Automatic Marshall compaction device and test method

An automatic, test piece technology, applied in the preparation of test samples, etc., can solve time-consuming problems, achieve the effects of speeding up compaction time, shortening surface change time, and improving compaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

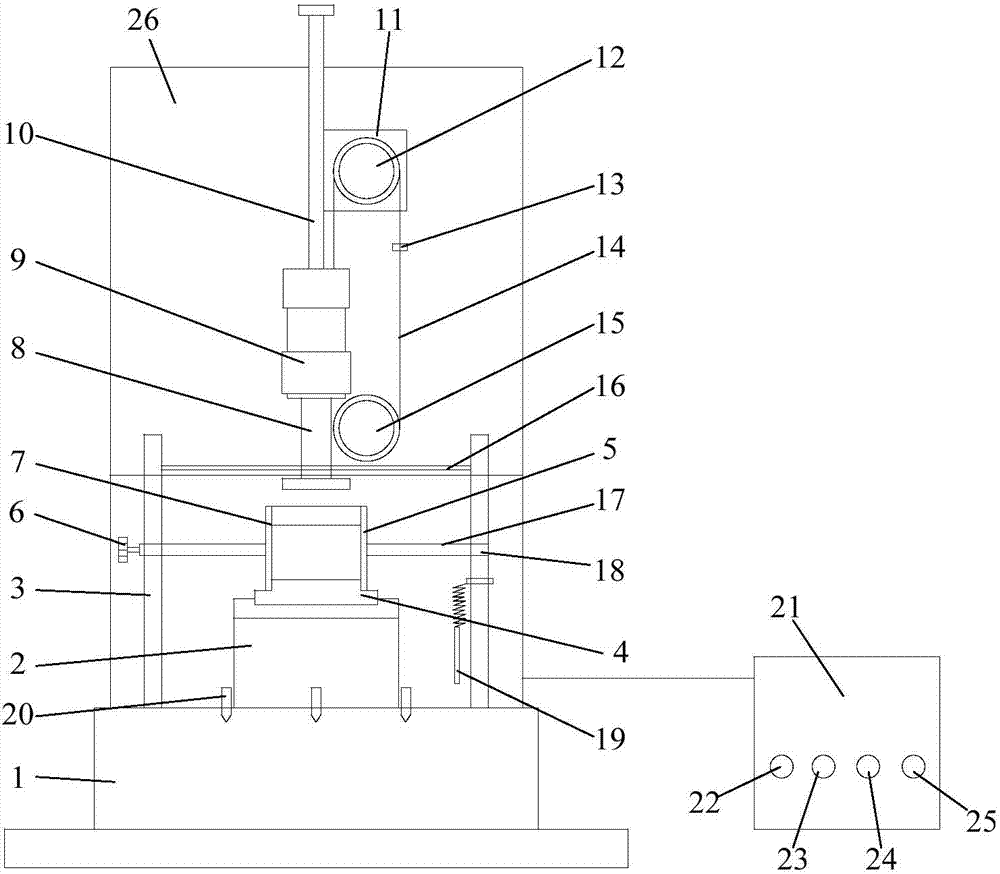

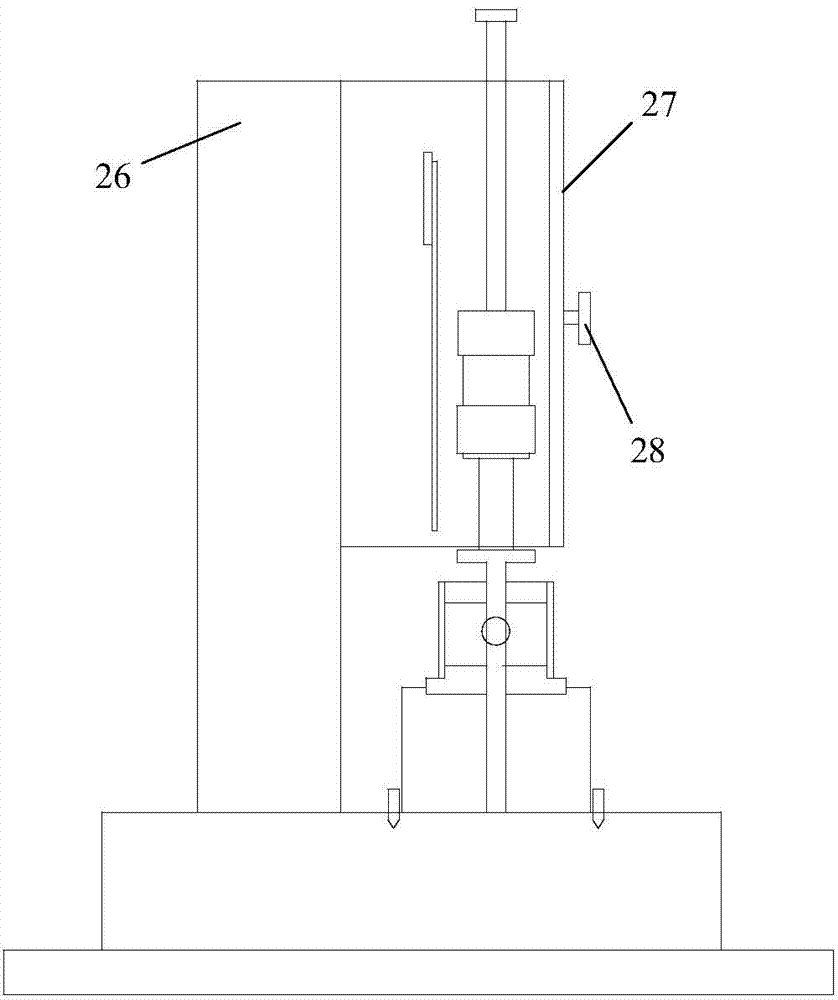

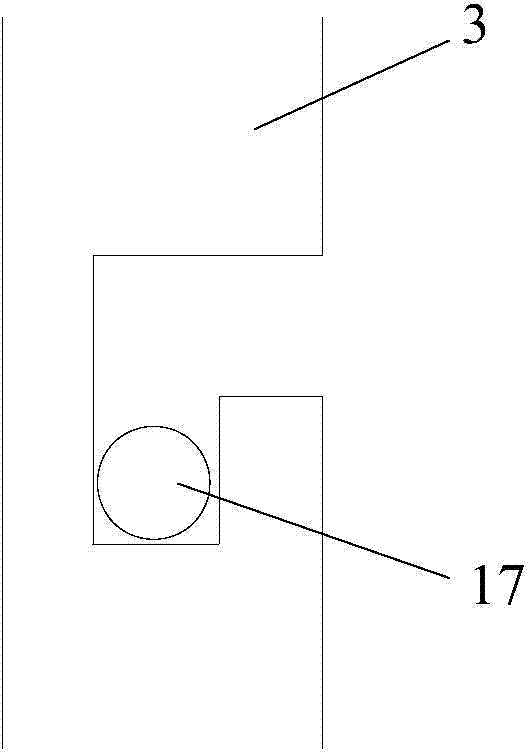

[0030] see figure 1 , the Marshall automatic compaction device of the present invention includes a controller 21 and a support member for adding asphalt mixture, the controller 21 is provided with a motor switch 22, a compaction times adjustment button 23, a compaction times reset button 24 and an emergency Brake button 25, emergency brake button 25 can stop compaction in time when machine breaks down, prevents accident. A safety protection component and a tamping rod 19 for evenly inserting and pounding the asphalt mixture are installed on the support component. The safety protection component includes a safety operating rod 16 arranged on the upper part of the support frame 3, and is used to connect the compacting component and power The casing 26 of parts wrapping; figure 2 As shown, a safety door 27 is installed in front of the casing 26, and a safety door handle 28 is installed on the safety door 27. A compacting component for compacting the asphalt mixture is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com