Patents

Literature

66results about How to "No shift" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

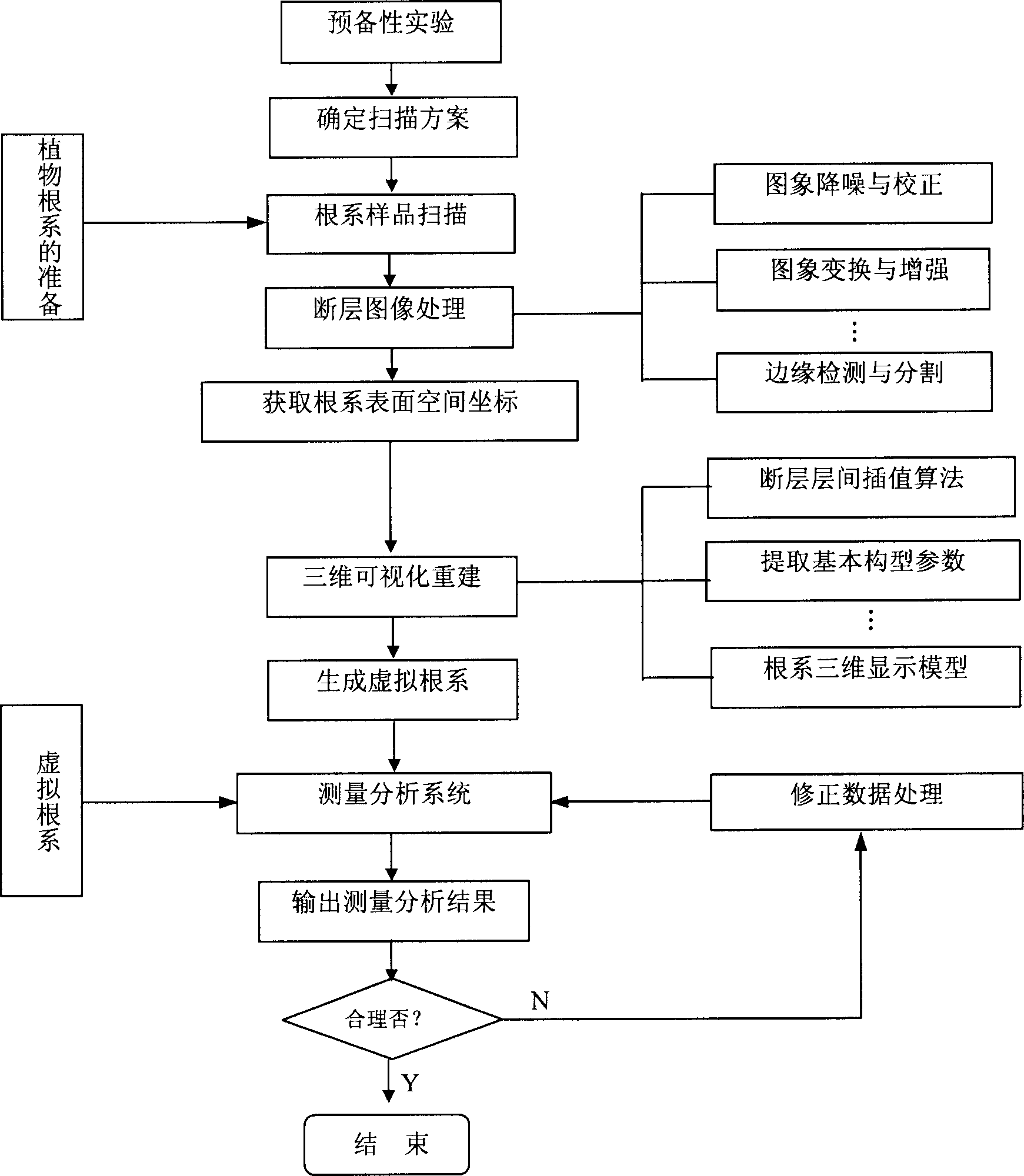

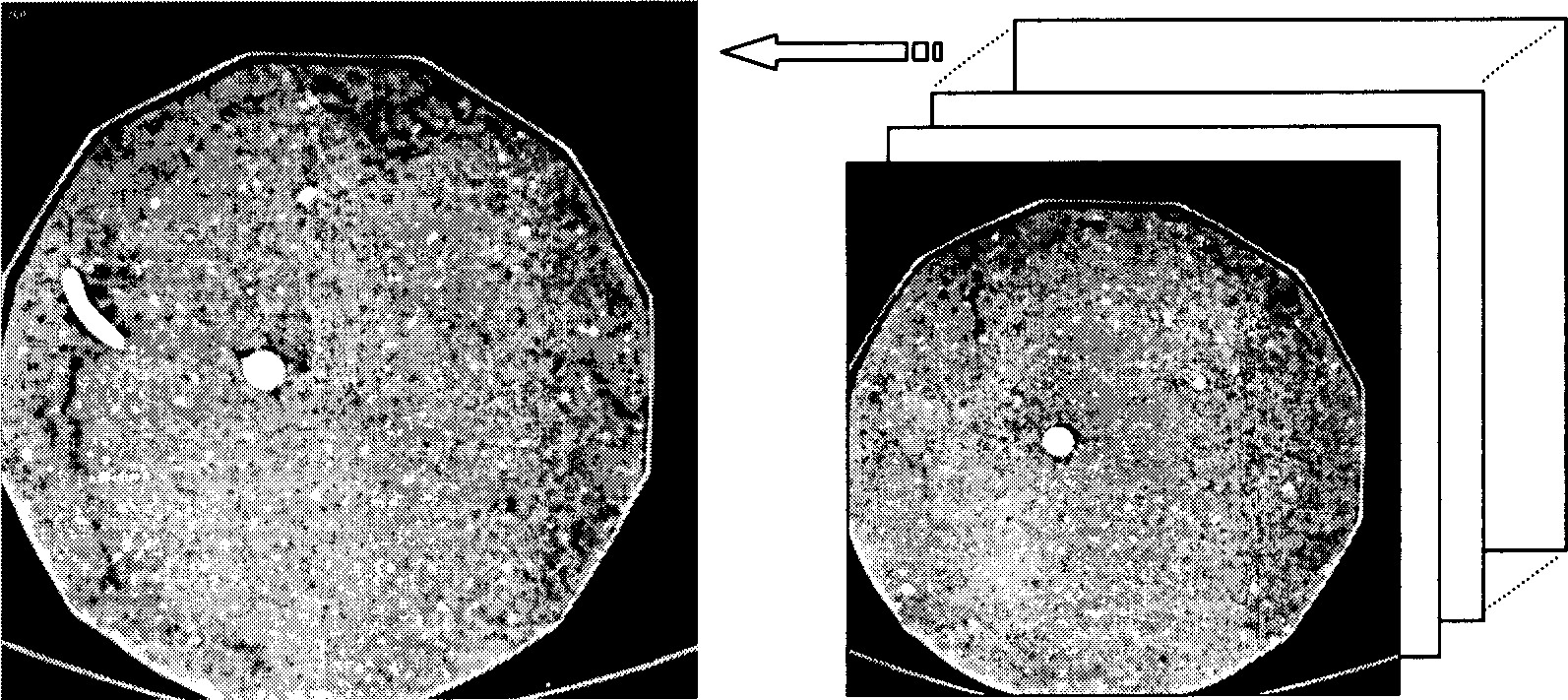

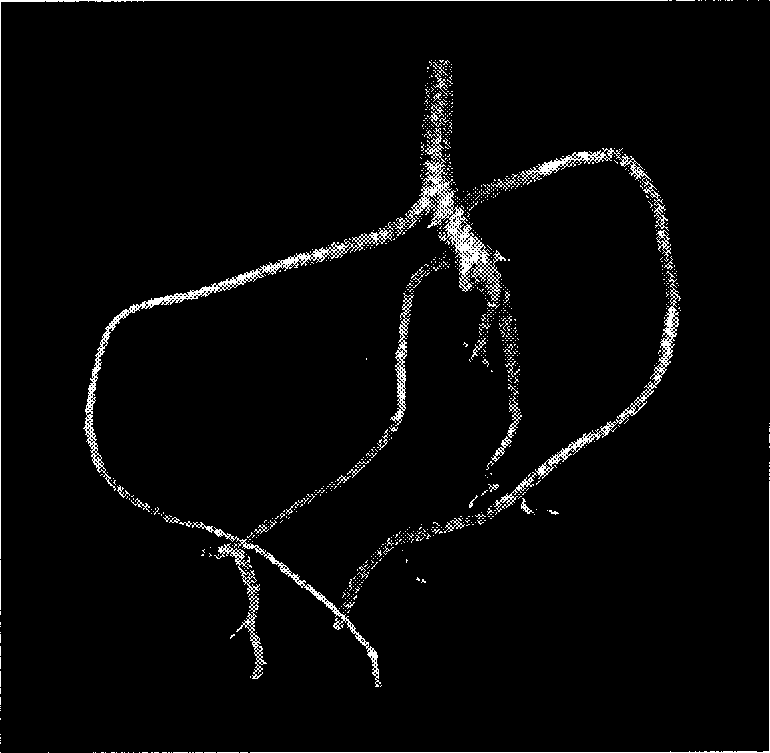

In-situ measuring method of plant root system geometry

The method includes steps: using imaging device of biomedicine obtains layered sequence images in situ of root system of plant grown at different opaque medium. Processing and analyzing the sequence images obtains spatial geometrical characteristic parameters in situ of root system of plant. Based on the said parameters, model of solid geometry is built. 3D visualized reconstruction is carried out for model of solid geometry so as to build 3D display model of root system. Features are: obtaining images in situ of root system of plant precisely and in non-destructive, sampling procedure is simplified so as to save labor to separate soil, greatly raised accuracy.

Owner:SOUTH CHINA AGRI UNIV

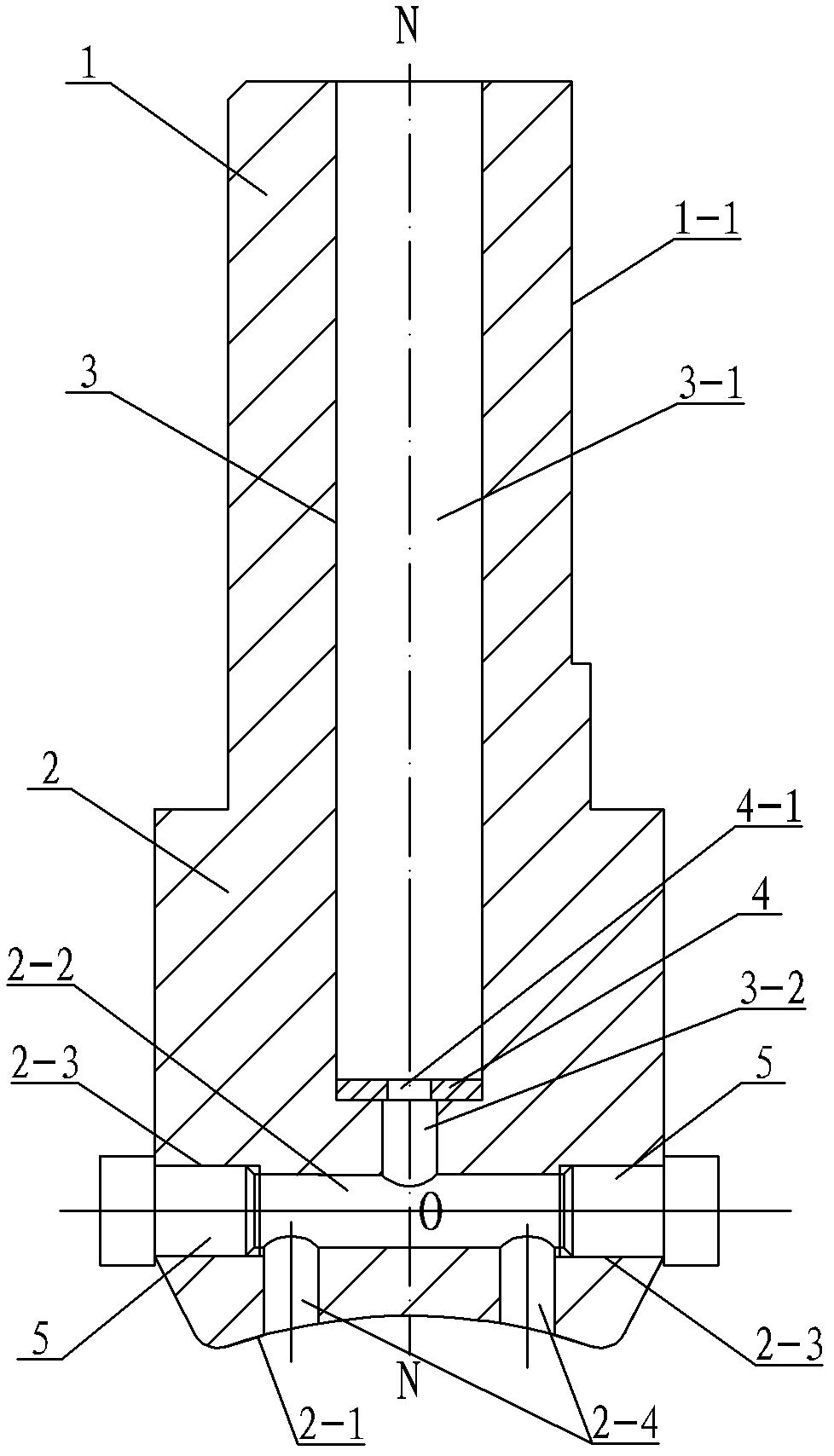

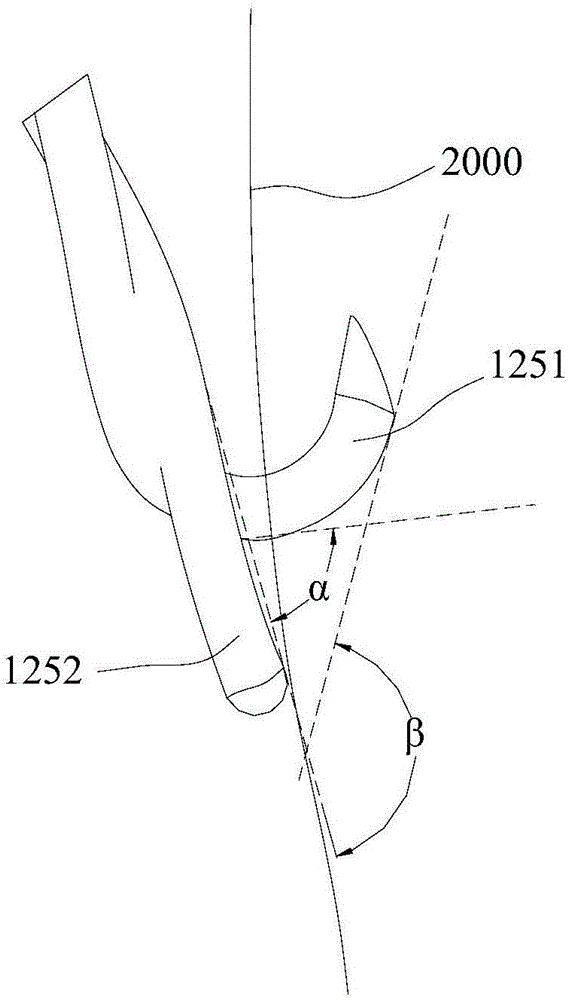

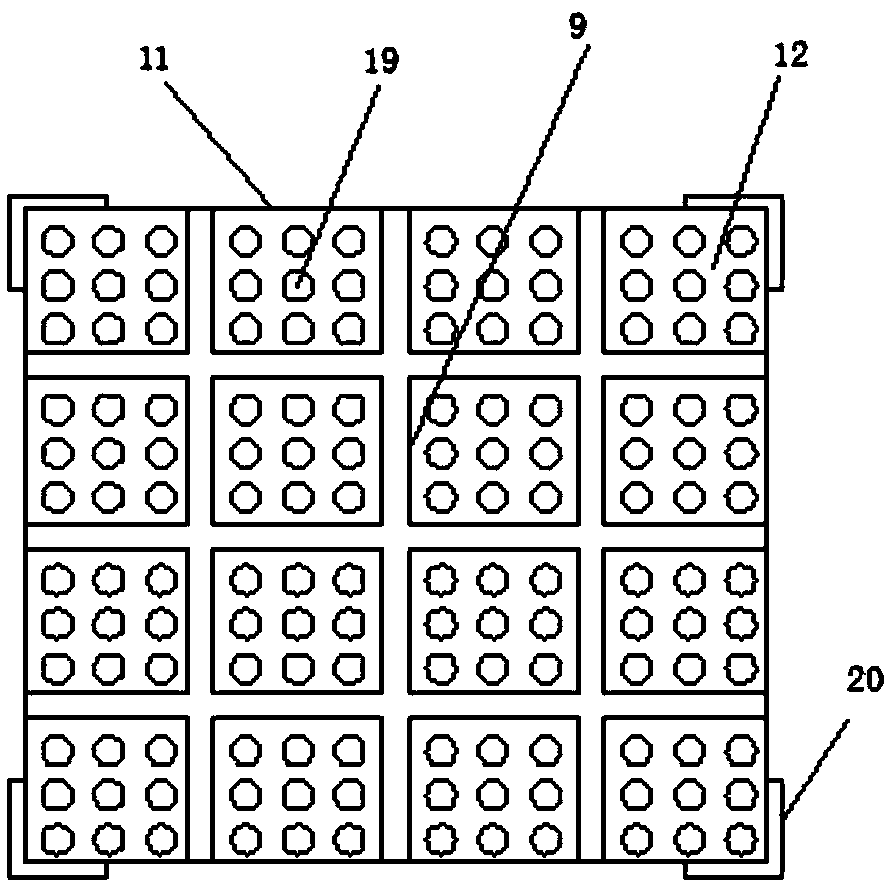

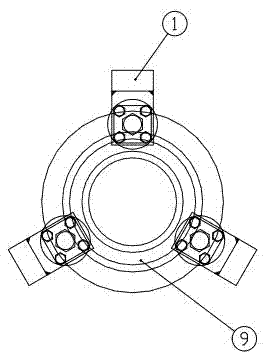

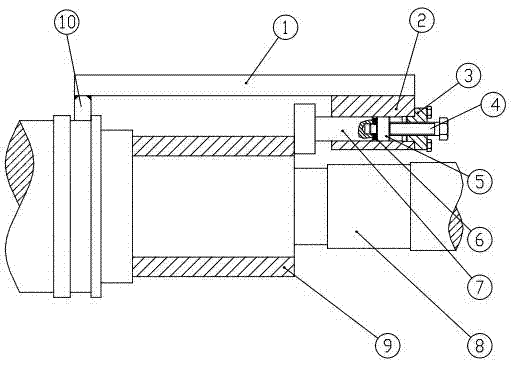

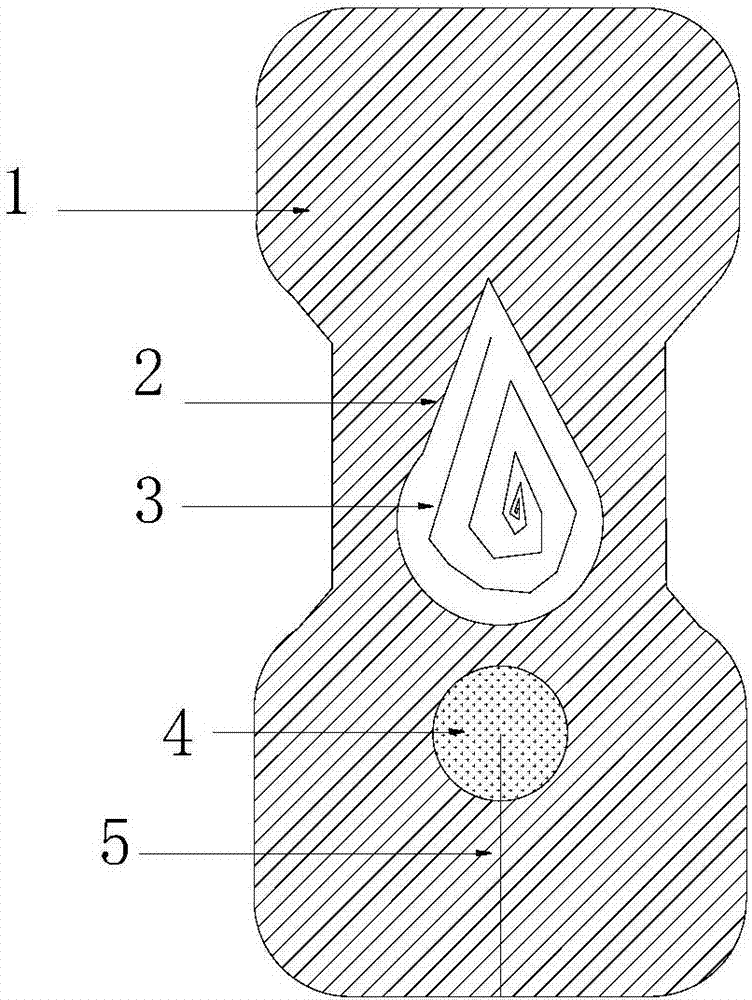

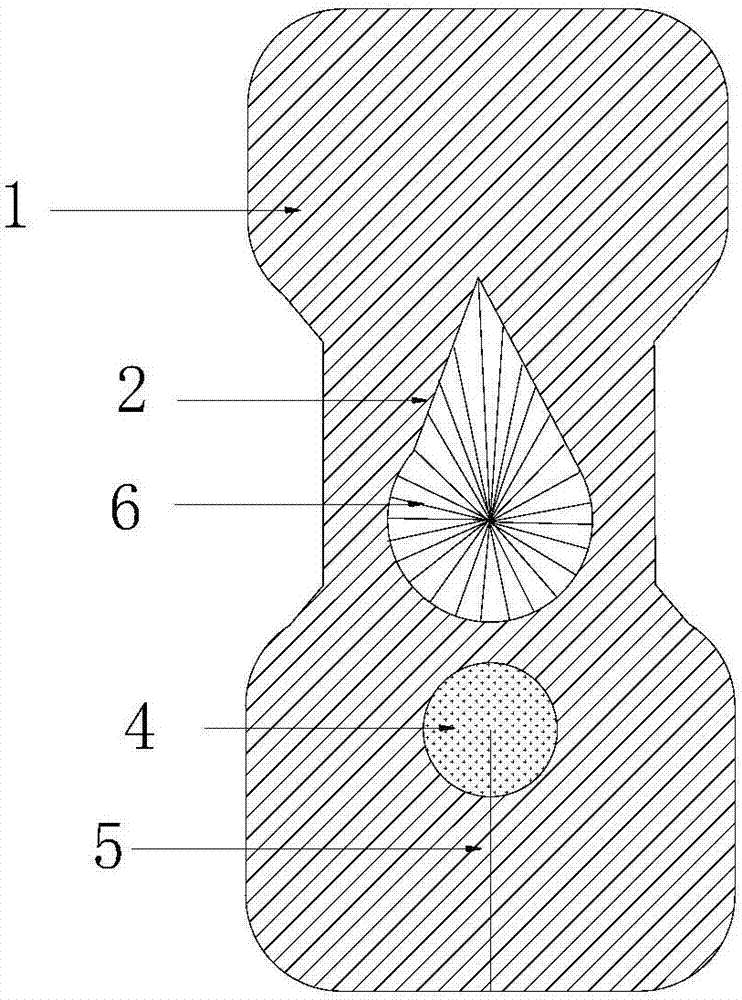

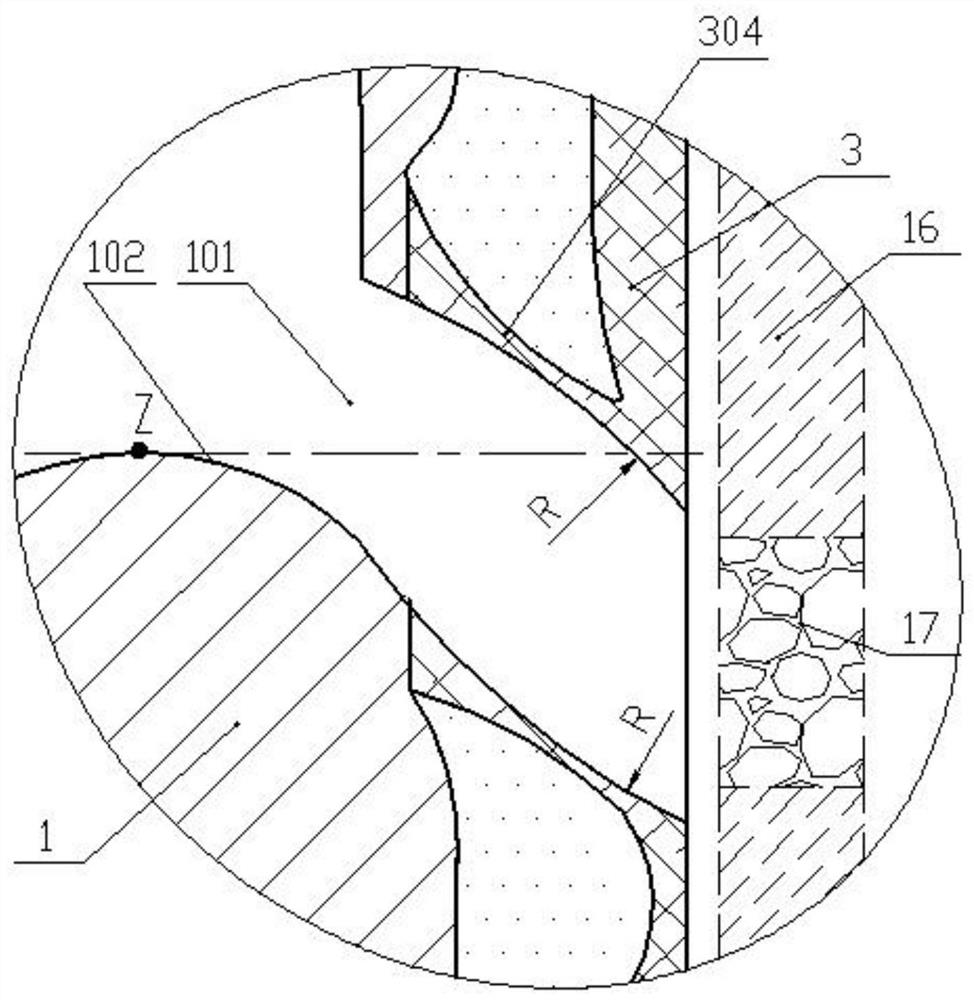

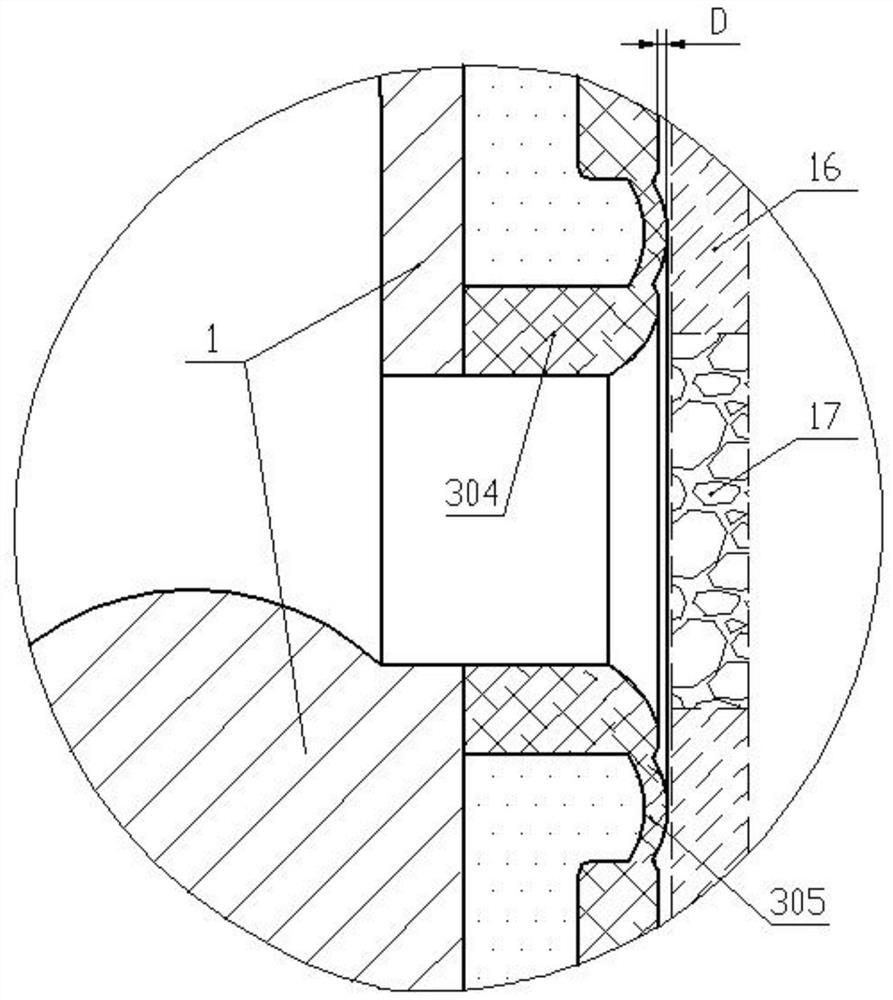

Hollow variable-diameter porous friction head and preparation method for surface composite material of metal material

InactiveCN102626822AImprove production efficiencyEvenly distributedNon-electric welding apparatusSlant angleMetallic materials

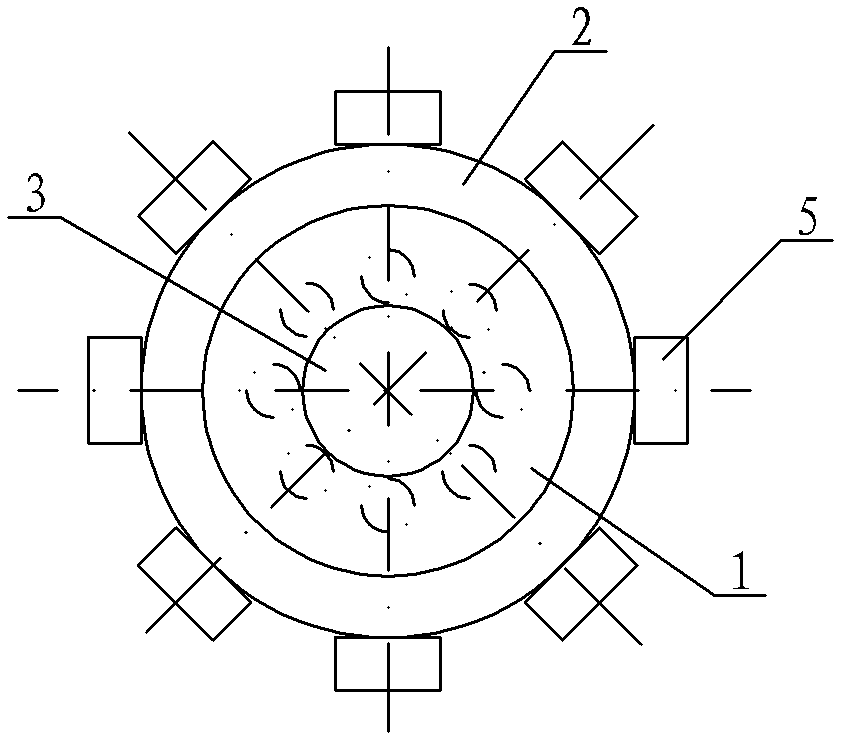

The invention relates to a hollow variable-diameter porous friction head and a preparation method for a surface composite material of a metal material, particularly relates to the friction stir welding friction head and a welding method, and solves the problem that for preparation of a metal matrix composite material, an enhanced phase is distributed unevenly because particles are splashed and translated in a material processing process caused by the fact that the enhanced phase is needed to be placed in a material to be processed. A welding tool comprises an upper cylinder body and a lower cylinder body which are vertically arranged and made into a whole, the upper cylinder body and the lower cylinder body are provided with an upper hole channel and a middle hole channel respectively along axes, four horizontal through holes are all communicated with the middle hole channel, each horizontal through hole is communicated with two lower vertical hole channels, a variable-diameter sheet is arranged at the bottom of the upper hole channel, and the inner diameter of a variable-diameter hole is less than the inner diameter of the middle hole channel. The method includes: 1 determining geometric dimension of the friction head; 2 adding enhanced-phase particles; 3 adjusting a slant angle of the friction head; and 4 performing the friction stir processing on the surface of a workpiece to be processed, and achieving preparation of one surface composite material. The hollow variable-diameter porous friction head and the preparation method for the surface composite material of the metal material are used for preparation of surface composite material layers of the metal material.

Owner:HARBIN INST OF TECH

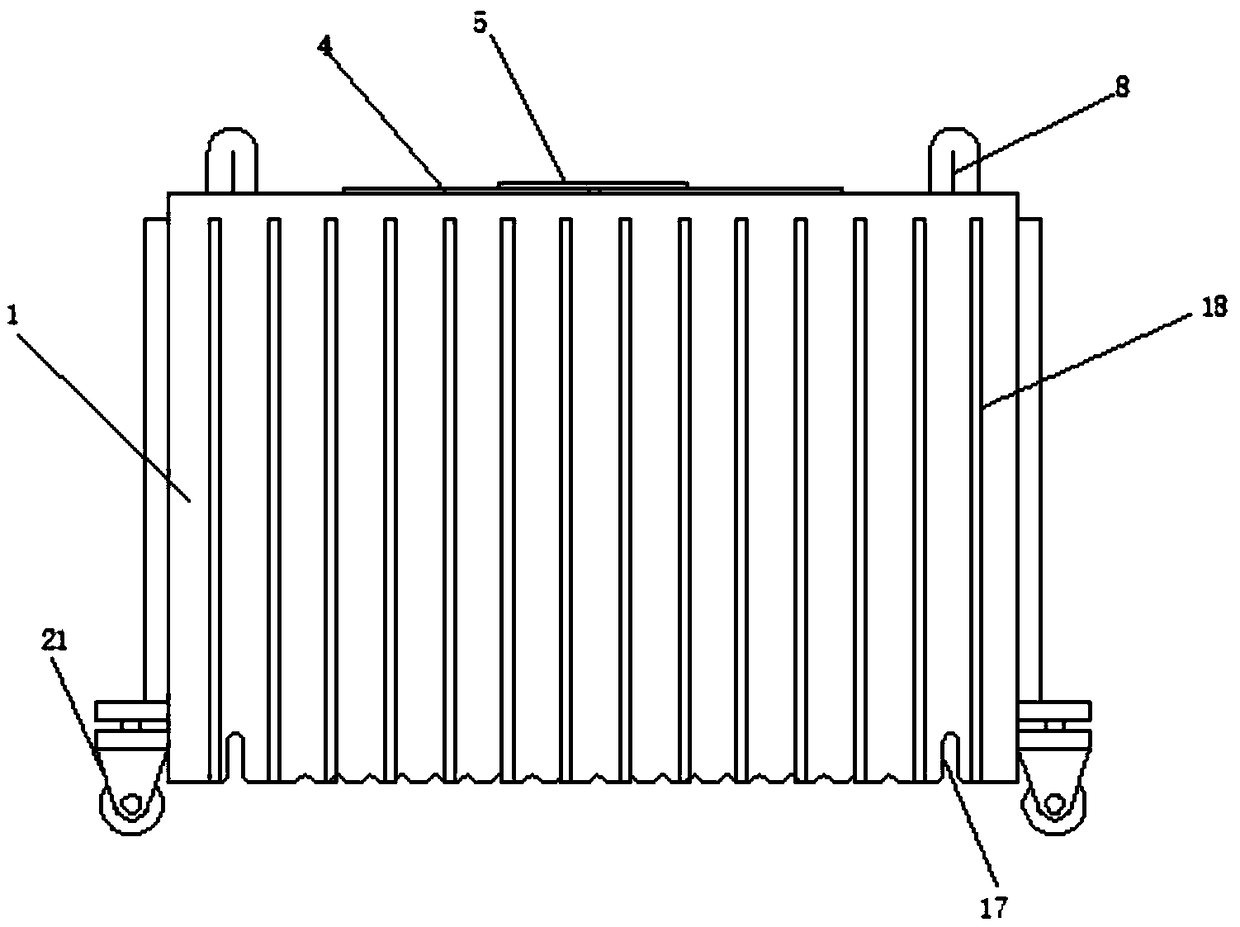

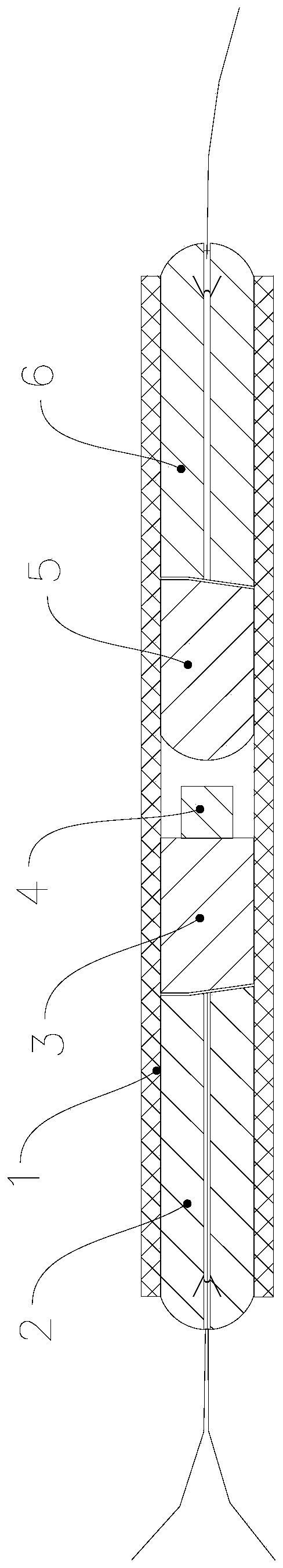

Durable intaglio printing rubber roller

InactiveCN102729588AReduce stressGuaranteed service lifePlate printingRotary pressesHardnessEngineering

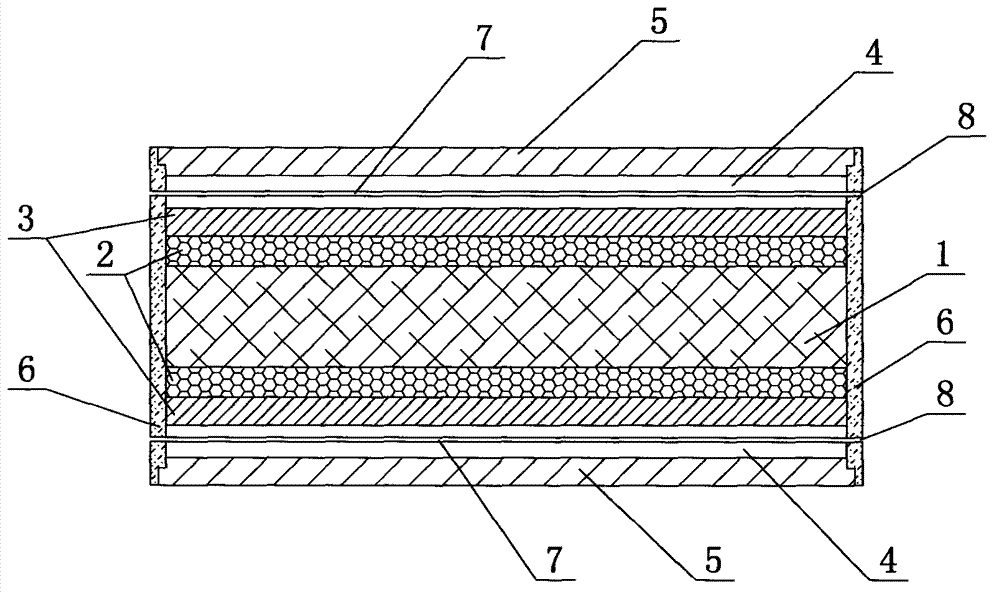

The invention provides a durable intaglio printing rubber roller which comprises a metal central spindle, a foaming layer, an inner-layer rubber layer, a middle-layer rubber layer and an outer-layer rubber layer which are sequentially packed outside the metal central spindle, and two end covers arranged at side faces of the metal central spindle, wherein the shore hardness of the inner-layer rubber layer is larger than that of the middle-layer rubber layer, and the shore hardness of the middle-layer rubber layer is larger than that of the outer-layer rubber layer; the middle-layer rubber layer is internally provided with hollow channels which are arranged with one another at intervals; and the two end covers arranged at the side faces of the metal central spindle are provided with holes which correspond to the positions of openings arranged at two ends of the hollow channels in the inner-layer rubber layer. The rubber roller provided by the invention is the ceramic tile intaglio printing rubber roller which is durable, can print on the concave-convex tile surface and the plane, is better in printing effect on the concave-convex tile surface, and is longer in service life.

Owner:GUANGDONG WINTO CERAMICS +2

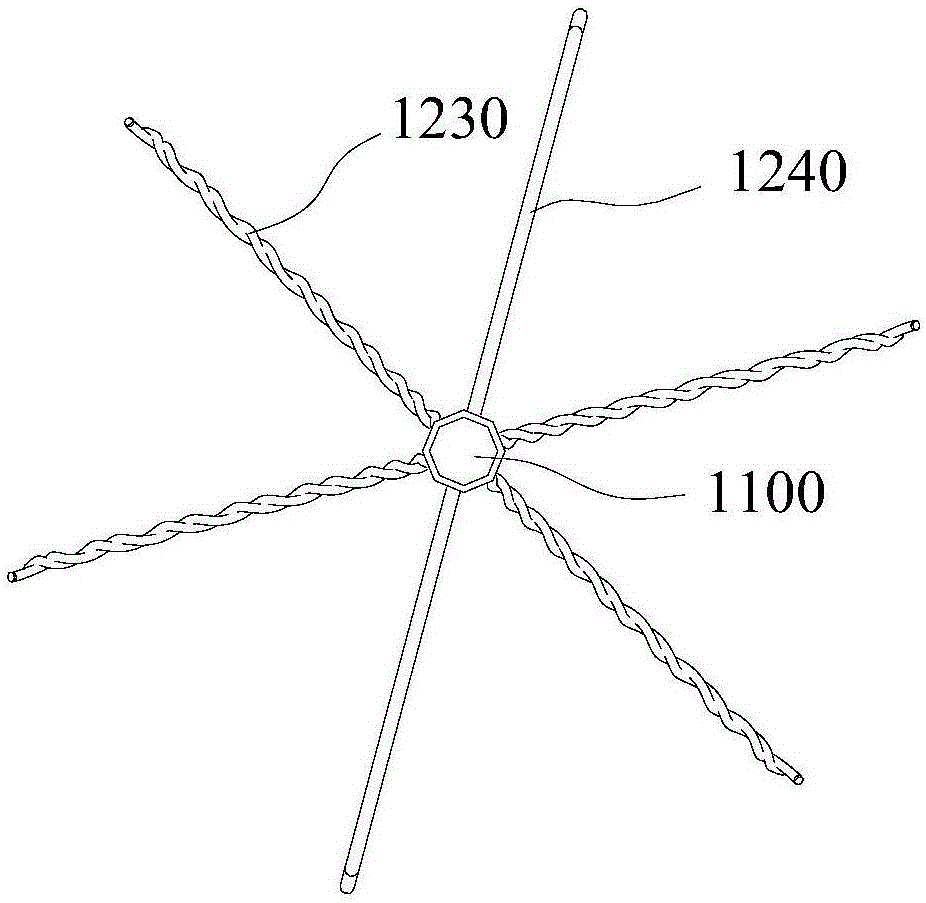

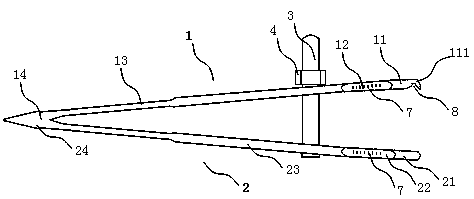

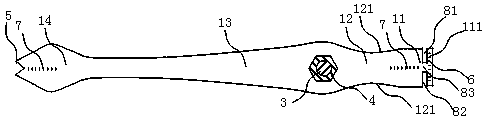

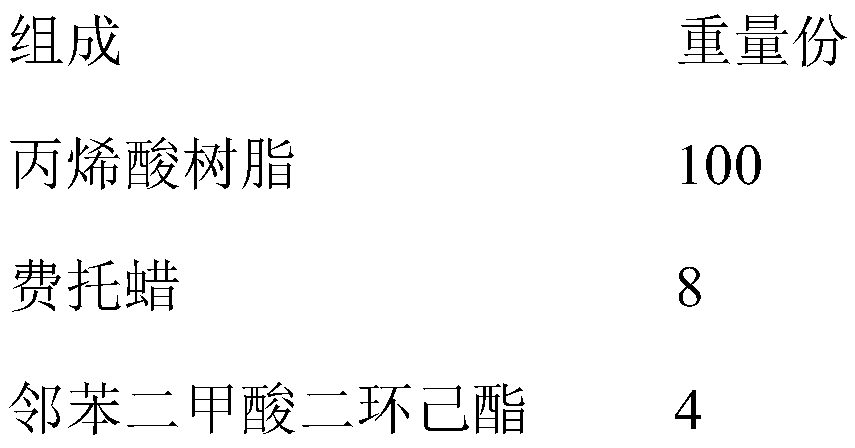

Vena cava filter

ActiveCN106725996AAvoid CatonPrevent penetrationBlood vessel filtersEngineeringUltimate tensile strength

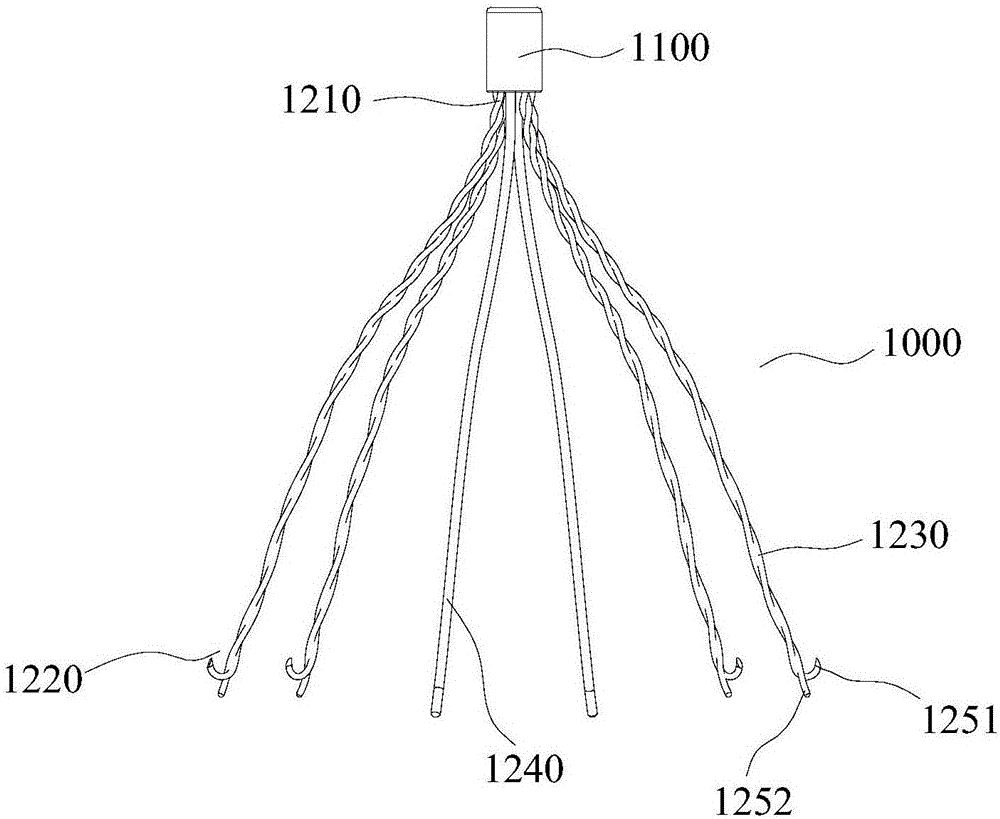

The invention discloses a vena cava filter. The vena cava filter comprises a plurality of support rods, wherein one end of each of the support rods is gathered, and the other end of each of the support rods is radially dispersed under a releasing state; at least one part of the support rods are twisting support rods which are respectively formed by twisting a plurality of metal wires; each twisting support rod is formed by twisting two or more metal wires; the diameters of the metal wires on the same twisting support rod are the same or are different; at least one metal wire of each twisting support rod is bent at a part close to the radial end to form an anchor hook. The vena cava filter has the advantages that the strength is higher, the compliance is better, the releasing and recycling process is smooth, and the falling and dislocation risks are avoided.

Owner:HANGZHOU WEIQIANG MEDICAL TECH CO LTD

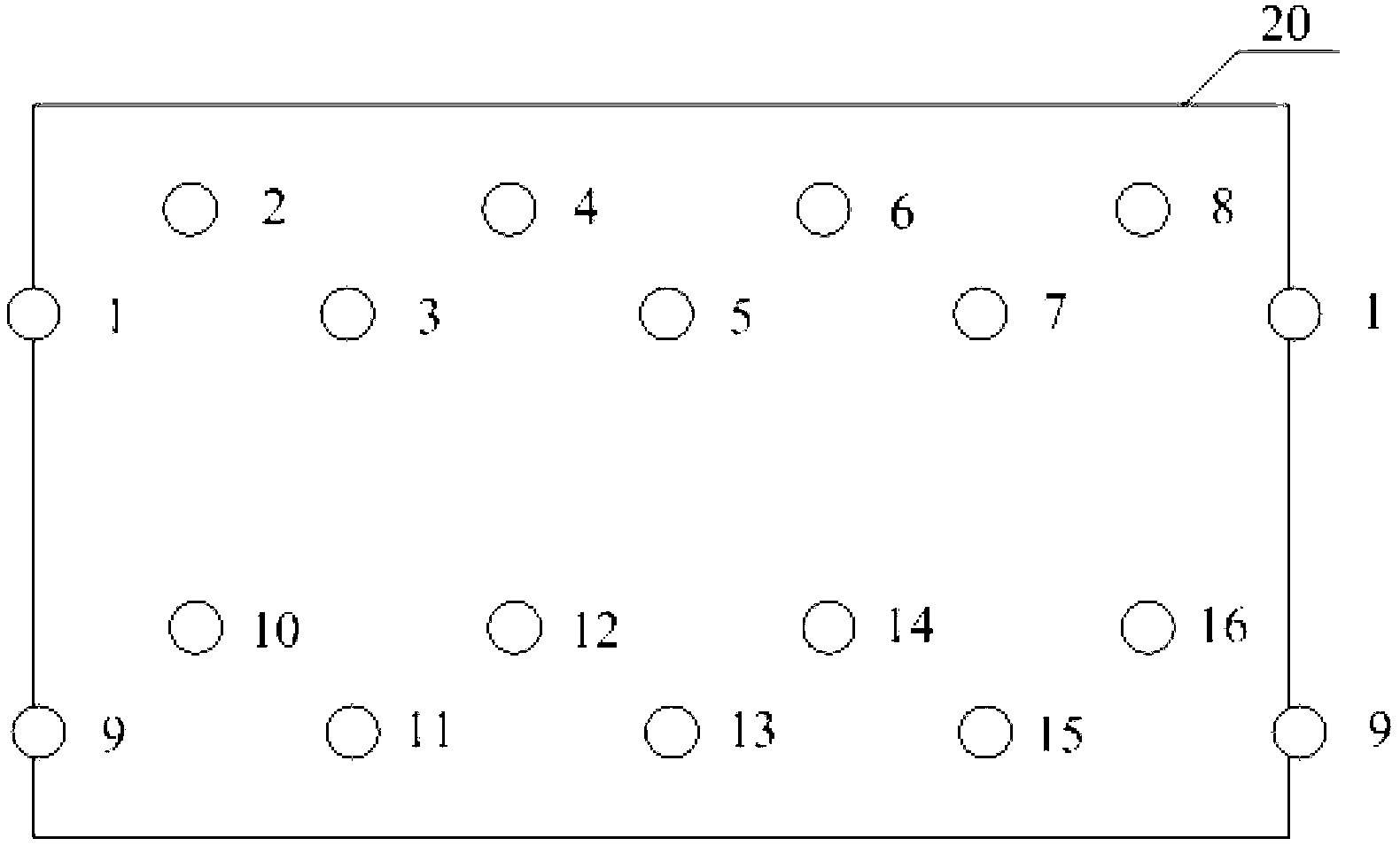

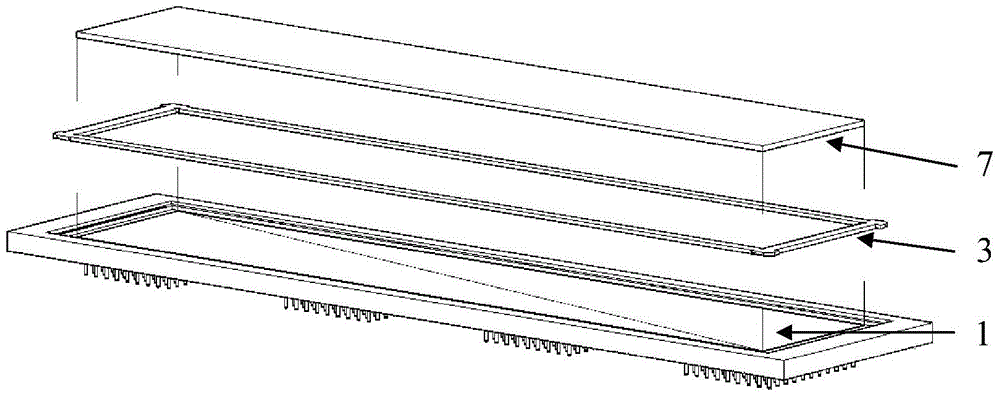

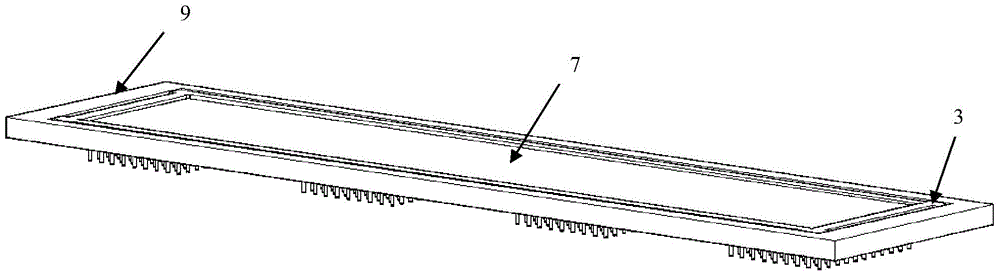

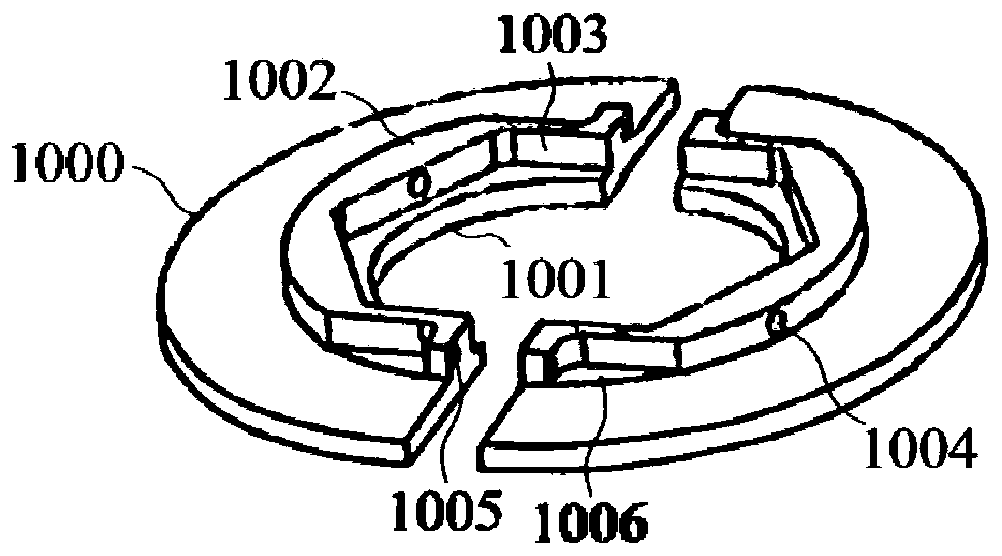

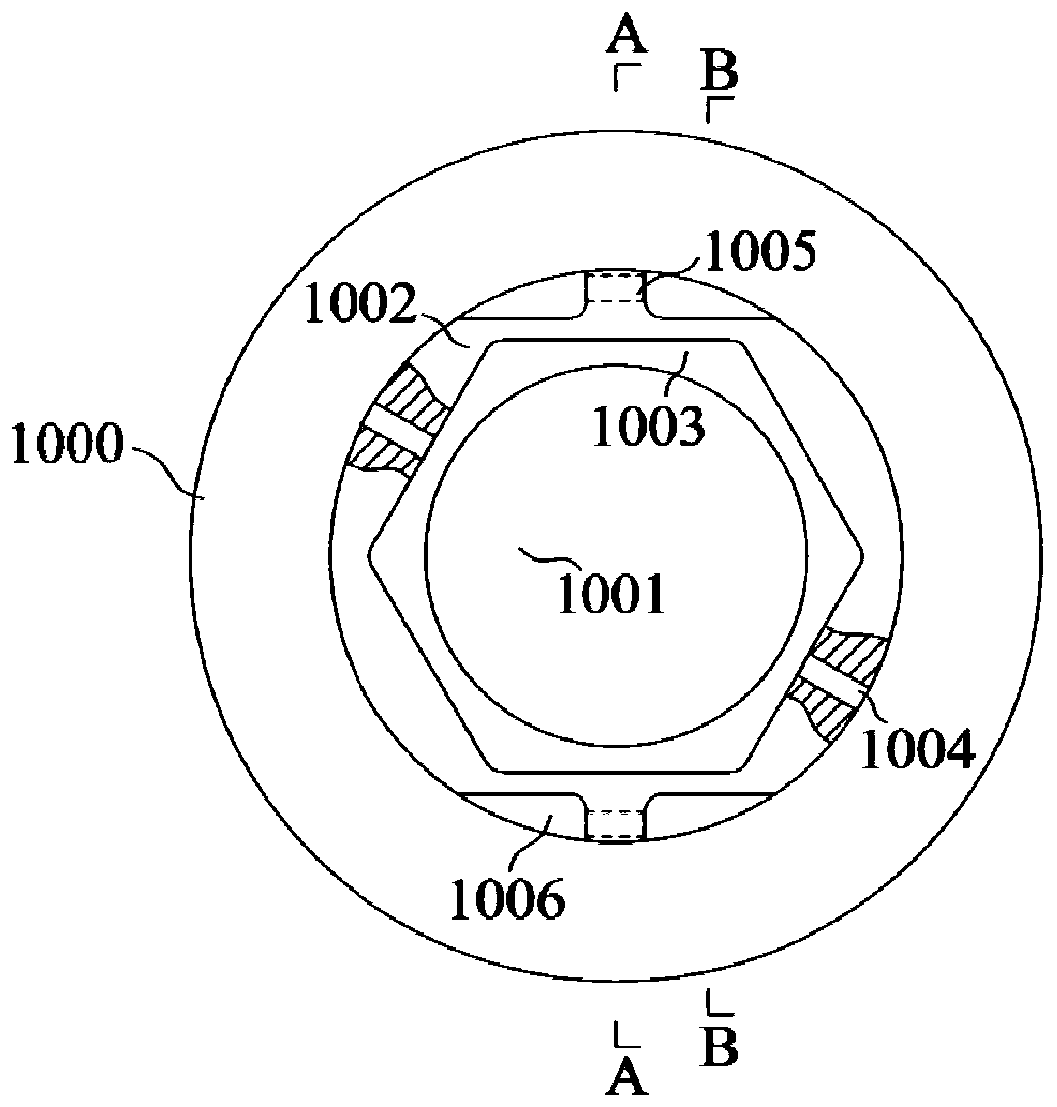

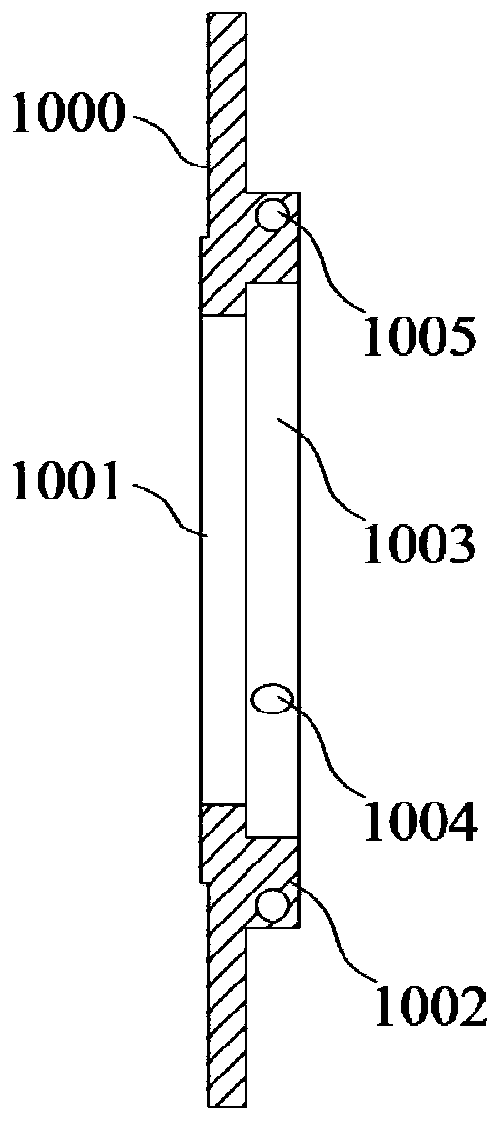

Wearable electrode array capable of being used for obtaining myoelectric signals of surfaces of arms and legs

InactiveCN103230271ANo shiftSimplify processing difficultyDiagnostic recording/measuringSensorsHuman bodyElastic substrate

The invention discloses a wearable electrode array capable of being used for obtaining myoelectric signals of surfaces of arms and legs. The wearable electrode array is used for measuring myoelectric signals of human bodies and comprises an elastic substrate which is worn on one of arms and legs and a plurality of dry electrodes which contact with surfaces of arms and legs. The plurality of dry electrodes are fixed on the elastic substrate and form at least one electrode ring which encircles the elastic substrate, all dry electrodes are led out through electrode leads, distances between any two adjacent dry electrodes are equal in the at least one electrode ring, a myoelectric passage is formed inside surface skin of arms and legs between any two adjacent dry electrodes in the at least one electrode ring, and all myoelectric passages are distributed in a zigzag shape. The wearable electrode array is simple in structure, convenient to manufacture and use and capable of guaranteeing that all dry electrodes contacting with surfaces of arms and legs are not displaced during usage and keeping the consistence of distances between all dry electrodes, so that the difficulty in post processing of myoelectric signals is reduced, and the robustness of a system is improved.

Owner:SHANGHAI JIAO TONG UNIV

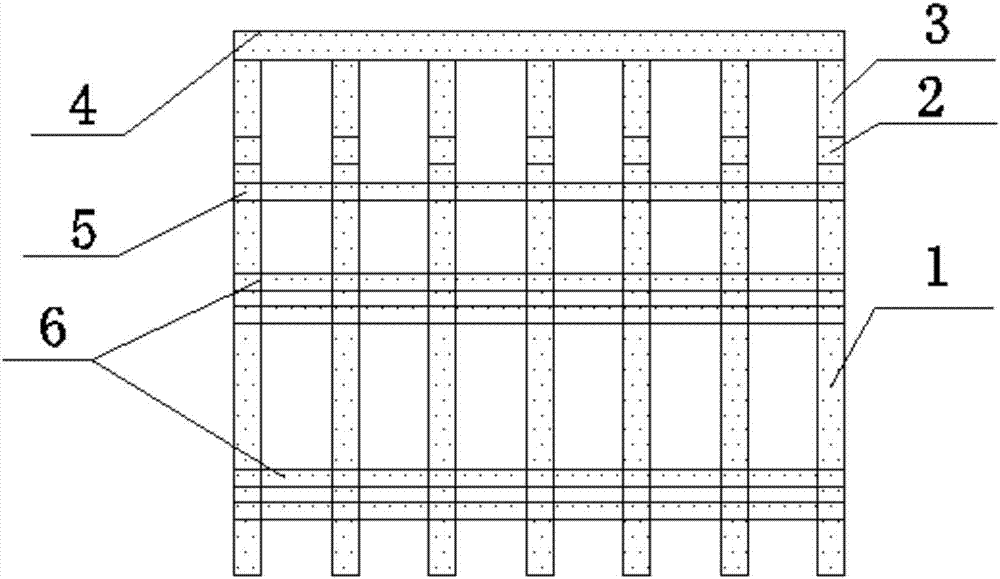

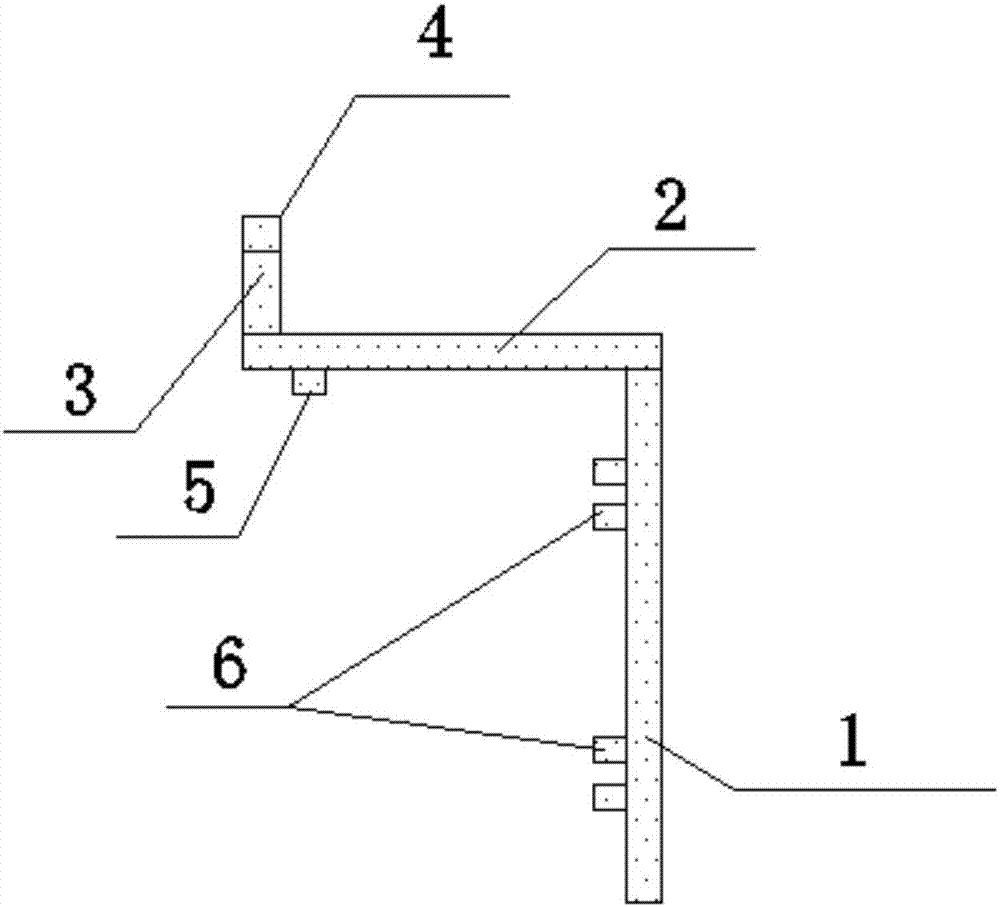

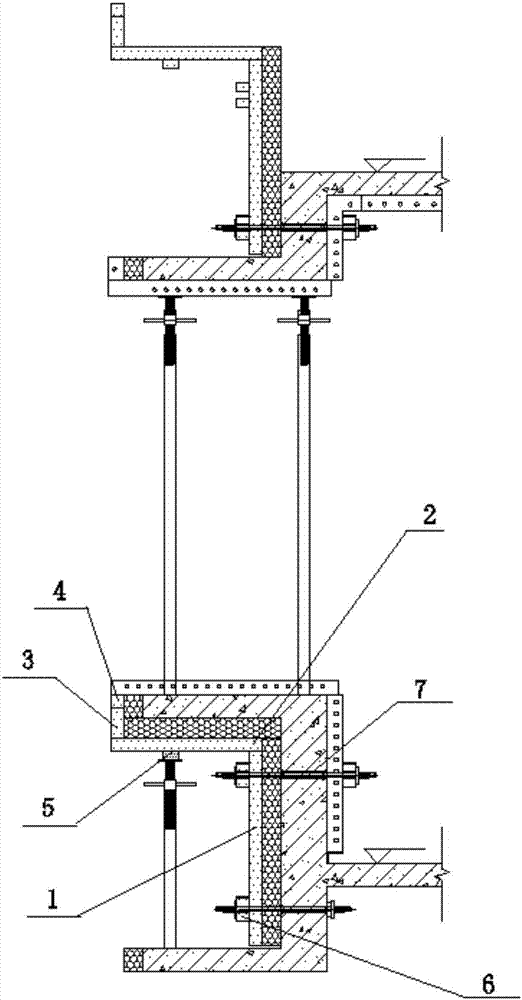

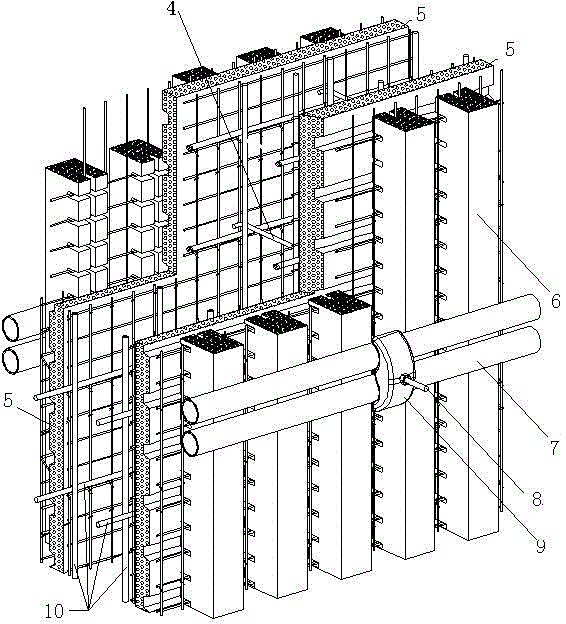

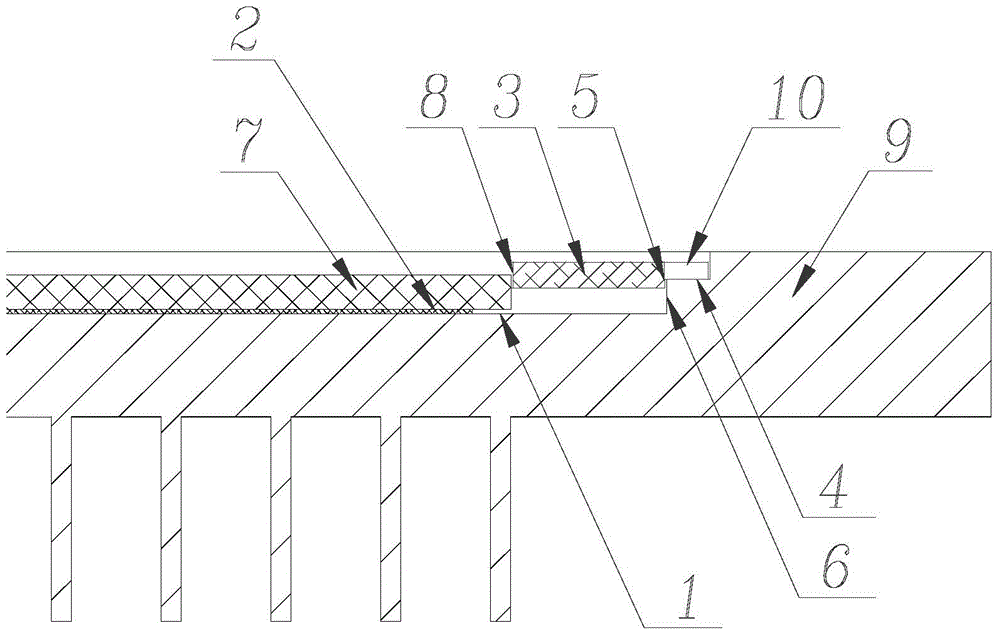

Template support installed at bay window through heat-preservation and template integrated plates and strengthening method thereof

InactiveCN107035143AGuaranteed stabilityNo shiftForms/shuttering/falseworksMarine engineeringSupport point

The invention belongs to the technical field of building construction and discloses a template support installed at a bay window through heat-preservation and template integrated plates and a strengthening method thereof. The template support comprises a plurality of under-window wall body vertical support bodies, outer bay window plate bottom mold horizontal supporting bodies, bay window plate outer side face vertical supporting bodies, top connecting square tubes, upright supporting point connecting square tubes and four opposite-pull screw pull node connecting square tubes. The top ends of the window lower wall body vertical support bodies are perpendicularly connected with one ends of the outer bay window plate bottom mold horizontal supporting bodies, and the other ends of the outer bay window plate bottom mold horizontal supporting bodies are perpendicularly connected with the bottom ends of the bay window plate outer side face vertical supporting bodies; and the top connecting square tubes are fixed to the top ends of the bay window plate outer side face vertical supporting bodies, the upright supporting point connecting square tubes are fixed below the outer bay window plate bottom mold horizontal supporting bodies and located in front of the bay window plate outer side face vertical supporting bodies, and the four opposite-pull screw pull node connecting square tubes are correspondingly fixed to the side faces of the window lower wall body vertical support bodies in pairs. The template support has the advantages of being firm and not out of the position, high in construction speed, not prone to falling off and the like.

Owner:SHANXI CONSTR ENG CO LTD +2

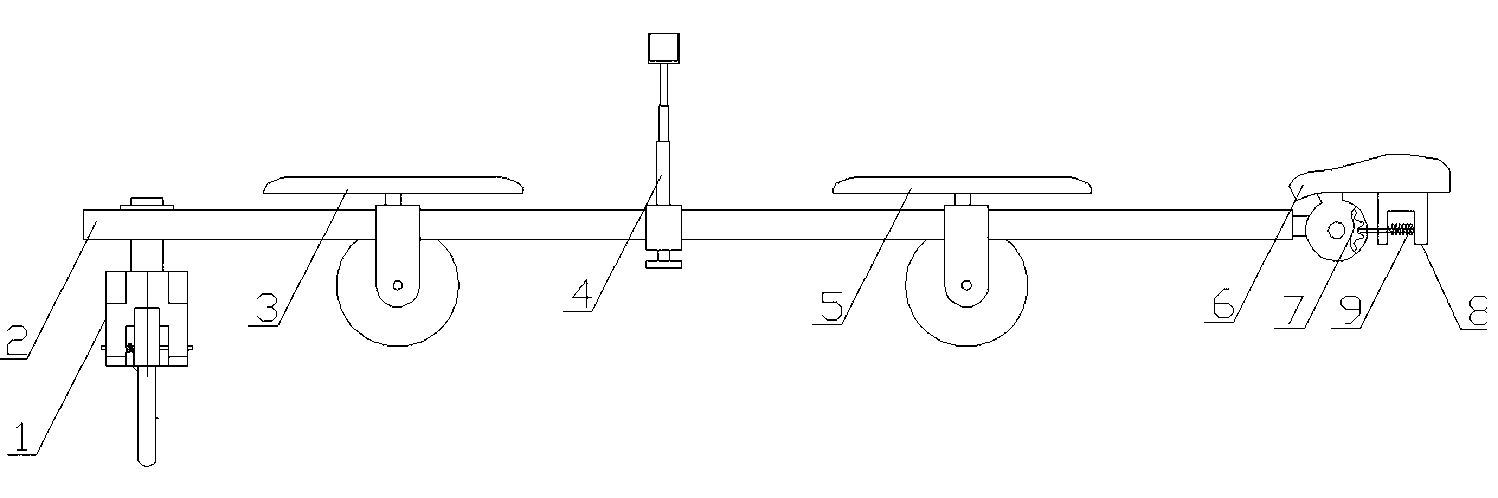

Palm rest fixing support for radial artery puncture

ActiveCN102973322AImprove comfortIncrease success rateDiagnosticsSurgical needlesArtery punctureRadial artery puncture

The invention relates to a palm rest fixing support for radial artery puncture. The palm rest fixing support comprises a palm rest rod, a fixing clamp, an elbow portion tray, a wrist portion tray, and a movable palm portion tray, wherein the elbow portion tray and the wrist portion tray are successively arranged on the palm rest rod from left to right, one end of the palm rest rod is provided with the fixing clamp, the other end of the palm rest rod is provided with the movable palm portion tray, and a telescopic actuator bracket is connected with the palm rest rod. The palm rest fixing support enables the palm rest rod to be adjusted for matching with the lengths of different patients according to the lengths of the different patients, the movable elbow portion tray can enable the elbow portion of a patient to be fixed so as to prevent the elbow portion of the patient from displacement, and success rate of puncture and comfort degree of the patient are raised.

Owner:冯大鹏 +1

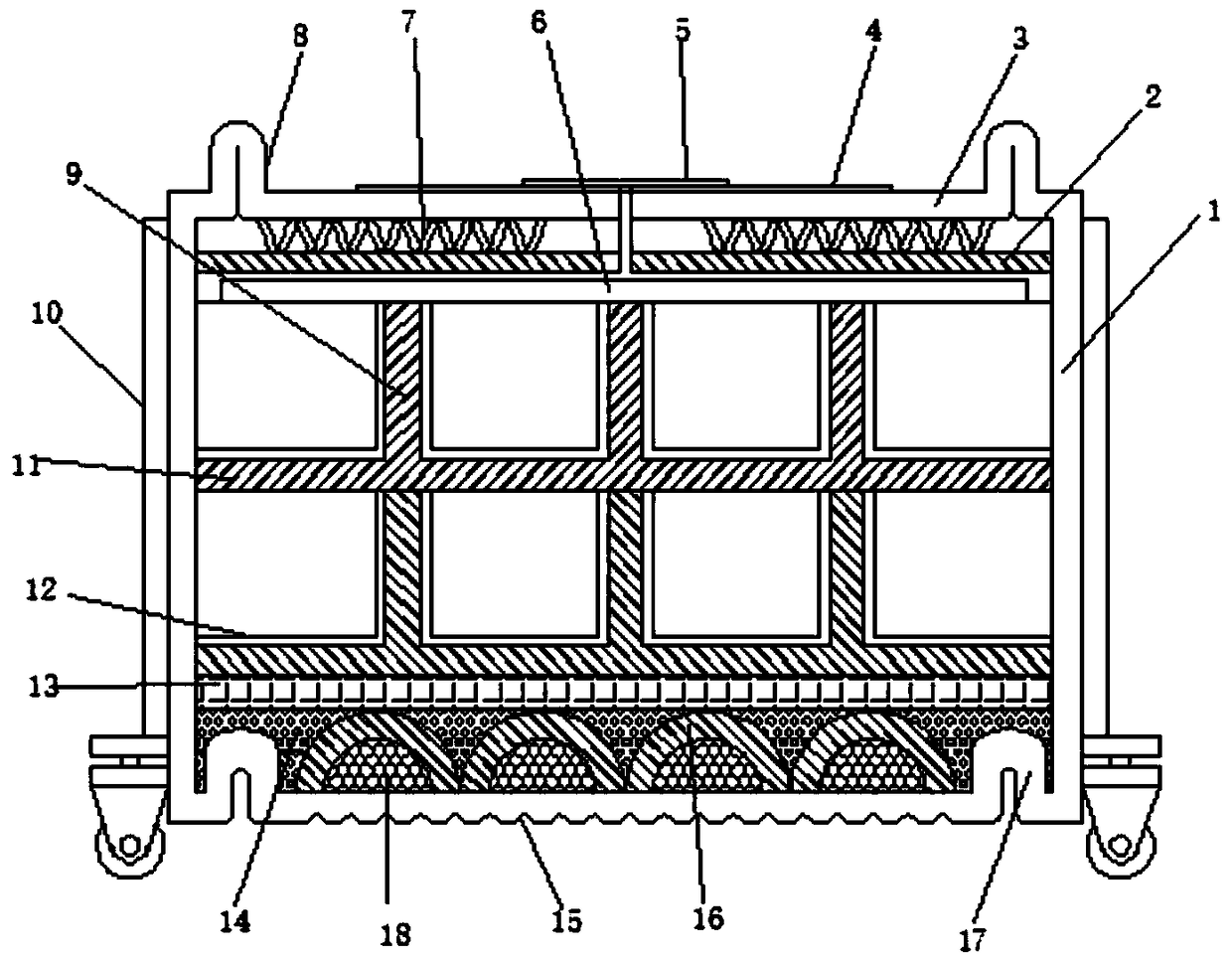

Corrugated case for transporting fruits

InactiveCN108750329ANo shiftAvoid deformationContainers preventing decayContainers to prevent mechanical damageAbsorbent cottonSmall hole

The invention relates to the technical field of corrugated cases, in particular to a corrugated case for transporting fruits. The corrugated case comprises a case body, wherein both sides of the bottom of the case body are sunken inwards so as to form second wrinkles, movable covers are symmetrically arranged on both sides of the top of the case body, the two movable covers are connected by virtueof a connecting mechanism, the positions, which are located just above the second wrinkles, of the movable covers are bulged outwards so as to form first wrinkles, a backing plate is horizontally arranged near the bottom in the case body, small holes are densely distributed in the backing plate, a plurality of cushions are arranged at the bottom of the case body, the cushions are semicircular tubular, air holes are densely distributed in the cushions, gaps between the cushions and the bottom of the case body are filled with drying agents, absorbent cotton is arranged between the cushions andthe backing plate, and a plurality of fruit storage mechanisms are stacked on the backing plate. According to the corrugated case, fruits in case body are buffered and protected by adopting the cushions, so that vibration is reduced; in addition, the absorbent cotton and the drying agents are arranged at the bottom of the case body, so that the case body can be effectively prevented from deformingdue to damp.

Owner:HUBEI TAIYOU PAPER CO LTD

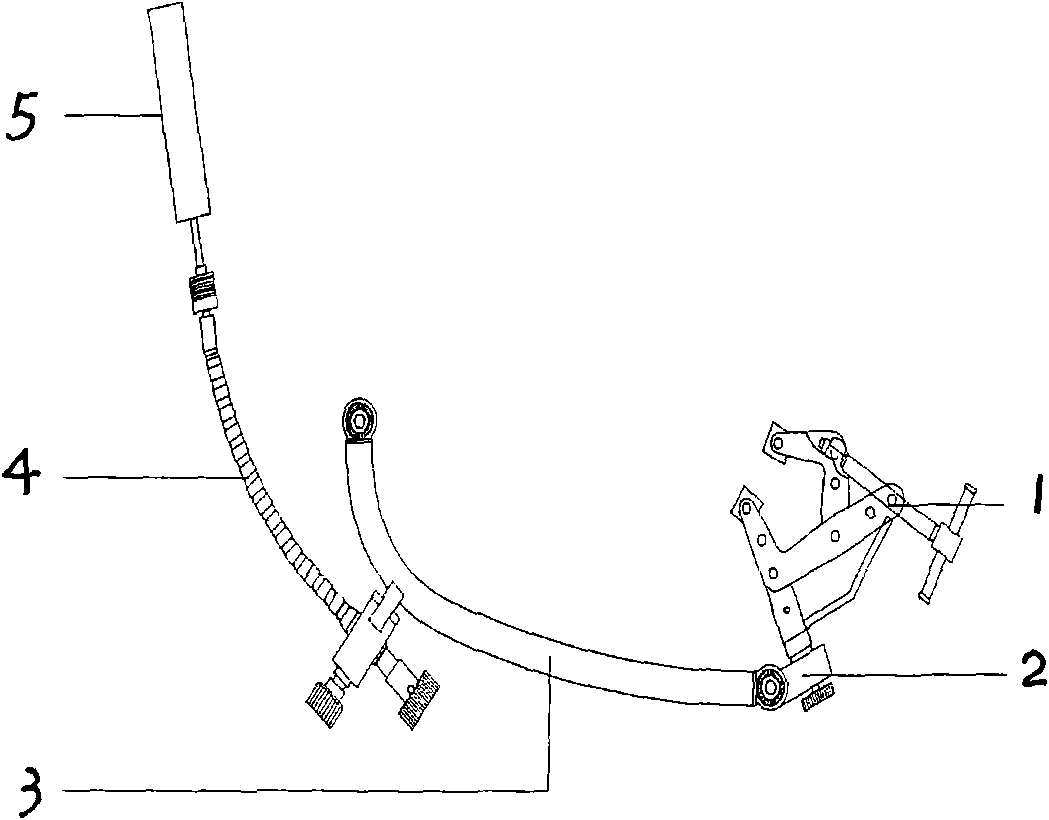

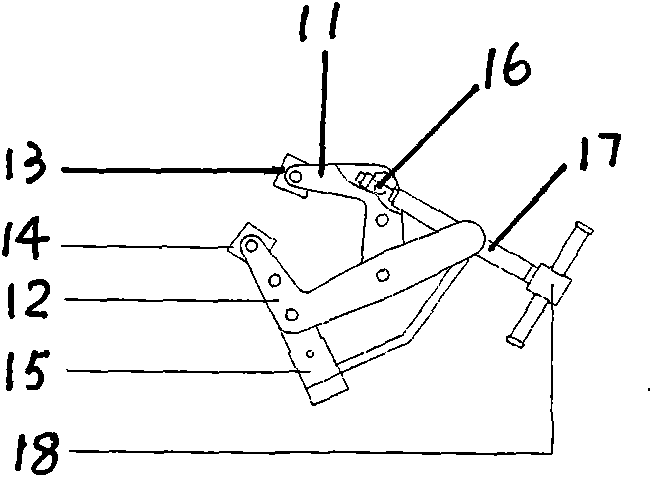

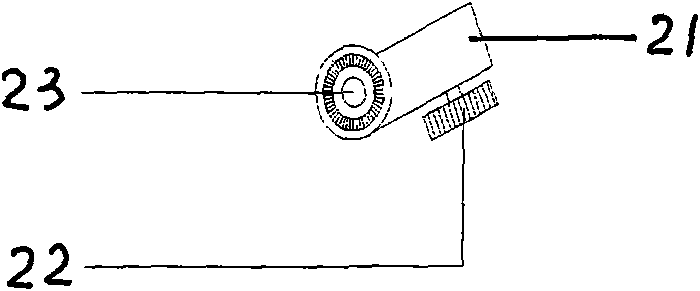

Automatic traction device for neurosurgical operation

InactiveCN101828964ADoes not affect image scanningNo shiftSurgical navigation systemsDiagnostic recording/measuringResonanceEngineering

The invention relates to an automatic traction device for a neurosurgical operation, which is used for being connected to a special headrest for magnetic resonance navigation and comprises a connector, a connecting member, a C-shaped arm, a snakelike arm and a brain spatula which are connected in sequence, wherein the connector, the connecting member, the C-shaped arm, the snakelike arm and the brain spatula are all made of titanium alloy materials which are magnetically compatible. The automatic traction device for the neurosurgical operation can be used in the presence of a magnetic field without generating displacement or influencing operations during the neurosurgical operation. When in use, the automatic traction device is fixed on the special headrest for the magnetic resonance navigation without influencing magnetic resonance image scanning and has simple structure and practicability.

Owner:AFFILIATED HUSN HOSPITAL OF FUDAN UNIV

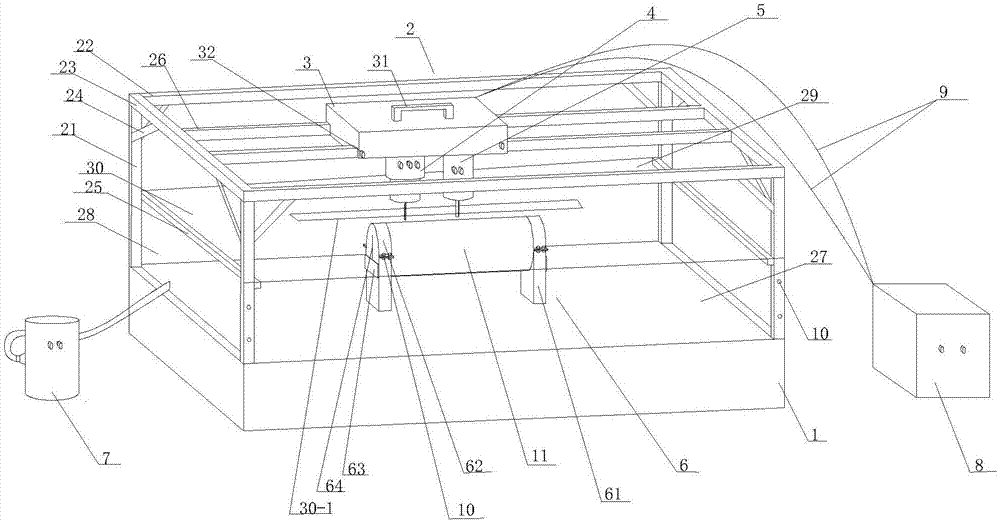

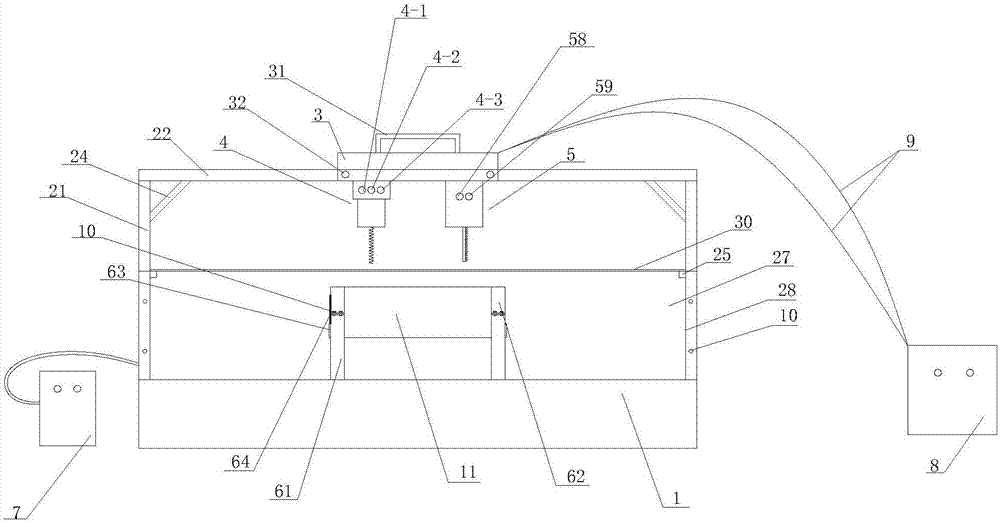

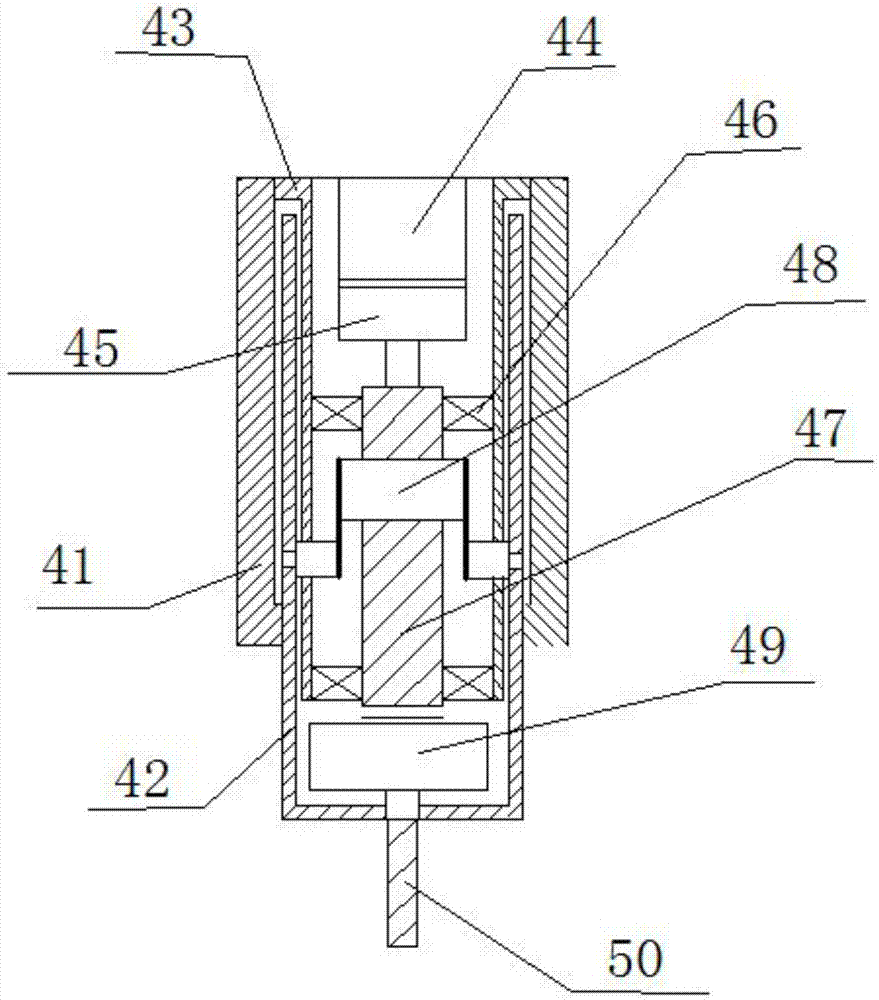

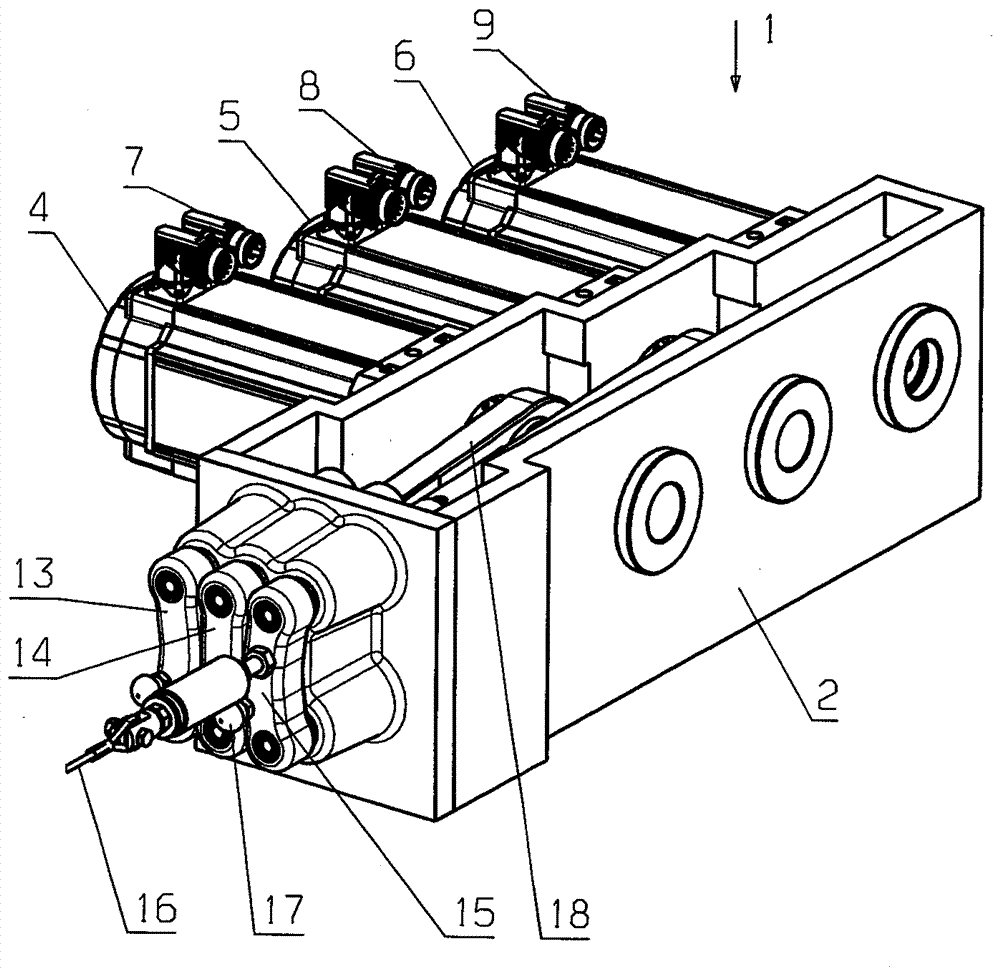

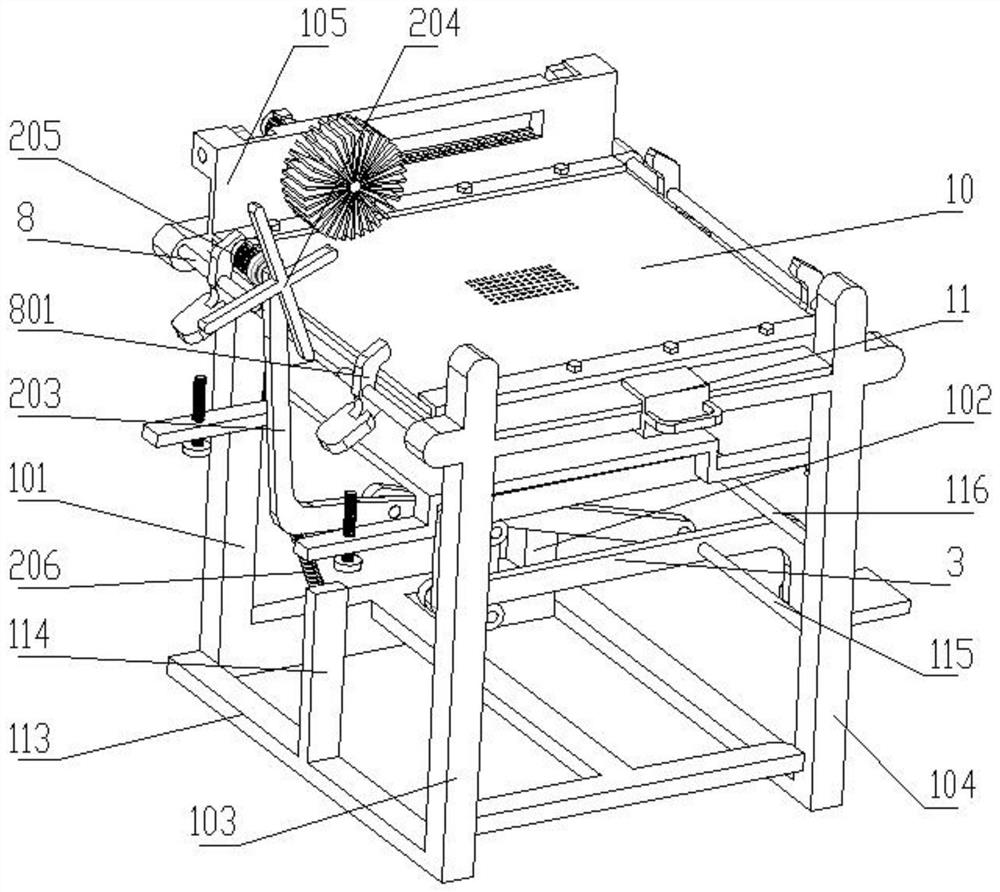

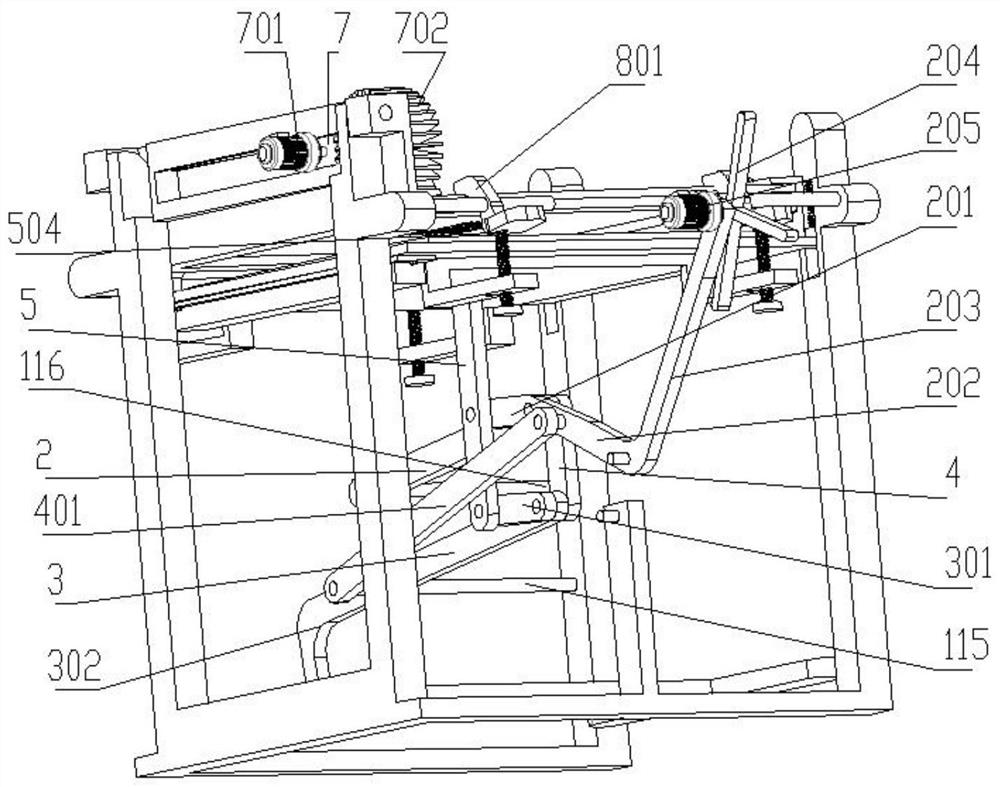

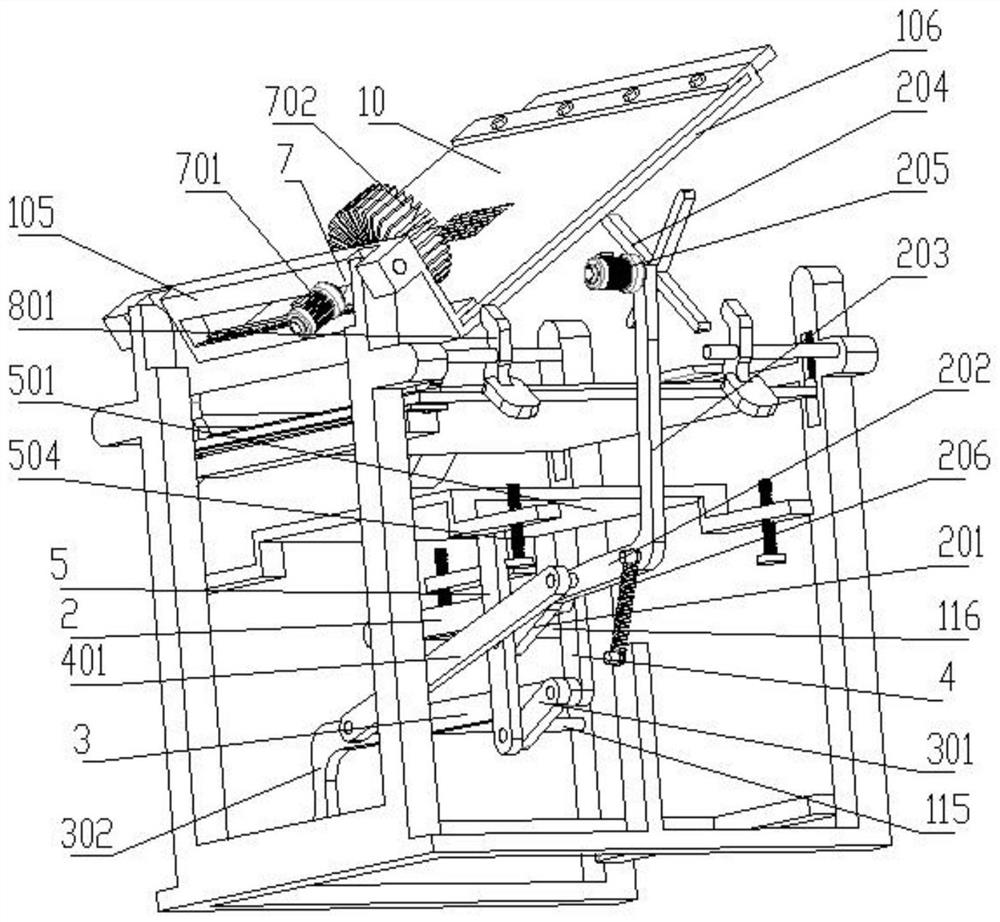

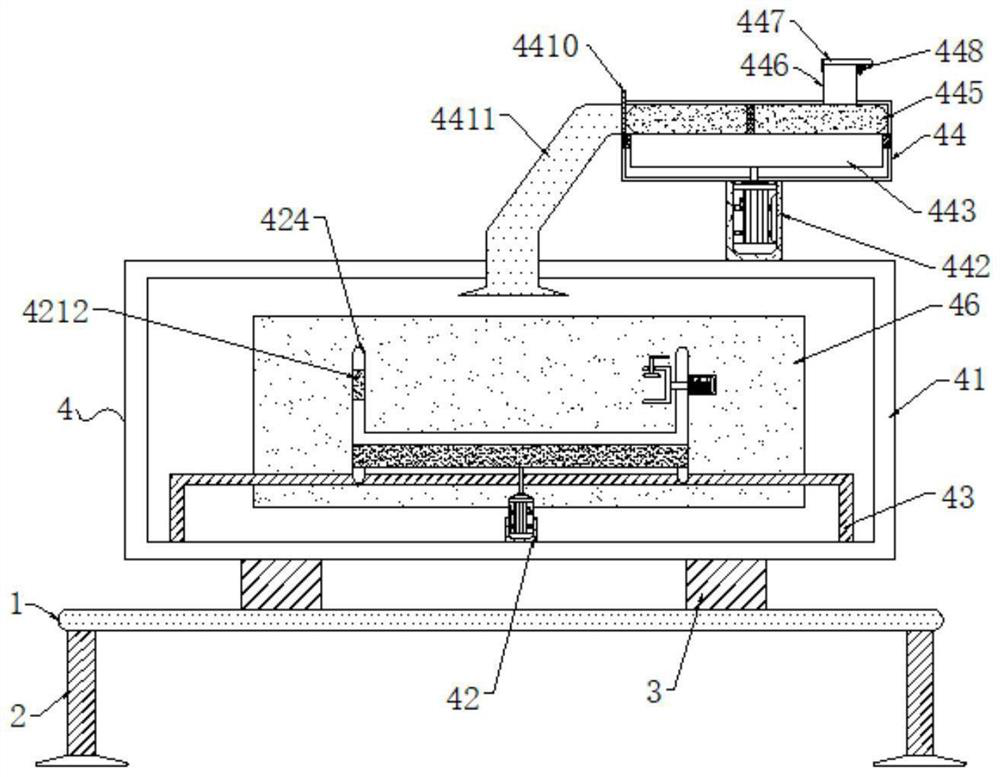

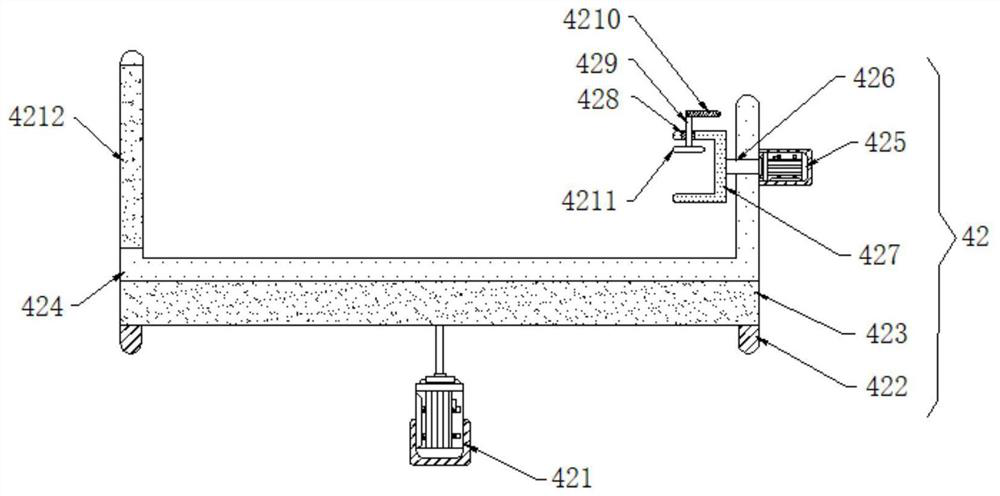

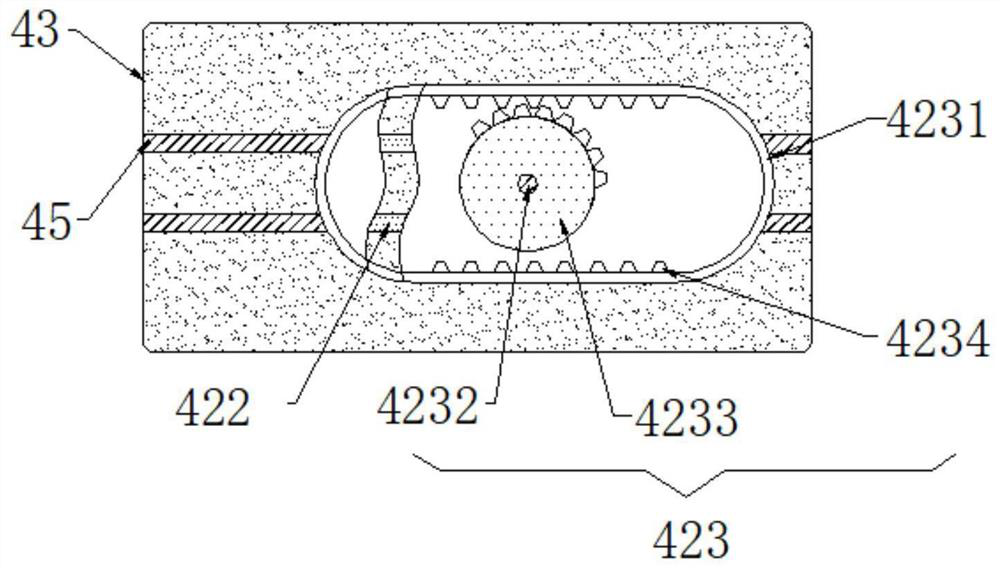

Apparatus for forming penetrating cracks in rock sample and operation method thereof

ActiveCN107290192AEliminate the effects ofNo change in mechanical propertiesPreparing sample for investigationGlass coverClassical mechanics

The invention discloses an apparatus for forming penetrating cracks in a rock sample and an operation method thereof. The apparatus includes a pedestal, a support structure, a workbench, a drilling device, a cutting device, a sample fixing device, a dust removal device, and a power source. The support structure is fixed on the pedestal and includes four vertical columns, two crossbeams, two linking beams, two support rods, two slide rails, a front glass board, side glass boards, a rear glass board and a glass cover board. The four vertical columns are vertically fixed on the pedestal. The two crossbeams and two linking beams are fixedly connected to form a rectangular frame which is fixed on the upper ends of the vertical columns. Each support rod is fixed on the middle parts of two vertical columns. The two support rods are symmetrically disposed and are located on the same horizontal plane. The apparatus can effectively increase the precision and efficiency of forming the penetrating cracks in the rock sample, so that subsequent test on the rock sample is convenient to carry out. In addition, the production process also includes dry-type dust removal, so that the apparatus does not change the original mechanical properties of rock and is free of influence on surrounding environment and body health.

Owner:HUNAN UNIV OF SCI & TECH

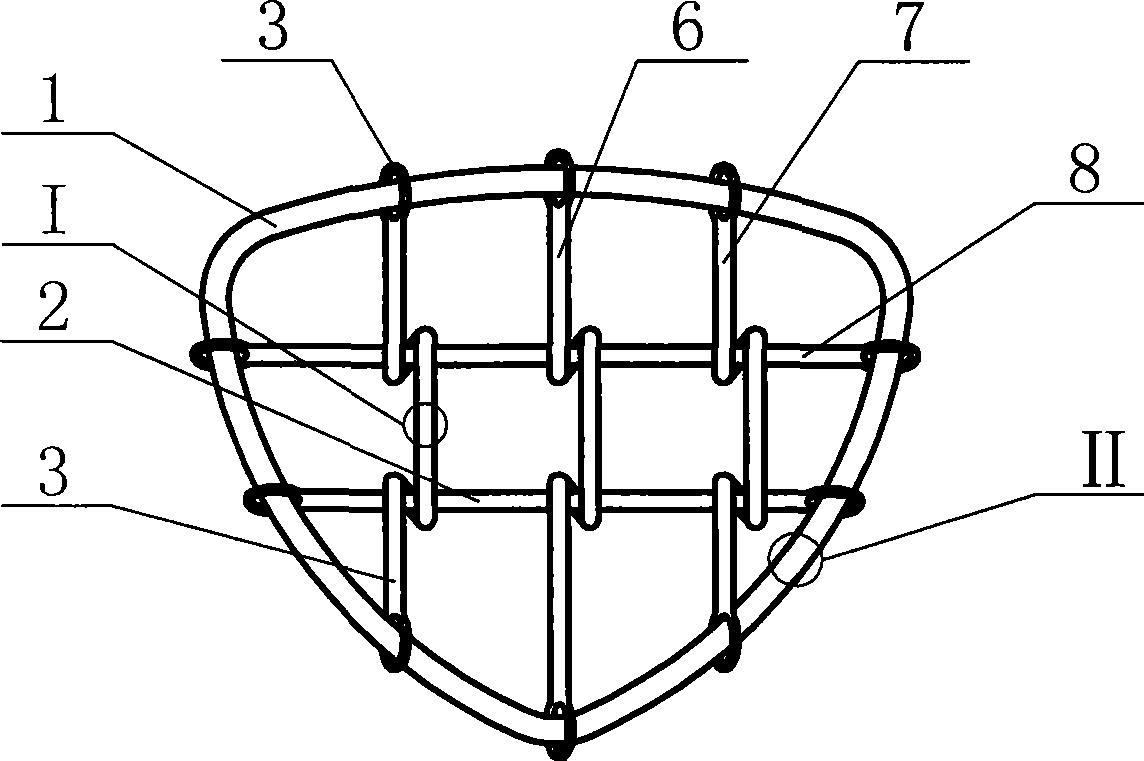

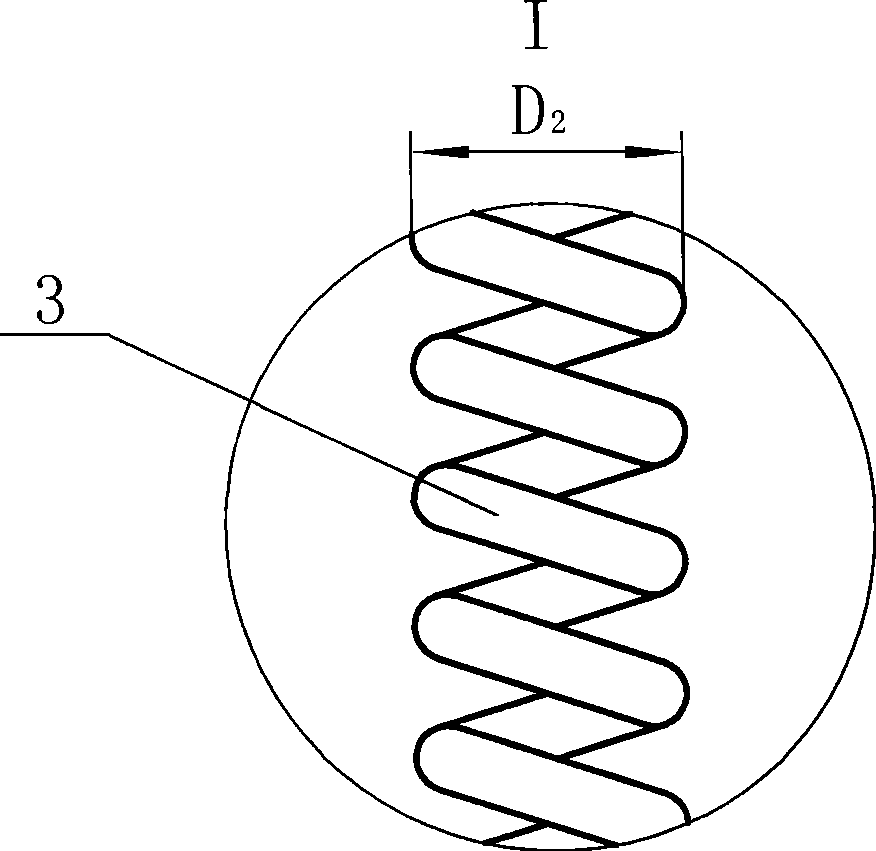

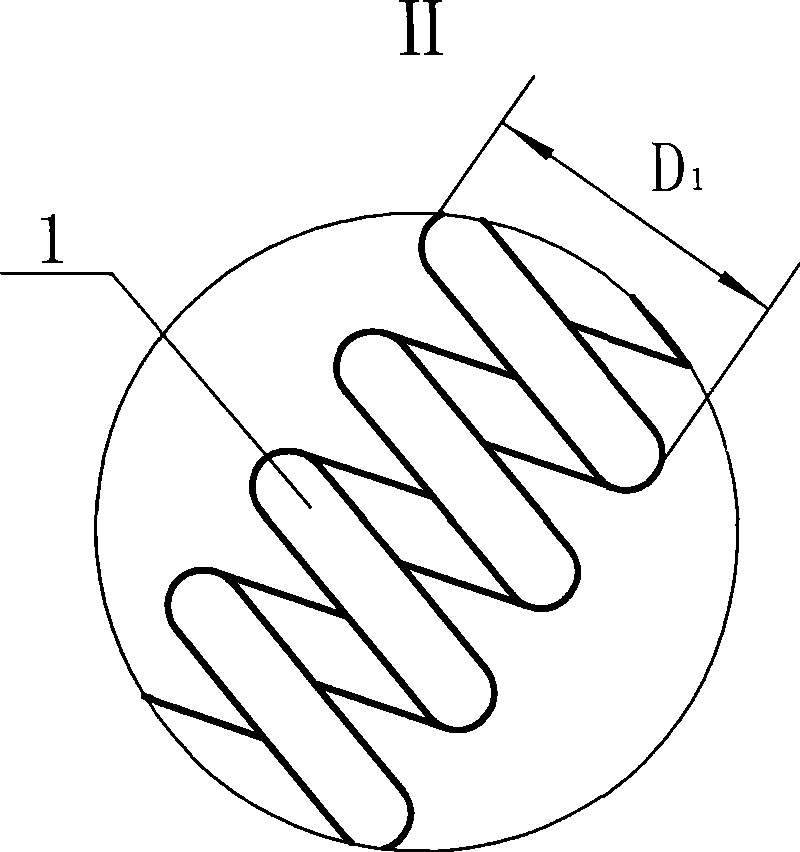

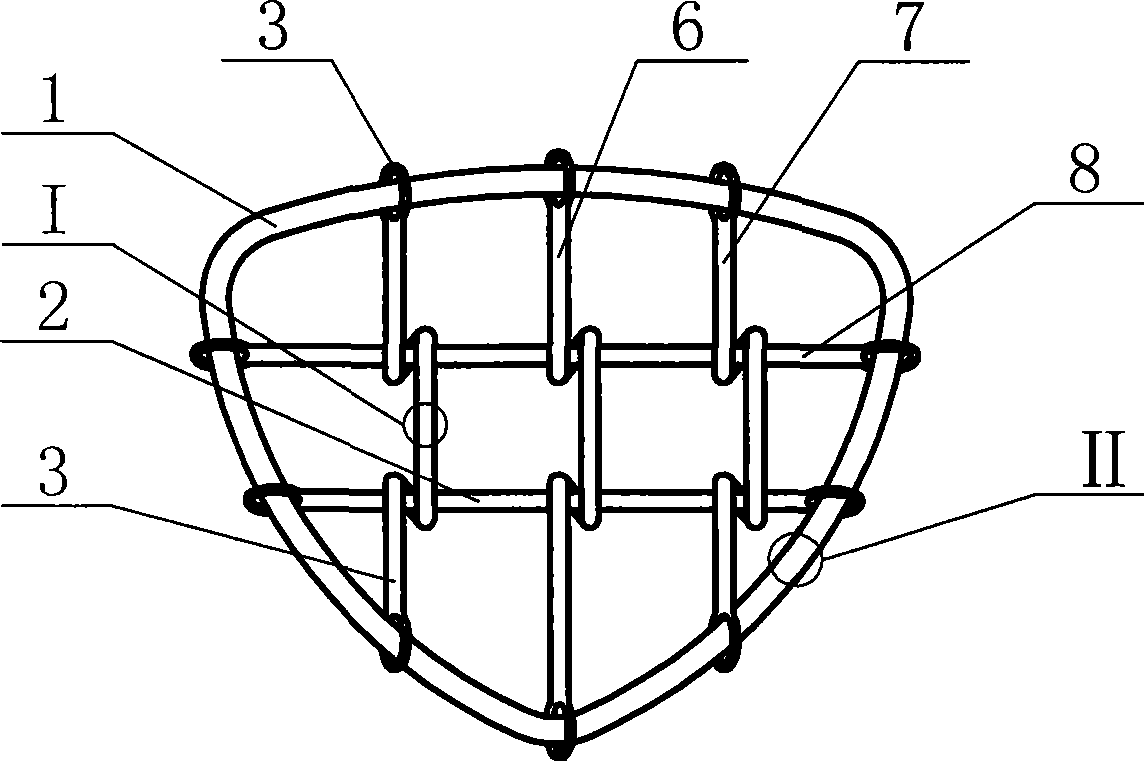

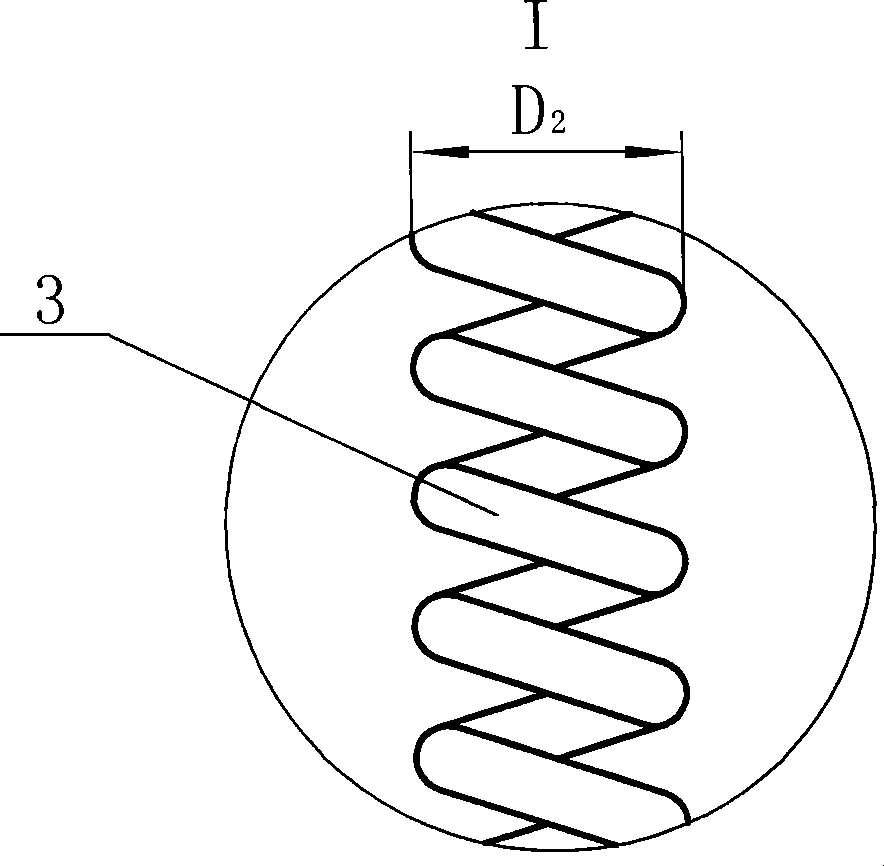

Grille intrauterine device

The invention discloses a grid intrauterine device, which comprises an elastic ring. The elastic ring takes the shape of a triangle, and three corners take the shape of an arch; a first elastic wire is arranged through starting from one corner of the elastic ring and ending up at the middle part of a straight flange vertically corresponding to the corner; a second elastic wire is installed on the right side of the first elastic wire, and a third elastic wire is arranged on the left side of the first elastic wire; the distance between the first elastic wire and the second elastic wire is equal to the distance between the first elastic wire and the third elastic wire; a fourth elastic wire and a fifth elastic wire are installed between two equivalent edges of the elastic ring; intersecting parts between the first elastic wire, the second elastic wire as well as the third elastic wire and the fourth elastic wire as well as the fifth elastic wire adopt encircling related joint; the diameter D1 of the elastic ring ranges from 0.9 to 1.2mm; and the diameter D2 of each elastic wire ranges from 0.6 to 0.8mm. Through clinical application, the grid intrauterine device is proved to have the characteristics of no desquamation, no occurrence of displacement, and the like, and the phenomena such as infection, low back pains, abdomen tenesmus and the like are not found. The structure of the grid intrauterine device can withstand uterine contraction force, adapt to the uterine tension, and have the characteristics of reducing the pressure to a uterine and avoiding hemorrhage.

Owner:SHANDONG PROVINCIAL FAMILY PLANNING INST OF SCI & TECH

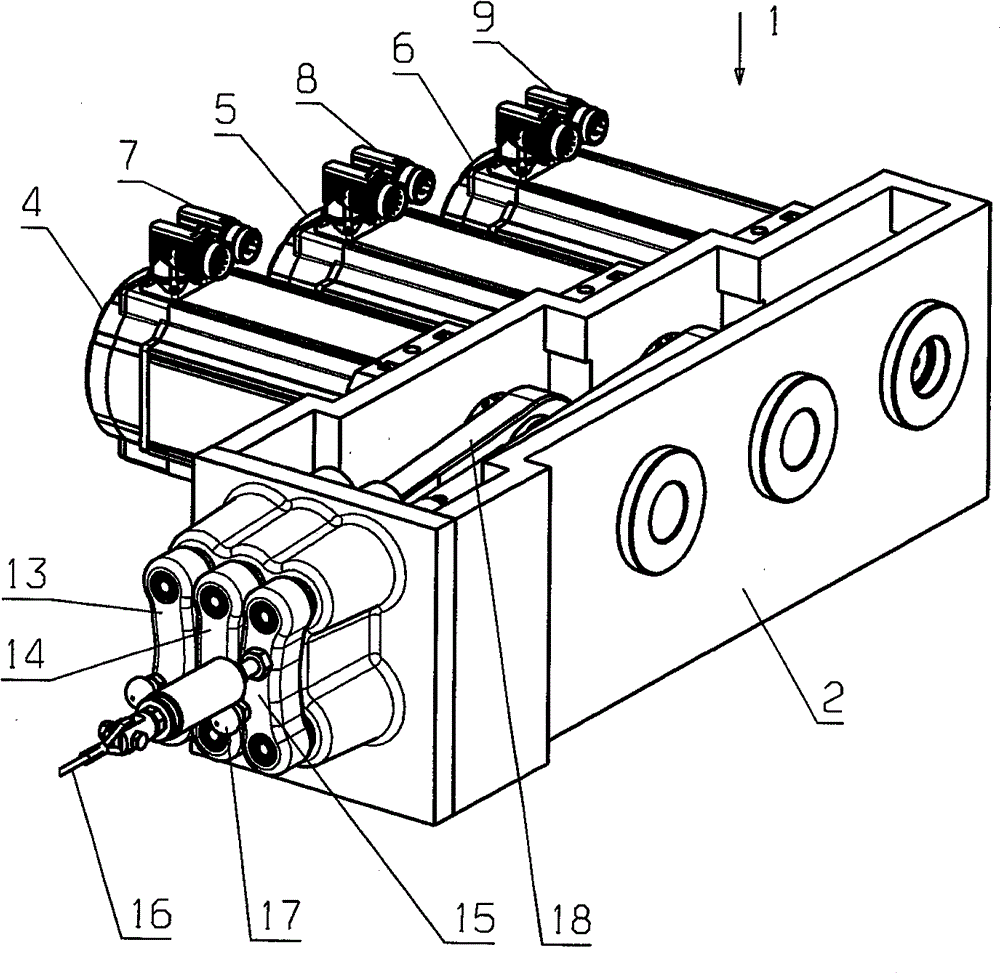

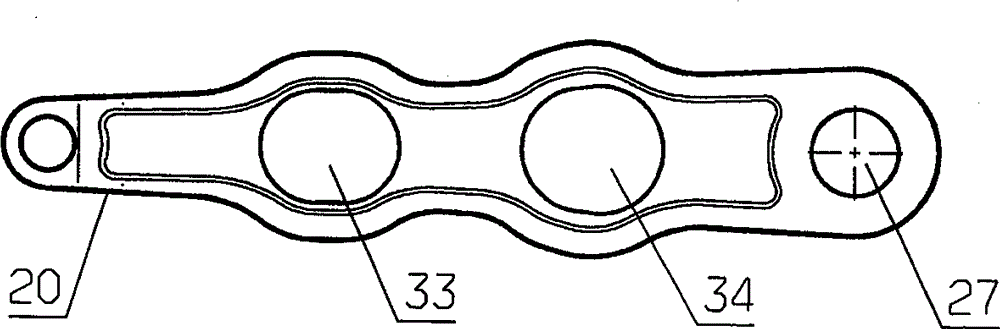

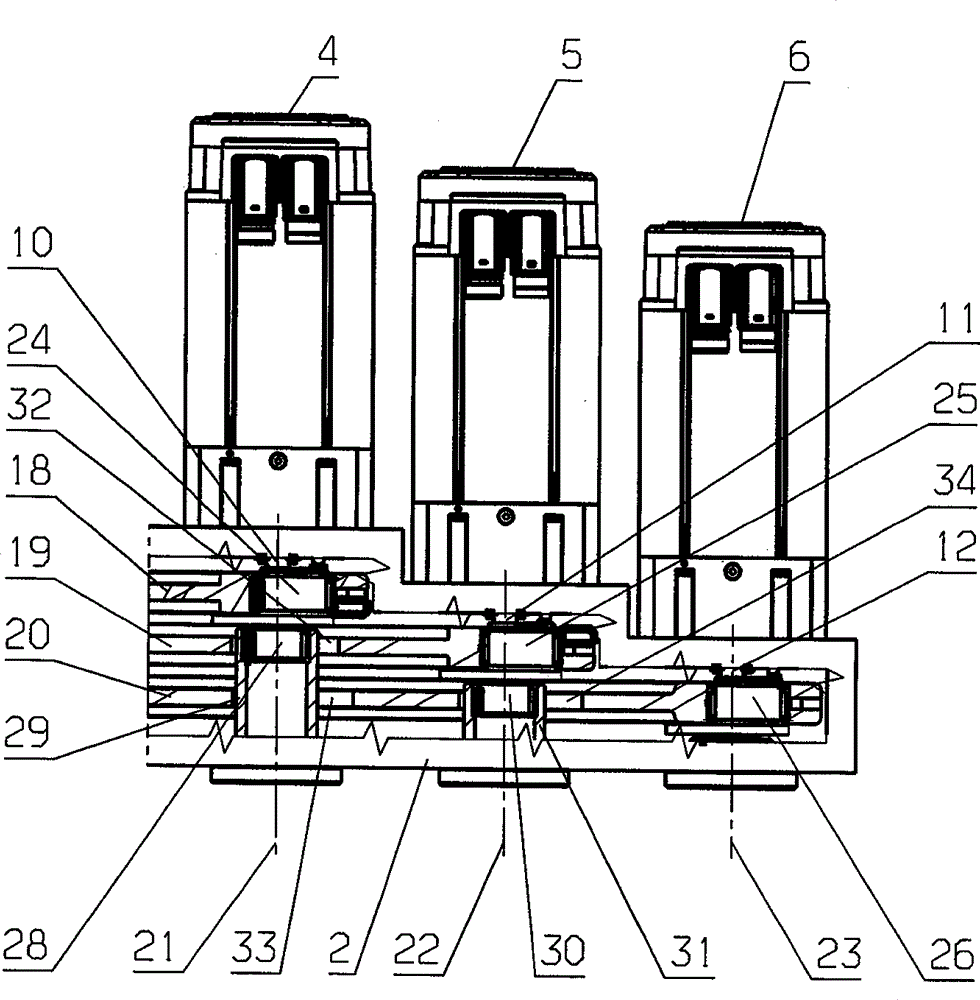

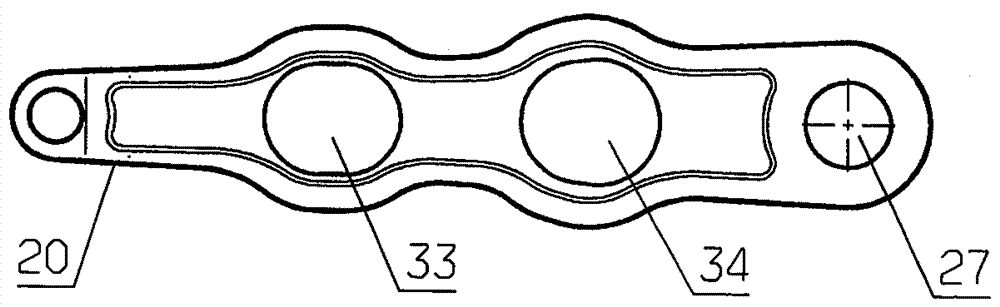

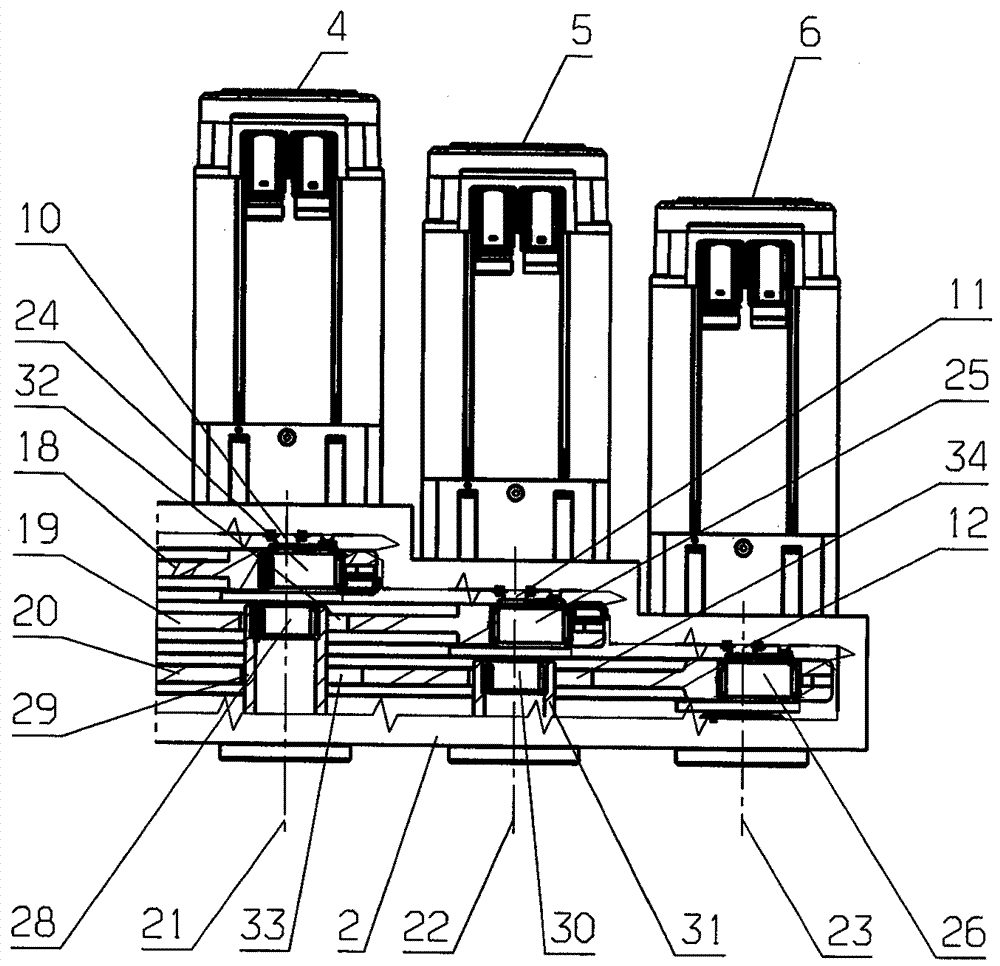

Knitting machine

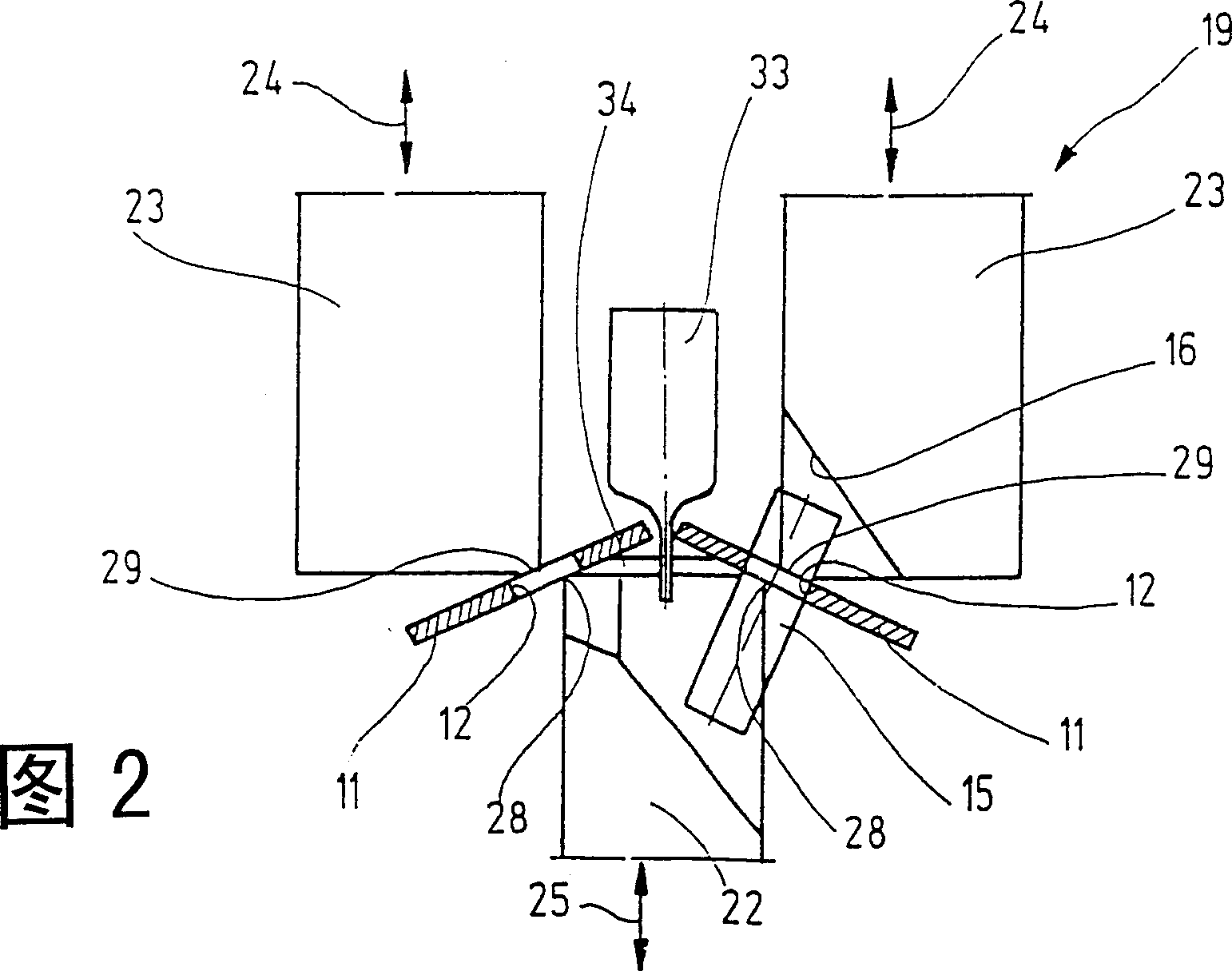

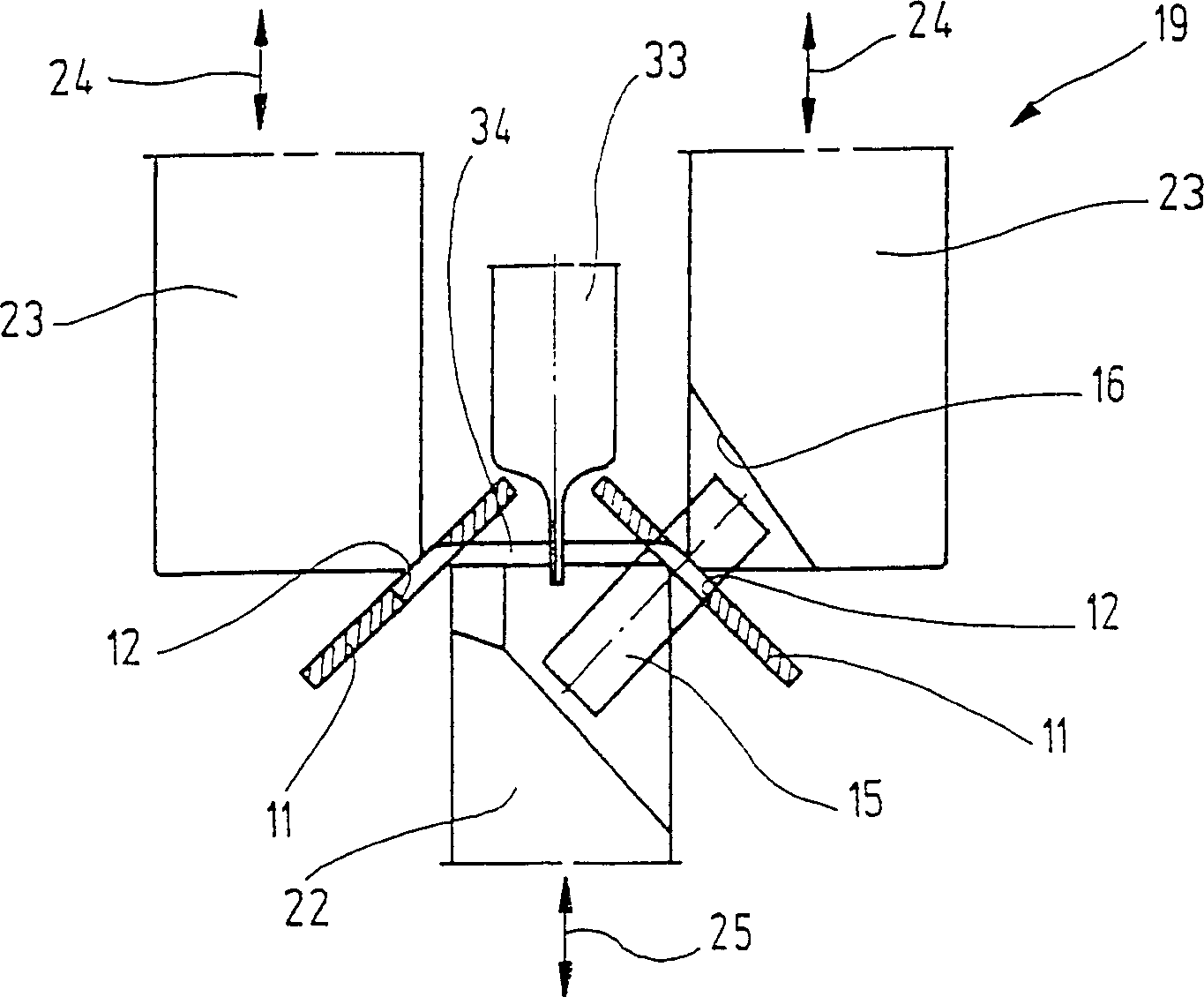

A knitting machine provided with at least one first drive shaft assembly (10, 28, 29) and a second drive shaft arrangement (11, 30, 31), said first drive shaft assembly (10, 28, 29) and the second drive shaft arrangement (11, 30, 31) running parallel axes (21, 22) have, the first drive shaft arrangement (10, 28, 29) having at least a first connecting rod (18) having a first connecting rod end, is connected, and the second drive shaft arrangement (11, 30, 31) is connected to at least one second connecting rod (19) having a second connecting rod eye. Great freedom in the design is expected of the knitting machine. For this purpose, it is provided that the at least one second connecting rod (19) has a recess which is passed through the first drive shaft arrangement (10, 28, 29).

Owner:KARL MAYER STOLL R&D GMBH

Clamp for preventing shrinkage fit from shifting

InactiveCN102398238ANo shiftThere will be no situation where the cooling cannot be resetWork holdersMetal working apparatusMalletMechanical engineering

The invention discloses a clamp for preventing a shrinkage fit from shifting. The middle part of the clamp is rectangular flat steel. One end of the clamp is fixed with the steel flat while the other head is welded with a steel block provided with a circular hole. A pressure head, a disc spring and a pin are arranged in the circular hole of the steel block of the clamp in series. A bump of the pin head is inserted into the hole in the rear of the pressure head. A lid is fixed on the end surface of the steel block through a closing bolt and a central screwed hole of the lid is screwed to a limiting bolt. The rear end of the limiting bolt leans against the rear end surface. Materials required by the invention are easy to prepare and the invention is convenient to process. When the clamp is installed on a shaft, no tolerance fit is required so that the clamp is easy to install and disassemble, and convenient to use without a specially-assigned person. Because the pressing force applied by the clamp is persistent, the situation that the workpiece is cooled and not able to reset due to the spacing interval of mallet hitting manually can be avoided; and potential danger due to the shaft which erects up can be avoided, too. The invention not only reduces the working hours and improves the pressing quality, but also guarantees the safety under the premise that the shrinkage fit work does not shift.

Owner:SEC ELECTRIC MACHINERY

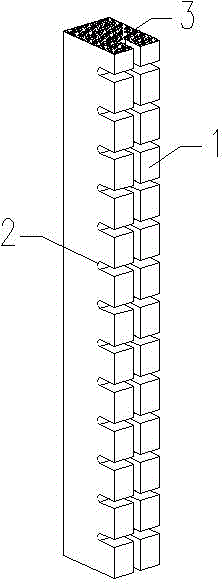

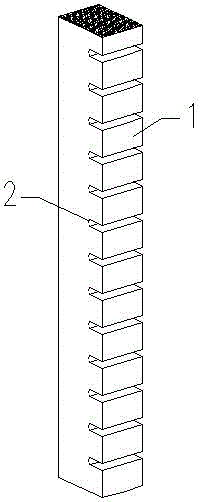

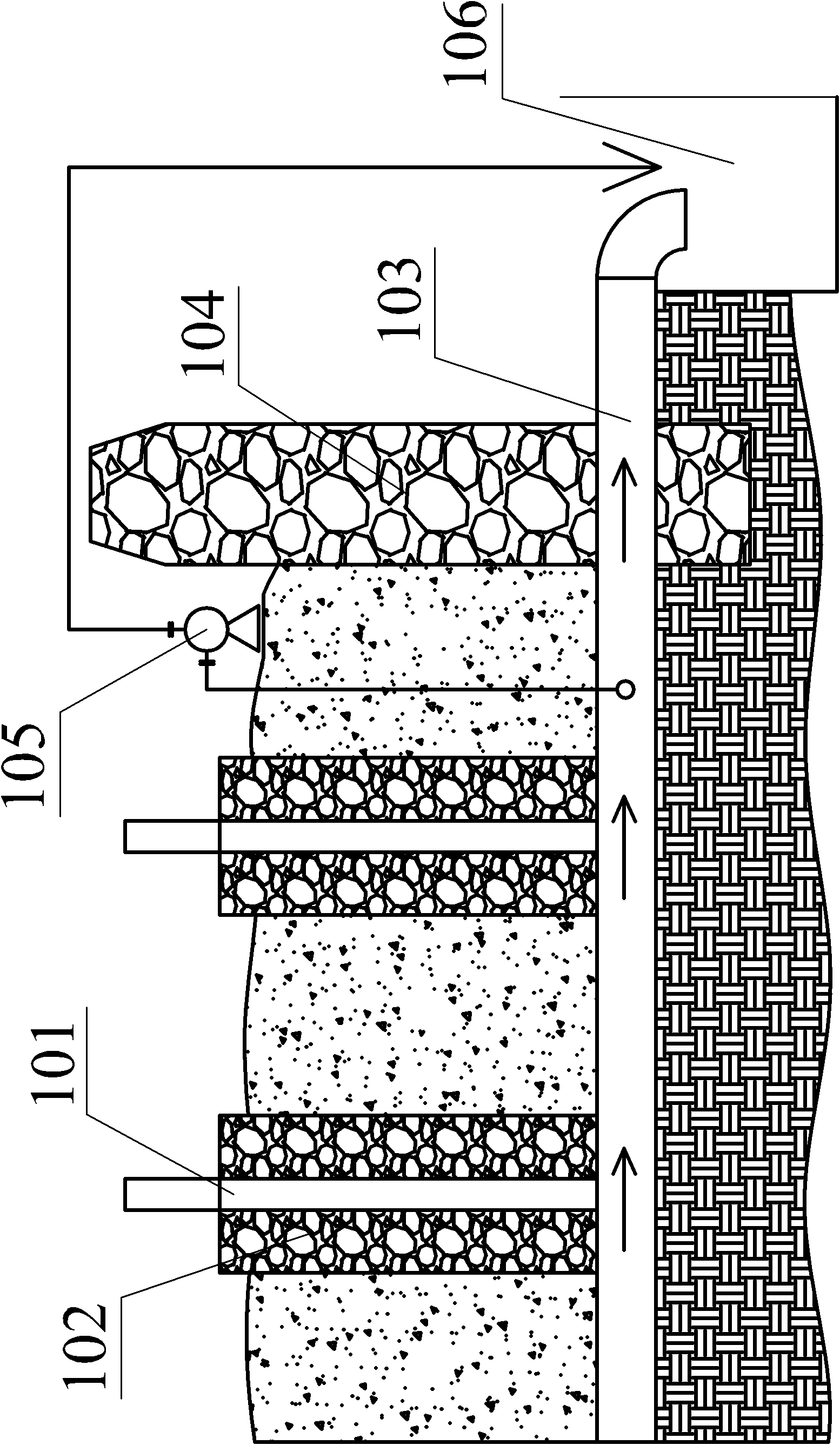

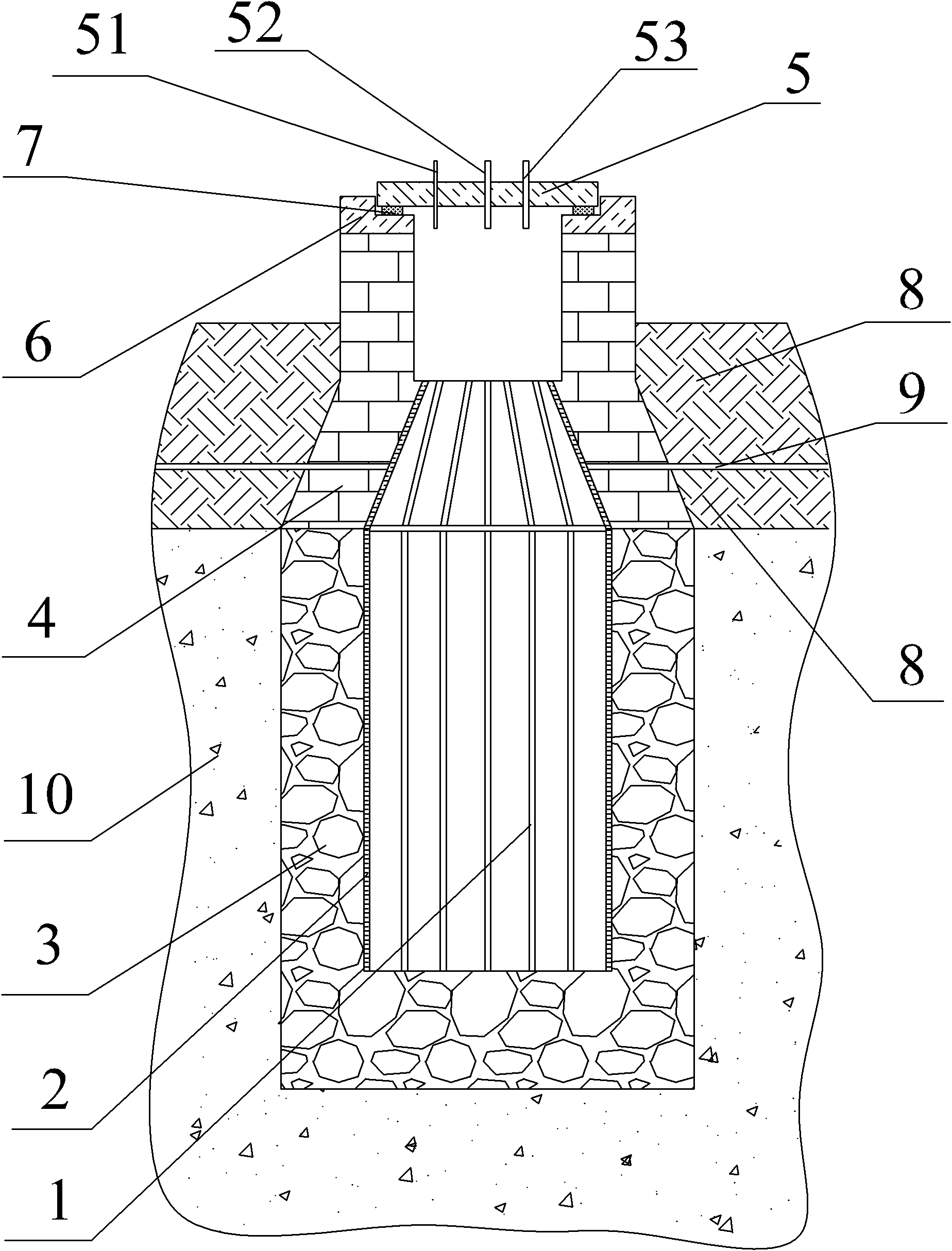

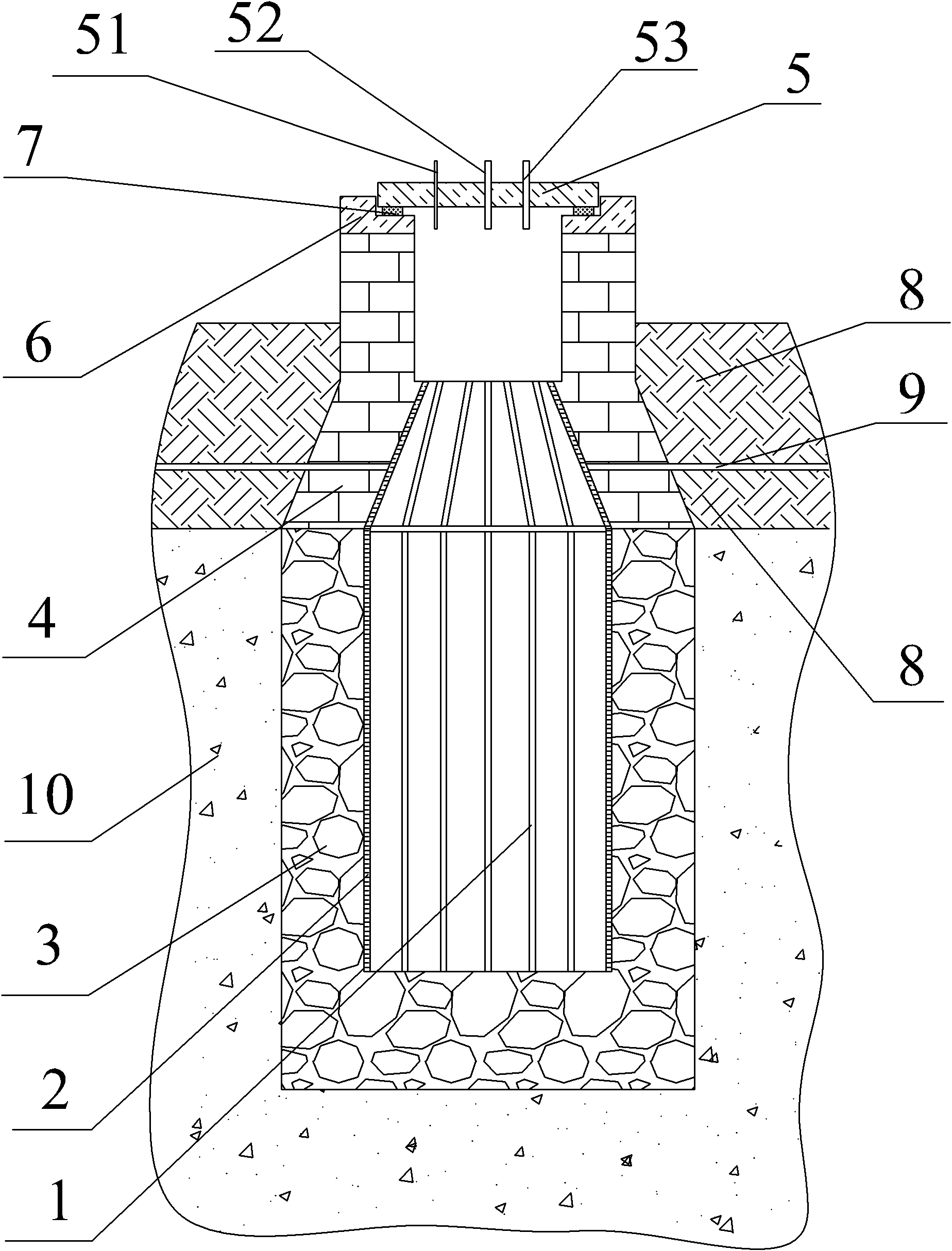

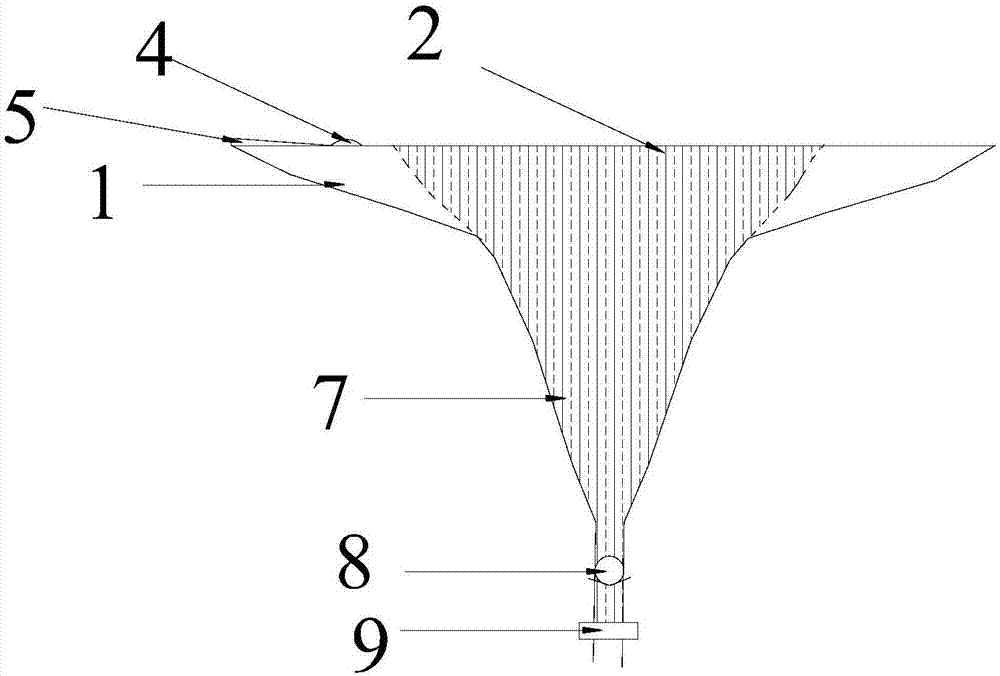

Large-sized material storage yard gas guide and discharge well and well cementing construction method

ActiveCN102155024AAvoid cloggingSimple structureArtificial islandsLandfill technologiesChemical industrySludge

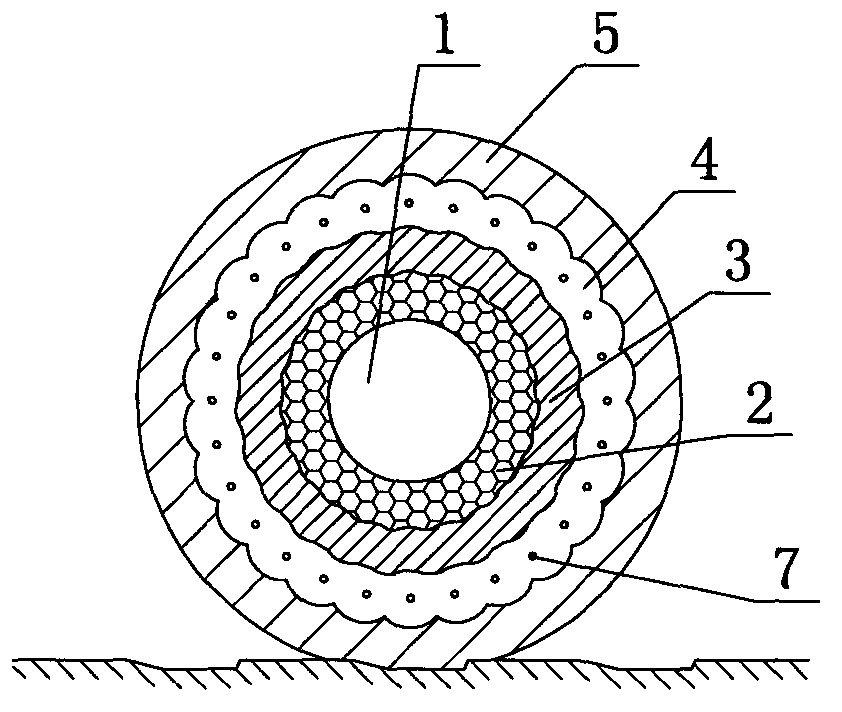

The embodiment of the invention relates to a large-scale material storage yard gas guide and discharge well and a well cementing construction method. The guide and discharge well comprises a guide and discharge well hole arranged in a material storage yard, a barrel-shaped skeleton arranged in the guide and discharge well hole, a flexible filtering layer wrapping the barrel-shaped skeleton, a crushed rock filtering layer filled between the wall of the guide and discharge well hole and the flexible filtering layer, a sealed barrel which is sealed outside the flexible filtering layer and arranged at the upper part of the guide and discharge, well as well as a well cap which seals and covers the sealed barrel and is provided with a gas guide and discharge port. The large-scale material storage yard gas guide and discharge well provided by the embodiment of the invention has simple structure, and better stability, is convenient for well cementing construction and maintenance and hardly generates displacement. Air exhaust and water draining can be simultaneously realized, and the guide and discharge well can be prevented from being blocked by sludge and crushed garbage. The gas guide and discharge well also can be popularized and applied to the processes of drying, ventilating, gas replacing and water draining and the line in a large and medium-sized material aggregating process inthe industries of grain and deep processing, chemical industry, medical industry and the like.

Owner:HENAN BCCY IND

knitting machine

Owner:KARL MAYER STOLL R&D GMBH

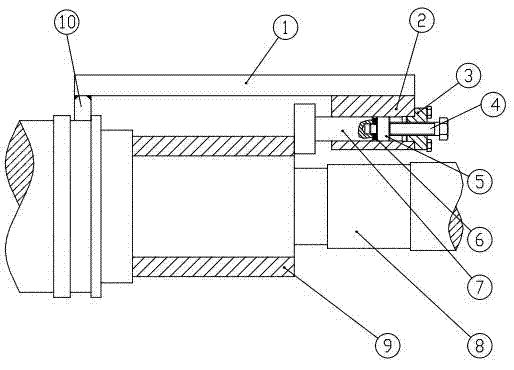

Wavelength division multiplexer

PendingCN110275251ASimple structureEasy to assembleFibre mechanical structuresMultiplexerLength wave

The invention provides a wavelength division multiplexer. The wavelength division multiplexer comprises a substrate, an incident end optical fiber, a reflecting end optical fiber, a passing end optical fiber and a filtering sheet; an incident end groove, a reflecting end groove and a passing end groove are formed in the first side wall of the substrate; the incident end groove and the reflecting end groove are arranged at a preset angle in an intersecting manner; the passing end groove and the incident end groove are coaxially arranged; the filtering sheet is installed at the intersection of the incident end groove and the reflecting end groove; the incident end optical fiber is installed in the incident end groove; the reflecting end optical fiber is installed in the reflecting end groove; the passing end optical fiber is installed in the passing end groove; the end surface of the incident end of the incident end optical fiber, which is located at the intersection, is parallel to the first plane of the filtering sheet, wherein the first plane faces the intersection; the end surface of the reflecting end of the reflecting end optical fiber is parallel to the first plane; and the end surface of the passing end of the passing end optical fiber is parallel to the second plane of the filtering sheet, wherein the second plane faces the passing end groove. The wavelength division multiplexer of the invention has the advantages of structural simplicity and convenience in assembly.

Owner:A-ONE TECH LTD

Template positioning device for circuit board production

ActiveCN111726944ADoes not affect smearingAccelerated disengagementPrinted circuit assemblingStructural engineeringMechanical engineering

The invention provides a template positioning device for circuit board production and belongs to the technical field of circuit board manufacturing. An ink pad comprises a first stand column, a secondstand column, a third stand column and a fourth stand column which are symmetrically arranged, wherein vertical plates are hinged to outer sides of the first stand column and the second stand column,rectangular frames are fixedly arranged on inner sides of lower ends of the vertical plates, external connection plates are fixedly arranged on outer sides of the other ends of the rectangular frames, fixing plates are arranged between upper portions of the third stand column and the fourth stand column, a placement plate is arranged on the ink pad and located under the rectangular frames, an upper swing rod is rotationally arranged on a first polished shaft, a lower swing rod is rotationally arranged on a second polished shaft, the other end of the upper swing rod is connected with the otherend of the lower swing rod through a first connecting rod, an upper rocker is hinged to the other side, opposite to the first connecting rod, of the upper swing rod, a lower rocker is hinged to the other side, opposite to the first connecting rod, of the lower swing rod, and a limiting plate is arranged below a placing plate. The device is advantaged in that the device assists workers in positioning and fixing the position of a circuit board.

Owner:DEZHOU UNIV

Swimming safety paste

PendingCN106880438AImprove adhesionImprove breathabilityBathroom accessoriesBodily discharge devicesAnimal scienceMedicine

The invention discloses swimming safety paste, and belongs to the field of swimming and sports equipment facilities. The swimming safety paste is mainly composed of a main part, an opening and a pipeline, wherein the position, at female genitalia, of the main part is provided with the opening, the vertical axis of the opening coincides with that of the main part, the lower portion of the opening is provided with the pipeline, the pipeline is connected to the main part in a sealed mode, and the inner wall of the pipeline is provided with a drainage pipeline. The swimming safety paste solves the problem that contaminated water has a negative impact on genitals when female people swim. The swimming safety paste is mainly made from silica gel, is pasted outside the genitals so that the genitals can be safely isolated from water, and thus the swimming safety paste is a female hygienic supply which is convenient for urinate and menstrual blood to discharge. The swimming safety paste guarantees that female people can freely swim whenever at ordinary times or during menstruation, breeding of inflammation caused by invasion of bacteria is avoided, and thus the swimming safety paste is the safe hygienic supply for protecting the reproductive health of the female people.

Owner:孙秋云

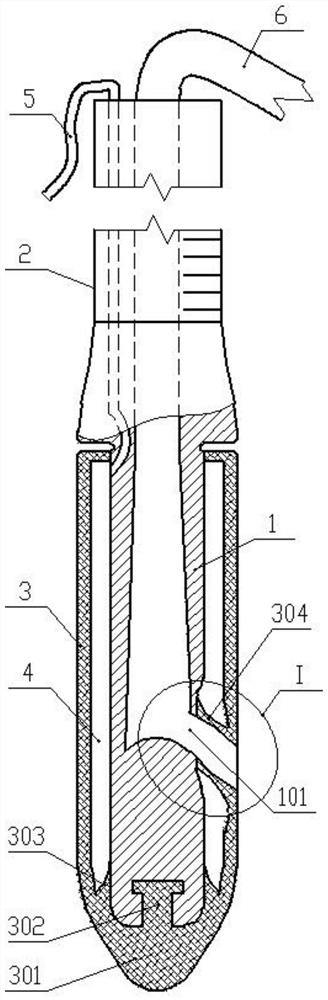

An anorectal drug delivery device

The invention provides an anorectal drug delivery device, the front part of the drug delivery tube is used to be inserted into the anorectum and the bottom of the drug delivery channel of the front part is closed and the side wall has a drug outlet hole; the outside of the front part is also fixedly covered with An elastic bullet-shaped hollow elastic sleeve, the end of the elastic sleeve facing away from the warhead is fixedly sleeved on the surface of the front section, the direction of the bullet head of the elastic sleeve is sleeved at the free end of the front section and the free end is integrally embedded in the side of the center of the bullet head of the elastic sleeve Inside the wall; the side wall of the elastic sleeve facing the drug outlet hole is integrally and protrudingly provided with a drug cartridge, one end of the drug cartridge is connected to the drug outlet hole, and the other end runs through the drug outlet hole. The side wall of the elastic sleeve is used for contacting the inner wall of the anorectum, and an annular expansion chamber connected with the inflation device for containing air is formed between the elastic sleeve and the front section of the administration tube. The anorectal drug delivery device of the present invention can more accurately realize drug delivery to the affected part of the anorectum, reduce the waste of medicinal liquid, and improve the curative effect.

Owner:川北医学院附属医院

Device for forming linear double eyelids

The invention discloses a device for forming linear double eyelids. The device solves the problems that an existing device is likely to damage the eyeballs, inaccurate in positioning and unreliable in adhesion. The device is characterized by comprising an upper clamping piece and a lower clamping piece, wherein the shape of the upper clamping piece is similar to that of the lower clamping piece; the tail of the upper clamping piece and the tail of the lower clamping piece are connected together, a two-point double eyelid positioner is arranged at the tail ends, and a bolt penetrates through the top end of an upper clamping piece body and the top end of a lower clamping piece body and is sleeved with a nut; a needle moving groove is formed in the lower surface of an upper clamping piece head, a front edge is arranged at the tail end of the upper clamping piece head, the needle moving groove comprises a needle inlet and a needle outlet, and the two side faces of an upper clamping piece neck and the two side faces of a lower clamping piece neck are Bessel curved surfaces in smooch transition. The device is simple in structure and integrates protecting, designing, positioning and fixing; it is guaranteed that double eyelids are not influenced while the lower clamping piece protects the eyeballs absolutely reliably, the upper clamping piece and the lower clamping piece perform clamping to accurately fix the positions of double eyelid lines, it is guaranteed that no displacement is generated in an operation, pendulous orbital phrenic fat moves upwards, the orbicularis oculi muscle is compressed at the same time, and reliable adhesion is guaranteed.

Owner:刘生

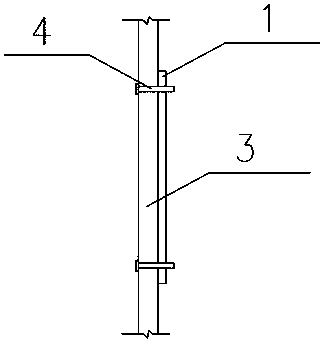

Method for prevent displacement of embedded steel plate by bolt fixation

The invention relates to the field of concrete construction, in particular to a method for preventing displacement of embedded steel plate by bolt fixation. The utility model is characterized in thatthe drilling hole comprises an embedded steel plate; Fabrication of embedded steel plate; Install embedded steel plate; Position the drill hole on the formwork; Installing bolts; After the initial setting of concrete pouring, take out the fixing bolts, which can be reused. The fixing method is feasible, and can be used for construction of vertical embedded parts and horizontal embedded parts according to actual needs, and can ensure that the embedded parts do not produce displacement, save rework cost and repair cost, and the bolts used can be recycled.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

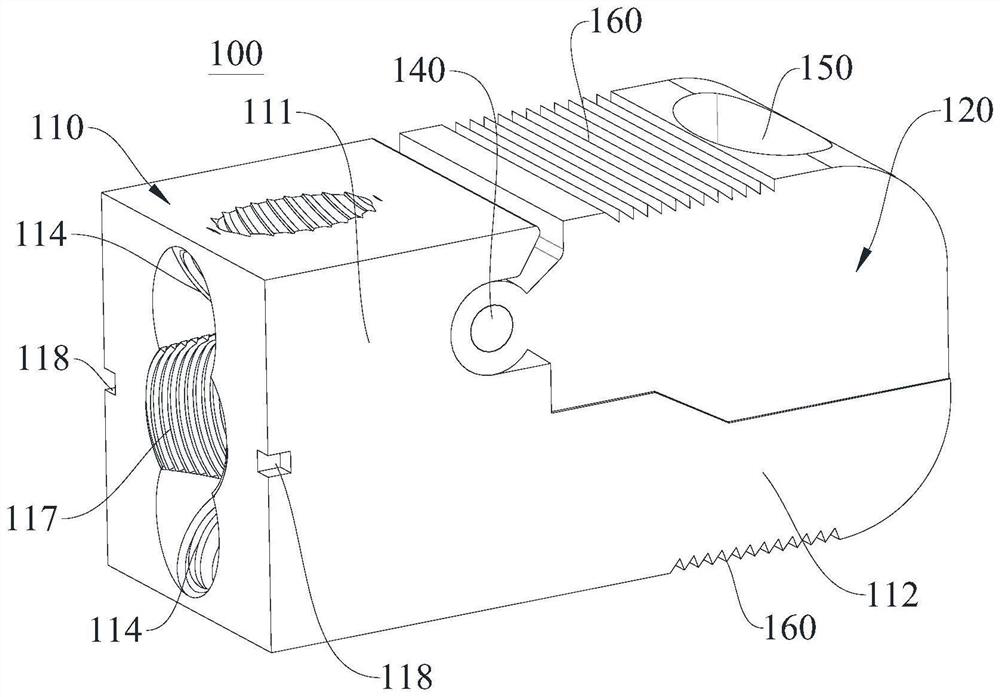

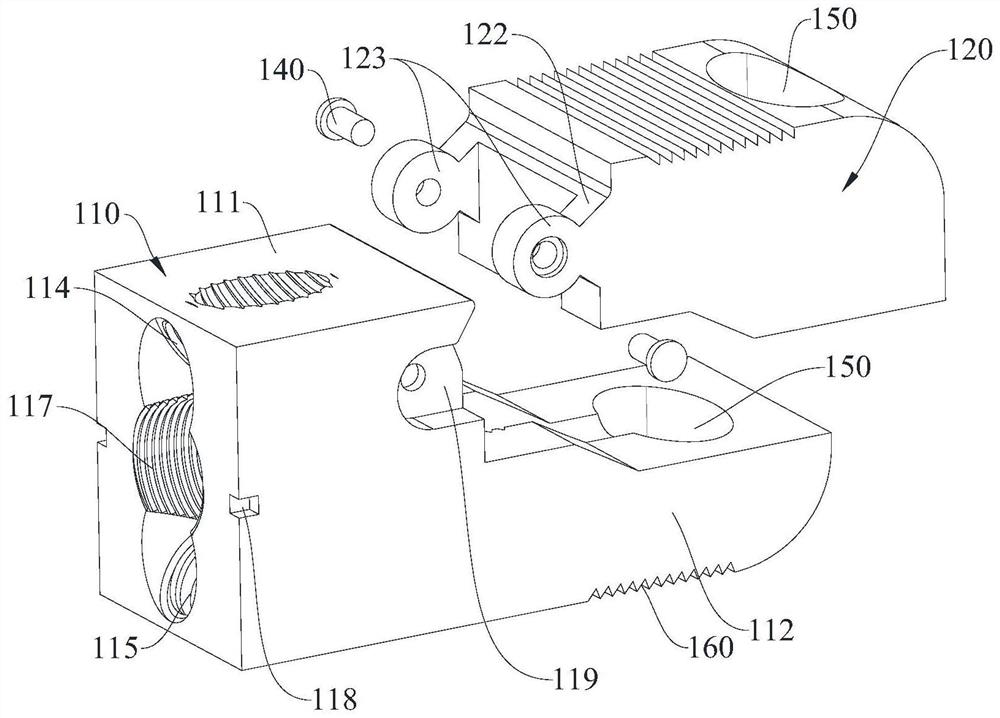

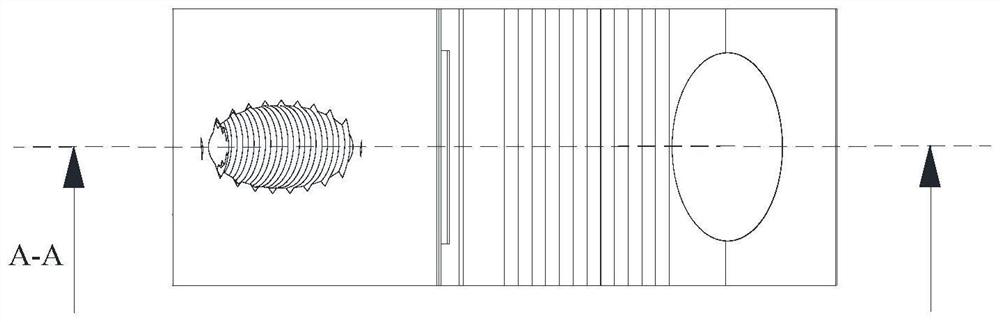

Lumbar vertebra posterior zero-incisura fusion cage, driving-in system and driving-in method

The invention discloses a lumbar vertebra posterior zero-incisura fusion cage, a driving-in system and a driving-in method. After the fusion cage is driven into the intervertebral body, the distraction angle of the distraction part rotationally connected to the fusion cage fixing part is controlled through the screwing-in depth of the distraction nail, and the selected-in depth of the distraction nail can be selected according to the actual situation requirement so as to meet the distraction height of different intervertebral bodies; meanwhile, the fusion cage is opened on one side, namely, the opening part is opened towards one side of the upper vertebral body, and after opening, compared with a fusion cage located on one side of the anterior vertebral body, the fusion cage located on one side of the posterior vertebral body can stably and effectively jack up the anterior column of the upper vertebral body upwards so that the anterior column of the upper vertebral body can recover the physiological camber of the anterior column of the upper vertebral body. Moreover, the fixing parts of the fusion cage are respectively locked on the upper vertebral body and the lower vertebral body through the lock nails, so that the expanded fusion cage is prevented from shifting, the problem of shifting of the fusion cage caused by the extrusion of the vertebral body during the movement of a human body after an operation is avoided, and the position of the fusion cage between the vertebral bodies is kept stable and unchanged.

Owner:黄振强

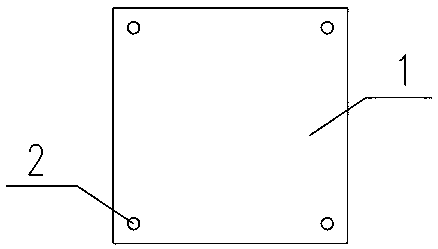

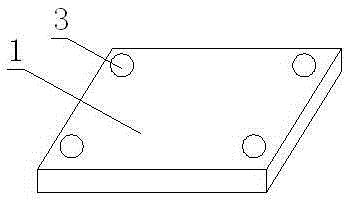

Special-purpose heating table for concentrating photovoltaic photoelectric conversion receiver

InactiveCN105304530ASimple structureEasy to take outSemiconductor/solid-state device manufacturingSolder pasteEngineering

The invention relates to a special-purpose heating table for a concentrating photovoltaic photoelectric conversion receiver, and belongs to the technical field of solar generating. The special-purpose heating table comprises a heating table body, a fixation groove and fixation hole positions, wherein one surface of the heating table body is provided with the fixation groove, and the other surface of the heating table body is provided with the four fixation hole positions. The special-purpose heating table is simple in structure, an object to be heated can be quite conveniently placed thereon and removed therefrom, and the heating table, after solder paste or fixation glue is solidified, can ensure that a concentrating photovoltaic battery chip on a concentrating photovoltaic circuit substrate is not displaced, and at the same time, also ensures that the heating table can be replaced at any time at a subsequent stage.

Owner:成都聚合科技有限公司

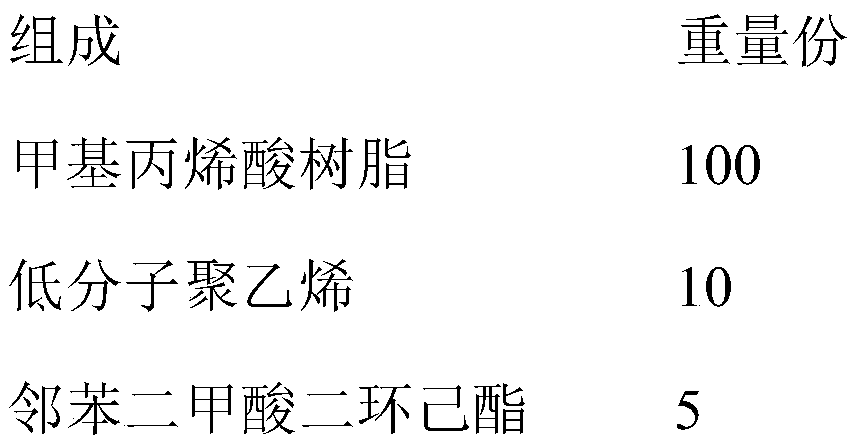

Asphalt concrete interlayer bonding material and preparation method and application method thereof

ActiveCN109868093ARight melting pointNo shiftMineral oil hydrocarbon copolymer adhesivesIn situ pavingsBlow moldingEpoxy

The invention discloses an asphalt concrete interlayer bonding material and a preparation method and an application method thereof. The interlayer bonding material is hollow spheres with a diameter of1-4 mm and a wall thickness of 0.3-1 mm which are formed by uniformly melting mixing thermoplastic resin, viscosity reducing resin and a plasticizer, and performing blow molding. When the interlayerbonding material is applied, a layer of epoxy resin coats a base surface of a concrete bridge deck, a tunnel or a steel bridge deck, the amount of the epoxy resin is 0.6-1.0Kg / m<2>, and then the hollow spherical bonding material prepared by the invention is spreaded to cover the base surface completely, and the firmly-unbonded superfluous bonding material is cleaned and recovered after the epoxy resin is cured. The interlayer bonding material provided by the invention is heated, melted and squeezed into the interior of the asphalt concrete during the spreading and rolling process of the asphalt concrete, so that the asphalt concrete and the base surface form a whole, the interlayer bonding strength and shear strength are high, and the asphalt concrete is not easy to delaminate.

Owner:CHONGQING PENGFANG PAVEMENT ENG RES INST

Grille intrauterine device

InactiveCN101427953BNo shiftAdapt to tensionFemale contraceptivesIntrauterine deviceUterine contractility

The invention discloses a grid intrauterine device, which comprises an elastic ring. The elastic ring takes the shape of a triangle, and three corners take the shape of an arch; a first elastic wire is arranged through starting from one corner of the elastic ring and ending up at the middle part of a straight flange vertically corresponding to the corner; a second elastic wire is installed on theright side of the first elastic wire, and a third elastic wire is arranged on the left side of the first elastic wire; the distance between the first elastic wire and the second elastic wire is equalto the distance between the first elastic wire and the third elastic wire; a fourth elastic wire and a fifth elastic wire are installed between two equivalent edges of the elastic ring; intersecting parts between the first elastic wire, the second elastic wire as well as the third elastic wire and the fourth elastic wire as well as the fifth elastic wire adopt encircling related joint; the diameter D1 of the elastic ring ranges from 0.9 to 1.2mm; and the diameter D2 of each elastic wire ranges from 0.6 to 0.8mm. Through clinical application, the grid intrauterine device is proved to have the characteristics of no desquamation, no occurrence of displacement, and the like, and the phenomena such as infection, low back pains, abdomen tenesmus and the like are not found. The structure of the grid intrauterine device can withstand uterine contraction force, adapt to the uterine tension, and have the characteristics of reducing the pressure to a uterine and avoiding hemorrhage.

Owner:SHANDONG PROVINCIAL FAMILY PLANNING INST OF SCI & TECH

A semiconductor chip mounting and positioning method and positioning tool

ActiveCN104332415BNo shiftImprove consistencySemiconductor/solid-state device manufacturingAdhesiveSemiconductor chip

The invention relates to a method for mounting and positioning a semiconductor chip and a positioning jig. The method comprises the steps of firstly distributing an adhesive on the chip bonding region of a housing, putting the positioning jig on a bonding finger step in the cavity of the housing, putting the chip in the inner frame of the positioning jig so that the chip can be prevented from shifting out of a required position due to that the adhesive flows under heat when being cured, after the chip is placed, putting the semi-finished product device into a curing oven for curing the adhesive, after finishing curing, taking out the positioning jig from the cavity of the housing and obtaining the cured device. The method for mounting and positioning the semiconductor chip aims at preventing the chip from shifting due to the adhesive flowing in the curing process, and the positioning jig simple and reasonable in structure is adopted for realizing the chip positioning method, and the existing mounting device, the existing fixture, technical conditions and the like are not changed; after the chip is mounted and cured, the chip does not shift and satisfies the technical index of the location degree; the consistency of a batch of products is good and the rate of the finished products is high.

Owner:WUXI ZHONGWEI GAOKE ELECTRONICS +1

Precise machining method of shaft end piece sealing ring B of stirrer

ActiveCN110355396APrevent movementGuaranteed machining accuracyPositioning apparatusMetal-working holdersDrill bitMachining process

The invention discloses a precise machining method of a shaft end piece sealing ring B of a stirrer, and belongs to the field of shaft end piece machining. According to the method, the to-be-machinedshaft end piece sealing ring B is assembled on a machining tool, a to-be-machined installation hole of the shaft end piece sealing ring B is perpendicular to the horizontal plane, by forming a guide hole, the position of the to-be-machined installation hole can be located fast and accurately, then by fixing the machining tool, the machining tool is prevented from moving in the machining process, and the machining precision is guaranteed. By means of the method, machining of the installation hole can be conducted without line marking, the machining efficiency is improved, in addition, the machining precision is high, and the machining qualification rate is high.

Owner:马鞍山万力重工机械制造有限公司

A shot blasting device suitable for large steel processing

ActiveCN112207720BNo shiftGuaranteed shot blasting effectImpeller wheelsRotor bladesStructural engineeringMechanical engineering

The invention discloses a shot blasting device suitable for large-scale steel processing in the technical field of steel processing devices. The bottom is connected with a plurality of groups of bottom columns, and the bottom columns are fixedly connected to the top of the base plate. The shot blasting device includes an outer cylinder. The bottom of the inner cavity of the outer cylinder is provided with a lower bracket, and an inner adjustment is arranged on the lower bracket. The rear end surface of the outer cylinder is provided with an opening and closing door, and the opening and closing door and the outer cylinder are connected by hinge rotation, and the top of the outer cylinder is provided with a shot blasting component, and the shot blasting device for steel processing can be used for steel processing. Shot blasting at different angles and positions increases the use range of the device, greatly improves the working efficiency of the shot blasting device, and ensures the shot blasting effect of the device on steel.

Owner:临沂兴晟钢结构工程有限公司

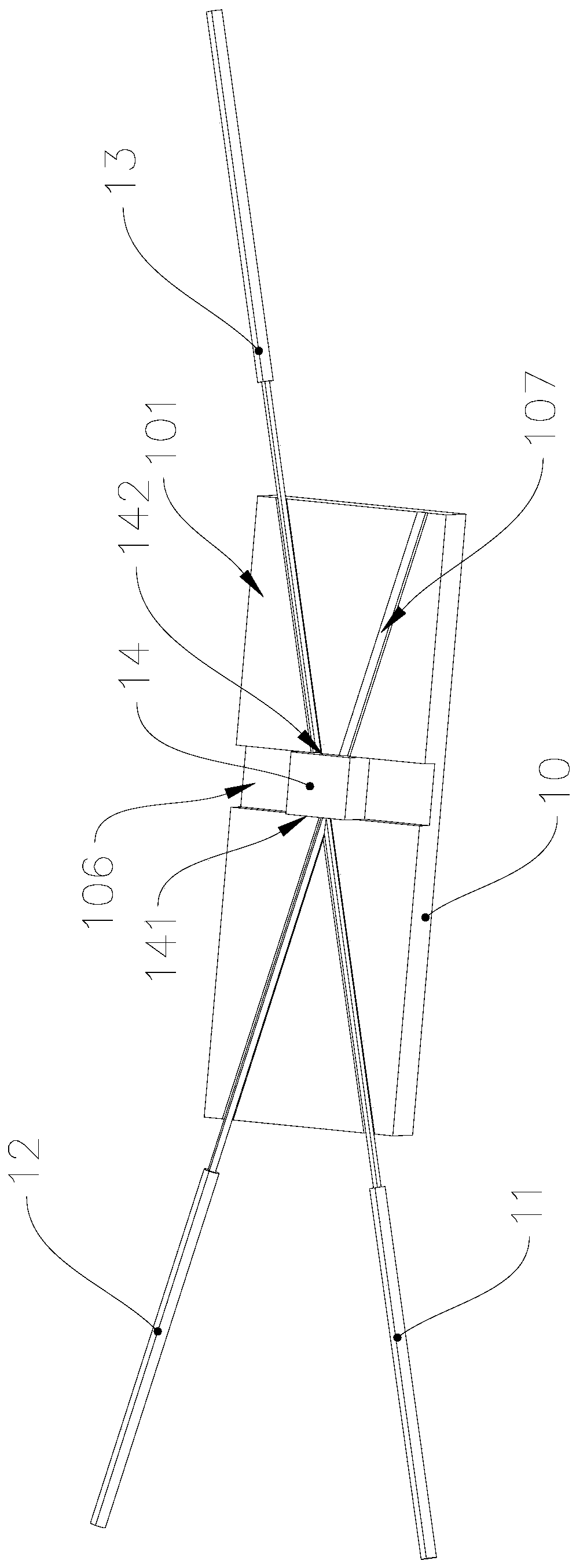

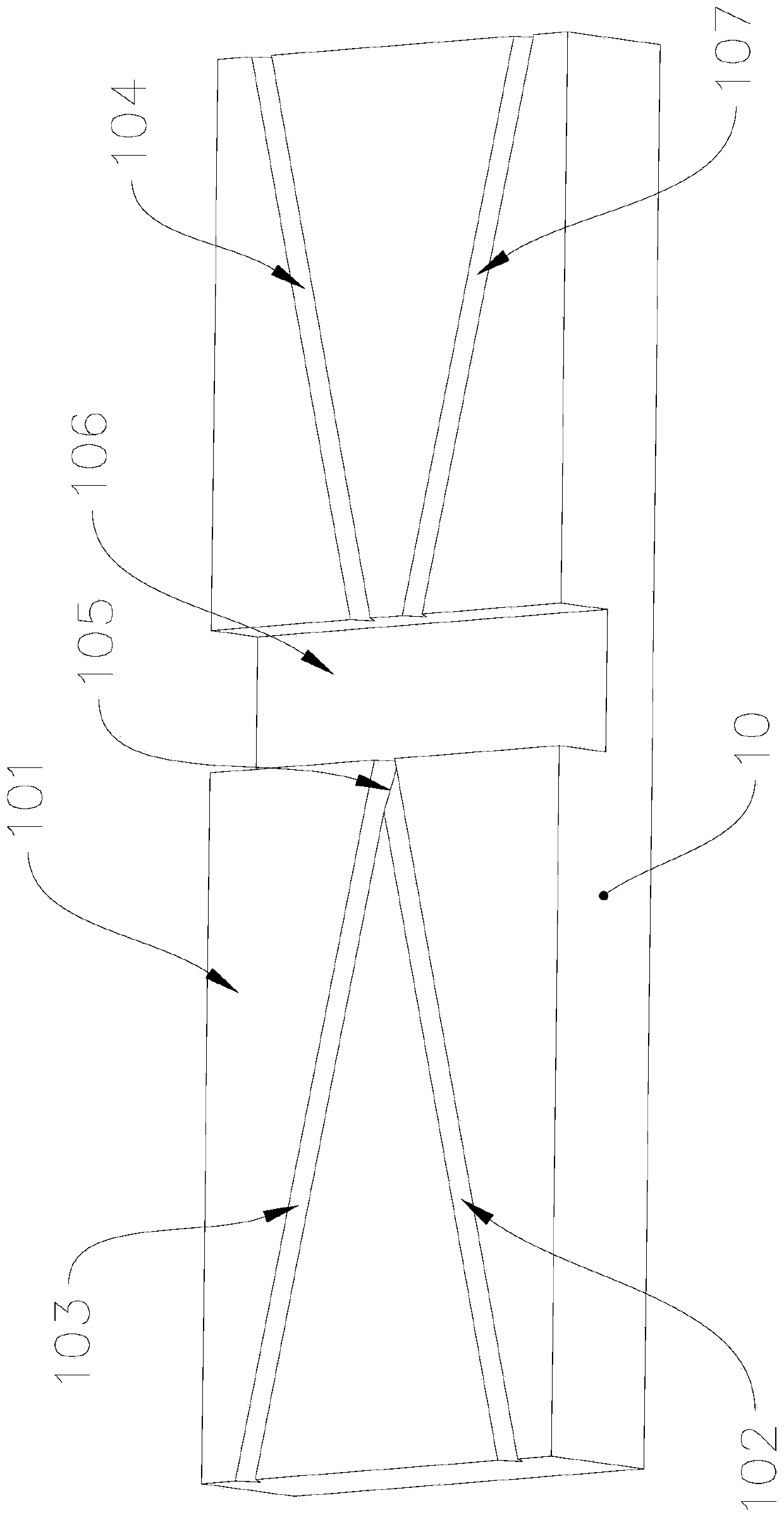

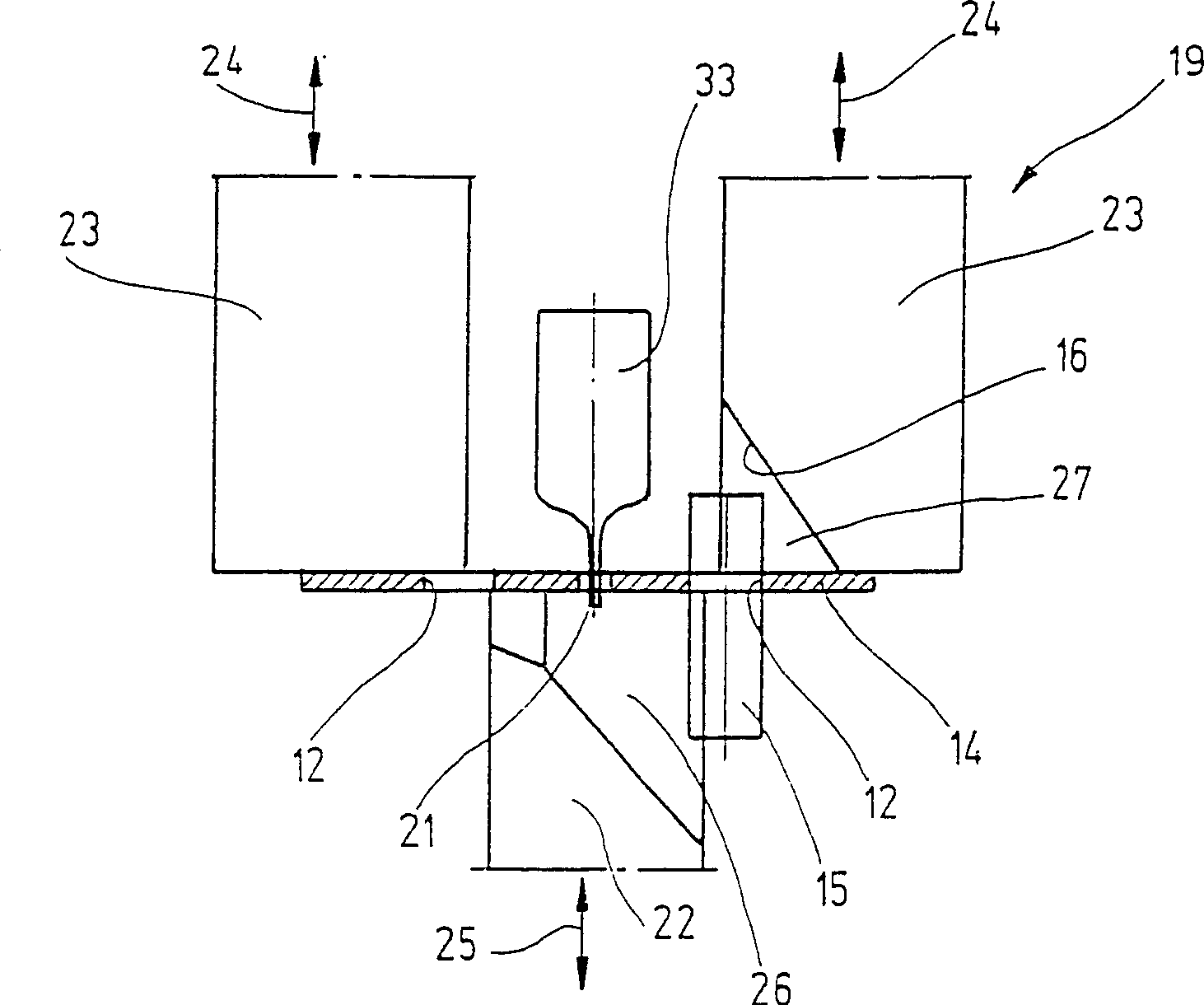

Method for production of a windscreen wiper arm with a U-profile cross-section and the corresponding device

A method for producing a windshield wiper bracket (10) with a U-shaped cross section, with two through holes (12) disposed in the legs (11) of the bracket (10), through which a rivet (13) extends, wherein the method includes the following steps:production of through holes (12) in a flat bracket blank (14);insertion of a rivet slug (15) into one of the through holes (12);folding of the legs (11) to produce the U-shaped profile and to thereby position the rivet slug (15) in a position aligned with the other through hole (12);sliding of the rivet slug (15) into the position extending through both of the through holes (12), andriveting of the rivet slug (15).

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com