Waterproof sound-transmitting membrane assembly and MEMS equipped with waterproof sound-transmitting membrane assembly

A waterproof and sound-permeable membrane, waterproof and sound-permeable technology, applied in MEMS. In the field of steel mesh, it can solve the problems of low elastic deformation of steel mesh, burrs on stainless steel mesh, and high price of steel mesh, and achieve good elastic modulus and mechanical properties, excellent waterproof and sound permeability, and easy installation and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

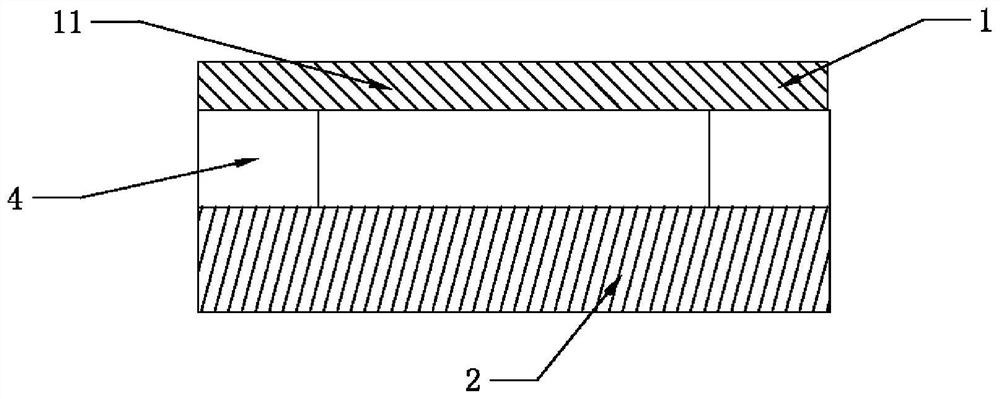

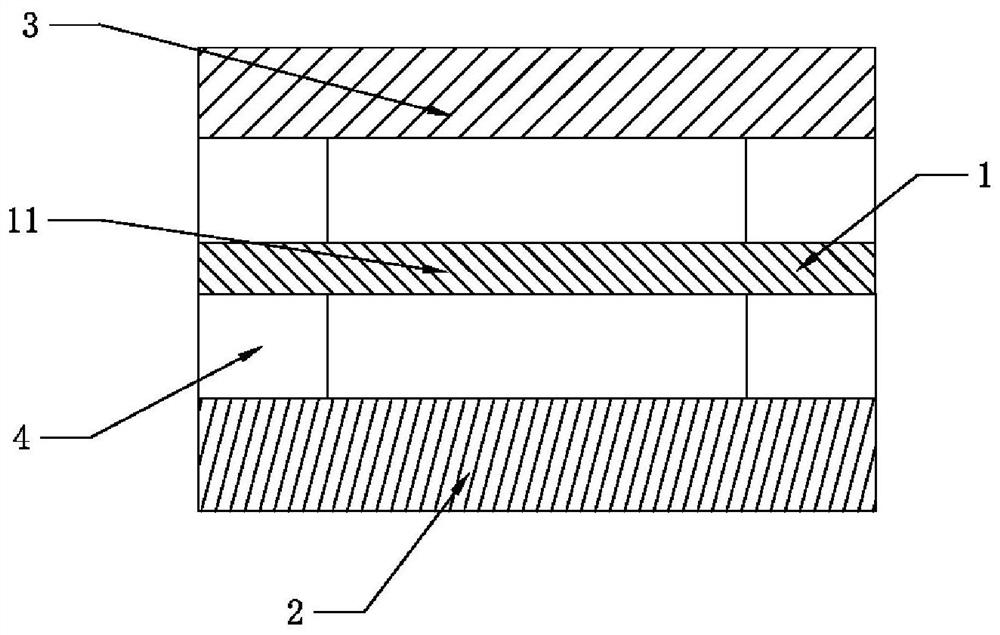

[0064] A waterproof sound-permeable membrane assembly, including a waterproof sound-permeable membrane 1 and a support layer 2, the support layer 2 is located on the side of the waterproof sound-permeable membrane 1 facing away from the external environment;

[0065] The pore diameter of the waterproof sound-permeable membrane 1 is 1 μm, the thickness is 10 μm, and the water pressure resistance is 200 kPa; the sound blocking capacity of the waterproof sound-permeable membrane 1 in the sound frequency range of 100-10000 Hz is 0.7-1.0 dB.

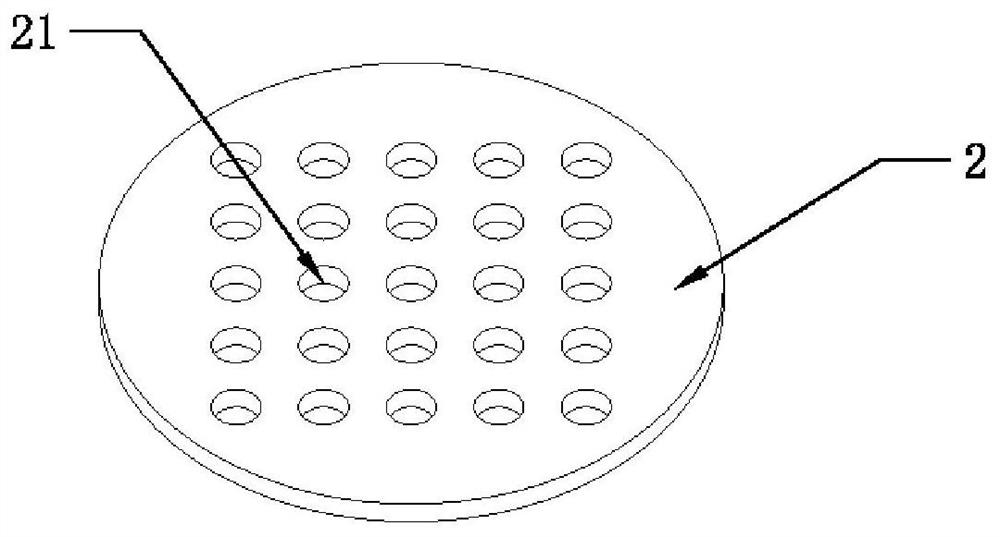

[0066] The support layer 2 is a PI support layer 2; the support layer 2 is provided with several support holes 21, the aperture of the support holes 21 is 0.3mm, and the area ratio of the support holes 21 on the outer surface of the support layer 2 is 35 %; the arrangement of the support holes 21 on the support layer 2 is a rectangular distribution; the air permeability of the support layer 2 is 13.7L / (min·cm 2 )@7kPa, the elastic modulus of ...

Embodiment 2

[0071] The thickness of the support layer 2 in Example 1 is set to 0.06mm, and other conditions remain unchanged; at this time, under the pressure of 500KPa, the relative deformation A of the support layer 2 is 0.76%;

[0072] When subjected to a pressure of 500kPa, the maximum relative deformation E=(2d+AD) / D=(2*0.05+0.76%*3) / 3=4.09% of the waterproof and sound-permeable section 11 is smaller than that of the waterproof and sound-permeable section 11 The relative deformation S of the elastic limit; the scope of the relative deformation S of the elastic limit of the waterproof sound-permeable section 11 in the present invention is 6%;

Embodiment 3

[0074] The thickness of the support layer 2 in Example 1 is set to 0.04mm, and the other conditions remain unchanged; at this time, under the pressure of 500KPa, the relative deformation A of the support layer 2 is 0.98%

[0075] When subjected to a pressure of 500kPa, the maximum relative deformation E=(2d+AD) / D=(2*0.05+0.98%*3) / 3=4.31% of the waterproof and sound-permeable section 11 is smaller than that of the waterproof and sound-permeable section 11 The relative deformation S of the elastic limit; the scope of the relative deformation S of the elastic limit of the waterproof sound-permeable section 11 in the present invention is 6%;

PUM

| Property | Measurement | Unit |

|---|---|---|

| water pressure | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com