Zero damage multifunctional steel wire rope tension tester fixture

A tensile testing machine and steel wire rope technology, applied in the field of non-damaging multifunctional steel wire rope tensile testing machine fixtures, can solve problems such as single function, clamping end damage, and inability to objectively evaluate the safety status of steel wire ropes, so as to reduce compression damage and increase Grip contact area and length, and the effect of tensile test to ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention relates to a multifunctional tensile test fixture for clamping special flexible bodies and U-shaped rings combined with a direct clamping method, which can realize non-damaging clamping of slender flexible bodies and The tensile test of multiple U-shaped rings used for cable tension erection provides an effective guarantee for random online tensile tests of steel wire ropes.

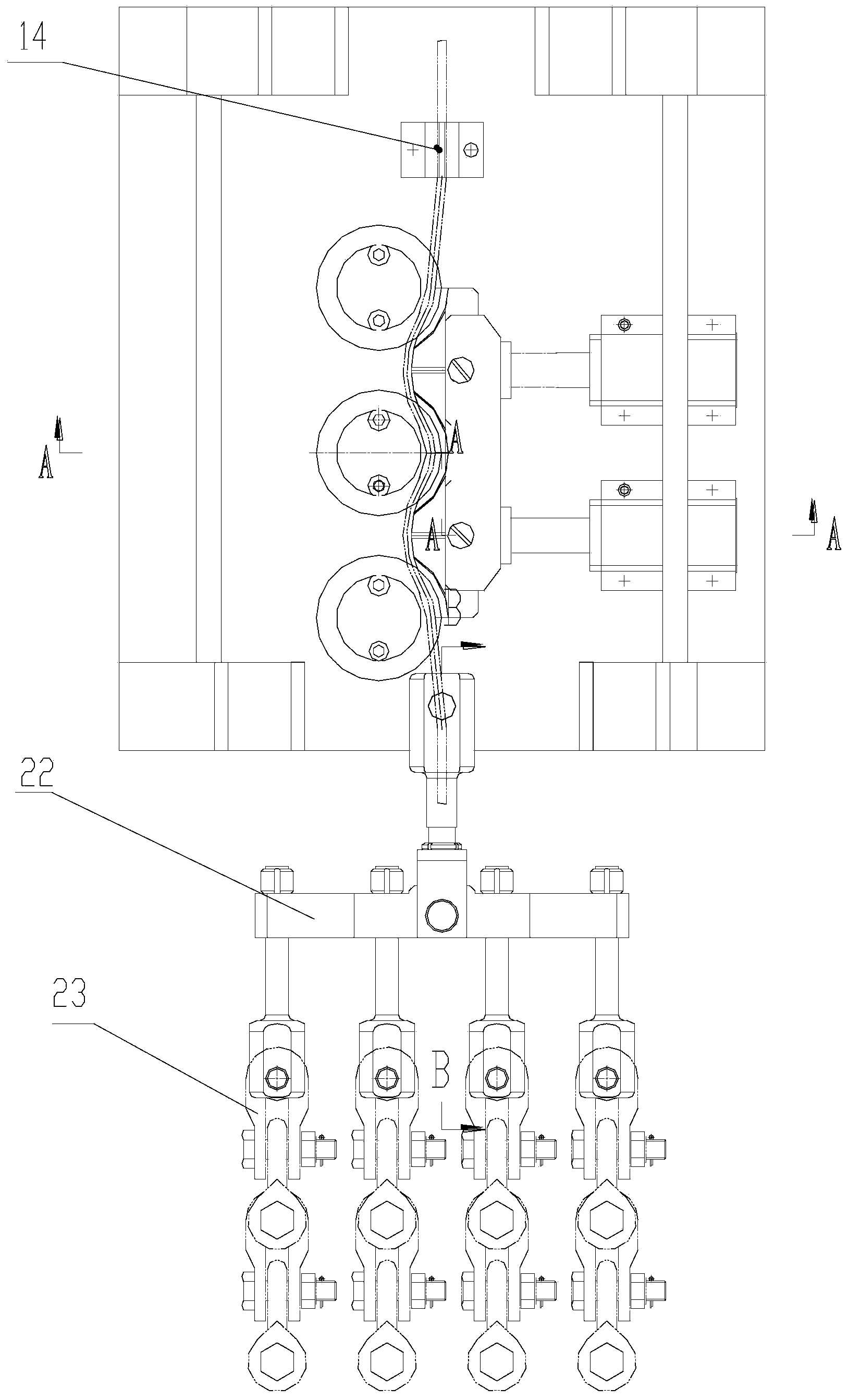

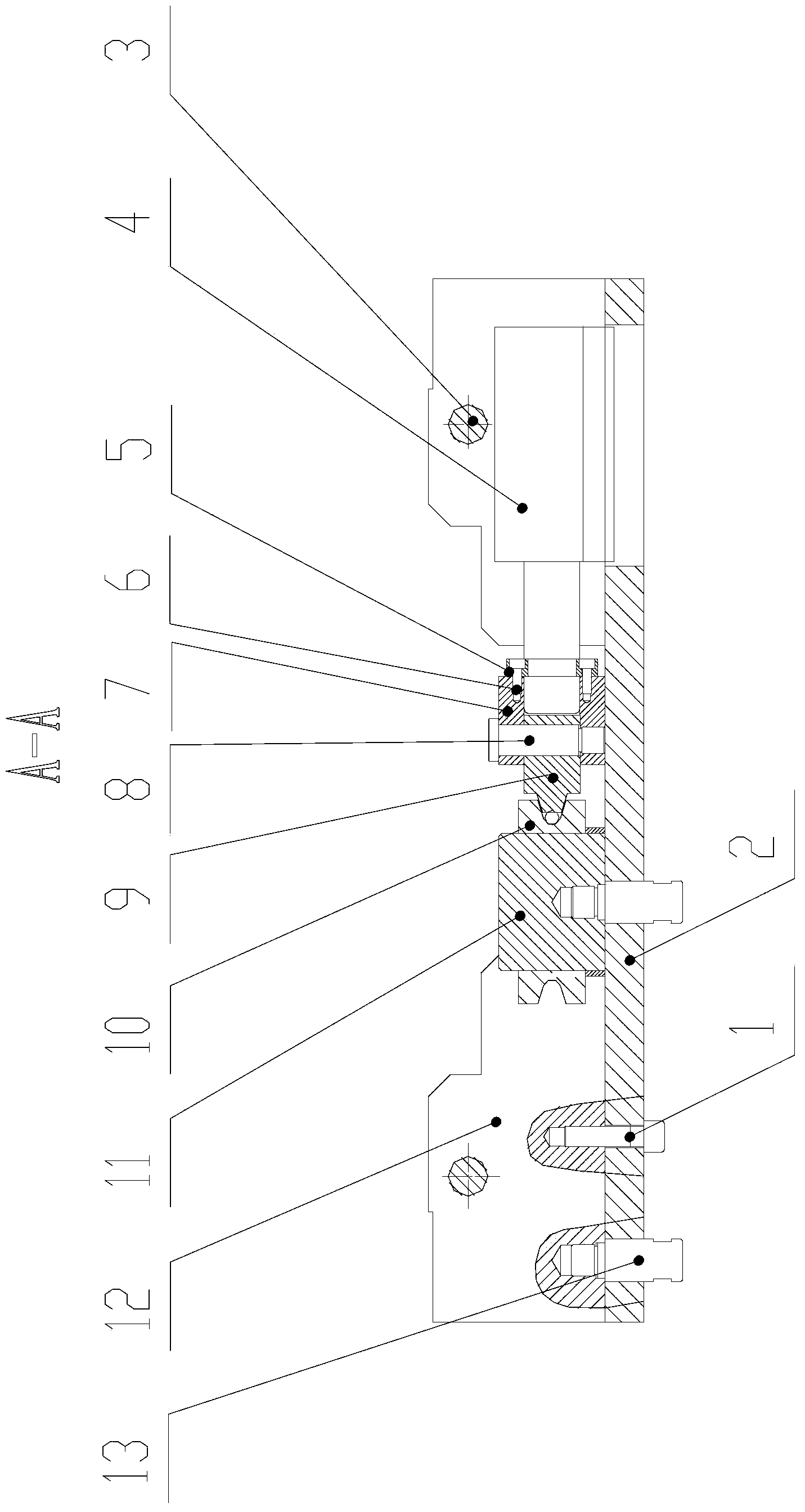

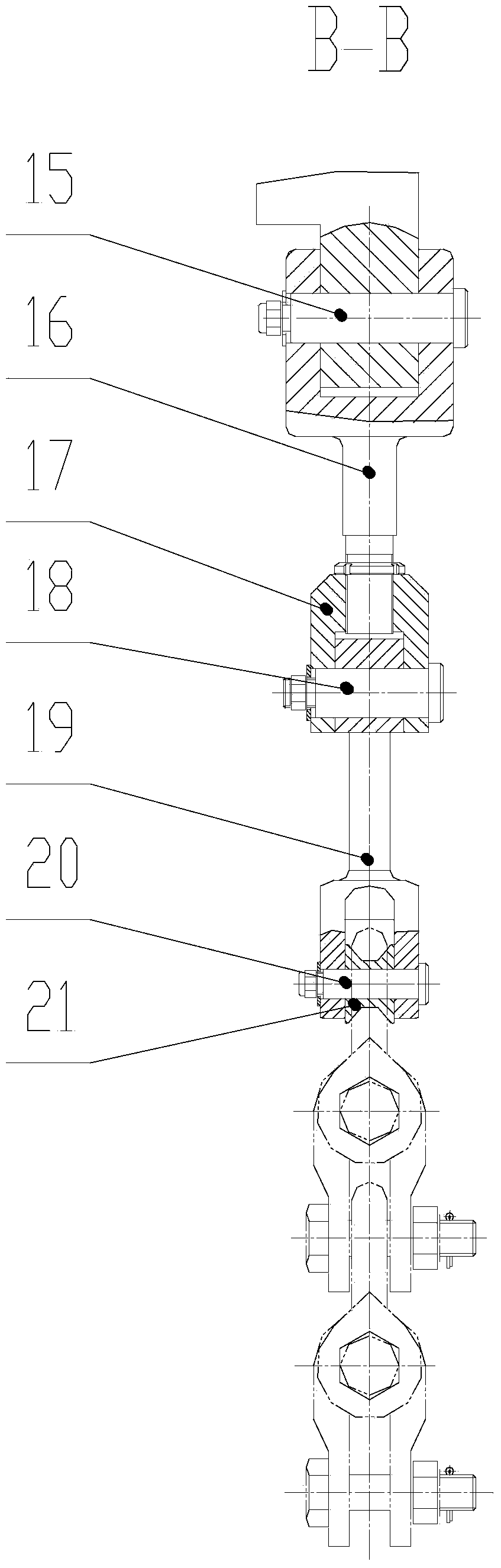

[0030] The structure of the jaw part of the fixture is as follows figure 1 , figure 2As shown, it is mainly composed of connecting screw 1, base 2, tie rod 3, hydraulic cylinder 4, two semicircular flanges 5, screw 6, connecting piece 7, pin 8, dynamic clamping jaw 9, winding wheel 10, thick pier Shaft 11, tie rod seat 12, coupling pin 13, steel wire rope V-shaped positioning block 14 etc. are formed. The winding wheel 10 is fixed on the base 2 through the pier thick shaft 11 and the same threaded pin as the connecting pin 13, the S-type dynamic clamping jaw 9 is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com