Wheel hub motor and control method thereof

A technology of hub motor and control method, which is applied in the direction of electronic commutation motor control, control system, synchronous motor with stationary armature and rotating magnet, etc., which can solve the problems of increasing processing difficulty, weak anti-interference ability, and installation of position detection device Limited space and other issues, to save cost and installation space, strong impact and oil pollution resistance, and improve rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

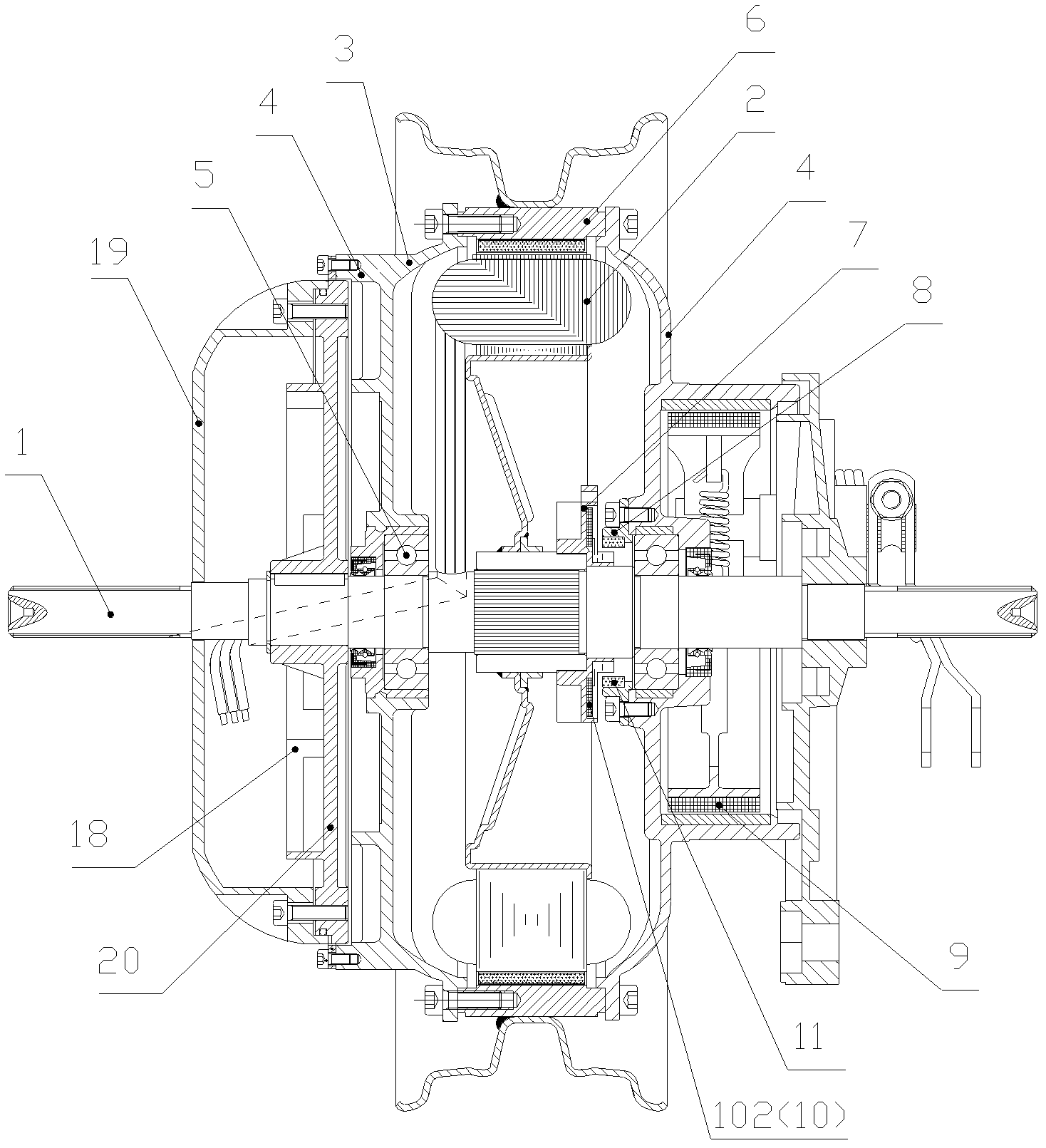

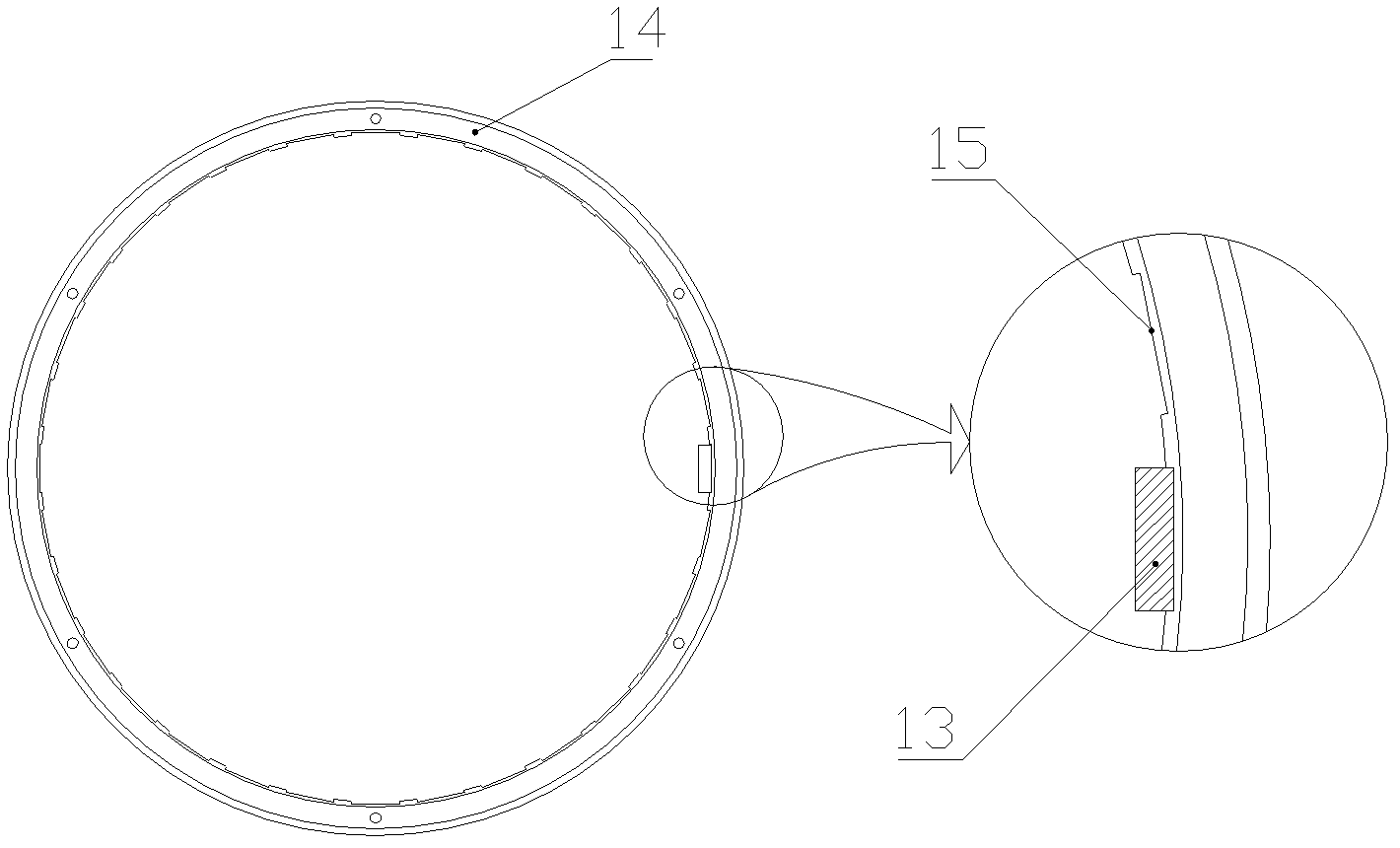

[0064] figure 1 It is a schematic diagram of the overall structure of an external in-wheel motor in an embodiment of the present invention, figure 2 It is a schematic diagram of the three-dimensional structure of an in-wheel motor mounted on the opposite side according to Embodiment 1 of the present invention. Such as figure 1 and combine figure 2 As shown, the present invention provides an in-wheel motor, which includes a motor shaft 1 and a stator 2 fixed thereon. The stator 2 is covered with a rotor housing 3, and the front and rear ends of the rotor housing 3 pass through the rotor end cover 4 and the bearing respectively. 5 is rotatably fixed on the motor shaft 1, the outer side of the rotor cover 4 at the rear end is connected with the hub brake assembly 9, and the rotor shell 3 is connected with the hub 6. The corresponding position of the hub motor is provided with a position detection device, and the position detection device includes: a cage 7 fixed on the motor...

Embodiment 2

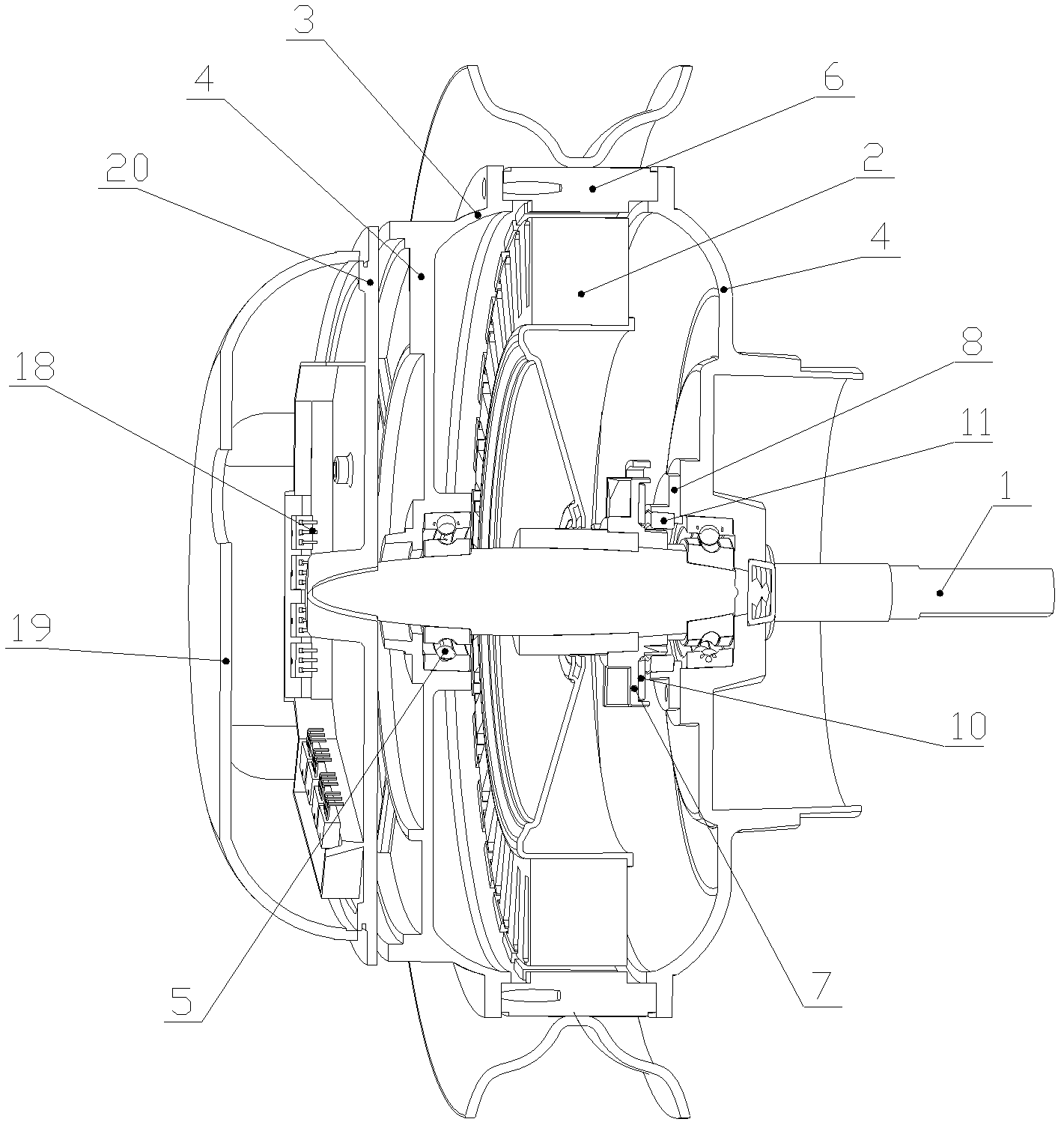

[0075] Figure 5 It is a cross-sectional view of the overall structure of the hub motor on the same side as the second embodiment of the present invention; Image 6 It is a schematic diagram of the three-dimensional structure of the hub motor on the same side as the second embodiment of the present invention. Such as Figure 5 and combine Image 6 As shown, in this embodiment, the position detection device and the servo controller 18 are arranged on the same side of the stator 2, and the servo controller 18 is fixed on the opposite side of the stator 2 where the hub brake assembly 9 is installed, The mounting holes on the PCB board of the servo controller 18 and the threaded holes on the chassis 20 are fixed by screws; the magnetic steel ring 11 in the position detection device is installed on the inside of the motor rotor end cover 4 on the opposite side of the hub brake assembly 9 The step portion of the position detection device is clearance fit and fixed; the Hall PCB b...

Embodiment 3

[0119] Figure 12 It is a schematic diagram of the overall structure of the built-in hub motor in Embodiment 3 of the present invention; Figure 13 It is the assembly diagram of the built-in hub motor of the third embodiment of the present invention. Such as Figure 12 and combine Figure 13 As shown, in the hub motor in this embodiment, the servo controller 18 is arranged in the inner cavity of the motor, and the servo controller 18 is installed with a hub brake through the mounting hole on the servo controller PCB board and the stator bracket 22. The threaded holes on the opposite side of the component 9 are positioned and locked on the stator bracket 22 by screws, and the outer cover is provided with the rotor end cover 4 .

[0120] Such as Figure 12 and combine figure 1 , Figure 5 As shown, the controller built-in structure in this embodiment is compared with the external structure in Embodiment 1 and Embodiment 2. The servo controller 18 is arranged in the inner c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com