Four-quadrant frequency converter

A four-quadrant frequency converter and frequency converter technology, applied in the field of frequency converter control, can solve the problems of inability to suppress the pumping voltage in time, waste of energy, good dynamic performance, etc., to achieve high efficiency utilization, avoid harmonic pollution, and eliminate huge The effect of fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

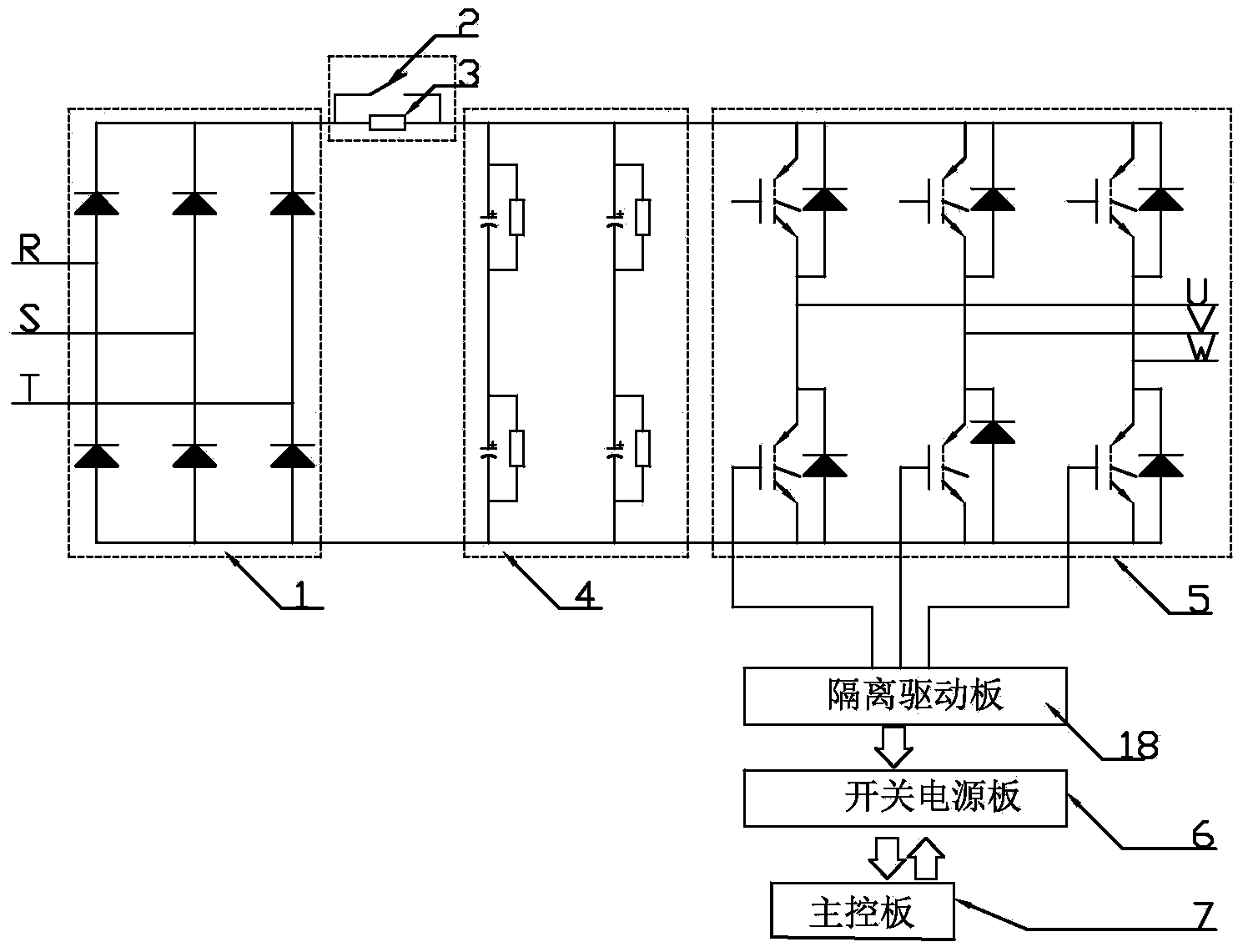

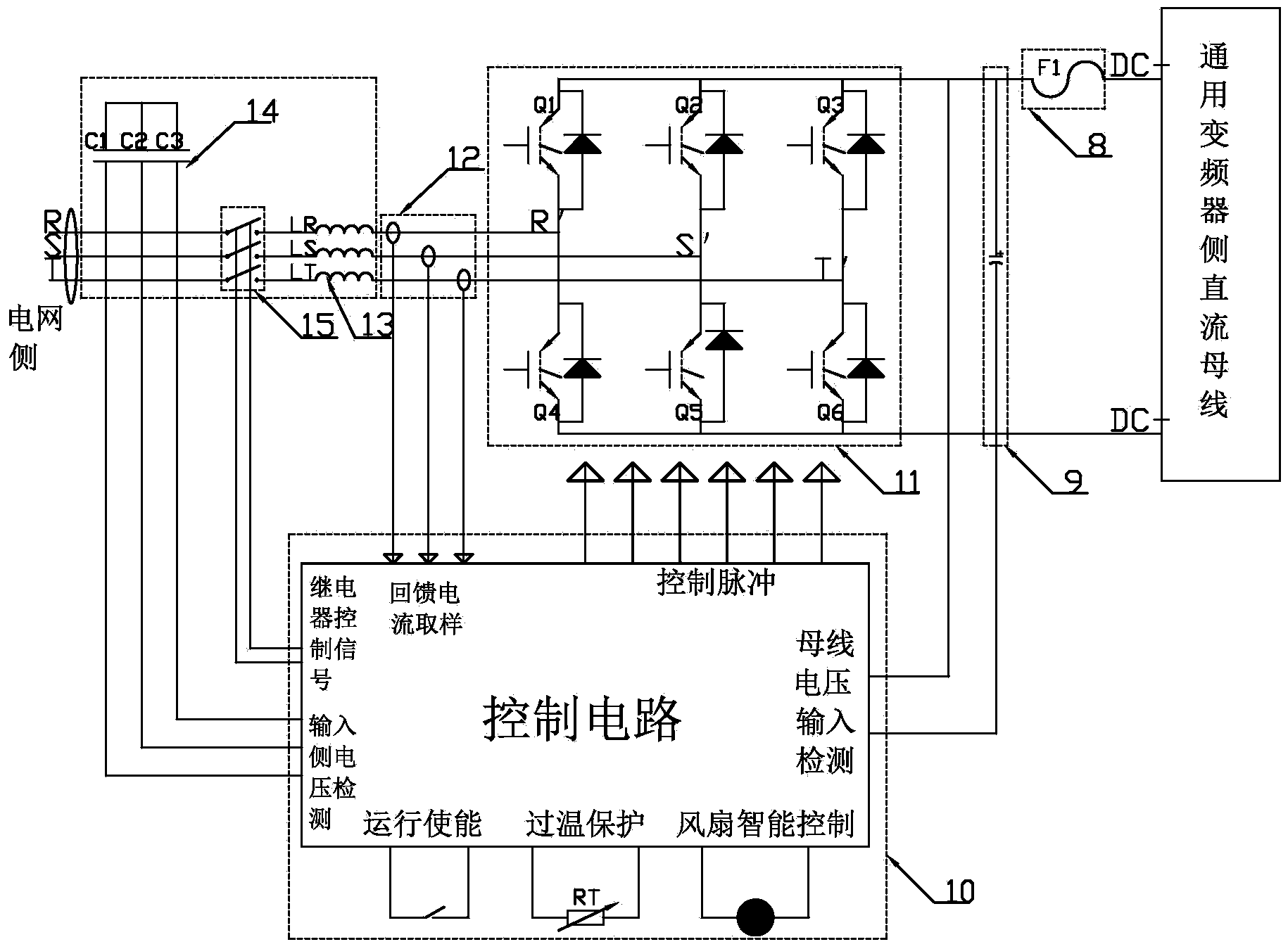

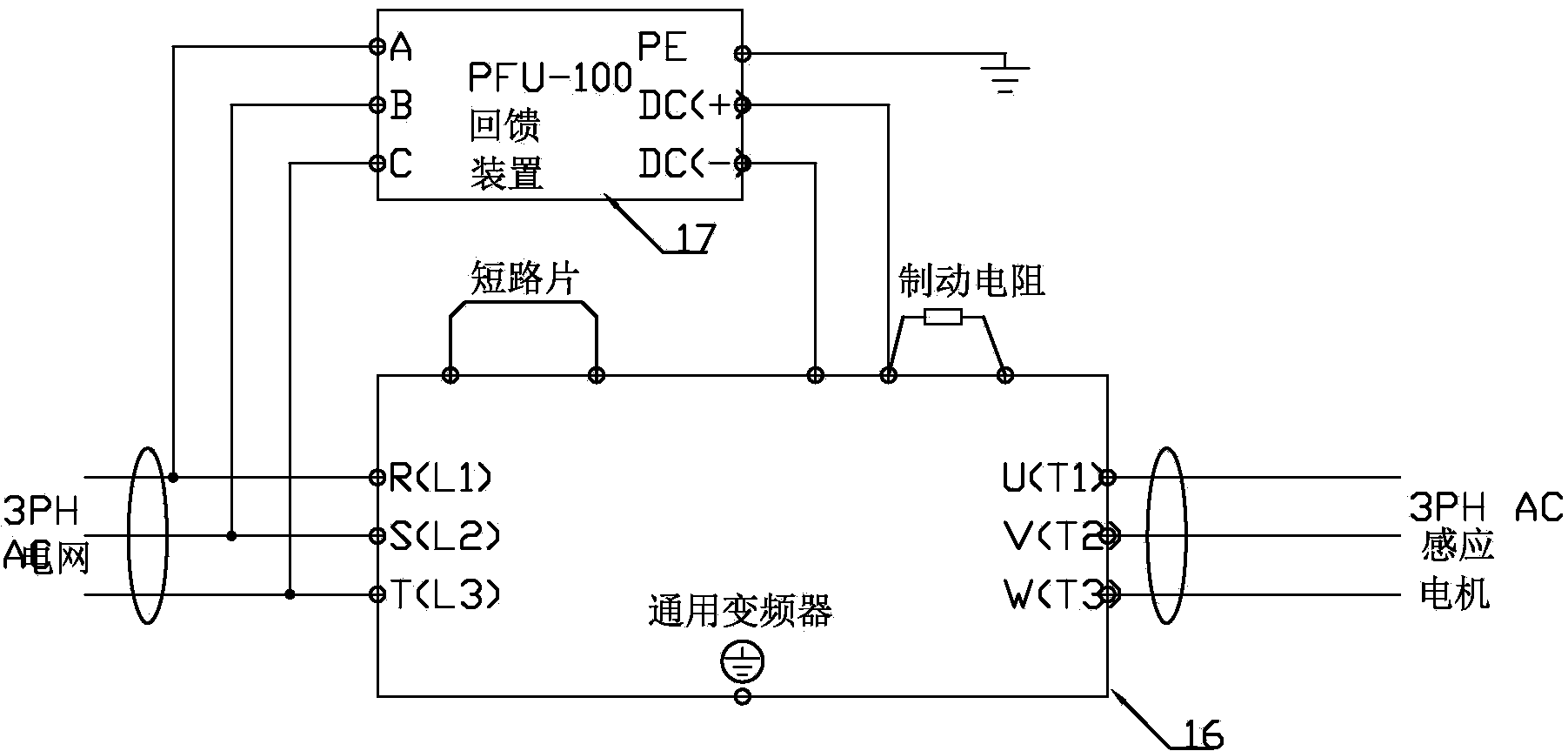

[0022] In the figure, rectifier part 1; contactor 2; charging resistor 3; electrolytic capacitor 4; inverter part 5; switching power supply board 6; main control board 7; fuse 8; large-capacity electrolytic capacitor 9; energy feedback power board 10; Inversion module 11; Hall sensor 12; AC reactor 13; AC filter capacitor 14; AC contactor 15; frequency converter 16; energy feedback unit 17; isolation drive board 18.

[0023] Such as image 3 As shown, in the four-quadrant frequency converter, the frequency converter 16 is arranged between the power grid and the induction motor, and an energy feedback unit 17 for real-time monitoring and control of the bus and making the four-quadrant operation stable and energy-saving is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com