Break-free safety release buckle and fastener

a safety release buckle and buckle technology, applied in the direction of clothing, applications, household appliances, etc., can solve the problems of unsuitable use in other applications, and achieve the effects of reducing manufacturing costs, facilitating adaptation, and facilitating application flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will generally be constructed of semi-rigid material similar to that used in the manufacture of plastic fasteners and buckles which are generally formed by injection molding, although other suitable material and methods of forming may be used.

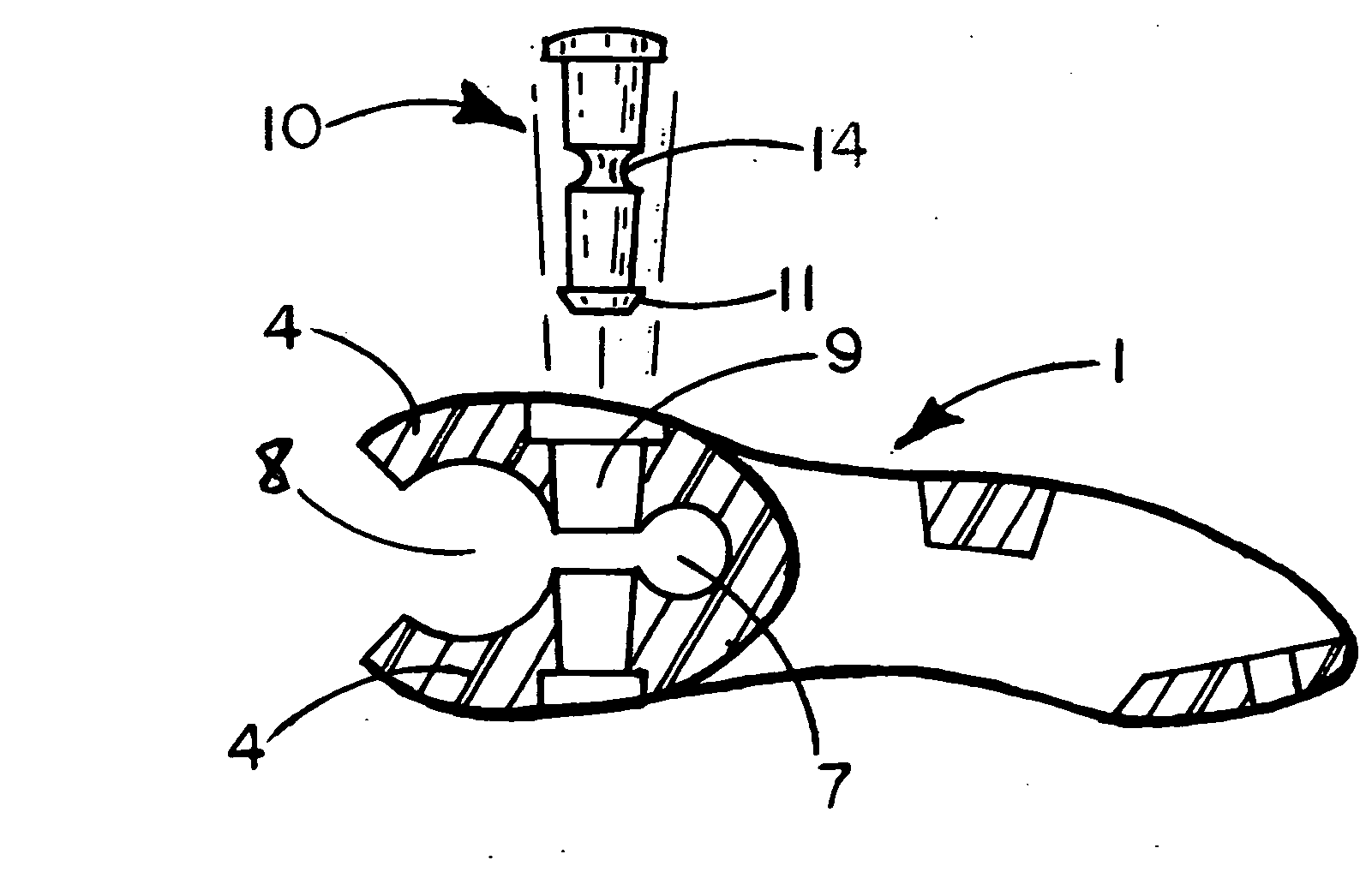

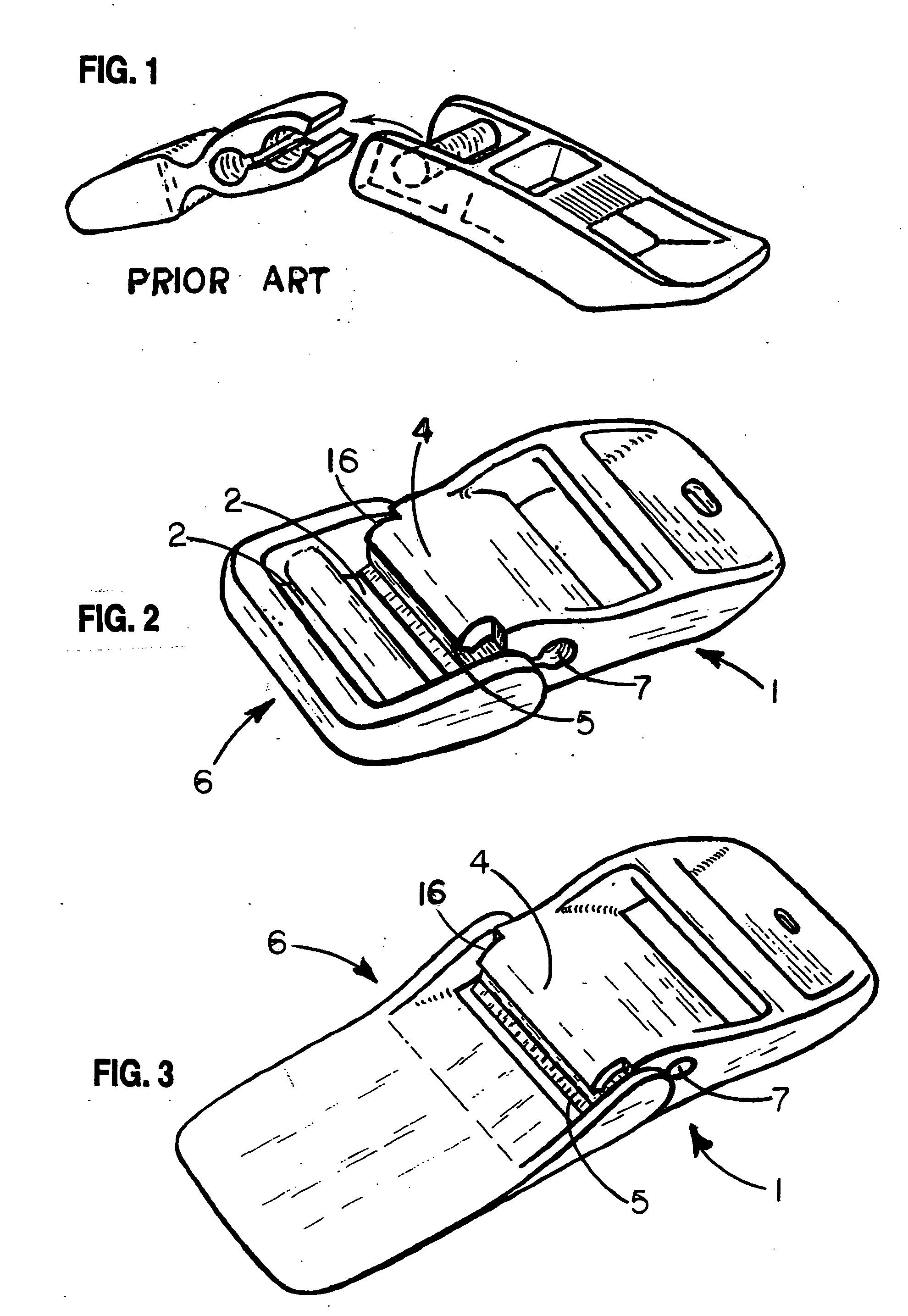

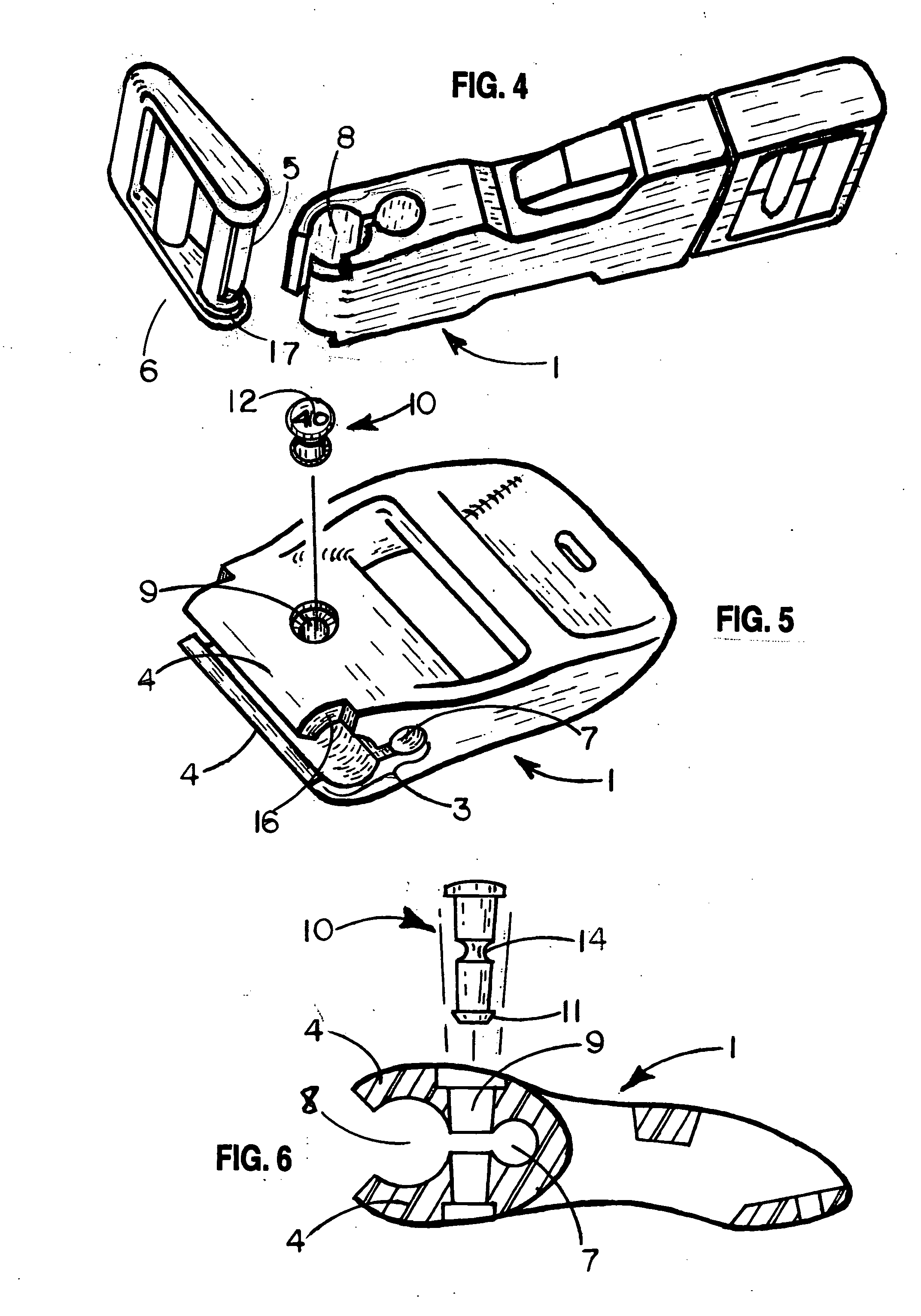

[0024] In the following description major parts of the assembly will be referred to as a release member 1 and a fastening link 6. While the jaws 4, stud 5, and related structures can be incorporated on either buckle portion, in the preferred and illustrated embodiment the jaws 4 will be incorporated as part of the primary buckle member to which the break free invention is adapted. In this manner, when the rivet 10, bridge 13, or other such limiting device is broken or the jaws 4 eventually fail, the broken or failed members can be easily replaced as part of a replacement release member. If the jaws were reversed, as being part of the fastening link, it would be necessary to remove stitching or other fastenings whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com