Method for production of a windscreen wiper arm with a U-profile cross-section and the corresponding device

A technology for windshield glass and bow-shaped parts is applied in the field of manufacturing U-shaped cross-section bow-shaped parts of windshield glass wipers, which can solve the problems of complex and time-consuming U-shaped bow-shaped parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

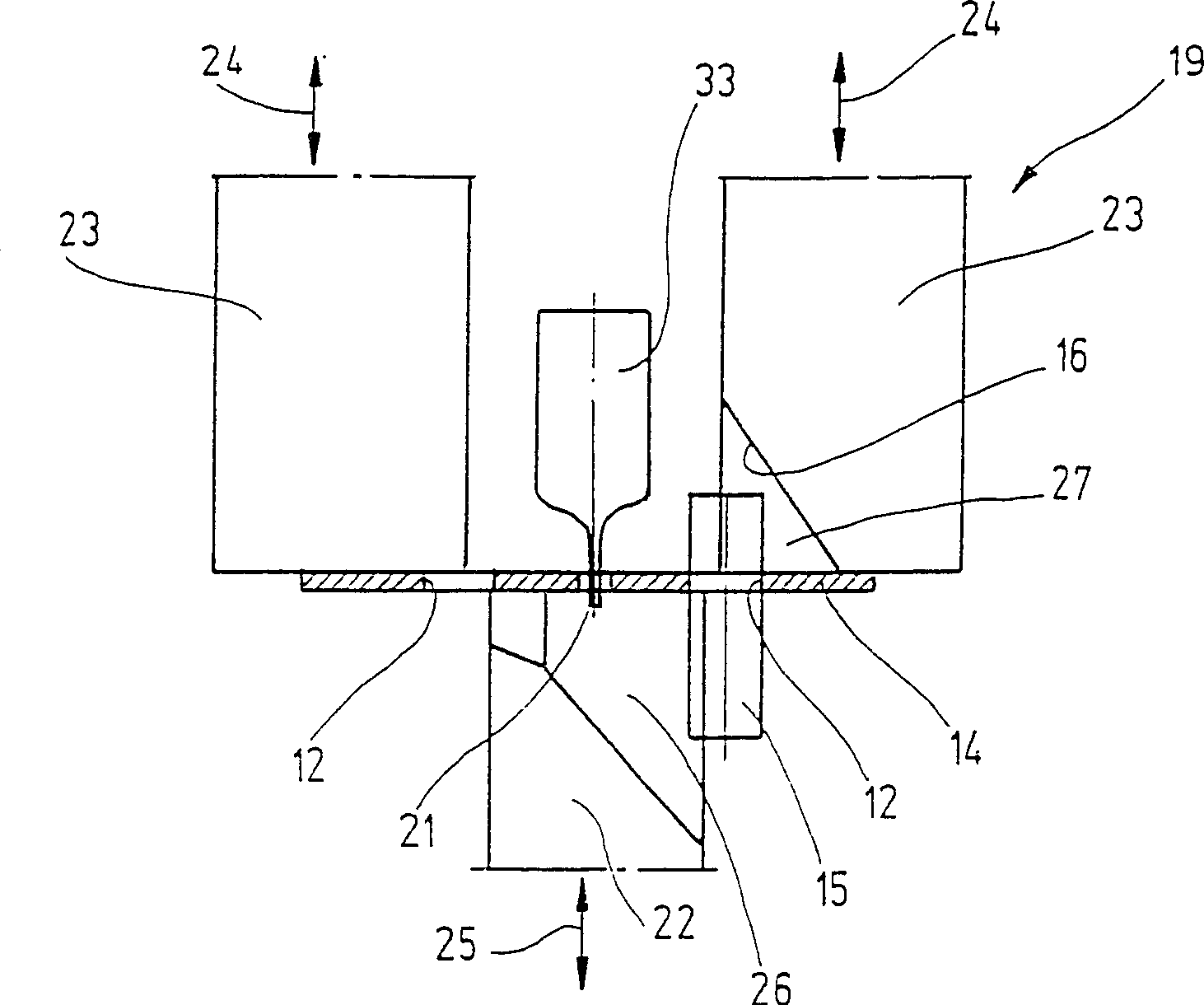

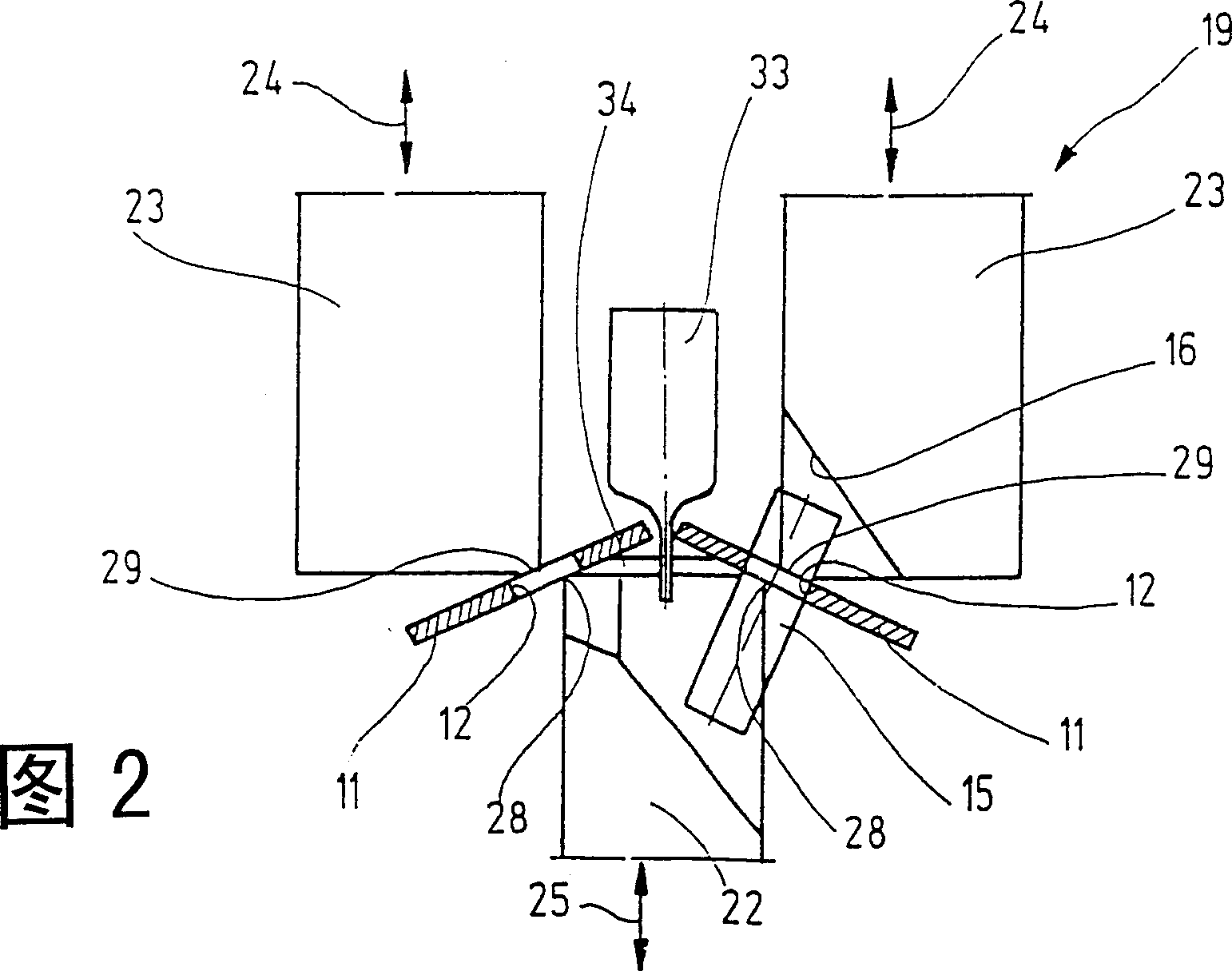

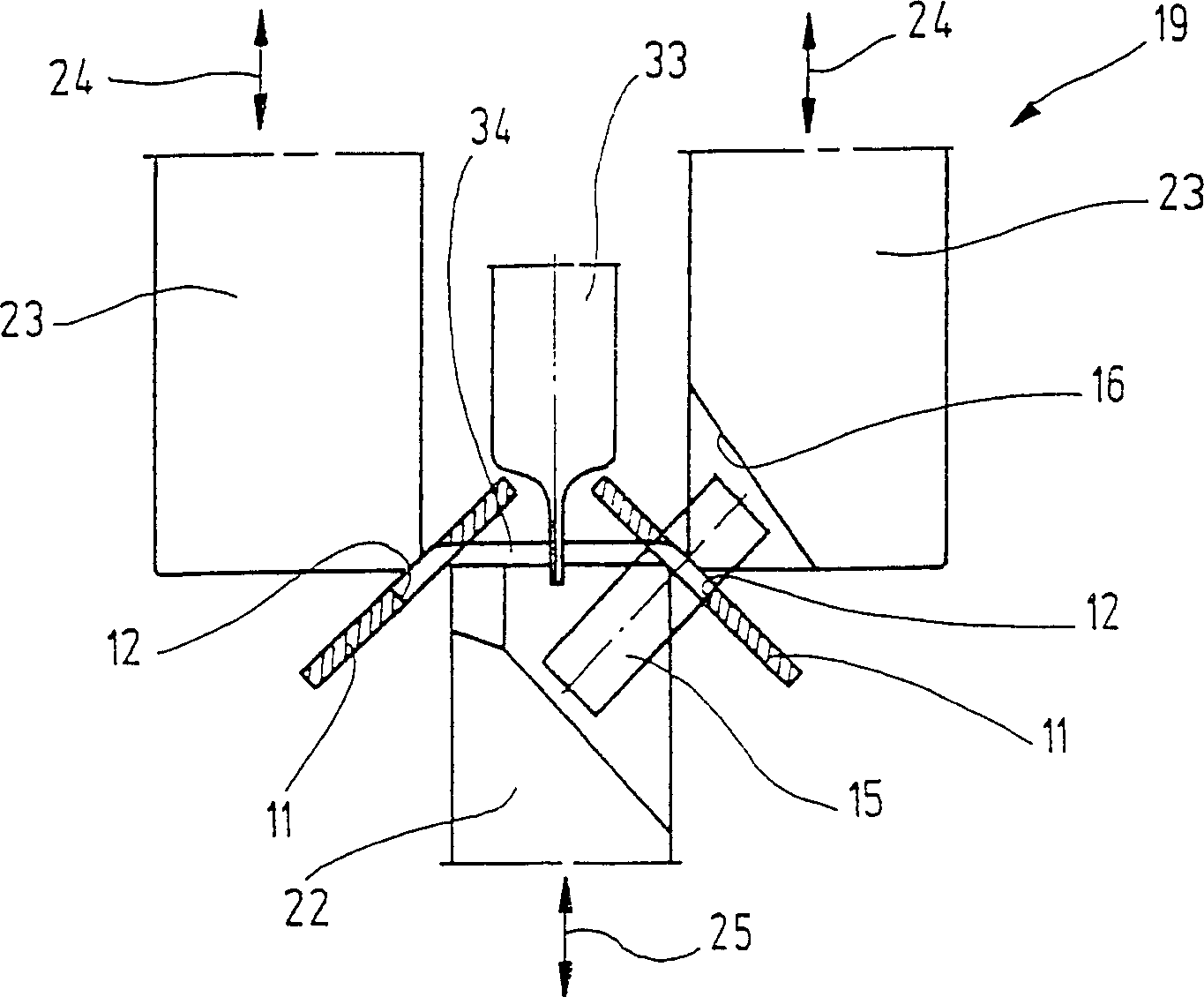

[0039] figure 1 A flat segment blank 14 is shown, which is provided with two through-holes 12 spaced apart from one another. A blank rivet 15 is fixed in place in one of the two through holes 12, forming a press fit. The flat segment blank 14 is fixed by a device 19 comprising two upper punches 23 and a lower punch 22 such that the central section of the segment blank 14 rests on the end face of the lower punch 22, while the segment The two lateral outer sections of the blank 14 protrude beyond the lower punch 22 . The two upper punches 23 of the device 19 are arranged opposite to the lower punch 22 and spaced laterally apart, and they rest with their respective end faces on the part of the flat segment blank 14 protruding beyond the lower punch 22 . on the side section. The lower punch 22 and the two upper punches 23 can be moved toward or away from each other simultaneously or successively along the arrow lines 24 and 25 in such a way that the flat bow arranged between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com