Method for positioning jaw opening of coiler mandrel

A positioning method and jaw technology, which is applied in the field of coiler reel jaw positioning to avoid scratches on the inner ring of the steel coil, can solve the problem that the expansion and contraction of the reel is not enough to meet the gap requirements, the steel coil is scratched, and the uncontrollable and other problems, to achieve the effect of reducing the probability of scratches, improving the yield of products, and avoiding frequent scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

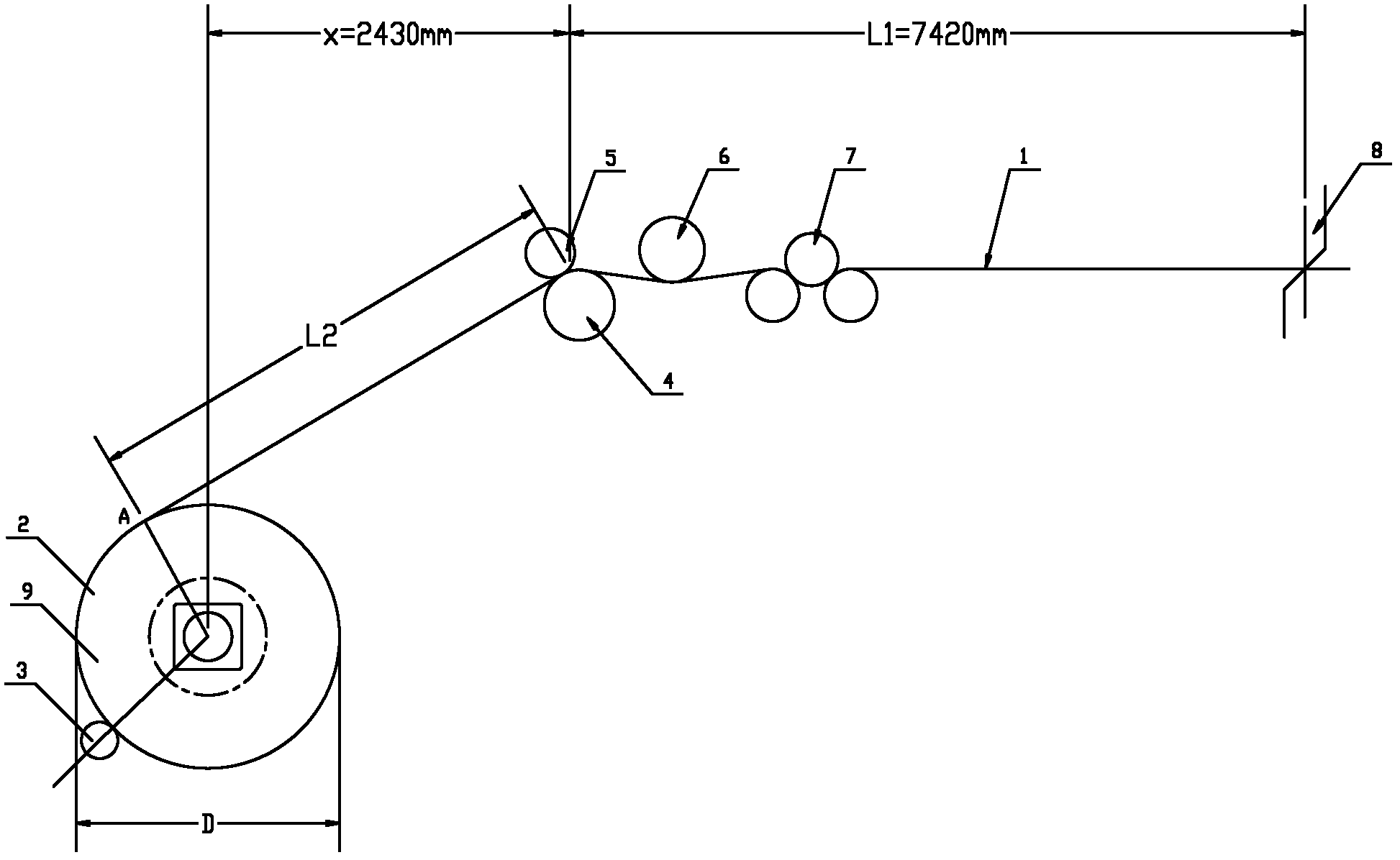

[0022] See figure 1 , is a schematic diagram of the coiling and cutting state in the method for positioning the jaws of the reel of the coiler according to the present invention. The bending roll 6 and the tension roller group 7 are connected to the leveling unit, the outlet buffer roller 3 is located at the eight o'clock position of the steel coil 9, and the cutting shears 8 are located behind the tension roller group 7.

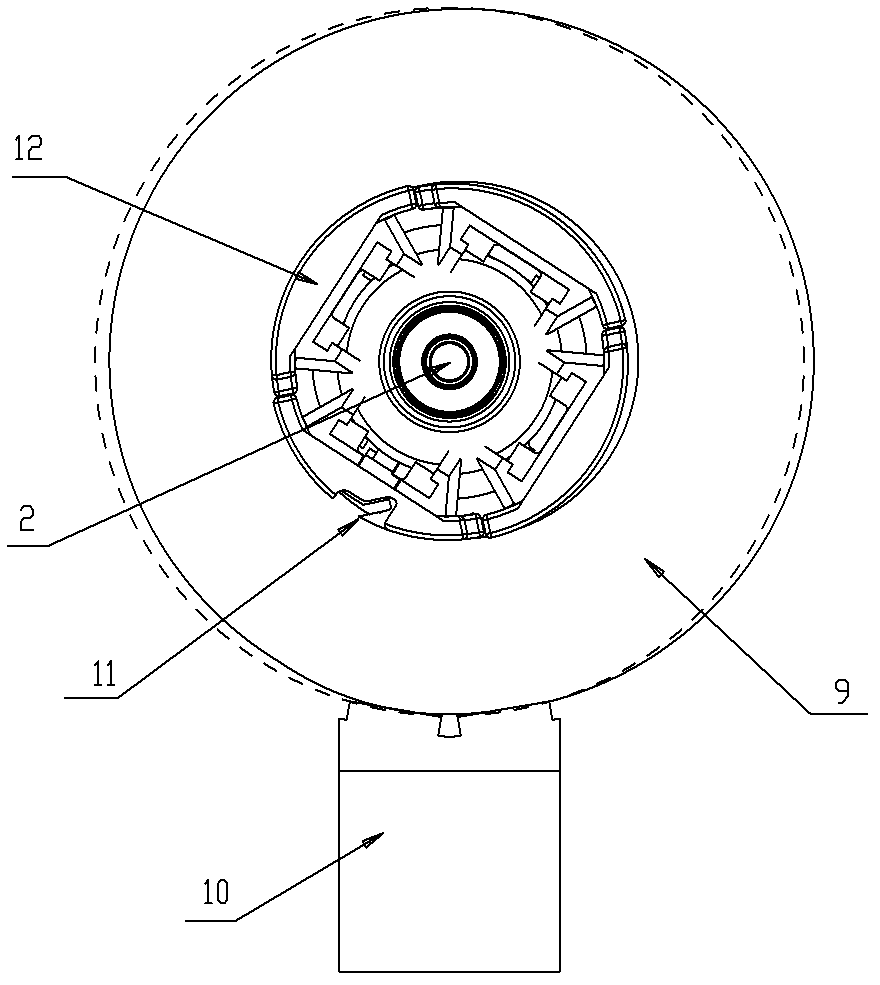

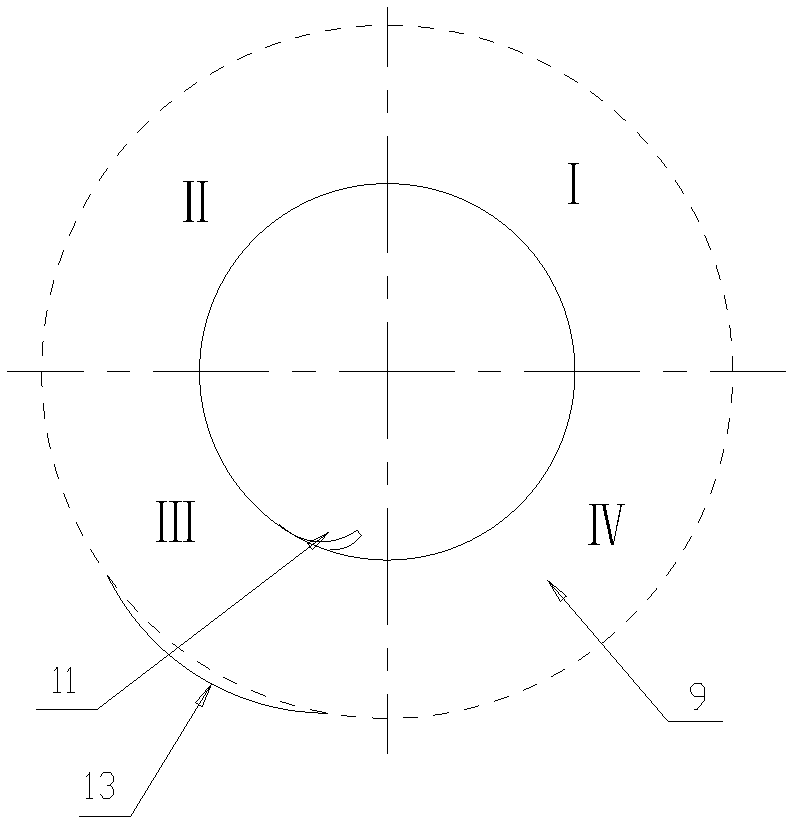

[0023] See figure 2 , is a schematic diagram of the deformation analysis of the steel coil 9 on the roll support trolley 10. When the jaw 11 is located at the position from four o’clock to eight o’clock, after the steel coil 9 is lifted up, the position of the jaw 11 corresponds to the outer surface with a local protruding outer ring. 13, the radius of curvature suddenly decreases. During the roll-holding process, the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com