Slipping type all-hydraulic turner

A fully hydraulic, sliding technology, applied in the field of construction machinery, can solve the problems of large turning radius, poor turning effect, and low turning efficiency of the turning machine, and achieve soft start and stepless speed change, improve quality and Efficiency and the effect of reducing the working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

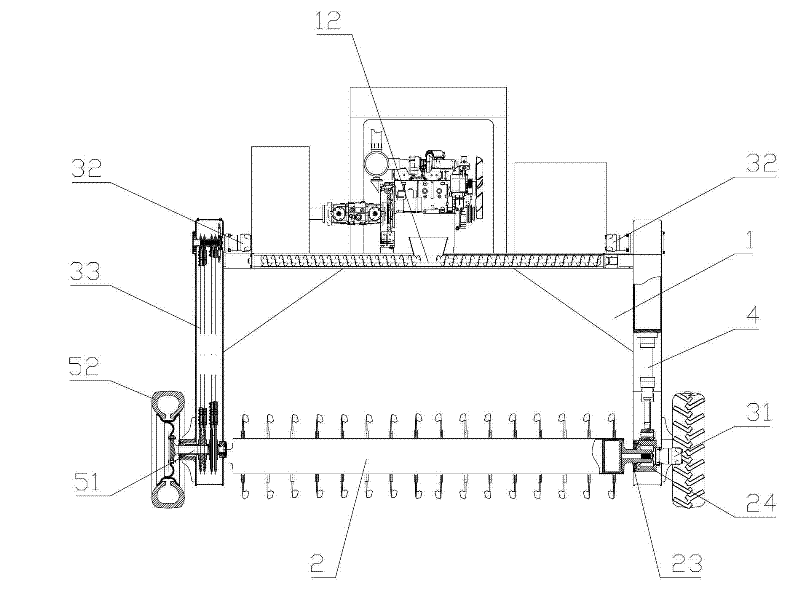

[0023] Such as Figures 1 to 7 Shown in an embodiment of the present invention, a sliding type full-hydraulic turning and throwing machine includes a fuselage 1, a drive assembly is provided on the fuselage, and a turning and throwing mechanism is also provided at the bottom of the fuselage, and the turning and throwing mechanism is arranged on the fuselage. The mechanism includes a turning drum 2, and the drive assembly includes a hydraulic motor 31 that drives the turning drum to rotate. The turning drum is provided with an adjustment mechanism that connects the turning drum to the fuselage and simultaneously adjusts the height of the turning drum relative to the fuselage. components.

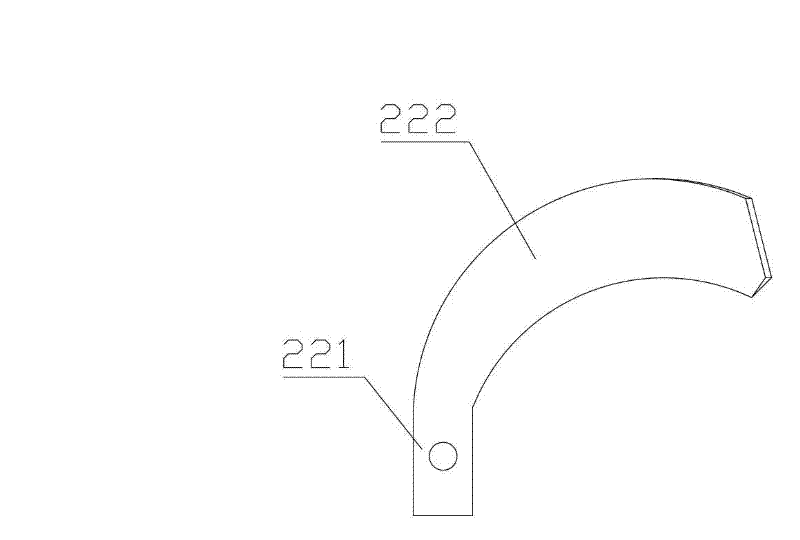

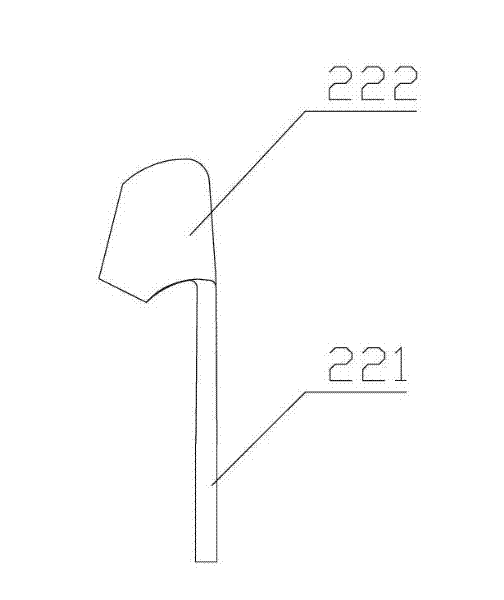

[0024] The turning and throwing drum includes a cylinder body 21 and a rotary knife 22 arranged on the cylinder body, a rotating shaft 23 is provided at both ends of the cylinder body, and a bearing seat 24 is provided at both ends of the rotating shaft, and the hydraulic motor is fixed on O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com