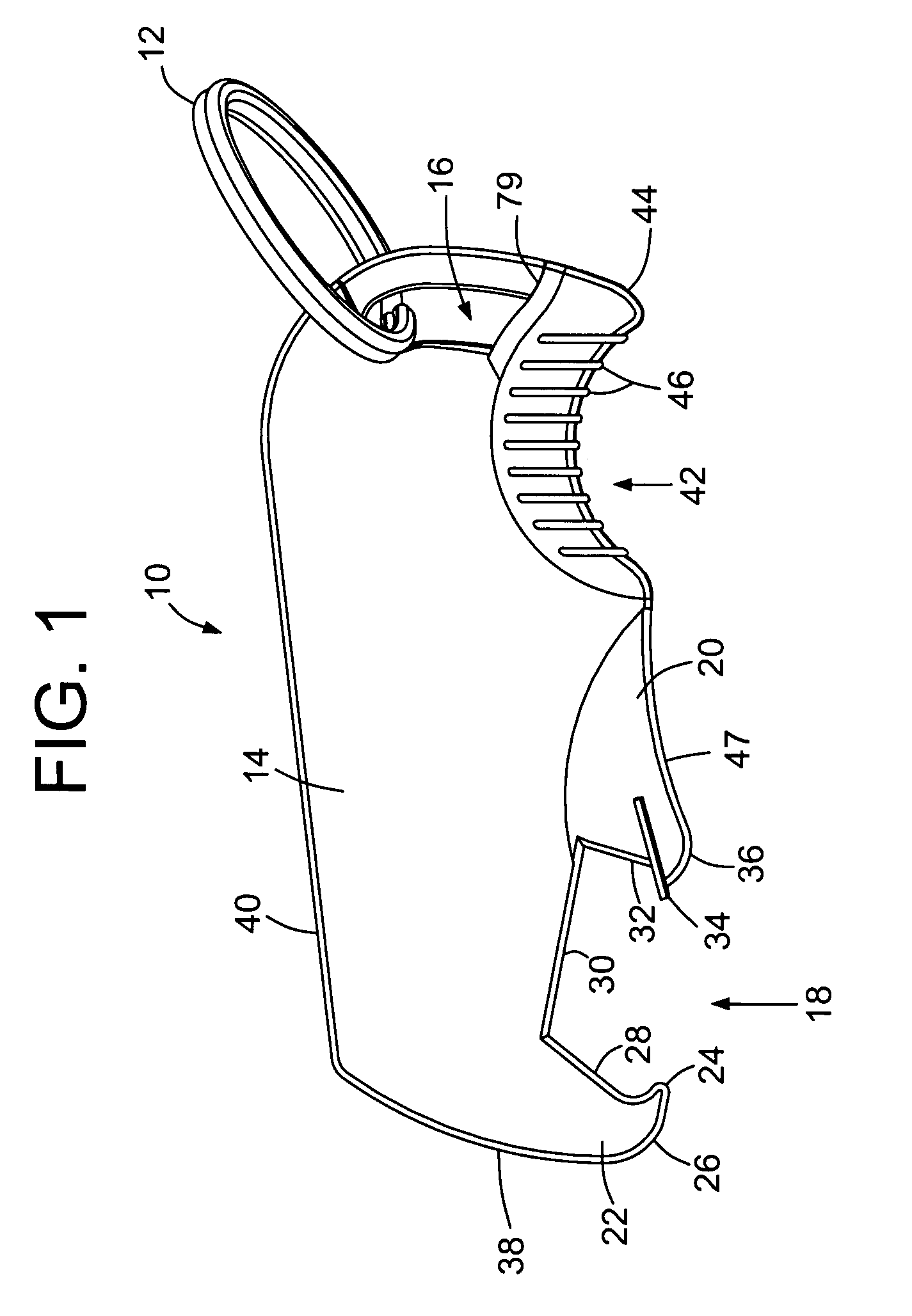

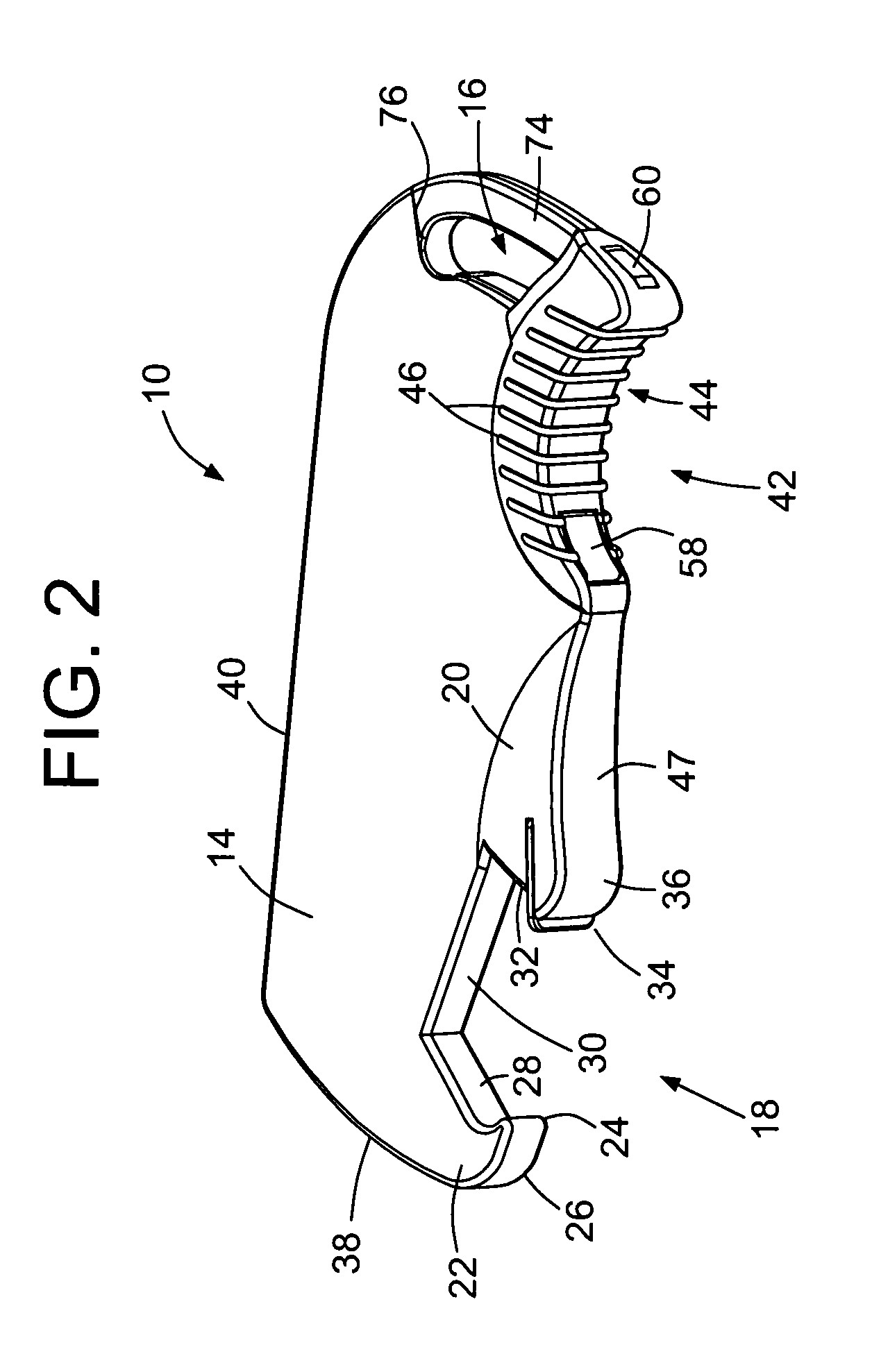

Bottle opener

A compact, ergonomic, pocket-sized bottle opener having a thin, generally flat body. The bottom edge of the body includes a jaw opening and at least one area for receiving a lifting finger. A plug of resiliently yielding material is mounted in the finger-receiving area to cushion the lifting finger. A hook at the forward end of the jaw opening forms a fulcrum point for engaging the top of the bottle cap. The hook also serves to lift pull-tabs on cans. An opening at the rear of the body holds a key ring. The key ring can be slipped into the opening during assembly by flexing the leg so as to open a slot that separates the distal end of the leg from the body. The cushioning plug mounts over both the distal end of the leg and the lower edge of the body so as to hold the leg in place after the ring has been installed. The two sides of the body form broad, generally flat display surfaces for application of logos, advertising, or other information. The body is preferably formed of strong, molded plastic, with a metal insert being installed in the jaw opening for engaging the edges of bottle caps.

Owner:BOOK STEVEN C

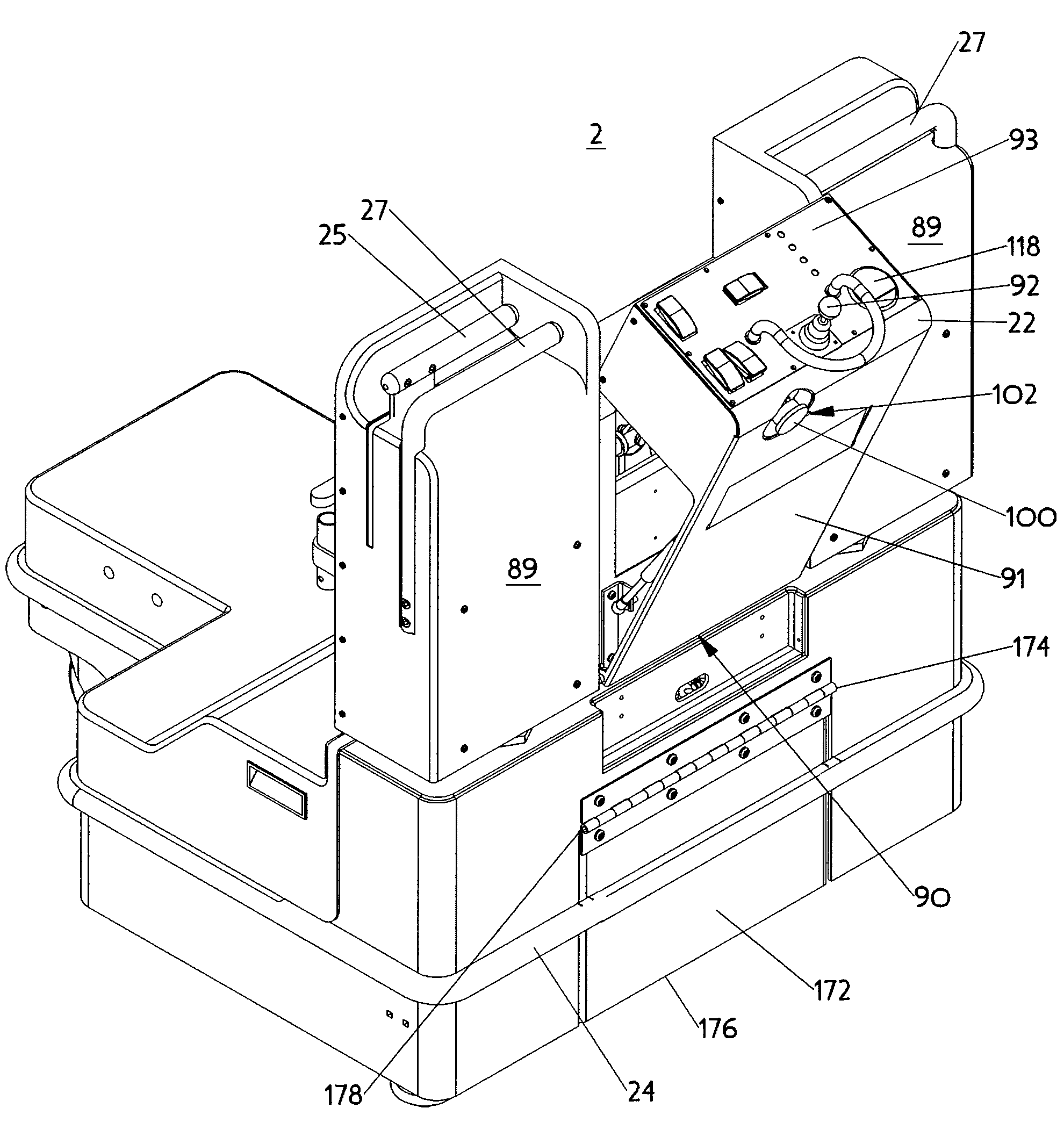

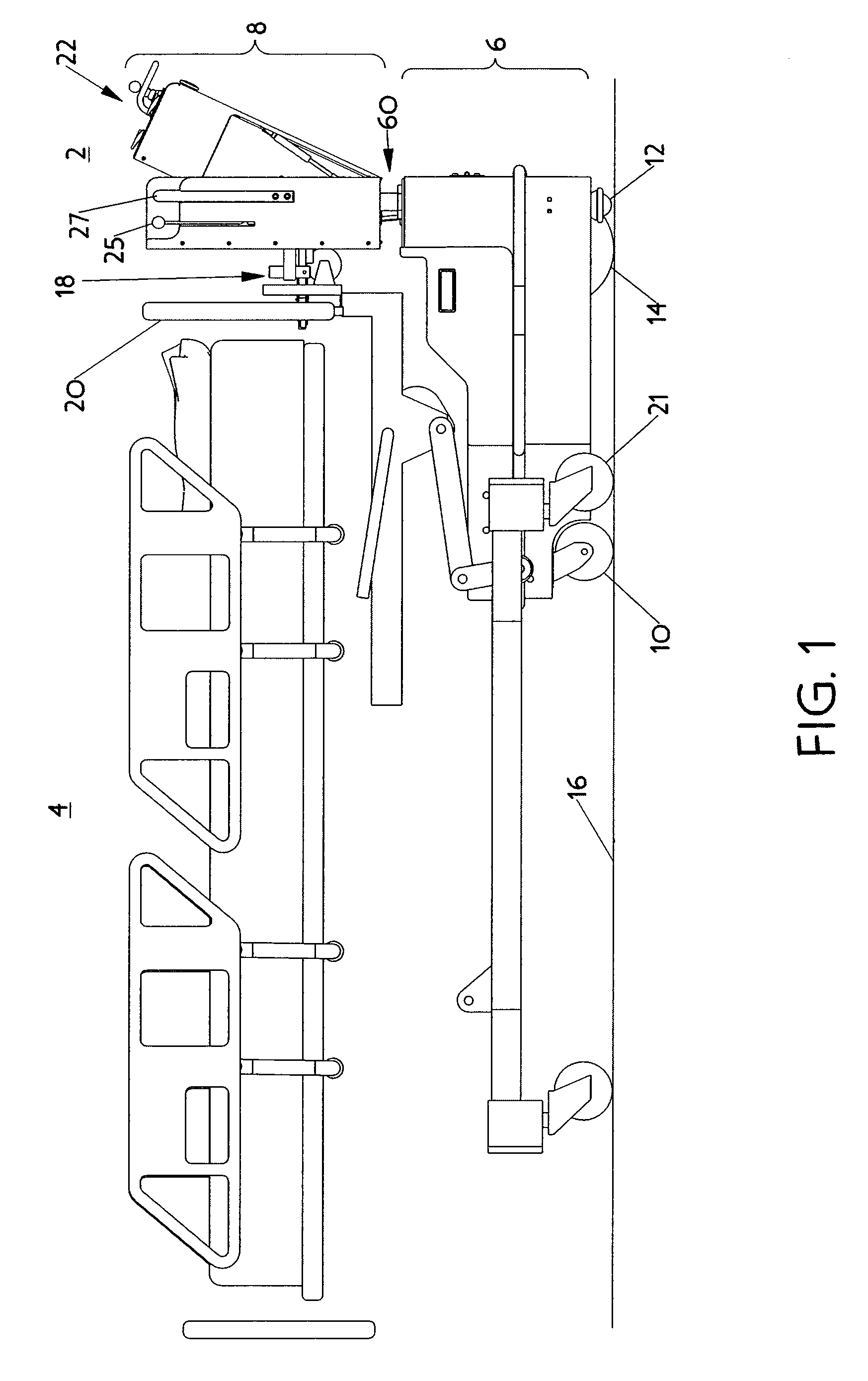

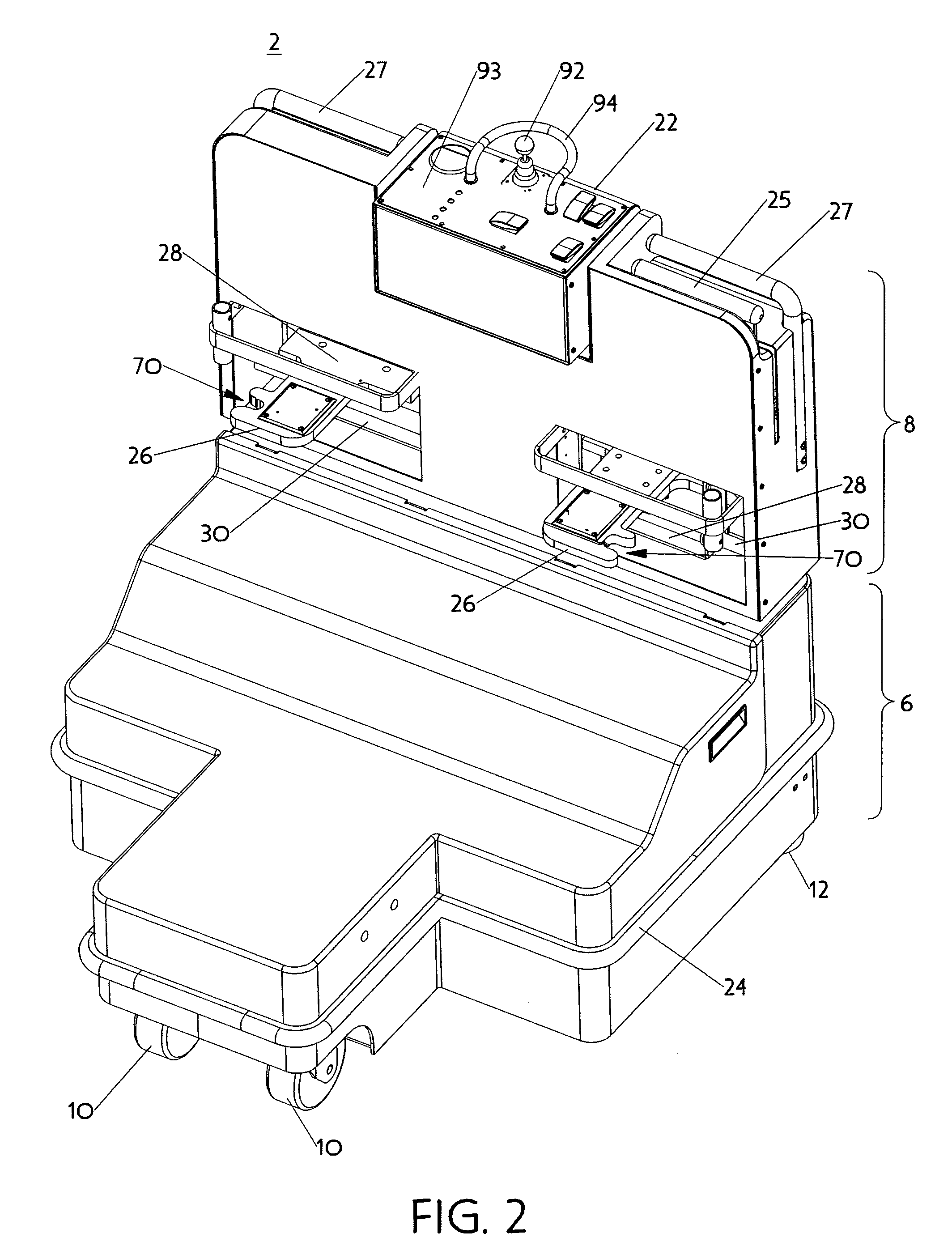

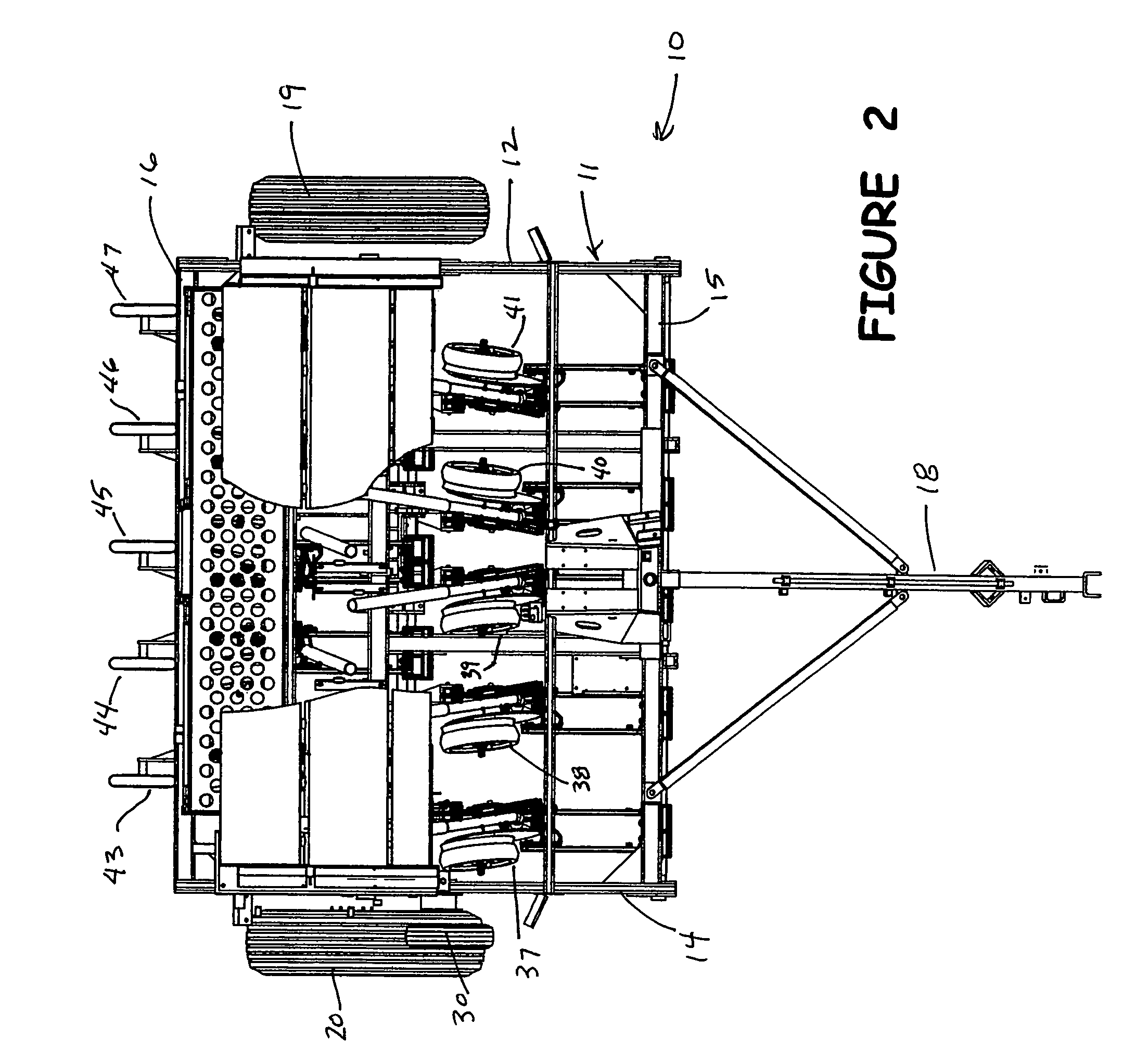

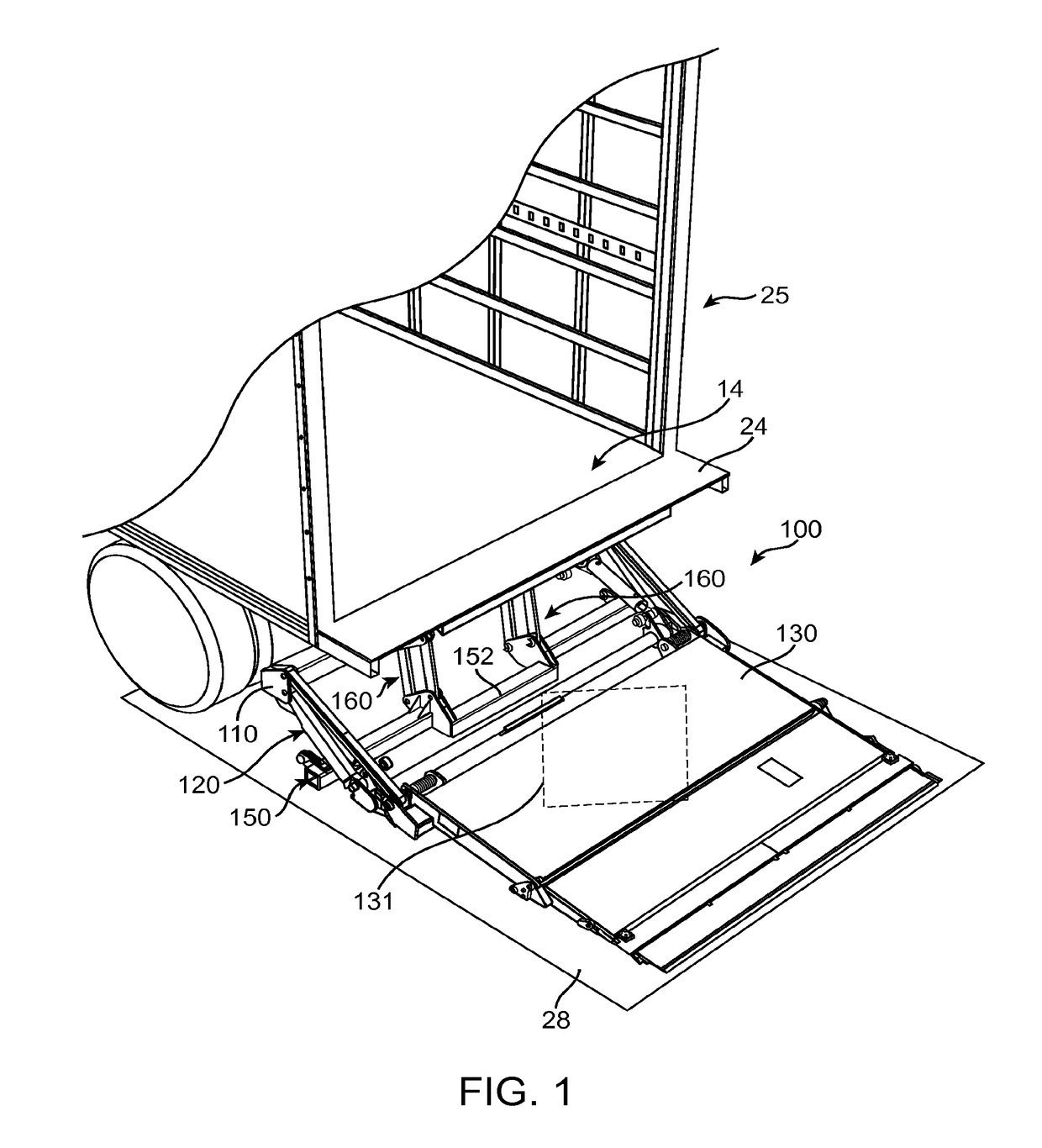

Bed transfer system

The present invention is a powered hospital bed mover or bed transfer system. The bed mover includes a bed attachment mechanism that is vertically displaceable relative to a base that includes an electrically powered drive wheel and a pair of support castors. The attachment mechanism includes a pair of horizontally oriented jaws with jaw openings that face away from each other. Each jaw includes a contact switch in its bottom surface and a contact switch in its jaw opening. The contact switches indicate to the mover and its user that the mover is properly engaged with the frame of a hospital bed. The jaws are horizontally displaceable and diverge from each other to engage vertical frame members of a hospital bed. A control panel has a joystick adapted to control the speed and direction of travel for the mover. The control panel also has controls for actuating the jaws, changing the elevation of the attachment mechanism, and locking at least one of the support castors. The control panel is hinged to the mover such that it may pivot outwardly away from the mover. A hinged panel also is provided to allow the pivoting of the drive wheel about a vertical pivot axis.

Owner:DANE INDS

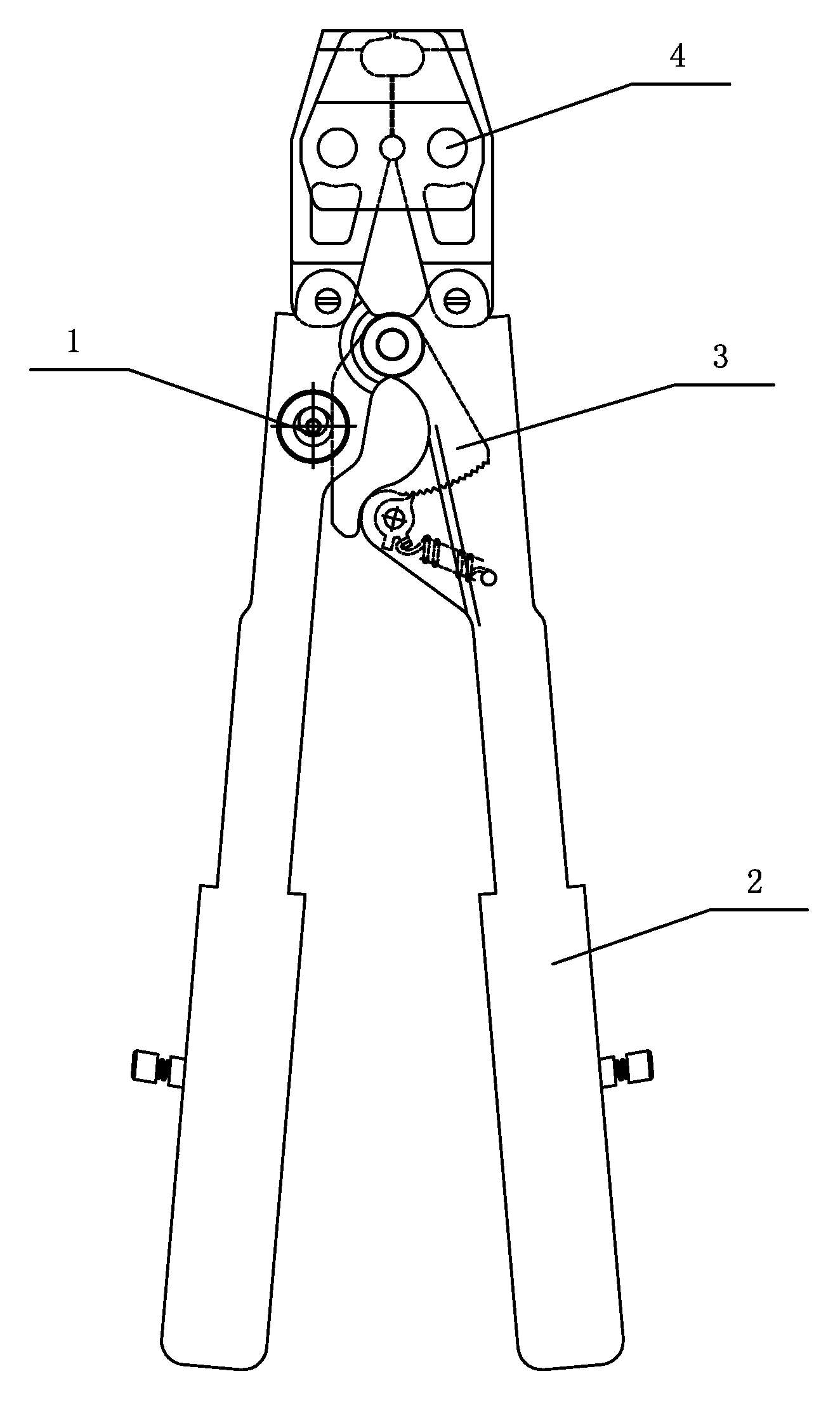

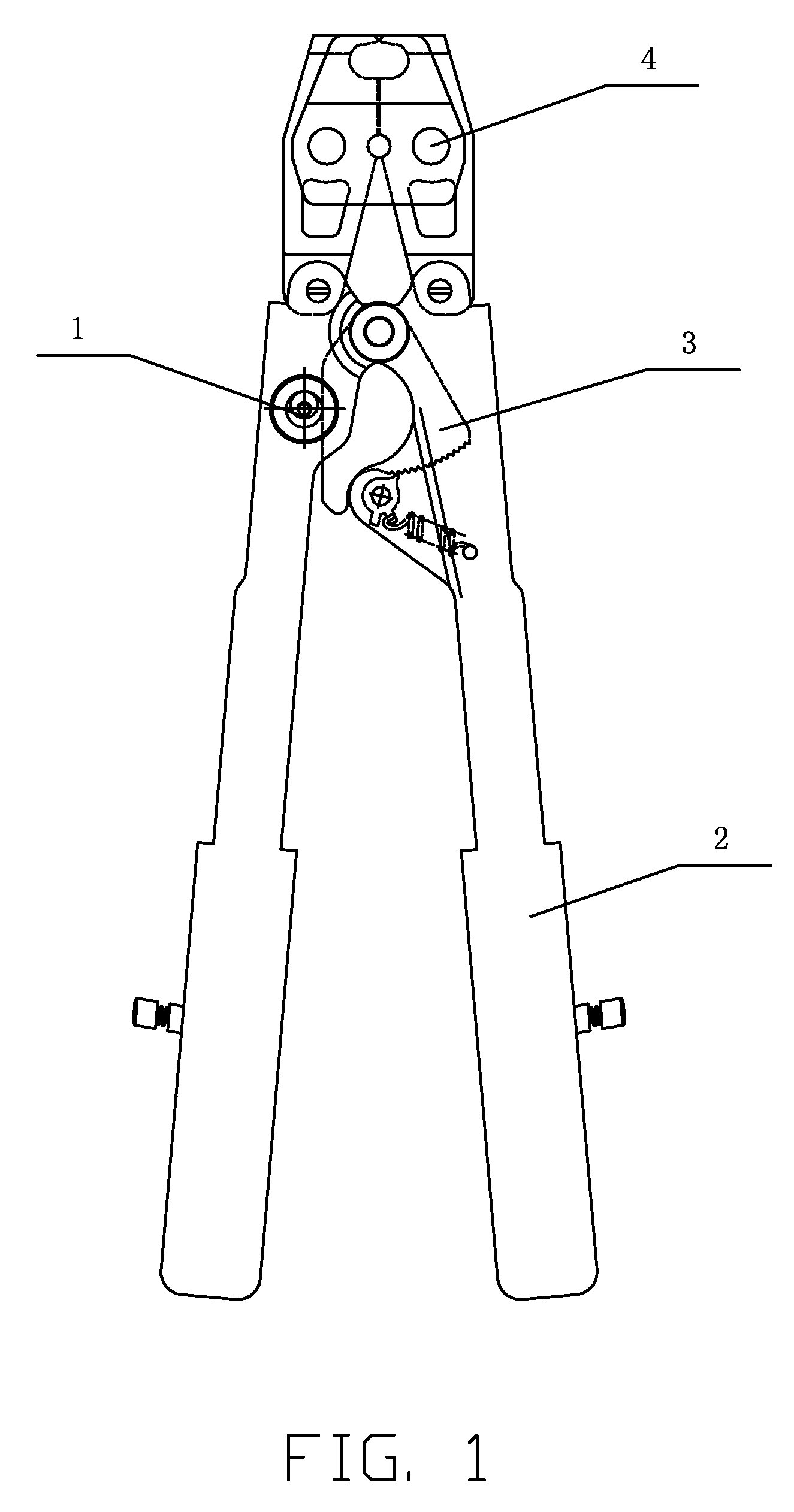

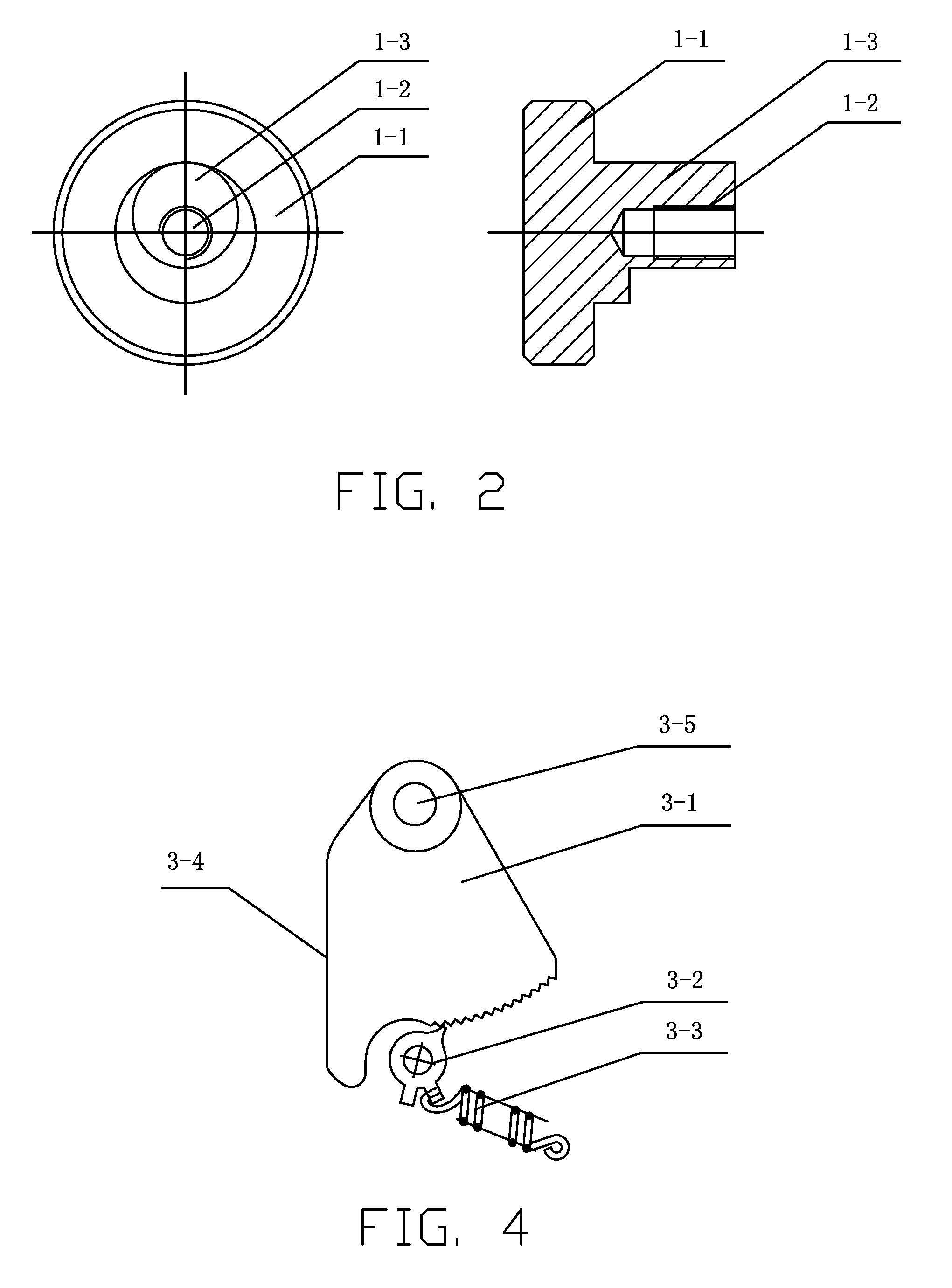

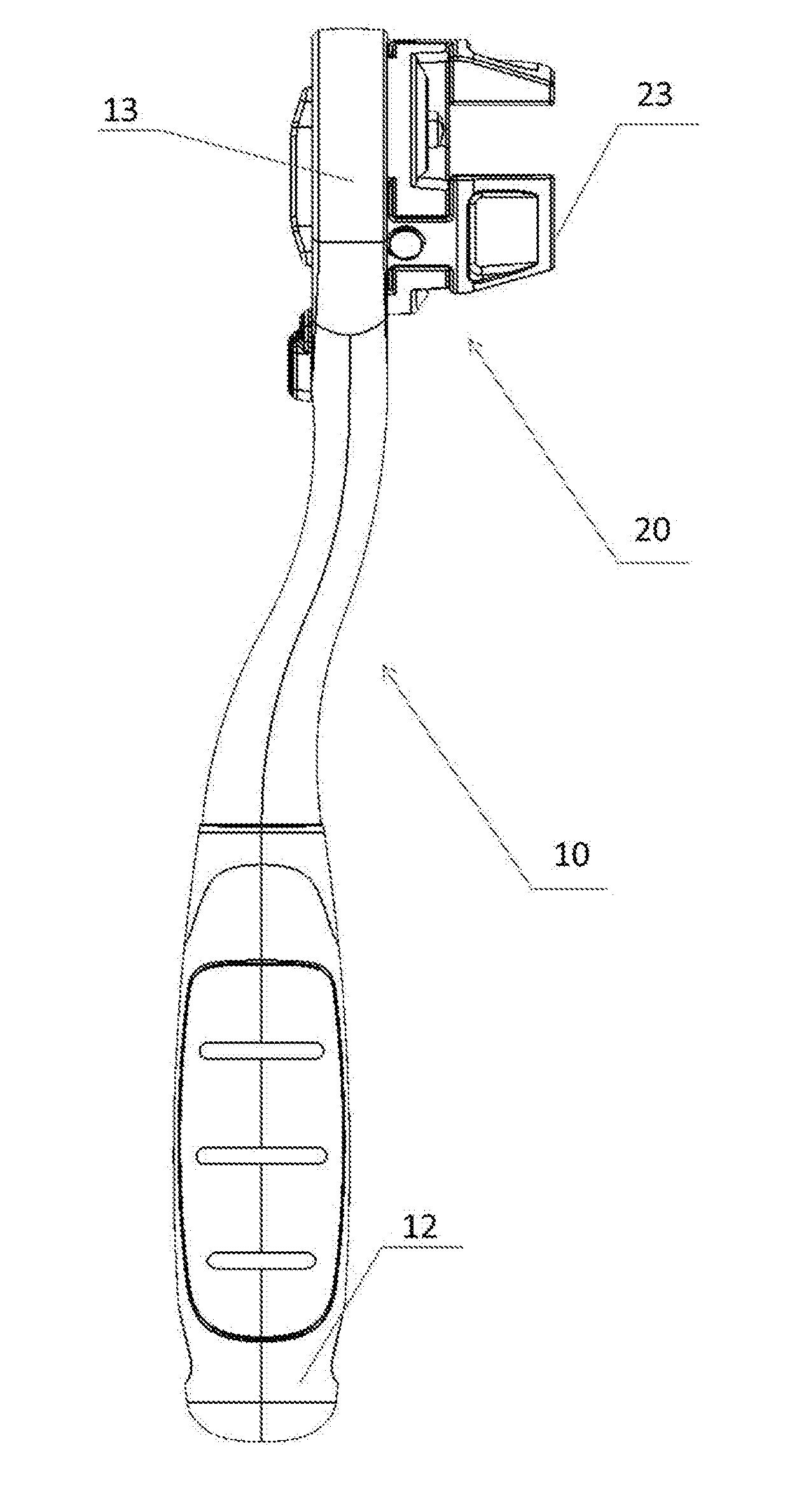

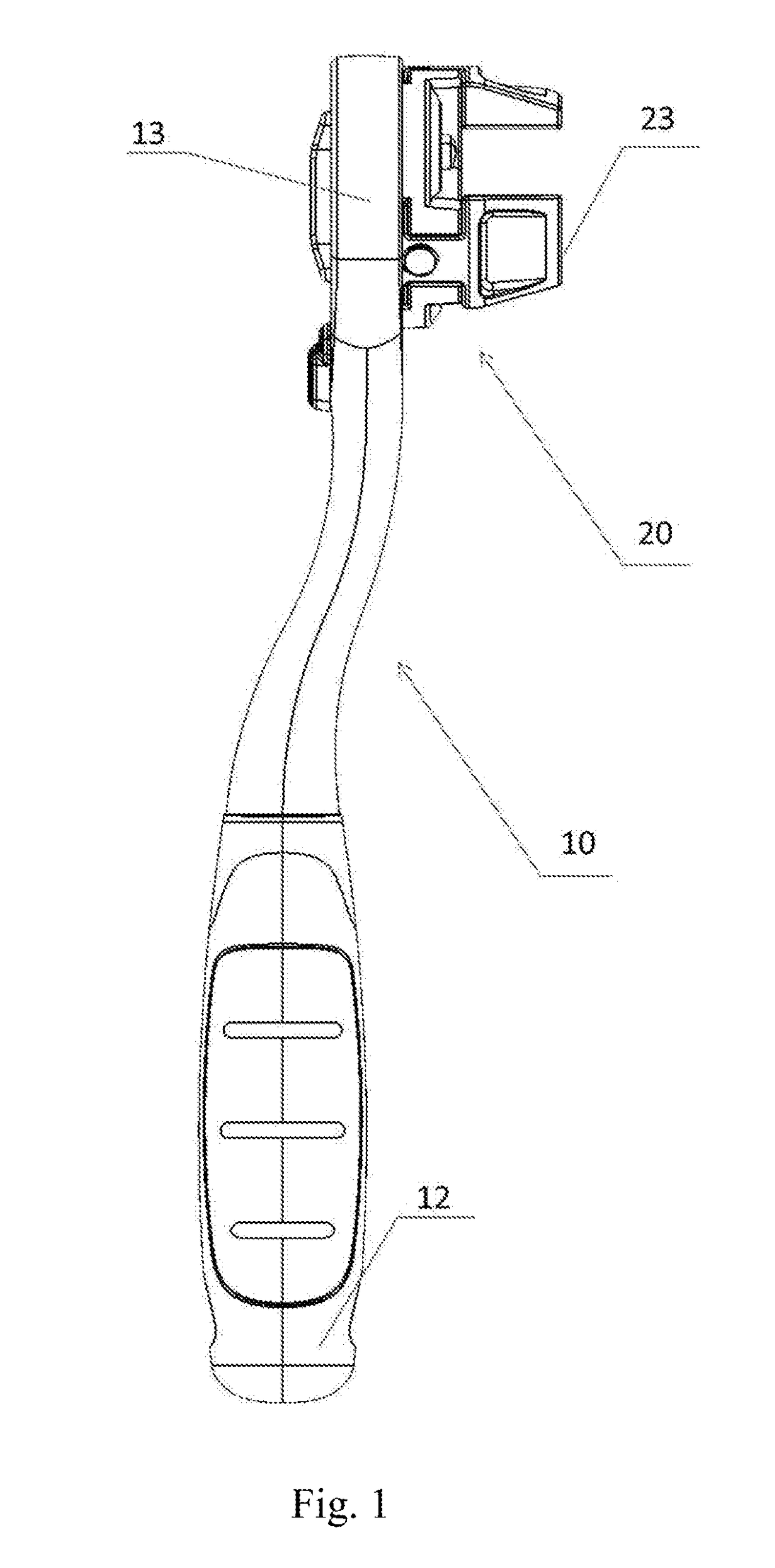

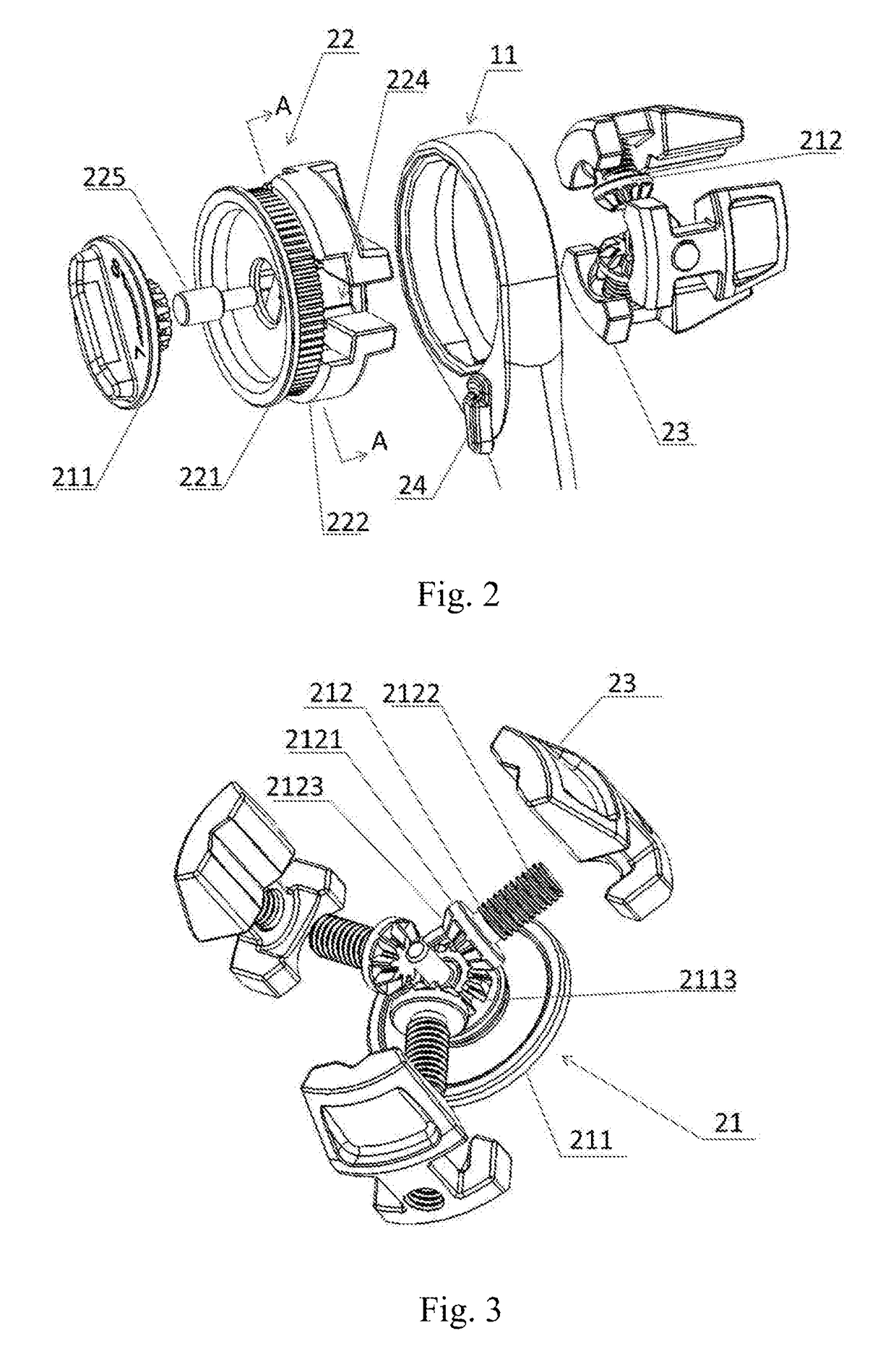

Ratchet pliers with adjustable jaw

Owner:LINK TECH TIANJIN METAL PROD

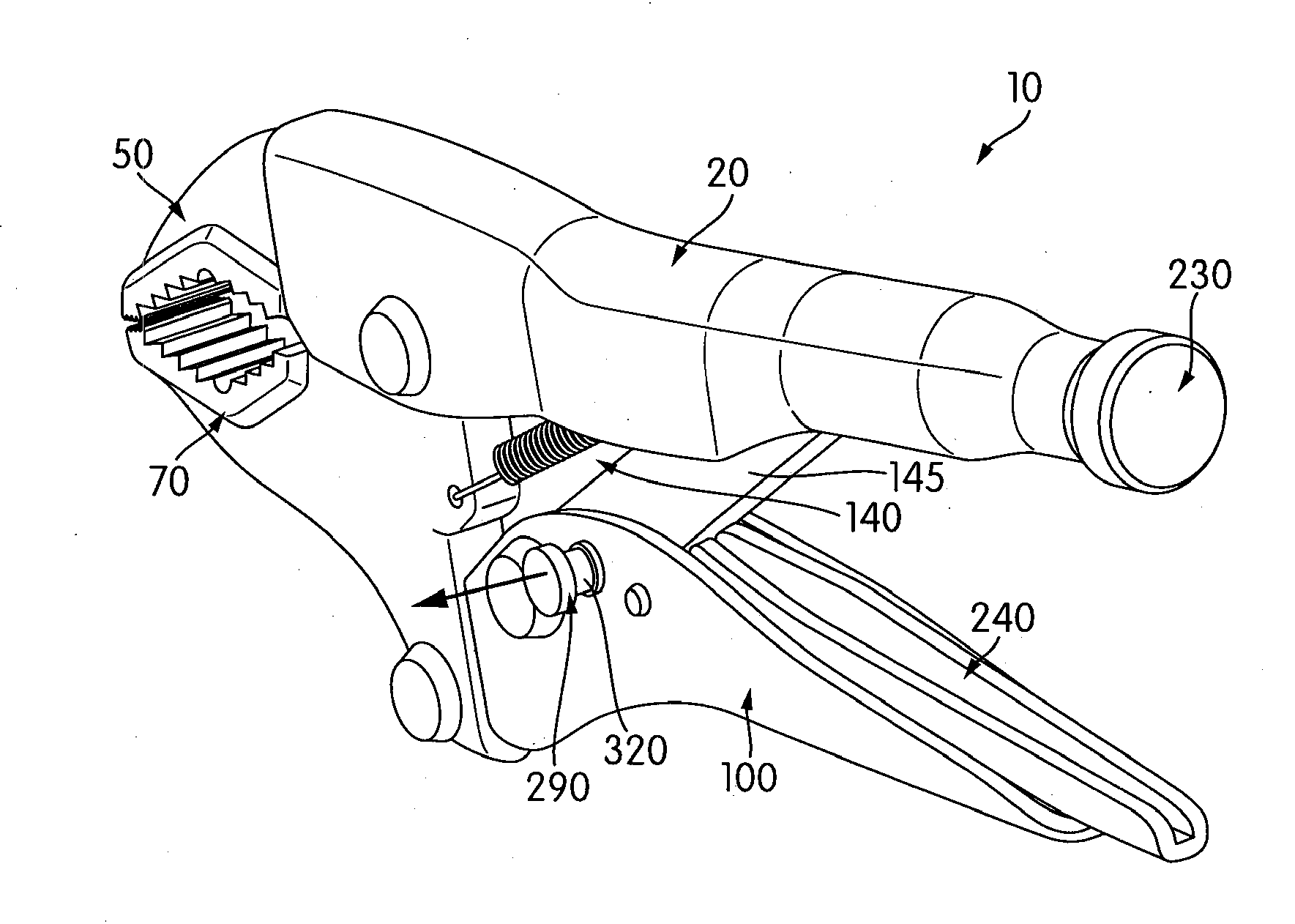

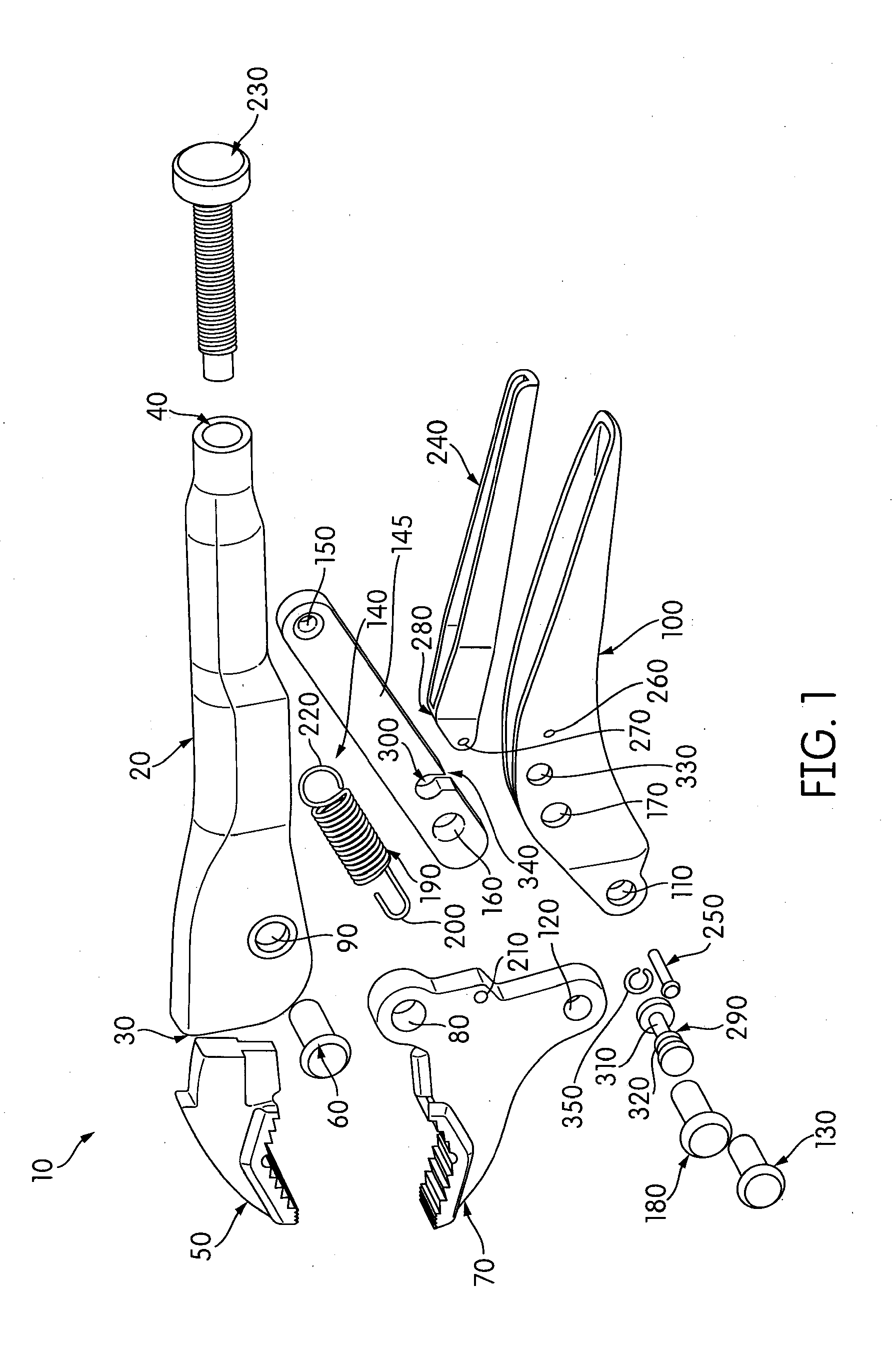

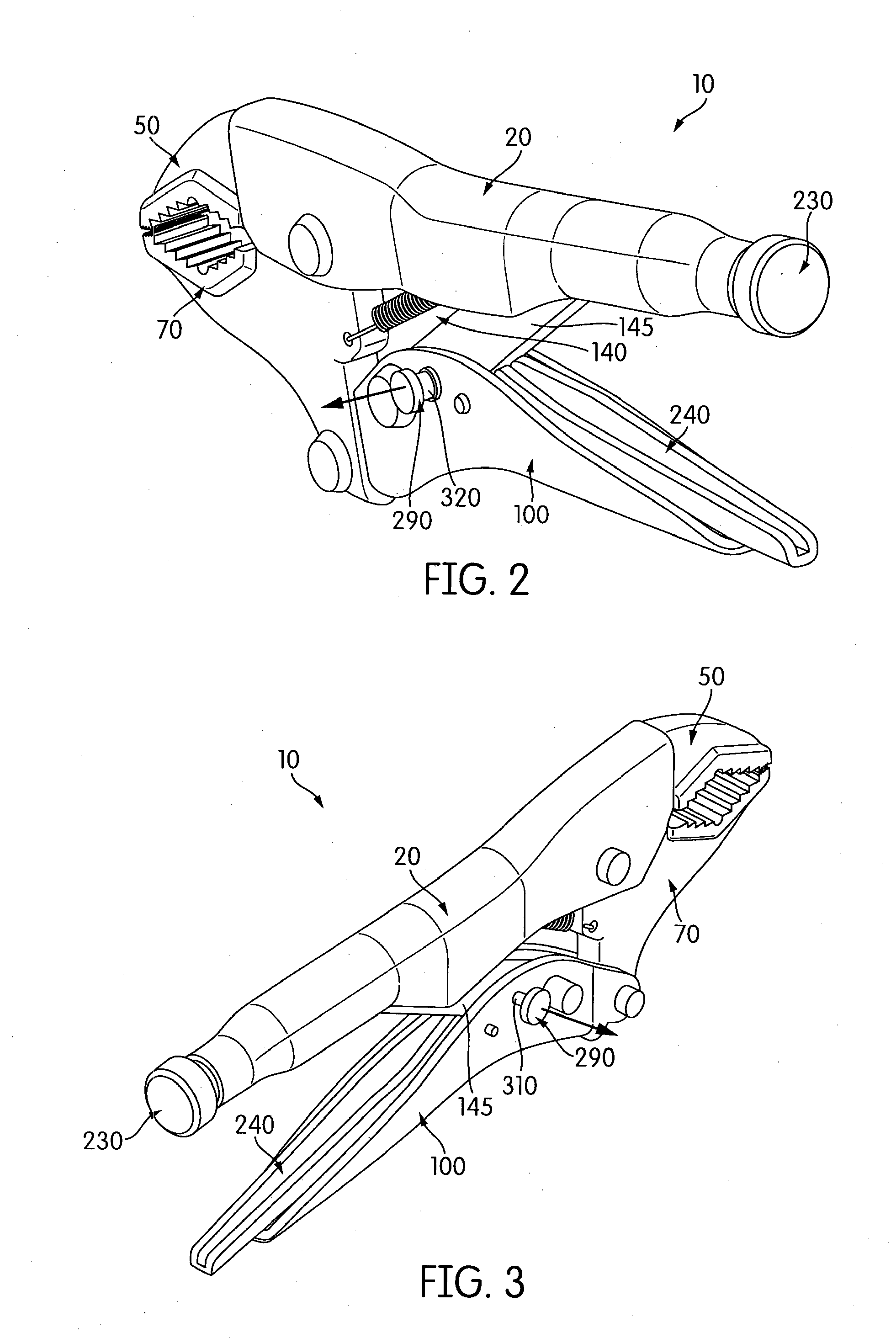

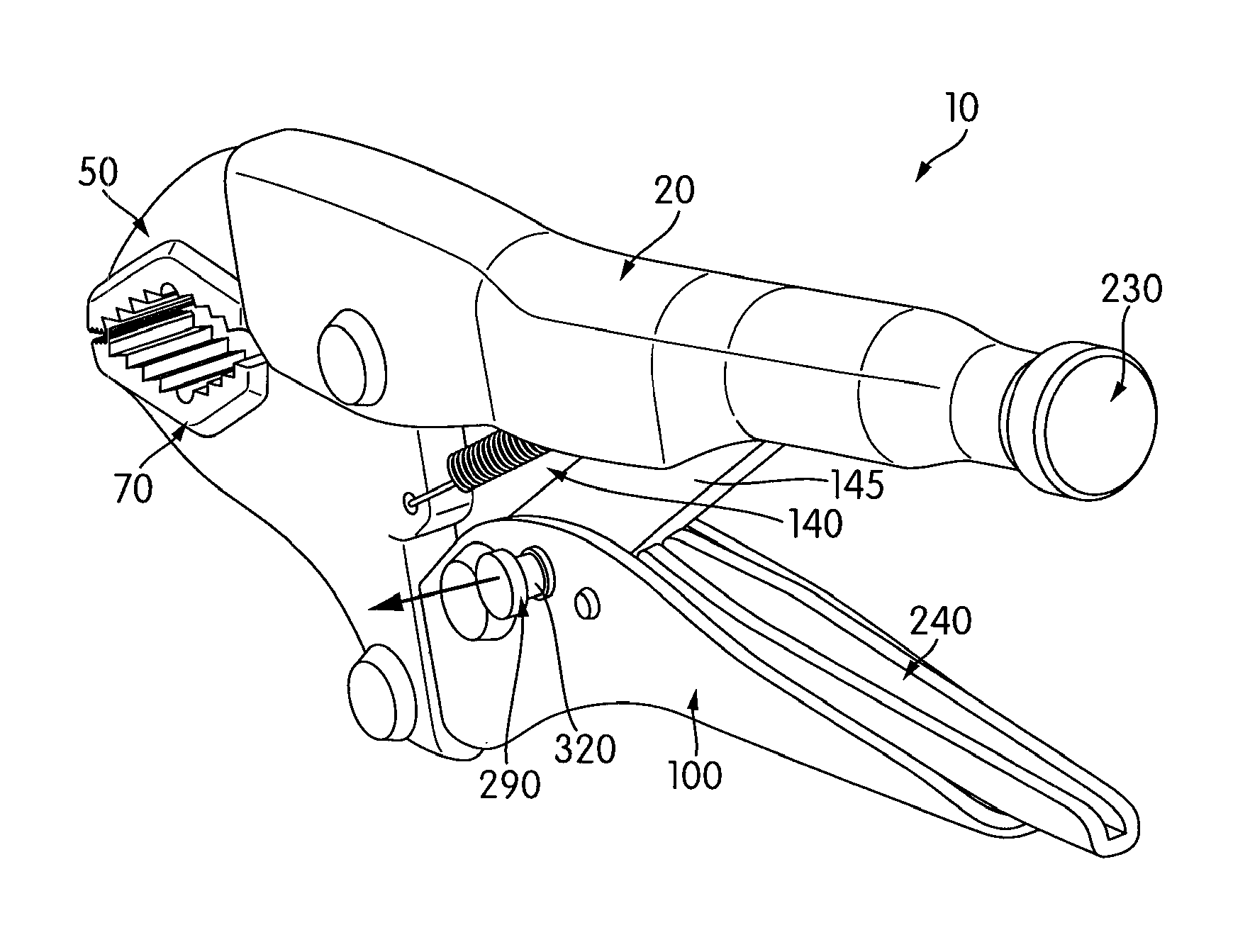

Locking pliers with handle locking mechanism

Pliers include upper structure including an upper jaw and handle extending therefrom, and lower structure including a lower jaw and handle. The lower jaw may pivot relative to the upper jaw, and the lower handle may pivot relative to the lower jaw. An overcenter linkage operatively connects between the upper and lower structure, biasing the lower handle and jaw away from the upper handle and jaw, respectively, when in a jaw-opening position, and enabling the lower jaw and handle to be retained in a closed configuration when the linkage is in a jaw-closing position. A lock member is movable between a locking configuration preventing pivoting of the lower handle from the closed configuration and retaining the jaws in a closed position, and a release configuration enabling the lower handle to be moved away from the closed configuration, allowing the jaws to move to an open position.

Owner:STANLEY WORKS THE

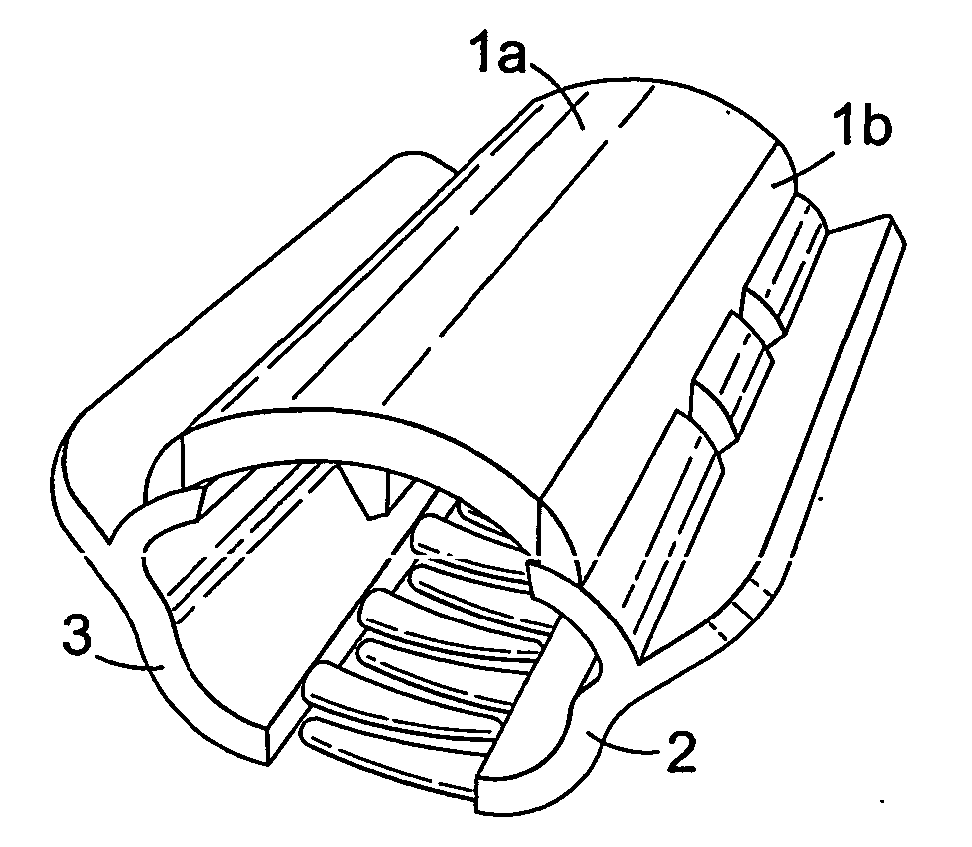

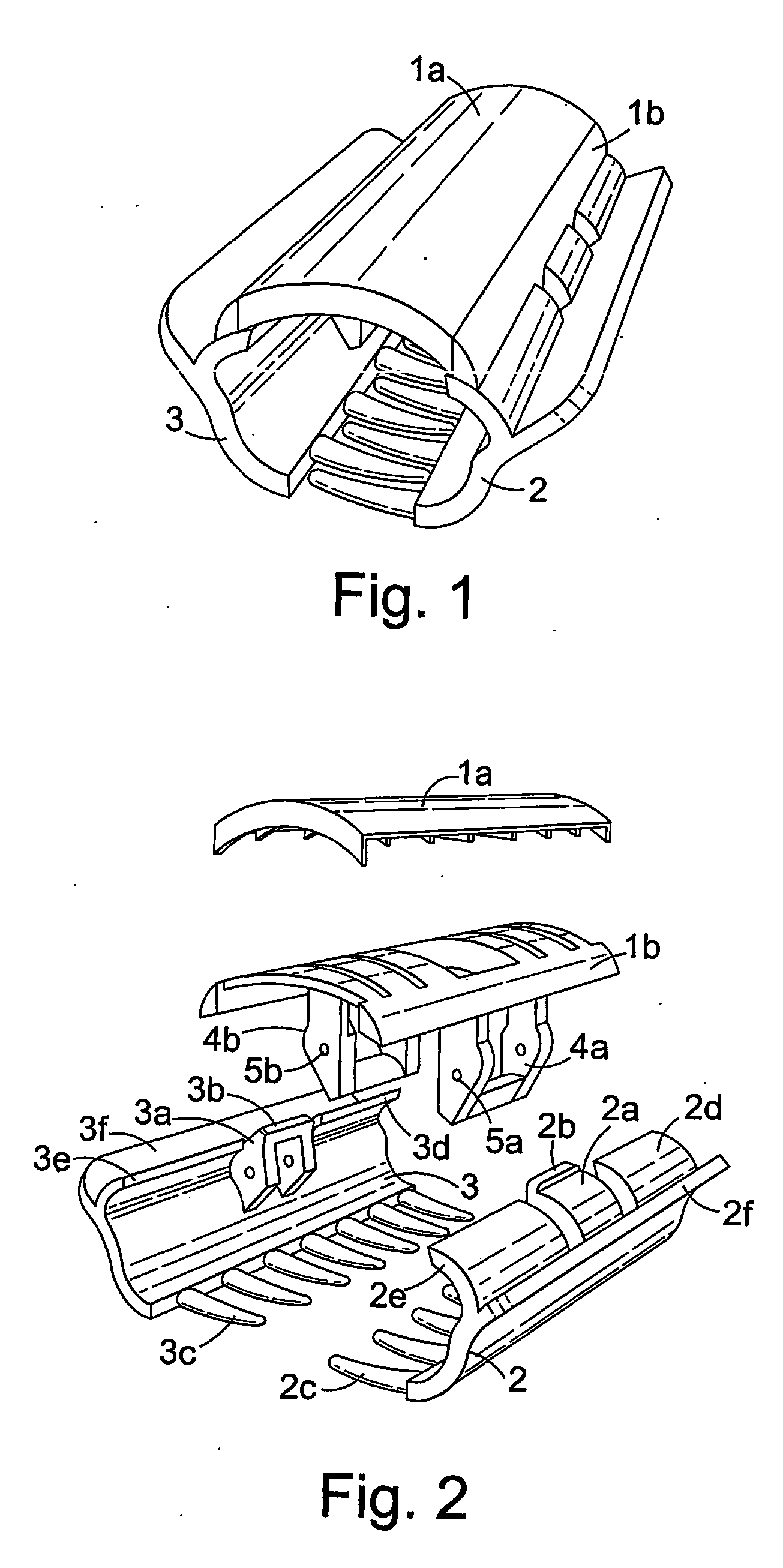

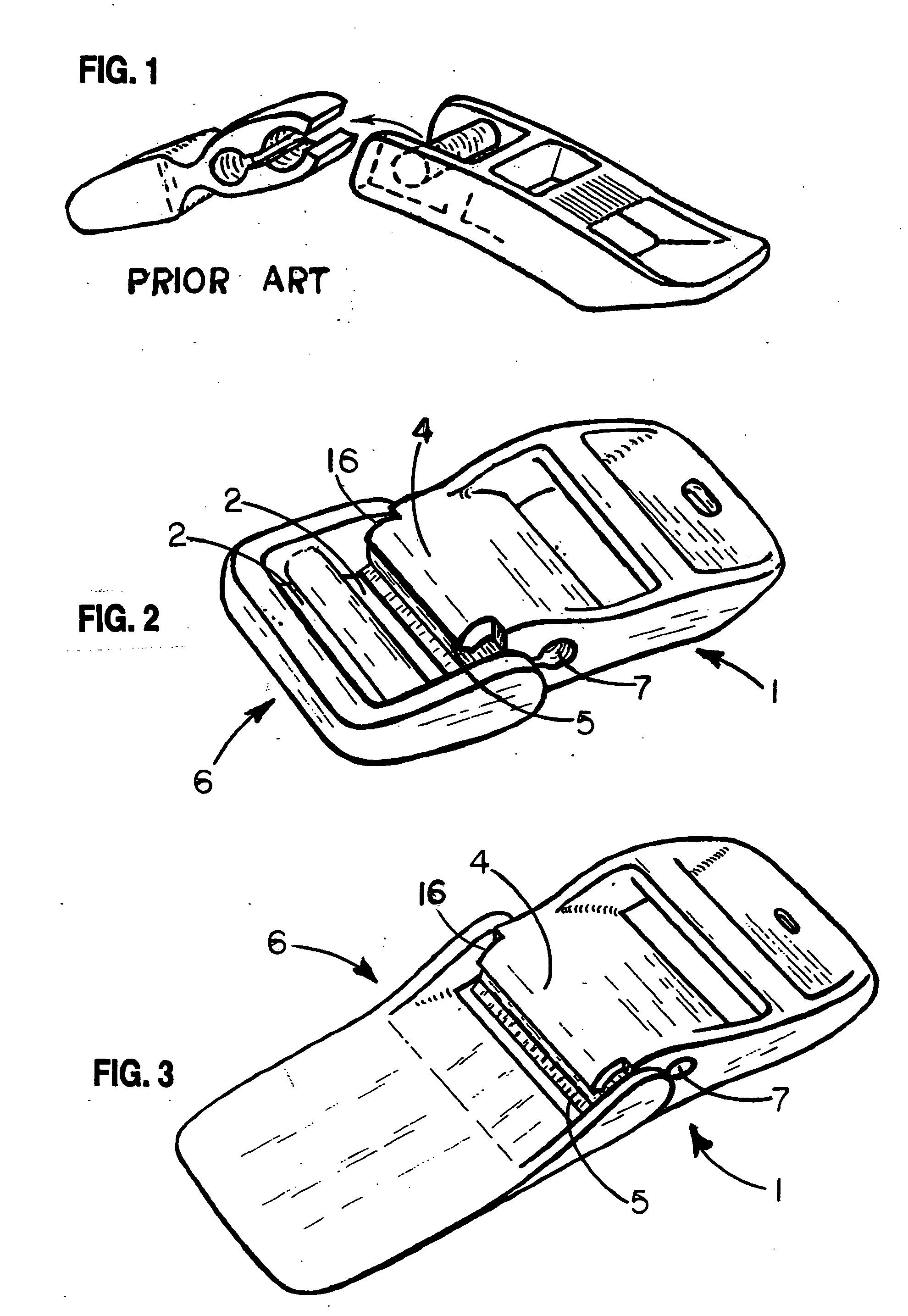

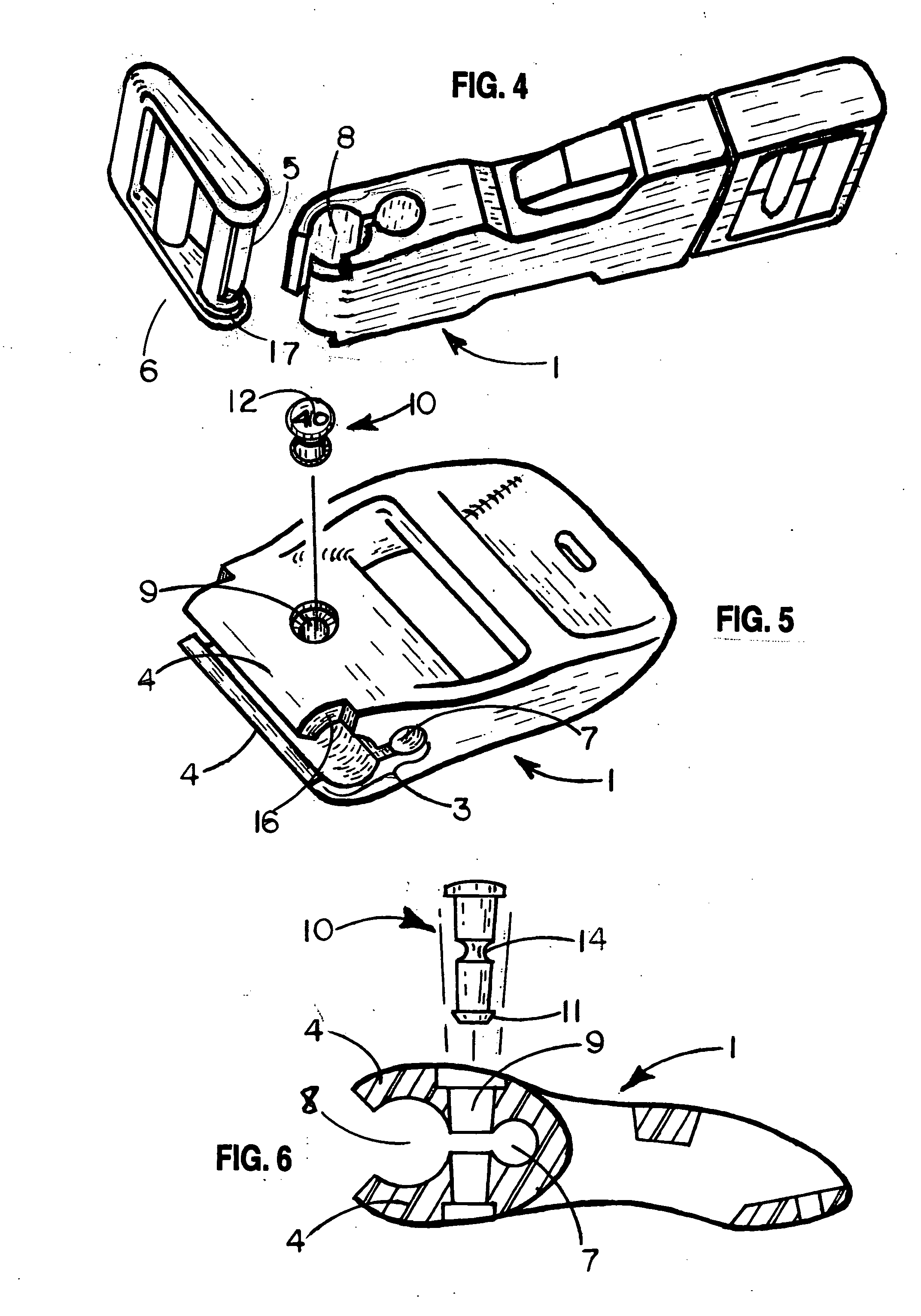

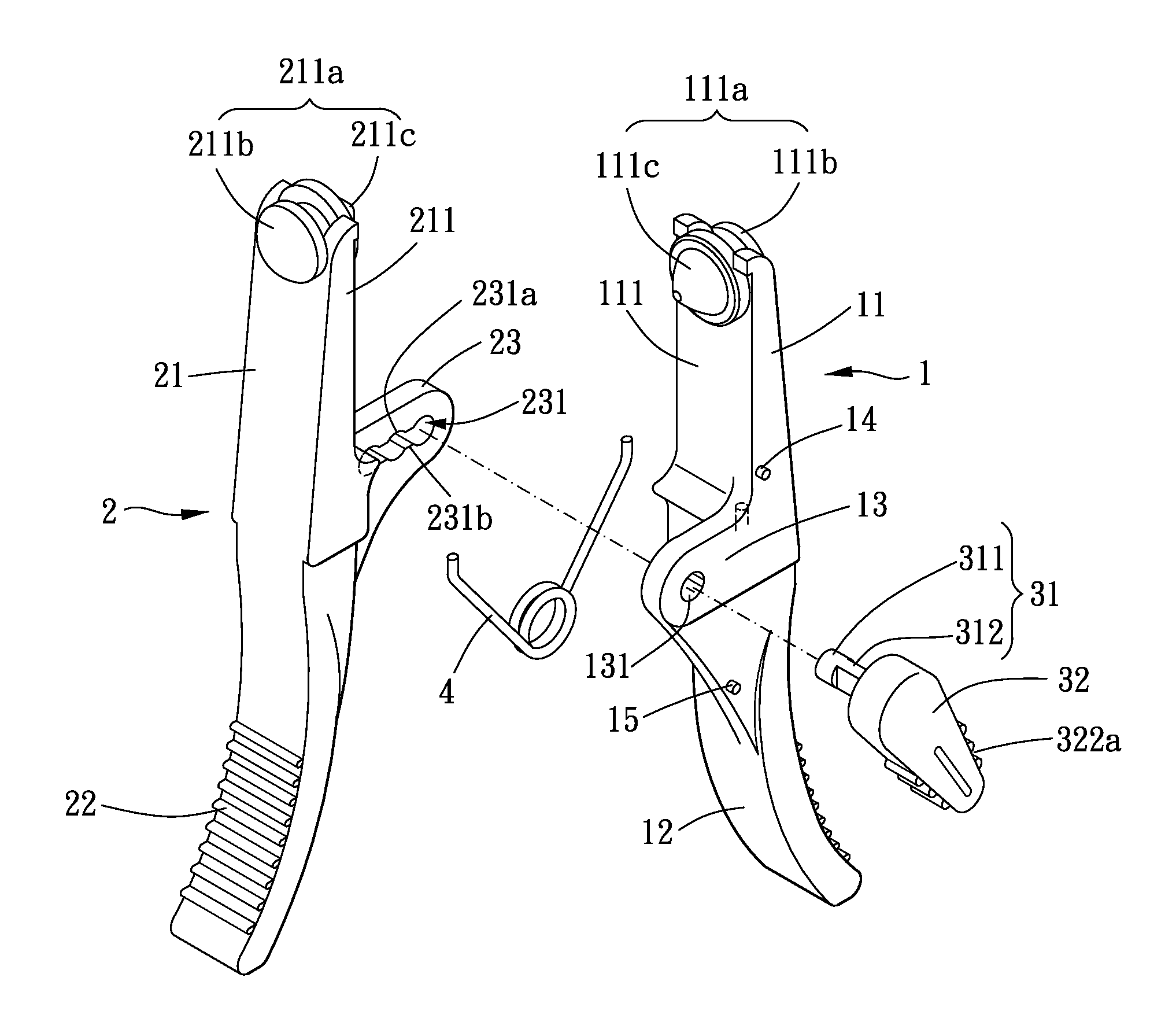

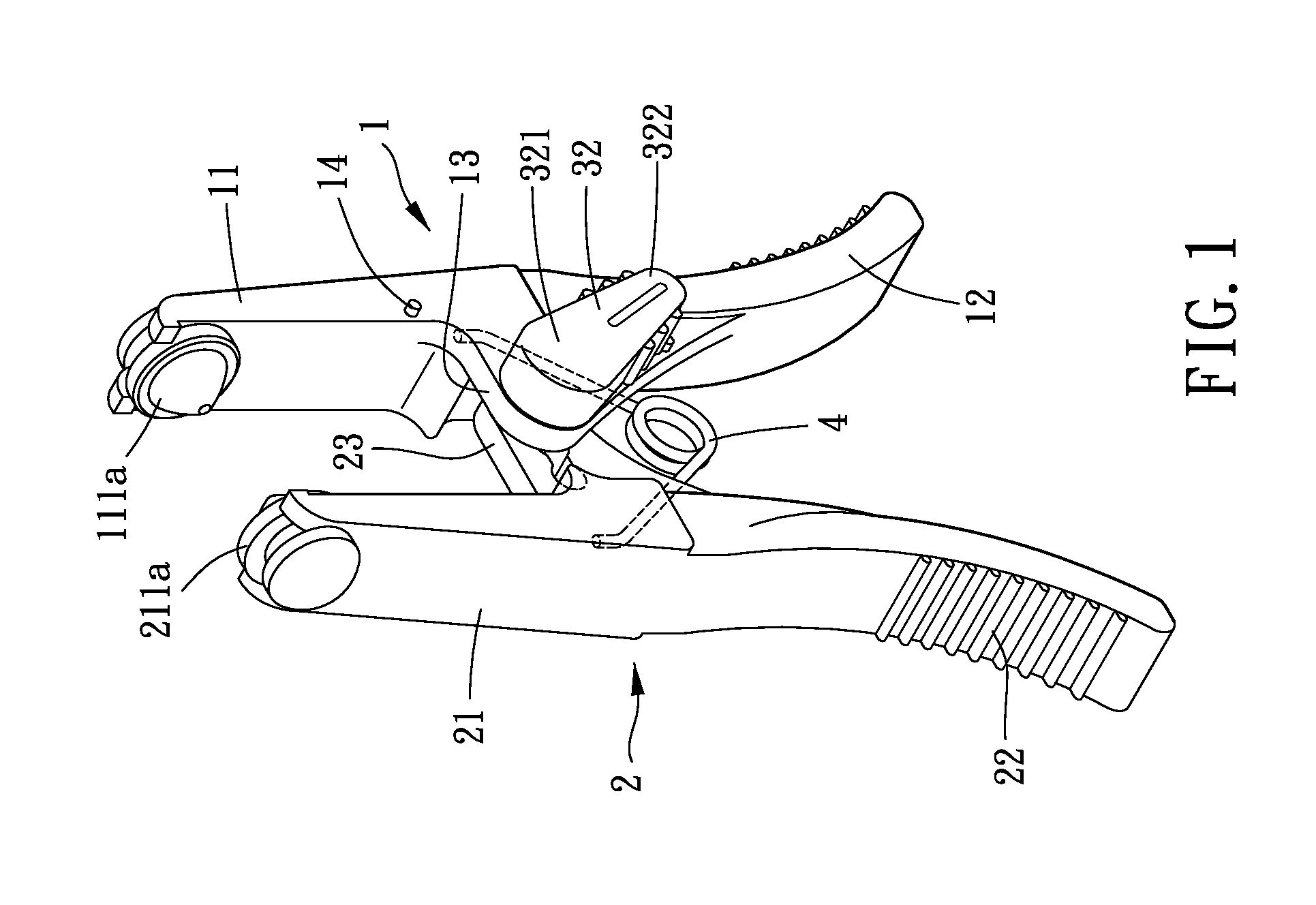

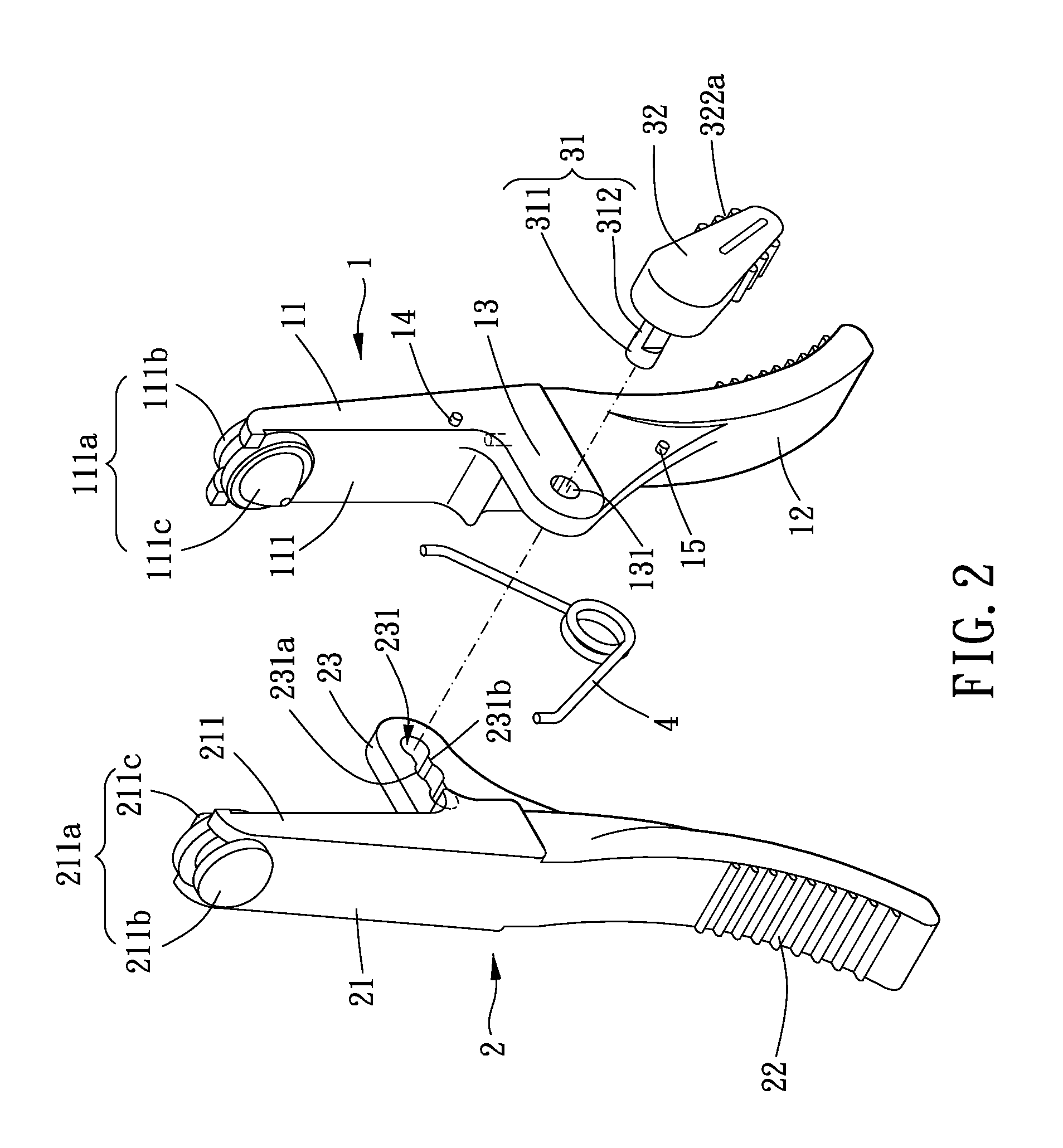

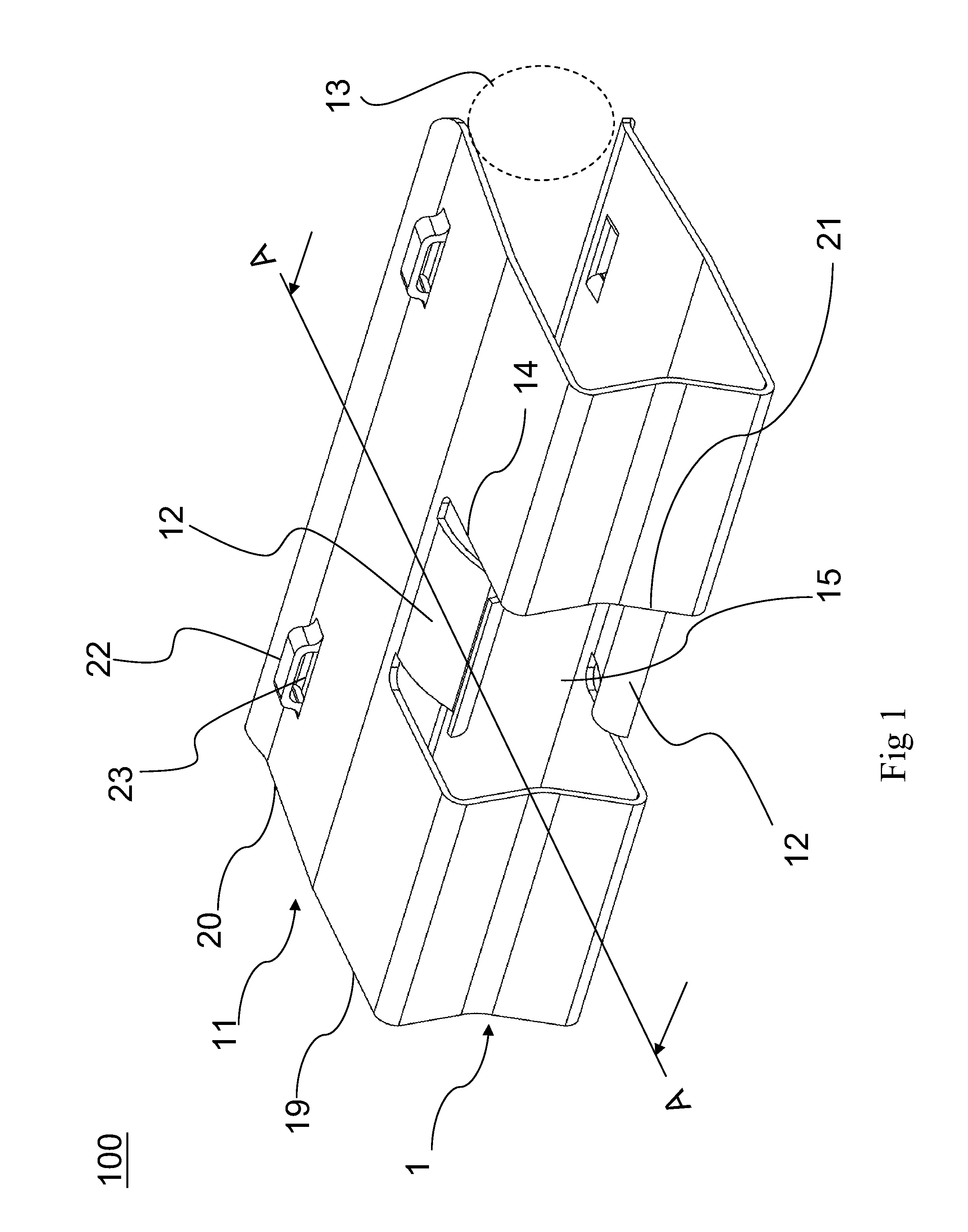

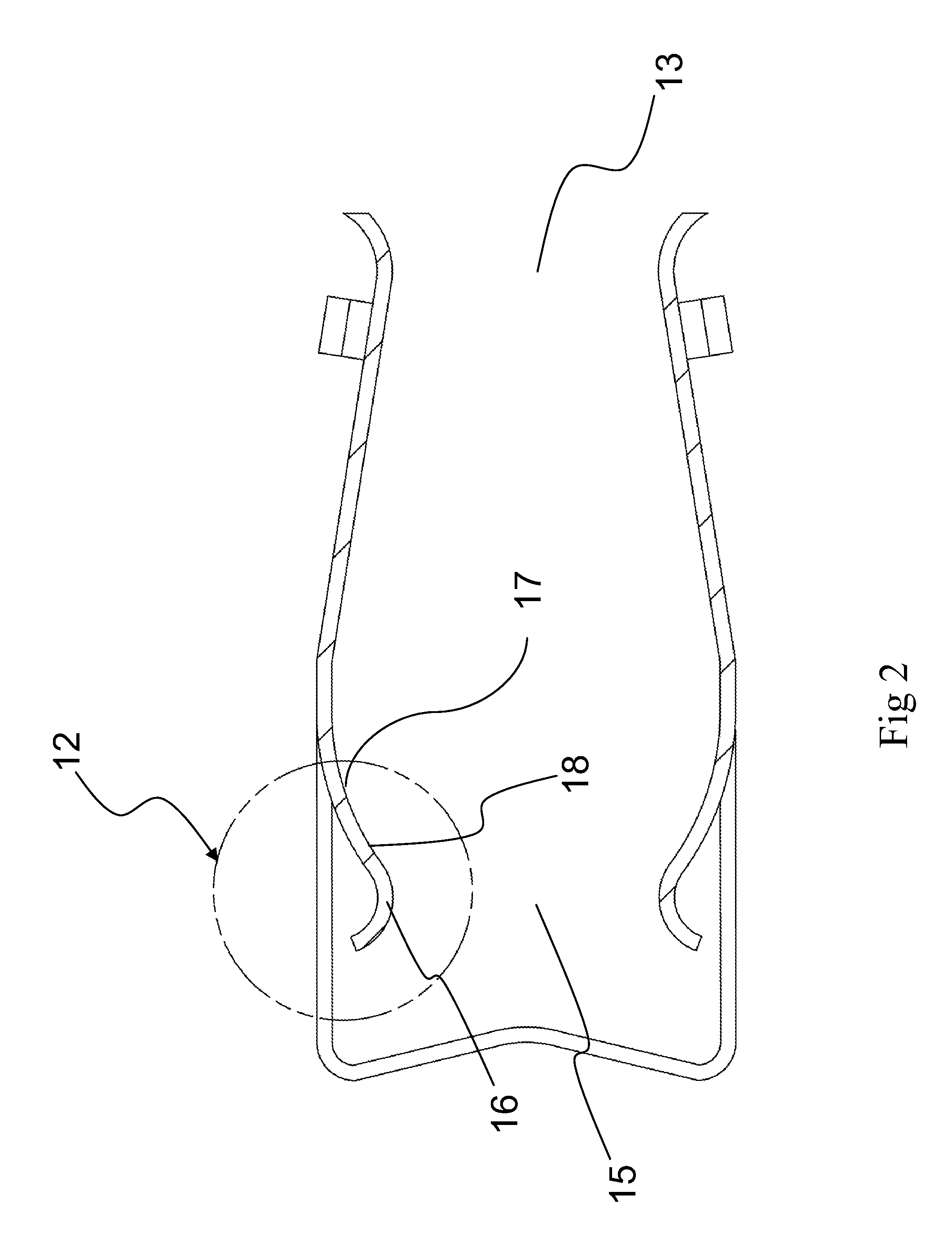

Hair clip

InactiveUS20060124149A1Improve aestheticsImprove visibilityCurling devicesTravelling articlesJaw openingBiomedical engineering

A hair clip comprises a body, jaws mounted on the body and a jaw opening arrangement to allow the jaws to be opened single handed. The jaws have tines and are mounted at spaced positions on the body so as to be pivotable at the positions to resiliently grip hair in the tines. The spacing of the pivot positions on the body enables a body to be used which can be decorated or hollow to enhance the aesthetics of the hair clip.

Owner:LINSHELL HLDG LTD

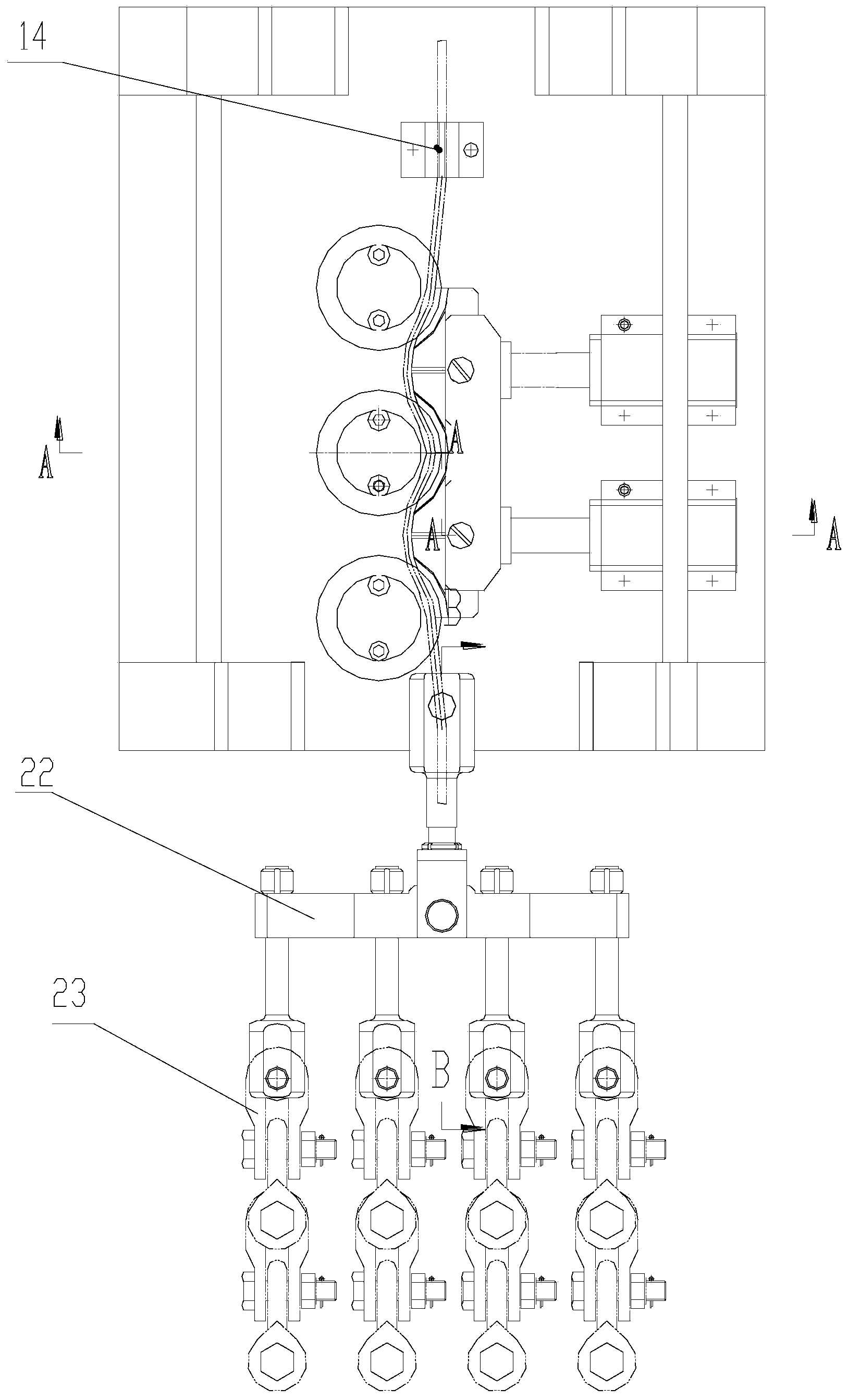

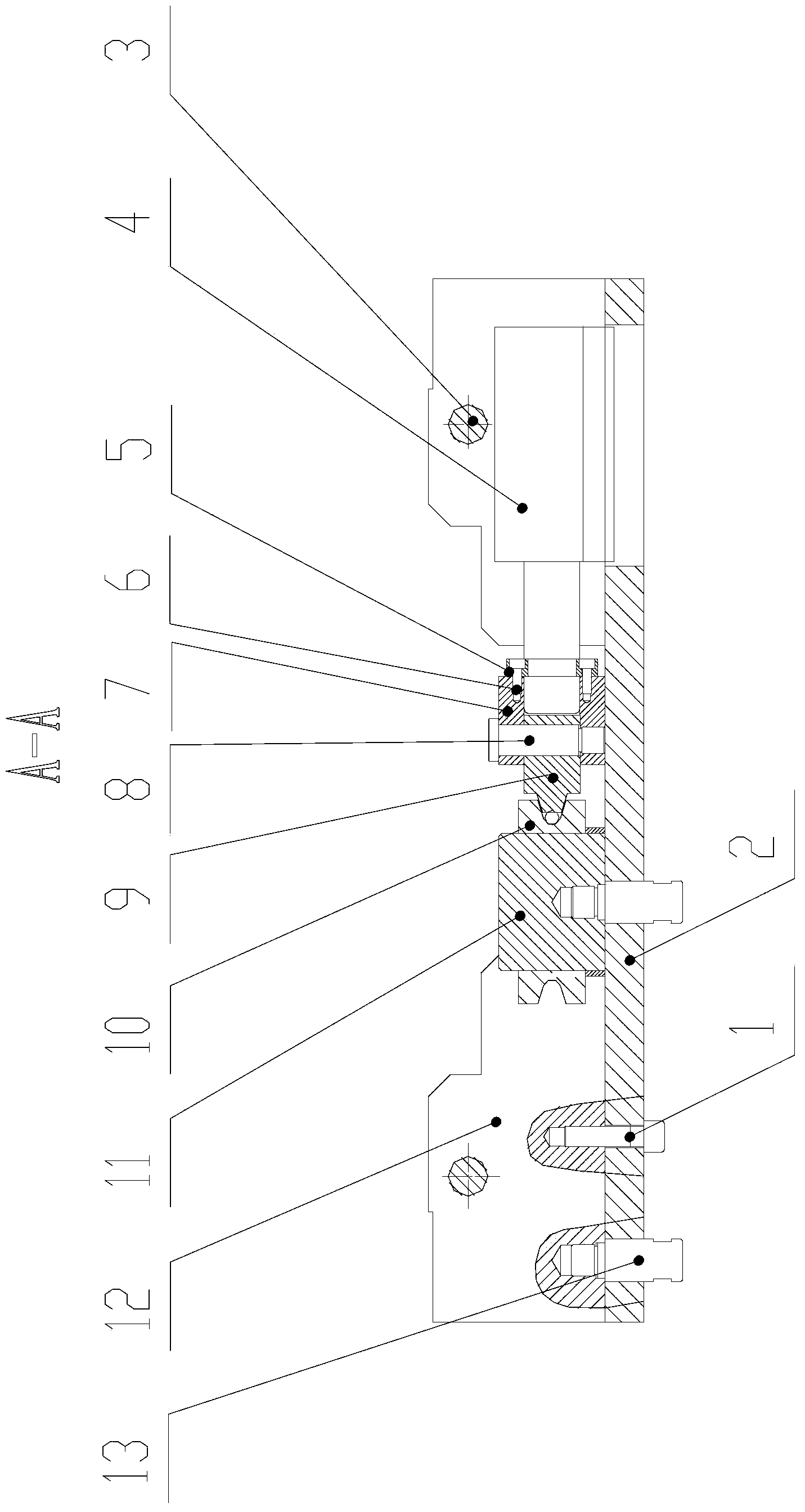

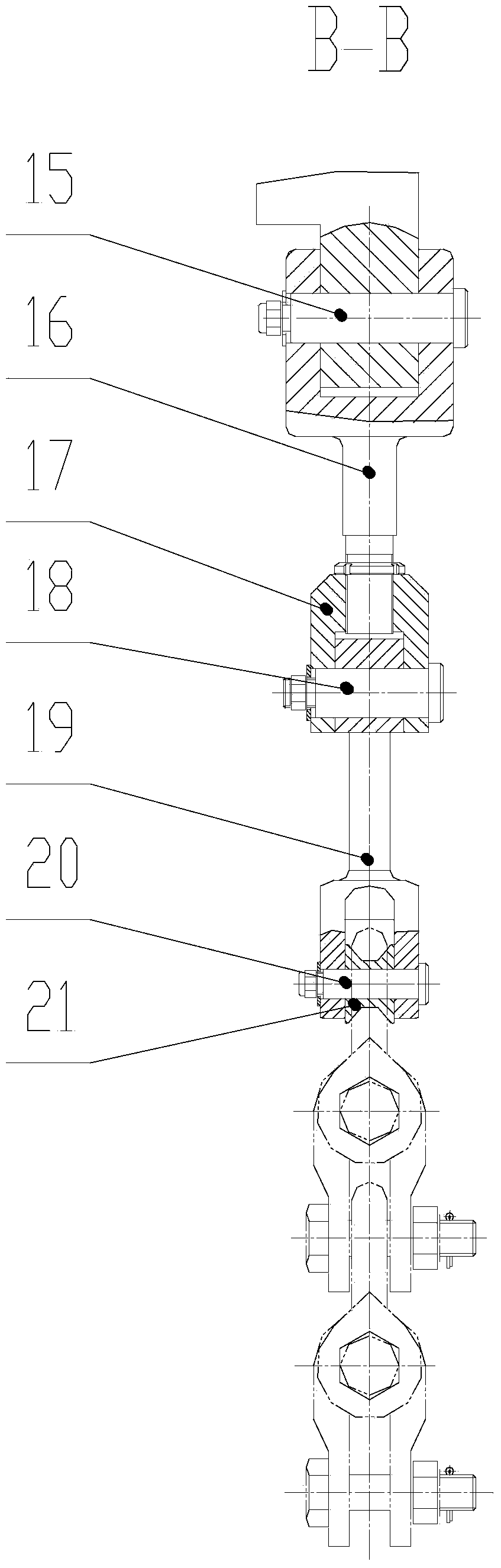

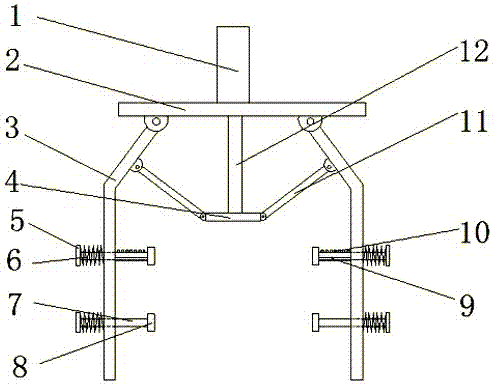

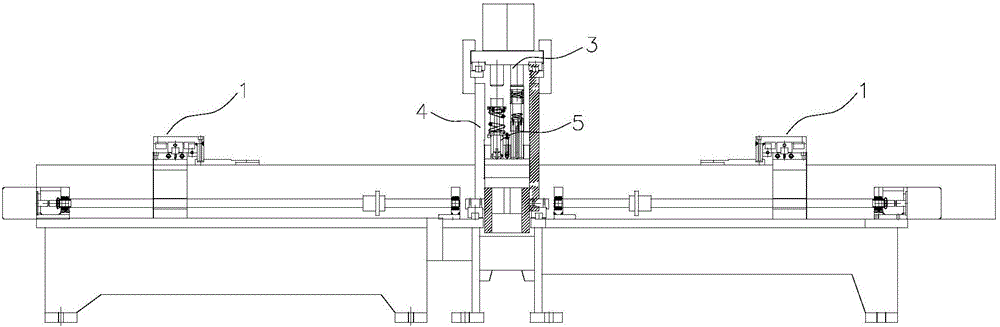

Zero damage multifunctional steel wire rope tension tester fixture

The invention particularly discloses a zero damage multifunctional steel wire rope tension tester fixture which comprises a base, wherein at least one movable clamping jaw opening driven by an air cylinder is formed in the base; at least one fixed clamping jaw opening is formed in the base; an S-shaped gap shaped like a circular tube and used for enabling a steel wire rope to penetrate through is formed between the movable clamping jaw opening and the fixed clamping jaw opening. The fixture can realize zero fracture random sampling on-line tensile test of the steel wire rope and provides valid guarantee for safe use of the entire coil of steel wire rope. The fixture can realize zero damage clamping of a flexible body under the condition of larger tension, can perform random on-line tensile test of the steel wire rope, and can guarantee safety tension test of the steel wire rope at any unwinding section.

Owner:UNIV OF JINAN

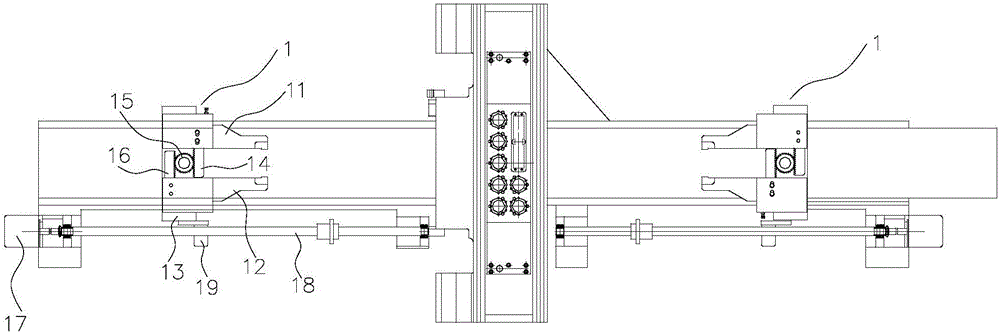

Zero damage multifunctional horizontal type online tension tester

InactiveCN103411835AIncrease the areaIncrease the lengthMaterial strength using tensile/compressive forcesSteering wheelOnline test

The invention particularly discloses a zero damage multifunctional horizontal type online tension tester which comprises a trough bracket, wherein an upper jaw trolley and a lower jaw trolley are arranged on the trough bracket; both the upper jaw trolley and the lower jaw trolley can slide along the trough bracket; the upper jaw trolley is driven by an actuator cylinder arranged on the trough bracket; the lower jaw trolley is driven by a motor built in the lower jaw trolley; two slippage steering wheels are arranged at two ends of the trough bracket respectively; S-shaped clamping jaw openings are formed in the upper jaw trolley and the lower jaw trolley; both the upper jaw trolley and the lower jaw trolley are arranged between the two slippage steering wheels; the slippage steering wheels can transversely move along the trough bracket. The tension tester fully adopts the technologies and principles of the existing winding method and the direct clamping method and performs organic integration on the basis so as to form the winding clamping method and realize zero damage clamping of a flexible body for online test of large tension safety.

Owner:UNIV OF JINAN

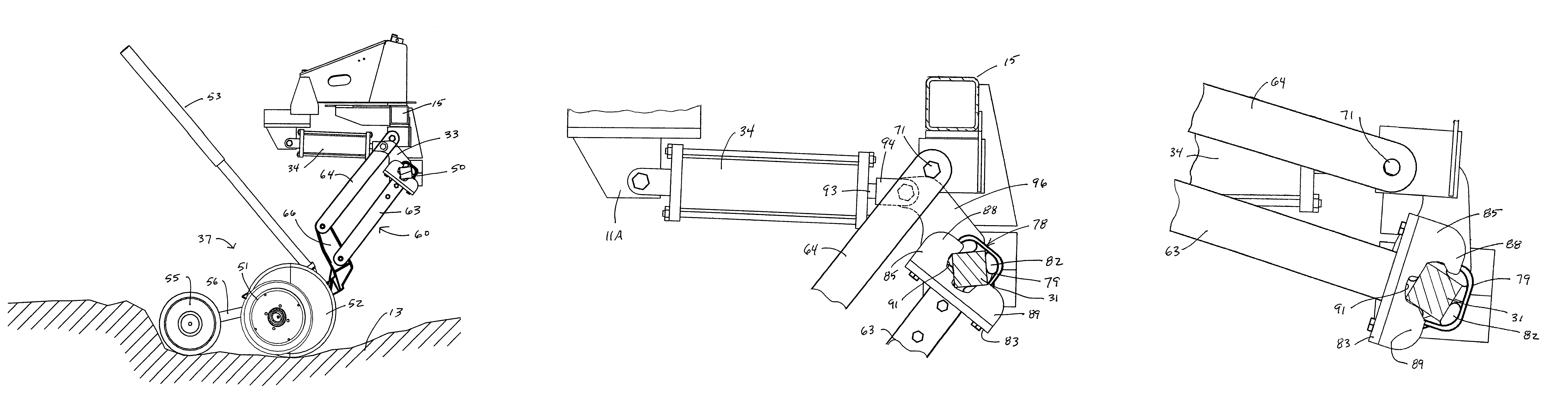

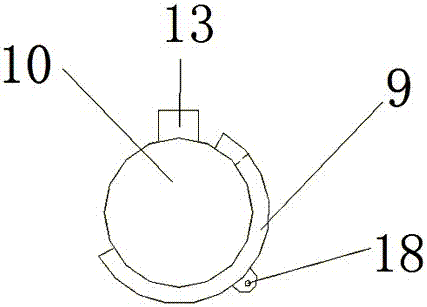

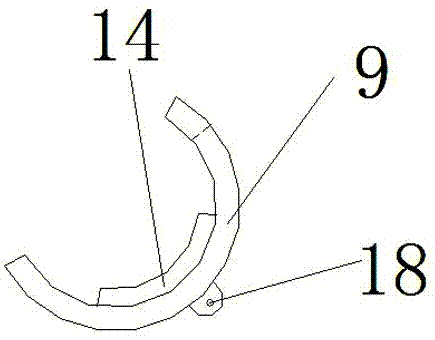

Terminal clamping device for iron tower automatic overhauling climb robot

ActiveCN105690414ARealize huggingAchieve releaseGripping headsApparatus for overhead lines/cablesEngineeringDrive motor

The invention provides a manipulator device for an iron tower automatic overhauling climb robot. The manipulator device comprises two pairs of jaw opening / closing mechanisms oppositely arranged and with the same structure, and two pairs of holding clamping mechanisms for urging the two pairs of jaw opening / closing mechanisms to hold and clamp tower components and with the same structure; the two pairs of jaw opening / closing mechanisms are respectively fixed on nut slide blocks of the two pairs of holding clamping mechanisms through connecting plates; and through respectively controlling rotating directions and speeds of driving motors of the jaw opening / closing mechanisms and the holding clamping mechanisms, fingers of the jaw opening / closing mechanisms hold and clamp tower angle steel. The manipulator device not only can realize reliable clamping of the angle steel from different directions, but also can realize reliable clamping of such rod parts with circular, rectangular and I-shaped sections, so that a robot not only can climb in a tower frame consisting of the angle steel, but also can freely climb in a tower structure consisting of components with other section shapes, and carries maintenance equipment to finish various overhauling tasks.

Owner:SICHUAN UNIV

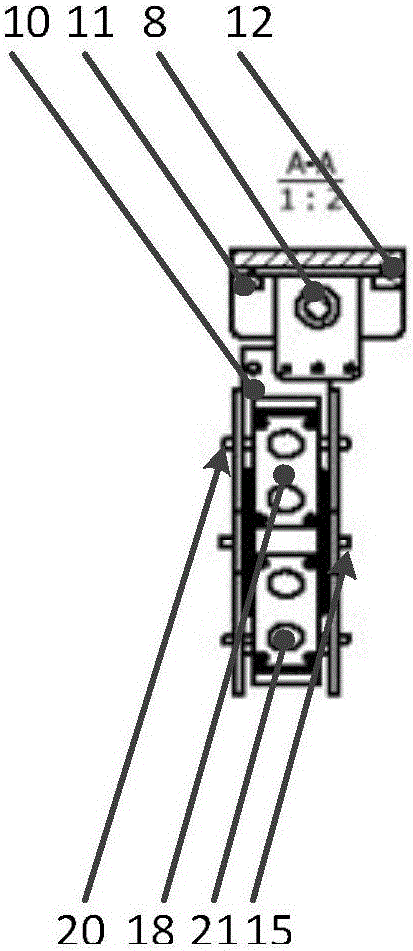

Seed planter

A seed planter has at least one rock shaft carrying a rank of planter assemblies. Each planter assembly includes a torsion joint assembly connected to the rock shaft, a planting equipment linkage connected to the torsion joint, a planting equipment yoke connected to the linkage and planting tools or equipment connected to the yoke. The planting equipment linkage is a modified parallelogram linkage that keeps the planting equipment in consistent alignment over the ground even as the seed planter traverses irregular terrain. The seed planter includes a stop mechanism that limits the amount of permissible rotation of the torsion joint on the rock shaft. A stop plate is attached to the torsion joint housing for rotation with it relative to the rock shaft. An edge of the stop plate faces the rock shaft and has a jaw opening defined by upper and lower jaws that at least partially encompasses the rock shaft. Upon rotation beyond limits, the jaws intercept and lock on the rock shaft surfaces to stop further rotation between the torsion joint housing and the rock shaft. The weight of the planter assembly is thereafter carried by the stop plate and the rock shaft and not by torsion spring elements of the torsion joint assembly.

Owner:TRUAX CO INC

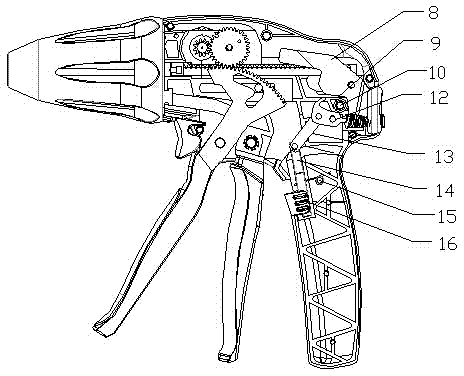

Intracavity incision anastomat

ActiveCN104224262ANo need to unlockEasy to useSurgical staplesSurgical forcepsJaw openingElectrical and Electronics engineering

The invention discloses an intracavity incision anastomat. The intracavity incision anastomat comprises a fixed handle, a closed handle and a jaw opening and closing transmission mechanism which is connected with the closed handle. The closed handle is used for opening and closing a jaw, the closed handle is further connected with a closed handle linkage part, and a locking area is arranged on the closed handle linkage part. The locking area can be locked with an unlocking switch which is fixed on the fixed handle. The fixed handle is provided with a jaw closing safety device, and the unlocking switch can be limited by opening the jaw closing safety device. The locking area can not be locked with the unlocking switch when the jaw is closed, the jaw closing safety device is closed, and the locking area is locked with the unlocking switch when the jaw is closed. In the instrument original state, the jaw closing safety device is placed in the opened mode, closing and opening of the jaw can be operated freely, unlocking operation is needless, and using is convenient.

Owner:SHANDONG WEIRUI SURGICAL MEDICAL PROD

Break-free safety release buckle and fastener

A quick-release fastening device is disclosed. The device includes a first fastening component having upper and lower surfaces and first and second end portions. A pair of first and second elongated jaw elements are disposed on the first component first end portion and form a channel-like socket therebetween. The jaws define a gripping mechanism having an elongated jaw opening accessing the socket. The first jaw element has a length dimension less than the second jaw element. A tubular pocket is defined in the first member first end portion adjacent the channel-like socket to form a pivot point for the jaw elements. A second fastening component has first and second end portions, the second fastening component first end portion being adapted for releasable engagement with the first fastening component first end portion. Finally, a stud is mounted in the second fastening component first end portion. The stud is sized for releasable engagement within the channel-like socket and further includes an elongated cut-out portion which forms a slot along a substantial portion of the length of the stud, the slot being sized to match the first jaw element to enhance engagement of the stud within the socket without affecting release resistance of said stud imposed by said jaw elements.

Owner:DUX FIN

Locking pliers with handle locking mechanism

Pliers include upper structure including an upper jaw and handle extending therefrom, and lower structure including a lower jaw and handle. The lower jaw may pivot relative to the upper jaw, and the lower handle may pivot relative to the lower jaw. An overcenter linkage operatively connects between the upper and lower structure, biasing the lower handle and jaw away from the upper handle and jaw, respectively, when in a jaw-opening position, and enabling the lower jaw and handle to be retained in a closed configuration when the linkage is in a jaw-closing position. A lock member is movable between a locking configuration preventing pivoting of the lower handle from the closed configuration and retaining the jaws in a closed position, and a release configuration enabling the lower handle to be moved away from the closed configuration, allowing the jaws to move to an open position.

Owner:STANLEY WORKS THE

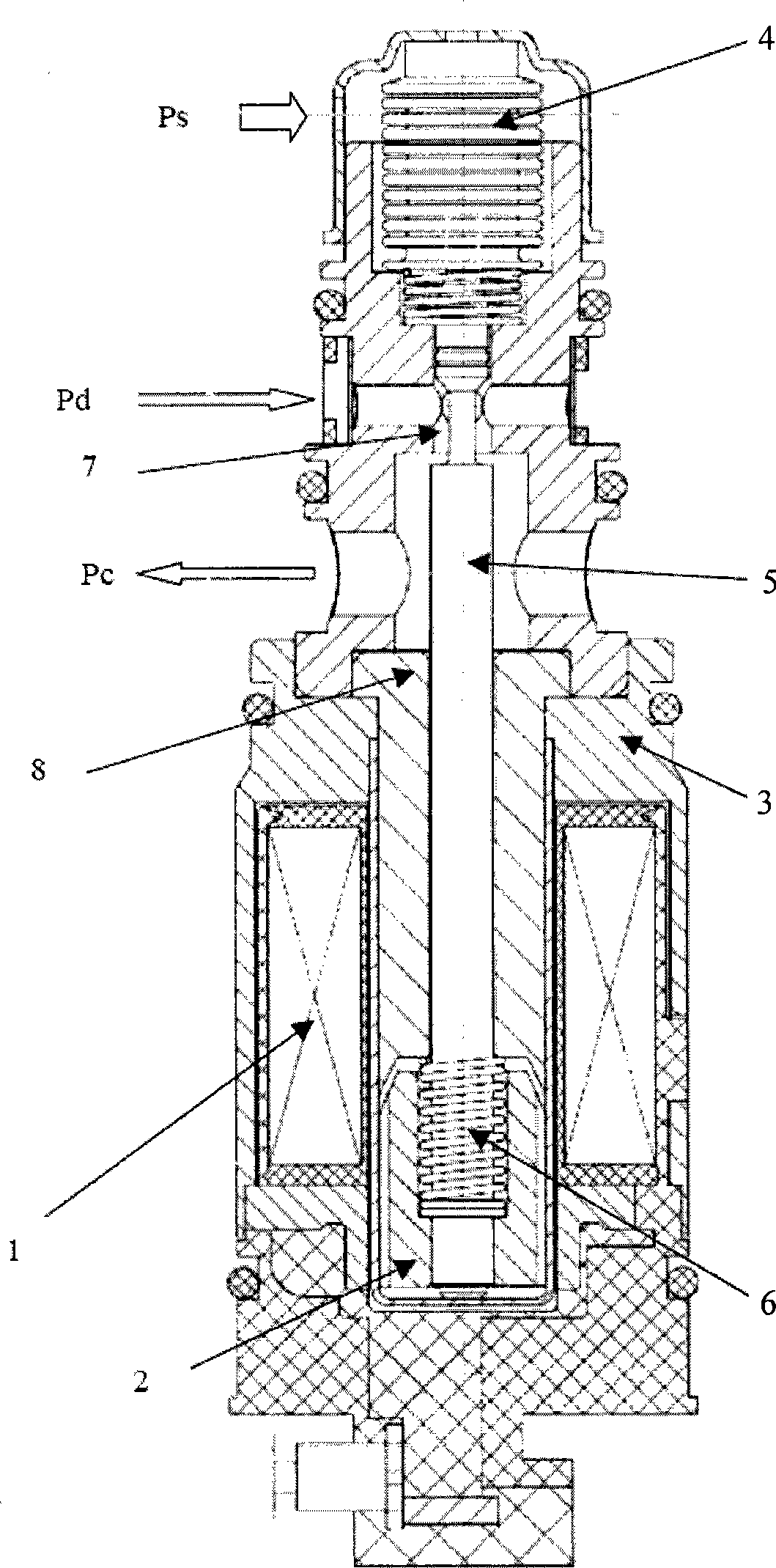

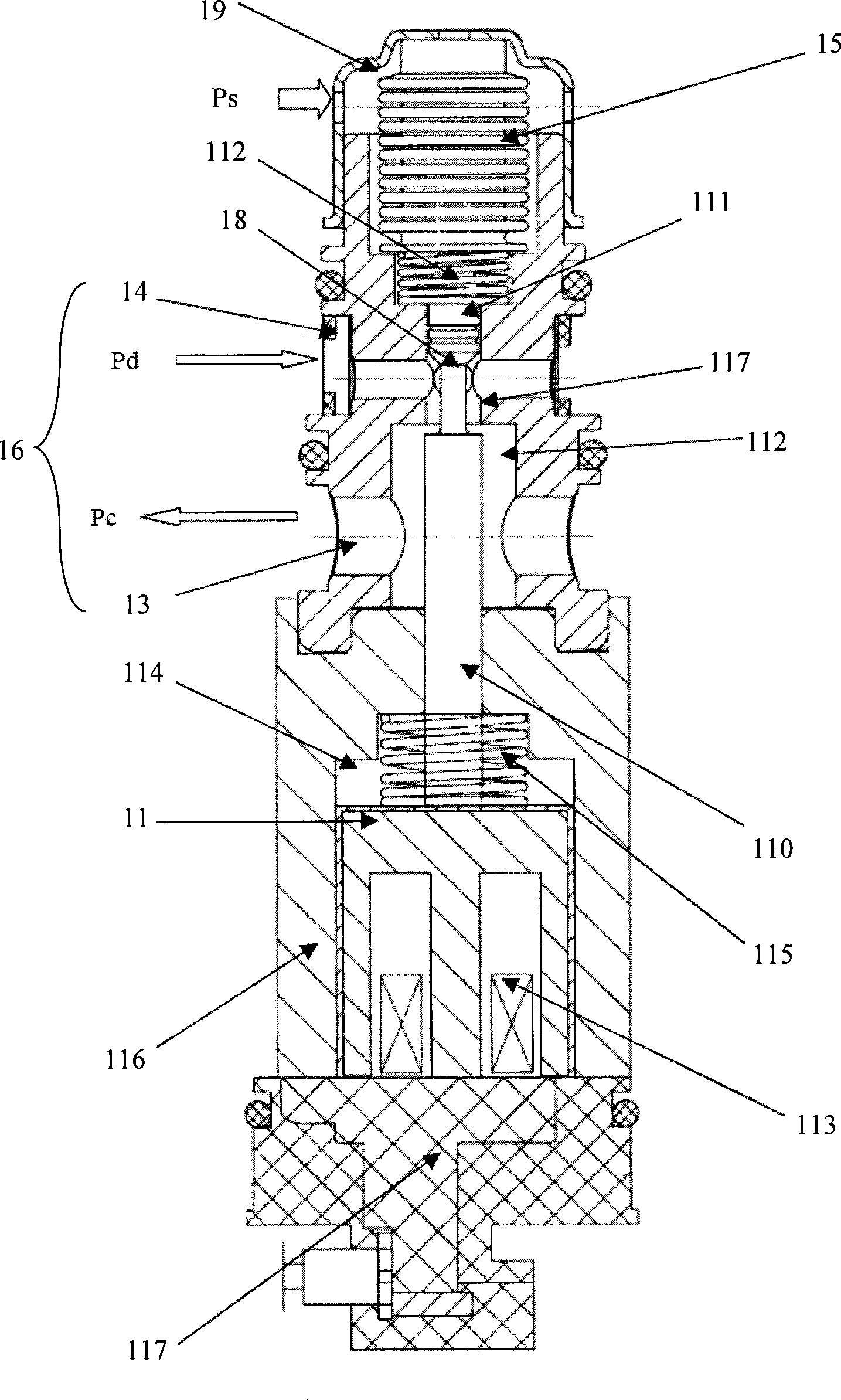

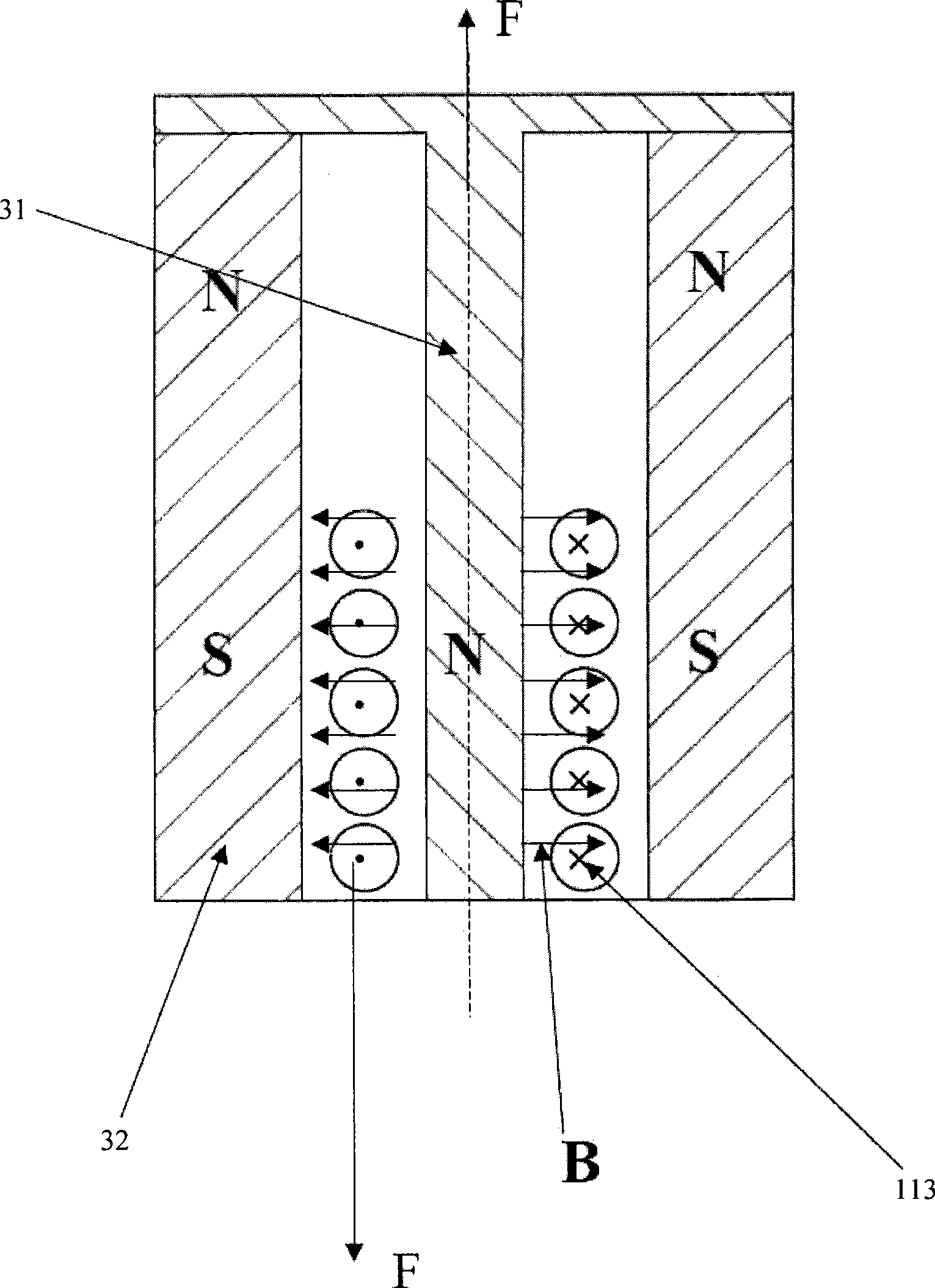

Electrical controlled valve of variable displacement compressor

InactiveCN101469694AReduce volumeReduce usageOperating means/releasing devices for valvesPositive displacement pump componentsElectrical controlDevices fixation

The present invention discloses a electrical controlled valve in discharge variable compressor, which includes a gas supply passageway, a pressure sensor and a valve rod, also includes: valve case that fixedly connects with the gas supply passageway and the pressure sensor, wherein the valve case includes a coil cavity, and the valve rod extends into the coil cavity in the valve case; a permanent magnet component that contained in the coil cavity; a coil that disposed in the coil cavity and nested inside the permanent magnet component; a offsetting spring that disposed on the top of the coil cavity and between the permanent magnet component and the valve case, and the offsetting spring generates reset force to the valve rod; a electrical source component that connects with the coil and control electrical current size to be inputted into the coil according to external signal, wherein, after the coil electrified, electromagnetic force is generated between the permanent magnet components to make the permanent magnet component perform relative movement to the coil, so as to drive the valve rod move and adjust jaw opening of the valve rod.

Owner:SANDEN HUAYU AUTOMOTIVE AIR CONDITIONING CO LTD

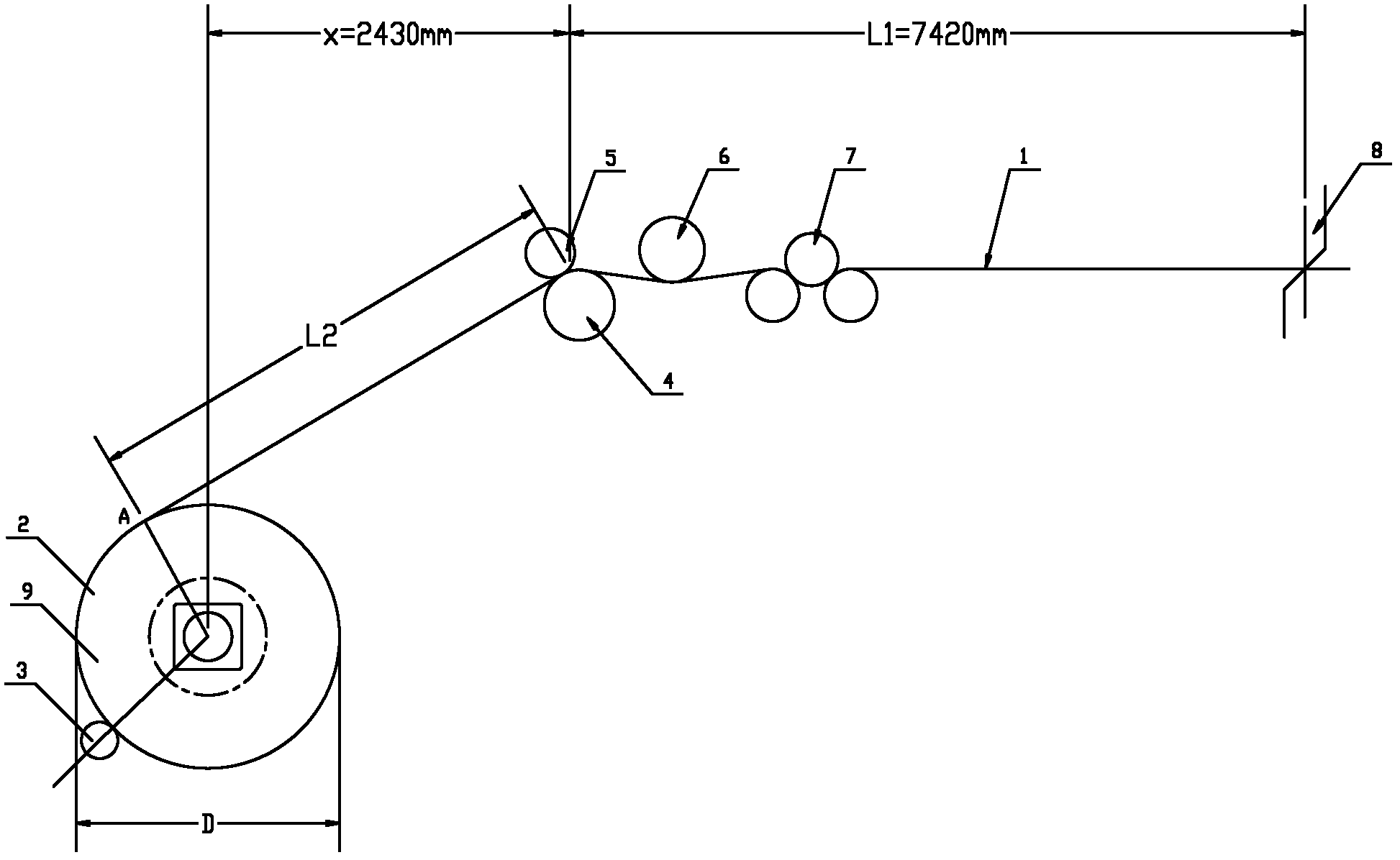

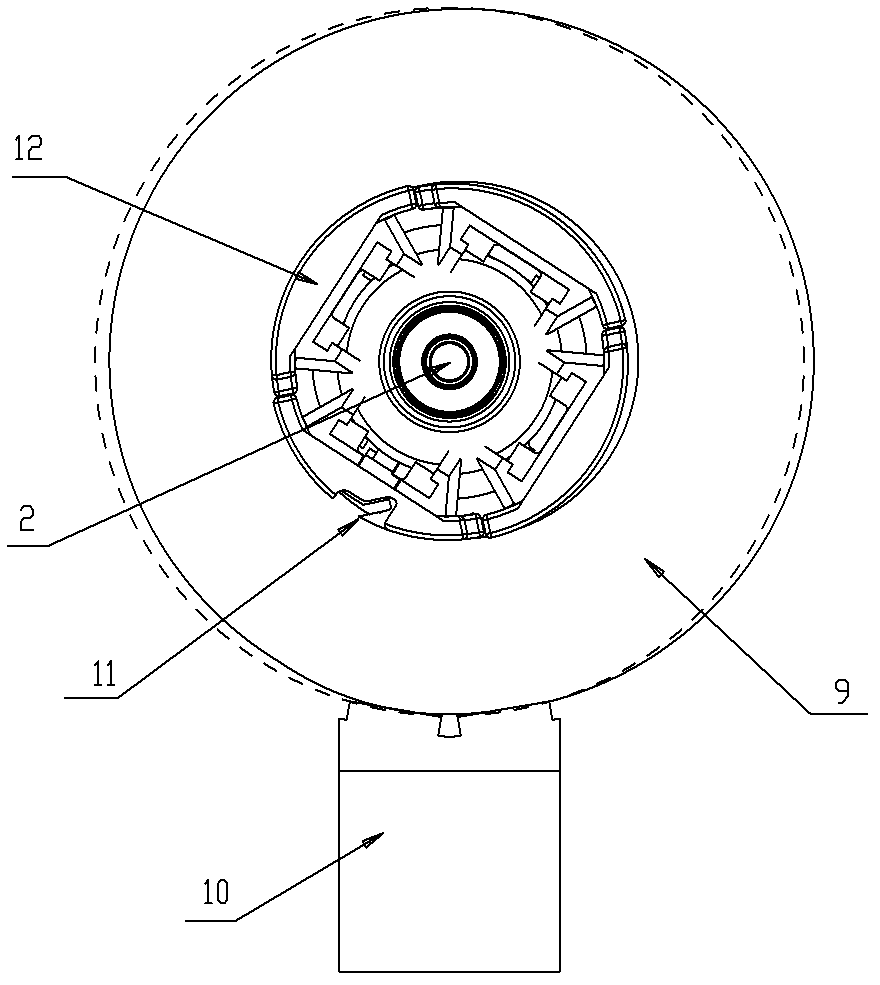

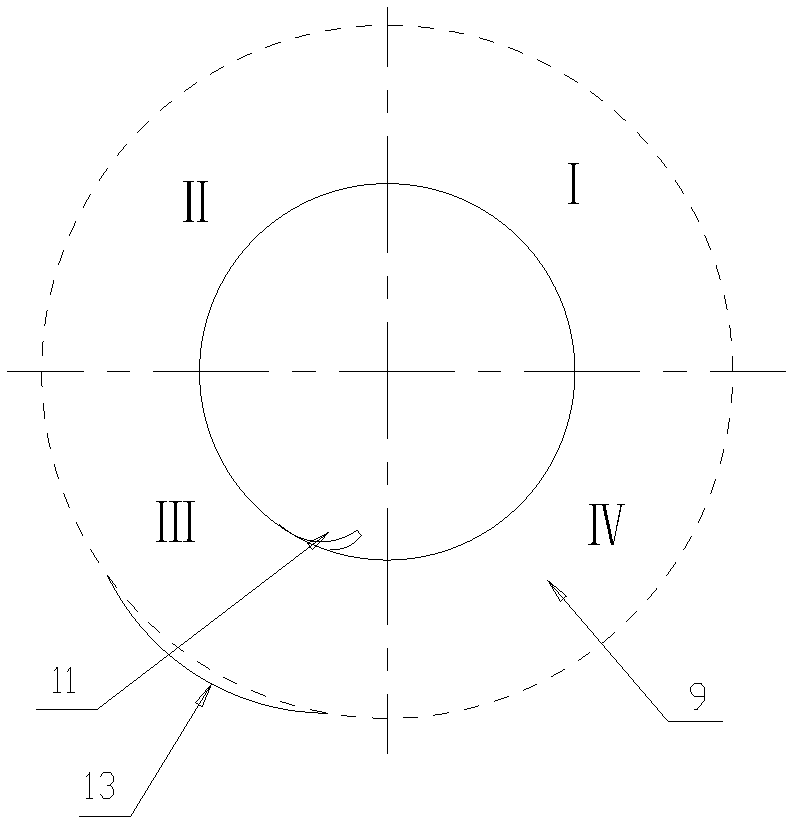

Method for positioning jaw opening of coiler mandrel

The invention relates to a method for positioning jaw opening of coiler mandrel, which is characterized in that: 1) when the length of the steel coil reaches requirement, after the detection device sends signal, the mandrel motor is stopped; 2) the cycle N of rotation of the jaw opening after cutting is calculated, wherein N=1 / 3+(L1+L2) / PiD, the position of the jaw opening when the plate coiling is terminated is calculated by combining the cycle N, and the jaw opening must be located on the horizontal line at center of the mandrel; 3) the mandrel motor is started, to start to establish tension and perform cutting operation; 4) the tape tail is stopped at the position of the cradle roll under the guide of a tape tail grating detection device, and the mandrel motor is stopped. Compared with the prior art, by the sectioning operation of a sectioning machine, and controlling the position of the jaw opening at cutting, the probability of the scratch of inner circle of the plate steel coil longer than 8 mm is greatly reduced, and the product yield is improved by 0.4-0.5% or above.

Owner:ANGANG STEEL CO LTD

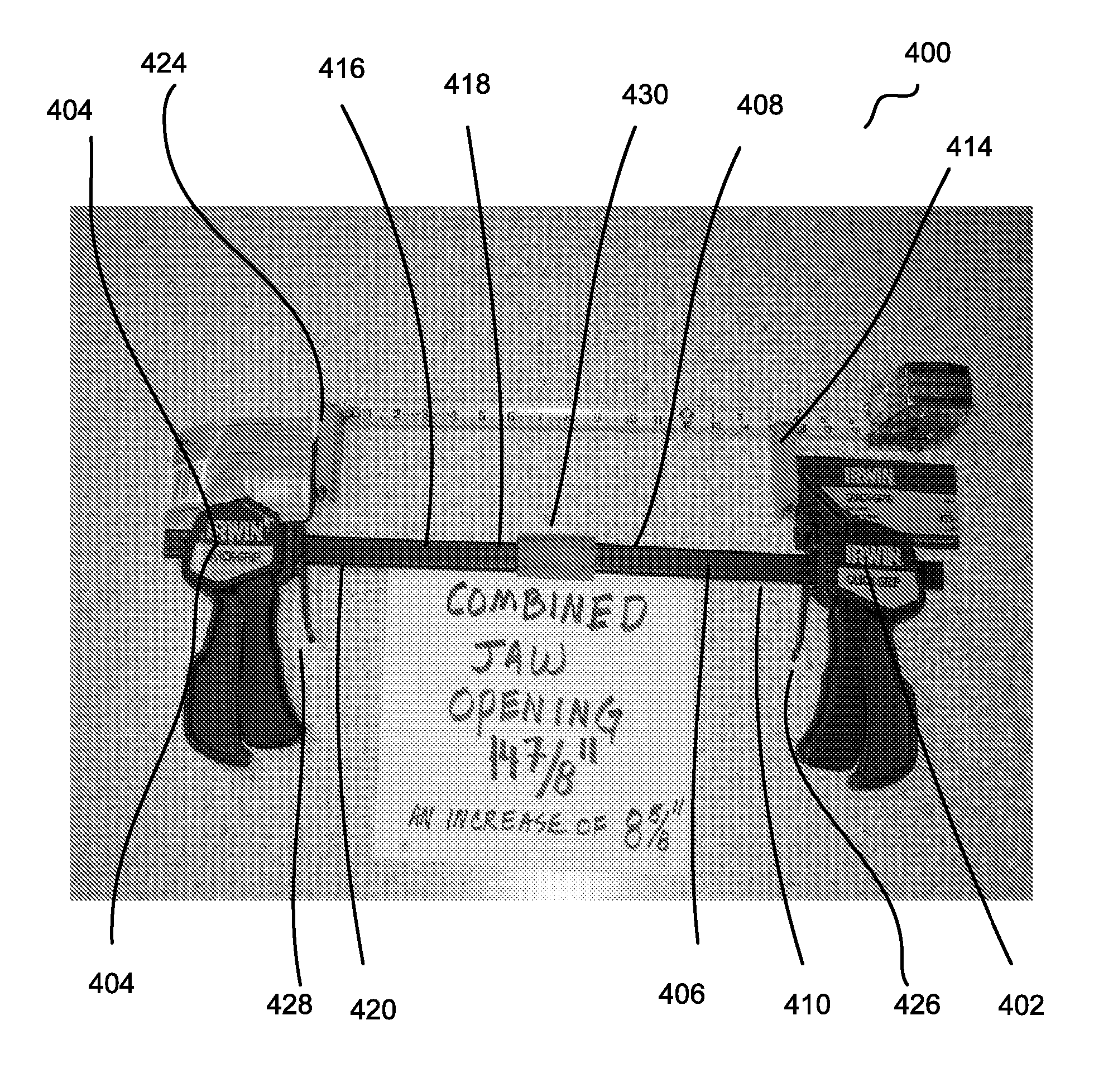

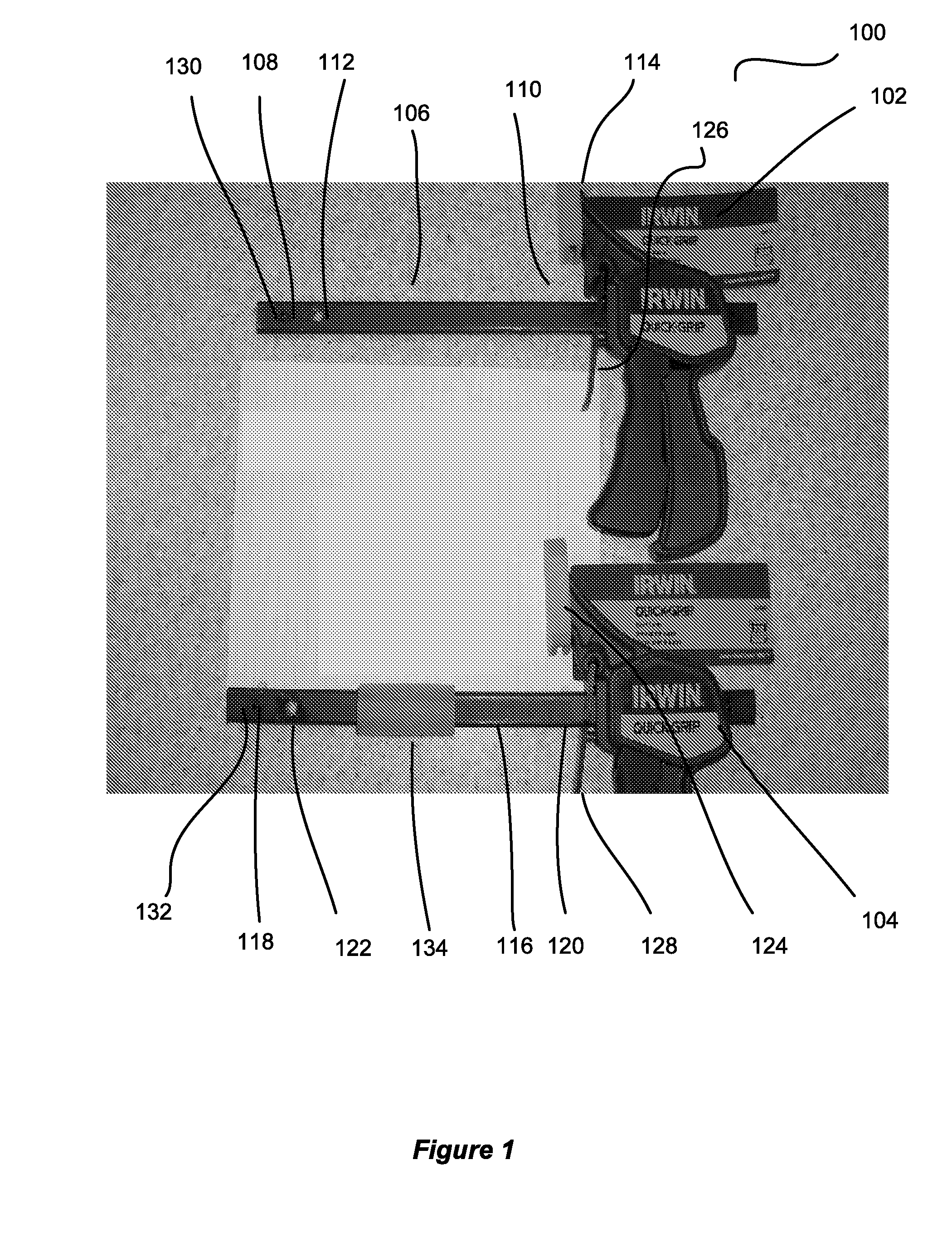

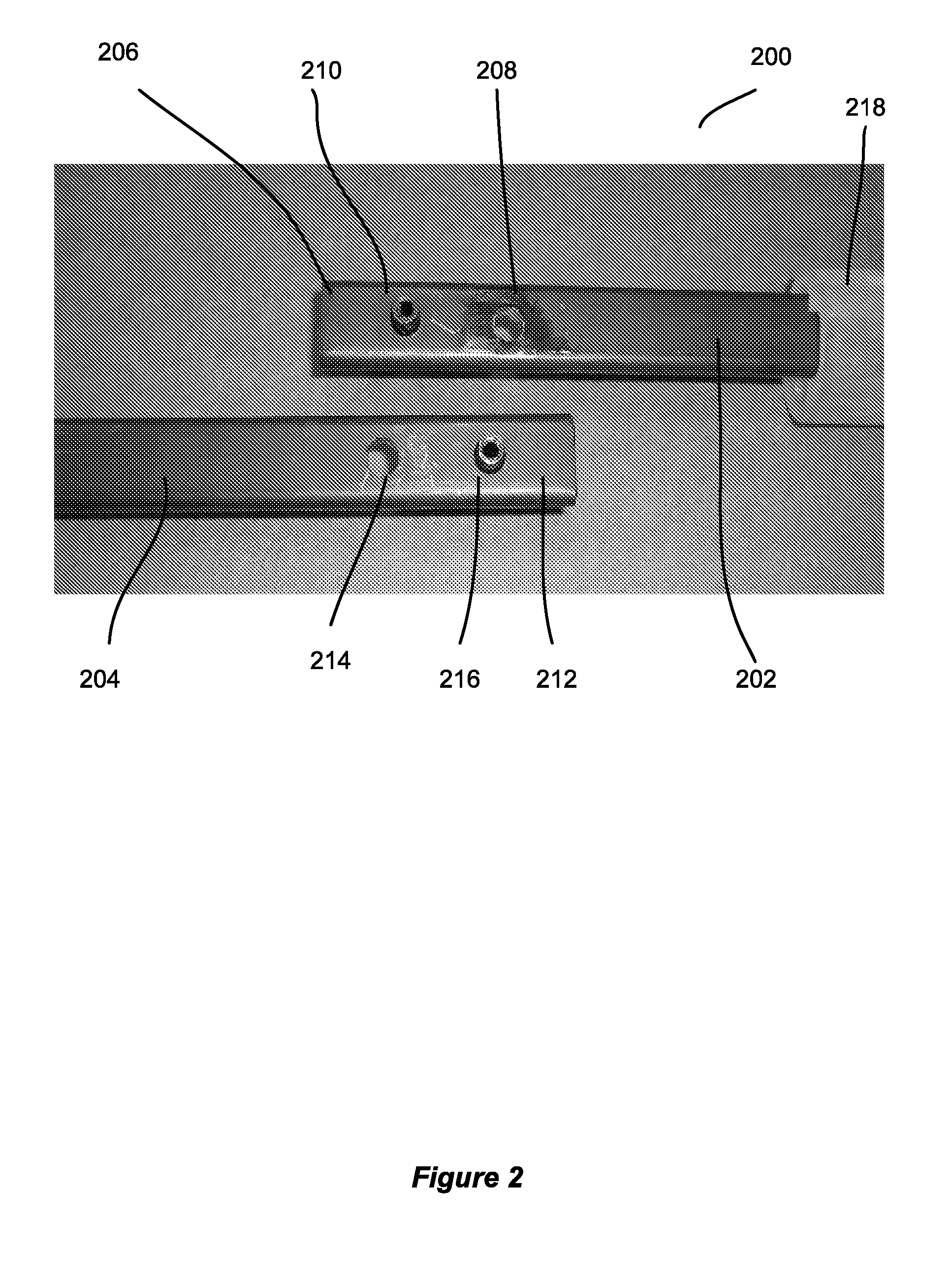

Adjustable clamp system

An adjustable clamp system and method for extending the jaw opening of an adjustable clamp are presented. The adjustable clamp system includes a first slide-adjustable clamp and a second slide-adjustable clamp, with each clamp having a fixed jaw and a movable jaw. The system further comprises, for each of the slide-adjustable clamps, a rail, along which the movable jaw travels. The ends of the rails of the two adjustable clamps, relieved subsequent to the removal of the fixed jaw member, are engaged. Upon engagement of the rails, a coupling member suitably aligns and secures them, so as to maintain the joining thereof. The jaw opening of the adjustable clamp is formed by the jaw member movably attached to the first rail and the jaw member movably attached to the second rail, being substantially increased thereby.

Owner:FRATIANNE GARY

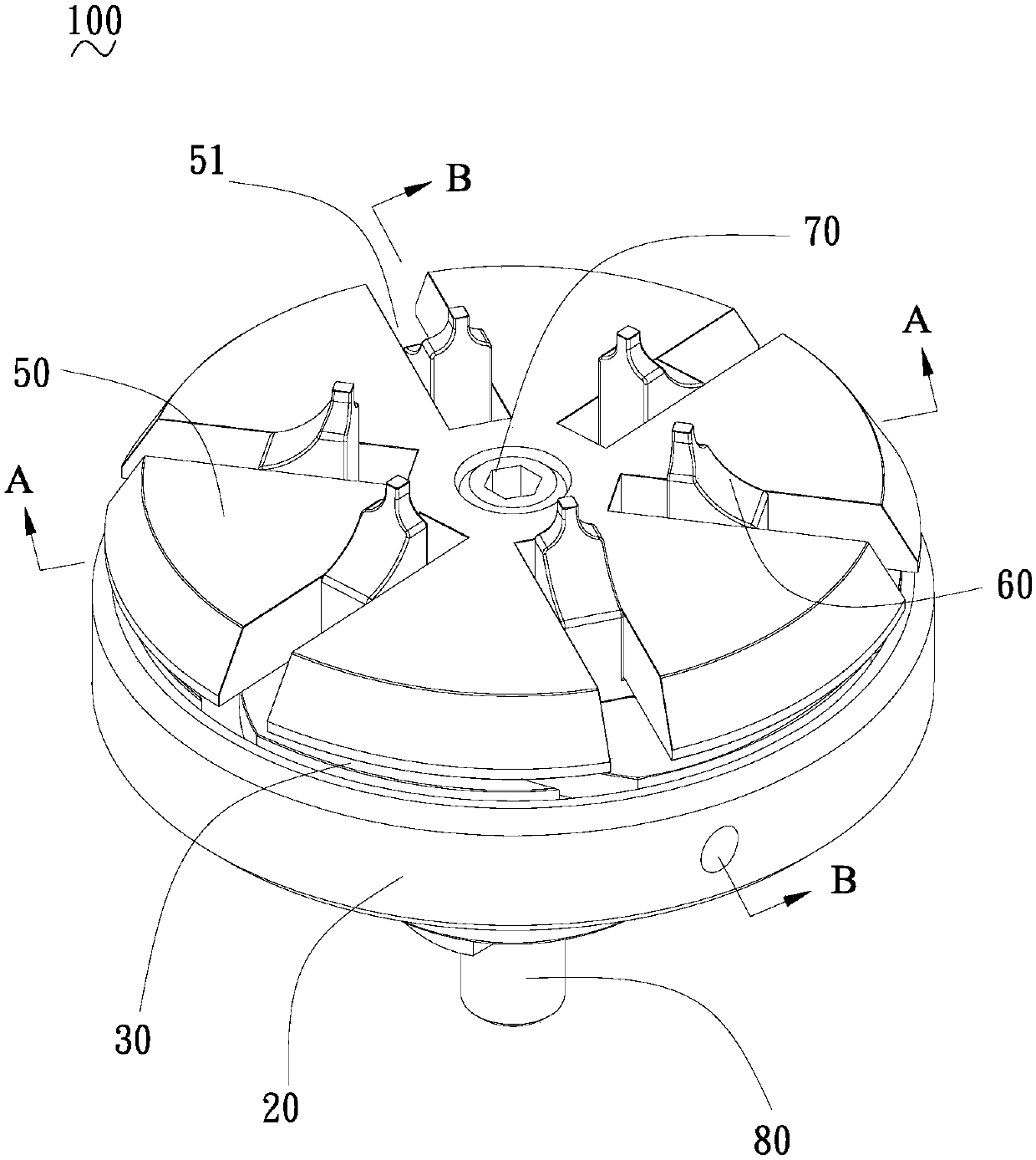

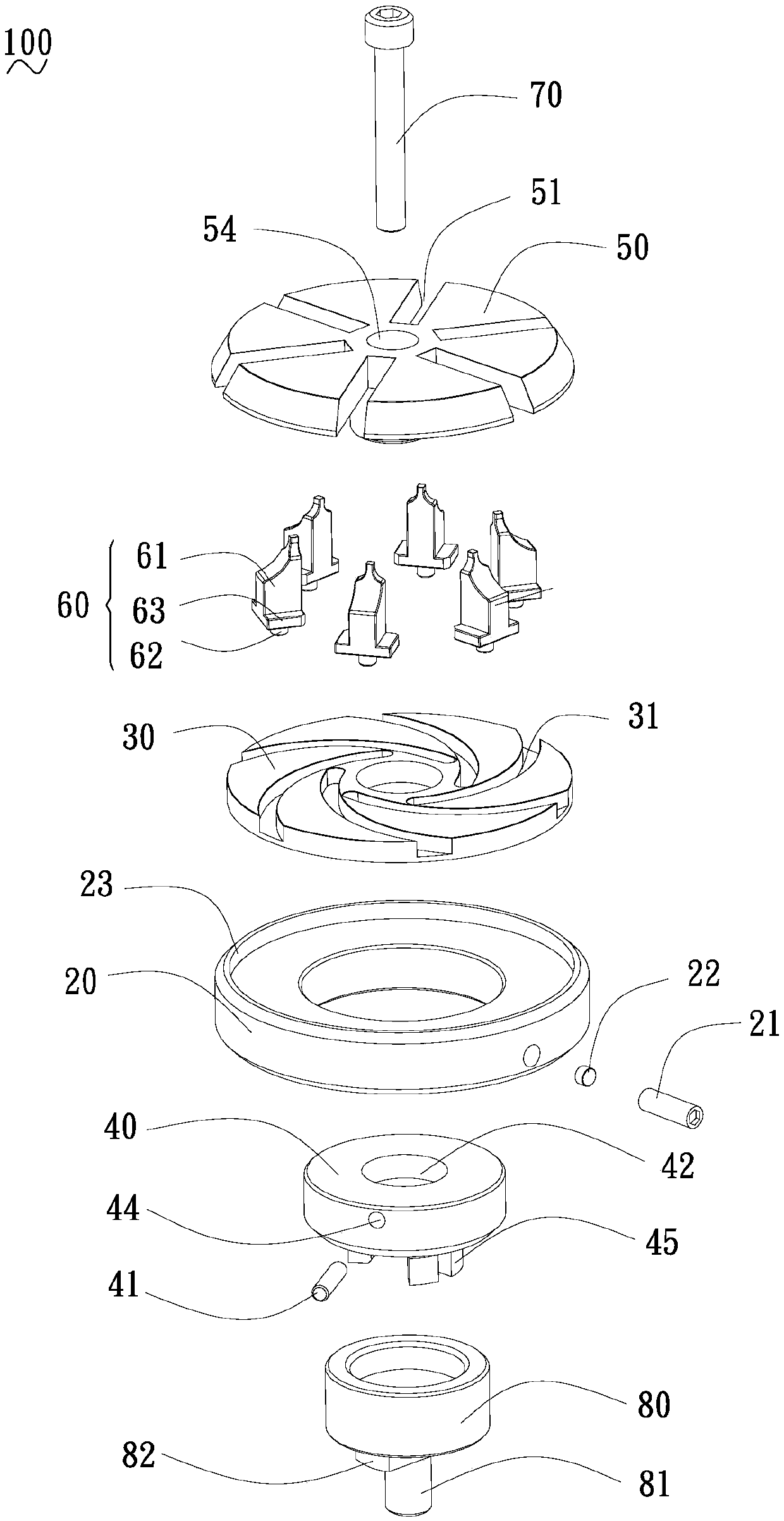

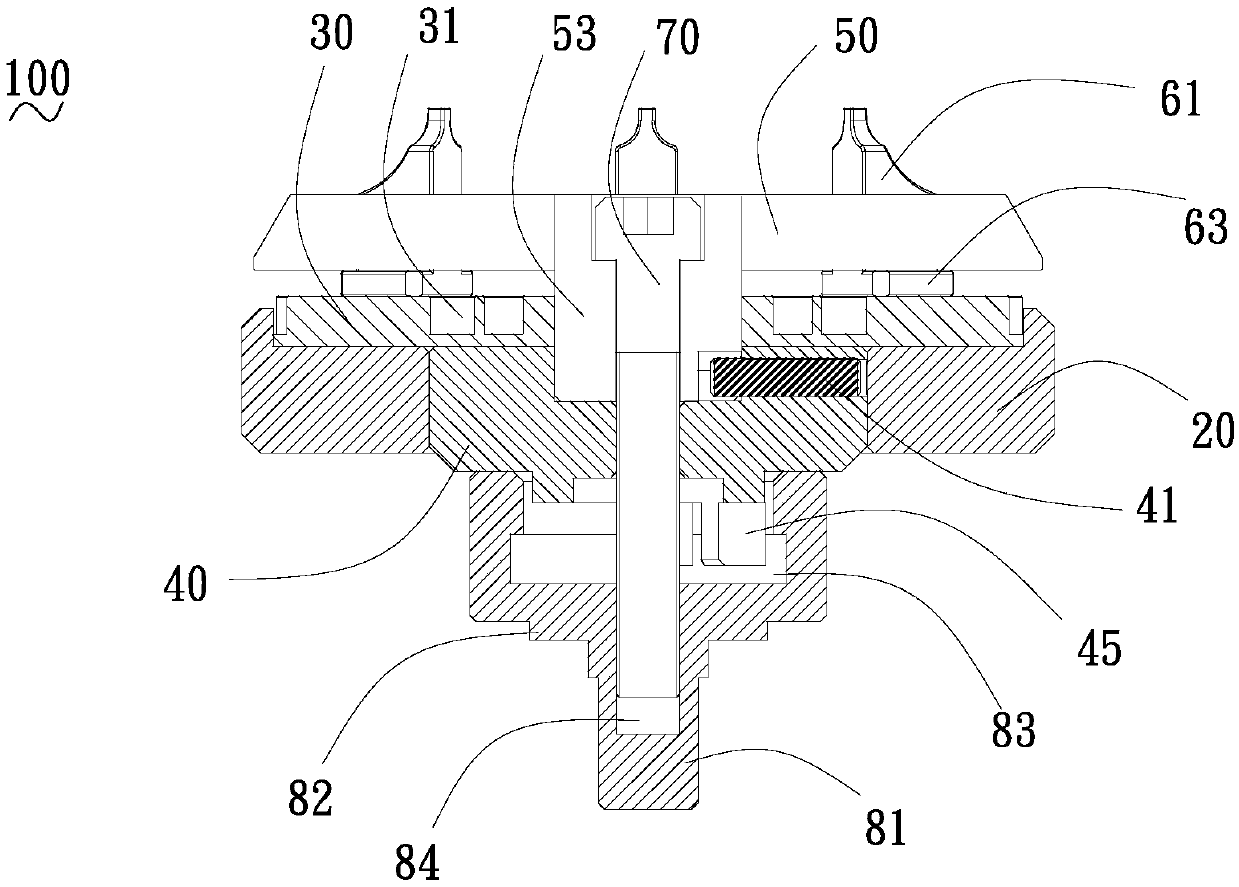

Clamping jaw device

The invention relates to a clamping jaw device. The clamping jaw device comprises a supporting seat, a guide disk, a hand-hold seat, a locating plate, at least two clamping jaws mounted on the locating plate and the guide disk in a clamping mode, and locking bolt, wherein the guide disk and the hand-hold seat are mounted on the supporting seat and arranged oppositely, the locating plate is mountedon the guide disk and abuts against the hand-hold seat, and the locking bolt penetrates through the locating plate and is connected with the hand-hold seat. At least two arc-shaped grooves rotatablyand symmetrically distributed are formed in the guide disk. At least two clamping jaw openings rotatably and symmetrically distributed are formed in the locating plate, and the clamping jaw openings extend in the radial direction of the locating plate. The clamping jaws comprise clamping jaw parts, guide columns convexly extending from the clamping jaw parts and clamping blocks convexly extendingfrom the clamping jaw parts, the clamping jaw parts penetrate through the clamping jaw openings, the guide columns are located in the arc-shaped grooves, and the clamping blocks correspondingly abut against the guide disk and the locating plate. The clamping jaw device can be adjusted adaptively according to actual requirements, the clamping jaws are closely matched with disassembly and assembly grooves and cannot slip, the operation efficiency is high and the protection performance is high, the clamping jaws with different types and numbers can be correspondingly replaced according to the sizes and numbers of the disassembly and assembly grooves, the universality is high, the using cost is low, and the clamping jaw device is quite practical.

Owner:DONGGUAN CHANGYING PRECISION TECH CO LTD

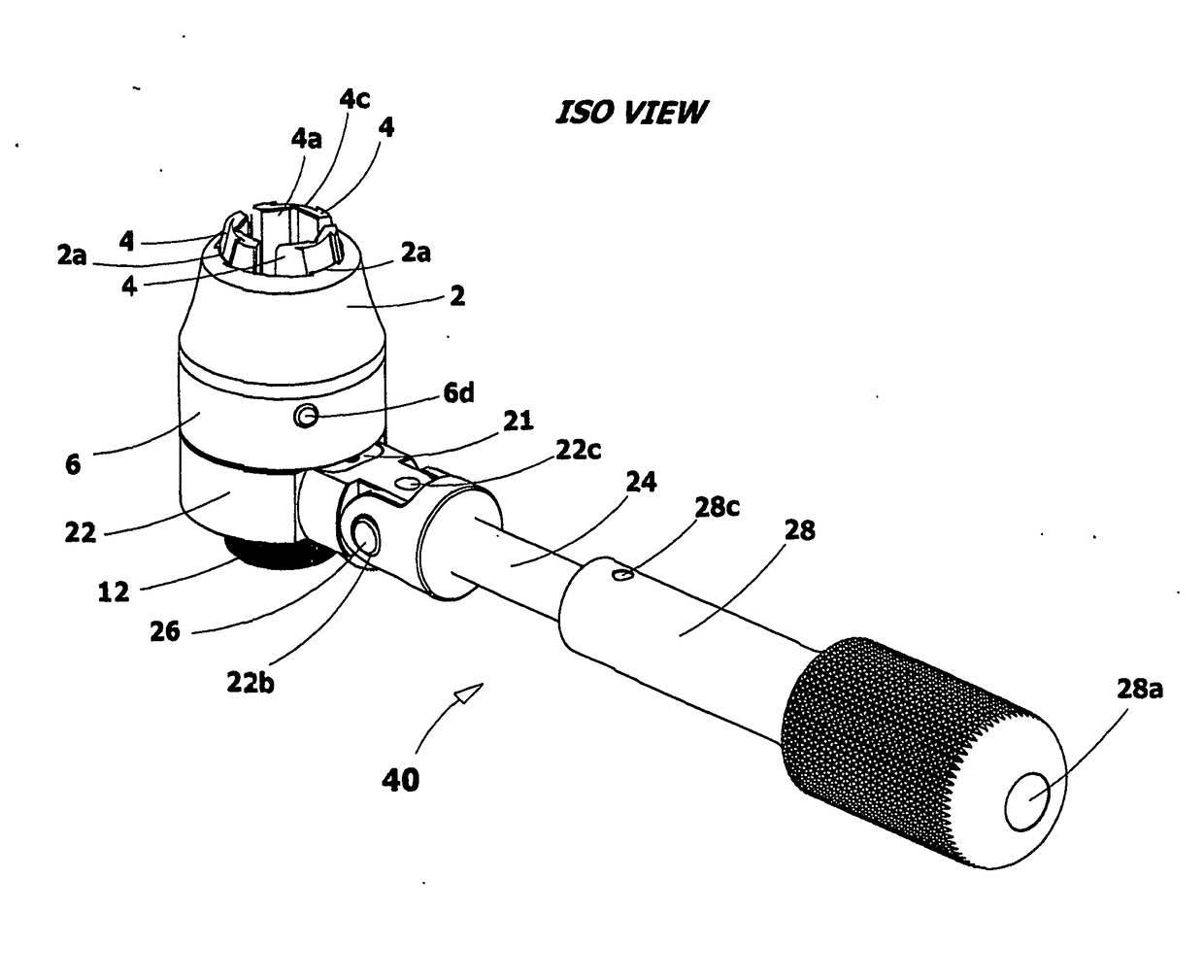

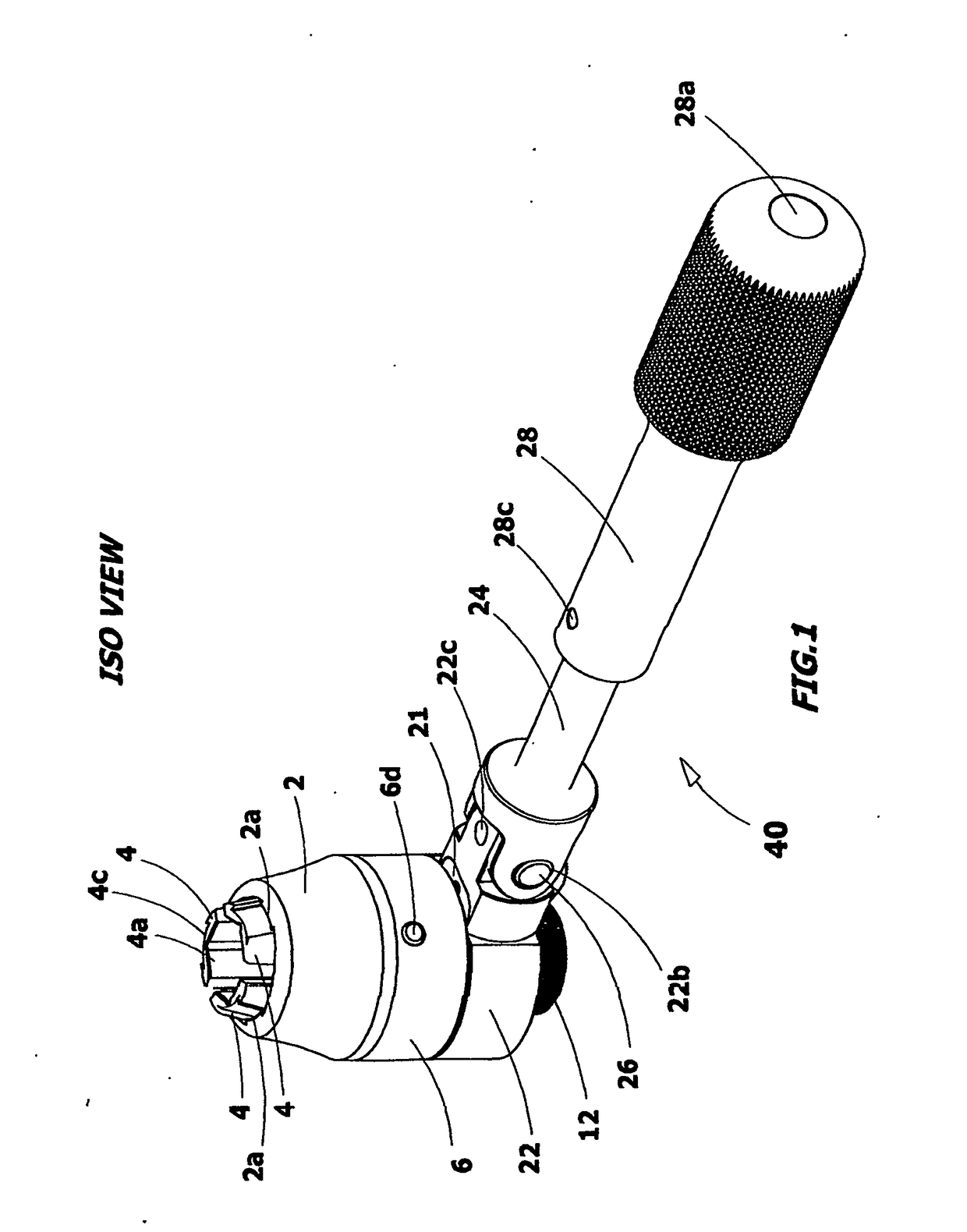

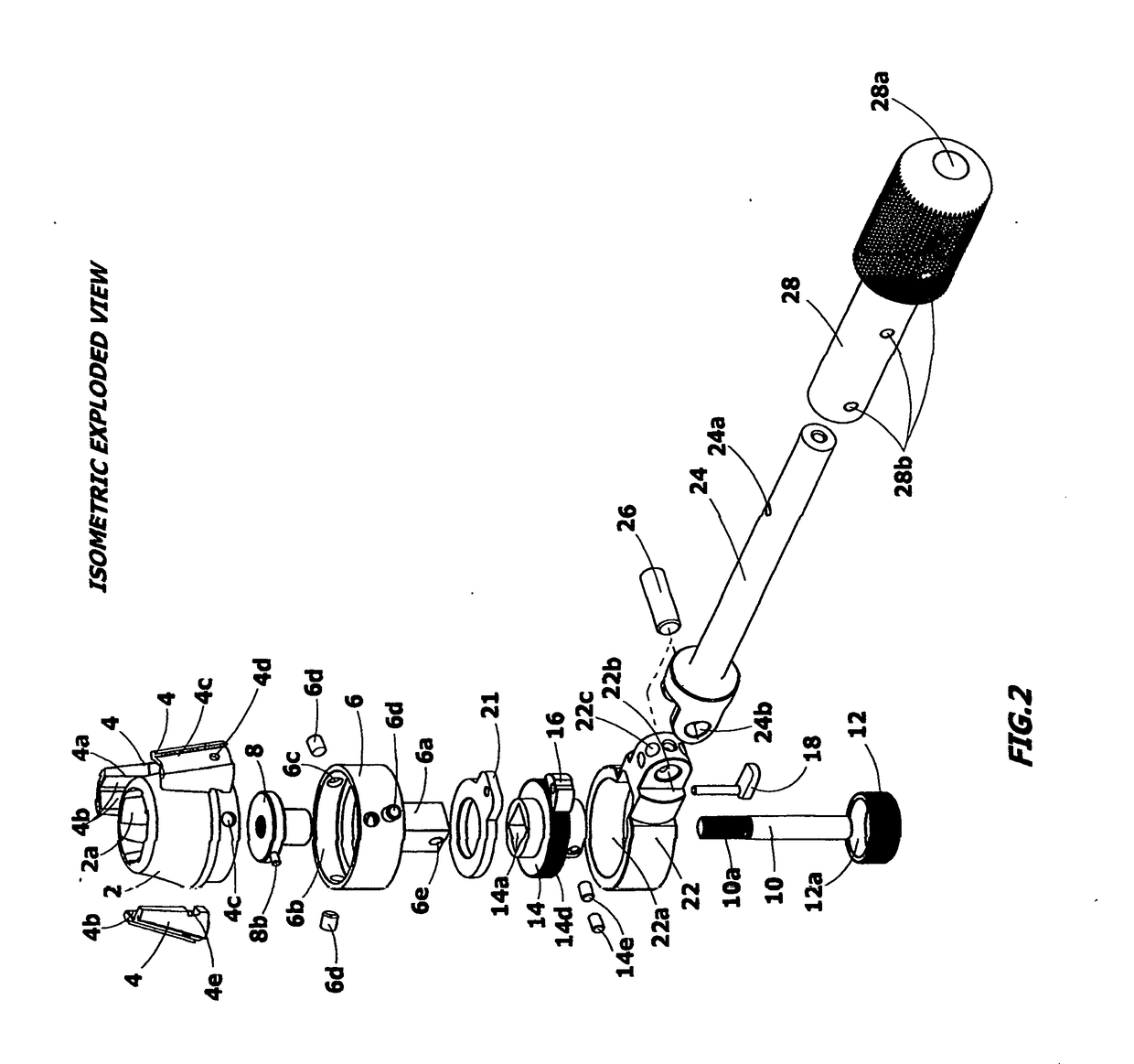

Three jaw adjustable socket ratchet wrench

A three jaw adjustable socket ratchet wrench apparatus comprised of a permanently attached adjustable socket head assembly having three radially positioned jaws which ride trilaterally within an upper cylindrical housing; the extended wrench embodiment has a flexible ratcheting head and a permanently attached three jaw adjustable socket that swivels angularly from +90 folded to +45 to 180 degrees to −45 degrees back to 180 degrees; the extended swiveled arm female lug end is attached onto the male lug of the ratcheting head which has an and an extending cylindrical, shelled, knurled handle which extends outward in two extended distal lengths which can be locked in any of those three positions with the aid of a spring induced détente steel ball bearing; the extended swiveled solid arm has a longitudinal horizontal channel where the outer knurled slide handle rides outward from fully retracted to mid extension adjustment to full extension for extra leverage for high torque requirements; the three vertical jaw members of the adjustable socket head end are abutted inward at 15 degrees to the jaws upper housing radial walls of the same angular taper; each of the jaw member have an interior 120 degrees V-notch which becomes a hexagonal configuration when they are trilaterally spaced apart to accept standard hexagonal configured nuts and bolt type fasteners of various; the adjustable socket's head has a lower driver embodiment having a vertical ⅜ square male shaft that protrudes downward and within the internal central and vertical portion of the ratcheting wheels square female slot; the square male shaft has a vertical through vertical hole to accept a vertical male threaded shaft to control the three jaws to be activated during manual rotation in either a clockwise rotation to expand the jaws opening, and counterclockwise rotation cause the jaws to close in a tapered path; the vertical interior shaft has an upper helix pitch thread screw to accept a horizontal threaded disk of the same thread pitch, the horizontal disk nestles within the horizontal and interior slot on each of the three jaws members, the jaws adjustment in ether rotation is influenced by the users rotation of the lower affixed serrated adjusting knob on the exterior bottom end of the ratcheting head, the ratcheting head having a protective cover plate that is located just below the adjustable sockets lower driver embodiment and nestles into the ratcheting head cavity; the internal vertical adjusting threaded shaft is located between the bottom exterior surface of the ratcheting head and between the radially located jaw members of the sockets' upper housing; when the knurled bottom knob, attached to the main vertical jaw adjusting screw, is rotated by the user, in either direction, this rotation activates the radially positioned jaw members to either move upwards or downwards in a 15 tapered degrees path depending on the axial rotation the use user wish to adjust the three jaw members to; the interior of three jaws are configured hexagonally, 120 degrees v-notch, to grasp a an hexagonal fastener to either tighten or loosen upwards or downward depending on the axial rotation of the main vertical bottom knob; the three jaws maneuvering is accomplished by a smaller, upper diameter actuator ring horizontally seated within a lower internal pocket of each jaw member to influence their movement in either an upward or downward and tapered motion; the main vertical thread screw is attached and retained to the bottom of the adjusting knurled knob; the ratcheting head has a ratcheting pawl that swivels to a reverse to forward ratcheting directions, when the user clicks the ratcheting pawls thumb lever to either a forward or a reverse direction this option will either lock the ratcheting head to tighten a selected bolt fastener or loosen a selected bolt size in the pawls opposing direction; the ratcheting wrenches extending arm has three extended positions for a type of torque requirement needed.

Owner:CARNESI THOMAS

Adjustable clamping device

InactiveUS20130212844A1Good sealingPrevent disengagementSnap fastenersValve arrangementsEngineeringMechanical engineering

An adjustable clamping device is provided. The device includes a first and a second clamping body, an adjusting mechanism and an elastic member. The first clamping body includes a first jaw formed with a first locking member and a first connecting portion formed with first limiting portion. The second clamping body includes a second jaw formed with second blocking member and a second connecting portion formed with at least two second limiting portions. A jaw opening is formed between the first and second jaws. The adjusting mechanism includes a shaft which is rotatably positioned at the first limiting portion and selectively positioned at one of the second limiting portions.

Owner:CHEN JUN FAN

Mechanical claw

The invention discloses a mechanical claw, which includes a connecting seat, a clamping jaw is connected to the connecting base, a clamping jaw opening and closing device is connected between the connecting base and the clamping jaw, a clamping guide column is arranged on the clamping jaw, and There is a spring connected between the guide post and the jaws. The guide post includes a movable guide post and a positioning guide post. A rotating sleeve is arranged on the outside of the positioning guide post. The rotating sleeve is connected to the central turntable through a linkage mechanism. Connection, the servo motor is connected with the control device. When picking up objects with irregular outer surfaces, the rotating sleeve is rotated by the central turntable so that the positioning guide post is in a free state, so as to facilitate picking up the objects. When clamping an object with a regular outer surface, the rotating sleeve is rotated so that the positioning guide post is in a fixed positioning state, and the clamping of the object is more stable. By setting the positioning guide column, the clamping function of the mechanical claw is more diverse, and the needs of people are more satisfied.

Owner:ANHUI KUDZUVINE ROOT PRODUCTIVITY PROMOTION CENT CO LTD

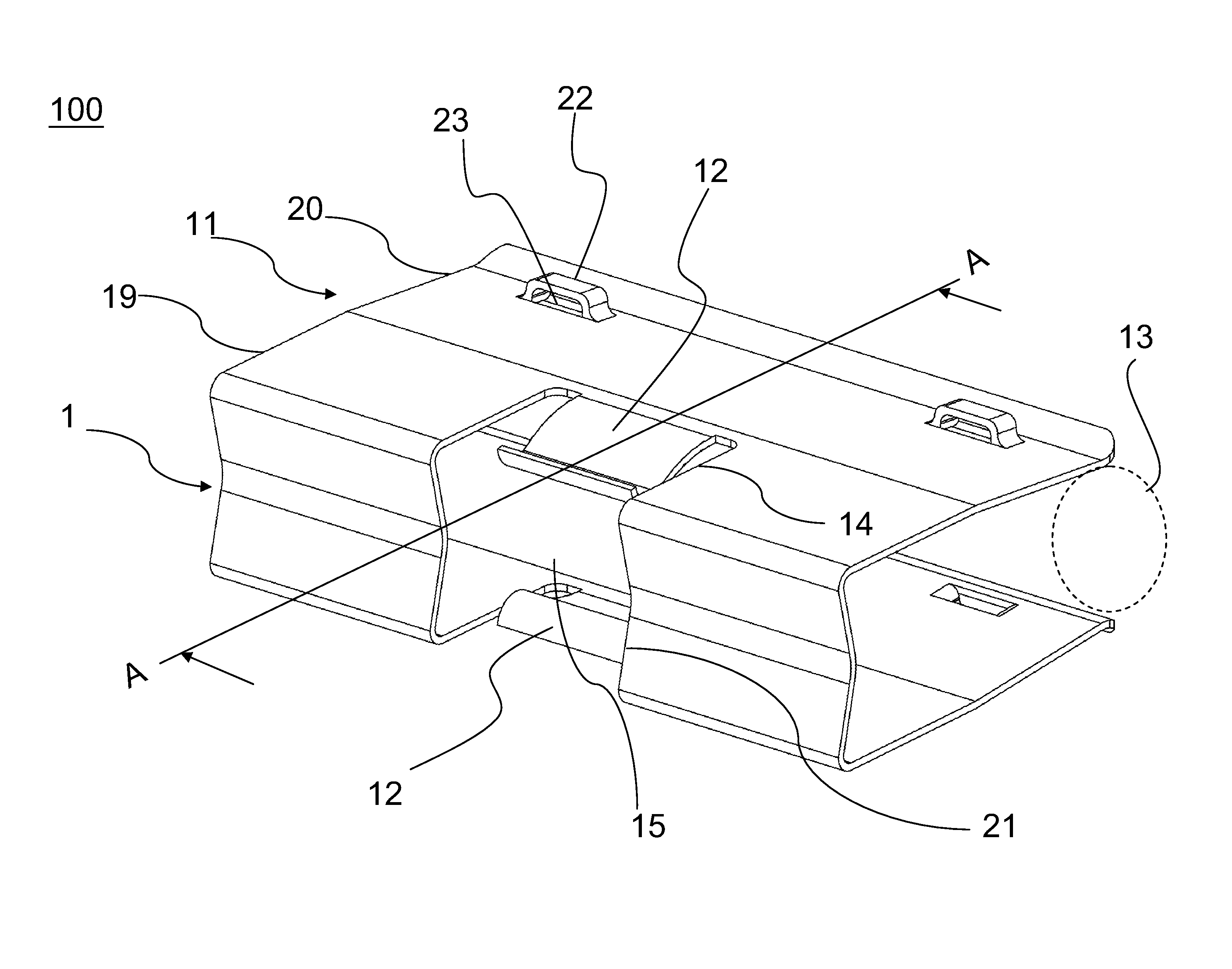

Clamp structure

ActiveUS20120151721A1Improve yieldFirmly connectedSnap fastenersSolar heating energyEngineeringJaw opening

A clamp structure includes a base plate, a pair of first jaws, and a pair of second jaws. The first jaws extend respectively from two sides of the base plate in a face-to-face manner and form a first jaw opening at their ends. The first jaws are also formed with a pair of cutouts that face each other. The second jaws extend respectively from the pair of cutouts towards the base plate and form a second jaw opening at their ends. Each second jaw has a hook-shaped configuration composed of a first arc near the second jaw opening and a second arc away from the base plate, wherein the first arc has a greater curvature than the second arc. A junction box and a solar panel which are bonded together can be inserted into and thus clamped by the clamp structure so as to be secured against lateral shifting.

Owner:KS TERMINALS INC

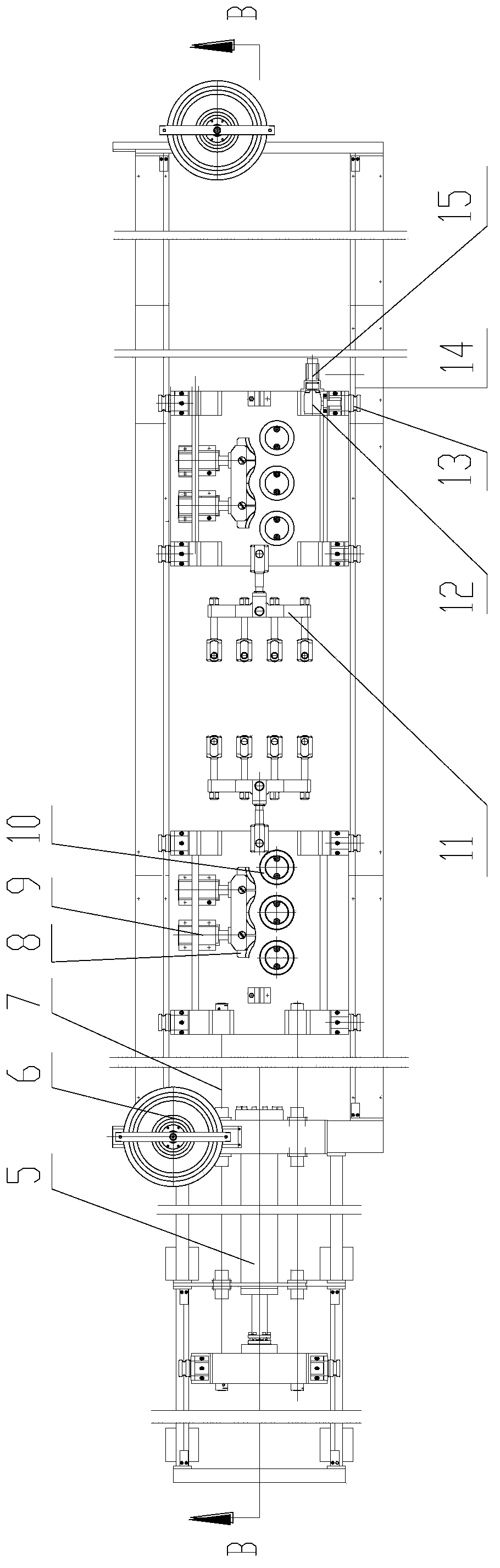

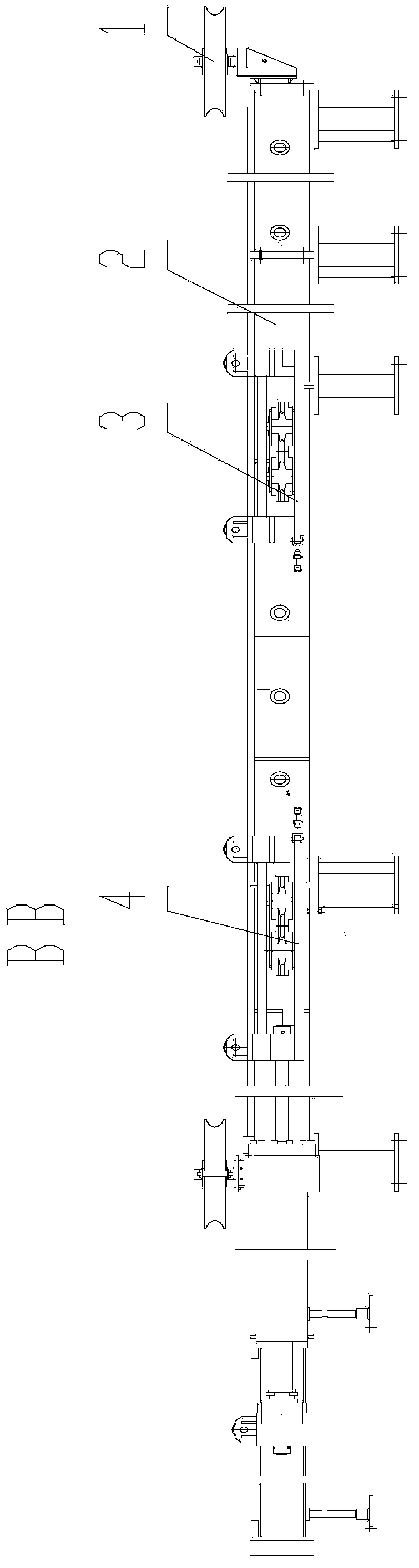

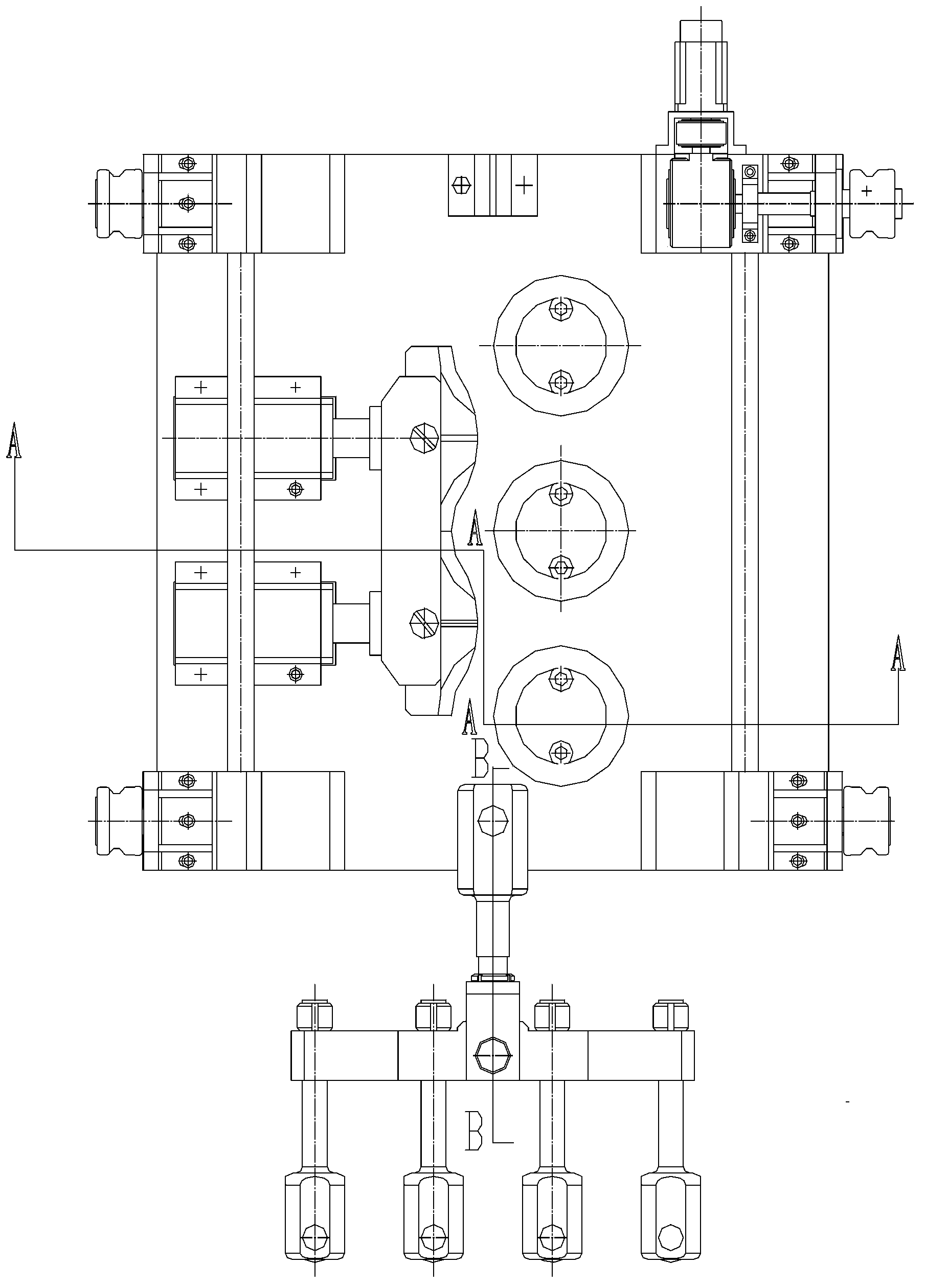

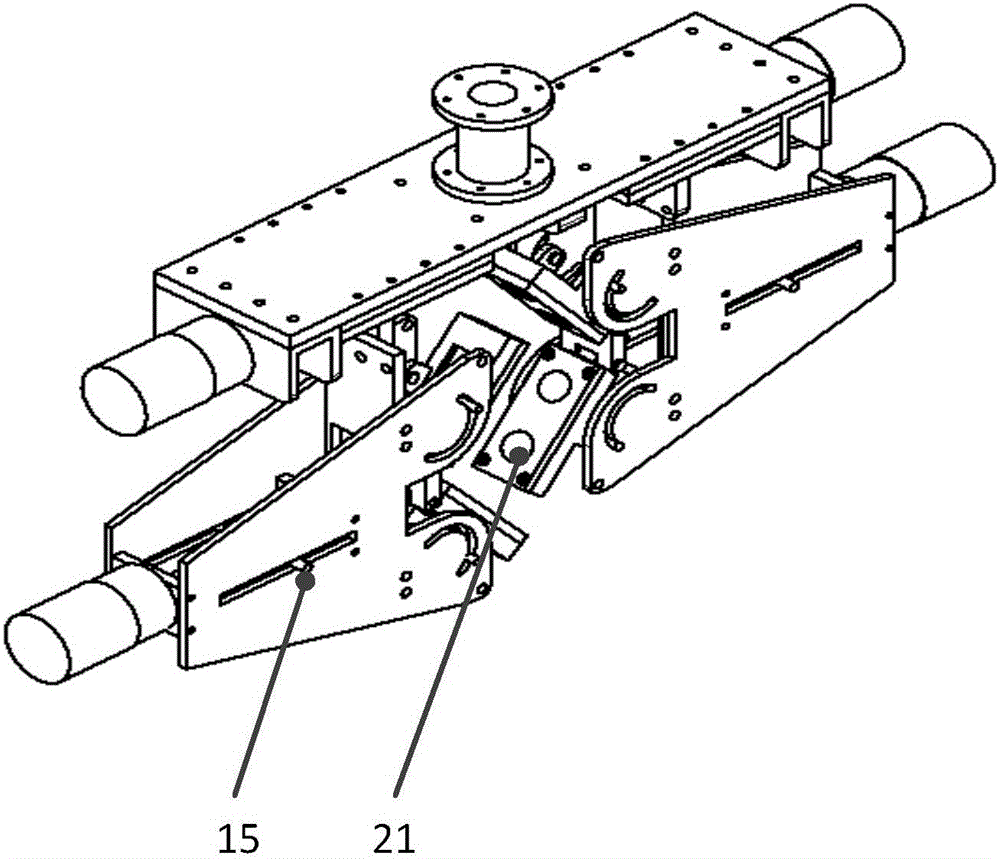

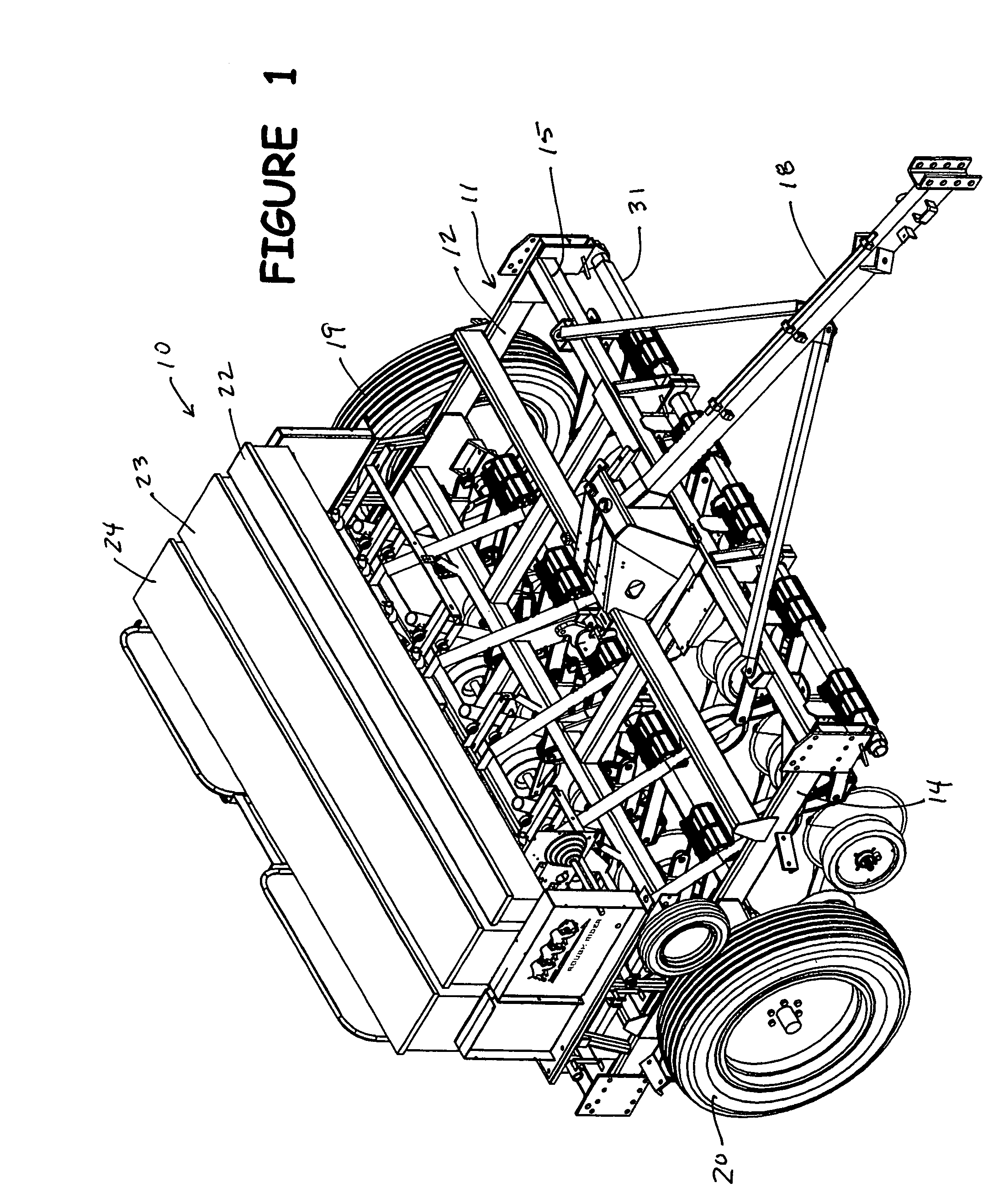

Numerically controlled bus punching shearer

InactiveCN105710240ASolve rigid problemsSolve processabilityShaping toolsMetal-working feeding devicesPunchingEngineering

A numerically controlled bus punching shearer comprises a rack, wherein a feeding assembly part and a striking assembly part are arranged on the rack; the feeding assembly part comprises a gripper assembly; the gripper assembly comprises a main gripper assembly I and a main gripper assembly II; the main gripper assembly I and the main gripper assembly II are respectively positioned on two sides of the striking assembly part; each of the main gripper assembly I and the main gripper assembly II comprises a gripper seat, a jaw, an active jaw opening and closing driving component and a gripper seat X-axis moving driving component; each gripper seat is arranged on an X-axis moving guide track of the rack in a matched manner; each jaw comprises an active jaw and a passive jaw; and each gripper seat X-axis moving driving component is connected to the corresponding gripper seat. The traditional gripper design philosophy in the design of the bus punching shearer is changed, and technical prejudice is overcome. The numerically controlled bus punching shearer has the advantages of high machining efficiency (which can be three times that of the traditional bus processing machinery), and high workpiece positioning and machining precision.

Owner:SHANDONG SHANHE CNC EQUIP CO LTD

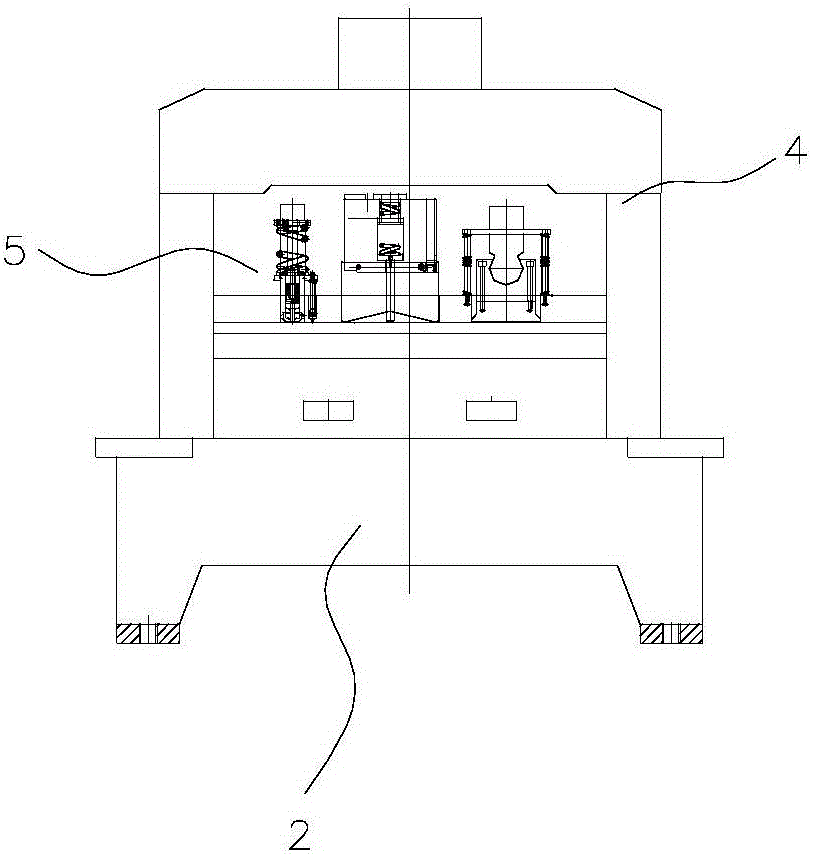

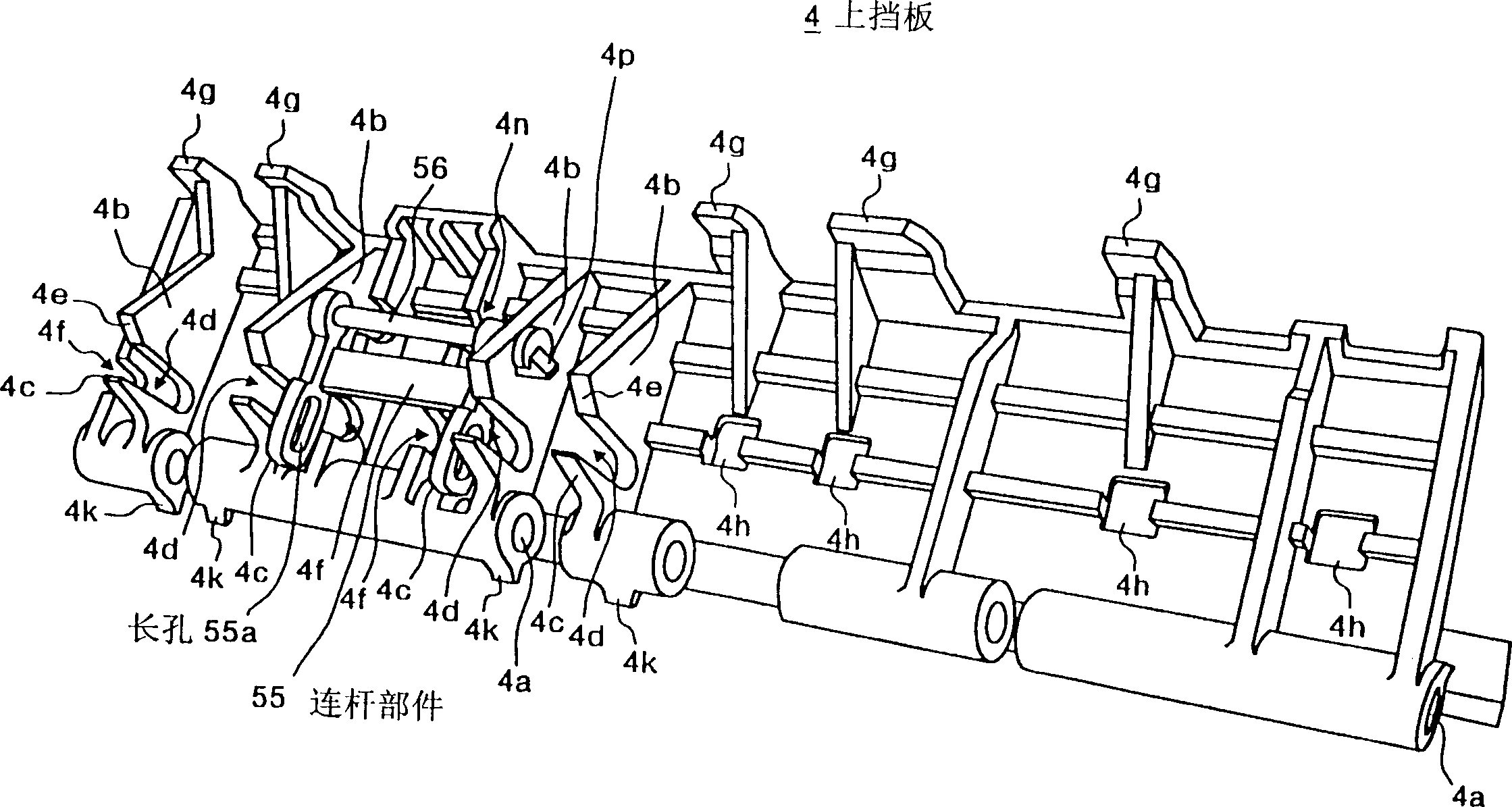

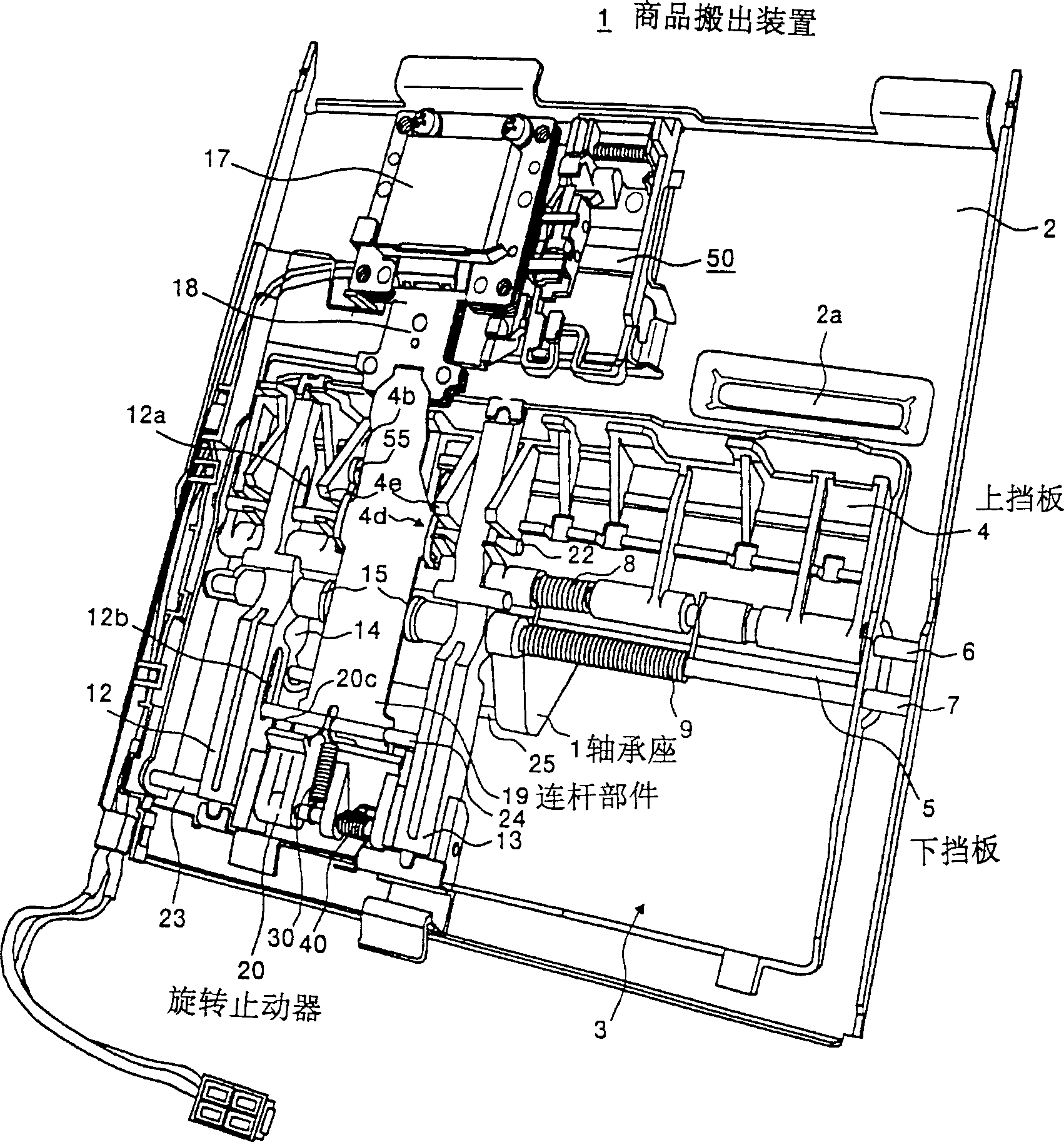

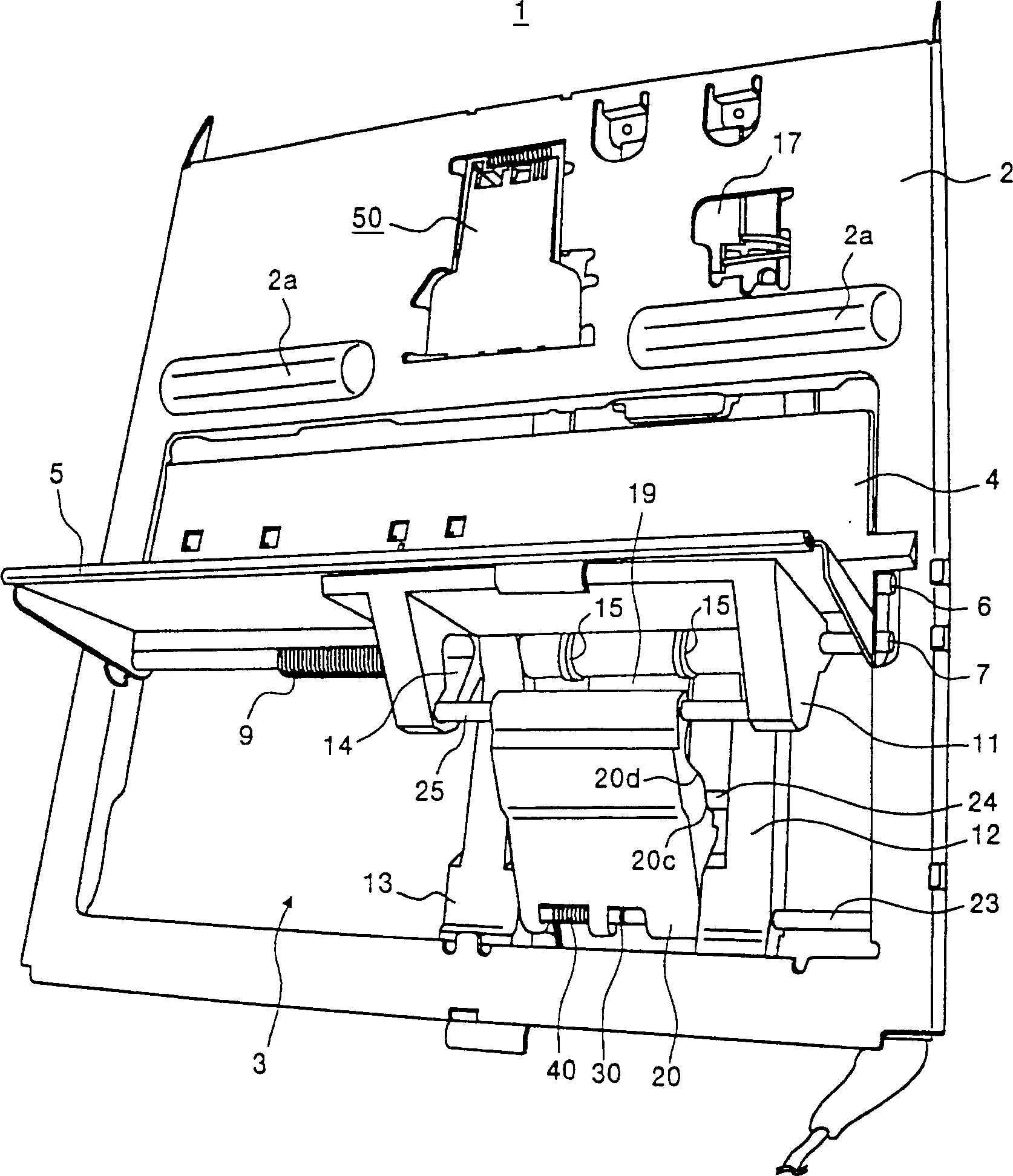

Commodity moving out device for automatic vending machine

InactiveCN1523542AGuaranteed driving forceCoin-freed apparatus detailsApparatus for dispensing discrete articlesReciprocating motionJaw opening

The invention is a kind of product pushing device of automatic vending machine, it has: the upper and subjacent baffle plates which are supported at the aperture of the base board with shaft, and prominent from the aperture to product channel, and which maintains the first and the second product from low side; the link device which is used to control close and open of the baffle plates and which moves in shuttle through driving device, the device can push out the product with different diameter without changing the width of the channel, the character lies in: the revolution retainer is jointed with the link peg on the link device, it can lock the revolution of itself, it can restrain the rotation of the subjacent plate by using the retainer peg, maintains the maximal jaw opening state; the assistant retainer element prevents the rotation of the subjacent plate.

Owner:FUJI ELECTRIC CO LTD

Adjustable Wrench

Disclosed is an adjustable wrench including a handle and a working portion. The working portion includes an adjusting device and at least two jaws. The jaws are distributed along the circumferential direction of the working portion, and the adjusting device is arranged such as to adjust the jaws to simultaneously move in a radial direction of the working portion, closer to or away from the center of the working portion, that is, the jaw opening defined by the plurality of jaws are adjustable. The adjustable wrench provided by the invention is adapted for workpieces of various specifications, and can realize rapid adjustment.

Owner:HANGZHOU GREAT STAR TOOLS +1

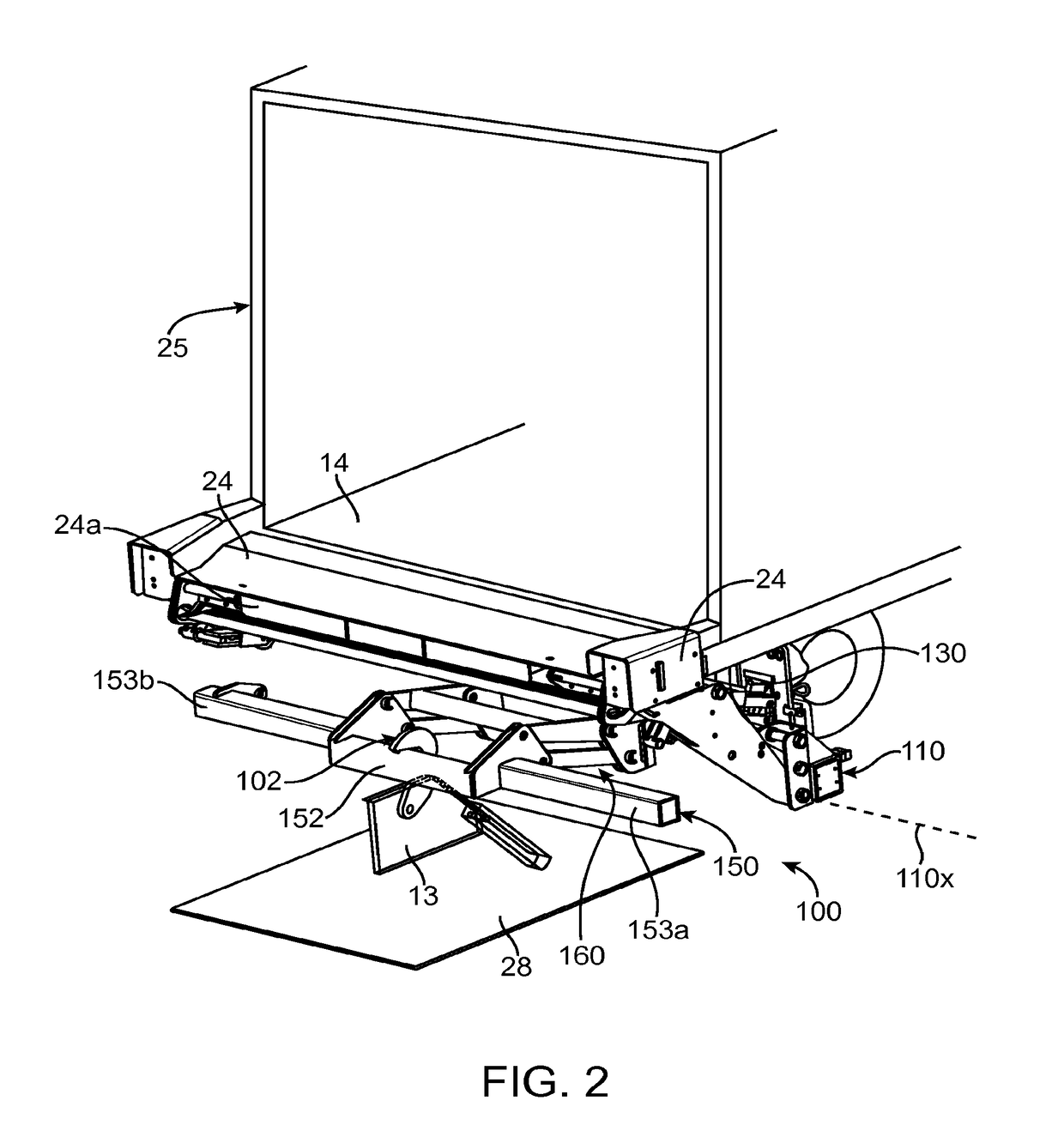

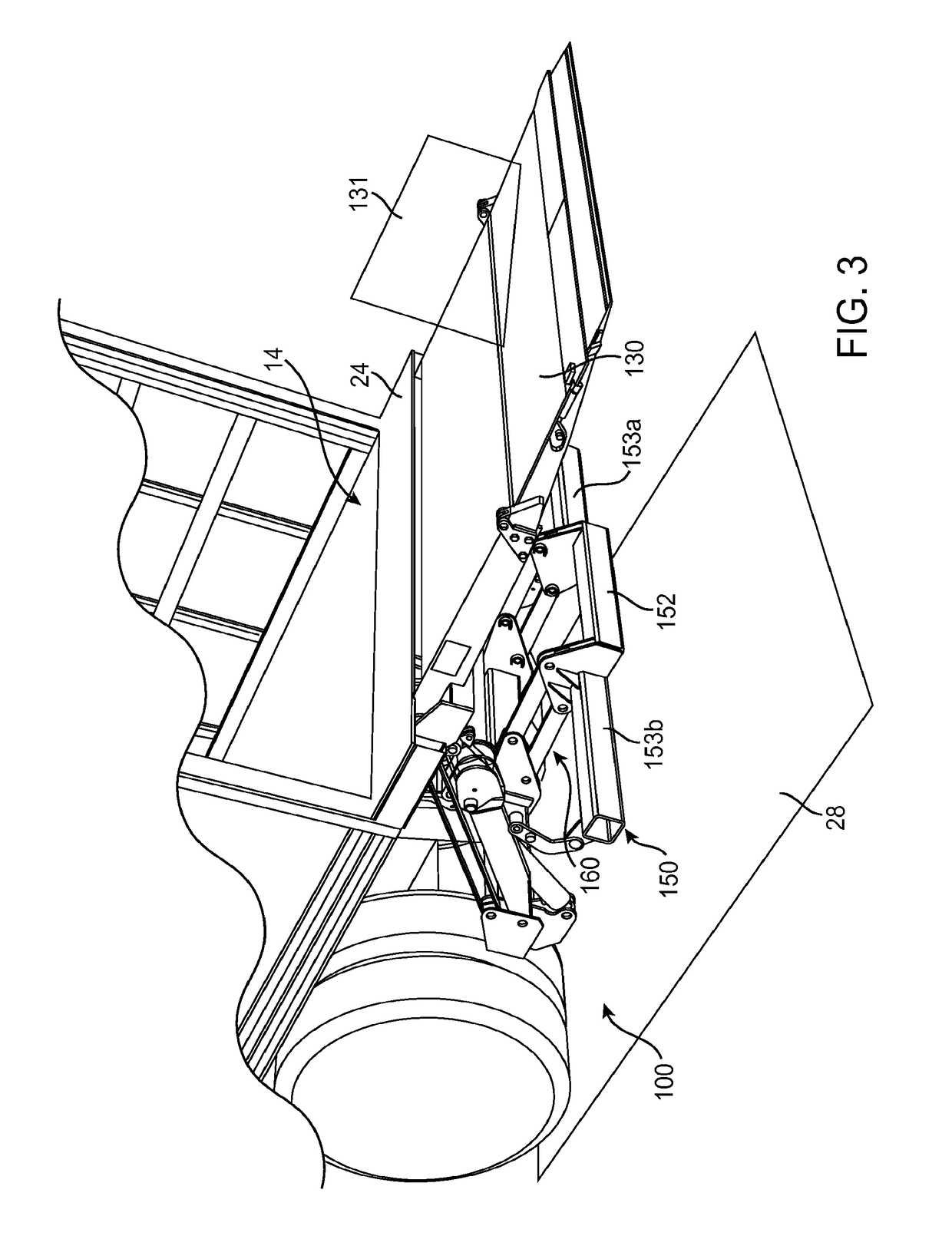

Mounting system for vehicle underride

ActiveUS10220759B2Vehicle with raised loading platformVehicular safety arrangmentsEngineeringMechanical engineering

A mounting mechanism for mounting an underride system on a structure, comprises a pair of clamping jaws, and a first bracket including a first edge for coupling the underride system thereto. The first bracket further includes a second edge for coupling the pair of clamping jaws thereto. Wherein, the first bracket and the pair of clamping jaws define a jaw opening therebetween configured to receive at least a portion of the structure for removably mounting the underride system on the structure using the mounting mechanism.

Owner:MAXON INDS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com