Compressor variable frequency energy saving reforming method of constant speed centrifugal water cooling machine set

A technology for energy-saving transformation and chiller units, which is applied to refrigerators, refrigeration components, heating methods, etc., can solve the problems of high energy consumption, low energy efficiency, inability to achieve energy saving and economical operation of compressors, and achieve maintenance cost savings, life extension, Anti-shock effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

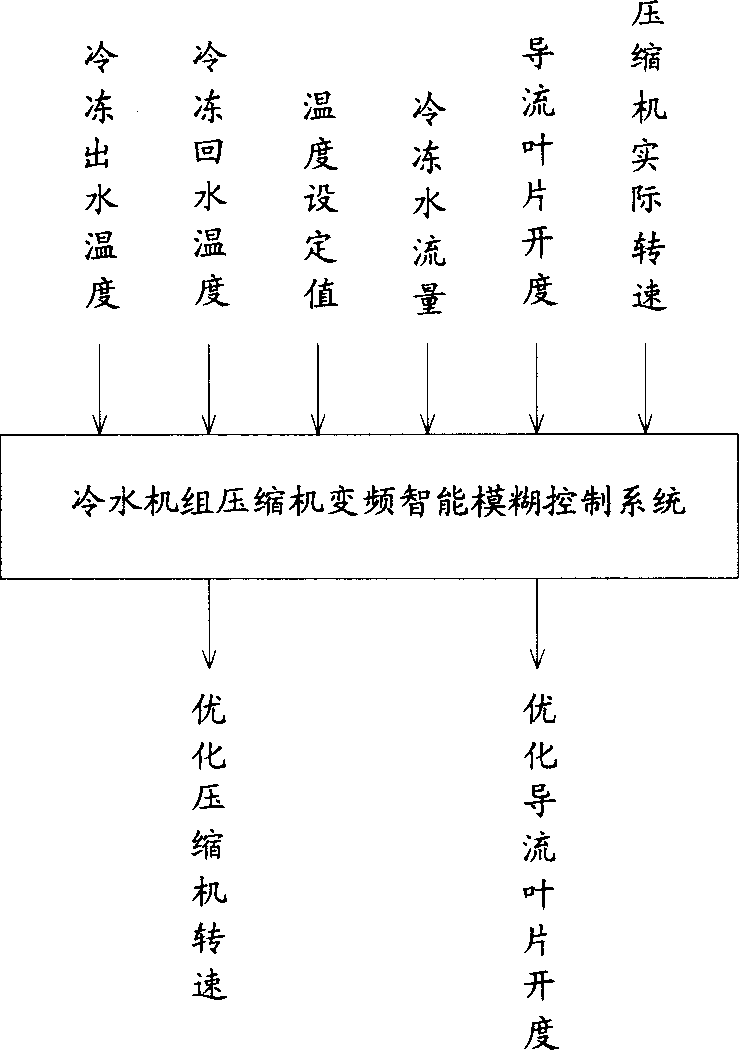

Method used

Image

Examples

Embodiment Construction

[0016] Carrier 19XR5555457DHS centrifugal chiller, the cooling capacity of the unit is 2461KW / 700 refrigeration tons, the compressor motor power is 472KW, the rated current is 817A, and the evaporator flow rate is 423M 3 / H, condenser flow 508M 3 / H, two refrigeration pumps 75KW, flow 500M 3 / H, two refrigeration pumps 55KW, flow 630M 3 / H, pump 1 is running in standby mode.

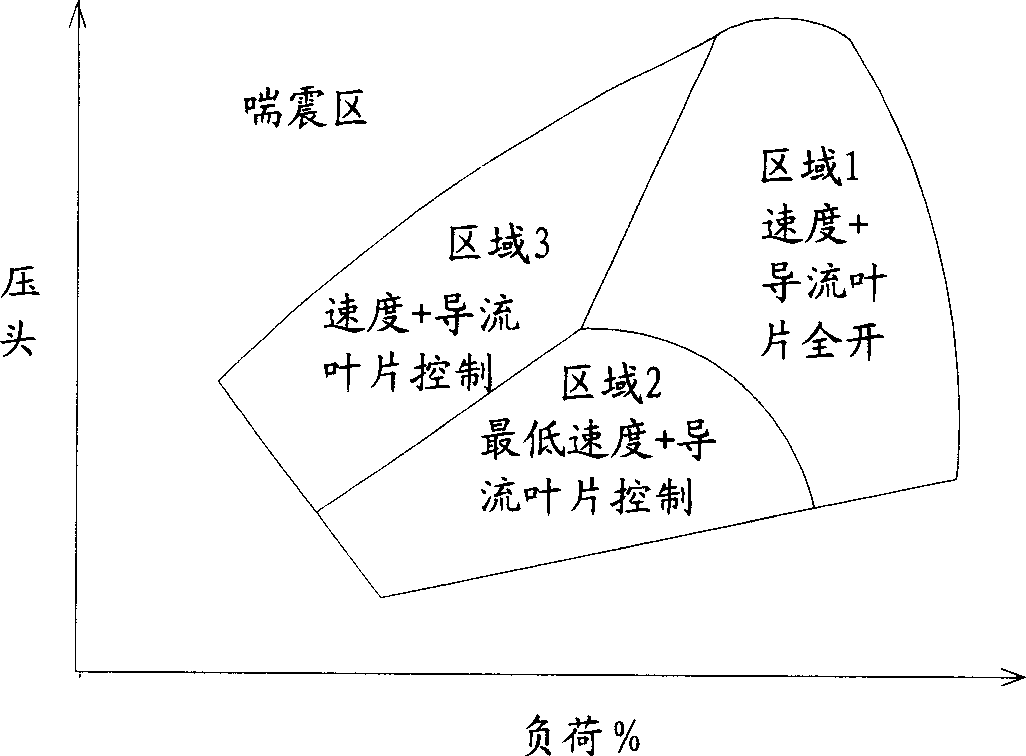

[0017] According to the investigation and analysis of the operation records of the unit in the past two years, when the chiller is at the maximum load, the temperature of the chilled water outlet and return water is 8°C to 11.5°C, the temperature of the cooling water inlet and outlet is 31°C to 35°C, and the current load rate of the compressor is 83. %, and most of the time throughout the year, the chilled water temperature difference is within 3°C, the average current load rate is 60%, and the unit operates under partial load, although it is possible to change the direction of gas entering the impelle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com