A semiconductor chip mounting and positioning method and positioning tool

A mounting positioning, semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of reducing the yield of packaged products, no process method for chip mounting position shift, and can not meet the quality requirements of wire bonding alignment and other problems, to achieve the effect of high yield and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below the present invention will be further described in conjunction with embodiment.

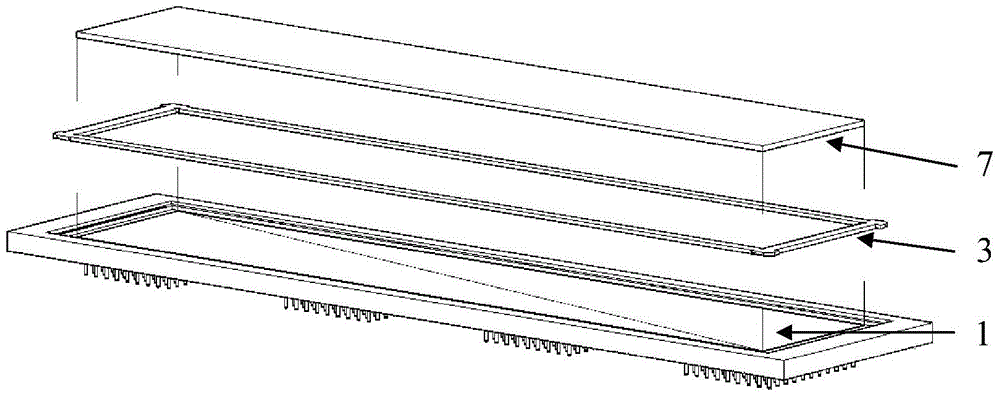

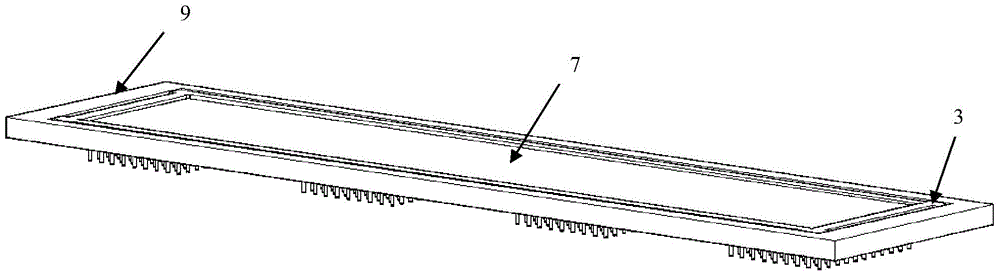

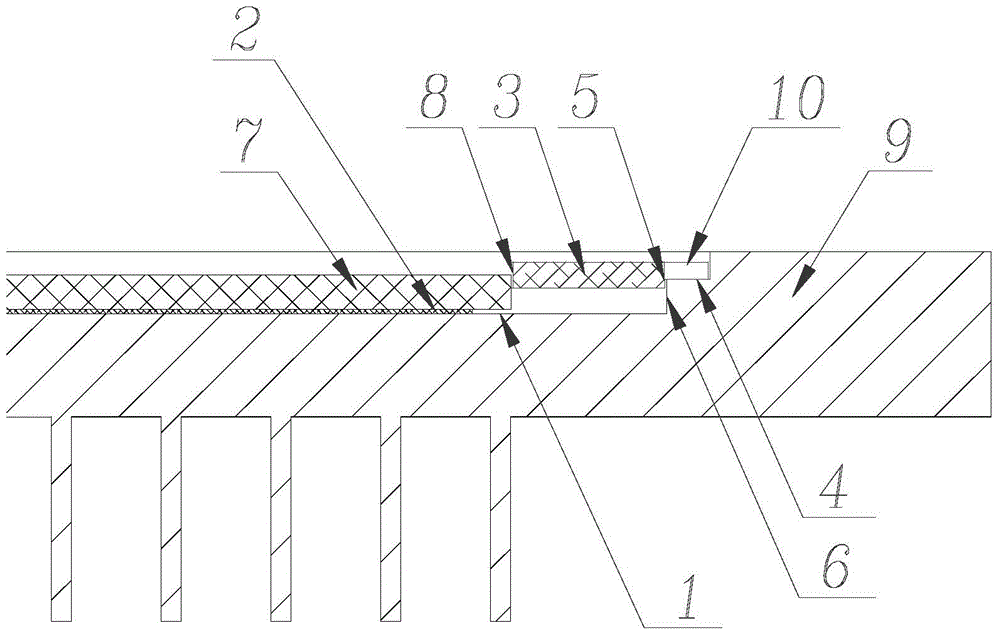

[0021] The invention utilizes a positioning tool to complete precise positioning and bonding of semiconductor chips. The outer frame of the positioning tool used should be adapted to the size of the core cavity of the shell, and the inner frame should be adapted to the size of the chip, so as to achieve the positioning function. In the embodiment of the present invention, the chip size is 168.3mm×31.29mm×0.76mm, the shell adopts CPGA packaging form, the shell core cavity bonding finger step size is 177mm x 38mm, and the shell core cavity size is 175mm x 36mm. Therefore, the design positioning fixture is a rectangular frame, and the four corners of the rectangular frame stretch out a foot rest 10 respectively. The thickness of the foot rest 10 is smaller than the thickness of the rectangular frame, and the lower edge of the foot rest 10 is higher than the lower edge of the rectangular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com