Bottle blank conveying device

A transmission device and preform technology, applied in the direction of non-rotational vibration suppression, etc., can solve the problems of metal rail wear, etc., and achieve the effects of reducing noise, improving user experience, and reducing vibration noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

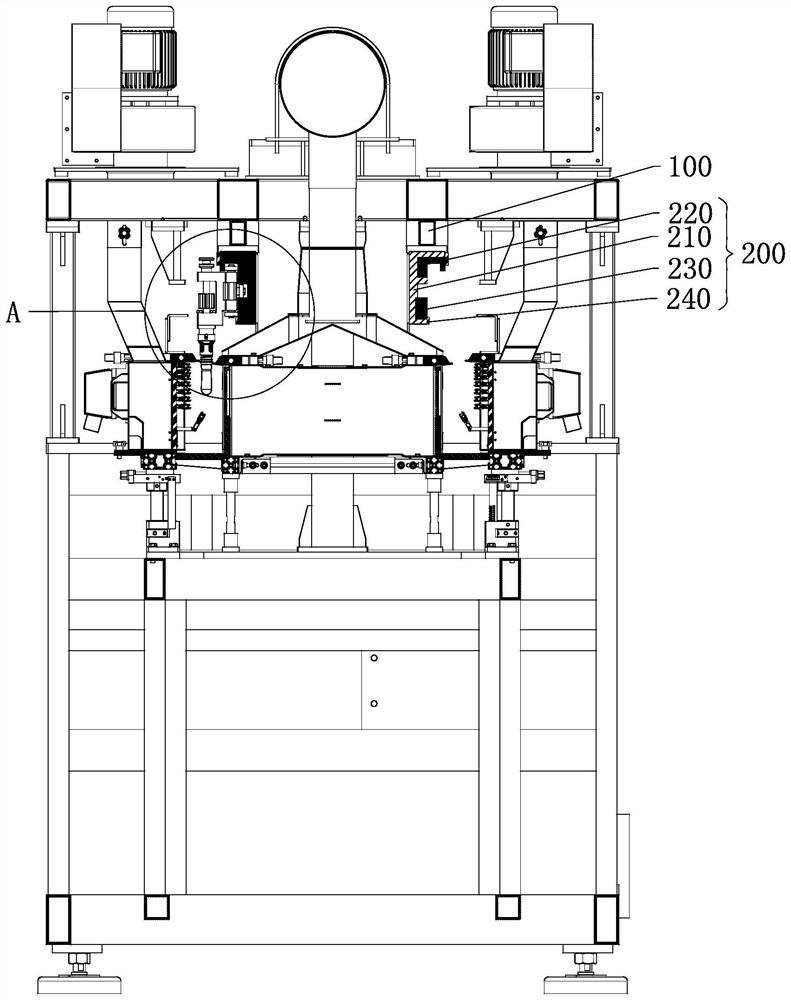

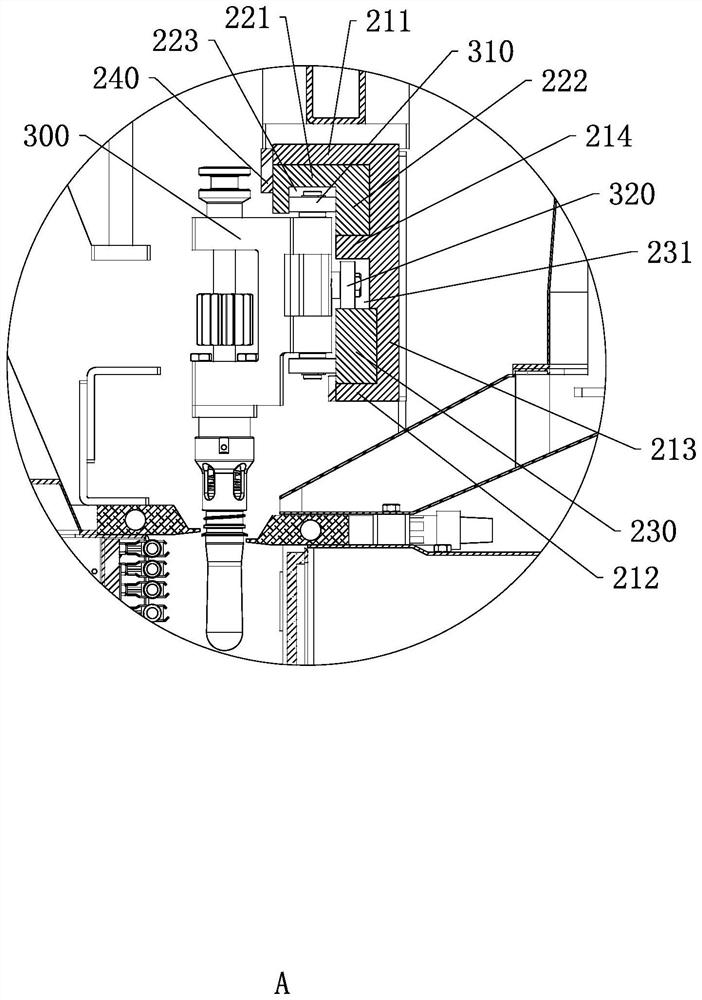

[0034] A preform transfer device, such as figure 1 and figure 2As shown, it includes a frame 100, a driving wheel, a driven wheel and a heating chain. The driving wheel and the driven wheel are arranged on the frame 100 to jointly tension the heating chain and drive the heating chain to move. The blank is transported. A guide rail 200 is provided on the rack 100. The guide rail 200 includes a base plate 210 and a shock absorbing member that are arranged separately. The base plate 210 includes a top plate 211, a bottom plate 212 and a side plate 213. On the top of the plate 213, the bottom plate 212 is shorter than the top plate 211 and is horizontally arranged at the bottom of the side plate 213. The top plate 211, the bottom plate 212 and the side plate 213 are integrally arranged to enclose a guide groove with an opening facing the side link 300. There is a spacer 214 connected to the side plate 213, the spacer 214 is shorter than the top plate 211, and the spacer 214 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com