Mechanical claw

A mechanical claw and gripper technology, which is applied in the field of mechanical automation, can solve the problem of not being applicable to the gripping of irregular objects on the outer surface, etc., and achieve the effect of diverse gripping functions and stable gripping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

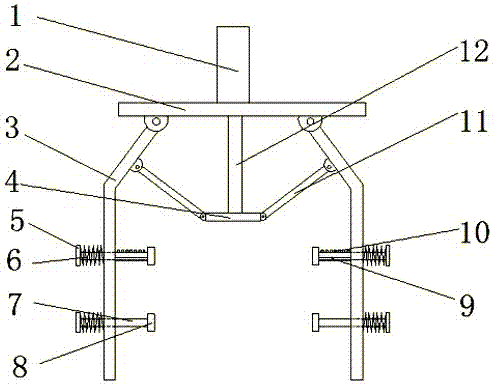

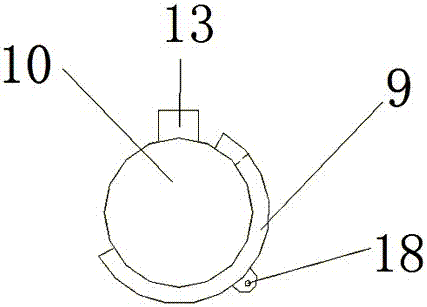

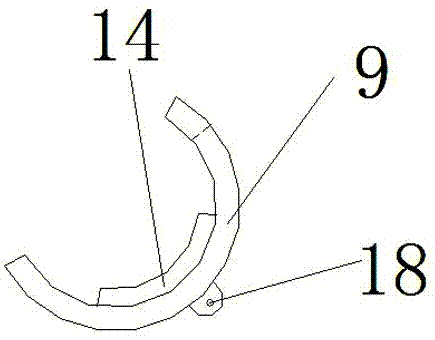

[0018] Examples such as Figure 1-Figure 5 As shown, a mechanical claw includes a connecting seat 2 for connecting with a mechanical arm, a gripper 3 is connected to the connecting seat 2, and a gripper opening and closing device is connected between the connecting seat 2 and the gripper 3 .

[0019] The jaw opening and closing device includes a cylinder 1 provided on the connecting seat 2, the piston 12 of the cylinder 1 protrudes from the lower end of the connecting seat 2 through the connecting seat 2, and the lower end of the piston 12 is connected to the movable seat 4, and the movable seat 4 and the jaw 3 Jaw connecting rods 11 are connected therebetween. The cylinder 1 drives the movable seat 4 to move up and down through the expansion and contraction of the piston 12, and then drives the jaw 3 to open and close through the jaw connecting rod 11.

[0020] In order to facilitate the clamping jaw 3 to pick up objects with irregular surfaces, a spring 6 and a movable guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com